Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

154results about How to "Guaranteed normal input" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

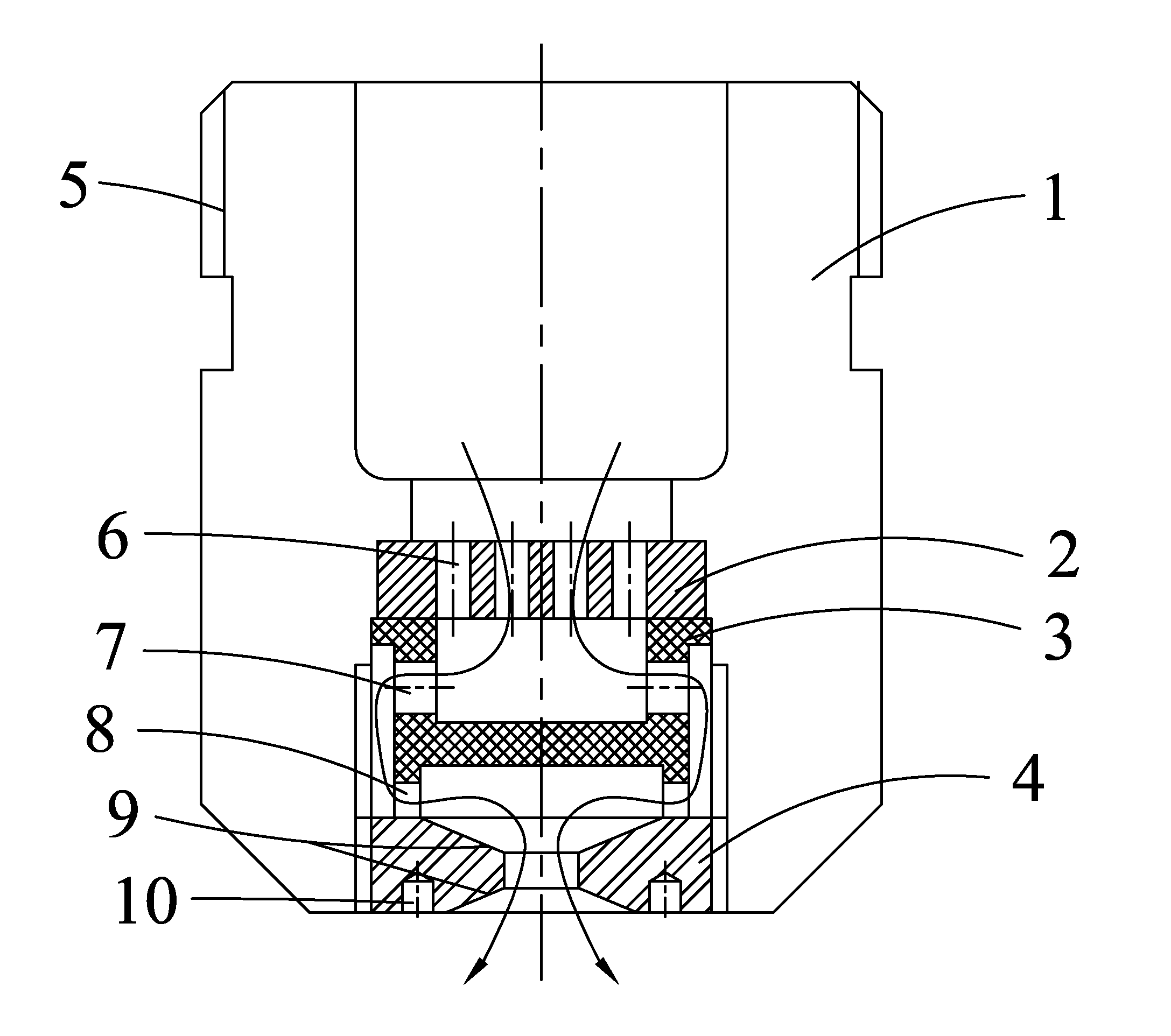

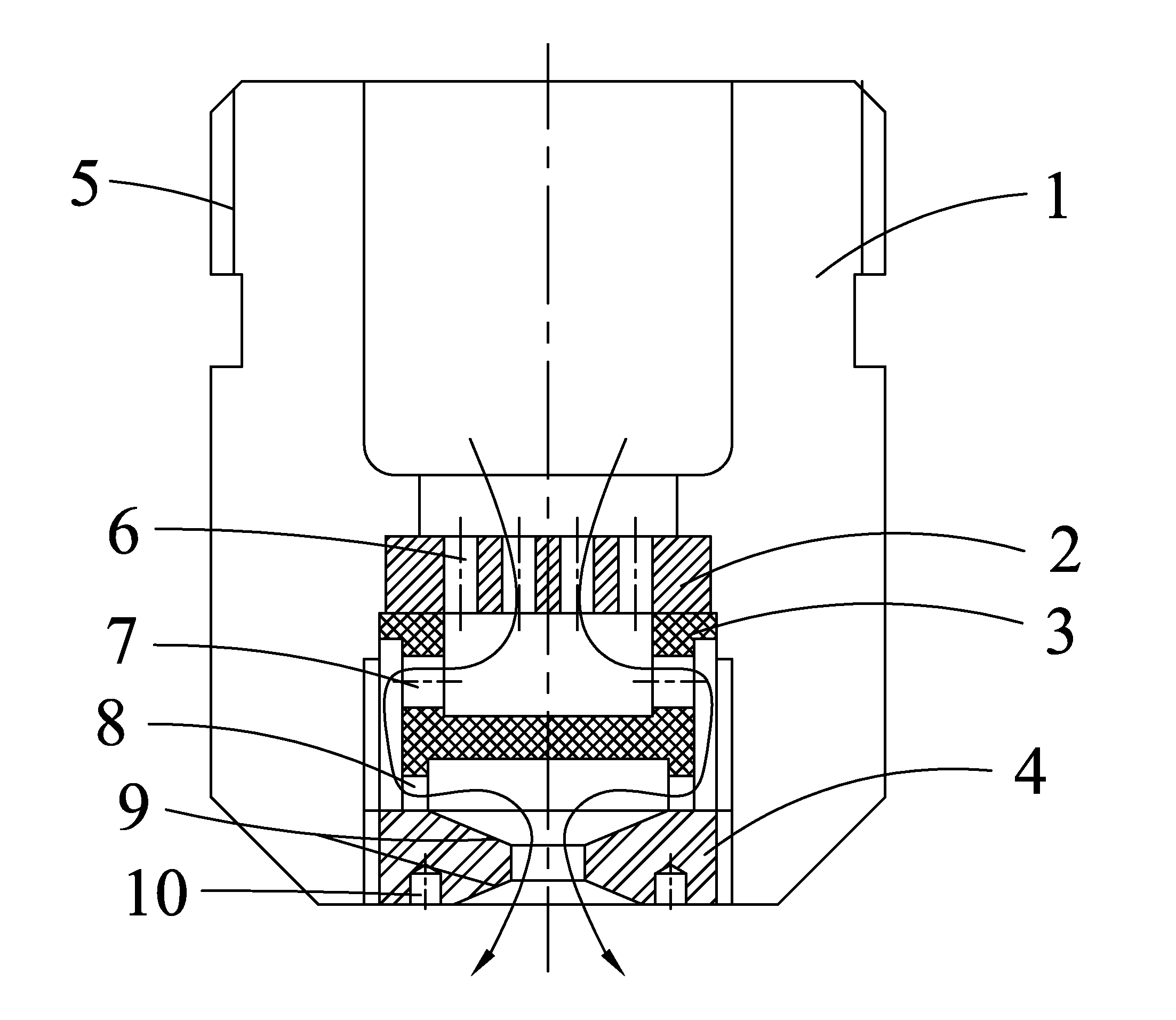

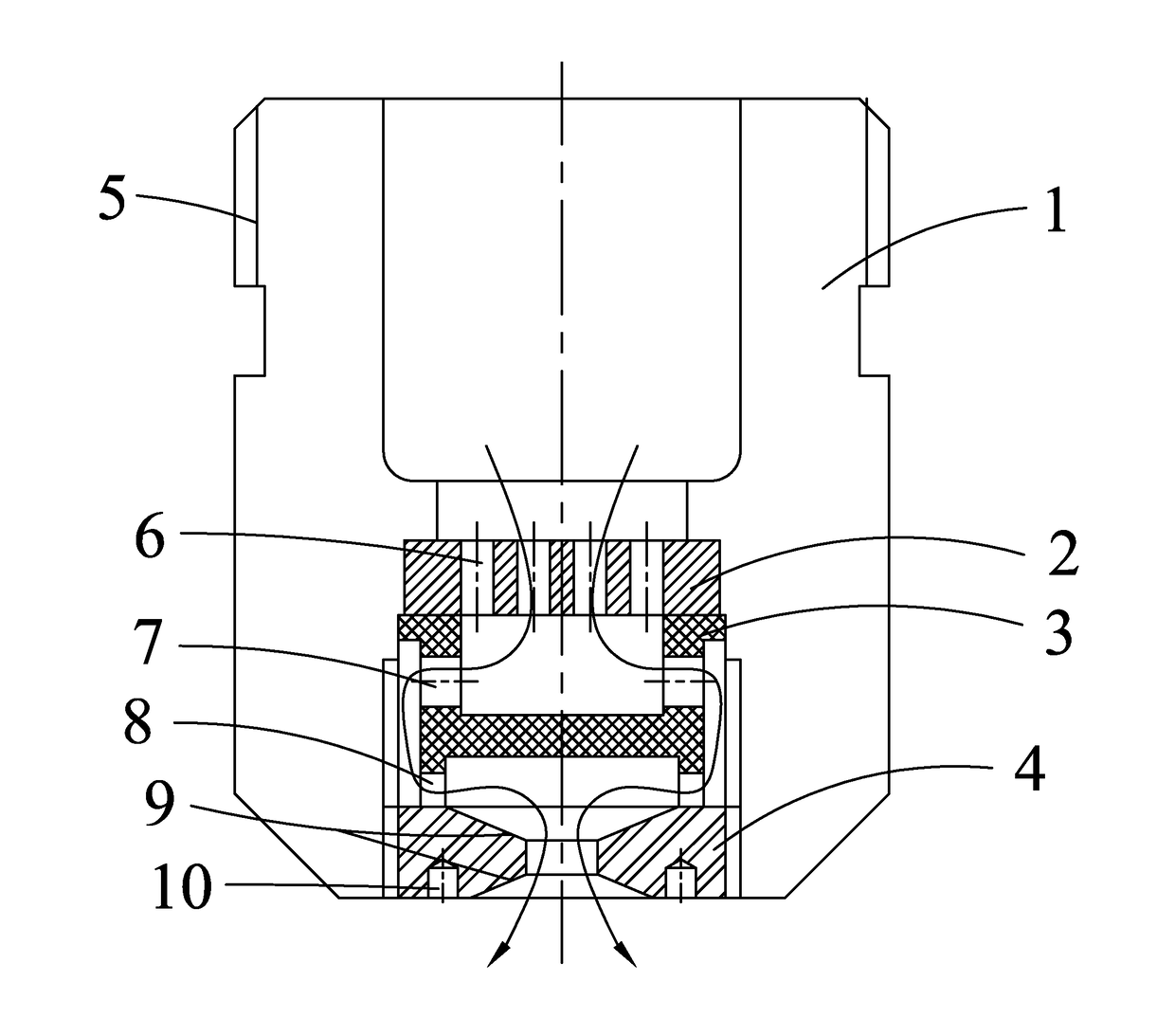

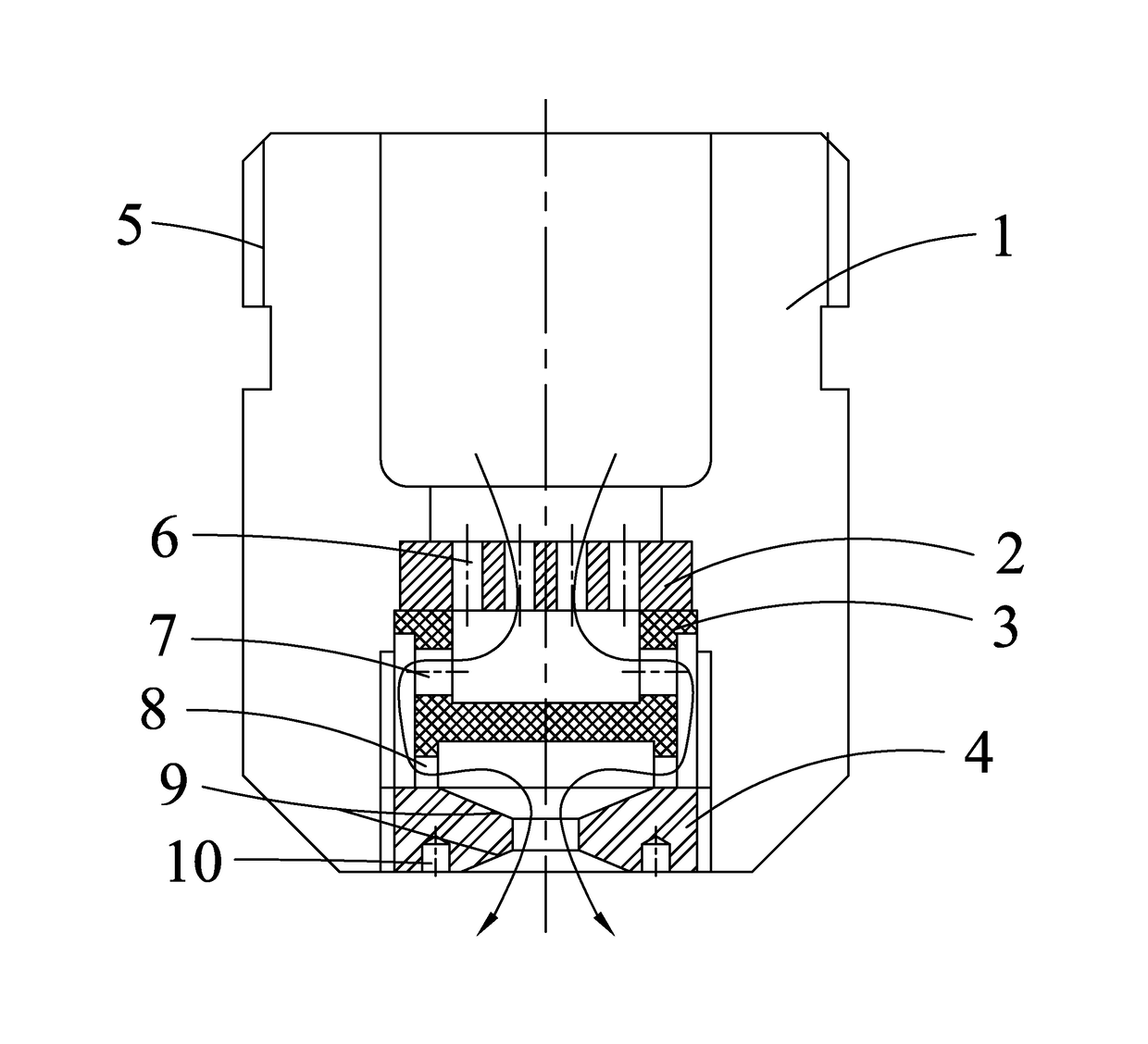

Multistage decompression and micro flow atomizing nozzle

InactiveUS20160375449A1Extended service lifeAccurate flowSpray nozzlesVena contracta diameterOrifice plate

An atomizing nozzle including a nozzle body, a flow orifice plate, a multi-stage decompression sleeve and a dual-conical surface nozzle head. One end of the nozzle body opposite to the dual-conical surface nozzle head is provided with an external thread; one end of the nozzle body close to the dual-conical surface nozzle head is provided with an internal hole and an internal thread. The external thread of the nozzle body is connected to external equipment. The flow orifice plate, the multi-stage decompression sleeve and the dual-conical surface nozzle head are arranged in the internal hole. The flow orifice plate is arranged on one end of the dual-conical surface nozzle close to the external thread of the nozzle body. The multi-stage decompression sleeve is arranged on the flow orifice plate.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

