Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

180 results about "Morse taper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Morse taper is a standard system for securely attaching drill bit tools to the drill press machine spindle. During rotation, the part is held in place by friction of tapered shanks against the hollow spindle that holds the tool.

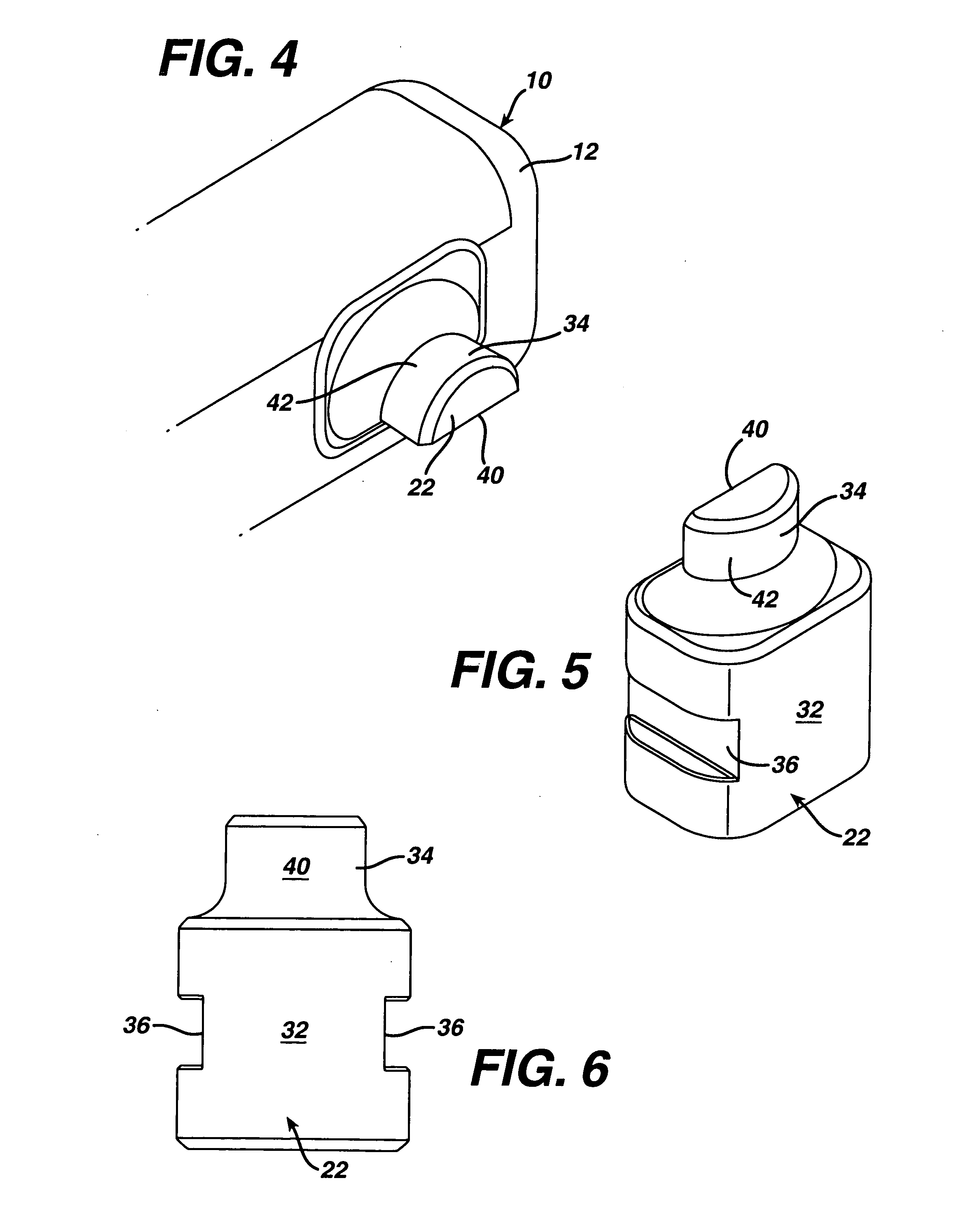

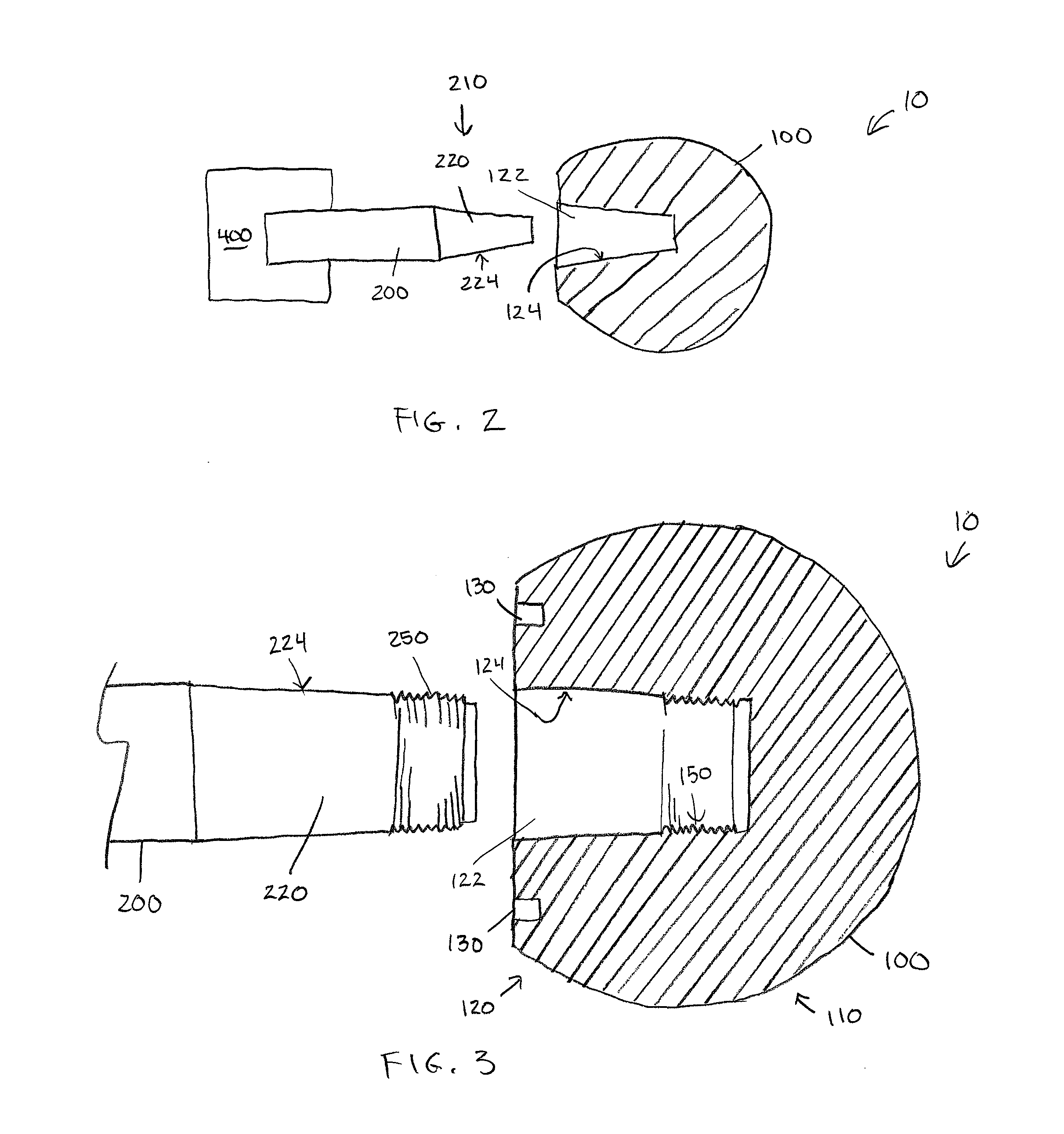

Modular implant system with fully porous coated sleeve

A modular knee implant system allows a surgeon to select between several different styles of distal femoral implant components and several different styles of stem extensions while also allowing for use of a metaphyseal component. The metaphyseal component can be a universal one that is usable with all of the styles of distal femoral implant components through use of an adapter. A second adapter allows for use of stem extensions with different types of connectors with the metaphyseal component. A separate metaphyseal component could also be provided with a distal Morse taper post to mate with a distal femoral component having a proximal Morse taper bore. The metaphyseal component may have an outer surface that is configured to maximize contact area with the patient's bone, and may have a surface finish over a substantial part of its overall length that is conducive to bone ingrowth.

