Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68 results about "Molecular distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing branched high vinyl polybutadiene rubber using molybdenum series catalysis

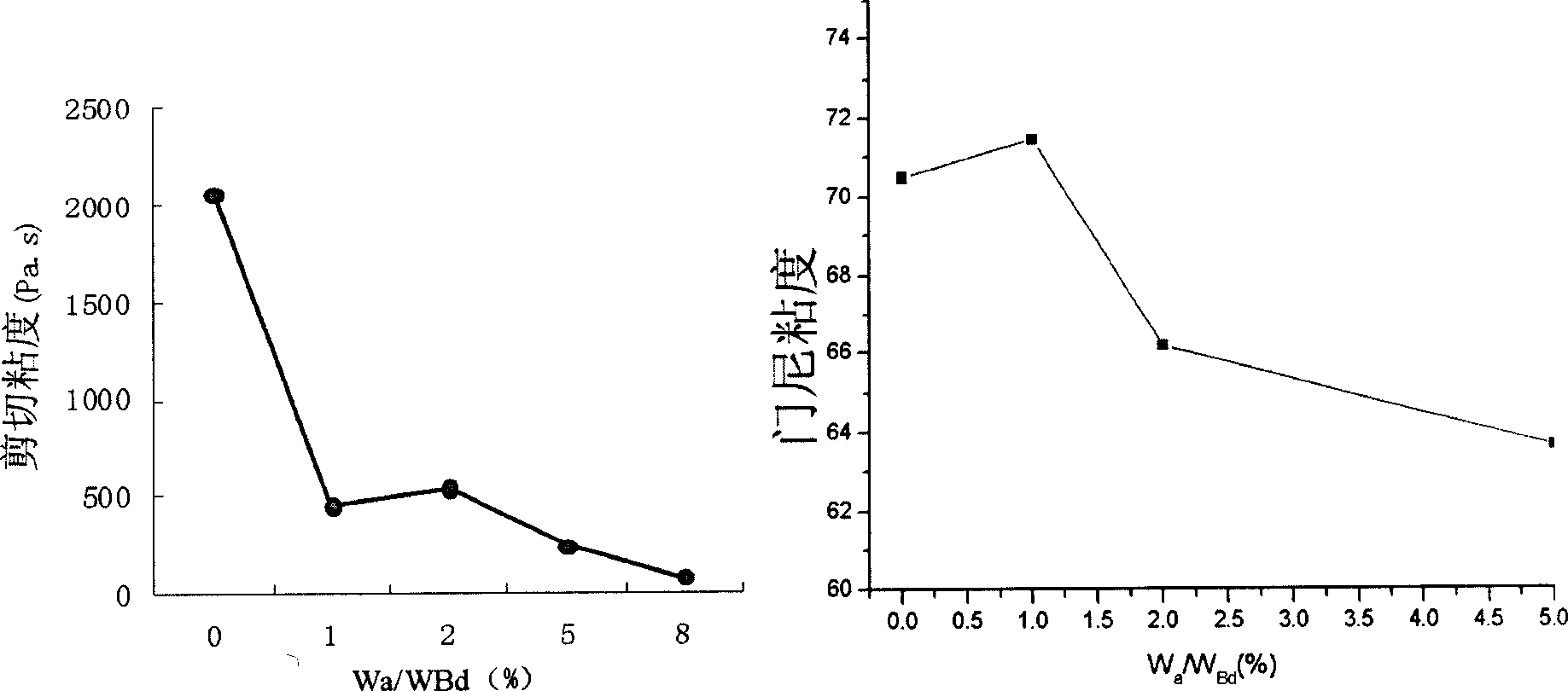

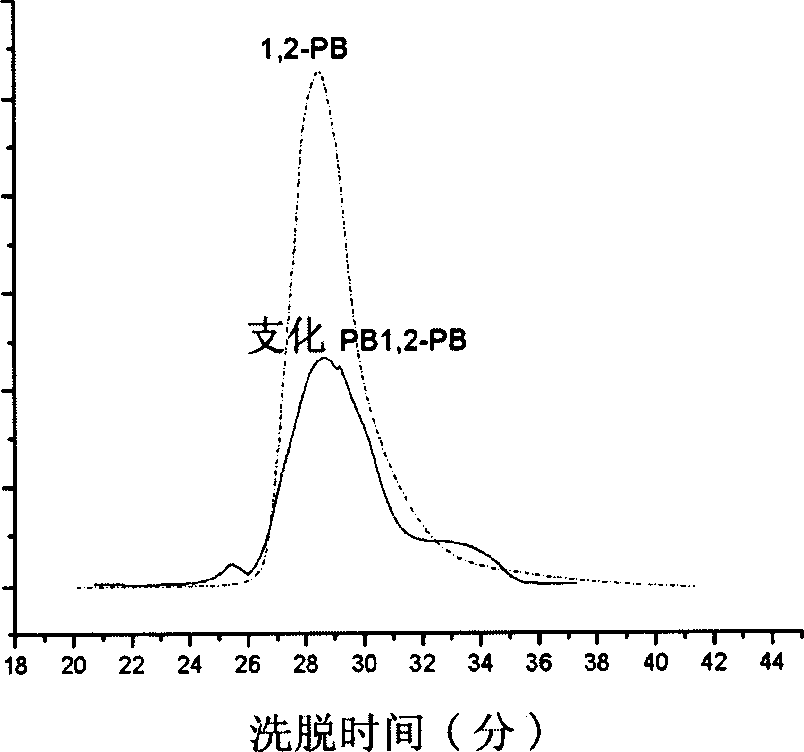

The invention relates to a method for preparing branched high ethenyl butadiene rubber with molybdenum catalyst, recombining macromolecular monomer prepared through polymerization of molybdenum catalyst butadiene atom free radical or butadiene anion initiated by organic lithium, naphthalene sodium, with coordinate polymerization of butadiene or original position polymerization, to prepare said product with controllable construction. The method is characterized by simple process, special construction of polymer, proper molecular weight and molecular distribution, more than 80% of ethenyl content, controllable property, length, distribution and degree of branching of branch chain in a certain range, good processing behavior and physical mechanics property and low production cost.

Owner:QINGDAO UNIV OF SCI & TECH

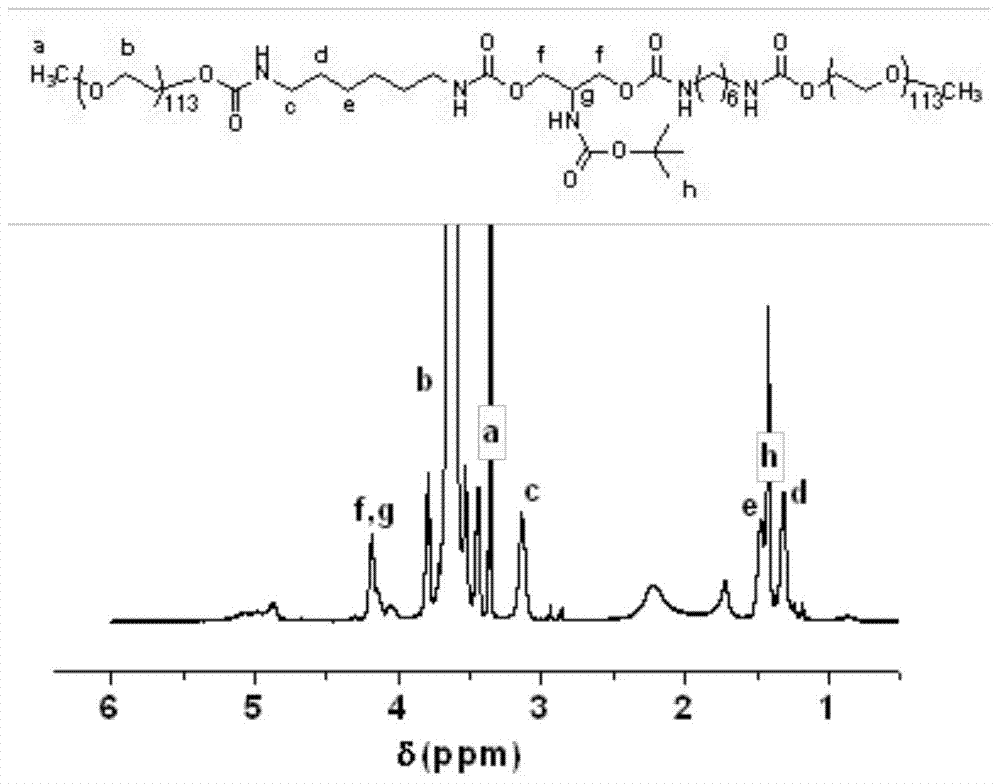

ABA type triblock biodegradable polyurethane with amino side chains and preparation method and uses thereof

InactiveCN103497306ASimple structureMolecular weight controllablePharmaceutical non-active ingredientsIn-vivo testing preparationsSide chainFluorescence

The invention provides ABA type triblock biodegradable polyurethane with amino side chains and a preparation method and uses thereof, belongs to the field of biomedical materials and solves the problem that the existing biodegradable polyurethane has molecular weight uncontrollable, wide molecular distribution index and complexity in self-assembly. The ABA type triblock biodegradable polyurethane with amino side chains is shown as in a structural formula I or II. The ABA type triblock biodegradable polyurethane is controllable in polymer molecular weight and wide in molecular weight distribution and can serve as a drug carrier; drug molecules, target molecules or fluorescence molecules are grafted to active side groups of the polyurethane by means of physical encapsulation or chemical bonding, so that a carrier drug system having one or multiple of functions such as being untargeted, being targeted, pH sensitivity, photosensitivity, enzyme sensitivity and fluorescence probing is constructed.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

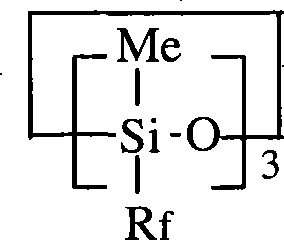

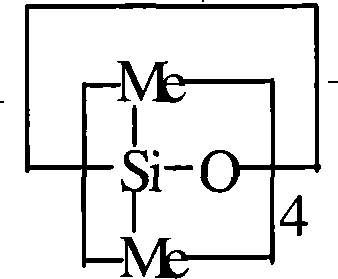

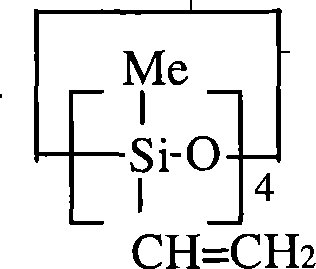

Fluorine-silicon copolymer rubber and preparation method thereof

The invention discloses a fluorine-containing silicon copolymer which comprises the fluorine-containing silicon copolymer which has the following general formula, wherein Me represents CH3-, Rf represents CF3 CH2 CH2-, wherein X / Y / Z=400-500 / 600-400 / 1-10, property molecular weight is 10-100 ten thousand, better is 30-80 ten thousand, molecular distribution parameter is 1-3, better is 1.2-1.8, and volatilization parts are less than 3%, and ethenyl chain link content is within 0.3-0.8%. And a preparation process of fluorine-containing silicon copolymer is disclosed.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD

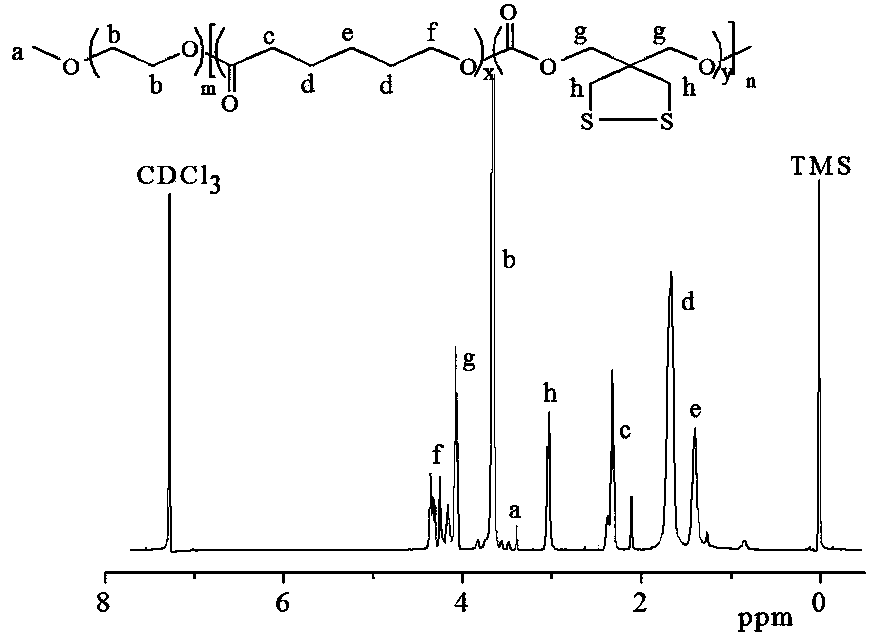

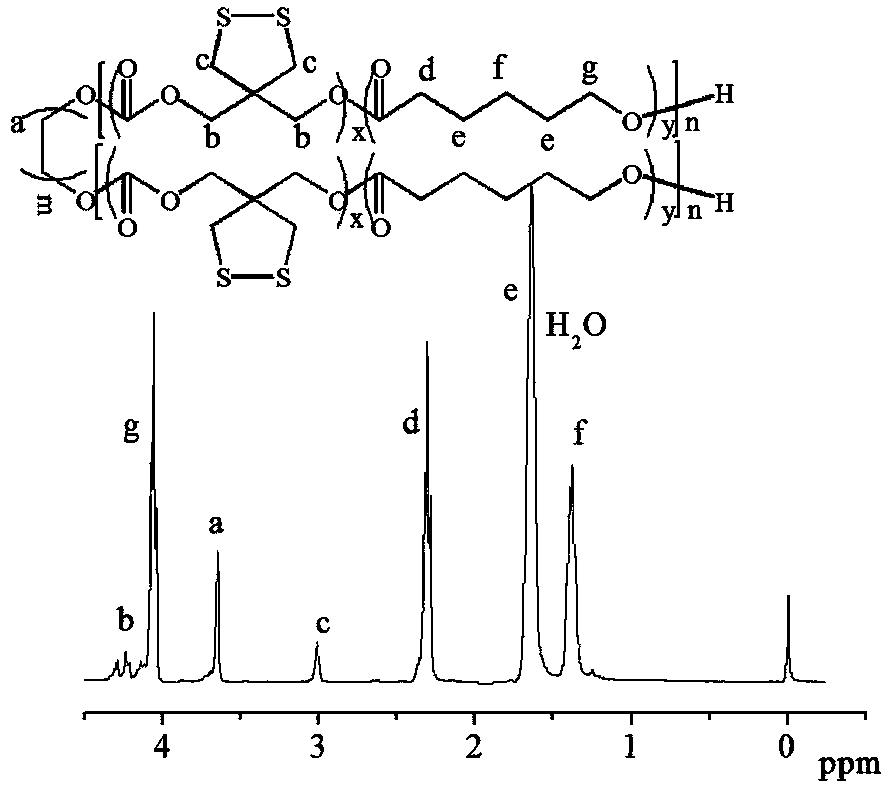

Carbonate polymer with disulfur five-membered ring functional group on side chain and application thereof

ActiveCN104031248AMolecular weight controllableNarrow molecular weight distributionOrganic active ingredientsPharmaceutical non-active ingredientsCancer cellSide chain

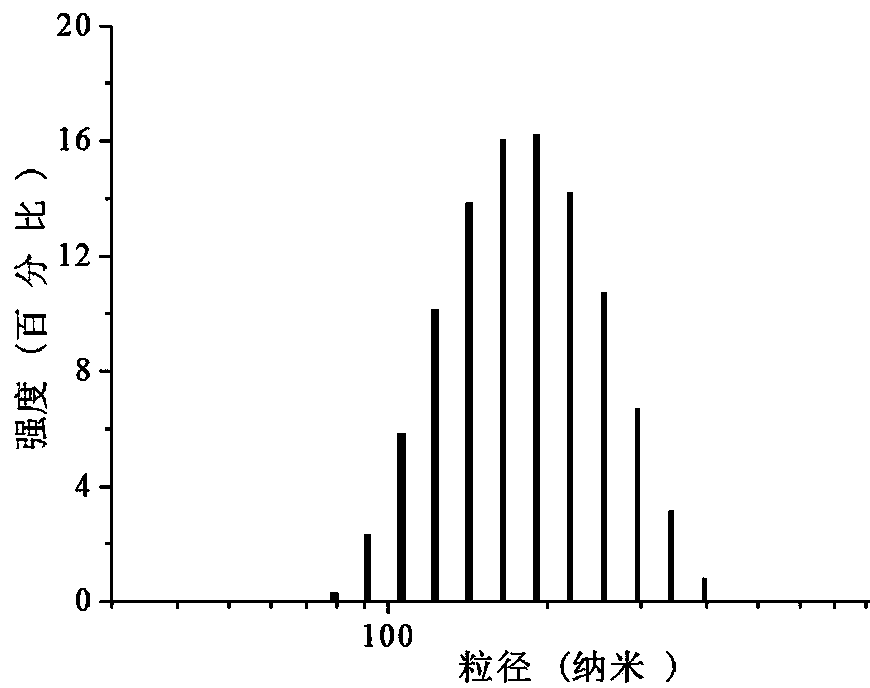

The invention discloses a carbonate polymer with a disulfur five-membered ring functional group on a side chain and an application thereof. The polymer is obtained by active ring opening polymerization from a cyclic carbonate monomer containing the disulfur five-membered ring functional group; the polymer is controllable in molecular weight, narrower in weight molecular distribution and free from protecting and deprotecting process. The polymer obtained by active ring opening polymerization of the cyclic carbonate monomer has biodegradability and can be used for controlling a drug release system; a reduction-sensitive reversible crosslinking nano medicine carrier targeting tumor supports long circulation in vivo but is highly enriched in tumor cells and is quickly crosslinked to release medicine in cells so as to efficiently kill the tumor cells with specificity. Meanwhile, the carbonate polymer has an application prospect in aspects such as tissue engineering scaffolds and biochip coatings and the like.

