Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

189 results about "Oil burner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An oil burner is a heating device which burns #1, #2 and #6 heating oils, diesel fuel or other similar fuels. In the United States ultra low #2 diesel is the common fuel used. It is dyed red to show that it is road-tax exempt. In most markets of the United States heating oil is the same specification of fuel as on-road un-dyed diesel.

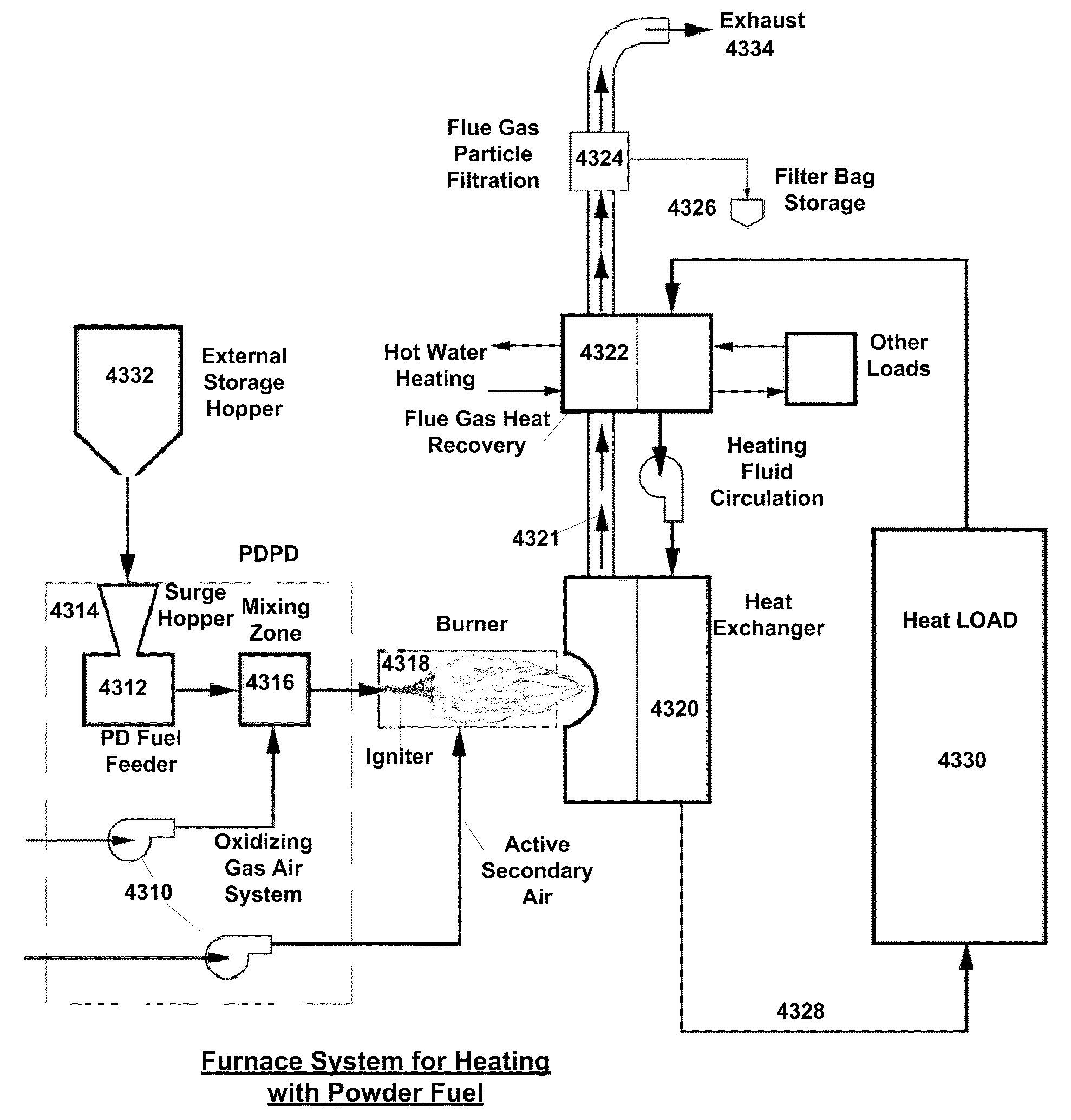

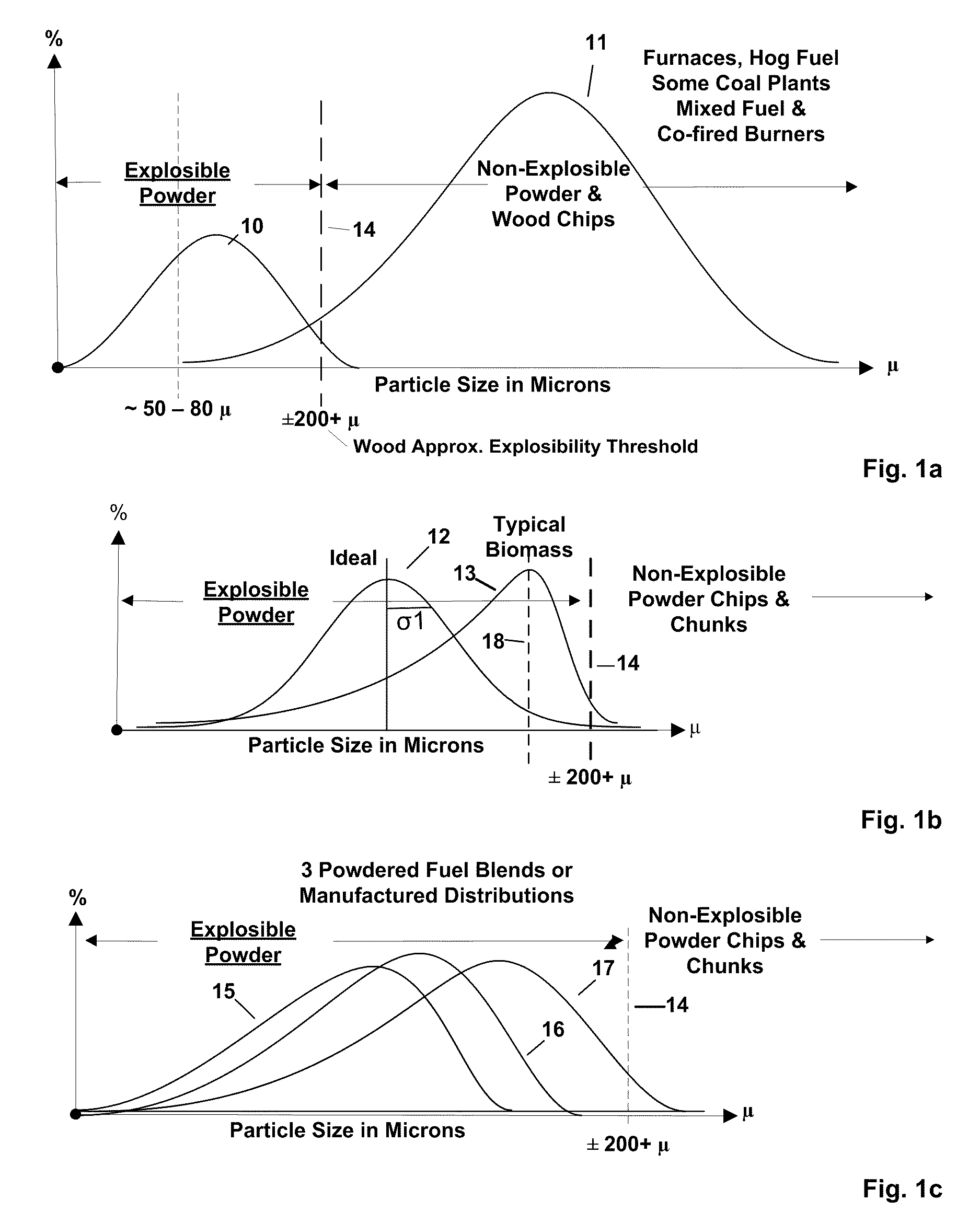

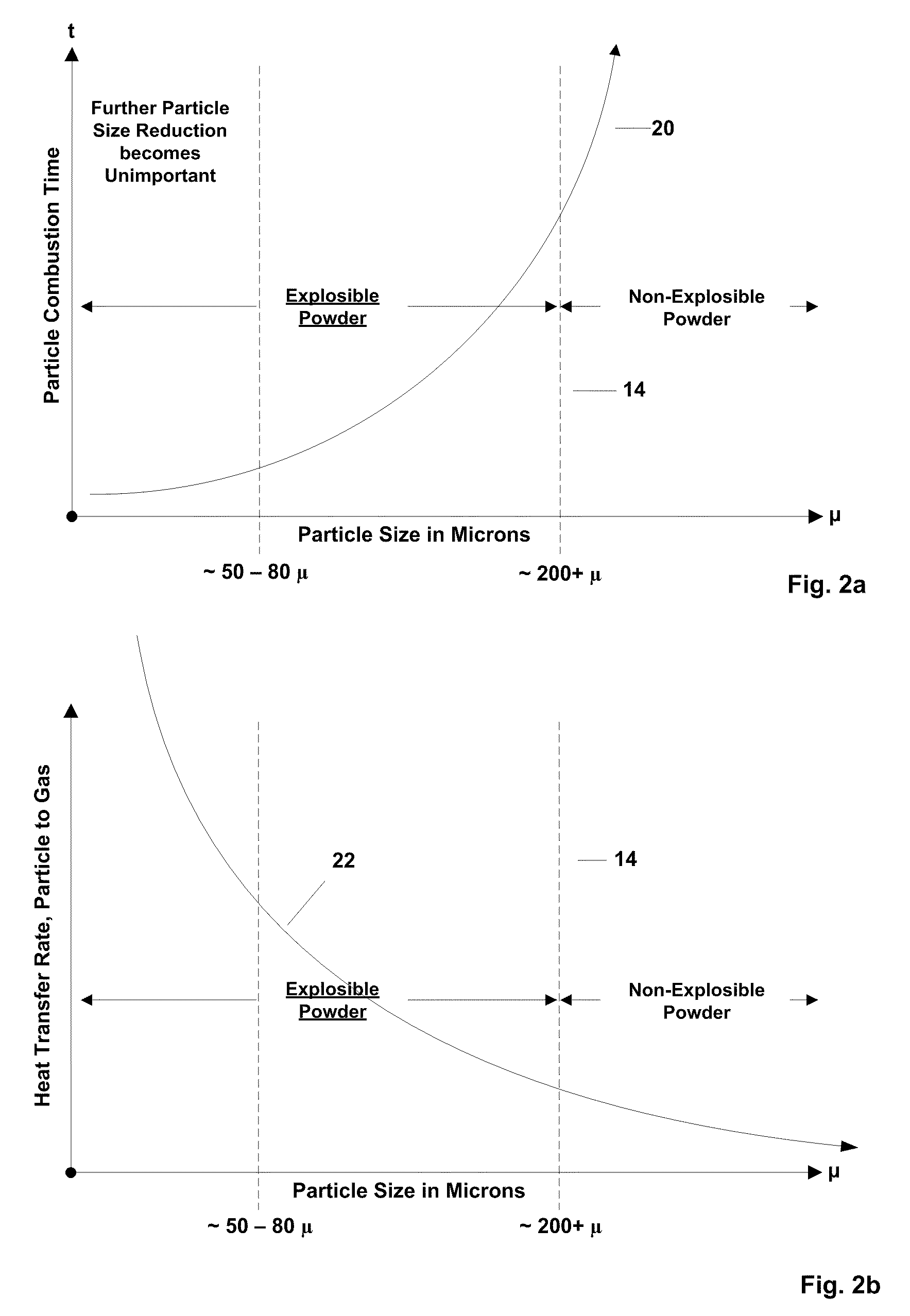

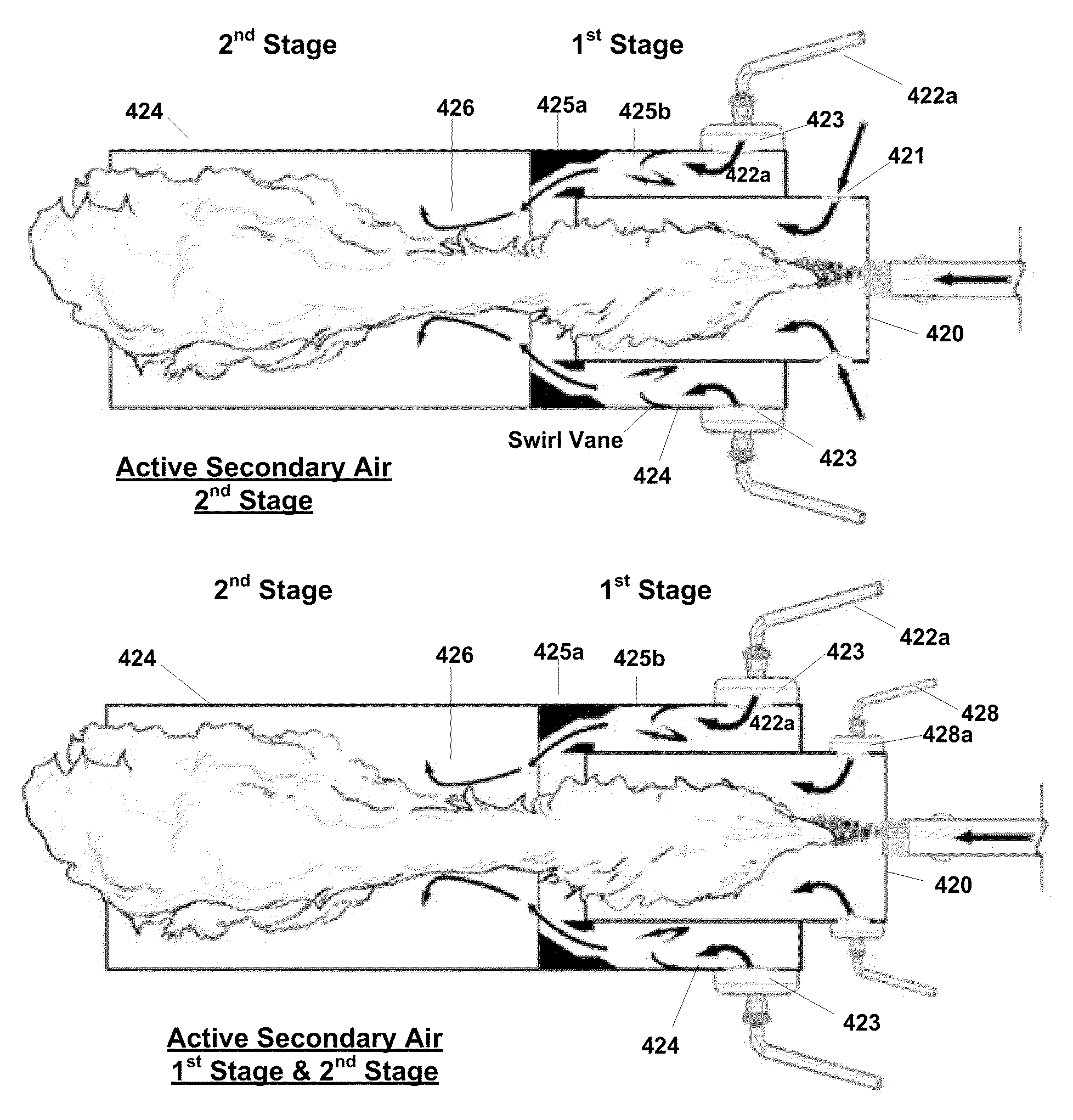

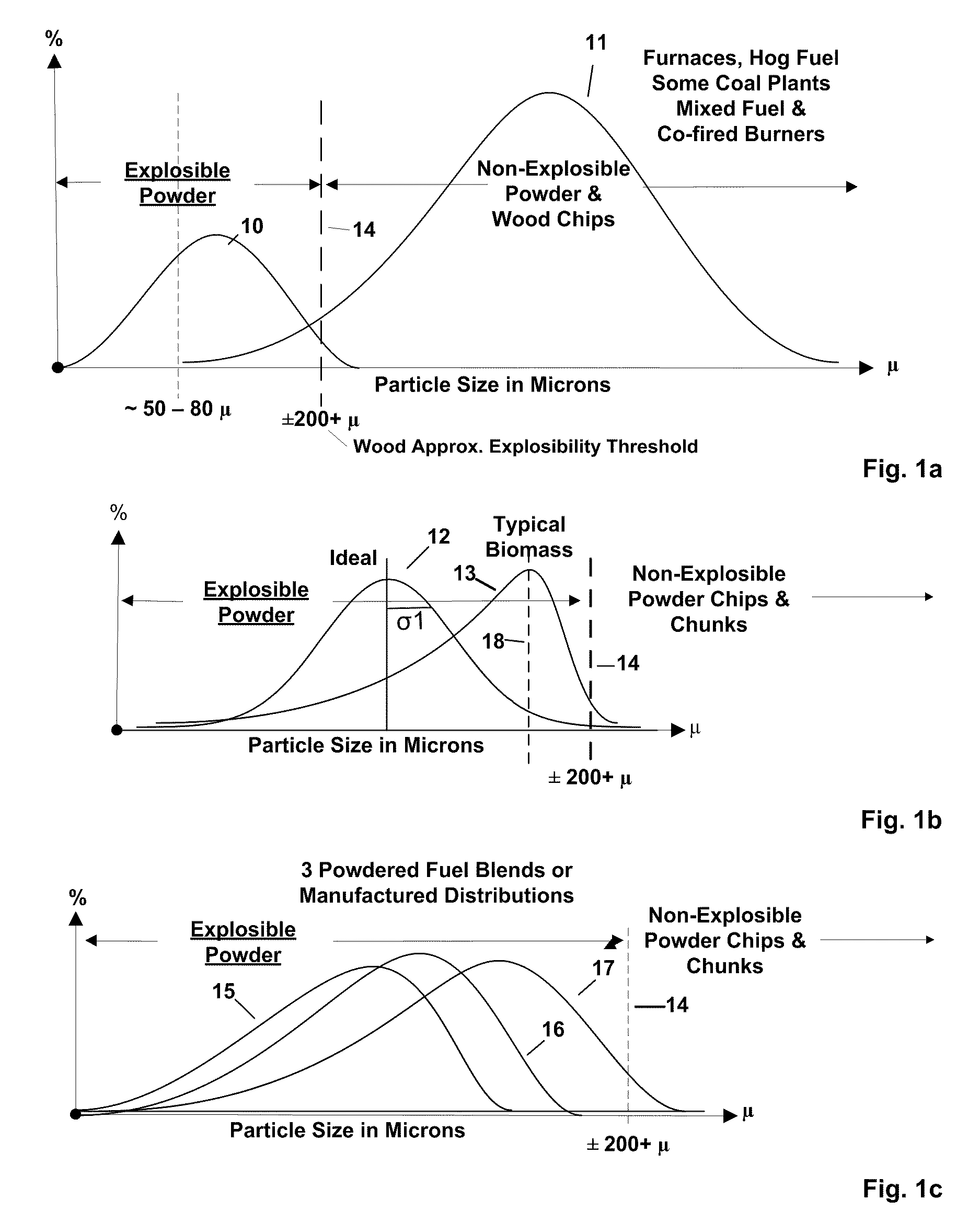

Powdered fuel conversion systems and methods

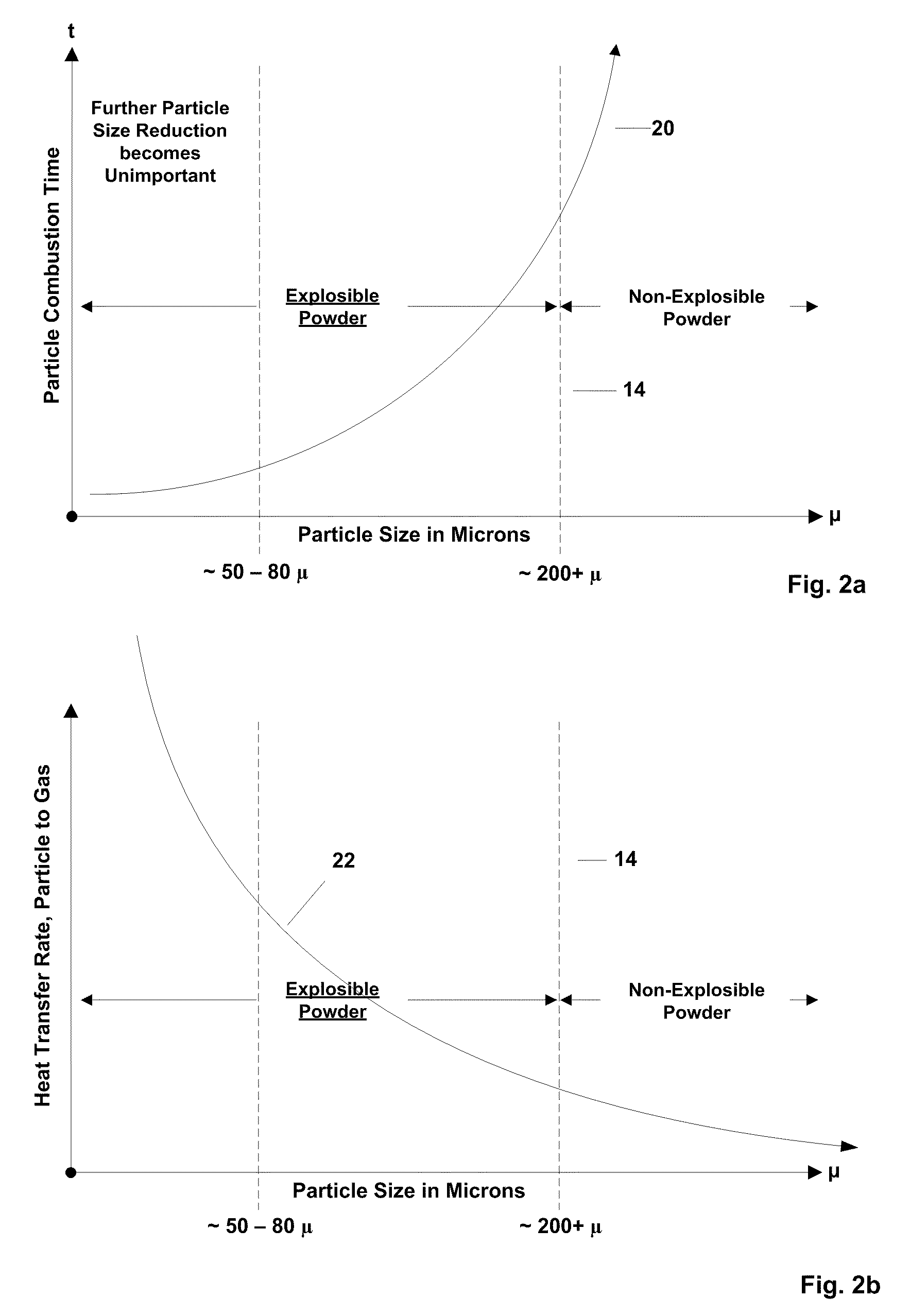

The burner preferably exclusively burns substantially explosible solid fuels and preferably has instant ON-OFF thermostat control, wastes no energy preheating the enclosure or external air supply, achieves stable combustion the moment the powder-air mix is ignited in our burner, is used in the upward vertical mode except for oil burner retrofits, burns a solid fuel in a single-phase regime as if it were a vaporized liquid or gas, is designed to complete combustion within the burner housing itself rather than in a large, high temperature furnace enclosure which it feeds, has an ultra-short residence time requirement, is a recycle consuming burner with self-contained management of initially unburned particles, is much smaller, simpler and lower cost, has a wider dynamic range / turndown ratio, is more efficient in combustion completeness and thermal efficiency, and operates with air-fuel mix approximately at the flame speed.