Owner:DEPUY PROD INC

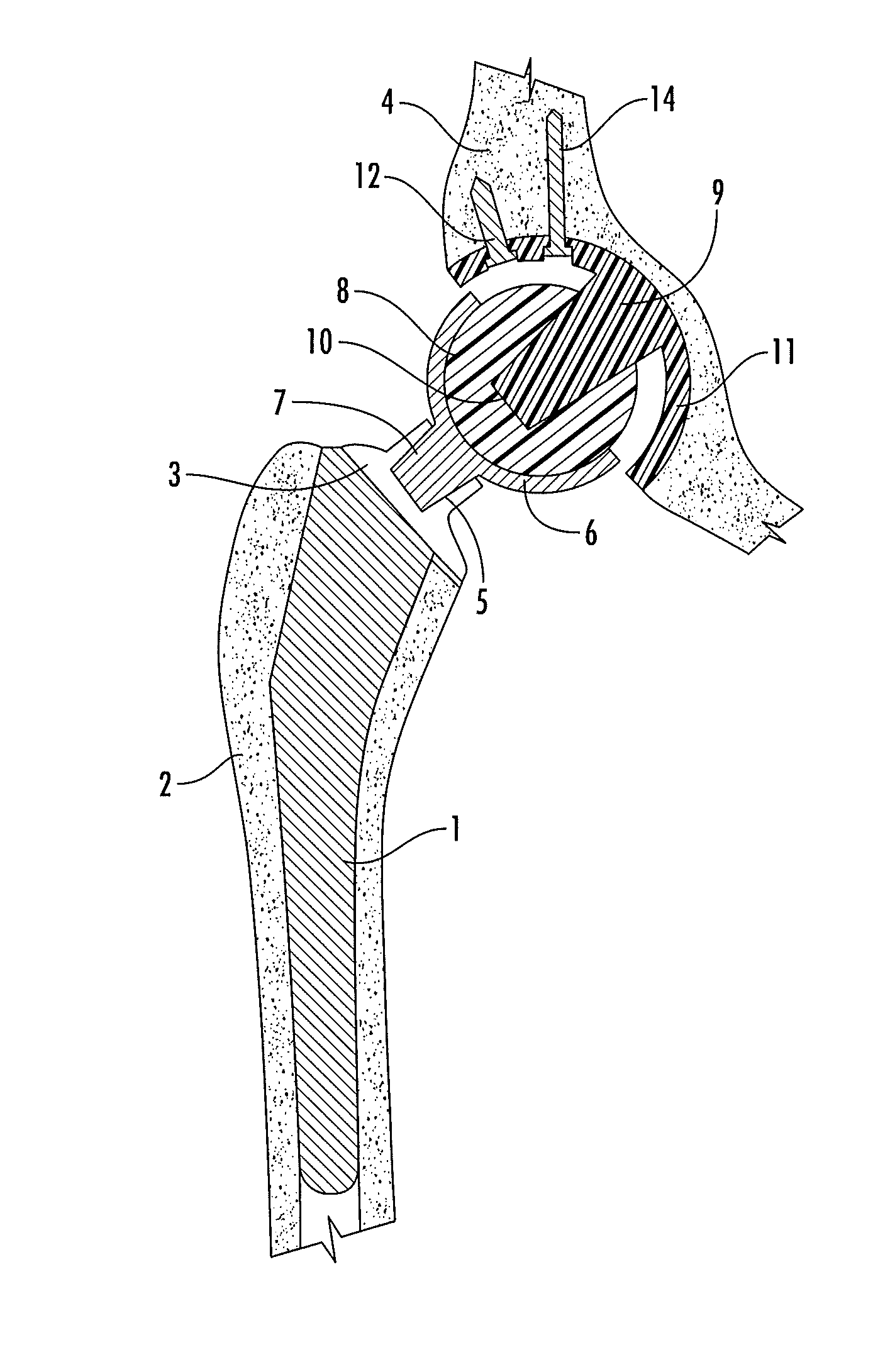

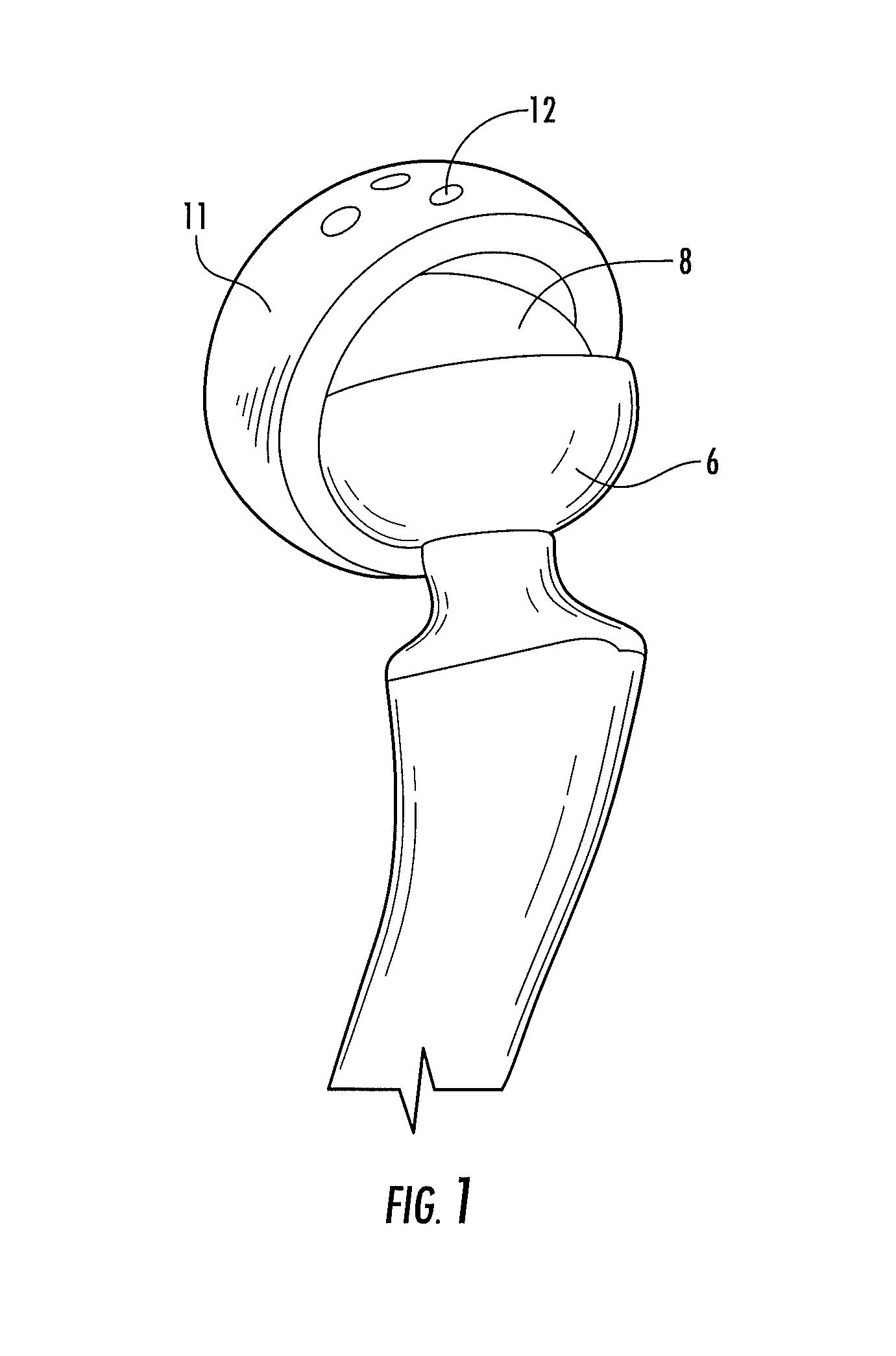

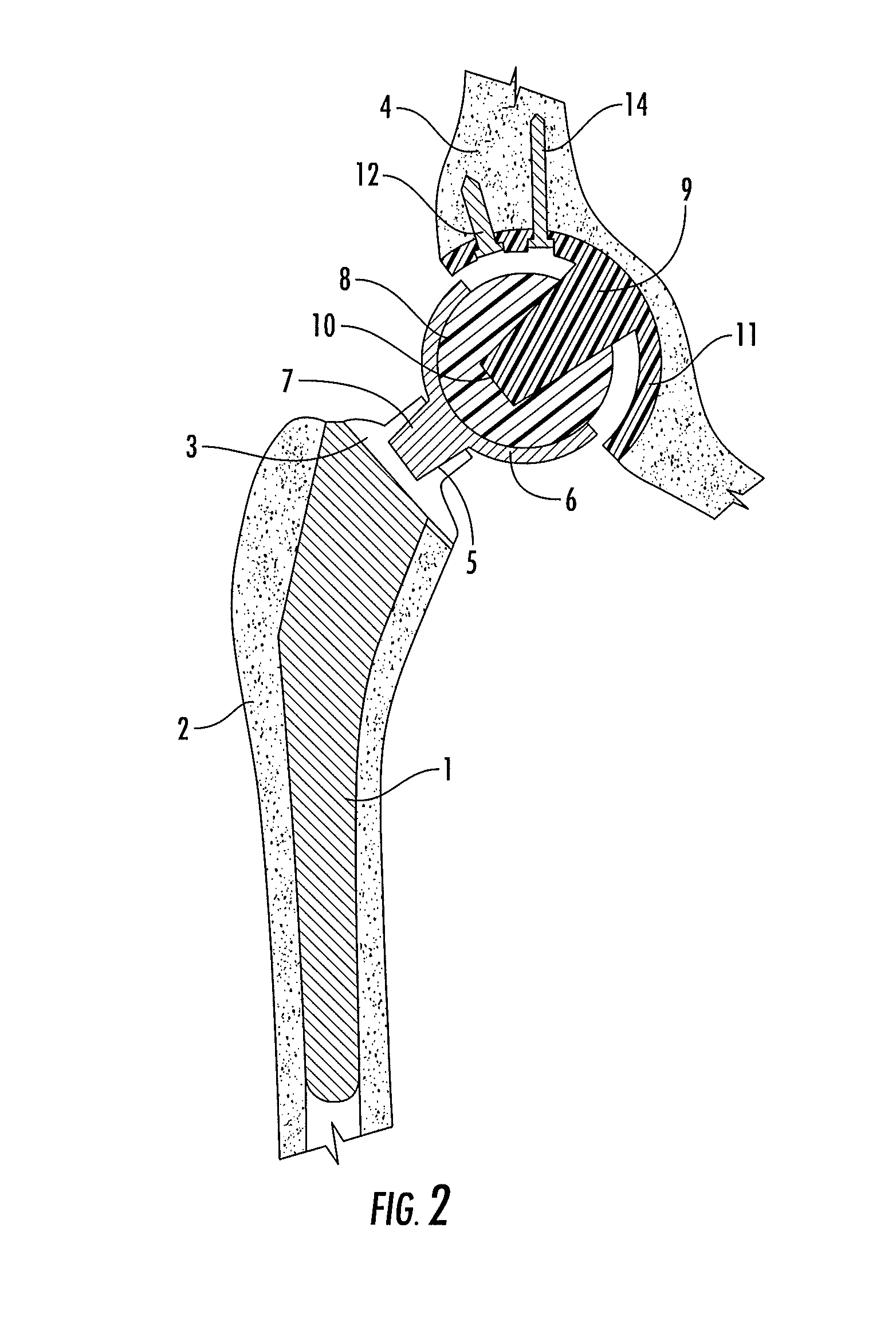

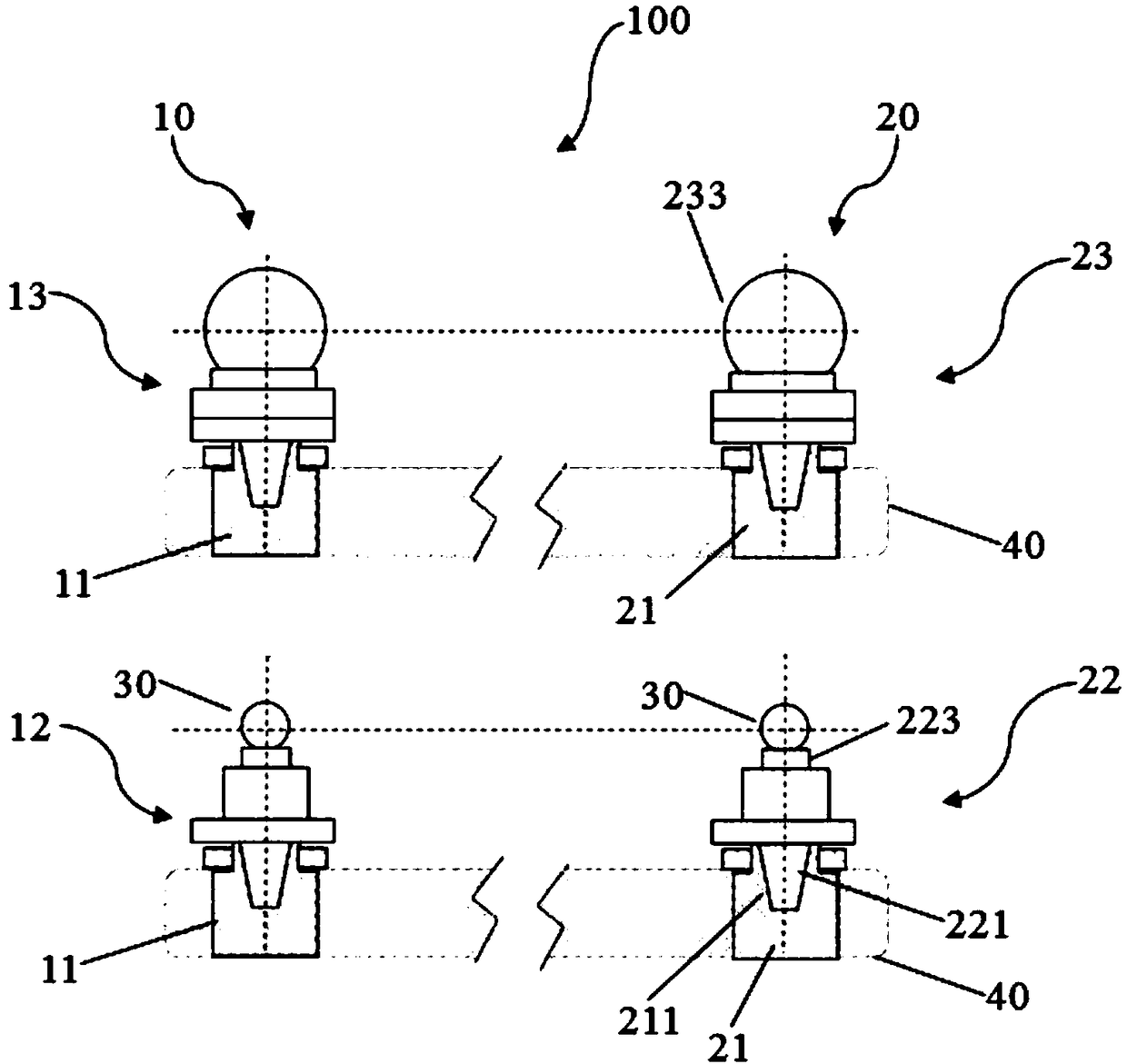

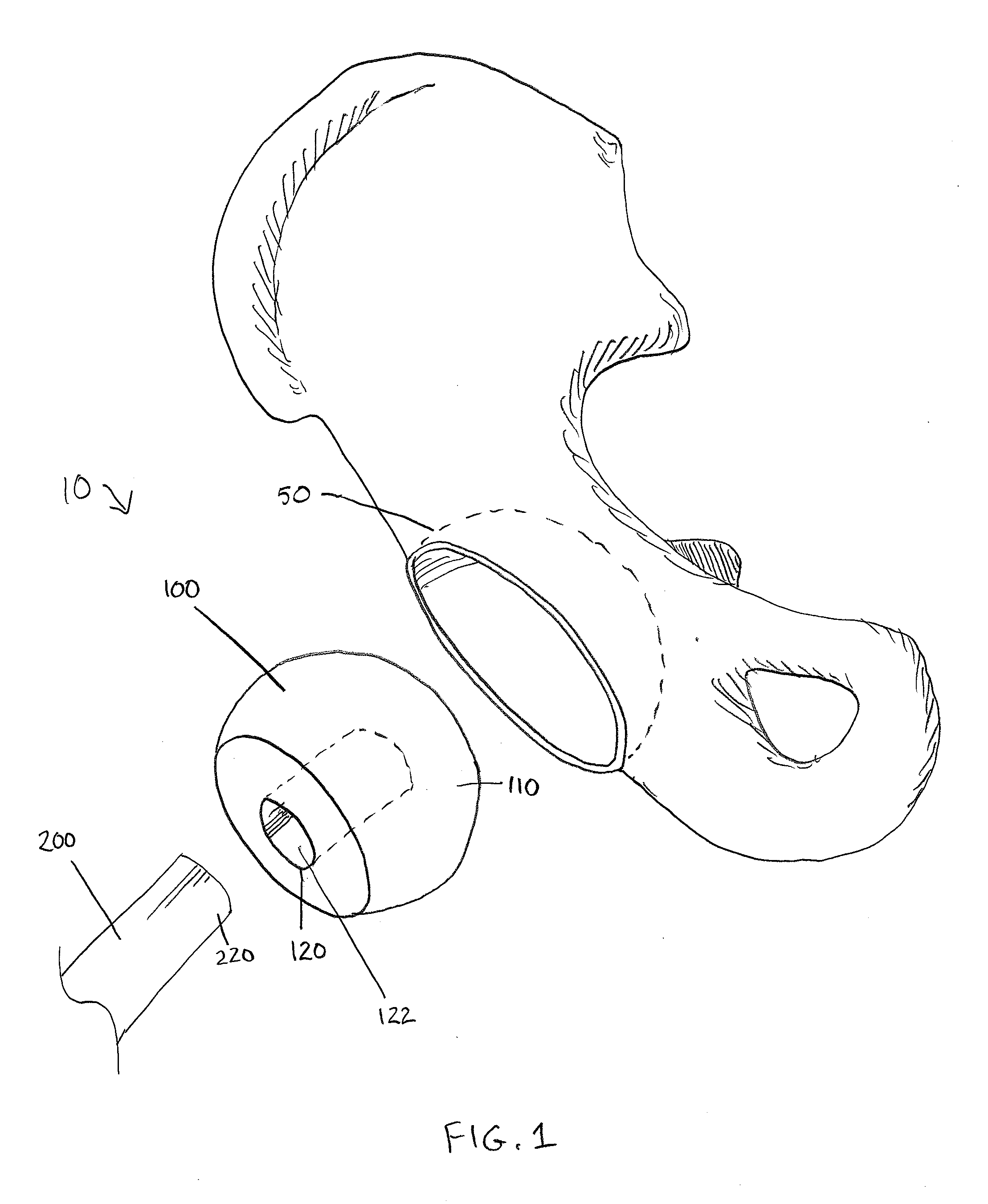

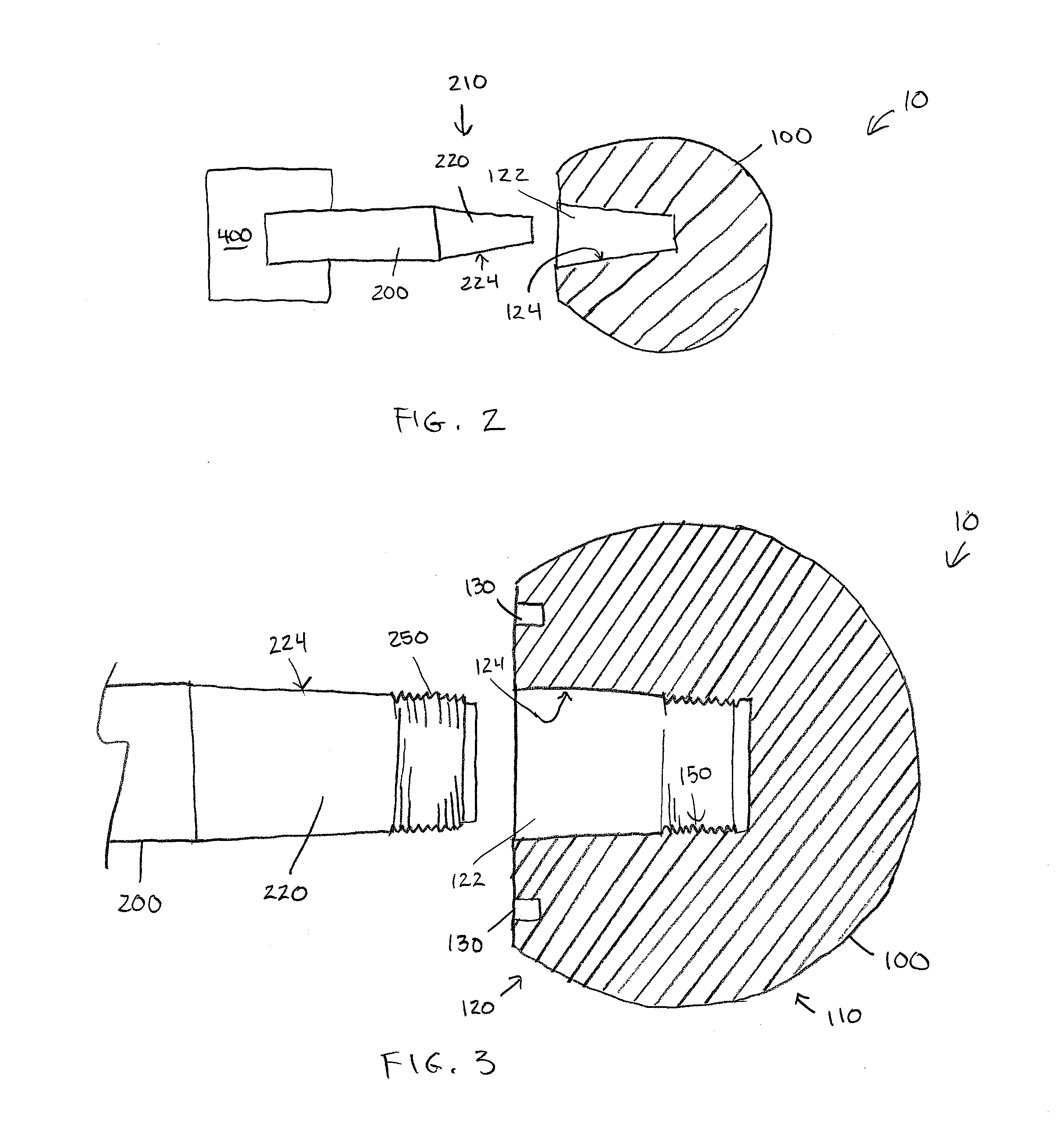

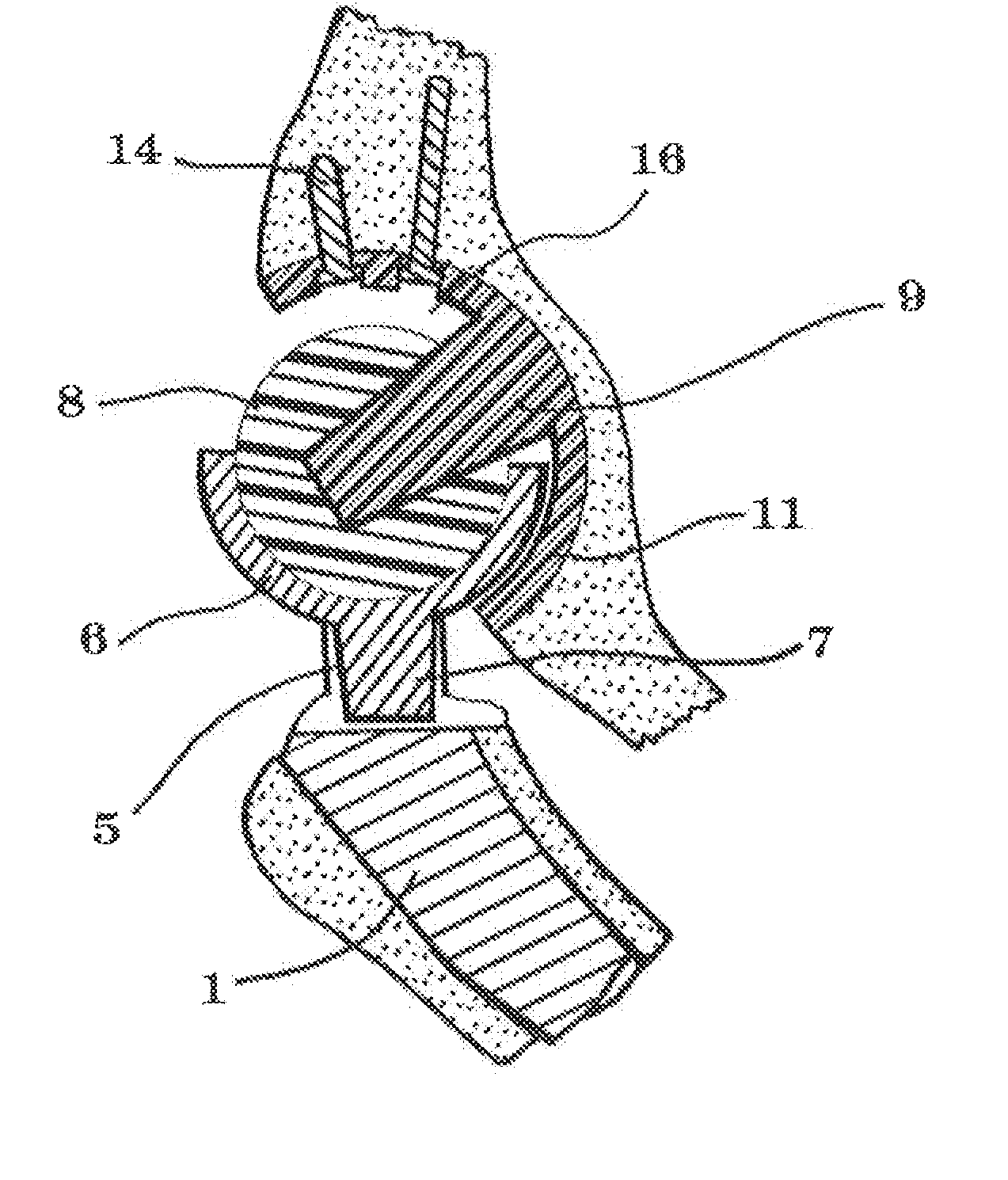

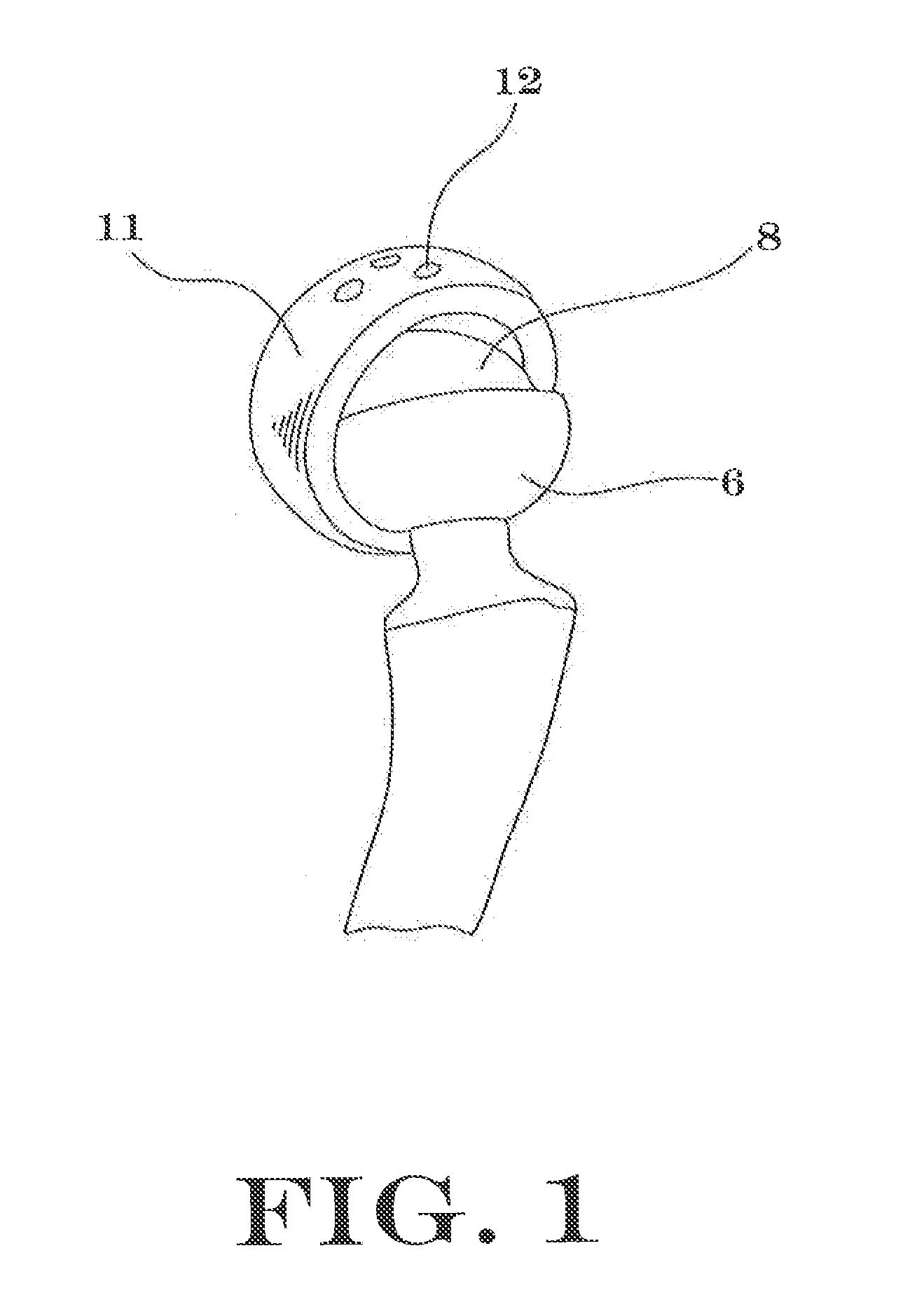

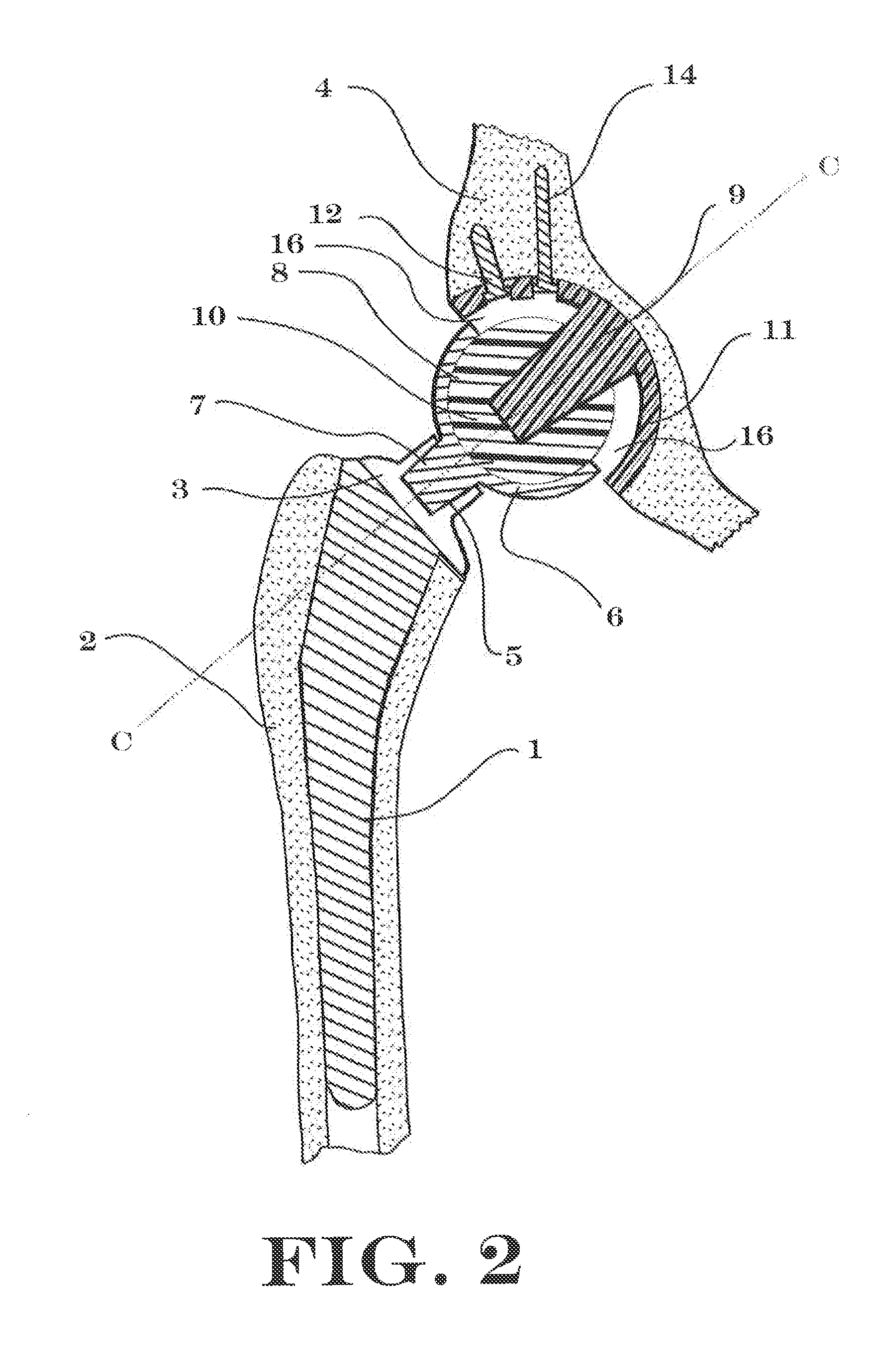

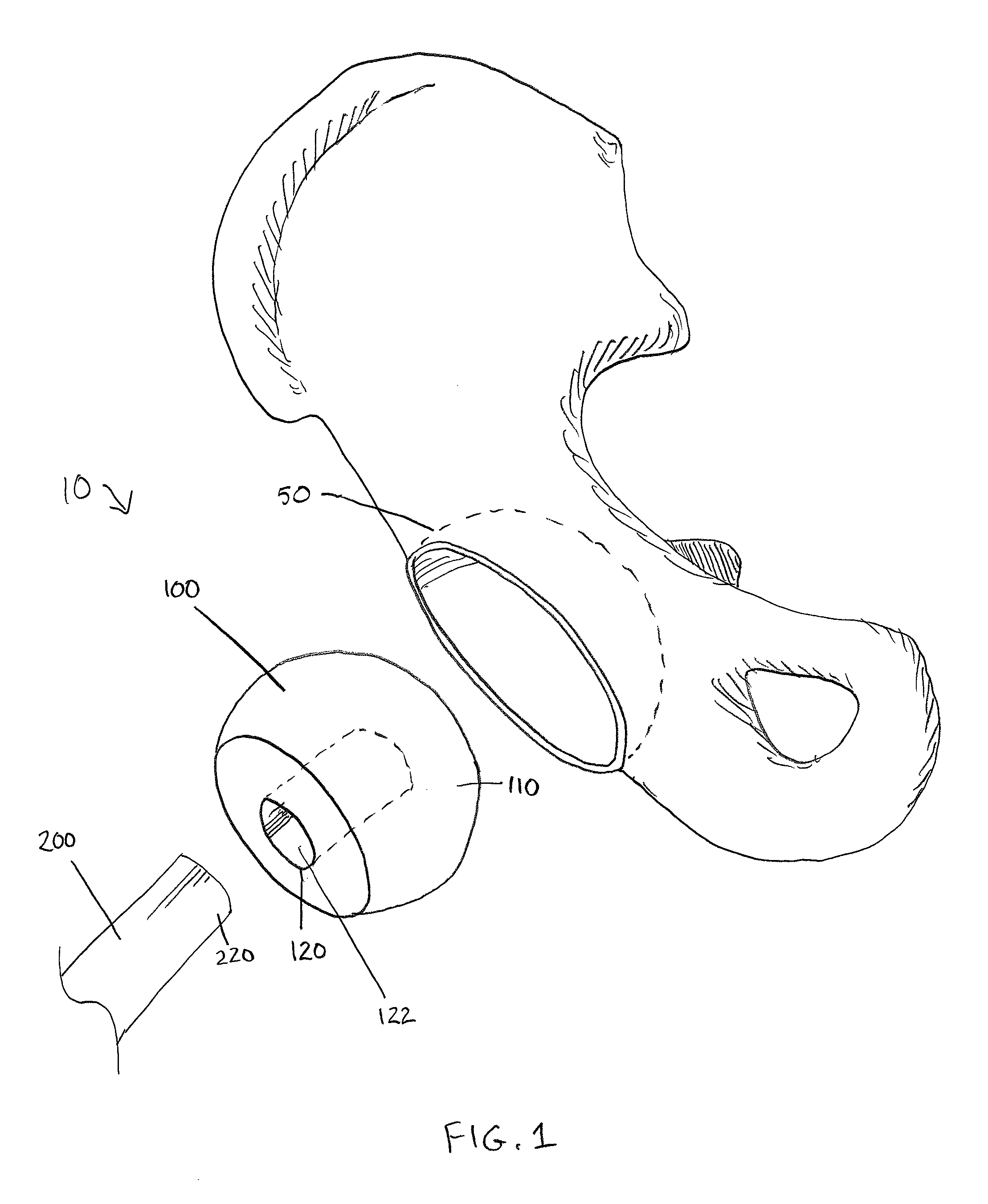

Interlocking reverse hip prosthesis and method

ActiveUS8313531B2Reduce wearReduce in quantityBone implantJoint implantsRange of motionFemoral component

An interlocking reversed hip prosthesis including an acetabular cup being implanted in the acetabular cavity having an acetabular articular ball, firmly attached to the central portion of the cup via Morse taper. The femoral component having a hemispherical cup attached to the neck of the implant via Morse taper in a modular fashion thereby allowing use of several length necks. After implantation of the acetabular cup and the femoral cup, the two members are assembled together for relative movement. The acetabular cup secured by several screws or resorbable fixation studs. During range of motion, the edge of the femoral cup becomes inserted into space located between the acetabular cup and the acetabular ball and becomes restrained thus reducing the likelihood of dislocation during extreme range of motion.