Owner:BRIGHTGENE BIO MEDICAL TECH (SUZHOU) CO LTD

Preparation for low molecular weight hydroxy-terminated polybutadiene

The invention provides a method for preparing hydroxyl-terminated polybutadiene of low molecular weight. The method adopts butadiene as a monomer, lithium alkylide of aliphatic series which contains silane protecting hydroxyl as an evocating agent, an organic non-polar compound as a solvent, an epoxy compound as an end capping reagent and fluoride as a detaching reagent for protecting groups. Anion polymer technology is adopted and polymerization is carried out at a temperature of 20 to 80 DEG C in the environment of inert gases; a prepolymer obtained goes through acid hydrolysis and a series of hydroxyl-terminated polybutadiene fluid rubber with narrow molecular distribution and controllable molecular weight is obtained. In the process of preparing hydroxyl-terminated polybutadiene polymer of the invention, the polymer does not encounter with a fake gel phenomenon during the process of end capping and detaching protecting group and the polymerization process is easy for control; the micro-structure of molecular chains is adjustable and controllable. The obtained hydroxyl-terminated polybutadiene has a molecular weight distributing index less than or equal to 1.2; the average functionality is close to 2; the cured products of hydroxyl-terminated polybutadiene have extremely good mechanical property and can be applied to the fields of rocket technology, optical fiber communication technology, etc.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

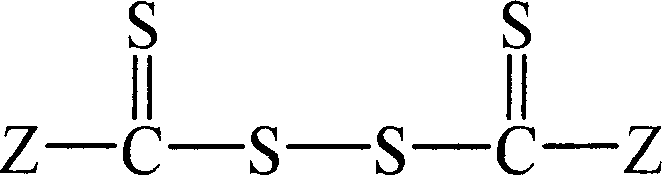

Preparation method of acrylic nitrile homopolymer (copolymer)

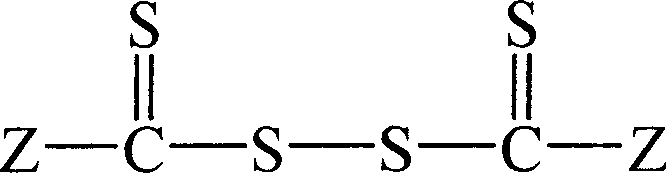

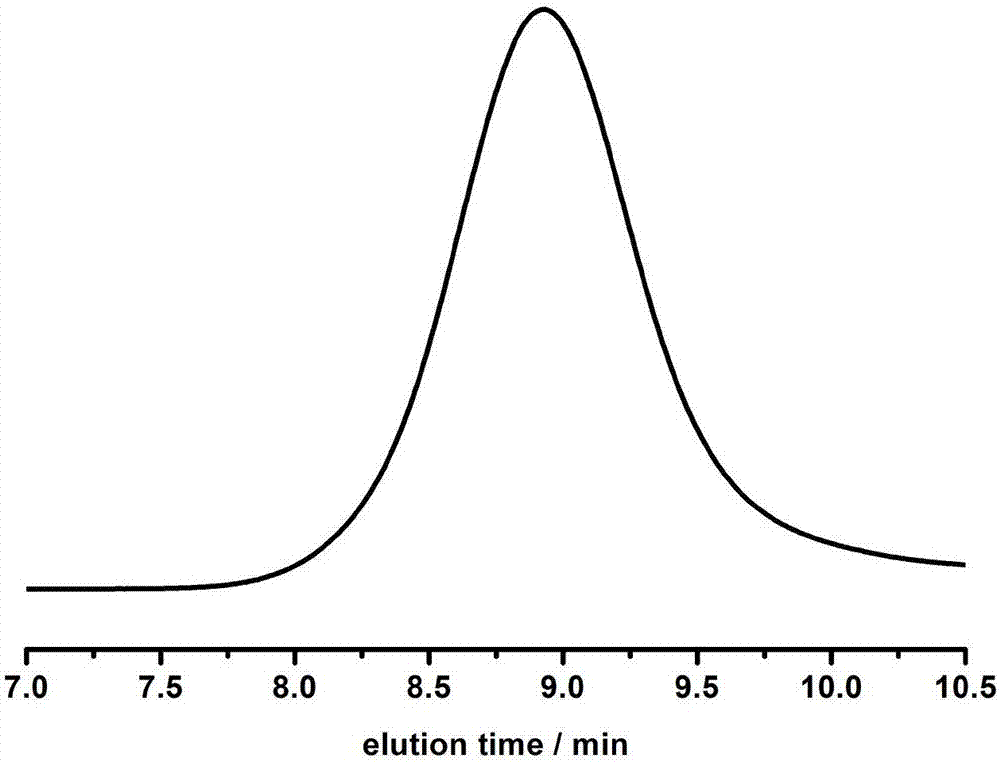

The invention discloses a preparing method of acrylon even (co-) polymer with high molecule and narrow molecular distribution, which is characterized by the following: the carbamodithioic material can be moduling agent of free acrylon radical, wherein Z is phenyl or benzyl, which can produce RAFT chain transmitting agent acted by azo-diisobutyronitrile at original position, which copolymerizes acrylon with other monomers; when Z is benzyl, the number average molecular weight is about 230000 with molecular distribution under 2.0 (1.70 as minimum value).

