Bale processor and binding remover

A technology of binding and bag processing, applied in agricultural machinery and implements, packaging, loaders, etc., can solve the problems of difficult, difficult, time-consuming, etc. to completely remove the binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

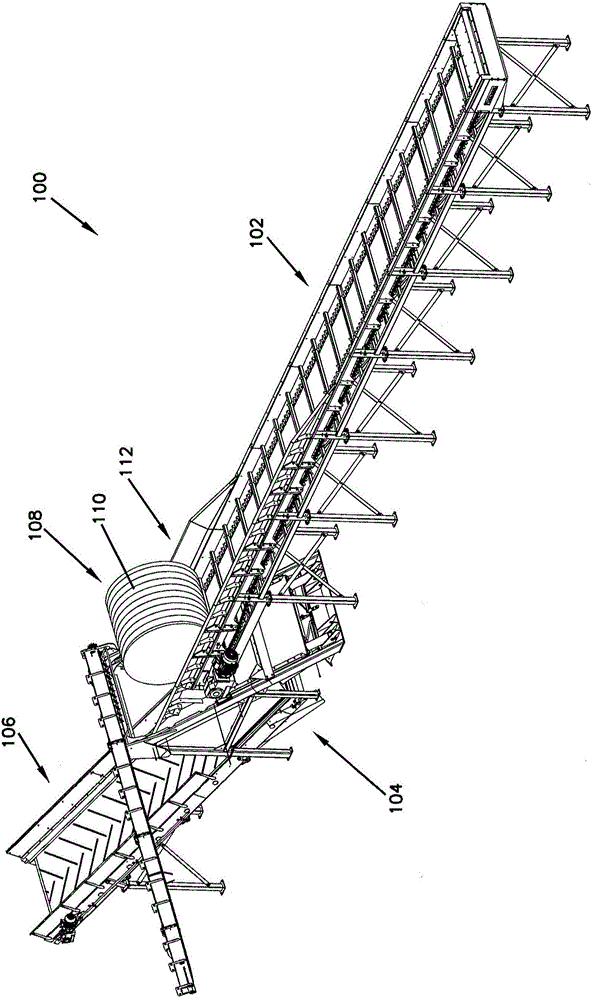

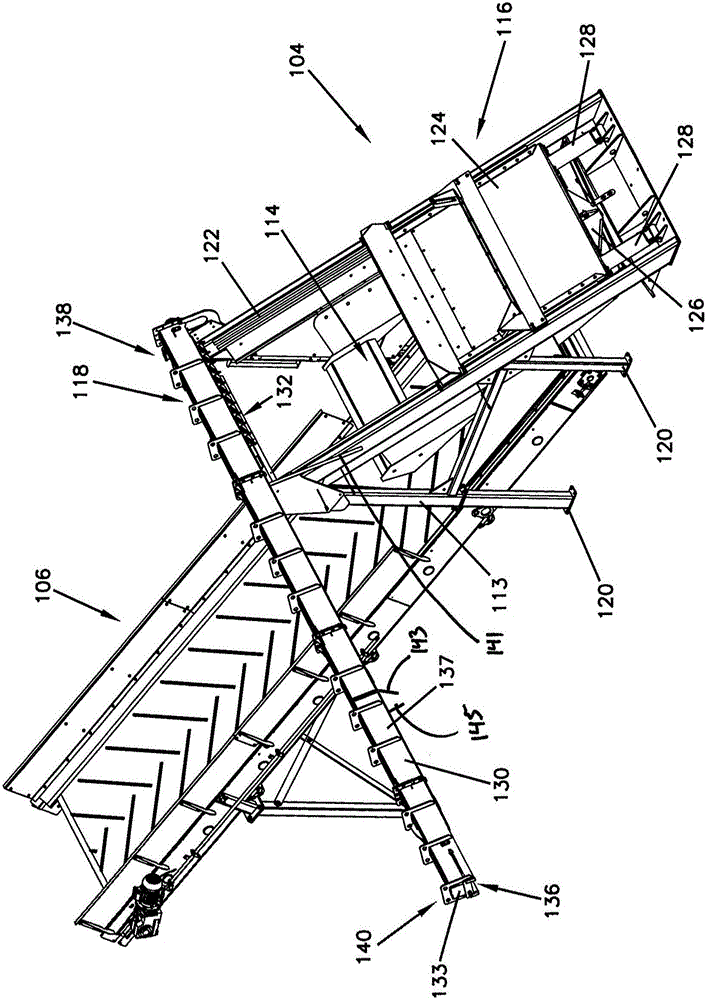

[0048] Various embodiments will be described in detail with reference to the drawings, wherein like reference numerals indicate like parts and assemblies throughout the several views. Reference to various embodiments does not limit the scope of the claims associated therewith. Additionally, any examples set forth herein are not to be considered limiting and merely set forth some of the many possible embodiments for the appended claims.

[0049] The bale handling machinery disclosed herein has several advantages. Bale handling machinery is configured to process large quantities of bales quickly with less downtime. Additionally, the bale handling machinery can handle a variety of different sized bales. Bale handling machinery removes bale quickly and efficiently by lifting the bale and removing the weight of the bale from the bale during handling to allow complete removal of the bale by the machine. Additionally, the bale handling machinery also handles the bale by separating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com