Owner:HIP INNOVATION TECHONOLOGY LLC

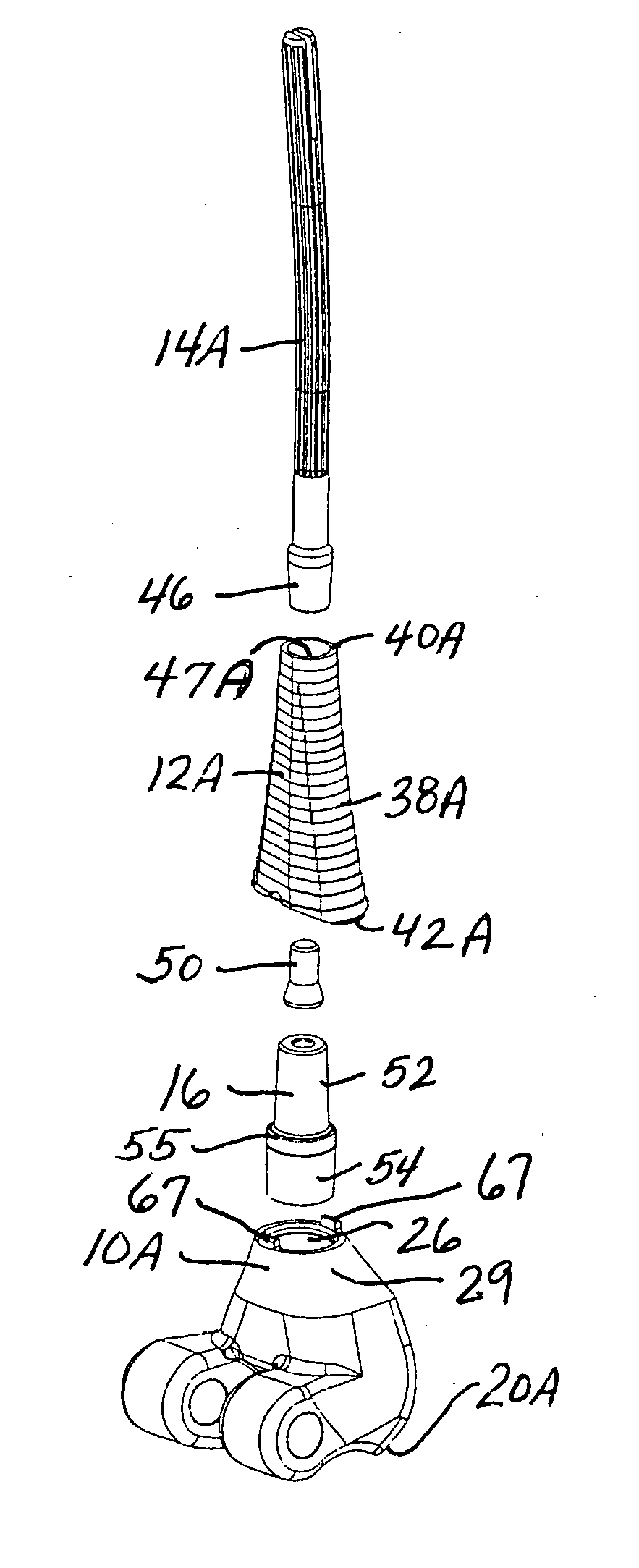

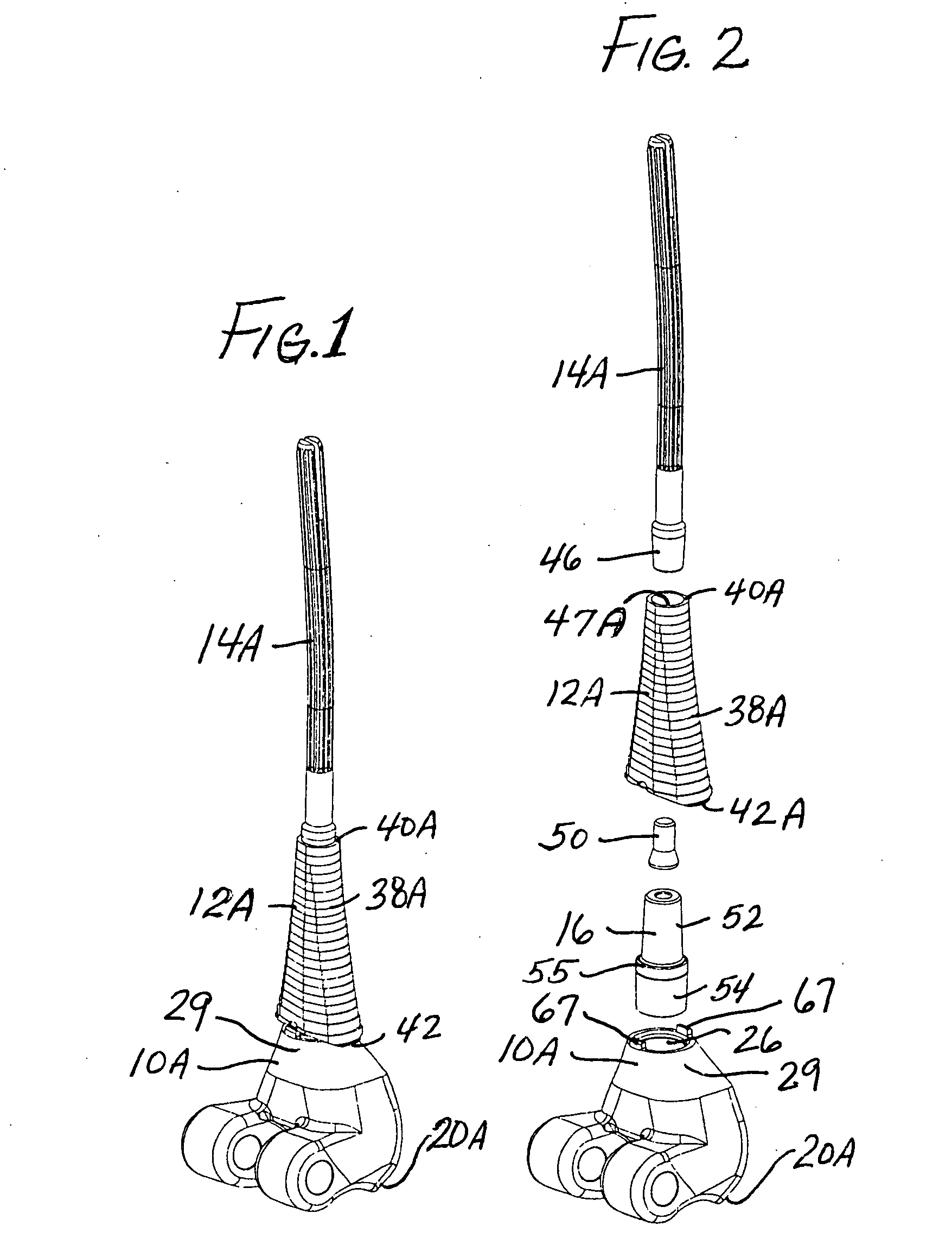

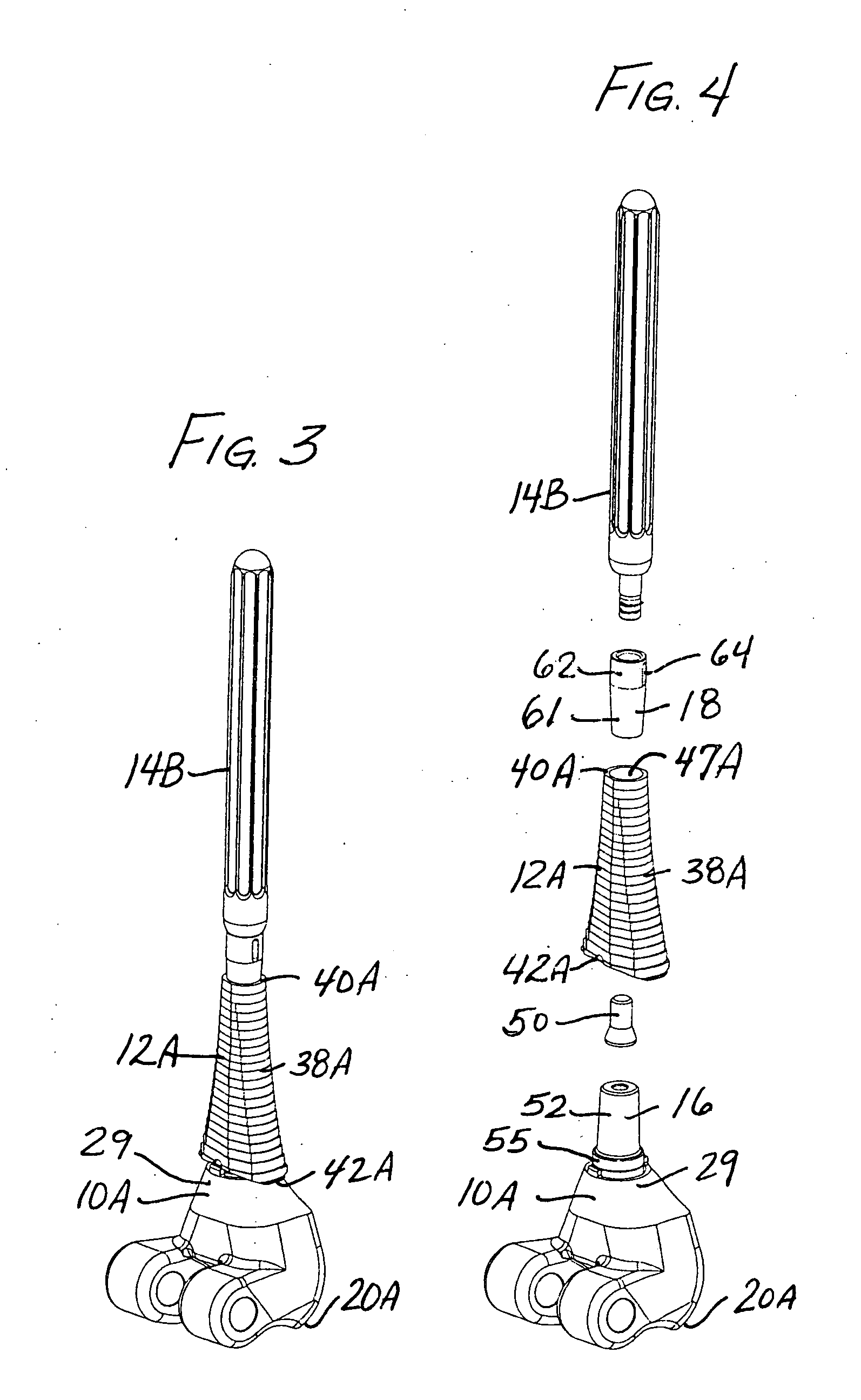

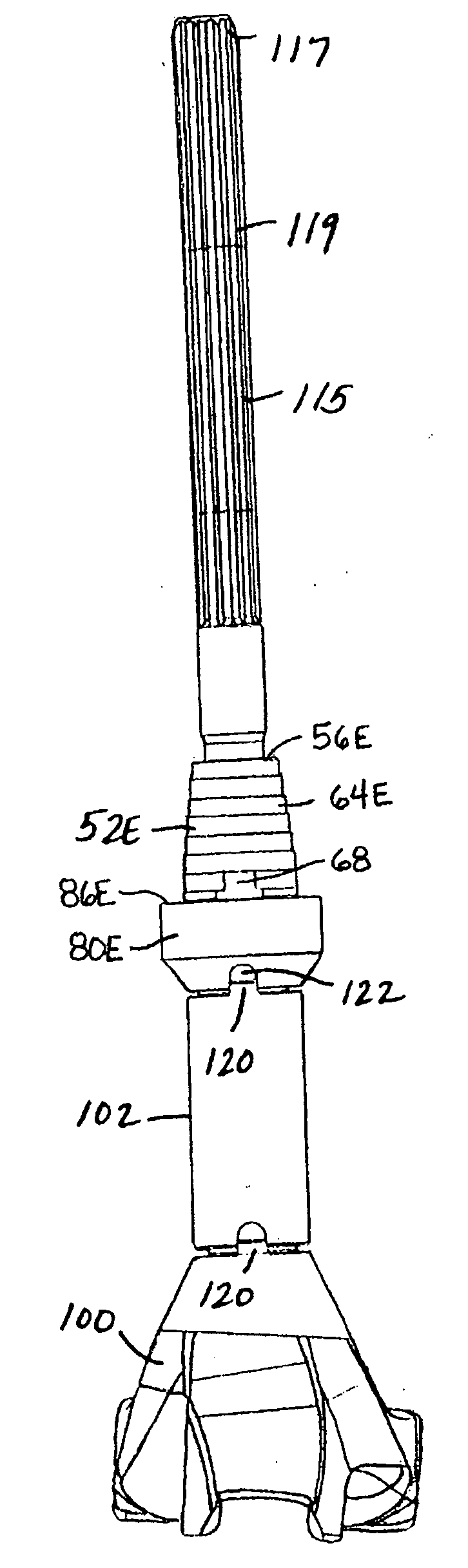

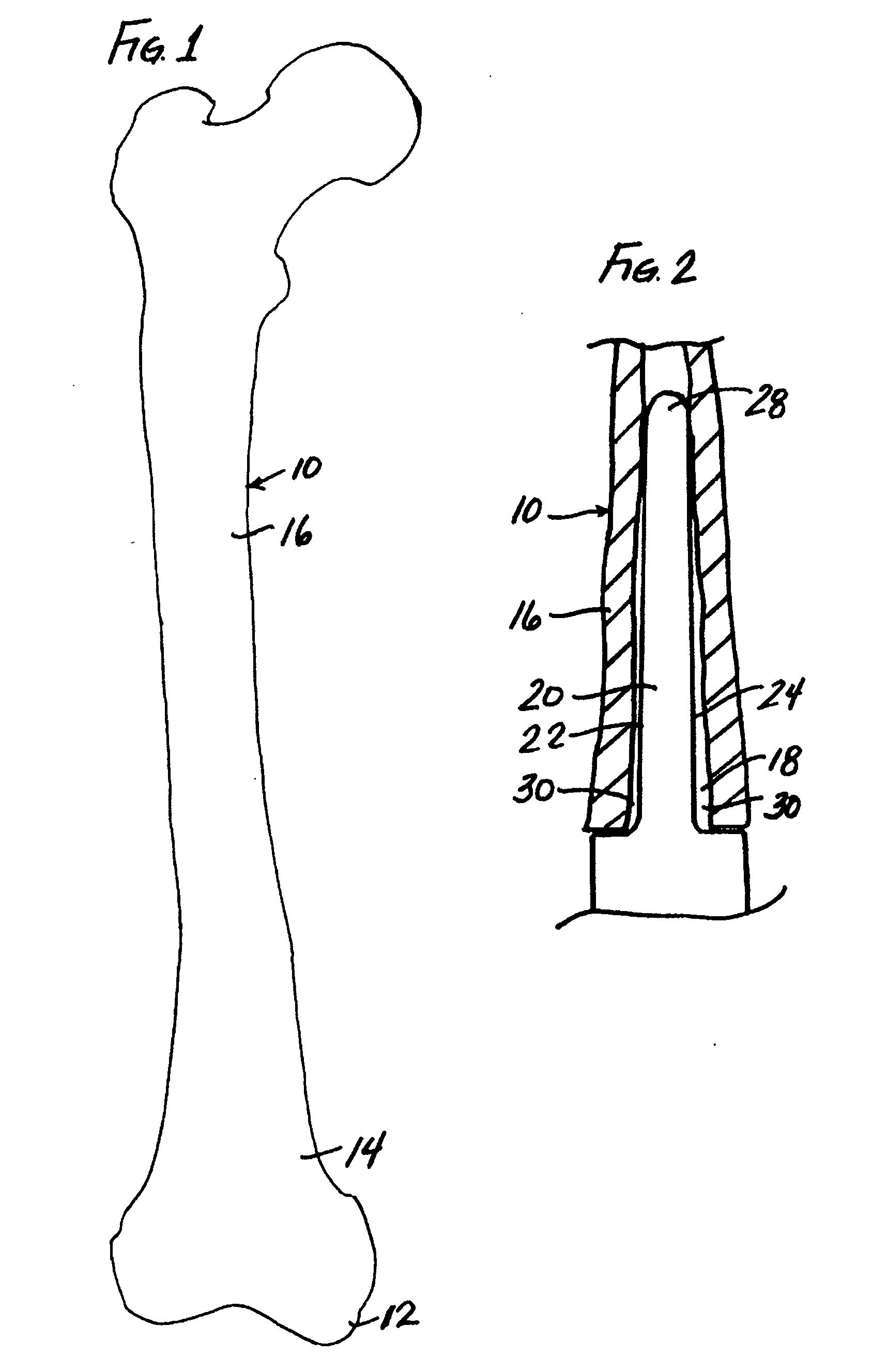

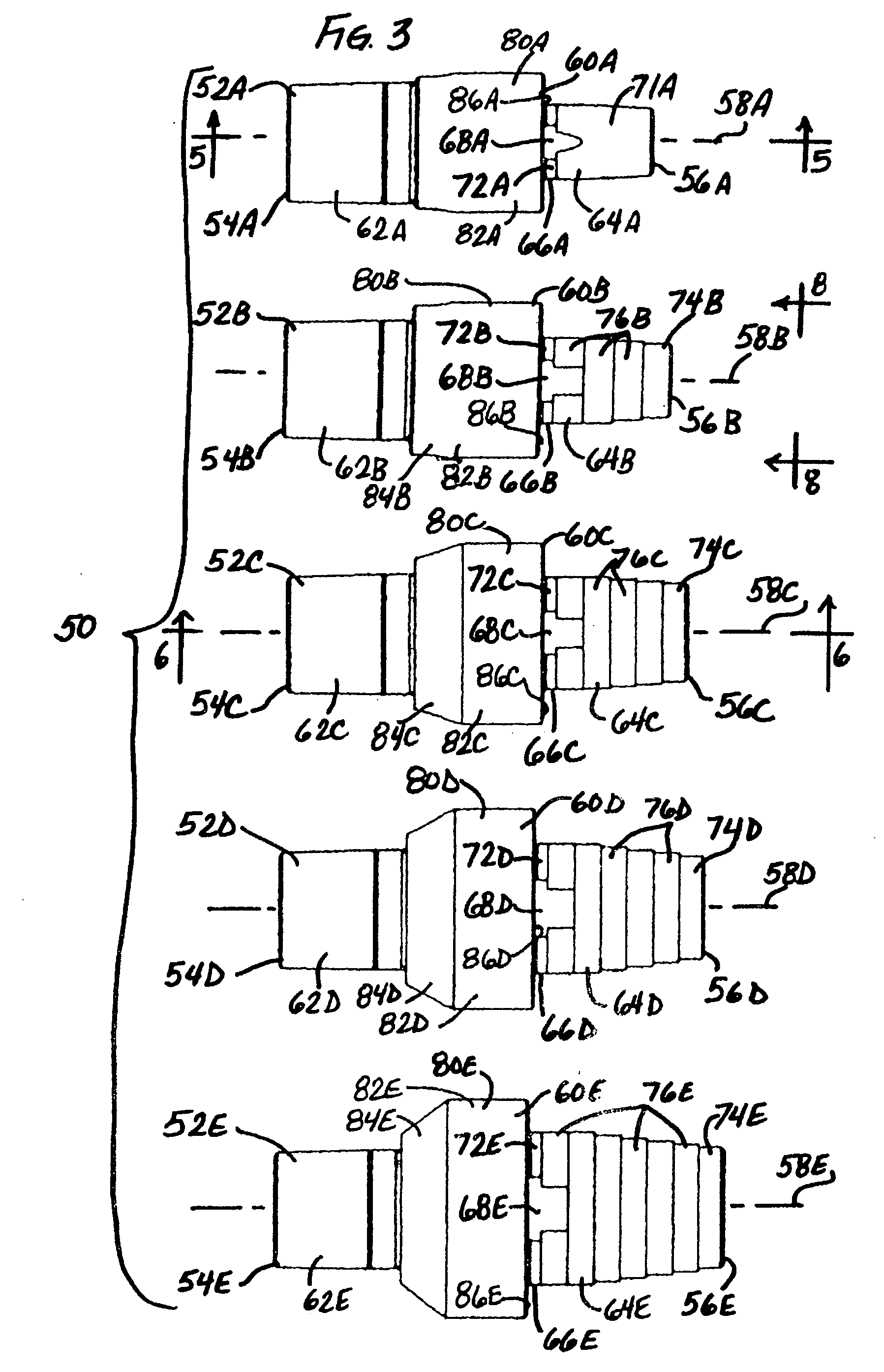

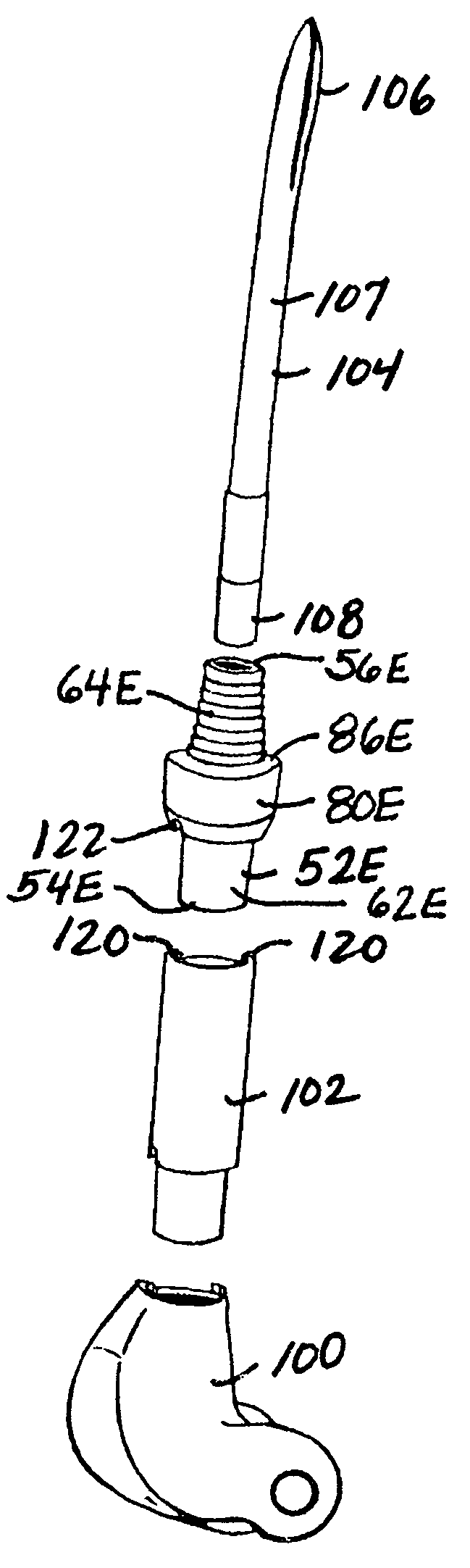

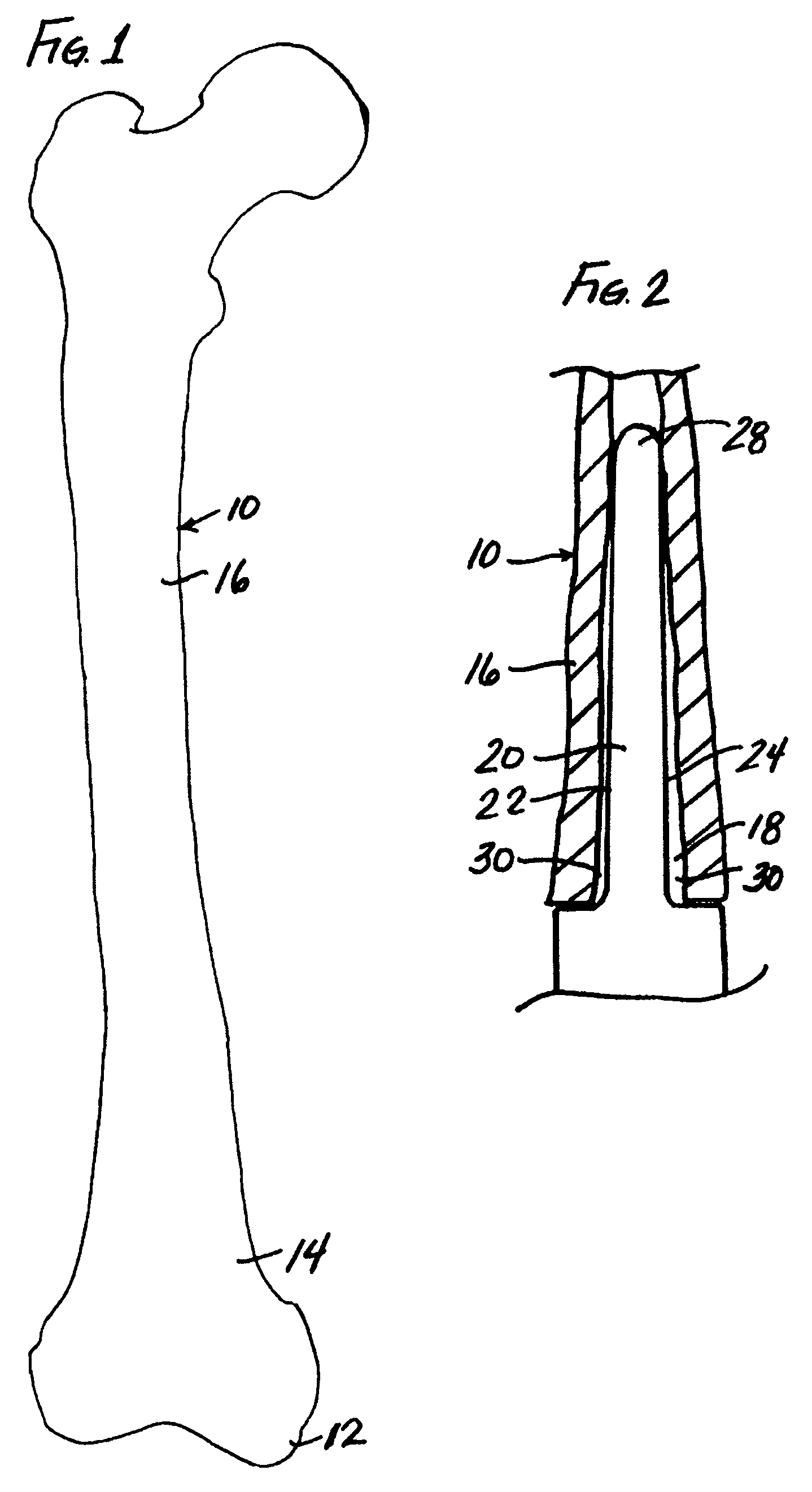

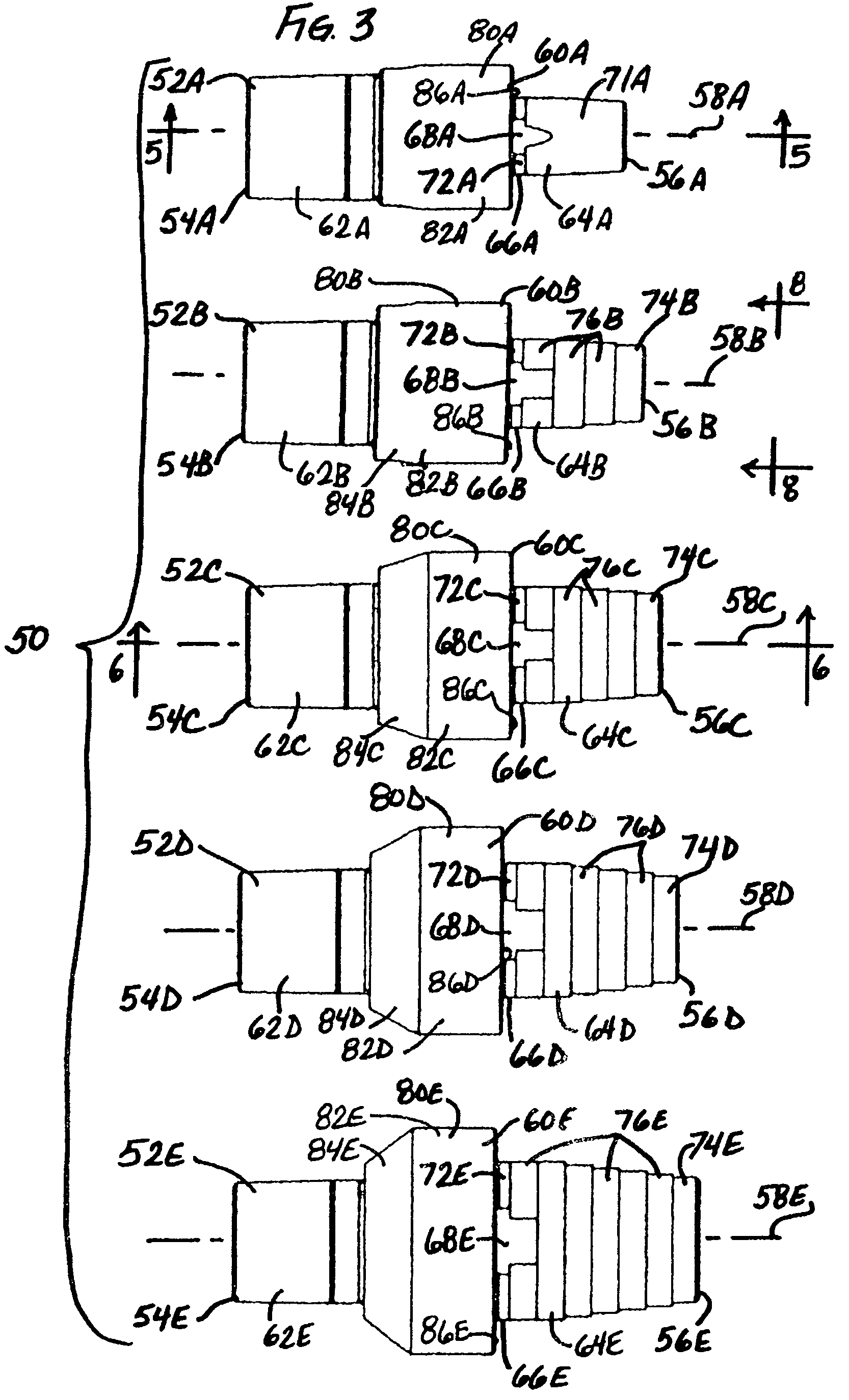

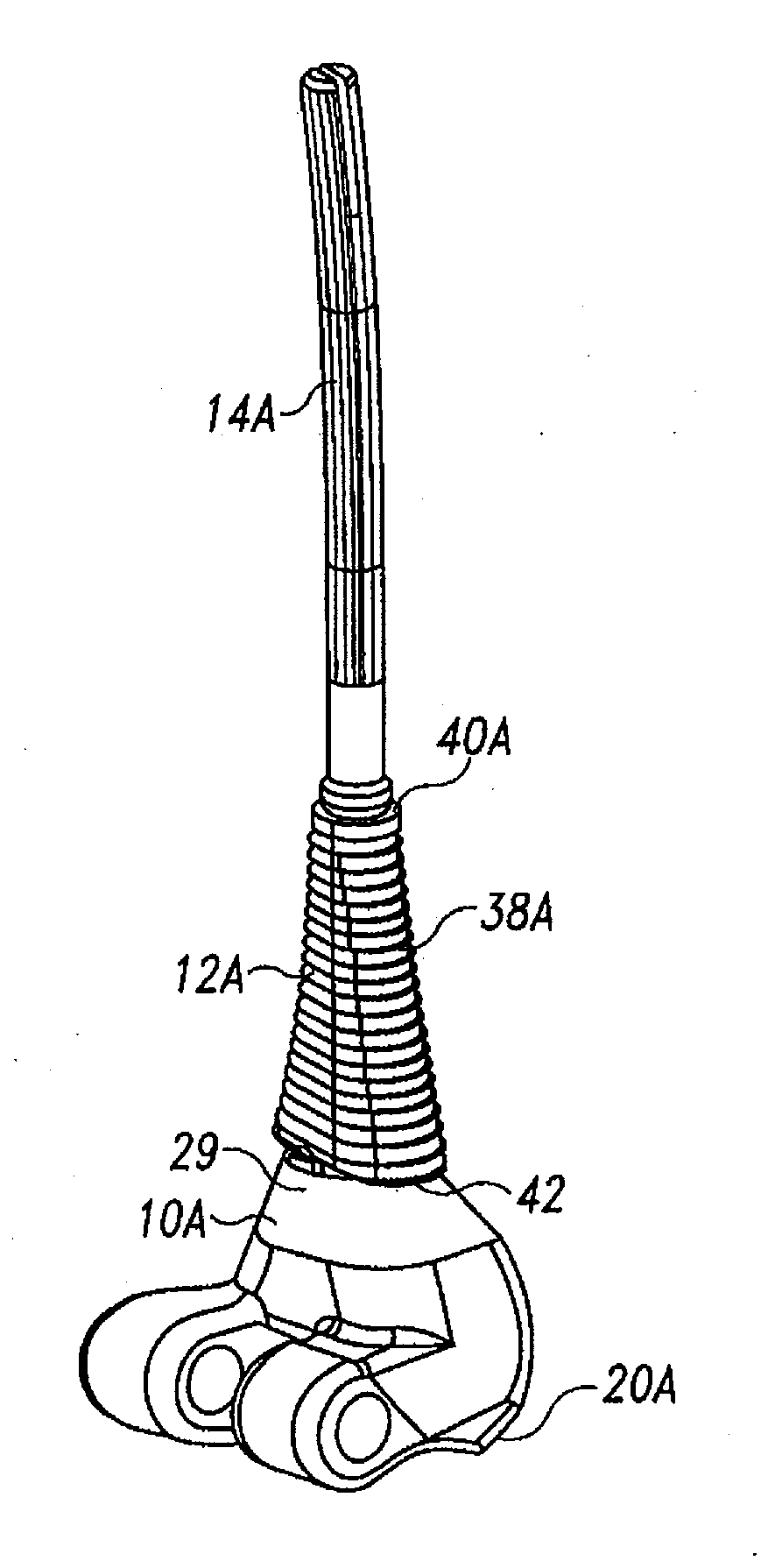

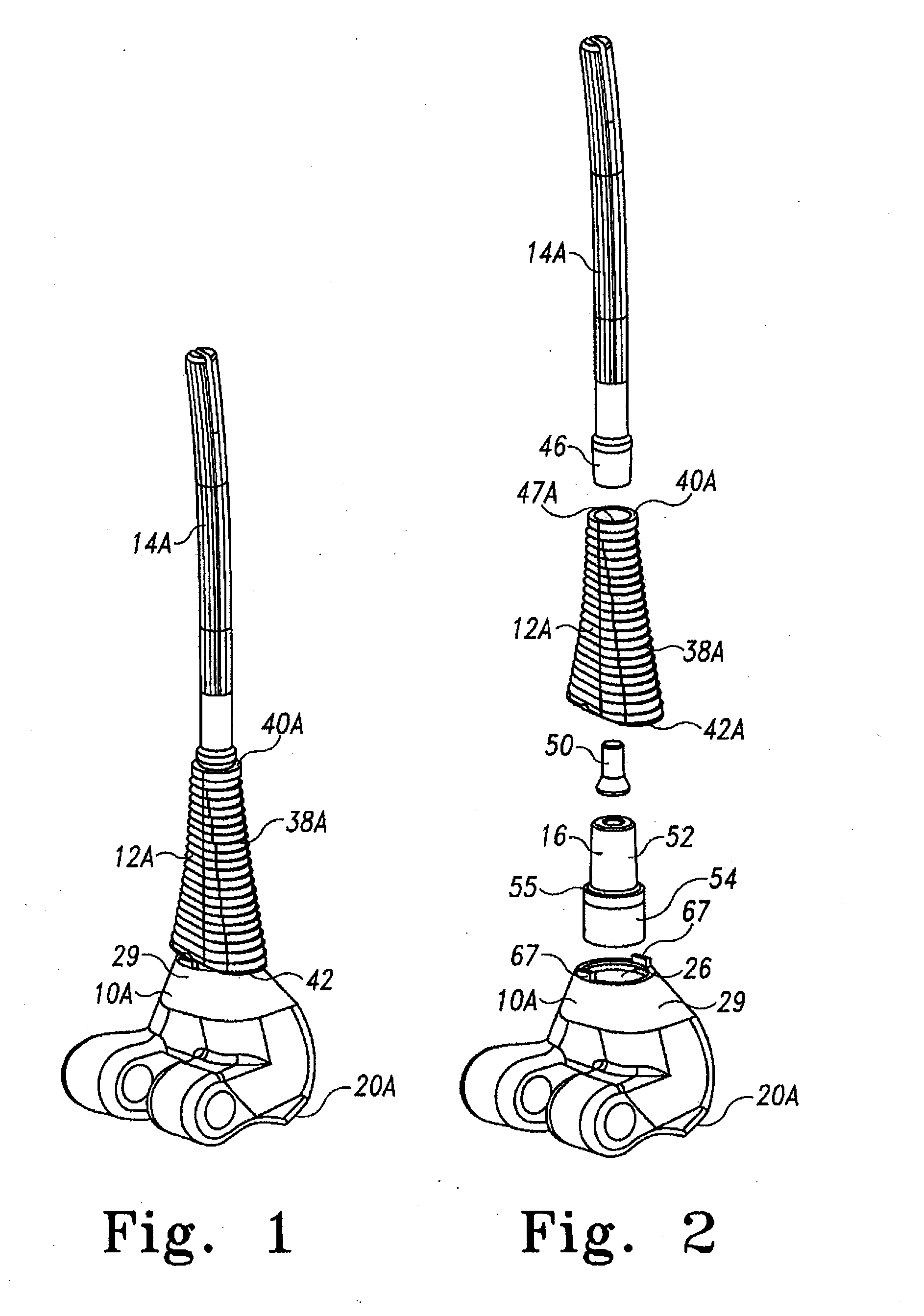

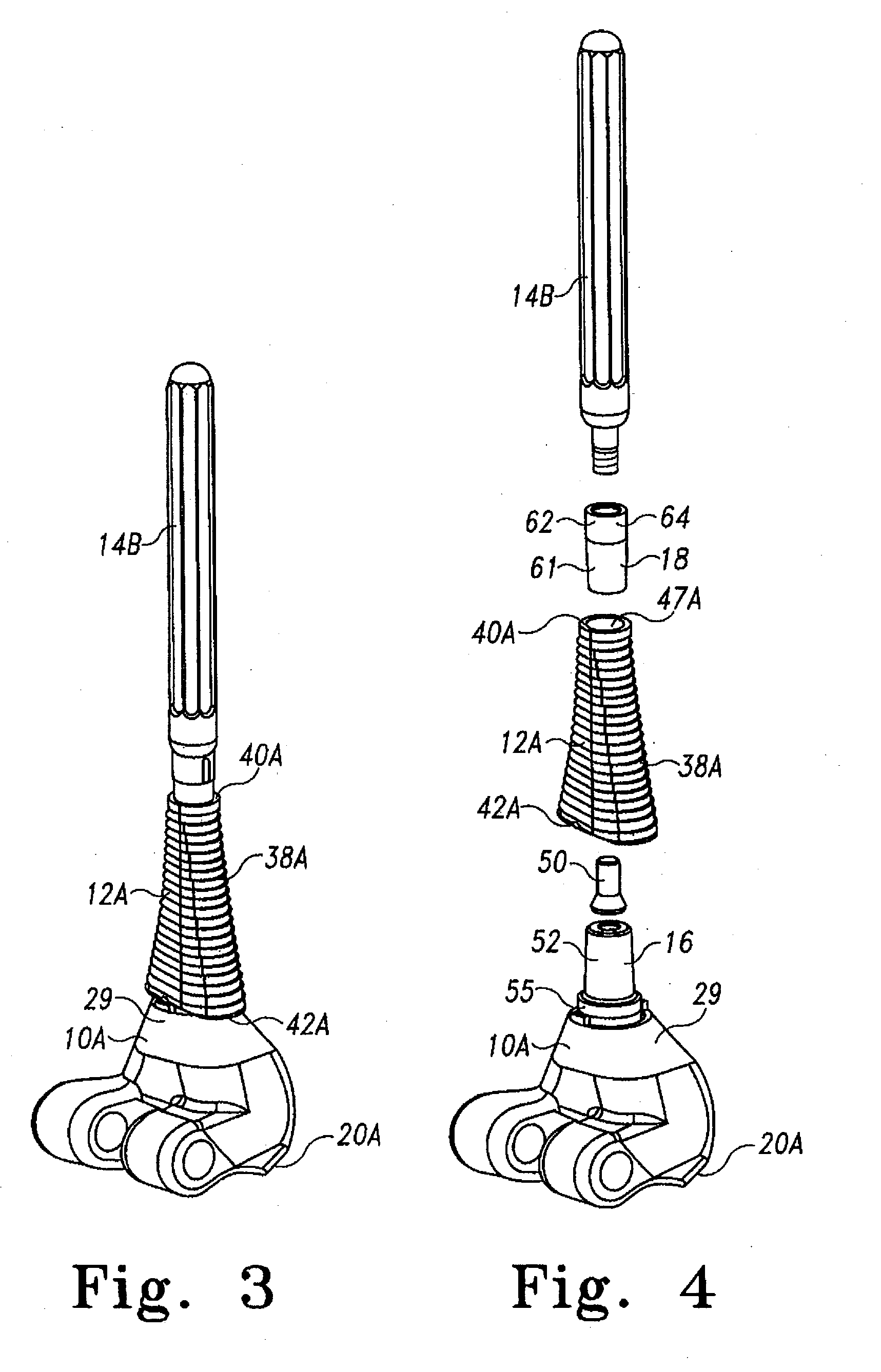

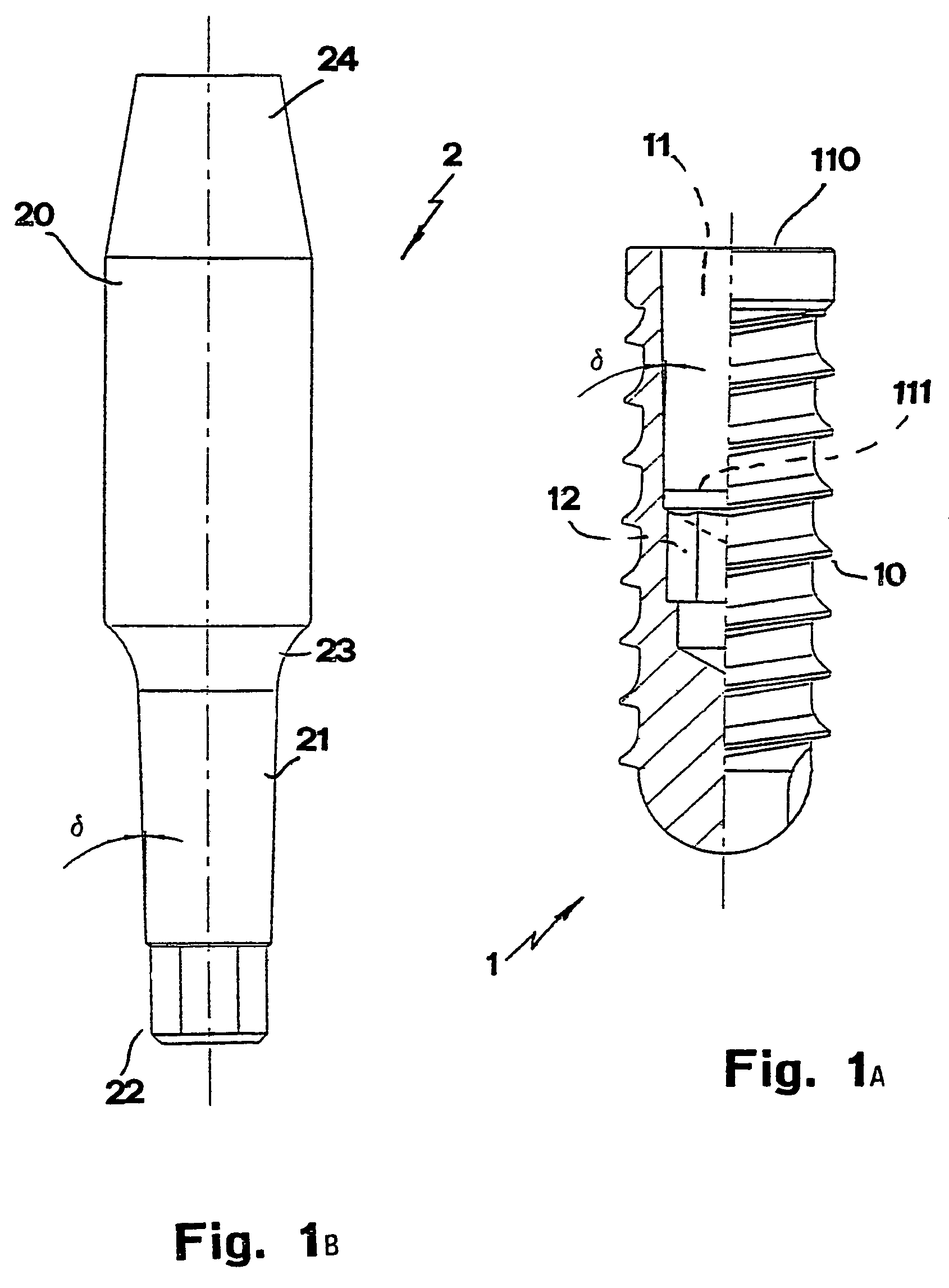

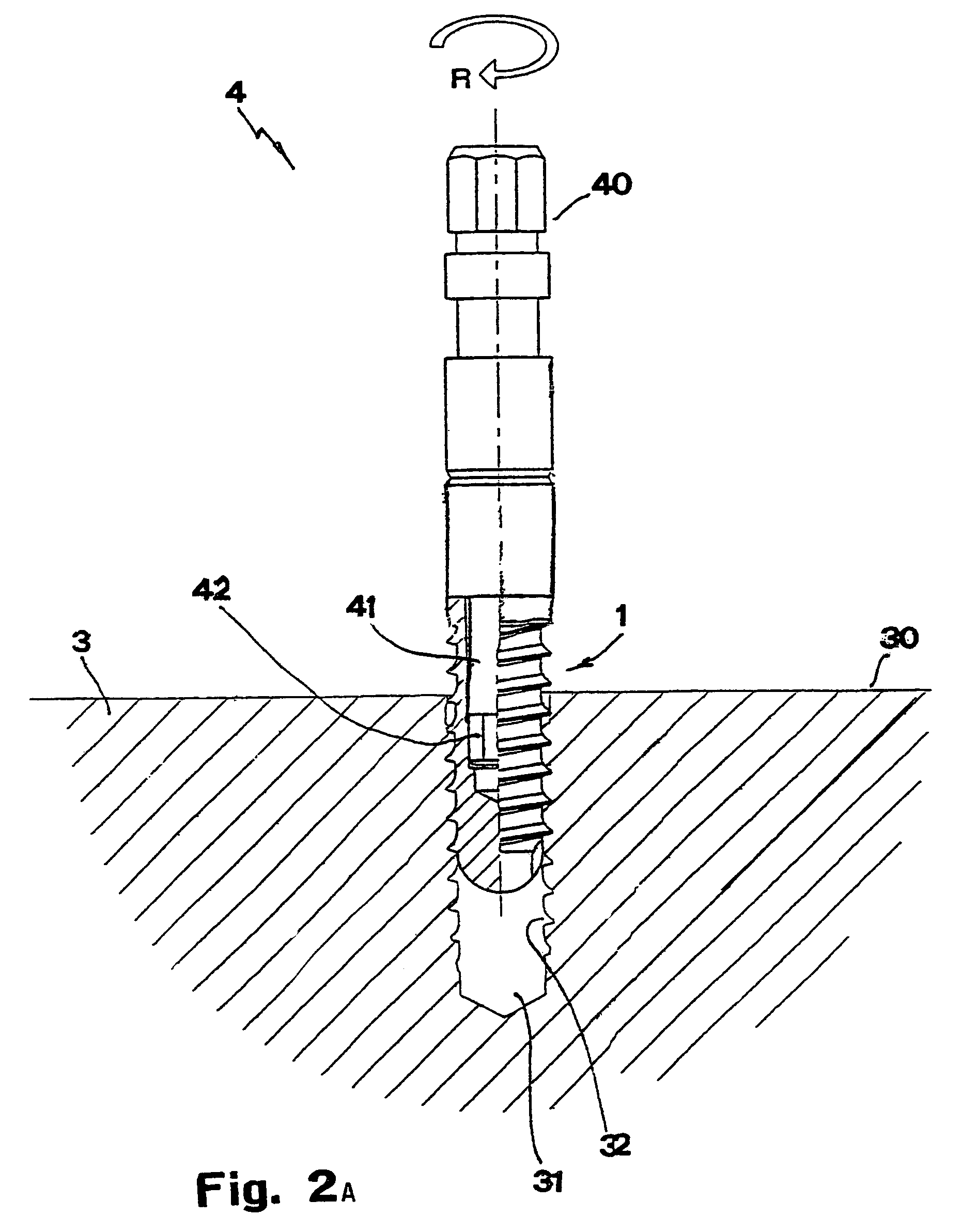

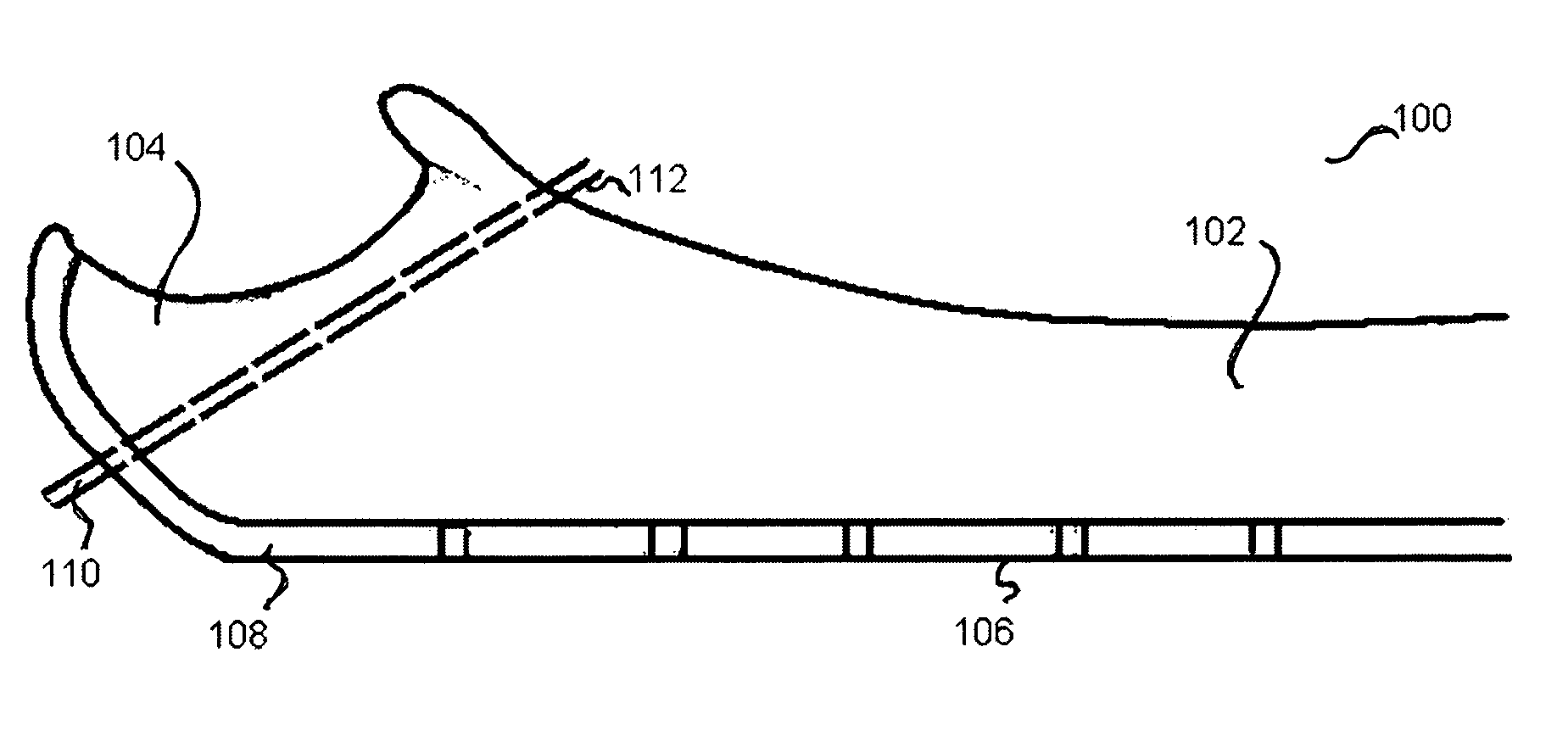

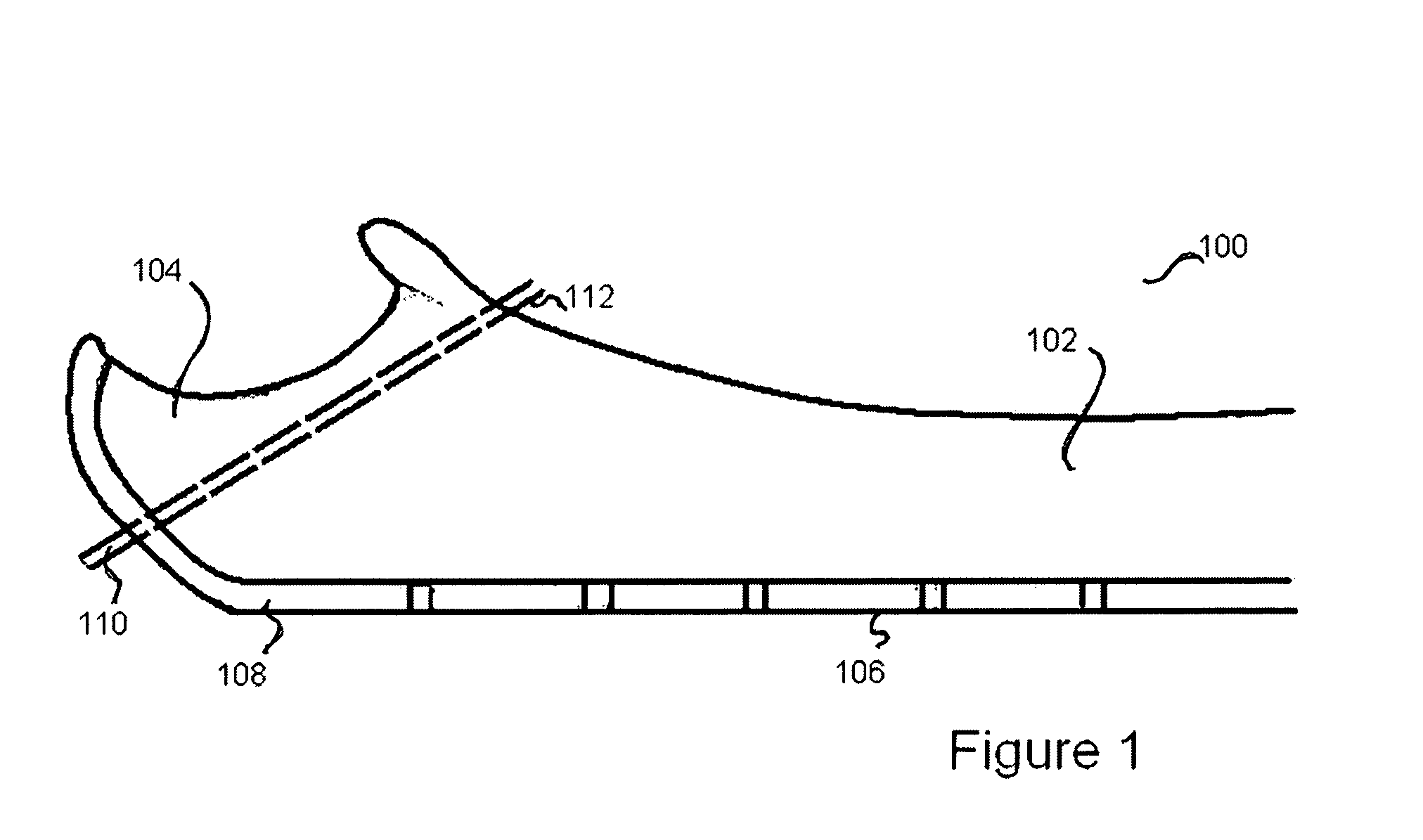

Modular implant system and method with diaphyseal implant

A modular implant system allows a surgeon to secure an implant assembly to thee diaphysis of a long bone. The system includes a set of anatomically-designed diaphyseal fitting modular implant components. One end of each diaphyseal implant component is a Morse taper post for connection to another implant component such as a modular articular component, a segmental component or an intercalary component. The other end of each diaphyseal component is a tapered porous surface. In some sizes, the tapered porous surface includes a plurality of steps. The tapered porous surface is received