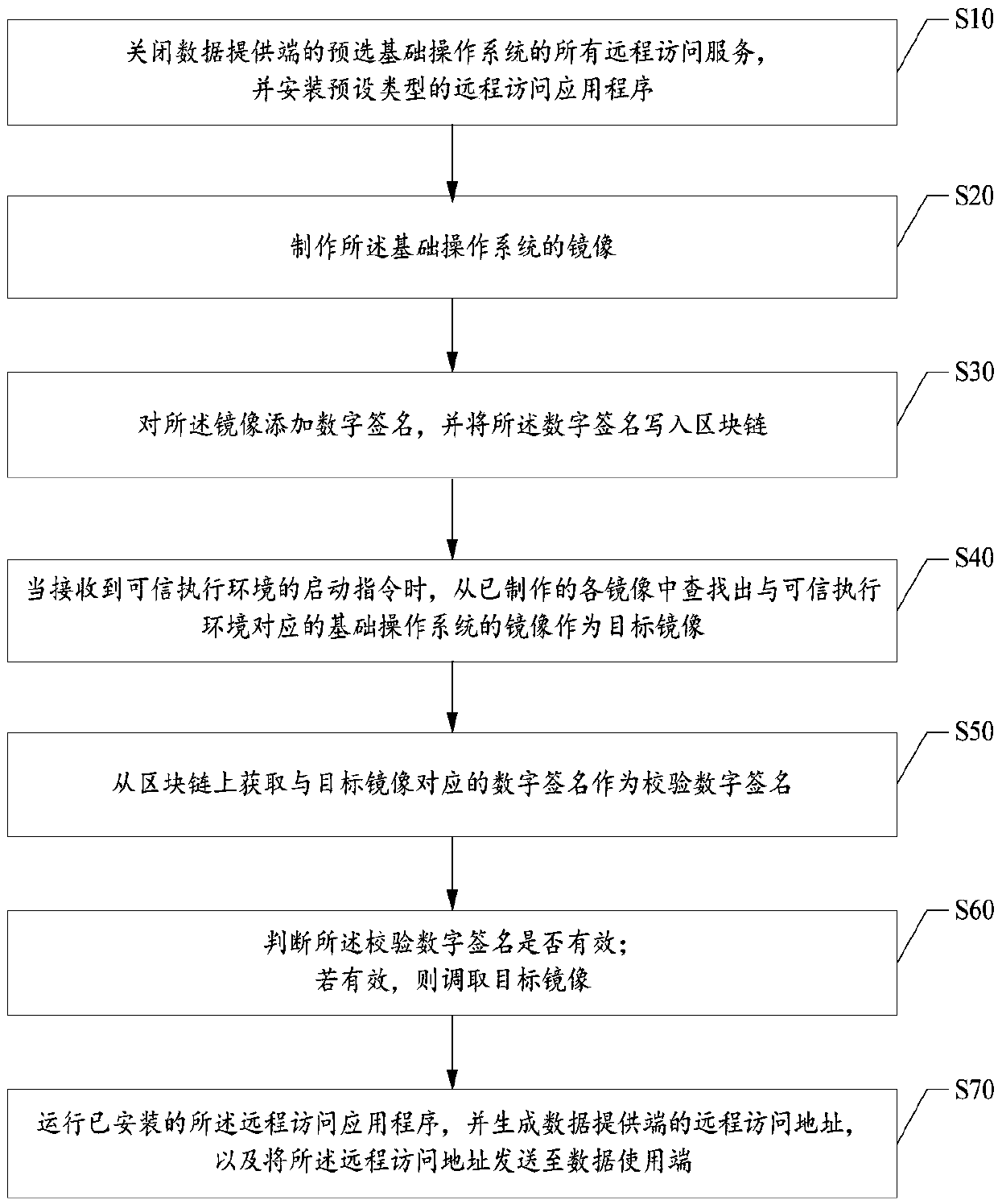

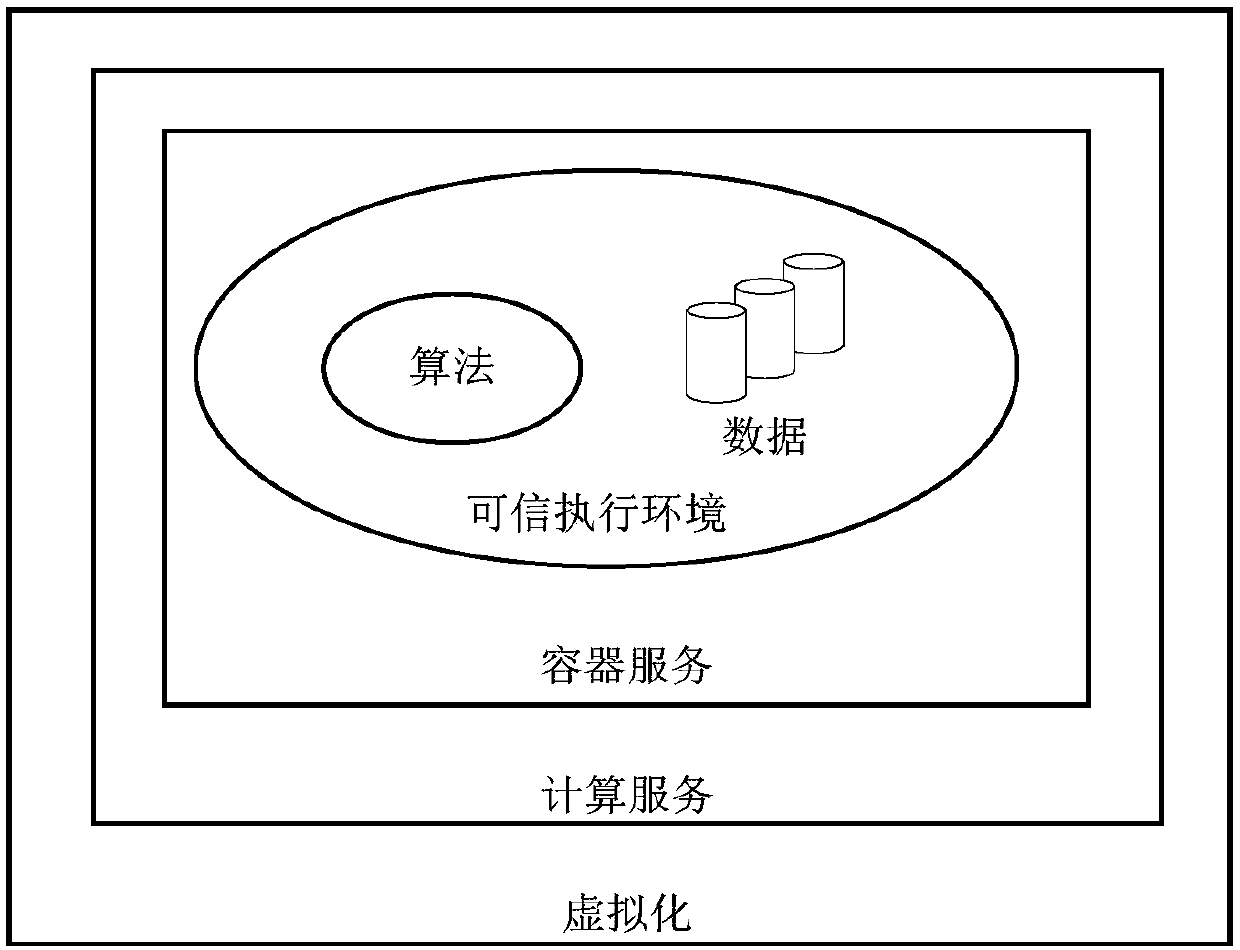

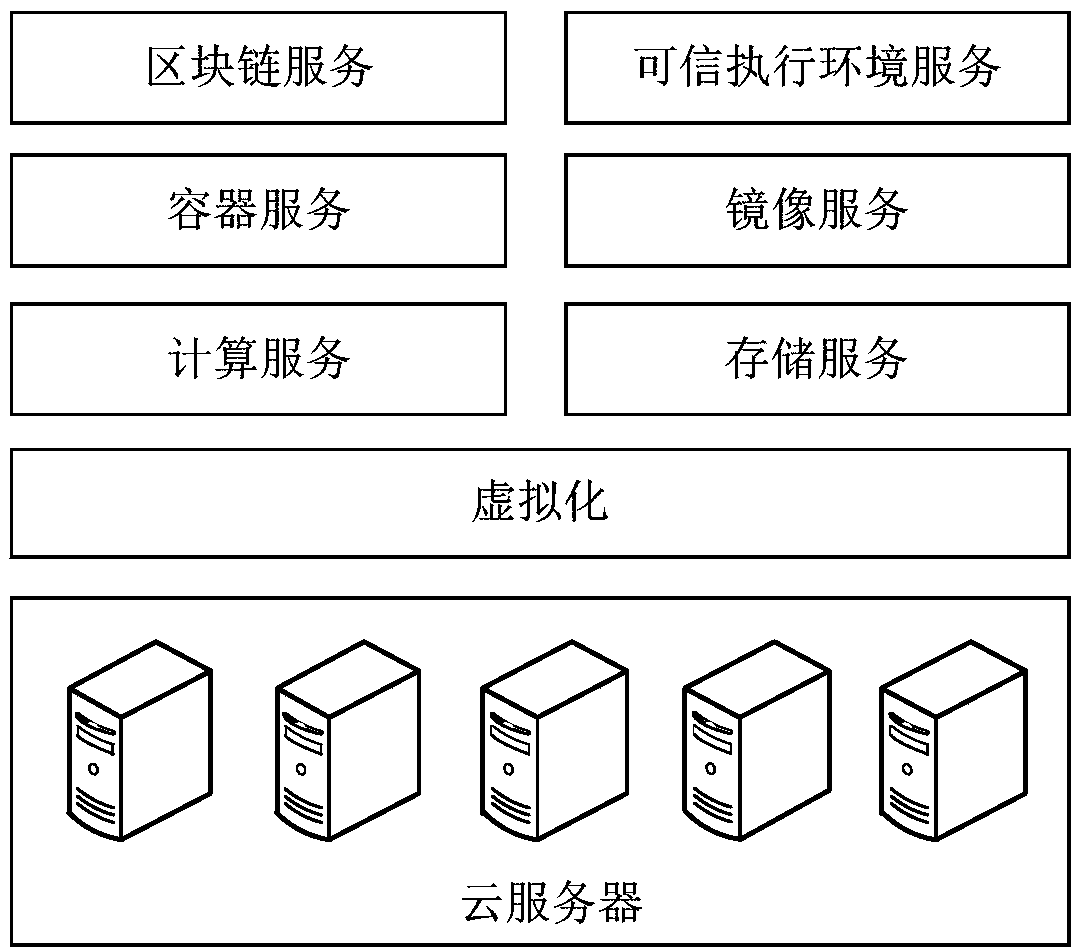

Trusted execution environment implementation method and device, terminal device and readable storage medium

ActiveCN109634619AReduce leakageEnsure safetyDigital data protectionPlatform integrity maintainanceOperational systemDigital signature

The invention provides a credible execution environment implementation method, which comprises the following steps of: closing all remote access services of a pre-selected basic operation system of adata providing end, and installing a remote access application program of a preset type; manufacturing a mirror image of the basic operation system; adding a digital signature to the mirror image, andwriting the digital signature into the block chain; when a credible execution environment starting instruction is received, a digital signature corresponding to the target mirror image is obtained from the block chain to serve as a verification digital signature; if it is judged that the verification digital signature is valid, calling a target mirror image; and running the installed remote access application program, generating a remote access address of the data providing end, and sending the remote access address to the data using end. The invention further provides a credible execution environment implementation device, terminal equipment and a readable storage medium. The technical problems that an existing data providing mode is prone to data leakage and algorithm leakage are solved.

Owner:中移动信息技术有限公司

Method for preparing sludge and mud sintered brick

InactiveCN106938914AImprove dehydration efficiencyEffective dispersionCeramic materials productionClaywaresBrickFiltration

The invention belongs to the technical field of building materials, and discloses a method for preparing a sludge and mud sintered brick, and the method is as follows: adding a dehydrating agent and a filtration aid agent into wet sludge, stirring and dewatering to obtain a mixture mud cake; adding dry river lake mud powder into the mixture mud cake, stirring and aging to obtain a blank forming material; pressing and forming the blank forming material to obtain a to-be-died brick blank; in turn drying the to-be-died brick blank at room temperature and drying in a drying room to obtain a to-be-burnt brick blank; and firing the to-be-burnt brick blank at 950 to 1050 DEG C. The method for preparing the sludge and mud sintered brick achieves the effects of improving finished product yield and quality, reducing energy consumption and realizing recycling of resources.

Owner:JIANGSU ZHONGYI ECOLOGICAL SOIL INST +1

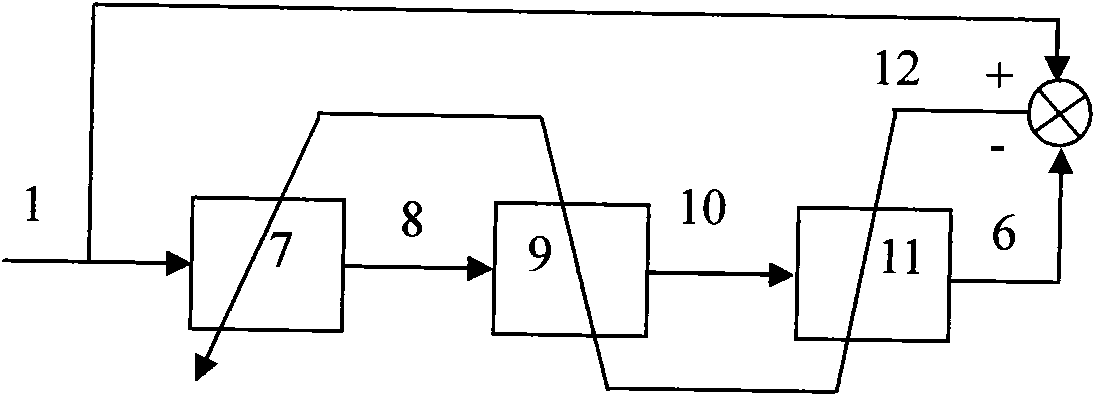

Robust adaptive autopilot control algorithm for navigation simulator

InactiveCN101615000AImprove convergence rateSolve nonlinear problemsNeural learning methodsAdaptive controlLow speedWater model

The invention relates to a robust adaptive autopilot control algorithm for a navigation simulator. Aiming at various ship models in navigation simulator training, a nonlinear mathematic model for ship motion is obtained based on half theoretical calculation and half experimental result, and the nonlinear mathematic model considers the interferences of wind, wave, current, and the like and relates to a low-speed shallow-water model. The designed autopilot algorithm is based on a closed-loop gain shaping simple robust control algorithm and is a new ship autopilot robust adaptive control algorithm having robustness and adaptability by combining a neurotic network direct controlling training method. The robust adaptive autopilot control algorithm has adaptability by considering the robustness of a ship motion control algorithm as well as the complexity of ship navigation and solves the problem that the prior algorithm has either robustness or adaptability and can not have both.

Owner:DALIAN MARITIME UNIVERSITY

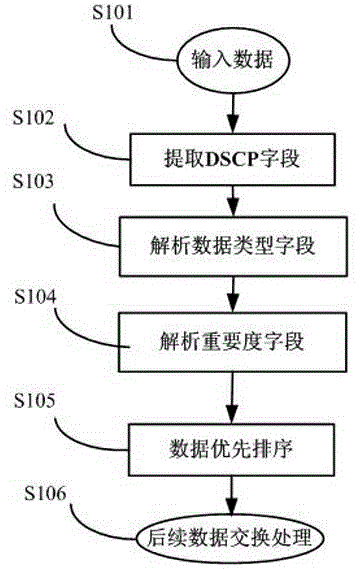

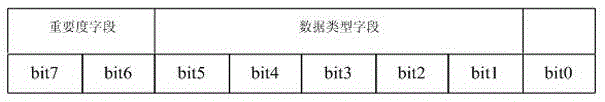

IP data priority setting method

InactiveCN103916330AEasy to implementGuaranteed equipment investmentData switching networksData transmissionService system

The invention relates to the field of IP data transmission, in particular to an IP data priority setting method. The IP data priority setting method aims to solve problems in the prior art. Under an existing distinguishing service system, importance priority identifications are added on the basis of data service types, service data of the same type can be further distinguished, the service data of the same type have identifications with priority differences when generated by different users or on different situations, and accordingly more elaborated data transmission service can be provided. Importance fields of data with the same priority level are analyzed, then the data are classified according to the second priority level, and data exchange processing is carried out according to DSCP coded values composed of the first priority level classification of data classification fields and the second priority level classification required by the important fields and according to the priority level of the data.

Owner:NO 30 INST OF CHINA ELECTRONIC TECH GRP CORP

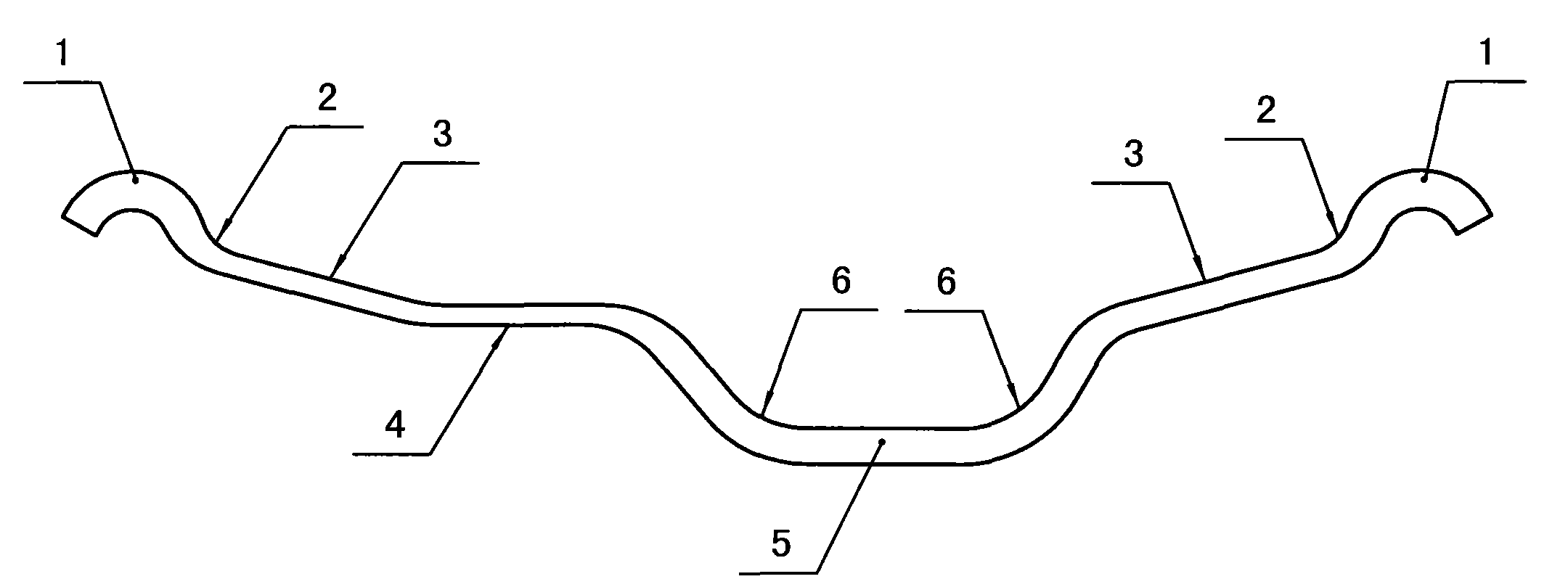

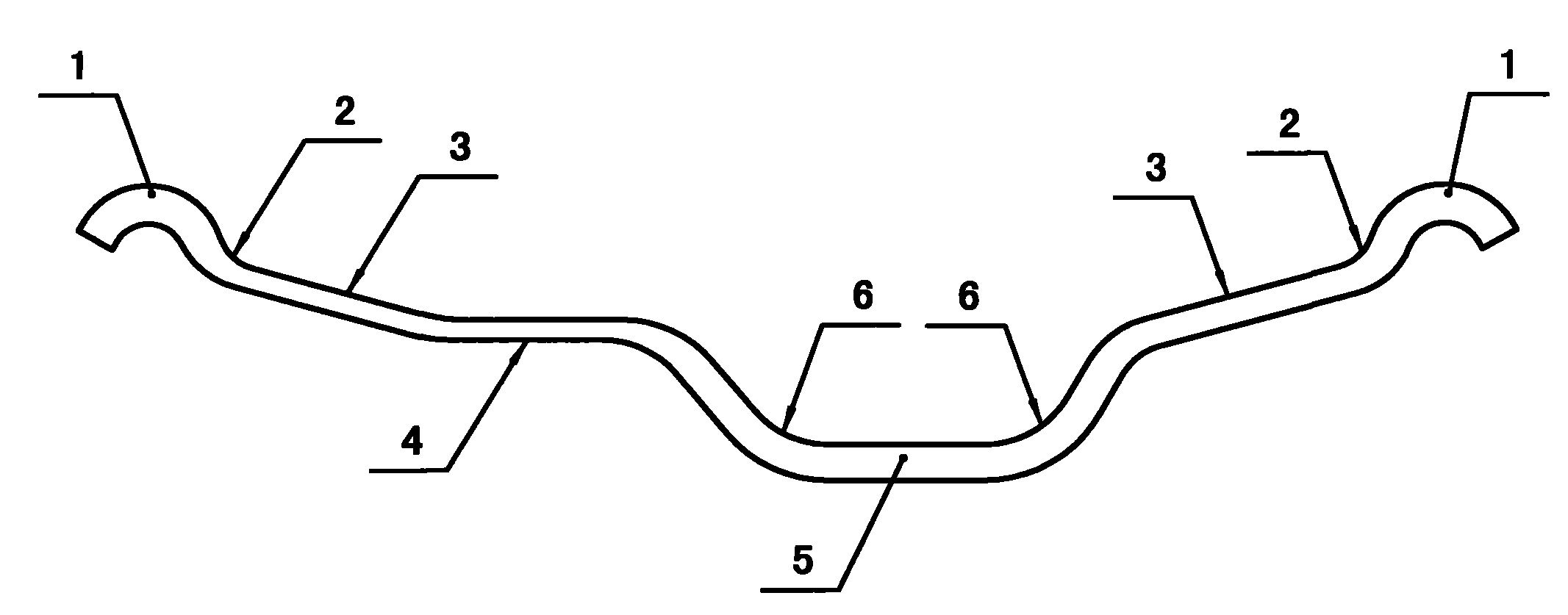

Tubeless unequal-thickness and variable-section rim for automobile wheel

The invention relates to a tubeless unequal-thickness and variable-section rim for an automobile wheel, which is characterized in that (1) the thickness of the structure of the shape of the section of the rim can be changed randomly at different parts according to the design and practical use requirements and differences of stress, and the material of certain parts with less stress is thinned, thus reducing the weight of the rim, further reducing the weight of a whole automobile and saving oil consumption; the thickness of the raw material of certain parts with larger stress is ensured to be constant, thus ensuring the strength of the parts, further not only reducing the weight, but also ensuring the strength of the wheel; (2) the technique is simple: as the forming procedure of the rim adopts one-time spinning, and the technique is simplified and equipment investment is saved compared with the original mode with three-time roll forming; (3) the raw materials are saved and the material utilization ratio is improved: the spinning is utilized to make a tyre bead to be at 15-degree position, the materials saved at the thinned parts of matched parts of spokes and the like are added to the width direction of the whole rim, thus being capable of saving the width by about 5-8% compared with the original discharging width.

Owner:赖建辉

Drying device for tea processing

ActiveCN106958996AClean upImprove cleaning qualityPre-extraction tea treatmentTea dryingFiltrationGear wheel

The invention discloses a drying device for tea processing. The drying device for tea processing comprises a rack, a first conveyor, a second conveyor belt, a cleaning drum and a drying drum, and water filtration holes are distributed in a second conveyor; a water inlet is formed in the bottom of the cleaning drum, multiple nozzles are installed in the cleaning drum, a push rod is connected to the rack, drying holes are distributed in the bottom in the drying drum, a helical guide slot is formed in the drying drum, and the push rod is connected in the helical guide slot in a sliding manner; a supporting frame is fixed to the rack, multiple pushing shafts are connected to the supporting frame in a sliding manner, pushing blades are axially and evenly distributed on the pushing shafts, and a driving rod is fixed to the multiple pushing shafts; and a protruding block is fixed to the cleaning drum, wheel teeth are fixed to the cleaning drum, a first gear is meshed with the cleaning drum, a main shaft is connected to the rack, and a first gear is fixed to the main shaft. Compared with the prior art, according to the drying device for tea processing, by means of matching arrangement of the cleaning drum and the drying drum, the cleaning quality of tea is better; the cleaning drum can rotate to indirectly drive the drying drum to rotate, and the drying efficiency of the drying drum is improved.

