Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

285results about "Binding material removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

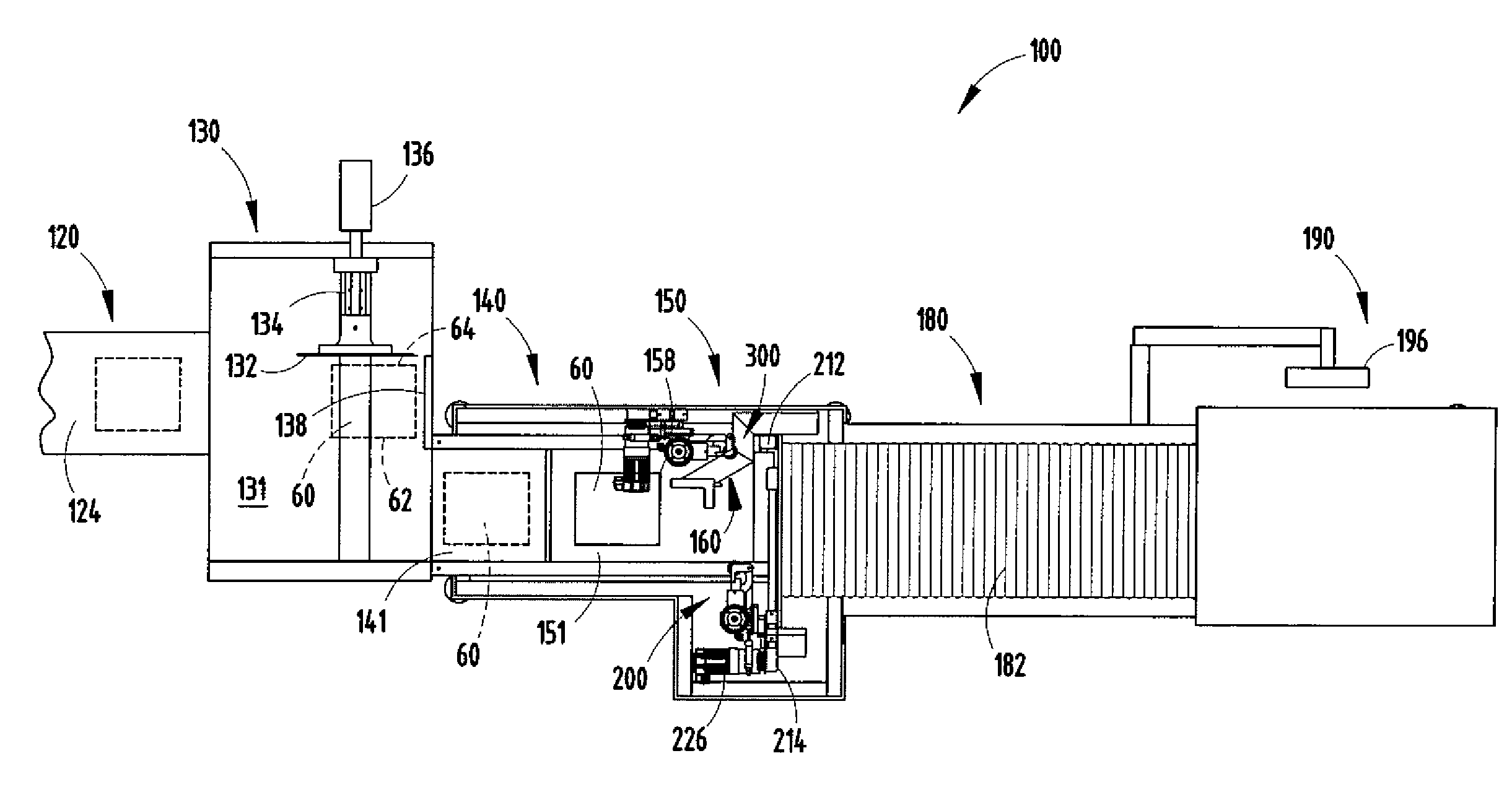

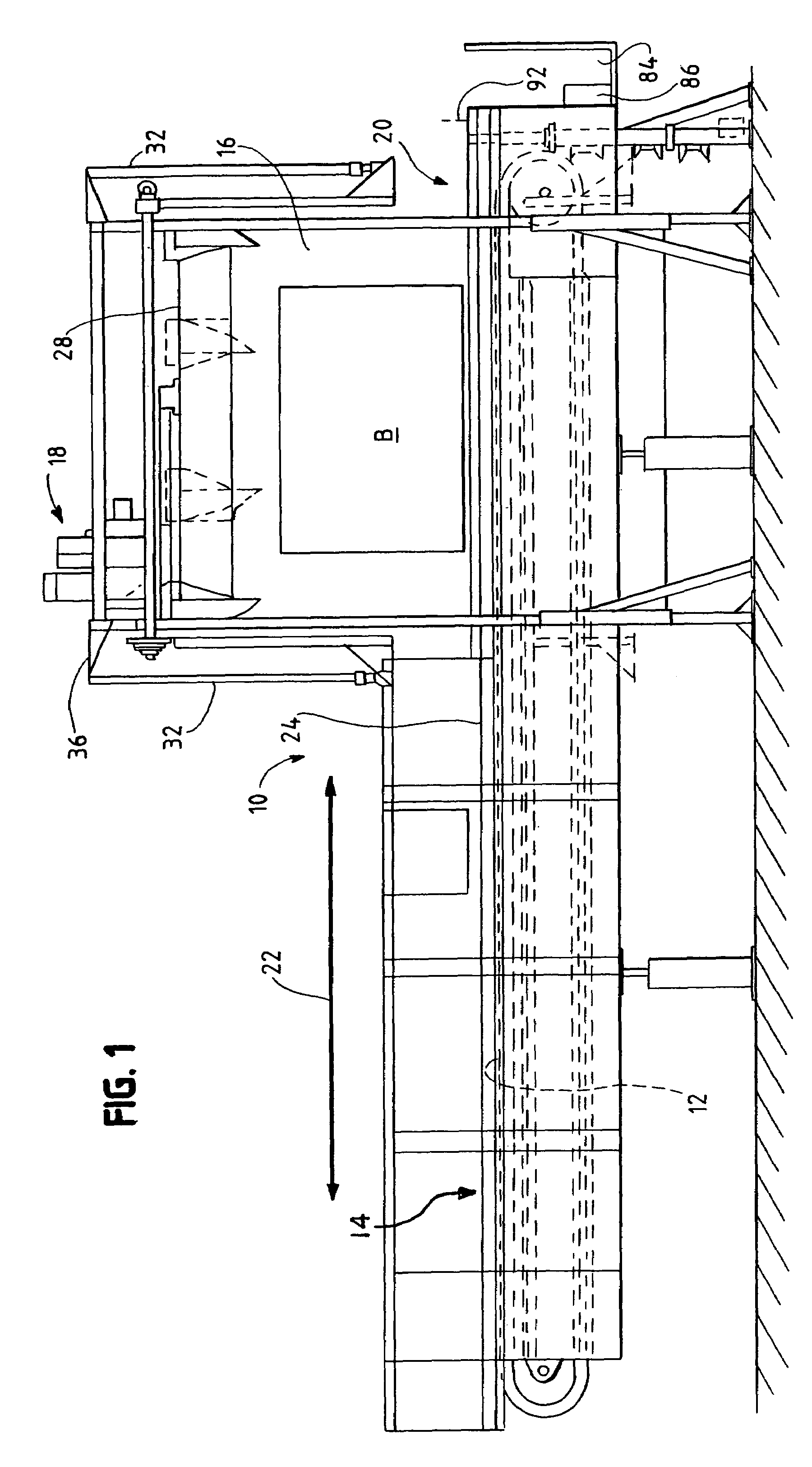

De-packaging machine

InactiveUS20040250670A1Opening closed containersBottle/container closureWrap aroundPackaging machine

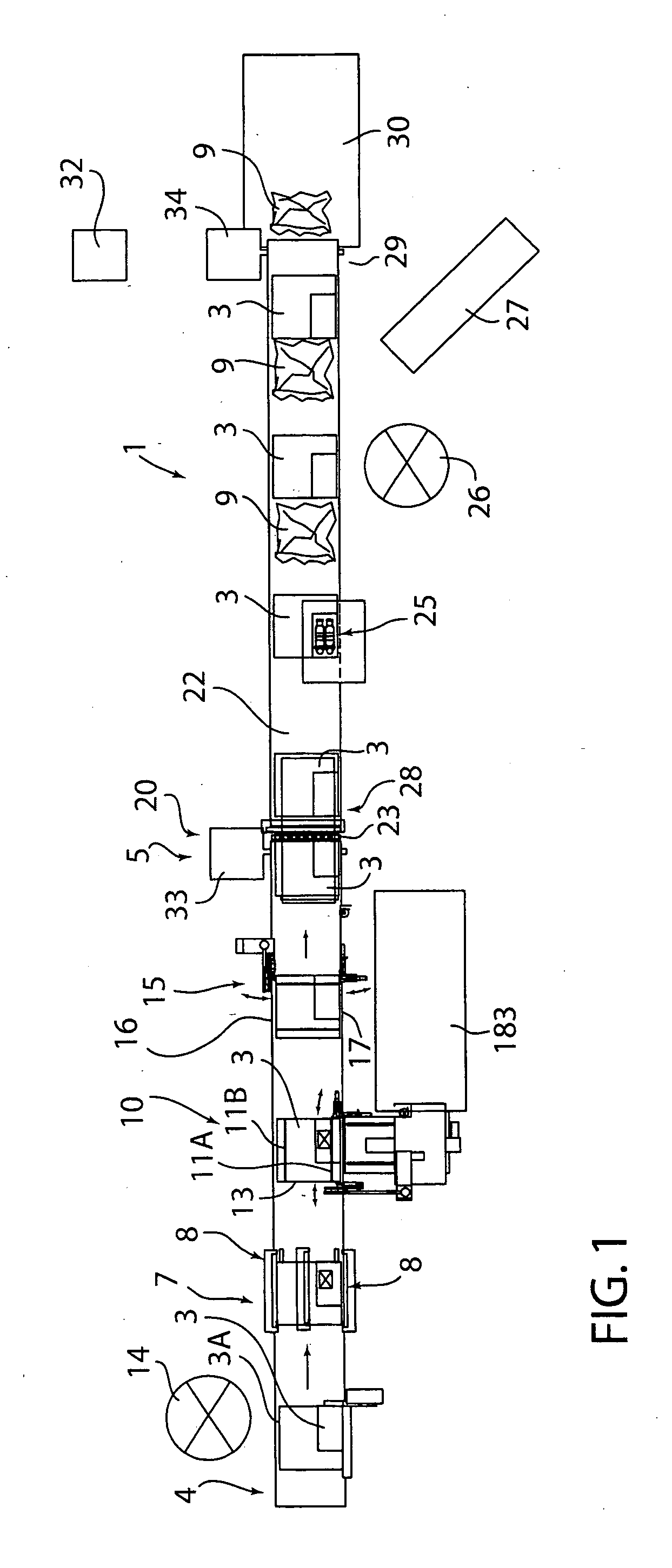

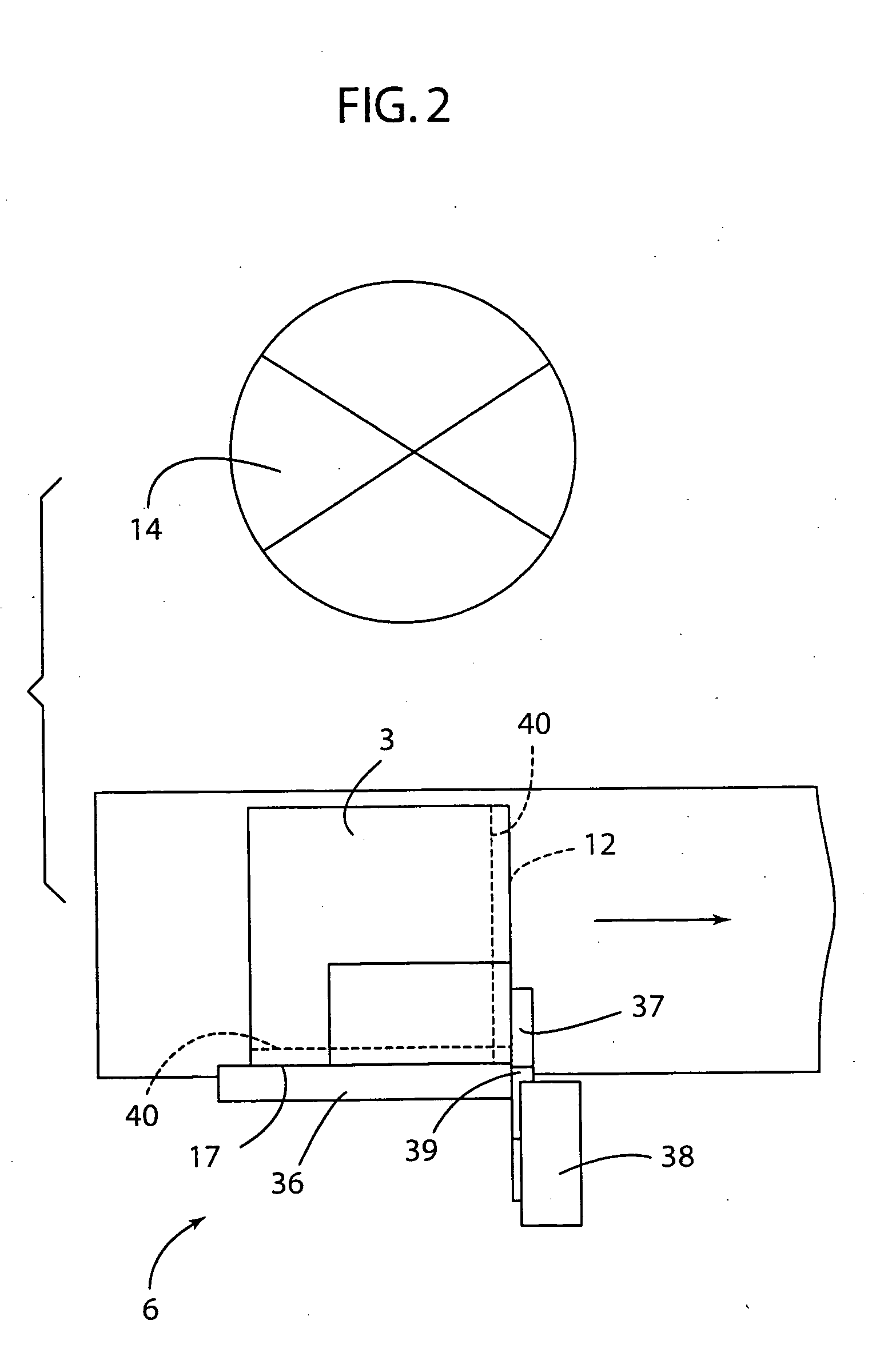

A de-packaging system for removing film and bands from packages includes a first conveyor configured to move packages. The de-packaging system also includes a loading station for loading packages onto the conveyor, and a film cutting station associated with the first conveyor. The film cutting station includes a cutter having an elongated cutting element that can be heated to cut film on packages. A band cutting station includes a cutter for cutting bands wrapped around packages. A clamp device includes a clamp configured to clamp bands on packages for removal of the bands. The de-packaging system further includes a second conveyor having an upstream end adjacent a downstream end of the first conveyor. A device applies force to packages to move packages from the first conveyor to the second conveyor, and at least one friction member strips film from packages as they are moved from the first conveyor to the second conveyor.

Owner:PORTER TECH

De-packaging machine

Owner:PORTER TECH

Method and device for removing a cover from a storage box

InactiveUS20050160704A1Reduced adhesion strengthNarrow sizeOpening closed containersBottle/container closureEngineering

The present invention relates to a method and a device for removing a cover from a storage box that is closed using a lid-like cover attached thereto at the edges. For removal, the adhesive strength of the cover is reduced in the region of a few of the sealed edges and the cover is then removed by peeling it off the storage box, whereby the cover is peeled off by rolling it onto a roller.