Owner:MCKNIGHT JAMES K +2

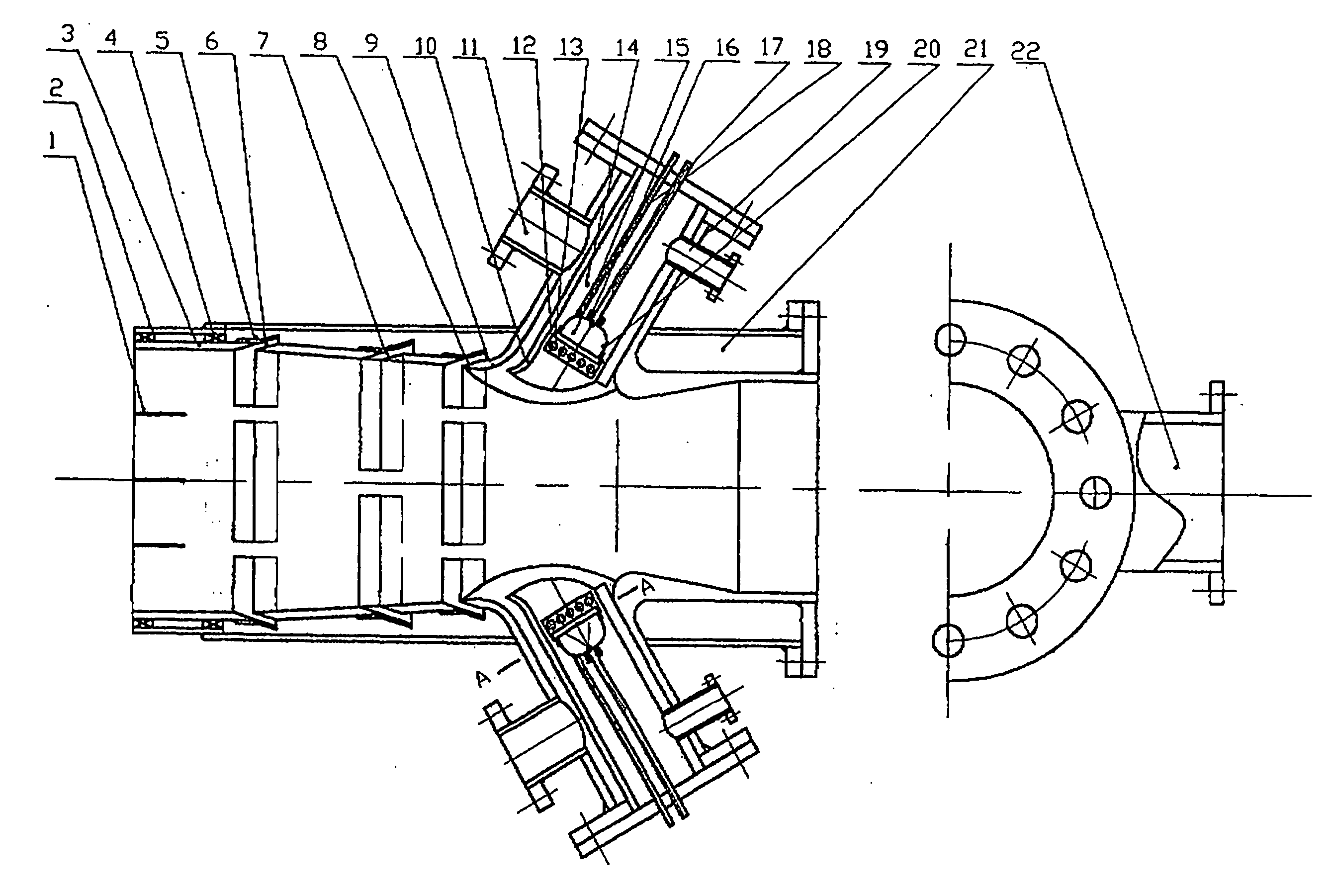

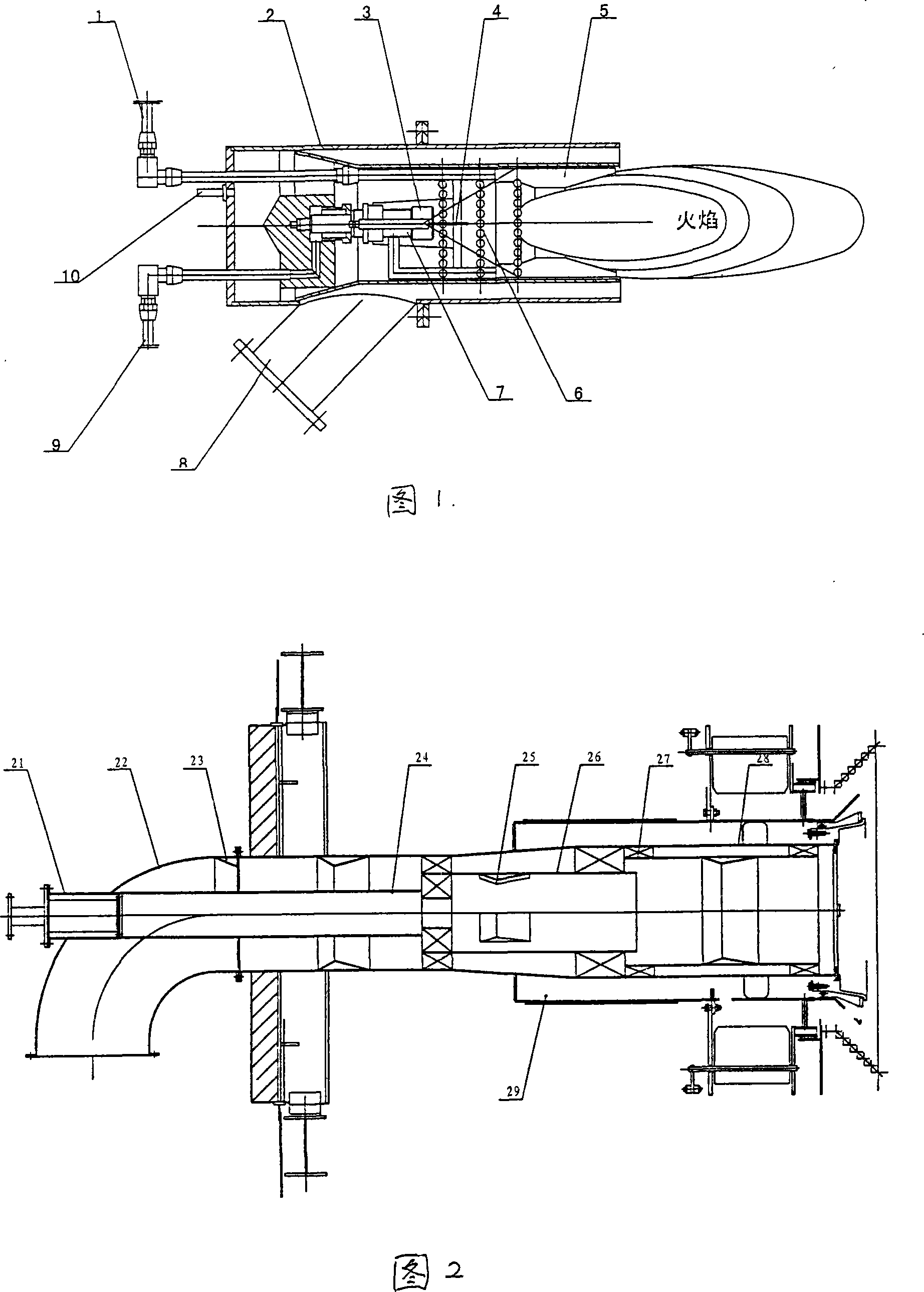

Cold static ignition under meagre coal and tiny oil, and steady burning burner in ultra low load

InactiveCN1687641AImprove reliabilityLow investment costPulverulent fuel combustion burnersCombustion chambersCombustion chamberLow load

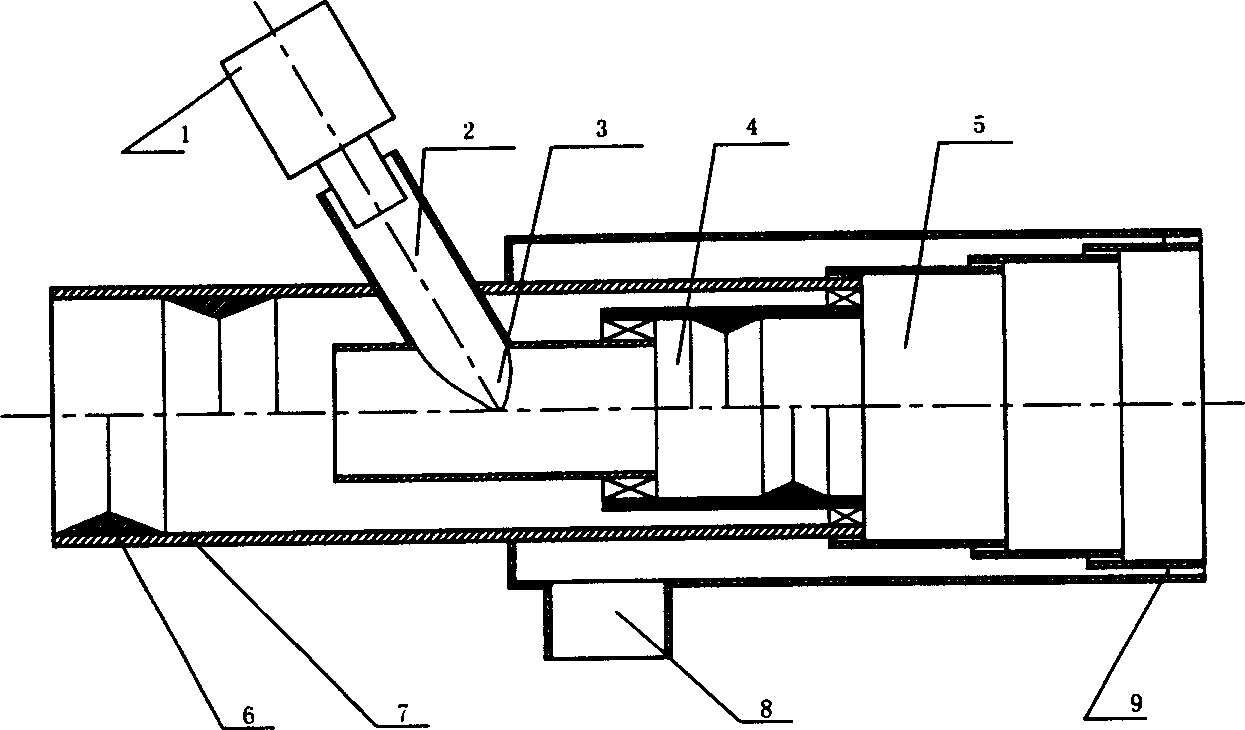

The invention discloses the lean coal micro-oil cold ignition and super-low load stable combustor. It comprises the coal powder pipe with the primary powder combustion chamber and the secondary powder combustion chamber connected with in; the oil combustion chamber is obliquely equipped at the front end of the primary powder combustion chamber; the secondary powder combustion chamber and one end of the coal powder pipe connect the third grade powder combustion chamber; the cooling air intake pipe is outside of the powder pipe and the third grade powder combustion chamber; the multiple circumferential welded air films are between the third powder combustion chamber and the cooling air intake tube; the other end of the powder pipe has the coal powder strong concentrator. The invention uses 50-70kg / h oil through energy level amplifying principle to light large amount of coal powder and its oil saving ration is above 90%; it has the low load stable combustion function and can be used to electric dusting as soon as the boiler ignition; the ignition system is reliable and the investment is low.

Owner:傅宁娟

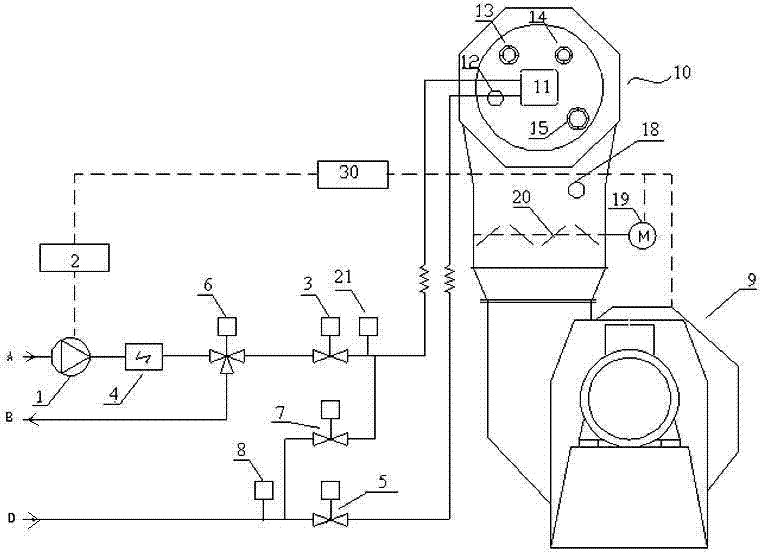

Combustion control system of an oil burner

The invention discloses a combustion control system of a fuel oil burner, which comprises an oil delivery channel, an atomization medium channel, an ignition device, an air volume adjustment device, an oil volume adjustment device and a controller; the oil delivery port of the oil delivery channel is provided with an oil delivery pump , there is an oil pressure sensor in the oil delivery channel, and the oil volume adjustment device is the oil inlet valve; the ignition device includes an igniter and an atomizer; the ignition device is equipped with a flame signal sensor, a wind pressure sensor, and an atomization medium pressure sensor; The adjustment device includes a damper and a damper driver; the damper driver is provided with a damper position sensor; the controller controls the fuel pump, blower device, igniter, atomizer, heater, the start of the damper driver and the opening or closing of the oil inlet valve; The controller receives the output signals of each sensor, and controls the oil intake, the oil pressure in the oil delivery channel, the position of the damper and the air pressure according to the relevant signals. The invention can realize the independent adjustment of oil volume and air volume, has low energy consumption and high system reliability.

Owner:JIANGSU OUBIAO

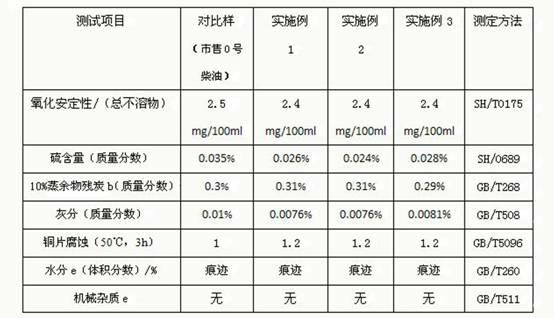

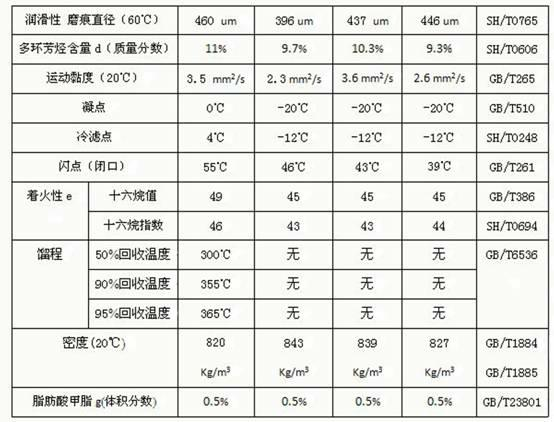

Methanol diesel oil additive and methanol diesel oil

InactiveCN102161922AImprove powerHigh calorific valueLiquid carbonaceous fuelsIsobutanolOil additive

The invention discloses a methanol diesel oil additive and simultaneously discloses methanol diesel oil with the methanol diesel oil additive. The methanol diesel oil prepared by the invention is prepared by mixing 0.04-0.07 part of ferrocene, 2-5 parts of acetone, 4 parts of diemethyl carbonate, 2-3 parts of isobutanol, 2-3 parts of toluene, 70 parts of diesel oil and 20-25 parts of methanol. The methanol diesel oil has the advantages of low corrosion, good intersolubility and swelling property, uniform texture, high flash point, low condensation point and high cetane number, is safe to use and meets all indexes of automobile diesel oil GB19147-2009. The methanol diesel oil can be applied to internal-combustion engines, general engines, power plant fuels, burner substances and the like, thus the applicable range of the methanol diesel oil is wide.

Owner:SUIPING CHEM FACTORY OF CHINA PINGMEI SHENMA GRP LANTIAN CHEM

Coal-burning boiler's ignition burner

InactiveUS20050028712A1Improve economySaving oil considerablyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneCombustion

The present application disclosed an ignition and burning apparatus used in coal boiler, comprising one or more combustion-enhancing miniature oil guns and a pulverized coal burner, wherein the combustion-enhancing miniature oil gun comprises an atomizing nozzle, a cyclone, an oil burner, an air supplying cylinder and an ignition device, and the pulverized coal burner comprises ail external nozzle, a window type air film cooler and an expansion channel. During the combustion of the pulverized coal, a certain amount of dry steam may be added for generating carbon monoxide and hydrogen for further enhancing the combustion of the pulverized coal. The ignition and burning apparatus used in coal boiler according to the present invention may save more than 90% of oil and demonstrates excellent economic performance.

Owner:XUZHOU COMBUSTION CONTROL RES INST

Oil burner with high-efficiency burning and low pollution emission

InactiveCN102563640AEfficient combustionReduce pollutionBurnersPollutant emissionsEnvironmental engineering

The invention discloses an oil burner with high-efficiency burning and low pollution emission. An oil burner body comprises an oil gun sleeve, a primary air pipe, a secondary air pipe and a grading air pipe, wherein the oil gun sleeve is arranged on the central axis of the oil burner body; the primary air pipe, the secondary air pipe and the grading air pipe are sheathed at the periphery of the oil gun sleeve; the grading air pipe, the secondary air pipe and the primary air pipe are respectively in the same central axis with the oil gun sleeve; a primary air channel is formed between the primary air pipe and the oil gun sleeve; the end part of the primary air channel is provided with a flame stabilizer; a secondary air channel is formed between the secondary air pipe and the oil gun sleeve; an axial cyclone with an adjustable axial position is arranged in the secondary air channel; a grading air channel is formed between the grading air pipe and the secondary air pipe, and an inlet position of the grading air pipe is provided with a tangential cyclone; and one end of the primary air pipe, which is far away from a nozzle of the oil burner, is provided with a flame segmenting ring. The oil burner has the advantages that high-efficiency burning and low pollution emission can be effectively realized, and the problems of incomplete burning with black smoke, and high pollutant emission and the like easily occurring on the original oil burner in operation can be effectively avoided.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

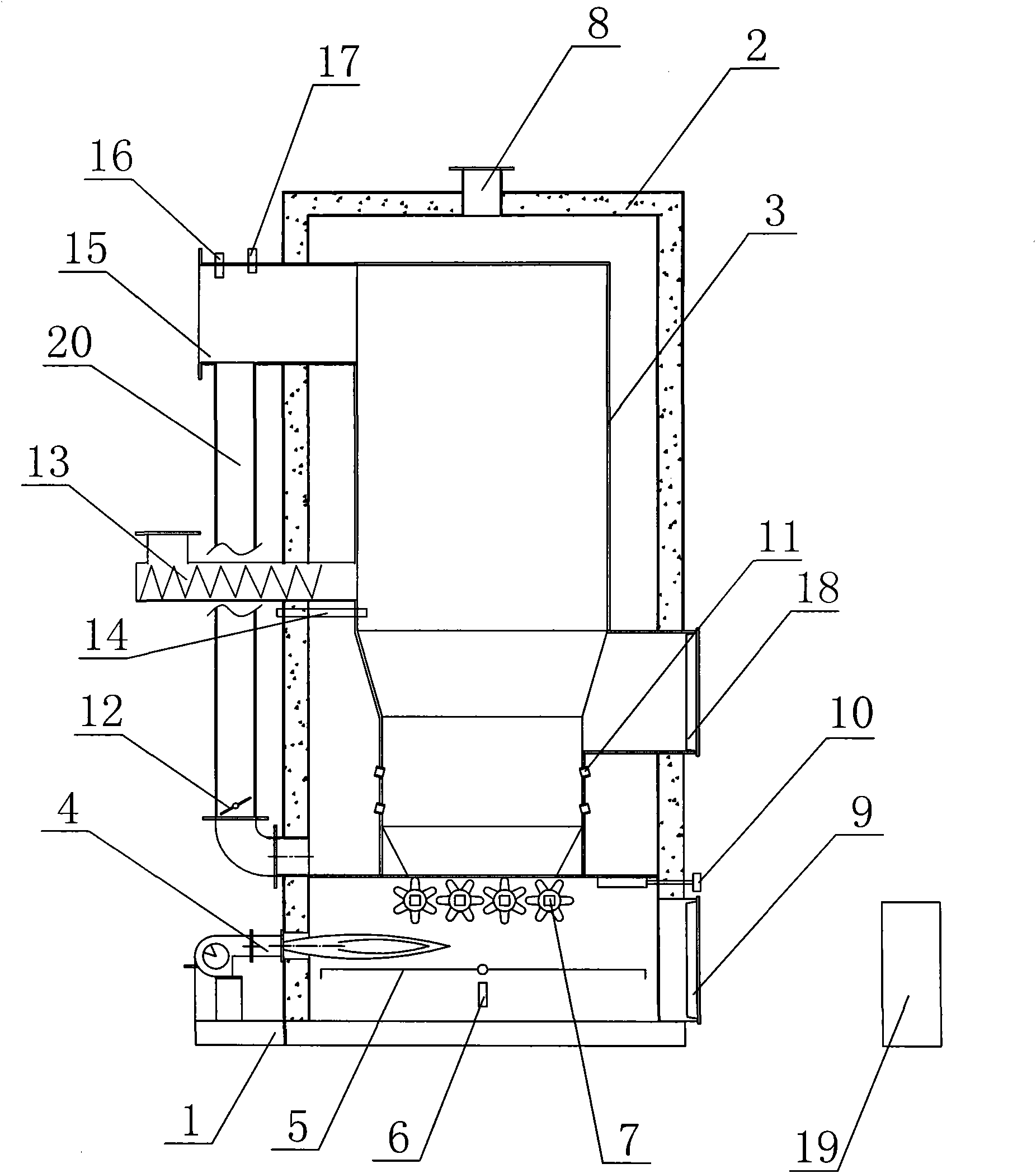

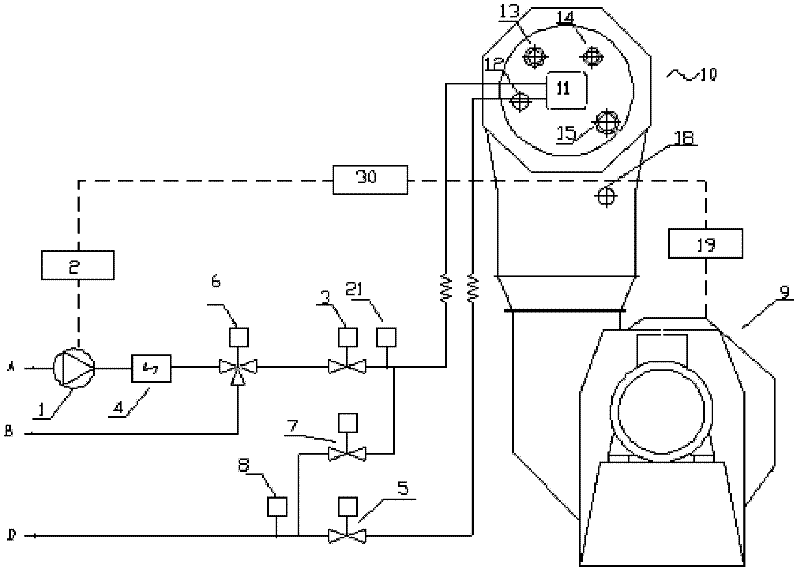

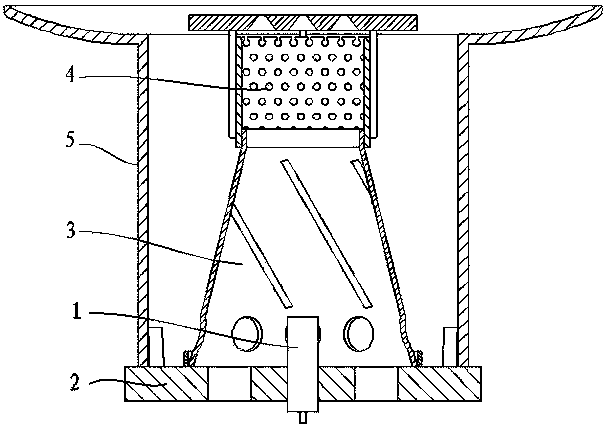

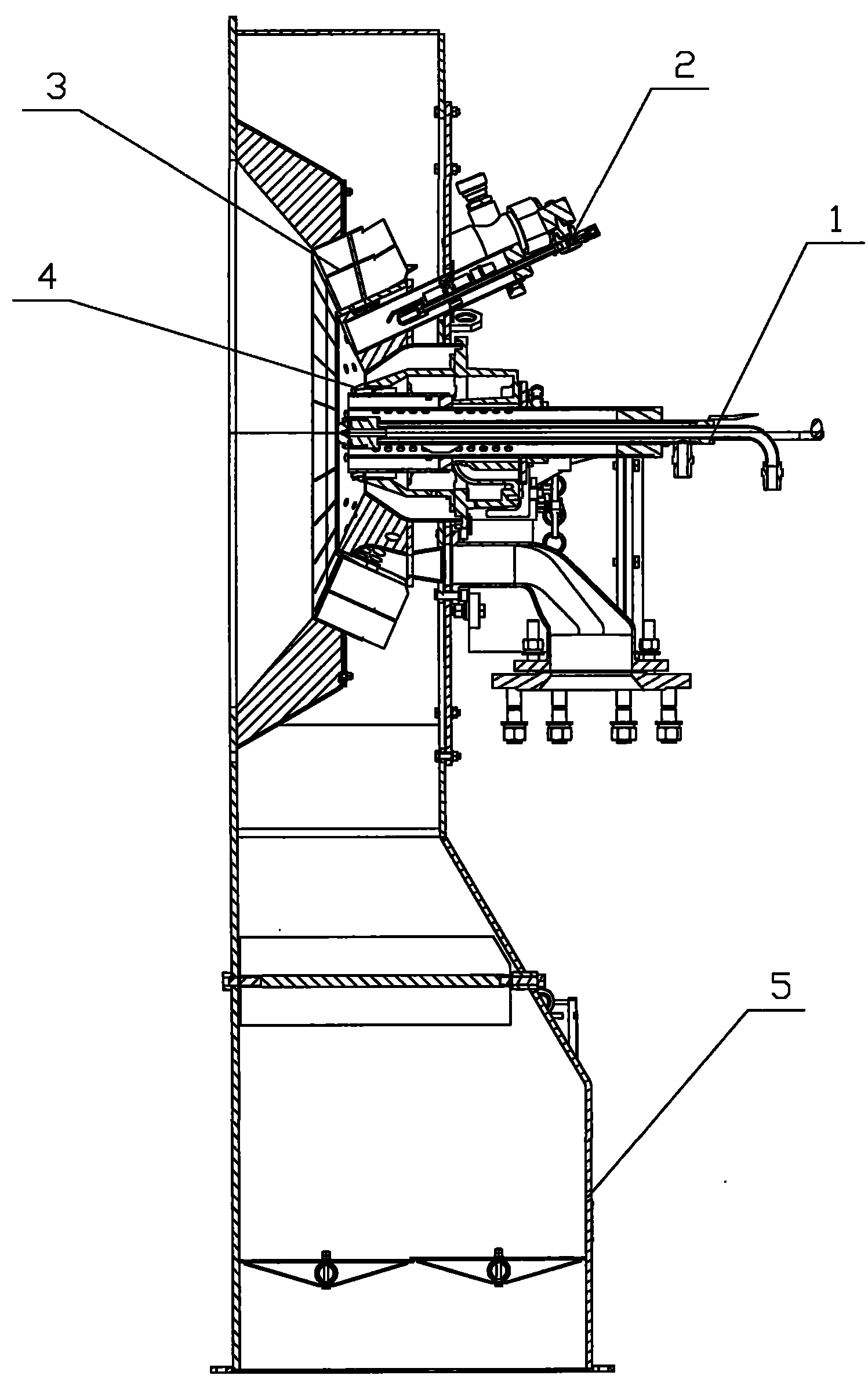

Intelligent sludge incinerator

InactiveCN101956987AIncineration stableHarmless treatmentIncinerator apparatusAutomatic controlCombustion

The invention discloses an intelligent sludge incinerator. The sludge incinerator comprises an outer furnace body, an inner furnace body, a base, an electrically driven automatic slag discharge grate, a screw feeder, an automatic slag discharge device, a diesel oil burner, a primary air inlet system, a secondary air inlet system and a controller, wherein the controller is used for controlling one or more temperature sensors arranged at a hearth, a smoke outlet and a primary inlet, an oxygen quantity sensor arranged at the smoke outlet and a weight sensor for automatic slag discharge. The intelligent sludge incinerator can realize reduction and harmlessness of sludge by adopting a bubbling suspension combustion method, and meanwhile realizes low discharge of pollutants; the combustion is stable by automatic control of parameters of primary and secondary air inlet, and the temperature in the incinerator is controlled at 850 to 950 DEG C all the time for combustion; and the sludge incinerator has high automation degree, saves labor, relieves labor intensity, realizes stable incineration of the sludge, obviously reduces the fault rate, and has low maintenance expense and humanized operation.

