Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Solve easy burns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

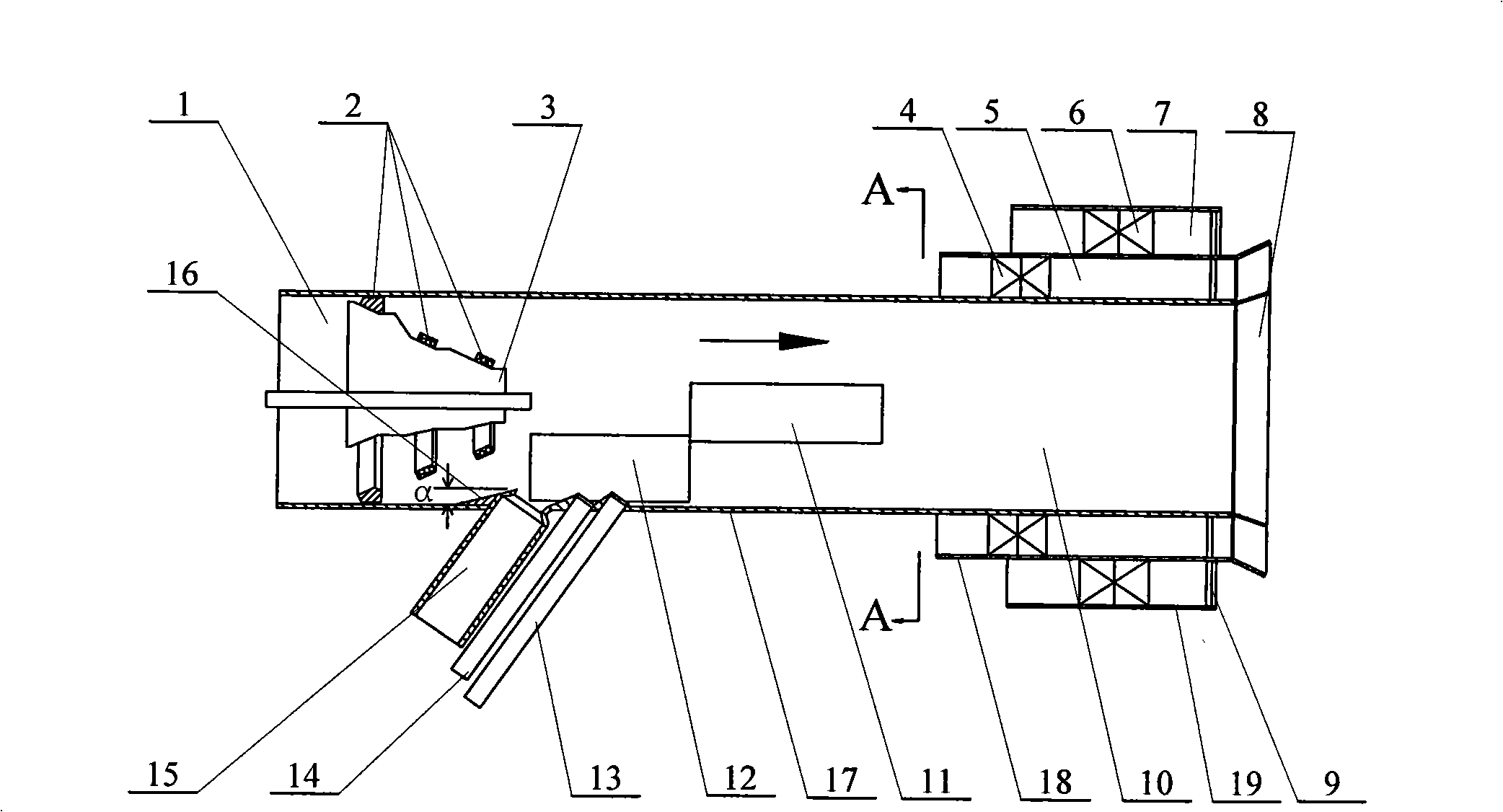

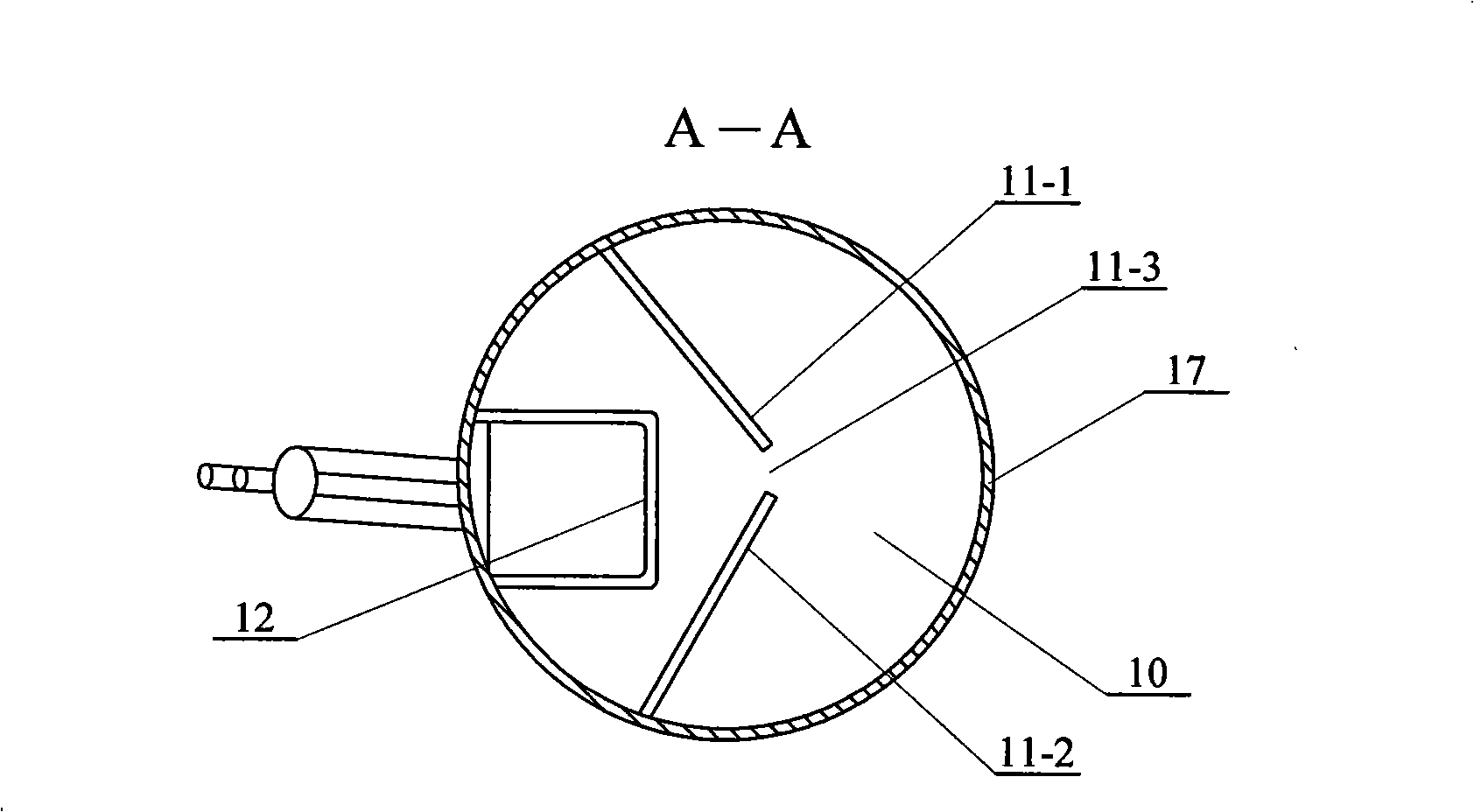

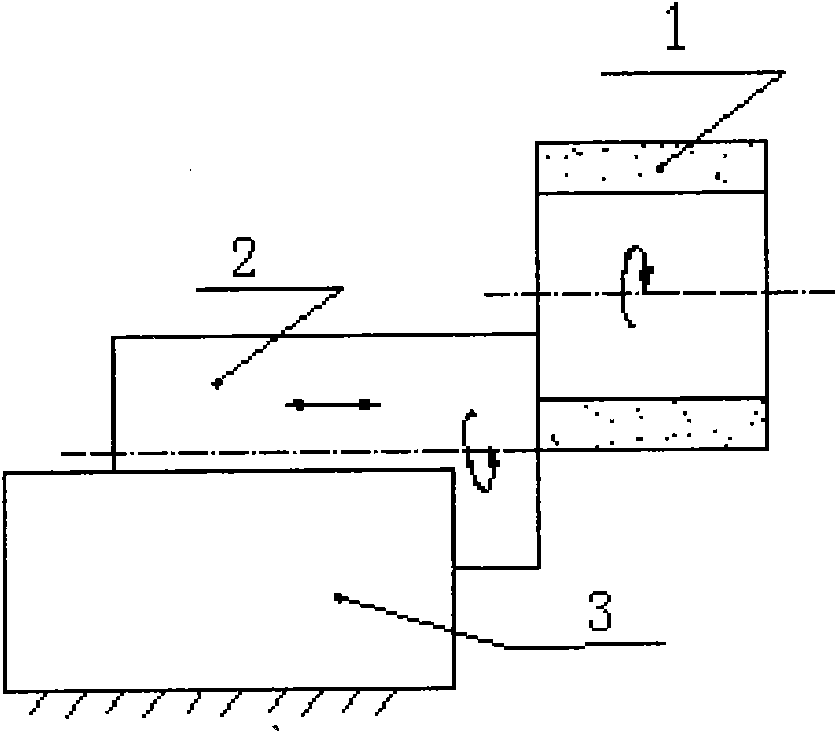

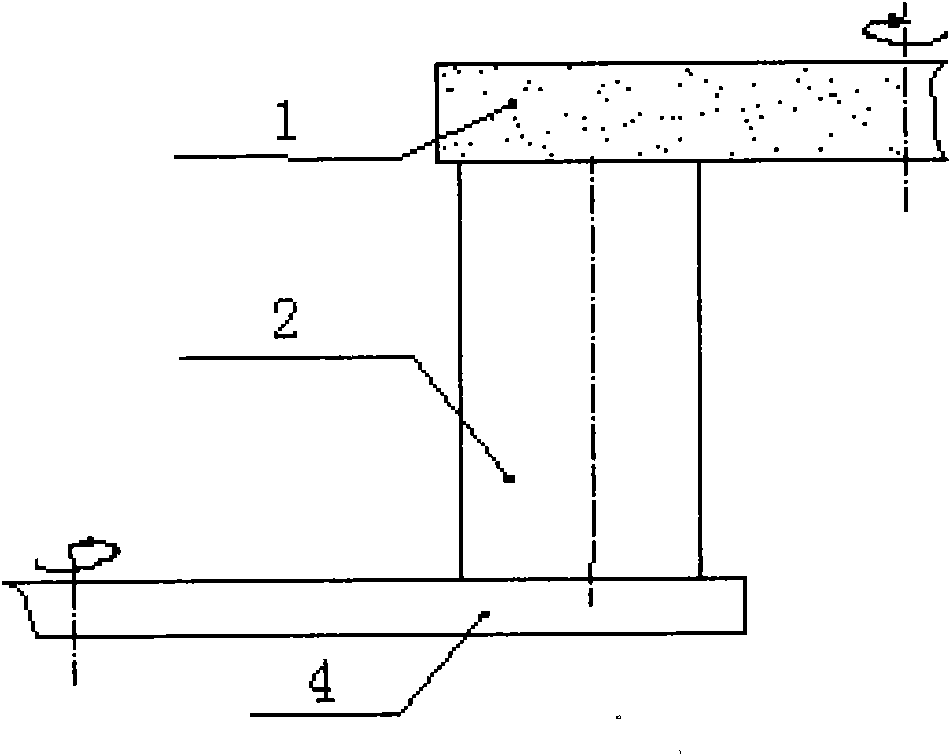

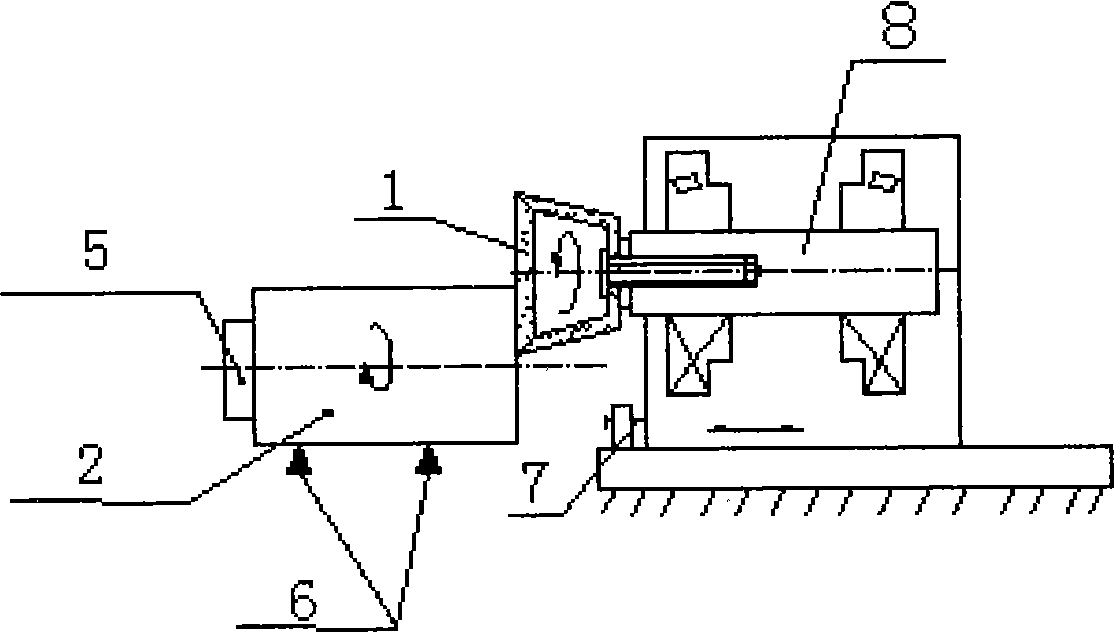

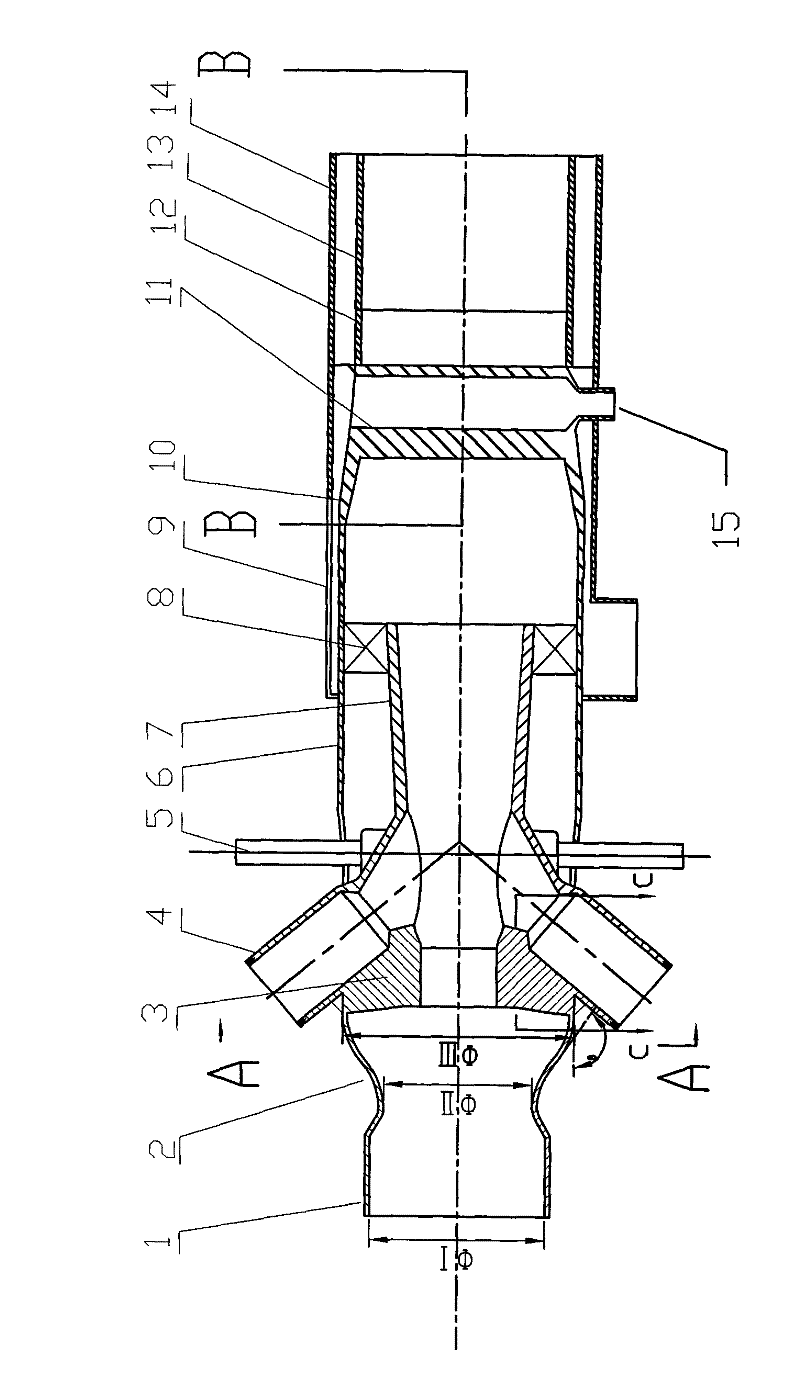

Side direction multilevel open type igniting center powder feeding vortex combustor of small oil mass gasification combustion

InactiveCN101329064ASmoke resistance is smallReduce ignition energyPulverulent fuel combustion burnersCombustion chamberLarge capacity

The invention discloses a low fuel-consumption gasified-combustion, side-multilevel open-ignition and central powder-supply turbulent burner which relates to the turbulent burner and aims at solving the problems about how to reduce the large quantity of coal powder to be ignited when the existing micro fuel-consumption ignition turbulent burner is applied to large-volume boilers, and how to conserve fuel consumed by a power-station boiler on the conditions that the boiler is started and stopped and works with low load when reducing the NOx discharged by a large-scale coal powder boiler adopting the turbulent burner. A first-class firebox of the invention is fixed in a first air-channel pipe at the front end of a support board; a second-class firebox is fixed in a first air-channel pipe at the front end of the first-class firebox; a third-class firebox is arranged in the first air-channel pipe at the front of the second-class firebox; a primary fuel-gun is communicated with a primary air channel of the burner. In the invention, the coal powder is combusted under a low oxygen reduction condition to prolong the stay time of the coal powder so as to control the generation of consumption-typed NOx. As the secondary air is divided into two pars of inner and outer, classified combustion is formed, low NOx discharge is realized and fuel is saved.

Owner:HARBIN INST OF TECH

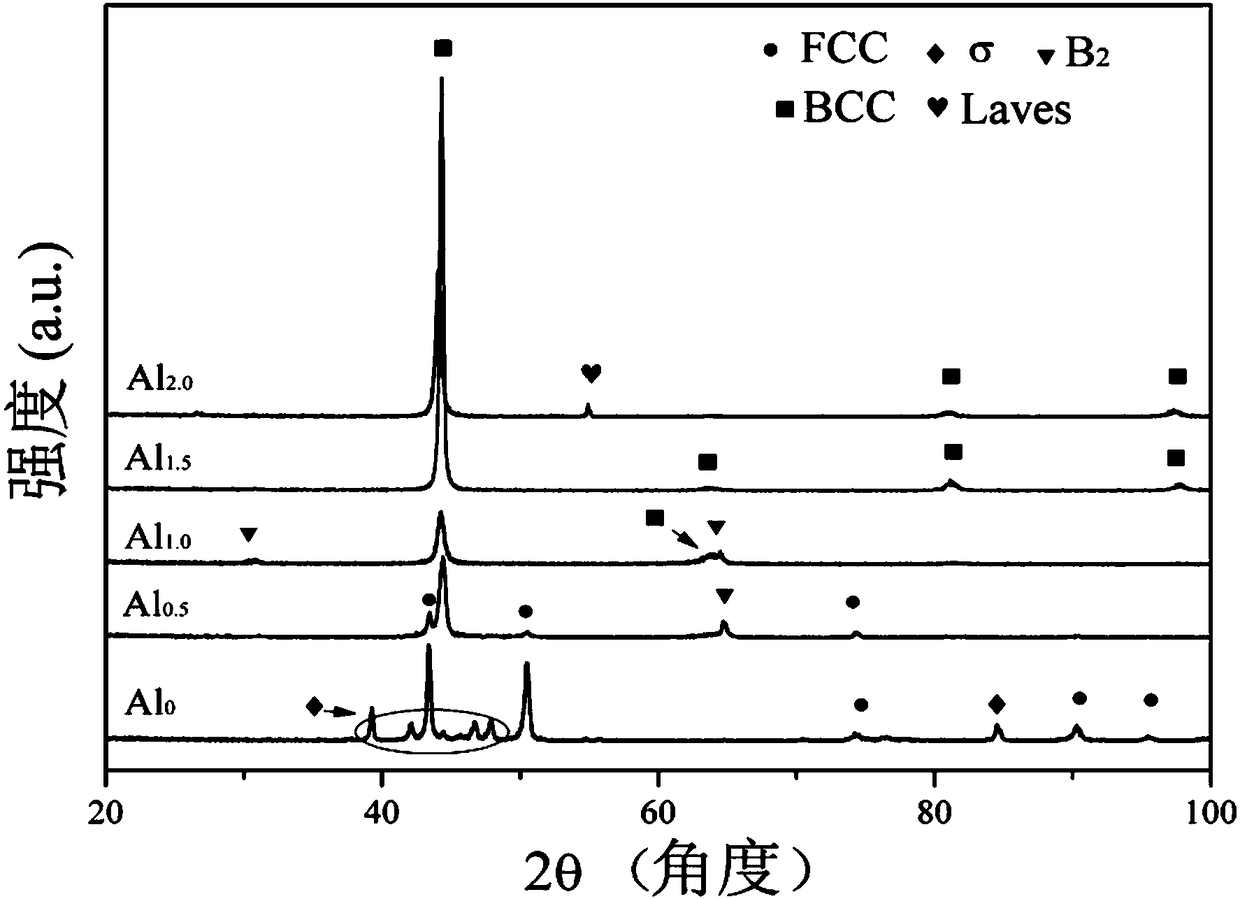

High-strength refractory six-element high-entropy alloy CoCrFeNiVAlx and preparation method thereof

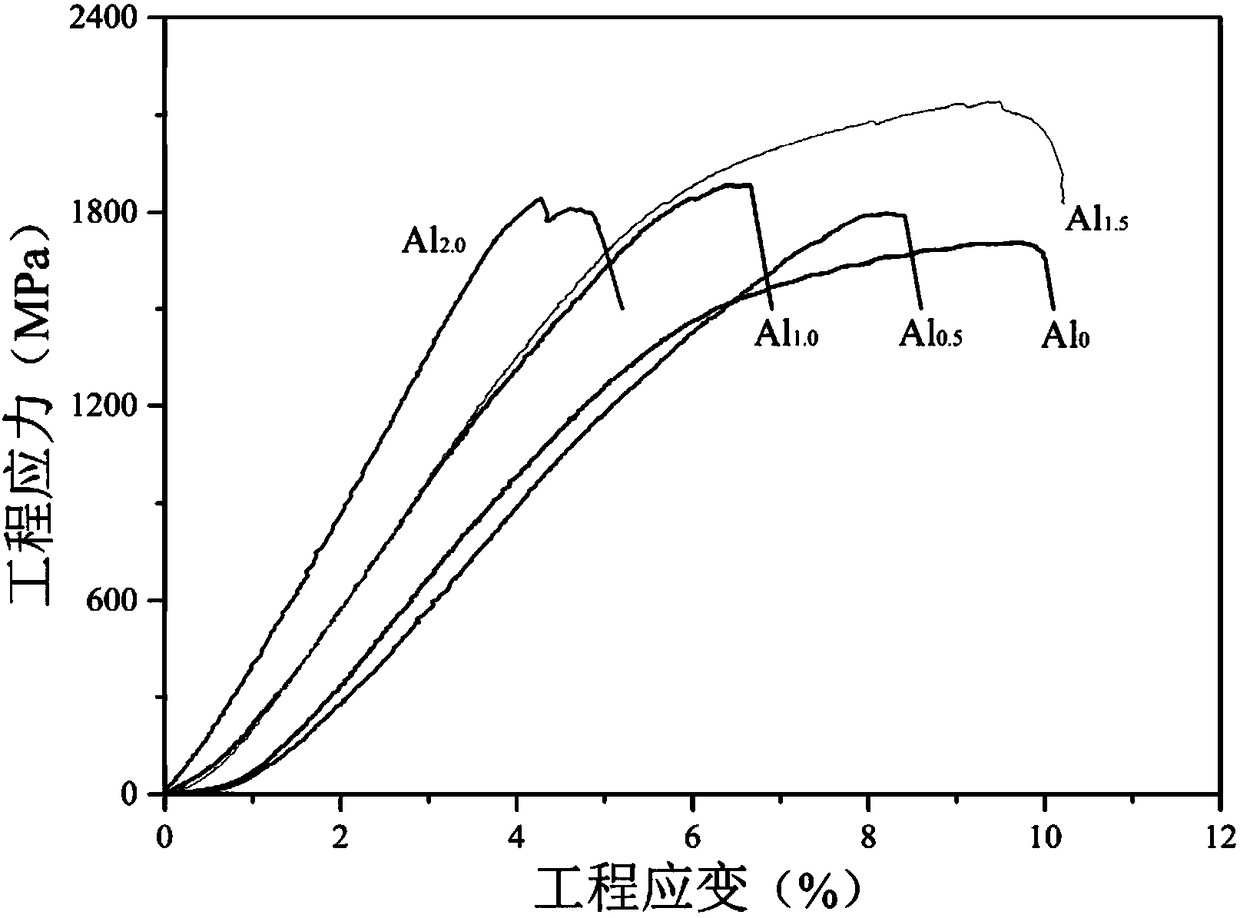

The invention discloses a high-strength refractory six-element high-entropy alloy CoCrFeNiVAlx and a preparation method thereof. The high-strength refractory six-element high-entropy alloy is composedof cobalt, chromium, iron, nickel, vanadium and aluminum which all have the purity of at least 99.9%; and all the elements are calculated according to the atomic percent, specifically, Co is 14-20 at%, Cr is 14-20 at%, Fe is 14-20 at%, Ni is 14-20 at%, V is 14-20 at%, and Al is 0-30 at%. The alloy is prepared through an intermediate alloying method, and the preparation steps include that Co, Ni,Fe and Al which are low in melting point are mixed and molten, Cr and V which are high in melting point are mixed and molten, smelting is performed repeatedly for several times, then two intermediatealloys are smelted, and smelting is performed repeatedly for several times so as to guarantee the uniformity. By means of the high-entropy alloy CoCrFeNiVAlx obtained through the method, the problemsthat Al is prone to being damaged by burning and multi-element alloy smelting is non-uniform can be solved excellently, the strength, hardness and plasticity are high, and the high-strength refractorysix-element high-entropy alloy CoCrFeNiVAlx and the preparation method thereof can be applied to the fields of aerospace, mechanical heavy industries and the like.

