Film scratching device of film coated metal plate and application method of film scratching device

A technology of scribing and sheet metal, applied in the field of scribing devices, can solve the problems of low work efficiency, difficult to control force, high labor intensity, etc., and achieve the effect of ensuring the scribing force, preventing scratches, and improving the degree of equipment automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only a part of the present invention, rather than Full examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts shall fall within the protection scope of the present invention.

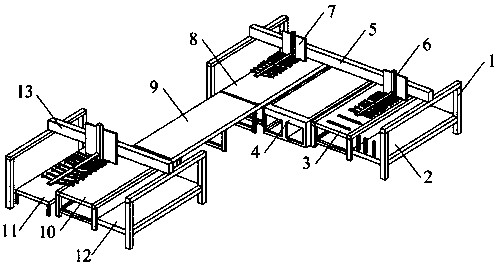

[0026] as attached figure 1 to attach figure 2 shown.

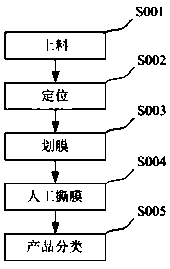

[0027] A film-coated sheet metal film-scribing device provided by the present invention includes a frame body 1, a feeding platform 2, a positioning platform 3, a film-scribing platform 4, a screw slide table 5, a feeding manipulator 6, a translation manipulator 7, a transition Platform 8, film tearing belt line 9, blanking platform 10, defective product platform 11, qualified product p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com