Preparation method and application of high molecular weight narrow distribution cross-linked polyacrylamide

A technology of polyacrylamide and high molecular weight, applied in the direction of adding retention aids, reinforcing agents, paper, etc., can solve the problems of inability to obtain effective strength improvement, increase the amount of flocculant, gel and foaming, etc., to achieve Concentrated active ingredients, less operational trouble, less gel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

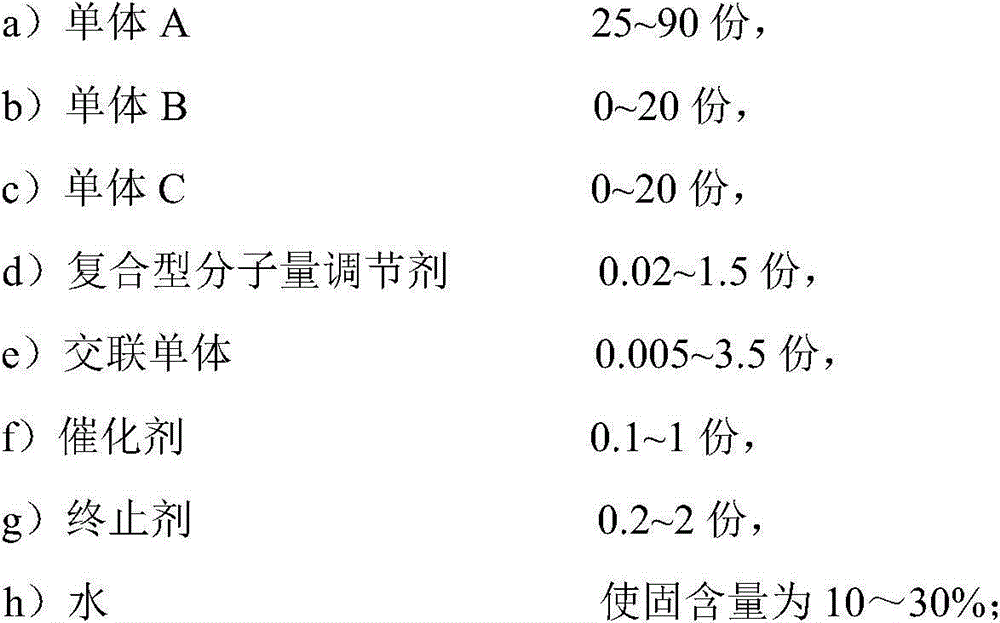

Method used

Image

Examples

Embodiment 1

[0040] Add primary monomers to a 1000ml four-necked flask equipped with a stirrer, thermometer, reflux condenser, feeding port and nitrogen conduit: 72.8 parts of acrylamide, 2.1 parts of dimethylaminoethyl methacrylate, methacryloyloxyethyl 1.4 parts of trimethylammonium chloride, 2.1 parts of N,N-dimethylaminopropyl acrylamide, 1 part of acrylic acid, 0.13 parts of 2,4-diphenyl-4-methylpentene, allylsulfonic acid 0.23 parts of sodium, 0.25 parts of sodium methallyl sulfonate, 0.16 parts of dimethylacrylamide, and 53.3 parts of deionized water are made into a primary monomer solution with a concentration of 27.1%, and the pH is adjusted to 2.8, blow nitrogen into the reaction vessel for more than 30 minutes, and heat it to a temperature of 65°C, then add 0.06 part of catalyst ammonium persulfate once into the reaction vessel to initiate the reaction. During the addition process, the temperature of the polymerization reaction was controlled at 65° C., and after the addition wa...

Embodiment 2~8

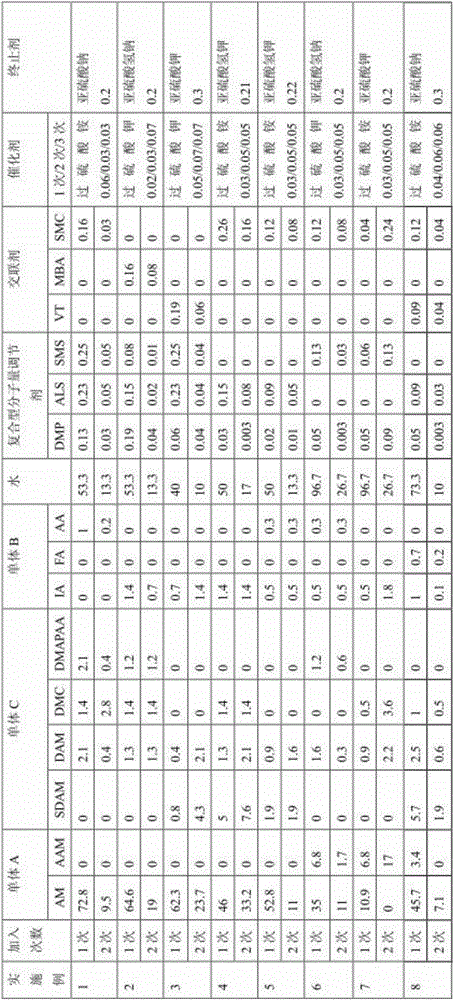

[0043] According to the preparation method of the example, the types and proportions of materials were changed, and various process parameters were adjusted to prepare a kind of high molecular weight narrow distribution cross-linked polyacrylamide A2-A8. The material proportions are listed in Table 1, and the preparation process conditions And the final product indicators are shown in Table 2.

[0044] Table 1, experimental example 1~8 material ratio (weight part)

[0045]

[0046] Symbol Description:

[0047] AM acrylamide, AAM methacrylamide, SDAM methacryloyloxyethyltrimethylbenzyl chloride DAM dimethylaminoethyl methacrylate, DMC methacryloyloxyethyltrimethylammonium chloride DMAPAAN , N-dimethylaminopropylacrylamide, IA itaconic acid, FA fumaric acid, AA acrylic acid DMP2, 4-diphenyl-4-methylpentene, ALS sodium allylsulfonate, SMS methylene Sodium Propyl Sulfonate, VT Vinyl Toluene, MBA Methylene Bisacrylamide, SMC Dimethacrylamide.

[0048] Table 2, Experimental Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com