Preparation method and system of polyhydroxycarboxylate or polyhydroxycarboxylic acid polymer

A technology of polyhydroxycarboxylate and polyhydroxycarboxylic acid, which is applied in the field of polymer preparation, can solve the problems of complex process flow, fluctuating product quality, low yield and the like, and achieves simple system, high material utilization rate and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of polyhydroxycarboxylate or polyhydroxycarboxylate polymer, the method may further comprise the steps:

[0049] (a) Under the action of a catalyst, the raw material hydroxycarboxylate monomer or hydroxycarboxylic acid monomer is pre-polymerized for 0.5-48h under the conditions of an absolute pressure of 100-600kPa and a temperature of 100-250°C. Polymerization products, raw materials and by-products;

[0050] (b) Reduce the pressure of the pre-polymerization product obtained in step (a), and conduct a medium-polymerization reaction at an absolute pressure of 5-20kPa and a temperature of 130-280°C for 1-72h to separate and obtain the medium-polymerization product, raw materials and by-products ;

[0051] (c) Depressurize the intermediate polymerization product obtained in step (b), and perform a final polymerization reaction at an absolute pressure of 0.1-1kPa and a temperature of 160-280°C for 0.5-20h to obtain the product polyhydroxycarboxylate o...

Embodiment 2

[0065] A preparation method of polyhydroxycarboxylate or polyhydroxycarboxylic acid polymer and a preparation system of polyhydroxycarboxylate or polyhydroxycarboxylic acid polymer are specifically shown in Example 1.

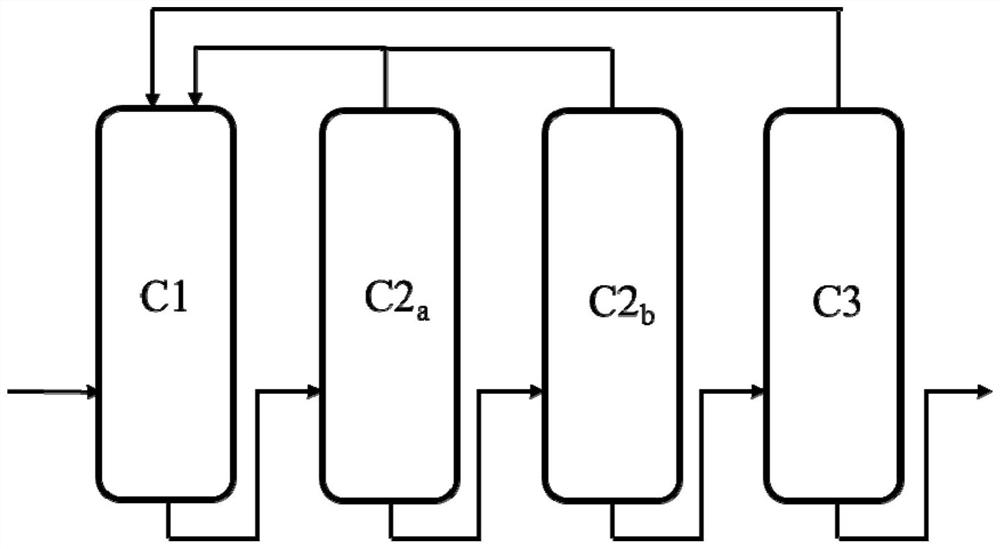

[0066] use figure 1 The preparation system shown is prepared, specifically, the methyl glycolate containing 0.1% mole fraction zinc oxide catalyst is transported to the pre-polymerization reactor C1 with an absolute pressure of 150kPa and a temperature of 153°C for 2h to carry out the pre-polymerization reaction, During the pre-polymerization process, the reaction by-products such as monohydric alcohol or water are continuously separated, and then the pre-polymerized products are sent to the intermediate polymerization reactor at a temperature of 180°C, an absolute pressure of 80kPa, and a temperature of 205°C, and an absolute pressure of 10kPa. C2 a 、C2 b Stay in the conditions for 2.5h and 3h respectively to carry out the middle polymerization reaction. Dur...

Embodiment 3

[0072] A preparation method of polyhydroxycarboxylate or polyhydroxycarboxylic acid polymer and a preparation system of polyhydroxycarboxylate or polyhydroxycarboxylic acid polymer are specifically shown in Example 1.

[0073] use figure 1 The preparation system shown was prepared. Specifically, the methyl glycolate containing 0.2% mole fraction tetrabutyl titanate catalyst was transported to the prepolymerization reactor C1 with an absolute pressure of 150kPa and a temperature of 160°C for 2h for prepolymerization. Polymerization reaction, the reaction by-products such as monohydric alcohol or water are continuously separated during the pre-polymerization process, and then the pre-polymerized products are sent to the medium with a temperature of 180 ° C, an absolute pressure of 15 kPa and a temperature of 205 ° C, and an absolute pressure of 10 kPa. Polymerization Reactor C2 a 、C2 b Stay in the conditions for 2h and 4h respectively to carry out the intermediate polymerizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com