Owner:ZHENGAN COUNTY FUYAN TEA IND CO LTD

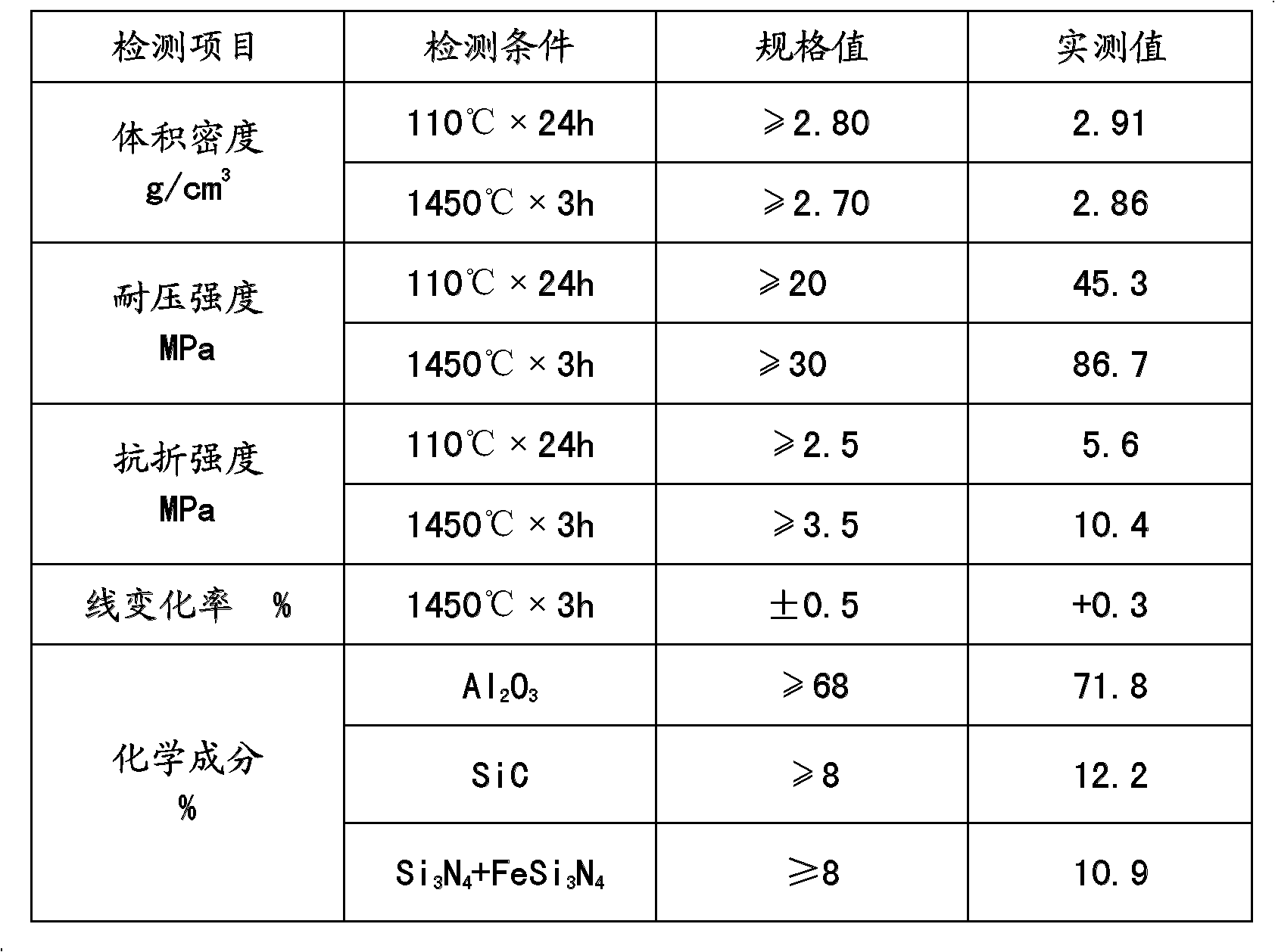

Aluminum nitrogen demanganization swing spout castable

The invention discloses aluminum nitrogen demanganization swing spout castable, which comprises electric smelting densified corundum, brown fused alumina, tabular corundum, activated alumina powder, silicon carbide, ball pitch, silicon nitride, metal powder, sodium hexametaphosphate, coagulant, detonation inhibitor, silica powder and ferro-silicon nitride. In order to prevent SiC from being oxidized, Si3N4 and Si are added in Al2O3-SiC-C castable, and a SiAlON matrix generated by Al2O3 in-suit reaction is combined to improve solid-solid direct bonding rate of the matrix. In addition, FeSi3N4 is added, a fondant covered on the surface of a material is formed at high temperature, so that the silicon carbide and carbon are prevented from being oxidized.

Owner:长兴煤山新型炉料有限公司

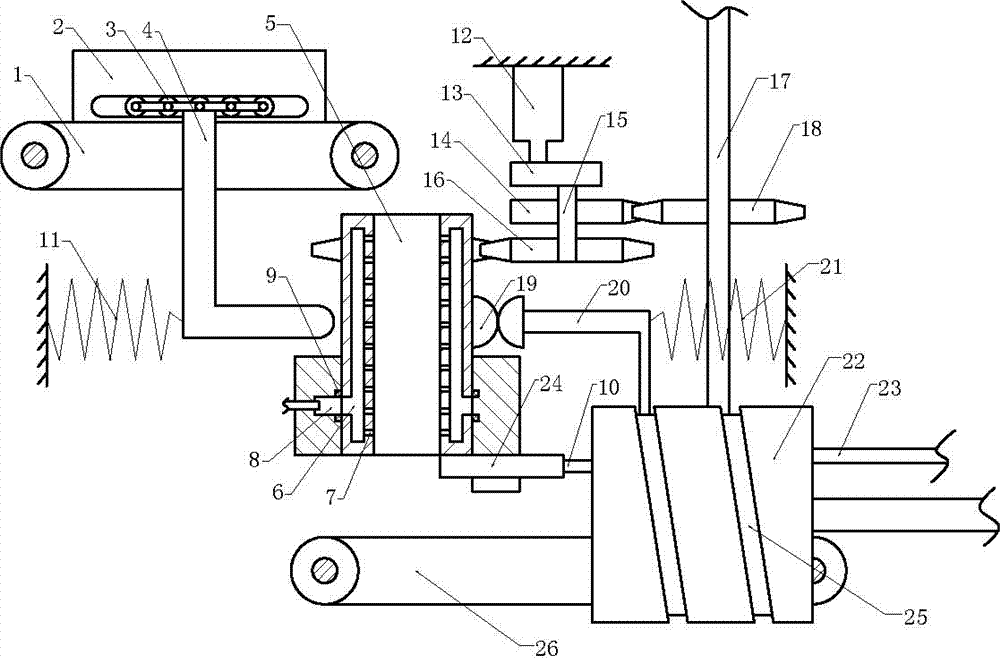

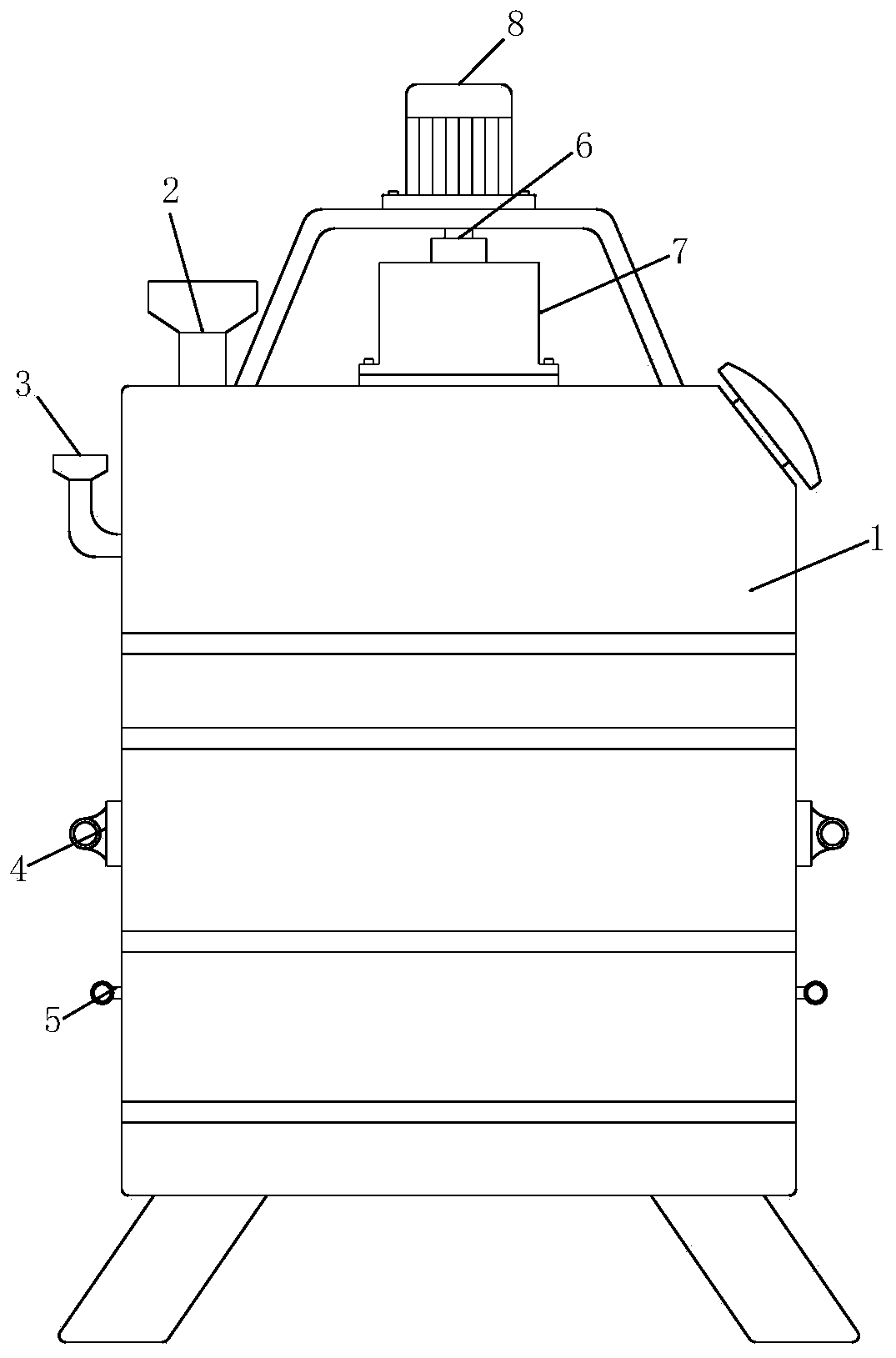

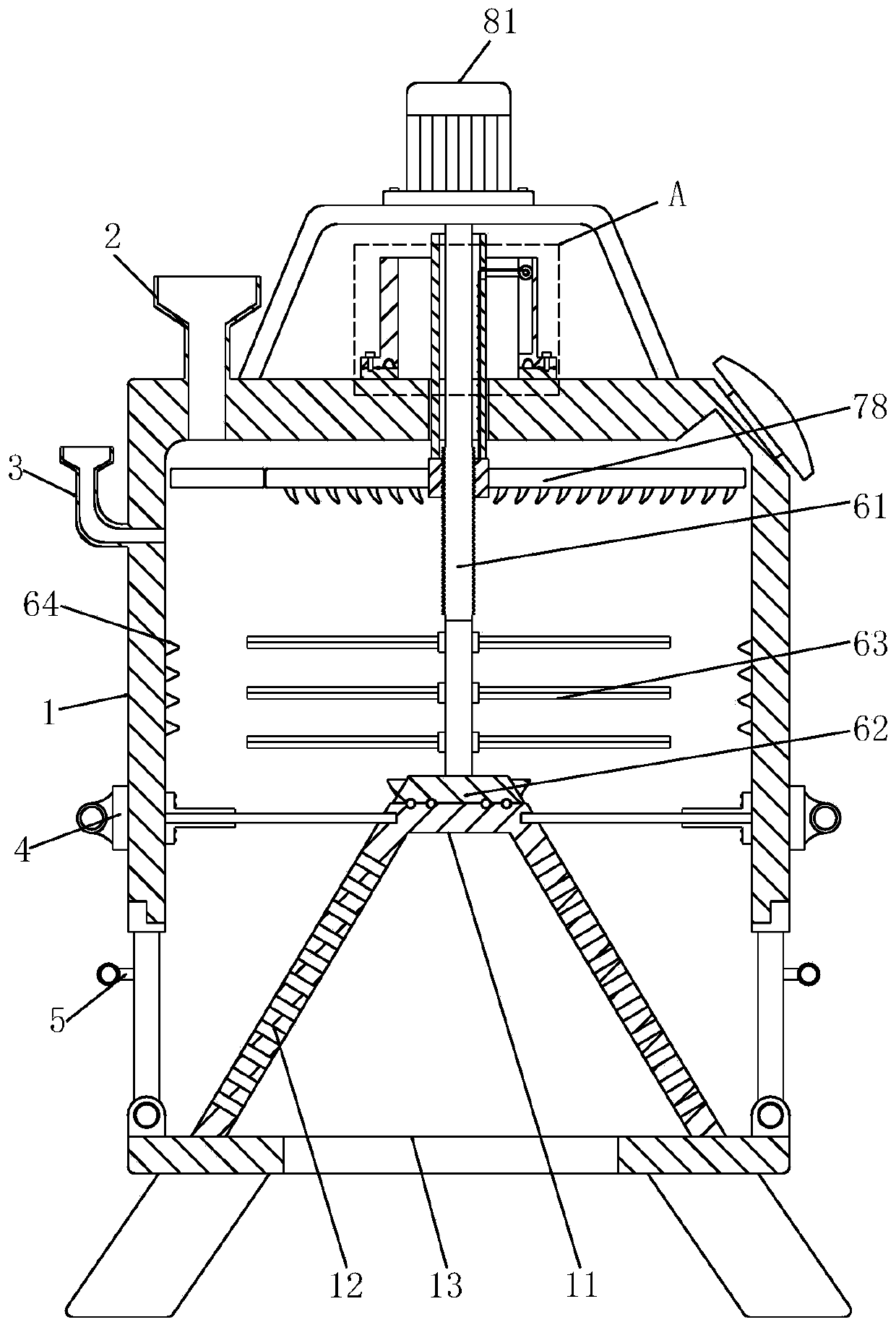

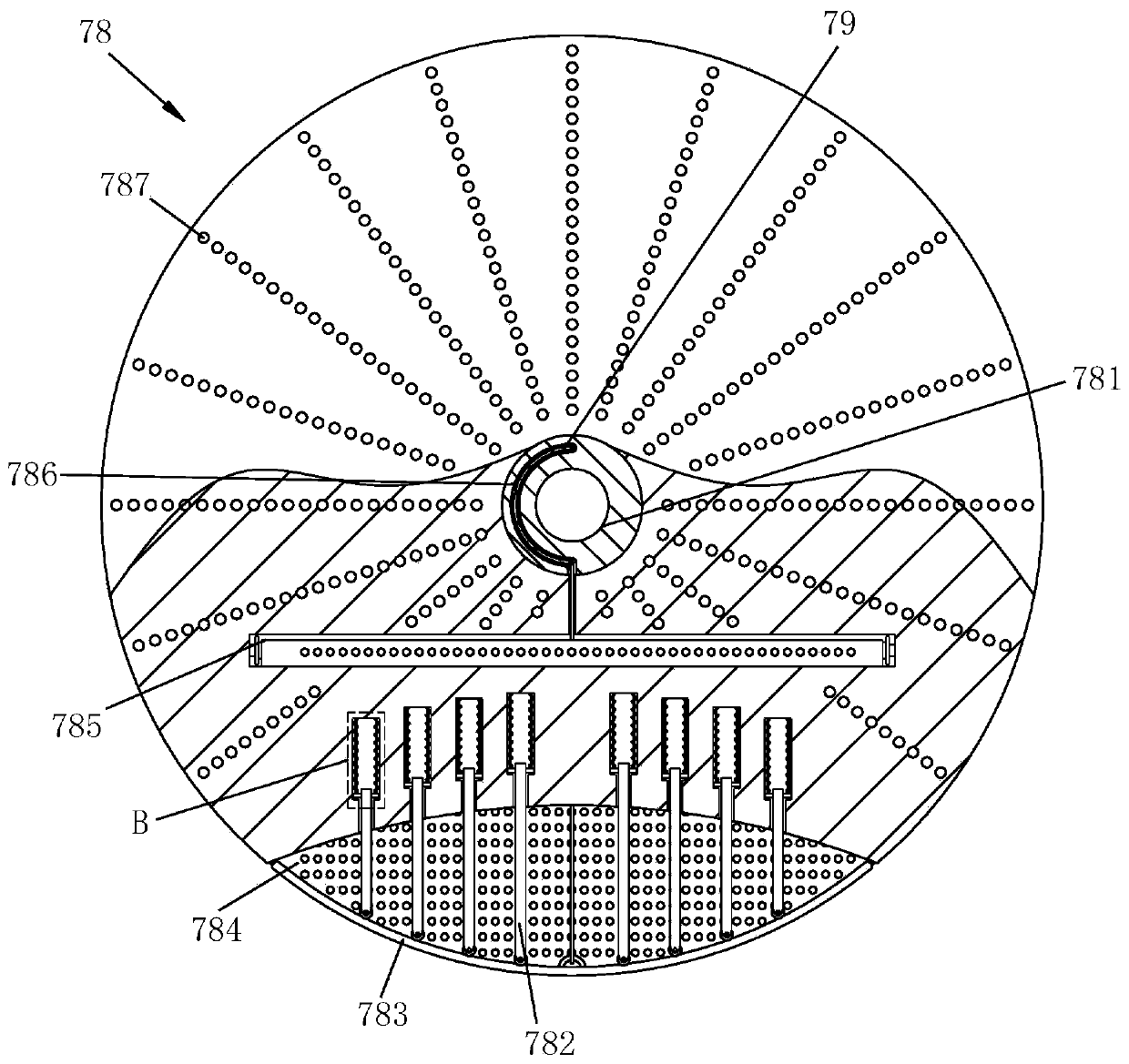

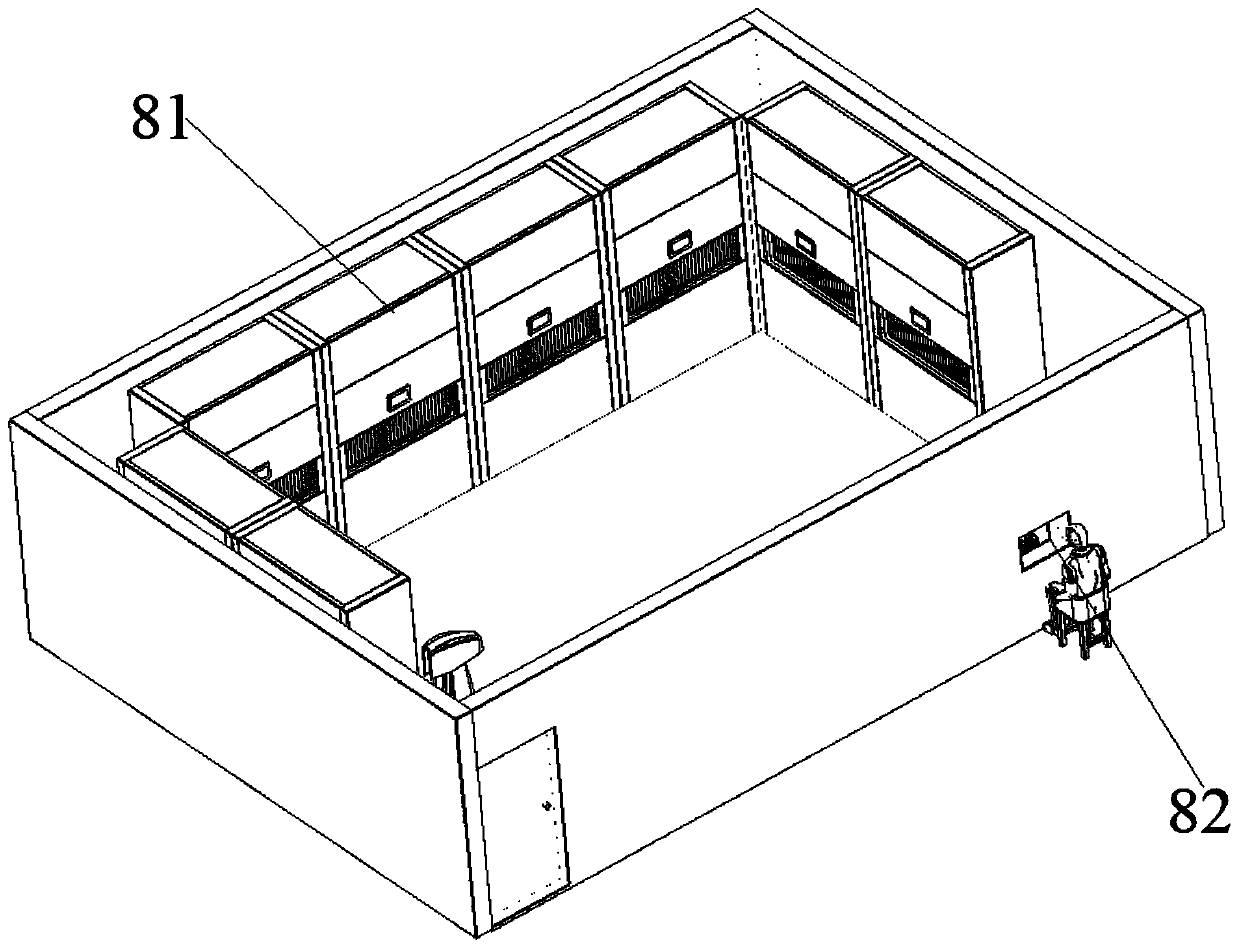

Cosmetic rose essential oil extraction raw material pretreatment system

ActiveCN111375470ANarrow down the active areaGuaranteed normal inputEssential-oils/perfumesCleaning using liquidsElectric machineryDrive motor

The invention relates to a cosmetic rose essential oil extraction raw material pretreatment system. The cosmetic rose essential oil extraction raw material pretreatment system comprises a tank body, afeeding port, a water injection port, a partition plate, unloading plates, a cleaning mechanism, a positioning mechanism and a driving motor; the unloading plates are arranged on the two sides of thebottom of the tank body; the partition plate is arranged at the middle section position of the tank body; the driving motor is mounted at the top of the tank body; the lower part of the driving motoris connected with the cleaning mechanism; the positioning mechanism is arranged on the outer side of the cleaning mechanism; the feeding port is connected to one end of the top of the tank body; thewater injection port is formed in the outer wall of the tank body; a rotating rod is connected to the central position in the tank body in an inserting manner; the top end of the rotating rod is connected with an output shaft of the driving motor; a thread groove is formed in the outer wall of the middle area of the rotating rod; cutting blades are arranged on the outer wall of the bottom of the rotating rod at equal distance; and the bottom of the rotating rod is welded with a stirring disc. The cosmetic rose essential oil extraction raw material pretreatment system effectively ensures full contact between rose petals and cleaning water as well as the cutting blades, so that the cleaning and cutting effects are better; and the device is easy, convenient and quick to operate.