Owner:GRONINGER

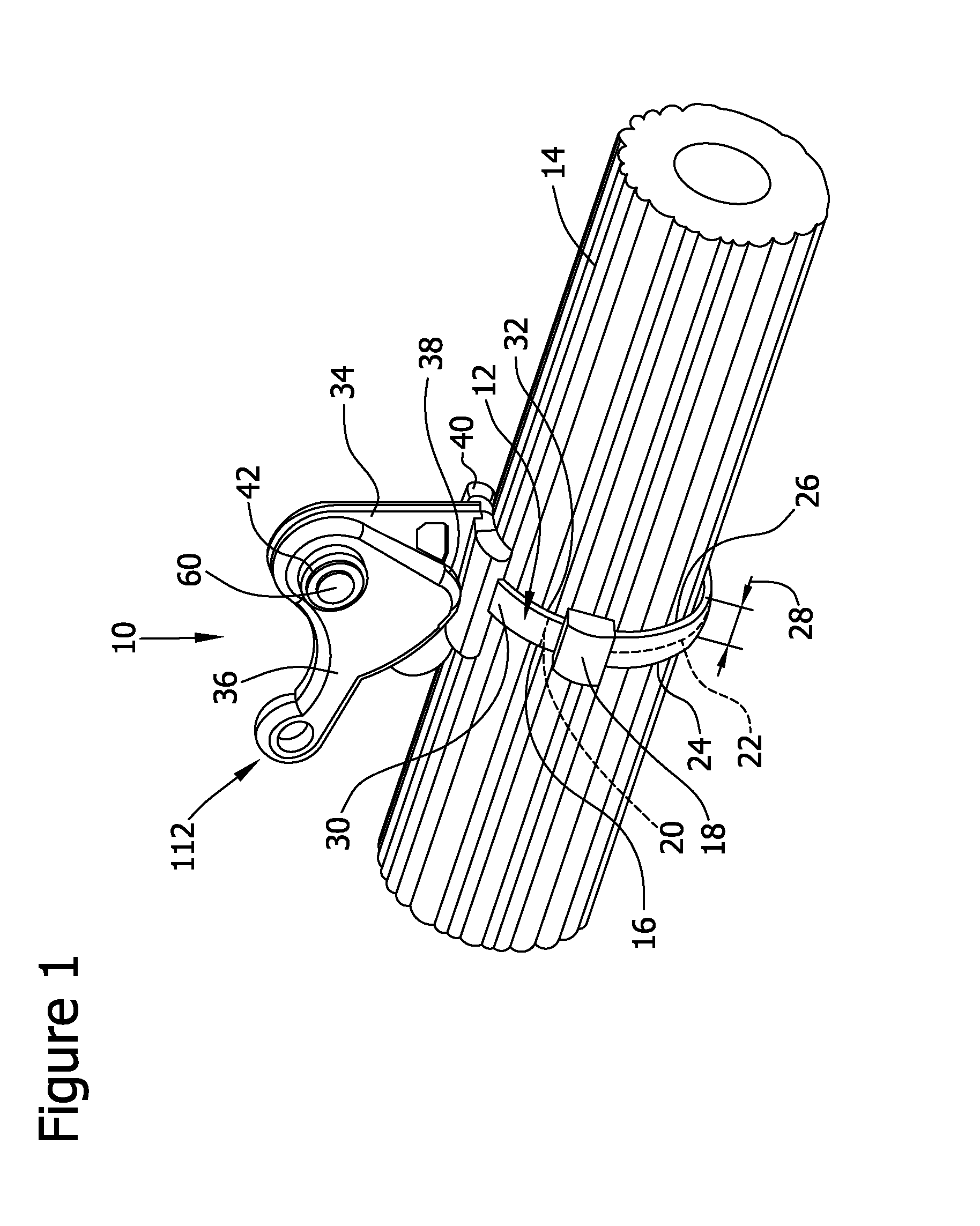

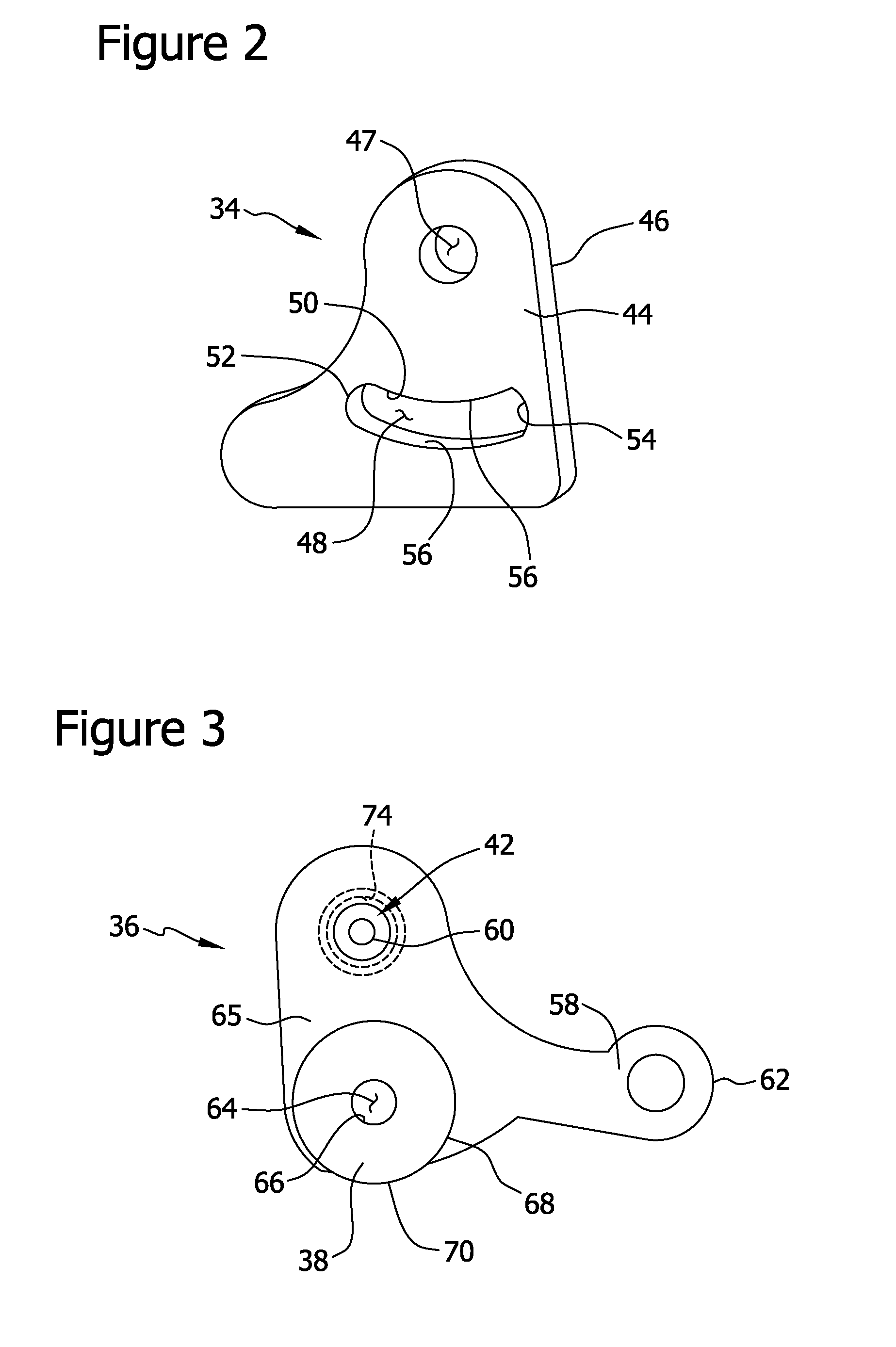

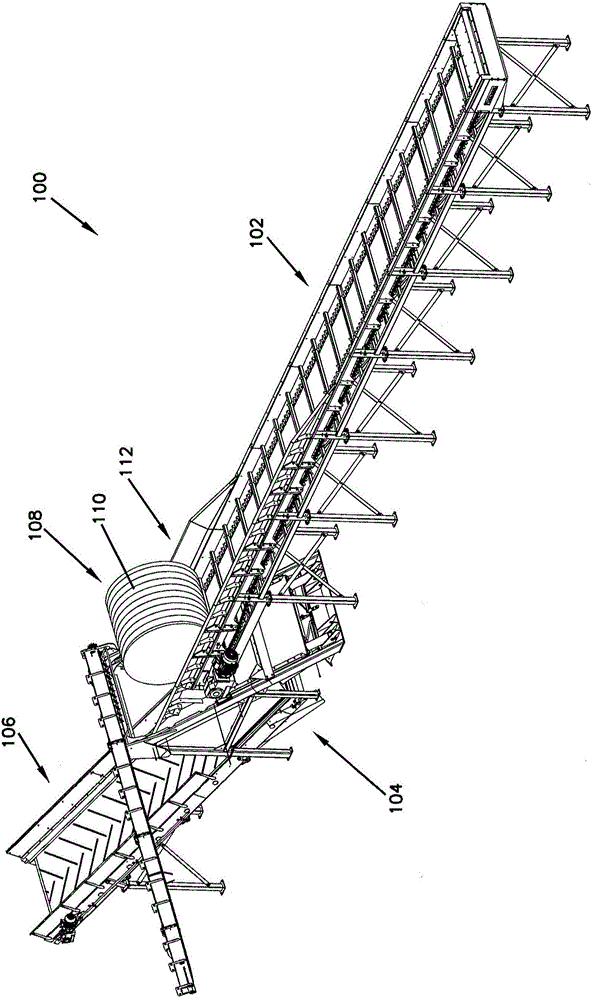

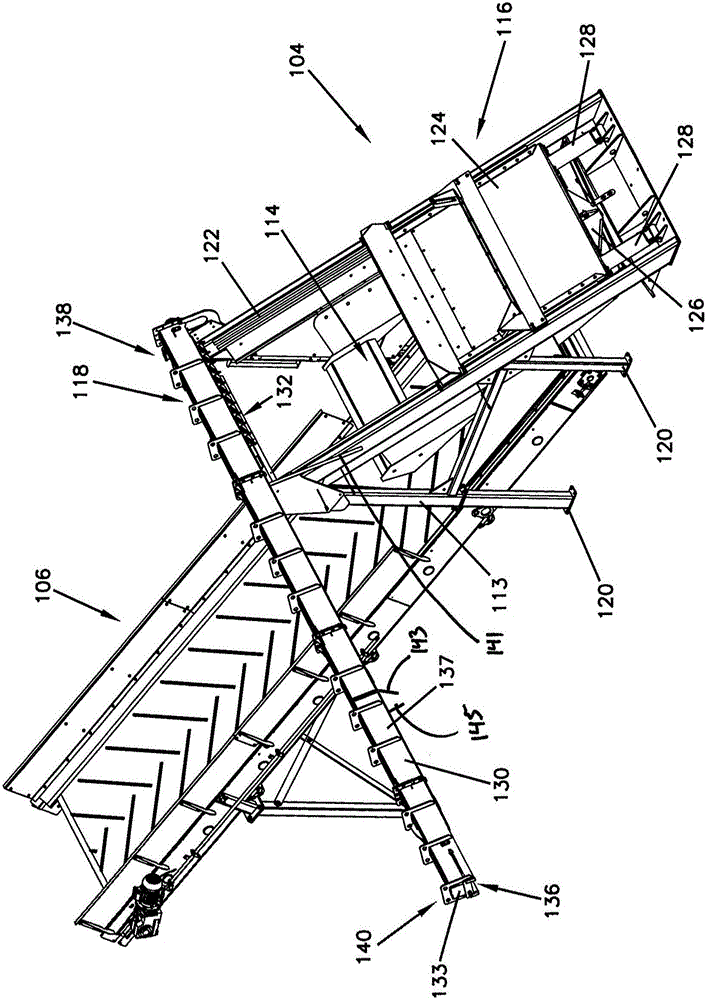

Module Handler Cylindrical Tines Equipped With Retractable Spikes, And Mounting And Drive Arrangements For The Tines

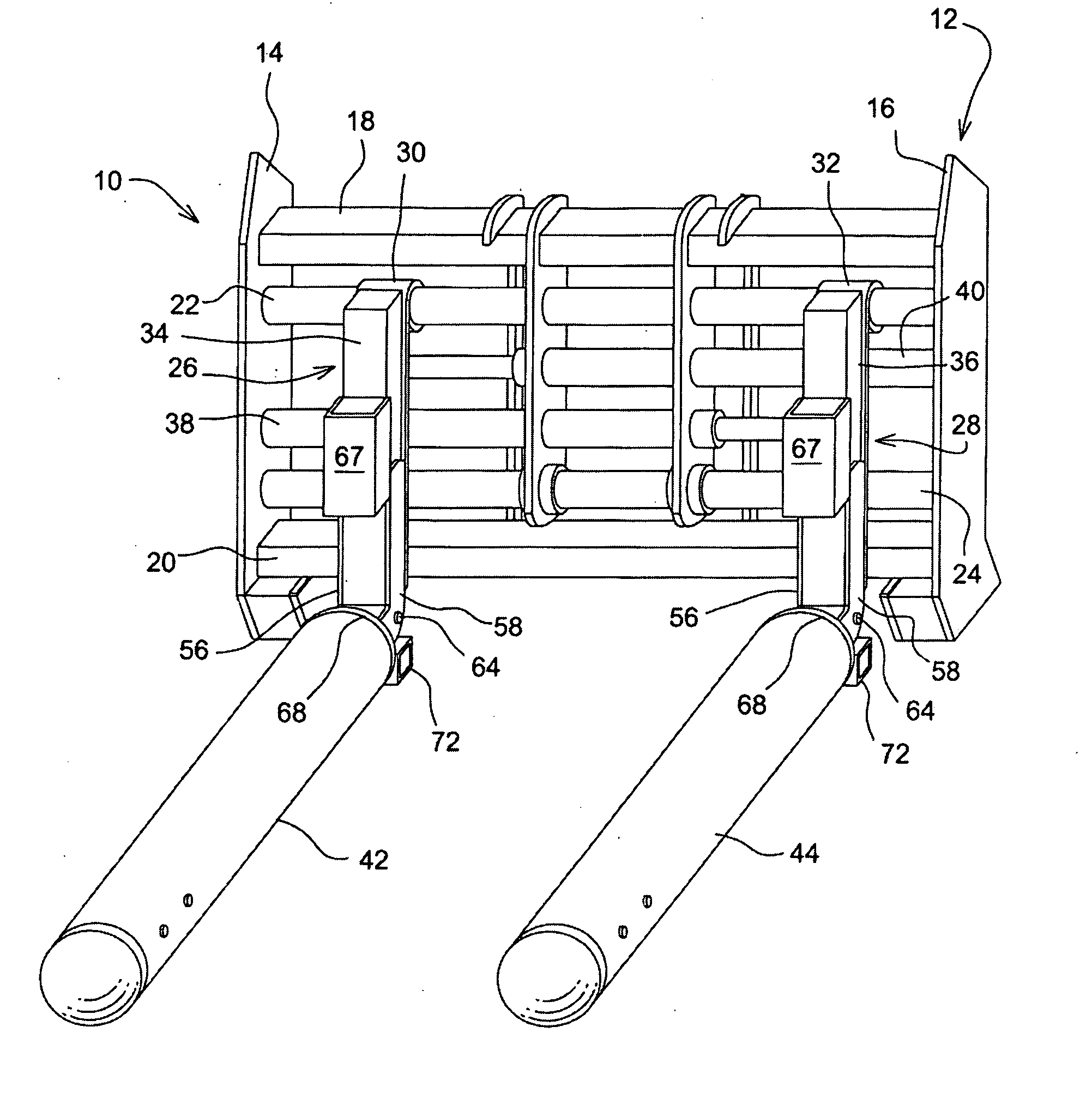

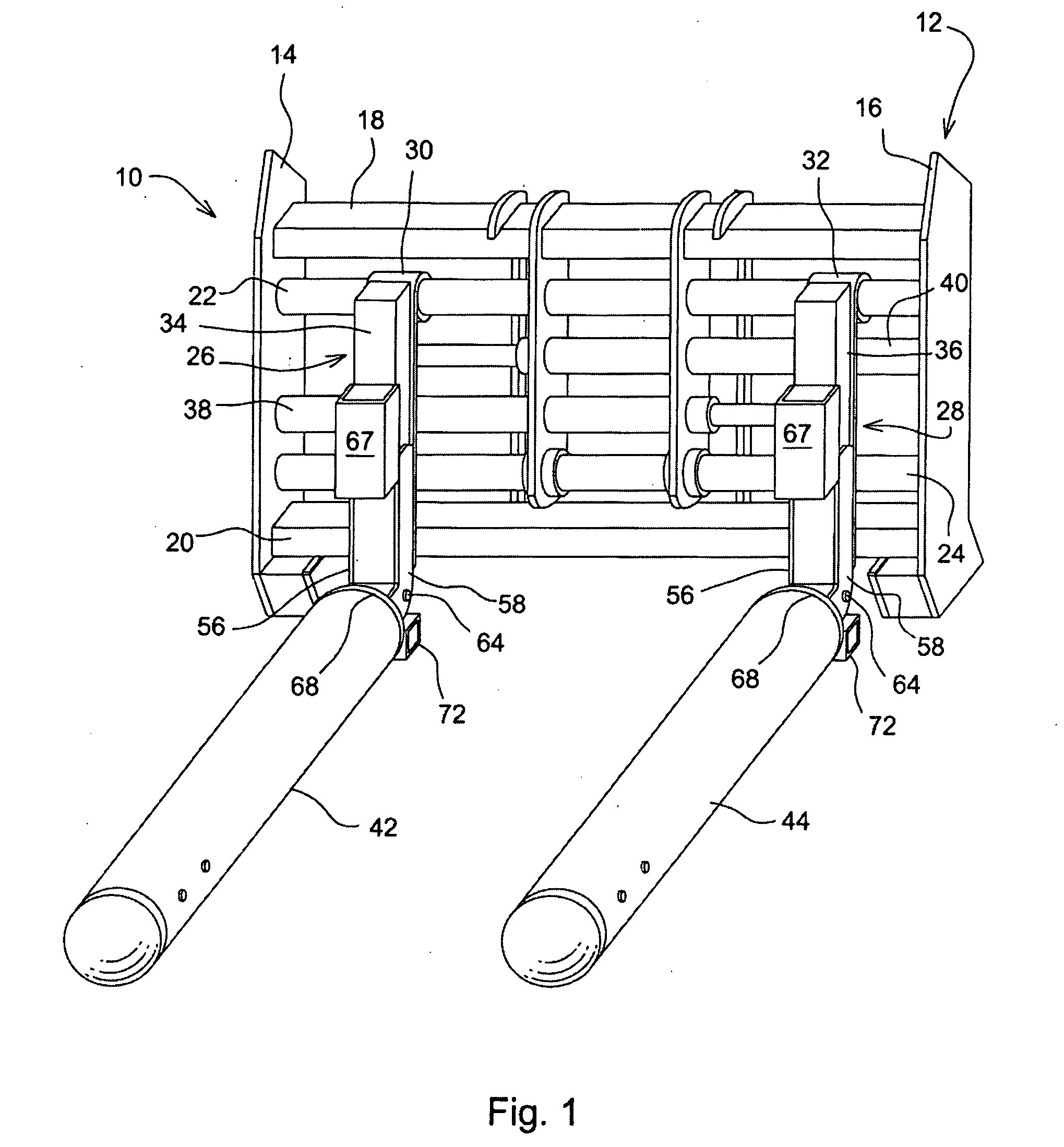

A cylindrical cotton module handling device includes an attachment having a pair of selectively spreadable, powered cylindrical tines adapted for supporting and rotating a module. Each powered tine is constructed from a cylindrical tube supported from a conventional L-shaped fork by a tubular sleeve received on, and dimensioned for fitting closely to, the horizontal leg of the conventional fork. The tubular sleeve is held in place by an L-shaped bracket forming a rearward extension of the sleeve and formed for embracing a region of the convention fork at the junction of its vertical and horizontal legs, with a retaining pin extending through vertical side plates of the bracket at a location just to the rear of the junction. An endless roller chain bearing arrangement is secured in encircling relationship to the tubular sleeve and supports the associated cylindrical tine for rotation. A hydraulic motor drive arrangement is mounted to the sleeve and has a shaft borne chain sprocket meshed with a drive chain carried by a rotating drive plates that are keyed to the cylindrical tube. A hydraulically retractable spike assembly is located inside a forward end section of the cylindrical tube and includes a plurality of spikes mounted for being selectively extended outwardly through holes in the tube for engaging a module wrapping during removal of the wrapping from the module.