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

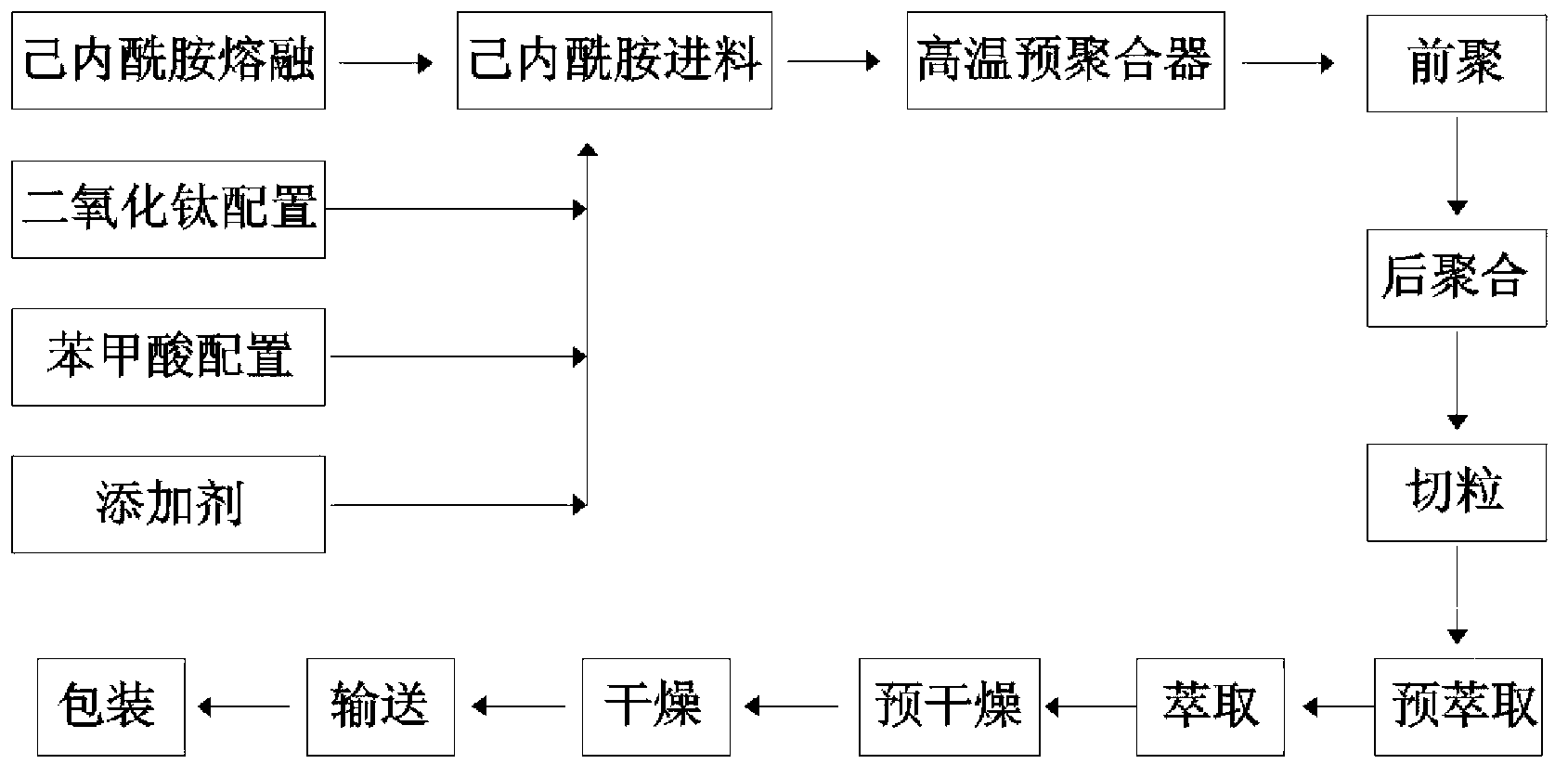

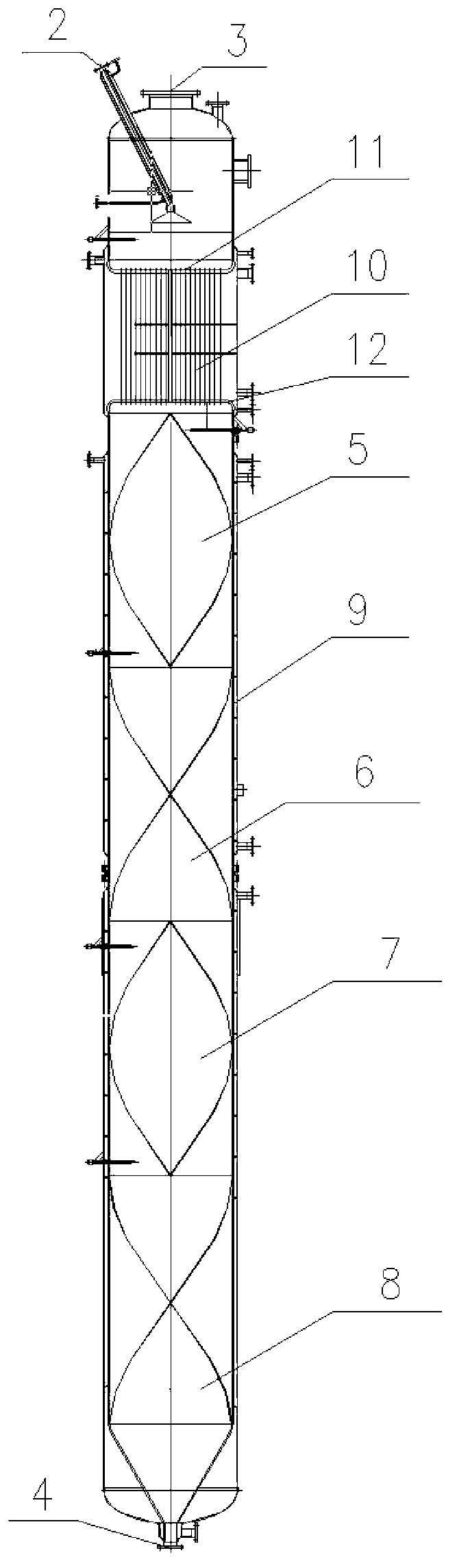

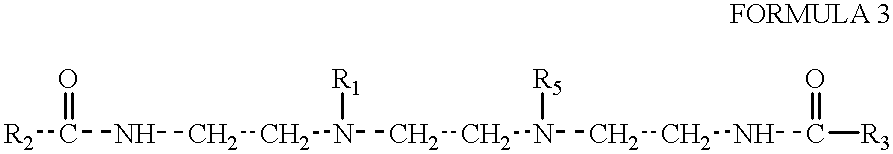

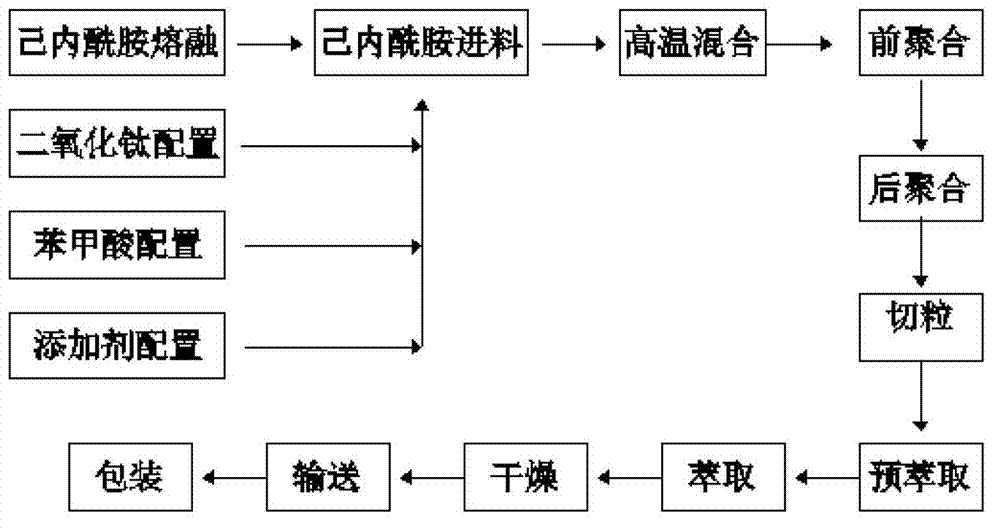

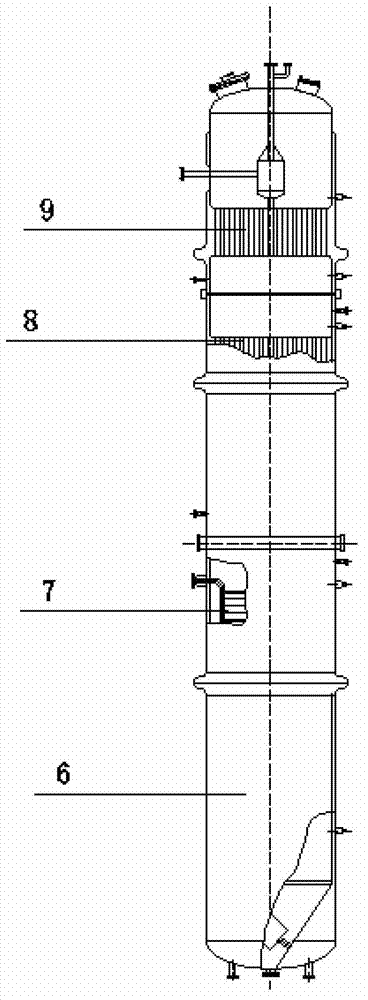

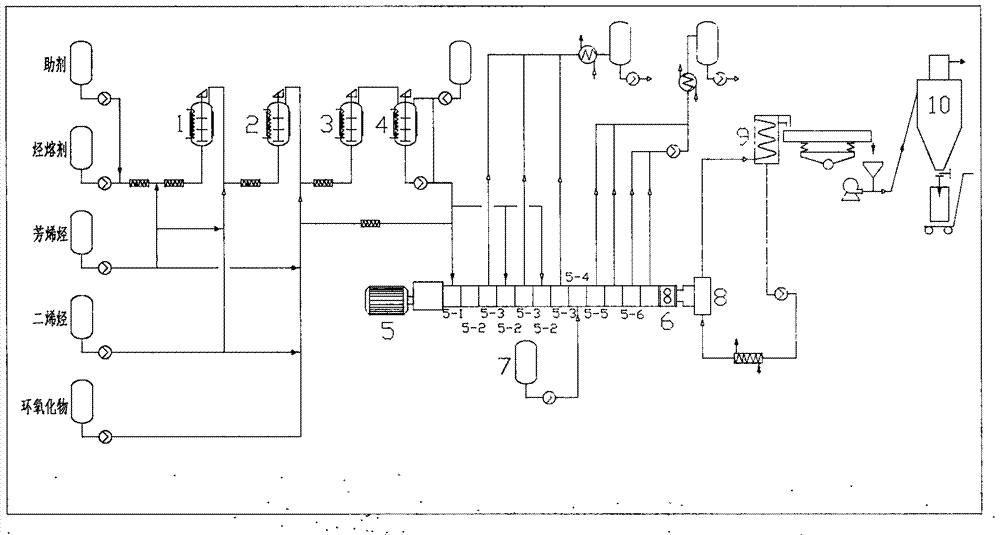

Polyamide polymerization production process and equipment for same

The invention relates to a polyamide polymerization production process and equipment for the same. The polyamide polymerization production process comprises the following steps of: carrying out prepolymerization on melted caprolactam, titanium dioxide, benzoic acid, and the like at a high temperature, and then carrying out front polymerization and post polymerization; pelleting; pre-extracting; extracting; pre-drying; and drying to obtain a product. The production equipment comprises a hexanolactam melting system, a preparation system, a feed system, a high-temperature prepolymerization device, a front polymerization tower, a rear polymerization tower, a pelleting system, a pre-extraction tower, an extraction tower, a pre-drying tower, a drying tower, and the like. According to the invention, static state flow guide spiral mixer assemblies are additionally arranged in the extraction tower and the lower sections of each row of tubes of the high-temperature prepolymerization device, the front polymerization tower and the post polymerization tower; the polyamide hydrolyzing ring opening and dewatering are more uniform and sufficient and faster; the front polyaddition reaction is sufficient and stable; the rear polycondensation stage is more uniform and stable in molecular distribution; the extraction tower more sufficiently and stably extracts a caprolactam monomer; the pre-drying tower can be used for removing the surface moisture of a slice; the drying tower dries combined water; a recovery system can be used for recovering an oligomer and extracts the caprolactam monomer contained in water.

Owner:武汉森大科技研究发展中心

Method for preparing polylactone through ring opening

ActiveCN107141457ANon-toxic reactionSimple conditionsOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholTransesterification

The invention discloses a method for preparing polylactone through ring opening, and belongs to the technical field of organic catalysis and high polymer materials. A novel catalytic mechanism is put forward, organic alcohol is adopted as an initiator, under the catalysis of an organic catalyst, ring opening polymerization of a cyclic monomer is initiated, and polylactone is obtained; the catalyst is pyridine salt, the method has the advantages that no toxin is generated during the reaction, conditions are simple, and the process is controllable, compared with 4-(N,N-dimethyl amino) pyridine catalysis, during solvent-free polymerization, narrow molecular distribution can be obtained, and the transesterification can be effectively restrained.

Owner:NANJING TECH UNIV

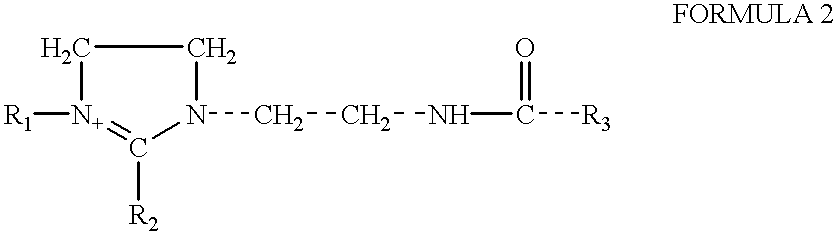

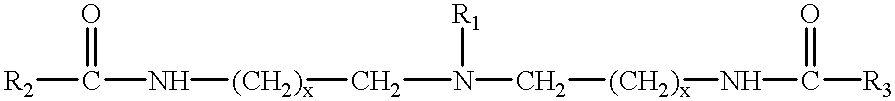

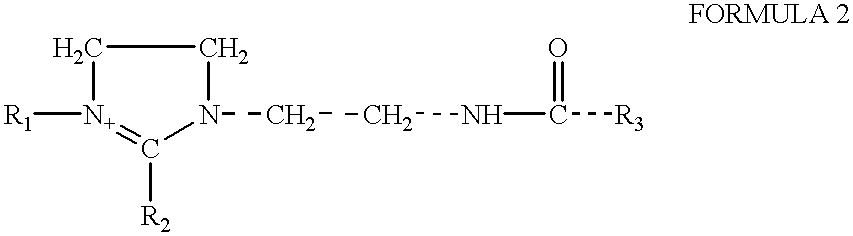

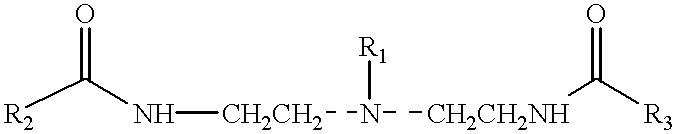

Amphoteric derivatives of aliphatic polyamines with fatty acids, esters or triglycerides for consumer products and industrial applications

InactiveUS6200938B1Effective softenerBiocideCosmetic preparationsDiethylenetriamineChloroacetic acids

Amphoteric derivatives of aliphatic polyamines, such as diethylenetriamine or triethylenetetramine reacted with long chain fatty acids, esters or triglycerides from various natural or synthetic sources are effective in the softening / texture modification of substrates such as paper, textiles, human skin surfaces and hair tresses, as well as in applications for metal working and lubrication. The polyamines are first reacted with fatty acids, esters or triglycerides derived from various animal, vegetable or synthetic sources ranging in molecular distribution from butyric through erucic acids (e.g. milkfat, soy bean oil, rapeseed oil) to form polyamines or imidazolines; they are then further reacted with unsaturated or halogenated carboxylic acids, carboxylated epoxy compounds or acid anhydrides (e.g. acrylic acid, itaconic acid, chloroacetic acid, maleic anhydrides octadecenyl anhydride) to form the various amphoteric structures.

Owner:MONA INDS

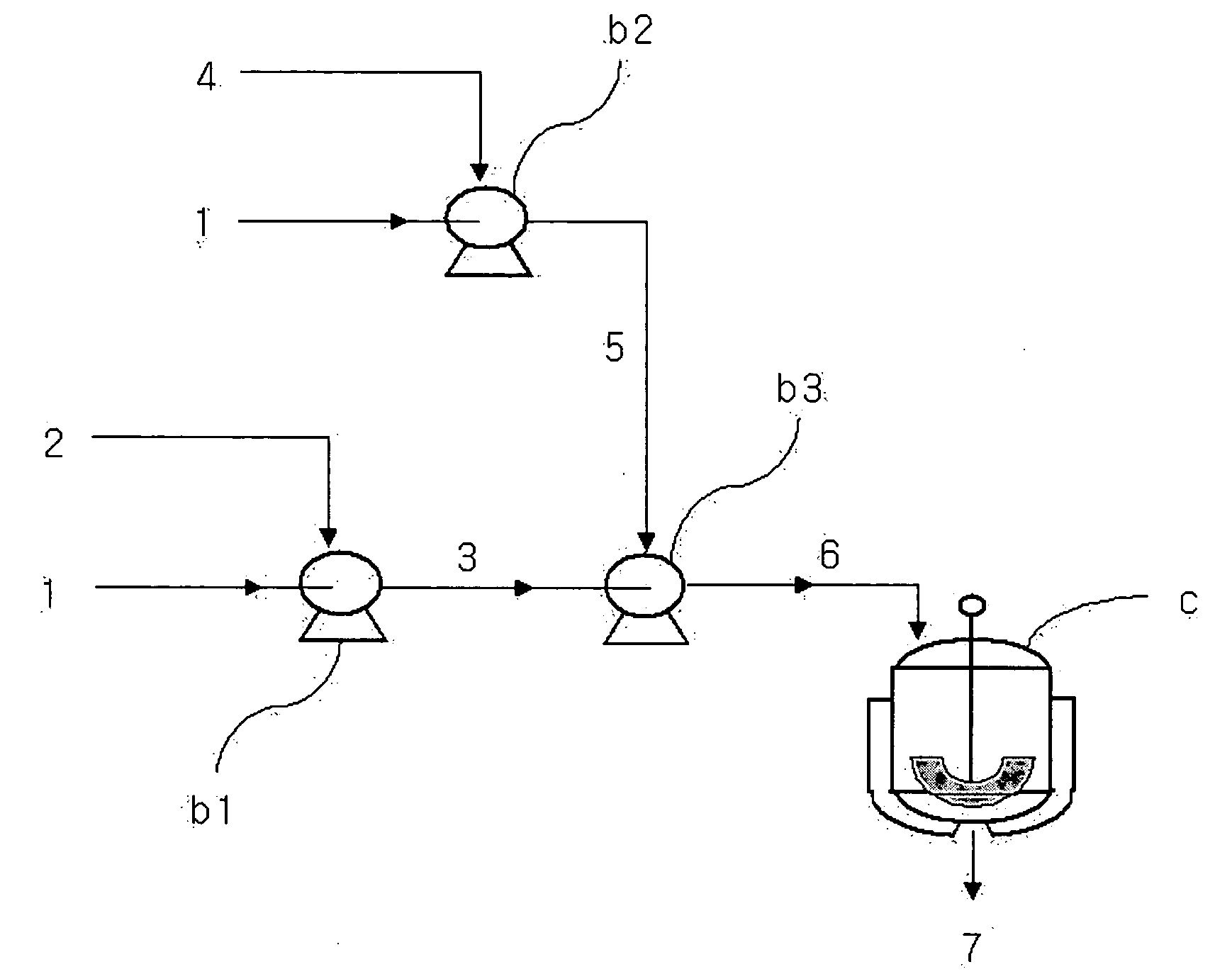

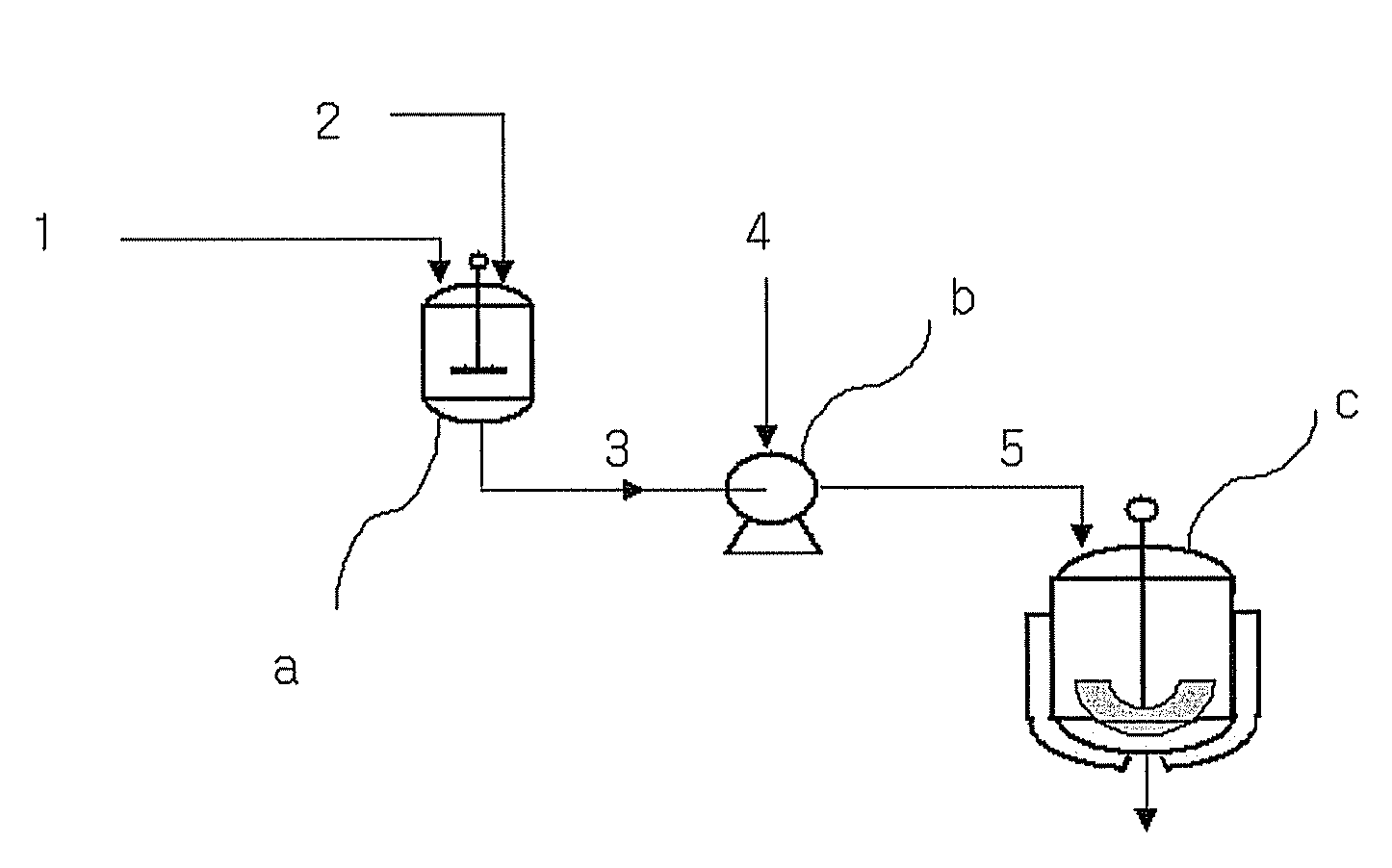

Polymerization manufacturing technique and device for polyamide

The invention relates to a polymerization manufacturing technique and device for polyamide. The manufacturing technique comprises the steps of feeding molten caprolactam, titanium dioxide, benzoic acid and an additive, dynamically mixing at a high temperature for prepolymerization and postpolymerization, granulating, pre-extracting, extracting and drying to obtain the final product. The device comprises a melting system, a feed system, a high-temperature dynamic mixing system, prepolymerization and postpolymerization towers, a pre-extraction column, an extraction column, a recycling system and a drying tower. According to the invention, a high-temperature dynamic mixing tank is set additionally. The mixing of the raw materials and hydrolysis for ring opening and dehydration of polyamide are performed at a state of dynamically mixing to achieve a more sufficient and stable pre-addition polymerization and a more uniform and stable molecular distribution of post-polycondensation. A slice and a water separator of the extraction column are used for mainly extracting oligomers through the pre-extraction column and extracting a caprolactam monomer through the extraction column with a stable concentration. A slice cooler of the drying tower is used for cooling the slices rapidly. An extraction water recycling system is used for recycling the oligomers in the pre-extraction water and the caprolactam monomer in the extraction water.