Owner:GUANGXI UNIV

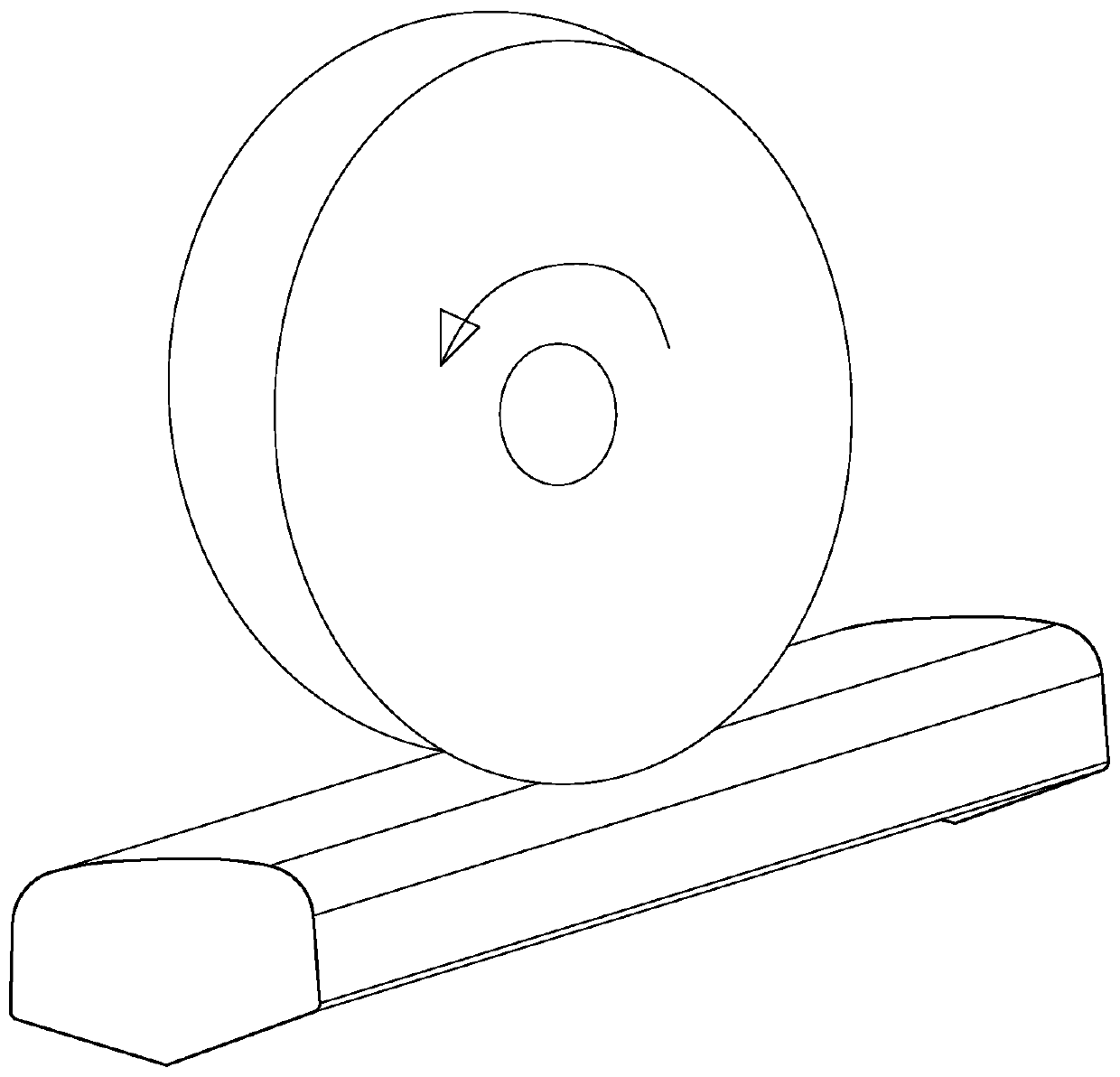

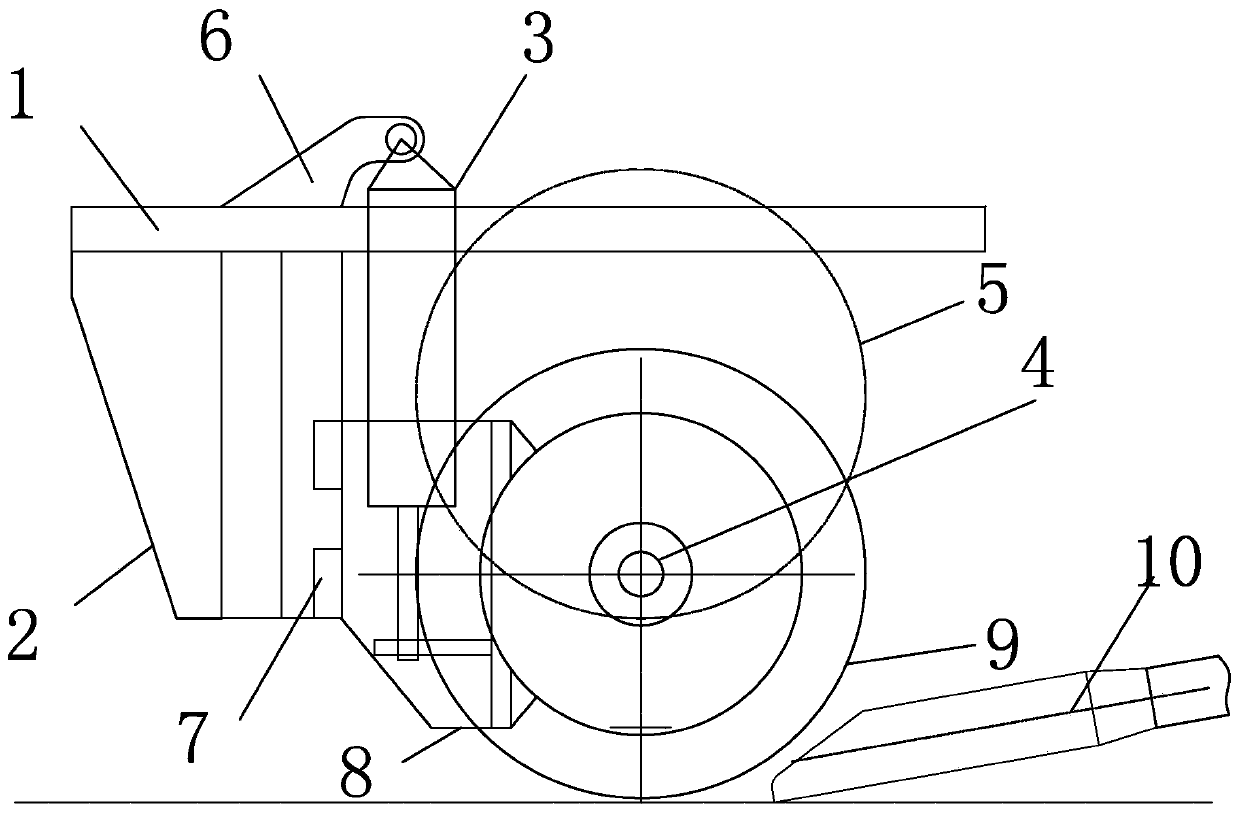

Method for performing precision grinding to end surface of super-large cylindrical roller

InactiveCN101972957ASolve the problem of installation and positioningSolve control problemsPlane surface grinding machinesMagnetic polesGrinding wheel

The invention discloses a method for performing precision grinding to the end surface of a super-large cylindrical roller. The method is as follows: one end surface of the cylindrical roller is closely adsorbed by a magnetic pole, the rolling surface of the cylindrical roller is positioned on a positioning mechanism which forms a certain angle to the vertical line, the roller rotates in the driving manner of rotating magnetic pole adsorption, the centre line of the roller is parallel to the rotating centre line of the grinding wheel while the roller and the grinding wheel rotate around the separate centre lines; a grinding head provided with the grinding wheel performs axial movement to grind; after the end surface of the roller is grinded, the grinding head moves backward, the processed workpiece is taken down; and another workpiece to be processed is arranged, the above steps are repeated to perform the next processing cycle. Compared with the prior art, the method of the invention can be used to position the workpiece stably and accurately; and the workpiece can operate steadily during processing, the grinding wheel is convenient for dressing, and the feeding position is easy to control.