Owner:DEERE & CO

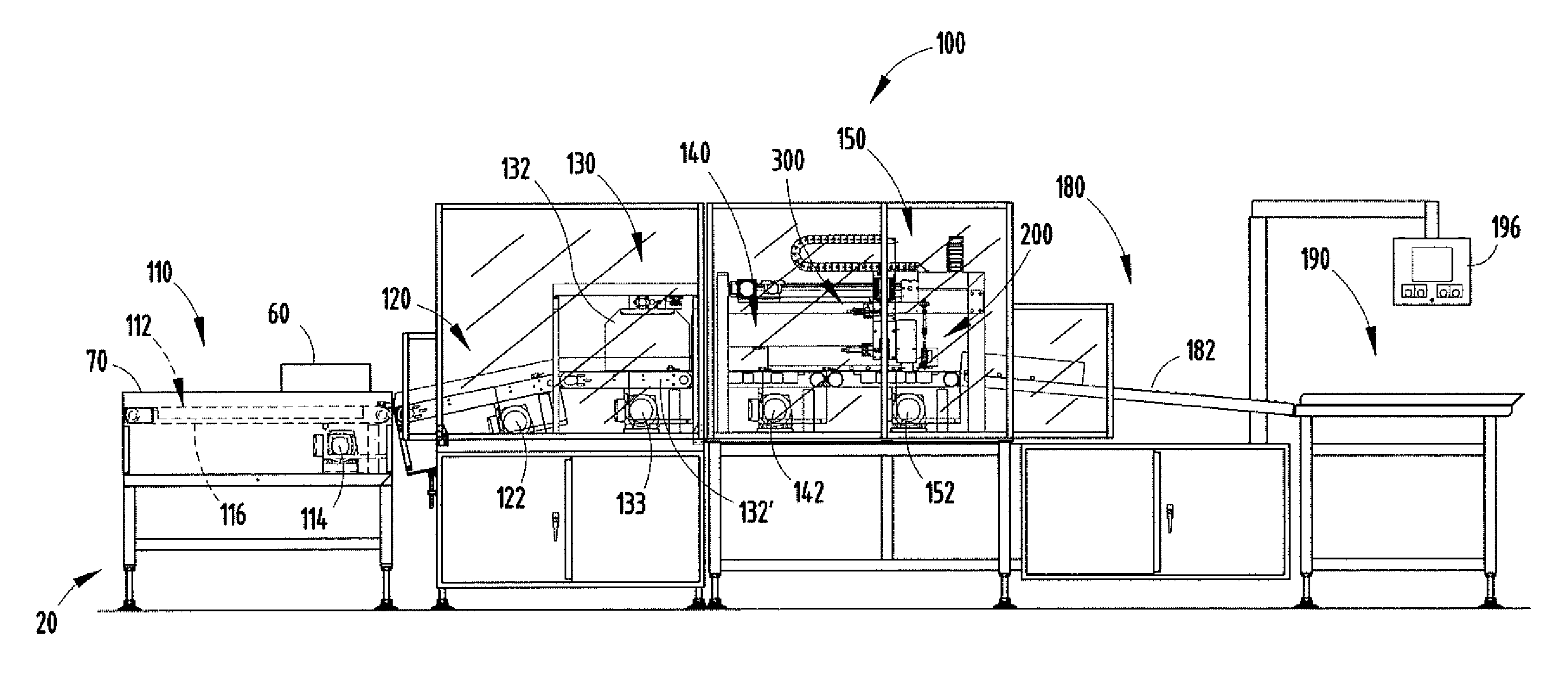

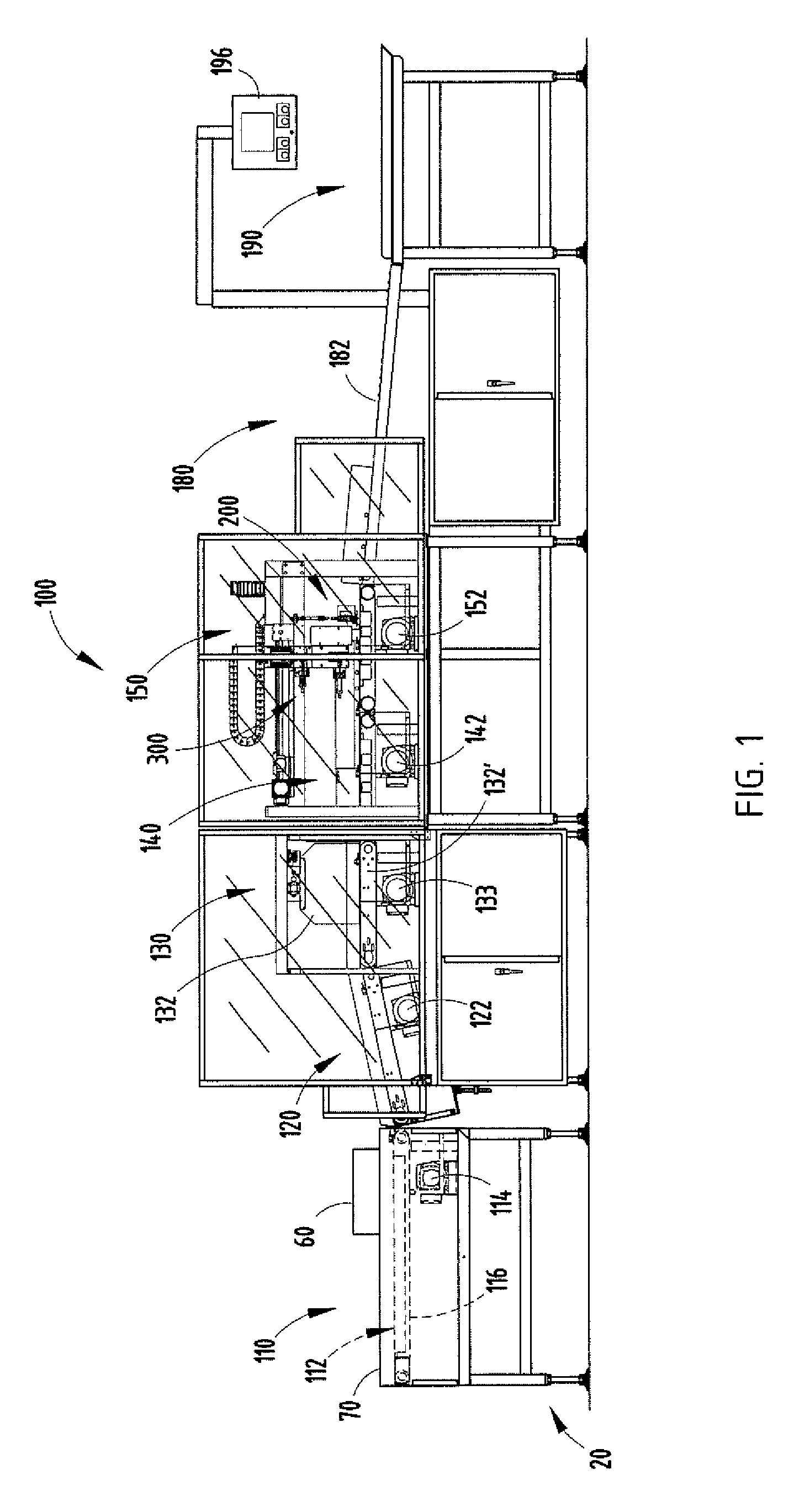

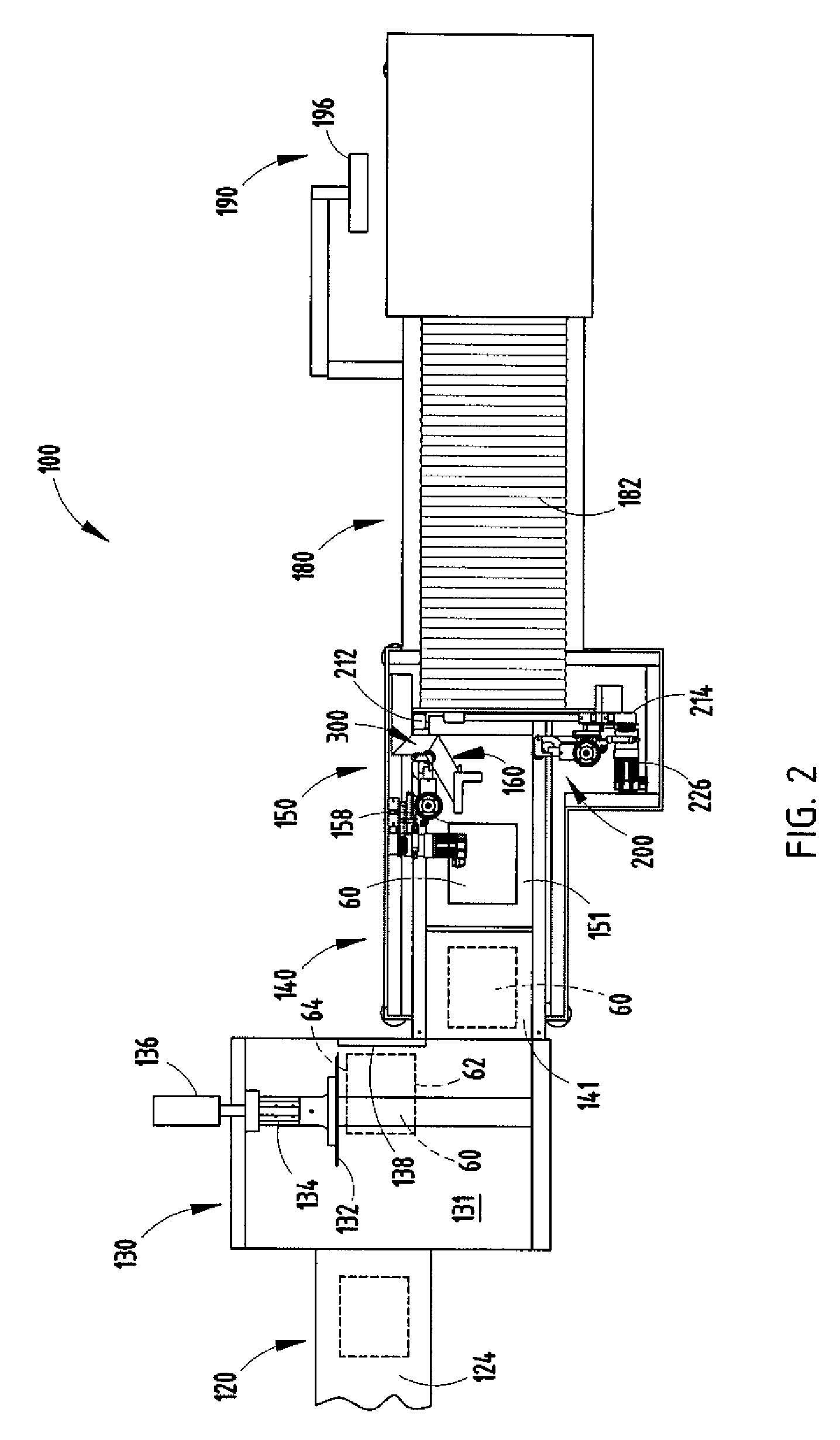

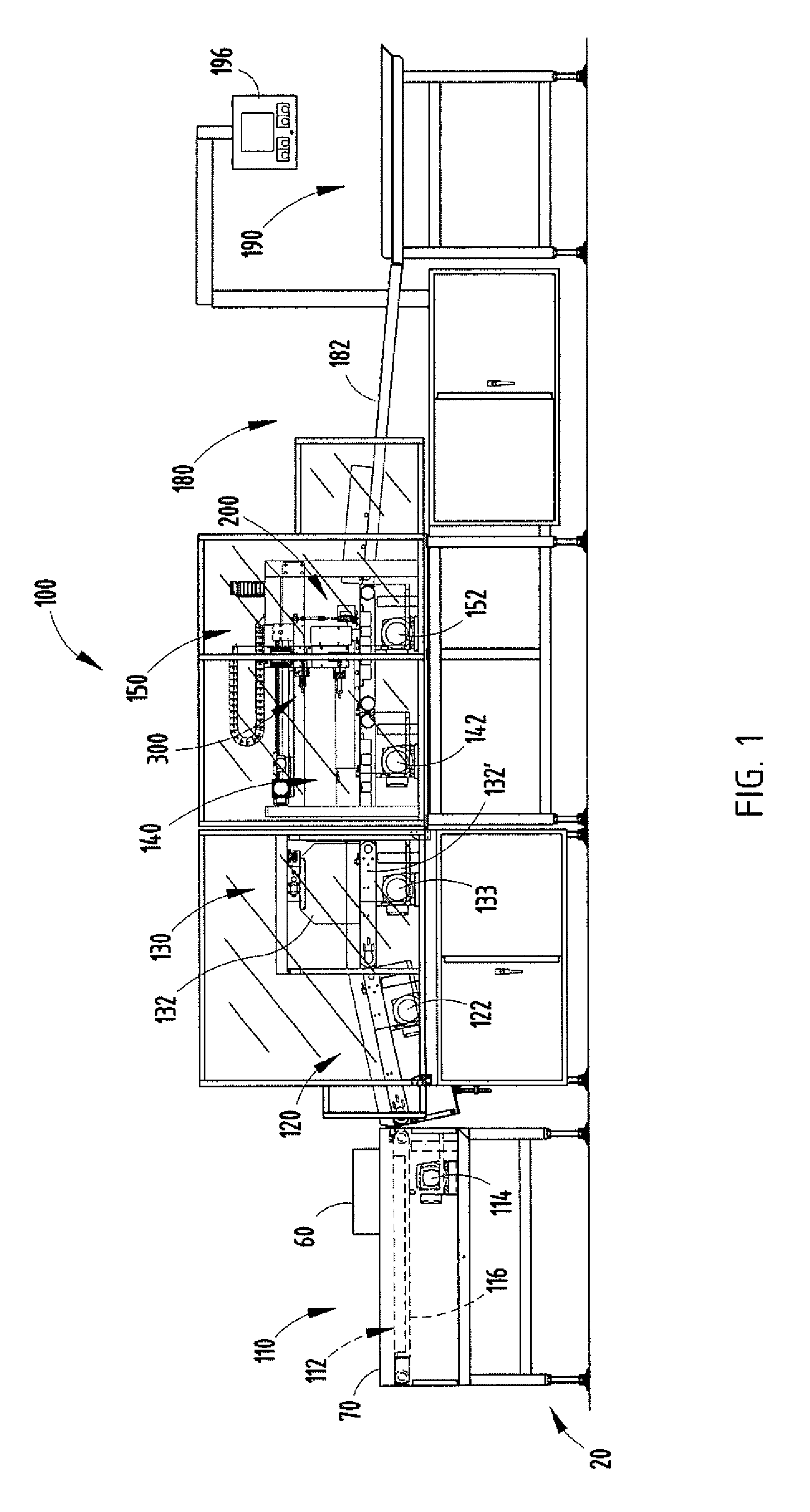

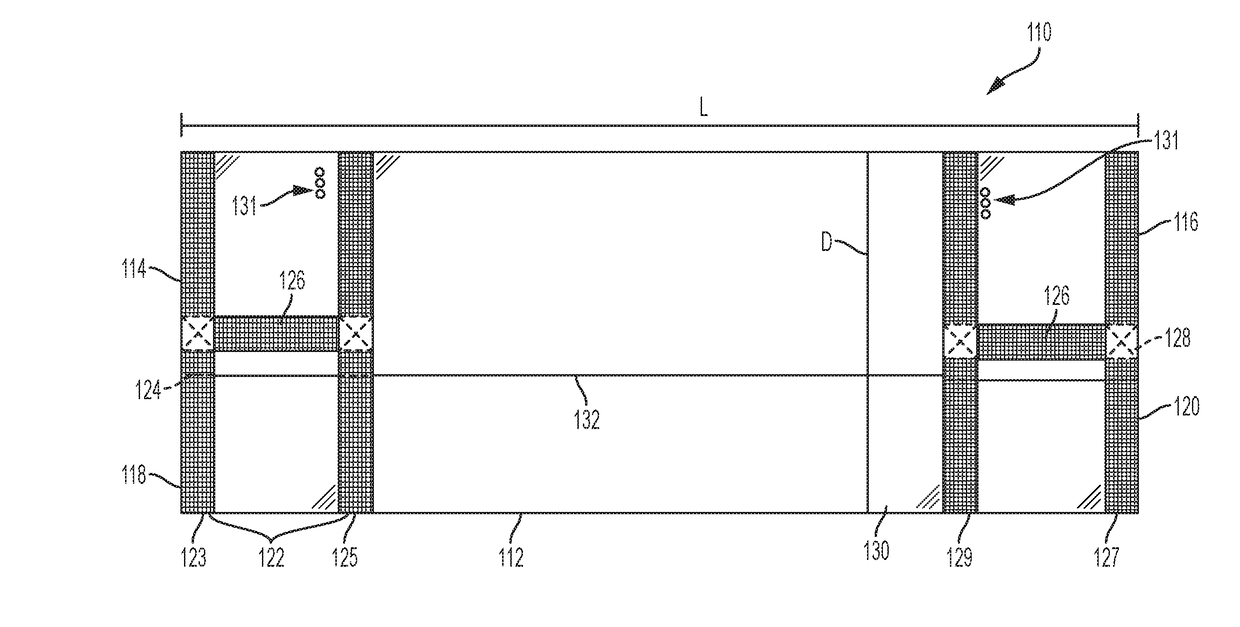

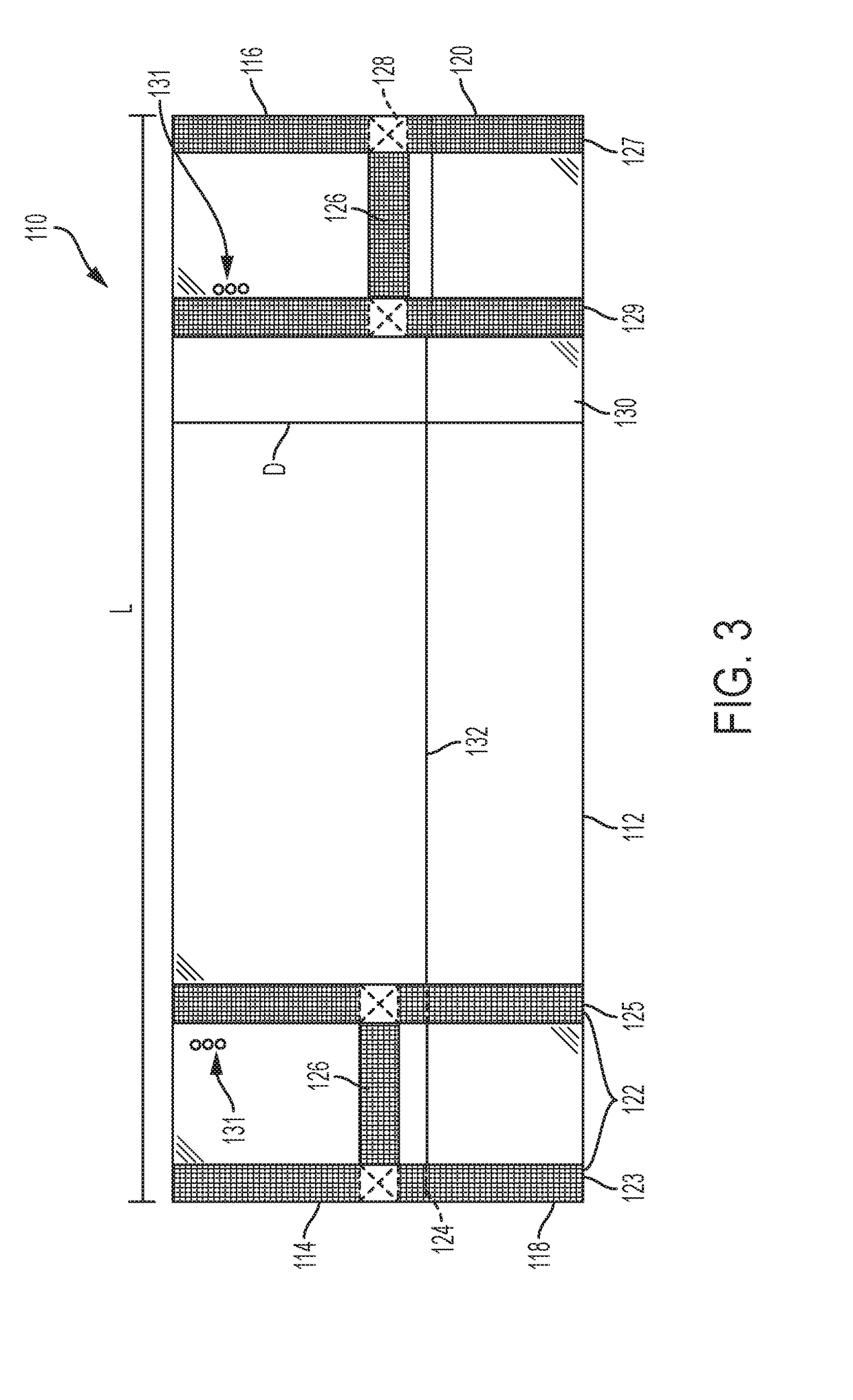

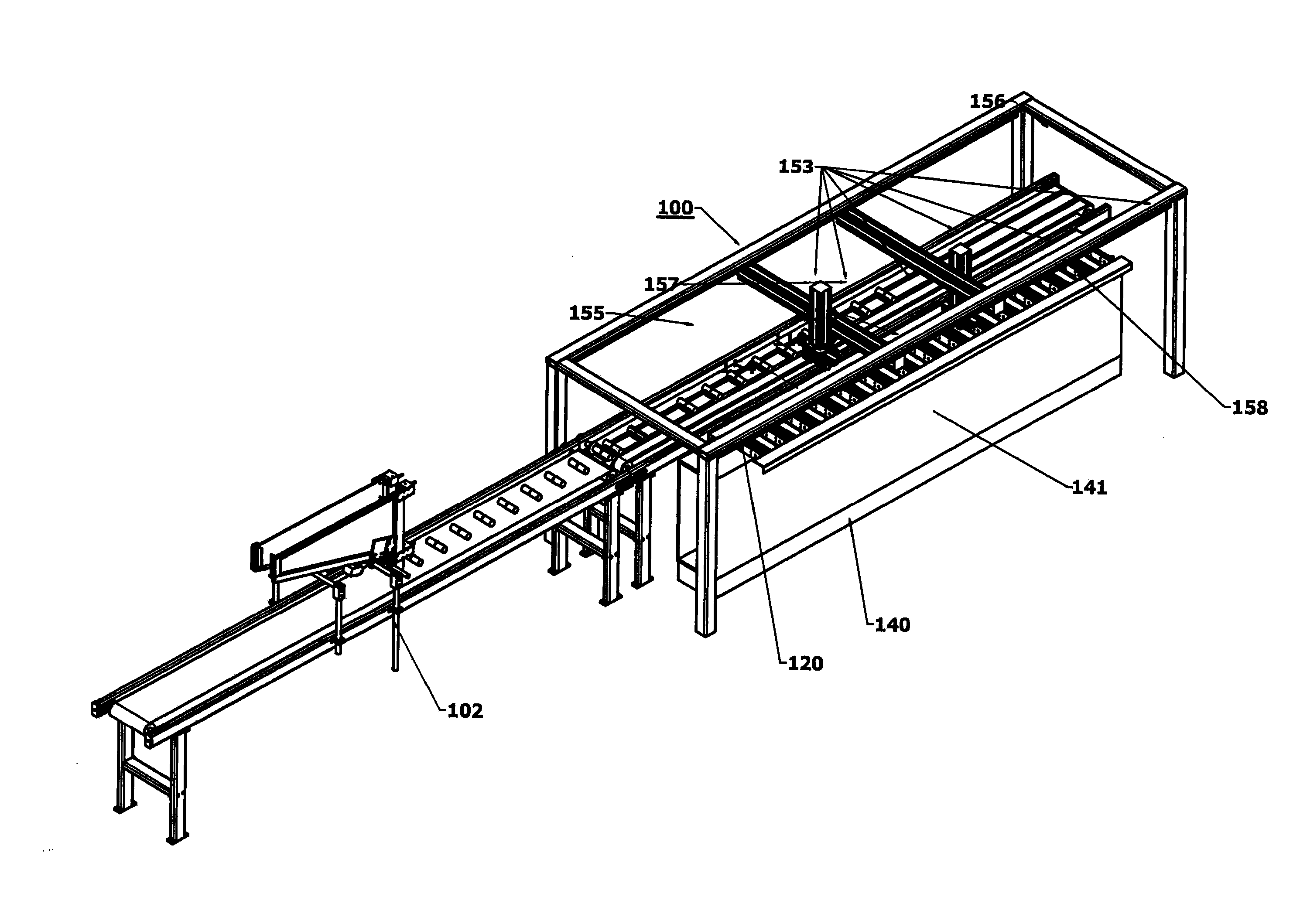

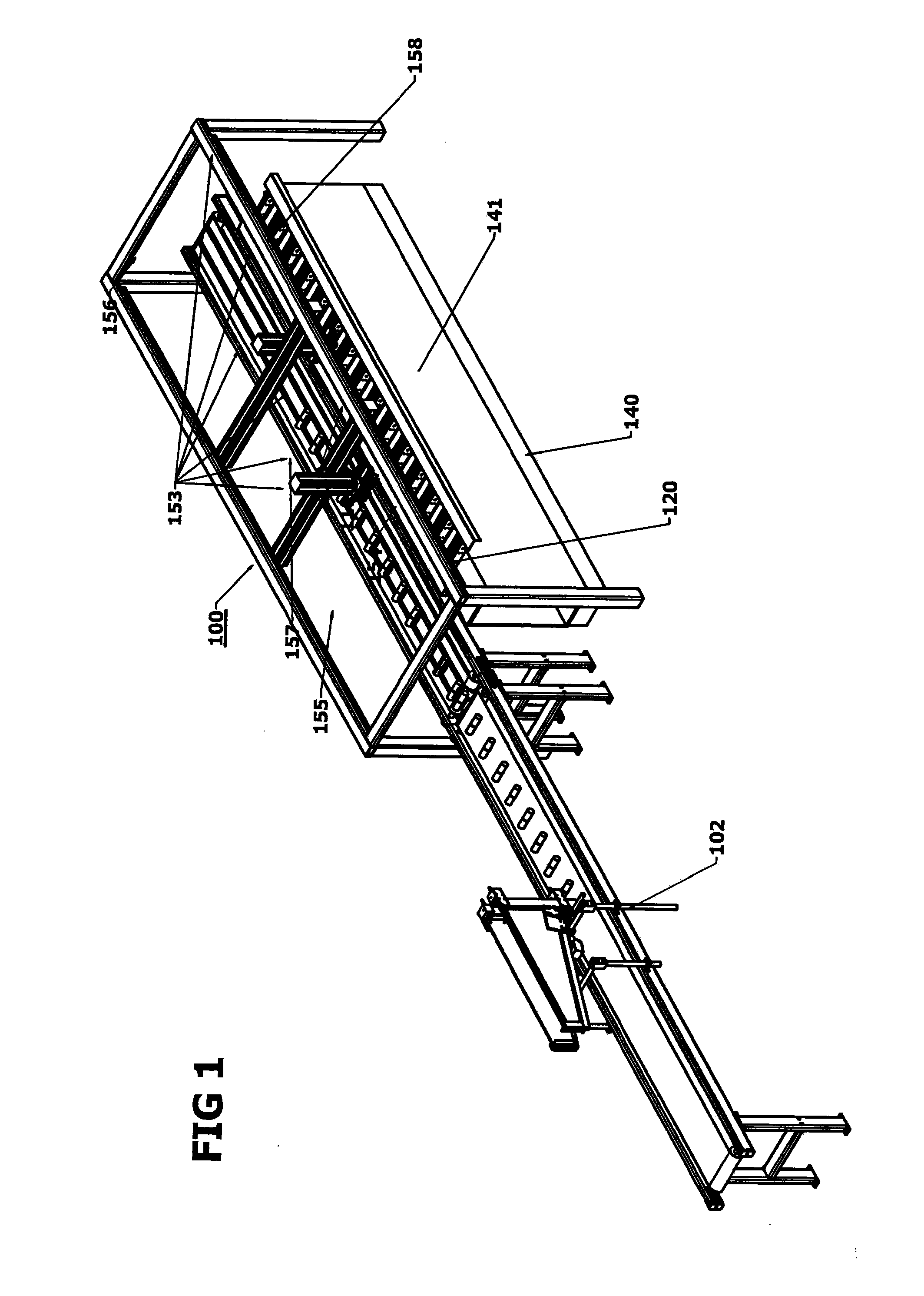

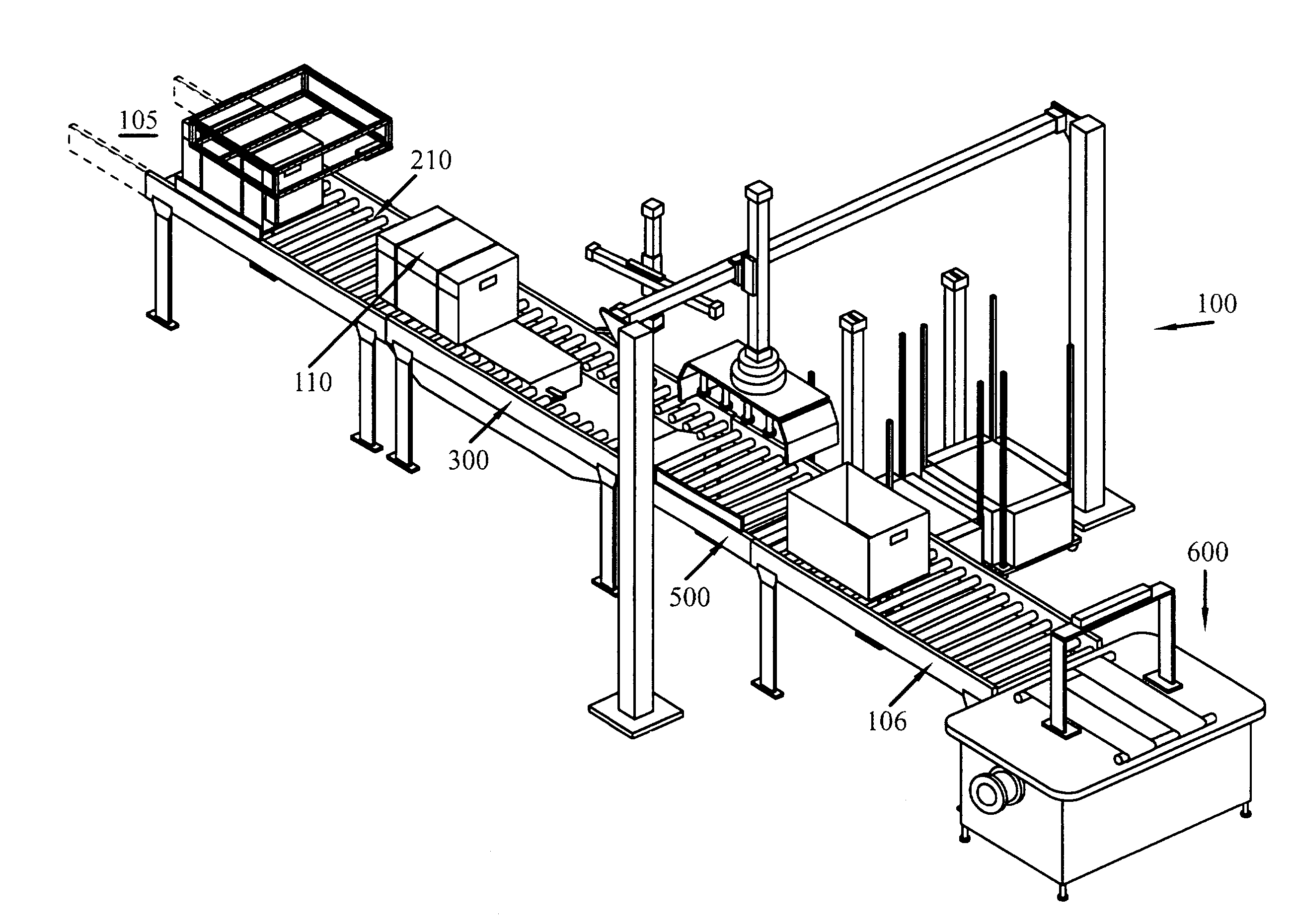

Package unbundling system

InactiveUS20090113853A1Easy to disassembleOpening closed containersBottle/container closureBand shapeFixed position

A package unbundling station receives bundles of articles to be unwrapped. The station includes a clamp for holding a bundle in a fixed position and a pair of spaced-apart movable cutter assemblies which cut at least one of wrapping and banding on at least two sides of the bundle, resulting in an “open envelope” which is transferred to a work station for easy removal of the articles which are then conveyed for subsequent sorting. In one embodiment, an unbundling station is coupled with a package sorting system and receives banded and / or wrapped bundles of articles and includes at least a pair of spaced-apart movable cutter assemblies which cut at least one of the banding and / or wrapping materials of the bundle and subsequently outputs the opened bundle to an output station for subsequent processing.