Owner:武汉森大科技研究发展中心

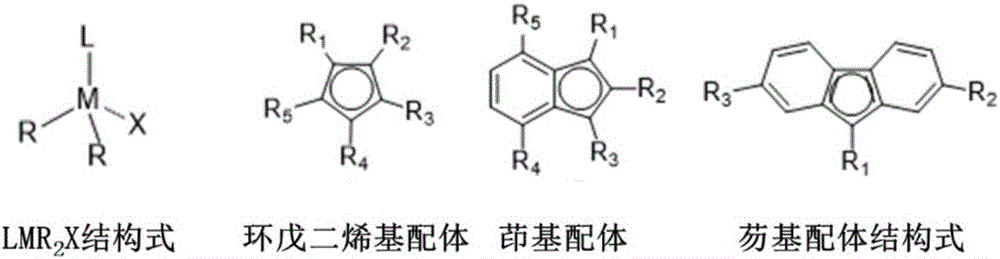

Rare-earth catalyst of nitrogen-containing heterocyclic carbene ligand and olefin polymerization catalyzing method of rare-earth catalyst

The invention provides a rare-earth catalyst of a nitrogen-containing heterocyclic carbene ligand and an olefin polymerization catalyzing method of the rare-earth catalyst. The rare-earth catalyst comprises a part A and a part B, wherein the part A is nitrogen-containing heterocyclic carbene coordinated rare-earth complex LMR2X, L is a cyclopentadienyl ligand selected from a cyclopentadienyl ligand, an indenyl ligand and a fluorenyl ligand, X is the nitrogen-containing heterocyclic carbene ligand selected from imidazolyl carbene, imidazolinyl carbene, triazolyl carbene and thiazolyl carbene, M is rare-earth metal selected from Sc, Y, Lu, Gd, Sm and Nd, and R is alkyl directly connected with the rare-earth metal; the part B is organoboron reagents. By using the rare-earth catalyst of the nitrogen-containing heterocyclic carbene ligand, the chain transfer reaction of propylene monomers can be effectively inhibited so as to prepare the homopolymer and copolymer, with higher molecular weight and narrower molecular distribution, of the propylene monomers.

Owner:DALIAN UNIV OF TECH

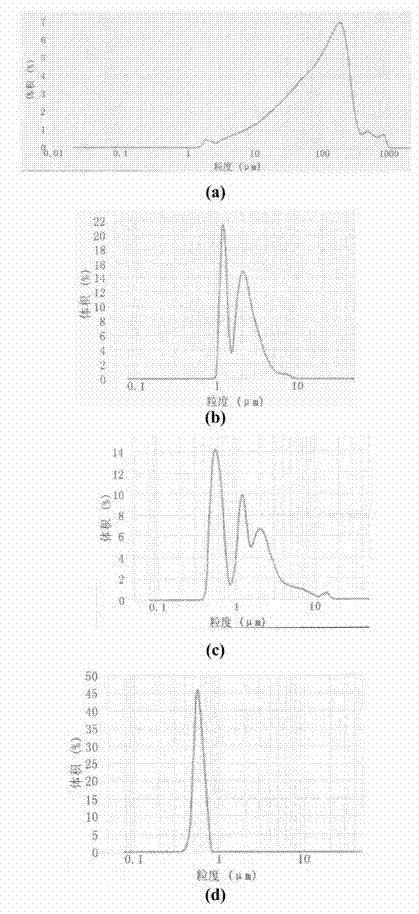

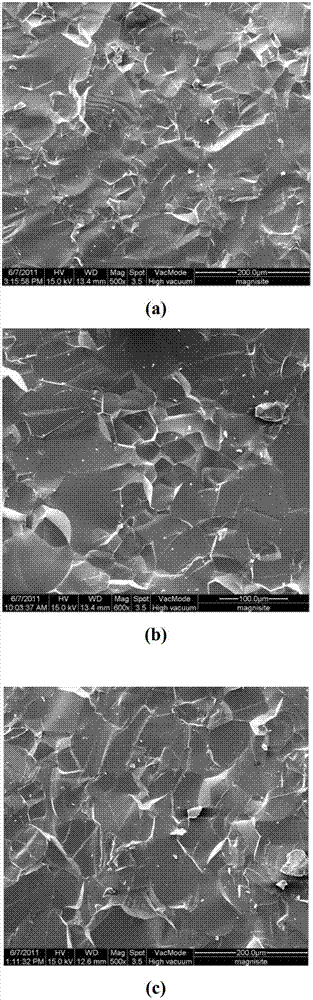

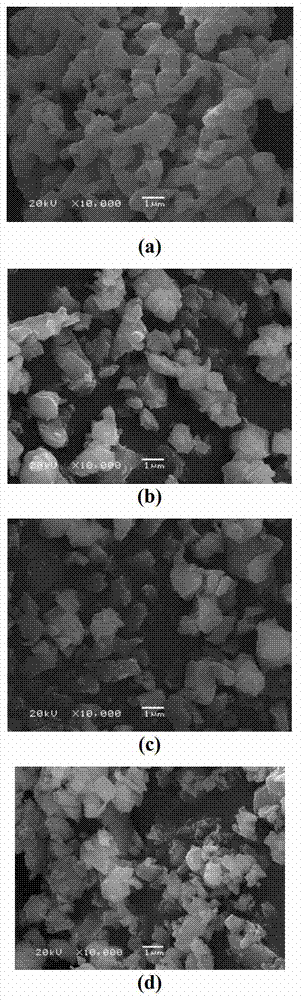

Low temperature fast preparation method of AlON crystalline ceramics

The invention relates to a low temperature fast preparation method of AlON crystalline ceramics, and belongs to the technical field of crystalline ceramic preparation. The preparation method provided by the invention applies ball-milling modification to AlON powder by adopting a planetary ball mill, the modified powder has tiny particles, and has the grain size distribution characteristics of single-modal, double-modal, multi-modal and the like, while possessing the characteristic of narrow molecular distribution, so as to be beneficial to improve the compactness of blank bodies and promote the sintered densification. The AlON powder which is manufactured through ball-milling modification and has the grain size distribution characteristics can be formed through preforming without adding binder, and further isostatic cool pressing is not required. The compactness of the blank bodies is high, and AlON crystalline ceramics with transmittance greater than 80% can be obtained through keeping the heat of the blank bodies at a temperature below 1900 DEG C with the effect of sintering agents. The preparation method has the advantages of low sintering temperature, short heat preservation time and good energy-saving effect; and the requirement for equipment is not high. The preparation method can be used for preparing construction members in abnormal shapes, so that the applied range is wide, the cost is low, the operation is simple and easy, and the industrialization is easy to realize.

Owner:DALIAN MARITIME UNIVERSITY

Amphoteric derivatives of aliphatic polyamines with fatty acids, esters or triglycerides, which are useful for various consumer products and industrial applications

Amphoteric derivatives of aliphatic polyamines, such as diethylenetriamine or bis (hexamethylene) triamine reacted with long chain fatty acids, esters or triglycerides from various natural or synthetic sources are effective in the softening / texture modification of substrates such as paper, textiles, human skin surfaces and hair tresses, as well as in applications for metal working and lubrication. The polyamines are first reacted with fatty acids, esters or triglycerides derived from various animal, vegetable or synthetic sources ranging in molecular distribution from butyric through erucic acids (e.g. milkfat, soy bean oil, rapeseed oil) to form amidoamines or imidazolines; and are then further reacted with unsaturated or carboxylated epoxy compounds (e.g. acrylic acid, itaconic acid, verndic) to form the various amphoteric structures.

Owner:MONA INDS

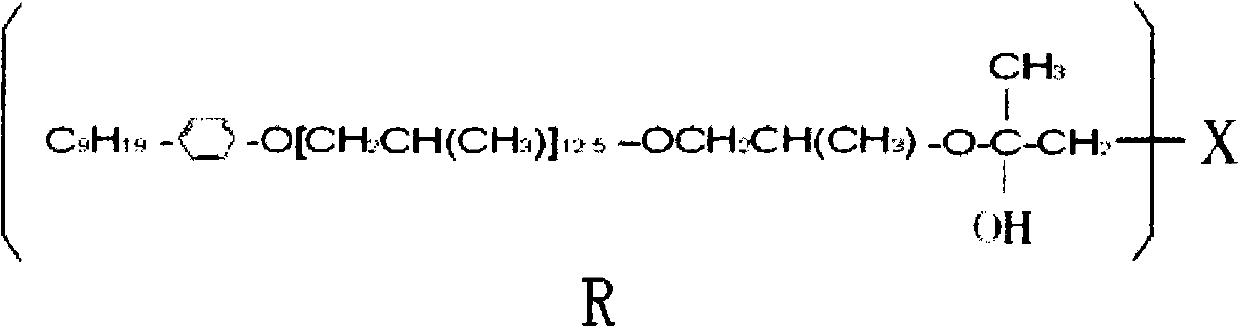

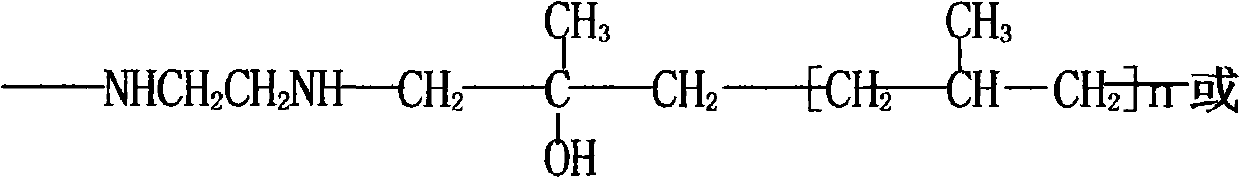

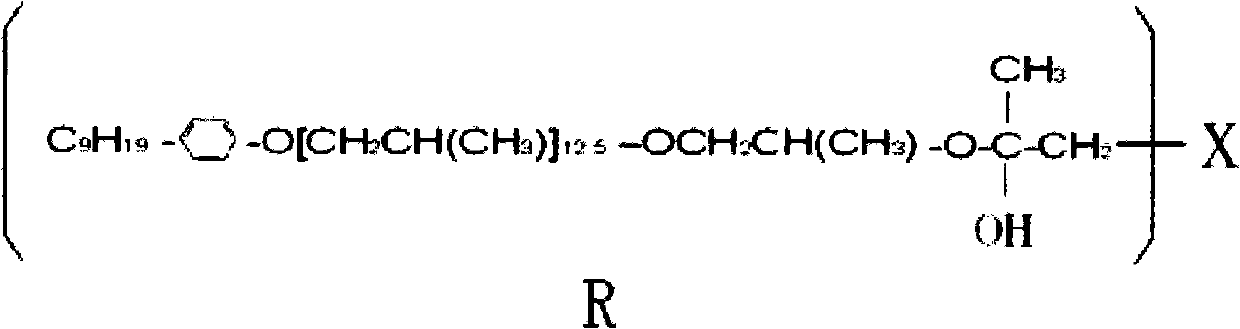

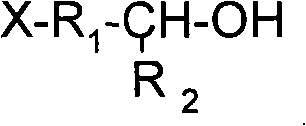

Nonyl phenol poly-oxypropylene ether amine

InactiveCN101565377AGuaranteed cleanlinessLow viscosityOrganic chemistryLiquid carbonaceous fuelsGasolineEther

The invention relates to a nonyl phenol poly-oxypropylene ether amine detergent dispersant of R-X in the technical field of petrochemical industry, wherein R is nonyl phenol poly-oxypropylene ether, the number average molecular weight of the R is Mn500-1800 and the molecular distribution Mw / Mn is 1-3; X is an organic gene containing amino group or amine group; meanwhile, the structure formula is R-X. The nonyl phenol poly-oxypropylene ether amine has better detergent dispersing property and low production cost, can be widely applied to motor petrol and fuel additive of a light diesel engine, and ink dispersant and polyether curing agent, and is especially used for matching with polyisobutene amine, and can effectively prevent carbon distribution from producing in an engine cylinder.

Owner:天津市澳林特石油科技有限公司

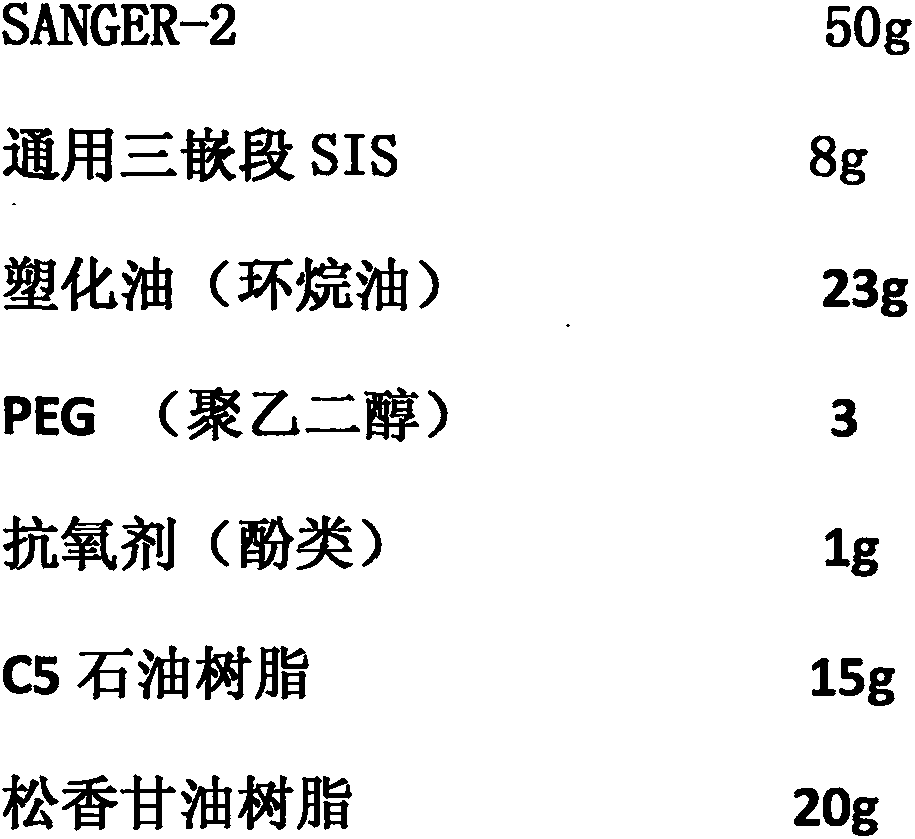

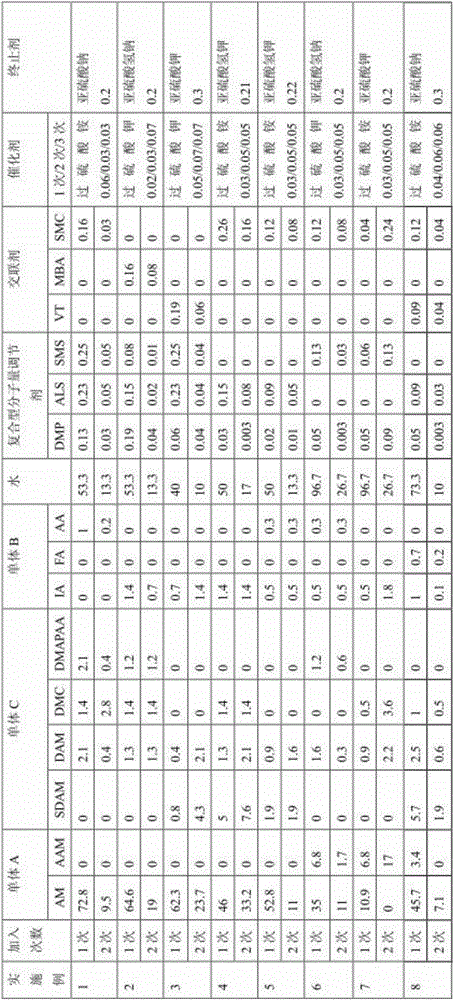

Temperature-controlled and slow-release fertilizer production process

InactiveCN102464506AReduce white pollutionReduce manufacturing costFertilizer mixturesCross-linkNetwork size

The purpose of the invention is to provide a temperature-controlled and slow-release fertilizer production process. According to the process, a natural turpentine oil is added to the raw material so as to adjust polymer molecule structure, functional groups, adhesion, glass transition temperature, molecular weight, molecular distribution, cross-linked network size, hydrophilicity and hydrophobicity; the process comprises the following steps: (1) preparing a coating liquid; (2) spraying the coating liquid with temperature controlling; (3) treating waste gas; (4) packaging the finished product. With the production process of the present invention, the temperature-controlled and slow-release fertilizer can control the nutrient release along with the soil temperature curve and according to different requirements of the effective nutrients in composite fertilizer by different crops in different periods. With the present invention, the waste packaging bag can be recycled to adopt as the coating agent of the composite fertilizer, such that the white pollution is reduced, and the production cost is reduced. In addition, the used solvent adopts the natural raw material, such that no pollution is generated, and the effects of energy saving and environmental protection are significant.