Owner:WUXI AMDI ENVIRONMENTAL PROTECTION TECH CO LTD

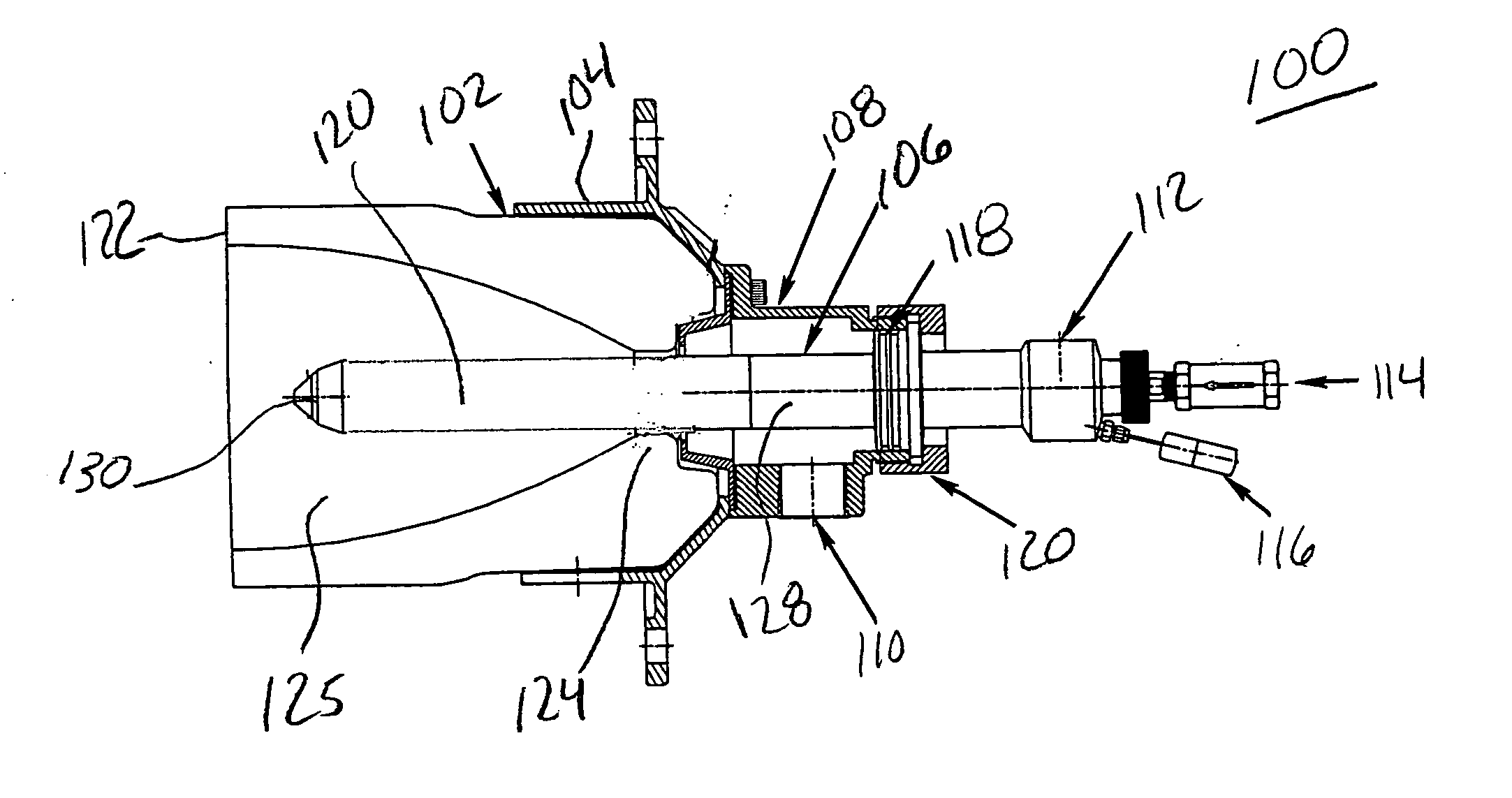

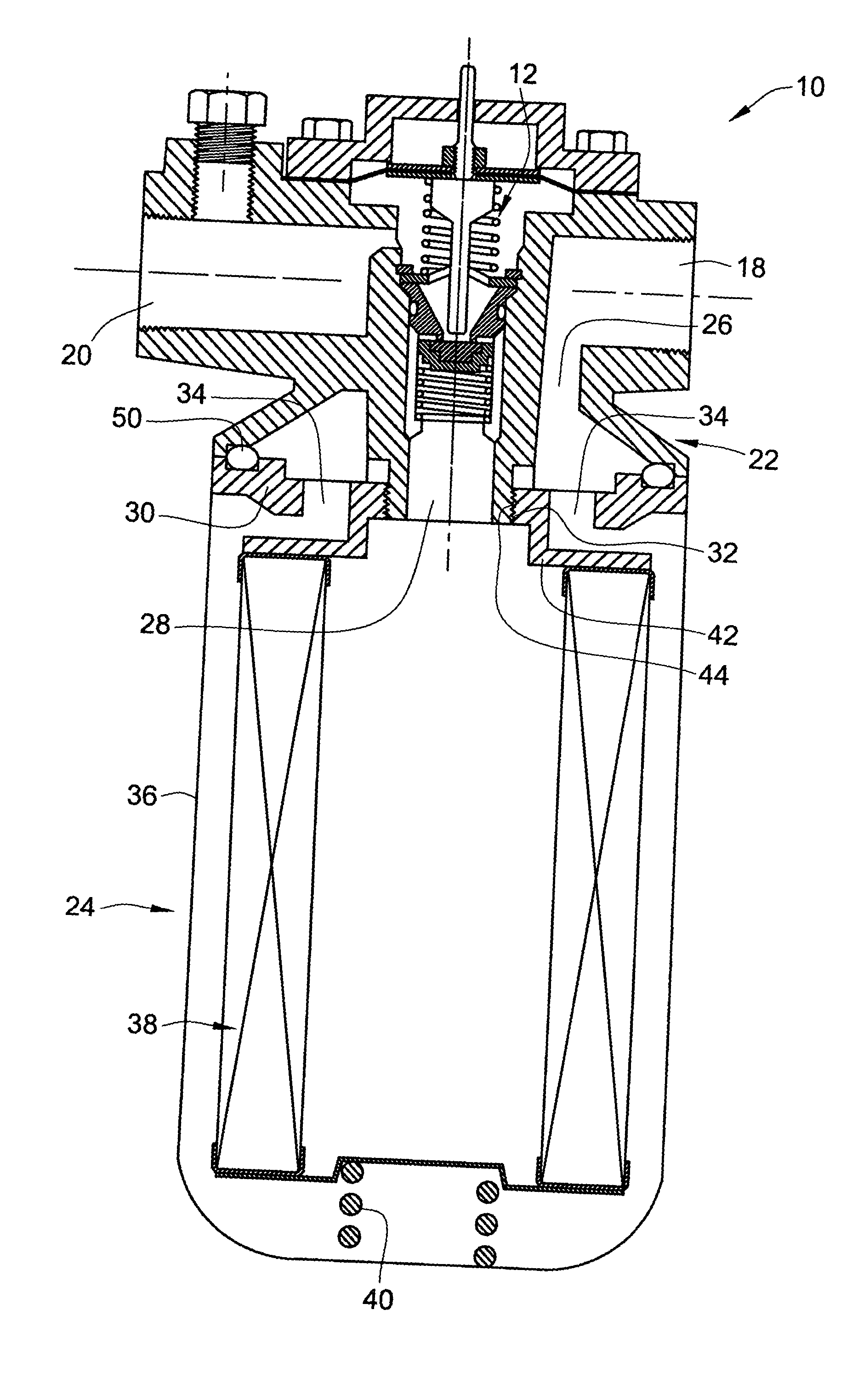

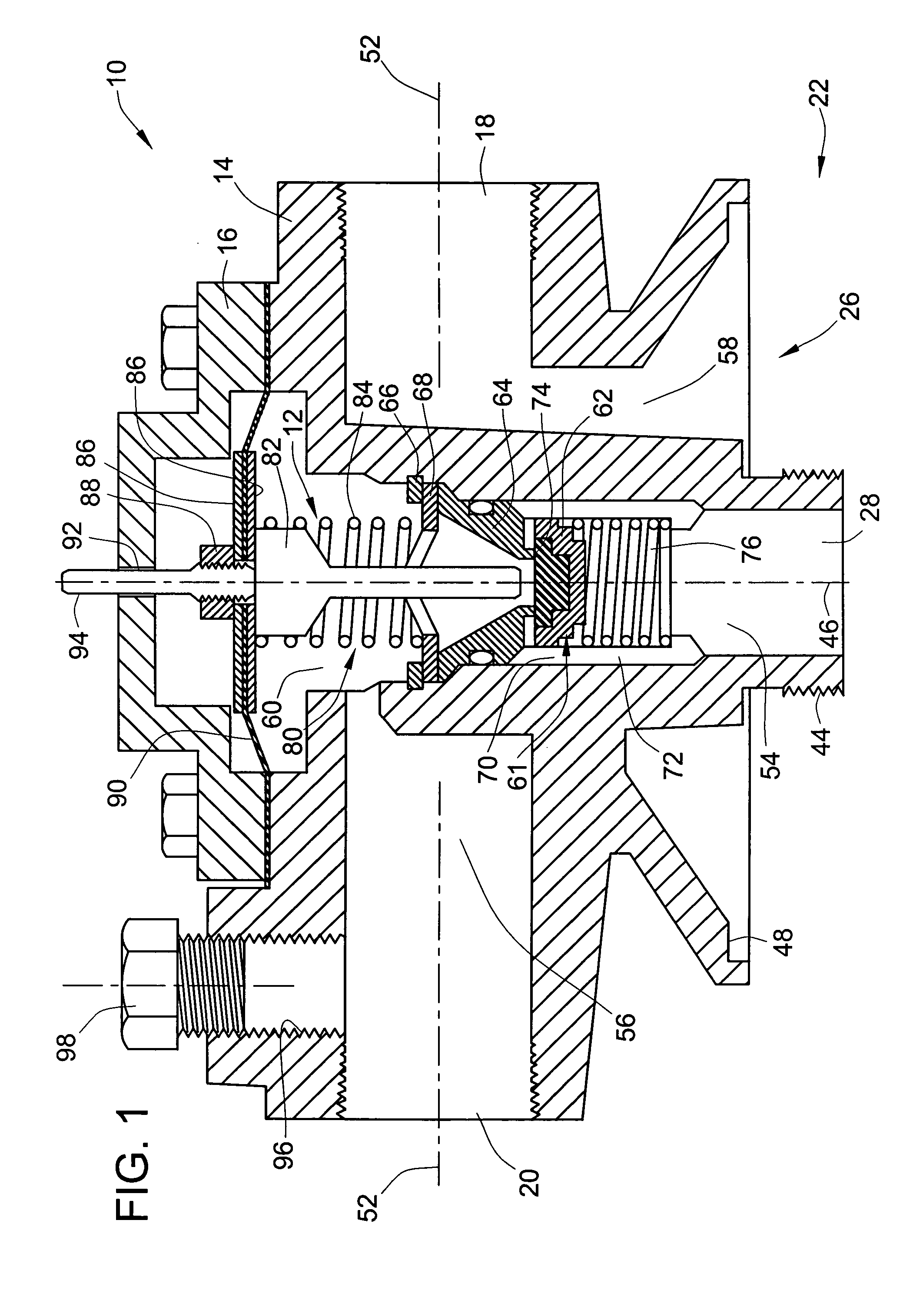

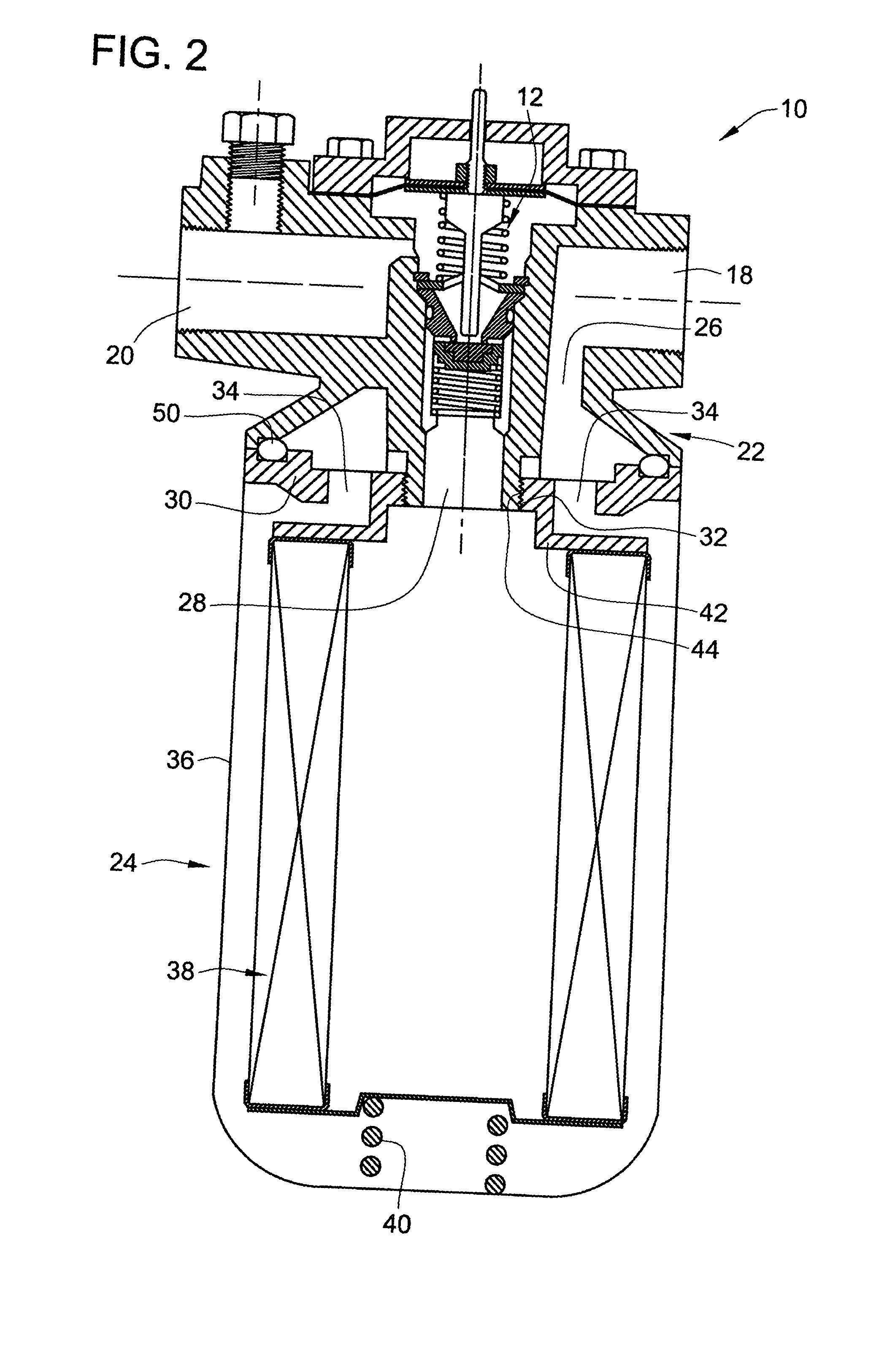

Filter head and burner system incorporating same

InactiveUS20050029172A1Cost for installation is reducedReduce in quantitySettling tanks feed/dischargeMembrane filtersVacuum pressureSafety valve

The present invention is directed toward a filter head that is adapted to mount a filter between an upstream fluid supply and a downstream fluid pump such as might be used for an oil burner system that includes a combination of the filter head and the safety valve in a single unit that may be interposed at a location along an oil conduit. The filter head comprises a filter head housing having an inlet port and an outlet port and a filter mounting stub that is adapted to mount the filter thereto. The filter mounting stub provides a filter head entrance port and a filter head exit port fluidically between the inlet and the outlet ports for communication with the filter when mounted thereto. A safety valve is mounted in the filter head housing and is arranged fluidically between the inlet and outlet port of the filter head housing. The safety valve has open and closed positions and opens in response to vacuum pressure at the outlet port.

Owner:SUNTEC INDS

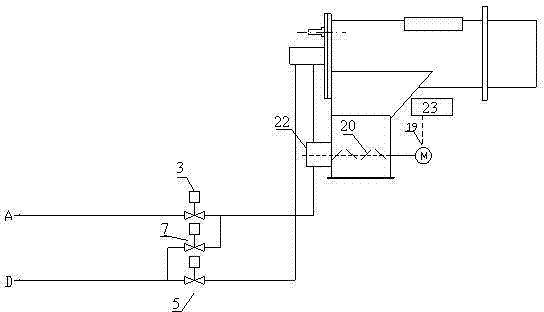

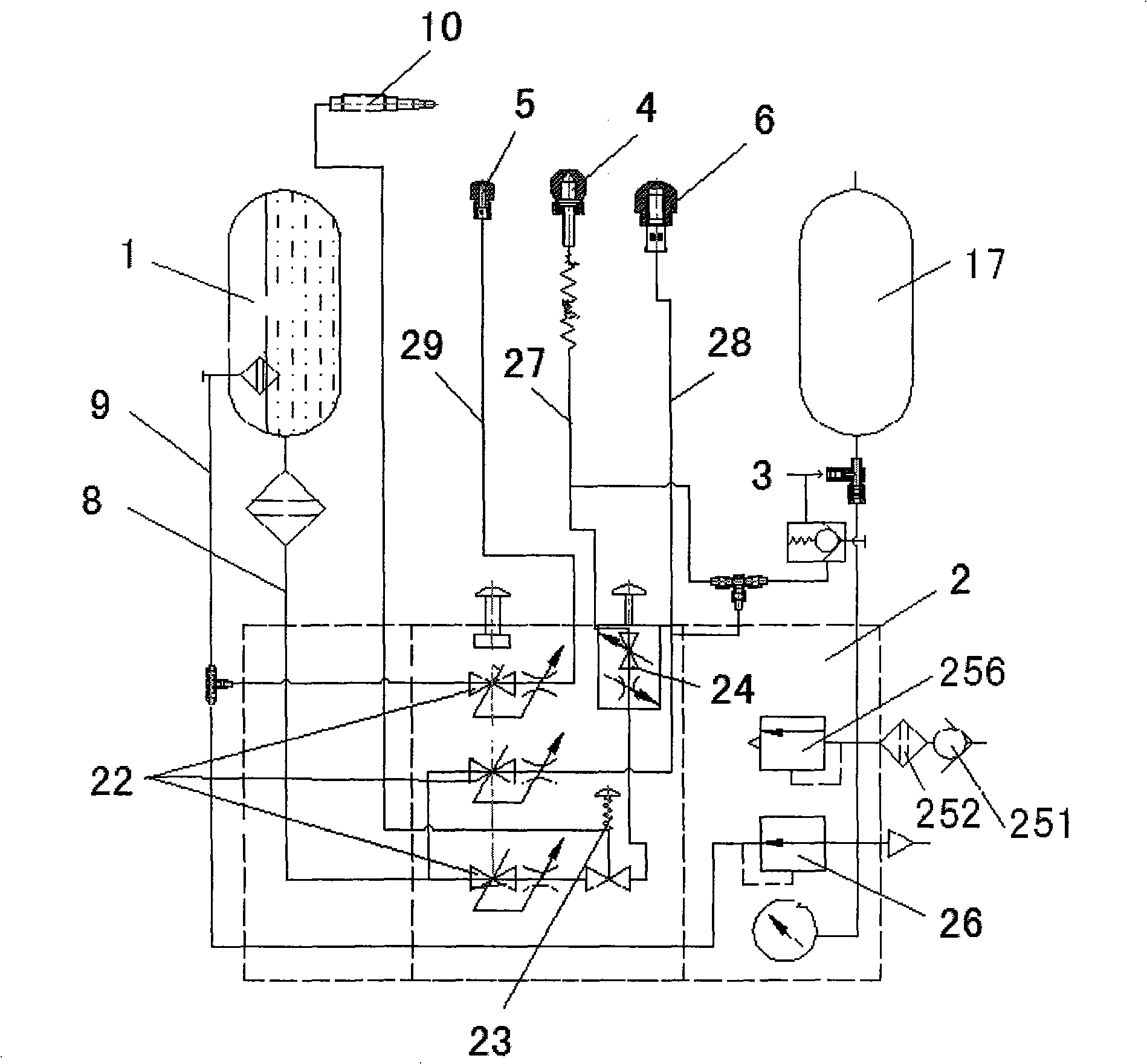

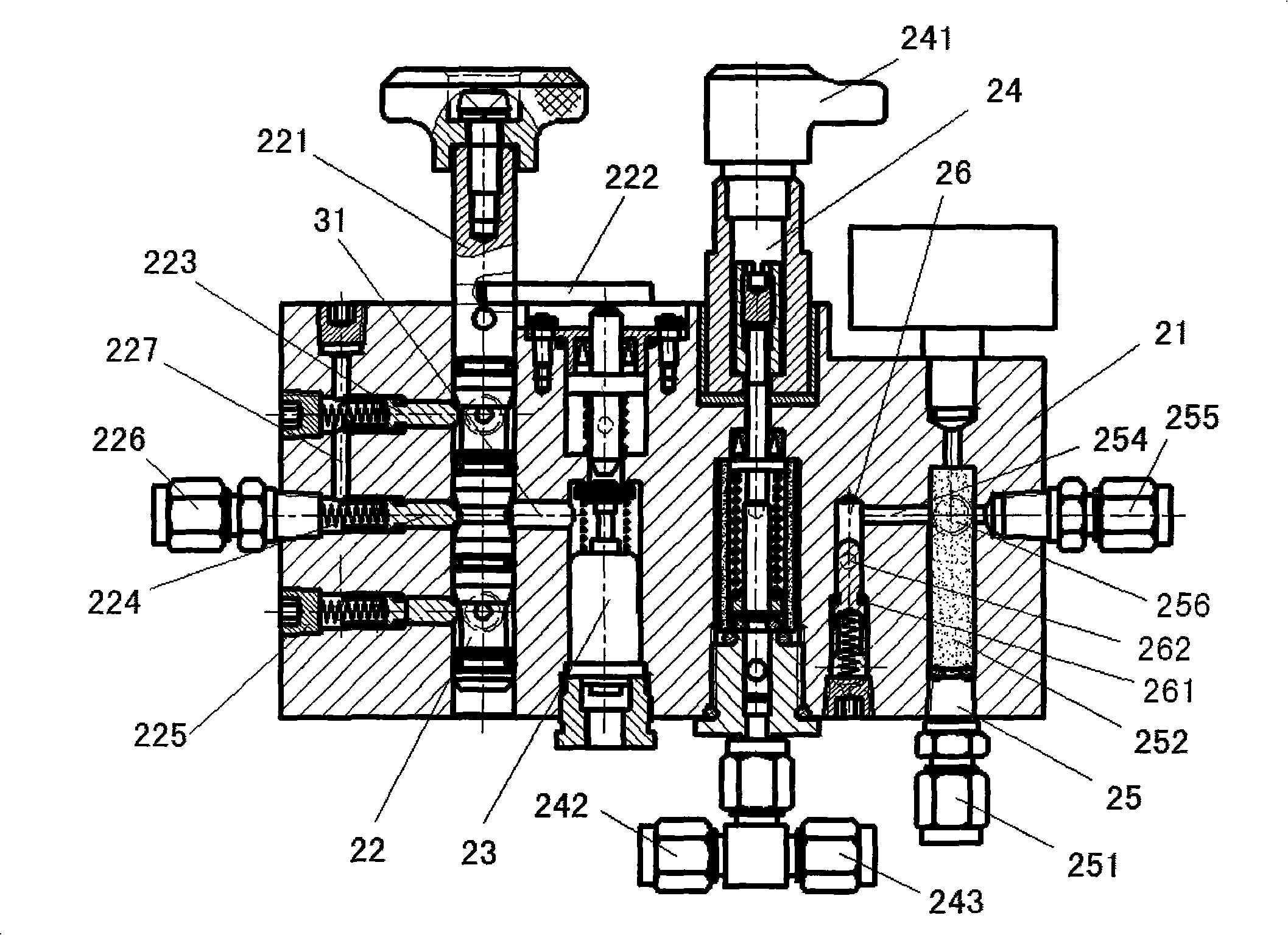

Burning control system of fuel oil burner

InactiveCN102538001AExtended service lifeEasy maintenanceBurnersCombustion regulationAir volumeControl system

The invention discloses a burning control system of a fuel oil burner, which comprises an oil transportation passage, an atomizing medium passage, an ignition device, a blower device, an air quantity adjusting device and an oil quantity adjusting device. The burning control system of the fuel oil burner additionally comprises a controller. The controller controls the operation of the blower device, an igniter and an atomizer. The air quantity adjusting device comprises a fan and a fan driver. A fan driver feedback device is arranged on the fan driver. An air pressure sensor is arranged in the ignition device. The air pressure sensor outputs an air pressure signal to the controller. The controller controls the operation of the fan driver according to the feedback signal of the fan driver and the air pressure signal. The fan driver changes the output air quantity of the fan by changing the working frequency of the fan. A flame signal sensor is additionally arranged in the ignition device and outputs a flame signal to the controller. The burning control system of the fuel oil burner can automatically adjust the air quantity and the oil quantity according to preset air-to-oil ratio and can overcome the defect of wear or deformation caused by long-term operation of the traditional burner which adopts a mechanical connecting rod.