Owner:LUOYANG LYC BEARING

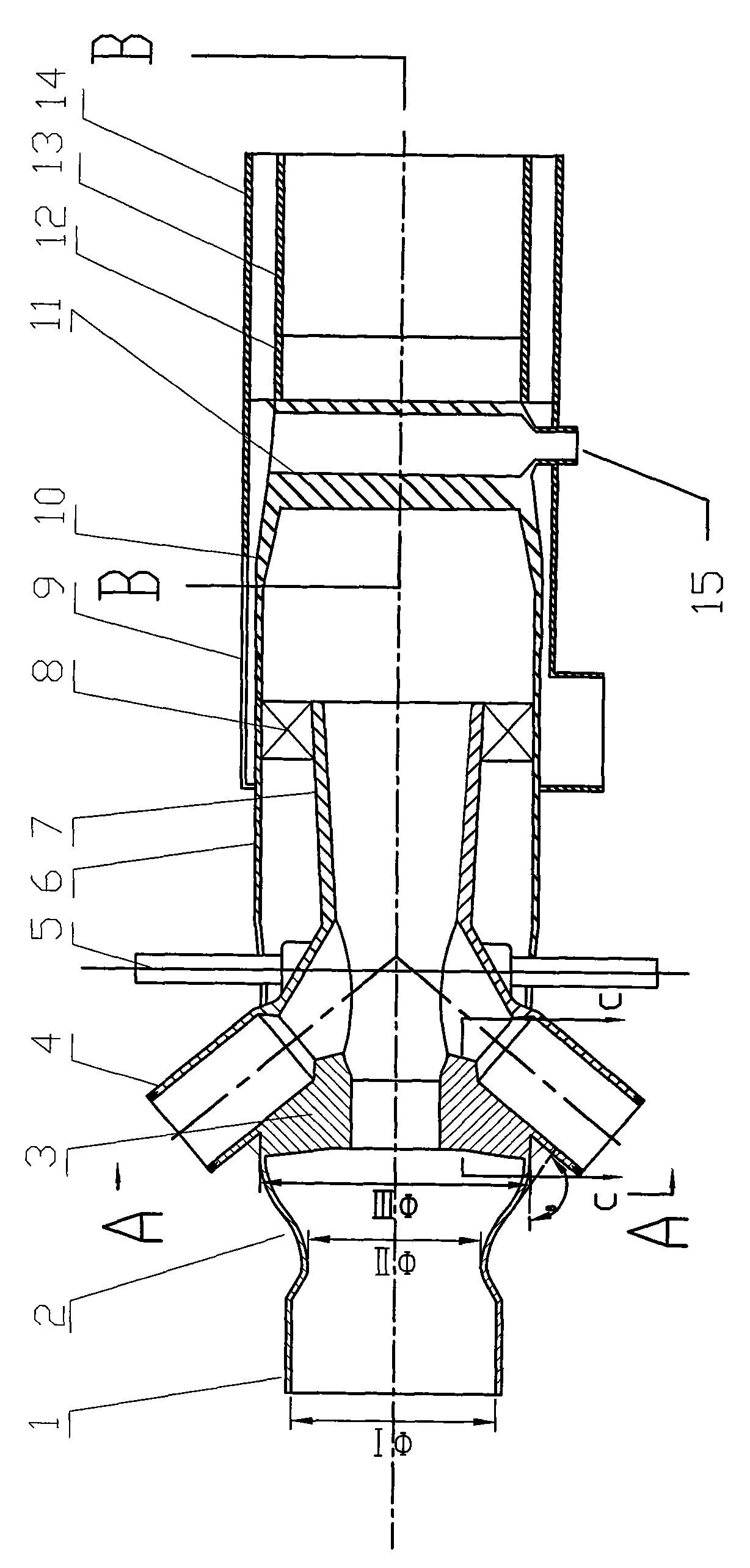

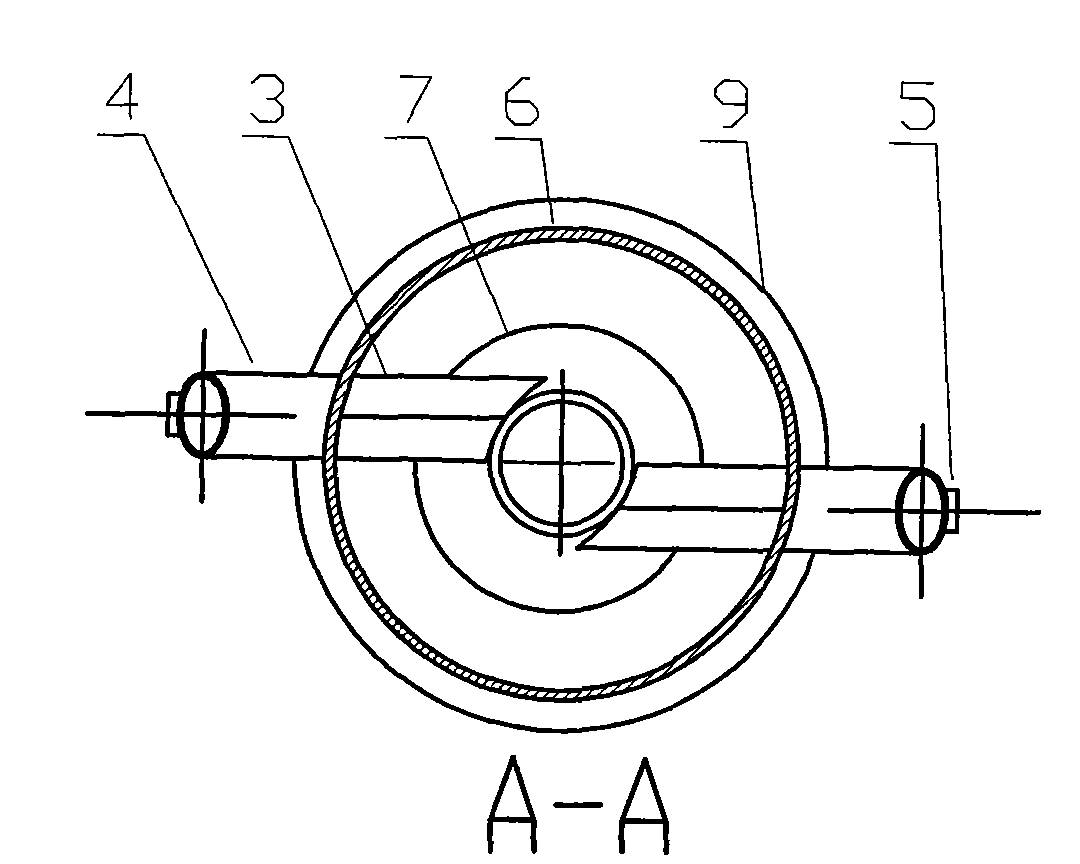

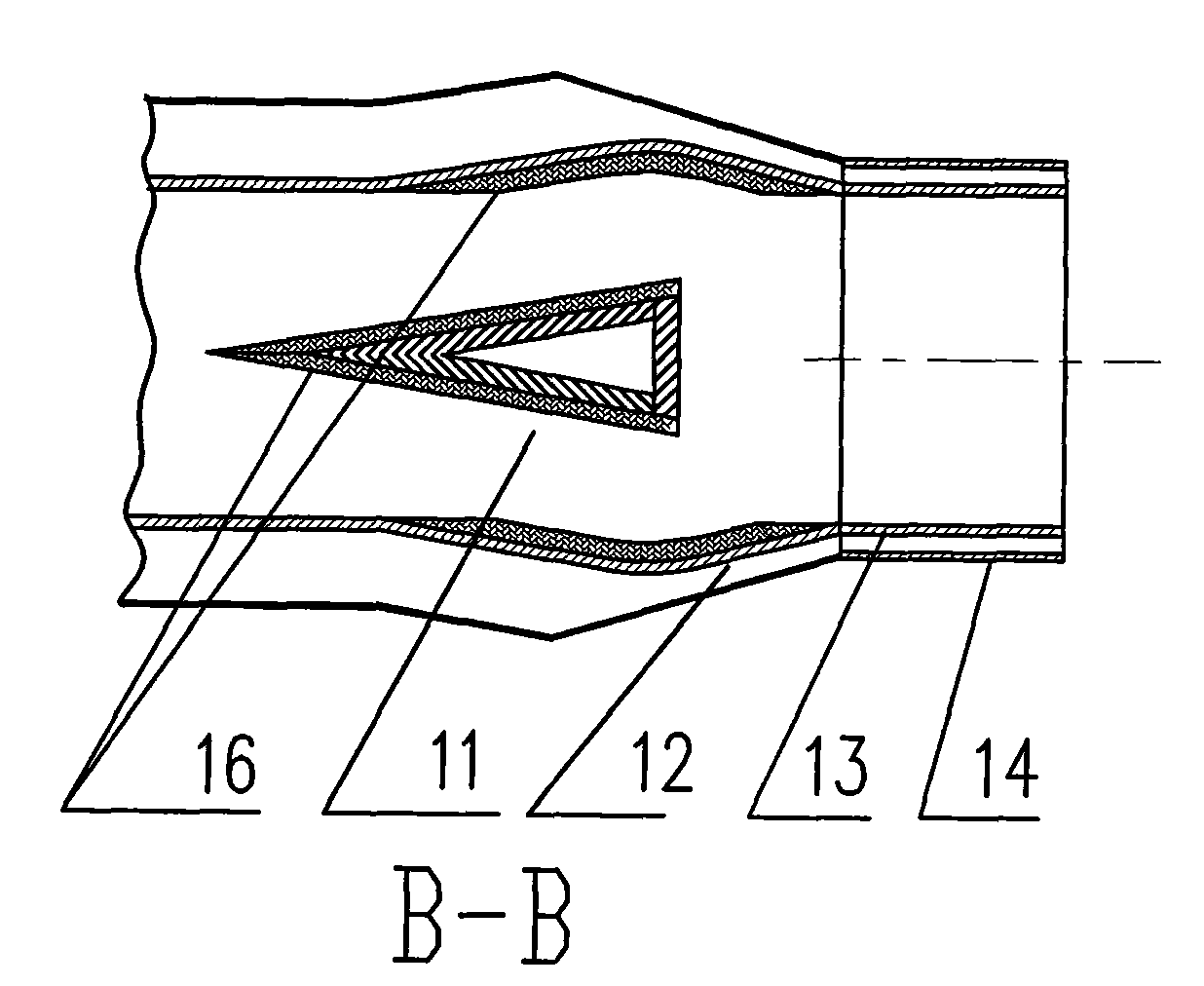

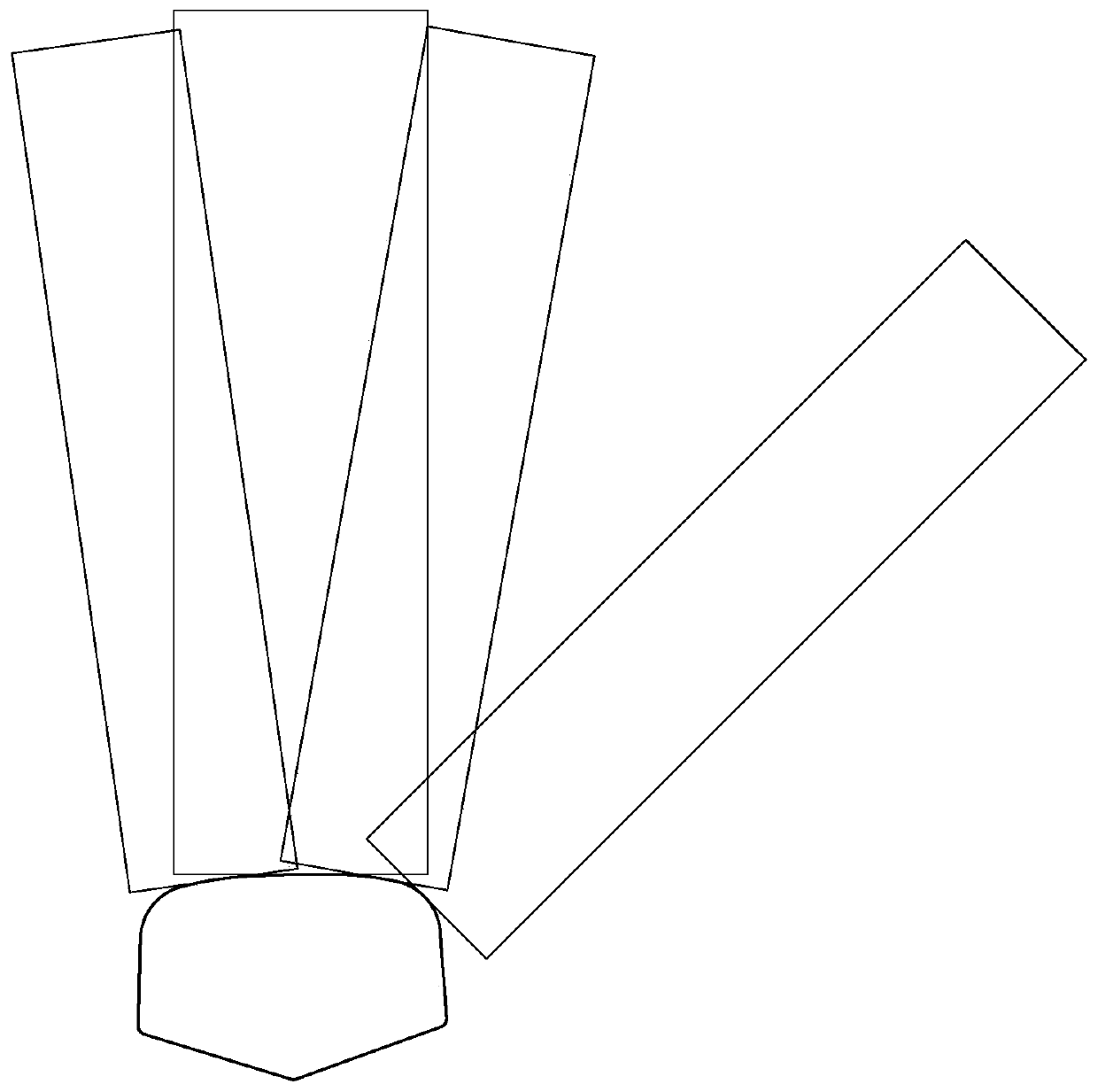

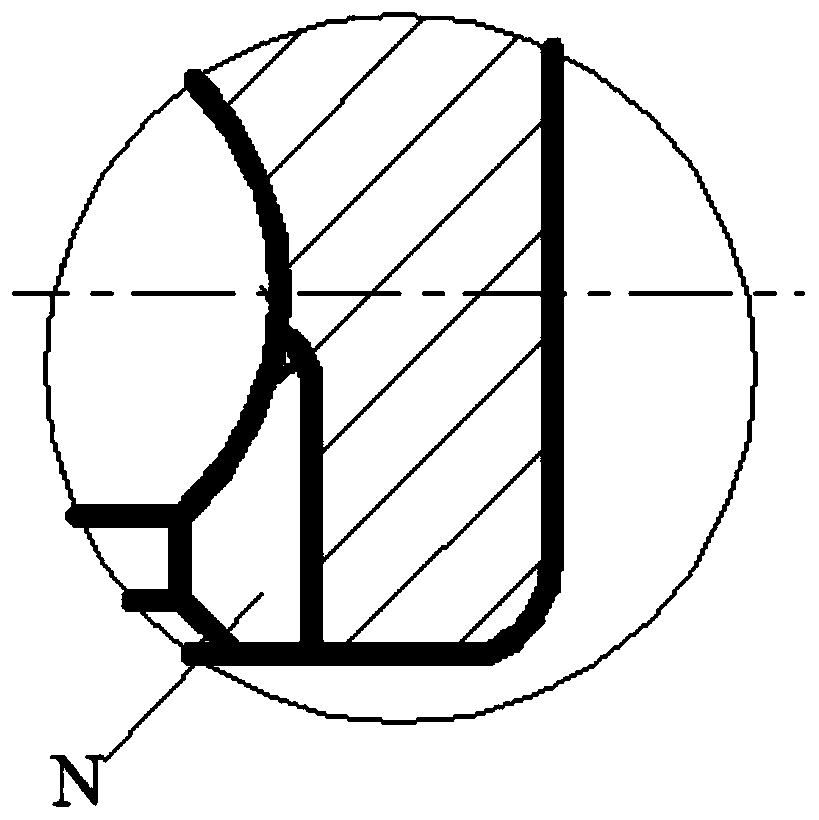

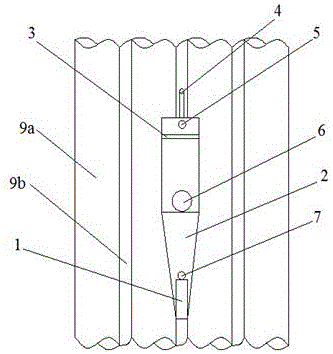

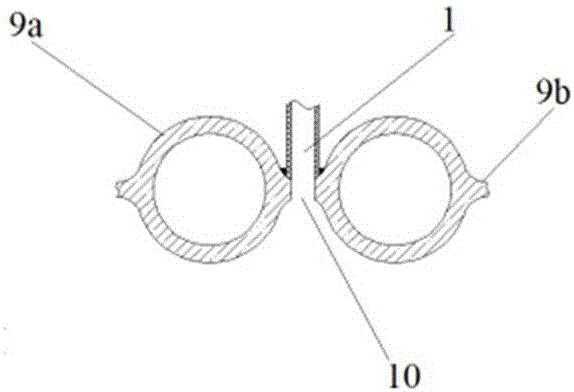

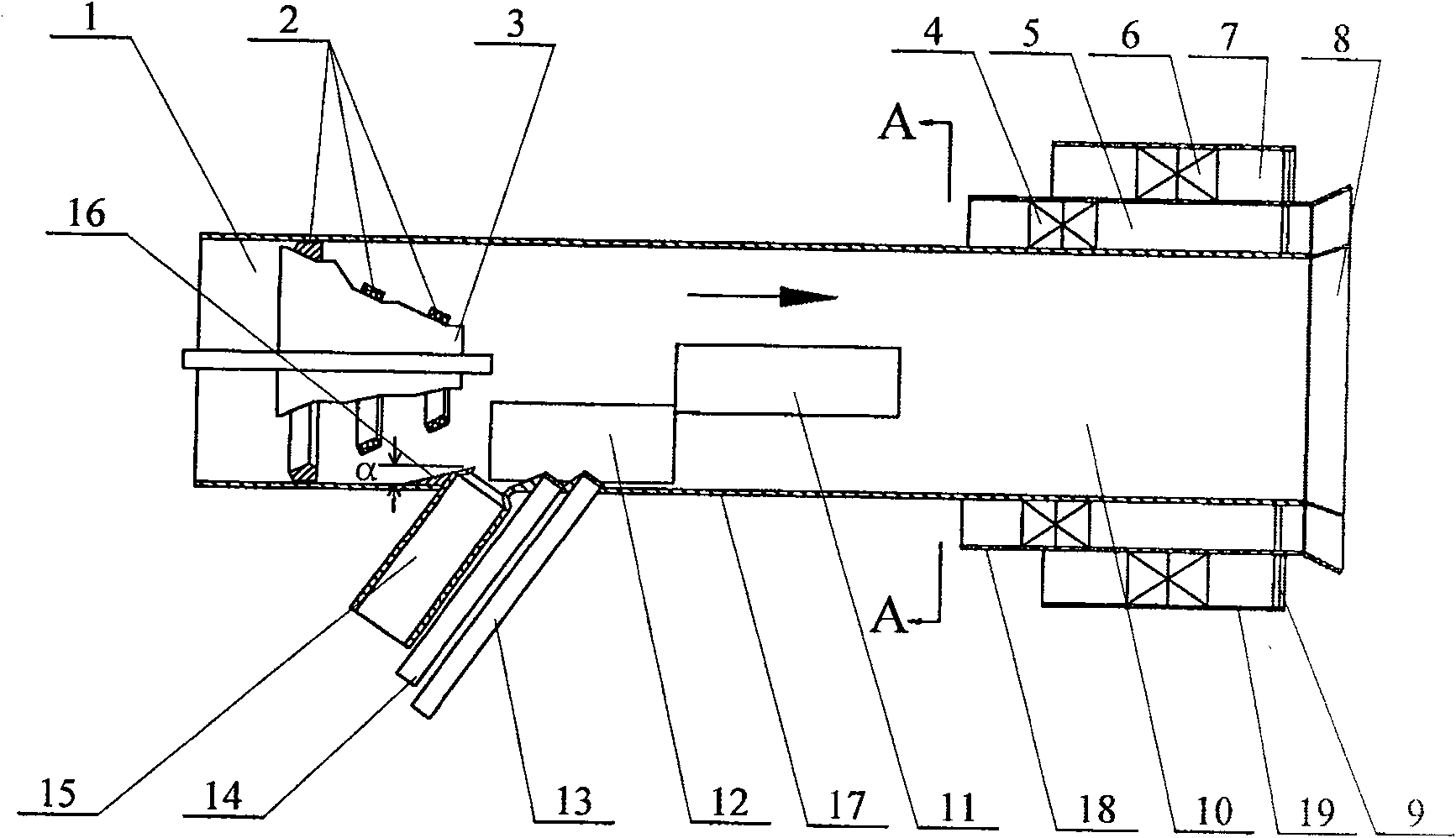

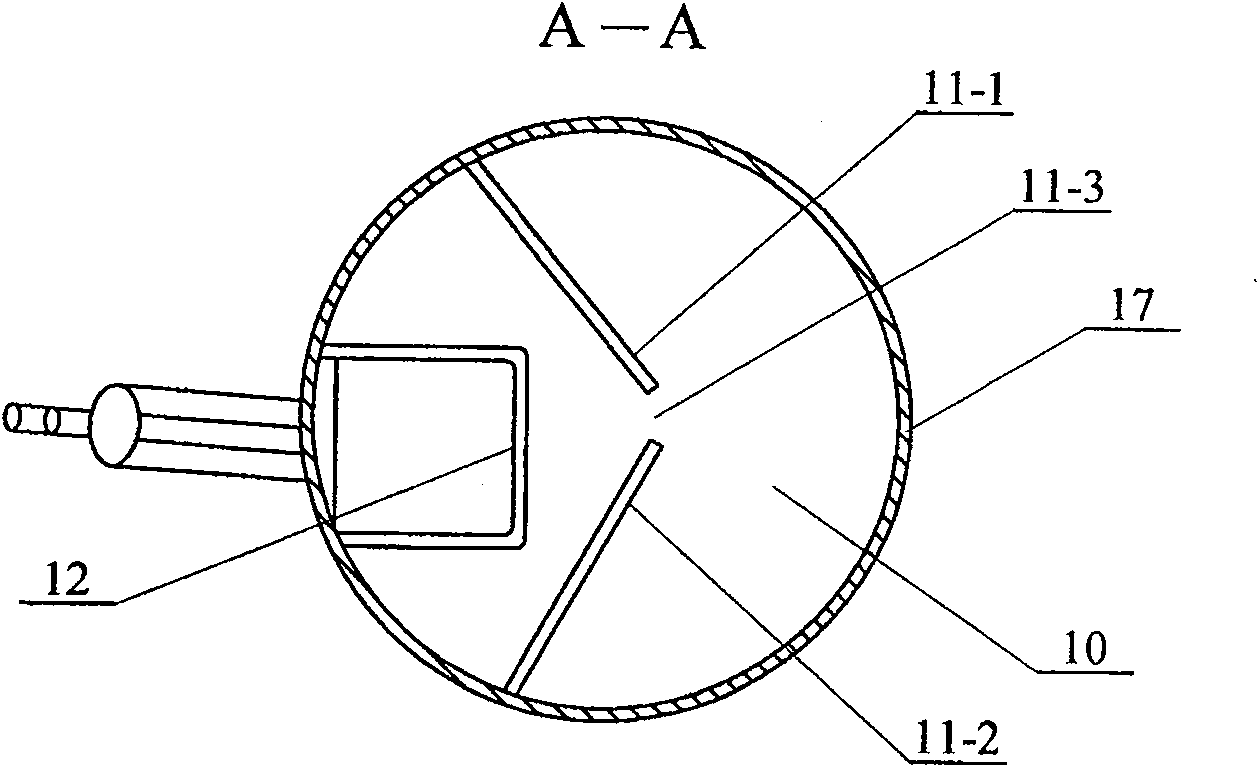

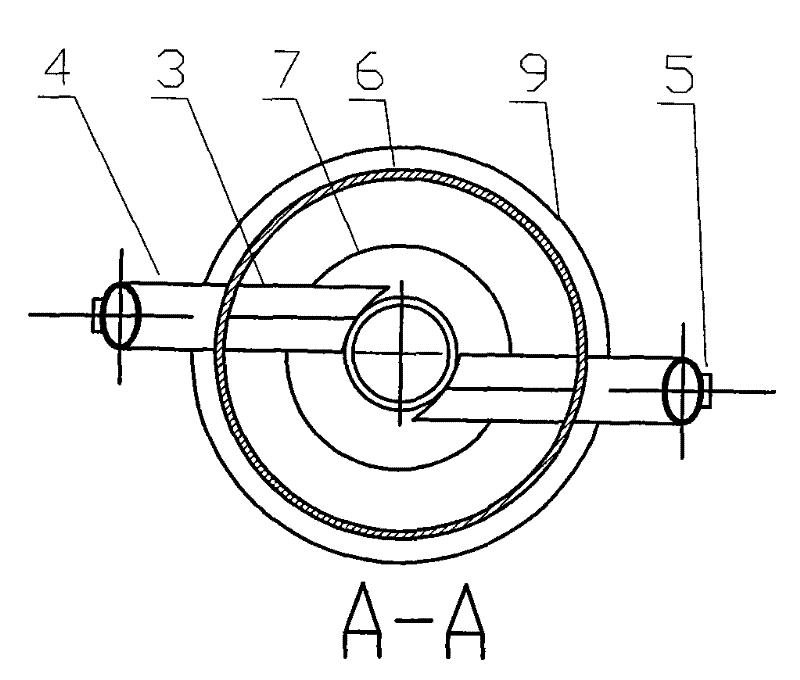

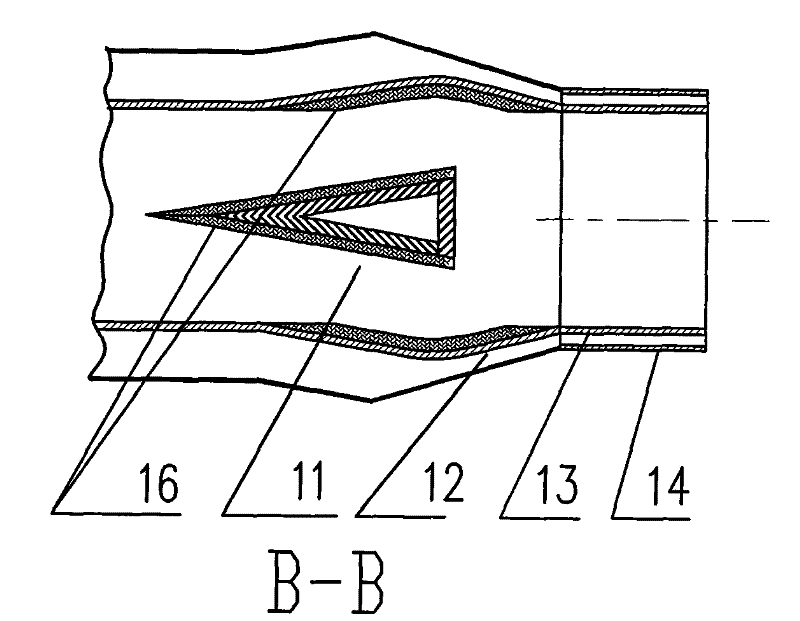

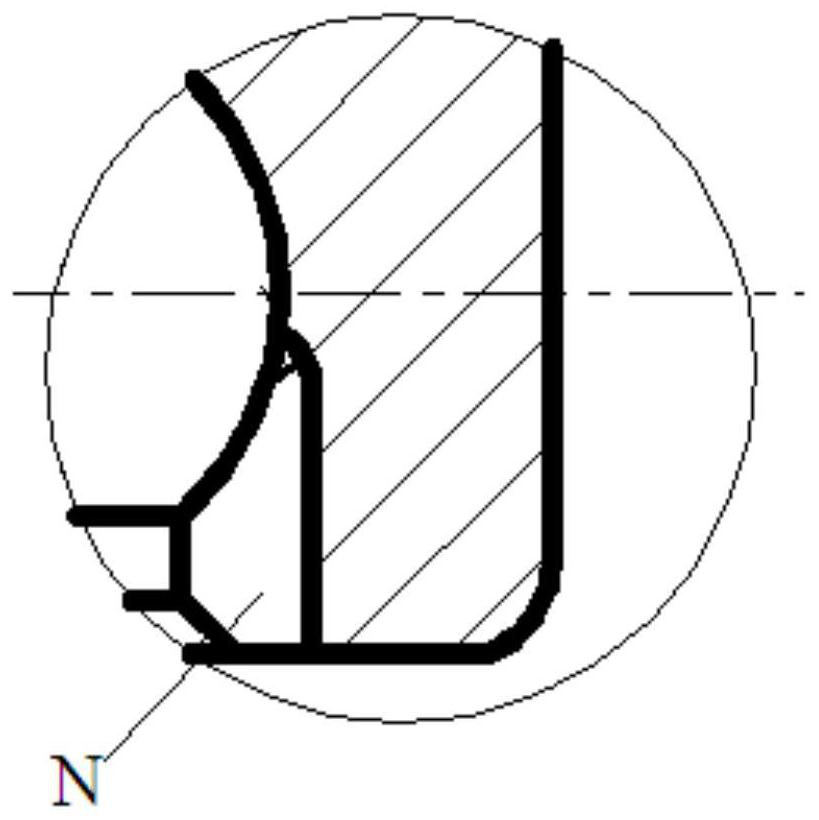

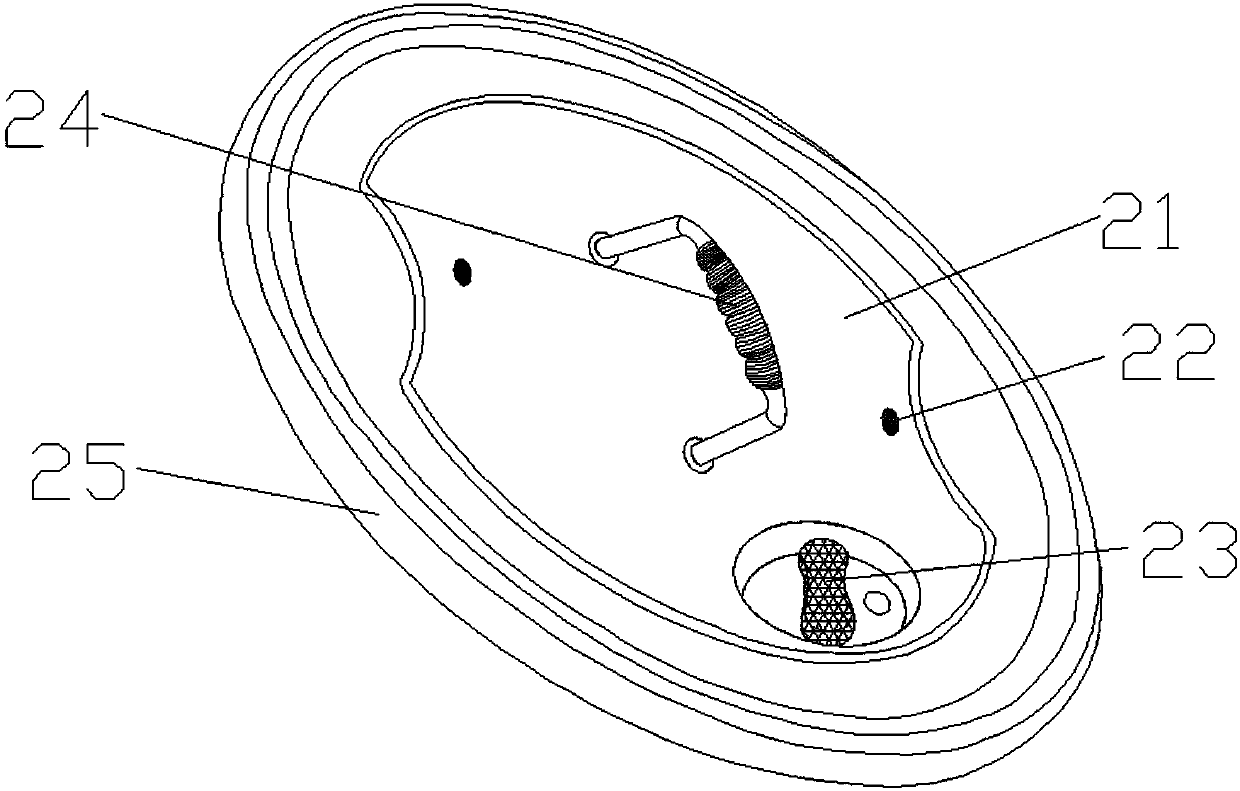

Inferior coal micro-oil ignition combustor

InactiveCN101603683AExtended service lifeSolve easy burnsPilot flame ignitersPulverulent fuel combustion burnersCycloneCombustion chamber

An inferior coal micro-oil ignition combustor comprises a streamlined air powder separation ring, a bidirectional cyclone oil combustor, a wing-shaped anti-friction block, a primary dense-phase coal powder combustion chamber, a secondary dilute-phase coal powder combustion chamber, a V-shaped cavity backflow blunt body, a circumferential cooling bellows and the like, employs a principle of gas-solid two phase flow separation, a principle of oil flame two-way cyclone ignition, backflow high-temperature flue gas of a blunt body, a principle of energy repeated utilization, a principle of coal powder graded ignition and energy gradual enlargement, forms a power field with low air speed, high density, strong eddy flow, strong backflow in the combustor, and creates favorable condition for firing coal powder, so as to effectively solve the problems of firing difficulty and low burn-out ratio of inferior coal. The combustor is capable of igniting inferior coal of 4 to 10 tons by using oil capacity of 150kg / h, which has an oil-saving ratio more than 80%, service life more than 4 years, and is beneficial for popularization in related industries.