Owner:两当沁香怡玫瑰生物科技有限公司

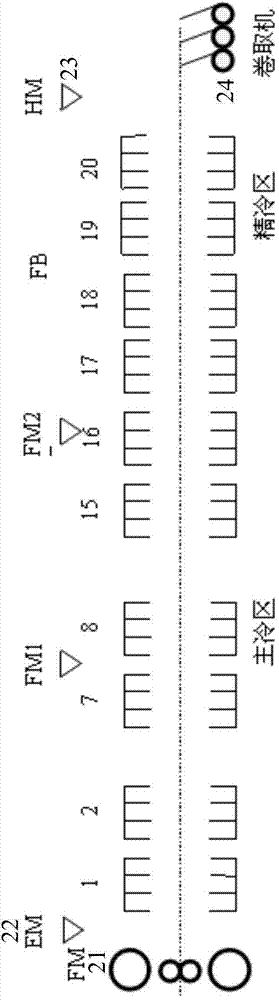

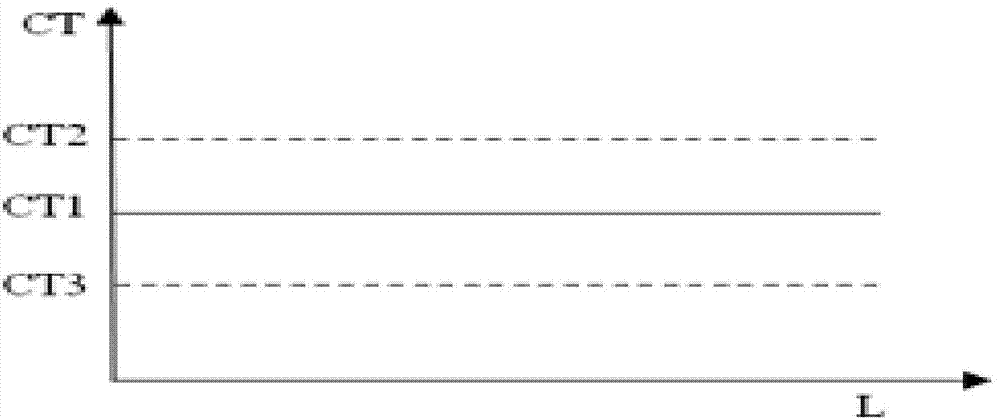

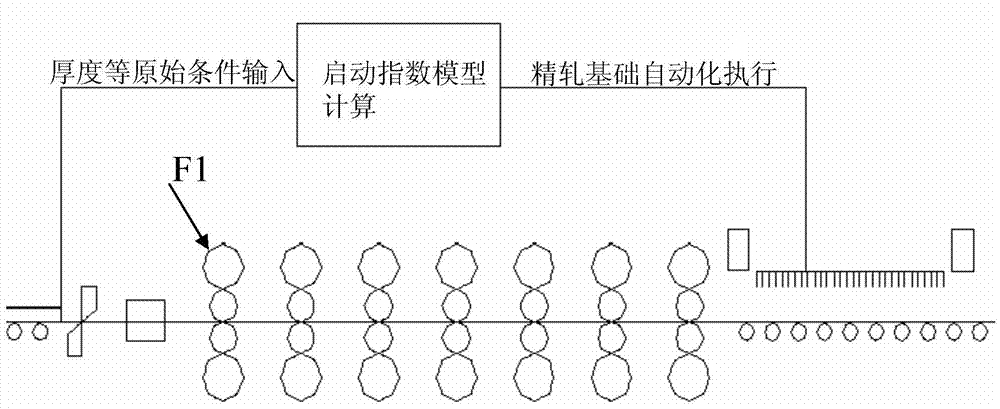

Sheet coiling temperature control method in big-speed-reduction rolling of hot-rolled strip steel

ActiveCN104841701AIncrease the actual coiling temperatureImproved coiling temperature accuracyTemperature control deviceLaminar coolingStrip steel

The invention discloses a sheet coiling temperature control method in big-speed-reduction rolling of hot-rolled strip steel. The method comprises the steps of: inputting such data as the thickness of the strip steel into a laminar cooling model module of a laminar cooling process machine; and judging if a finish rolling steel casting speed difference is not smaller than 3 M / S and the steel casting time point is reached, if not, increasing the cooling water quantity through opening a concentrated distribution control valve of a finish rolling basic automation computer, and enabling the actual temperature of the strip steel to approach a target value through adjusting the feedback water quantity, and if so, calculating the tail heating length of the strip steel according to a rolled length before the finish rolling speed-reduction rolling through the laminar cooling model module, raising the tail temperature, re-calculating the valve opening magnitude, sending a signal to the finish rolling basic automation computer to perform the valve reducing treatment so as to reduce the tail cooling water quantity, and enabling the actual temperature of the strip steel to approach the target value through adjusting the feedback water quantity. The method can prevent the tail coiling temperature of the thin-specification strip steel from exceeding the control range in the big-speed-reduction rolling.

Owner:BAOSHAN IRON & STEEL CO LTD

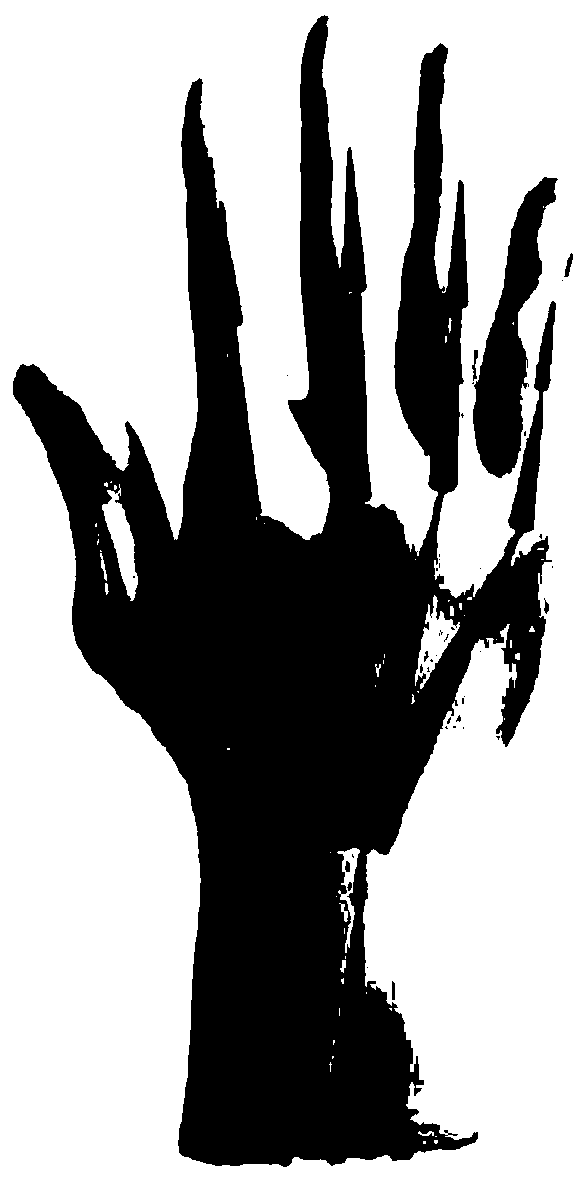

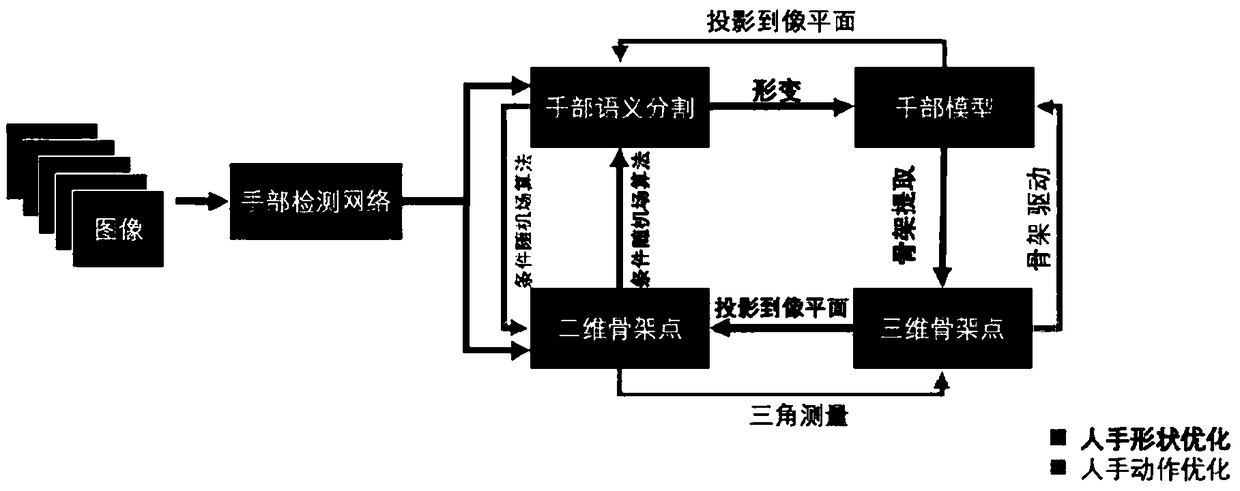

A low-resolution multi-view hand reconstruction method based on a human hand parametric model

ActiveCN109325995APrecise shape of the human handGood robustness3D modellingHand partsImage resolution

A low-resolution multi-view hand reconstruction method based on a human hand parameter model comprises the following steps of acquiring a multi-view image of a whole human body; extracting a mask, two-dimensional joints, converting into three-dimensional skeletal points; carrying out the motion deformation of the human hand parameter model and obtaining the human hand motion deformation model; optimizing the shape parameters of the human hand parameter model, and obtaining the human hand shape deformation model; reversely projecting skeletal points and models onto multi-view images, and optimizing and updating the existing two-dimensional skeletal points and masks to obtain the final hand model; splicing the mannequin. The whole process of the invention is automatically completed, the gesture movement and shape characteristics are accurately expressed, the reconstruction precision is high, the hand model and the human body model are spliced and recombined, and a more accurate and complete model effect is obtained.

Owner:PLEX VR DIGITAL TECH CO LTD

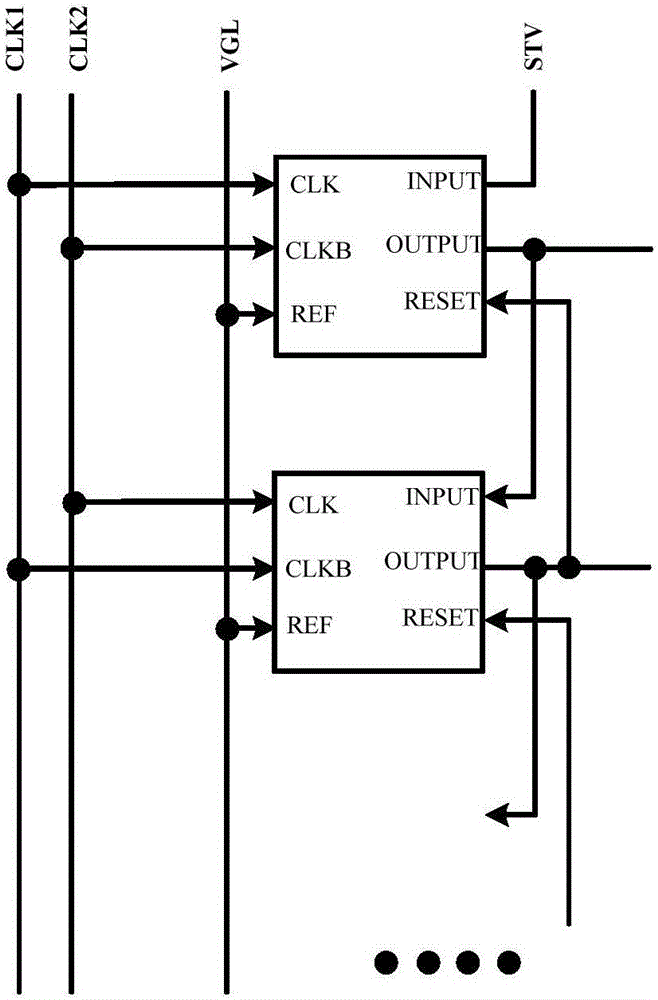

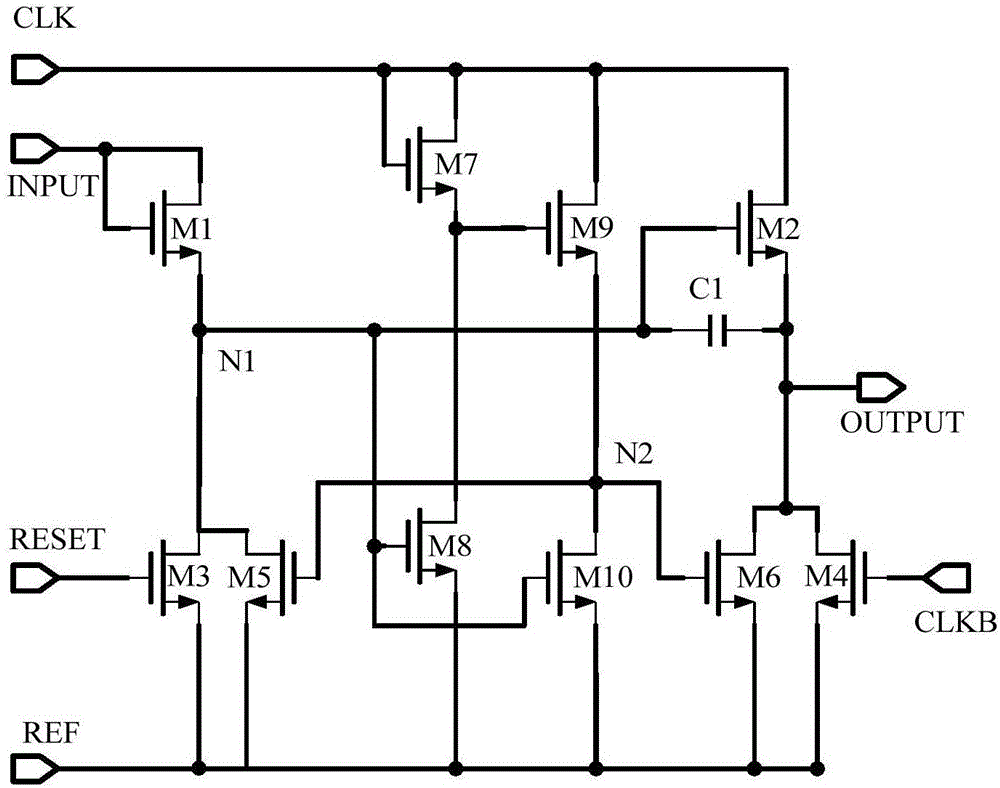

Shift register unit, grid driving circuit, and display device

ActiveCN106486047AImprove reset abilityAvoid wastingStatic indicating devicesDigital storageShift registerProcessor register

The invention provides a shift register unit, a driving method of the shift register unit, a grid driving circuit and a display device. In the shift register unit, an input module controls the potential of a first node according to an input signal, an output module controls an output signal of an output end according to the potential of the first node and a first clock signal, a pull-down control module controls the potential of a second node according to the potential of the first node and the first clock signal, and keeps the output end in a resetting state before that the input end receives a next input signal, and the resetting module enables a pull-down module to work, according to a resetting signal and the input signal, so as to reset the first node and the output end, and also resets the first node and the output end according to the resetting signal and a second clock signal. The shift register unit has an improved resetting capability, and can avoid resource waste caused by that components in the shift register unit are idle.