Owner:JIANGSU OUBIAO

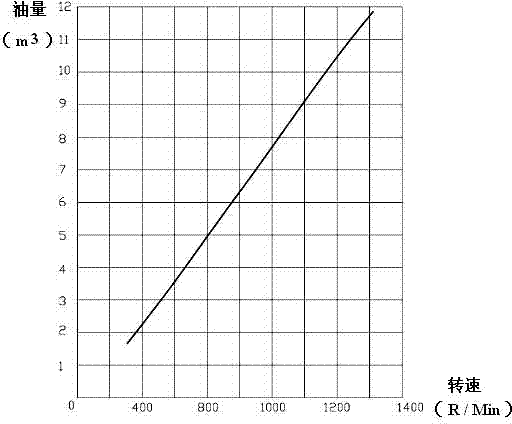

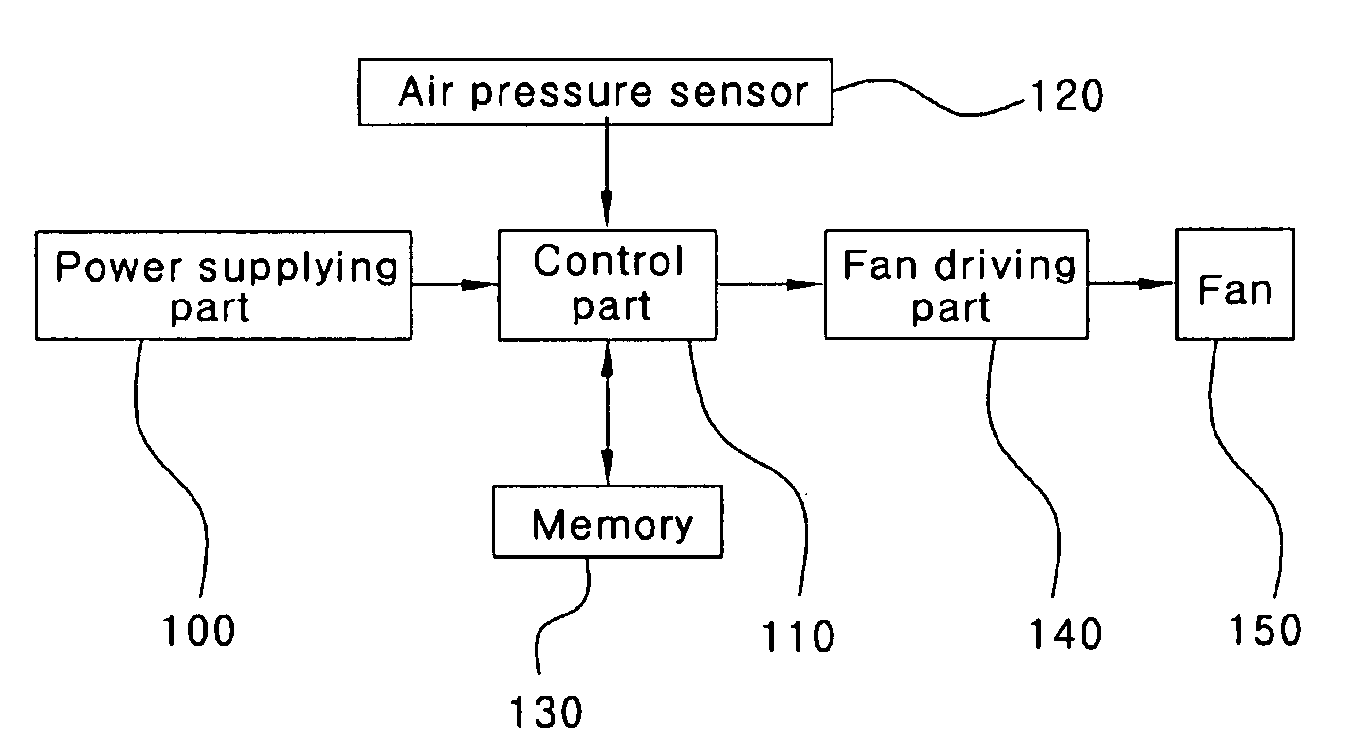

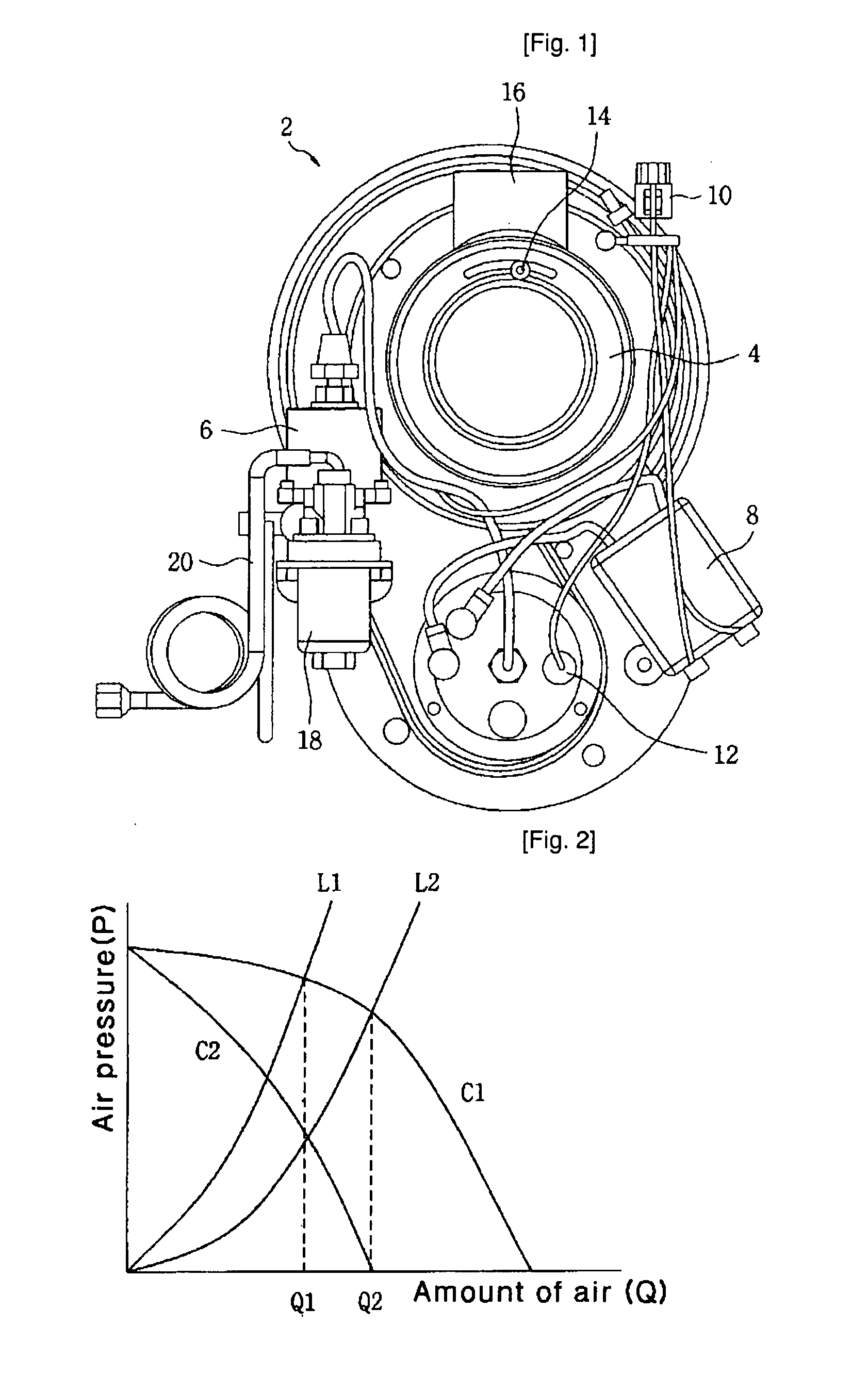

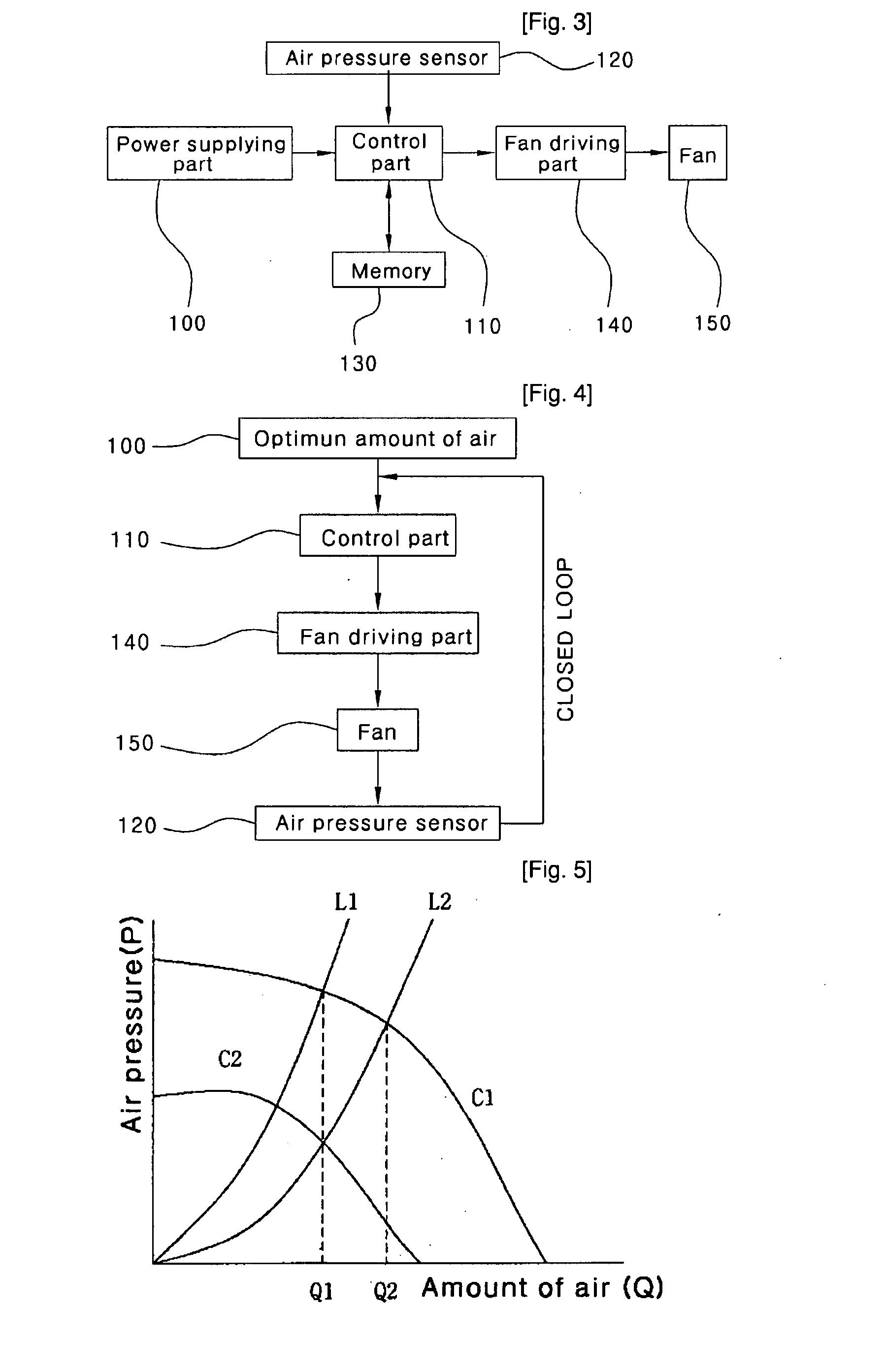

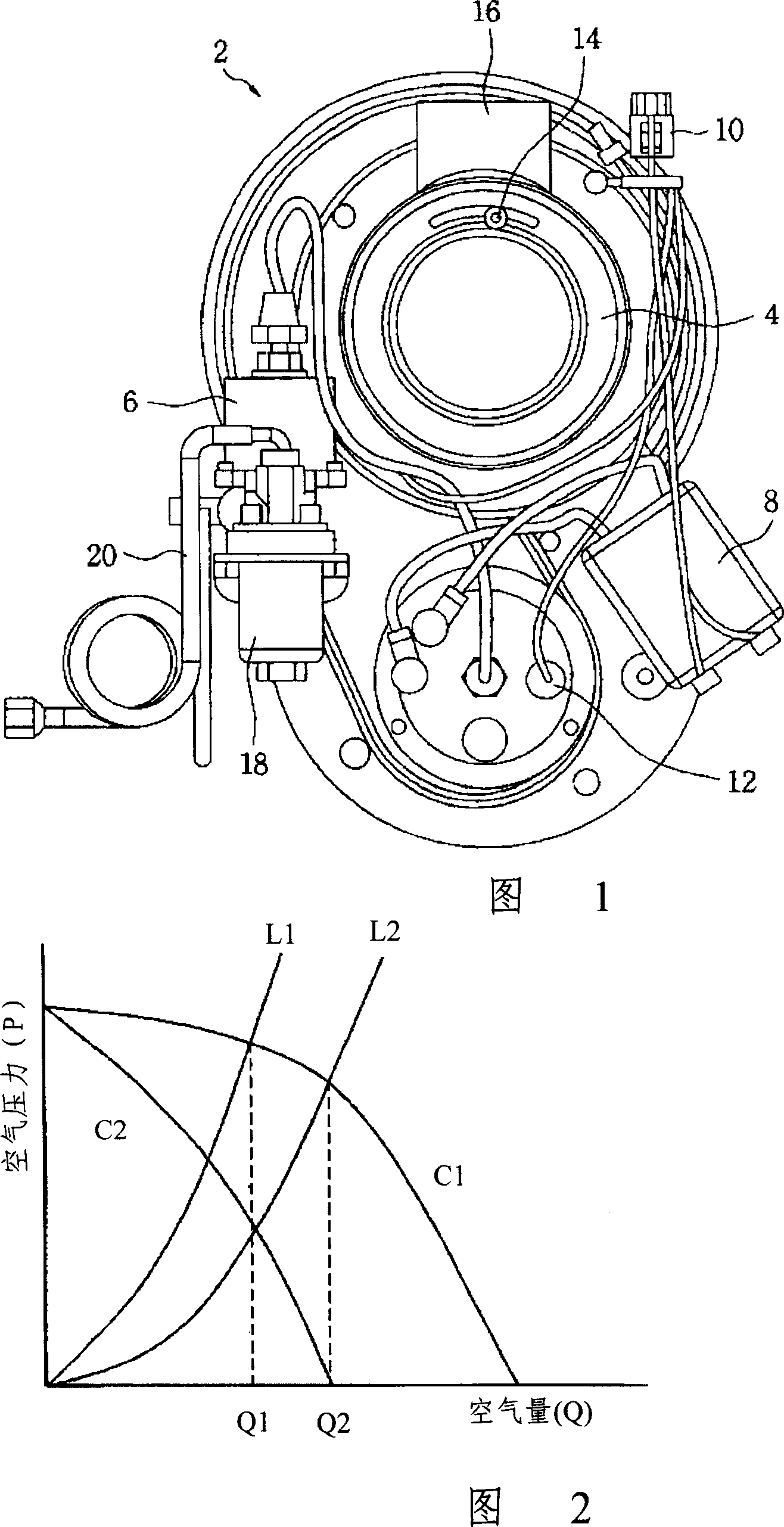

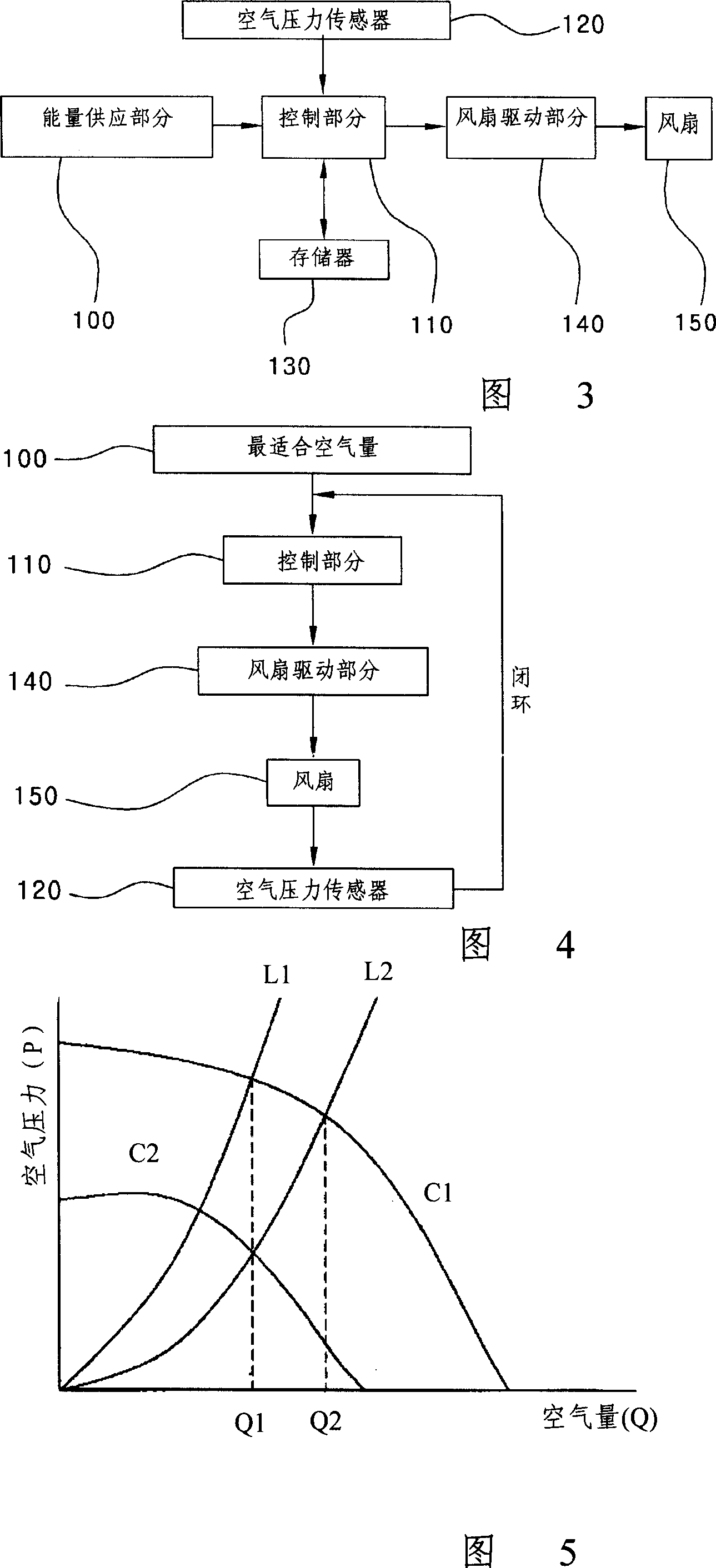

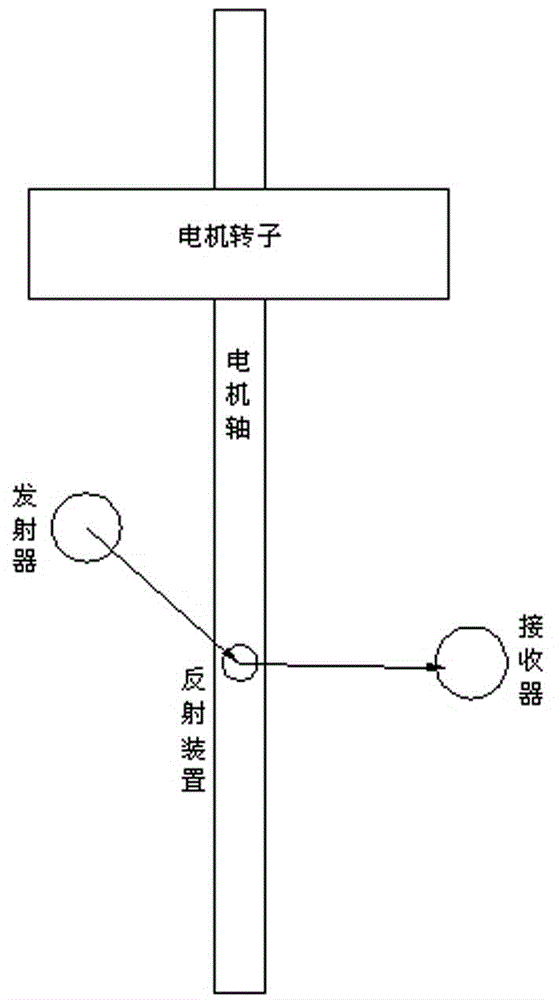

System and Control Method of Oil Burner's Suitable Burning Ratio Using Air Pressure Sensor

InactiveUS20080118877A1Stably control air fuel ratioBurnersFluid heatersControl theoryGas pressure transducer

Disclosed are a system and a method for precisely controlling an air fuel ratio of an oil burner, which is extensively used in a household boiler, an industrial boiler, or a heater, using an air pressure sensor. The system includes a power supplying part, a fan for supplying air required for combustion of the oil burner by receiving driving voltage from the power supplying part, a fan driving part serving as a controller which drives the fan, an air pressure sensor, which is installed at a side of a flow path of air supplied from the fan so as to detect an amount of the supplied air, and a control part for outputting an optimum RPM of the fan to the fan driving part by comparing a signal detected by the air pressure sensor with preset data related to an optimum amount of air. The method includes the steps of detecting an amount of air being supplied through a fan using the air pressure sensor, calculating an optimum RPM of the fan using a controller by comparing a signal about the amount of the air with preset data related to an optimum amount of air, outputting the RPM calculated by means of the controller to a fan driving part, and rotating the fan according to the calculated RPM input into the fan driving part.

Owner:KYUNGDONG NETWORK

Preparation method for environment-friendly fuel from hydrodesulfurized residue oil

InactiveCN104498082ANo pollutionShorten the production cycleLiquid carbonaceous fuelsRefining to eliminate hetero atomsHydrodesulfurizationFuel oil

The invention relates to a preparation method for an environment-friendly fuel from hydrodesulfurized residue oil. The preparation method comprises the following steps: by adopting 50-80 parts by weight of hydrodesulfurized residue oil as a main material, adding 15-30 parts by weight of hydrocarbons with small molecular weight as an igniter composition, adding 0.1-1.0 part by weight of an emulsifier and 0.5-1.5 parts by weight of a stabilizer, and adding the balance of water, thereby preparing the environment-friendly fuel. The fuel oil disclosed by the invention has characteristics of relatively good liquidity, sufficient combustion, and no smoke dust or sulfur-containing gas, and can be used for effectively reducing environmental pollution problems caused by the fuel; the heat of combustion value of the fuel is higher than that of diesel oil by about 30%, the raw material source is rich, the preparation process is simple, and therefore, the environment-friendly fuel is suitable for occasions such as a combustion boiler, an oil burner and an oil burning cellar which take fuel oil as the fuel.

Owner:JIANGSU JIANSHEN BIOLOGY AGROCHEM

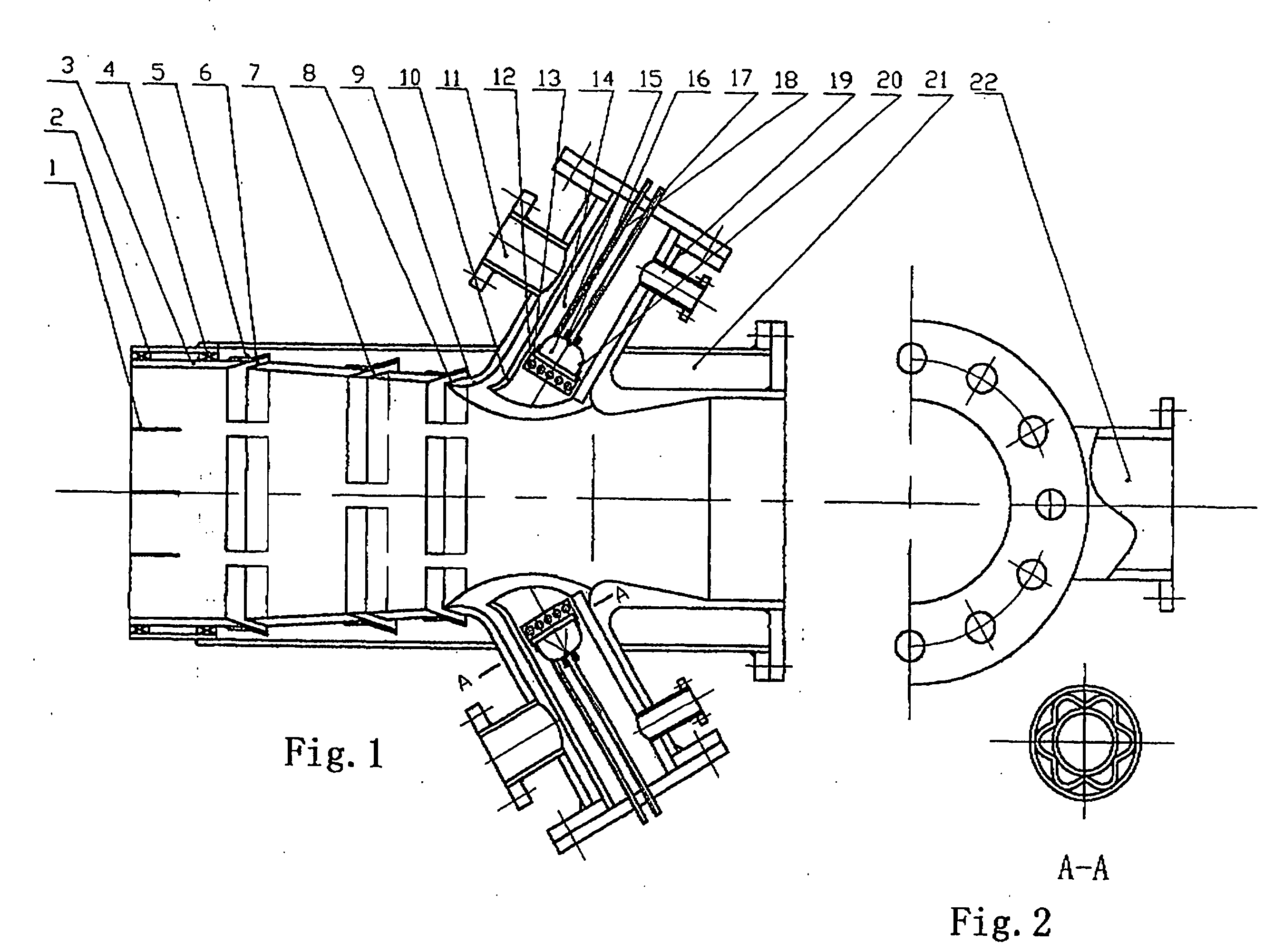

Lean oil heat intensified firing actuating apparatus of pulverized coal boiler

InactiveCN101178175AStrong wind resistanceImprove combustion efficiencyCombustion using gaseous and pulverulent fuelBurnersButt jointEngineering

The invention relates to a lean oil thermal reinforcement burning starting device for a pulverized coal boiler. A pulverized coal thermal reinforcement cracking pre-burning chamber is provided with a first wind pipe which is used for wind feeding. The left part of the first wind pipe is provided with a bent pipe and the right part thereof is provided with a straight pipe. A tube-shaped lean oil thermal reinforcement oil burner and an oil long fire feeding pipe which is connected with the tube-shaped lean oil thermal reinforcement oil burner extend to an entrance segment of a dense phase powder thermal reinforcement cracking burning pipe after passing through the first wind pipe. The left end of the dense phase powder thermal reinforcement cracking burning pipe is butt-jointed with the oil long fire feeding pipe, and the right end thereof is respectively connected with a thin phase powder thermal reinforcement cracking burning pipe and a thin phase powder wind-cooling pipe. The periphery of the dense phase powder thermal reinforcement cracking burning pipe is surrounded and connected by a secondary wind case for feeding air. The invention is characterized in that the existing oil burner is replaced by the pulverized coal burner which can be fired with extremely small quantity of oil during the firing, combustion-supporting and stable burning processes of the pulverized coal boiler, thereby greatly saving the fuel with an oil conservation rate of more than 95 percent, a pulverized coal burn-off rate of more than 90 percent and a flame temperature of 1800 DEG C. besides, the invention has the advantages of high burning efficiency, quick burning speed and strong wind resistance capability.