Owner:范昌 +2

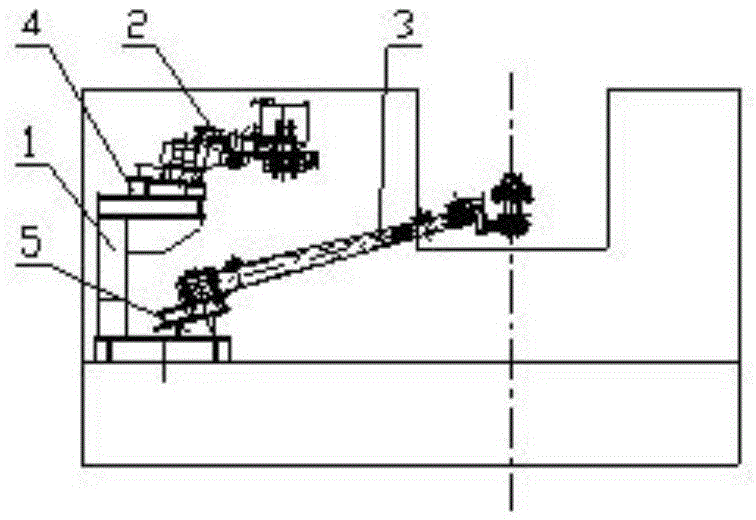

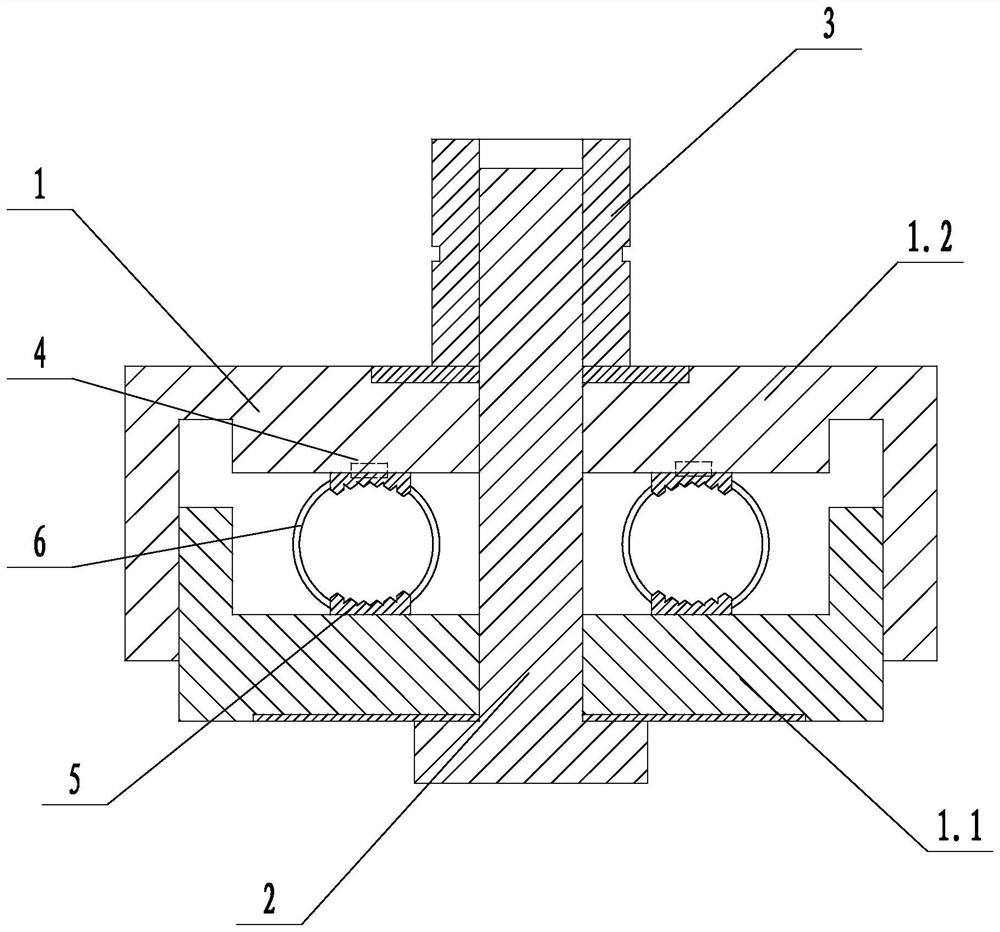

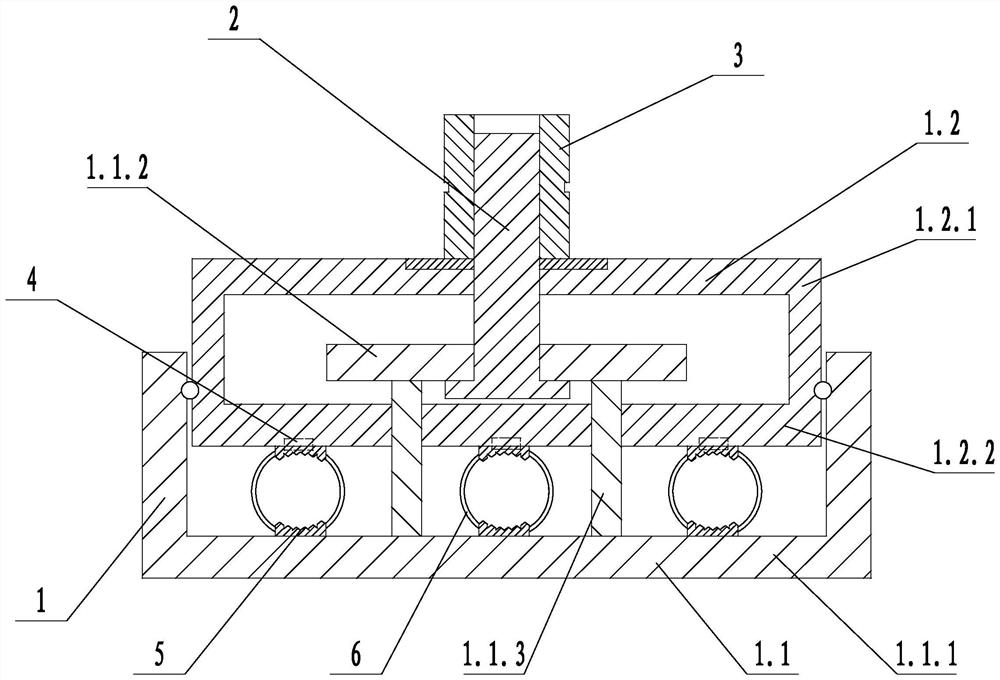

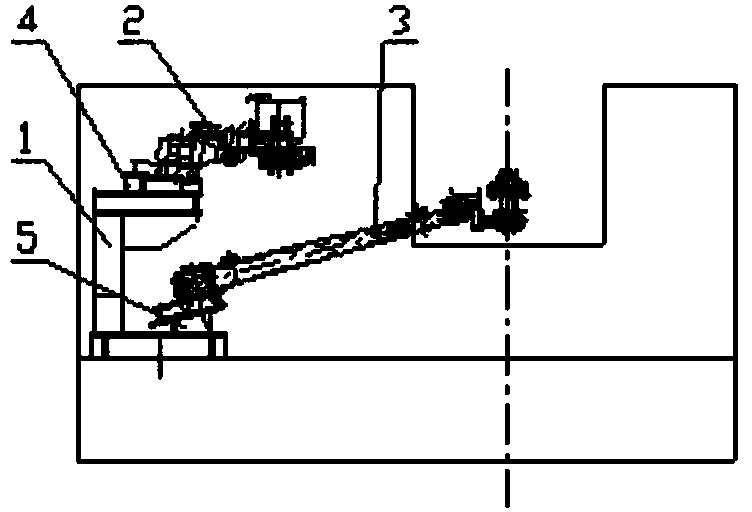

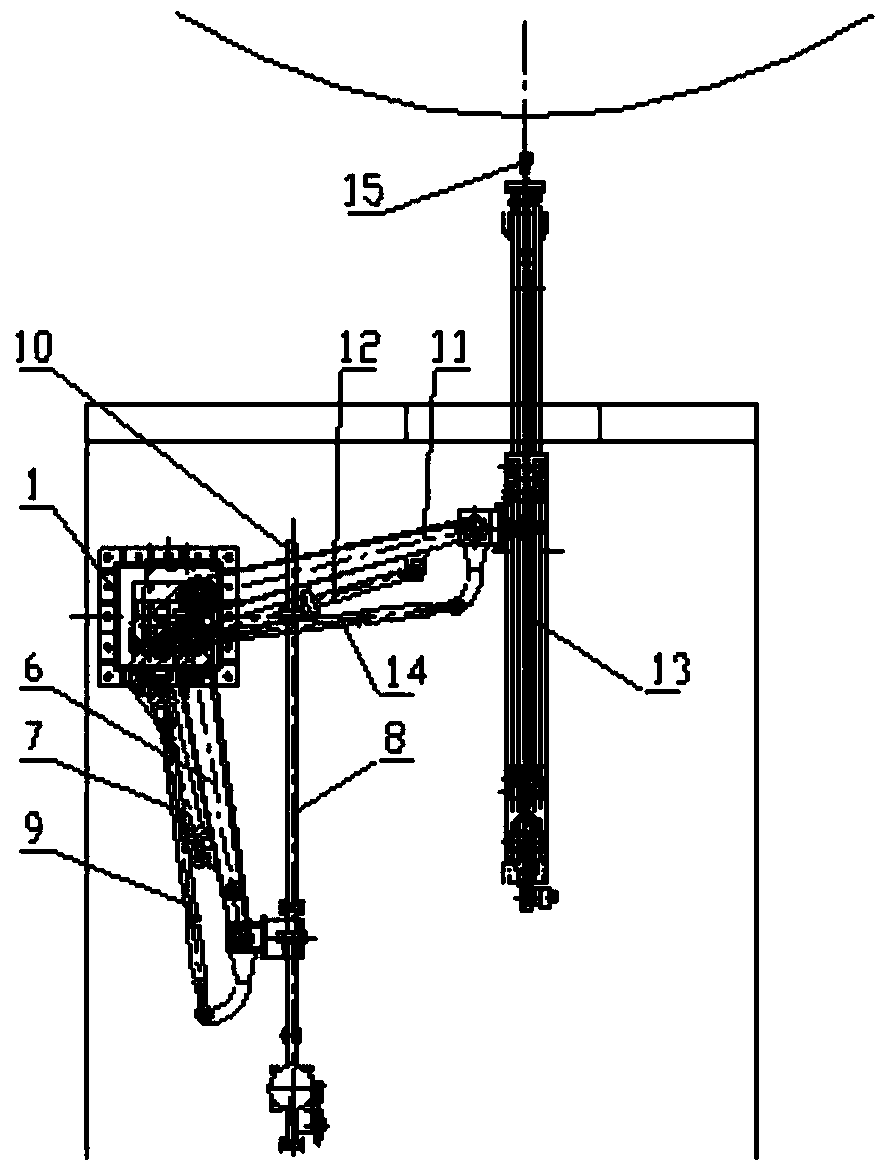

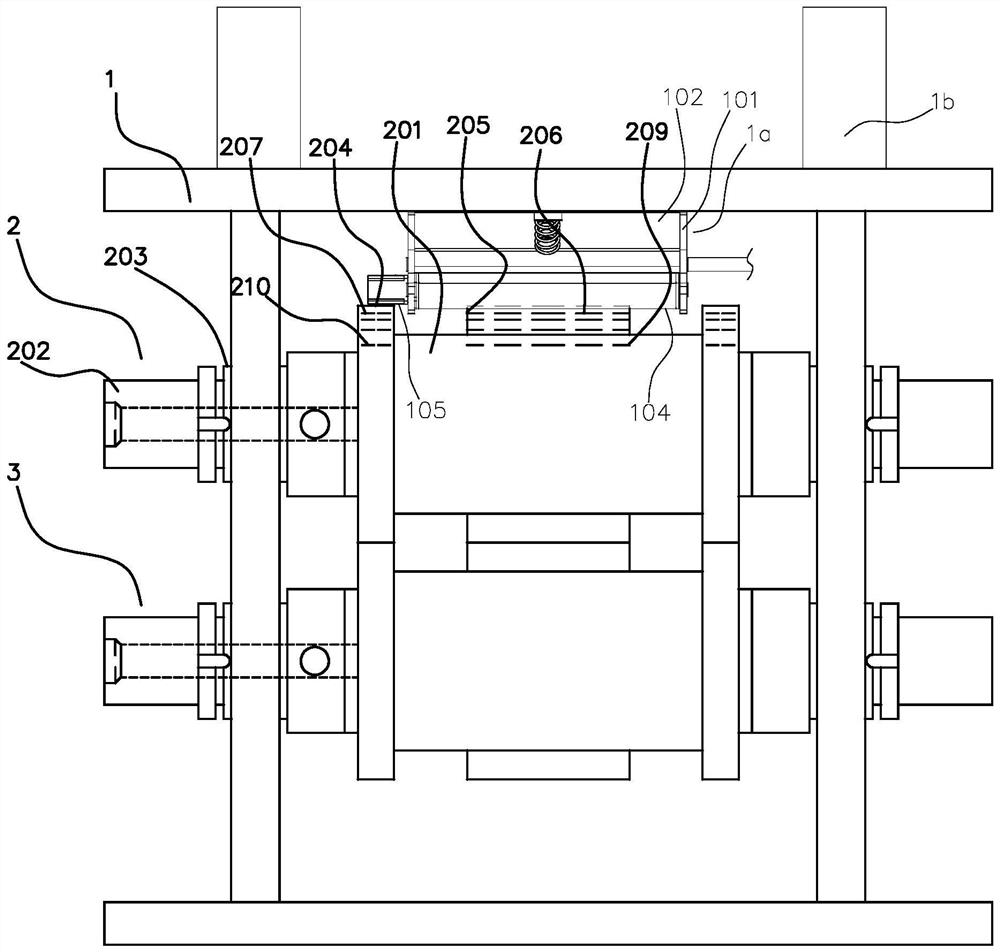

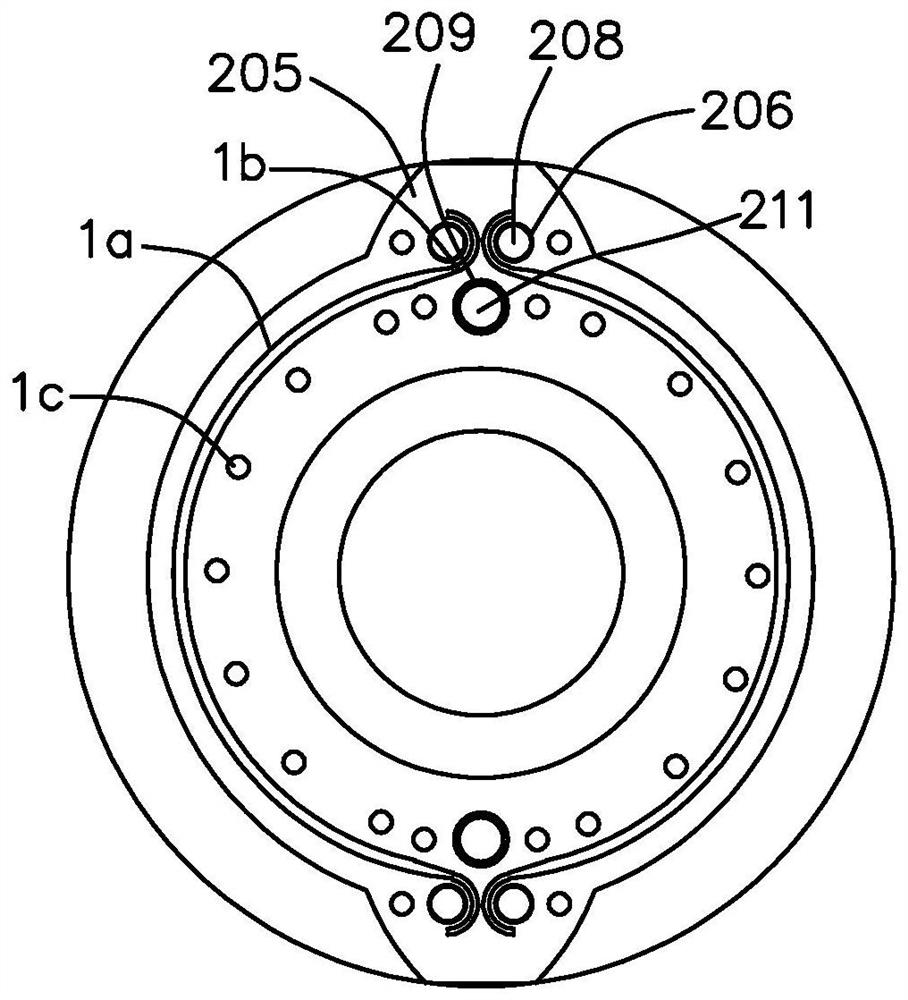

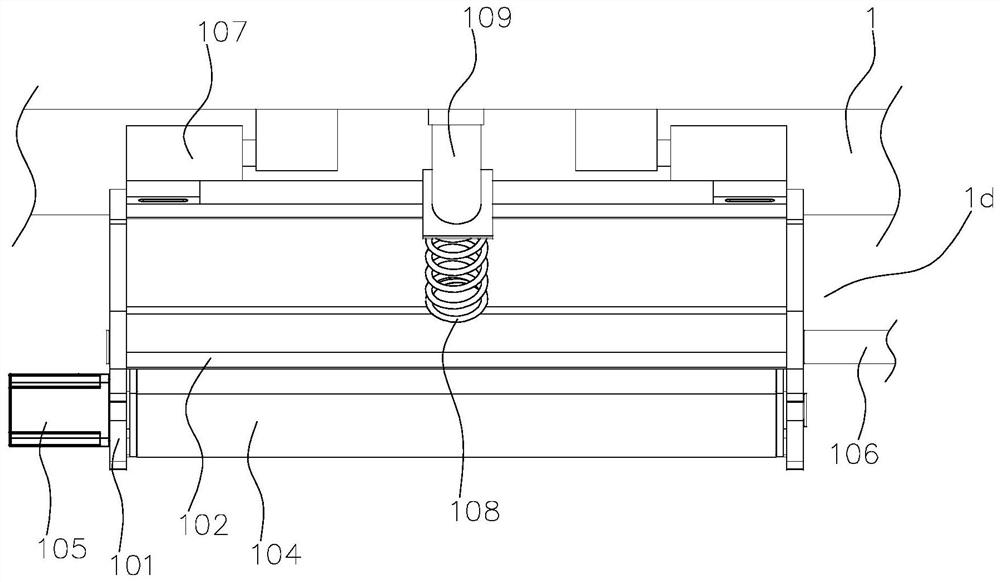

Tap-hole opening and plugging device for calcium carbide furnace

ActiveCN105674752AReduce power consumptionLess material consumptionCharge manipulationControl devices for furnacesEngineeringControl system

The invention discloses a tap-hole opening and plugging device for a calcium carbide furnace. The tap-hole opening and plugging device comprises a machine base, a tap-hole plugging driving mechanism, a tap-hole plugging device, a tap-hole opening driving mechanism, a tap-hole opening device and a control device, wherein the machine base is connected with the tap-hole plugging driving mechanism and the tap-hole opening driving mechanism, the tap-hole plugging driving mechanism is connected with the tap-hole plugging device, the tap-hole opening driving mechanism is connected with the tap-hole opening device, the control device comprises a hydraulic control system and a pneumatic control system, the tap-hole plugging driving mechanism, the tap-hole opening driving mechanism and the tap-hole opening device are connected with the hydraulic control system, and the tap-hole plugging device is connected with the pneumatic control system. The tap-hole opening and plugging device solves the problem that tap-hole opening and plugging machines for alloy furnaces in the prior art have a poor tap-hole plugging effect on the calcium carbide furnace. Tap-holes can be opened and plugged easily.

Owner:SINOSTEEL XIAN MACHINERY

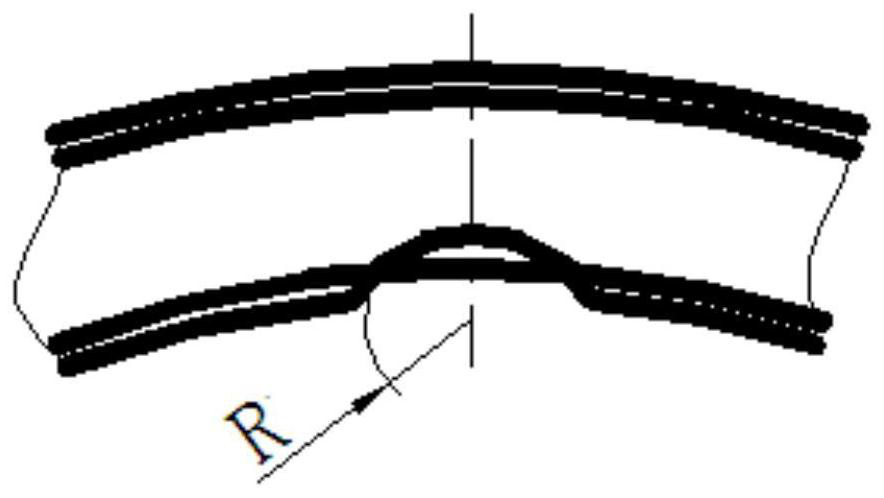

Flexible steel rail grinding device and steel rail grinding wagon

PendingCN111455753AIncrease collection rateJob cleaningDirt cleaningRailway track constructionSlide plateGrinding wheel

A flexible steel rail grinding device comprises an installation frame, a vertical plate, a supporting rod, a feeding mechanism, grinding units and a guide rail sliding block mechanism, and the feedingmechanism is connected with the guide rail sliding block mechanism. The guide rail sliding block mechanism comprises a sliding plate installed on the vertical plate in a sliding mode, and the slidingplate is further provided with a plurality of grinding units. Each grinding unit comprises a flexible polishing wheel, a driving device and a driving device accessory mechanism. A flexible steel railgrinding wagon comprises a wagon body, a cab is arranged at the front end of the wagon body, a mechanical and electric appliance room is arranged in the middle the wagon body, a dust collecting device is arranged at the rear end of the wagon body, a walking driving system and a plurality of grinding devices are arranged under the mechanical and electric appliance room, and the grinding devices are mounted in the bottom of the wagon body and used to grind a steel rail. According to the steel rail grinding device and the grinding wagon, the flexible grinding wheel is adopted, grinding head angle control and vertical feeding can be conducted, the grinding amount can be automatically controlled, tool abrasion can be automatically compensated, and grinding at all angles can be conducted on thesteel rail.

Owner:邝文建 +1

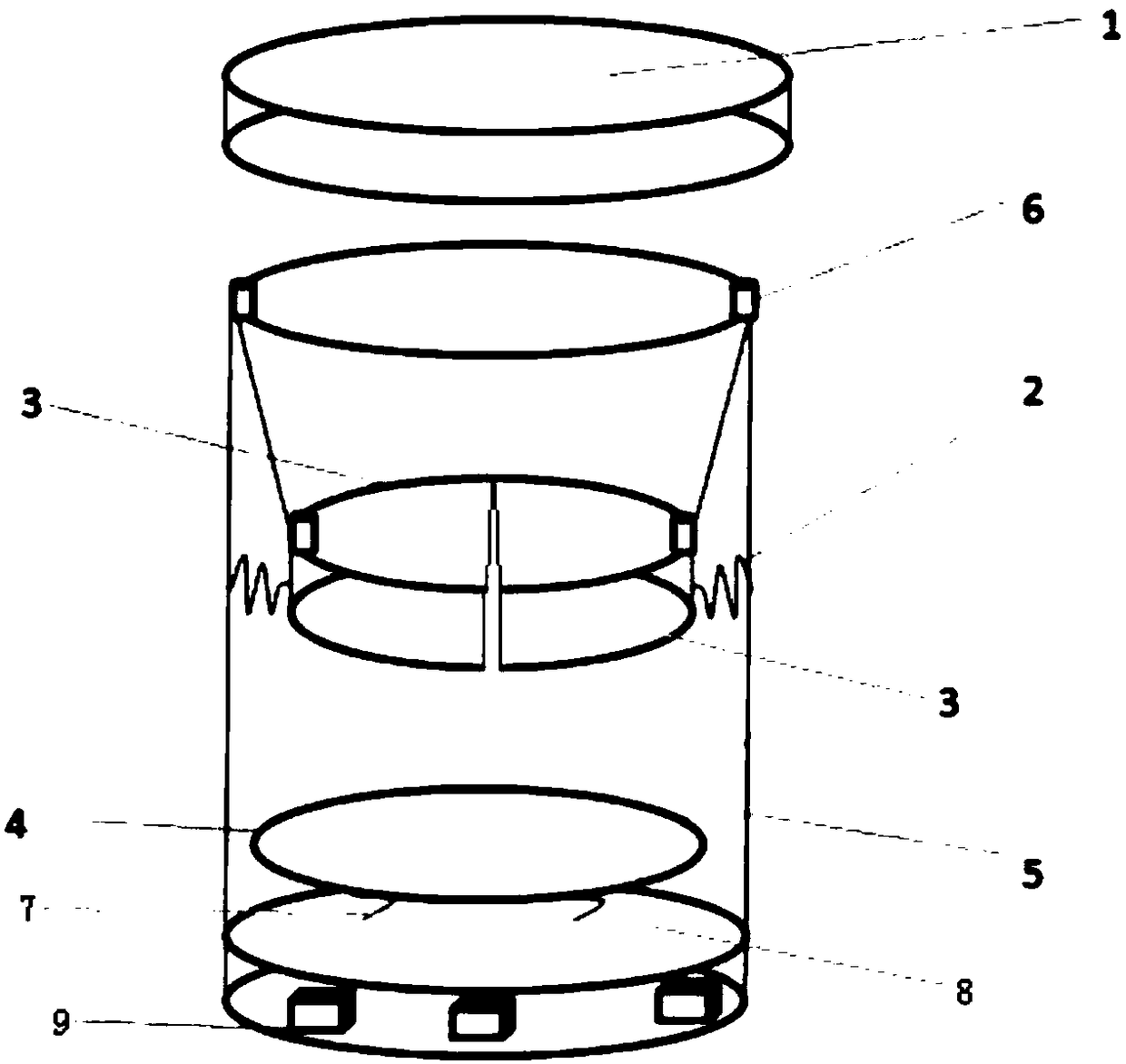

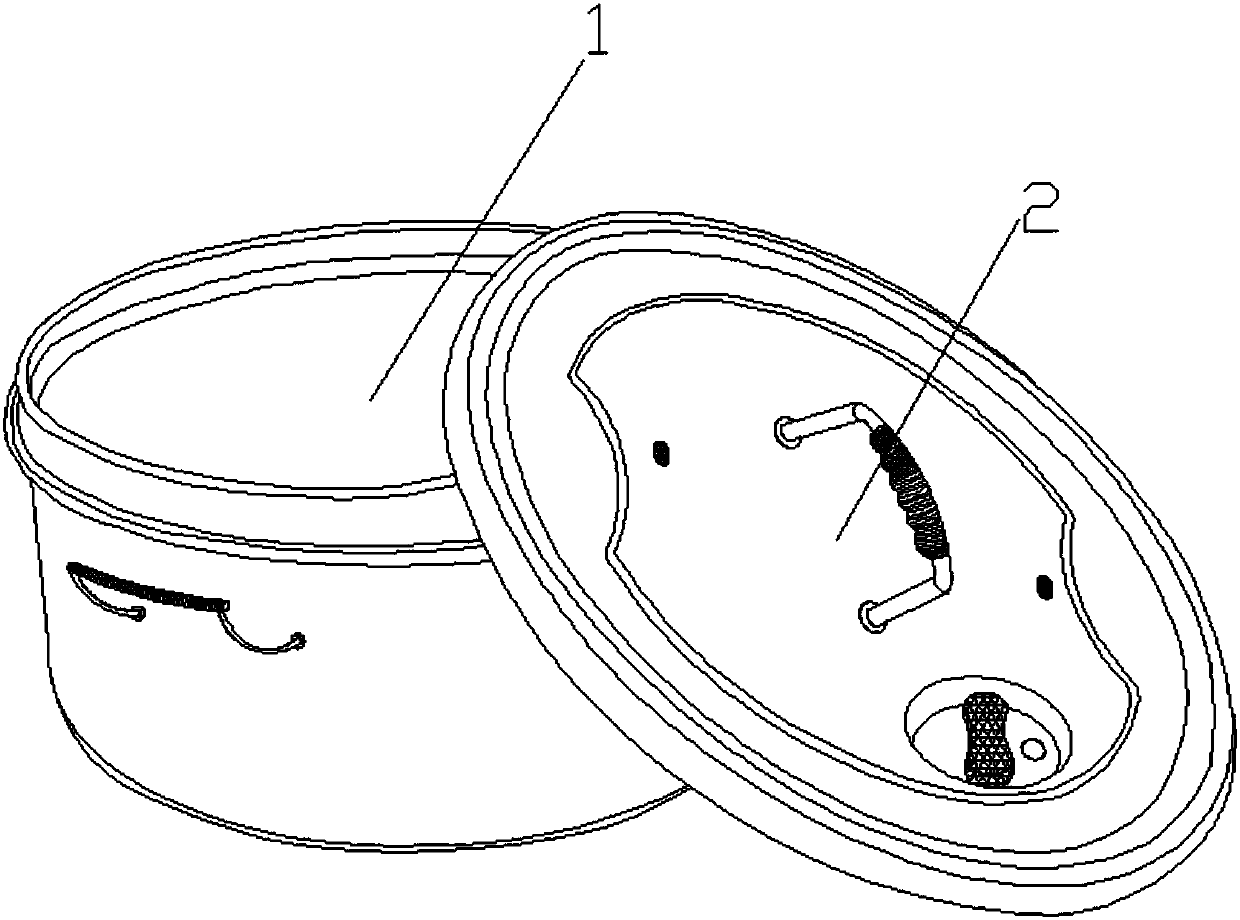

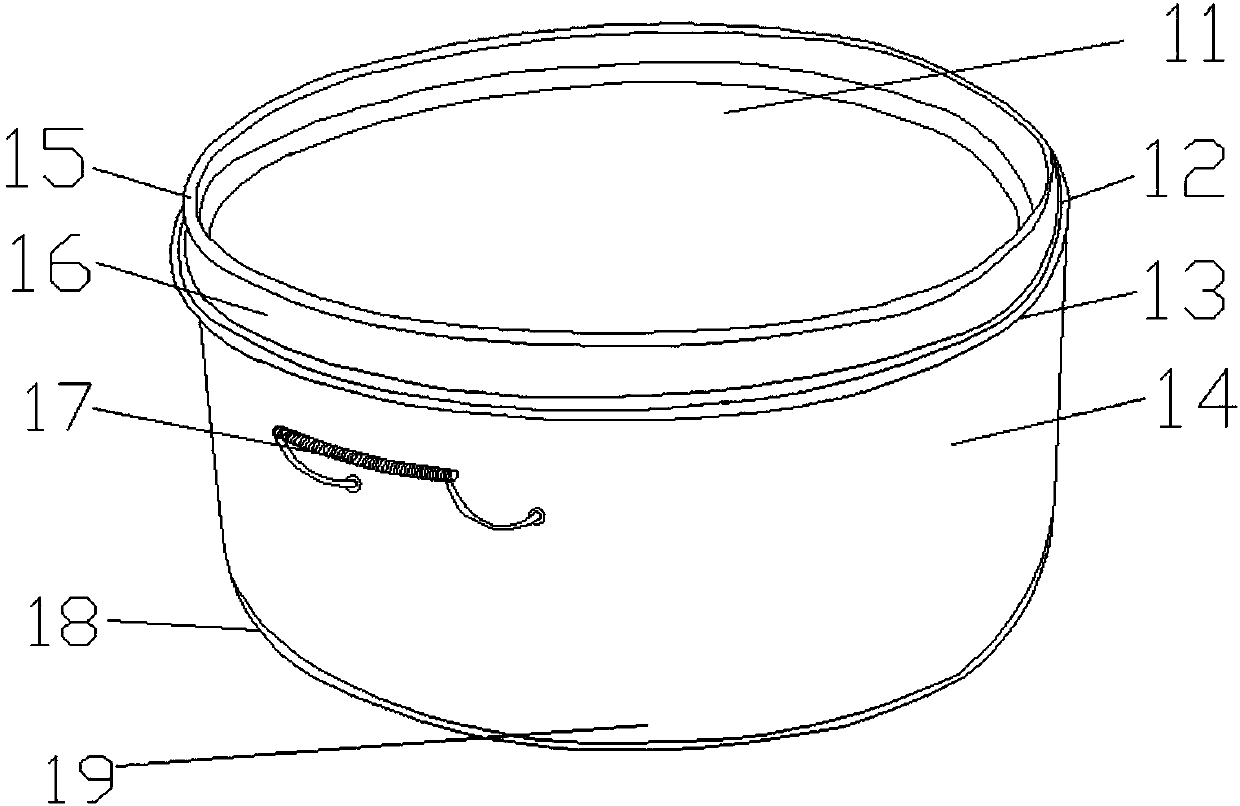

Protective cup sleeve for glass cup

The invention discloses a protective cup sleeve for a glass cup. The protective cup sleeve comprises a cup sleeve body, a cup sleeve cover, and arc-shaped pads, a shockproof pad and a partition platearranged in sequence inside the cup sleeve body, the arc-shaped pads are axially and symmetrically arranged in the cup sleeve body and connected to each other with a symmetry axis as a center to forma hollow inverted circular truncated cone structure, the shockproof pad is fixedly connected with the partition plate through a bottom spring, lead blocks are arranged between the cup sleeve body andthe partition plate, the lower ends of the arc-shaped pads are fixedly connected with the cup sleeve body through side wall springs, the upper ends of the arc-shaped pads are hinged to movable hinges,the other ends of the movable hinges are hinged to the upper edge of the cup sleeve body, magnetic layers with opposite polarities are arranged on the lower end face of the shockproof pad and the upper end face of the partition plate, and magnetic layers with opposite polarities are arranged on the inner wall of the cup sleeve body and the outer walls of the arc-shaped pads. The protective cup sleeve effectively solves the problems that the glass cup is damaged during the transportation process, hands are easily scalded when the glass cup is used for containing hot water, and the glass cup has poor heat preservation in winter are effectively solved through spring shock absorption, the arc-shaped pads, the shockproof pad and the magnetic layers. The protective cup sleeve has a simple structure and convenient use and is suitable for popularization and use.