with a tapered bore in the bone diaphysis that is prepared to match the size and shape of the tapered porous surface. The diaphyseal implant is easy to insert and remove, does not bind before fully seating, is designed to prevent stress shielding and provides the surgeon with a host of stem options with its modularity.

Owner:DEPUY PROD INC

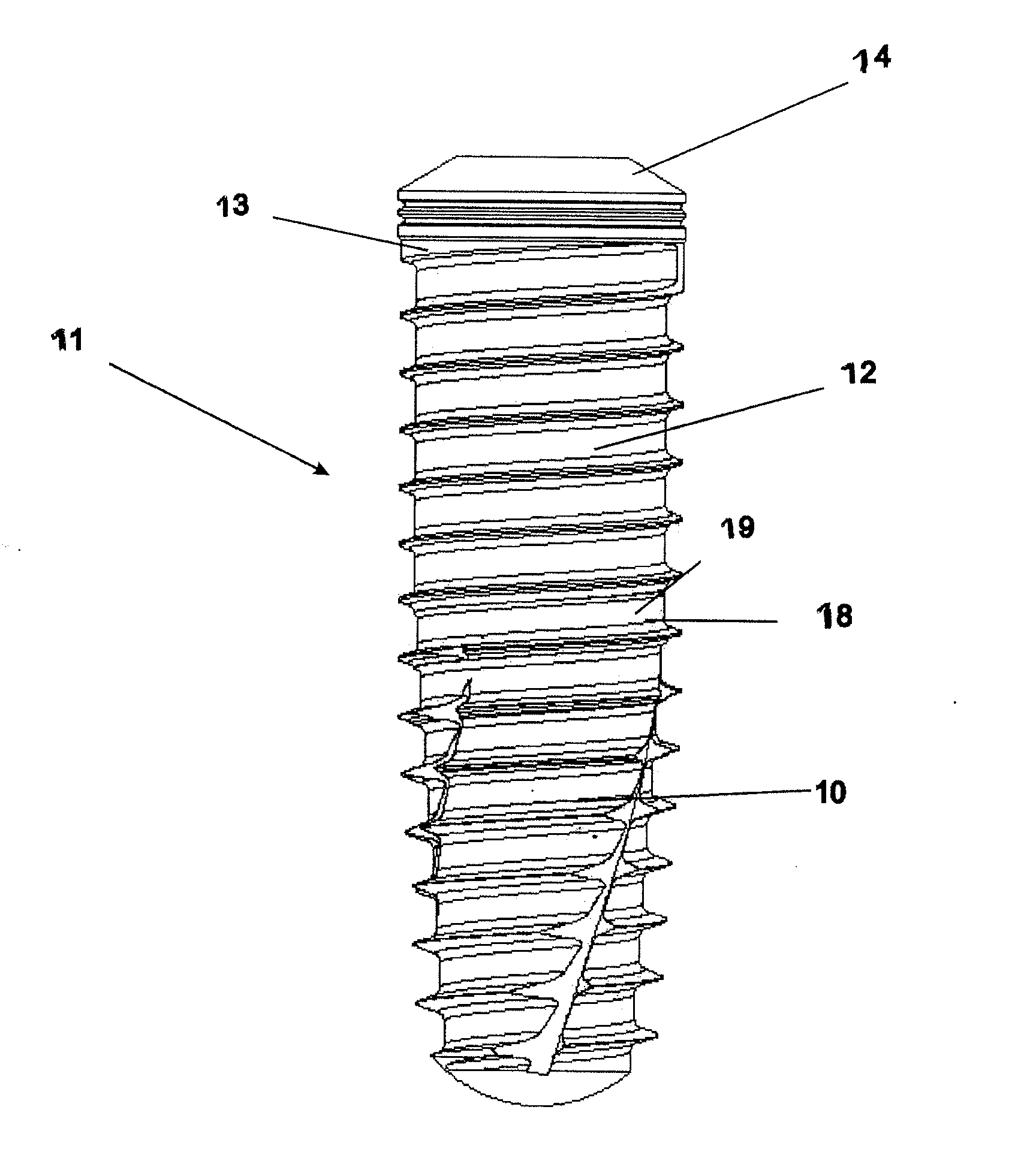

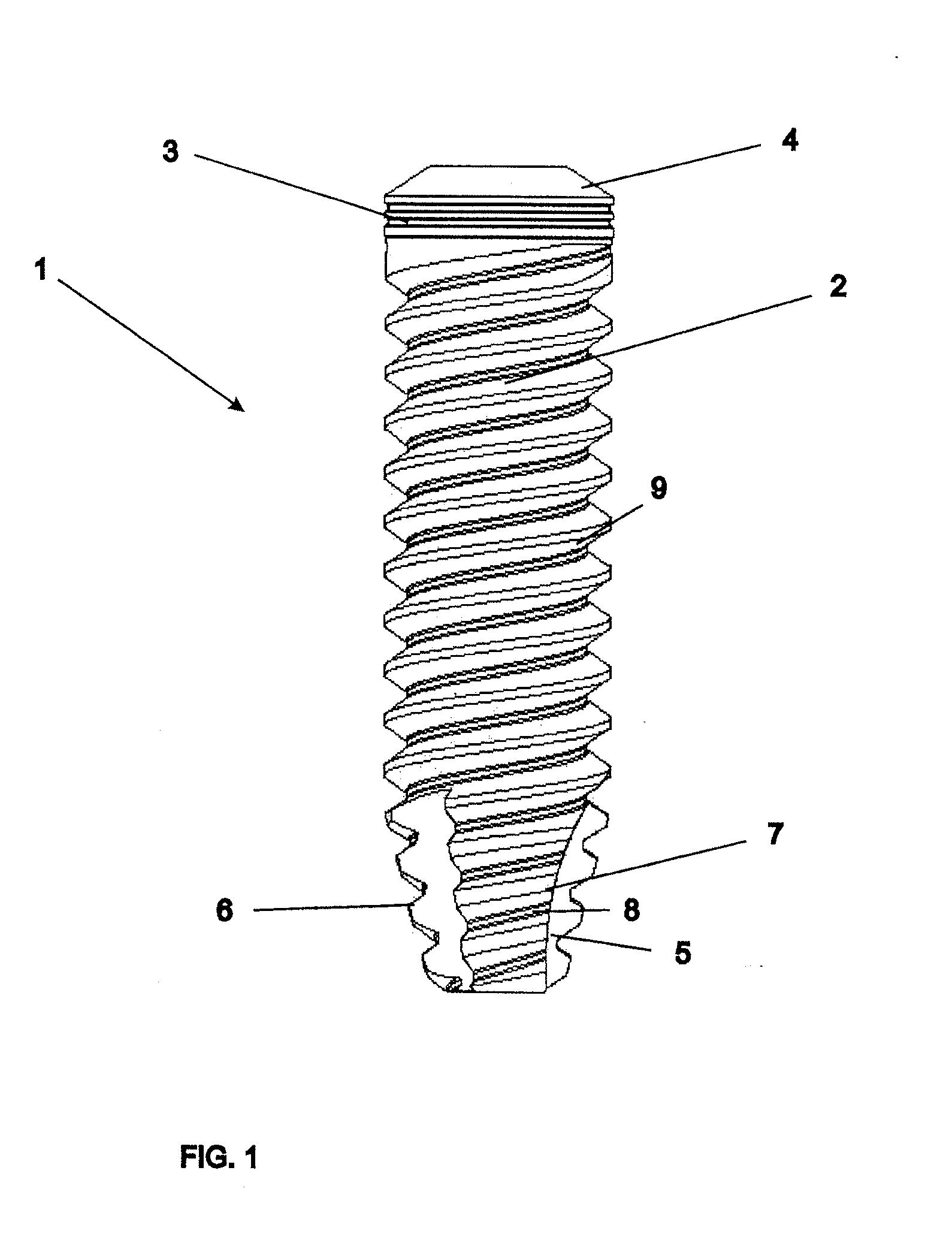

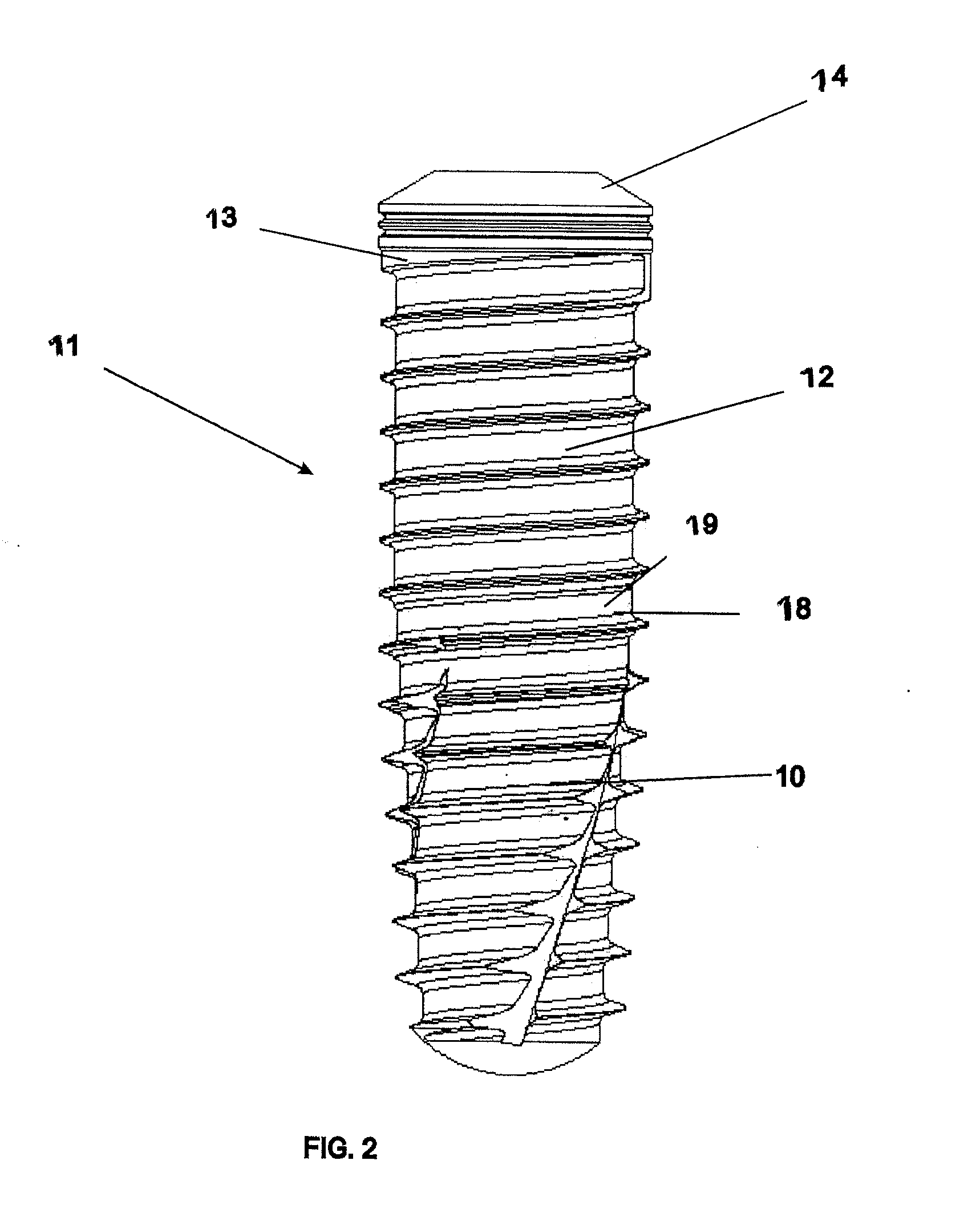

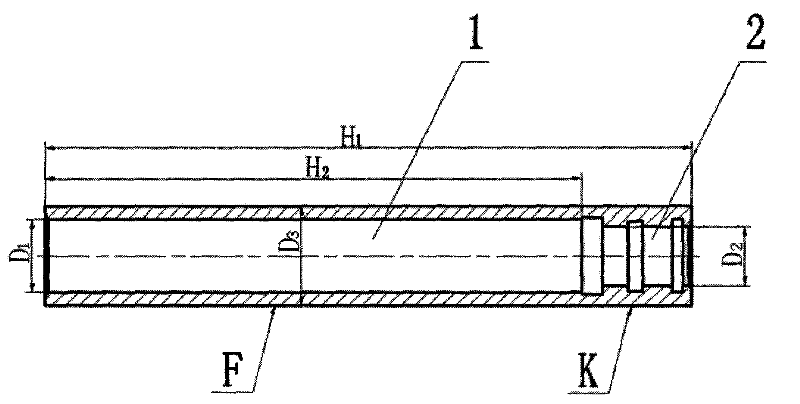

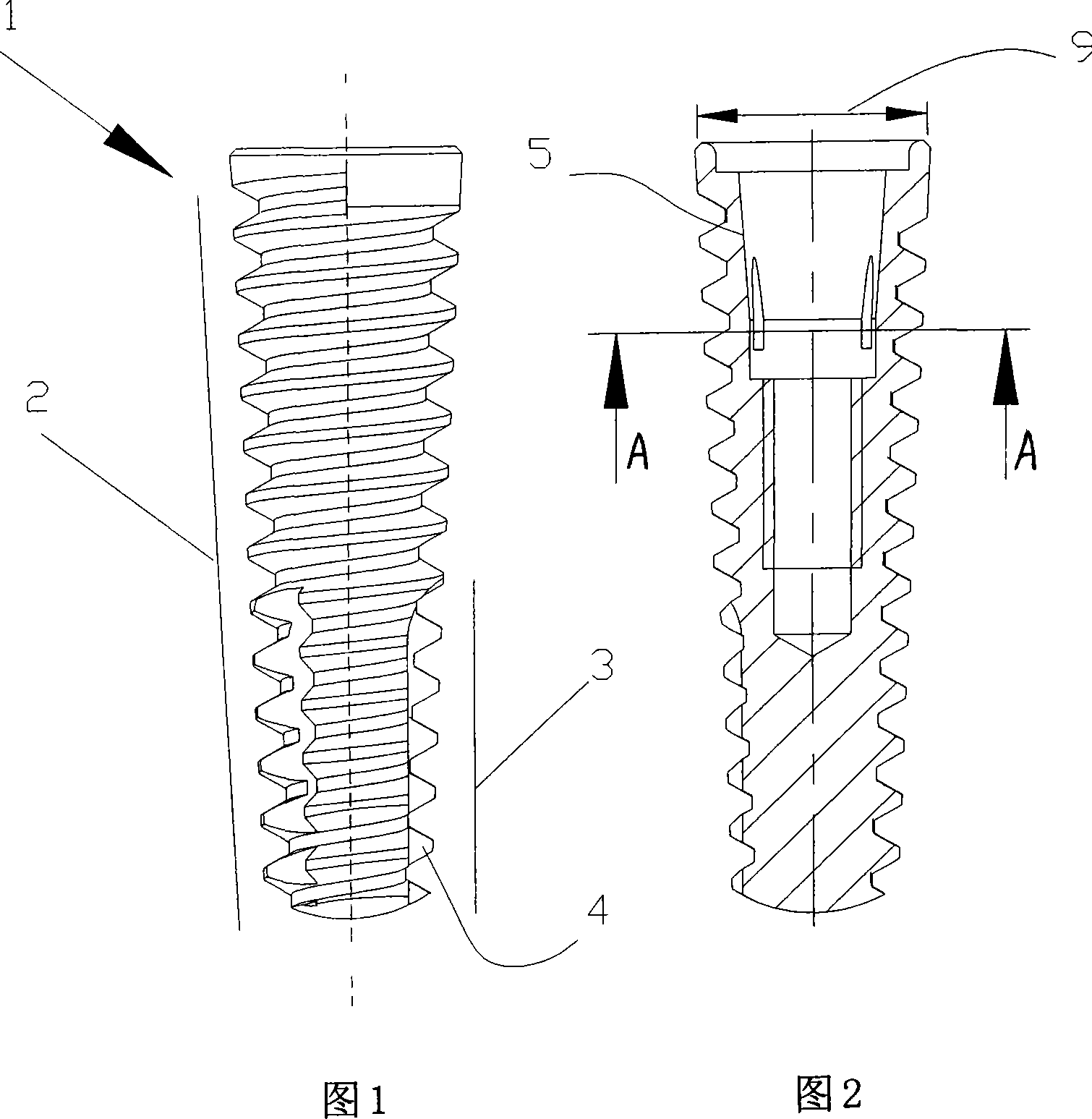

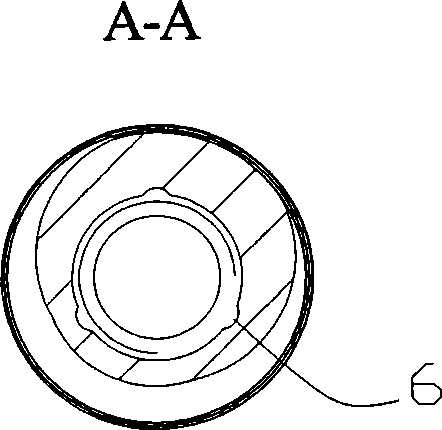

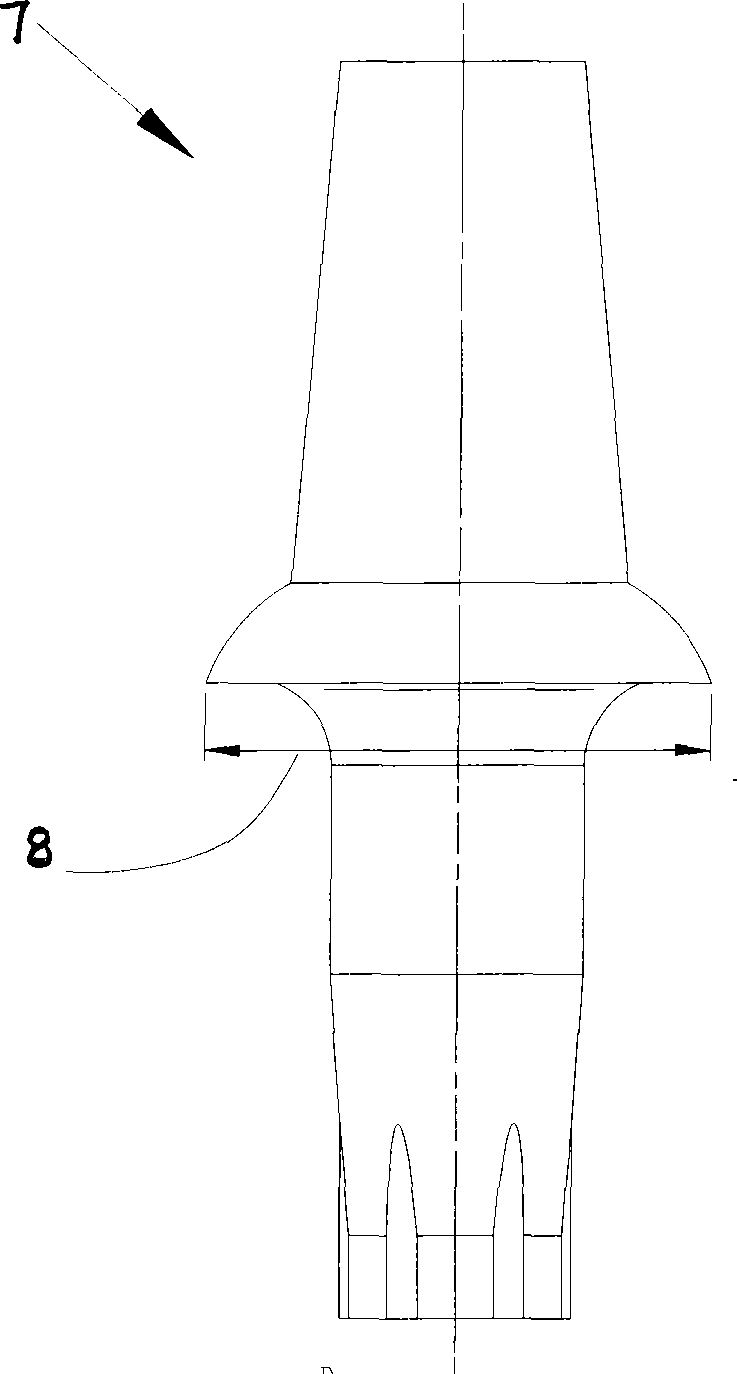

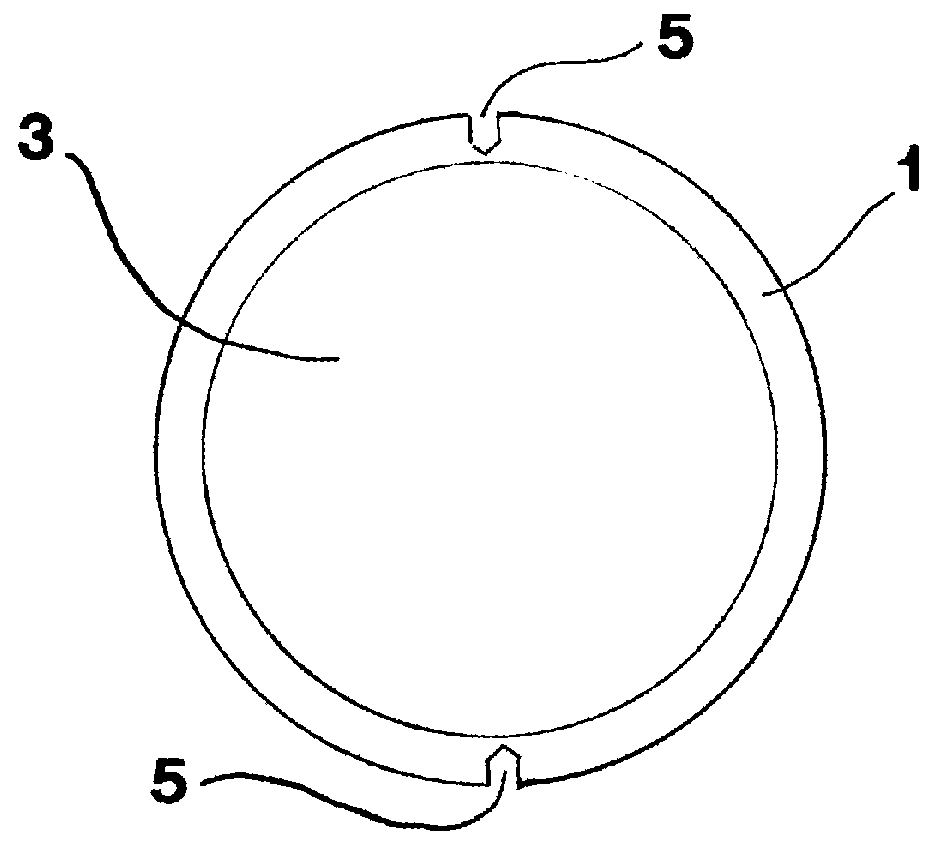

Morse Taper Dental Implant

A morse taper dental implant with possibility for adaptation of components directly on the implant platform, the implant is a morse taper implant with grooves, which together with the surface treatment, promote adhesion of bone tissue to the implant, and further on the outside details, the implant has a platform switch, i.e. a notch at the top of the implant, leaving the same basis of settlement in whatever the outside diameter of the implant, thus allowing an adjustment of the components directly on the base of the implant (implant level), through the adaptation of the components through the morse taper that reaches heights exceeding 1 mm.