Owner:BOE TECH GRP CO LTD +1

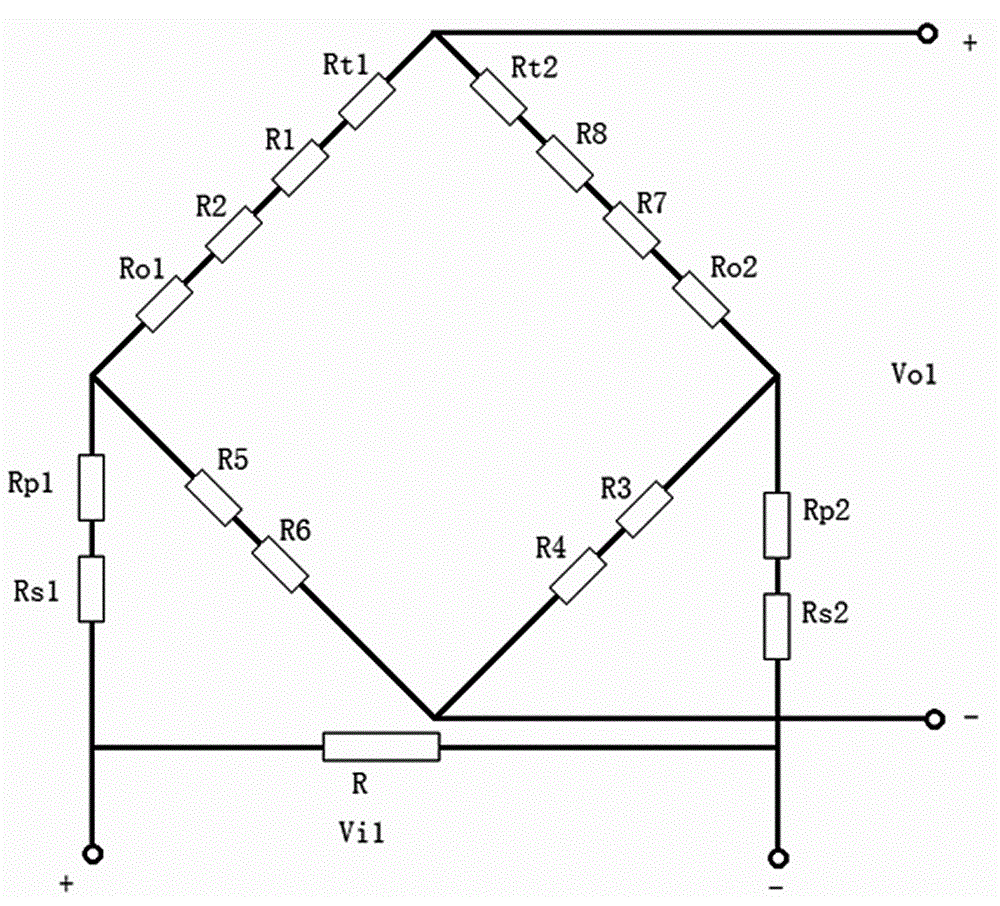

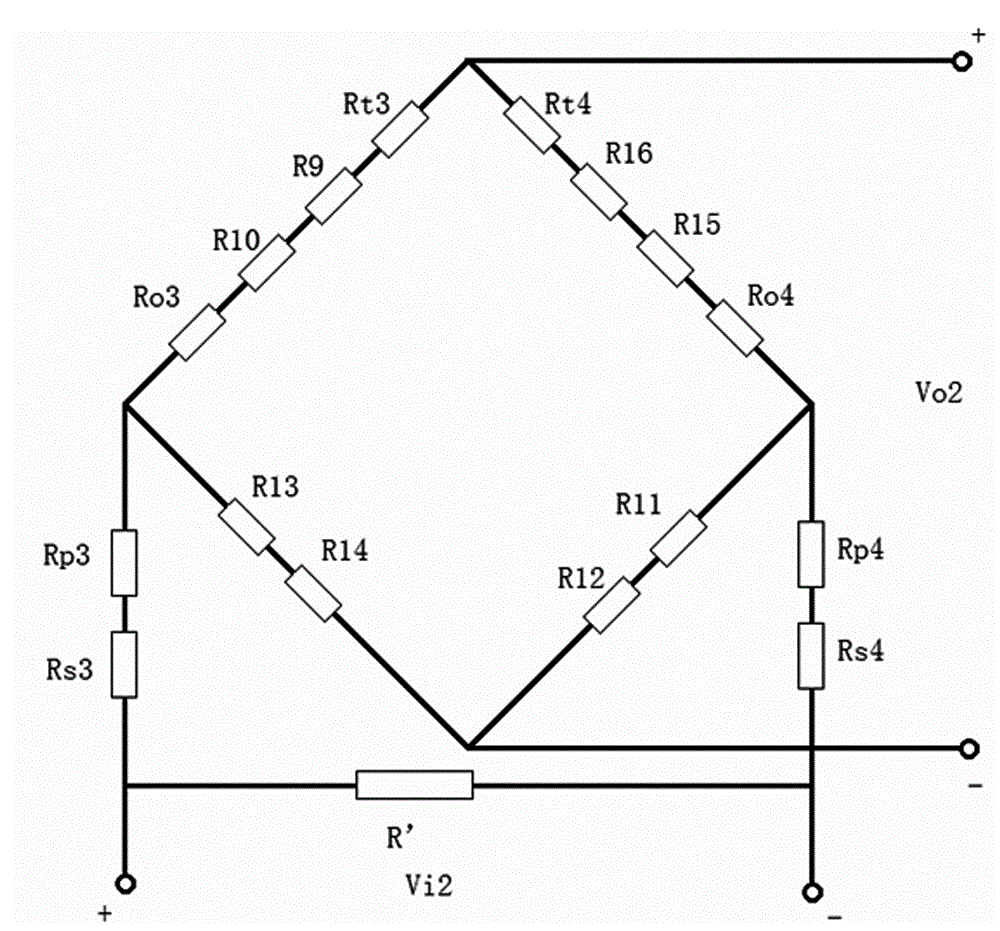

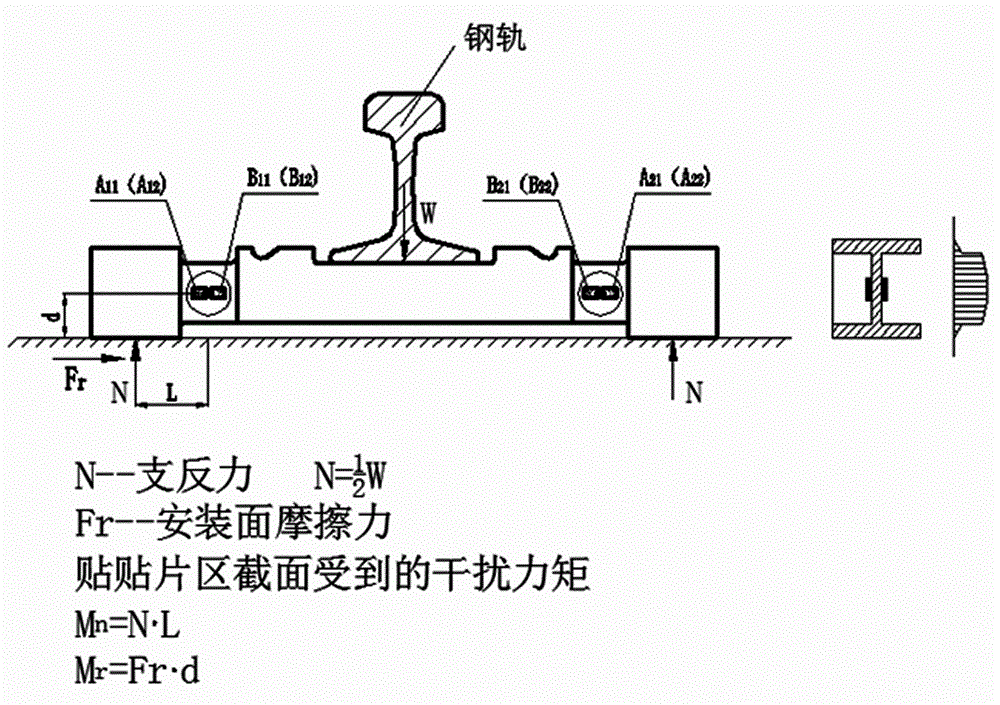

Dynamic-static double-output rail weighbridge

ActiveCN105043518AAvoid drudgeryGuaranteed normal inputSpecial purpose weighing apparatusElastomerEngineering

The invention provides a dynamic-static double-output rail weighbridge. A resistance strain sensor device with double vertical force outputs is adopted. In the sensor device, strain gauges of two bridge circuits of the same composition are arranged on the bottom surface of a web plate of a shearing strain blind hole of the same beam or plate type sensor elastomer in a specific configuration mode, so that double vertical force output signals can be output at high accuracy under the same load, wherein the two output signals are respectively used for measurement of static and dynamic rail weighbridges. Meanwhile, a dynamic-static weighing measurement method which is simple and effective and is not affected by the operating environment is provided for the rail weighbridge. In addition, corresponding improvement is made on the power module of the rail weighbridge in view of the working environment of the rail weighbridge.

Owner:HANGZHOU QIANJIANG WEIGHING TECH

Assembling method for jacketed pipe and its pipe lining apparatus

InactiveCN101463923AGuarantee welding qualityGuaranteed installation qualityPipe laying and repairEngineeringStructural engineering

The invention discloses an assembly method of jacketed pipes and a pipe inserting device. The method comprises the following steps: firstly, welding inner pipes of the jacketed pipes in pairs, and sheathing outer pipes of the jacketed pipes after heat treatment, weld seam detection and a hydraulic test; lifting the welded inner pipes while sheathing the outer pipes, and then lifting the outer pipes to ends of the inner pipes; mounting the pipe inserting device respectively on a front end and a rear end of the outer pipe; translating and sheathing the outer pipes outside the inner pipes one by one; and finally welding various outer pipes, and finishing assembly. The assembly method has the advantages of saving construction materials, having low equipment investment and simple construction steps, being capable of effectively protecting jacketed pipe materials and the like; and the pipe inserting device has the advantages of simple structure, convenient installation and use, less construction materials, lower equipment investment, simplified construction steps and the like.

Owner:五矿二十三冶建设集团有限公司

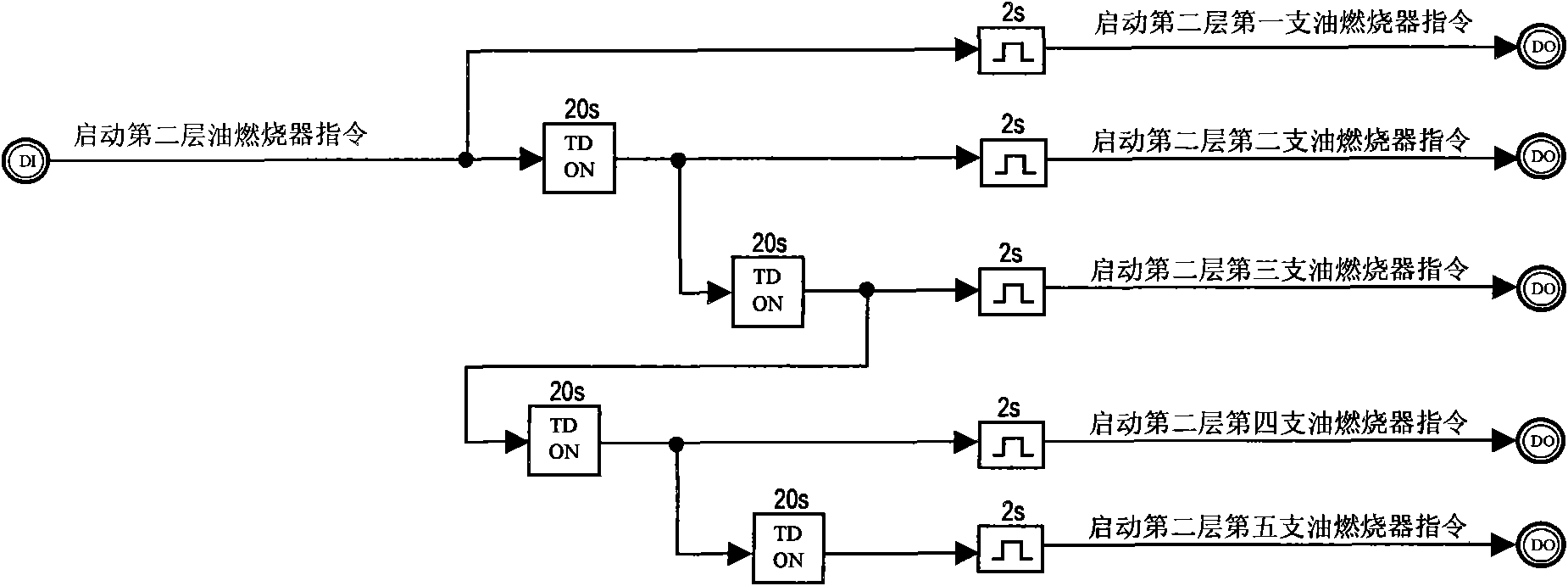

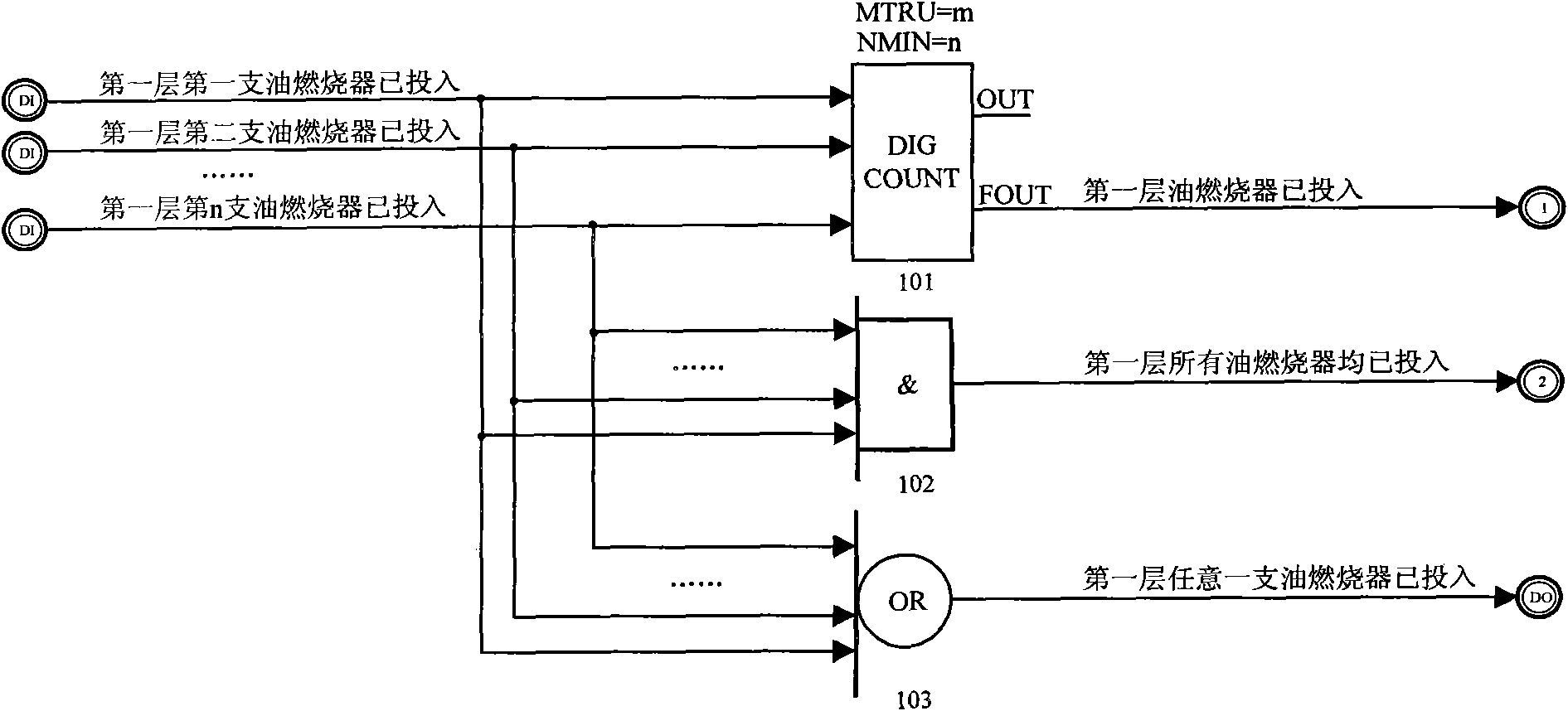

Automatic control method for boiler oil burner and device thereof

The invention relates to an automatic control method for boiler oil burners, which comprises the following steps: a, the oil burner is partitioned into a plurality of layers; b, the oil boiler is operated taking a layer as a unit when an instruction of inputting or quitting is received; c, the next layer of the oil burner is operated until all of layers of the oil burner are operated when the operating amount of the oil burner in one layer is larger than 80 percent; and d, when an instruction of operating or stopping operating is received in one layer, a corresponding oil burner is sequentially operated, if the oil burner is operated, or the operation is not allowed, the next oil burner is operated. The device for realizing the automatic control method comprises an oil burner layer operating judgment loop, a boiler oil burner layer management loop and a layer oil burner management loop, wherein the oil burner layer operating judgment loop inputs the operating signals of the oil burners in the layer and outputs the signals to the boiler oil burner layer management loop; the boiler oil burner layer management loop also inputs an oil burner ignition instruction and the last signal of the failed starting of the oil burner in each layer, and outputs starting instructions of the oil burners in each layer to each oil burner management loop; and the layer oil burner management loop inputs operating allowing and operating signals of the oil burners of each layer and starting instructions of the oil burner of each layer and outputs ignition instructions of the oil burner of each layer.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

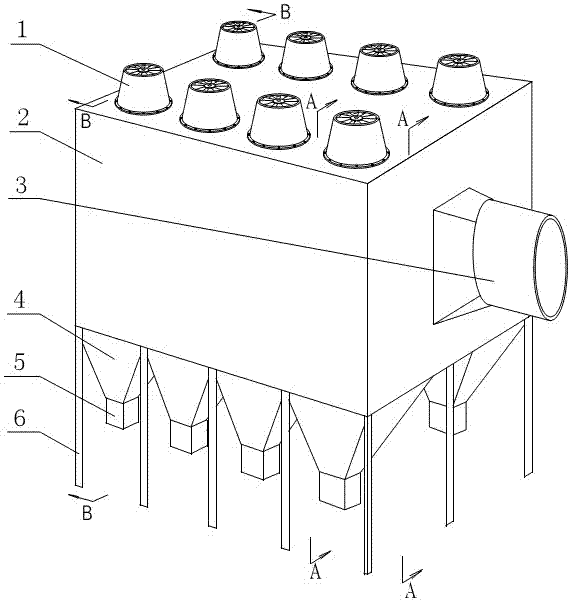

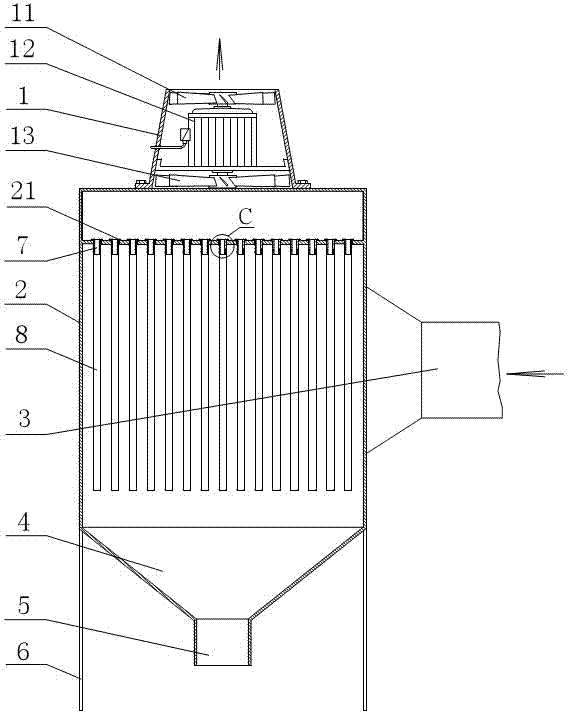

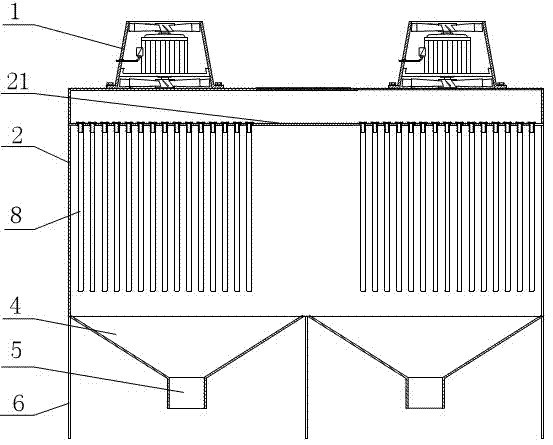

Dust collector for energy-saving environment-friendly axial flow fan group

InactiveCN103480210AReduce investmentGuaranteed normal inputDispersed particle filtrationImpellerAir volume

A dust collector for an energy-saving environment-friendly axial flow fan group. A sidewall of a casing is equipped with an air-supply pipe, which directly penetrates into the casing; more than two air outlets are arranged on the end face of the casing; each air outlet is installed with an axial flow fan; the rotating shaft of each axial flow fan is provided with more than one impellers for generating high pressure effect through progressive increase of wind pressure of the fan; filter bags are arranged opposite to corresponding axial flow fans; the upper end of each filter bag is fixed on a separator plate with through holes in the casing; a dust bucket and a dust box are arranged below the filter bags corresponding to each axial flow fan; the separator plate and the air outlet keep a distance of 1-3 m, and the space above the separator plate forms a cleaning chamber; each axial flow fan runs in a process of forward rotation, stop, reverse rotation, stop and forward rotation; and the axial flow fans carry out cycling air-discharge and dedusting procedure in turns. The forward rotation induces air to dedust, the reverse rotation conducts back flushing ash removal with large air quantity, so as to substantially reduce filtering resistance and maintain the dust thickness in the filter bags within 0.5 mm for a long time, reduce power consumption for dedusting, thoroughly omit auxiliary facilities including a high pressure recoil pipe, a gas tank, a pulse valve and an air compressor, and realize a total energy saving of 70-80%.