Owner:PORTER TECH

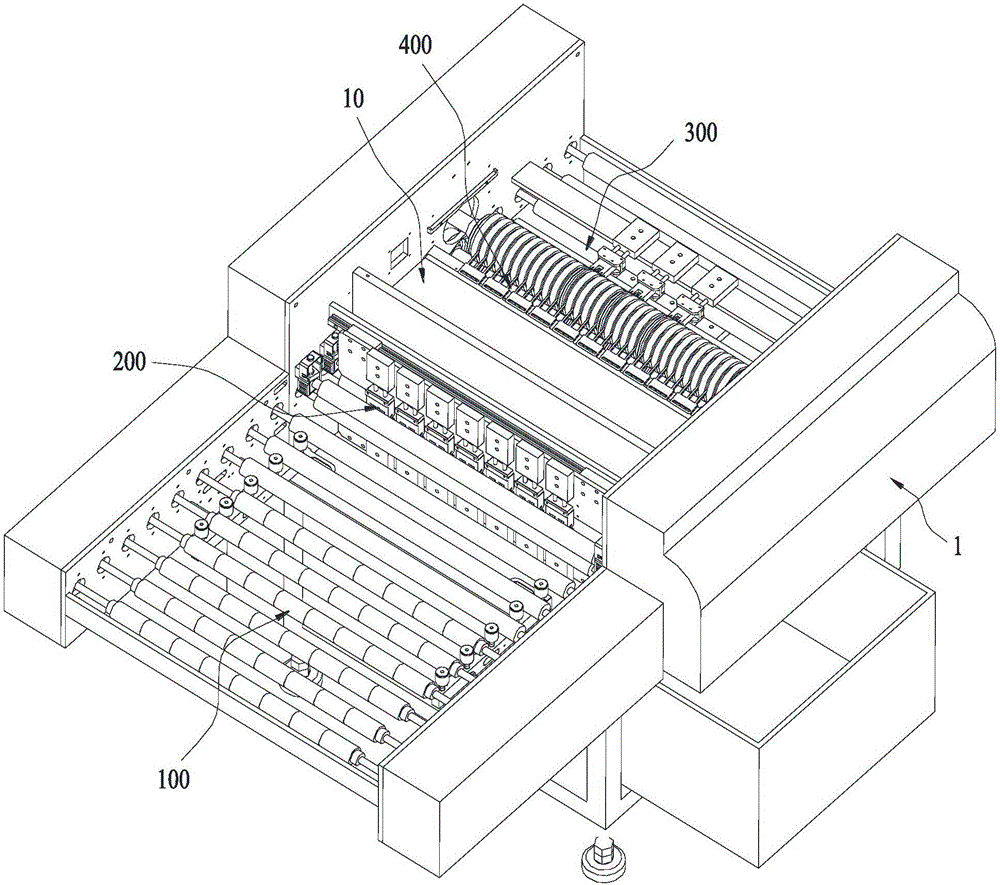

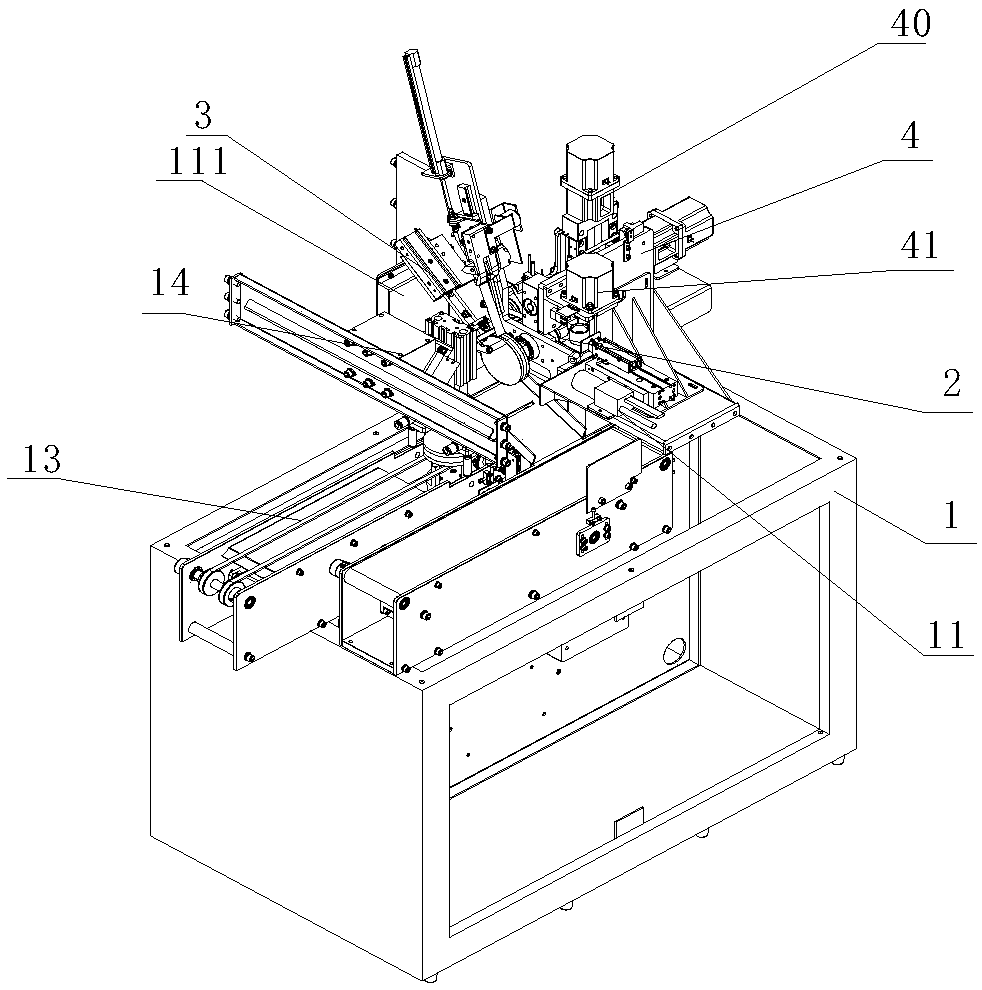

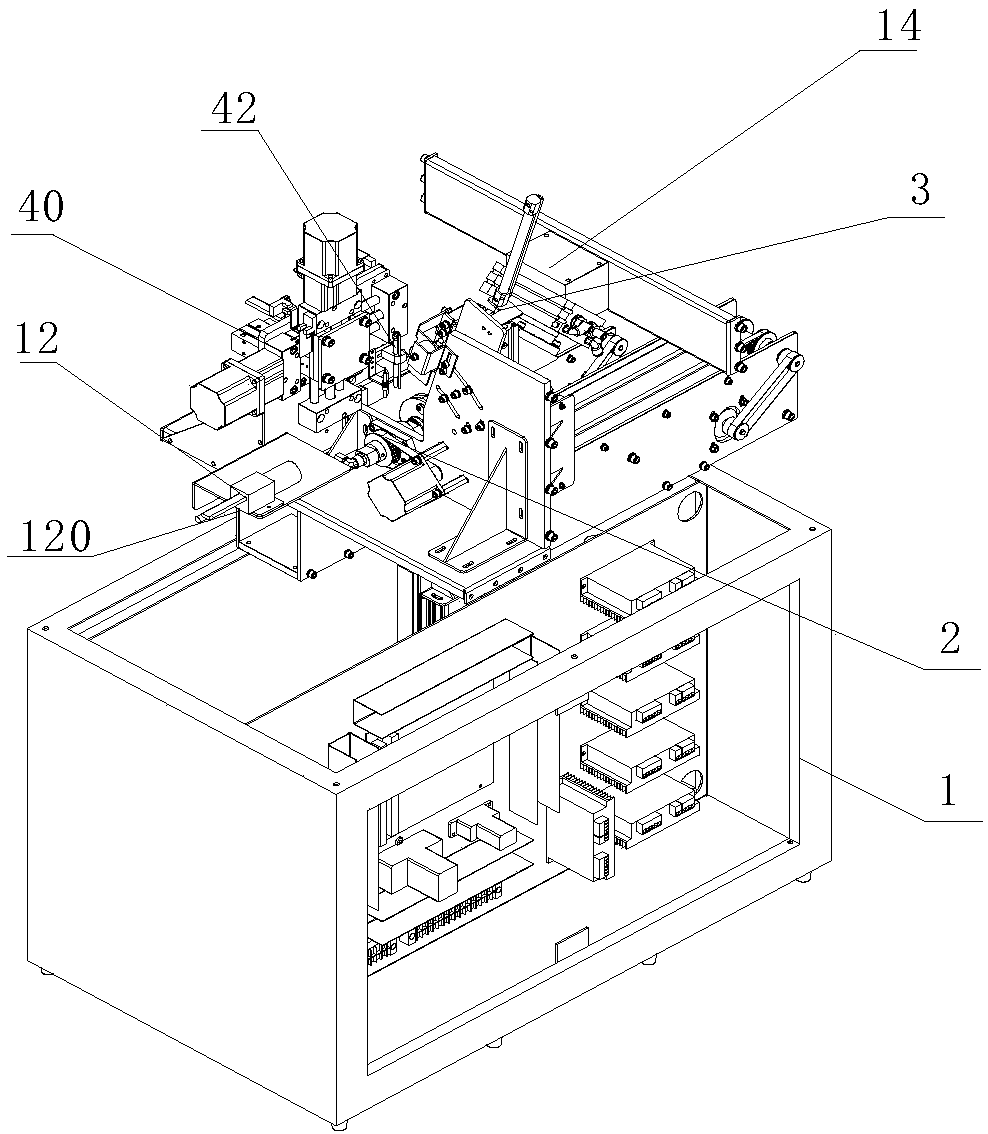

Full-automatic film tearing machine

InactiveCN105129170AAvoid confusionAvoid stickingBinding material removalTectorial membraneConductive rubber

The invention discloses a full-automatic film tearing machine which comprises a support, a conveying mechanism, a film lifting mechanism, a conductive rubber covered roller mechanism, a collection board and a comb-shaped film separation mechanism. The conveying mechanism is used for conveying a PCB with film protective films bonded to the two faces; the film lifting mechanism is installed on the support, used for lifting the edges of the film protective films and provided with a first gap where the PCB penetrates; the conductive rubber covered roller mechanism is pivoted to the support, used for bonding and winding the film protective films, located behind the film lifting mechanism in the conveying direction of the PCB and provided with a second gap where the PCB penetrates; the collection board is used for stacking and collecting the film protective films and fixed to the portion, between the conductive rubber covered roller mechanism and the film lifting mechanism, of the support; and the comb-shaped film separation mechanism is installed on the collection board, used for separating the film protective films wound around the conductive rubber covered roller mechanism and located between the collection board and the conductive rubber covered roller mechanism. By the adoption of the full-automatic film tearing machine, the film protective films on the two faces of the PCB can be automatically torn away, the torn-away film protective films can be stably stacked and collected in order layer by layer, and the film tear-away success rate is increased.

Owner:SHENZHEN YONGNENG MACHINERY

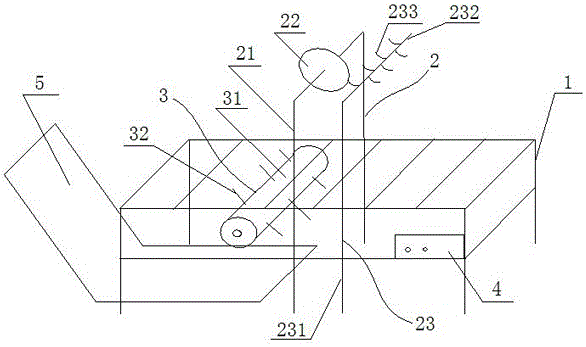

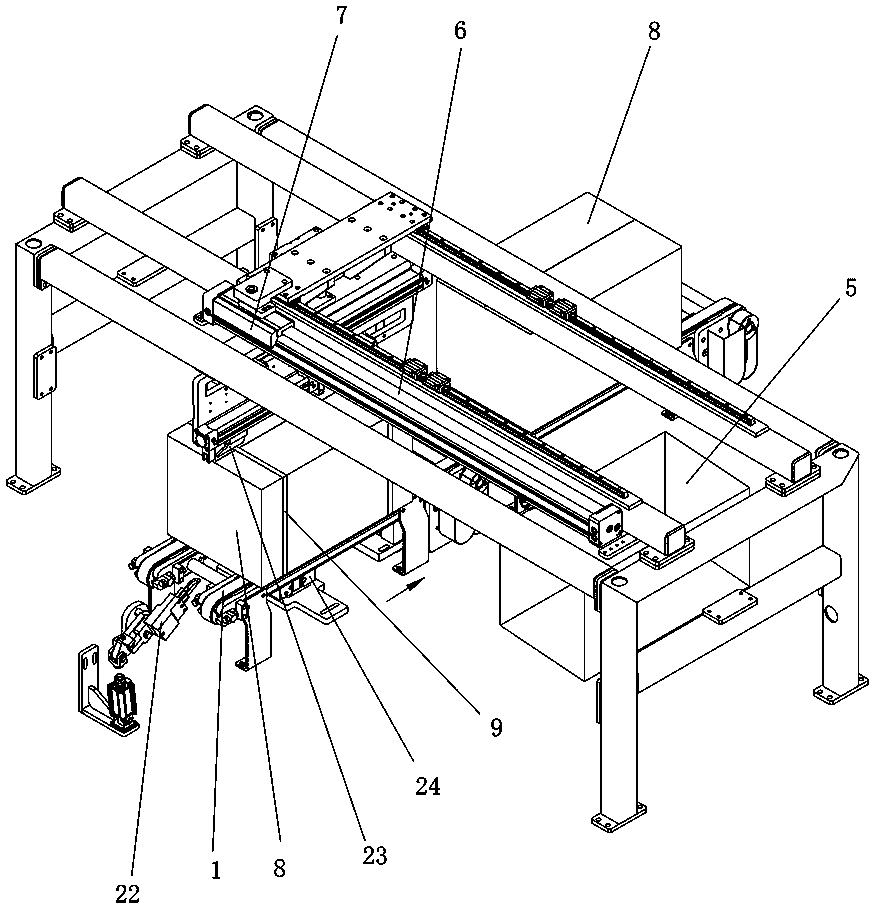

Automatic opening method and device for cigarette box

The invention discloses an automatic opening device and method for a cigarette box. The device comprises a conveying track, wherein the conveying track conveys cigarette packet cartons; an inner plastic bag cutting machine is arranged on the middle section of the conveying track; four cutting knives are arranged on the inner plastic bag cutting machine and are respectively mounted on four knife holders; the cutting knives are driven by a rotating cylinder; a static weighing device is arranged at the tail end of the conveying track; and a cigarette packet removing device is arranged on one side of the static weighing device. The inner plastic bag cutting machine is added to cut and grab plastic bags of liners, so that a whole box opening process is perfect; and after unpacking is finished, the static weighing device is added to detect measures of cigarette packets, unqualified cigarette packets are removed, production quality of the cigarette packets is guaranteed, and quality control level is improved.

Owner:CHINA TOBACCO ZHEJIANG IND

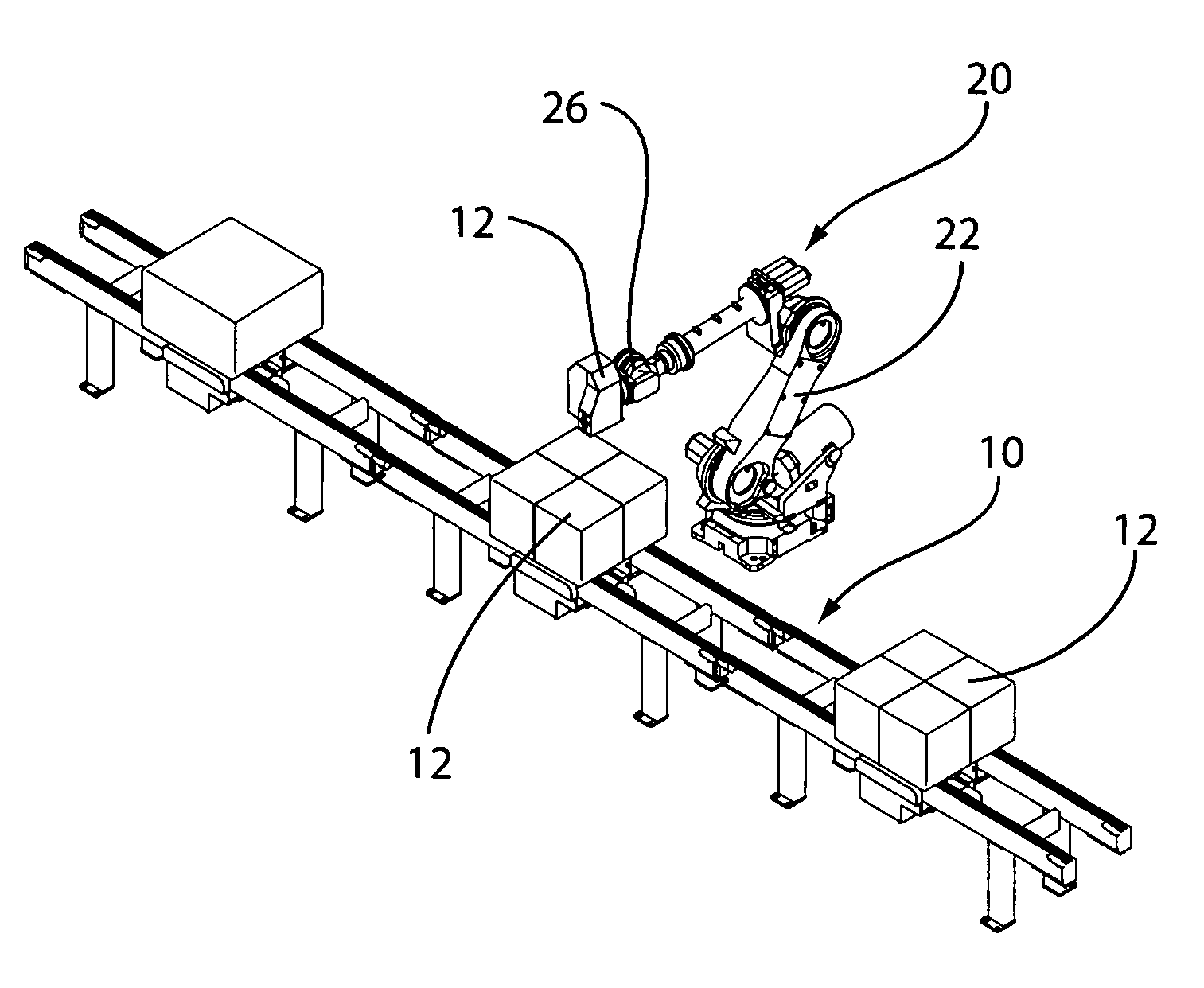

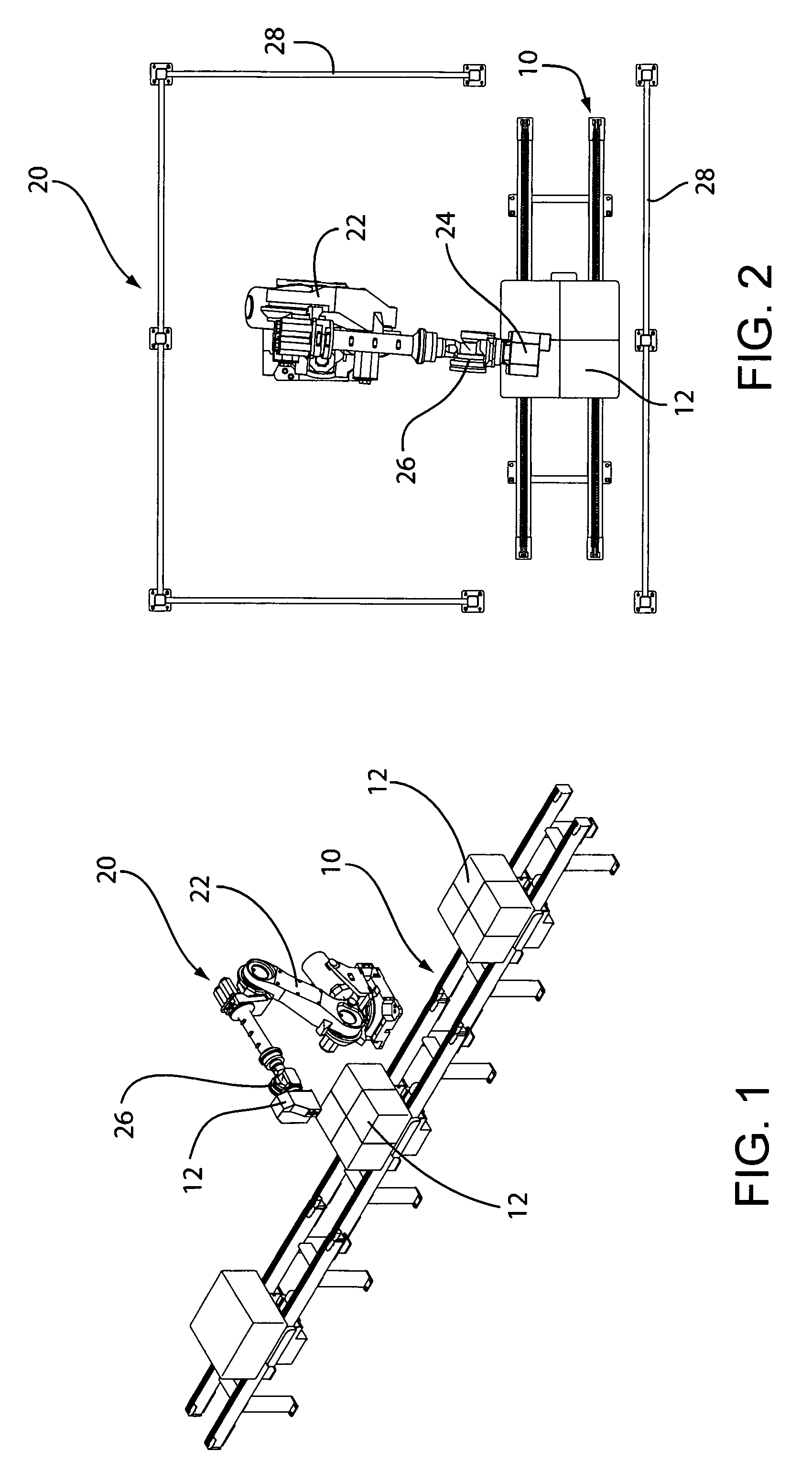

Method and apparatus for removing wires from a bale

A method and apparatus for removing wires from a bale includes a conveyor system for moving one or more bales and a de-wiring station positioned adjacent the conveyor system. The de-wiring station includes a robot with an end tool. A bale that is bound by one or more wires is transferred by the conveyor system to a position proximate the de-wiring station. The robot with end tool moves to sense the location of the wires, cut the wires, collect the wires and deposit the wires in a collection hopper.

Owner:FIVE BROS PROPERTIES

Package unbundling system

A package unbundling station receives bundles of articles to be unwrapped. The station includes a clamp for holding a bundle in a fixed position and a pair of spaced-apart movable cutter assemblies which cut at least one of wrapping and banding on at least two sides of the bundle, resulting in an “open envelope” which is transferred to a work station for easy removal of the articles which are then conveyed for subsequent sorting. In one embodiment, an unbundling station is coupled with a package sorting system and receives banded and / or wrapped bundles of articles and includes at least a pair of spaced-apart movable cutter assemblies which cut at least one of the banding and / or wrapping materials of the bundle and subsequently outputs the opened bundle to an output station for subsequent processing.

Owner:PORTER TECH

Cutting tool and method of operating same

A tool for use in cutting a tie wrap that is bound about at least one wire and a method of operating the tool. The tool includes a housing having a first side and a second side, wherein the first side and the second side are coupled together to define a cavity. The housing further includes a groove formed in the first side and in the second side, wherein the groove is in flow communication with the cavity. A blade is coupled to the first side and positioned with the cavity, wherein the blade includes a cutting surface partially extending into the groove. The tool also includes a spacer coupled to the housing and configured to maintain the wire a distance away from the cutting surface when the housing is applied to the tie wrap.