Owner:江瀚元

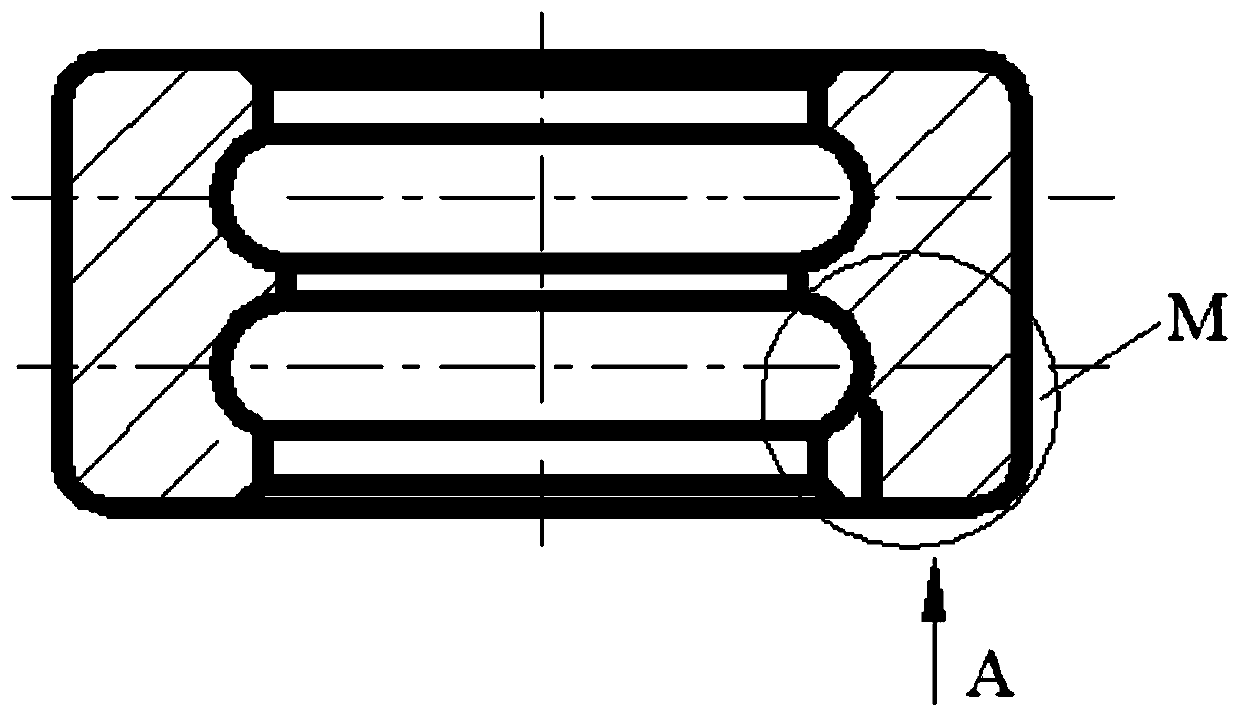

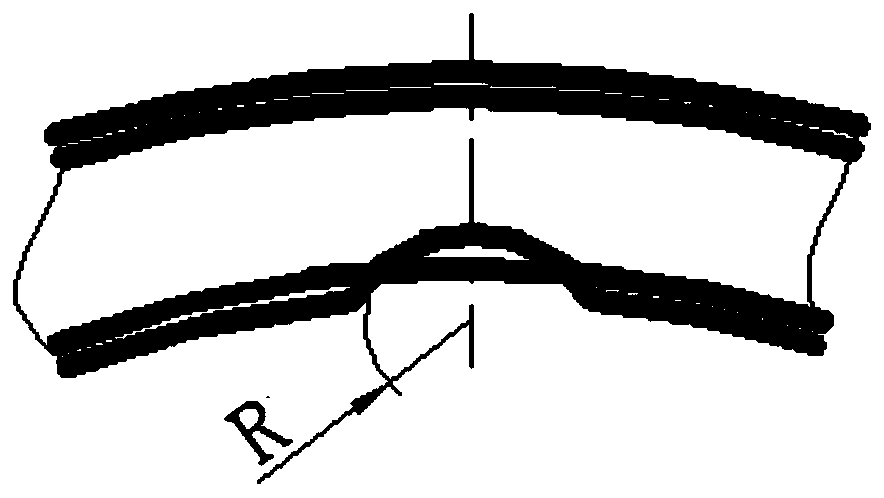

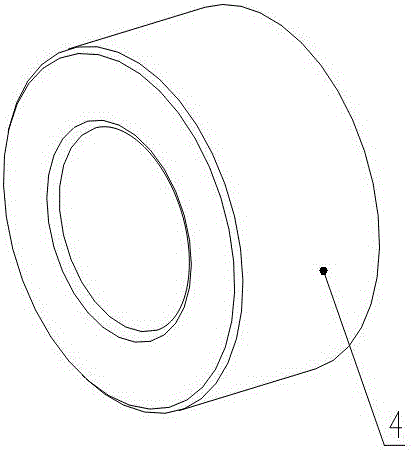

Machining method for ball-head cylindrical ball-containing notch outer ring of double-column angular contact ball bearing

ActiveCN110919474ADifficult to enterUnable to processRevolution surface grinding machinesGrinding drivesBall bearingStructural engineering

The invention discloses a machining method for a ball-head cylindrical ball-containing notch outer ring of a double-column angular contact ball bearing, and belongs to the field of bearing ferrule grinding. The invention aims to solve the problem that an existing machining method cannot meet the machining requirement of the ball-head cylindrical ball-containing notch outer ring of the double-column angular contact ball bearing. The machining method comprises the following steps of 1 preparing a to-be-machined notch part, 2 preparing a machined notch grinding wheel, 3 grinding a notch and 4 performing subsequent treatment to obtain the double-column angular contact ball bearing. The machining method has the advantages that various requirements of the double-column angular contact ball bearing are met; and a spiral groove is formed, and the easy-to-burn problem is solved. The machining method is mainly used for machining the ball-head cylindrical ball-shaped notch outer ring of the double-column angular contact ball bearing.

Owner:AVIC HARBIN BEARING

Wig with good hand feeling and preparation method thereof

The invention discloses wig with good hand feeling and a preparation method thereof. The method comprises the following steps of crushing human hair into human hair powder with the average particle diameter being 1 to 10 micrometers and the maximum particle diameter not exceeding 30 micrometers; then, uniformly distrusting the human hair powder into polyacrylonitrile fiber, wherein the content ofthe human hair powder is 1 to 30 weight percent; the content of polyacrylonitrile fiber is 70 to 99 weight percent. A wet process acrylic spinning technology is used for obtaining protein acrylic wighair. The ingredients comprise PET, PBT, bromine-containing flame retardants, antimony-containing flame retardant synergists and processing auxiliary agents. The method has the advantages that the wigis prepared from human hair through being crushed; the chemical extraction is not needed; the operation is simple and convenient; the raw material sources are wide; the price is low; the protein acrylic wig hair has the characteristics that the texture is full; the hand feeling is good; the vivid effect is achieved; the combustion properties are similar to that of the human hair.

Owner:宿迁广和新材料股份有限公司

Method for cast-bonding of journal of finished product roller through protective jacket

The invention discloses a method for cast-bonding of a journal of a finished product roller through a protective jacket, and belongs to the field of roller repairing. The method comprises the steps of flaw detection, truncation, protective jacket manufacturing, protective jacket installation, cast bonding, protective jacket dismounting and the like. The method effectively solves the problem that a traditional cast bonding process is prone to scalding and bumping the roller, the cast-bonding repairing success rate is improved, and the cast-bonding repairing difficulty of the finished product roller is greatly reduced.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

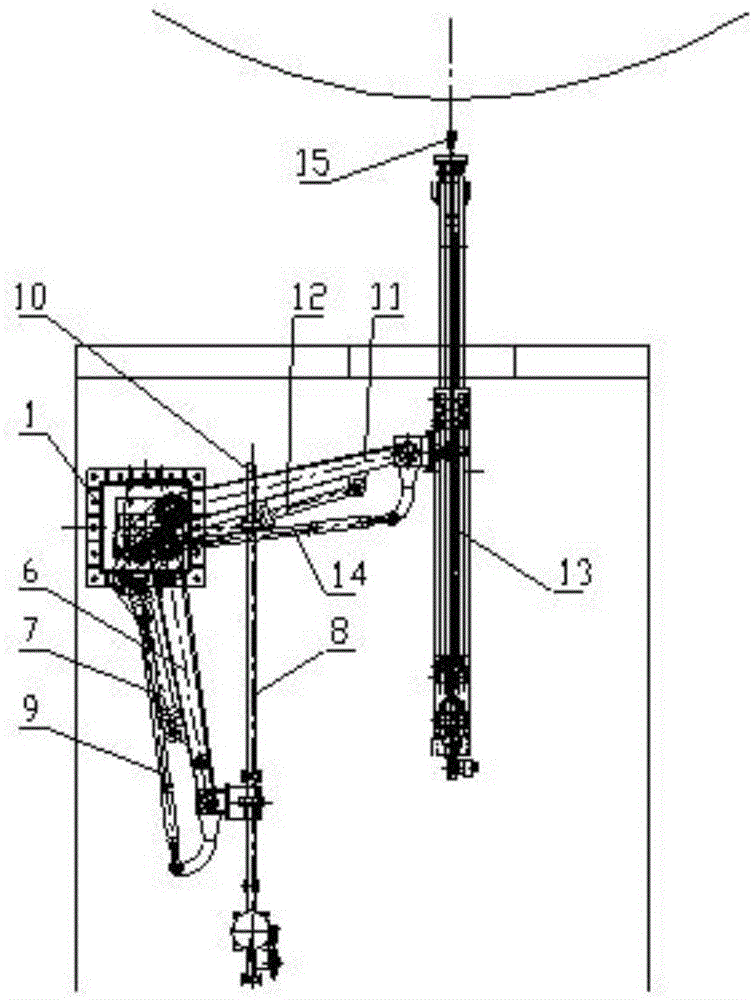

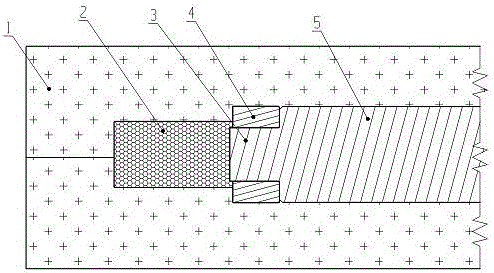

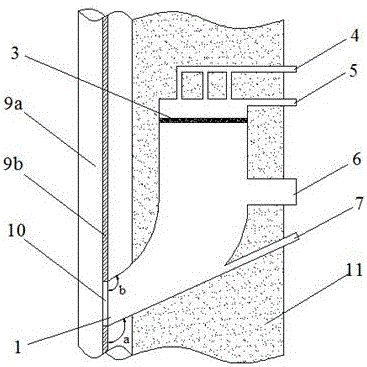

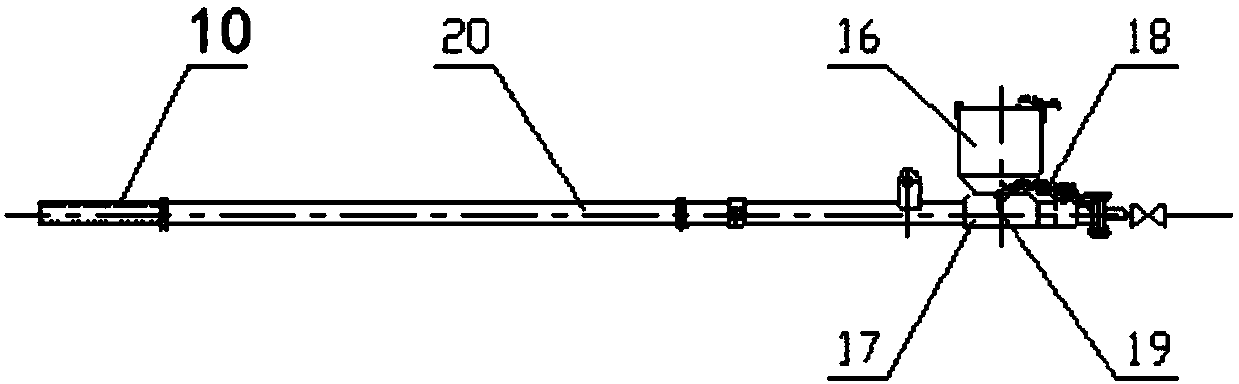

Sampling device for flue gas in close-to-wall zone of boiler water wall

ActiveCN106644613ASolve easy burnsSolve easy blockageWithdrawing sample devicesInsulation layerFlue gas

The invention relates to a sampling device for flue gas in a close-to-wall zone of a boiler water wall. The sampling device is provided with a shell; the cavity of the shell is a flue gas channel; and two sides of the flue gas channel are respectively provided with a flue gas inlet and a flue gas outlet. The sampling device is mounted in a heat-insulation layer located at the unexposed-to-fire side of the boiler water wall; a sampling port mating with the flue gas inlet is formed in a fin of the boiler water wall; and the flue gas inlet is mounted on the sampling port via the unexposed-to-fire side of the boiler water wall and communicated with the boiler via the sampling port. The sampling device provided by the invention has the beneficial effect that the problems of burning loss and obstruction of a flue gas sampling probe (gun) and obstruction of a flue gas sampling pipeline are overcome.

Owner:GUODIAN SCI & TECH RES INST +1

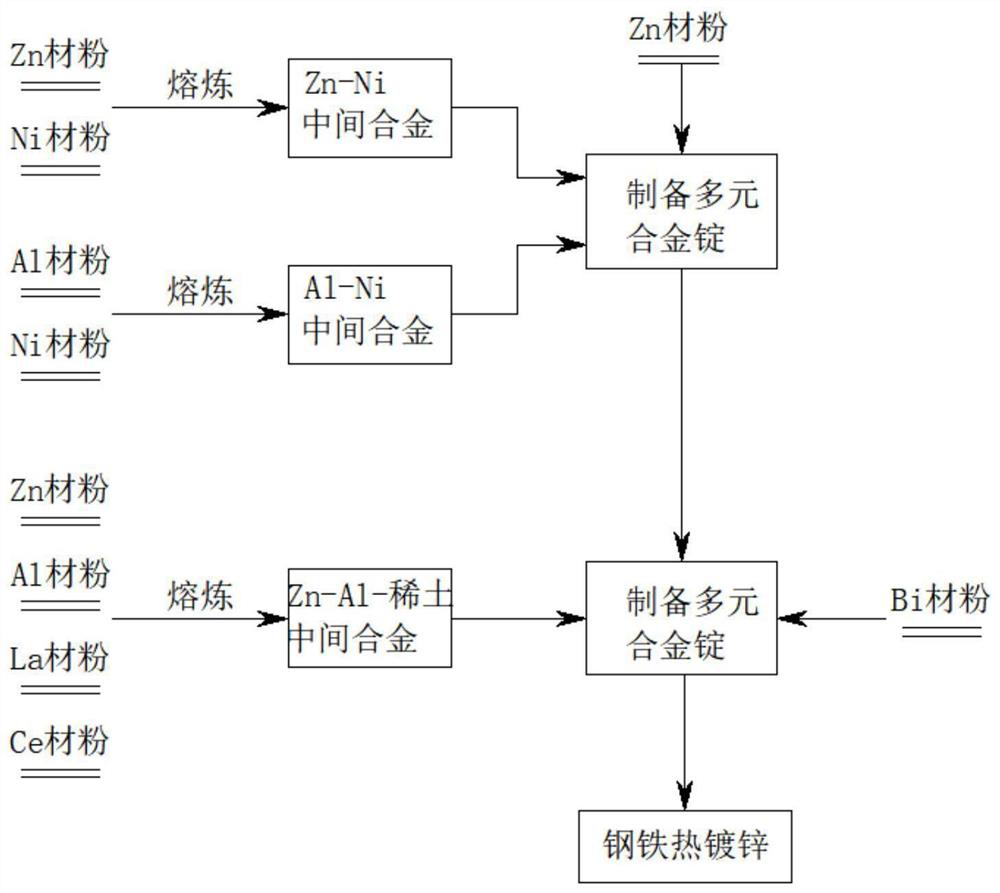

Alloy element adding method for steel hot galvanizing

The invention discloses an alloy element adding method for steel hot galvanizing, and relates to the technical field of metallurgical engineering. The preparation method comprises the following steps: S1, crushing an Al material, a Ni material, a Bi material, a La material, a Ce material and a Zn material in batches, and carrying out weighing according to a weight ratio after crushing; S2, smelting a Zn-Ni intermediate alloy; S3, smelting an Al-Ni intermediate alloy; S4, smelting a Zn-Al-rare earth intermediate alloy; and S5, a preparing a multi-element alloy ingot, adding the remaining Zn material powder into an intermediate frequency furnace, raising the temperature to 500-550 DEG C, melting the Zn material powder into molten zinc, adding the Zn-Ni intermediate alloy and the Al-Ni intermediate alloy into the intermediate frequency furnace at the same time, raising the temperature to 650-750 DEG C, carrying out heat preservation for 20-30 min, and carrying out then full stirring. According to the method, the multicomponent alloy is smelted in the mode of the metal ingot and the intermediate alloy. By making full use of the characteristic that the intermediate alloy is low in melting point, the smelting time of the intermediate alloy is greatly shortened, oxidation burning loss of easily-oxidized elements is reduced, the metal yield is increased, and the production efficiency is improved.

Owner:HAIXI HUAHUI CHEM MASCH CO LTD +1

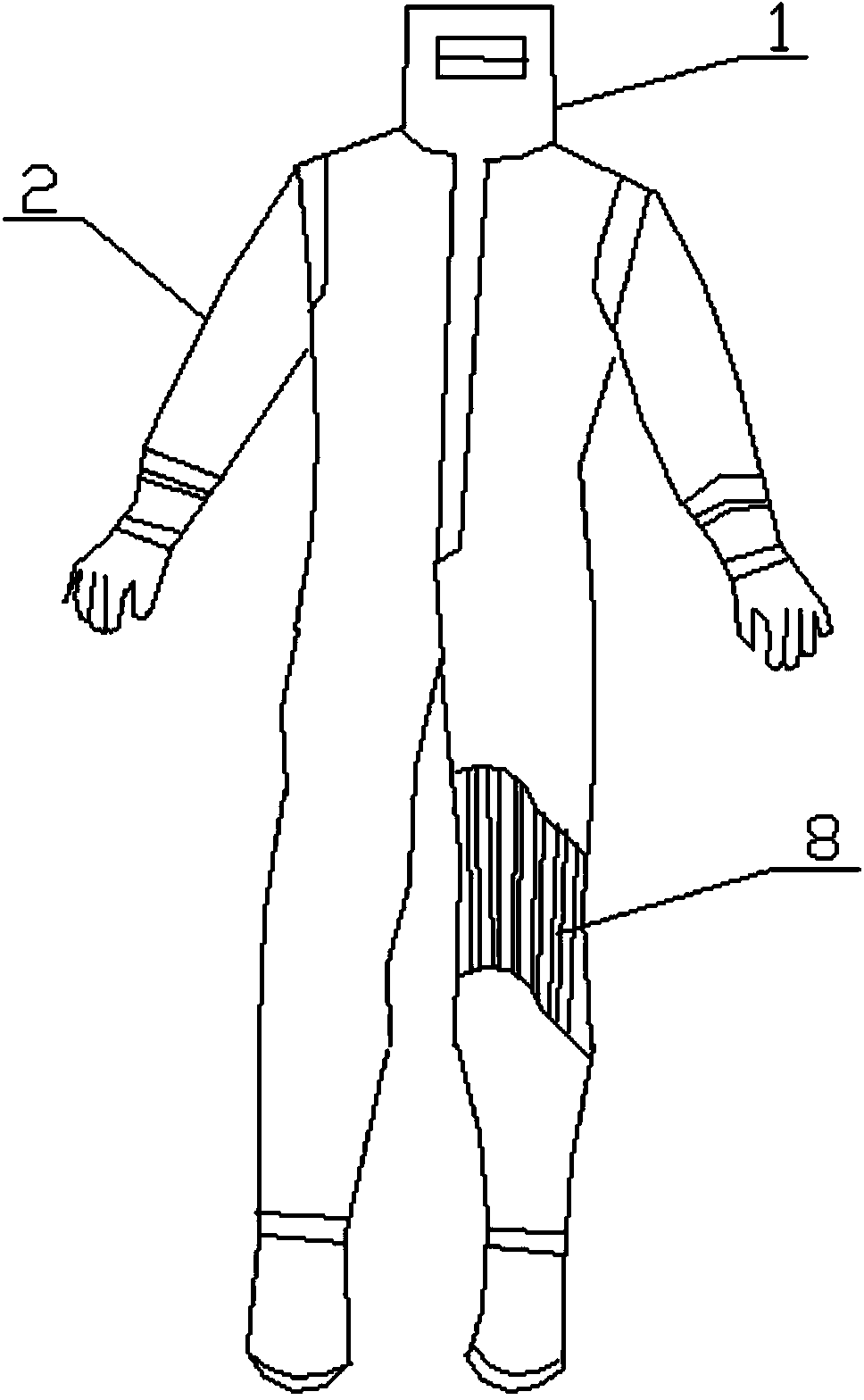

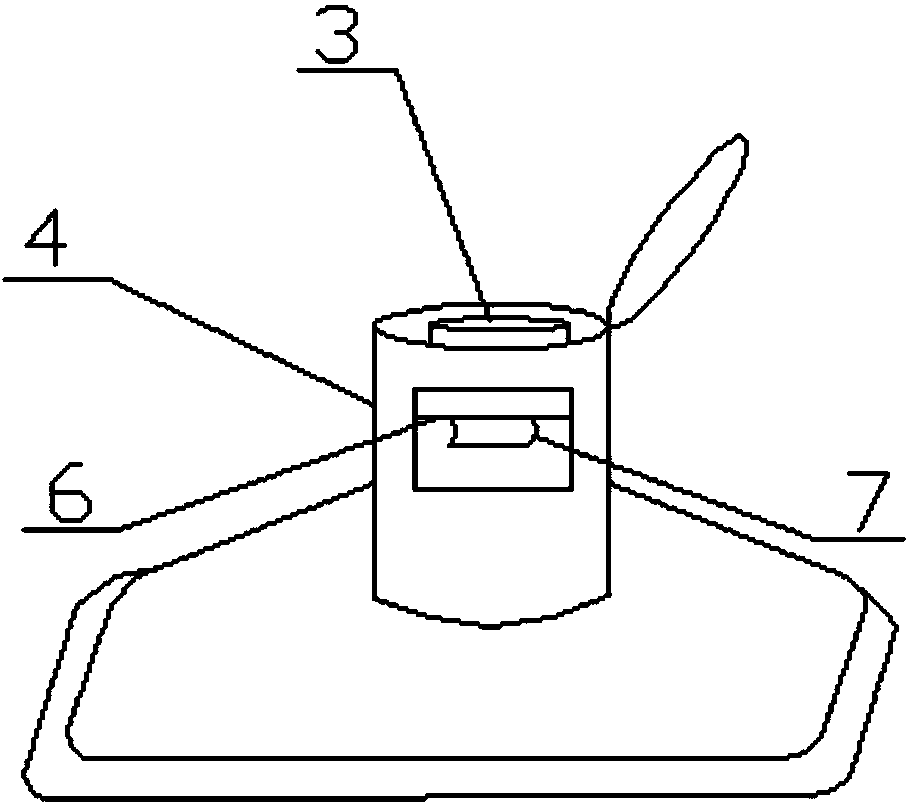

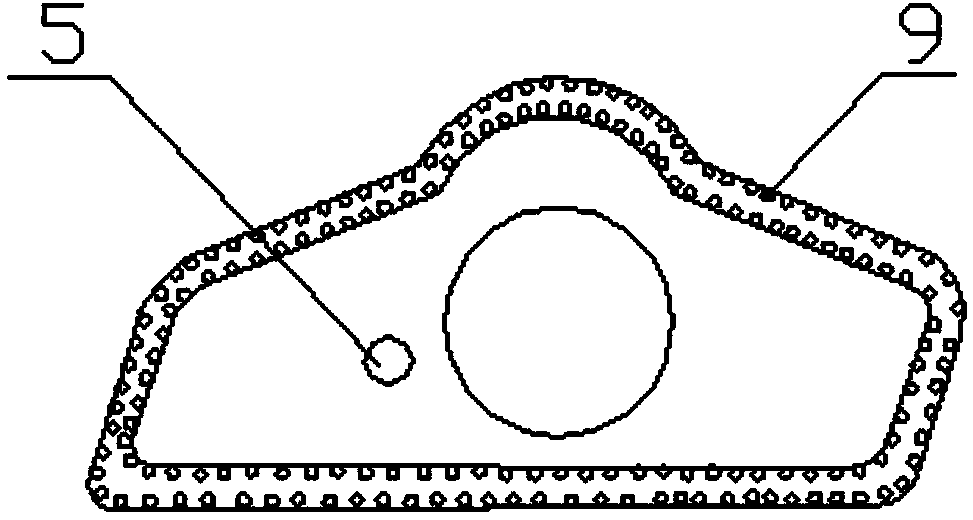

High temperature resisting fire-proof suit

InactiveCN103961820AImprove cooling effectSolve easy burnsChemical protectionHeat protectionEngineeringLife saving

The invention belongs to the technical field of life-saving devices, and particularly relates to a high temperature resisting fire-proof suit. The technical problem that the skin and the eyes of firefighters are easily burnt by an existing fire-proof suit is mainly solved. According to the technical scheme, the high temperature resisting fire-proof suit comprises a helmet and a fire-proof suit body composed of an inner fire-proof suit layer and an outer fire-proof suit layer, the helmet and the fire-proof suit body are connected into a whole, a plurality of water outlets formed in the lower end of the helmet are made to be connected with one ends of a plurality of water guide pipes of the fire-proof suit body, and the other ends of the water guide pipes are arranged on shoe soles of the fire-proof suit body. The helmet is composed of an inner layer, an outer layer, a guide pipe with a turbine at one end and brush cloth. The high temperature resisting fire-proof suit has the advantage of being capable of preventing the skin and the eyes of the firefighters from being burnt by high temperature caused by fires.