Owner:SHANDONG HUAKEN FERTILIZER IMPORT & EXPORT

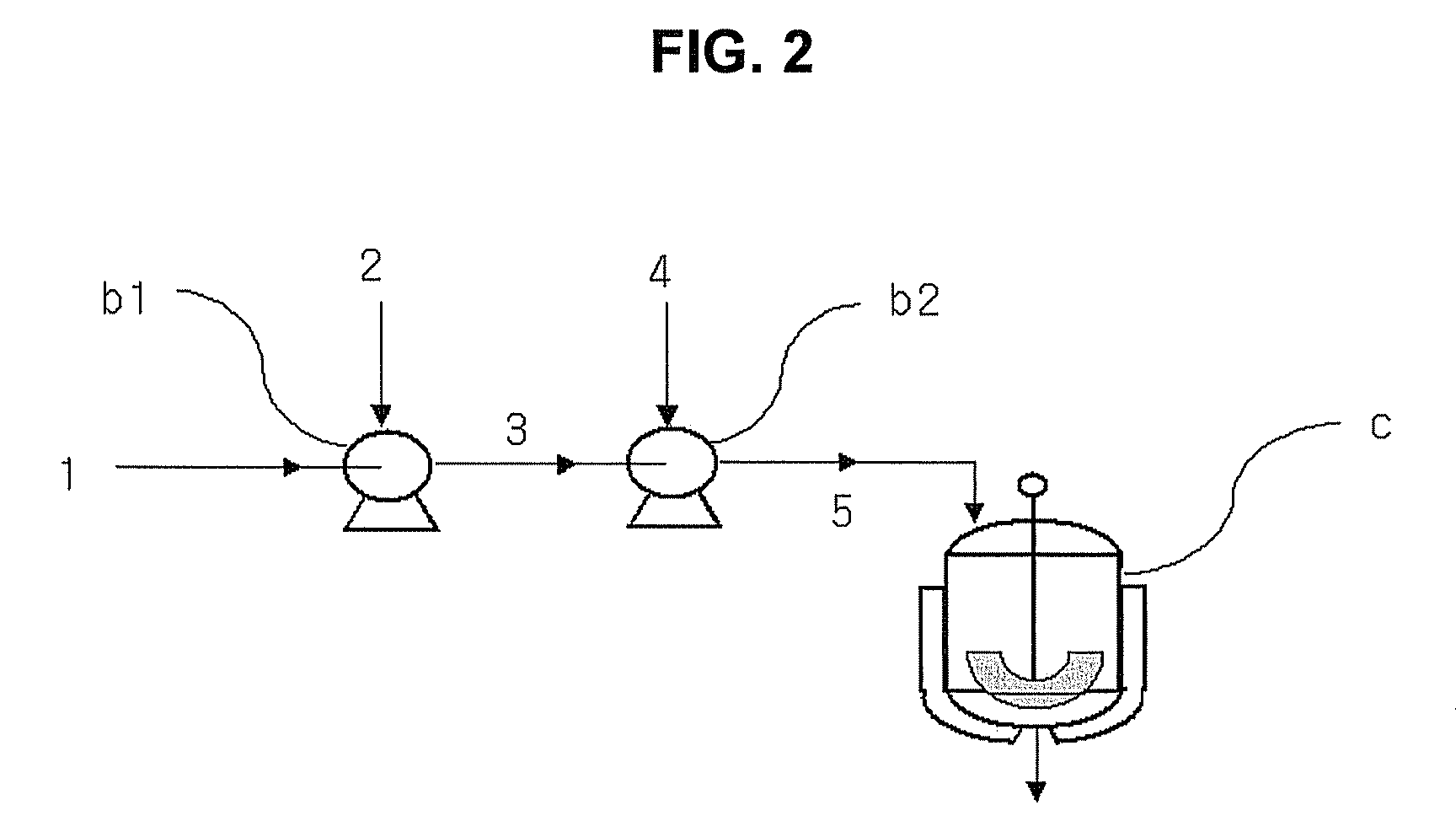

SAN (styrene-acrylonitrile copolymer) preparation method

ActiveCN102382228AGood molecular weight control abilityMolecular weight controlHalohydrocarbonAcrylonitrile

The invention relates to an SAN (styrene-acrylonitrile copolymer) preparation method. The SAN preparation method includes steps of adding polymerized monomers into a closed reactor which is filled with nitrogen and dried to be mixed uniformly, adding uniformly-mixed solvent and catalyst at one step by an injector, controlling the temperature of a reaction system within a range from 60 DEG C to 110 DEG C, and pouring reacted mixture into hydrochloric acid carbinol mixed solution containing 2% to 10% by weight of hydrochloric acid after two to eight hours of reaction so as to stop polymerization. The catalyst is titanium complex, and the preparation method of the titanium complex includes steps of adding titanium tetrachloride, ligand, halohydrocarbon and solvent into a closed vacuum container sequentially so as to react for 15 minutes to 60 minutes at the constant temperature ranging from 40 DEG C to 100 DEG C, and then producing the catalyst of the titanium complex after cooling. Compared with the prior art, the SAN preparation method utilizes the catalyst which is the metal coordination catalyst, has excellent molecular weight control ability, and can well control the molecular weight of copolymers, dispersion of the molecular distribution is narrow, and Mw / Mn=1.3 to 2.0.

Owner:ZHEJIANG OCEANKING DEVELOPMENT CO LTD

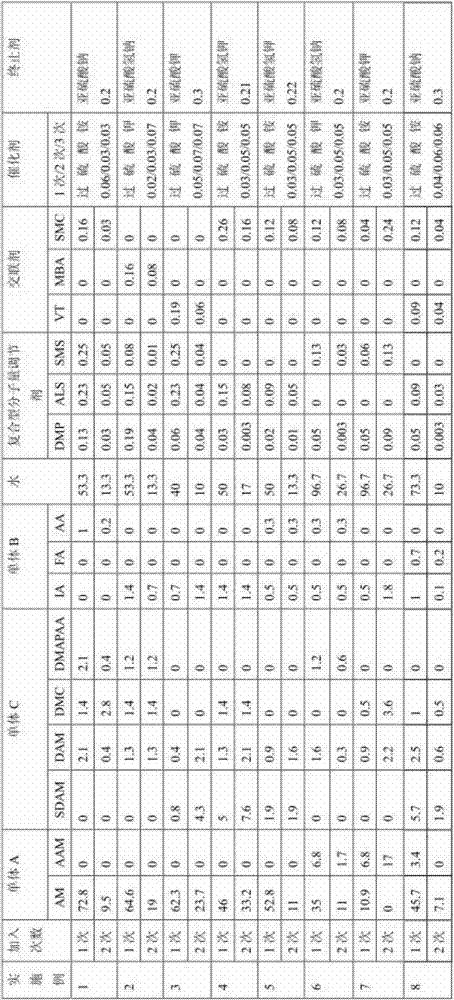

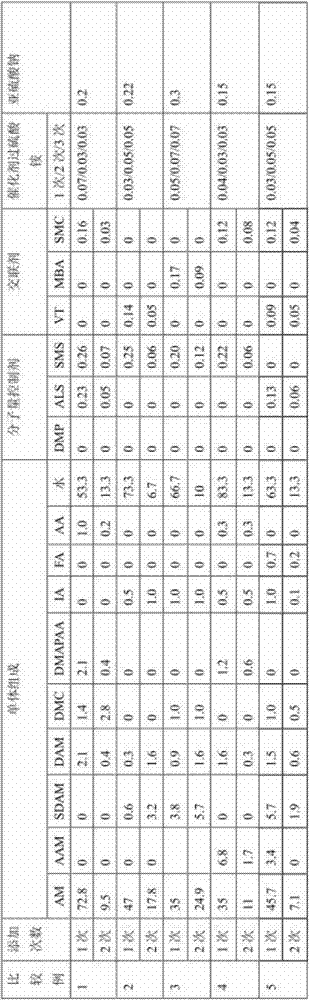

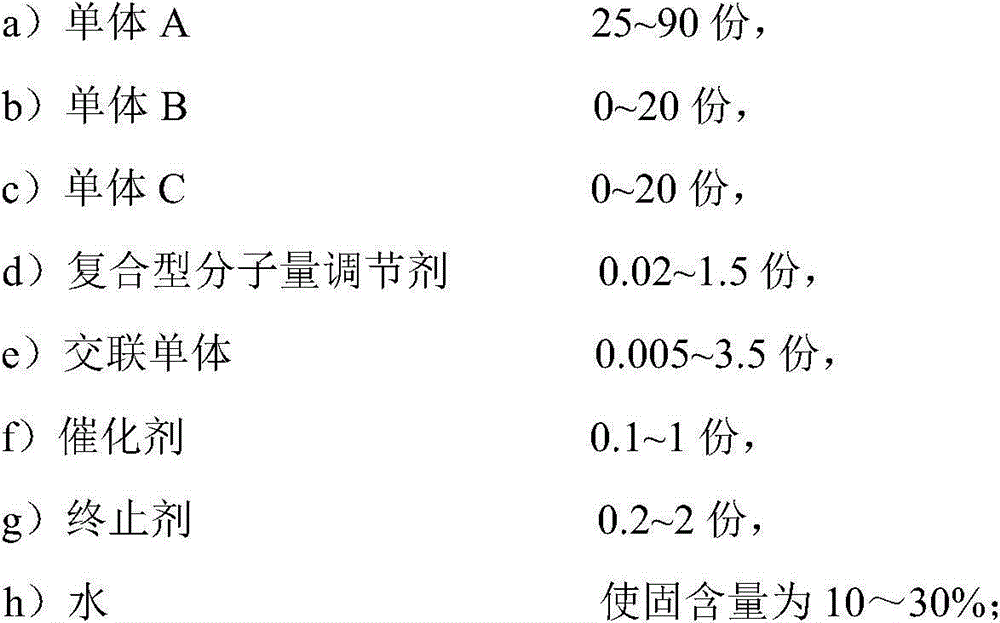

Preparation method and application of cross-linked polyacrylamide with high molecular weight and narrow distribution

ActiveCN103772603AReduce churnImprove acceleration performanceReinforcing agents additionPaper/cardboardCross-linkWhite water

The invention relates to the field of papermaking and paper chemicals, aims to solve the problem that a paper used polyacrylamide dry strength additive, which has an efficient enhancement effect, and is good in adhesiveness, and environmentally friendly, is required to be prepared in the papermaking industry at present, and provides a preparation method of cross-linked polyacrylamide with high molecular weight and narrow distribution and application of the cross-linked polyacrylamide to papermaking. The cross-linked polyacrylamide prepared with the preparation method has higher weight-average molecular weight and narrower molecular distribution, and has the advantages of good enhancement effect, low loss of white water, good adhesiveness, less jello, environmental protection and the like. When the cross-linked polyacrylamide is applied to various fields, actual effective constituents are concentrated better, the operating barrier is reduced, and fewer side effects are caused.

Owner:HANGZHOU HANGHUA HARIMA PAPER CHEM

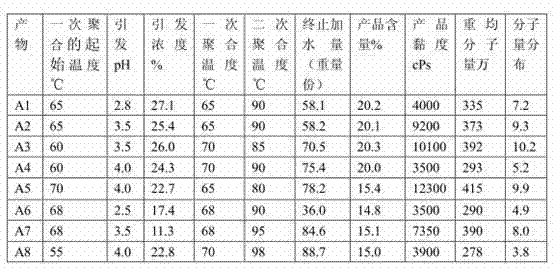

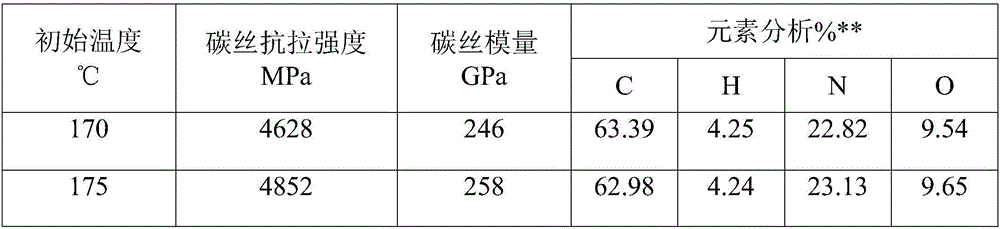

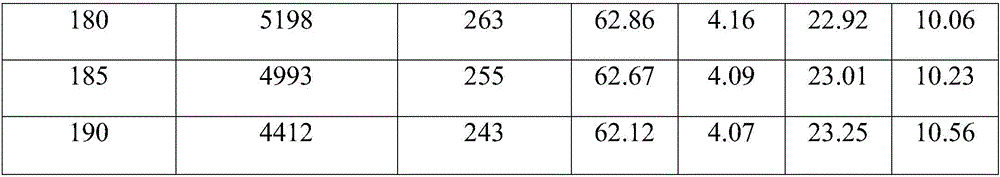

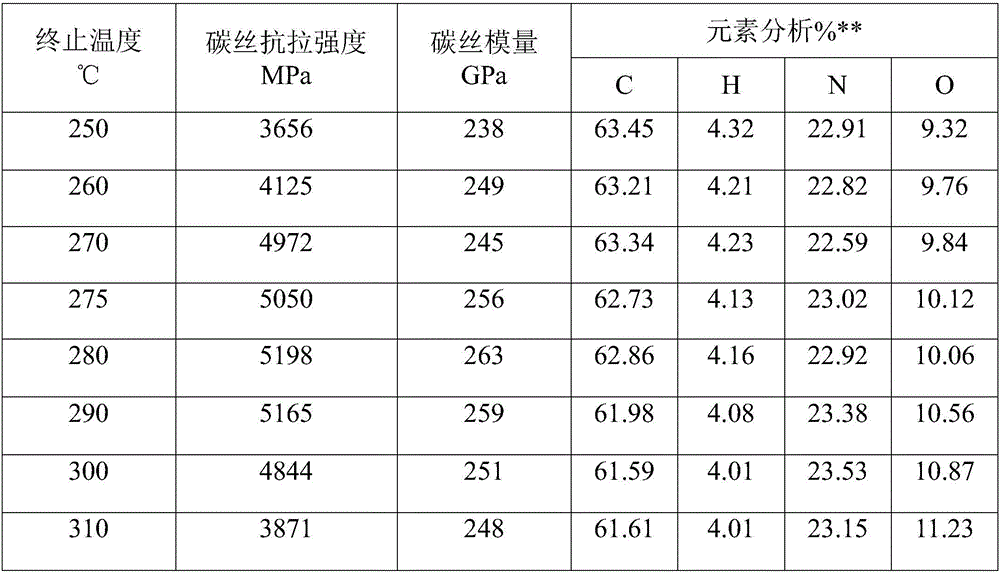

Method for preparing carbon fibers by carbonizing polyacrylonitrile precursors

ActiveCN106835365AImprove heat resistanceHigh degree of molecular orientationFibre chemical featuresPolymer scienceCarbon fibers

The invention provides a method for preparing carbon fibers by carbonizing polyacrylonitrile precursors. The method comprises the following steps: 1, pre-oxidizing in multiple temperature zones at the temperature of 160-310 DEGC for 60-120 minutes with the draft degree of 0.5-10 percent; 2, carbonizing in multiple temperature zones at low temperature of 400-1000 DEG C for 60-120 seconds with the total draft degree of 1-8 percent; and 3, carbonizing in multiple temperature zones at high temperature of 800-1600 DEG C for 60-120 seconds with the draft degree of negative 8 percent-negative 1 percent. According to the method, the temperature gradient, temperature range, draft ratio, wire traveling speed and other parameters in each stage of the carbonizing process are reasonably designed, so that the pre-oxidizing and carbonizing processes can be performed smoothly, and pre-oxidized fibers have good heat resistance, high molecular orientation degree and compact molecular distribution, uniform carbon fiber structure and few broken and paralleled fibers, and have a tensile strength of over 5000MPA, so that the aim of improving carbon fiber product quality can be achieved.

