Method for preparing carbon fibers by carbonizing polyacrylonitrile precursors

A polyacrylonitrile and carbon fiber technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of increased structural defects of carbon fibers, broken filaments and cross-linking of filaments, affecting the quality of carbon fibers, etc., and achieves molecular arrangement densification, The effect of fewer broken wires and fewer wires and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 pre-oxidation

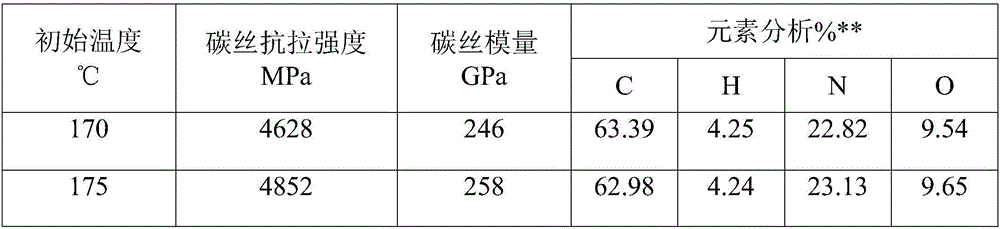

[0024] Table 1, Effect of pre-oxidation initial temperature on carbon fiber quality*

[0025]

[0026]

[0027] *Carbonization conditions: pre-oxidation termination temperature 280°C, low-temperature carbonization initial temperature 450°C, termination temperature 700°C, high-temperature carbonization initial temperature 800°C,

[0028] The termination temperature is 1350°C, and the wire speed is 0.8m / min.

[0029] **The table shows the elemental analysis data of the pre-oxidized silk.

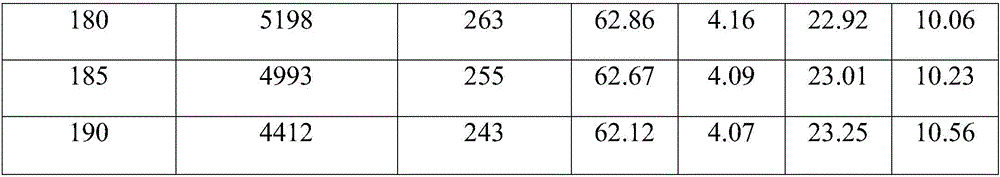

[0030] Table 2, Effect of pre-oxidation termination temperature on carbon fiber quality*

[0031]

[0032] *Carbonization conditions: the initial temperature of pre-oxidation is 180°C, the initial temperature of low-temperature carbonization is 450°C, the termination temperature is 700°C, the initial temperature of high-temperature carbonization is 800°C,

[0033] The termination temperature is 1350°C, and the wire speed is 0.8m / min.

[0034] **...

Embodiment 2

[0044] Embodiment 2 low temperature carbonization

[0045] Table 4, Effect of initial temperature of low-temperature carbonization on carbon fiber quality

[0046]

[0047] *Carbonization conditions: the initial temperature of pre-oxidation is 180°C, the end temperature is 280°C, the end temperature of low-temperature carbonization is 700°C, the initial temperature of high-temperature carbonization is 800°C, the end temperature is 1350°C, and the wire speed is 0.8m / min.

[0048] Table 5, Effect of low temperature carbonization termination temperature on carbon fiber quality

[0049]

[0050] *Carbonization conditions: the initial temperature of pre-oxidation is 180°C, the end temperature is 280°C, the initial temperature of low-temperature carbonization is 450°C, the initial temperature of high-temperature carbonization is 800°C, the end temperature is 1350°C, the wire speed is 0.8m / min; the temperature gradient of low-temperature carbonization and high-temperature carbo...

Embodiment 3

[0055] Embodiment 3 high temperature carbonization

[0056] Table 6, the effect of the initial temperature of high-temperature carbonization on the quality of carbon fiber

[0057]

[0058] *Carbonization conditions: the initial temperature of pre-oxidation is 180°C, the end temperature is 280°C, the initial temperature of low-temperature carbonization is 450°C, the end temperature is 700°C, the end temperature of high-temperature carbonization is 1350°C, and the wire speed is 0.8m / min; The temperature gradient is evenly distributed.

[0059] Table 7, the effect of high temperature carbonization termination temperature on carbon fiber quality

[0060]

[0061] *Carbonization conditions: the initial temperature of pre-oxidation is 180°C, the end temperature is 280°C, the initial temperature of low-temperature carbonization is 450°C, the end temperature is 780°C, the initial temperature of high-temperature carbonization is 800°C, and the wire speed is 0.8m / min.

[0062] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com