Owner:樊亮伟

Active HA coating prepared by compounding laser cladding and cold spraying and preparation method of active HA coating

InactiveCN114032543AGood metallurgical bondImprove bindingMolten spray coatingShielding gasPhysical chemistry

The invention belongs to the technical field of medical materials, and particularly relates to a preparation method of an active HA coating prepared by compounding laser cladding and cold spraying, and the preparation method comprises the following steps: 1, removing corrosion on the surface of a titanium alloy base material; 2, drying a first mixed powder and a second mixed powder; 3, clamping the titanium alloy base material; 4, setting inert gas protection, achieving the sealing of the inert gas protection box, injecting argon into the inert gas protection box, and detecting the oxygen content in the inert gas protection box, wherein the oxygen content in the inert gas protection box is kept to be not higher than 100 ppm; 5, preparing a fusion layer through a laser cladding technology, wherein argon serves as powder feeding carrier gas and molten pool shielding gas, remanufacturing forming is conducted in a four-way coaxial powder feeding mode, and the height of the fusion layer is not larger than 1 mm; and 6, preparing a covering layer through a cold spraying technology, and through an electric arc cold spraying technology, allowing a spray gun to conduct movable spraying on the fusion layer.

Owner:JIANGSU UNIV OF TECH

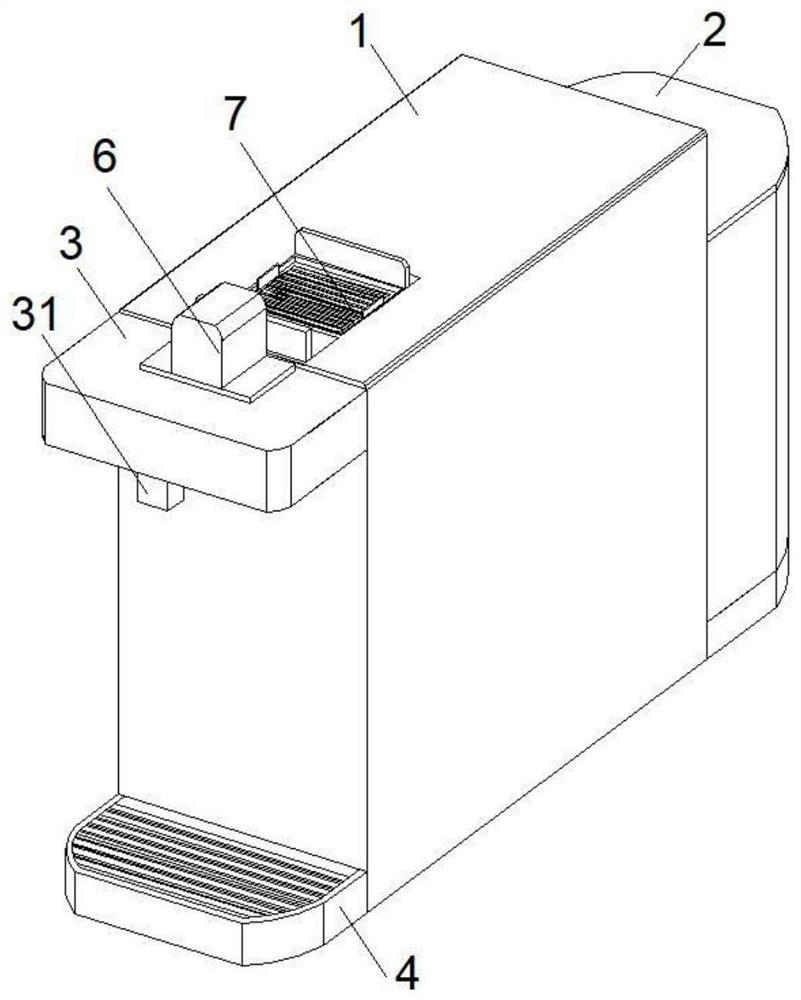

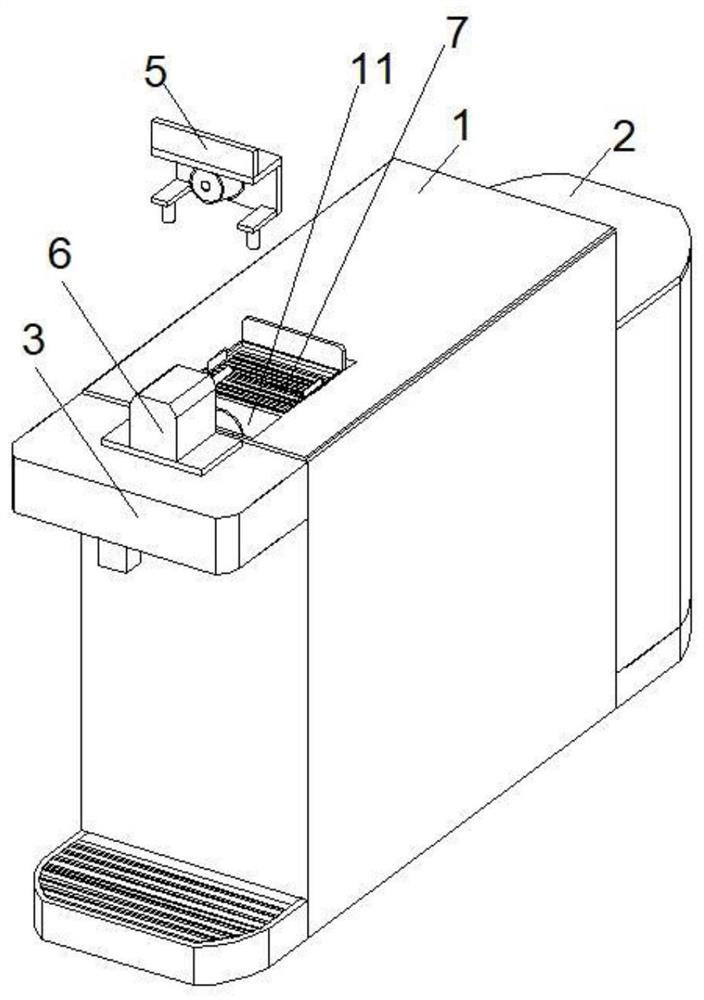

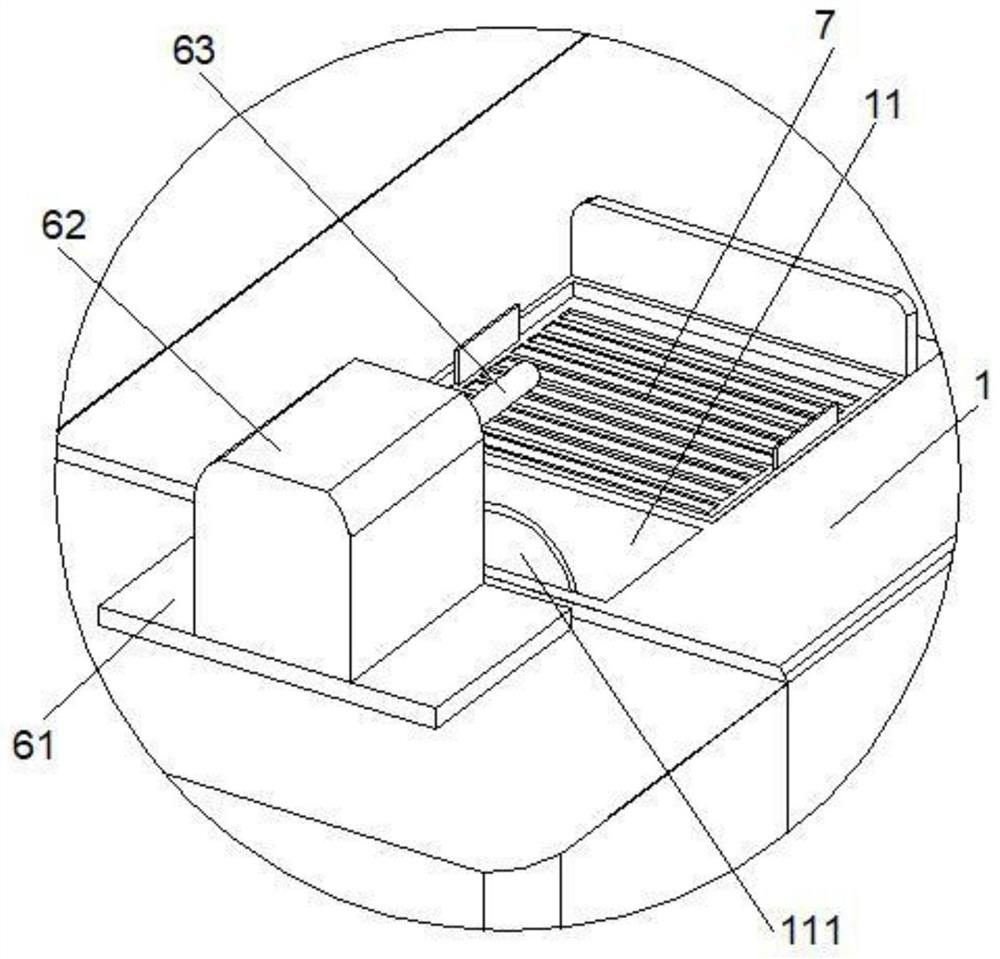

An automatic bag drop device for a coffee machine

ActiveCN111938441BSolve easy burnsEasy to operateBeverage vesselsProcess engineeringWaste management

The invention discloses an automatic bag-dropping device for a coffee machine, which comprises a machine case, a water pump arranged in the case, a water tank arranged on the rear wall of the machine case, and a water outlet part arranged on the front wall of the machine case, and also includes a bag-dropping drive arranged sequentially from front to back Mechanism, capsule clamping mechanism and waste bag collection box, the bag dropping drive mechanism is connected to the top surface of the water outlet, the waste bag collection box is movably embedded in the top surface of the chassis, the capsule compartment is embedded in the top surface of the chassis, and the capsule clamping mechanism is set in the capsule The compartment can be lifted up or retracted downward from the capsule compartment; an extraction mechanism is also provided in the chassis, and the extraction mechanism is located behind the capsule compartment. The present invention can be applied in the capsule coffee machine without manually taking out the waste bag, solves the problem of easy burns when taking out the waste bag manually, and is easy to operate.

Owner:LUAN SOYEA ELECTRIC APPLIANCE MFG CO LTD

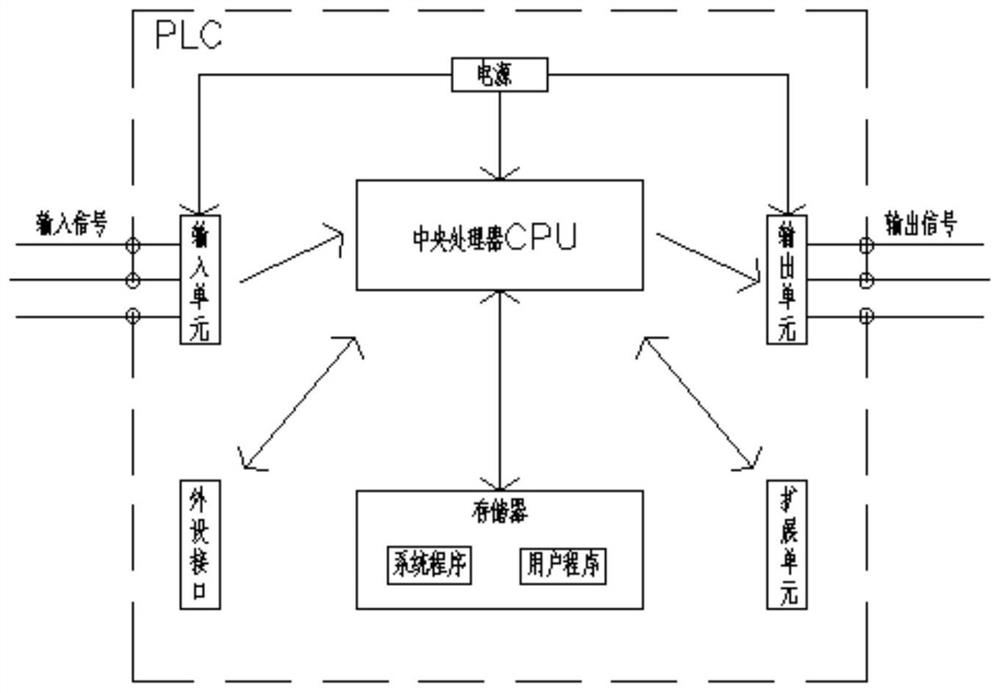

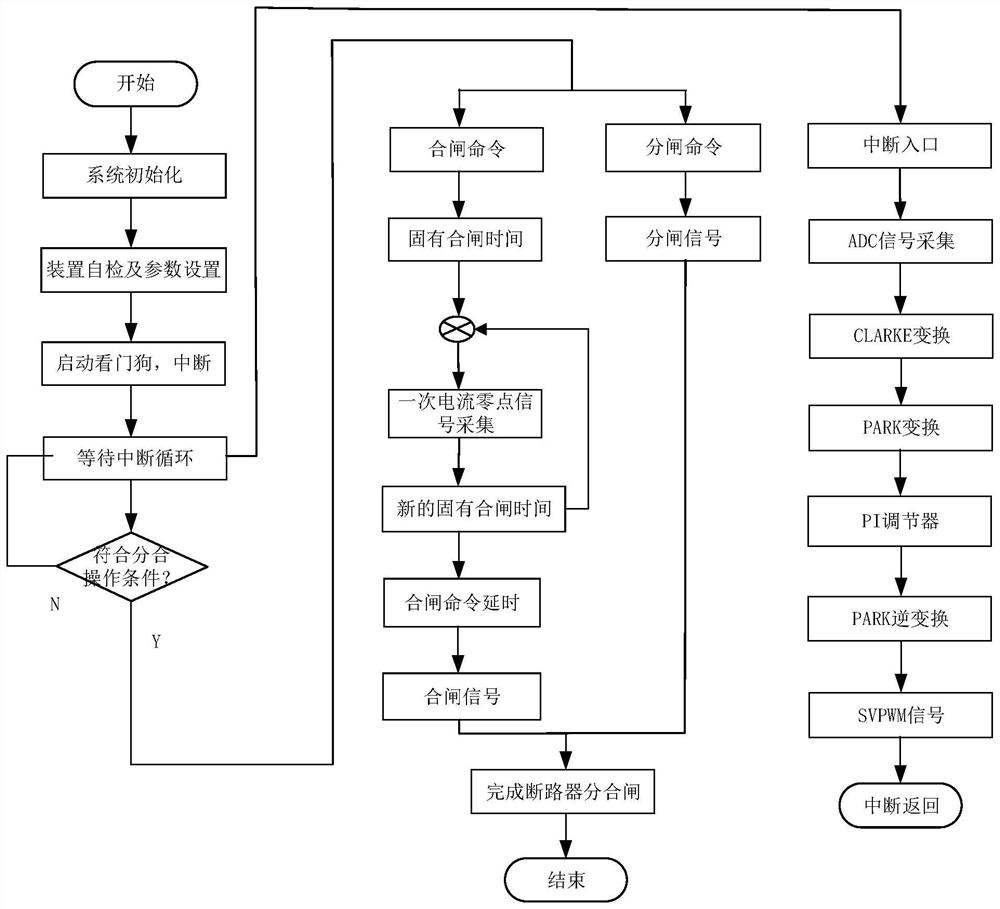

High-voltage circuit breaker and closing control method thereof

PendingCN114496675ASolve easy burnsAir-break switch detailsProtective switch operating/release mechanismsAC - Alternating currentResistor

The invention provides a high-voltage circuit breaker and a switching-on control method thereof, and belongs to the technical field of switching-on control of high-voltage circuit breakers. According to a traditional hydraulic spring operating mechanism circuit breaker, a switch is switched on at any angle of bus voltage in real time, and if a switching resistor is not connected in parallel, the danger of overvoltage exists when a high-voltage circuit breaker is switched on; for a high-voltage circuit breaker driven by a motor, when a closing command is received, the time delay of the random closing command is realized by capturing a random closing point and a next alternating-current voltage zero crossing point after an inherent closing time period and subtracting the inherent closing time from the two time periods. By adopting the invention, the phase selection closing of the motor-driven high-voltage circuit breaker can be realized, so that the design of burning loss of an arc contact of an arc extinguish chamber of the circuit breaker by a capacitive load is omitted on the structure of the circuit breaker, and the burning loss of the arc contact of the arc extinguish chamber is prevented.

Owner:PINGGAO GRP

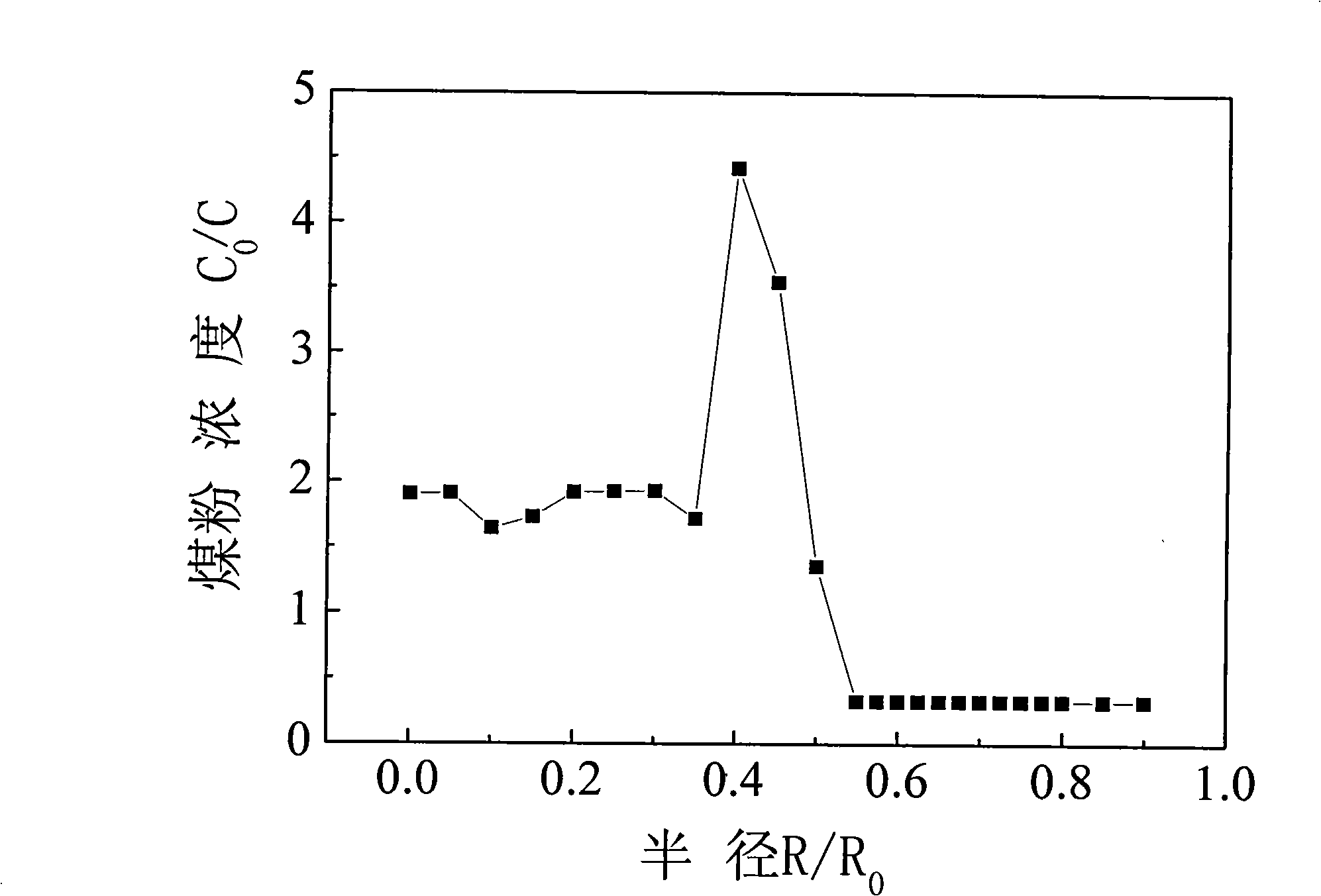

Side direction multilevel open type igniting center powder feeding vortex combustor of small oil mass gasification combustion

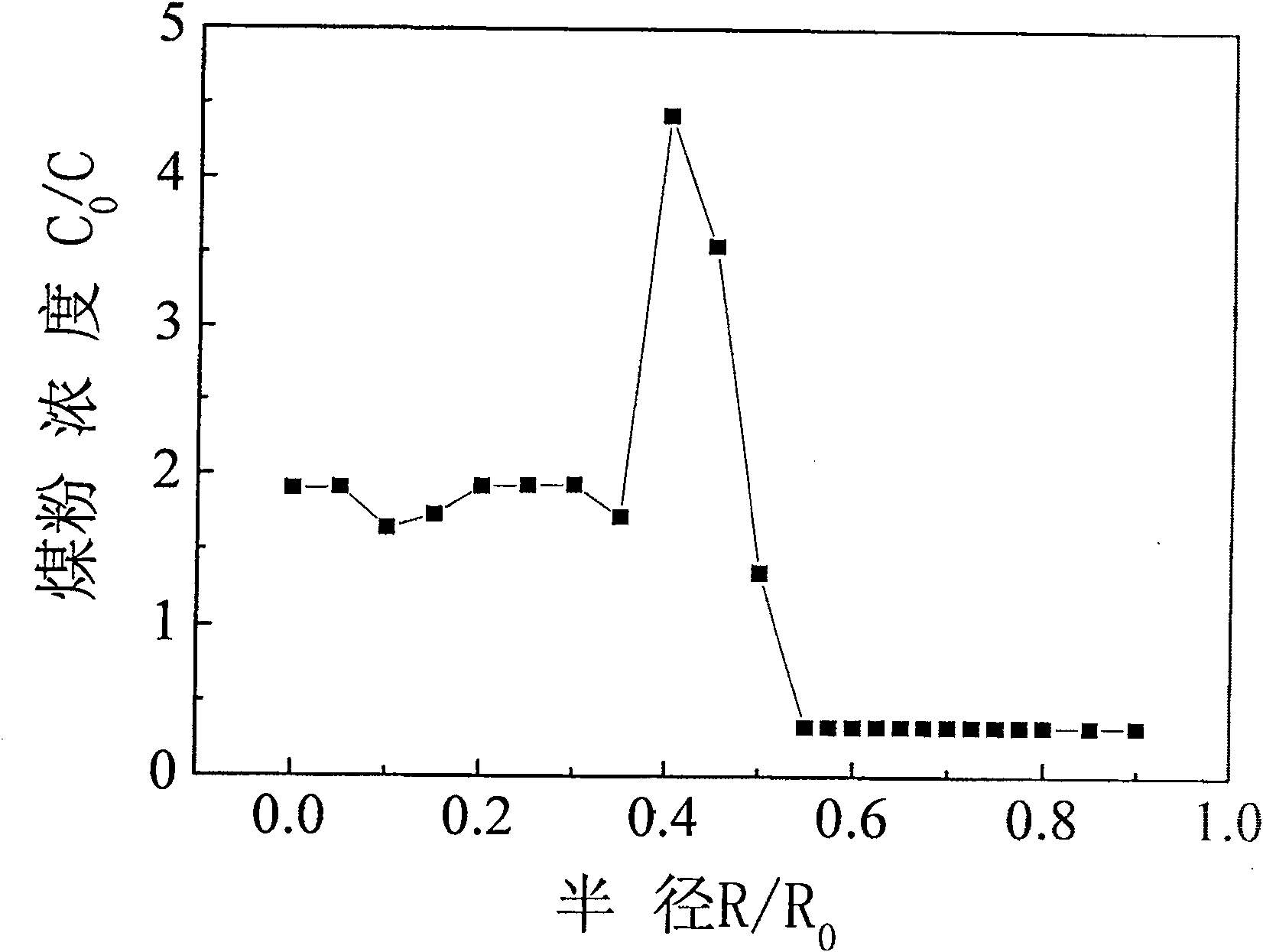

InactiveCN100585276CIncrease concentrationPromote firePulverulent fuel combustion burnersCombustion chamberLow load

The invention discloses a low fuel-consumption gasified-combustion, side-multilevel open-ignition and central powder-supply turbulent burner which relates to the turbulent burner and aims at solving the problems about how to reduce the large quantity of coal powder to be ignited when the existing micro fuel-consumption ignition turbulent burner is applied to large-volume boilers, and how to conserve fuel consumed by a power-station boiler on the conditions that the boiler is started and stopped and works with low load when reducing the NOx discharged by a large-scale coal powder boiler adopting the turbulent burner. A first-class firebox of the invention is fixed in a first air-channel pipe at the front end of a support board; a second-class firebox is fixed in a first air-channel pipe at the front end of the first-class firebox; a third-class firebox is arranged in the first air-channel pipe at the front of the second-class firebox; a primary fuel-gun is communicated with a primary air channel of the burner. In the invention, the coal powder is combusted under a low oxygen reduction condition to prolong the stay time of the coal powder so as to control the generation of consumption-typed NOx. As the secondary air is divided into two pars of inner and outer, classified combustion is formed, low NOx discharge is realized and fuel is saved.