Owner:MDT IND COMERCIO IMPORTACAO E EXPORTACAO DE IMPLANTES +1

Modular implant system and method with diaphyseal implant

A modular implant system allows a surgeon to secure an implant assembly to thee diaphysis of a long bone. The system includes a set of anatomically-designed diaphyseal fitting modular implant components. One end of each diaphyseal implant component is a Morse taper post for connection to another implant component such as a modular articular component, a segmental component or an intercalary component. The other end of each diaphyseal component is a tapered porous surface. In some sizes, the tapered porous surface includes a plurality of steps. The tapered porous surface is received with a tapered bore in the bone diaphysis that is prepared to match the size and shape of the tapered porous surface. The diaphyseal implant is easy to insert and remove, does not bind before fully seating, is designed to prevent stress shielding and provides the surgeon with a host of stem options with its modularity.

Owner:DEPUY PROD INC

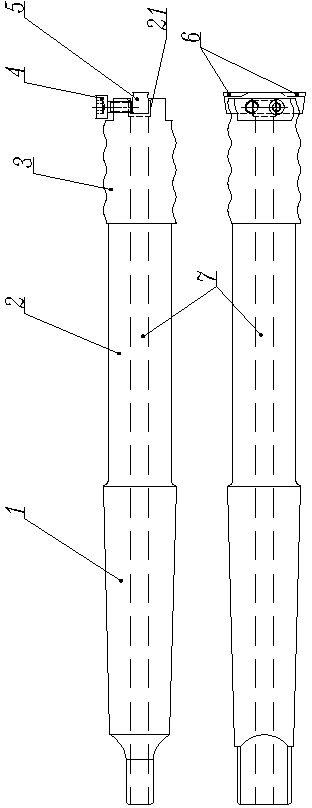

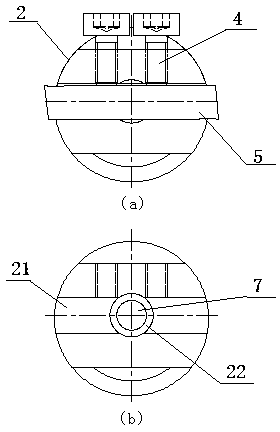

Split type calibration target, calibration device with same and calibration method thereof

PendingCN108489401APrecise positioningHigh repeatability accuracyUsing optical meansLaser scanningLaser tracker

The invention provides a split type calibration target which cooperates with a target lens to be used as a measurement target when a laser tracker is utilized for calibrating a spatial distance indication error of a laser scanner. The split type calibration target comprises a target seat, a target lens bearing component and a sphere target component, wherein the target lens bearing component is provided with a taper shank, a connecting piece arranged on the taper shank and a target lens seat which is arranged on the connecting piece and used for being connected with the target lens through magnetic adsorption; and the sphere target component is provided with a sphere side taper shank, a three-dimensional regulating mechanism arranged on the sphere side taper shank and a sphere target arranged on the three-dimensional regulating mechanism, wherein the taper shank and the sphere side taper shank are morse taper shanks respectively, the morse taper shanks have the same size and tolerance,taper tips are arranged downward, a morse taper sleeve is arranged on the target seat, the taper tip of the morse taper sleeve is downward, an opening is upward, and the morse taper sleeve is matchedwith the taper shank and the sphere side taper shank. The invention also provides a calibration device provided with the split type calibration target and a method for calibrating the laser scanner by utilizing the calibration device.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

Modular implant system with fully porous coated sleeve

A modular knee implant system allows a surgeon to select between several different styles of distal femoral implant components and several different styles of stem extensions while also allowing for use of a metaphyseal component. The metaphyseal component can be a universal one that is usable with all of the styles of distal femoral implant components through use of an adapter. A second adapter allows for use of stem extensions with different types of connectors with the metaphyseal component. A separate metaphyseal component could also be provided with a distal Morse taper post to mate with a distal femoral component having a proximal Morse taper bore. The metaphyseal component may have an outer surface that is configured to maximize contact area with the patient's bone, and may have a surface finish over a substantial part of its overall length that is conducive to bone ingrowth.

Owner:DEPUY PROD INC

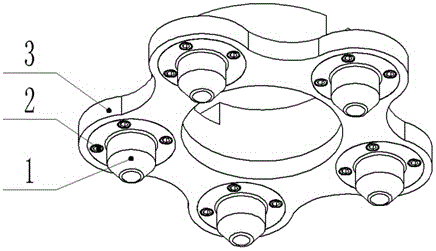

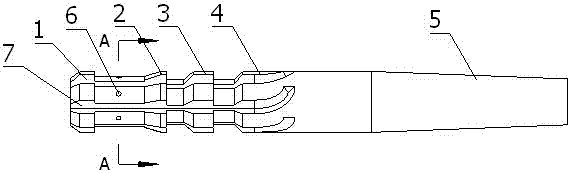

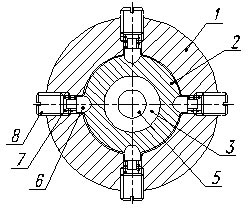

Multi-head rolling surface polishing cutter

InactiveCN104827239AEasy to adjust pressureSolve the problem of unregulated pressureWear resistantEngineering

The invention discloses a multi-head rolling surface polishing cutter, and belongs to the technical field of machining cutters. The multi-head rolling surface polishing cutter comprises a cutter rest and five cutter bits, wherein the cutter bits are rolling bits, and mainly consist of balls, support frames, wear resistant plates, lower pressing plates, compression springs, upper pressing plates, pressing screws and the like. The cutter rest can be connected with a machine tool spindle through a Morse taper handle and the like; the balls are put into the support frames, and are pressed with the wear resistant plates having circular grooves; the wear resistant plates are pressed with the lower pressing plates and the upper pressing plates; and the compression springs are mounted between the upper and lower pressing plates. The multi-head rolling surface polishing cutter has the following advantages: through the cutter bit mechanical rolling effect, the material surface smoothness and levelness are improved, the surface pressure stress is improved, the material surface grain size is reduced, and the material surface performance is enhanced; and through the cutter multi-head design, the cutter machining efficiency and using performance are improved.

Owner:UNIV OF JINAN

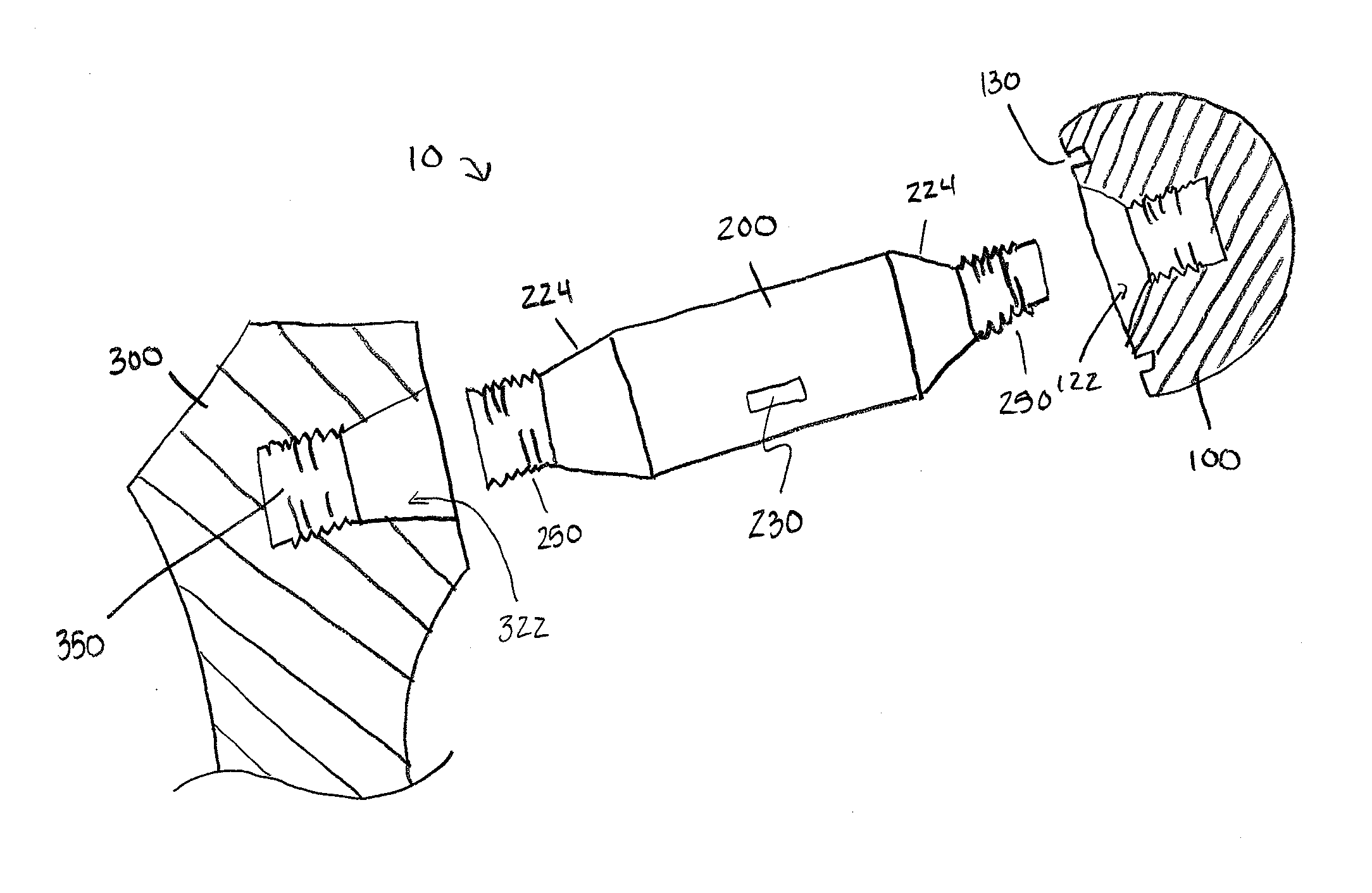

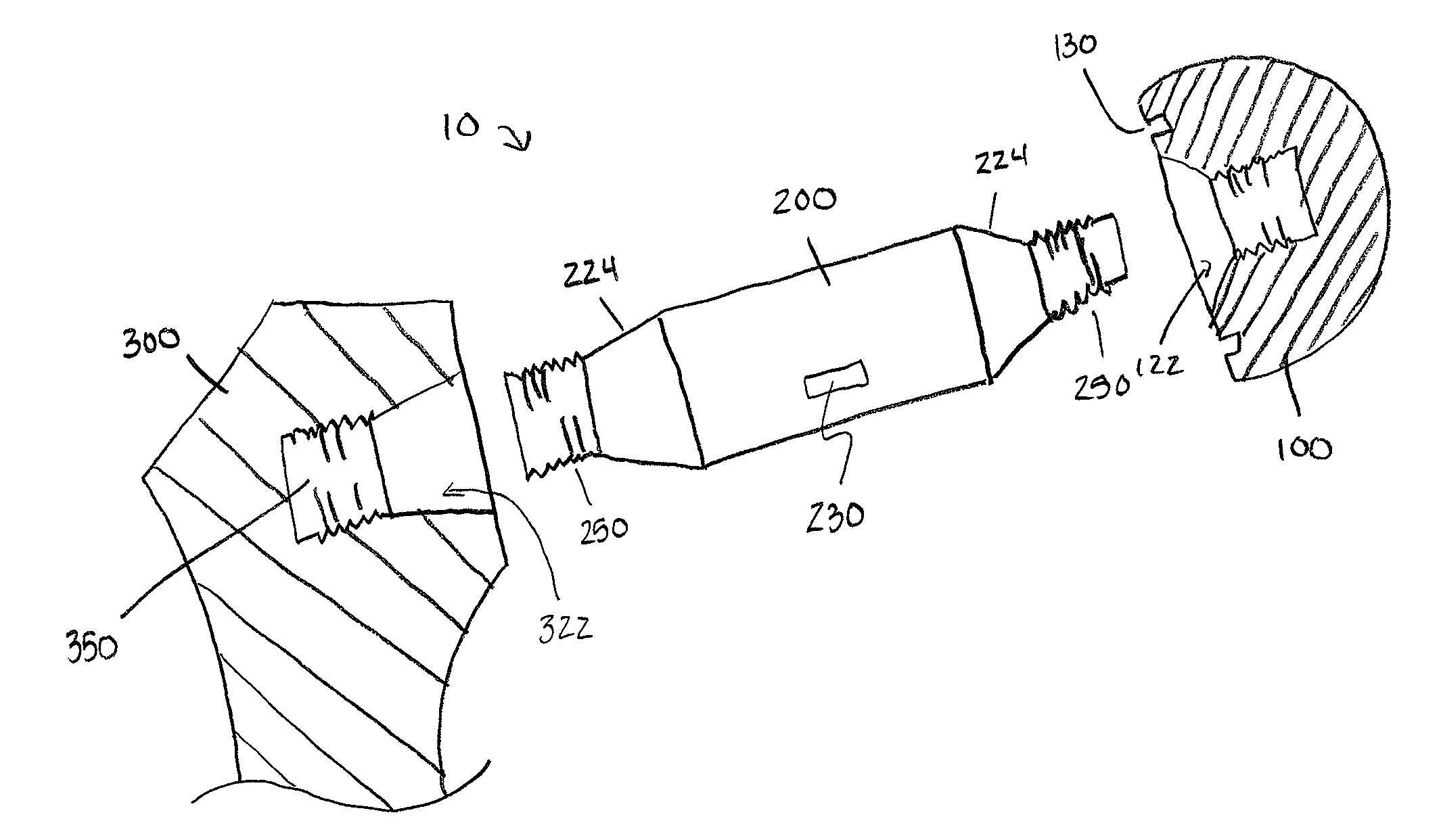

Method and apparatus for attachment in a modular hip replacement or fracture fixation device

InactiveUS20130204390A1Quality improvementImprove reliabilityJoint implantsFemoral headsInterference fitRight femoral head

Methods and apparatus for orthopedic replacement of the hip and hip fracture fixation devices include structures and techniques for fixing or enhancing interconnection of implant components, such as by increasing the interconnection in an interference fit with one or more tapers, threads, and / or cooling of components prior to assembly. For example, a prosthetic femoral neck implant can include a thread and a Morse taper for lockable attachment to a prosthetic femoral head and / or intramedullary stem.

Owner:IHIP SURGICAL LLC

Interlocking Reverse Hip and Revision Prosthesis

ActiveUS20110218638A1Improved weight distributionReduce wearBone implantJoint implantsRange of motionModularity

A reverse hip prosthesis comprising an acetabular cup for implanting in an acetabular socket. The acetabular cup is secured to the acetabular socket of the pelvis using fasteners. The acetabular cup has a stem extending from the center of a concave portion thereof and an acetabular ball is attached to the stem, preferably by means of a Morse taper. A femoral implant is provided with a femoral cup attached to the proximal end thereof. The femoral cup has a stem which can be constructed in a modular fashion with several stem lengths in order to accommodate the various sizing requirements of different patients. After implantation of the acetabular cup and ball and the femoral cup, the members are assembled together so that the femoral cup can articulate on the acetabular ball. The prosthesis of the invention has a wide range of motion and substantially improved tribology. As the femoral cup is articulated, the edge of the femoral cup moves into a space located between the acetabular cup and the acetabular ball and thereby becomes restrained, thus reducing the likelihood of dislocation during extreme ranges of motion.

Owner:HIP INNOVATION TECHONOLOGY LLC

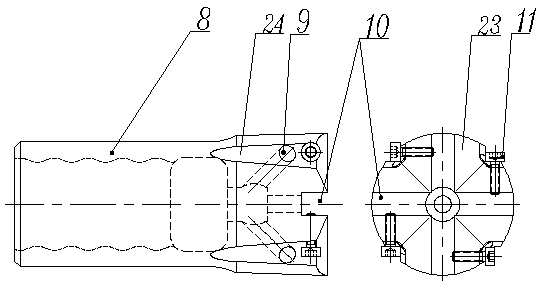

Processing Technology of Small Diameter, Thin Wall, Deep Hole and High Precision Parts and Its Special Grinding Tools

The invention relates to a processing technology of small-diameter, thin-walled, deep-hole, high-precision parts and its special grinding tool, which relates to a processing technology of thin-walled, deep-hole, high-precision parts and its special grinding tool. The invention solves the problems that it is difficult to meet the design requirements and processing difficulties of the cylinder body parts by conventional mechanical processing methods. The process steps of the present invention are as follows: turning the outer circle and end face of the blank, and adopting a stepwise progressive drilling method to drill through the first inner hole and the second inner hole layer by layer; The head rotates, and the parts make a low-speed rotary motion relative to the grinding head, and the grinding head grinds the parts to complete the processing of the parts. The end of the extended handle of the grinding tool adopts a Morse taper structure, and the grinding head is fixedly installed at the head end of the extended handle. The grinding head is made of white jade, and the extended handle is made of alloy tool steel. The processing technology of the invention is especially suitable for the manufacturing technology of small-diameter, thin-walled, deep-hole and high-precision parts in the field of mechanical processing.

Owner:HARBIN JIANCHENG GRP

Mouth cavity planting body device

The invention discloses a dental implant assembly, which is characterized in that the diameter of the neck portion is slightly larger than that of the body portion of the dental implant and has a taper, the implant body portion has a dental root shape, the root portion of the dental implant has a self-tapping cut groove, the dental implant is provided inside with a Morse taper mechanism for fillet positioning, the neck portion is provided inside with a stepped cylindrical surface that is in clearance fit with an abutment, the junctions between the abutment and the dental implant are positioned on the stepped cylindrical surface, and the diameter of the upper part of the abutment is larger than that of the dental implant. The clearance between the abutment and the implant is helpful for in-growth of gingival and bone tissues. After implantation in vivo, the stress position for bondage between the dental plant and the abutment descends to prevent alveolar resorption due to overload on the neck portion of the dental implant; the marginal size of the abutment is enlarged to avoid food debris from entering implantation zone during chewing process. Additionally, the dental implant assembly fits well with a nut cap, thereby realizing implant esthetics.

Owner:WEIHAI WEIGAO BIOTECH

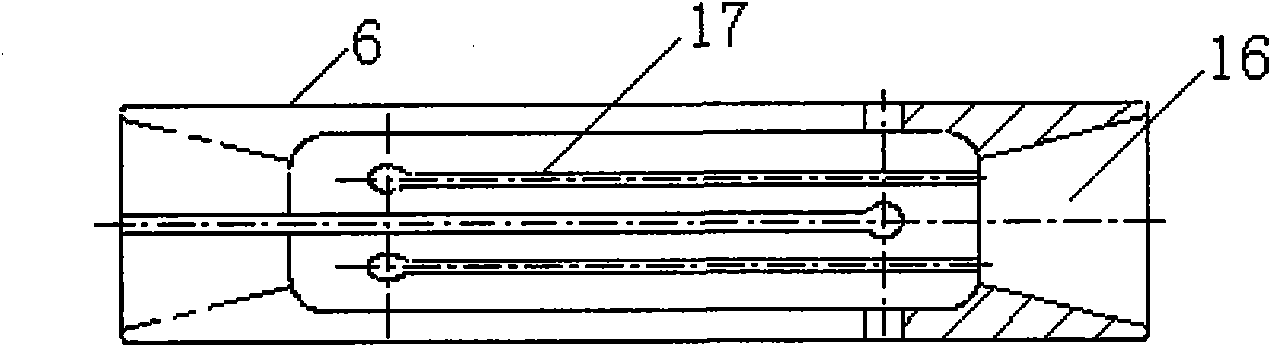

Method for processing oil grooves in inner bores of copper bearing bush

ActiveCN101712079AImprove quality and efficiencyIncrease productivityPositioning apparatusMetal-working holdersTool bitEngineering

The invention relates to method for processing oil grooves in inner bores of a copper bearing bush through a common lathe, which comprises the following steps: (1) fixing the copper bearing bush in a fixture body, and fixing the fixture body on a tool rest of the lathe; (2) inserting one end of an auxiliary positioning support tool into a Morse taper hole of a tail rack sleeve of the lathe, and processing a cutter arbor hole at the other end thereof; (3) passing a cutter arbor fixed with a blade through the copper bearing bush, clamping one end thereof on a lathe head, and extending the other end thereof into the cutter arbor hole; (4) starting the lathe to rotate the cutter arbor, moving the tool rest of the lathe, setting the starting position and depth of an oil groove, and flexibly processing the oil groove in the length; and (5) after the first oil groove is finished, retreating a tool bit, stopping the lathe, loosening a fastening piece, rotating the copper bearing bush 180 degrees in the fixture body, fixing the copper bearing bush, and repeating the step (4) to process the second oil groove. The method can be used for processing the oil grooves in the inner bores of the copper bearing bush through the lathe, the cutting force is small, high processing quality and production efficiency can be realized, and a requirement of mass production is met.

Owner:FAW GROUP

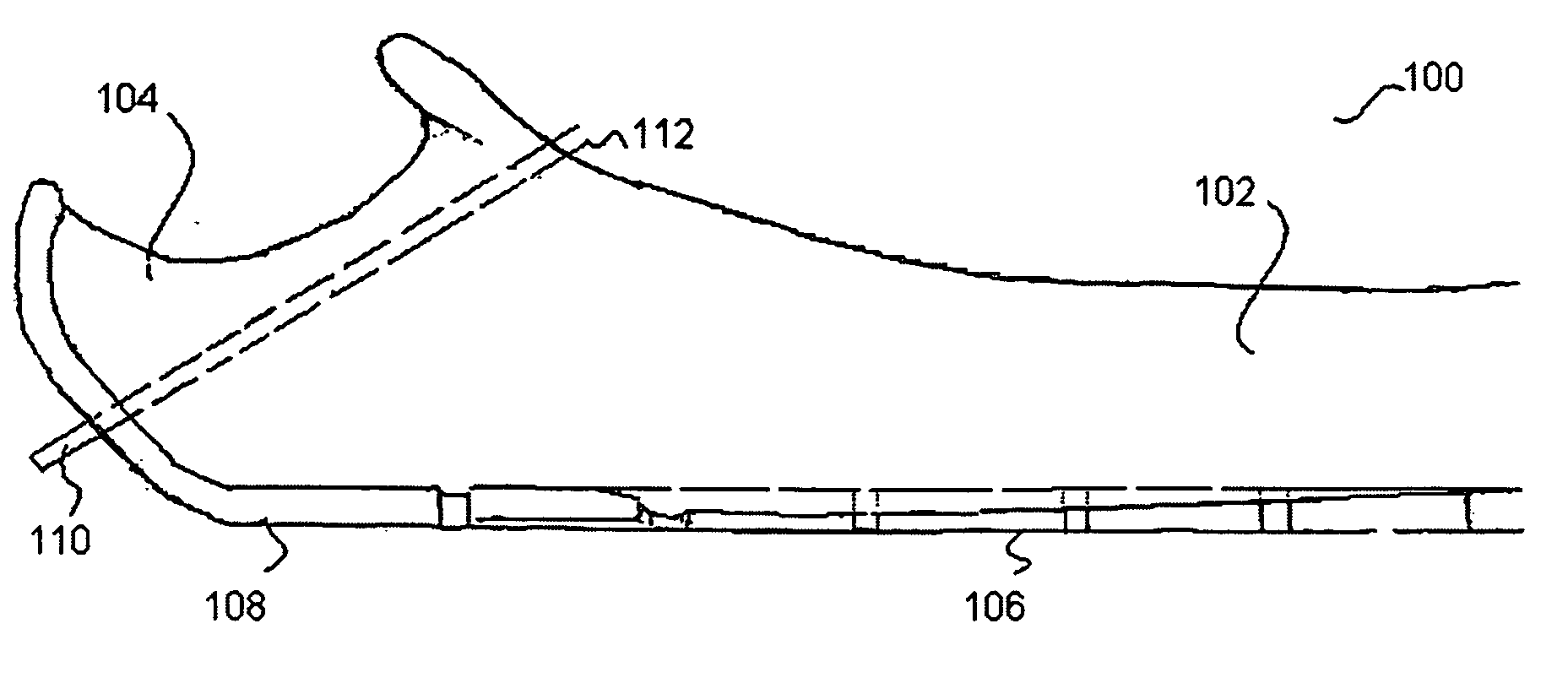

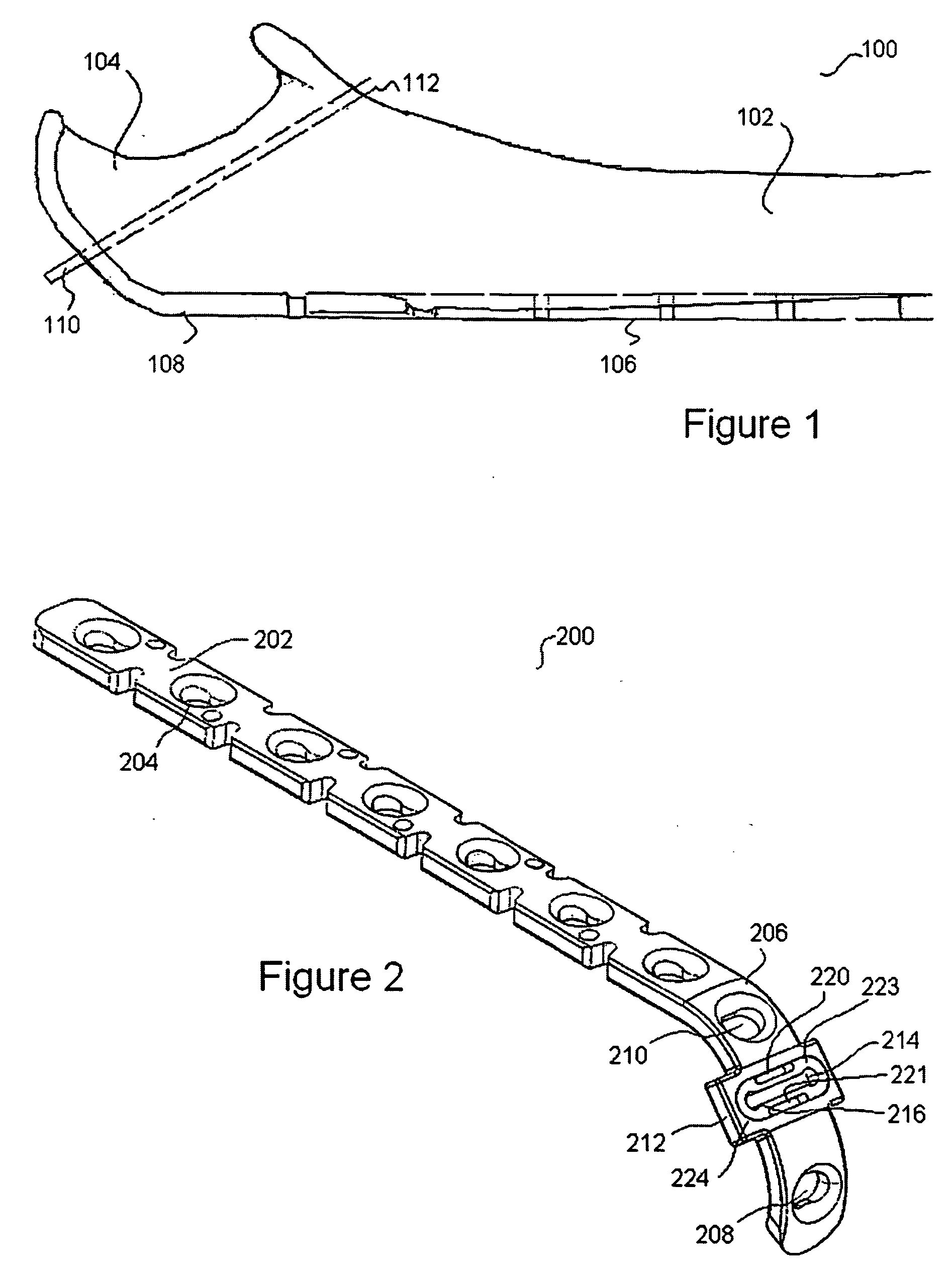

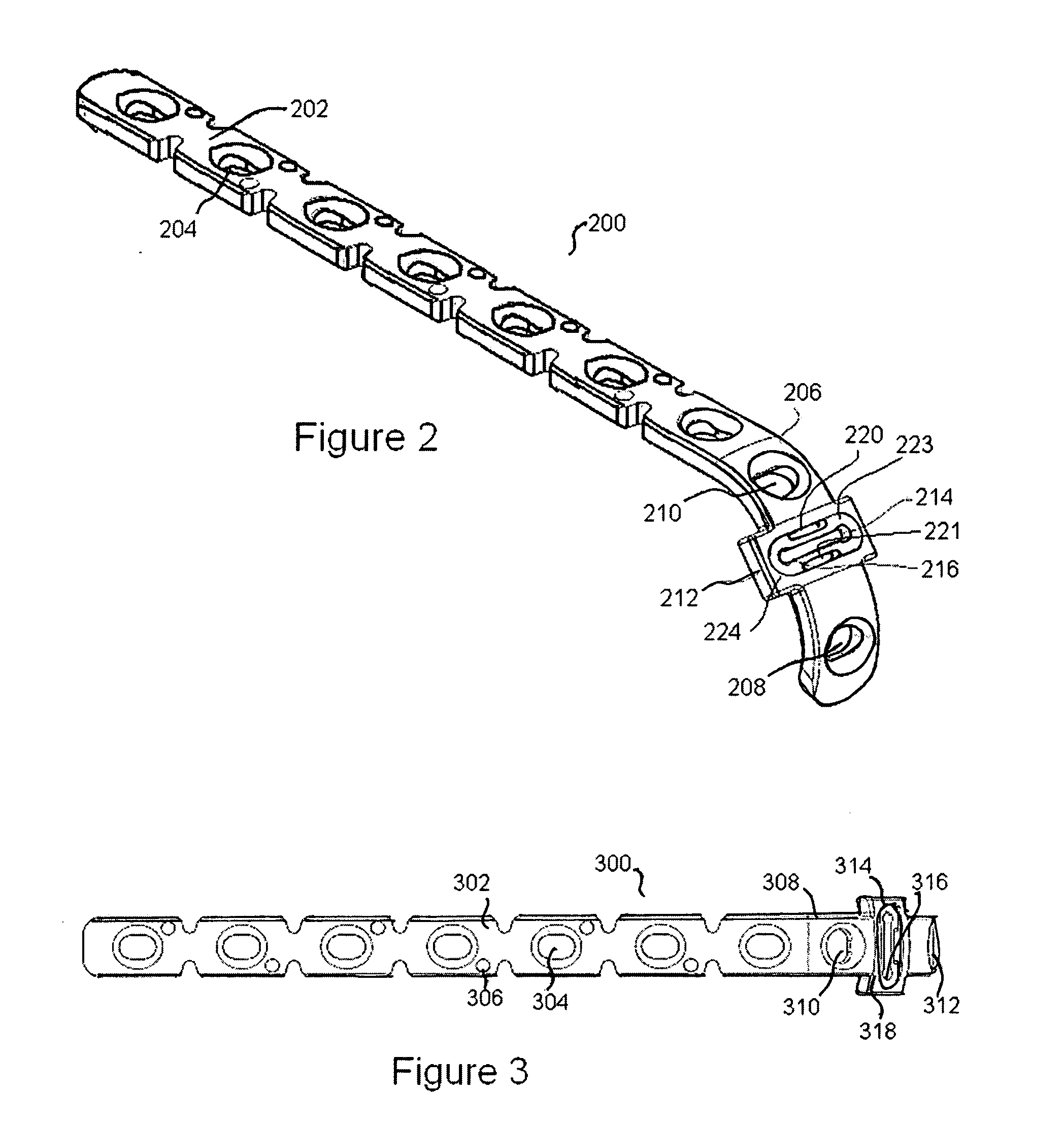

Orthopaedic appliances

InactiveUS20070043367A1Easy to disassembleSuture equipmentsJoint implantsHip joint replacement operationCoxal joint

Provided is a bone plate for the olecranon of the proximal ulna using a combination of screws and K wires. The plate is curved to fit the shape of the olecranon and is screwed in place. The plate has a locking section located in the curved section. A fastener is pushed over the ends of the K wires and locks in to the locking section of the plate. The fastener has a tapered wedge that secures the K wires allowing fixation to the plate and resists their withdrawal. A femoral stem cap is used during hip replacement surgery and protects the Morse taper of the femoral stem once the ball of the hip joint is removed. The femoral stem cap has an air vent to allow air to pass when being applied and removed.

