Rare-earth catalyst of nitrogen-containing heterocyclic carbene ligand and olefin polymerization catalyzing method of rare-earth catalyst

A nitrogen-heterocyclic carbene and rare-earth catalyst technology, applied in the field of rare-earth catalysts, can solve problems such as poor inhibition ability, difficulty in preparing high molecular weight polymers, and low polymerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1 Preparation of nitrogen-containing heterocyclic carbene rare earth catalyst

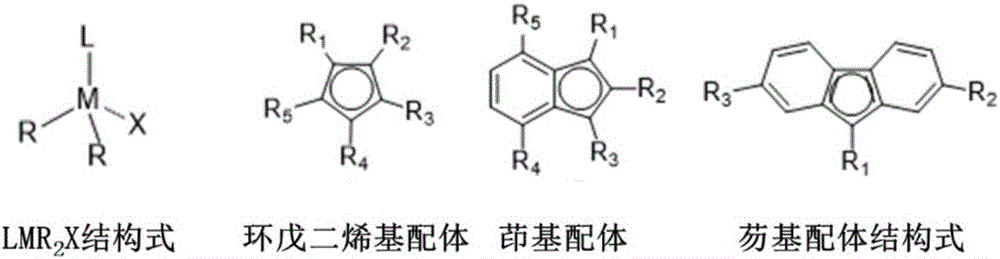

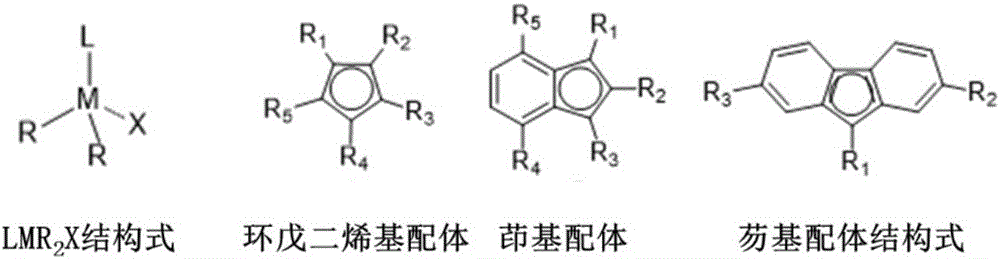

[0012] Different methenyl ligands and different azacyclic carbenes can be prepared by the following methods:

[0013] (1) In the glove box, weigh ScCl 3 (15mmol) was put into a Schlenk bottle filled with a magnetic stirrer, and 50mL of tetrahydrofuran was added. After sealing the Schlenk bottle, the Schlenk bottle was taken out of the glove box and stirred overnight at 80°C. Activated ScCl 3 (THF) 3 The white suspension was taken into the glove box, and the LiCH 2 SiMe 3 (45mmol) was dissolved in 15mL tetrahydrofuran, and slowly added dropwise to ScCl 3 (THF) 3 In the white suspension, react for 30min. Then, remove the solvent THF under reduced pressure, add 60mL of n-hexane for extraction, freeze the extract to remove by-products and filter while cold, and finally remove the n-hexane in the filtrate to obtain a white powder Sc(CH 2 SiMe 3 ) 3 (THF) 2 .

[0014] (2) In t...

Embodiment 2

[0017] Example 2 Preparation of polypropylene

[0018] In a glove box under the protection of inert gas nitrogen, add 20ml of toluene solution to a 100ml stainless steel reaction kettle, use a constant temperature bath to control the polymerization temperature, the polymerization temperature is -30°C, add propylene, the pressure of propylene is maintained at 0.1MPa, turn on the stirring, Add a rare earth catalyst, adopt the method provided in Example 1 to prepare a rare earth catalyst, and select 1,3-bis(trimethylsilyl)indenyl ligand (1,3-(Me 3 Si) 2 C 9 h 5 ), the nitrogen heterocyclic carbene ligand is selected from 1,3-diisopropyl-imidazolyl carbene, the amount of rare earth catalyst Sc is 2umol, the rare earth catalyst Sc and organoboron reagent [Ph 3 C][B(C 6 f 5 ) 4 ] molar ratio [Sc] / [B] is 1, after 30 minutes of polymerization reaction, methanol is added to terminate the reaction, the product is post-treated, vacuum-dried, analysis test: the number average molecu...

Embodiment 3

[0019] Example 3 Preparation of polypropylene

[0020] The polymerization reaction temperature is -20 ℃, and other polymerization reaction conditions are identical with embodiment 2, analysis test: the number average molecular weight of polypropylene is 123.9 * 10 4 g / mol, molecular weight distribution HI is 1.49.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com