Device and method for continuous production of amino resin

A technology of amino resin and production device, which is applied in the field of continuous production device of amino resin to achieve the effects of improving quality stability and optimizing environmental protection emission indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

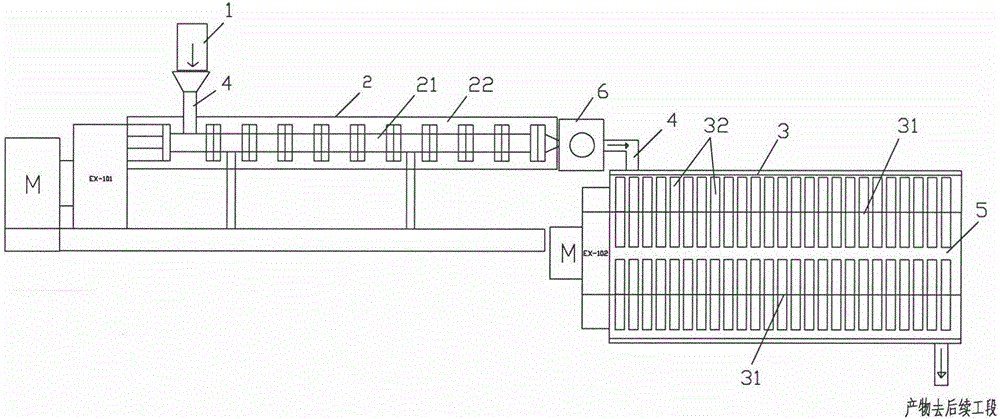

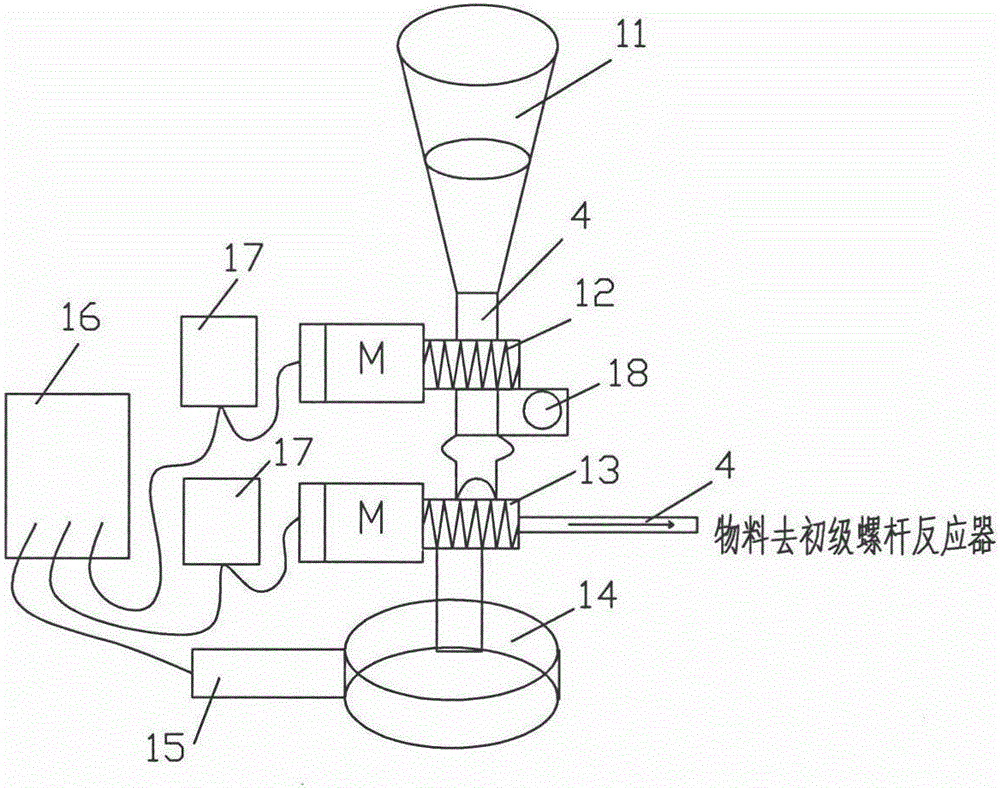

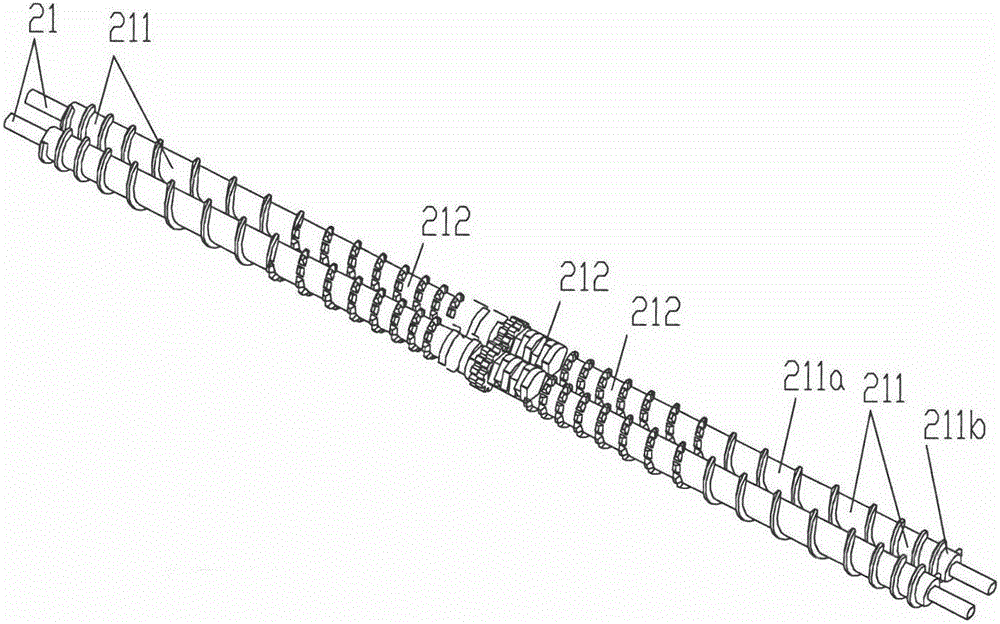

[0032] Embodiment 1: as Figure 1~4As shown, a continuous production device for amino resins includes an automatic continuous batching device for raw materials 1, a primary screw reactor 2 and a combined reactor 3 for twin-screw cylindrical steel blocks connected in sequence, and the automatic continuous batching device for raw materials 1 includes an automatic batching device for solid raw materials. The continuous batching device and the liquid raw material automatic continuous batching device are equipped with a plurality of solid raw material automatic continuous batching devices according to the type of solid raw material. In this embodiment, there are 3 kinds of solid raw materials: melamine, paraformaldehyde and sodium carbonate. Correspondingly, a plurality of automatic continuous batching devices for liquid raw materials are provided. In this embodiment, there are two kinds of liquid raw materials, desalted water and ethylene glycol; the automatic continuous batching d...

Embodiment 2

[0035] Embodiment 2: as Figure 1~4 As shown, a continuous production device of amino resin,

[0036] Compared with embodiment 1, the difference is:

[0037] There are 4 automatic continuous batchers for solid raw materials equipped with melamine, paraformaldehyde, sodium formate and phthalic anhydride and 2 automatic continuous batchers for liquid raw materials with desalted water and phosphoric acid;