Owner:HARBIN TIANSHUN CHEM TECH DEV CO LTD

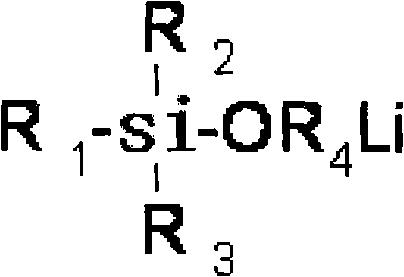

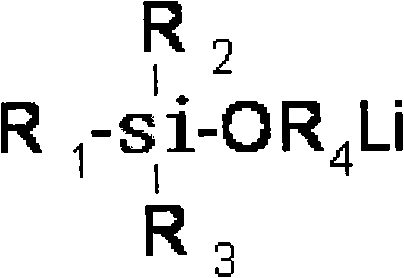

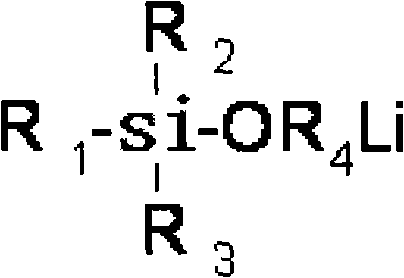

Acyclic lithium alkylide evocating agent with hydroxylic protected by silane, preparation thereof and application thereof

The invention provides an evocating agent for lithium alkylide of aliphatic series for silane protecting hydroxyl and a preparation method thereof. In a polar solvent, imidazole or pyridine is used as a catalyst, and halogenosilane is used for protecting the hydroxyl of haloalcohol and producing halogenoalkoxylsilaneaether; then in a non-polar solvent, halogenoalkoxylsilanea ether reacts with lithium metal or butyl lithium and produces the evocating agent for lithium alkylide of aliphatic series for silane protecting hydroxyl. The lithium aliphatic alkylide for protecting hydroxyl of silane in the invention has high activity, is easy to be dissolved in a non-polar organic solvent; protecting groups are easily hydrolyzed and an epoxy is extremely easy to be used for end capping and forming a polymer of which one end is provided with hydroxyl. When the evocating agent is used for evocating a polymer of hydroxyl-terminated polybutadiene liquor, the polymer with narrow molecular distribution (Mw / Mn is less than 1.2) is obtained; the polymer does not encounter with a fake gel phenomenon in the processes of end capping and removing the protecting groups and the average functionality thereof is close to 2.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

Preparation method of polydimethylsilane with uniform molecular weight distribution

The invention relates to a preparation method of polydimethylsilane with uniform molecular weight distribution. The method comprises the following steps: dissolving dimethyl dichlorosilane into methylbenzene to obtain a first mixed solution; putting sodium sand into the first mixed solution under the dark condition, carrying out heating reflux for the first time in an ammonia environment, and cooling to room temperature to obtain a second mixed solution; dropwise adding anhydrous ethanol into the second mixed solution, and carrying out suction filtration to obtain precipitate; mixing the precipitate with sodium sand, putting the mixture into methylbenzene, and carrying out heating reflux for the second time in the ammonia environment so as to obtain a third mixed solution; dropwise addinganhydrous ethanol into the third mixed solution, and carrying out suction filtration to obtain precipitate; then, washing and drying the precipitate to obtain the white powder product polydimethylsilane. The preparation method provided by the invention is simple and does not need complicated equipment; the prepared polydimethylsilane is high in yield, large in molecular weight and narrow in molecular distribution range; after the polydimethylsilane is subjected to cracking and rearrangement, polycarbosilane which is high in high molecular weight ratio and uniform in performance can be generated.

Owner:南昌嘉捷天剑新材料有限公司

Block copolymer of aromatic hydrocarbon, conjugated diene and epoxide and preparation method thereof

PendingCN107057005AImprove lipophilicityImprove protectionPharmaceutical non-active ingredientsSheet deliveryPolymer scienceEnd-group

The invention relates to a block copolymer of aromatic hydrocarbon, conjugated diene and epoxide and a preparation method thereof. The block copolymer forms 3-13 blocks through the homopolymer and / or copolymer of the monomers; the ordering of the main chain macromolecule block is that the blocks with different characters are adjacent, the block copolymer has both the thermoplastic elastomer attribute and the compatible feature of the polar compound through the composition, the molecular weight and the molecular distribution of each block, the microstructure, block sequence and number, functional end group and like parameter regulation. The preparation method is performed in two continuously connected processes, is high in efficiency, low in material consumption and non-toxic and pollution-free in the production process; the product meets the green environment-friendly and energy-saving requirement. The block copolymer is the new generation of hot-melting pressure-sensitive macromolecule general base material used as the traditional Chinese medicine paste patch, and has the excellent features of being low in medicating temperature, large in medicine loading capacity, good in biological compatibility and controllable in release force.

Owner:刘青 +1

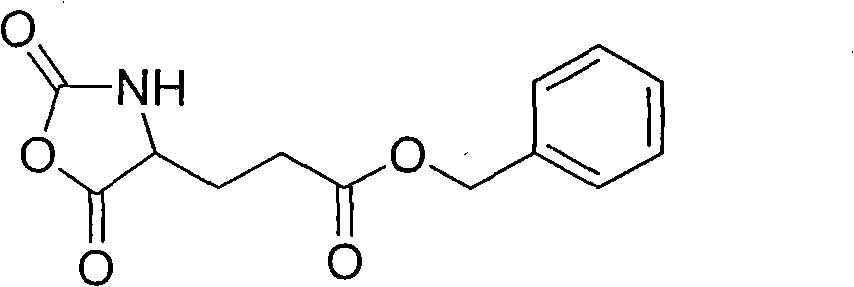

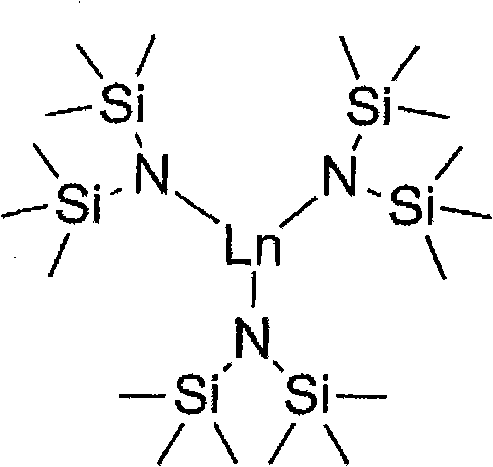

Method for synthesizing polypeptide in presence of ammonia-base rare earth catalyst

InactiveCN101906210ARaw materials are cheap and easy to getHigh activityRare earth metal compoundsTrimethylsilyl

The invention discloses a method for synthesizing polypeptide in the presence of ammonia-base rare earth catalyst, which is characterized in that: tri(bis(trimethylsilyl)) rare earth metal compound is used as a catalyst to catalyze the ring-opening polymerization of a benzyl-gama-glutamate-N-carboxylic anhydride monomer to synthesize the polypeptide of which the molecular weight is 18,000 to 80,000, wherein the molar ratio of the catalyst to the monomer is 1:80 to 1:1,200; the reaction temperature is 0 to 60 DEG C; the reaction time is 1 to 3 days; a solvent is N,N-dimethylformamide; and the concentration of the monomer is 0.5mol / L. Compared with the prior art, the method has the advantages that: the used catalyst is cheap and easy to prepare and has high catalytic activity; and the molecular weight of the prepared polypeptide is controllable and the molecular distribution of the prepared polypeptide is narrow.

Owner:ZHEJIANG UNIV

Preparation method and application of high molecular weight narrow distribution cross-linked polyacrylamide

ActiveCN103772603BHigh weight average molecular weightSmall molecular weight distributionReinforcing agents additionPaper/cardboardCross-linkSide effect

The invention relates to the field of papermaking and paper chemicals, aims to solve the problem that a paper used polyacrylamide dry strength additive, which has an efficient enhancement effect, and is good in adhesiveness, and environmentally friendly, is required to be prepared in the papermaking industry at present, and provides a preparation method of cross-linked polyacrylamide with high molecular weight and narrow distribution and application of the cross-linked polyacrylamide to papermaking. The cross-linked polyacrylamide prepared with the preparation method has higher weight-average molecular weight and narrower molecular distribution, and has the advantages of good enhancement effect, low loss of white water, good adhesiveness, less jello, environmental protection and the like. When the cross-linked polyacrylamide is applied to various fields, actual effective constituents are concentrated better, the operating barrier is reduced, and fewer side effects are caused.

Owner:HANGZHOU HANGHUA HARIMA PAPER CHEM

Orthopaedic internal fixation fibroin component and preparation method thereof

ActiveCN108126247AStable alkalineSo as not to damageChemical industrySurgeryFreeze-dryingBiocompatibility Testing

The invention discloses an orthopaedic internal fixation fibroin component and a preparation method of the component. The preparation method comprises the steps of: 1, performing desalination by a diffusion dialysis-electrodialysis integrated technology to prepare a high-purity fibroin solution, 2, converting the fibroin solution into anhydrous fibroin by a vacuum freeze drying technology, 3, dissolving the anhydrous fibroin in hexafluoroisopropanol to form a hexafluoroisopropanol solution of the fibroin, 4, injecting the hexafluoroisopropanol solution of the fibroin into a mold to prepare a fibroin solid by a methanol treatment and airing technology, and 5, machining the fibroin solid into a bone nail and a bone plate. The orthopaedic internal fixation fibroin component prepared by adjusting molecular weight, molecular distribution, crystallization forming parameters and processing parameters has excellent mechanical strength and biocompatibility, is not required to be taken out by secondary operations, is controllable in a degradation rate and free from toxic and immunological rejection effects, and has wide clinical application prospects, and degradation products are amino acidand polypeptide capable of being absorbed by a human body.

Owner:GUANGZHOU ANZE REGENERATIVE MEDICINE TECH CO LTD

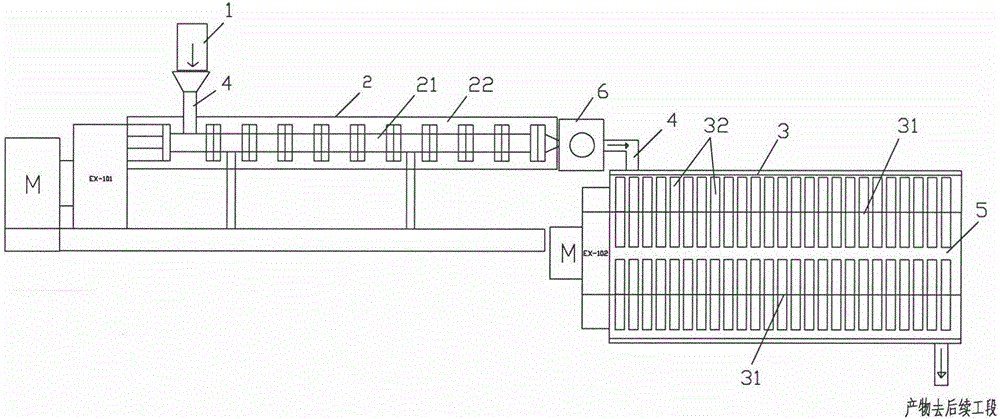

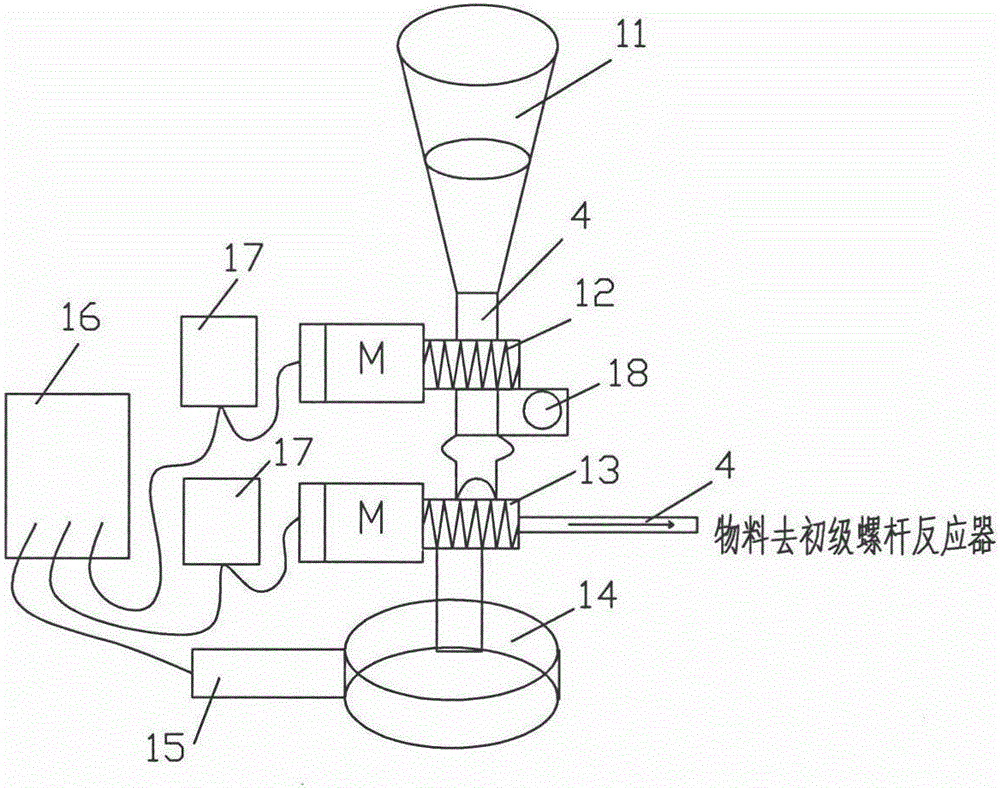

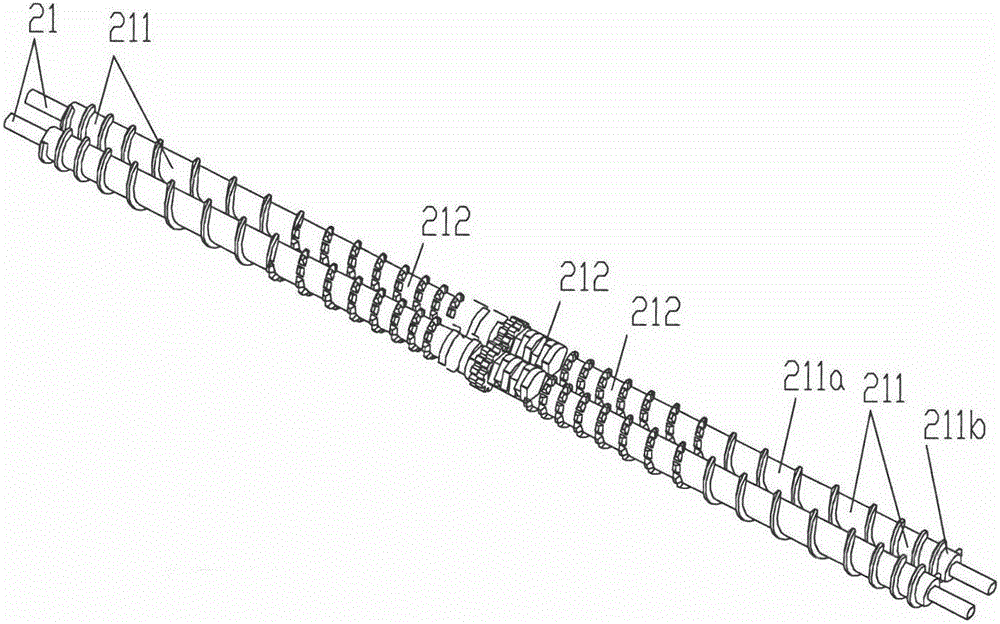

Device and method for continuous production of amino resin

ActiveCN106750072AOptimize environmental protection emission indicatorsImprove quality stabilityTemperature controlChemical composition

The invention relates to a device and a method for continuous production of amino resin. The device comprises an automatic and continuous raw material distribution device, a primary screw reactor and a double-screw cylindrical steel block combined reactor which are sequentially communicated. The method comprises the following step of continuously running a reaction material in the device under the action of automatic temperature control. The device and the method have the advantages that the raw material is added at the front end of the automatic and continuous raw material distribution device; a resin product is continuously escaped out of the tail end of the double-screw cylindrical steel block combined reactor; the method is used for replacing an intermittent reaction kettle resin production method, the stable quality requirement of resin semi-finished products in a subsequent section is met, the emission of chemical components in the macromolecular synthesis reaction of the traditional device is prohibited, and the defects of large viscosity difference, poor quality stability, wide molecular distribution and the like of produced resin in a traditional reaction kettle intermittent mode are overcome.