Owner:LAWRIE STEVEN

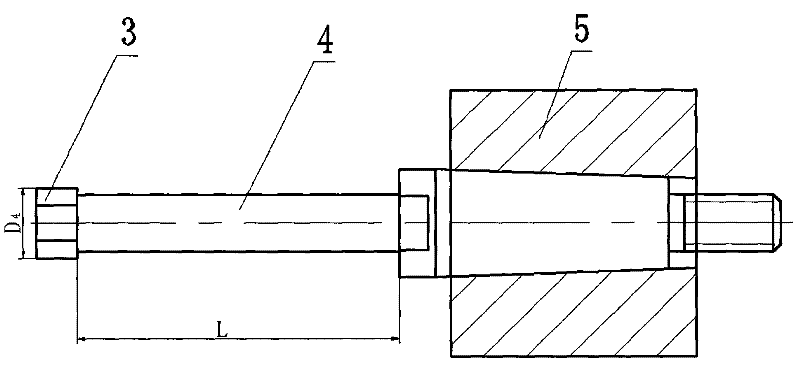

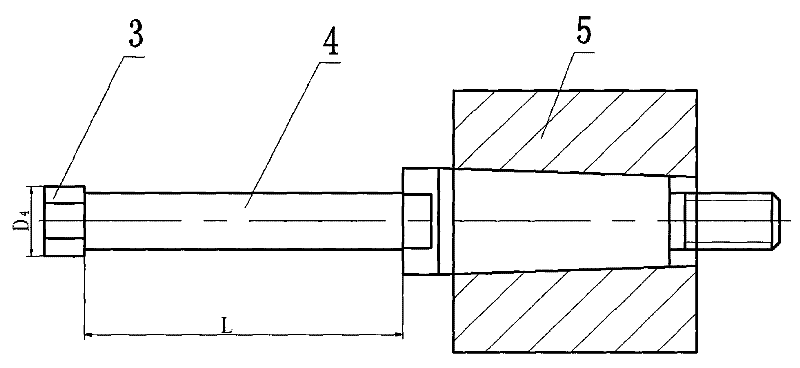

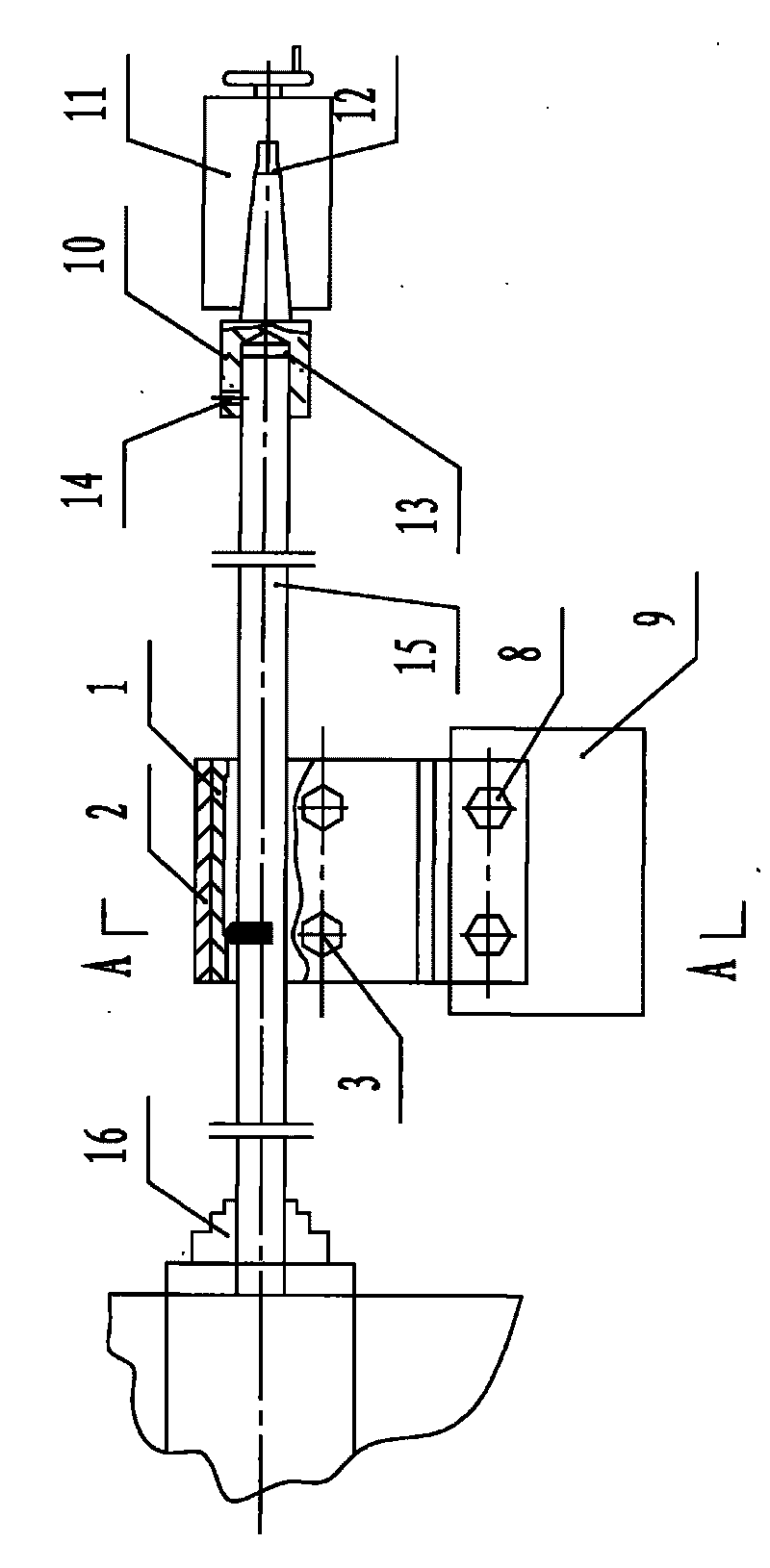

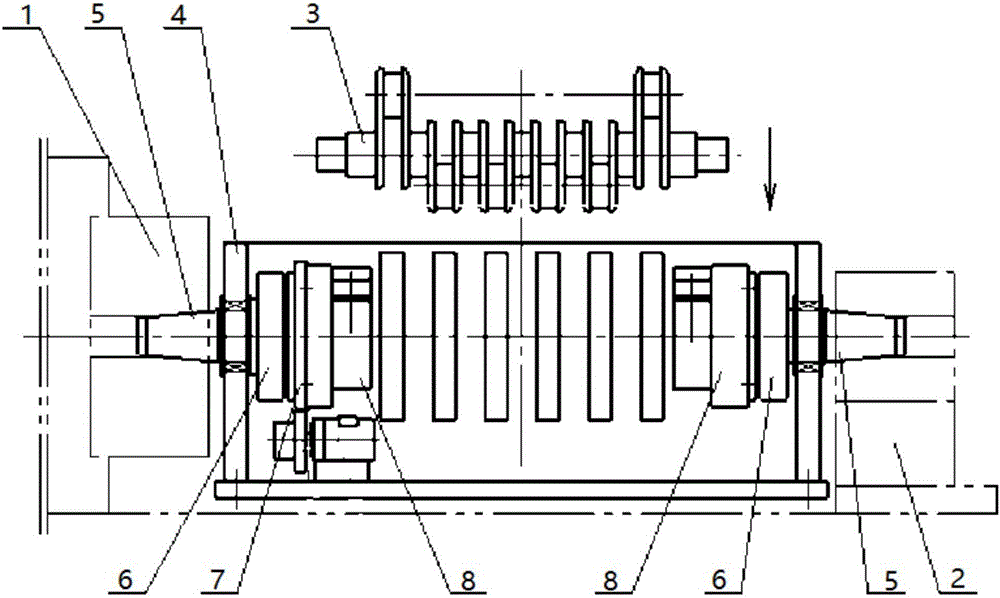

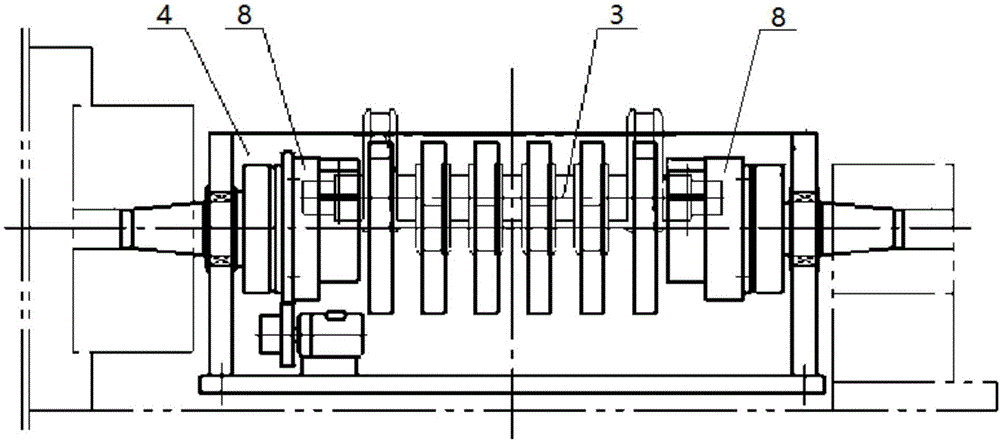

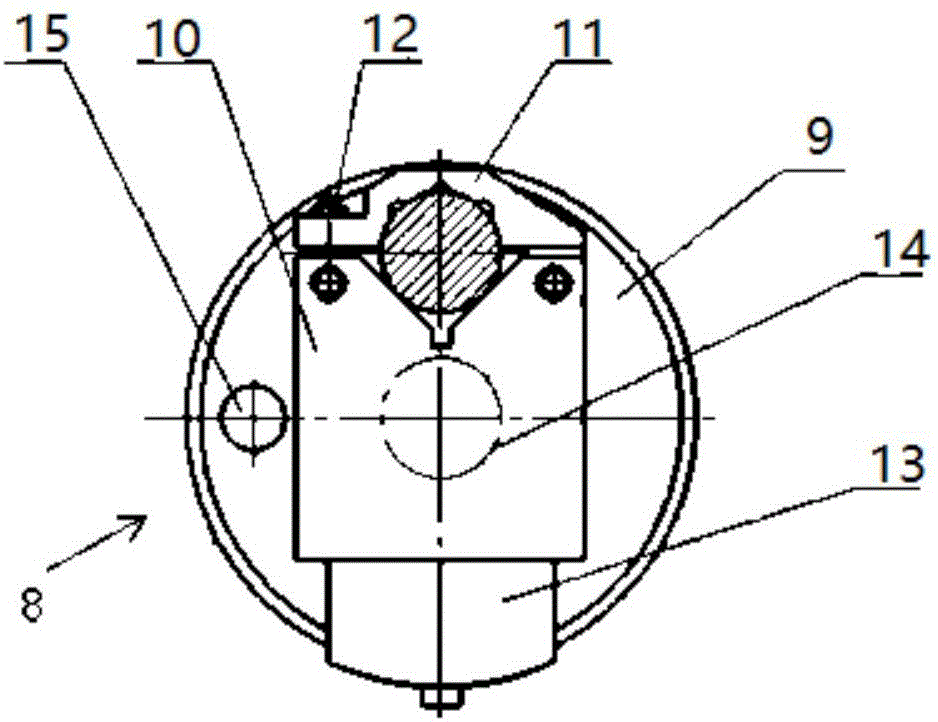

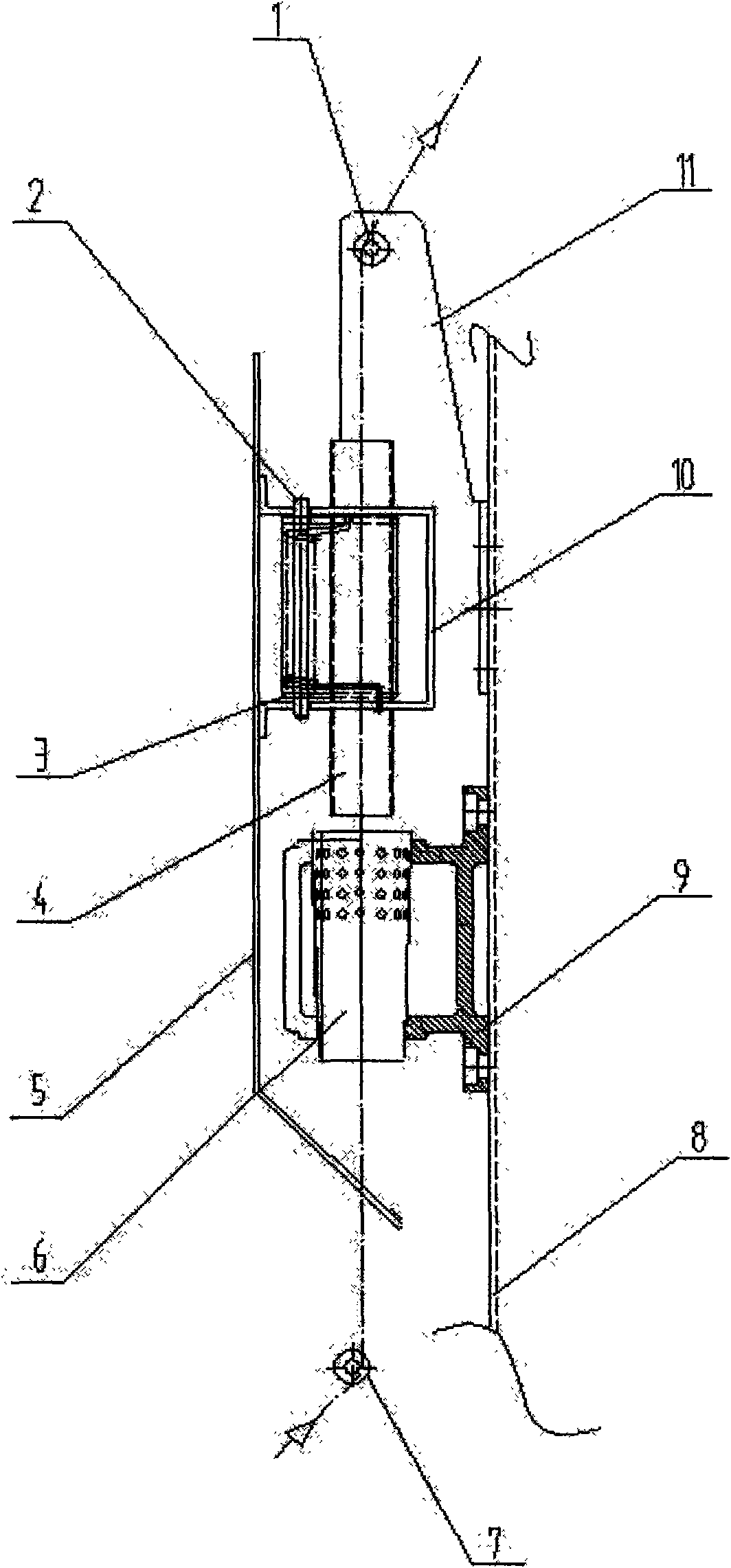

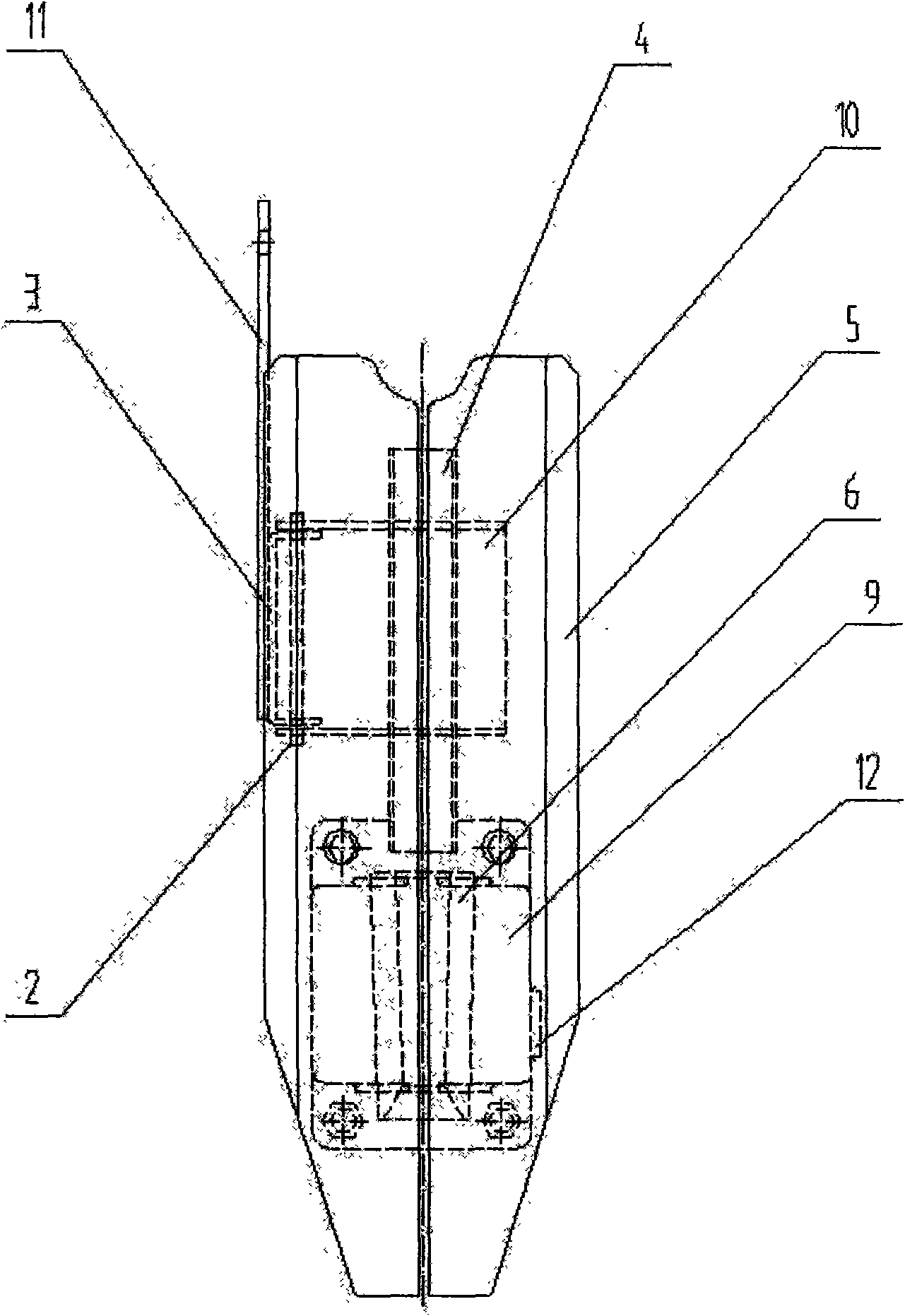

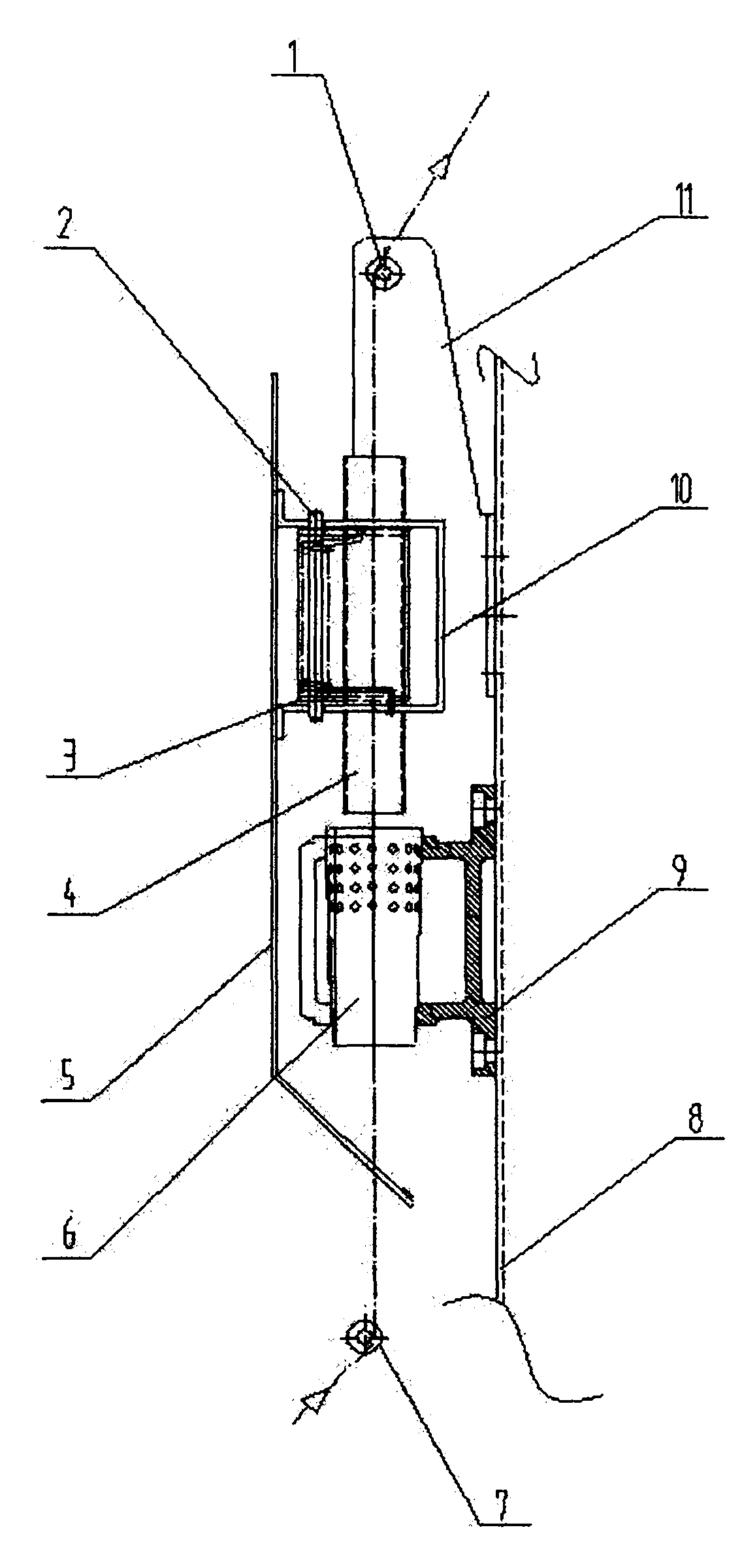

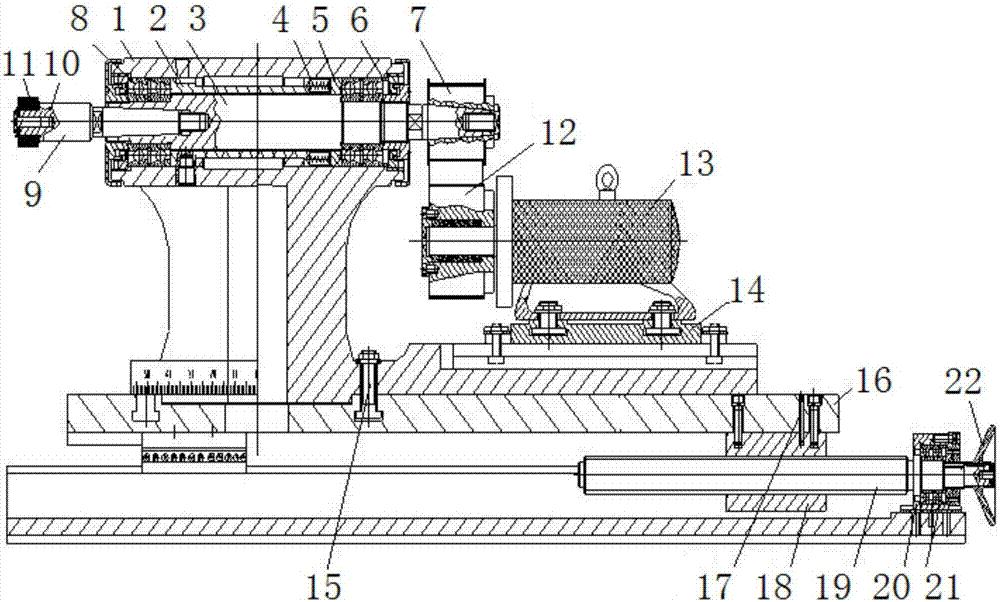

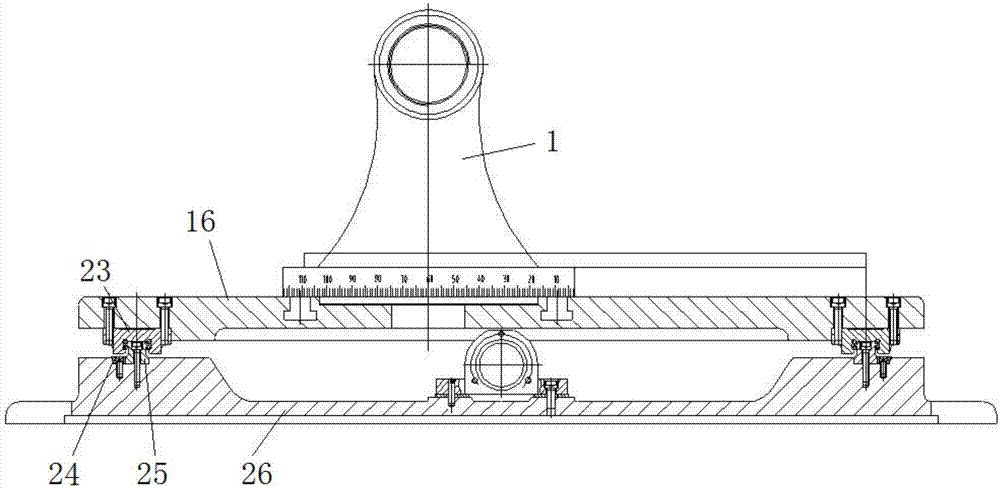

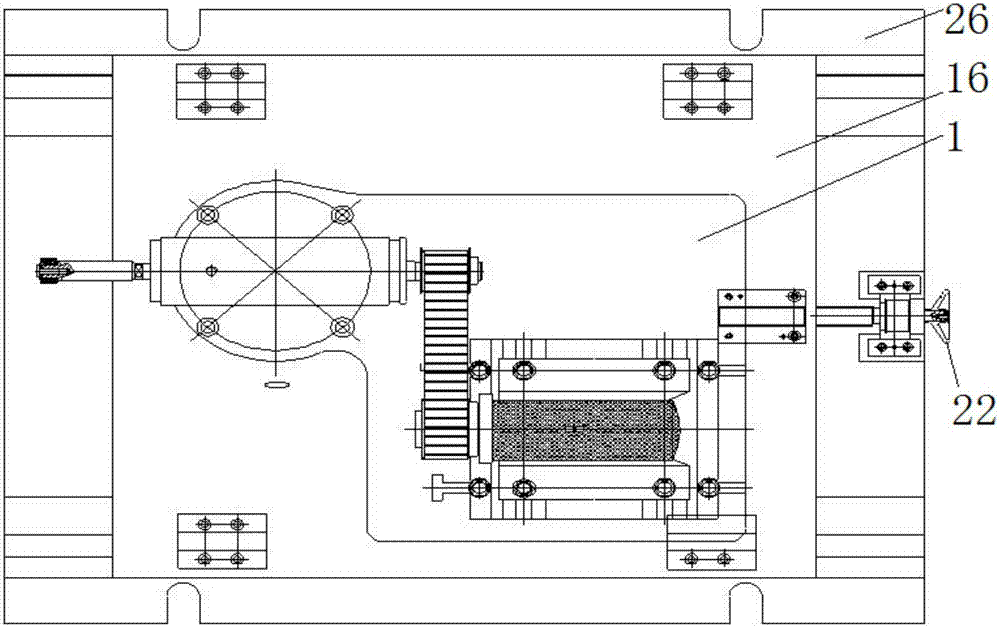

Crankshaft connecting rod shaft diameter processing tooling system

ActiveCN106312813AImprove quality controlGive full play to the technological ability of crankshaft grinderRevolution surface grinding machinesGrinding drivesElectromagnetic clutchEngineering

The invention discloses a crankshaft connecting rod shaft diameter processing tooling system and belongs to the technical field of fixtures. The crankshaft connecting rod shaft diameter processing tooling system comprises a clamp frame, and the bottom of the clamp frame is provided with a locating surface for being fixedly installed with a bed guide rail. A Morse taper shaft, an electromagnetic clutch, an indexing structure and a clamp device are sequentially installed at the front end of the clamp frame from outside to inside. A Morse taper shaft, an electromagnetic clutch and a clamp device are sequentially installed at the rear end of the clamp frame from outside to inside. The crankshaft connecting rod shaft diameter processing tooling system is combined with an ordinary crankshaft grinding machine to be used, and initial debugging is simple and practical; the process capability of the crankshaft grinding machine can be brought into full play, the requirements for skills of operators are reduced to the largest extent; and on the premise of meeting the processing technical requirements, effects of improving product quality stability and processing speed are improved.

