Device for small saw of machining center to adapt to plate thickness

A processing center and self-adaptive technology, which is applied in the direction of sawing machine, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient adjustment and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

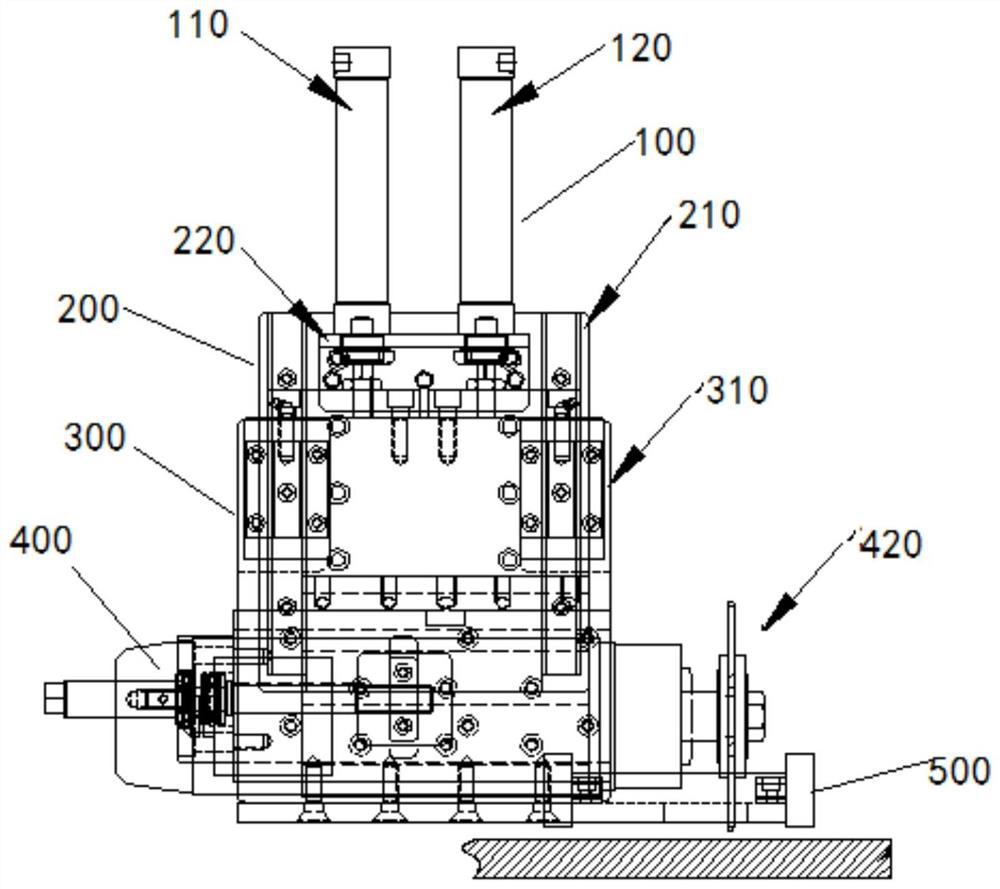

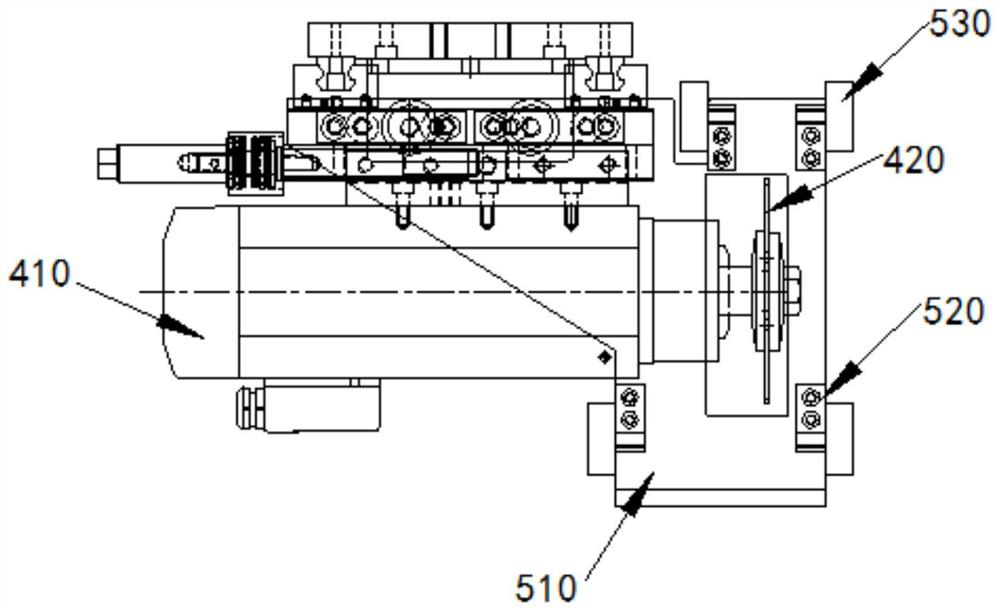

[0023] See figure 1 with figure 2 , this embodiment provides a small saw adaptive board thickness device in a machining center, which includes: a cylinder assembly 100, a slide assembly 200, a slide assembly 300, a small saw assembly 400 and an adaptive assembly 500, the slide assembly 300 is installed on the slide On the assembly 200, the top of the slide assembly 300 is connected to the cylinder assembly 100, the bottom of the slide assembly 300 is connected to the small saw assembly 400, the bottom of the small saw assembly 400 is connected to the self-adaptive assembly 500, and the adaptive assembly 500 is in contact with the board to drive the slide assembly 300 and The small saw assembly 400 on the slide assembly 300 is adjusted in height, and the cylinder assembly 100 is used to drive the slide assembly 200, and the slide assembly 300, small saw assembly 400 and adaptive assembly 500 on the slide assembly 200 to move up and down; The bottom of the saw assembly 400 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com