Copper-aluminum transition junction box for switch in front of meter

A junction box, copper and aluminum technology, applied in the direction of connection, conductive connection, electrical components, etc., can solve the problems of endangering the life safety of on-site operators, easy burning of joints, and improper handling of contact surfaces, so as to ensure the effect of contact conductivity and guarantee Cutting effect, solve the effect of easy burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

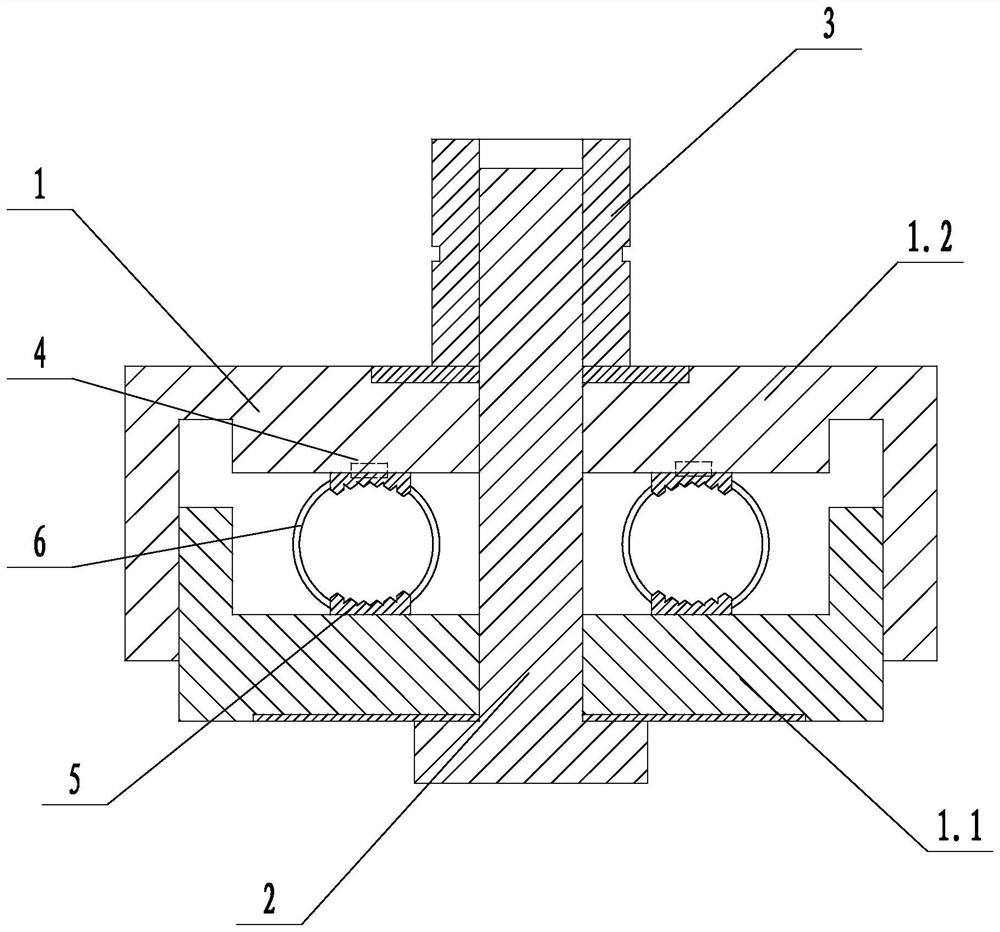

[0023] Such as figure 1 As shown, a copper-aluminum transition junction box for a switch in front of a meter includes a reinforced insulating case 1, a connecting bolt 2, a connecting nut 3 and a connecting piece 4, and the connecting bolt 2 is a high-strength bolt. The connecting nut 3 is a torque nut. The reinforced insulating shell 1 includes an upper shell 1.2 and a lower shell 1.1, one end of the connecting bolt 2 passes through the lower shell 1.1 and the upper shell 1.2 in turn, and is connected with the connecting nut 3, and the other end of the connecting bolt 2 is pressed down The casing 1.1, the upper casing 1.2 and / or the lower casing 1.1 are fixed with a puncture blade 5, the puncture blade 5 is arranged between the upper casing 1.2 and the lower casing 1.1, and the connecting piece 4 includes a copper end made of copper and the aluminum end made of aluminum, the aluminum end of the connecting piece 4 is connected with the piercing blade 5 , and the copper end of...