Owner:DANJIANGKOU DONGFA CRANKSHAFT

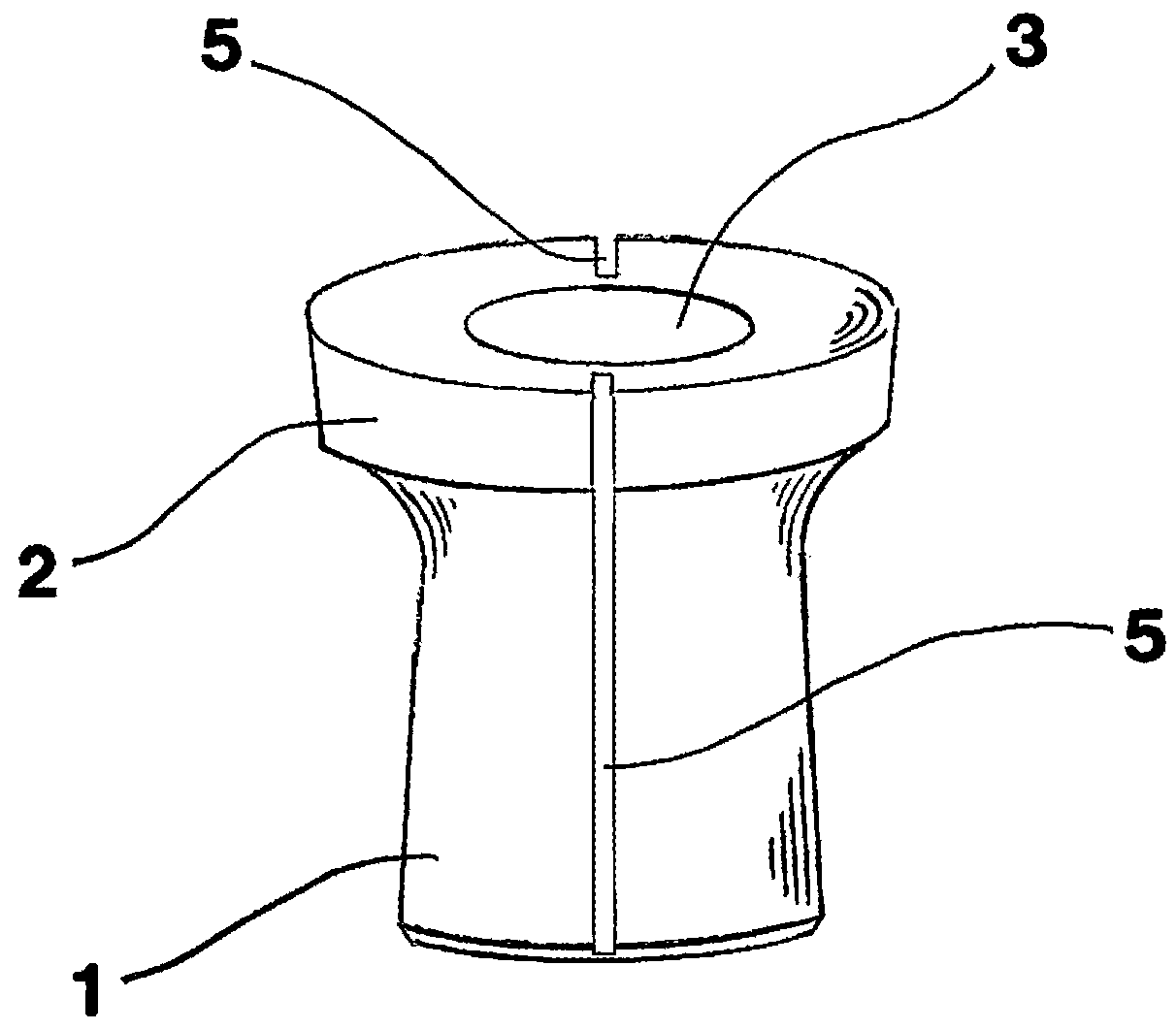

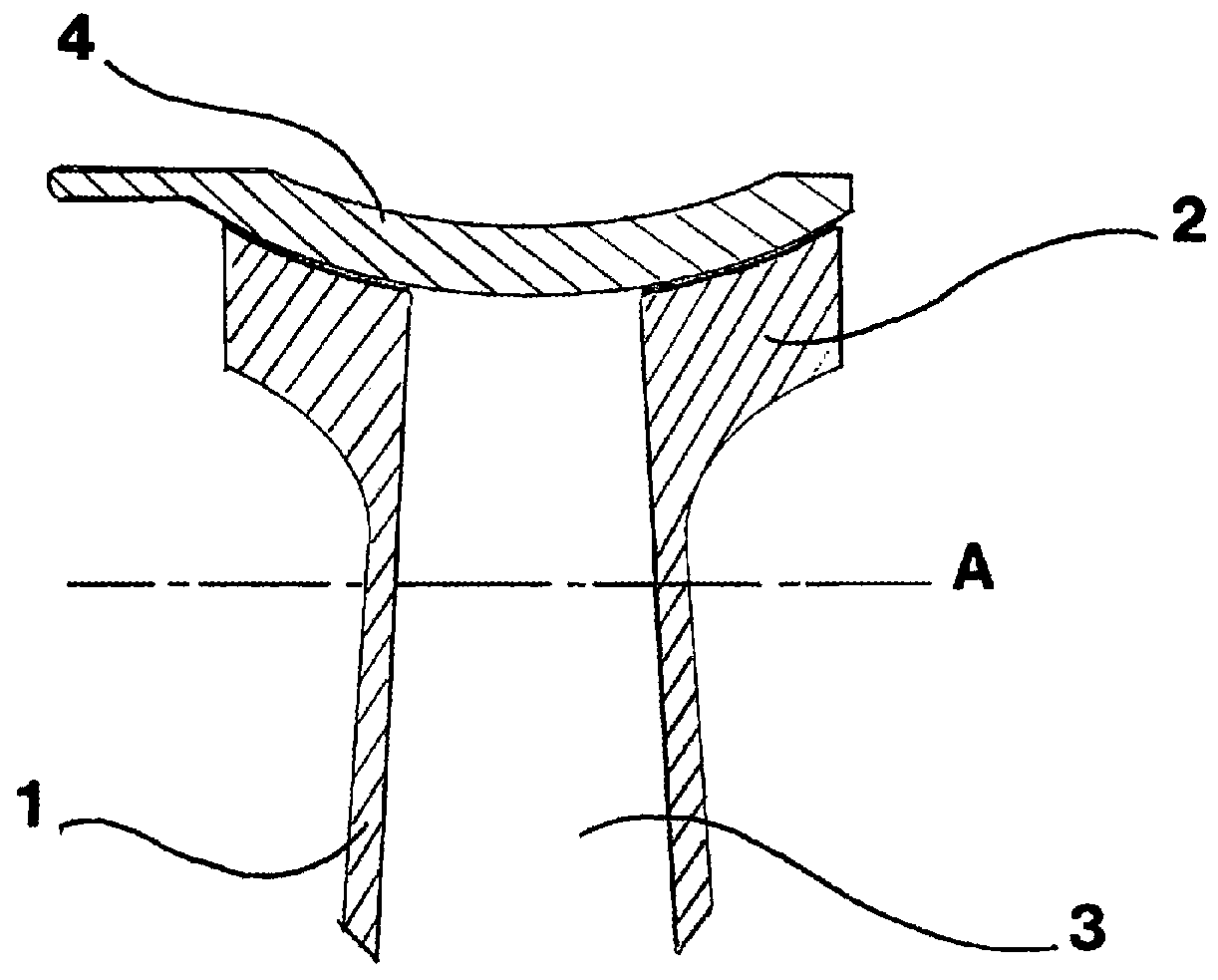

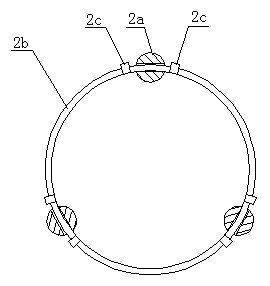

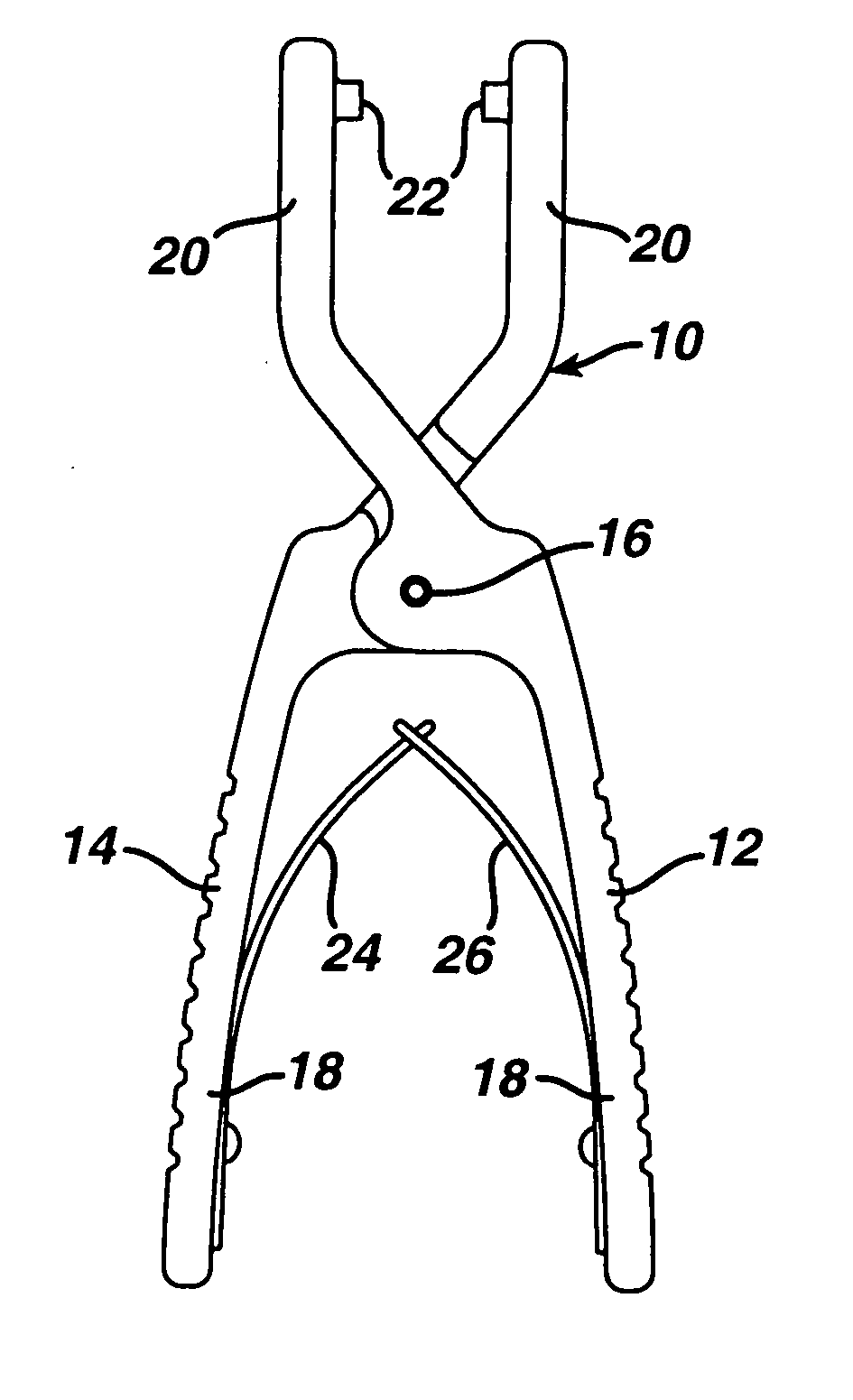

Morse taper protective sleeve

A removable orthopedic protective sleeve adapted to be applied over the male Morse taper of modular orthopedic implants thereby preventing contamination of the taper contact surface from blood, body fluid or tissue particles responsible for electrochemical corrosion and fretting at the level of Morse taper. Said sleeve having a conical tube shape and a rim at its upper narrow end. A plurality of vertical grooves situated on the outer surface of the protective sleeve will split open as the female Morse taper of the articular ball is slidingly pushed downward and seated over the male taper. The split sleeve is then removed after the male and female tapers are assembled in-situ.

Owner:JOINT INNOVATION TECH LLC

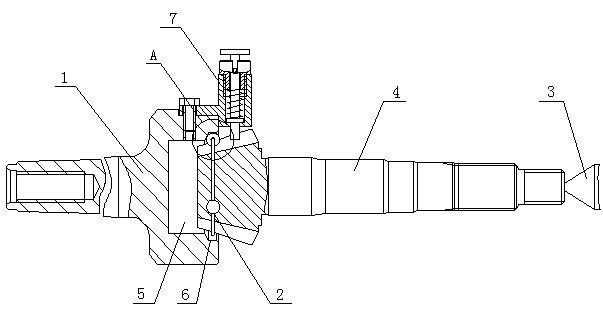

Bevel gear shaft tooth surface pitch cone locating tool

ActiveCN102145413APrevent slippingPrevent jumpingGear-cutting machinesGear teethSteel ballEngineering

The invention discloses a bevel gear shaft tooth surface pitch cone locating tool, comprising a tool body provided with a Morse taper shank, a floating type steel ball retaining ring and a tip, wherein the floating type steel ball retaining ring is sheathed in a tooth space at the front end of a processed product and is arranged in a groove arranged at one end of the tool body provided with the Morse taper shank, the floating type steel ball retaining ring leans against a limit step in the groove, and the tip leans against in a central hole at the tail end of the processed product. In the invention, the structural design that the groove is arranged at the end part of the tool body provided with the Morse taper shank is coordinated with the floating type steel ball retaining ring sheathed in the tooth space at the end part of the process product, thus the shaft diameter of the processed product and the cone pitch circle of a gear can be ensured to be maintained on the same axial lead to the utmost extent, the geometric eccentricity of the gear and the shaft diameter is corrected to the utmost extent, the problem that a gear ring runs out in the processing process can be prevented, and the product accuracy is greatly improved.

Owner:CHONCHE GRP SICHUAN DANCHI PARTS & COMPONENTS CO LTD

Jet combustion device for yarn singeing machine

The invention discloses a jet combustion device for a yarn singeing machine, and aims to solve the problems of insufficient combustion, a low flame temperature and short and instable flames of the conventional combustion device. The center of a fire distributor in the middle of an air supply support of the device is provided with a combustion channel for yarn singeing; the front surface of the air supply support and the circumferential wall of the fire distributor are provided with a vertically through yarn feeding and discharging channel; the circumferential wall of the fire distributor is provided with ventilation combustion holes which are formed radially and are communicated with a mixed gas inlet through the air supply support; the wall of a flame guiding pipe which is arranged over and adjacent to the fire distributor is provided with a vertically corresponding yarn feeding and discharging channel and a ventilation hole; the flame guiding pipe is fixed at the back of a protective mask; the middle of the protective mask is provided with a corresponding yarn feeding and discharging channel; the edge of the protective mask is provided with a hinge for resetting the protective mask; an upper yarn guiding ring and a lower yarn guiding pipe are arranged on the axis lines of the fire distributor and the flame guiding pipe; and the inside of the air supply support has a cavity structure, and the air supply support is in Morse taper fit with the fire distributor.

Owner:SHANDONG TONGJI ELECTROMECHANICAL

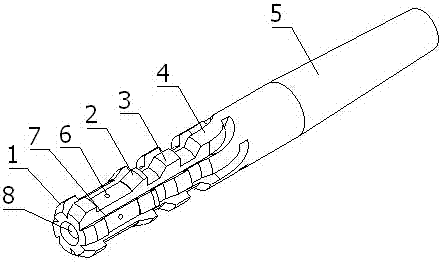

Broaching bit

InactiveCN107309474AGuarantee the quality of reamingSolve the phenomenon of melting and attaching to the drilling toolTransportation and packagingTrepanning drillsAlloyEngineering

The invention discloses a broaching bit comprising first cutting edges, second cutting edges, third cutting edges, fourth cutting edges, a Morse taper shank, outer side face cooling holes, cutting grooves and a center cooling hole. Through the center cooling hole and the outer side face cooling holes of the broaching bit, the cutting edges bearing most of cutting resistance and heat is cooled to the maximum extent, the phenomenon that a nickel-base heat resistant alloy is melted and attached to a drilling tool is avoided, and the service life of the bit is prolonged. The broaching bit is provided with the second cutting edges, the third cutting edges and the fourth cutting edges so that a broached hole and a reamed hole can be formed at a time, the production efficiency is improved, and the roughness of the hole surfaces is higher through the multiple cutting edges. The broaching bit is provided with the Morse taper shank, the interchangeability of existing machining equipment is guaranteed, and the application range is wider.

Owner:上海汉硕机械技术有限公司

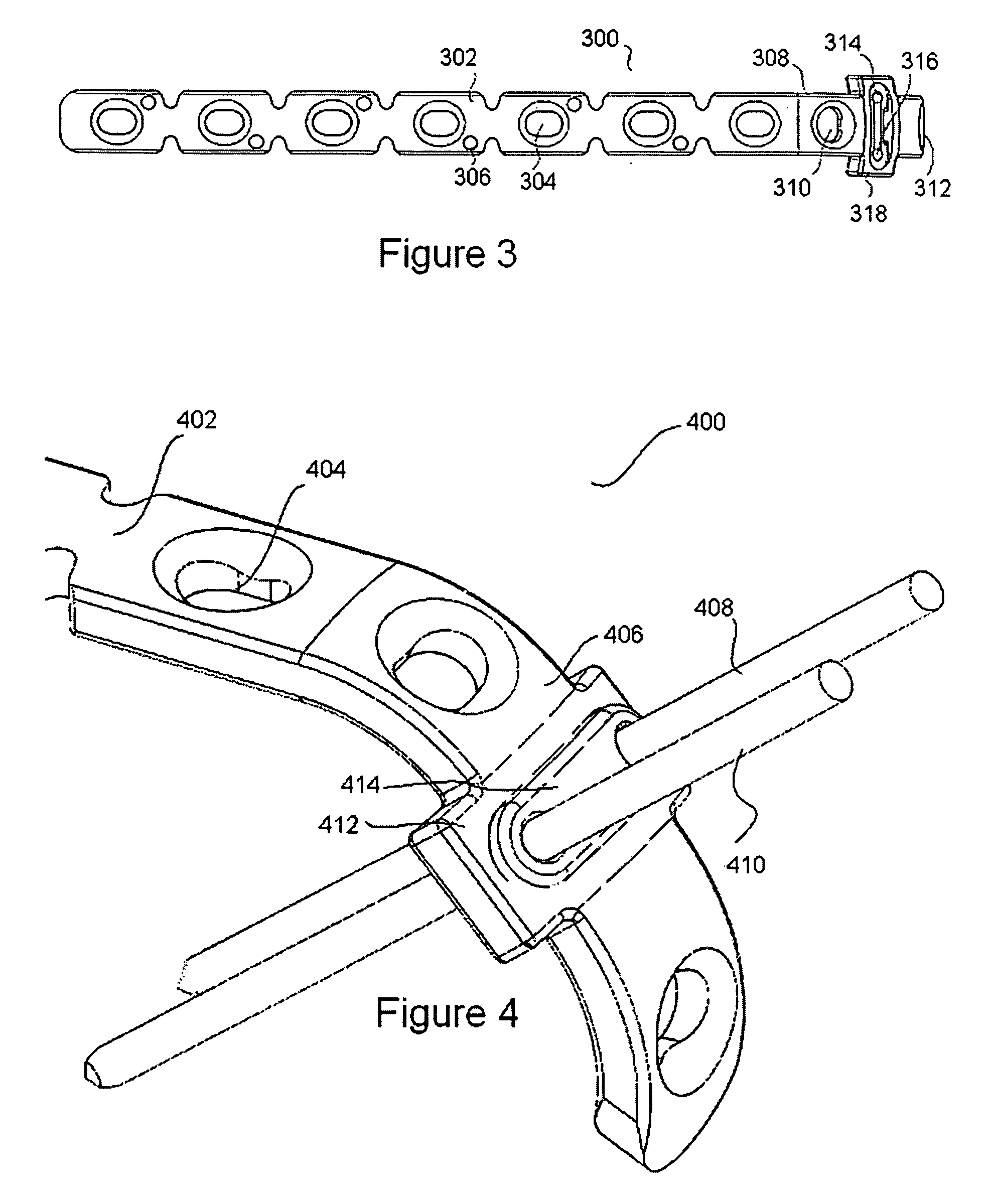

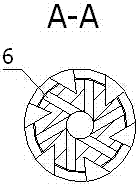

Device and method for separation of modular orthopaedic elements

A tool, system and method for separating connected orthopaedic components are disclosed. The system includes two orthopaedic components that are connected end to end. One of the orthopaedic components has a notch that receives a cam carried by the tool. The notch and cam are sized and shaped so that when the cam is turned, the cam forces the two components apart. The invention is particularly useful when Morse tapers are used to connect the components. The invention can be used with the modular orthopaedic implants as well as with modular trials used intraoperatively. The cam can be removably mounted on the tool.

Owner:DEPUY PROD INC

Turning clamp

InactiveCN101693344AEasy loading and unloadingImprove loading efficiencyPositioning apparatusTurning machinesWhole bodyEngineering

The invention discloses a turning clamp which comprises a clamp main body, wherein a Morse taper shank which is matched with a taper hole in a lathe spindle is arranged at one end of the clamp main body, and an inner taper hole is arranged at the other end of the clamp main body; the clamp also comprises a clamp accessory, wherein hollow tapered sleeve bodies are axisymmetrically arranged at a left part and a right part of the clamp accessory; the outer surface of each tapered sleeve body is in tapered-surface matching with the inner taper hole of the clamp main body, and the inner surface of each tapered sleeve body is in tapered-surface jointing with the outer tapered surface of a workpiece to be processed; a screw hole is arranged between the two tapered sleeve bodies of the clamp accessory along an axial line; and the inner taper hole of the lathe main body, the clamp main body and the clamp accessory are coincident along an axial line under a combined state. By using the turning clamp, the loading efficiency of the workpiece is high, and the whole body of the workpiece to be processed is tightly jointed with the whole body of the clamp, therefore, the workpiece is not easy to loosen and deviate from the spindle in the processing; and when the other end of the workpiece is processed after an inner hole at one end of the workpiece is processed, the distance between the axial lines of the inner holes at two ends can be effectively ensured to be less than 0.01mm, therefore, the processed workpiece accords with the coaxial precision requirement.

