Method for preparing branched high vinyl polybutadiene rubber using molybdenum series catalysis

A technology for branching high-vinyl polybutadiene and high-vinyl polybutadiene, which is applied in the field of molybdenum-based catalyzed preparation of branched high-vinyl polybutadiene rubber, which can solve branching tunability and physical and mechanical problems. Unsatisfactory performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Add the hydrogenated gasoline solution of butadiene into the stirred reactor that has been evacuated and filled with nitrogen, and then add stoichiometric benzyl chloride and PPh sequentially with a syringe. 3 Toluene solution, MoCl 3 (OC 8 h 17 ) 2 , m-cresol substituted triisobutylaluminum Al(OPhCH 3 )(i-Bu) 2 . Heating with an oil bath, the constant temperature is T=90°C, the reaction time is 8h, the reaction is terminated with ethanol, the polymer is precipitated, washed and dried. Among them, Al / Mo=30, Mo / Bd=2×10 -4 , benzyl chloride / PPh 3 / Bd=1 / 3 / 2000 (molar ratio).

[0045] aggregation method

C%

M n ×10 4

M w ×10 4

DPI

Gel(%)

P

P+A

100

83.4

19.6

9.3

37.1

24.1

1.9

2.6

0

1.36

[0046] P: coordination polymerization; A: ATRP; P+A: coordination polymerization and ATRP in situ polymerization.

[0047] Coordination polymerization conditions: Al / Mo=60, Mo / ...

Embodiment 2

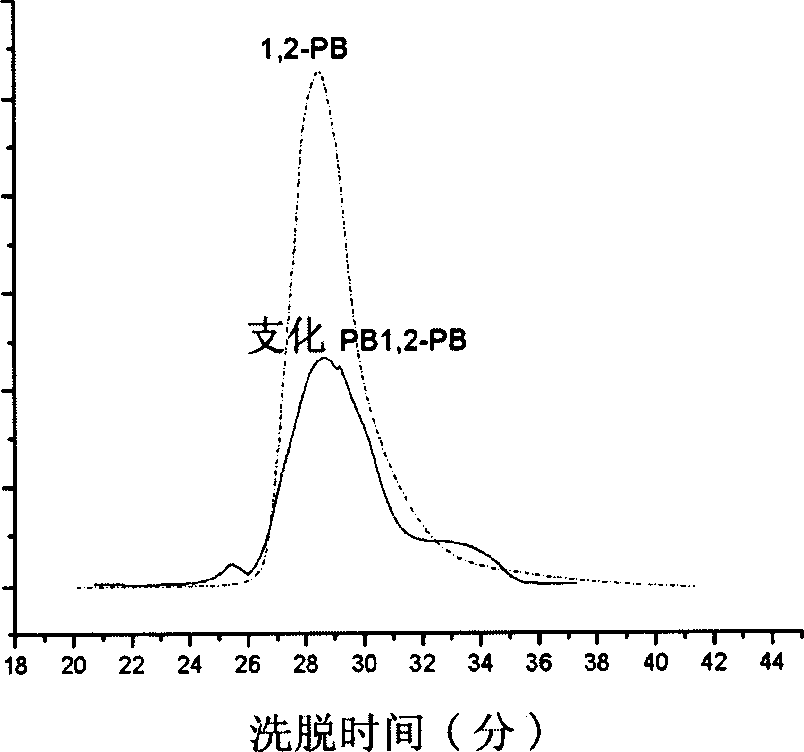

[0050] Add the hydrogenated gasoline solution of butadiene into the stirred reactor that has been evacuated and filled with nitrogen, and then add the stoichiometric amount of benzyl chloride as the initiator, octanol disubstituted MoCl 5 As a catalyst, triphenylphosphine was used as a ligand to initiate butadiene, reacted at 110 ° C for 40 h, and then sequentially added stoichiometric hydrogenated gasoline solution with additional monomer butadiene and Al(OPhCH 3 )(i-Bu) 2 、MoCl 3 (OC 8 h 17 ) 2 The GPC molecular weight distribution curve of the product obtained by the coordination polymerization of butadiene and the PB obtained by the direct coordination polymerization of butadiene under the same conditions is compared and analyzed as attached figure 2 .