Owner:张建美

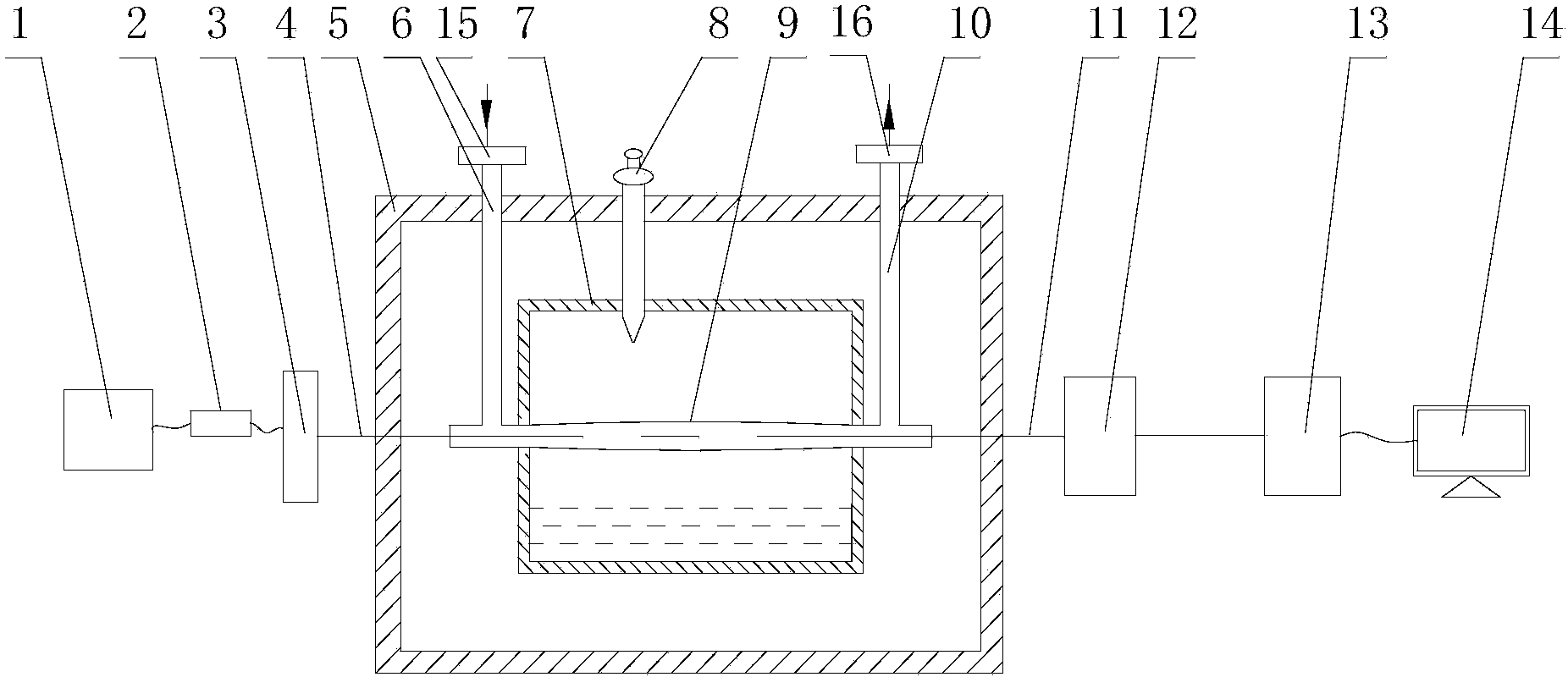

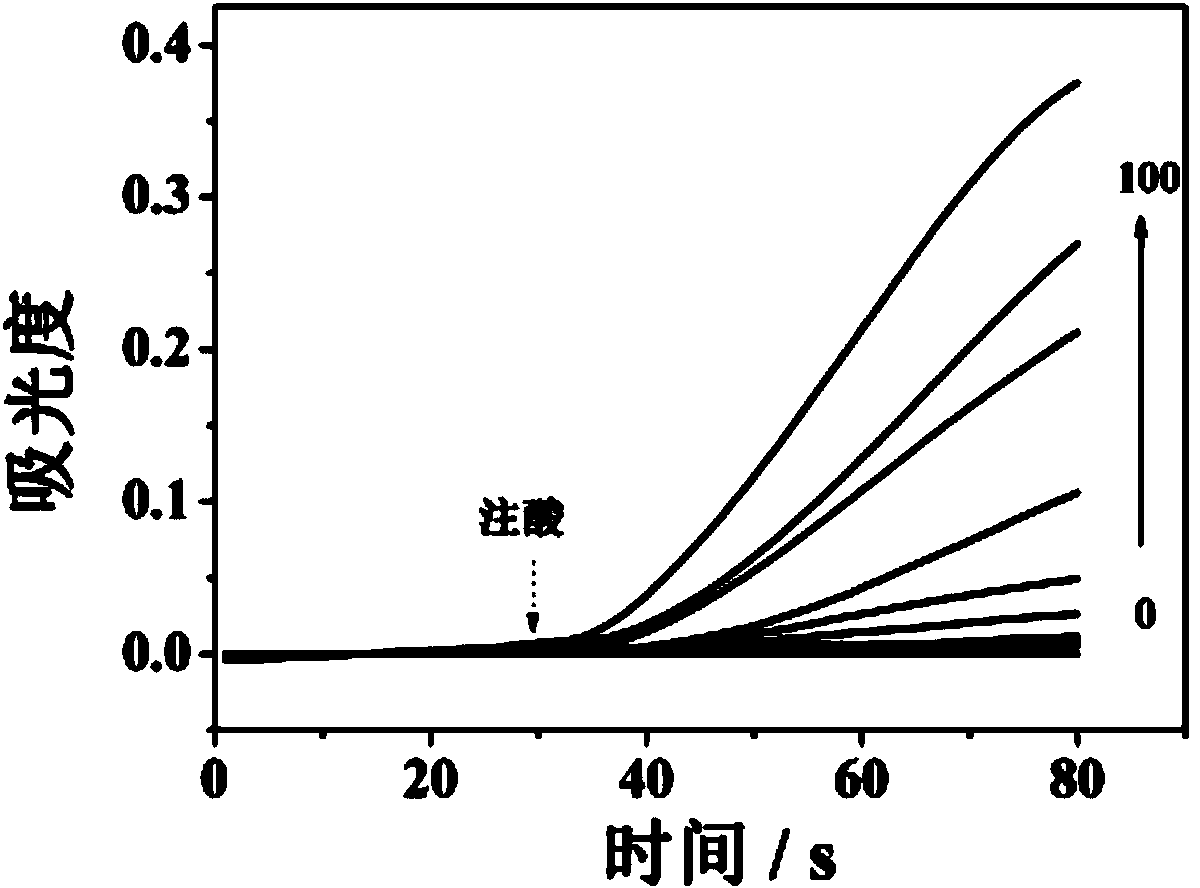

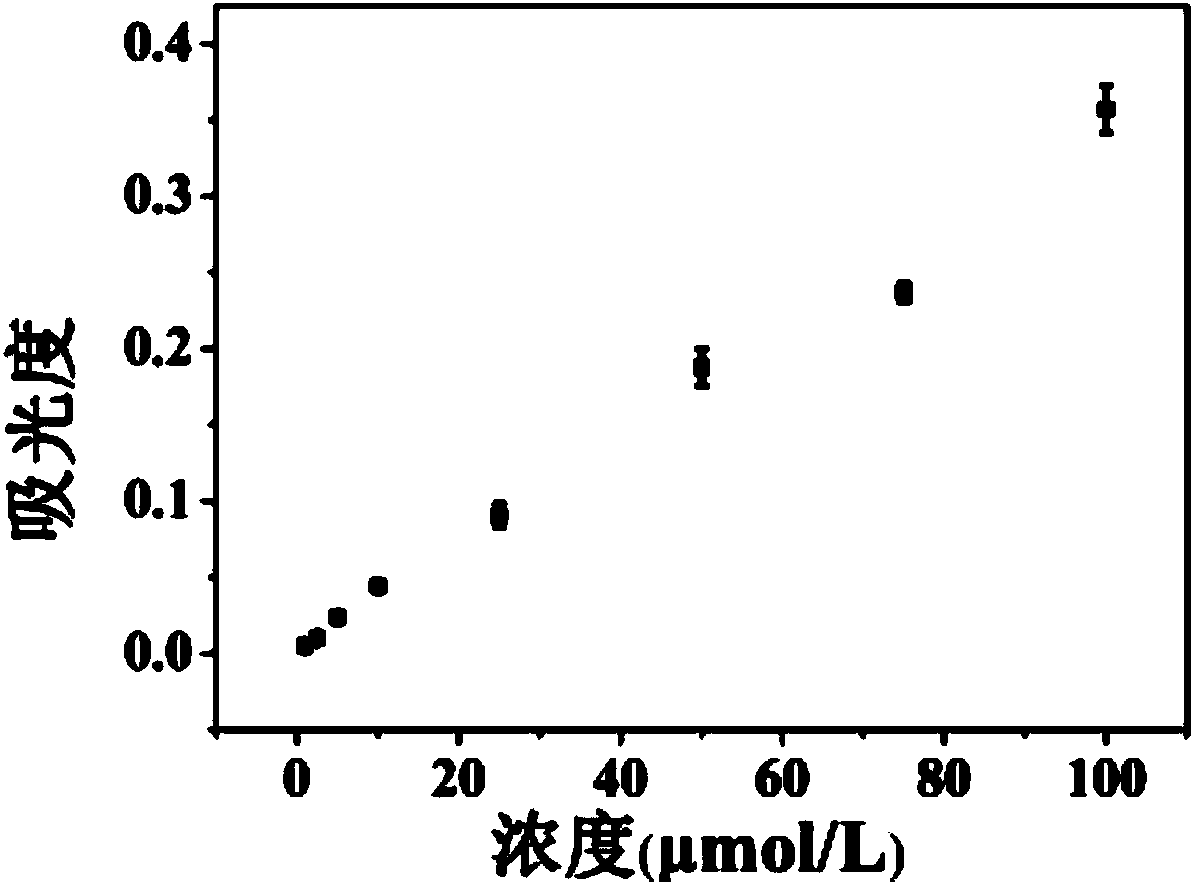

Device and method for detecting long-light-path liquid sulfide

InactiveCN103983590AGuaranteed normal inputAvoid interferenceColor/spectral properties measurementsInterference phenomenonData acquisition

The invention relates to a device for detecting long-light-path liquid sulfide. A rheostat is connected between a power supply and a light source; a light-preventing shell is arranged on an emergent light path of the light source; a reaction vessel is arranged in the light-preventing shell, and a dosing tube is arranged on the top of the light-preventing shell; a breathable film tube is arranged in the reaction vessel along the radial direction; the breathable film tube is connected with an incident optical fiber through a liquid inlet pipe and is connected with an emergent optical fiber through a liquid outlet pipe; the incident optical fiber is connected with the light source; the emergent optical fiber is connected with a photoelectric converter; the photoelectric converter is connected with a data acquisition unit; the data acquisition unit is connected with a computer. The sulfide overflows from a matrix to be detected by using an acid dosing method, an interference phenomenon of foreign ions existing in the complex pretreatment process is avoided, the measurement selectivity is improved, the pretreatment is not required, the measurement process is simplified, and interference of external light is avoided due to reaction under light-resistant conditions, so that the measurement process is not interfered by impurities, and the analysis efficiency and the detection sensitivity are improved.

Owner:SHAANXI NORMAL UNIV

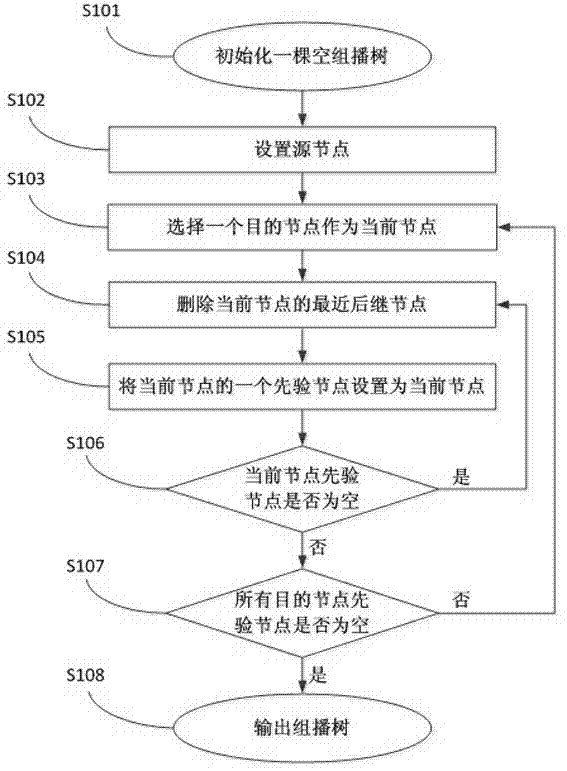

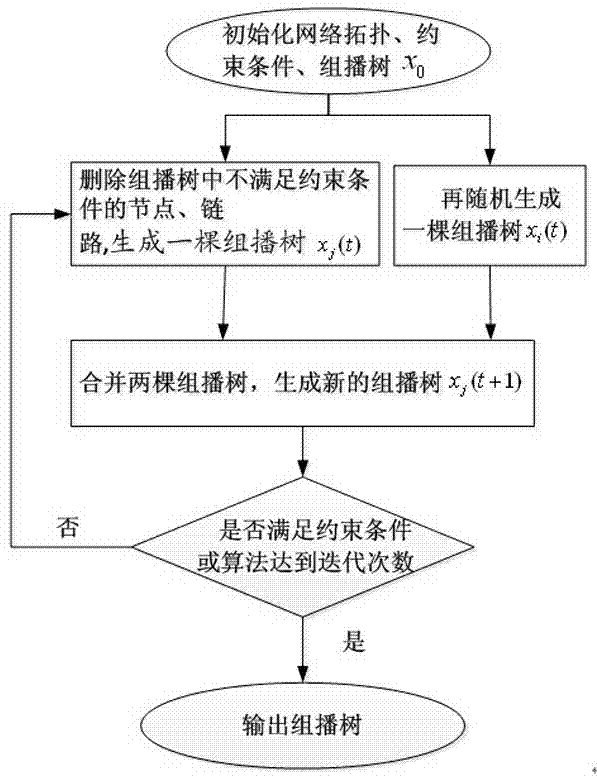

Multiple-constraint multicast routing algorithm based on iteration coding

ActiveCN103905319AEasy to implementSolve the multi-constraint multicast routing problemData switching networksComputation processNetwork communication

The invention relates to the field of network communication, in particular to a multiple-constraint multicast routing algorithm based on iteration coding. The multiple-constraint multicast routing algorithm based on iteration coding is applied to a communication network with multiple-constraint requirements aiming at the problems existing in the prior art. According to the method, a multicast tree coding method capable of eliminating a loop and high in coding and decoding applicability is designed, and meanwhile, the method can also eliminate a loop of a generated multicast tree. According to the method, a new multicast tree is generated by combining two multicast trees, and the new multicast tree is output after it is confirmed that the new multicast tree meets a routing constraint condition or the calculating process reaches iteration times.

Owner:NO 30 INST OF CHINA ELECTRONIC TECH GRP CORP

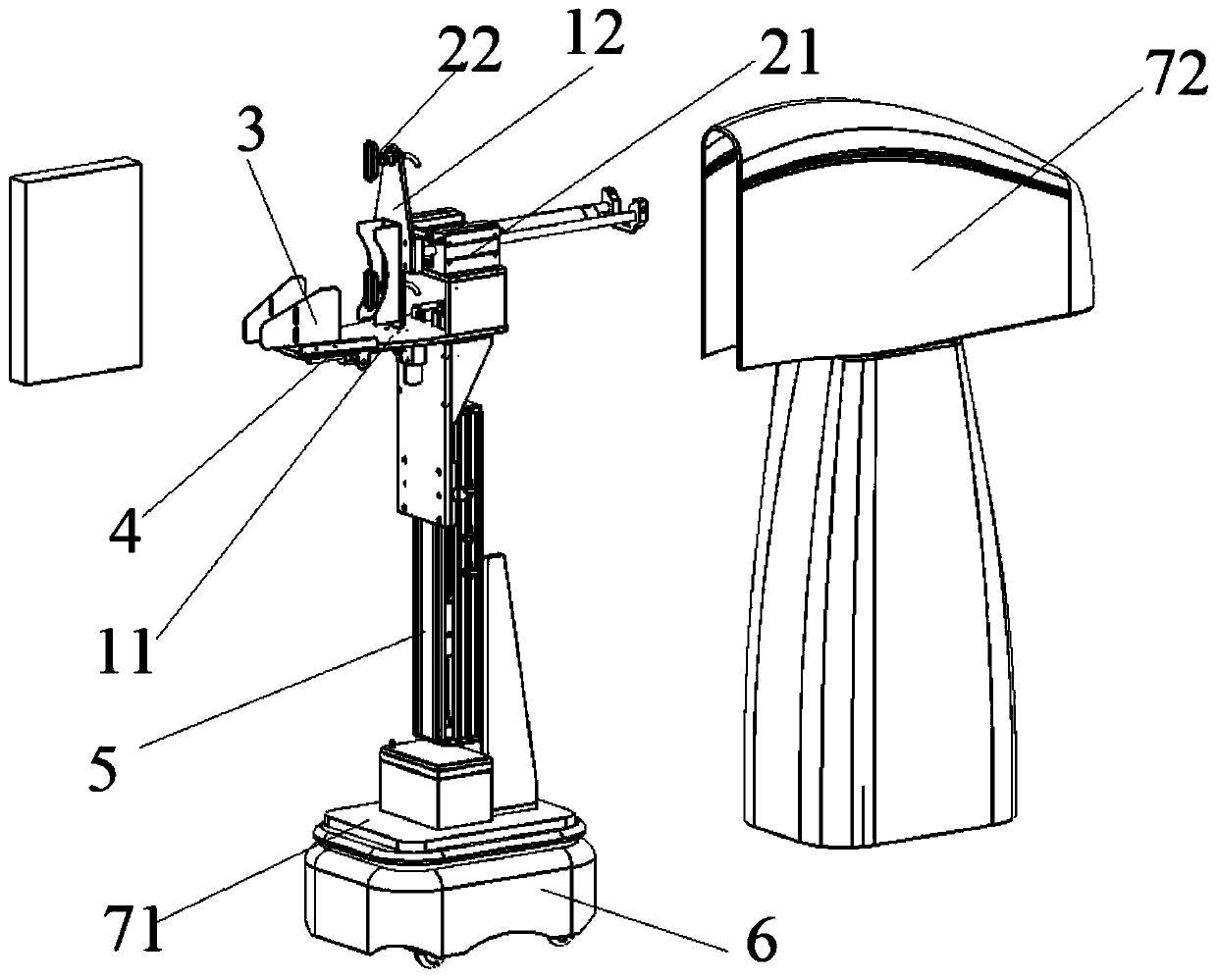

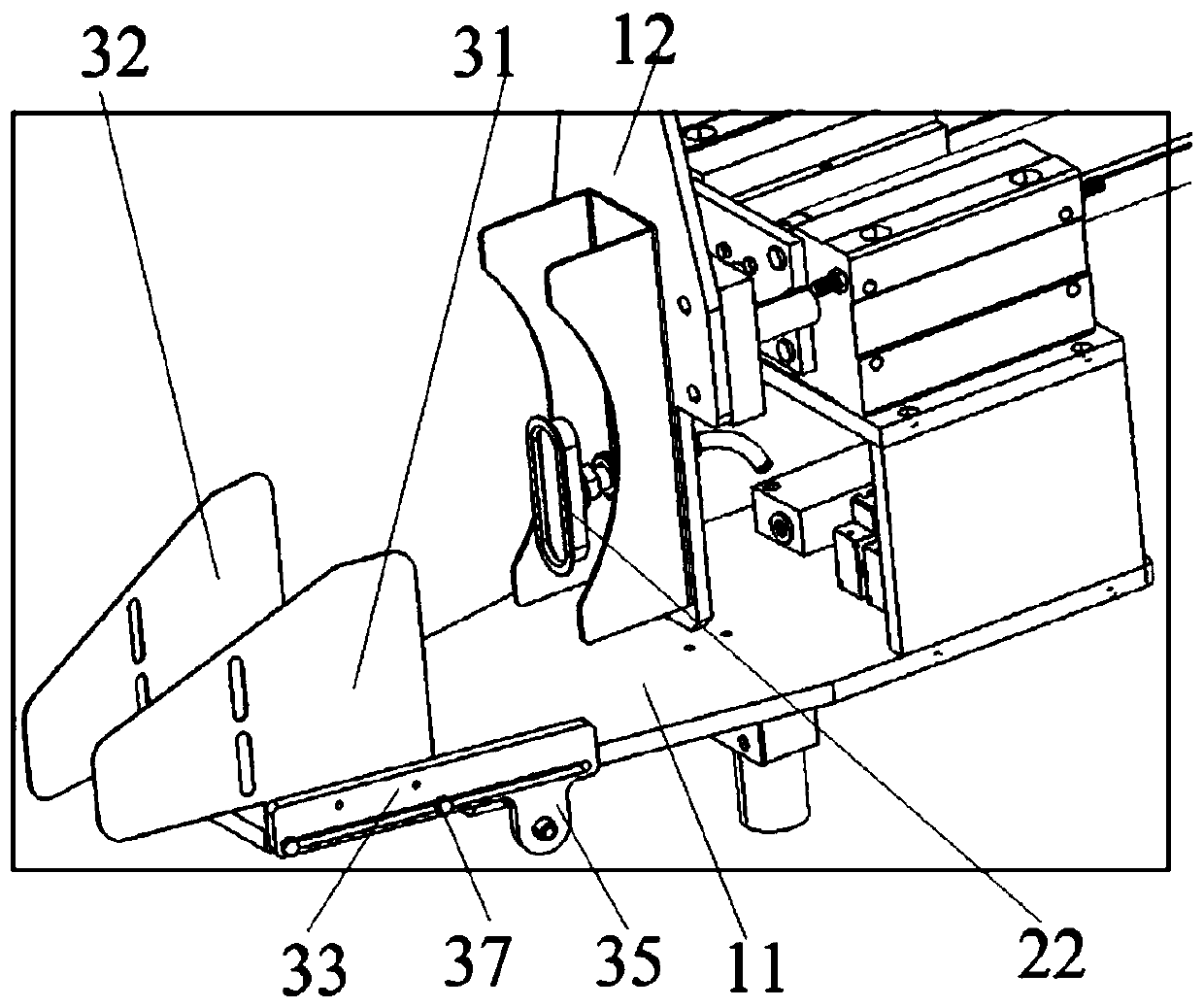

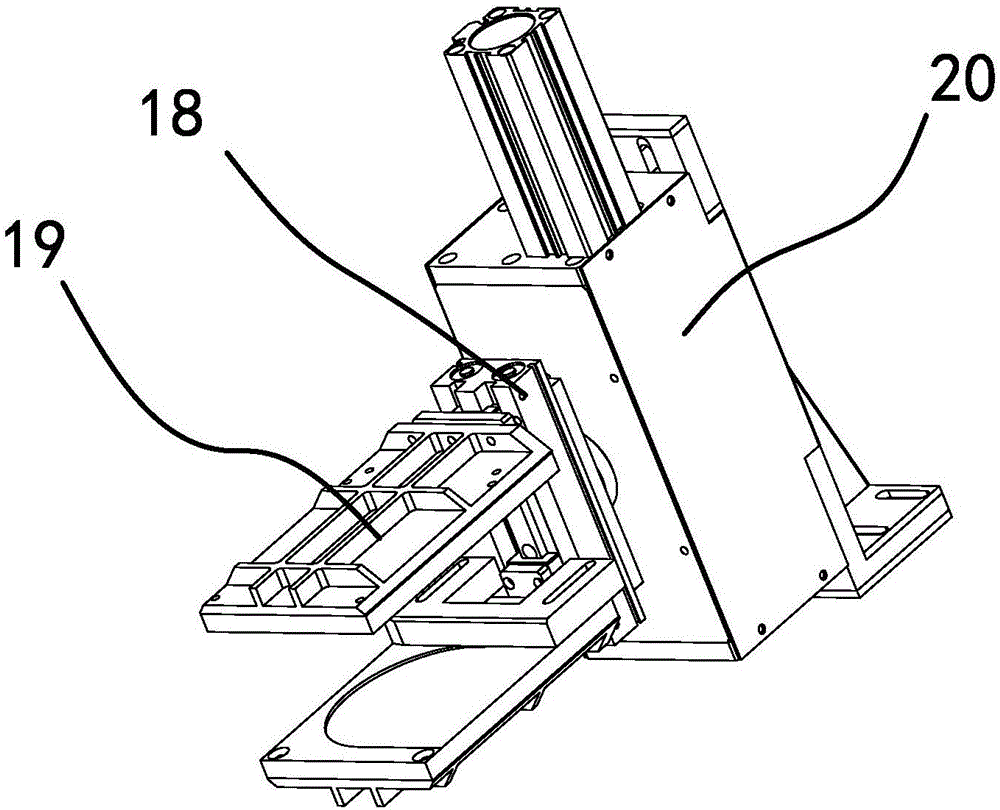

Pick-and-place device and archives management system

PendingCN110510307AGuaranteed normal inputGuaranteed normal outputStorage devicesPower unitManagement system

The invention discloses a pick-and-place device and an archives management system. The pick-and-place device comprises a material picking mechanism, a guiding mechanism and an adjustment mechanism, wherein the material picking mechanism comprises a driving unit and a material picking end; the driving unit is fixed on a supporting frame; the material picking end is fixedly connected to the drivingunit and driven by the driving unit to move; the guiding mechanism comprises a pair of guiding parts which are arranged oppositely; a passage is formed between the pair of guiding parts; the passage is positioned on a moving path of the material picking end; the passage comprises a material picking opening which allows materials to enter and exit; the adjustment mechanism comprises a first power unit and a transmission unit driven by the first power unit; the transmission unit is connected to the guiding parts; and the transmission unit is driven by the first power unit to drive the guiding parts to adjust the size of the material picking opening. In the event of a deviation of the driving unit during material handling, the materials can be re-regulated through the passage so as to achievethe purpose of always keeping the materials to move back and forth on the passage. The certainty of the exit position of the materials is guaranteed, and the exit position of the materials is not affected by the driving unit.