Owner:PUYANG GREEN FOAM CO LTD

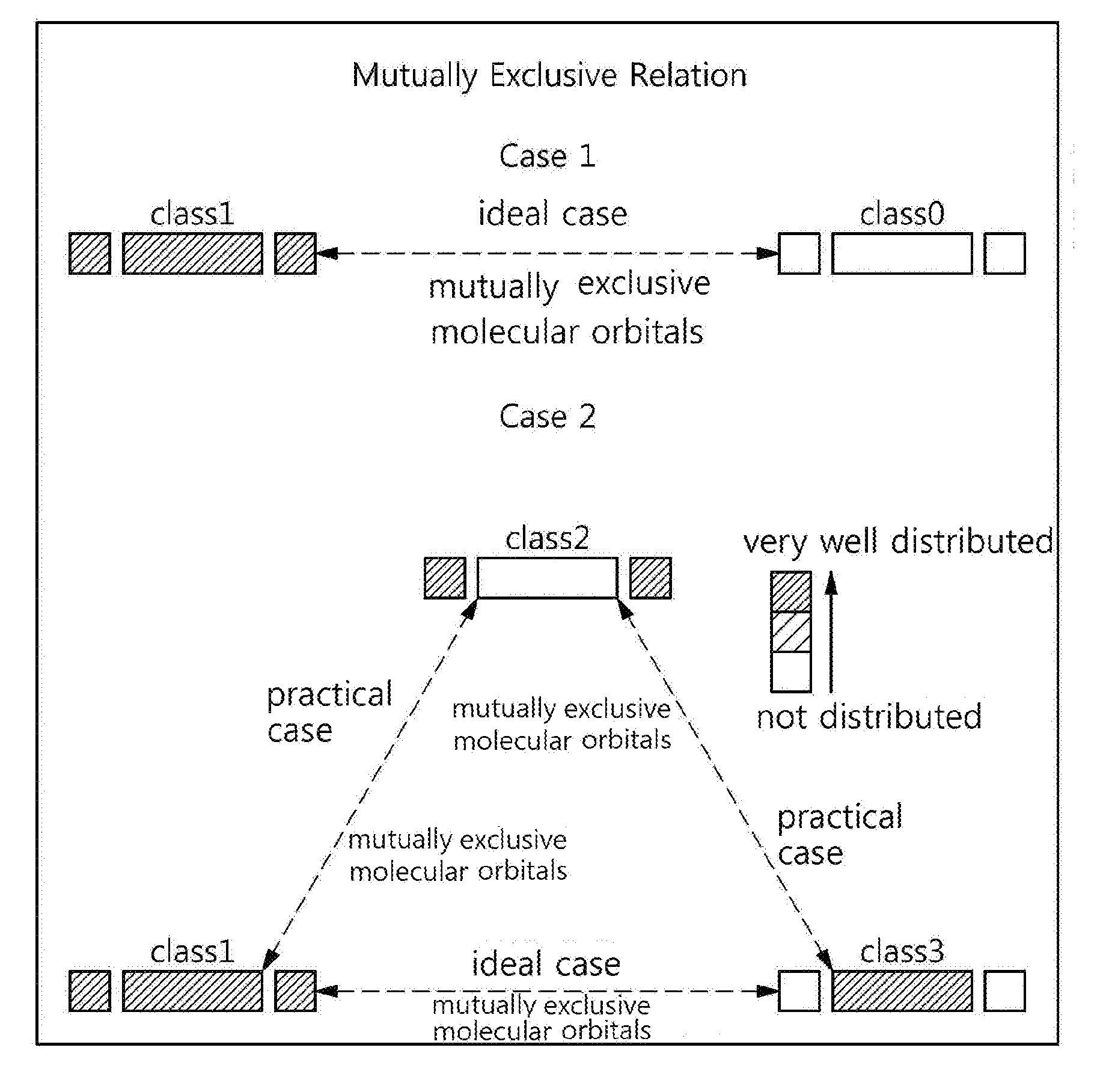

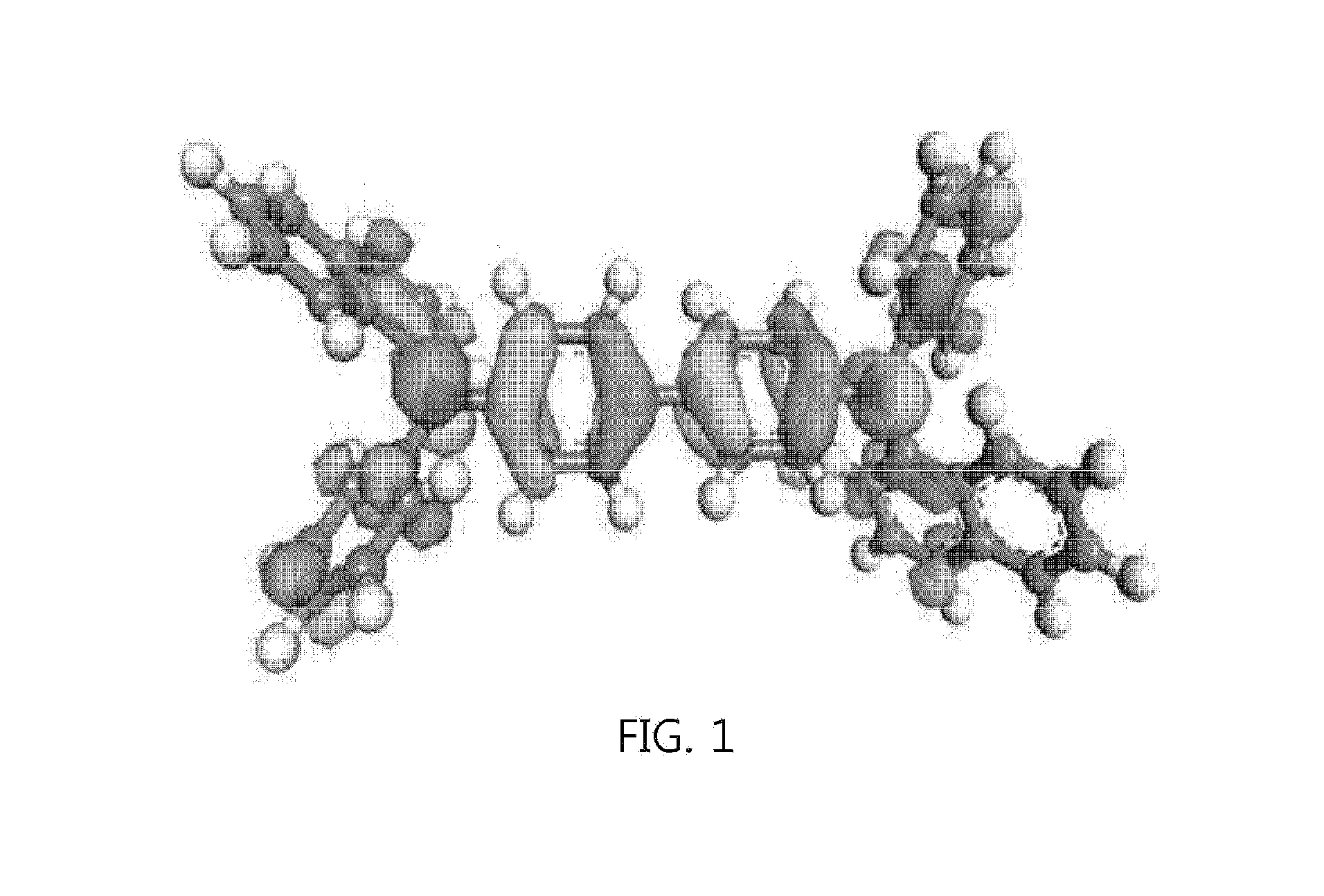

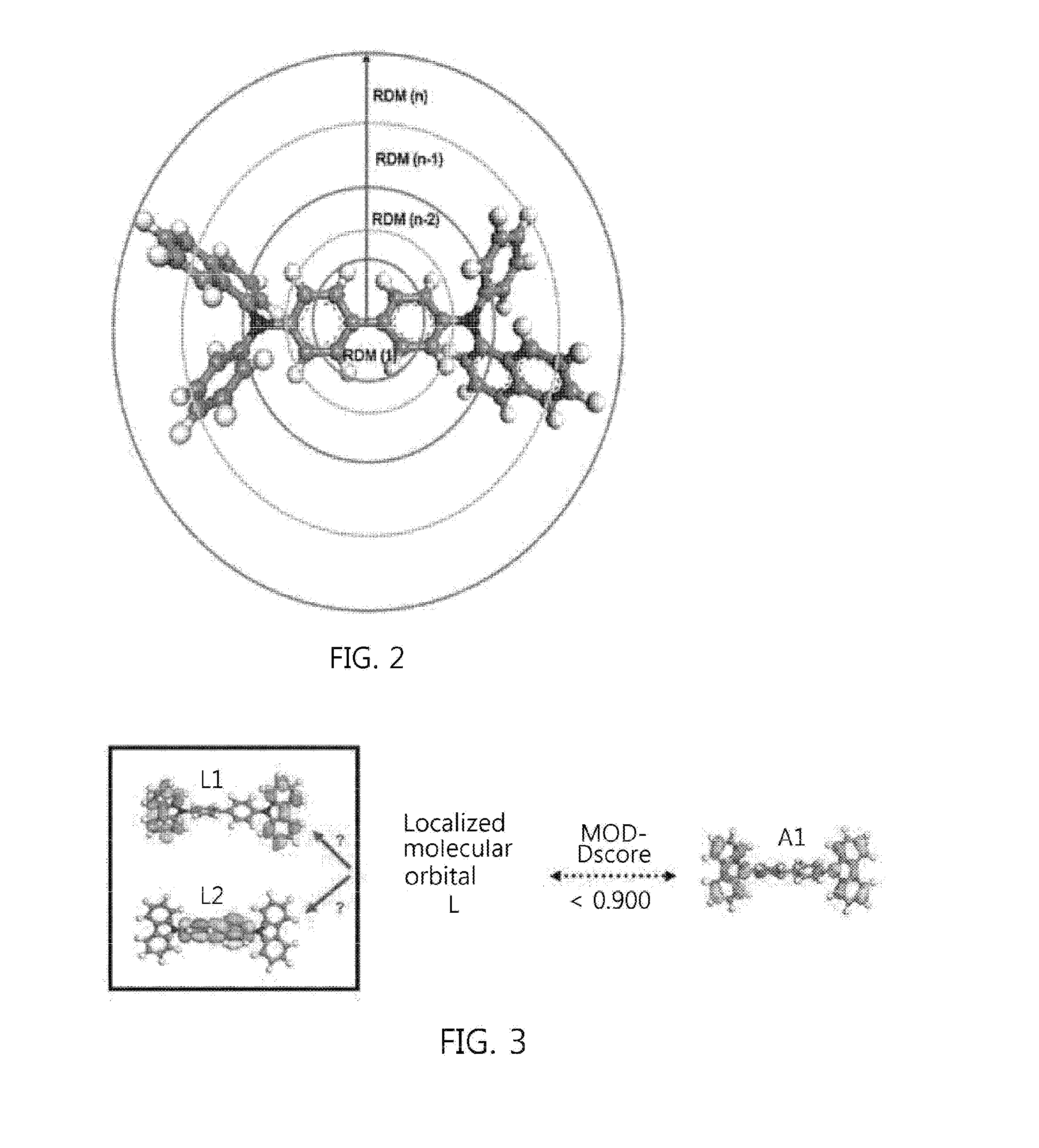

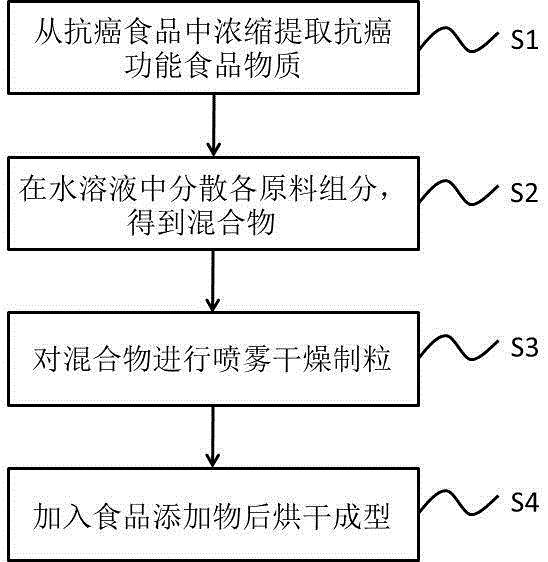

Molecular orbital library having exclusive molecular orbital distribution, molecular orbital distribution region evaluation method using same, and system using same

ActiveUS20160140325A1Accurate estimateExpand coverageOrganic chemistry methodsComputation using non-denominational number representationChemical physicsEstimation methods

Disclosed herein are a method for constructing an extended R-MO library with mutually exclusive molecular orbital distribution, calculation method of molecular orbital distributing region and a system using the same. The molecular orbital distributing region estimation method using a molecular orbital library with a mutually exclusive orbital distribution can accurately molecular orbital distributing regions in a quantitative manner by means of an extended R-MO library that expresses intrinsic molecular distributing region properties in various patterns. In addition, the coverage of the quantitative molecular orbital distribution estimation method can be extended to the systemic utilization of molecular orbital information in developing materials.

Owner:LG CHEM LTD

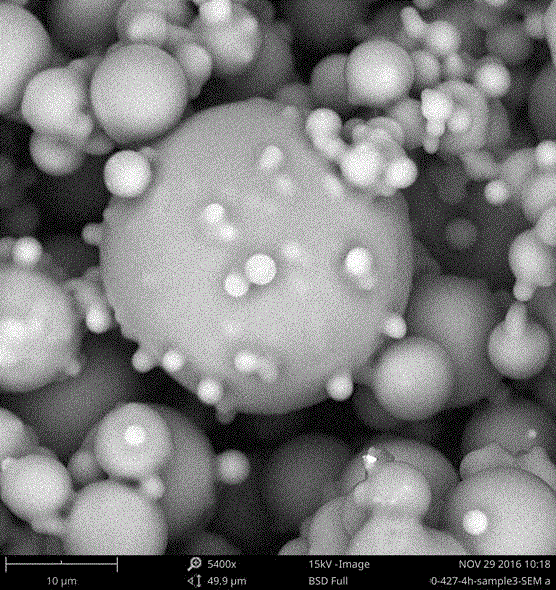

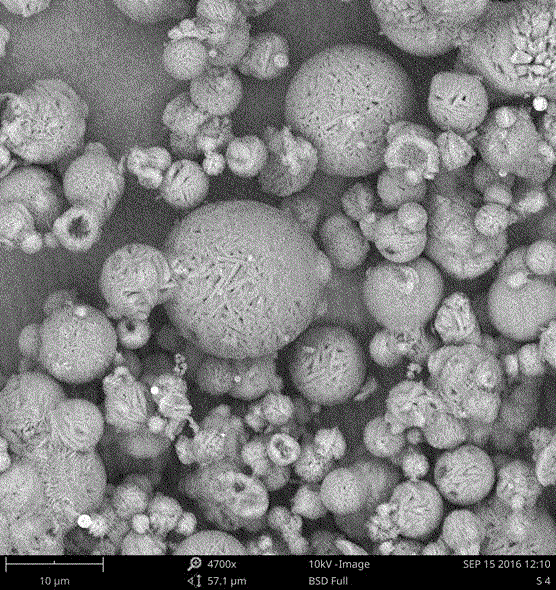

Quick-dissolving type anti-cancer meal replacement powder and preparation method and use method thereof

InactiveCN106722945AImprove anti-cancer effectHigh yieldFood ingredient functionsFood additiveMeal replacement

The invention relates to a quick-dissolving type anti-cancer meal replacement powder and a preparation method and a use method thereof. The quick-dissolving type anti-cancer meal replacement powder is prepared from the following raw material components in parts by mass: 10 to 30 parts of anti-cancer functional food matter, 10 to 30 parts of protein powder, 20 to 40 parts of carbohydrate, 1 to 10 parts of lipid, 1 to 10 parts of nutrient element and 1 to 10 parts of food additive, wherein the components are combined in an amorphous state or low crystalline state molecular distribution way to form a microparticle product with size of 1 to 100mu m. The preparation method of the quick-dissolving type anti-cancer meal replacement powder has the advantages that an anti-cancer matter extracting technique, a nutrient balance proportioning method and a spraying, drying and granulating technology are integrated and jointly used, the dietary therapy anti-cancer effect of the product and an absorbing rate of a human body are enhanced, and the intake of excessive nutrient and active matters by cancer tumor cells is avoided. The use method has the advantages that by flexibly changing the intake type of the quick-dissolving type anti-cancer meal replacement powder, the mouth feel requirement of different consumers can be met; the practicality and popularizing property of the product are further improved.

