Polyamide polymerization production process and equipment for same

A production process and technology of polyamide, which is applied in the field of polyamide polymerization production process and equipment used, can solve problems such as unreasonable design of equipment section functions, unsolved problems, and wide molecular distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

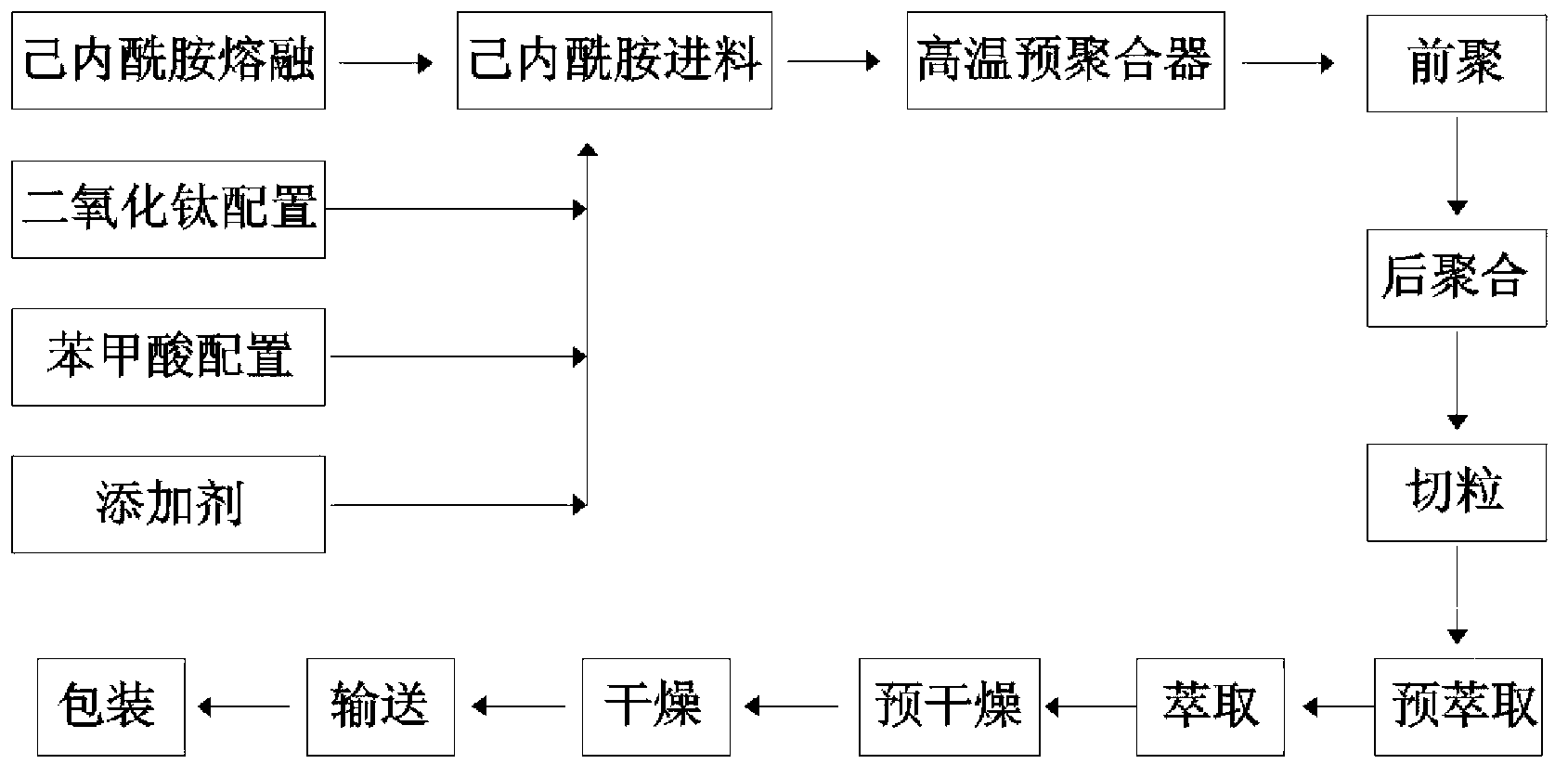

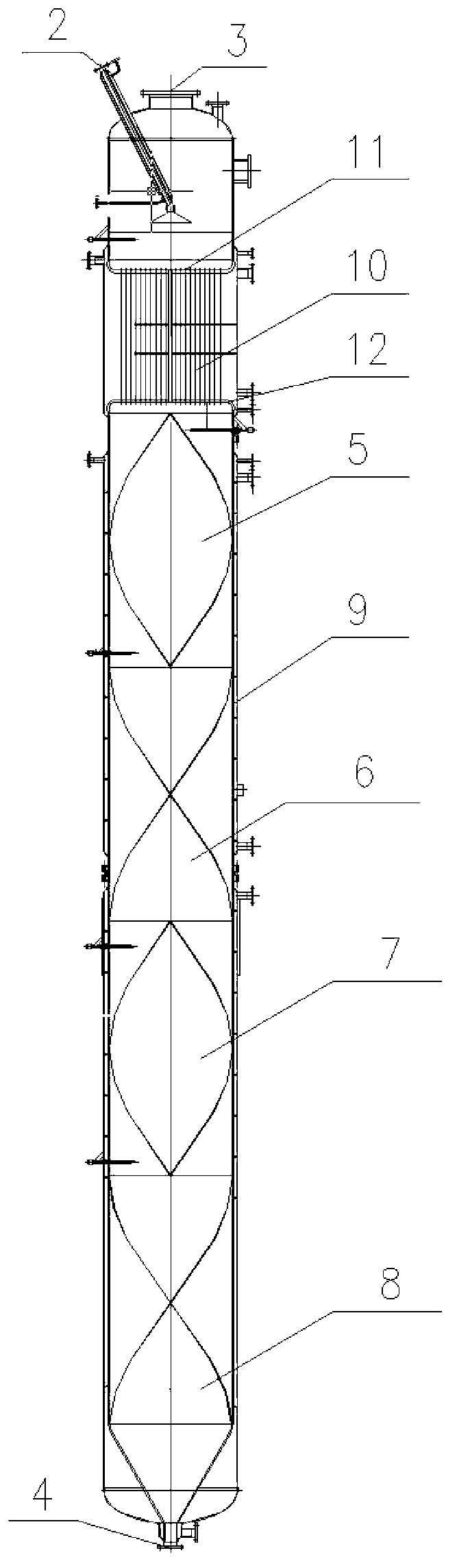

[0045] Example 1. Caprolactam is prepared with desalted water in the caprolactam melting system, and the preparation is melted under a nitrogen seal. The molten caprolactam enters the caprolactam feeding system and is prepared by a titanium dioxide preparation system. Its weight is caprolactam 2.0 ‰ of titanium dioxide, prepared by benzoic acid configurator, by weight caprolactam 1.2‰ benzoic acid and 1.2‰ of 2,2,6,6-tetramethyl-4-aminopiperidine and 3-(3,5- Di-tert-butyl-4-hydroxyphenyl)propionic acid is filtered with a standard fine filter, and then enters the caprolactam feeding system together, and is sent to the high-temperature pre-polymerizer, and after the high-temperature pre-polymerizer, the pre-polymerization tower and post-polymerization After the tower is polymerized, it enters the cutting system and the pre-extraction tower from the material outlet 3 13. The pre-extraction tower extracts the oligomers in the slices, and then separates the slices in the pre-extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com