Owner:江苏迅捷智能科技有限公司

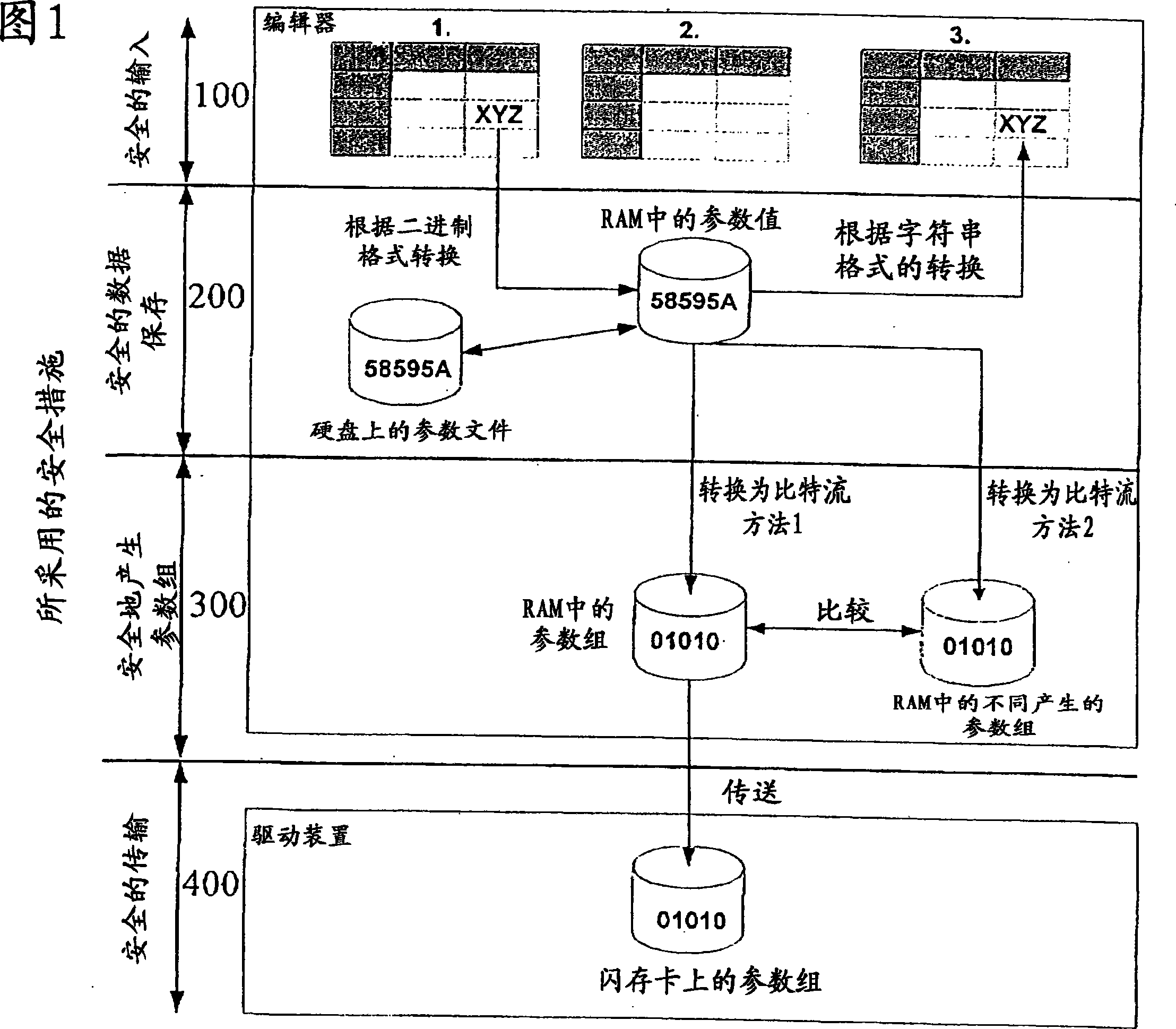

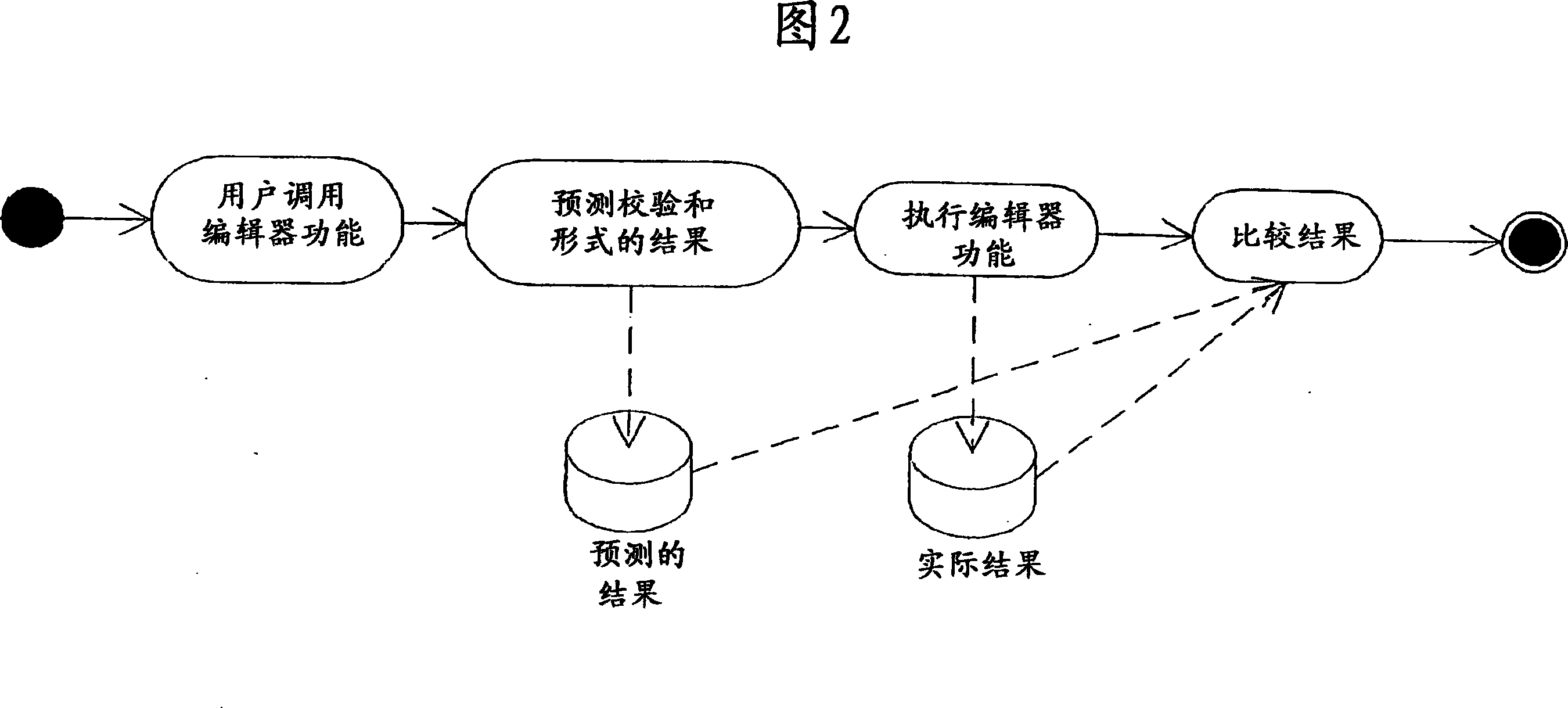

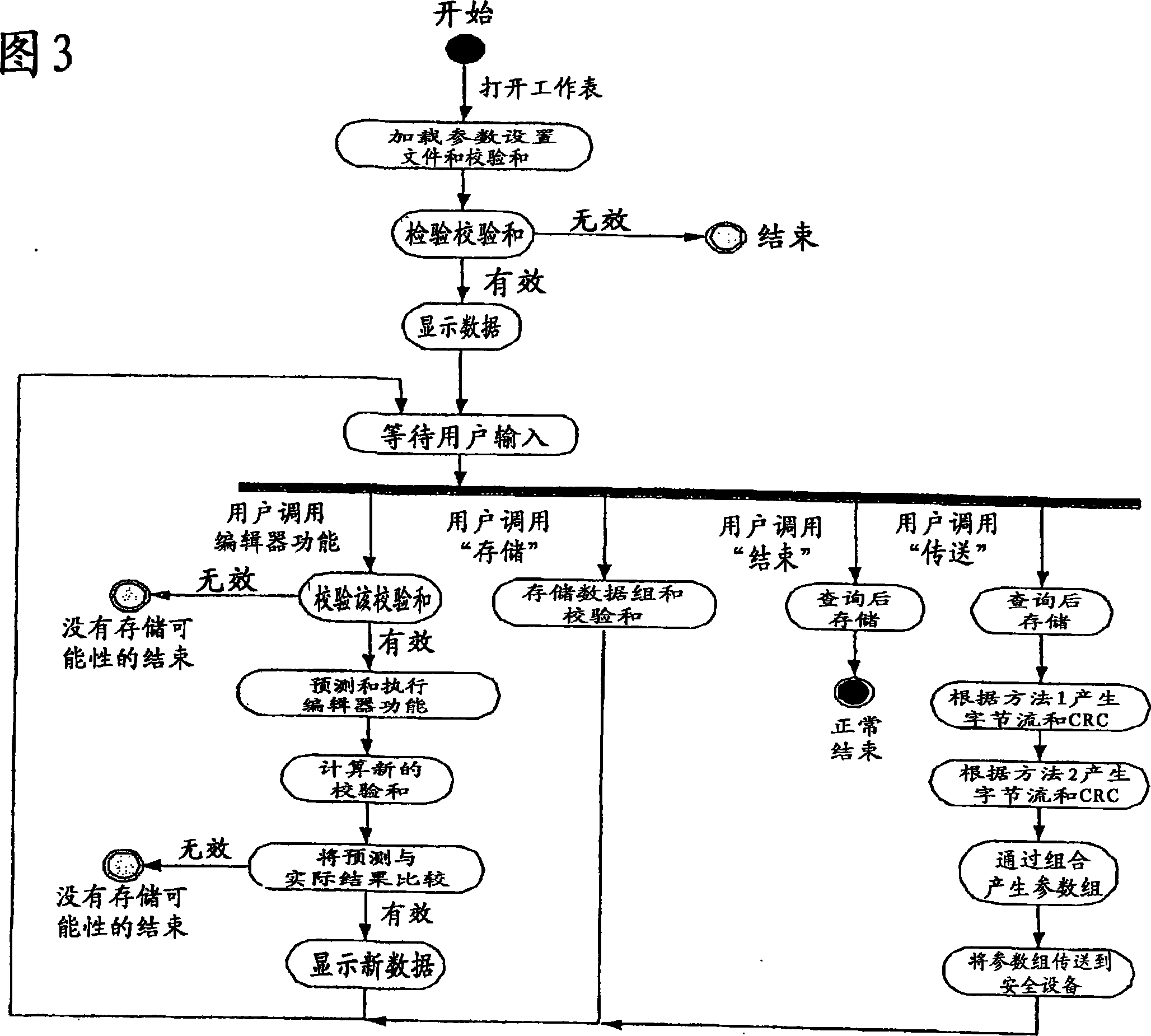

Method and device for secure parameterization of electronic devices

ActiveCN101088071APrevent tamperingGuaranteed normal inputProgramme controlComputer controlIEC 61508User interface

The invention relates to a method and device for secure parameterization, according to IEC 61508 SIL 1-3 or EN 954-1 category 1-4, of secure electronic devices. One aim of the invention is to indicate an approach which makes it possible to overcome explicit back-reading of the parameters from the secure device and confirmation of the respective parameters by the user. According to the invention, parameter values, which are provided for parametrization and which are selected or inputted by means of a user interface of an electronic operating device and which are subsequently transmitted to the electronic device, are kept in at least one memory which can be accessed by the operating device and can be read back from the memory at least once for verification of secure parameterization.

Owner:KW SOFTWARE

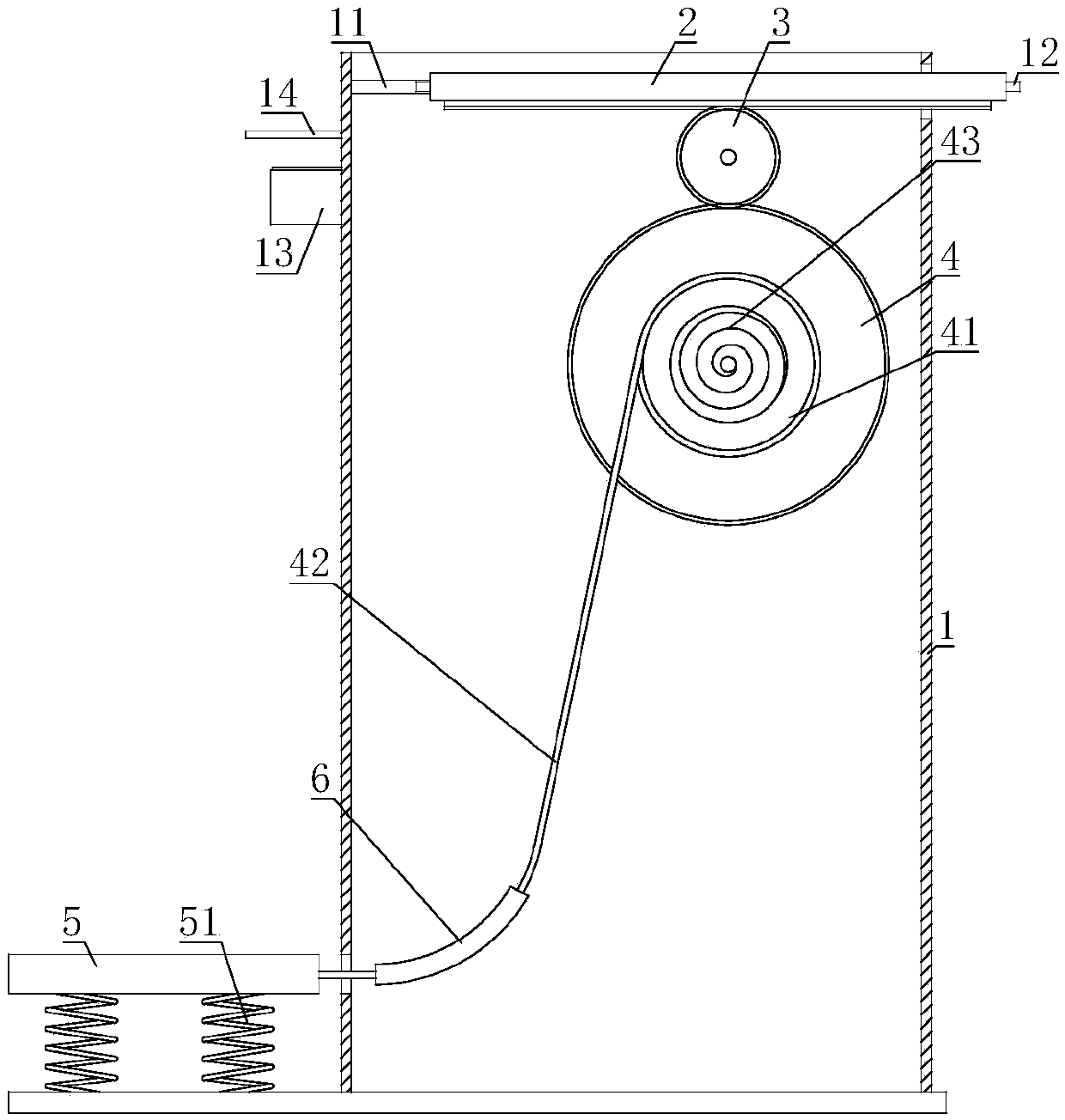

Automatically opened and closed multifunctional garbage can

The invention relates to the field of dustbins, in particular to a multifunctional dustbin with automatic opening and closing. The present invention comprises a dustbin main body, a chute is arranged on the top of the main body of the dustbin, a slide block is set inside the chute, a top cover is fixed on the slide block, a rack is connected to the top cover, and a reversing gear is meshed with the rack , the reversing gear meshes with a driving gear, both the reversing gear and the driving gear are installed on the main body of the garbage bin through bearings, a rotating ring is fixed on the driving gear, a pull rope is wound around the rotating ring, and one end of the pulling rope is fixed to the rotating ring. The other end of the stay rope is connected with a pedal, and a spring is connected between the pedal and the main body of the dustbin; a torsion spring is connected between the rotating circle and the main body of the dustbin; The battery box is provided with a cover for covering the battery box above the battery box, and the cover is fixed on the main body of the dustbin. The invention provides a garbage box which is convenient for putting in garbage and can store batteries separately.

