Machine-clamped center drill

A machine clamp and drill bit technology, applied in the direction of center drilling, repair drilling, drilling tool accessories, etc., can solve the problems of easy burning and cutting edge burning, achieve long service life, overcome easy burning, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Examples: The following specific examples illustrate the implementation of the invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

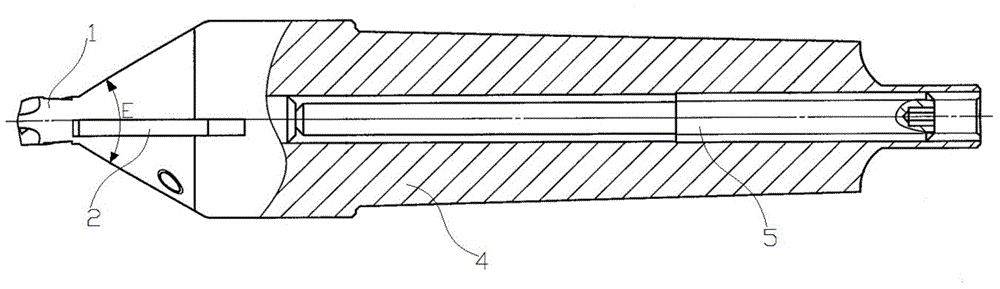

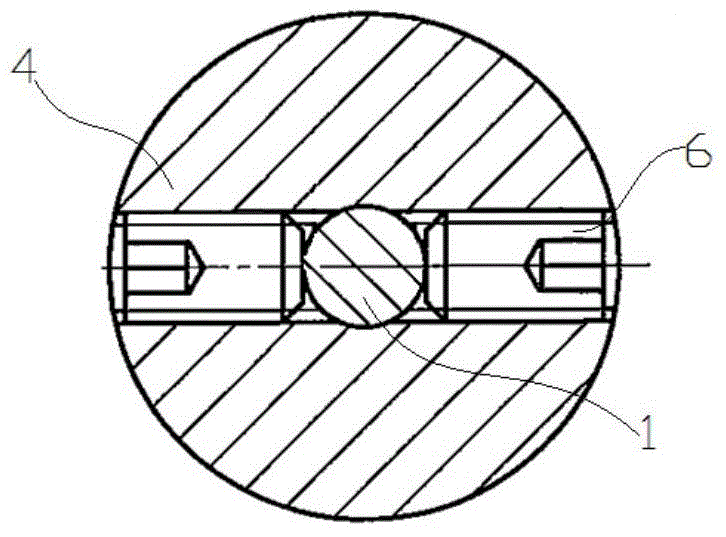

[0020] Such as Figure 1 to Figure 4 As shown, the clamp center drill of the present invention is composed of a center drill bit 1, a blade 2, a blade pressing screw 3, a cutter body 4, a drill adjusting screw 5, and a drill fixing screw 6. The cutter body 4 is a Morse taper rod with a flat tail, which is matched with the inner cone of the tailstock of the machine tool. The diameter of the head is 50mm, and the end face of the head is drilled Reaming, end face symmetrical milling two-axis symmetrical insert pocket 401, threaded hole on the bottom of insert pocket 401; the front end of the center drill bit (1) is a standard short type The twist drill, the back end angle E is 60° conical, The part that exceeds the taper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com