Owner:徐州燃烧控制研究院有限公司

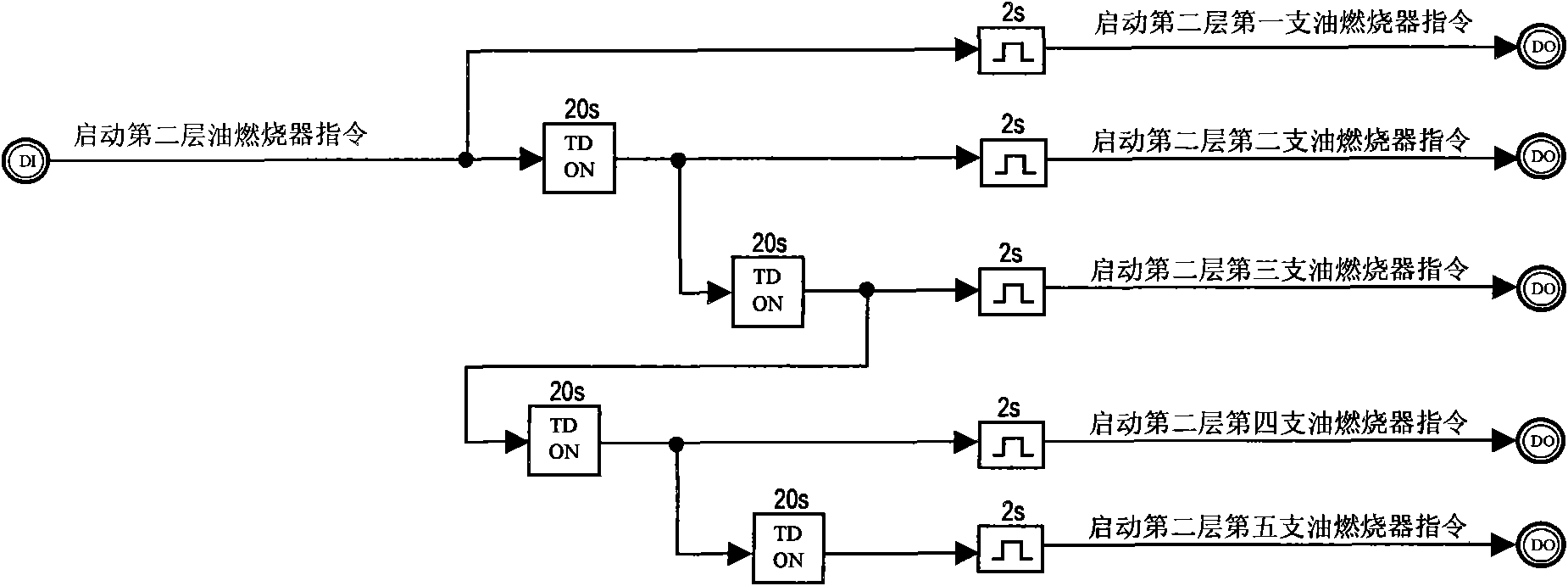

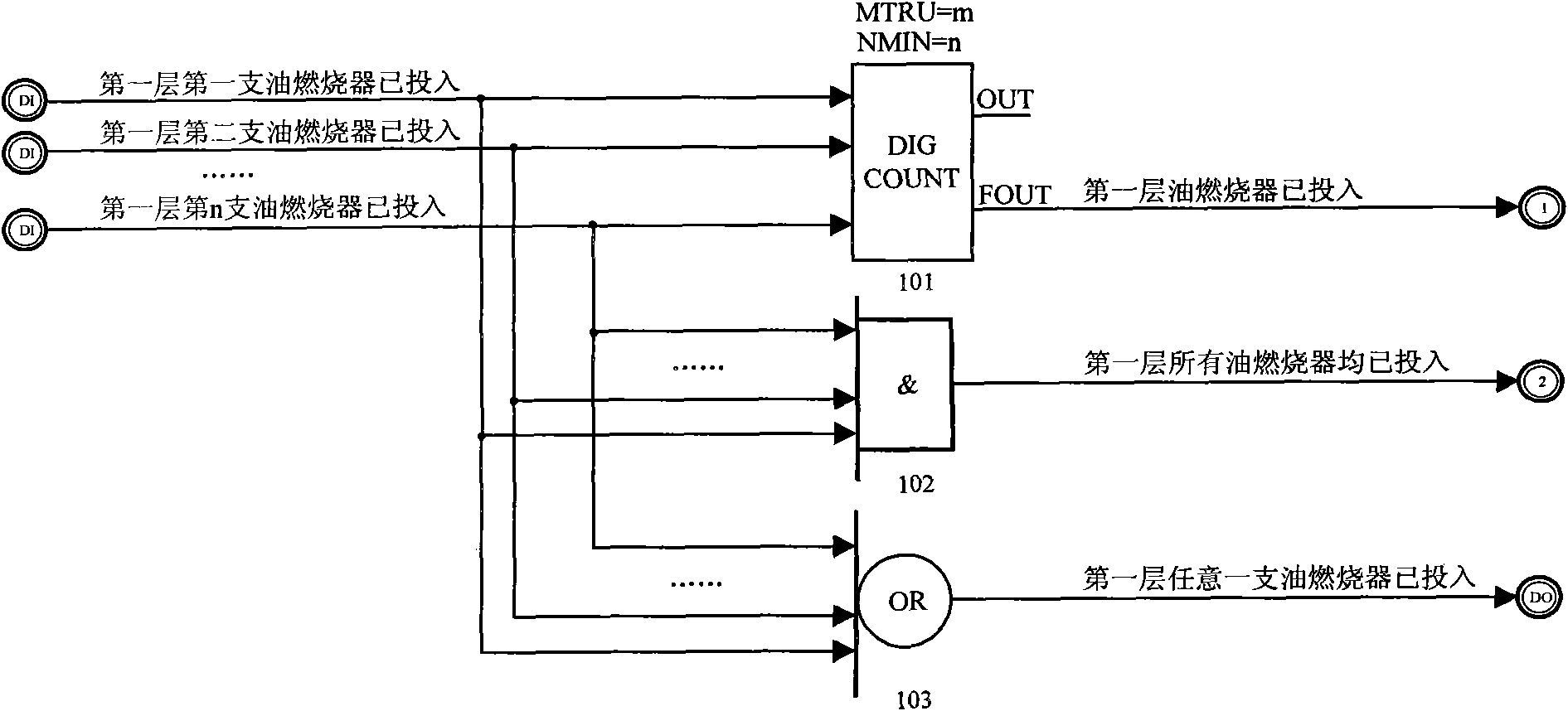

Automatic control method for boiler oil burner and device thereof

The invention relates to an automatic control method for boiler oil burners, which comprises the following steps: a, the oil burner is partitioned into a plurality of layers; b, the oil boiler is operated taking a layer as a unit when an instruction of inputting or quitting is received; c, the next layer of the oil burner is operated until all of layers of the oil burner are operated when the operating amount of the oil burner in one layer is larger than 80 percent; and d, when an instruction of operating or stopping operating is received in one layer, a corresponding oil burner is sequentially operated, if the oil burner is operated, or the operation is not allowed, the next oil burner is operated. The device for realizing the automatic control method comprises an oil burner layer operating judgment loop, a boiler oil burner layer management loop and a layer oil burner management loop, wherein the oil burner layer operating judgment loop inputs the operating signals of the oil burners in the layer and outputs the signals to the boiler oil burner layer management loop; the boiler oil burner layer management loop also inputs an oil burner ignition instruction and the last signal of the failed starting of the oil burner in each layer, and outputs starting instructions of the oil burners in each layer to each oil burner management loop; and the layer oil burner management loop inputs operating allowing and operating signals of the oil burners of each layer and starting instructions of the oil burner of each layer and outputs ignition instructions of the oil burner of each layer.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

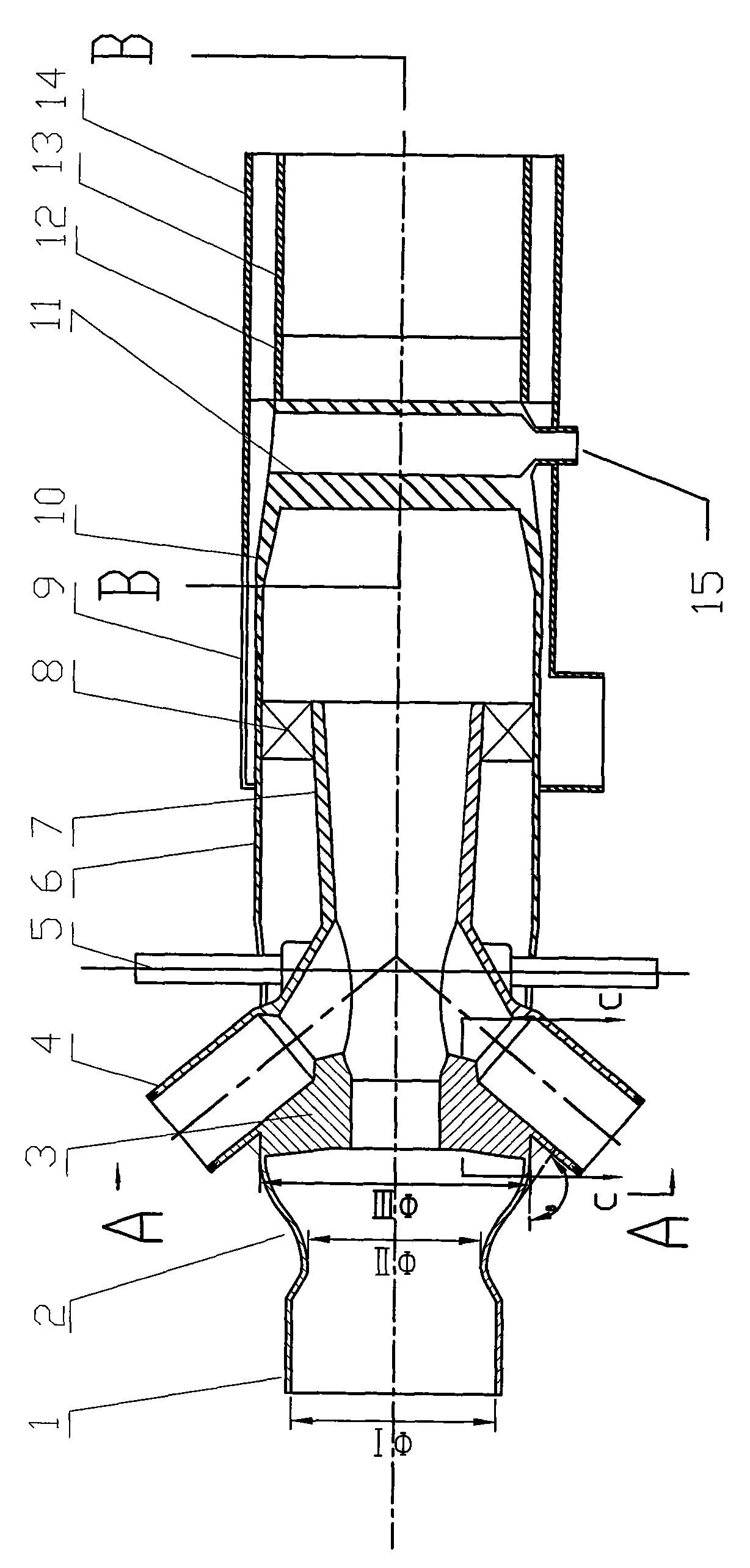

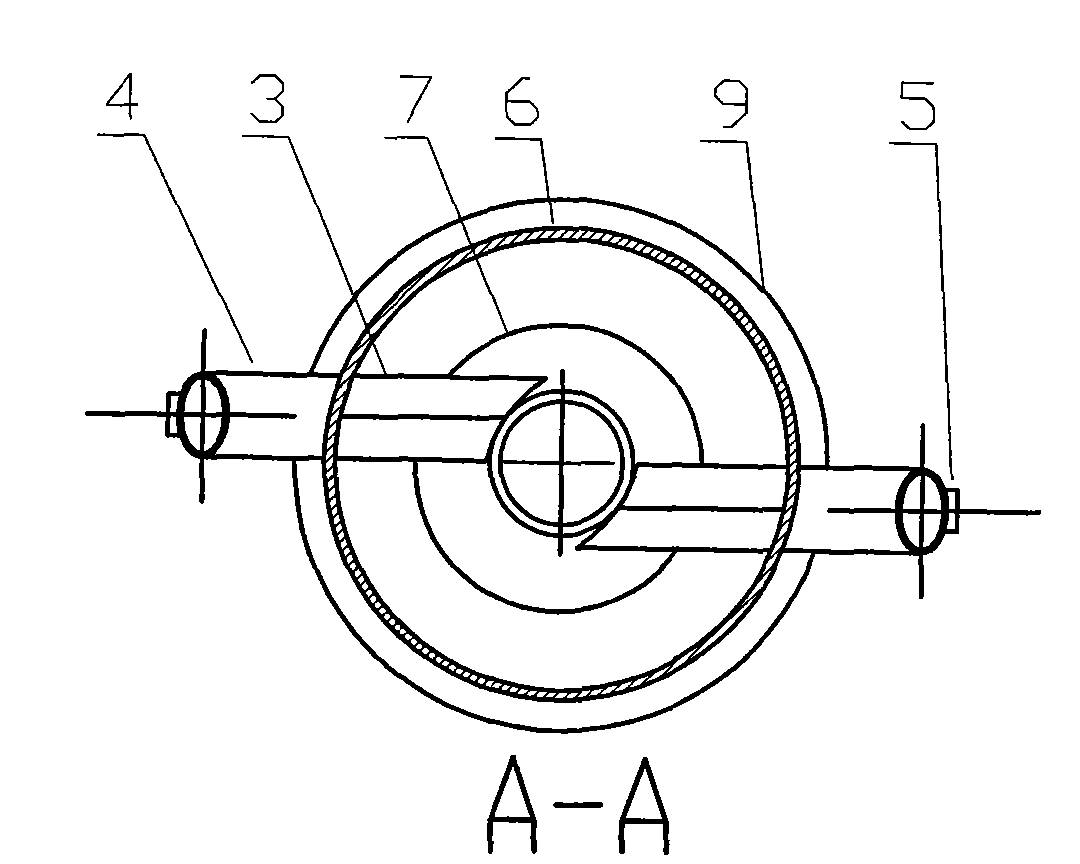

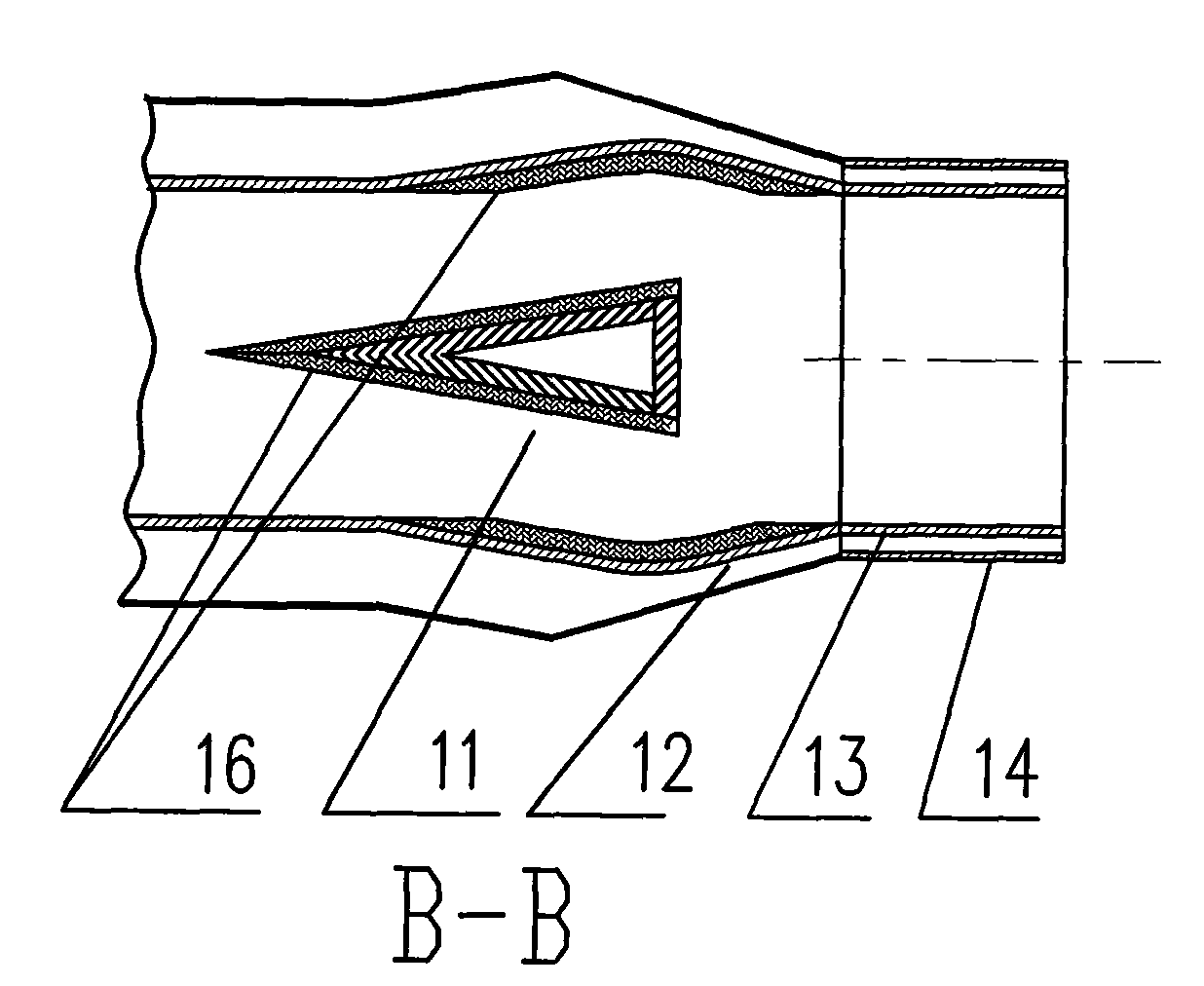

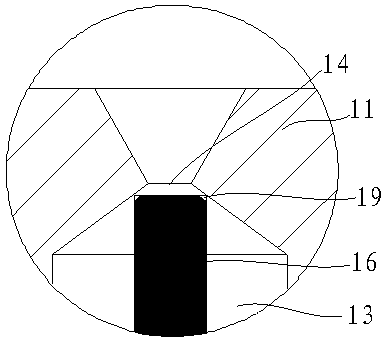

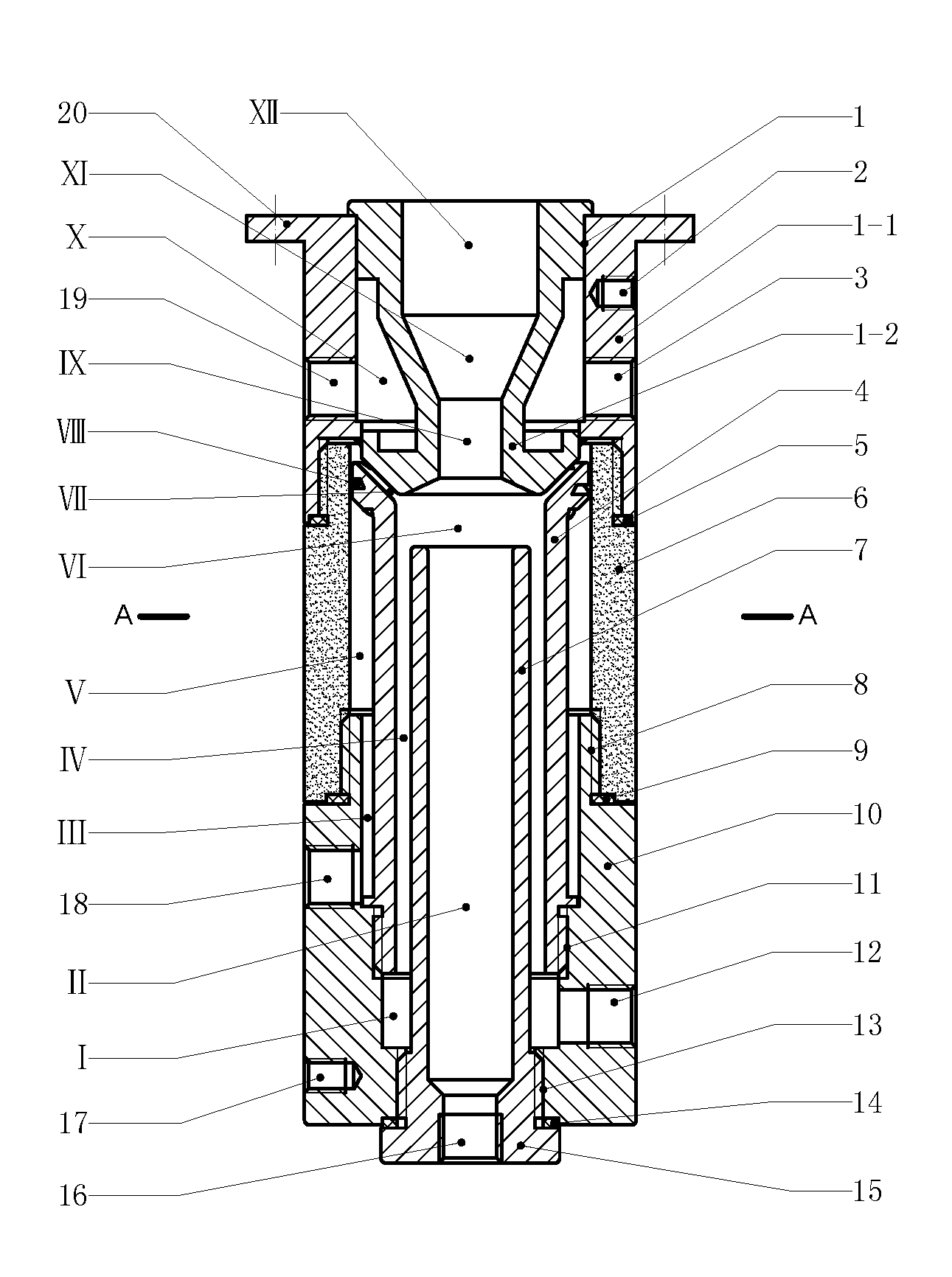

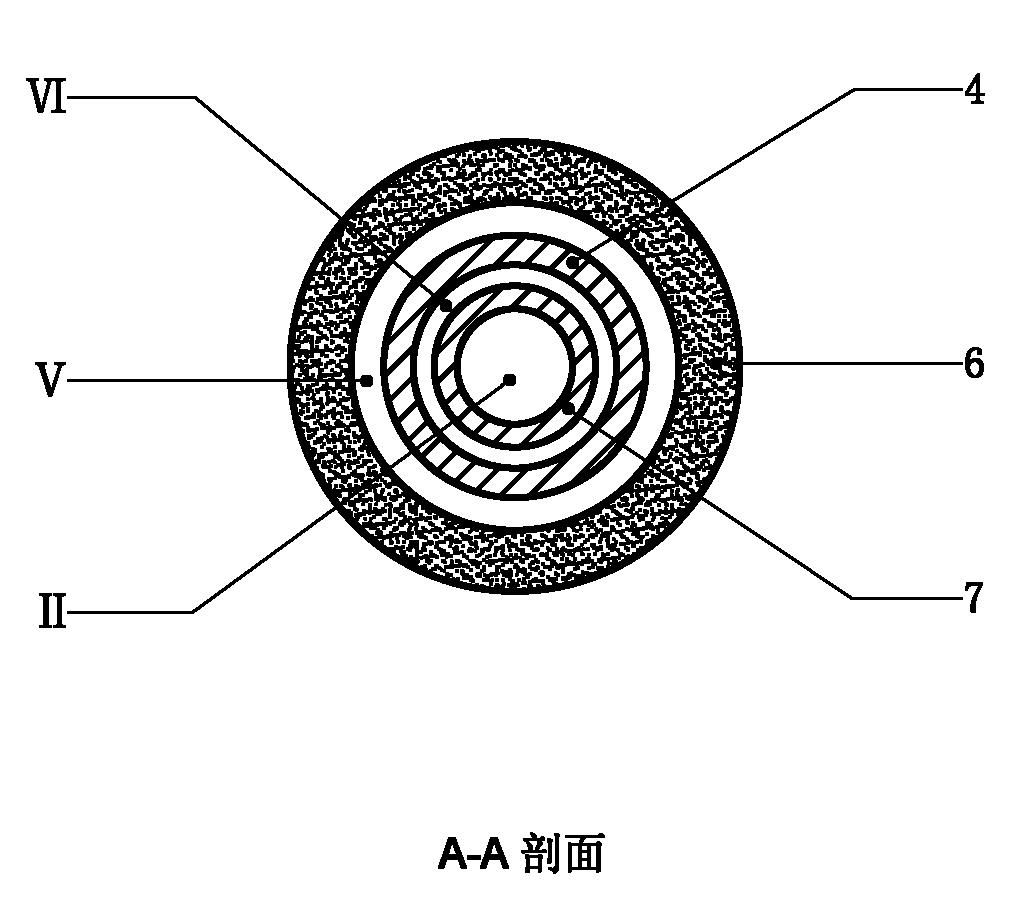

Inferior coal micro-oil ignition combustor

InactiveCN101603683AExtended service lifeSolve easy burnsPilot flame ignitersPulverulent fuel combustion burnersCycloneCombustion chamber

An inferior coal micro-oil ignition combustor comprises a streamlined air powder separation ring, a bidirectional cyclone oil combustor, a wing-shaped anti-friction block, a primary dense-phase coal powder combustion chamber, a secondary dilute-phase coal powder combustion chamber, a V-shaped cavity backflow blunt body, a circumferential cooling bellows and the like, employs a principle of gas-solid two phase flow separation, a principle of oil flame two-way cyclone ignition, backflow high-temperature flue gas of a blunt body, a principle of energy repeated utilization, a principle of coal powder graded ignition and energy gradual enlargement, forms a power field with low air speed, high density, strong eddy flow, strong backflow in the combustor, and creates favorable condition for firing coal powder, so as to effectively solve the problems of firing difficulty and low burn-out ratio of inferior coal. The combustor is capable of igniting inferior coal of 4 to 10 tons by using oil capacity of 150kg / h, which has an oil-saving ratio more than 80%, service life more than 4 years, and is beneficial for popularization in related industries.