Owner:谭淞文

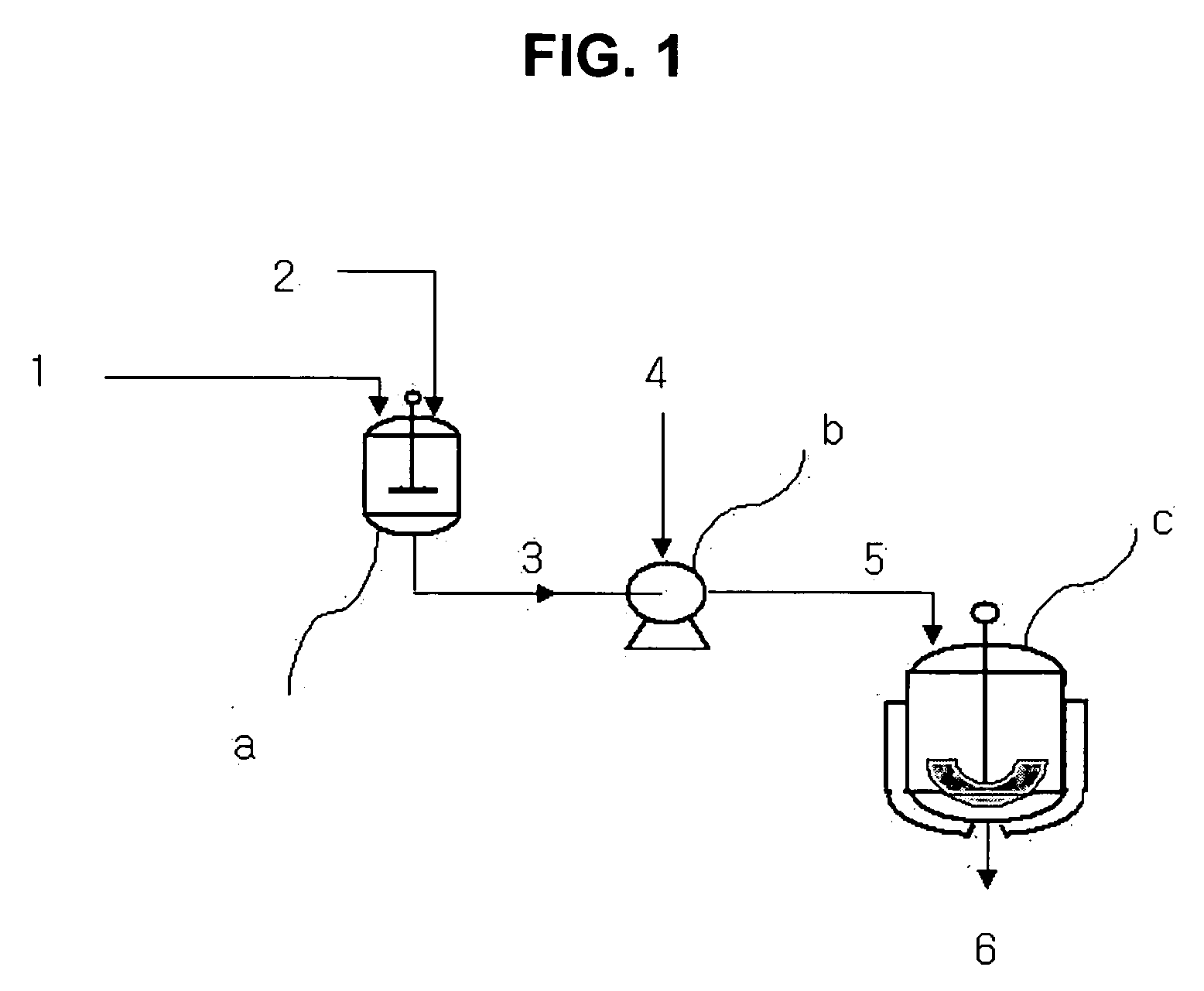

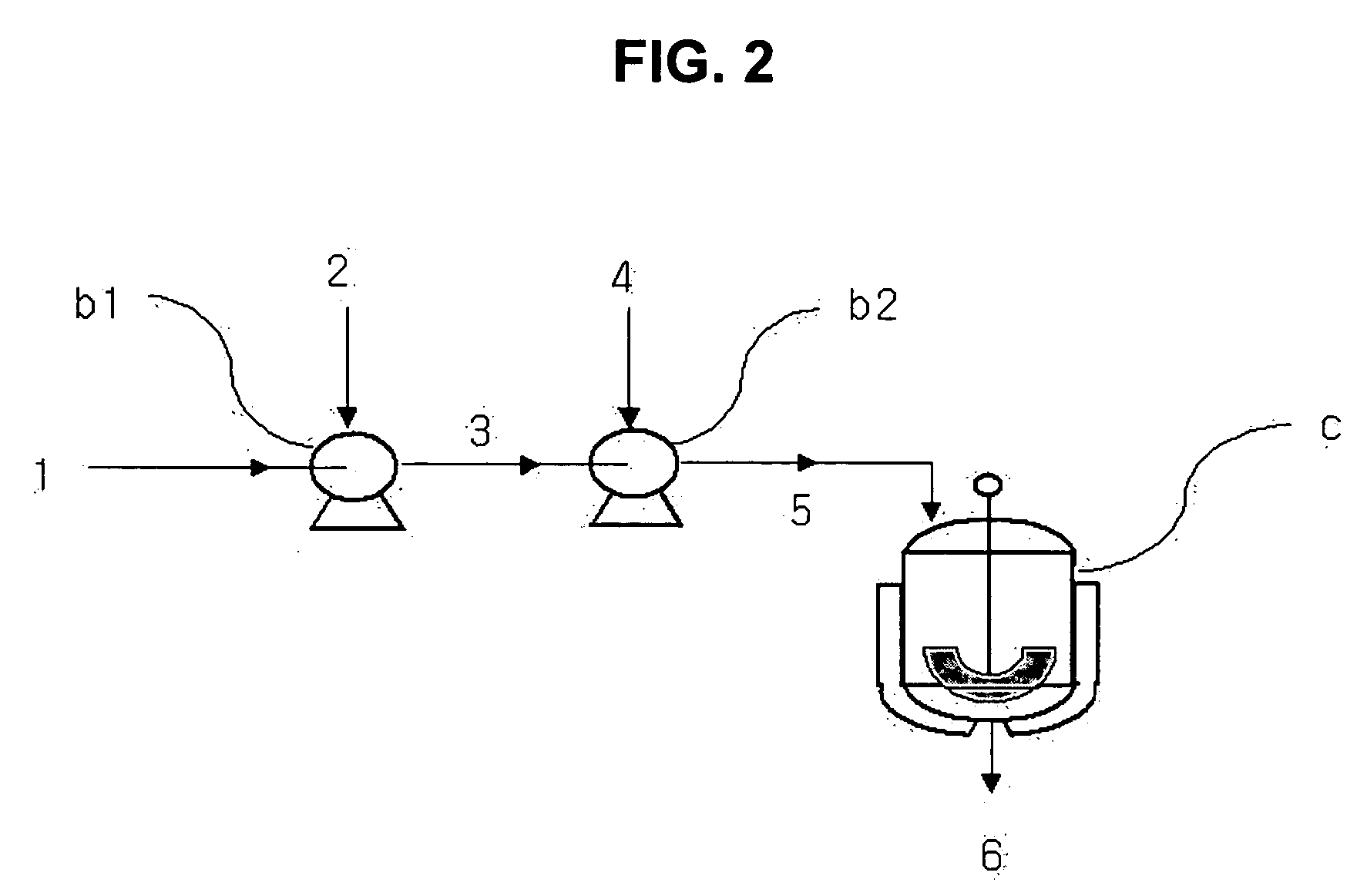

Method of producing styren polymers using high speed catalytic dispersion technology

InactiveUS20060247398A1High activityUniform molecular weight distributionPolymer scienceOrganic solvent

Provided is a method of preparing styrene polymers, the method comprising: homogeneously mixing a styrene monomer; a cocatalyst mixture of Group 13 metal-containing organic metal compound cocatalyst and an inert organic solvent; and a catalyst mixture of a metallocene catalyst and the inert organic solvent using a high speed homogenizing mixer to obtain a homogenized mixture; and providing the homogenized mixture to a reactor to initiate polymerization. In this method, catalyst is quickly dispersed among monomers using a high speed homogenizing mixer so that formation of gel, which occurs when a syndiotactic styrene polymer is produced, can be fundamentally prevented. In addition, a styrene polymer prepared using the method has high activity, good stereoregularity, and uniform molecular distribution.

Owner:LG CHEM LTD

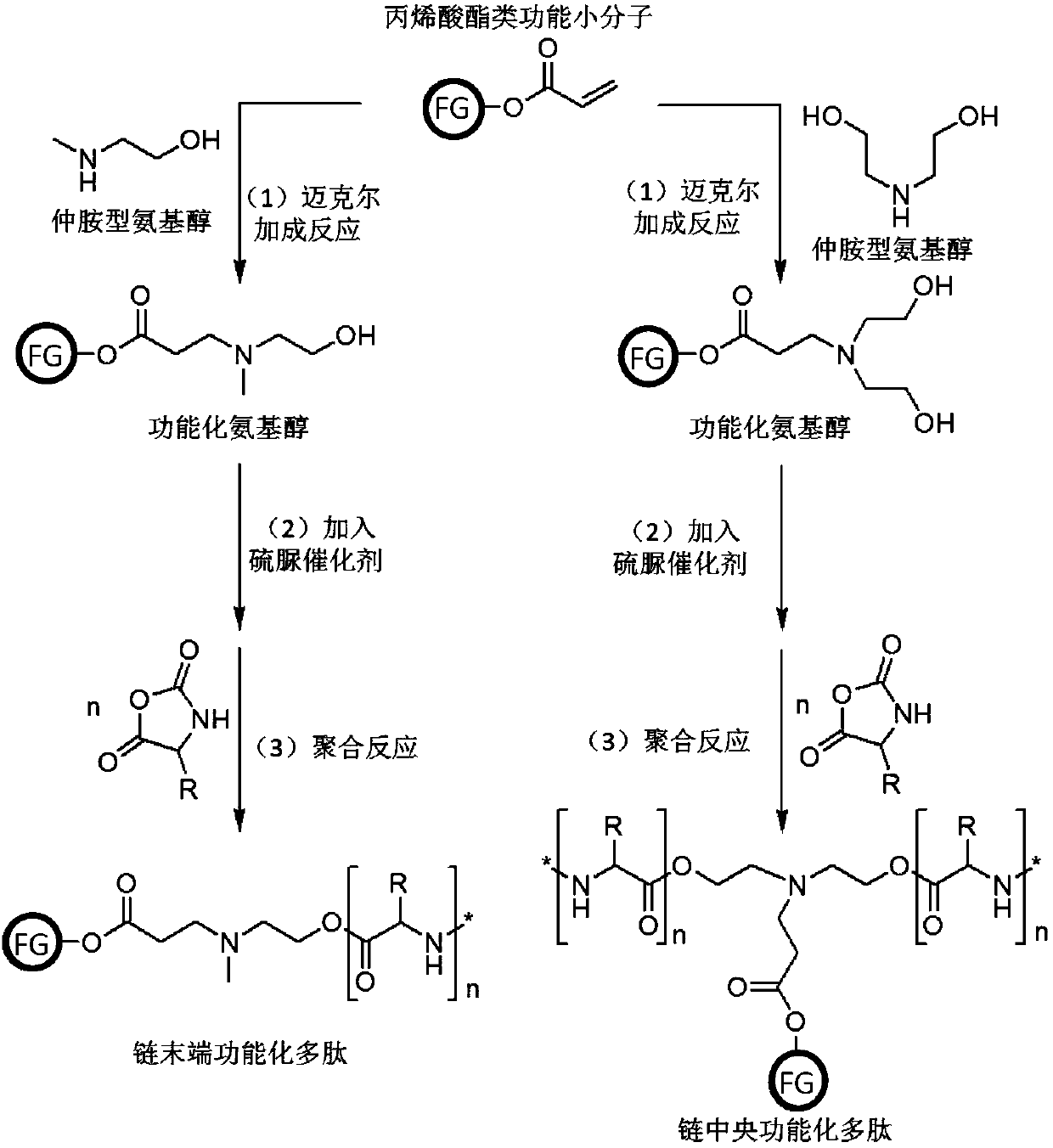

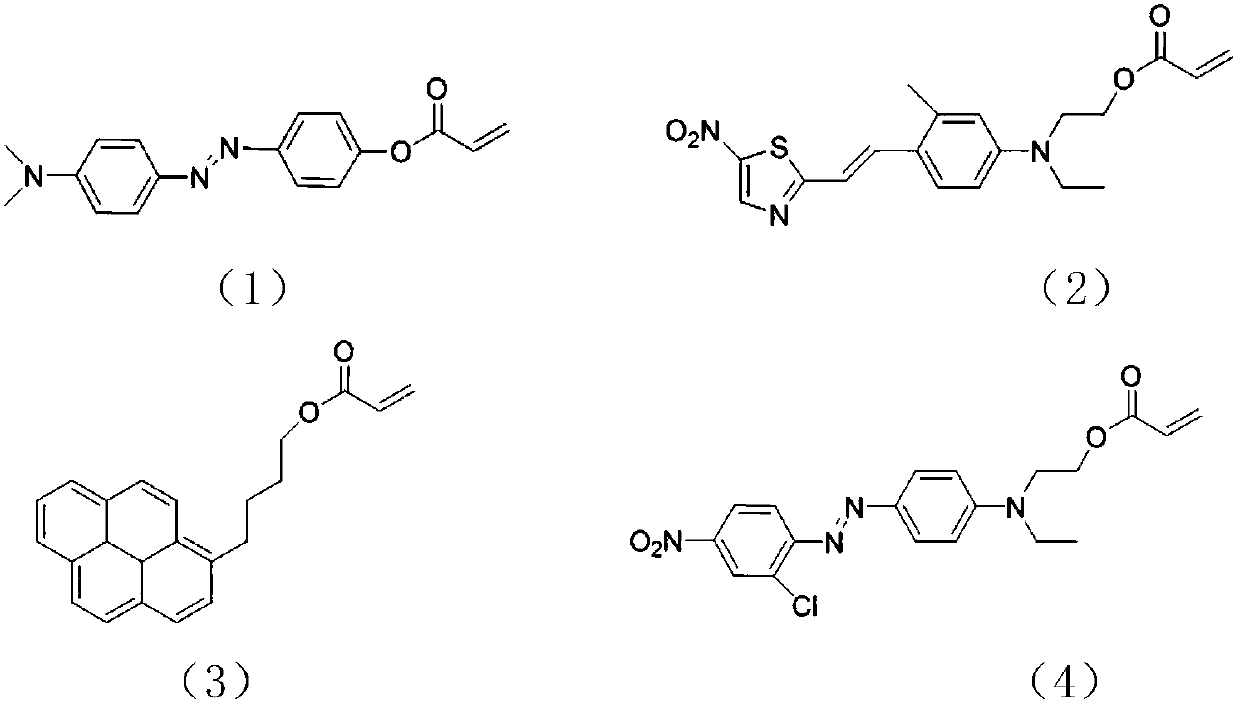

Method of preparing functional polypeptide by one-pot method

ActiveCN109593195AThe reaction route is simple and clearMolecular weight controllablePeptide preparation methodsDepsipeptidesThioureaRing-opening polymerization

The invention relates to a method of preparing functional polypeptide by a one-pot method. The method comprises the following steps: dissolving acrylate functional small molecules and secondary amineamino alcohol in an organic solvent at constant temperature to react to generate a functional tertiary amine amino alcohol initiator; and then successively adding a catalyst thiourea, an amino acid intra-annular anhydride monomer to initiate ring opening polymerization of an NCA monomer to generate a chain end or chain center functional polypeptide. The method is simple and clear in experimental route, low in price and easily available in raw material and mild in reaction condition, and the obtained functional polypeptide has the characteristics of being clear, free of metal residues and controllable in molecular weight and molecular distribution.

Owner:SHAANXI UNIV OF SCI & TECH

Method of producing styrene polymers using high speed catalytic dispersion technology

Provided is a method of preparing styrene polymers, the method comprising: homogeneously mixing a styrene monomer; a cocatalyst mixture of Group 13 metal-containing organic metal compound cocatalyst and an inert organic solvent; and a catalyst mixture of a metallocene catalyst and the inert organic solvent using a high speed homogenizing mixer to obtain a homogenized mixture; and providing the homogenized mixture to a reactor to initiate polymerization. In this method, catalyst is quickly dispersed among monomers using a high speed homogenizing mixer so that formation of gel, which occurs when a syndiotactic styrene polymer is produced, can be fundamentally prevented. In addition, a styrene polymer prepared using the method has high activity, good stereoregularity, and uniform molecular distribution.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com