Owner:THE BOEING CO

Bale dewiring system

A bale dewiring system for removing one or more wires wrapped around a bale from the bale includes a frame, a bale receiving region defined by the frame and defining a longitudinal direction, an upper compression platen mounted to the frame for vertically moving into contact with the bale to compress the bale, and side compression plates movable in the longitudinal direction into contact with the bale to compress the bale. A rail is operably mounted to the upper platen for vertical movement therewith. A cutting assembly is mounted to the rail for movement along the rail for cutting the one or more wires. A winding assembly is operably mounted to the frame and includes a rotating winding element having a wire receiving region and a wire winding region for winding the cut wires to remove the wires from the bale.

Owner:SIGNODE IND GRP

Cutting tool and method of operating same

ActiveUS20130139661A1Metal working apparatusBinding material removalEngineeringMechanical engineering

A cutting tool and method of operating cutting tool. The tool includes a support having a first side and a second side. The tool further includes a handle coupled to at least one of the first side and the second side. The handle includes a blade, wherein the handle is configured to move the blade between a first position and a second position. An alignment guide is coupled to the support. The alignment guide includes a channel configured to receive the blade positioned in the second position.

Owner:THE BOEING CO

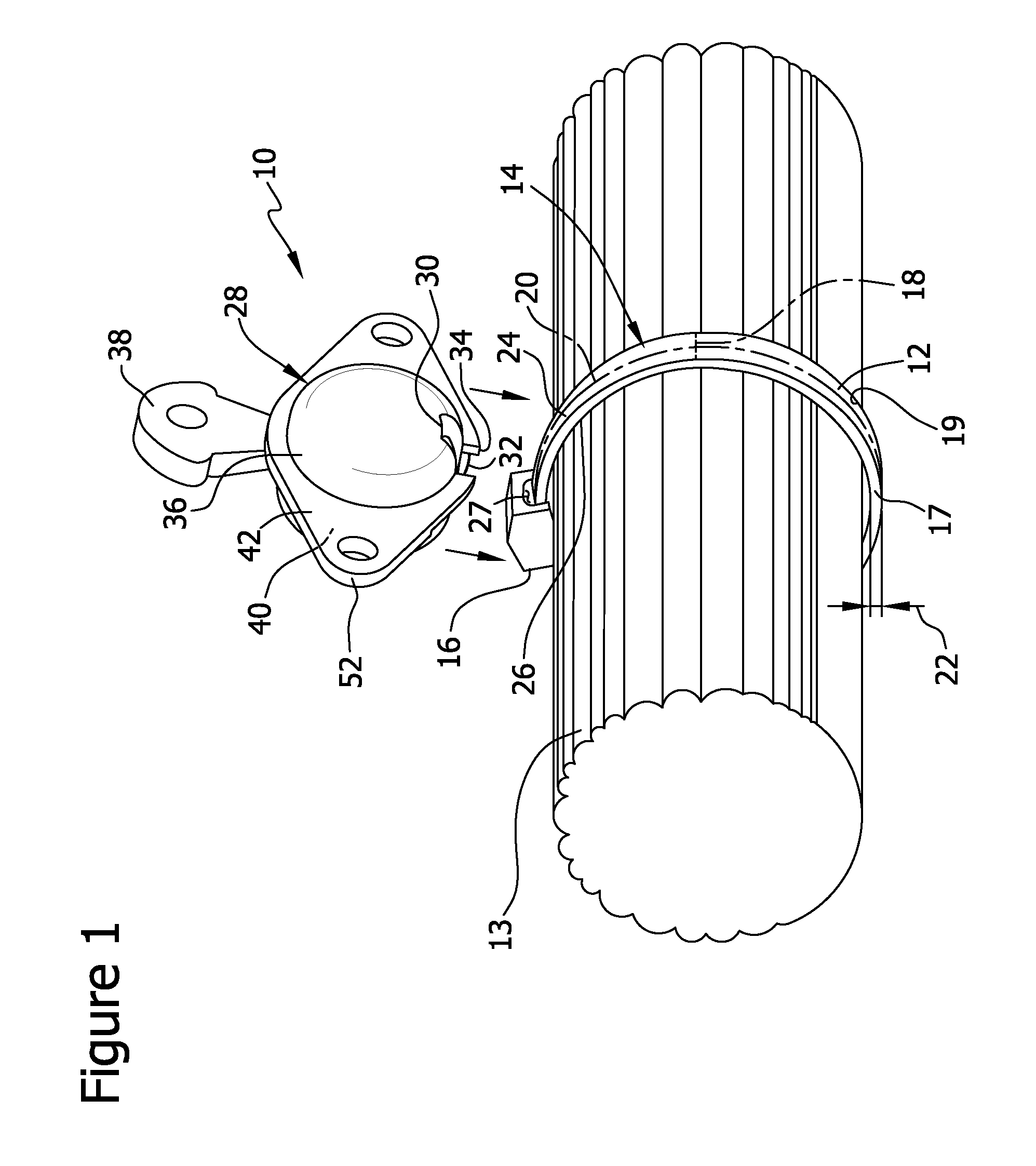

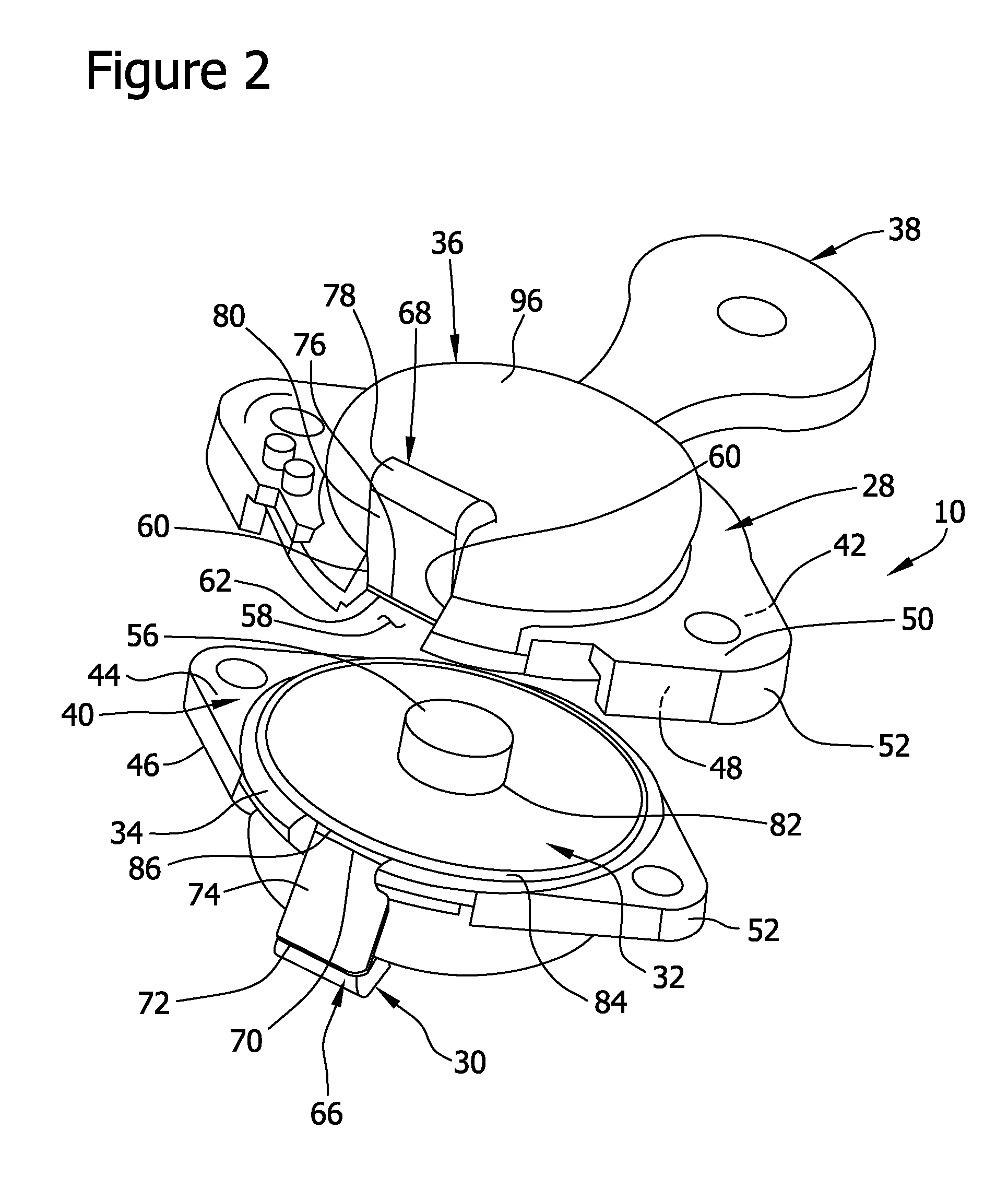

Bag for shipping a cushion and related methods

A bag for enclosing a cushion is disclosed. The bag comprises a tubular sleeve having first and second end pieces coupled to first and second longitudinal ends thereof, a plurality of reinforcing straps encircling a circumference of the tubular sleeve, and at least one handle extending between the plurality of reinforcing straps. The at least one handle is configured to lay flush against the tubular sleeve during shipping. Methods for packaging and shipping a cushion in the bag include roll packing a cushion into a cylindrical shape, disposing the cushion in a compressed form into the bag, and shipping the bag to a customer without inserting the bag in any other container. Methods of unpacking the cushion from the bag includes uncoupling the first end piece from the tubular sleeve, opening the tubular sleeve along a longitudinal length thereof, and unrolling the compressed cushion to an expanded form.

Owner:PURPLE INNOVATION LLC

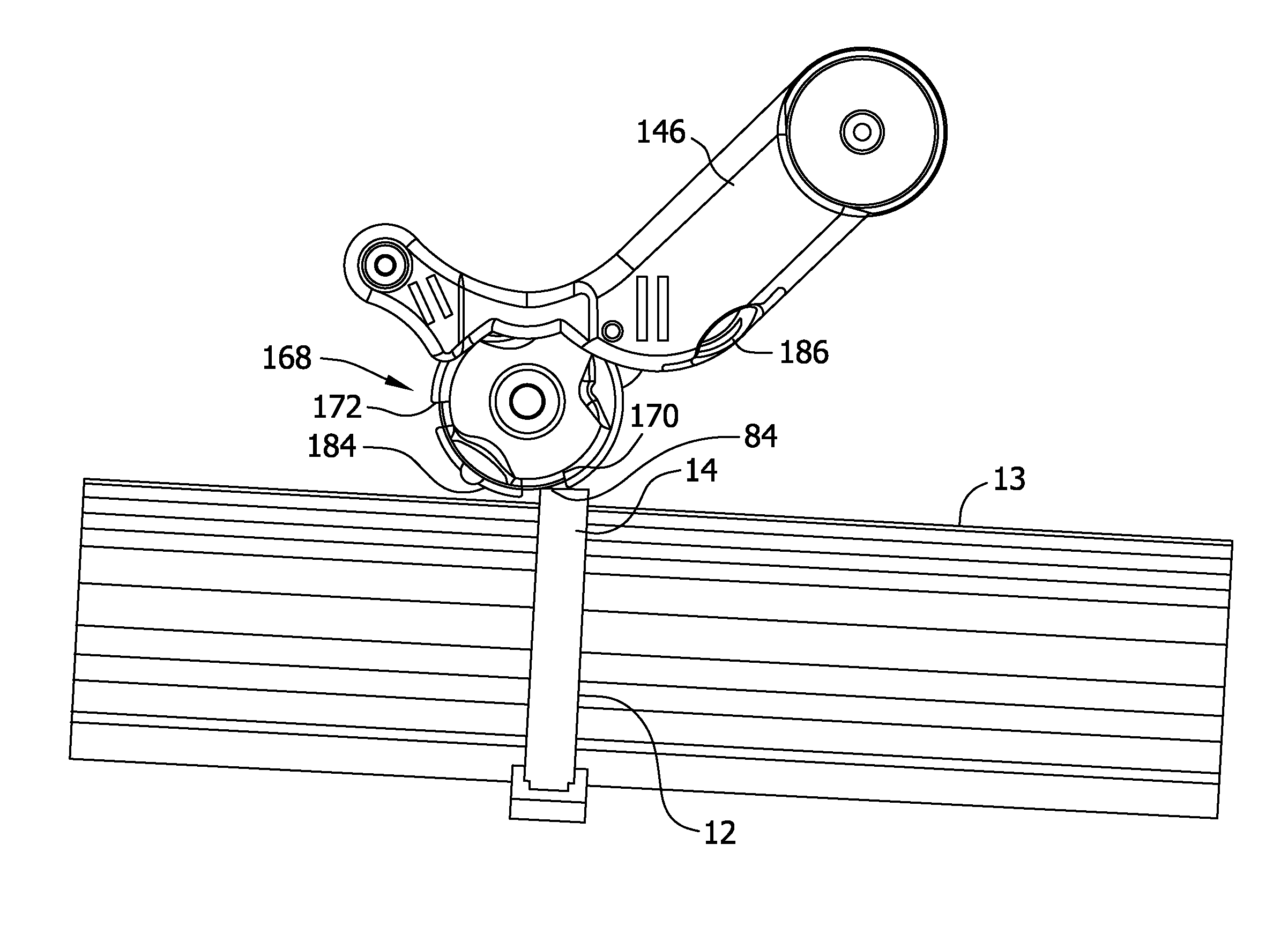

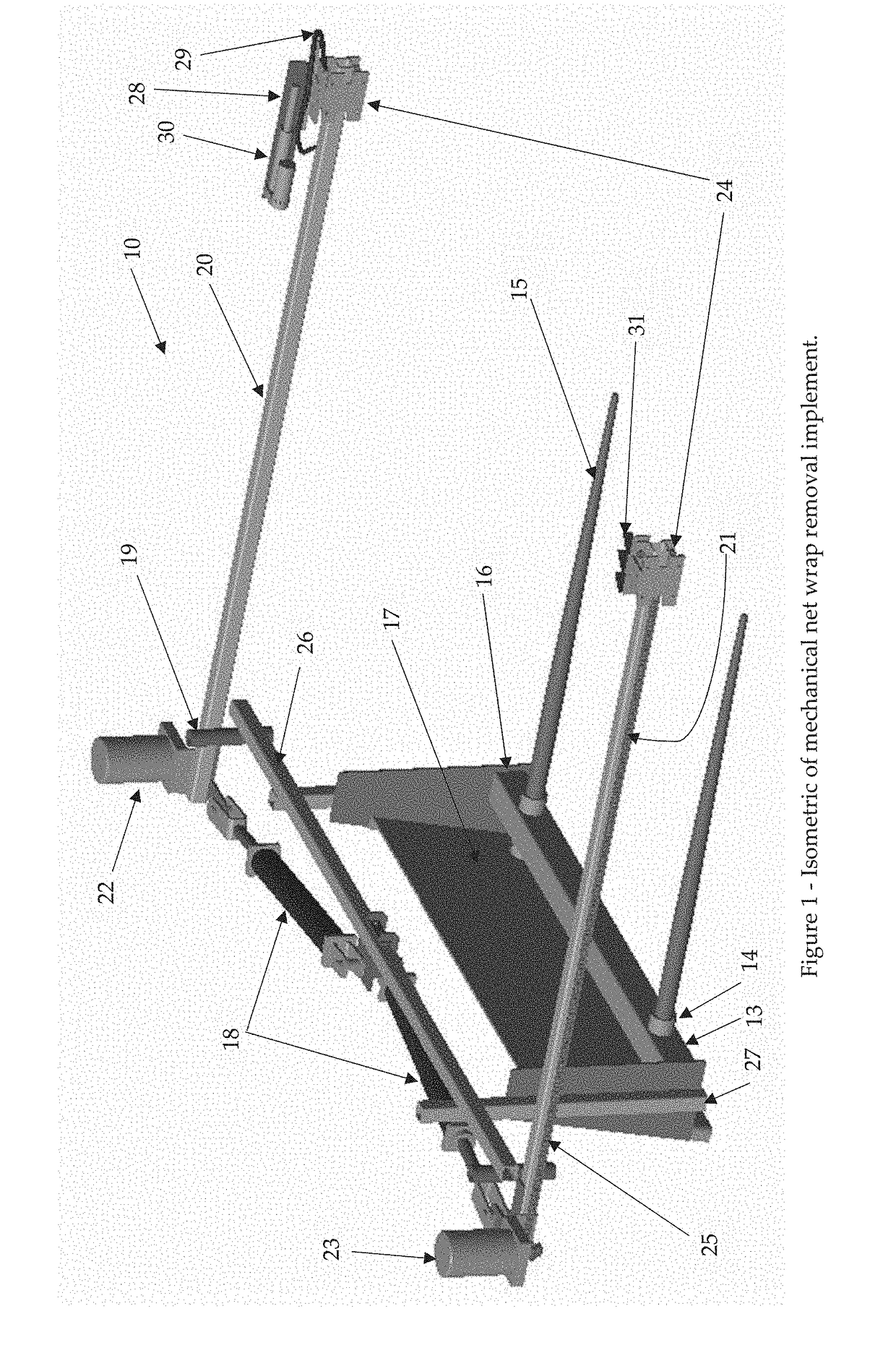

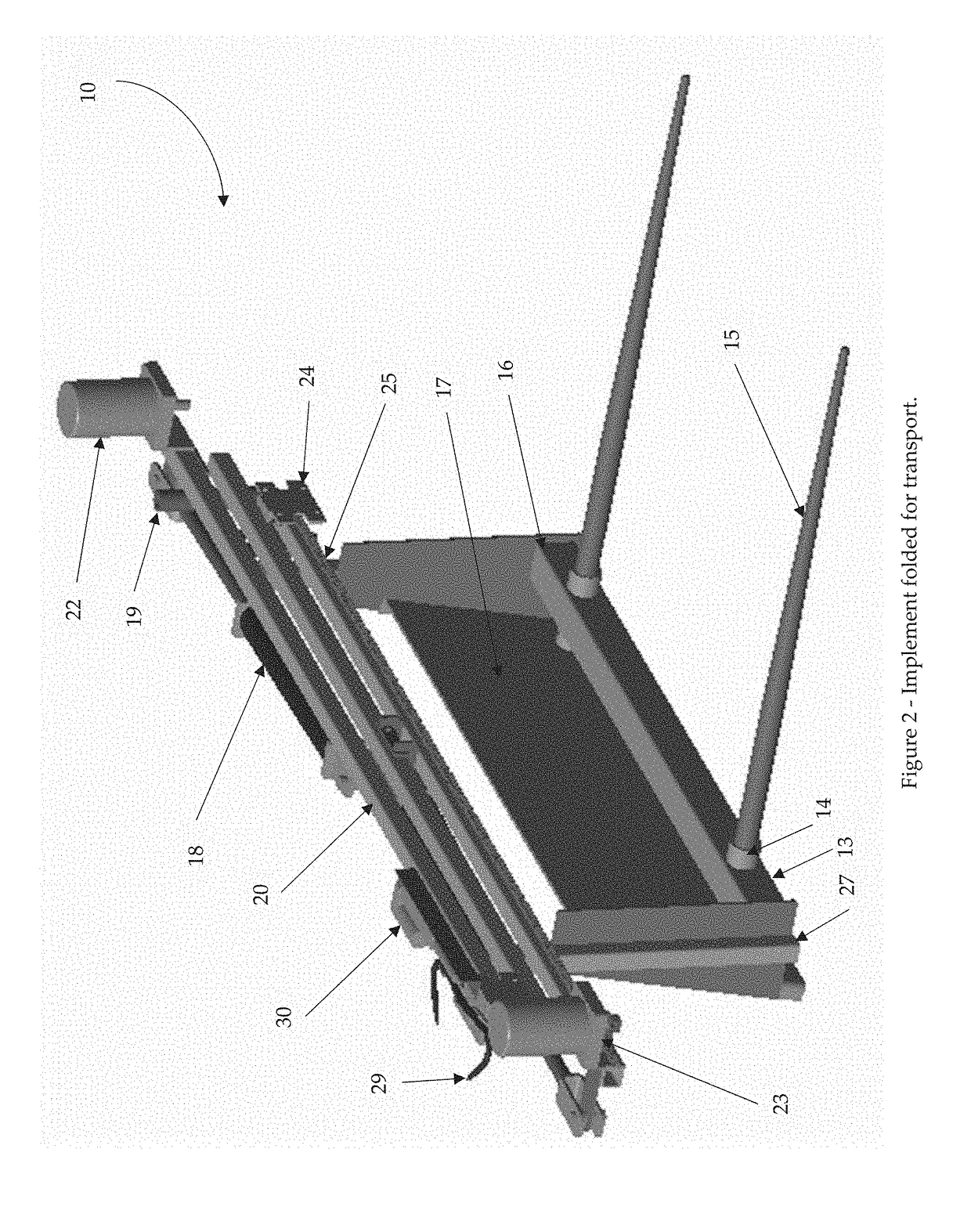

System and method for removing net wrap material

A system and method for removing material wrapped around a hay bale is provided. The system may comprise first and second generally opposing arms, a cutting device, and a grabbing device. The first and second arms are adapted for receiving a bale therebetween. One or both of the arms may be pivotably movable or linearly movable in order to receive and be positioned proximate a side of a bale. The cutting device may be movably coupled to the first arm and adapted for selectively traveling between first and second ends (e.g., a proximal end and a distal end) of the first arm. The grabbing device may be movably coupled to the second arm and adapted for selectively traveling between first and second ends (e.g., a proximal end and a distal end) of the second arm.

Owner:SCHMITZ AUSTIN ANTHONY +2

Film tearing mechanism

InactiveCN106829097AImprove adsorption capacityEasy to separateBinding material removalEngineeringMechanical engineering

The invention provides a film tearing mechanism, comprising: a film tearing electric cylinder mounting plate, a film tearing electric cylinder fixed on the film tearing electric cylinder mounting plate and a suction cup, the suction cup is fixed on the moving slider of the film tearing electric cylinder; Electric cylinder mounting plate, lifting electric cylinder fixed on the lifting electric cylinder mounting plate, clamping film cylinder mounting plate fixed on the lifting electric cylinder, clamping film cylinder and film tearing wheel fixed on the clamping film cylinder mounting plate, film tearing The wheel is fixed on the lower end of the clamping cylinder mounting plate, the film tearing wheel is located above a corner of the suction cup, and the lifting electric cylinder drives the tearing wheel to move up and down; the clamping plate is fixed on the clamping cylinder, and the clamping cylinder drives the clamping plate along the Movement in the horizontal direction, when the clamping cylinder is retracted, the clamping plate is in contact with the film tearing wheel. The invention adopts an electric cylinder to realize the forward and backward movement of the green ceramic sheet to realize the precise adjustment of the film tearing speed; the ratio of the upward moving speed of the film to the forward moving speed can be adjusted, thereby realizing the precise adjustment of the tearing film angle value.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 2 RES INST

Lens mold pouring system

ActiveCN108582615AImprove the exhaust effectPrecise size controlOptical articlesBinding material removalAdhesive beltLens plate

The invention belongs to the field of lens production equipment, and particularly relates to a lens mold pouring system. The lens mold pouring system comprises a machine frame, a seal tearing mechanism and a pouring assembly, wherein a retaining mechanism is arranged on the machine frame, and the retaining mechanism fixes a lens mold and drives the lens mold to rotate; the seal tearing mechanism is installed above the seal tearing mechanism and located on the side edge of the retaining mechanism, the seal tearing mechanism is used for grasping the end of an adhesive tape on the surface of thelens mold, and then drives the adhesive tape to separate from the lens mold to form an opening without adhesive tape covering; after the pouring is finished, the seal tearing mechanism is matched withthe retaining mechanism to enable the torn adhesive tape to be re-pasted, and the sealing is completed; and the pouring assembly is connected with the machine frame and located above the retaining mechanism, and the pouring assembly is used for injecting the lens base body into a cavity of the lens mold. The lens mold pouring system changes the way of tearing adhesive tape in the prior art, and improves the production efficiency and quality of the whole pouring system.

