Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1272results about "Unpacking by cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

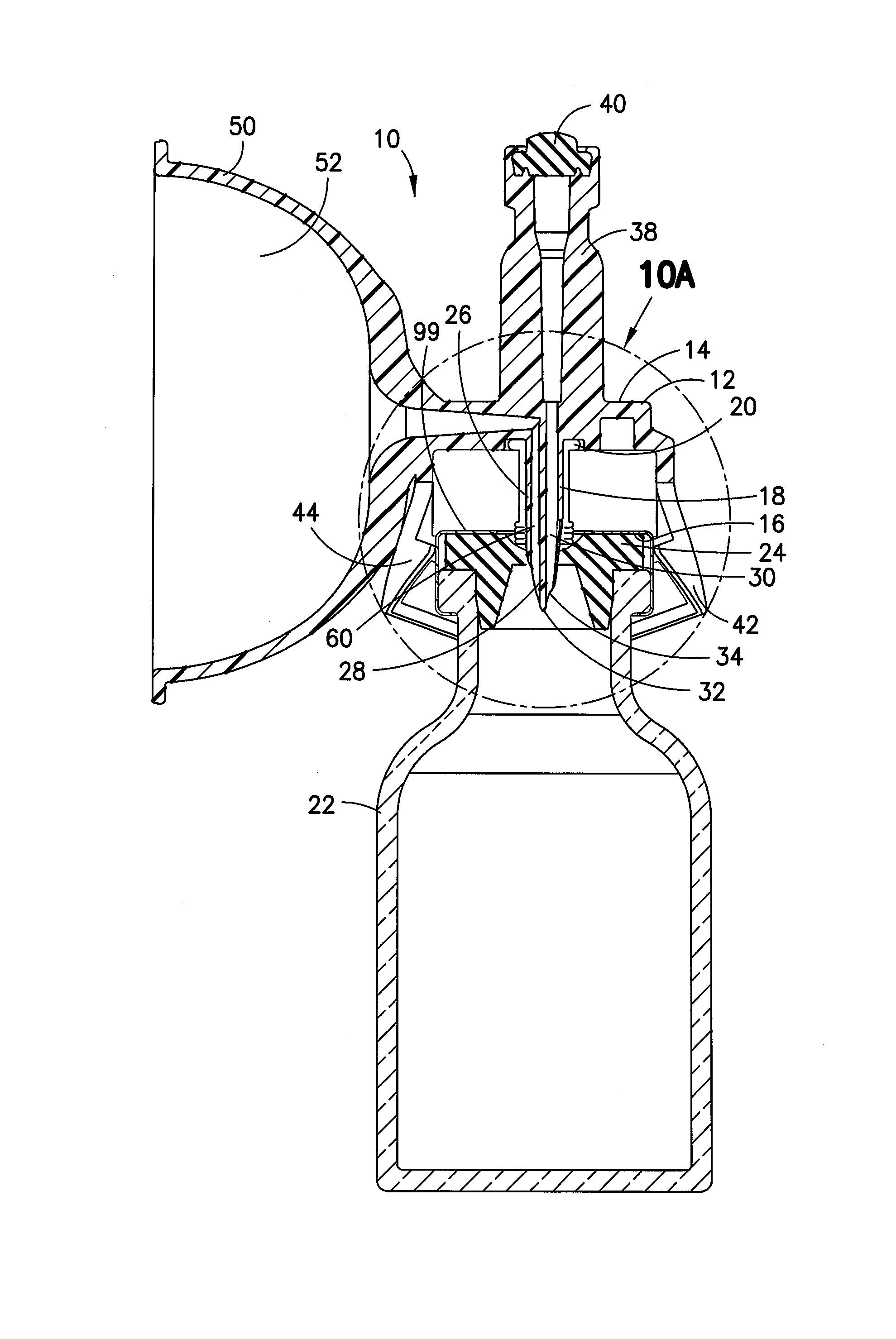