Owner:HARBIN INST OF TECH

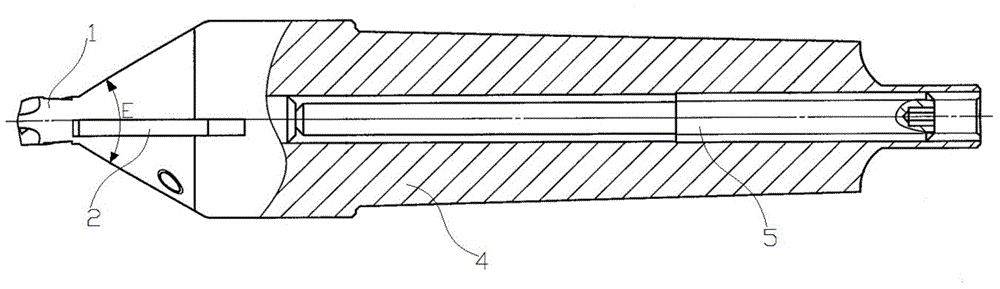

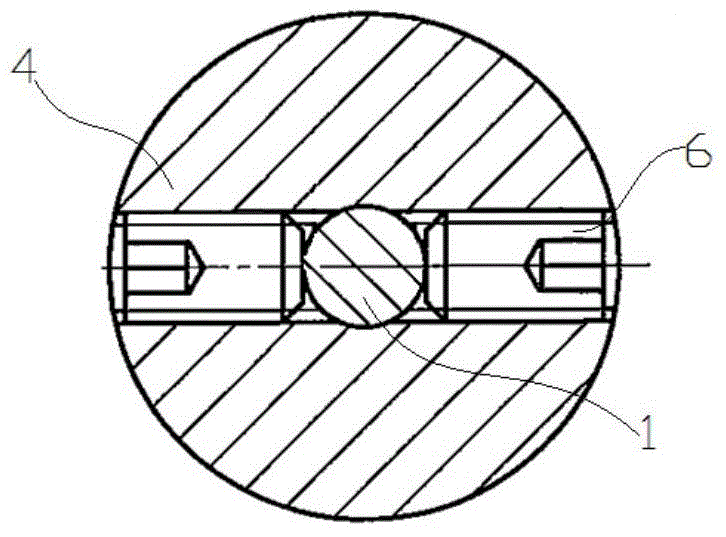

Machine-clamped center drill

InactiveCN104923837ASolve easy burnsEasy to manufactureTransportation and packagingCenter drillsEngineeringMachine tool

The invention discloses a machine-clamped center drill. The machine-clamped center drill is composed of a center drill bit, blades, blade pressing screws, a tool body, a drill bit adjustment screw and drill bit fastening screws. The tool body is a Morse taper rod with a flat tail and is matched with the inner cone of a machine tool tailstock, and a reamed hole is drilled in the end face of the head of the tool body; two blade grooves are symmetrically milled in the end faces, and threaded holes are formed in the bottom surfaces of the blade grooves; a standard short twist drill with the diameter being 12 mm is arranged at the front end of the center drill bit, and the rear end of the center drill bit is in the shape of a cone with the taper being 60 degrees; the standard short twist drill with the diameter being 12 mm partially stretches out of the cone shape to be matched with the drill bit adjustment screw so as to be installed on the tool body together with the drill bit adjustment screw through the reamed hole of the tool body, and axial position adjustment and clamping of the center drill bit can be conducted; the two drill bit fastening screws penetrate through the front portion of the tool body to be symmetrically placed so as to clamp the center drill bit in the radial direction; blade positioning grooves are formed in the drill bit with the diameter being 12 mm; the right vertical surfaces of the two blades are tightly attached to the bottom surface, the lower vertical surfaces of the two blades are tightly attached to the drill bit positioning grooves, and the blades are fixed through the blade pressing screws. The machine-clamped center drill solves the problem that burning losses of the blades are caused easily, and the service life of a tool is prolonged.

Owner:WUJIANG HONGYU MACHINERY

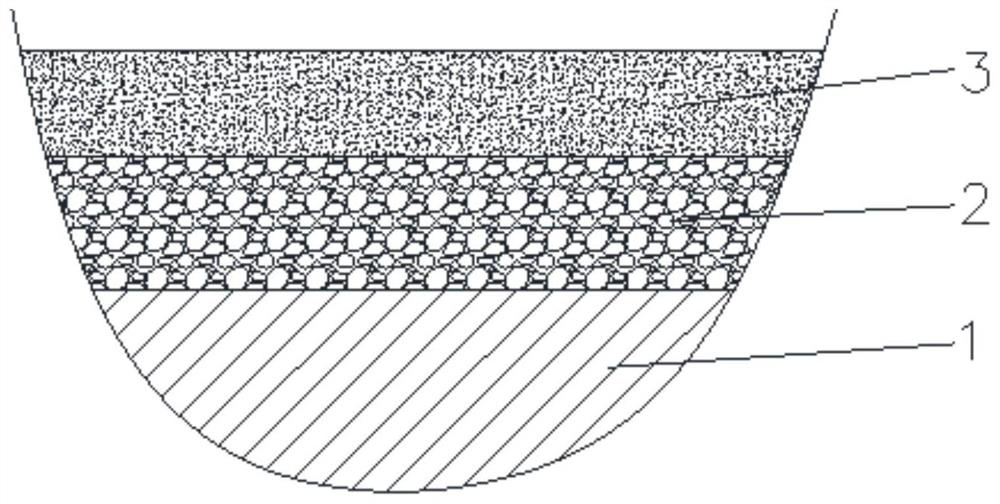

Green mulching film special for peanuts and production method of green mulching film special for peanuts

InactiveCN110643100AImprove weed control effectSolve easy burnsPlant protective coveringsPlastic mulchBotany

The invention relates to the field of production of agricultural films, in particular to a green mulching film special for peanuts and a production method of the green mulching film special for the peanuts. The green mulching film special for the peanuts is produced from the following raw materials by weight: 80-85% of linear polyethylene, 8-12% of metallocene and 5-9% of special filler. Not onlydoes the green mulching film special for the peanuts have functions of heat preserving, soil moisture preserving and weeding, but also the problem that pegs are liable to be burnt is solved, so that the survival rate of pegs and the fruit setting rate of the peanuts are improved; and the production method is scientific, reasonable, simple and easy to implement.

Owner:HENAN YINFENG PLASTIC

Inferior coal micro-oil ignition combustor

InactiveCN101603683BEliminate vortex zoneExtended stayPilot flame ignitersPulverulent fuel combustion burnersCycloneCombustion chamber

An inferior coal micro-oil ignition combustor comprises a streamlined air powder separation ring, a bidirectional cyclone oil combustor, a wing-shaped anti-friction block, a primary dense-phase coal powder combustion chamber, a secondary dilute-phase coal powder combustion chamber, a V-shaped cavity backflow blunt body, a circumferential cooling bellows and the like, employs a principle of gas-solid two phase flow separation, a principle of oil flame two-way cyclone ignition, backflow high-temperature flue gas of a blunt body, a principle of energy repeated utilization, a principle of coal powder graded ignition and energy gradual enlargement, forms a power field with low air speed, high density, strong eddy flow, strong backflow in the combustor, and creates favorable condition for firing coal powder, so as to effectively solve the problems of firing difficulty and low burn-out ratio of inferior coal. The combustor is capable of igniting inferior coal of 4 to 10 tons by using oil capacity of 150kg / h, which has an oil-saving ratio more than 80%, service life more than 4 years, and is beneficial for popularization in related industries.

Owner:范昌 +2

Copper-aluminum transition junction box for switch in front of meter

ActiveCN114336098AConsistent cutting depthConsistent pressing forceElectrically conductive connectionsPhotovoltaic energy generationEngineeringKnife blades

A meter-front switch copper-aluminum transition junction box disclosed by the present invention comprises a reinforced insulation shell, a connection bolt, a connection nut and a connection sheet, the reinforced insulation shell comprises an upper shell and a lower shell, one end of the connection bolt sequentially passes through the lower shell and the upper shell and then is connected with the connection nut, the other end of the connection bolt tightly presses the lower shell, and the connection sheet is connected with the connection nut. A puncture blade is fixed on the upper shell and / or the lower shell, the puncture blade is arranged between the upper shell and the lower shell, the connecting piece comprises a copper end made of copper and an aluminum end made of aluminum, the aluminum end of the connecting piece is connected with the puncture blade, and the copper end of the connecting piece extends out of the reinforced insulating shell. The invention provides a copper-aluminum transition junction box for a meter-front switch. The copper-aluminum transition junction box can solve the problem that copper-aluminum joints of the meter-front switch of a user meter box are easy to burn out due to different materials of drop wires (aluminum) and binding posts (copper).

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JIAXING POWER SUPPLY CO +2

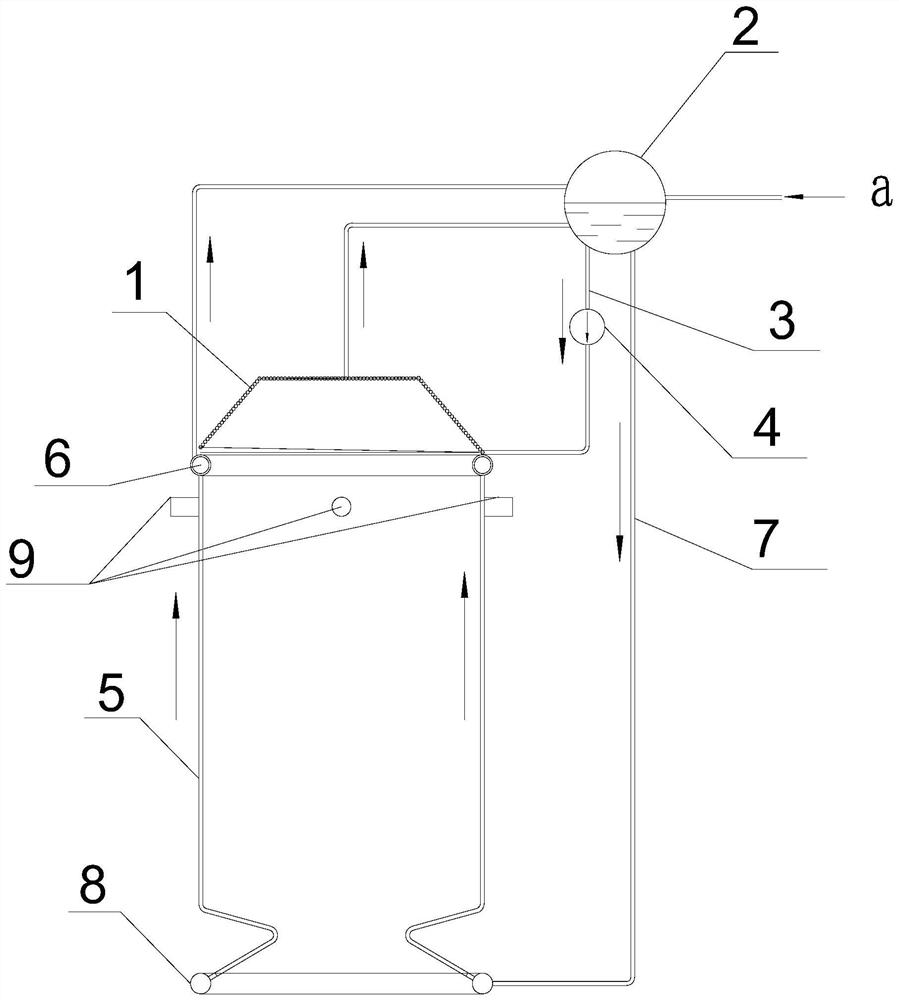

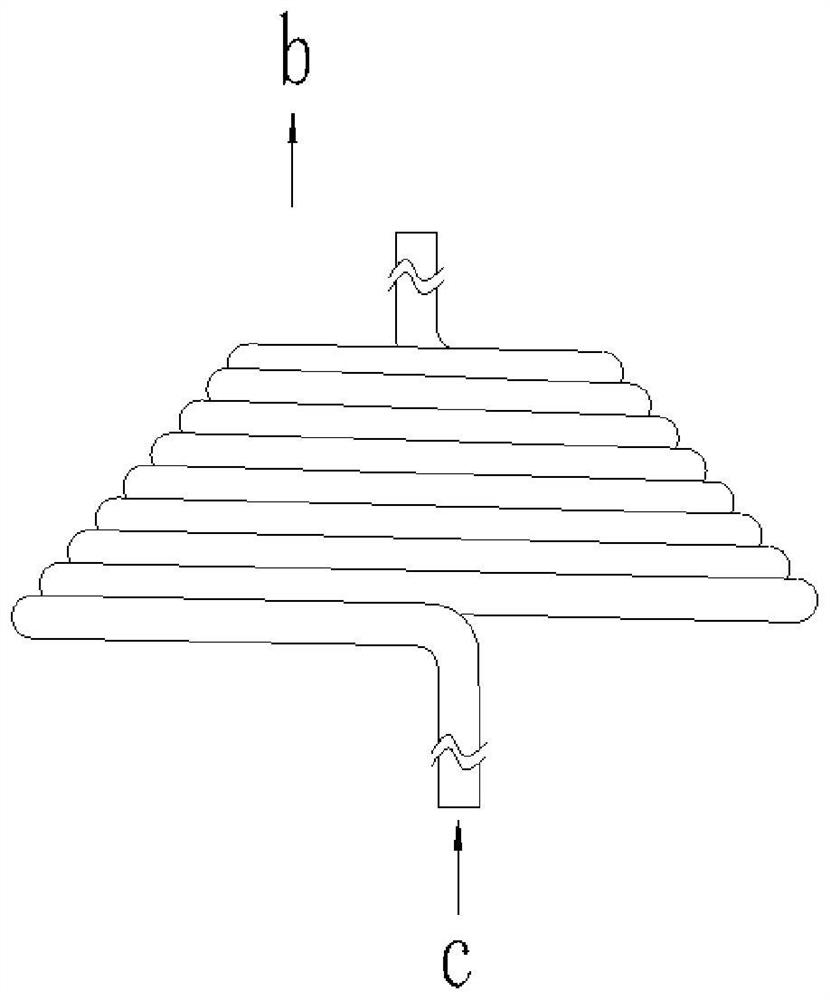

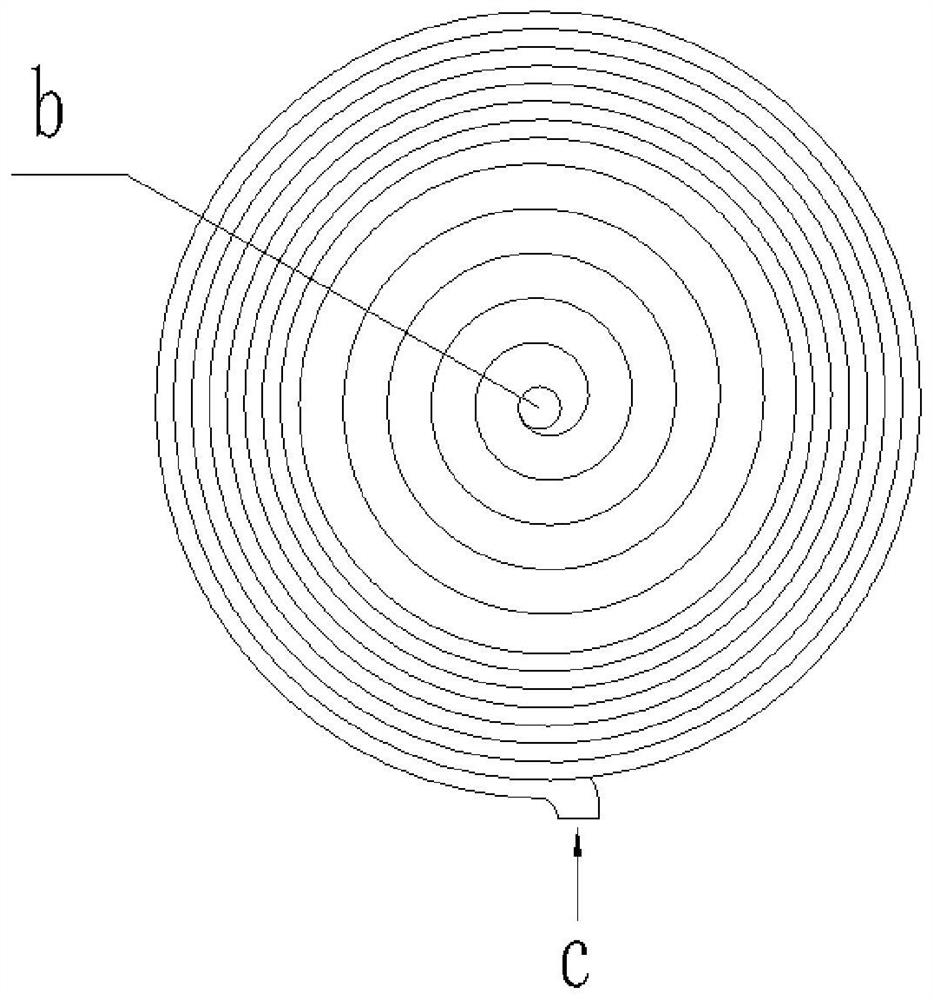

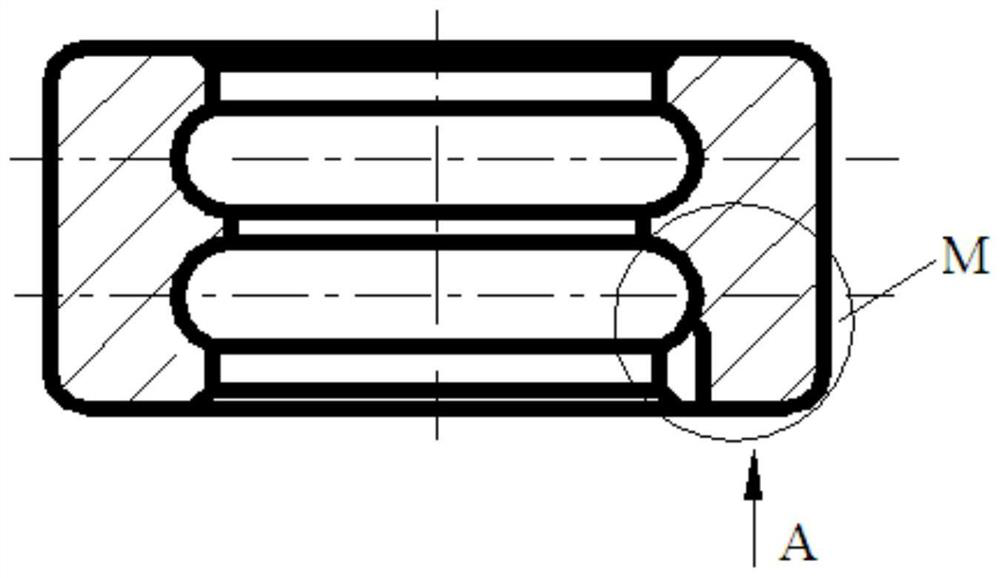

Water-cooled wall gasification furnace adopting natural circulation and forced circulation separately and cooling method

ActiveCN114395422ASolve the problem that maintenance is difficult and maintenance quality cannot be guaranteedHigh fluid flow rateChemical industryCombustible gas productionVertical tubeThermodynamics

The invention discloses a water-cooled wall gasification furnace adopting natural circulation and forced circulation separately and a cooling method, and relates to the field of gasification furnace equipment. The problems that in the prior art, a top circular truncated cone section water-cooled wall of a natural circulation water-cooled wall gasification furnace is prone to burning loss, the maintenance difficulty is high after burning loss, and the maintenance quality cannot be guaranteed are solved. A circular truncated cone section water cooling wall, an upper header, a cylindrical section water cooling wall and a lower header are sequentially arranged from top to bottom, the circular truncated cone section water cooling wall is located at the top of the gasification furnace and is an independent coil pipe type water cooling wall, the cylindrical section water cooling wall is located on the lower middle portion of the gasification furnace, and the cylindrical section water cooling wall is an independent vertical shell and tube type water cooling wall. The upper end and the lower end of each vertical tube nest of the cylindrical section water cooling wall are connected with an upper header inlet and a lower header outlet respectively. The top circular truncated cone section of the gasification furnace independently adopts the forced circulation water cooling wall which is higher in working medium flow speed, larger in convective heat transfer coefficient and stronger in heat exchange effect, and the problem that the top circular truncated cone section water cooling wall is prone to burning loss is solved.

Owner:HARBIN INST OF TECH

The processing method of the outer ring of the ball head columnar ball filling notch of the double row angular contact ball bearing

ActiveCN110919474BDifficult to enterUnable to processRevolution surface grinding machinesGrinding drivesBall bearingEngineering

The invention discloses a method for processing the outer ring of a ball-end columnar ball filling notch of a double-row angular contact ball bearing, which belongs to the field of grinding of bearing rings. The purpose of the present invention is to solve the problem that the existing processing method cannot meet the processing requirements of the outer ring of the ball head cylindrical ball filling notch of the double row angular contact ball bearing. Processing methods: 1. preparing notched parts to be processed; 2. preparing and processing notched grinding wheels; 3. grinding notches; 4. subsequent processing to obtain double-row angular contact ball bearings. Advantages: 1. Meet the requirements of double row angular contact ball bearings. 2. Set the spiral groove to solve the problem of easy burns. The invention is mainly used for the processing of the outer ring of the ball-end columnar filling notch of the double-row angular contact ball bearing.

Owner:AVIC HARBIN BEARING

Portable disposable plastic lunch box

The invention discloses a portable disposable plastic lunch box, the structure of which includes a microwave oven heated lunch box body and a microwave oven heated anti-scald lunch box cover, the microwave oven heated lunch box body is connected with the microwave oven heated anti-scald lunch box cover, The microwave oven heating lunch box body consists of the inner wall of the lunch box body, the inverted trapezoidal slot, the overturned edge interference, the outer wall of the lunch box body, the flat mouth of the box body, the outer wall of the connecting cover, the anti-scalding and anti-slip box handle, the anti-scalding The non-slip ring type support frame and the bottom of the lunch box are composed, and the microwave heating anti-scald lunch box cover includes a transparent heat insulation board, mosquito-proof air holes, a rotary switch, an anti-scald anti-slip box cover handle, and a meal cover connected to the outer wall , the handle of the anti-scald and anti-slip box cover is above the transparent heat insulation board, and the transparent heat insulation board is connected with the handle of the anti-scald and anti-slip box cover, which solves the problem of easy burns.