Owner:范昌 +2

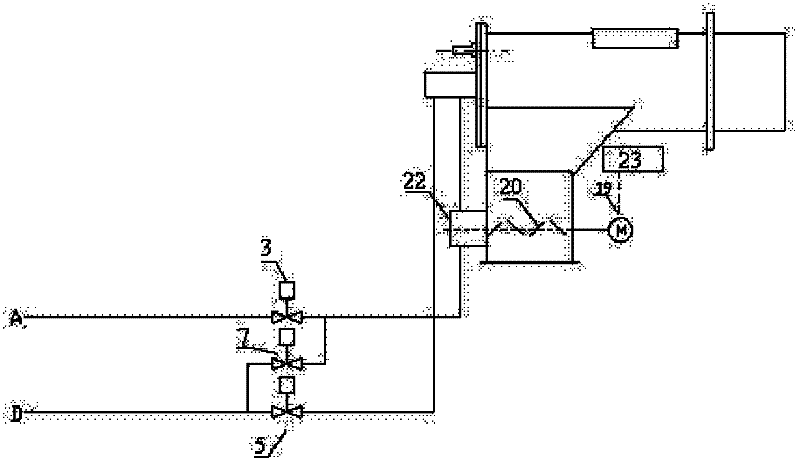

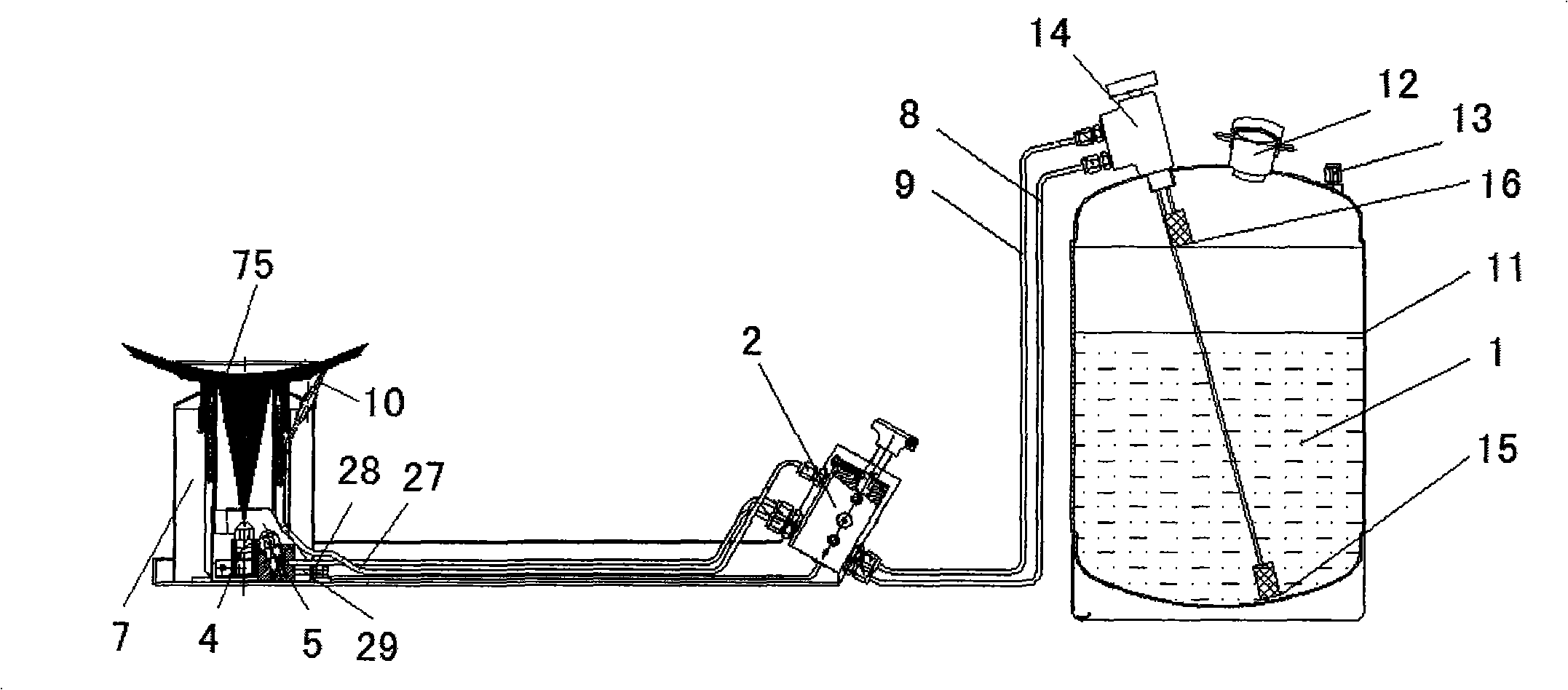

Mixed-oxygen preheating oil burning system

InactiveCN101539291AImprove combustion efficiencyBurn fullyCombustion using gaseous and pulverulent fuelBurnersCombustionEngineering

The invention relates to a mixed-oxygen preheating oil burning system. The system comprises an oil storage tank, a control valve, a combustion apparatus and corresponding connecting pipelines. The oil storage tank comprises a tank body. The top of the tank body is provided with an oil filling opening, a gas filling opening and an oil-gas switch. The inner end of the oil-gas switch is connected with an oil suction pipe extending to the bottom of the tank body and a gas transfer pipe at the upper part in the tank body. The outer end of the oil-gas tank is connected with an oil transfer pipeline and a gas transfer pipeline. The control valve comprises a valve body provided with a switch valve, an electromagnetic valve, an adjusting valve and a pressure maintaining valve thereon. The combustion apparatus comprises a grate, a heat-insulation cylinder, a preheating pipe, a fire cylinder, a fire distributing cylinder, a main oil burner, a preheating oil burner and a compressed air burner. The invention has the advantages of high preheating temperature, adequate combustion and safety. The invention can be widely used in the occasions needing oil burning stoves.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

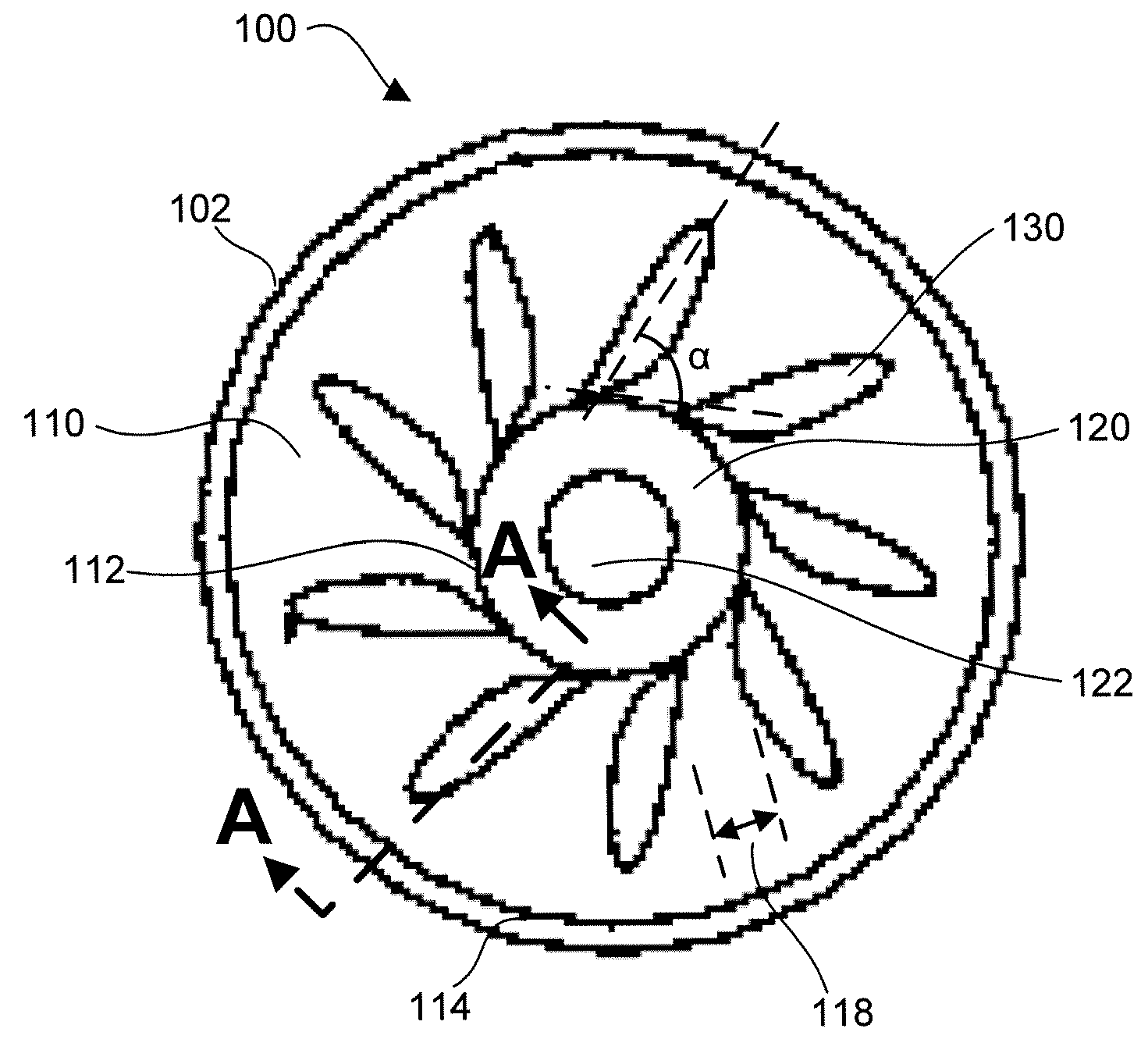

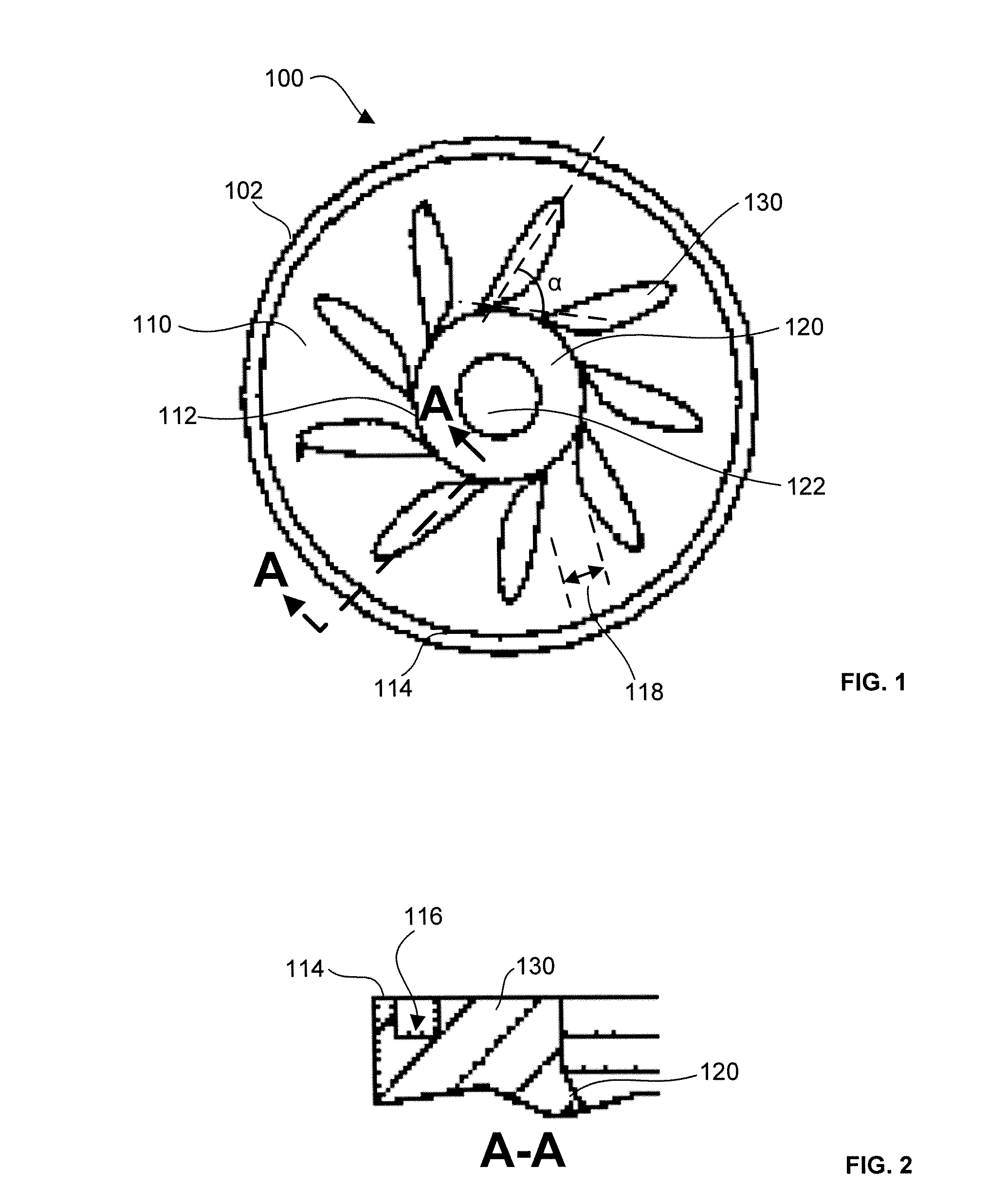

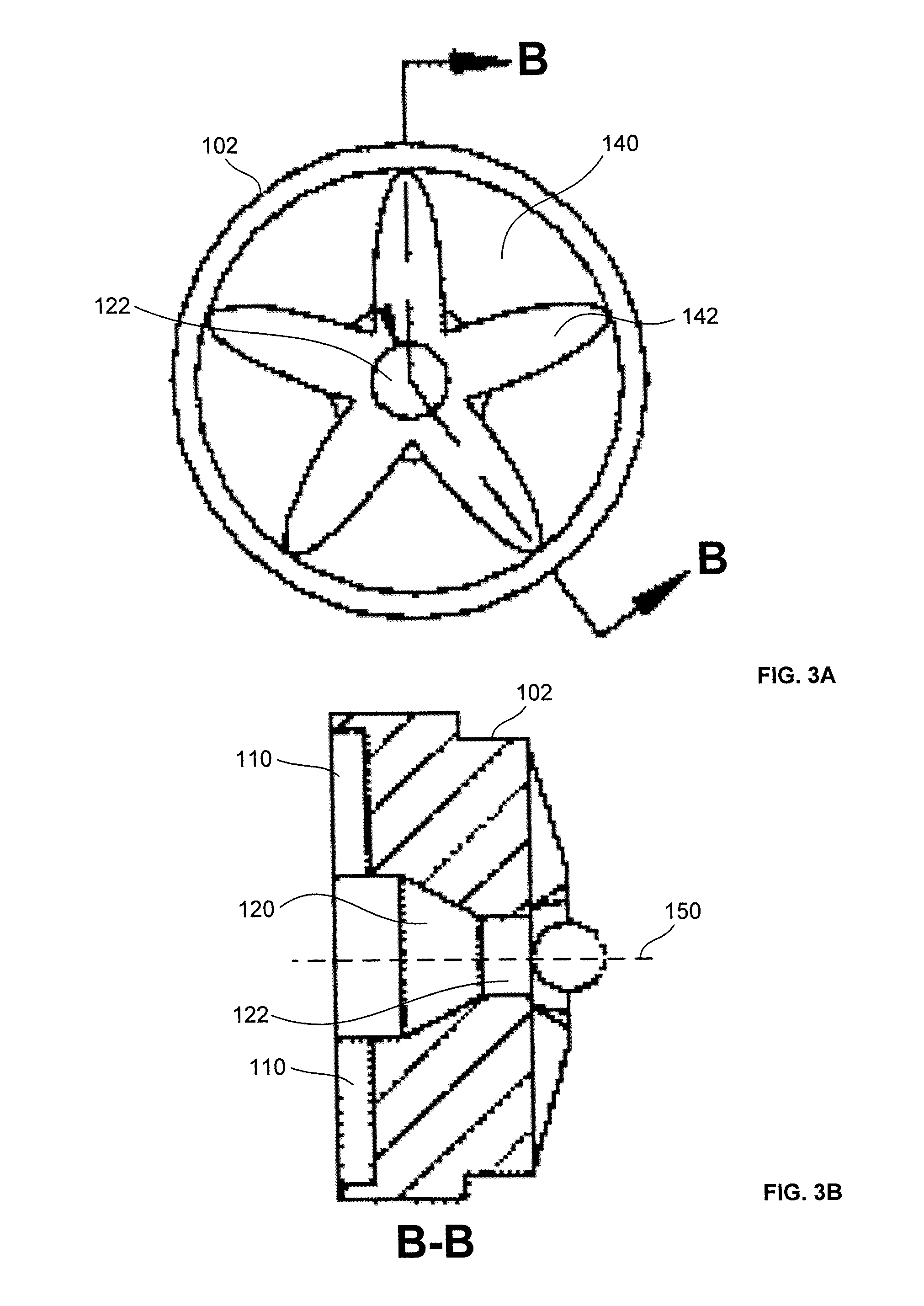

Advanced Mechanical Atomization For Oil Burners

An atomizer spray plate including a body having an inlet surface and an exit surface, a swirl chamber within the body and adjacent to the inlet surface, an atomizer hole extending through the body from the swirl chamber to the exit surface, and a plurality of elongated protrusions upon the inlet surface extending radially from the swirl chamber, wherein the plurality of elongated protrusions define a plurality of venturi inlets to the swirl chamber between adjacent protrusions.

Owner:CECO ENVIRONMENTAL IP INC

System and control method of oil burner's suitable burning ratio using air pressure sensor

InactiveCN101115955AStable control of air-fuel ratioControl air fuel ratioFluid heatersBurnersControl theoryAir–fuel ratio

Disclosed are a system and a method for precisely controlling an air fuel ratio of an oil burner, which is extensively used in a household boiler, an industrial boiler, or a heater, using an air pressure sensor. The system includes a power supplying part, a fan for supplying air required for combustion of the oil burner by receiving driving voltage from the power supplying part, a fan driving part serving as a controller which drives the fan, an air pressure sensor, which is installed at a side of a flow path of air supplied from the fan so as to detect an amount of the supplied air, and a contro 1 part for outputting an optimum RPM of the fan to the fan driving part by comparing a signal detected by the air pressure sensor with preset data related to an optimum amount of air. The method includes the steps of detecting an amount of air being supplied through a fan using the air pressure sensor, calculating an optimum RPM of the fan using a controller by comparing a signal about the amount of the air with preset data related to an optimum amount of air, outputting the RPM calculated by means of the controller to a fan driving part, and rotating the fan according to the calculated RPM input into the fan driving part.

Owner:KYUNGDONG NETWORK

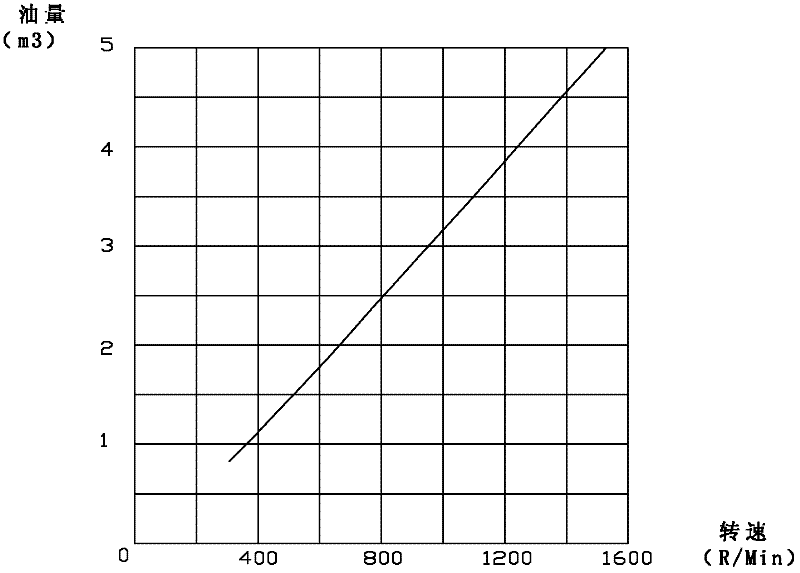

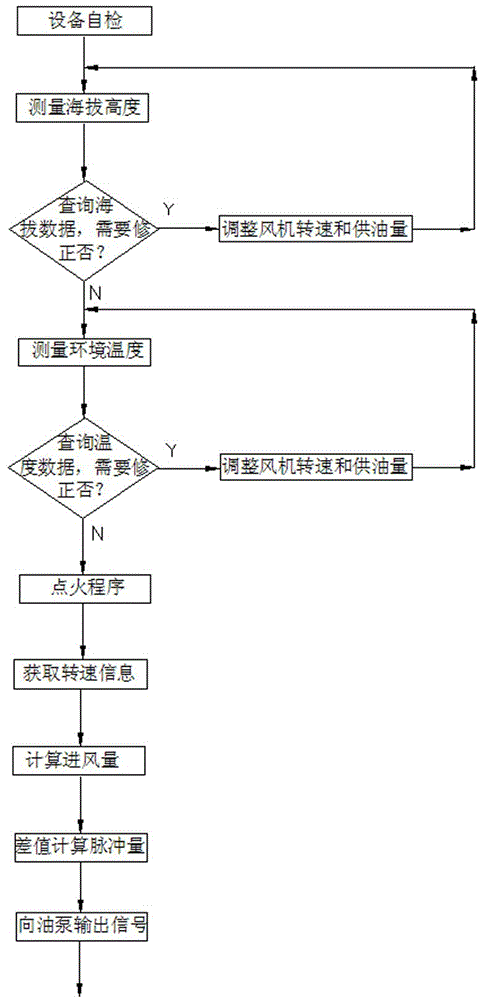

Effective fuel oil burner applied to plateau and plain

The invention discloses an effective fuel oil burner applied to a plateau and a plain. Air density correction tables corresponding to different altitudes are used in the burner. When the burner is positioned at different heights, an oil pump of the burner controls oil supply according to optimal oil supply amount corresponding to an altitude indicator; when the burner works under different temperature conditions, according to built-in sensor air density information, the burner calculates by adopting comparison parameter between an air supply amount and an oil supply amount, corresponding to the built-in sensor air density information to determine oil supply information of the oil pump, corresponding to the built-in sensor air density information. Under the condition of different altitudes and different temperatures, the burner can automatically adapt to change of altitude and temperature according to a built-in calculation oil supply rule curve, and the burner is always in a relatively good combustion state.

Owner:YUNNAN AEROSPACE IND

Direct flow oil-saving burner faulty coal for combustion

InactiveCN1793737AEasy to transformLow investment costIncandescent ignitionPilot flame ignitersCombustion chamberProcess engineering

The invention discloses a bad fuel coal oil-saving direct current burner, comprising coal powder combustion chamber, where the front end of the coal powder combustion chamber is provided with an impact coal powder concentrator, a primary combustion chamber is arranged in the coal powder combustion chamber, plural oil combustion chambers are arranged outside the middle of the primary combustion chamber, a small-oil quantity oil combustor is arranged in the oil combustion chamber, the tail of the primary combustion chamber is connected with the secondary combustion chamber, and heat storage fireproof heat-insulating material is laid in a heat storage coal powder stable combustion chamber. The advantages are using less oil to ignite large amount of coal powder, and oil-saving above 95%; stable combustion function; good environmental protection; high efficiency.