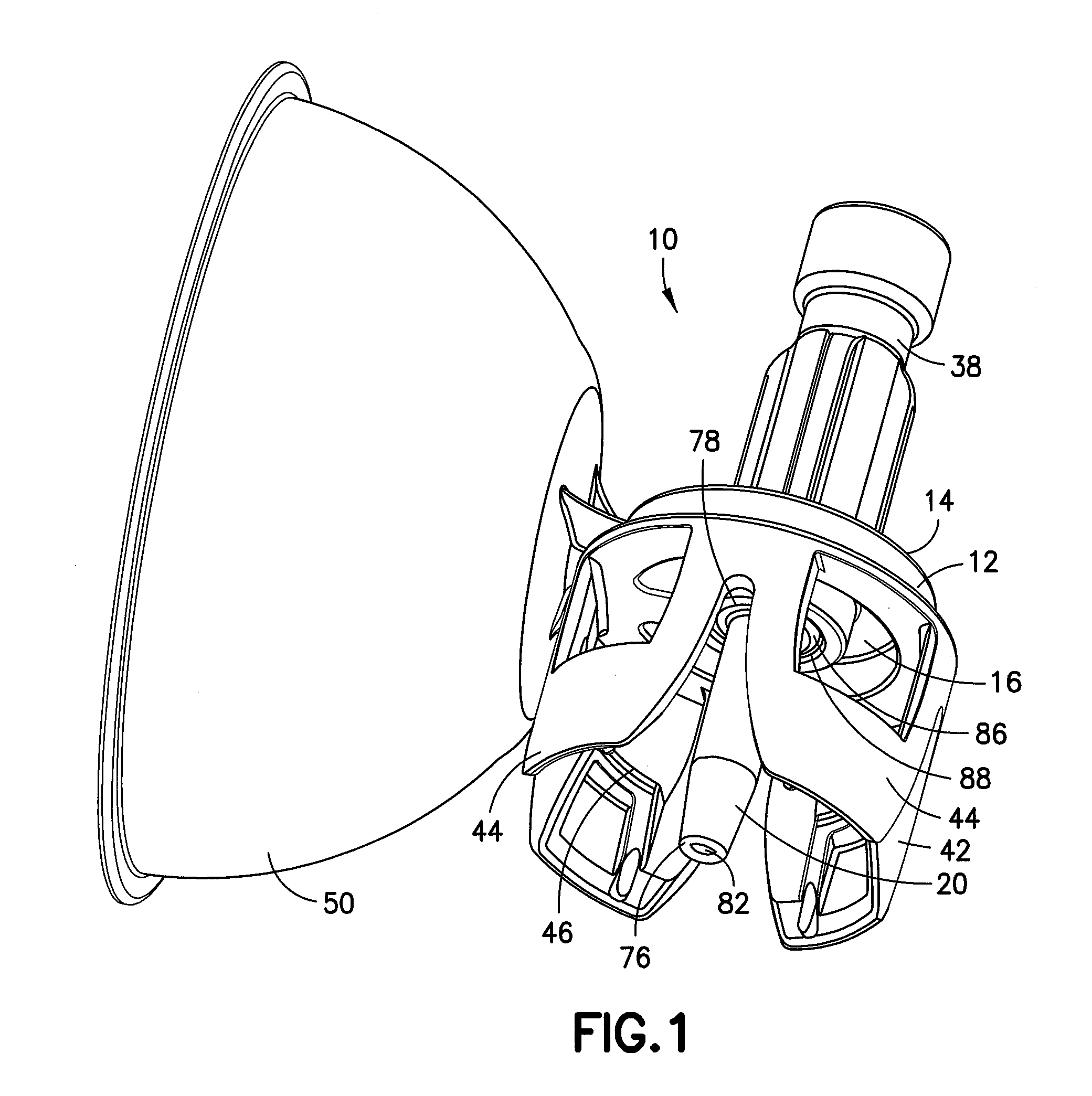

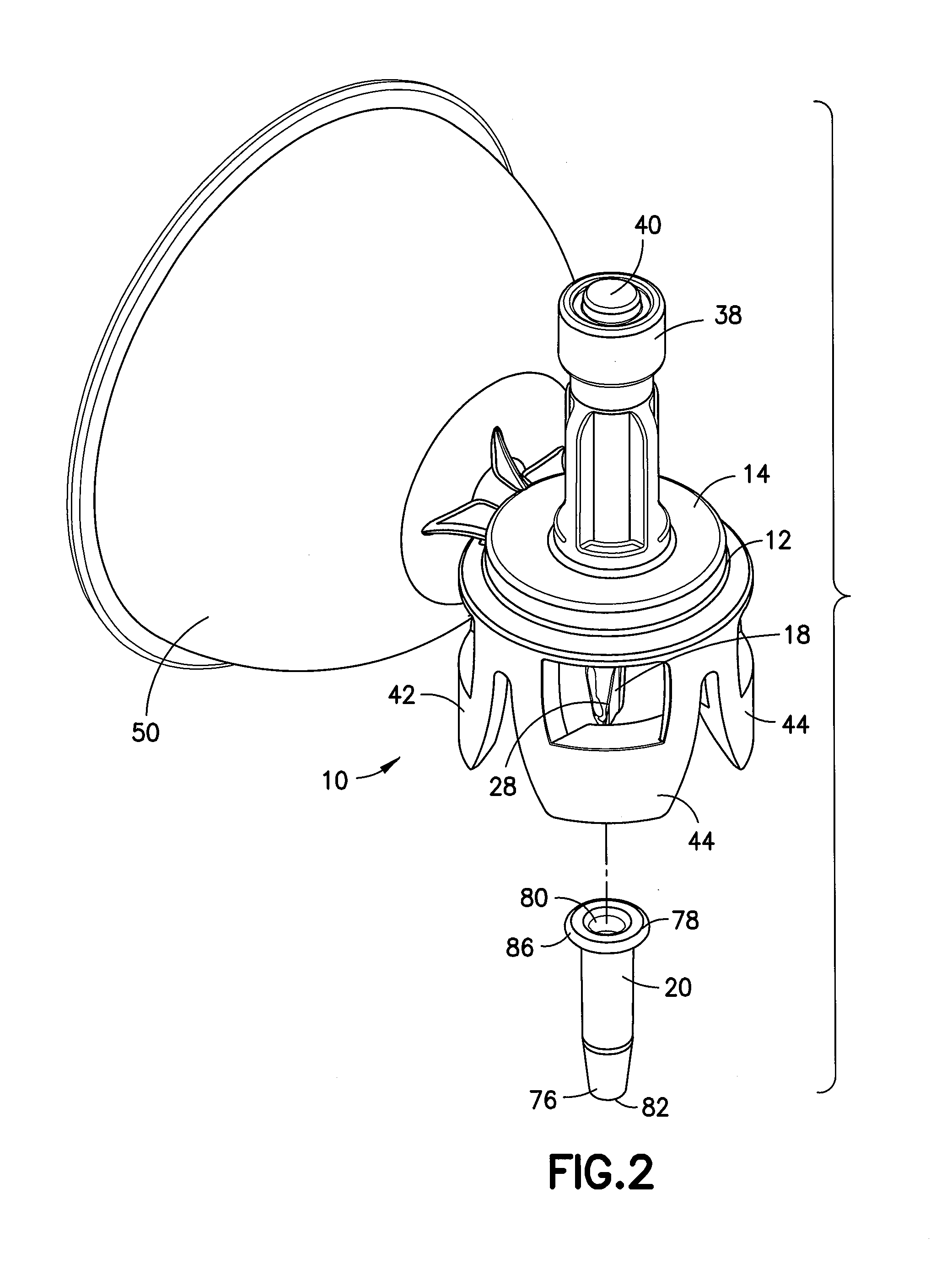