Owner:泉州泉风电机有限公司

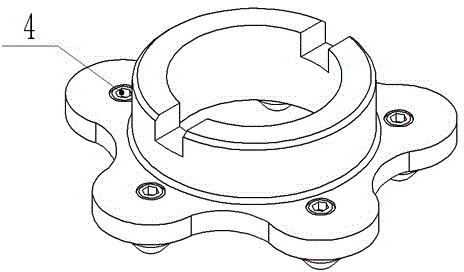

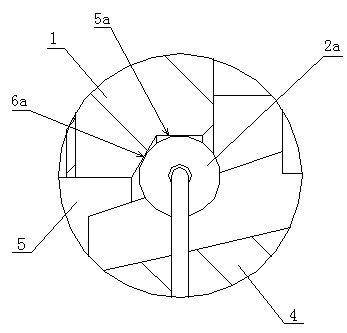

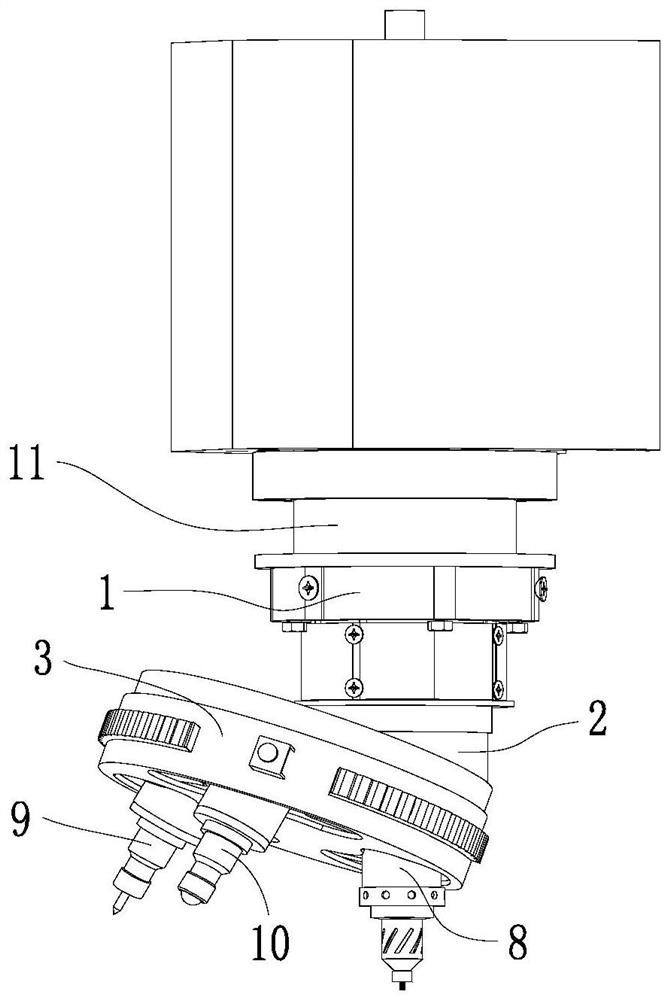

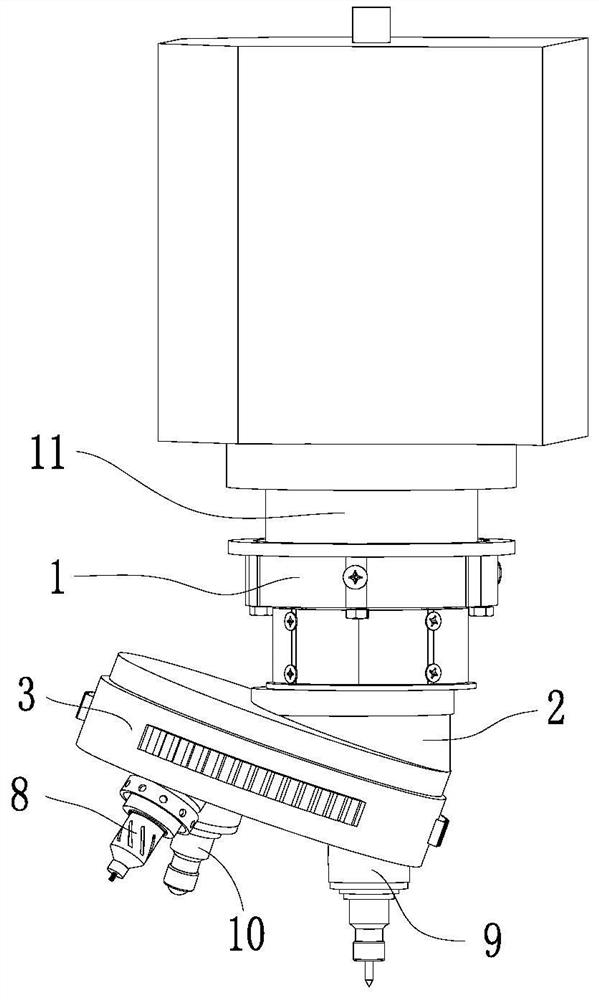

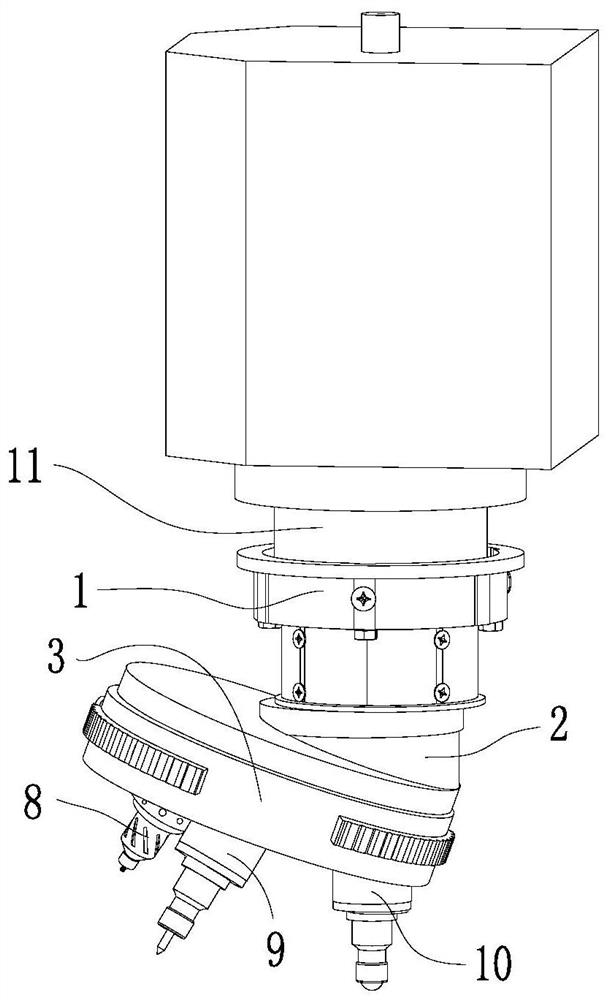

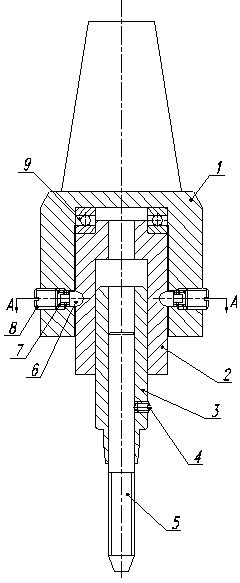

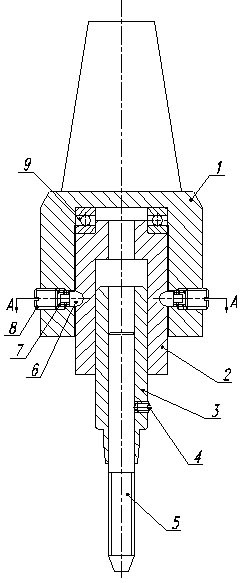

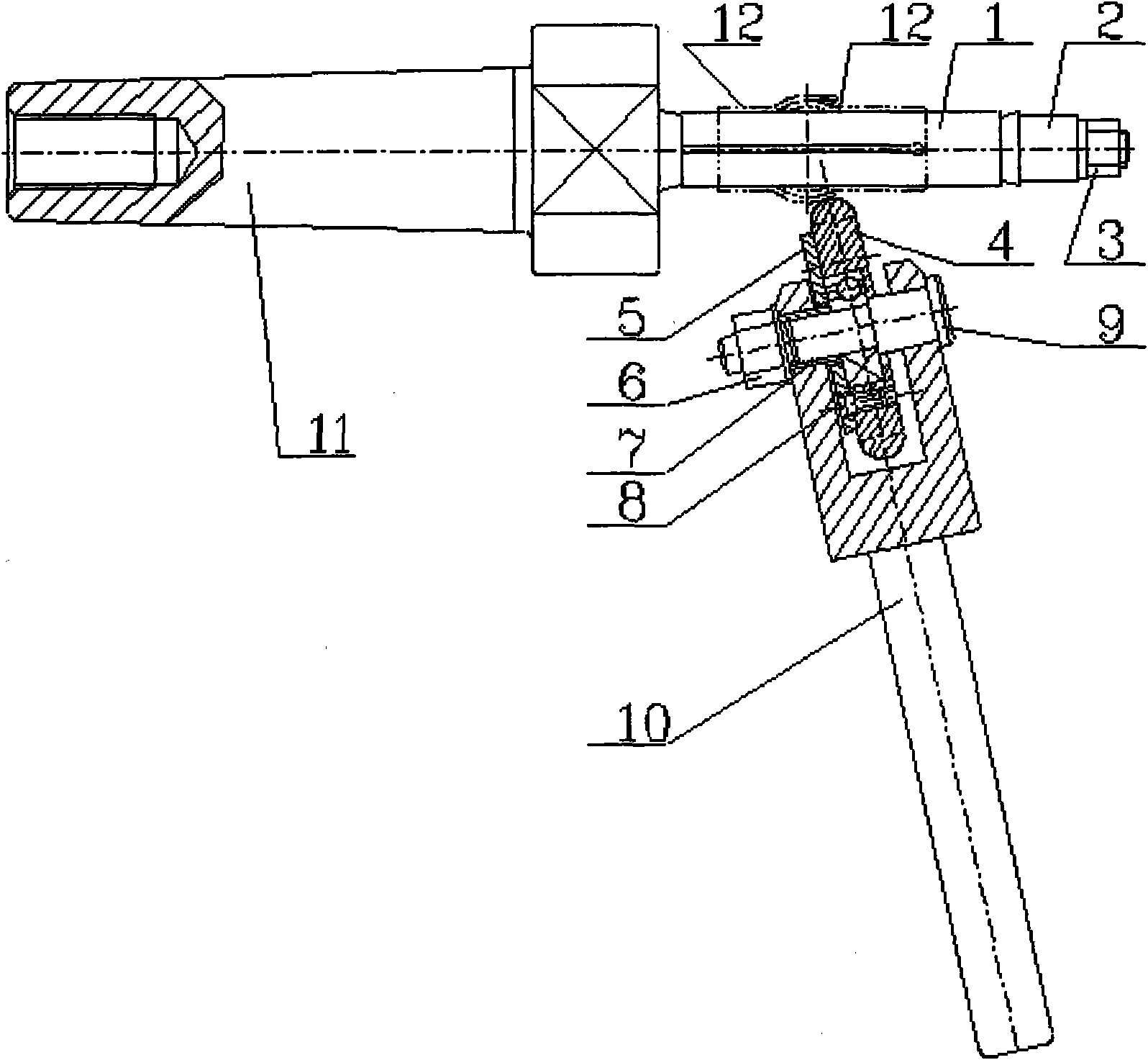

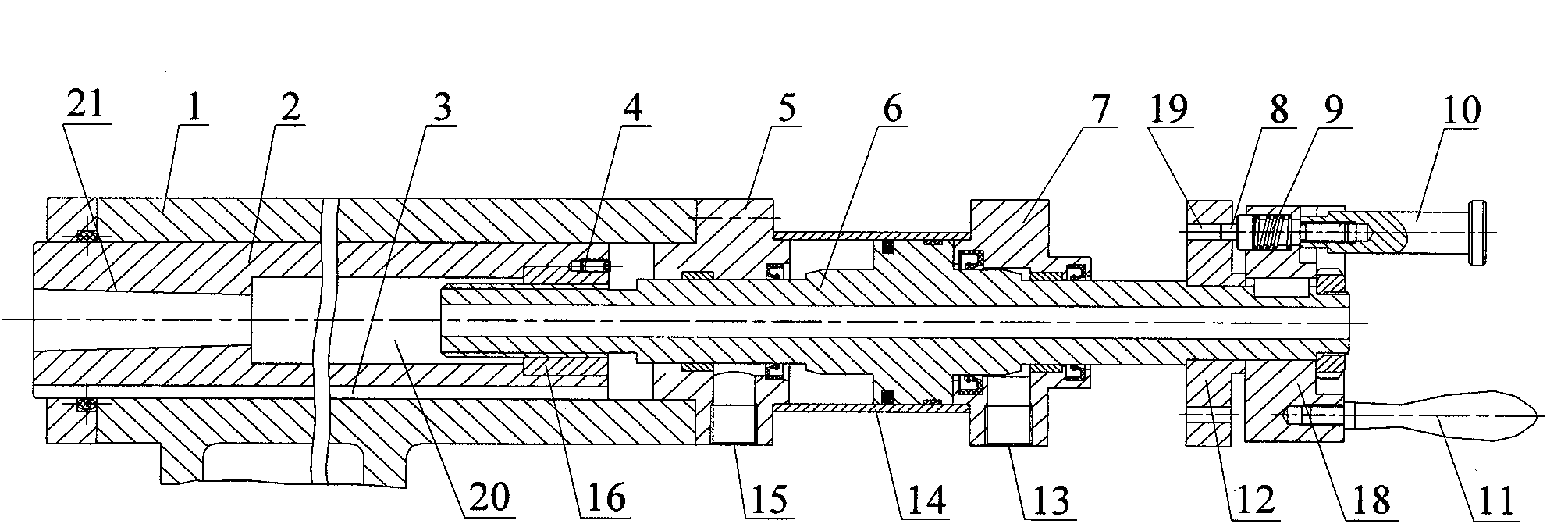

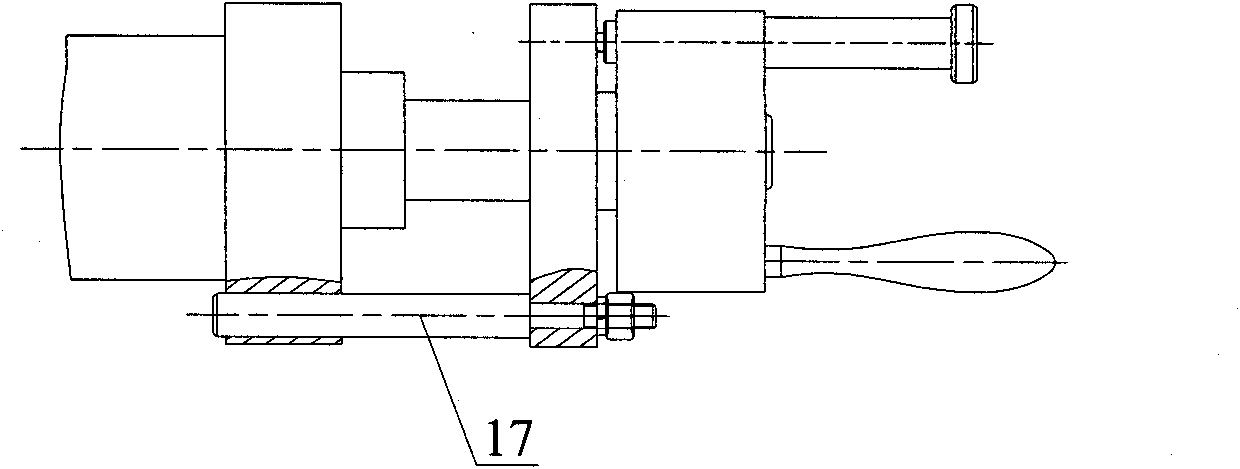

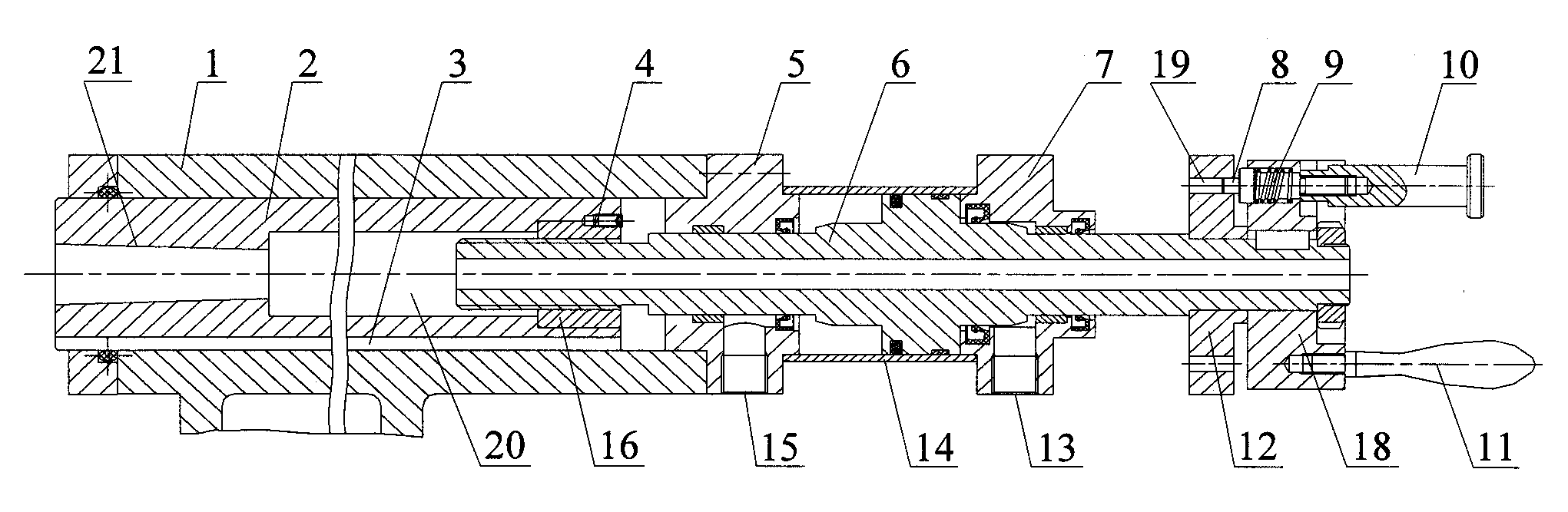

Convertible clamp with three cutters for ultrasonic milling, impacting and rolling

ActiveCN113199281ARealize switchingImprove processing efficiencyPositioning apparatusMetal-working holdersDrive wheelMilling cutter

The invention discloses a convertible clamp with three cutters for ultrasonic milling, impacting and rolling. The convertible clamp comprises a milling machine main shaft positioning mechanism, a clamp switching shell, a cutter changing driving wheel disc, a cutter mounting disc, a clutch, a clutch switching executing mechanism, a Morse taper shank and three ultrasonic cutters. The upper end of the clamp switching shell is fixedly connected with a milling machine main shaft through a milling machine main shaft positioning mechanism; the cutter changing driving wheel disc is arranged at the lower end of the clamp switching shell; the cutter mounting disc is arranged on the cutter changing driving wheel disc; the three ultrasonic cutters are uniformly distributed on the cutter mounting disc and have 30-degree inclination angles towards the circle center of the cutter mounting disc, the ultrasonic milling cutter can rotate, and the ultrasonic impact cutter and the rolling cutter cannot move; the Morse taper shank is fixedly connected with the milling machine main shaft; the clutch switching executing mechanism is connected to the Morse taper shank; the clutch is arranged between the clutch switching executing mechanism and the ultrasonic milling cutter, the upper half part of the clutch is arranged on the clutch switching executing mechanism, and the lower half part of the clutch is arranged on the ultrasonic milling cutter; and the cutter changing driving wheel disc is used for driving the clutch switching executing mechanism to act.

Owner:SHENYANG AEROSPACE UNIVERSITY

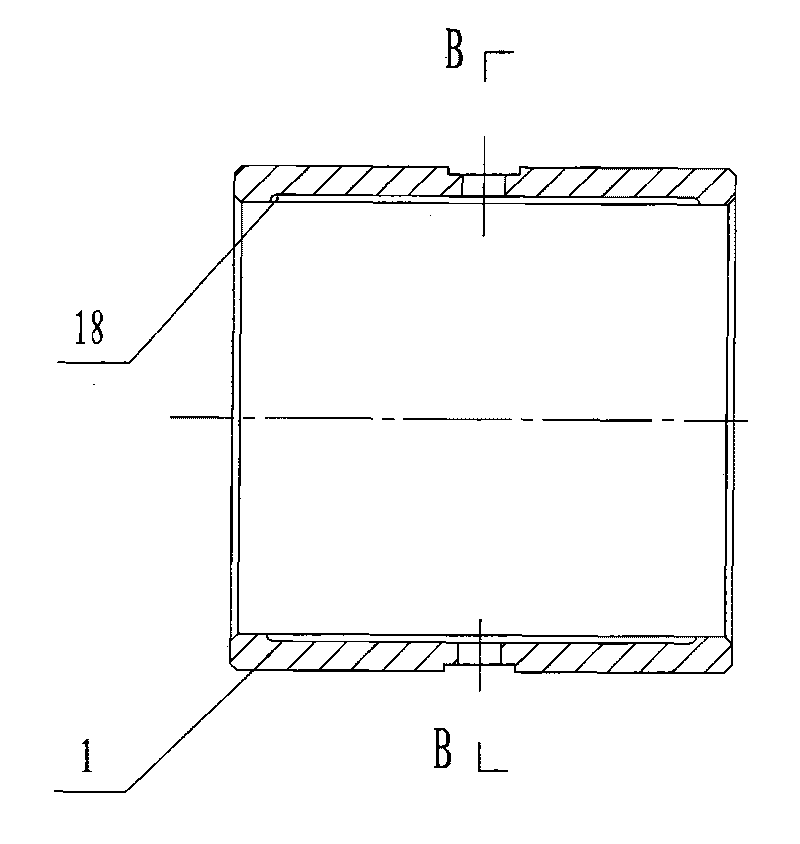

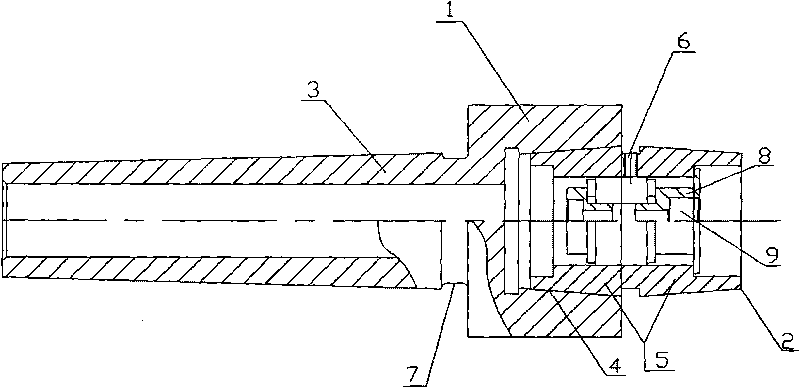

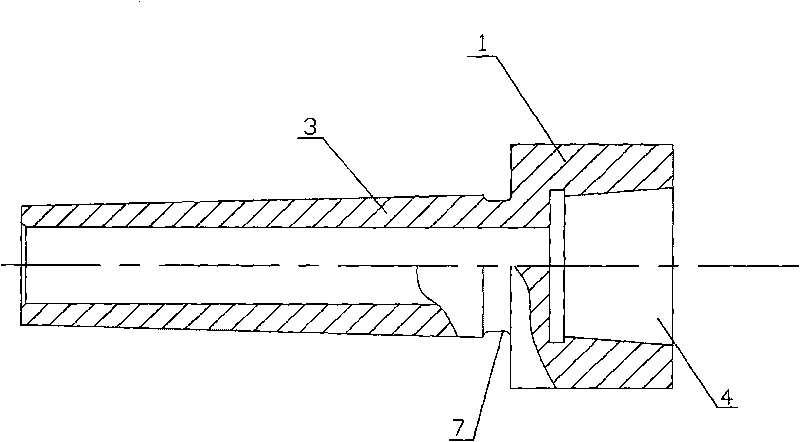

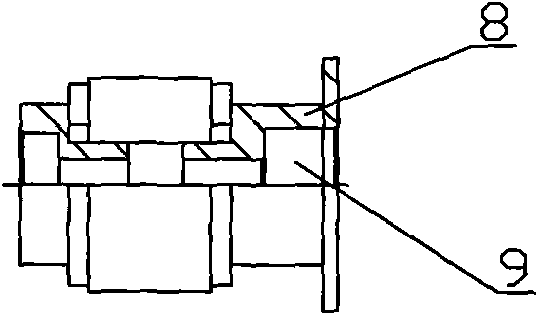

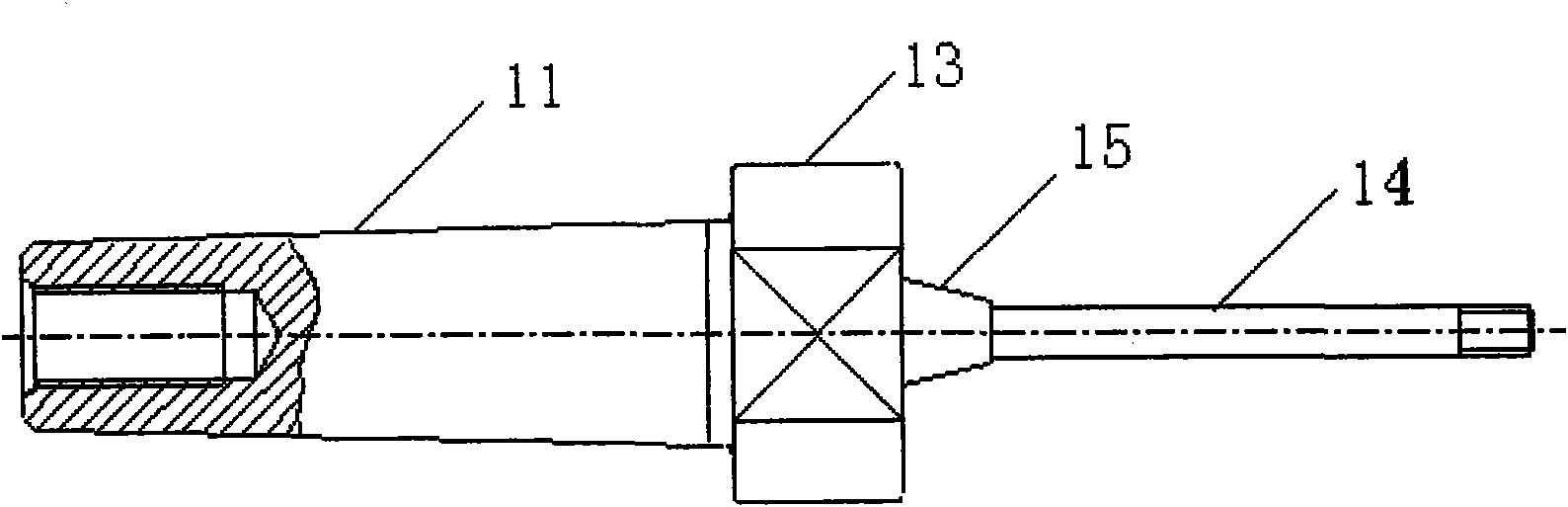

Central spindle capable of automatically centring and tapping internal screw thread

InactiveCN102672289AGuaranteed coaxiality requirementsSimple knotThread cutting machinesBall bearingScrew thread

The invention discloses a central spindle capable of automatically centring and tapping internal screw threads, which comprises a morse taper handle, an aligning sleeve, a screw tap sleeve, screws, a screw tap, joint column heads, springs, plugs and a thrust ball bearing. The upper half part of the morse taper handle is a morse taper body; the lower half part of the morse taper handle is a hollow sleeve body; four through holes which are uniformly distributed at an angle of 90 degrees are arranged on the wall of the sleeve body of the morse taper handle; the internal screw threads are tapped at the outer end ports of the through holes; the joint column heads, the springs and the plugs are sequentially arranged in the through holes from inside to outside; the thrust ball bearing and the aligning sleeve are sequentially arranged in the sleeve body of the morse taper handle from inside to outside; the screw tap sleeve and the interchangeable screw tap are sequentially arranged in the aligning sleeve from outside to inside and are fastened by the screws; and circular pits in fit with the sizes of semicircular balls of the joint column heads, which are uniformly distributed at an angle of 90 degrees, are arranged on the wall of the aligning sleeve. The central spindle has simple structure and can be automatically regulated and centred; the requirement on the coaxiality of the axis of the screw tap and the center of a screw thread bottom hole is ensured; the screw tap is avoided being broken; and a workpiece is avoided being scraped.

Owner:ZHEJIANG UNIV

Method and apparatus for attachment in a modular hip replacement or fracture fixation device

InactiveUS8974540B2Enhance quality and reliability and compatibilityJoint implantsFemoral headsInterference fitRight femoral head

Methods and apparatus for orthopedic replacement of the hip and hip fracture fixation devices include structures and techniques for fixing or enhancing interconnection of implant components, such as by increasing the interconnection in an interference fit with one or more tapers, threads, and / or cooling of components prior to assembly. For example, a prosthetic femoral neck implant can include a thread and a Morse taper for lockable attachment to a prosthetic femoral head and / or intramedullary stem.

Owner:IHIP SURGICAL LLC

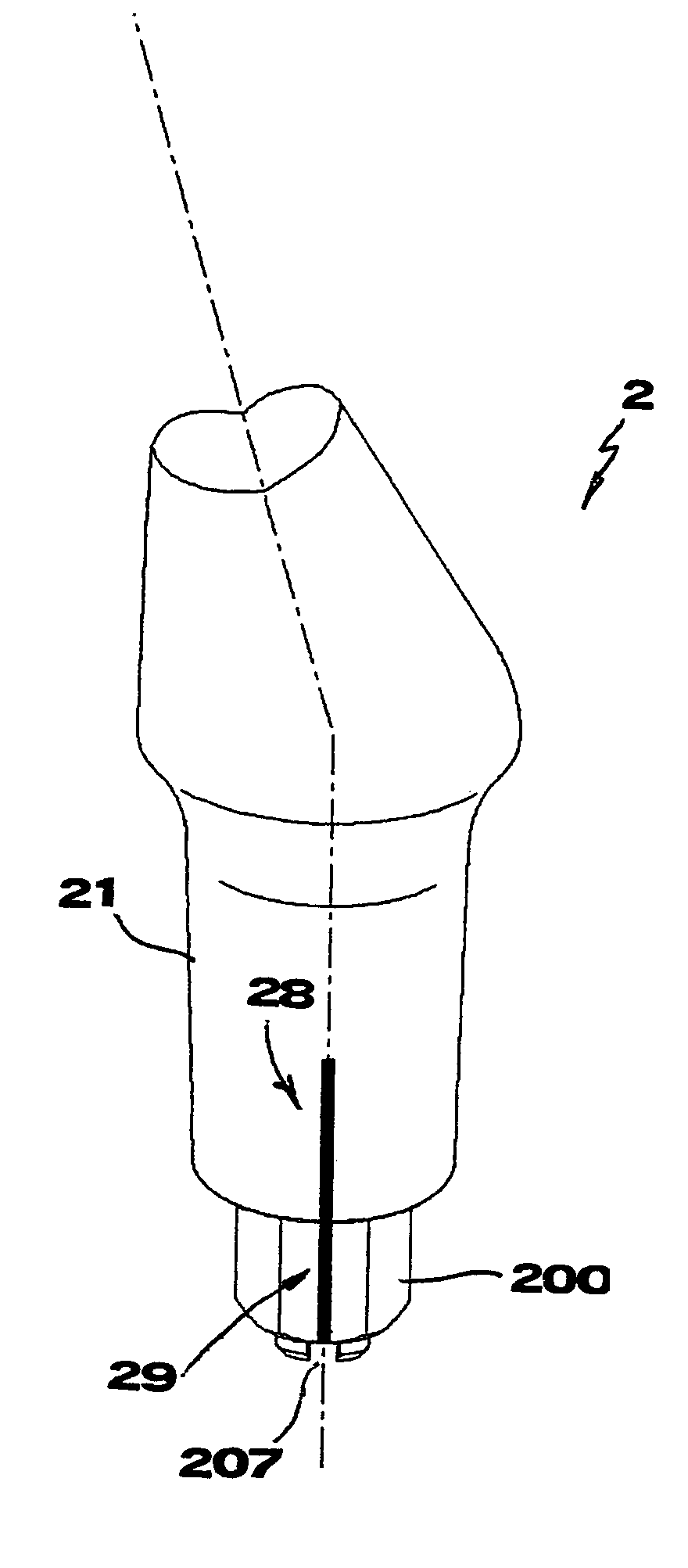

Dental implant

ActiveUS8328556B2Easy disconnectionAvoiding application of impulsive forceDental implantsFastening prosthesisEngineeringAbutment

Owner:LEONE SPA

Orthopaedic appliances

InactiveUS20080021475A1Easy to disassembleSuture equipmentsJoint implantsHip joint replacement operationProximal ulna

Provided is a bone plate for the olecranon of the proximal ulna using a combination of screws and K wires. The plate is curved to fit the shape of the olecranon and is screwed in place. The plate has a locking section located in the curved section. A fastener is pushed over the ends of the K wires and locks in to the locking section of the plate. The fastener has a tapered wedge that secures the K wires and resists their withdrawal. A femoral stem cap is used during hip replacement surgery and protects the Morse taper of the femoral stein once the ball of the hip joint is removed. The femoral stem cap has an air vent to allow air to pass when being applied and removed.

Owner:LAWRIE STEVEN ALAN

Spindle taper hole grinding miller and online repairing method for spindle taper hole

InactiveCN106975988AImprove repair accuracyReduce downtimeGrinding carriagesRevolution surface grinding machinesEngineeringActuator

The invention discloses a main shaft taper hole grinder. The lower seat is fixed on the working surface of the machine tool. The lower seat is connected upwardly by rolling two sets of rolling linear guide rail pairs to the upper sliding seat. A wire is additionally arranged between the upper sliding seat and the lower seat. Rod transmission mechanism; the upper surface of the upper sliding seat is equipped with a main shaft shell, and the bearings at both ends of the through hole on the upper part of the main shaft shell are set together with the main shaft. There is a main shaft pulley, and the motor pulley is connected to the main shaft pulley; the second bearing at the rear end of the lower seat is equipped with a screw, and the end of the screw is fixed with a hand wheel; the lower surface of the upper sliding seat is connected to an upper slide. The seat screw nut, the external thread on the circumferential surface of the lead screw is matched with the internal thread of the upper slide seat nut. The invention also discloses an online repair method for the taper hole of the main shaft. The device and method of the invention have simple structure and reliable operation.

Owner:MCC SFRE HEAVY IND EQUIP

Combined tools for machining holes and machining methods

ActiveCN104070212ASimple and easy hole reamingExtended service lifeTransportation and packagingBoring/drilling machinesMorse taperMachining

The invention discloses two kinds of combined tools arranged on lathes for machining holes and machining methods thereof; according to the combined tools for machining holes and the machining methods thereof, the problems that in machining, the existing hole machining methods are large in drill bit consumption, vertical positions of noses of the tools in workpiece holes are inconvenient to adjust and cooling liquid cannot be fully filled can be solved. The combined tool for machining holes comprises a toolbar and a tool bit, wherein one end of the toolbar is provided with a Morse taper shank while the other end is provided with a square groove; the tool bit is installed in the square groove through a fastener; two sides of the end of the tool bit are respectively provided with a chip breaker groove; the toolbar is provided with a through hole along the axis direction; one end, close to the tool bit, of the through hole is provided with a step-shaped hole, and the diameter of the step-shaped hole is more than the width of the tool bit. When the combined tool is used for machining a deep hole, the cooling liquid can be fully filled, so that cutting environment is improved, and service life of the tool and machining quality of product are enhanced; with improvement on the tool bit, compared with the original technology of repairing a waste connecting sleeve by a drill bit, the combined tool is greatly improved in machining efficiency.

Owner:NANJING MEISHAN METALLURGY DEV

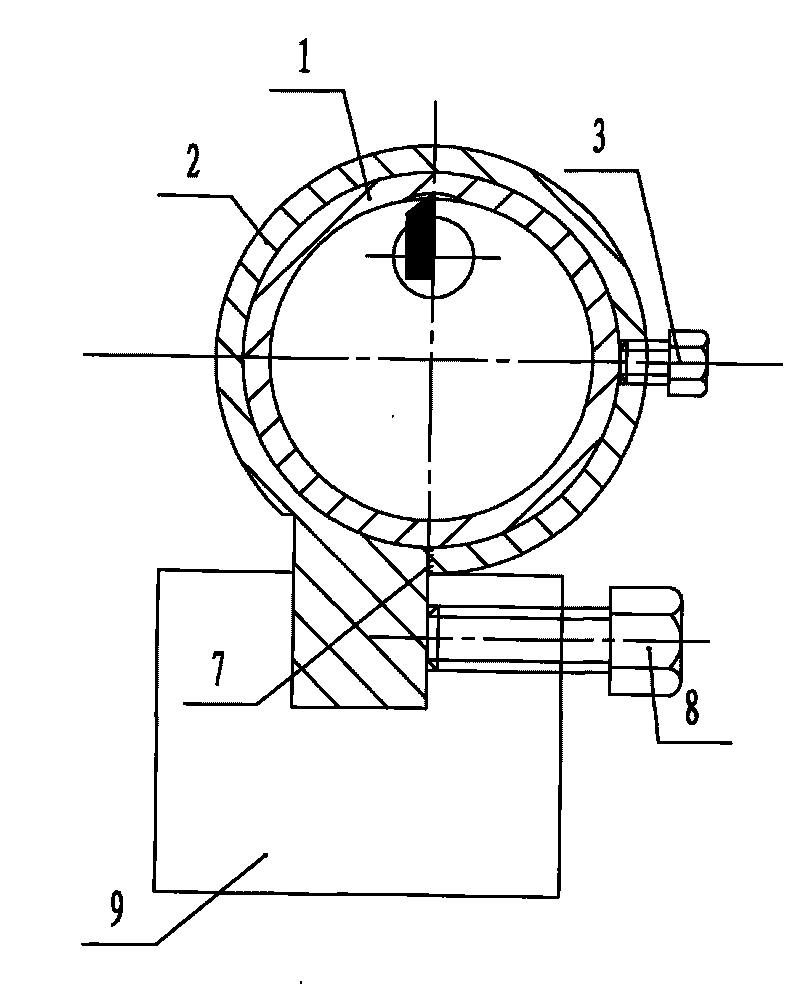

Universal closing-up device for spherical surface of spinning conduit

The invention discloses a universal closing-up device for a spherical surface of a spinning conduit, which comprises a locating component connected with a spindle of a machine tool through Morse taper, and a spinning component fixed on a knife rest of the machine tool; an expansion bushing (1) sheathed on a spindle cylinder is arranged on a front-end spindle (14) of the locating component; inner conical holes (16) oppositely symmetrical are arranged on the two end tube openings of the expansion bushing (1); moreover, two spherical conduit joint sleeves (12) sheathed on the spindle (14) are expanded, located and clamped into a closing-up nut 3 respectively through a cone (15) on the step end surface of the spindle and a taper plug (2) screwed on the free end of the spindle (14); a spinning roller component (4) is arranged on the free end of a spinning stick (10) of the spinning component; the spinning roller component (4) implements feed motions with the knife rest of the machine tool along X and Y directions; and the rollers implement spinning and closing-up forming on the spherical conduit joint closing-up sleeves (12). The universal closing-up device for the spherical surface of the spinning conduit has the advantages of high efficiency, low cost as well as simple and convenient manufacture and operation.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Self-tightening and position-adjustable tailstock for grinder

InactiveCN102218701ARealize automatic controlRealize the function of adjustable tensionGrinding work supportsAutomatic controlReciprocating motion

A self-tightening and position-adjustable tailstock for a grinder comprises a sleeve which is arranged inside a tailstock case body and is provided with a Morse tapered hole. The self-tightening and position-adjustable tailstock is characterized in that a longitudinal guide slot is arranged on the surface of the sleeve; the guide slot is connected with a guide key arranged inside the tailstock case body so as to be enabled to slide along the guide key; the non-working end of the tailstock case body is fixedly connected with a cylinder; the piston rod of the cylinder penetrates through the centers of a front end closure and a back end closure; and one end of the piston rod is provided with an external thread and inserted into the inner hole of the sleeve. After the adoption of the self-tightening and position-adjustable tailstock for the grinder, provided by the invention, a reciprocating movement of the sleeve is executed by the cylinder on the tail part of the device so as to drive a tip do the reciprocating movement to tighten and loose a workpiece; the cylinder instead of a manual wrenching handle is used as an executing component, so that the automatic control of equipment can be easily realized; and the self-tightening and position-adjustable tailstock for the grinder is provided with a hand wheel regulating device, so that the axial extension and retraction of the tailstock sleeve can be conveniently regulated.

Owner:安徽尚美电气科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com