Owner:丹阳市雷登智能科技有限公司

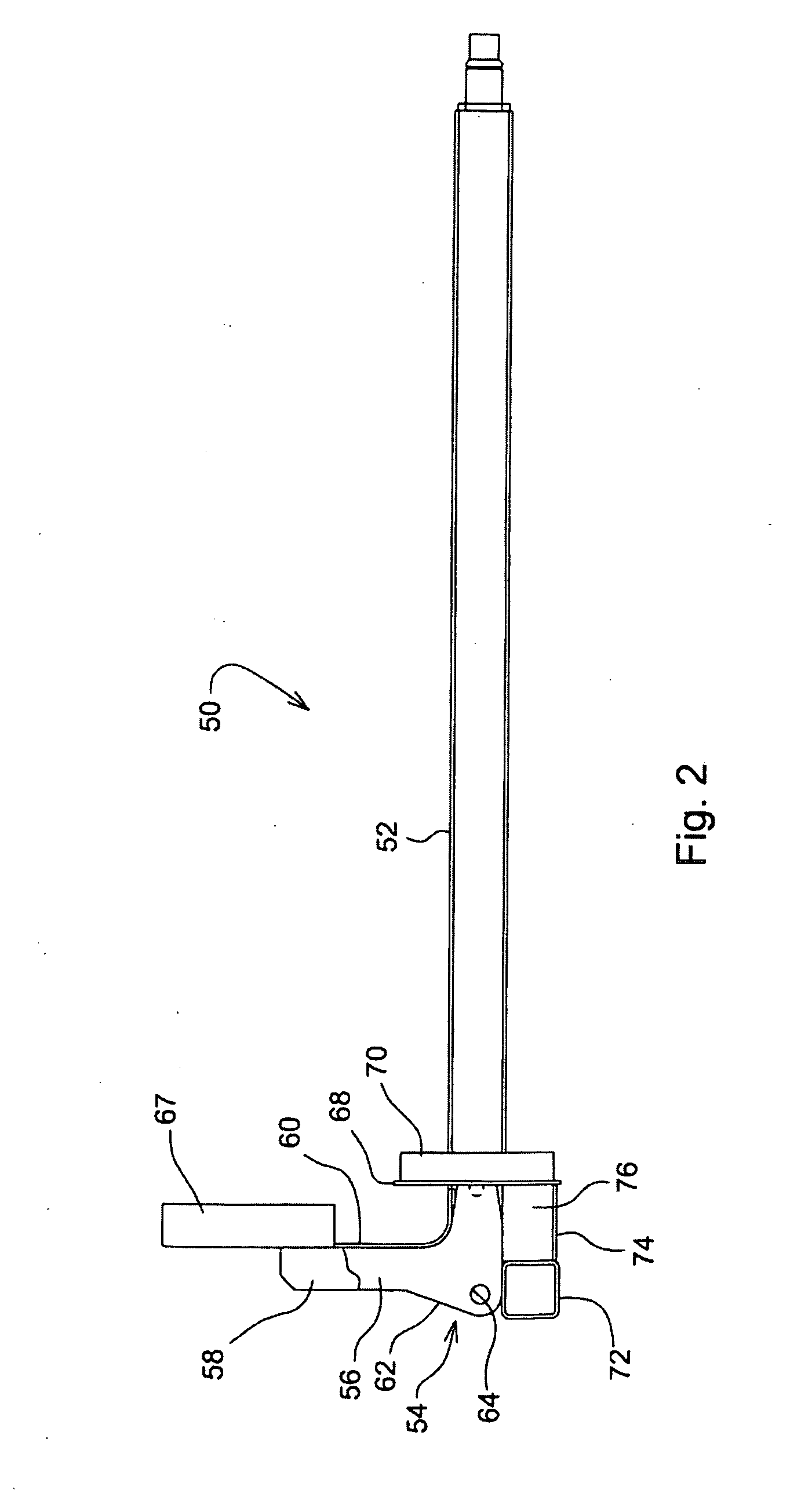

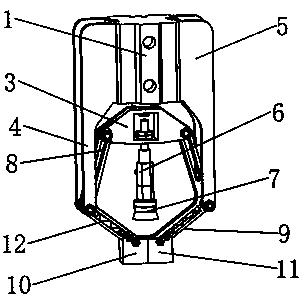

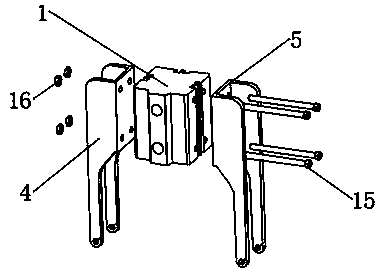

Method and apparatus for debanding a compressible bundle

InactiveUS20110000171A1Without risking damageOpening closed containersBottle/container closureEngineeringMechanical engineering

A method and apparatus for debanding a compressible bundle. The apparatus includes an End of Arm Tooling (EAT) component which is moved vertically downward over the bundle to a position where holding arms of the EAT component are manipulated to pick up and hold the bundle. At this position, one or more indenters of the EAT component are pressed into an upper surface of the bundle form a trough in the bundle that crosses under a band which surrounds the bundle. A cutting knife assembly of the EAT component is actuated to slide linearly along a longitudinal direction of the trough to cut the band without contacting the surface of the bundle, thereby enabling the band to drop away from the bundle. As a result, the bundle can be debanded without damaging the bags.

Owner:TRINITY PACKAGING CORP

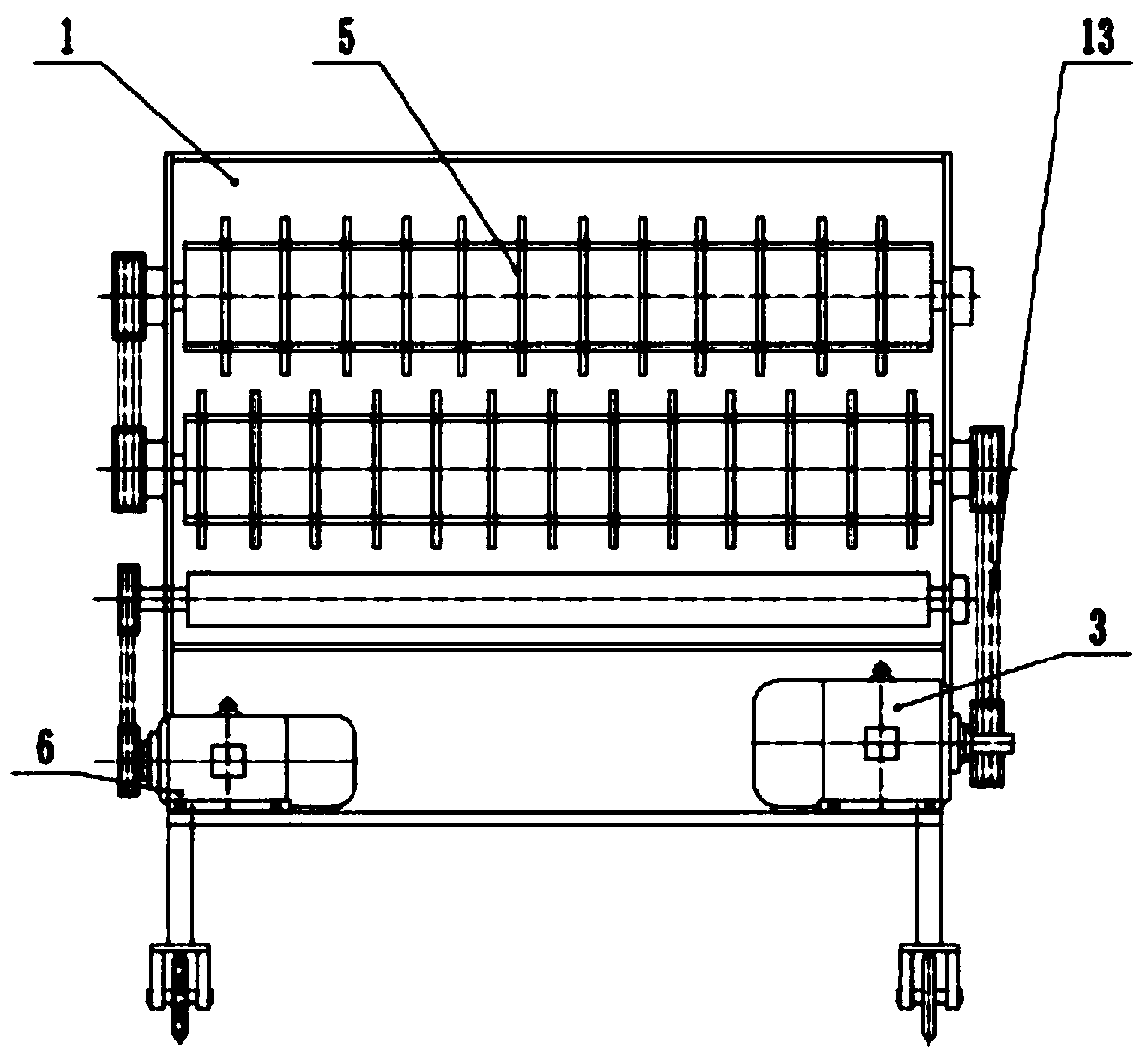

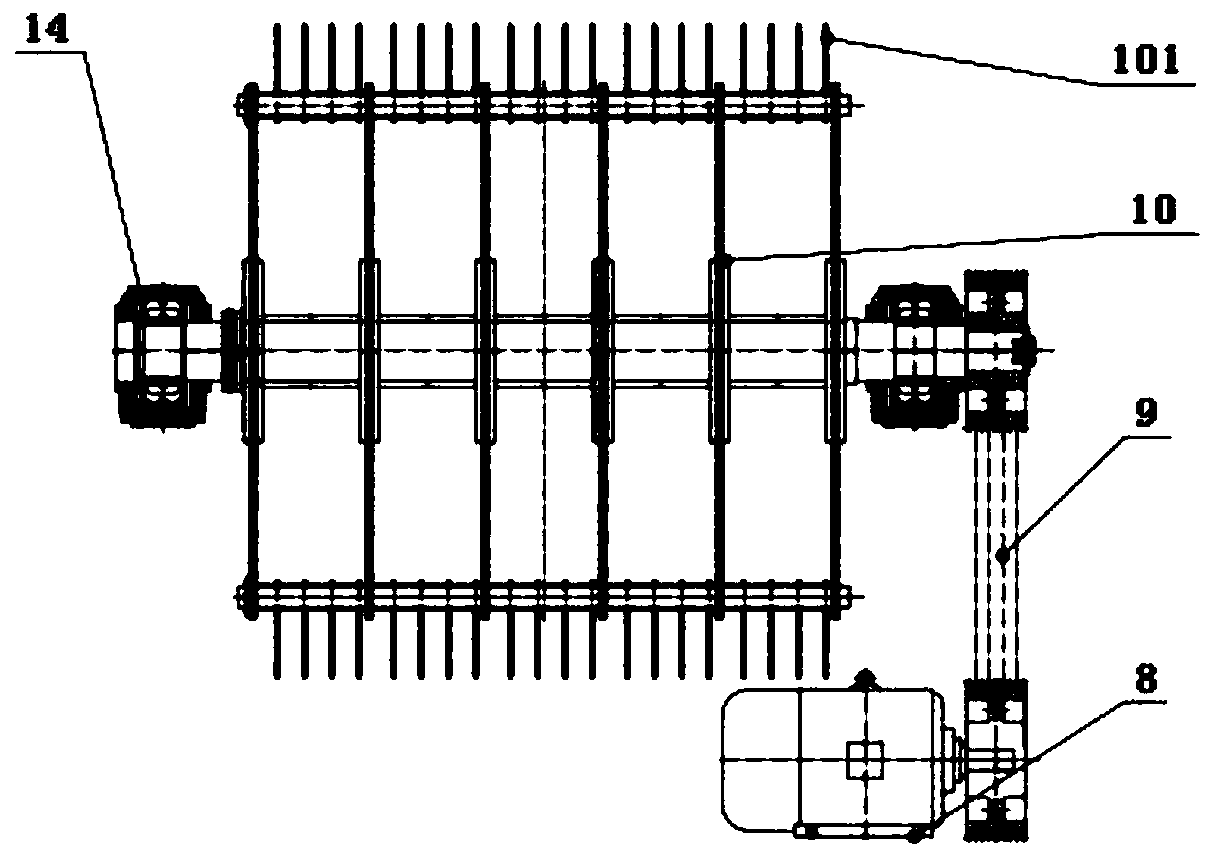

Straw package disassembling device and method

ActiveCN106240978ASave human effortIncrease productivityCuttersGrain treatmentsEngineeringElectric control

The invention discloses a straw package disassembling device and method. Disassembling is automatically completed through the straw package disassembling device. The straw package disassembling device at least comprises a conveying platform, a net film disassembling mechanism installed on the conveying platform, a straw crushing mechanism installed under the conveying platform and an electric control power mechanism installed on a conveying platform frame body; a straw package is placed into the conveying platform and conveyed to the net film disassembling mechanism at first, the electric control power mechanism controls the net film disassembling mechanism to disassemble a net film, and then, the conveying platform continues to convey the straw package with the net film disassembled to the straw crushing mechanism, so that the straw package is broken apart and crushed. According to the straw package disassembling device and method, automatic net film disassembling as well as breaking apart and crushing of the straw package are achieved through the net film disassembling mechanism, the conveying platform and the straw crushing mechanism, manpower is saved, the production efficiency is greatly improved, the bottleneck of large-scale processing is overcome, and an advantageous technical support is provided for straw utilization.

Owner:安徽省宿州市汇丰液压机械有限公司

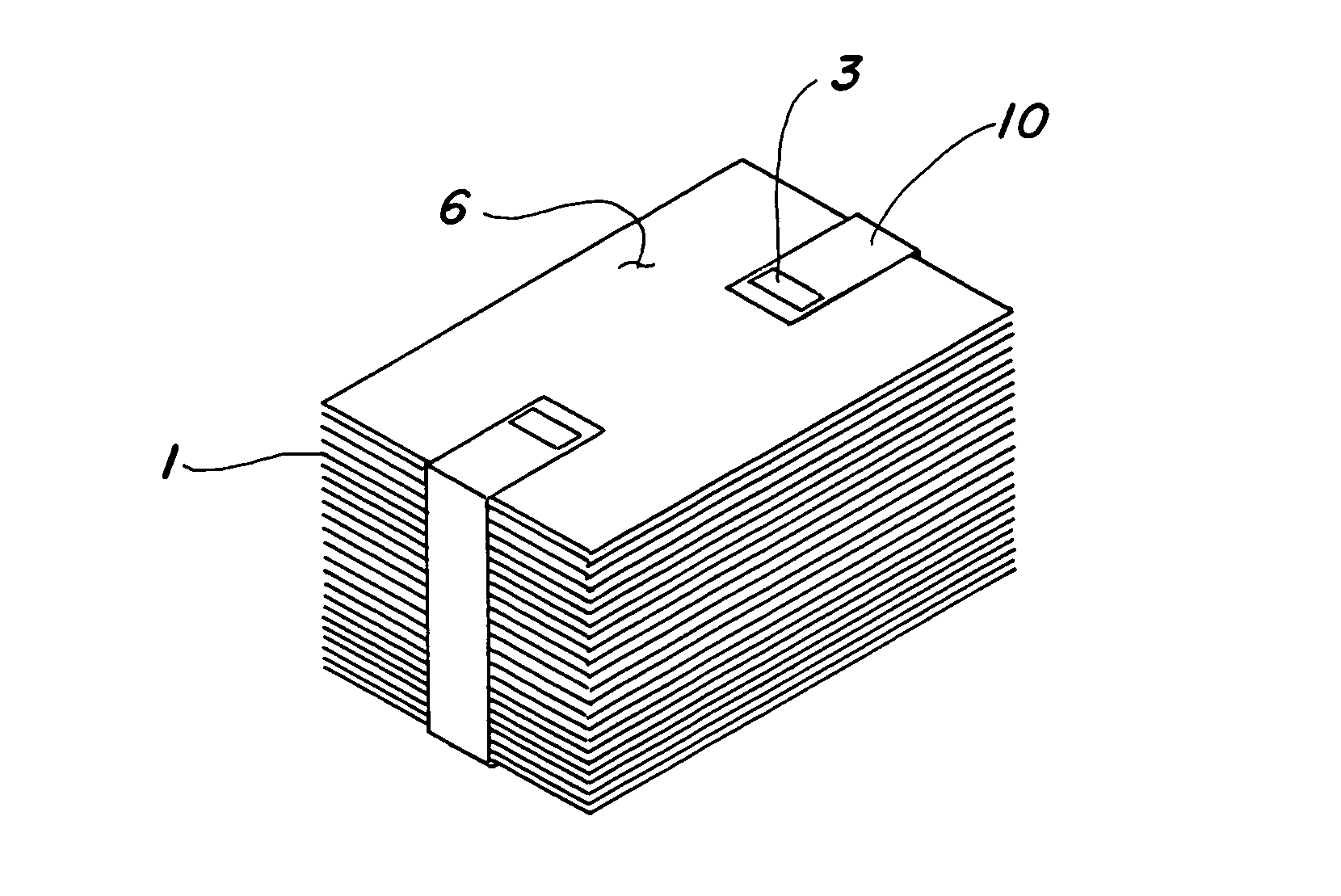

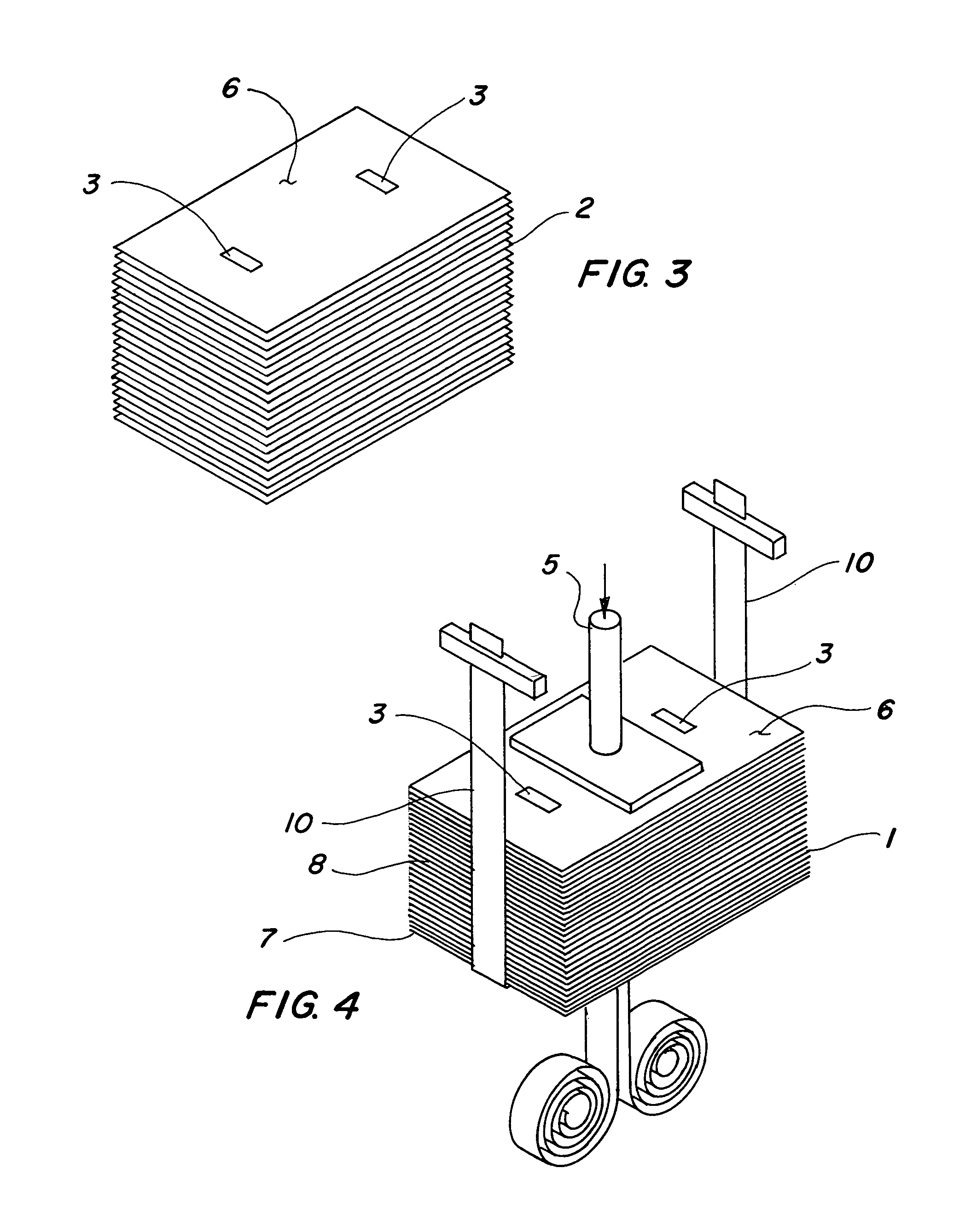

Apparatus and method for wrapping bulk products

An apparatus and method of bundling bulk items, such as for example papers and magazines, that includes applying a double-sided label to the top and bottom of the material stack, compressing the material stack, applying two binding materials around the material stack, and then relieving the compression on the material stack to allow the binding material to maintain the compression on the bundled material. The binding material, including the double-sided label, can be automatically removed from the bundled material by removing the binding material from the stack of materials and vacuuming the binding material away from the stacked material.