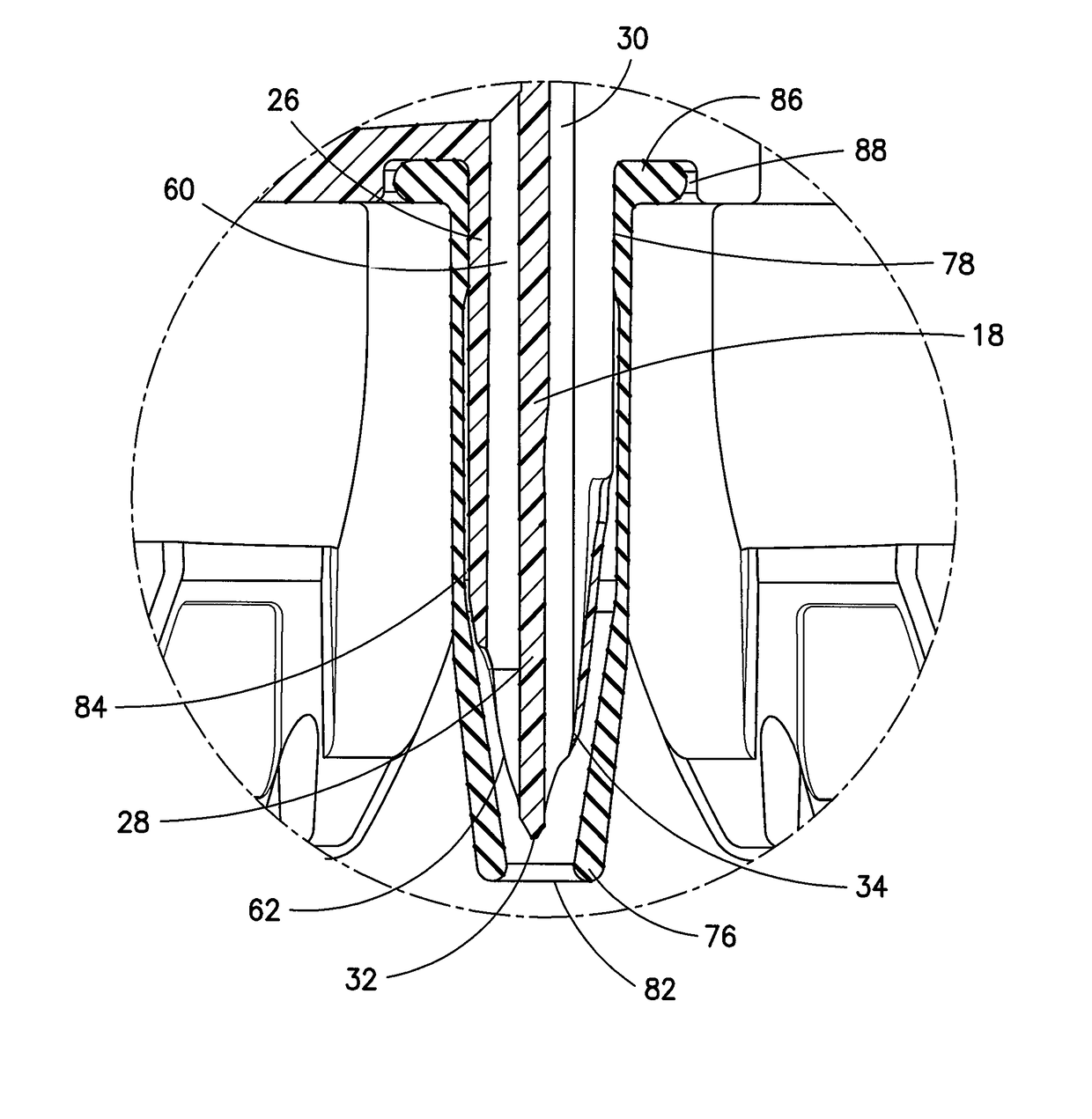

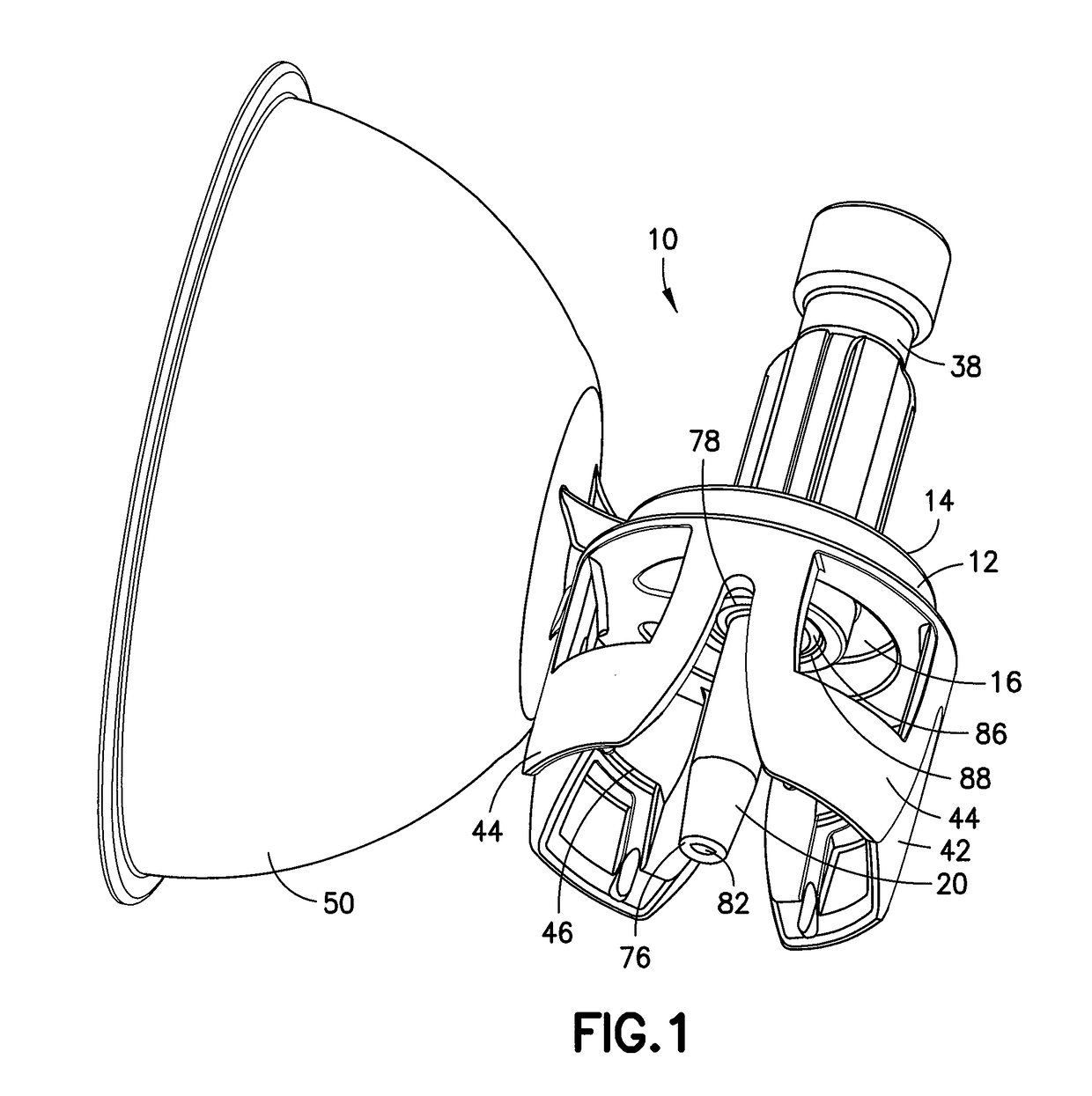

