Fluorine-silicon copolymer rubber and preparation method thereof

A technology of copolymerization and rubber, which is applied in the field of fluorosilicone copolymerization rubber and its preparation, which can solve the problems of cost reduction and poor low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

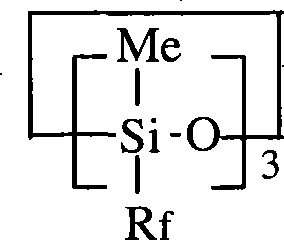

[0030] The invention provides a kind of preparation method of fluorosilicone copolymer rubber, it comprises providing 3,3,3-trifluoropropylmethyl cyclotrisiloxane monomer (hereinafter referred to as D 3 F ) step, the 3,3,3-trifluoropropylmethylcyclotrisiloxane monomer (D 3 F ) has the following structural formula:

[0031]

[0032] In the formula, Me represents CH 3 -, Rf stands for CF 3 CH 2 CH 2 -.

[0033] The 3,3,3-trifluoropropylmethylcyclotrisiloxane monomer (D 3 F ) is commercially available, for example it can be purchased from Zhejiang Sanhuan Chemical Co., Ltd.

[0034] In the polymerization reactant, the 3,3,3-trifluoropropylmethylcyclotrisiloxane monomer (D 3 F ) in an amount of 100 parts by weight.

[0035] In a better example of the present invention, need to 3,3,3-trifluoropropylmethyl cyclotrisiloxane monomer (D 3 F ) for dehydration. The specific dehydration step comprises 3,3,3-trifluoropropylmethylcyclotrisiloxane monomer (D 3 F ) into th...

Embodiment 1

[0110] Polymerization step

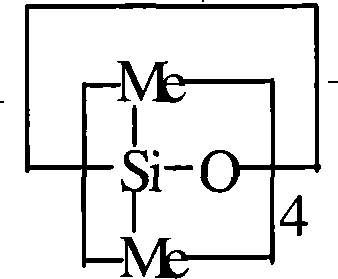

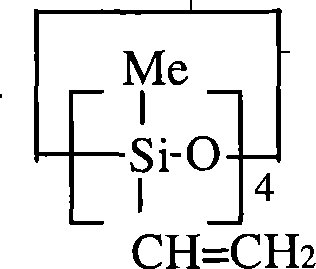

[0111] 5kg octamethylcyclotetrasiloxane monomer (D 4 Me ), 30g methyl vinyl cyclotetrasiloxane monomer (D 4 MeVi ) was filtered through a 2# sand core funnel, and added to a pre-dried 30L stainless steel polymerization reactor. 5kg D 3 F Put it into the dehydrator, heat it with infrared lamps, and heat it with electricity in the kettle.

[0112] The material needs to be dehydrated separately before polymerization, and pre-dehydrated with dry N2, that is, D 4 Me Monomer and D 4 MeVi The monomer is dehydrated in a 30L stainless steel reactor. The dehydration conditions are negative pressure 9303Pa, 70°C, dehydration for 2 hours, D 3 F Add it into the feeding bottle for dehydration. The dehydration conditions are negative pressure 7974Pa, dehydration at 80°C for 2 hours, and then add 60g of the catalyst component (ammonium gum) prepared above under normal pressure into a 30L stainless steel reactor to continue dehydration for 1 hour. , s...

Embodiment 2

[0117] The procedure described in Example 1 was repeated except that the polymerization time was 40 minutes. Six points were taken at different positions of the obtained polymer to compare the molecular weight distribution, and the results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com