Owner:INTELLIGRATED HEADQUATERS LLC

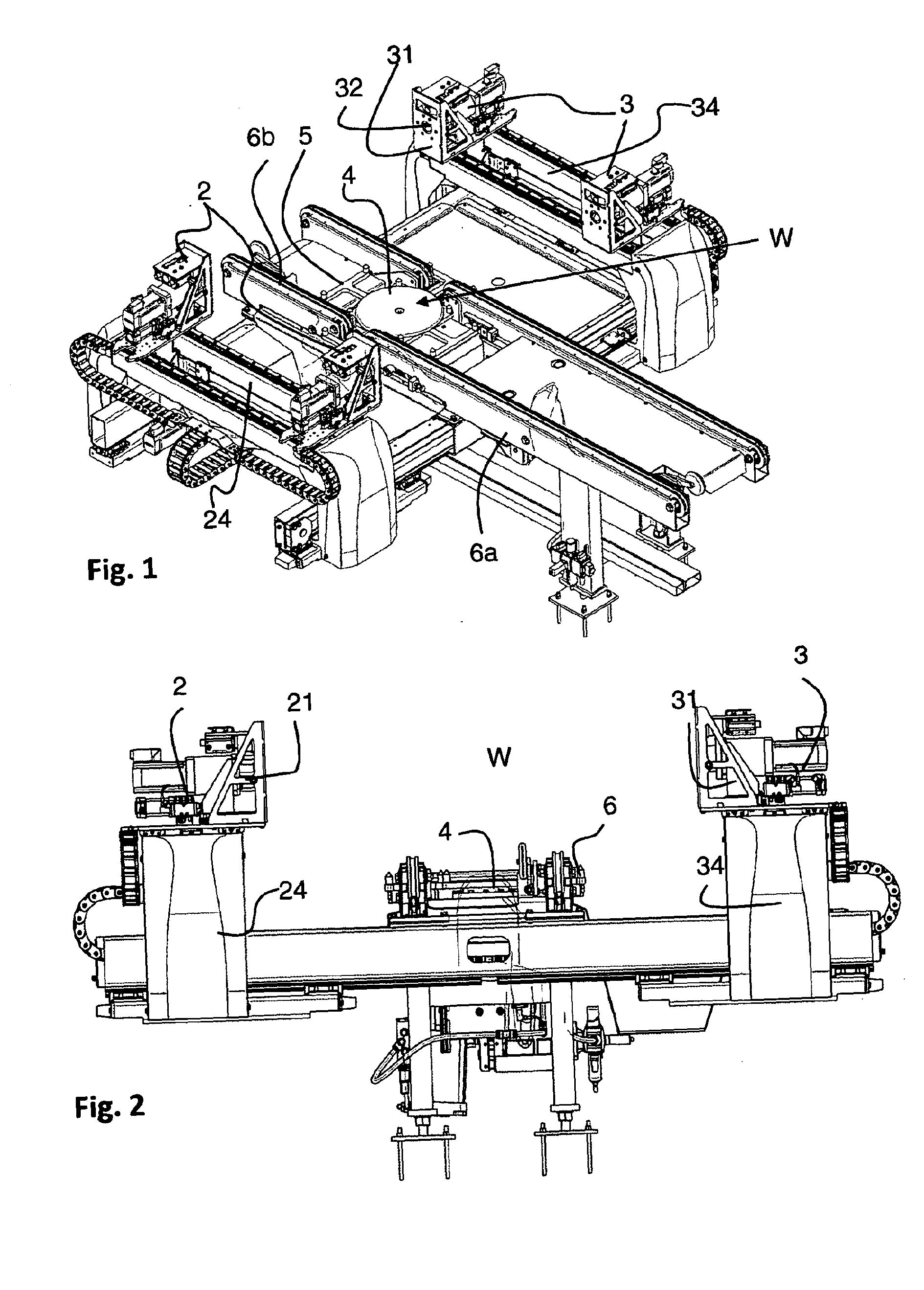

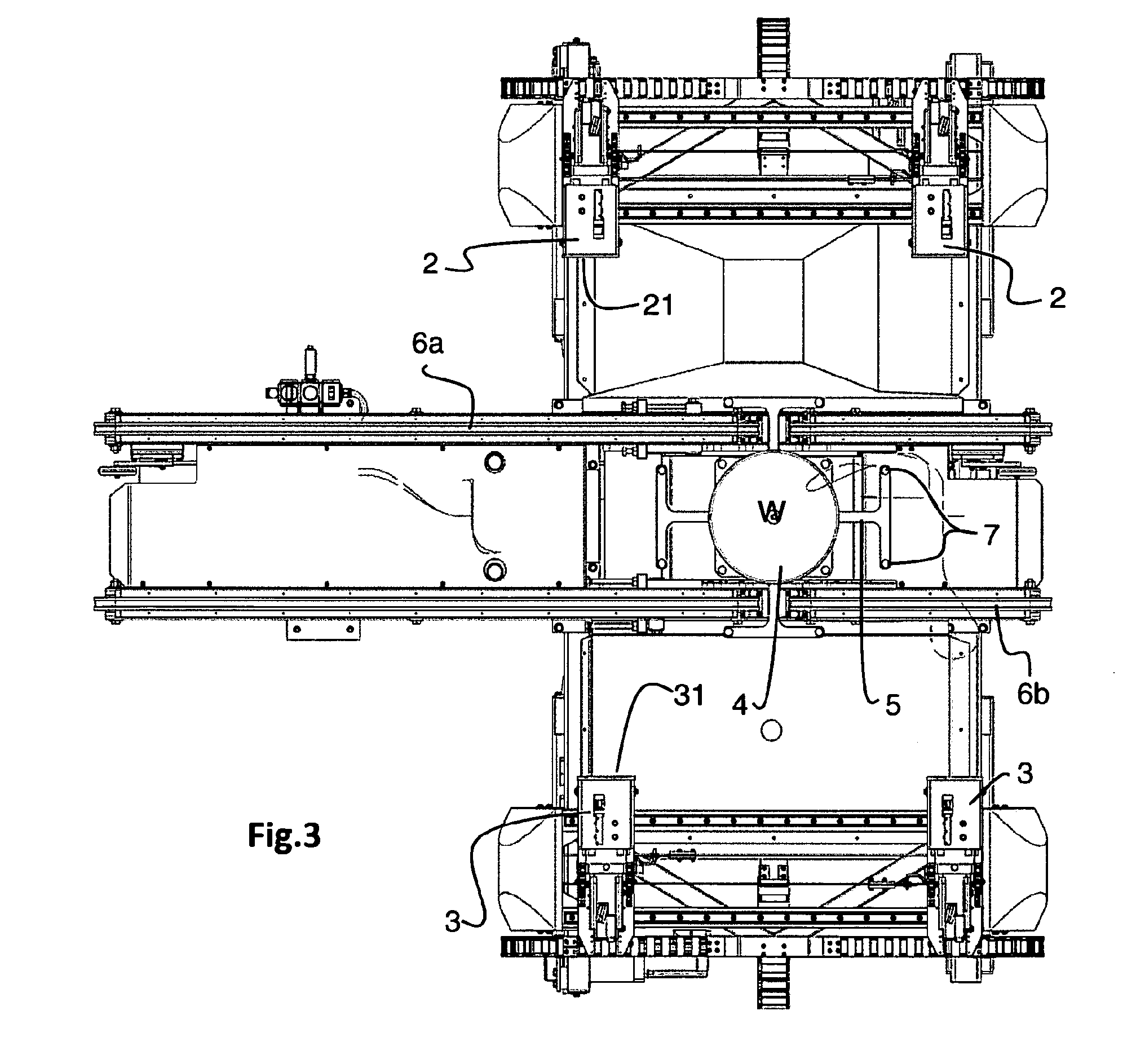

Device for cutting and removal of wires from bales

ActiveUS20110113941A1Packaging automatic controlOther manufacturing equipments/toolsElectric wireElectrical wiring

The device is for cutting and removal of wires from bales, such as pulp bales, paper bales and the like. The device is intended to remove all wires from a bale that is provided with at least two wires. The device has two cutting units and two winding units that are positioned pair-wise opposite each other, on one side each of a working location (W), for the pair-wise cutting off and removal of the two wires that are arranged in parallel.

Owner:VALMET TECHNOLOGIES INC

Method for removing wires or tapes from pressed bales of raw material and wire coiling device for carrying out the method

InactiveUS7152634B2Particularly cost-effectiveWire articlesOther manufacturing equipments/toolsWire rodMagnetic tape

Owner:VOITH PATENT GMBH

Automatic ton bag unpacking device and method

ActiveCN112429353ARealize automatic bag unpackingNo human assistance requiredFlexible bulk container emptying systemsBinding material removalHydraulic cylinderElectric machinery

The invention discloses an automatic ton bag unpacking device. The automatic ton bag unpacking device comprises a ton bag with an outer layer and inner tongue double-layer structure, a supporting frame made of an aluminum alloy material and used for mounting components, a rail arranged at the top of the supporting frame and a power device for driving the ton bag to transversely move and longitudinally move along the rail. The automatic ton bag unpacking device is characterized in that disassembling devices, a discharging barrel arranged at the bottom end of the supporting frame, ascending anddescending in the longitudinal direction and connected with an inner tongue in a sleeved mode, an inner bag knife arranged in the discharging barrel, and a barrel hoop arranged at the outer end of thejoint of the inner tongue and the discharging barrel and used for sealing and fixing are further included; and the disassembling devices are connected with three-level hydraulic cylinders through transition pieces separately and are driven by a control unit, the three-level hydraulic cylinders are all fixedly arranged on the supporting frame, the rail for lifting of the inner bag knife is arranged in the discharging barrel, and the inner bag knife drives a rope to ascend and descend in the rail through a motor. By means of the automatic ton bag unpacking device, automatic bag unpacking operation is achieved, and accidental leakage of powder in the bag unpacking process is avoided.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Container strap cutting method

InactiveUS7021033B2Increase chanceReadily apparentOpening closed containersCapsManipulatorBiomedical engineering

A device is disclosed that can automatically remove lids from trays and place lids on trays. Further the device can sense the presence of a lid on a tray and can sense the dimensions of the tray. Based on the sensed dimensions of the tray, the device can select an appropriate sized lid to place on the tray. In one embodiment of the invention, a device holds a lid with a lid manipulator having lid holders. At least one end mechanism is attached to at least one end of the lid manipulator, and the end mechanism folds the lid flaps of an appropriate lid. Guided by the lid manipulator, lids are then positioned on the tray.

Owner:US POSTAL SERVICE

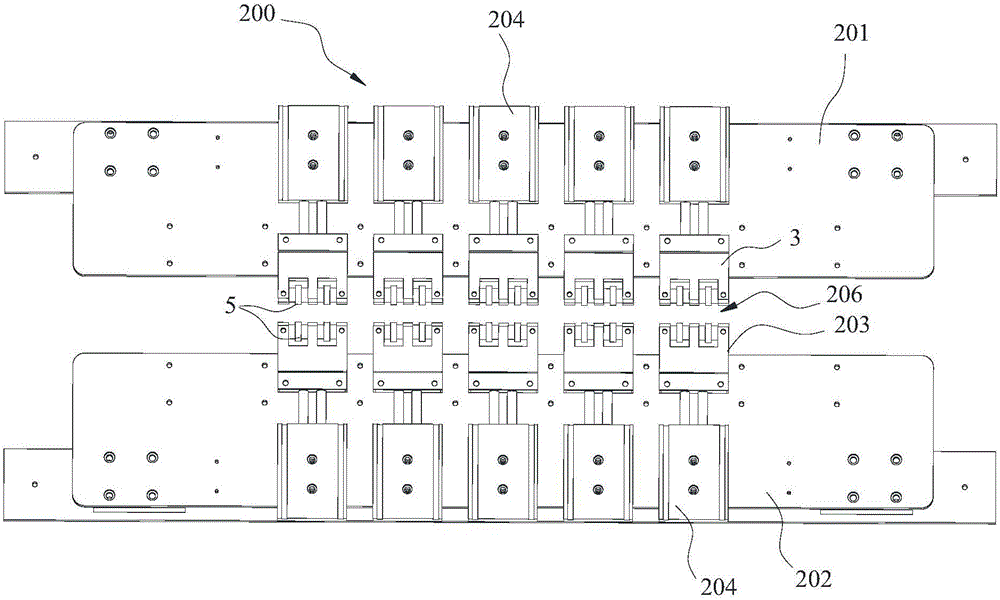

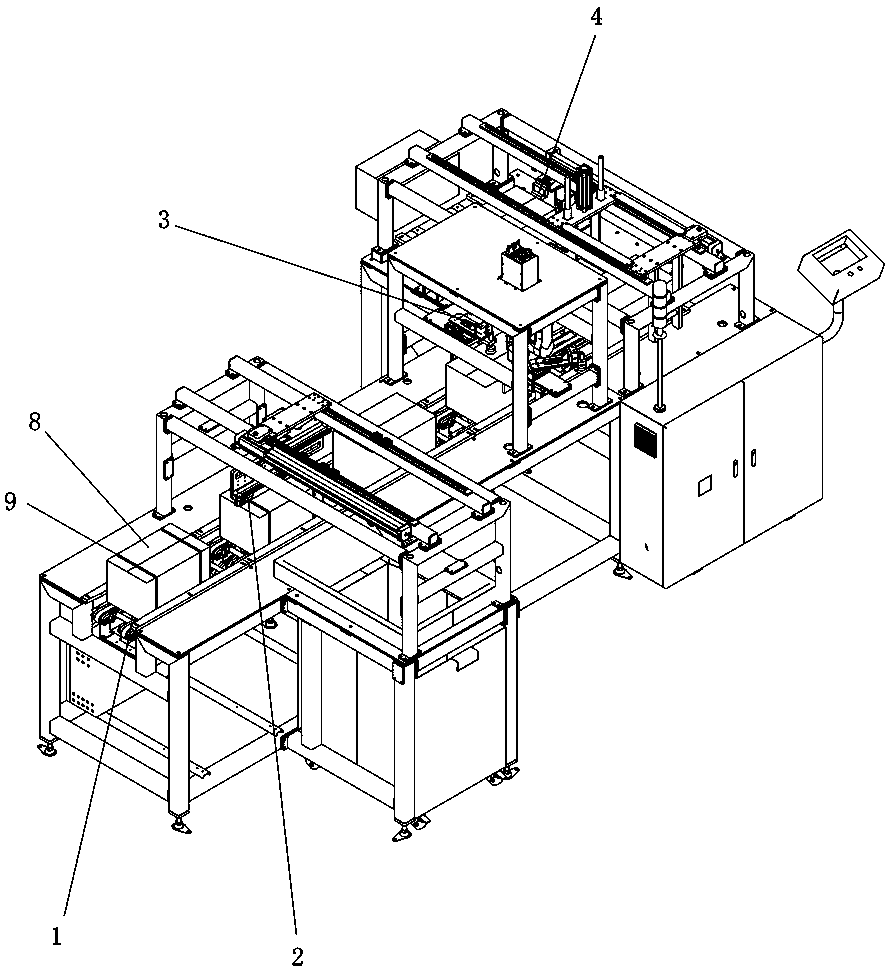

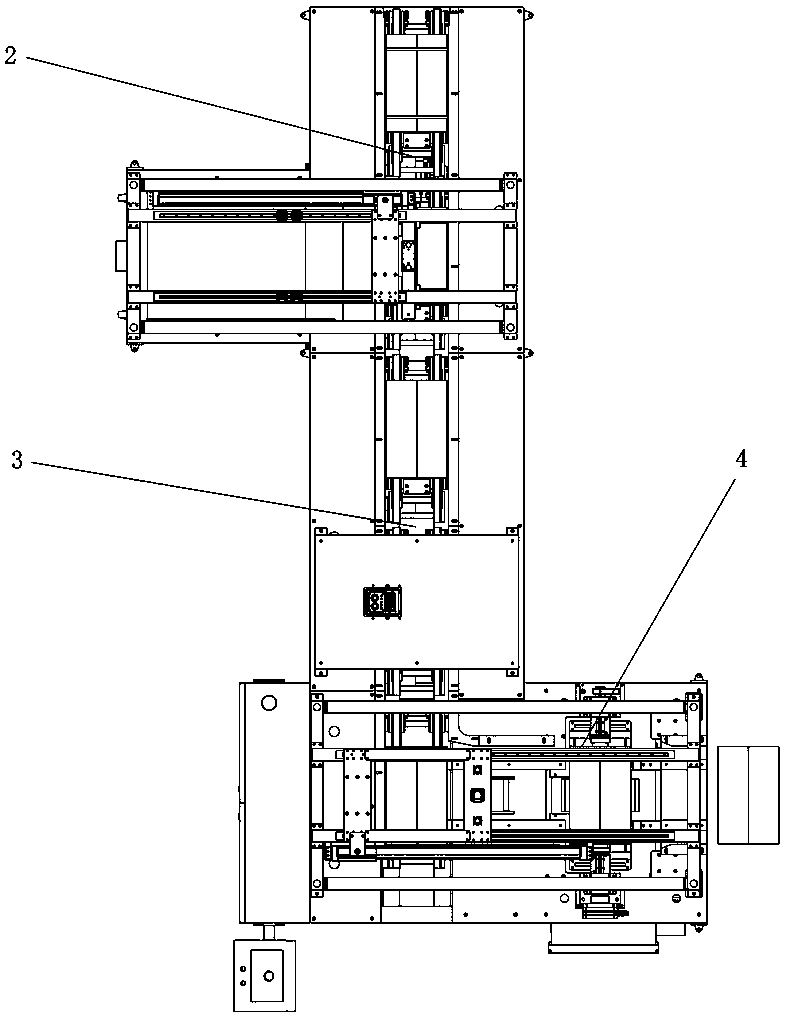

Film stripping and tape removing system

PendingCN111776382AEfficient and fast film removalEfficient and quick unpacking operationBinding material removalUnpacking by cuttingThin membraneMechanical engineering

The invention discloses a film stripping and tape removing system. The film stripping and tape removing system comprises a film stripping device and a tape removing device which are arranged sequentially along the material advancing direction, wherein the film stripping device comprises a film absorbing assembly, a cutting assembly and a conveying assembly; the film absorbing assembly comprises atleast one adsorbing body which has a telescopic function and is used for adsorbing films; the cutting assembly comprises a moving mechanism, a cutting part fixedly connected to the moving mechanism and a clamping part; the cutting part is used for performing cutting operation on the films adsorbed by the adsorbing bodies; the clamping part is used for clamping the cut films and feeding the cut films into the conveying assembly; the tape removing device comprises a tape shearing assembly and a tape feeding assembly; the tape shearing assembly comprises a plurality of clamps and shears having lifting functions; the clamps are used for clamping packaging tapes to shear the packaging tapes through the shears; the tape feeding assembly comprises a pushing part and a conveying part; and the pushing part is used for feeding the sheared packaging tapes into the conveying part. The film stripping and tape removing system is multifunctional, and can finish the film stripping and tape removing work efficiently and rapidly.

Owner:厦门德莱生物科技有限公司

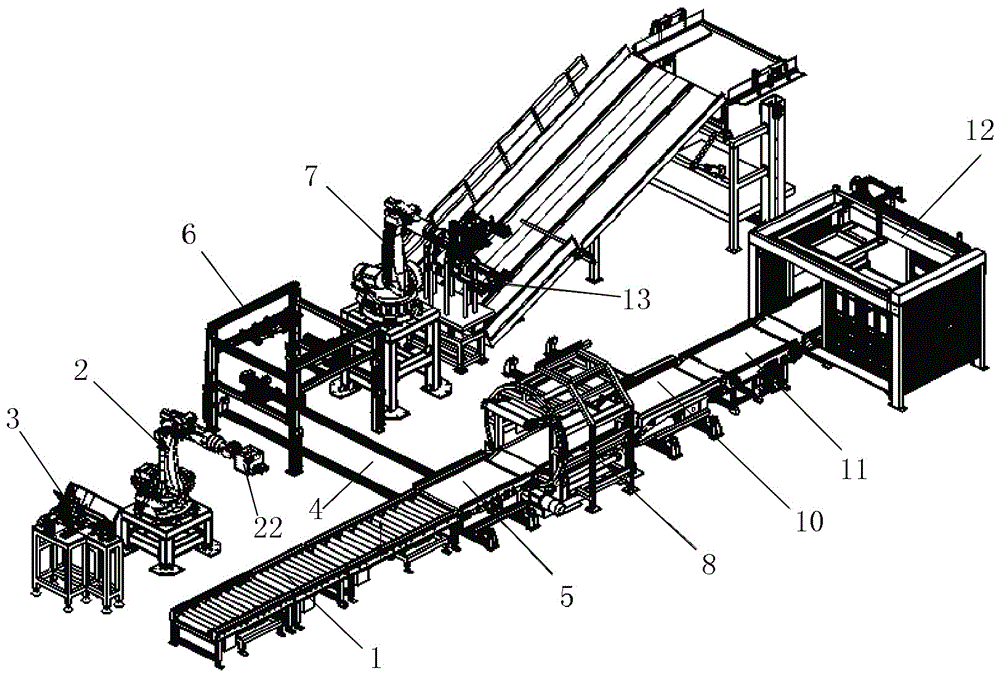

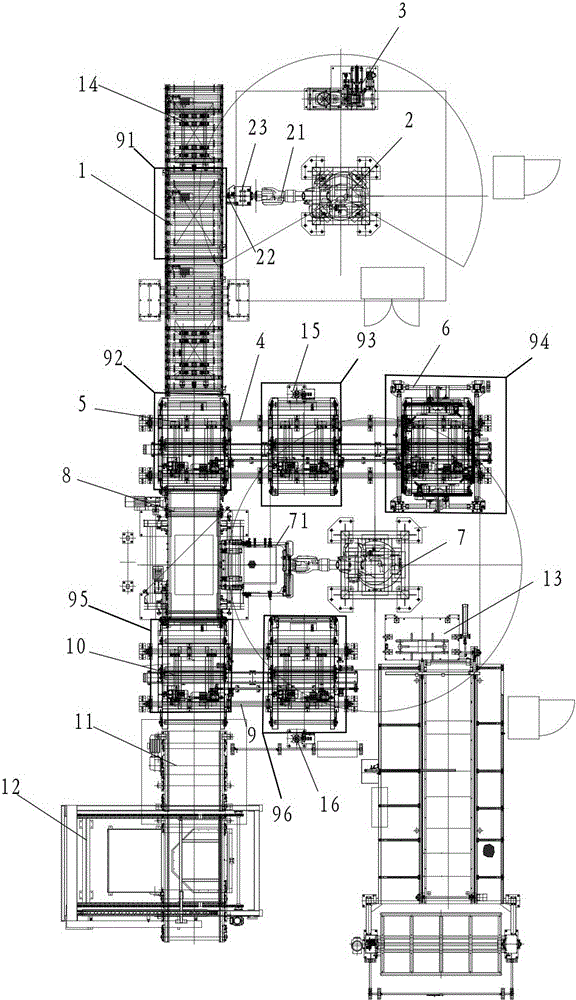

Intelligent box opening machine

PendingCN109677720AAvoid frequent contactReduce manual labor intensityBinding material removalUnpacking by cuttingAluminiumEngineering

The invention discloses an intelligent box opening machine. The intelligent box opening machine comprises a box body conveying part, an automatic bundling tape removing device, an automatic adhesive tape cutting device and an automatic blanking device, wherein a cutting station, a removing station and an adhesive tape cutting station are successively arranged along a conveying direction of the boxbody conveying part; the automatic bundling tape removing device comprises a cutter component and a bundling tape removing component; the cutter component is arranged in the cutting station and is capable of cutting bundling tapes at the bottoms of packaging boxes when the box body conveying part is used for conveying the packaging boxes to the removing station; the bundling tape removing component is arranged in the removing station and is capable of removing the cut bundling tapes; the automatic adhesive tape cutting device is arranged in the adhesive tape cutting station and is capable ofcutting adhesive tapes on the packaging boxes; the automatic blanking device is butted with the output end of the box body conveying part and is capable of clamping the packaging boxes, then overturning the packaging boxes and pouring aluminum cover packages out. The intelligent box opening machine has the advantages of high automation degree, high production efficiency and low pollution risk.