Piercing Member for Container Access Device

ActiveUS20150082746A1Reduce decreaseReduce penetrationInfusion devicesPharmaceutical containersBiomedical engineering

Owner:BECTON DICKINSON & CO

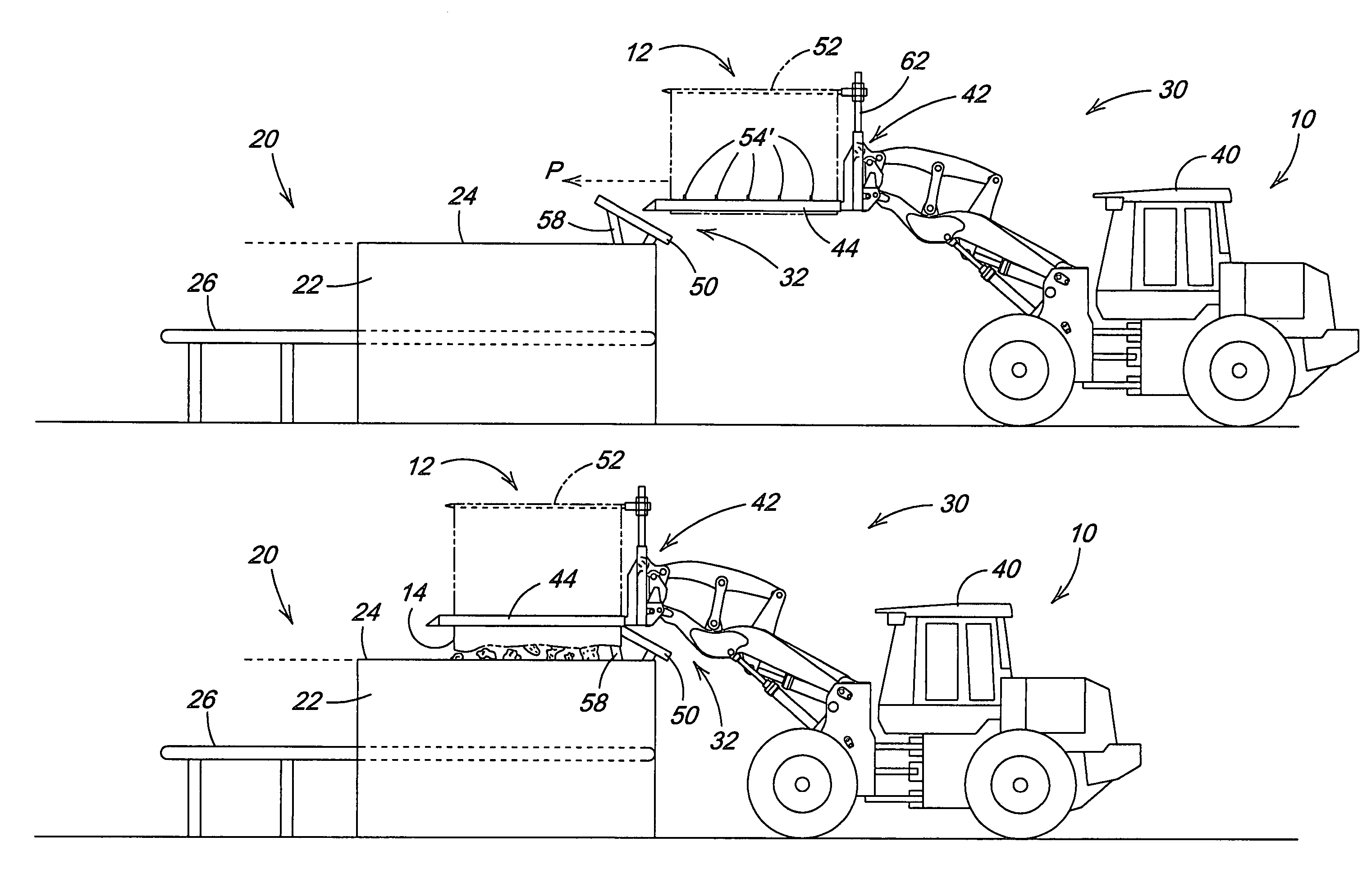