Embodiment 3

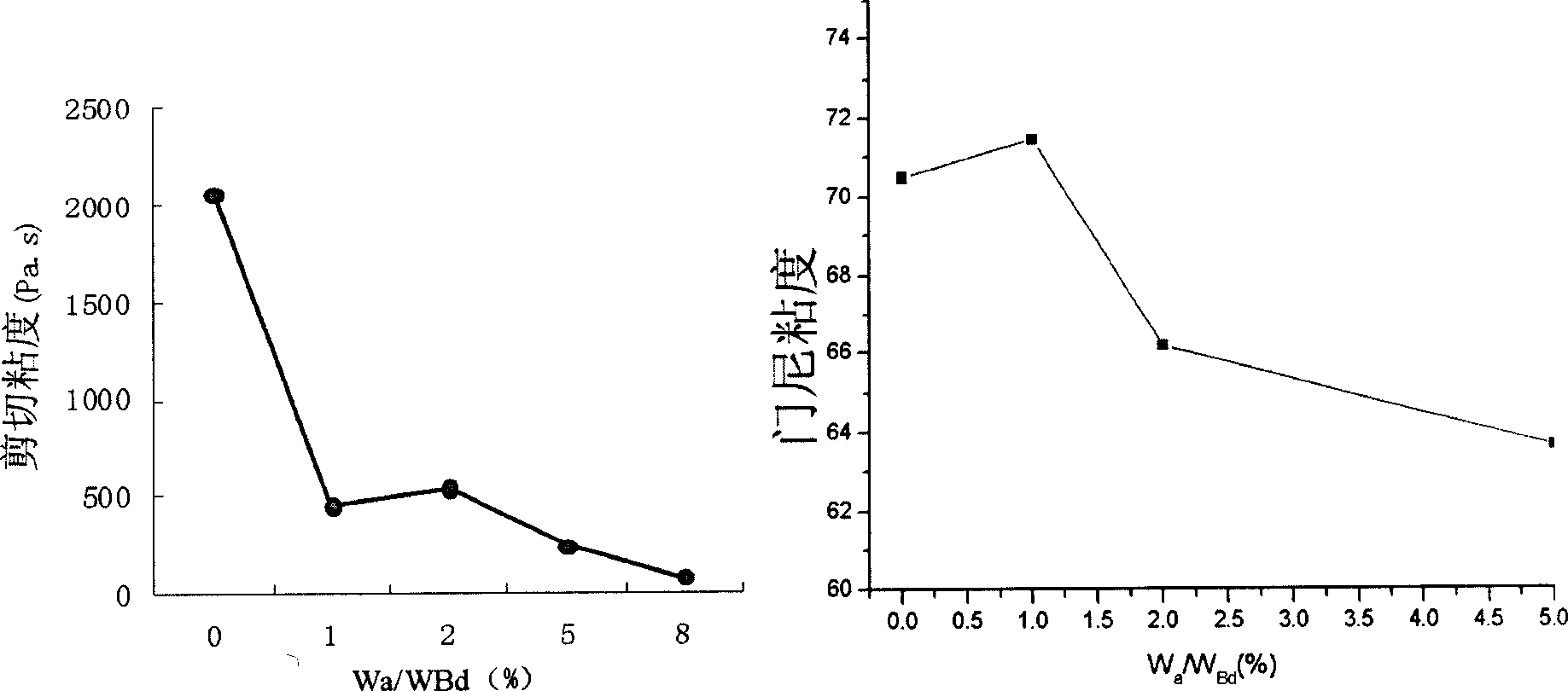

[0052] In toluene solution at 110°C, using benzyl chloride as the initiator, octanol disubstituted MoCl 5 As a catalyst, triphenylphosphine was used as a ligand to initiate the ATRP reaction of butadiene for 20 hours, and the conversion rate was 20%, Mn=1.19×10 4 , Mw / Mn=1.73 macromolecule glue polybutadiene macromonomer. Add the hydrogenated gasoline solution of butadiene in the stirred 3-liter polymerizer that has been evacuated and filled with nitrogen, and then add the stoichiometric medium with a syringe. Use this macromolecular glue as a macromolecular monomer, Al(OPhCH 3 )(i-Bu) 2 、MoCl 3 (OC 8 h 17 ) 2 Initiate the coordination polymerization of butadiene. The effects of different amounts of macromolecular glue on monomer conversion rate, polymer viscosity-average molecular weight, molecular weight distribution, 1,2 structure content, gel content and physical and mechanical properties of vulcanized rubber are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com