[0038] In this embodiment, the conveying spiral groove 211 is designed as a large-lead conveying spiral groove 211a;

[0039] The first heat exchange chamber 22 is the first automatic control heat exchange chamber, and the first heat exchange automatic control chamber corresponds to several conveying sections and several mixing sections of the primary screw 21 and is correspondingly designed into several sections, and each section is provided with a Automatically controlled heat exchanger for temperature control to ensure accurate and automatic control of reaction temperatur...

Embodiment 3

[0042] Embodiment 3: as Figure 1~4 As shown, a continuous production device of amino resin,

[0043] Compared with embodiment 2, the difference is:

[0044] There are 3 automatic continuous batchers for solid raw materials equipped with melamine, paraformaldehyde and sodium carbonate and 3 automatic continuous batchers for liquid raw materials with desalted water, sulfuric acid and hypophosphorous acid;

[0045] In the present embodiment, the conveying spiral groove 211 is designed as a large lead conveying spiral groove 211a. In the present embodiment, the maximum lead is 50mm (the flow rate is also related to the rotating speed, and the current rotating speed is 110 revolutions per minute, and the value of the flow rate is 3 kg / min. minutes of resin);

[0046] In this embodiment, the automatic continuous batching device 1 for raw materials, the primary screw reactor 2, and the twin-screw cylindrical steel block combined reactor 3 that are sequentially connected by pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com