Embodiment 2

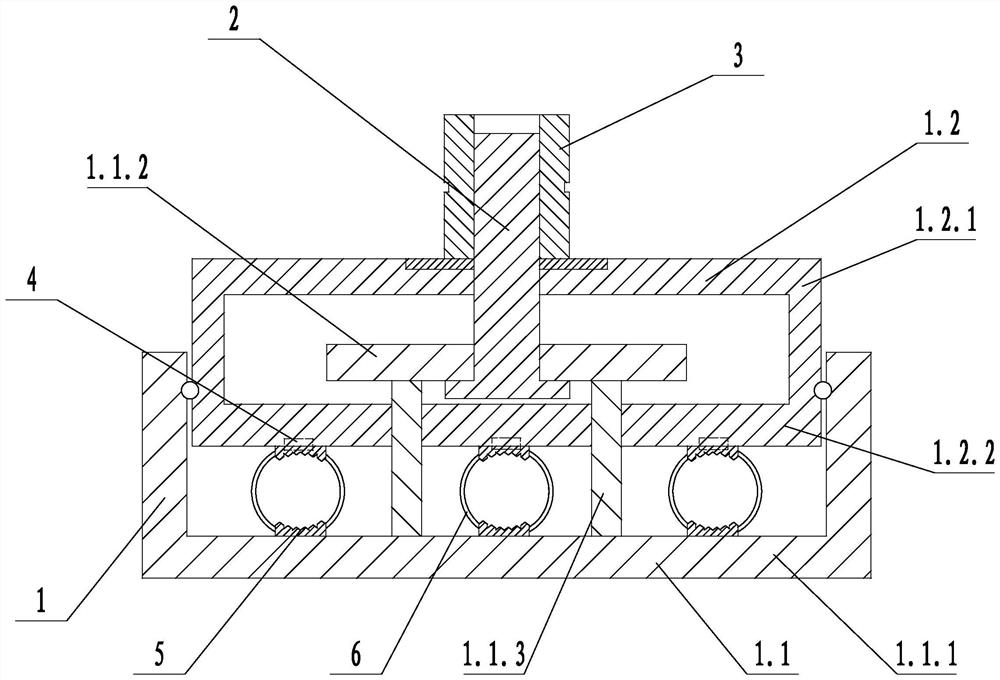

[0026] Such as figure 2 As shown, on the basis of Embodiment 1, the lower shell 1.1 includes a first outer shell 1.1.1 and a first inner shell 1.1.2, the first outer shell 1.1.1 and a first The inner shell 1.1.2 is fixed by two connecting columns 1.1.3, the upper shell 1.2 includes the second outer shell 1.2.1 and the second inner shell 1.2.2, the second outer shell 1.2. 1 is fixed with the second inner shell 1.2.2, the second inner shell 1.2.2 is arranged between the first outer shell 1.1.1 and the first inner shell 1.1.2, and the two connecting columns 1.1.3 passing through the second inner shell 1.2.2, the first inner shell 1.1.2 is arranged between the second outer shell 1.2.1 and the second inner shell 1.2.2, the The piercing blade 5 is arranged on the second inner shell 1.2.2 and / or the first outer shell 1.1.1, and the two connecting columns 1.1.3 are symmetrically arranged with the connecting bolt 2 as the axis of symmetry, and the number of blade groups is 3 , where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com