Owner:CHENGDU LINGGAN YUANSU TECH CO LTD

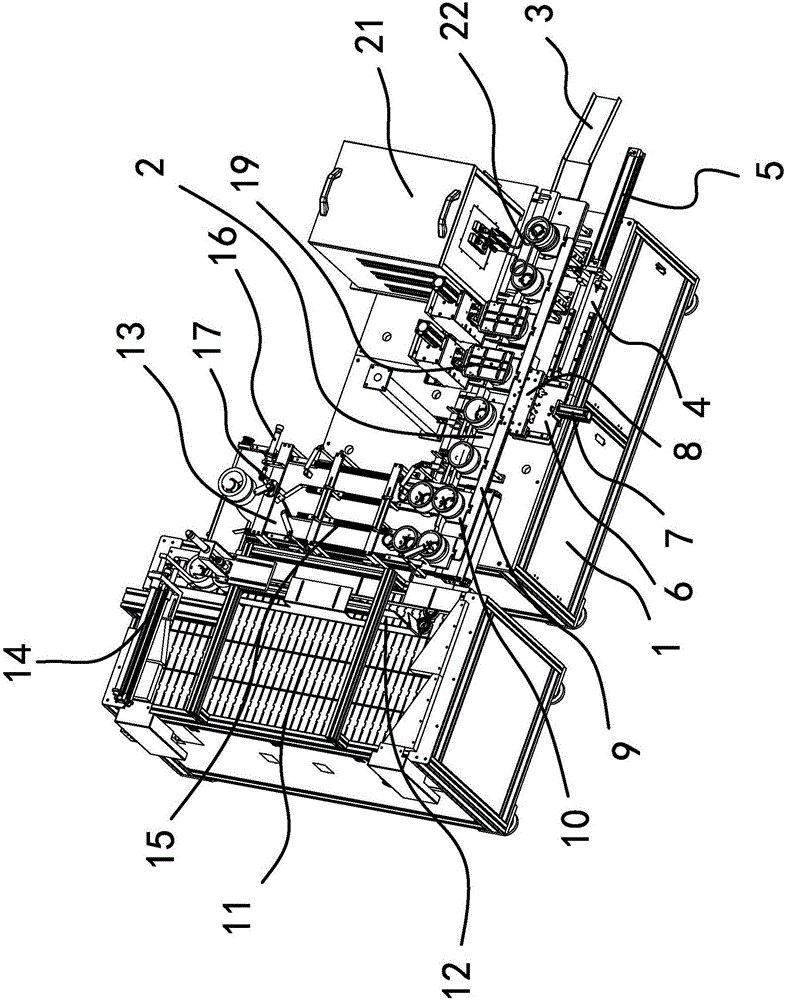

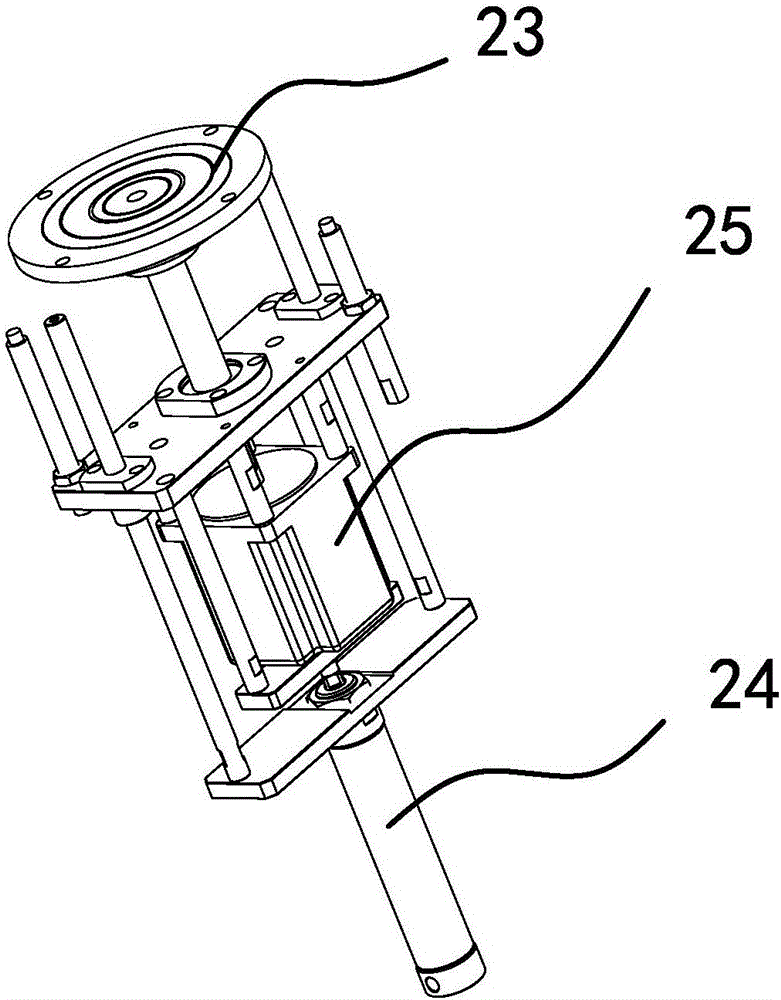

Full-automatic outer spherical bearing inner ring screw hole double-head induction heater

PendingCN106624970AGuaranteed normal inputMetal working apparatusSpherical bearingAutomatic train control

The invention provides a vehicle fuel saving control system, belongs to the technical field of automatic control, and solves the problem of low heating efficiency of traditional bearing inner ring screw holes. A full-automatic outer spherical bearing inner ring screw hole double-head induction heater comprises a frame, and is characterized in that a transition channel is arranged on the frame; a net belt supply device is arranged at the left end of the transition channel; a discharge conveying belt is arranged at the right end of the transition channel; a surface overturning device and a rotary heating device are arranged on one side of the transition channel in sequence from left to right; and a clamping transverse moving mechanism capable of pushing workpieces is arranged on the other side of the transition channel. The full-automatic outer spherical bearing inner ring screw hole double-head induction heater has the advantages of simple structure and high efficiency.

Owner:宁波培立新自动化设备有限公司

Multistage decompression and micro flow atomizing nozzle

InactiveUS10022735B2Extended service lifeAccurate flowSpray nozzlesVena contracta diameterEngineering

Owner:WUXI VOCATIONAL & TECHN COLLEGE

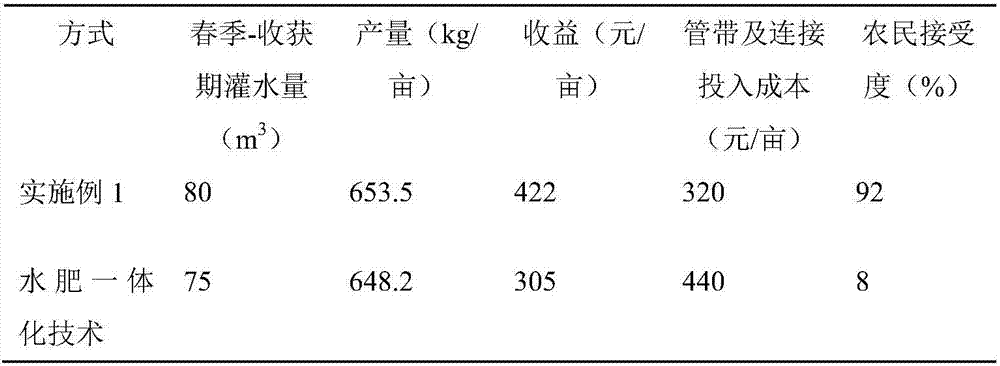

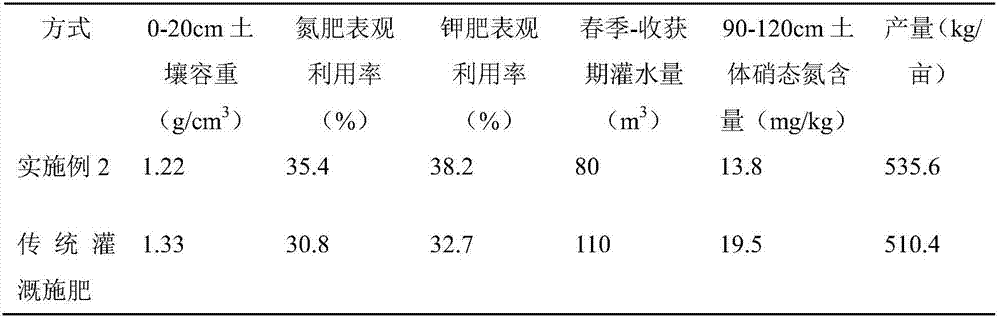

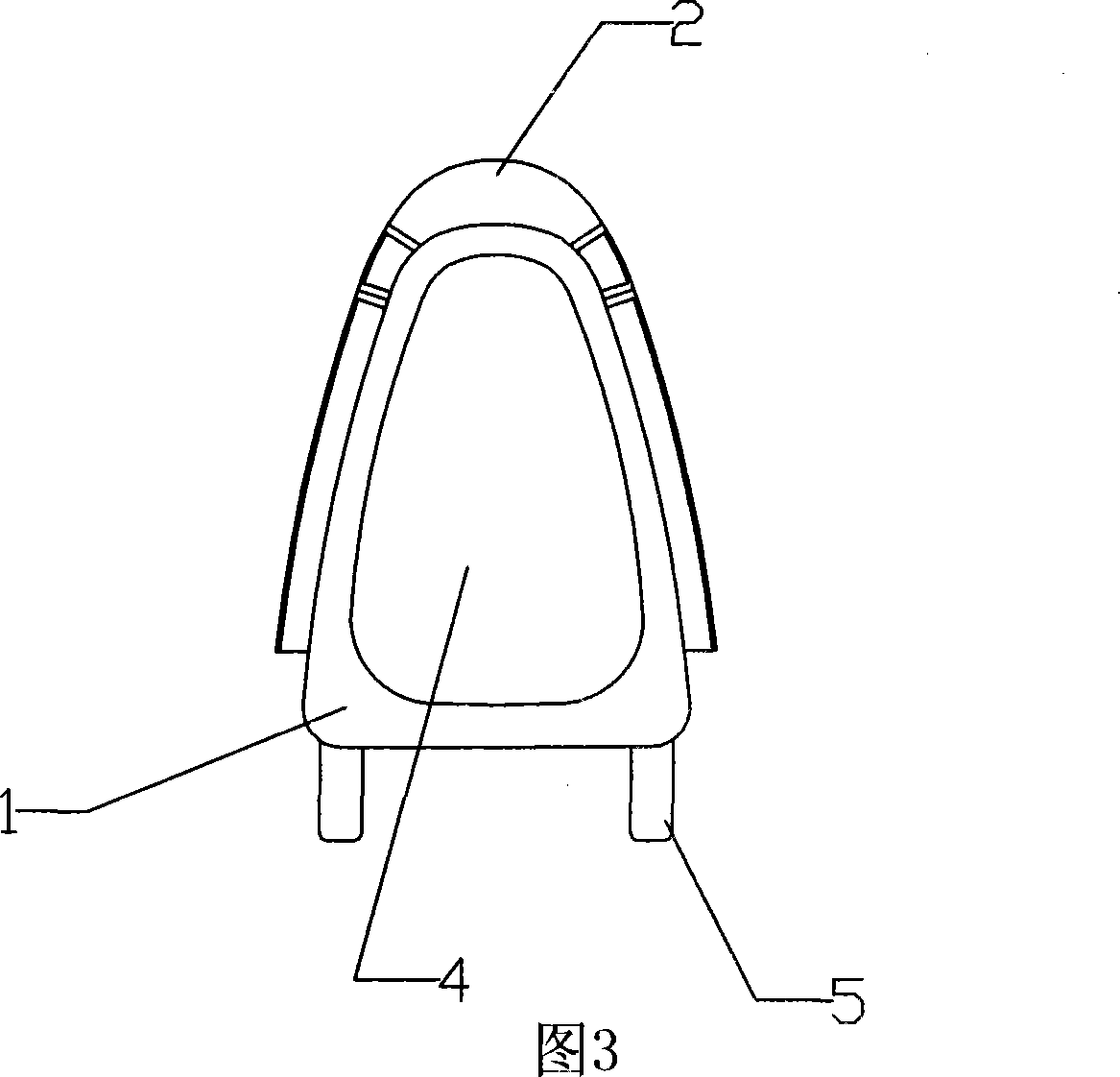

Drought-resisting and water-saving winter wheat spring irrigation and fertilization method

The invention relates to a drought-resisting and water-saving winter wheat spring irrigation and fertilization method. The drought-resisting and water-saving winter wheat spring irrigation and fertilization method is implemented in winter wheat regeneration and jointing stages. The method comprises the following steps of (1) applying nitrogenous fertilizer and potash fertilizer in wheat fields; (2) performing water irrigation through a simple micro-spraying device; (3) starting irrigation from the far end of the wheat fields, after water sprayed by micro-spraying hoses rests on the field surface for 3-5 minutes, removing a section of the micro-spraying hoses to irrigate other areas in sequence until reaching the other end of the fields, and ensuring the irrigation amount to be 35-40 m3 per mu (=0.0667 hectares). The drought-resisting and water-saving winter wheat spring irrigation and fertilization method achieves water irrigation through the simple micro-spraying device, and accordingly is low in cost, simple in installation and field operation, assures years of service, avoids risks of ageing and loss and facilitates water amount control and observation; meanwhile, the drought-resisting and water-saving winter wheat spring irrigation and fertilization method is easy to accept by farmers during production, and by matching fertilization with water irrigation, saves water consumption as well as input of nutrient of nitrogen, phosphorus and potassium, ensures the yield of wheat and improves the utilization rate of nitrogenous fertilizer.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Outdoor mobile advertisement propagation car

The present invention discloses an outdoor mobile advertisement loudspeaker which solves the problem that present outdoor mobile advertisement loudspeaker is set on ordinary truck, the shape is limited by the truck shape and has not considerable change, so advertisement effect is worse. A technical solution is: a mobile advertisement loudspeaker including a vehicle body, a window for setting advertisement picture mounted on vehicle body, a road wheel mounted on bottom is provided, and has characteristics in that said vehicle body is an enclosed case, said window is set on outer side along with vehicle body lengthwise direction and covers main parts of the outer side. A protuberant advertisement board can be vertical arranged on the vehicle body directly, and outer outline of the vehicle body is smooth arc transition.

Owner:徐君义

Cosmetic rose essential oil extraction raw material pretreatment process

InactiveCN111363628ANarrow down the active areaGuaranteed normal inputEssential-oils/perfumesElectric machineryStructural engineering

The invention relates to a cosmetic rose essential oil extraction raw material pretreatment process. The process uses a tank body, a feeding port, a water injection port, a partition plate, discharging plates, a cleaning mechanism, a positioning mechanism and a driving motor, the discharging plates are arranged on the two sides of the bottom of the tank body, the partition plate is arranged at themiddle section of the tank body, the driving motor is mounted at the top of the tank body, the cleaning mechanism is connected below the driving motor, the positioning mechanism is arranged on the outer side of the cleaning mechanism, the feeding hole is connected to one end of the top of the tank body, the water injection port is arranged on the outer wall of the tank body, a rotating rod is inserted into the central position in the tank body, the top end of the rotating rod is connected with an output shaft of the driving motor, a threaded groove is formed in an outer wall of a middle areaof the rotating rod, cutting blades are arranged on the outer wall of the bottom of the rotating rod at equal intervals, and a stirring disc is welded to the outer wall of the bottom of the rotating rod. According to the process, it is effectively guaranteed that rose petals make full contact with cleaning water and the cutting blades, the cleaning and chopping effects are better, and the device is easy and convenient to operate.

Owner:刘红梅

Municipal sewage sludge rice seedling-raising substrate and production method and application thereof

InactiveCN106007895AHarmlessAchieve stabilizationBioloigcal waste fertilisersGrowth substratesOxygenHydrolysis

The invention provides a municipal sewage sludge rice seedling-raising substrate and a preparation method and application thereof. The rice seedling-raising substrate contains sludge, bean pulp hydrolysis residues and wood vinegar and further comprises other fertilizers and chemical regulators such as ammonium sulfate, zinc sulfate, multi-effect triazole and choline chloride. The sludge is a black and tasteless particle product rich in various nutrient components formed by performing aerobiotic high-temperature biological drying technology treatment on domestic sewage. The municipal sewage sludge rice seedling-raising substrate has the advantages of being abundant in microcellular structure, high in plasticity, high in binding force and the like, the water and fertilizer retention and temperature increasing effects are remarkable, and the agricultural standard is completely met. Harmless, stable, reduction and resource recycling of sludge is achieved, time and labor are saved, consumption of chemical fertilizer and pesticide is greatly reduced, the purpose of seedling strengthening is achieved, the production bottleneck that seedling culture and soil sampling are hard is completely solved, and the application prospect is wide.

Owner:SHENYANG AGRI UNIV

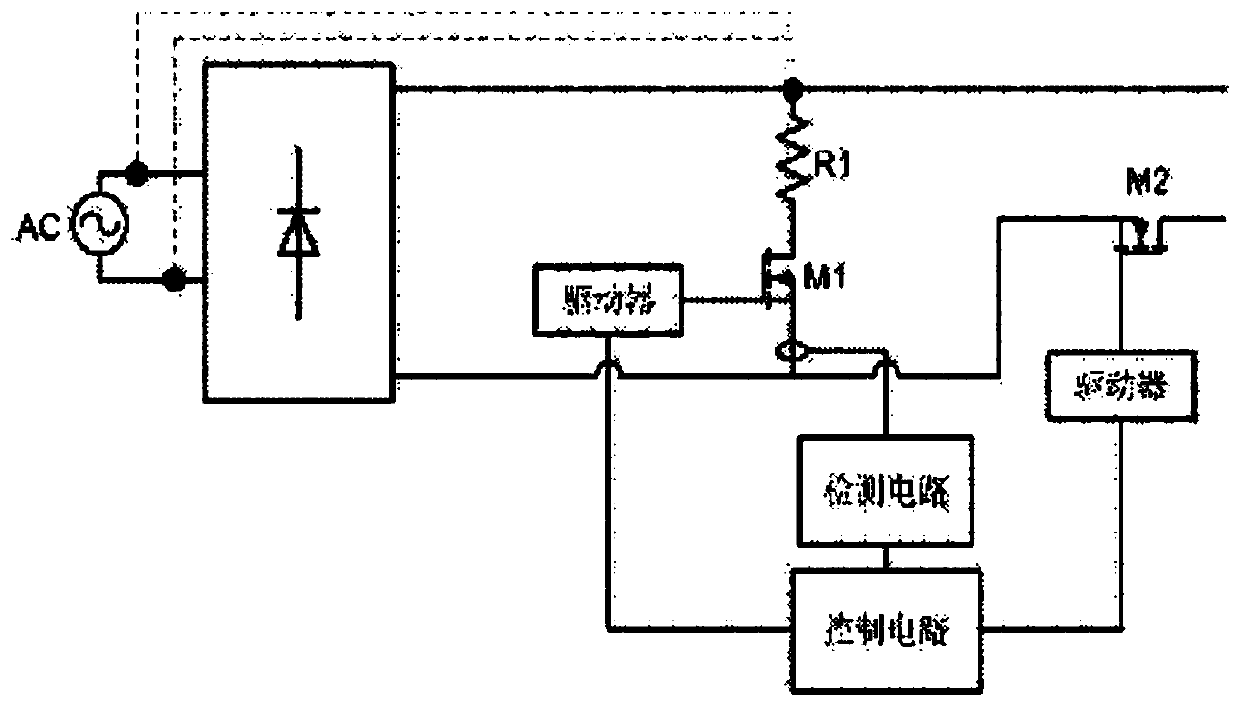

Lamp tube capable of being compatible with high frequency and power frequency and implementation method thereof

PendingCN110557868AEnsure safetyAvoid unusual risksElectrical apparatusElectroluminescent light sourcesDrain currentLED circuit

The invention discloses a lamp tube capable of being compatible with a high frequency and a power frequency, which comprises a safety protection circuit, a rectification circuit, an LED driving circuit, an electronic ballast driving circuit A, a leakage current detection protection circuit B1 and an on-site IC driving circuit B2, wherein the safety protection circuit is respectively connected withan input end L and an input end N, the safety protection circuit is also respectively connected with the rectification circuit, the leakage current detection protection circuit B1 and the electronicballast driving circuit A, and the rectification circuit is connected with the on-site IC driving circuit B2. The invention further discloses an implementation method of the lamp tube capable of beingcompatible with the high frequency and the power frequency. According to the invention, the leakage current detection protection circuit B1 is arranged, and due to the fact that the lamp tube is powered on from two ends, the safety of the lamp tube in the dismounting and mounting process is guaranteed; and the on-site IC driving circuit B2 is arranged, unwanted harmonic components in the rectified output current are filtered out, and the constant current is output through oscillation of the on-site IC and a peripheral circuit thereof.

Owner:HENGDIAN GRP TOSPO LIGHTING

Method for controlling nodulation of carbon blind hearth roller

ActiveCN102828014BReduce carryoverReduce productionFurnace typesHeat treatment furnacesFurnace temperatureHydrogen

The invention discloses a method for controlling nodulation of a carbon blind hearth roller. A transition steel coil does not enter into a high temperature furnace any longer when running speed of a high temperature furnace is more than or equal to 60m / min, surface of the high temperature furnace is seriously oxidized or the high temperature furnace runs for 15 times; oil content and iron content of alkaline washing alkaline liquor are controlled, and corresponding thermal compensation is carried out on rotating speed of a furnace roller according to temperature of strip steel, thus linear speed of the furnace roller is maintained to be consistent with the linear speed of the strip steel; alternate production of a high brand and a low brand is adopted, time for producing the high brand every time is not more than two days, and tension in the furnace is reduced when the high brand is produced; and the total air-fuel ratio of a non-oxidation furnace is controlled to be 0.92-0.98, a dew point of furnace gas at a carbon blind section is controlled to be 30-35 DEG C, hydrogen amount in a soaking pit furnace is controlled to be 16-20%, and furnace temperature of a furnace section corresponding to a nodulated carbon blind is reduced by 30 DEG C, thus nodulation generating conditions are destroyed. By adopting the method disclosed by the invention, almost no nodulation can be realized, thus service life of the carbon blind is prolonged by two months, halt frequency of a machine set and roller grinding frequency can be reduced, productivity of the machine set and surface quality of a steel plate are improved, consumption of energy source and medium is reduced, and production cost is reduced.

Owner:ANGANG STEEL CO LTD

Inputting method of two strokes including full shape and shape-sound

InactiveCN1661527ASolve the problem of poor encoding efficiency of the second keySolve the problem of poor coding efficiencyInput/output processes for data processingComputer hardwareChinese characters

The present invention relates to a two-stroke holomorph and form voice input method. It is a Chinese character input method which can be extensively applicable to computer, etc. containing digital terminal for inputting Chinese characters. Said invention is an improvement on original two-stroke holomorph code input rule, and adopts the mode of 'three-key + voice code' or 'three-key + consonant substitute key' so as to solve the problem of low original two-stroke holomorph code second key coding efficiency and greatly reduce duplication code rate.

Owner:陈劲松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com