Owner:TIANJIN ZHICHENGXIN ELECTRONICS

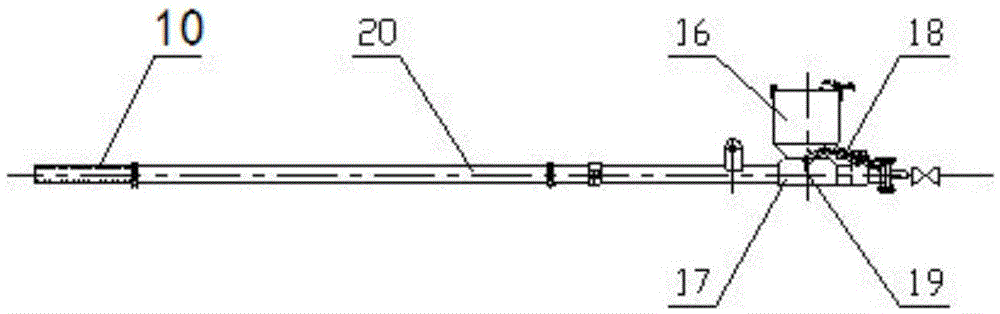

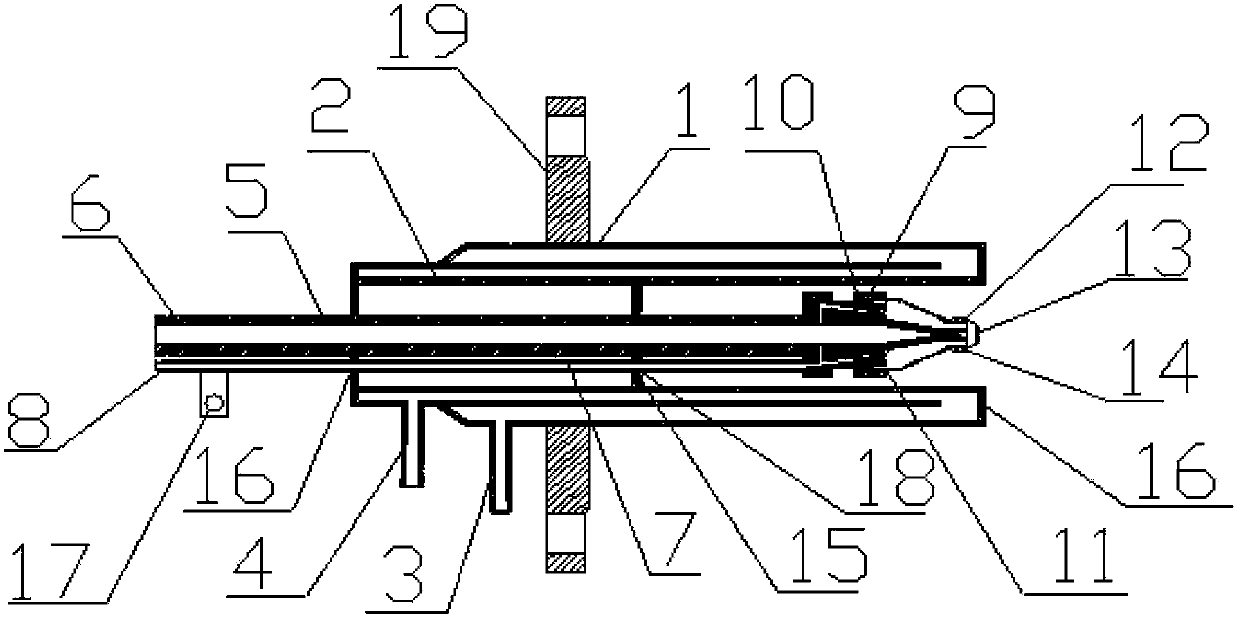

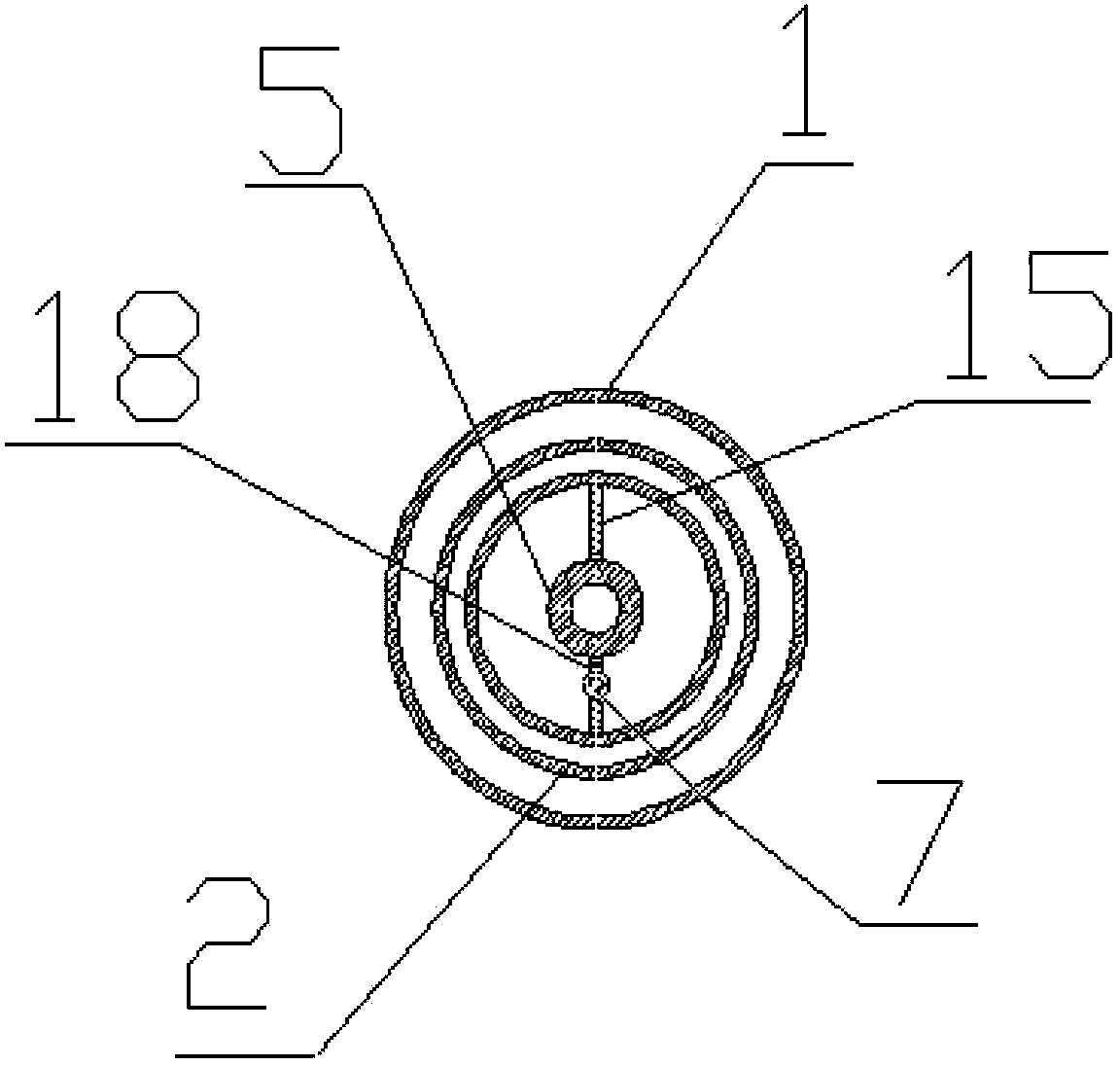

Water-cooled air atomizing spray gun suitable for denitration adopting SNCR method

ActiveCN102671518BReduce heat radiationSolve easy burnsDispersed particle separationLiquid spraying apparatusFlue gasSpray nozzle

The invention discloses a water-cooled air atomizing spray gun suitable for denitration adopting an SNCR (Selective Non-Catalytic Reduction) method. A cooling water inlet is formed on an inner sleeve, and a cooling water outlet is formed on an outer sleeve, so as to form inlet and outlet passages for cooling water; a water solution pipe and an air pipe are arranged inside the inner sleeve; connectors are arranged at one end of the water solution pipe and one end of the air pipe 7, and a spray nozzle and an air cap are arranged at the other end of the air pipe 7; recirculated cooling water enters the inner sleeve through the cooling water inlet, enters a front section of the spray gun along with a gun body, and finally returns to a circulating water return main pipe from the cooling water outlet of the outer sleeve; a movement connecting mechanism is connected with a cylinder so as to drive a spraying component to stretch out and draw back; and when the water-cooled air atomizing spray gun stops operating, the spraying component can be taken back to the inner parts of the water-cooled inner sleeve and the water-cooled outer sleeve, a spray nozzle is prevented from being burnt out, and problem, the problem that the spray nozzle is exposed in high-temperature flue gas for a long time in the past and is easy to be burnt out is solved.

Owner:HUANENG CLEAN ENERGY RES INST +1

A kind of manufacturing method of chrome bronze material for isolating switch contacts

The invention discloses a preparing method of a chromium bronze material for a disconnecting switch wafer. The chemical composition of the chromium bronze material comprises, by weight, 0.4-1.0% of Cr, 0.1-0.3% of Al, 0.1-0.3% of Mg and the balance Cu. The preparing method of the chromium bronze material includes the following steps of firstly, preparing the materials; secondly, conducting smelting; thirdly, conducting extruding and cooling to obtain a round bar profile for rolling an alloy wafer; fourthly, conducting rolling; fifthly, conducting drawing for cold deformation; sixthly, conducting ageing treatment; seventhly, conducting sizing and sawing off processing. The obtained disconnecting switch wafer has high conductivity larger than or equal to 60% IACS at 20 DEG C, high hardness HB larger than or equal to 130, high tensile strength Rm larger than or equal to 480 Mpa and high oxidization resistance. By means of the disconnecting switch wafer, the failures of oxidization, heating, softening and the like during use of a disconnecting switch are solved; meanwhile, the method is simple in preparing process, saves energy and reduces consumption.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

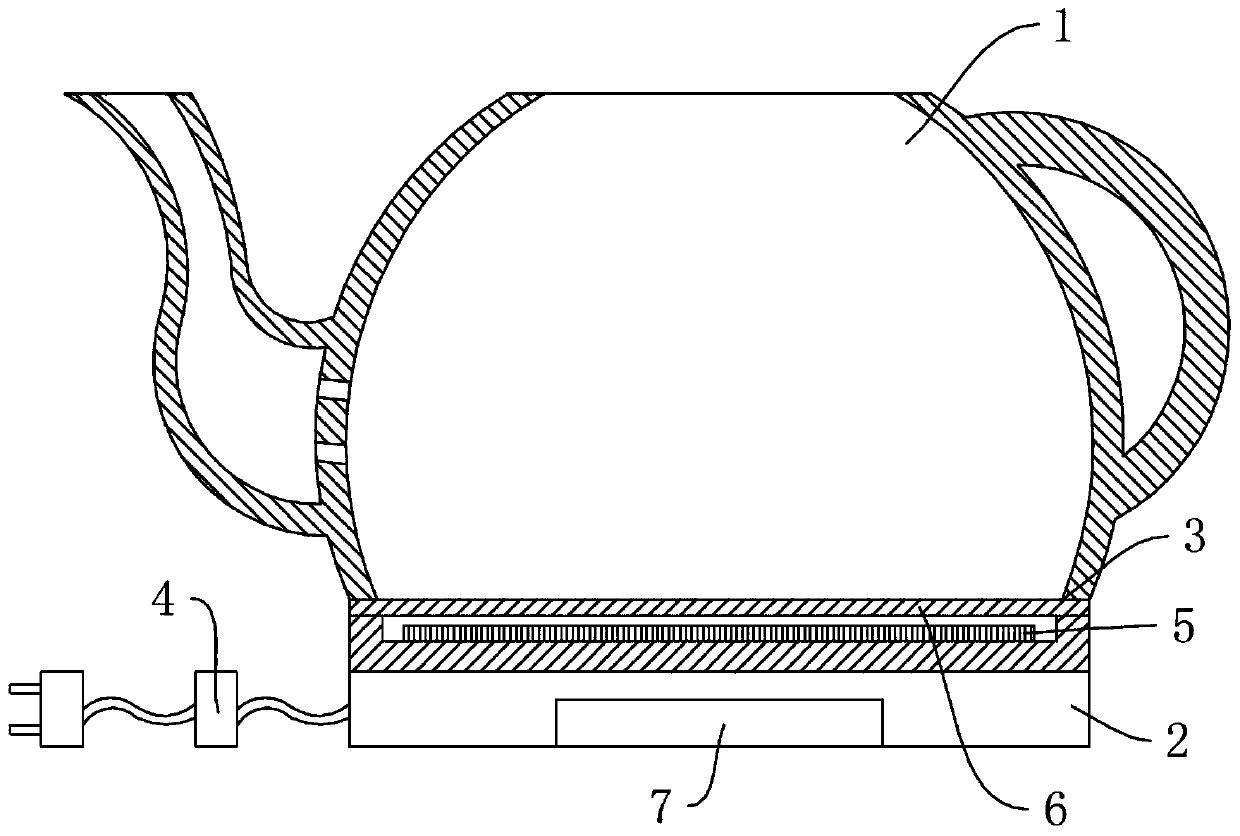

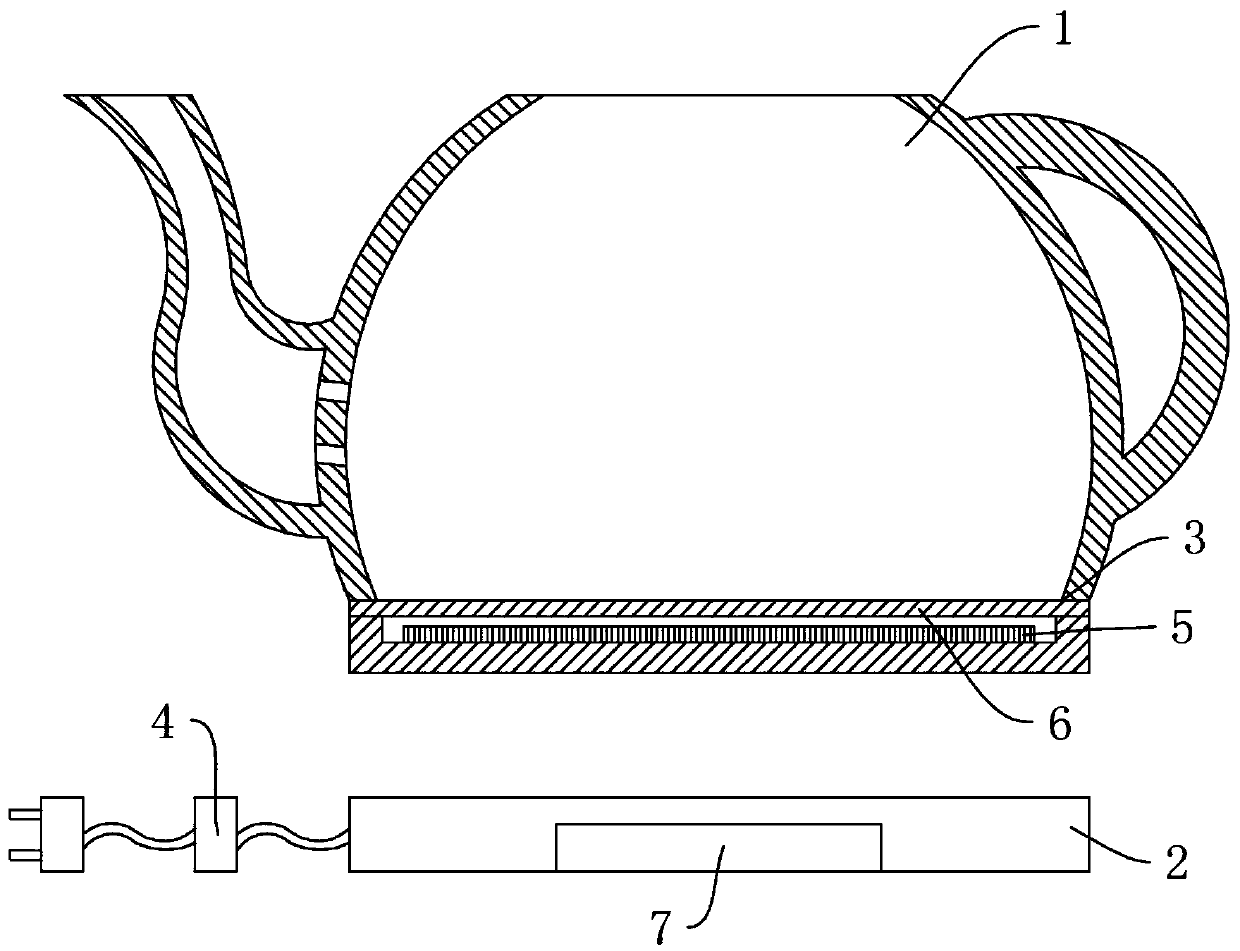

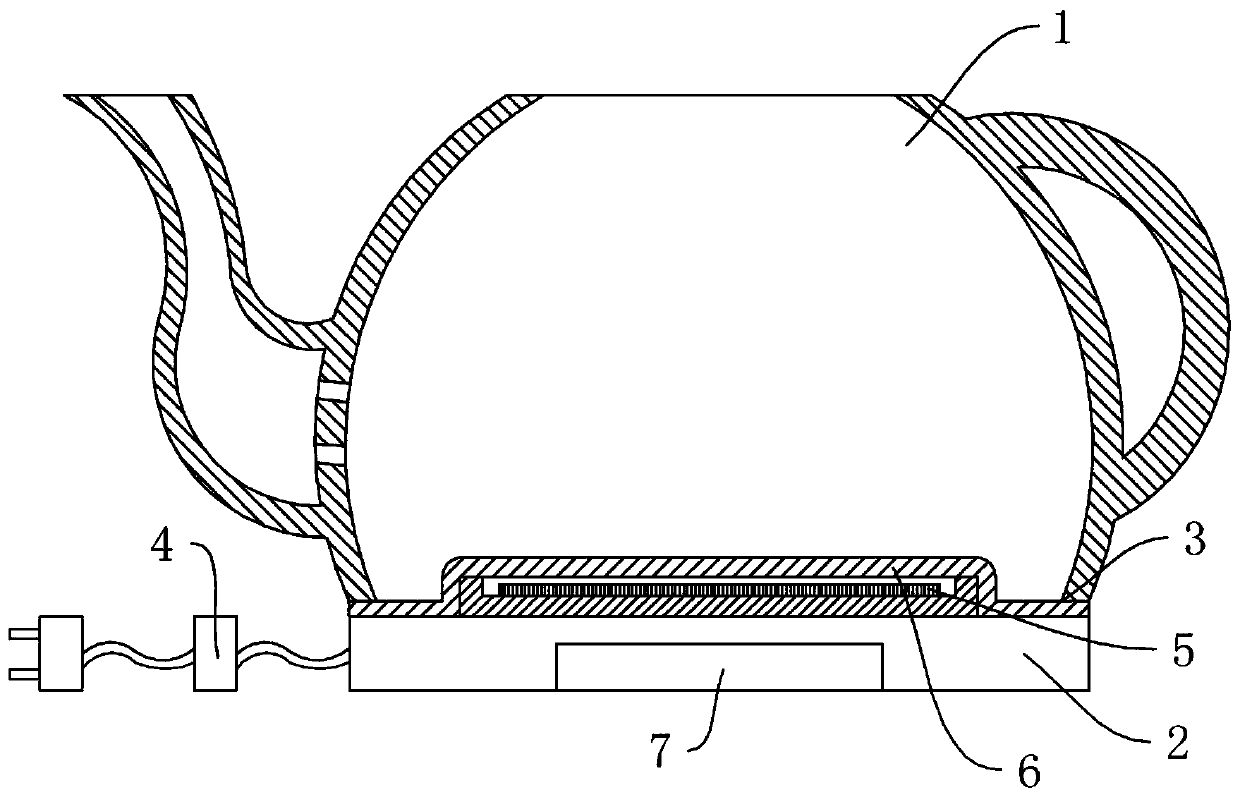

Novel liquid heater

The invention discloses a novel liquid heater. The novel liquid heater comprises a container and a base, the novel liquid heater is characterized by further comprising an electric ceramic heating disc, the base is provided with a power circuit, the electric ceramic heating disc is electrically connected with the base, the container comprises a container body and a protective plate located at the bottom of the container body, the protective plate is located above the heating face of the electric ceramic heating disc, and heat generated after the electric ceramic heating disc is powered on is transmitted into the container through the protective plate.

Owner:吴见

A device for unblocking holes of calcium carbide furnace

ActiveCN105674752BReduce power consumptionComply with the discharge processCharge manipulationControl devices for furnacesControl systemCarbide

The invention discloses a tap-hole opening and plugging device for a calcium carbide furnace. The tap-hole opening and plugging device comprises a machine base, a tap-hole plugging driving mechanism, a tap-hole plugging device, a tap-hole opening driving mechanism, a tap-hole opening device and a control device, wherein the machine base is connected with the tap-hole plugging driving mechanism and the tap-hole opening driving mechanism, the tap-hole plugging driving mechanism is connected with the tap-hole plugging device, the tap-hole opening driving mechanism is connected with the tap-hole opening device, the control device comprises a hydraulic control system and a pneumatic control system, the tap-hole plugging driving mechanism, the tap-hole opening driving mechanism and the tap-hole opening device are connected with the hydraulic control system, and the tap-hole plugging device is connected with the pneumatic control system. The tap-hole opening and plugging device solves the problem that tap-hole opening and plugging machines for alloy furnaces in the prior art have a poor tap-hole plugging effect on the calcium carbide furnace. Tap-holes can be opened and plugged easily.

Owner:SINOSTEEL XIAN MACHINERY

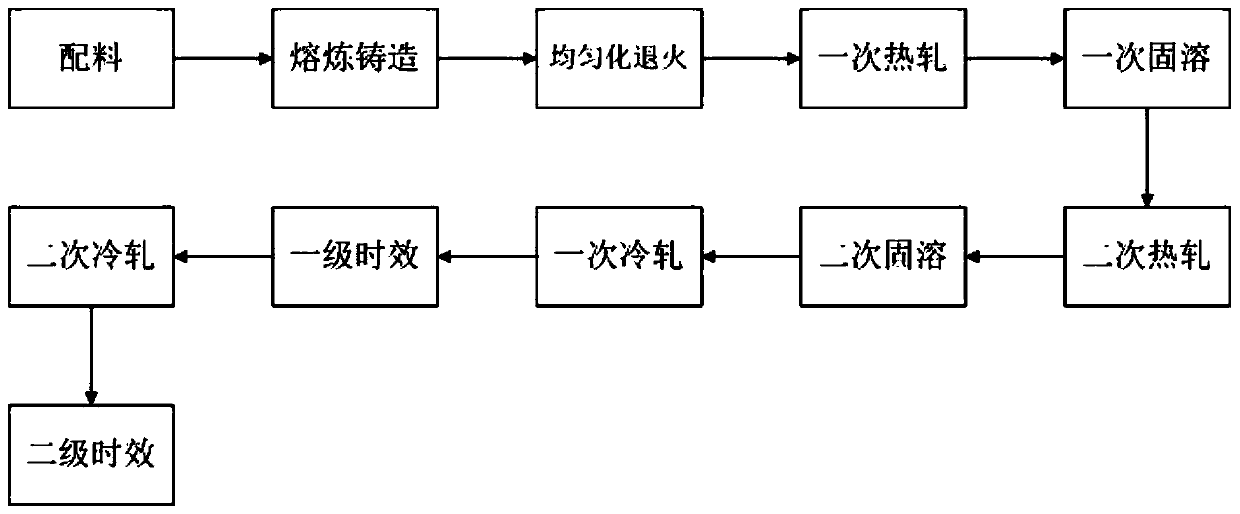

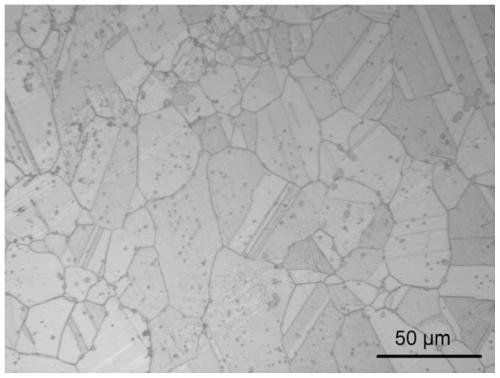

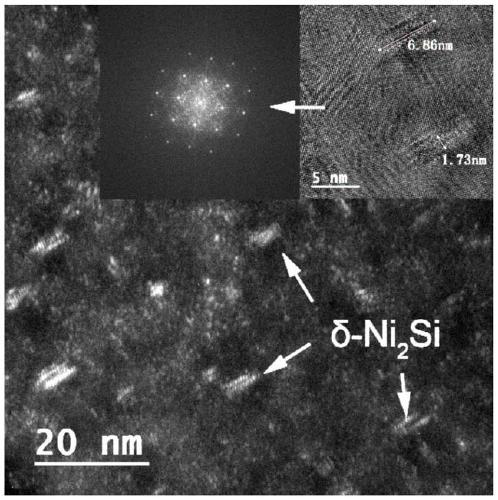

A kind of ultra-high-strength and high-conductivity copper alloy and preparation method thereof

The invention discloses an ultrahigh-strength high-conductivity copper alloy. The copper alloy comprises the following components of, by weight, 4.6-6.0% of Ni, 1.0-2.0% of Co, 1.0-2.0% of Si, 0.05-0.4% of Mg, 0.01-0.1% of Sr, 0.01-0.1% of Nb and the balance Cu, wherein the sum of the mass percentages of all the components is 100%. The preparation method of the copper alloy comprises the steps ofsmelting, casting, homogenization, hot rolling, solid solution treatment and combined deformation heat treatment. According to the ultrahigh-strength high-conductivity copper alloy, an element Be which is easy to burn is replaced by elements which are environment-friendly, easy to add and not easy to burn, second-phase particles are separated out through alloy element component design to prevent dislocation movement, and meanwhile, the solid solution elements in a matrix are reduced; a special two-stage hot rolling and solid solution treatment process is adopted, so that tissues are more uniform, coarse precipitation phase redissolution is promoted, and tissue preparation is provided for subsequent deformation heat treatment; and the precipitation of the nano-reinforced phase is promoted through combined deformation heat treatment, so that the system alloy has excellent mechanical property and conductivity, and the obtained copper alloy is excellent in mechanical property and high in conductivity.

Owner:CENT SOUTH UNIV

Waistline fitting type pull-ups device

ActiveCN112936894AHigh reject rateAvoid non-conforming product rateDomestic articlesEngineeringPhysics

The invention relates to the field of hygienic product equipment, in particular to a waistline fitting type pull-ups device which comprises a rack, a first welding roller and a second welding roller, wherein two heat conduction copper plates are arranged inside the first welding roller and close to the outer edge, the distance between each heat conduction copper plate and the first welding roller is 3-5 cm, and extending parts are arranged at the upper end and the lower end of each heat conduction copper plate. Each extension part surrounds a half of the periphery of a corresponding first mounting hole, and the extension parts and heating pipes are arranged at intervals. The extension parts at the head ends and the tail ends of the heat conduction copper plates surround the heating pipes by half, meanwhile the extension parts extend into welding blocks, and heat can be conducted to the surface of the middle of the first welding roller in the using process; and by means of heat dissipation holes formed in the first welding roller at intervals and located at the position close to the heat conduction copper plates, heat of the parts, close to the heat conduction copper plates, of the first welding roller can be taken away more quickly, then heat dissipation at the welding blocks is accelerated through the first welding roller, and the problem that the heating temperature of the part, close to the electric heating pipes, of the welding roller is not prone to being lowered is solved.

Owner:QUANZHOU LICHENG MINGHUI PAPER IND TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com