Owner:章联兵

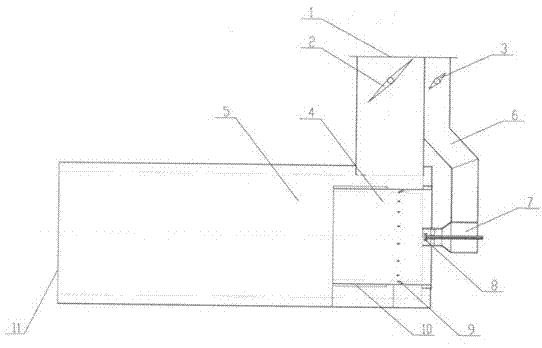

Air duct ignition burner

The invention discloses an air duct ignition burner, which belongs to the field of ignition devices. The air duct ignition burner of the present invention includes an inlet air duct and an outlet air duct, the inlet air duct and the outlet air duct (11) are connected to each other, and both are connected to the hot primary air duct, and the outlet air duct is provided with an inner A pre-chamber, at least one oil burner is arranged in the inner pre-chamber. The air duct ignition burner of the present invention has a simple structure and is easy to operate, and it has stable combustion during operation; the burning loss of the ignition air duct and the burner itself is small, and it can also be used as a non-combustion device for a preheating boiler; the structure is stable Reliable, not easy to be damaged by spontaneous combustion, long service life, and conducive to popularization.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Powdered fuel conversion systems and methods

Owner:MCKNIGHT JAMES K +2

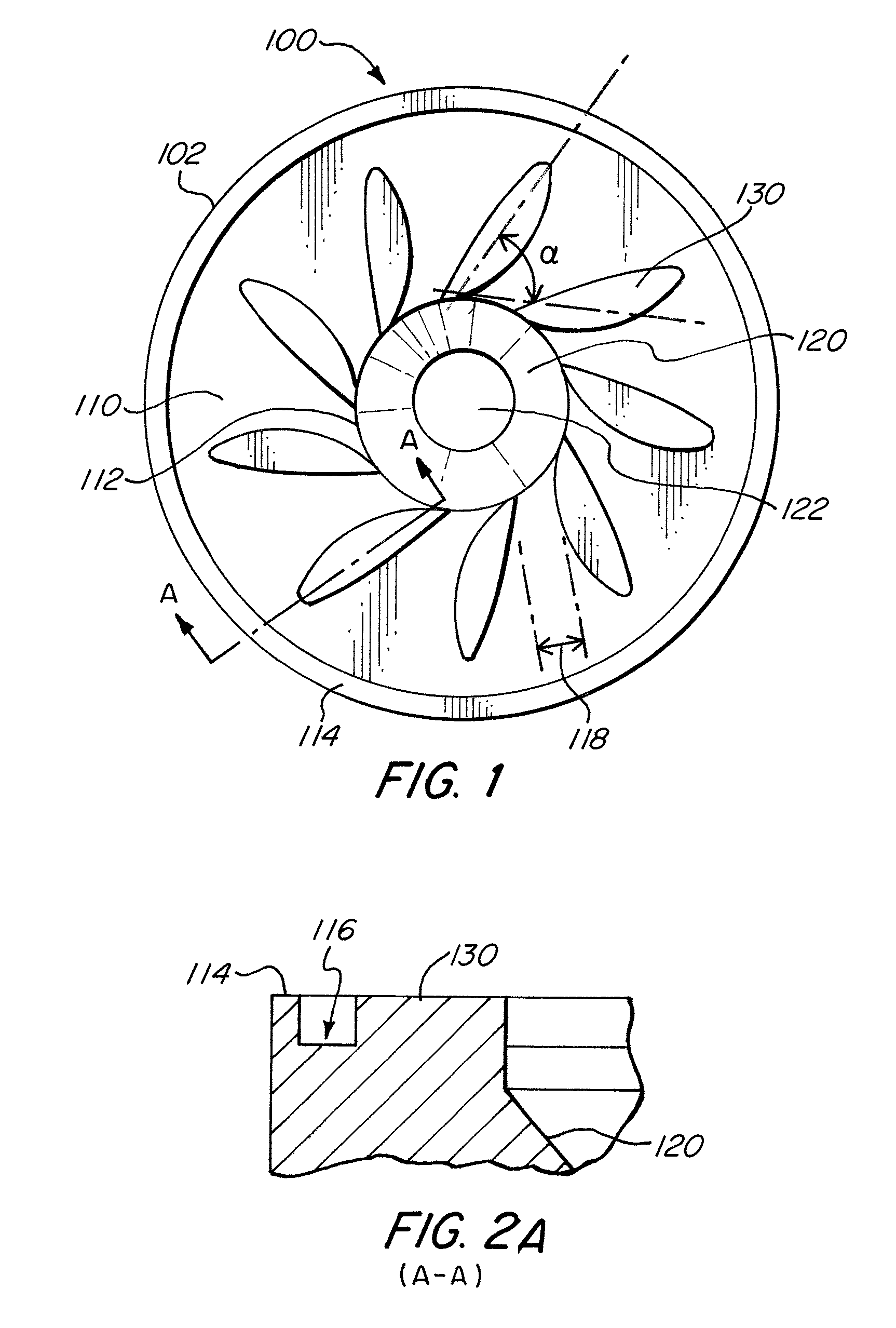

Advanced mechanical atomization for oil burners

An atomizer spray plate including a body having an inlet surface and an exit surface, a swirl chamber within the body and adjacent to the inlet surface, an atomizer hole extending through the body from the swirl chamber to the exit surface, and a plurality of elongated protrusions upon the inlet surface extending radially from the swirl chamber, wherein the plurality of elongated protrusions define a plurality of venturi inlets to the swirl chamber between adjacent protrusions.

Owner:CECO ENVIRONMENTAL IP INC

Novel domestic alcohol oil burner

The invention discloses a novel domestic alcohol oil burner which comprises a base, a straight spray nozzle, a big-end-down fire collection cover, a fire distribution cap and a sound insulation barrel, wherein an air inlet is formed in the base, the straight spray nozzle is installed in the center of the base, the top and the side face of the fire distribution cap are provided with fire distribution holes respectively, and the sound insulation barrel is installed on the base and surrounds around the fire collection cover and the fire distribution cap. The upper end of the sound insulation barrel is provided with a fire tray extending out of the barrel. According to the novel domestic alcohol oil burner, the straight spray nozzle is utilized for sufficiently spraying out alcohol oil in an atomization mode, the spraying force of the nozzle is greatly reduced, fire power is prevented from being too excessive, balance distribution of fire power is achieved through the fire collection effect of the fire collection cover and the fire distribution effect of the fire distribution cap, the fire spraying mode is more scientific and reasonable on the condition that the heat value is not lowered, the requirement for domestic miniaturization can be met, the sound insulation barrel can effectively prevent noise produced when the novel domestic alcohol oil burner is used from diffusing and can also play a certain fire collection role, and multiple problems in the prior art are effectively solved.

Owner:张建忠

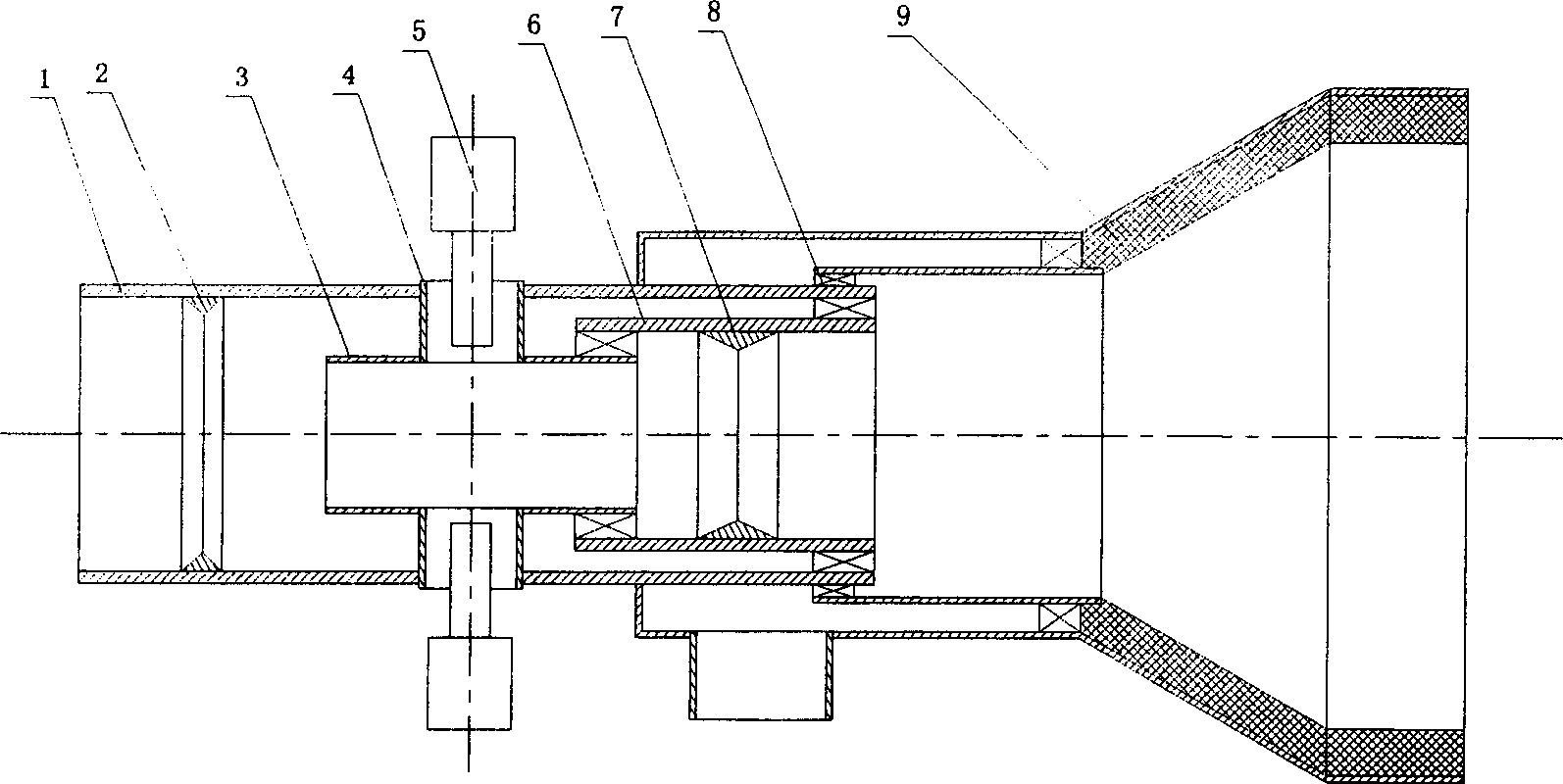

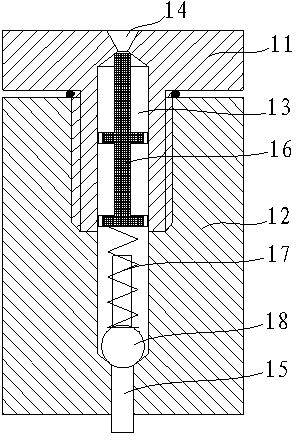

Plasma heavy oil burner

The invention discloses a plasma heavy oil burner, and relates to burning equipment. The plasma heavy oil burner mainly comprises an anode, an insulation connecting piece, a cathode, an inner sleeve and a rear seat, wherein the rear end of the anode is connected with the rear seat through the insulation connecting piece; the cathode is arranged in an inner space of the insulation connecting piece; the lower end of the cathode is connected to the rear seat; the inner sleeve extends into and enters an inner cavity of the cathode from the rear end of the rear seat; an axis through hole of the anode forms a compression duct; a cooling water sleeve is arranged in the anode; a torch outlet is formed at the front end of the anode; a tapered protruding structure at the rear end of the anode extends into the inner space of the insulation connecting piece; the upper end of a cylinder body of the cathode is bell-mouthed; a rotational flow groove is formed at the outer edge of a bell mouth; a space between the inner edge of the bell mouth at the upper end of the cathode and the tapered protruding structure at the rear end of the anode forms an annular airflow channel; the rear seat is provided with a revolving body structure; and an annular oil cavity is arranged in the revolving body structure, and communicated with the inner cavity of the cathode. The plasma heavy oil burner allows heavy oil fuel to be burnt completely, improves the burning efficiency of heavy oil, and reduces the environmental pollution.

Owner:南通东湖国际商务服务有限公司

Dual media atomizing combustor

The invention relates to a dual media atomizing combustor comprising a main oil gun, a main gas nozzle, an electronic igniter, an air bellow, a combustion air cyclone and a combustion air servo regulating mechanism as well as a medium-pressure atomizing media nozzle and a fuel and atomizing media control valve. A main oil gun nozzle, the medium-pressure atomizing media nozzle and the combustion air cyclone are in a concentric structure, the main oil gun is in the center, and the medium-pressure atomizing media nozzle and the combustion air cyclone are circularly and sequentially arranged on the external circumference centering about the main oil gun which is internally provided with liquid fuel and high-pressure atomizing media so as to realize the single combustion or the mixed combustion of the liquid fuel and the gaseous fuel. The combustor with the safe interlocking functions of automatic / manual control and continuous proportional adjustment of loads and air-fuel ratio greatly improves the atomizing performance, the combustion performance and the operation and maintenance performance of the fuel and is suitable for high-volume heat-load boilers or other oil burners.

Owner:中船九江锅炉有限公司

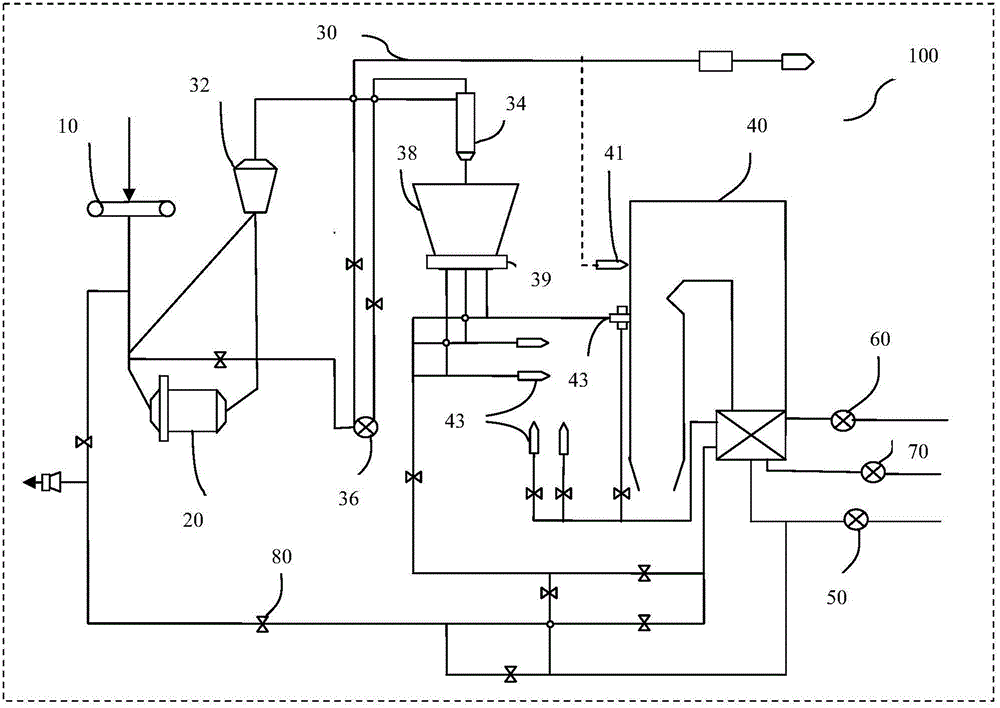

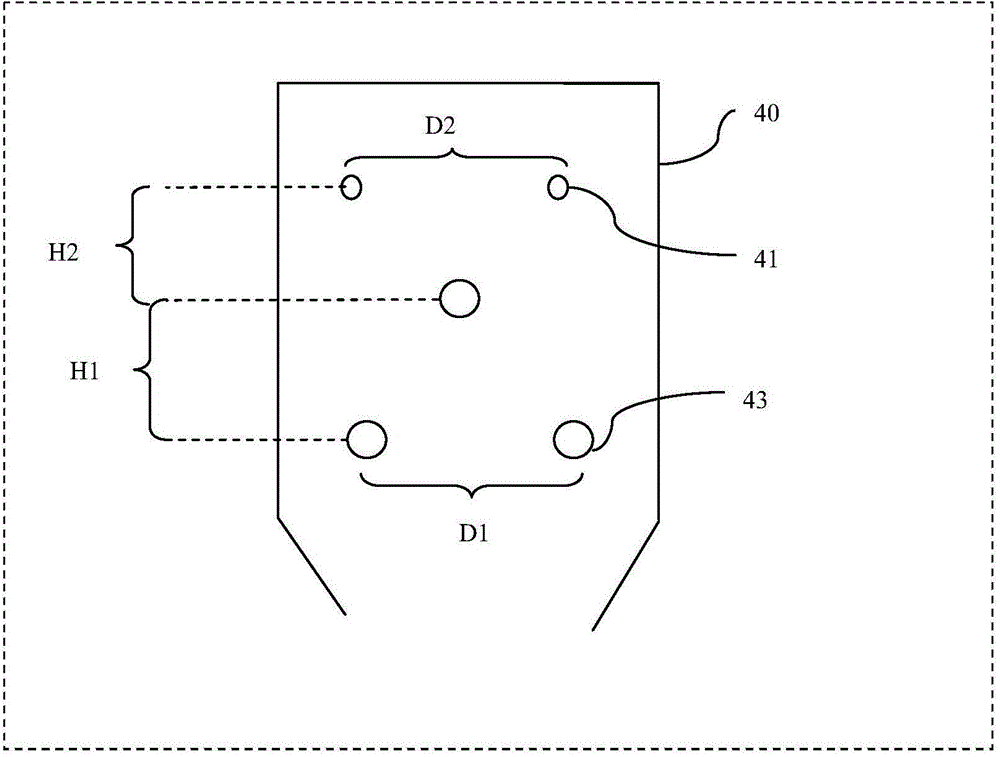

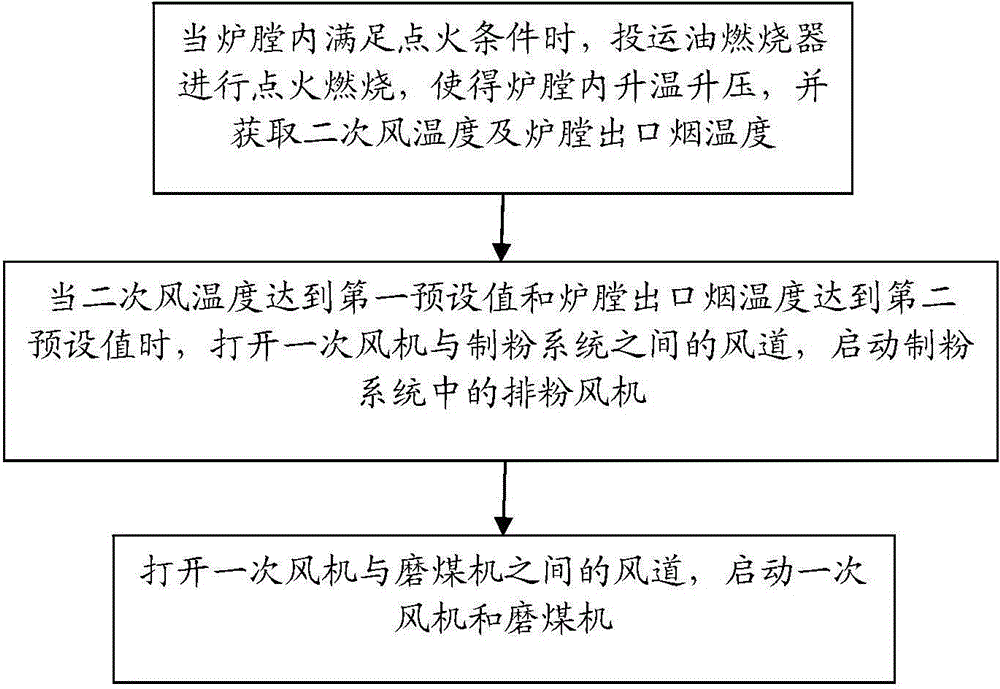

Combustion control method of boiler

ActiveCN104913325AEliminate distractionsEmission reductionCombustion regulationLump/pulverulent fuel preparationCoal dustEngineering

Provided is a combustion control method of a boiler. The boiler comprises a coal mill used for producing coal dust, a coal pulverizing system connected with the coal mill and used for screening coal dust, a hearth connected with the coal pulverizing system and used for combusting coal dust and a primary air fan connected with the coal mill, the coal pulverizing system and the hearth by means of air channels. The control method is described in that an operation oil combustor performs ignition and combustion when an ignition condition in the hearth is satisfied such that temperature and pressure in the hearth are increased and boosted; temperature of secondary air and of smoke at the outlet of the hearth are obtained; when temperature of secondary air reaches the first pre-set value and temperature of smoke at the outlet of the hearth reaches the second pre-set value, an air channel between the primary air fan and the coal pulverizing system is opened and a pulverized coal exhauster of the coal pulverizing system is started; and the primary air fan and the coal mill are started by opening the air channel between the primary air fan and the coal mill. The combustion control method of the boiler ensures that exhaust gas can be fully combusted after entering the hearth in such a manner that the pre-set condition in the hearth is reached by means of the operation oil combustor.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