Owner:TRUKING TECH LTD

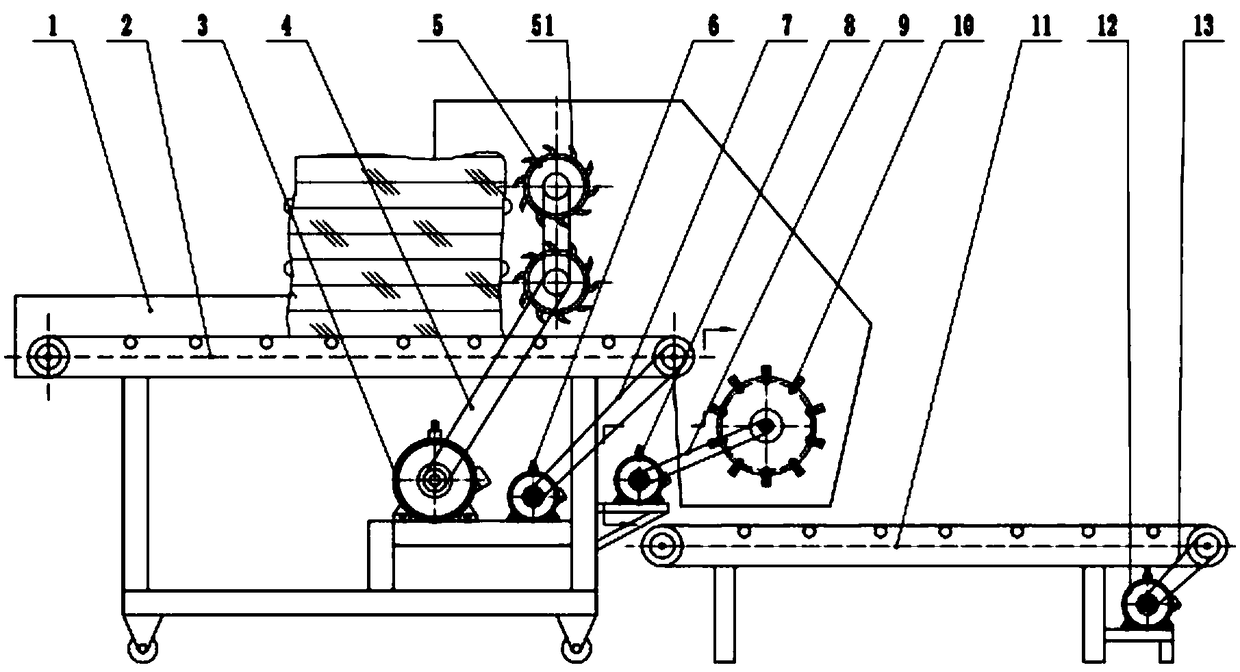

Integrated straw unpacking and smashing machine

PendingCN109463138AEasy to cut offExtended service lifeCuttersBinding material removalAgricultural engineeringMaterial resources

The invention discloses an integrated straw unpacking and smashing machine. The integrated straw unpacking and smashing machine comprises a machine shell, an input belt conveyor and an output belt conveyor, wherein the machine shell is internally provided with two groups of unpacking turnplates, the unpacking turnplates are connected through a belt, the unpacking turnplates are connected with an unpacking transmission mechanism, the unpacking transmission mechanism is connected with an unpacking driving motor, the inner portion of the machine shell is provided with the input belt conveyor, theinput belt conveyor is connected with an input transmission mechanism, and the input transmission mechanism is connected with an input driving motor. The integrated straw unpacking and smashing machine has the advantages that the structure is compact, automatic feeding, unpacking, smashing and discharging are integrated into a whole, one machine has multiple purposes, and the integrated straw unpacking and smashing machine is safe and reliable, can save a large amount of manpower and material resources, can greatly improve the production efficiency, and is equipment needed urgently by the straw comprehensive utilization industry.

Owner:河北天太生物质能源开发有限公司

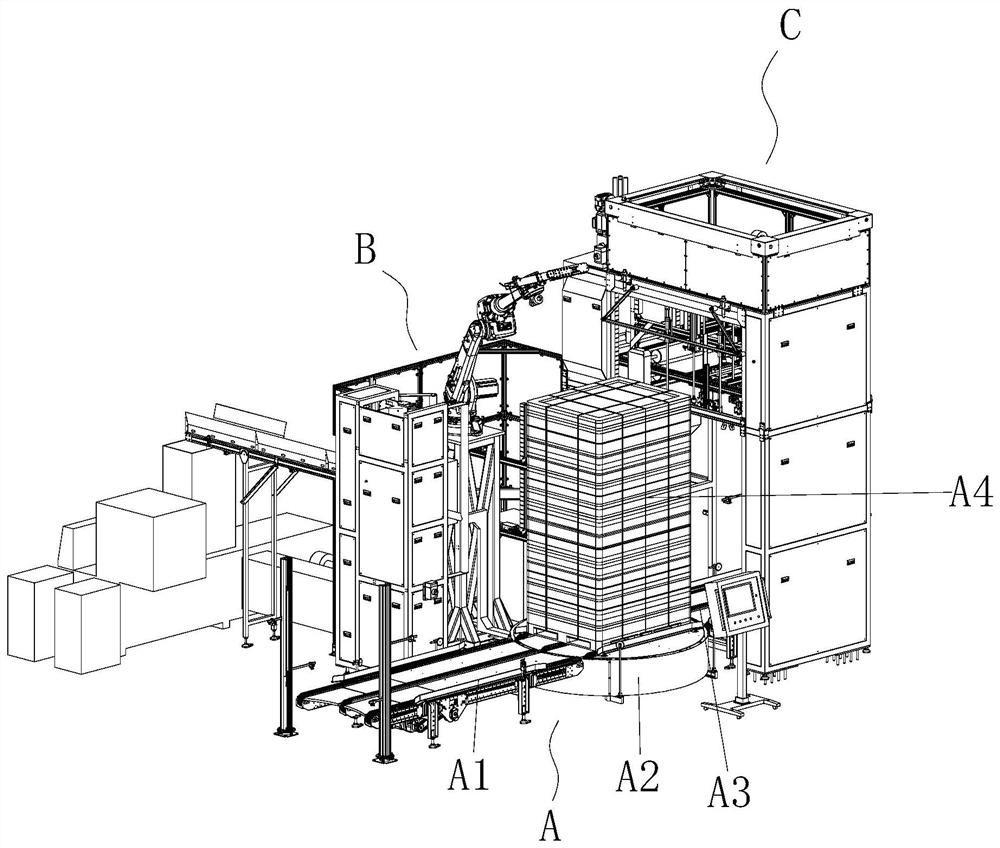

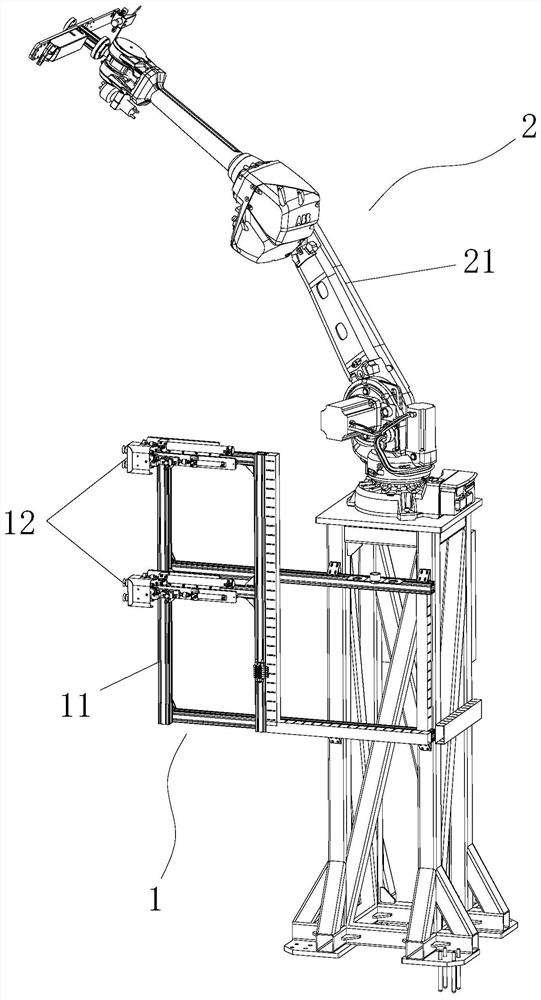

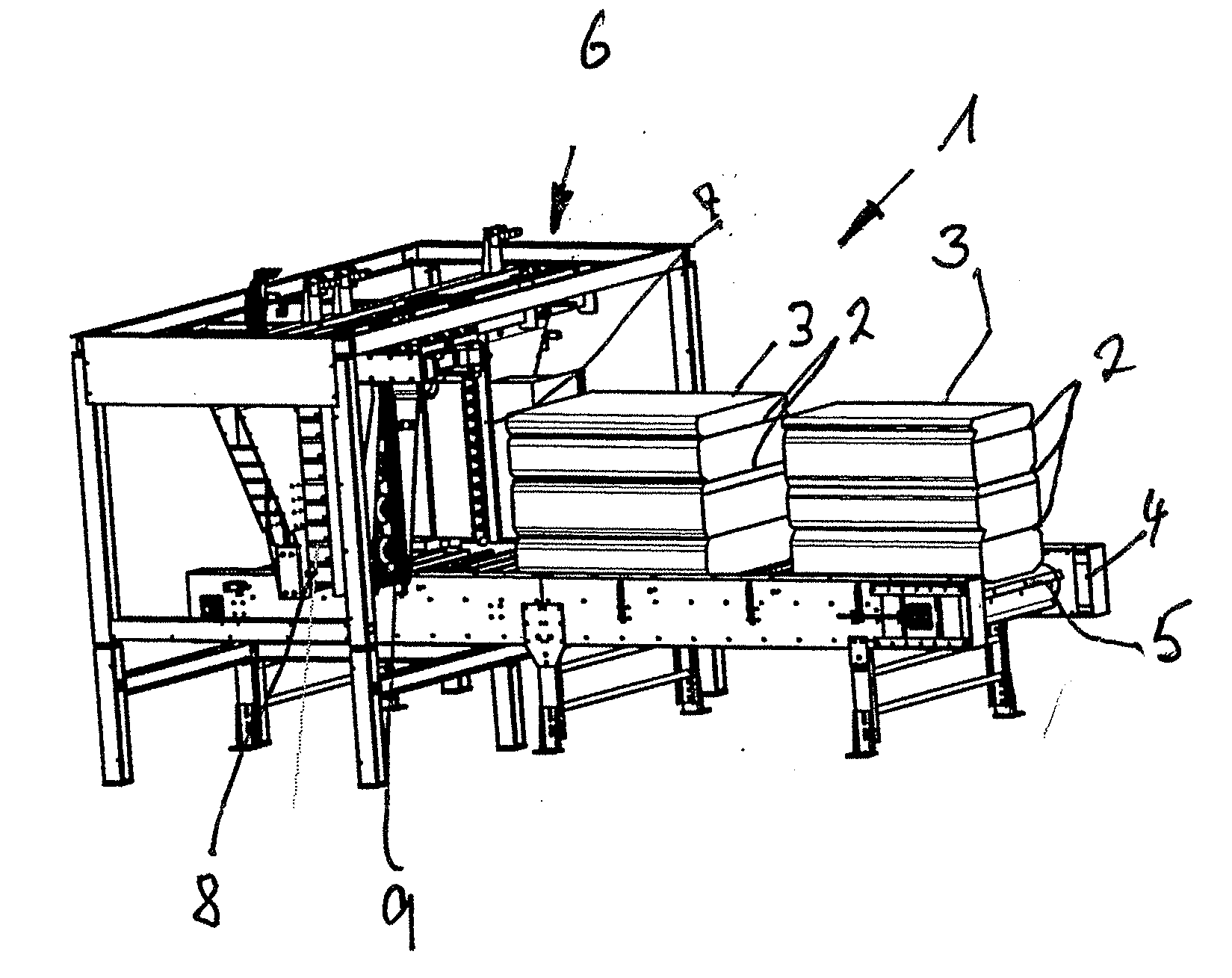

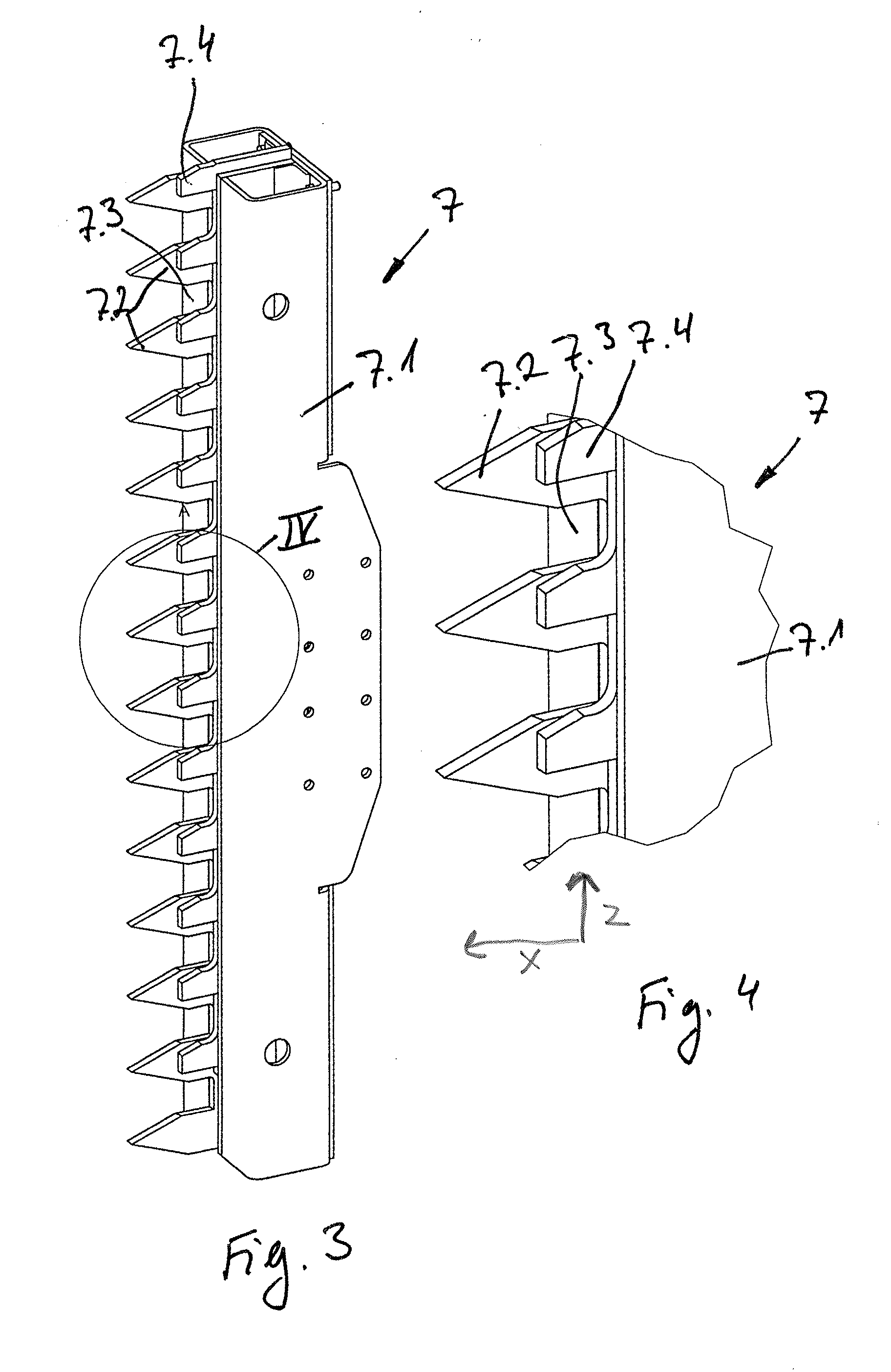

Device to remove binding materials from packaged bulk goods

The invention relates to a device 1 to remove binding materials 2 from packaged bulk goods 3, particularly binding wire or binding cord from compressed cuboid bales as packaged bulk goods. In order to have an automated process during removal of binding materials, a transport unit 4 is provided to transport the packaged bulk goods 3 into a gripping and cutting station 6 at which the package of bulk goods 3 is affixed on the one side by a clamping device 8 and on the other side of the package of bulk goods by a cutting device 7, and binding materials 2 are gripped by the clamping device 8 and cut by the cutting device 7.

Owner:KOMPOFERM

End effector for film tearing robot

ActiveCN110328685AThe protective film function is remarkableSave manpower and material resourcesGripping headsBinding material removalTectorial membraneEngineering

The invention discloses an end effector for a film tearing robot and belongs to the technical field of intelligent manufacturing of robots. The end effector comprises an air cylinder, a clamping finger movable mounting rack, a clamping finger fixed mounting rack I, a clamping finger fixed mounting rack II, a vacuum transfer rack, a vacuum chuck, a clamping finger I, a clamping finger II, a clamping block I and a clamping block II. When an air cylinder piston rod moves downwards, the vacuum chuck can tear up a protection film, when the air cylinder piston rod moves upwards, the clamping block Iand the clamping block II can clamp the torn film, and accordingly the protection film is torn apart. The end effector is high in practicability and good in performance, and manual film tearing can be replaced; the torn film can be a protection film of an electronic product, attachment films similar to a protection film for a glass plate and the like can also be torn apart, and the end effector is suitable for industrial production and application and popularization in the market.

Owner:KUNMING UNIV OF SCI & TECH

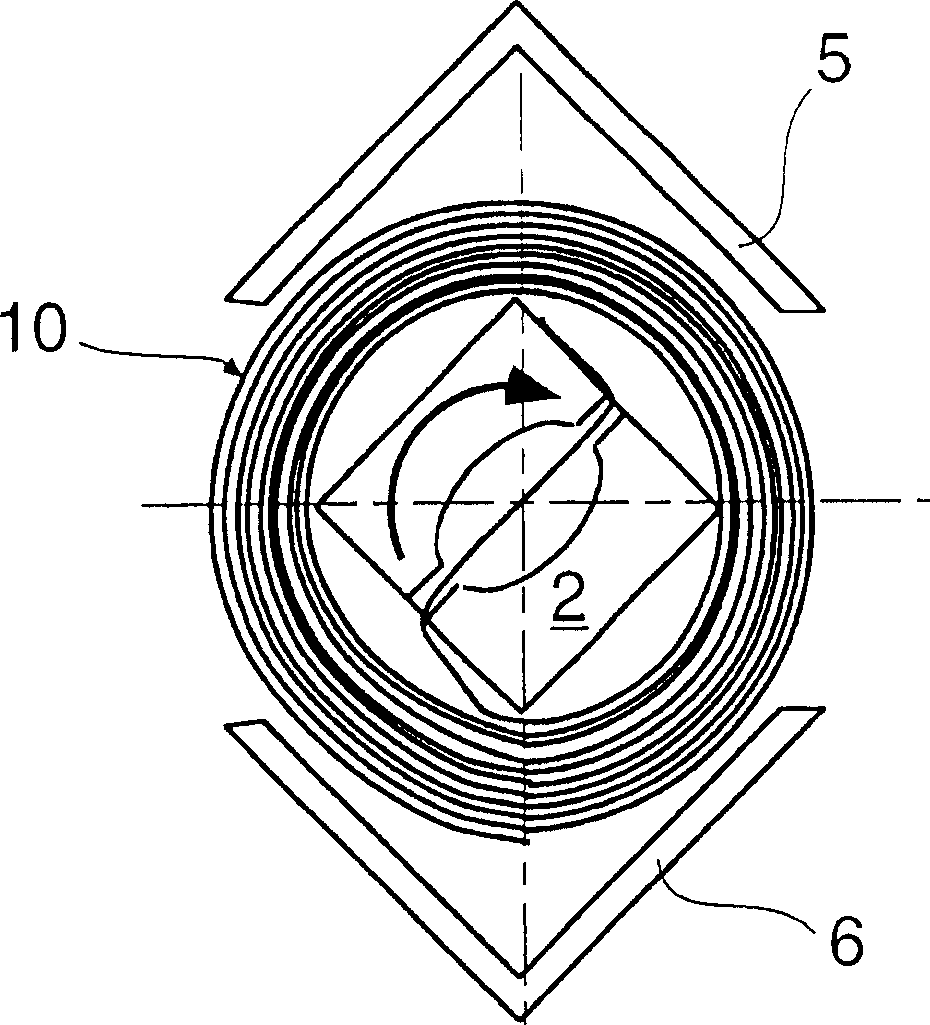

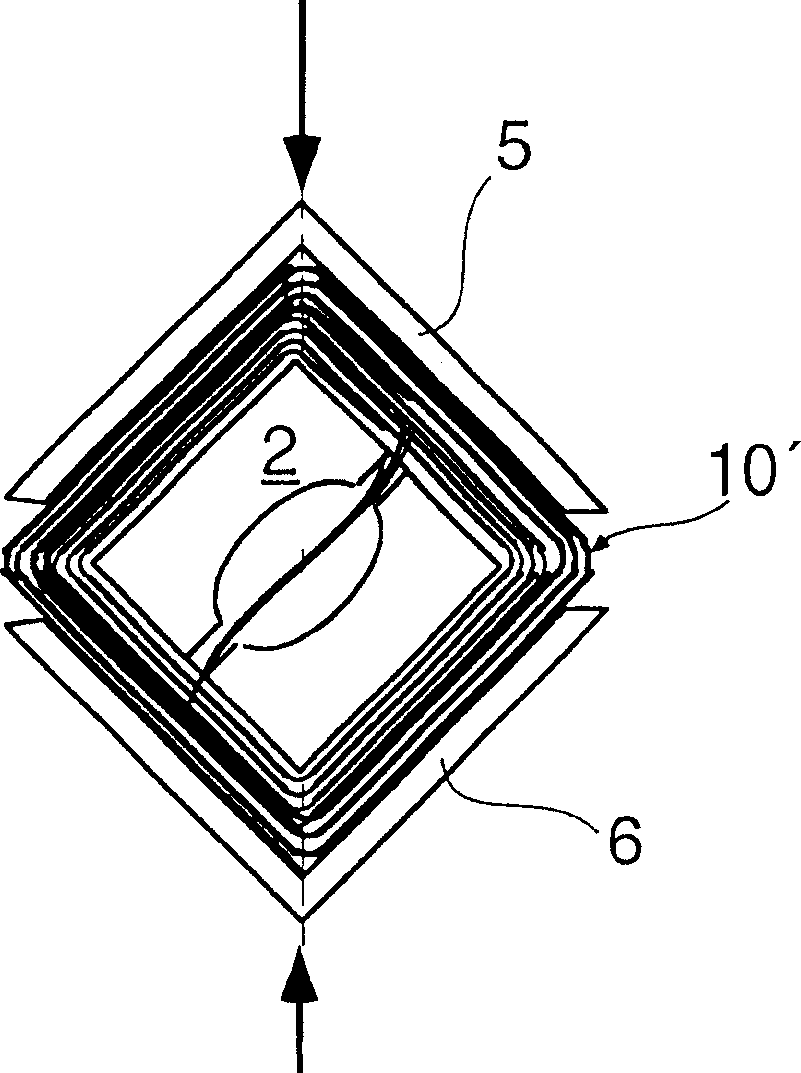

Winding device for removing cut binding material

In a winding device for removing cut binding material (1) (especially metal bands) from bales, comprising guide(s) for the material, a receiver (2) with a winding surface (4) and a receiving slit (3) for gripping the material (the receiver being rotatable relative to the guides) and a device for axially moving the wound product from the receiver, the winding surface has a polygonal (preferably square) cross-section, the receiver is enclosed by two spaced press parts (5, 6) movable inwards towards the receiver and the inner surface (7) of the press parts is geometrically similar or identical to part of the winding surface.

Owner:VOITH PATENT GMBH

Bale processor and binding remover

A bale processing machine that removes a binding from a bale allows for rapid bale processing. A method for removing the binding from the bale includes supporting the bale with a bale support at an elevated positon and securing the binding to a binding engagement device. The method also includes cutting the binding and removing the bale support from beneath the bale, such that at least a portion of the bale falls by gravity away from the binding secured to the binding engagement device.

Owner:VERMEER MFG CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com