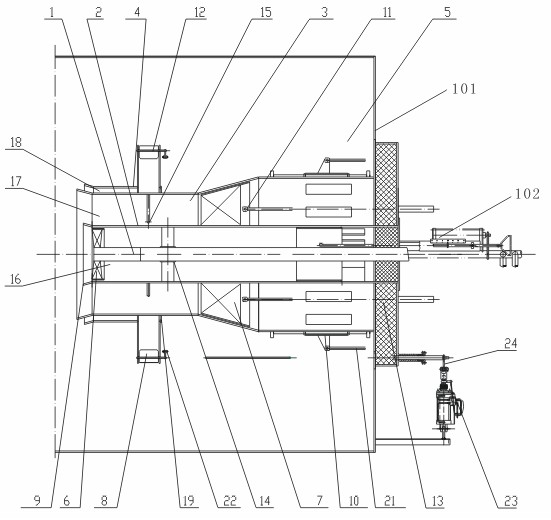

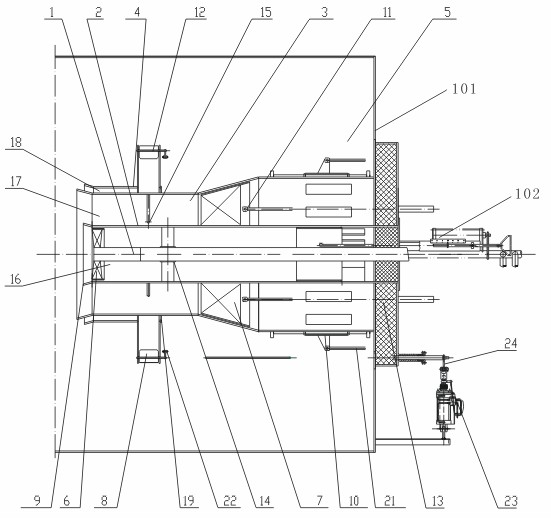

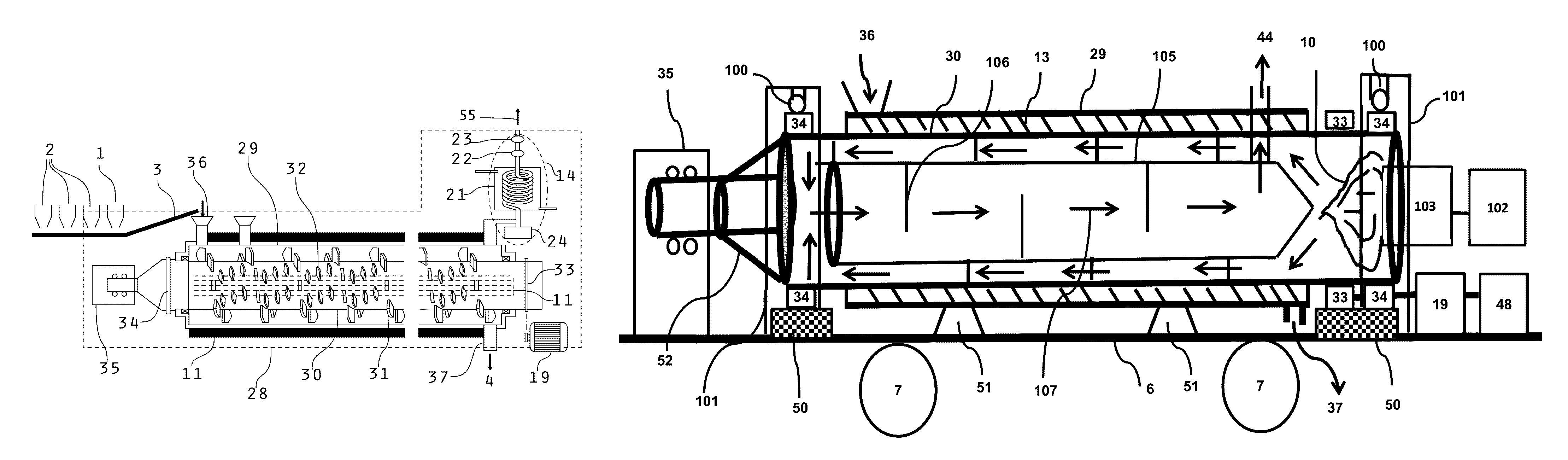

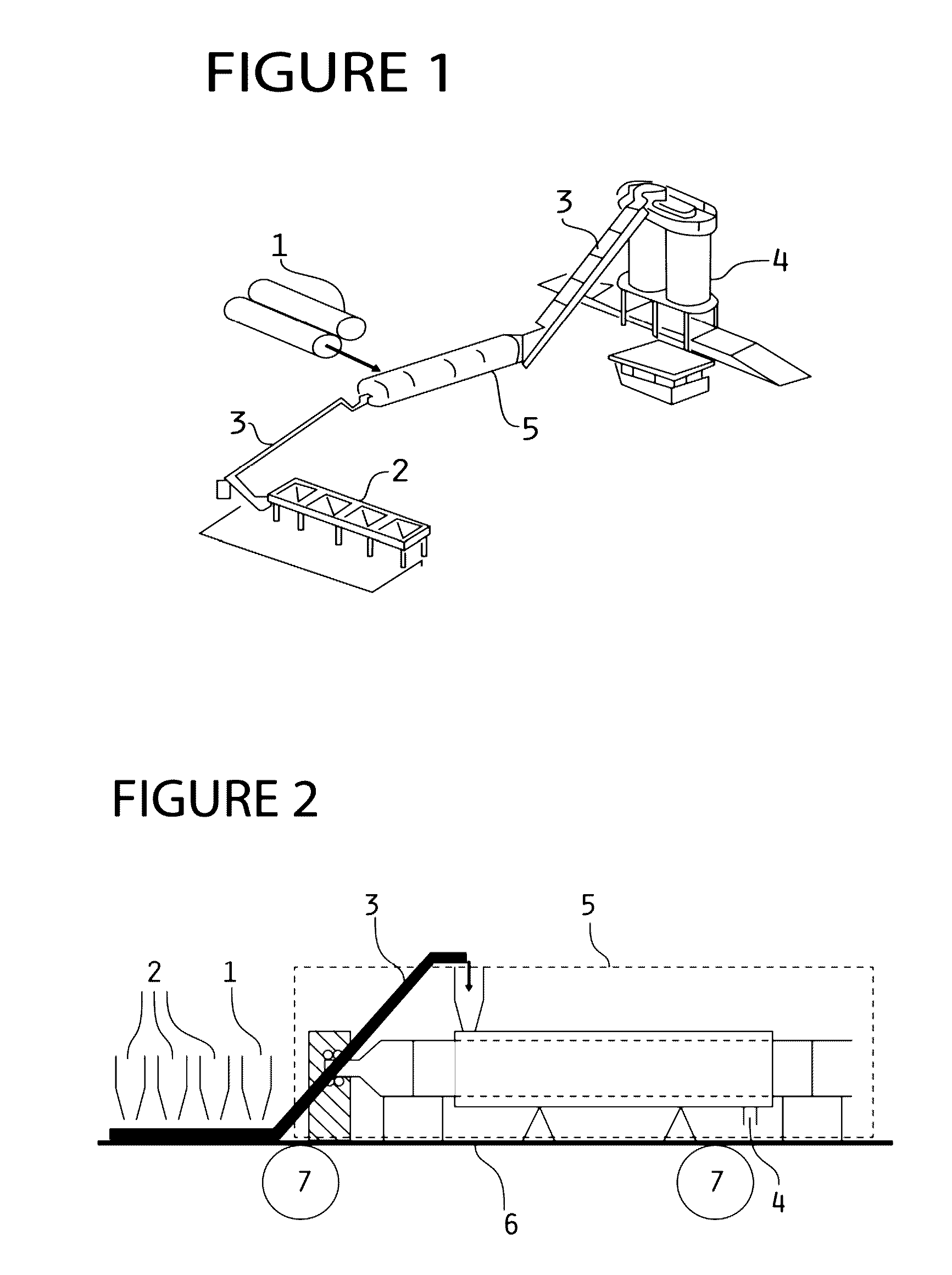

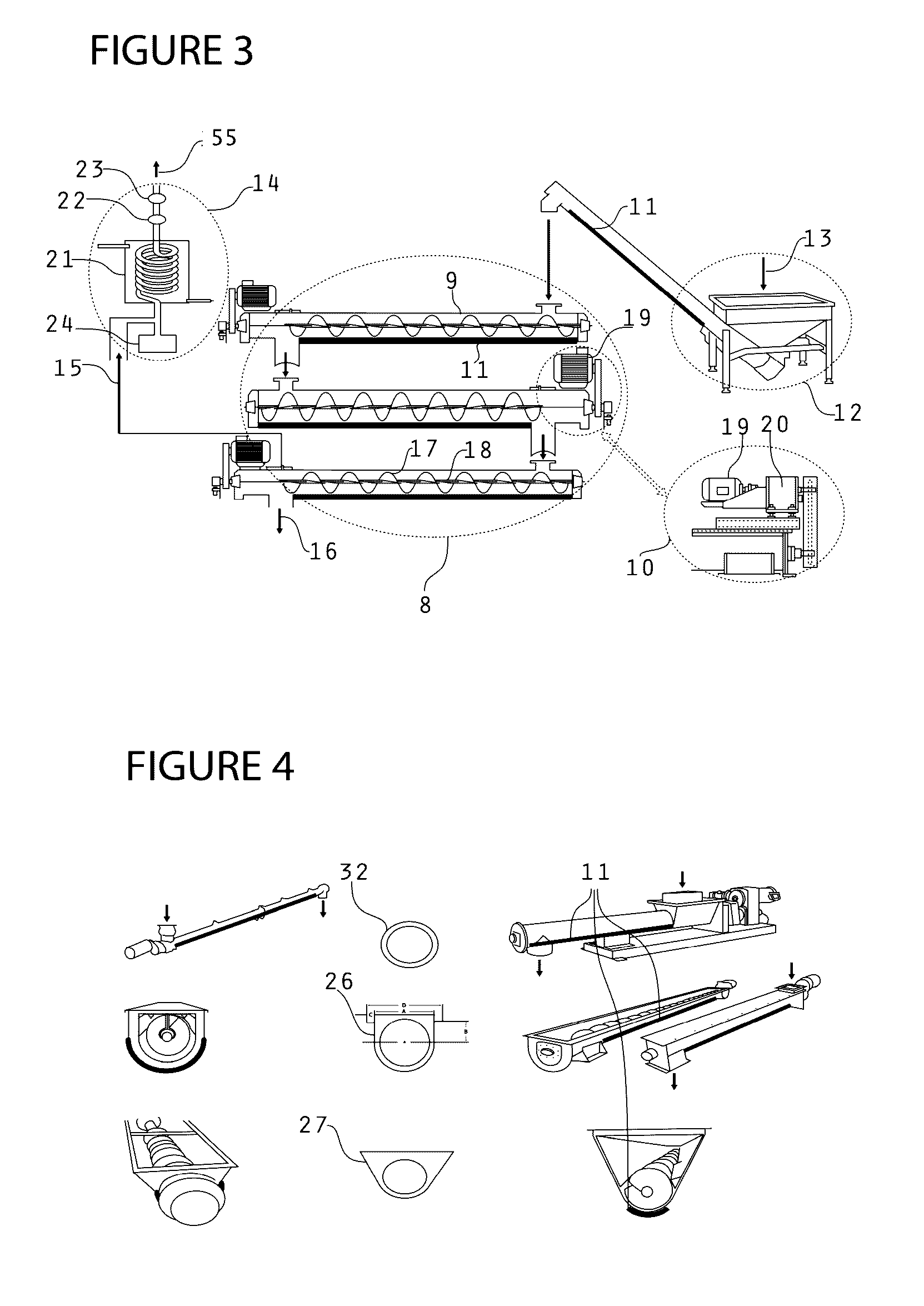

Hot (or warm) mix asphalt plants capability of producing up to 100 percent RAP (or ARS) recycled asphalt mixes

ActiveUS9566557B2Reduce air pollutionIncrease energy densityRotating receptacle mixersRotary stirring mixersCombustionEngineering

A hot mix asphalt (HMA) or warm mix asphalt (WMA) plant features material transfer by shear action of segmented screws and directional flights standing on an inner drum. Indirect convective material heating is initiated by a heating source located inside of the inner drum. Material mixing, heating, melting, and uniform coating, all take place as a single simultaneous process. As the result of processing, regular HMA (or WMA) or up to 100% RAP (or ARS) recycled HMA (or WMA) can be produced. Many heat sources, such as a conventional oil burner and the surface combustion burner, may also be utilized in the plant. The plant may be combined with paving units for an integrated, mobile paving system.

Owner:HUH JUNG DO

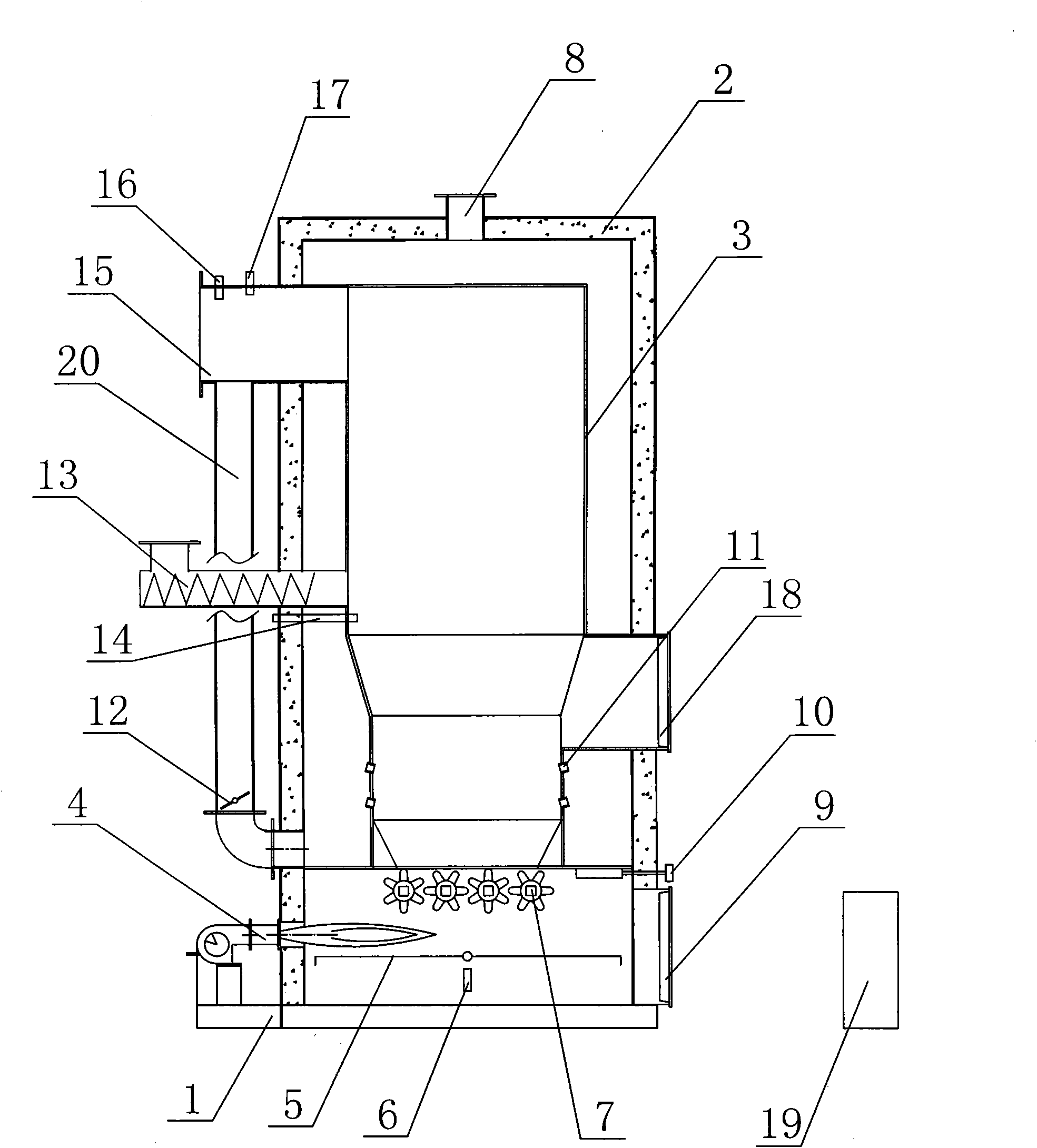

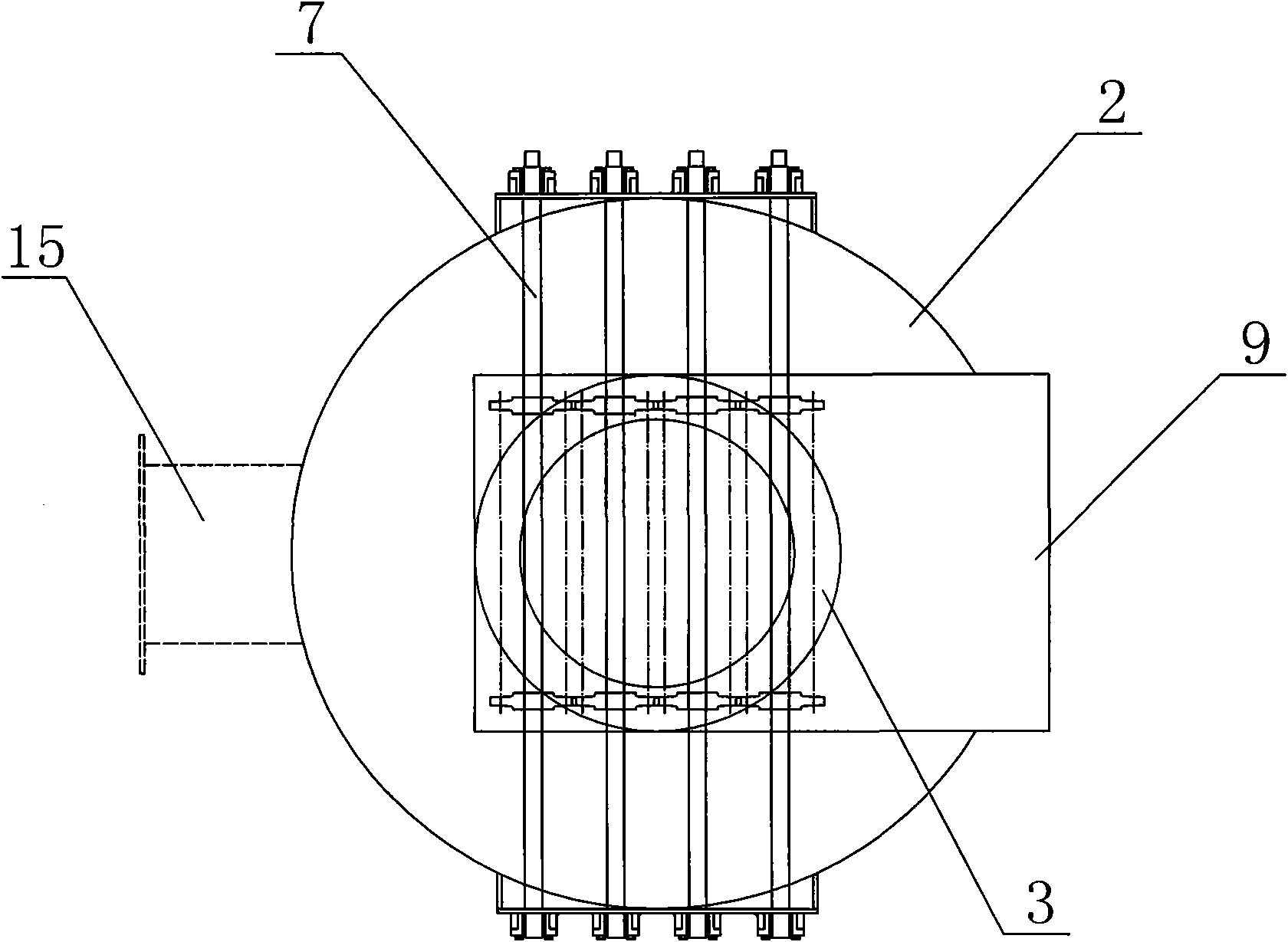

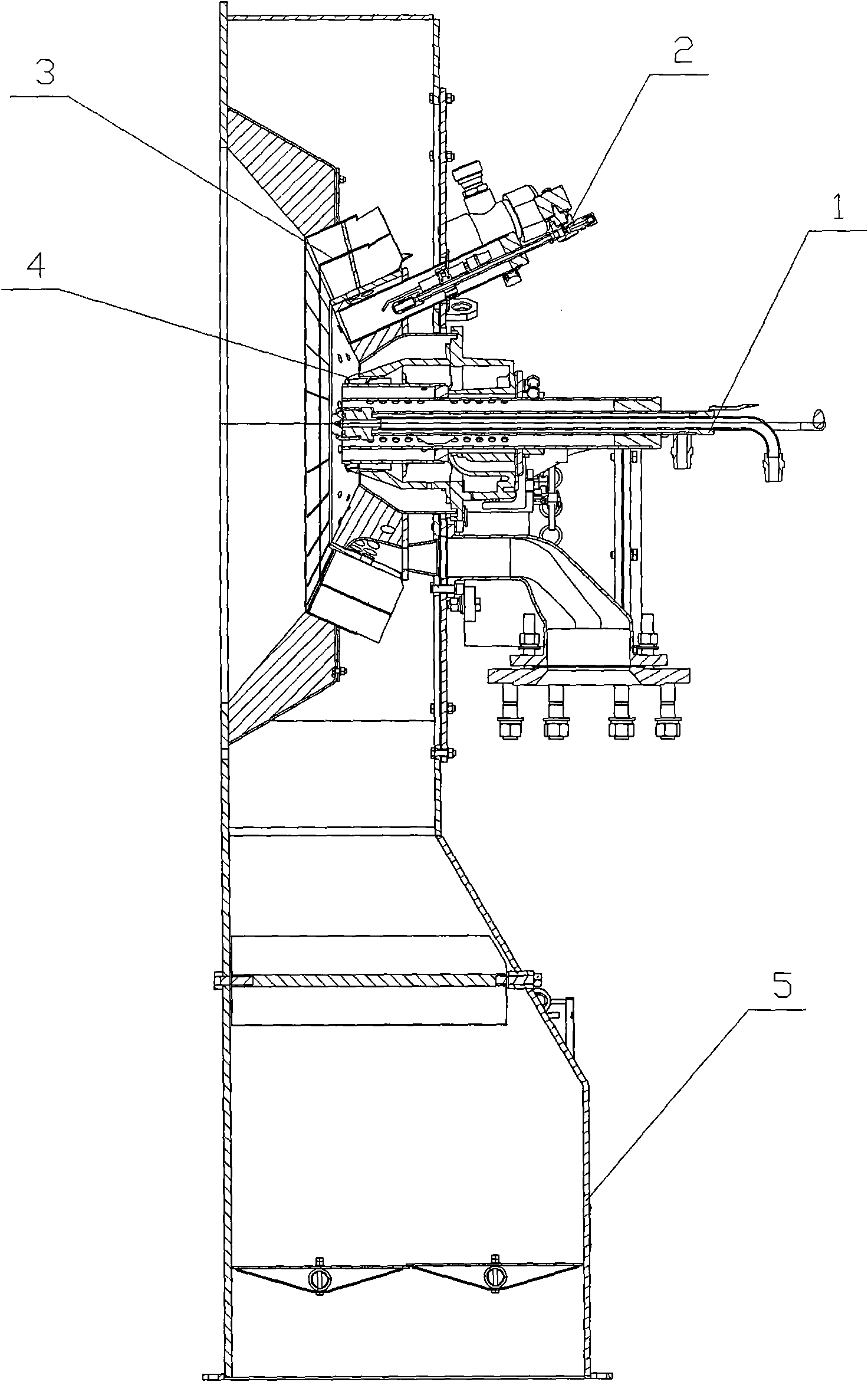

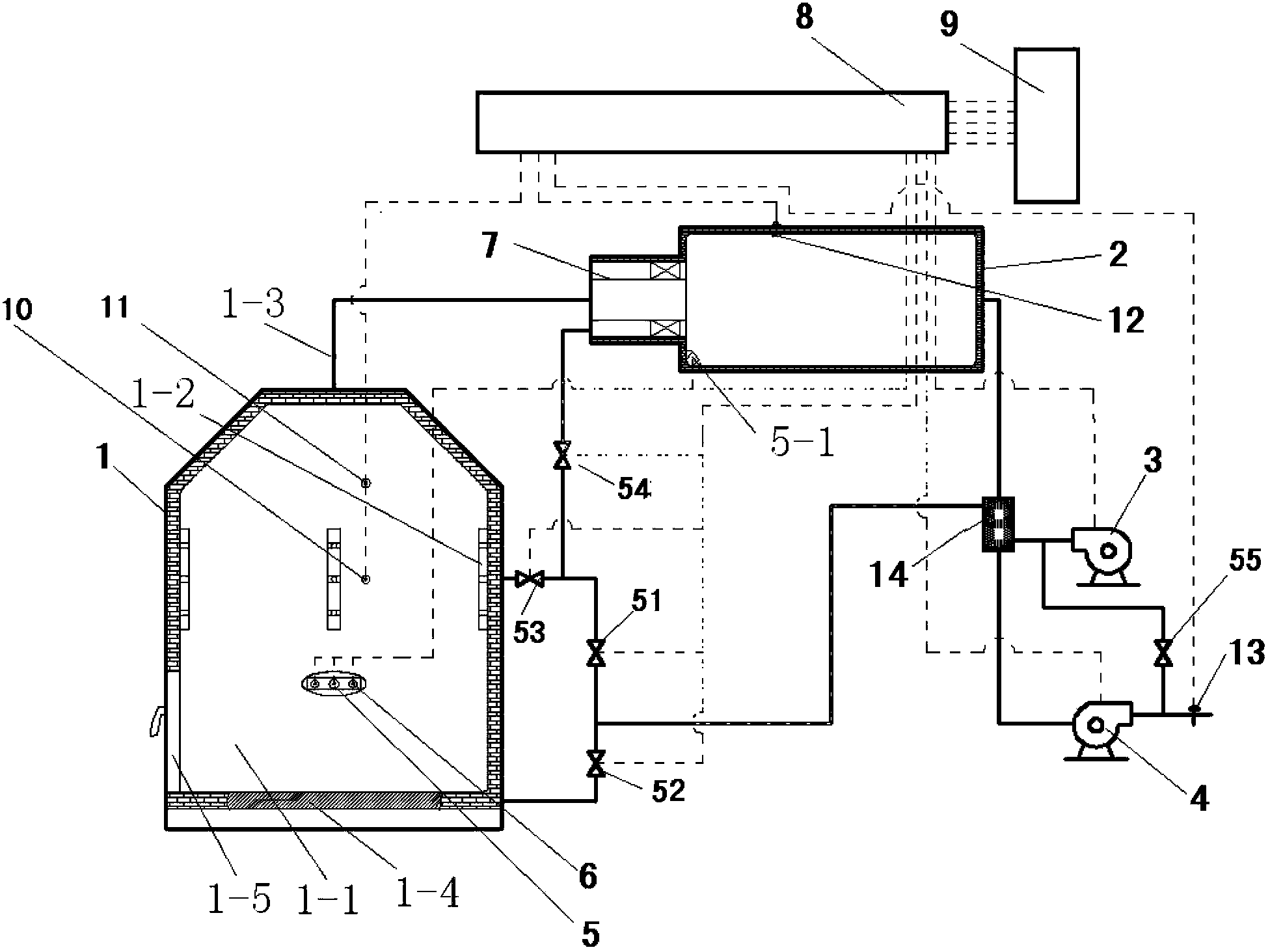

Combustion system with dual combustion chambers for marine incinerator and control method thereof

ActiveCN103363526AEmission reductionImprove combustion efficiencyIncinerator apparatusCycloneCombustion chamber

The invention discloses a combustion system with dual combustion chambers for a marine incinerator and a control method thereof. The combustion system comprises an incinerator, a second combustion chamber, an air blower, a draught fan, a combustor, a cyclone, a control unit, auxiliary control equipment, a temperature sensor, a pressure sensor, a second combustion chamber temperature sensor, an air outlet temperature sensor, a valve, a heat exchanger device and the like, wherein the second combustion chamber is a horizontal cyclone combustion chamber; swirl vanes and a dirty oil combustor are arranged inside the second combustion chamber; the second combustion chamber is used for performing secondary combustion on flue gas which is not combusted fully; the flue gas outlet of the second combustion chamber is connected with the heat exchanger, and primary and secondary air are heated by using residual heat of flue gas; the flue gas outlet of the second combustion chamber is communicated with the atmospheric air through the draught fan; and a ventilation branch is formed at a tail flue gas outlet, and is connected with primary and secondary air pipelines to prevent the exhaust gas temperature from getting too high. According to the control method, various possible conditions occurring in the working condition of the incinerator are considered comprehensively, so that the combustion efficiency is increased, efficient and stable running of the marine incinerator is realized, and the pollutant emission is reduced effectively.

Owner:SOUTH CHINA UNIV OF TECH

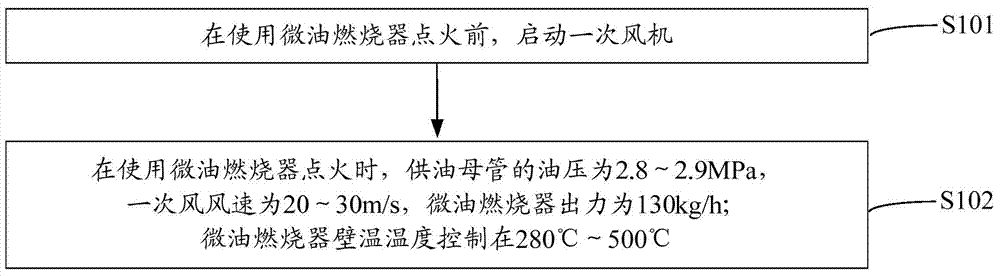

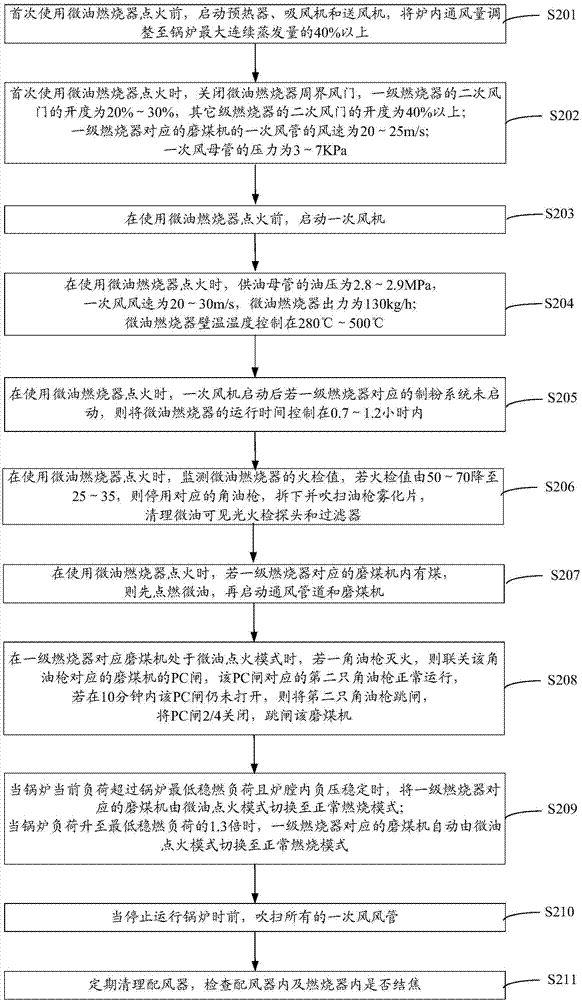

Method for controlling operation of minitype oil burner of 1050 MW ultra-supercritical pulverized coal boiler

The invention relates to a method for controlling the operation of a minitype oil burner of a 1050 MW ultra-supercritical pulverized coal boiler. The method for controlling the operation of the minitype oil burner of the 1050 MW ultra-supercritical pulverized coal boiler comprises the steps that a primary draught fan is started before the minitype oil burner is used for ignition; when the minitype oil burner is used for ignition, the oil pressure of a main oil supply pipe is 2.8-2.9 Mpa, the primary wind speed is 20-30 m / s, the output force of the minitype oil burner is 130 kg / h, and the temperature of the wall of the minitype oil burner is controlled to be 280-500 DEG C. According to the method for controlling the operation of the minitype oil burner of the 1050 MW ultra-supercritical pulverized coal boiler, the primary draught fan is started before the minitype oil burner is used for ignition, when the minitype oil burner is used for ignition, the oil pressure of the main oil supply pipe is 2.8-2.9 Mpa, the primary wind speed is 20-30 m / s, the output force of the minitype oil burner is 130 kg / h, and the temperature of the wall of the minitype oil burner is controlled to be 280-500 DEG C, in this way, the situation that the minitype oil burner is coked due to the fact that the temperature of the wall is too high is solved, and normal operation of the burner and the boiler is guaranteed.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com