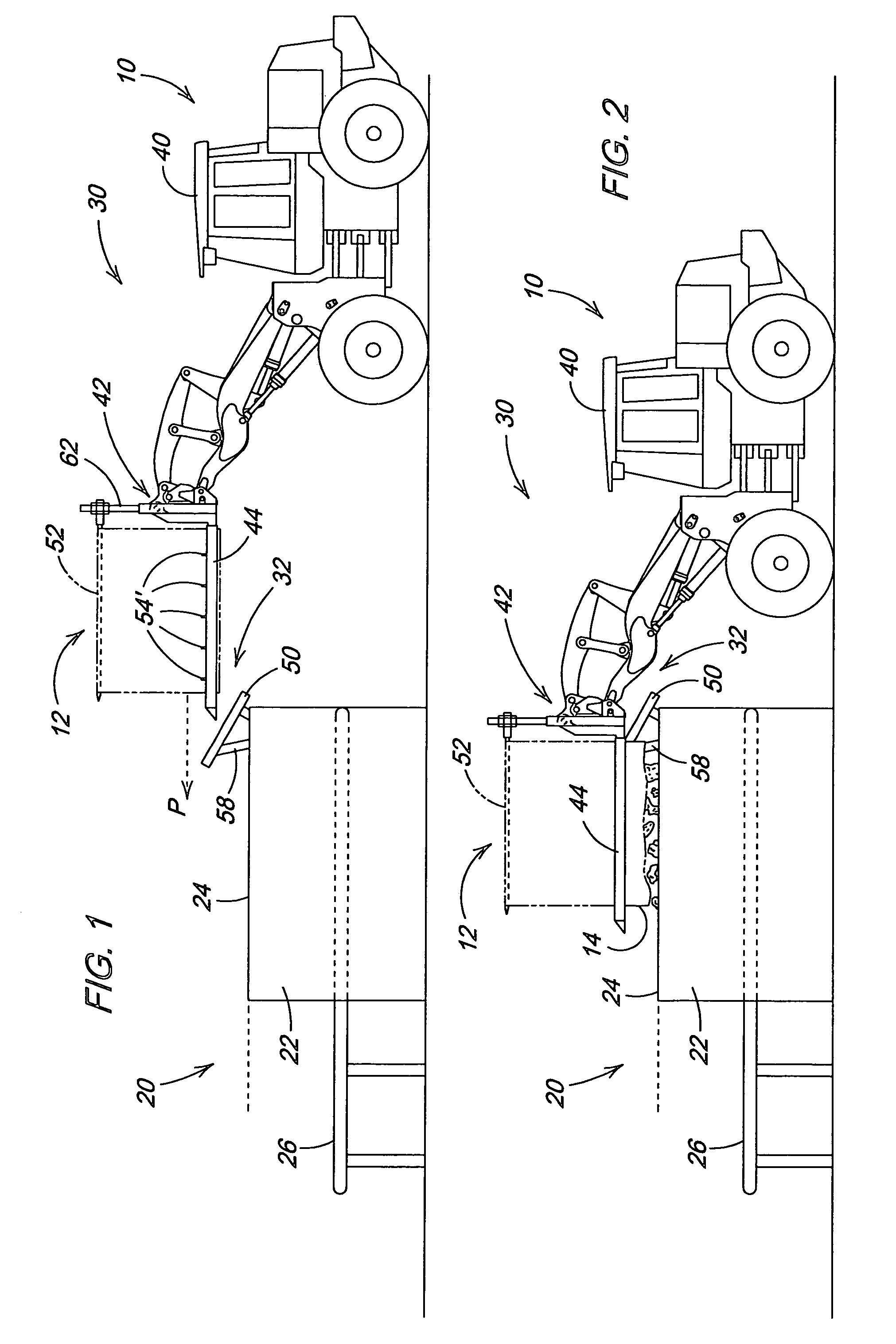

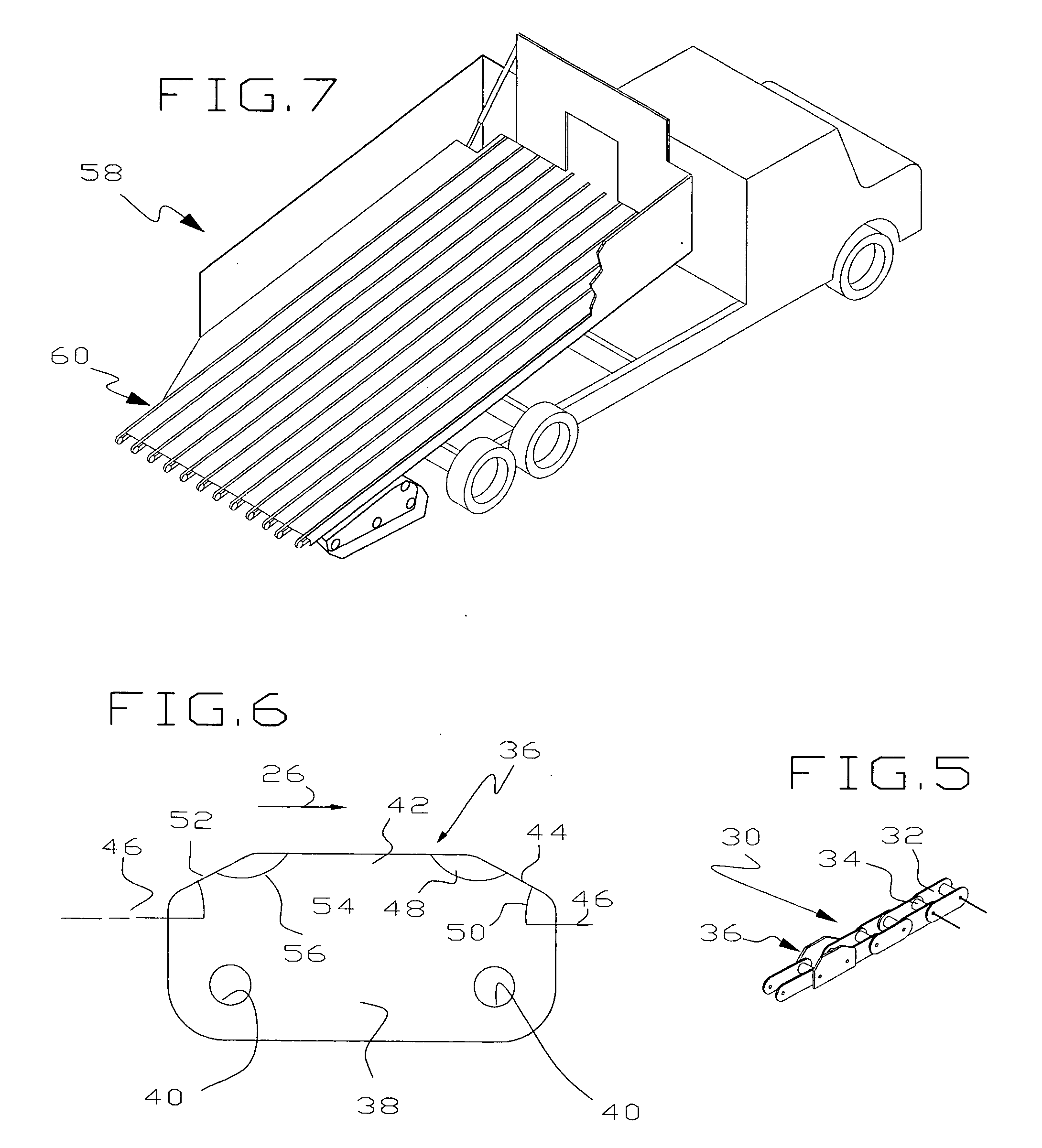

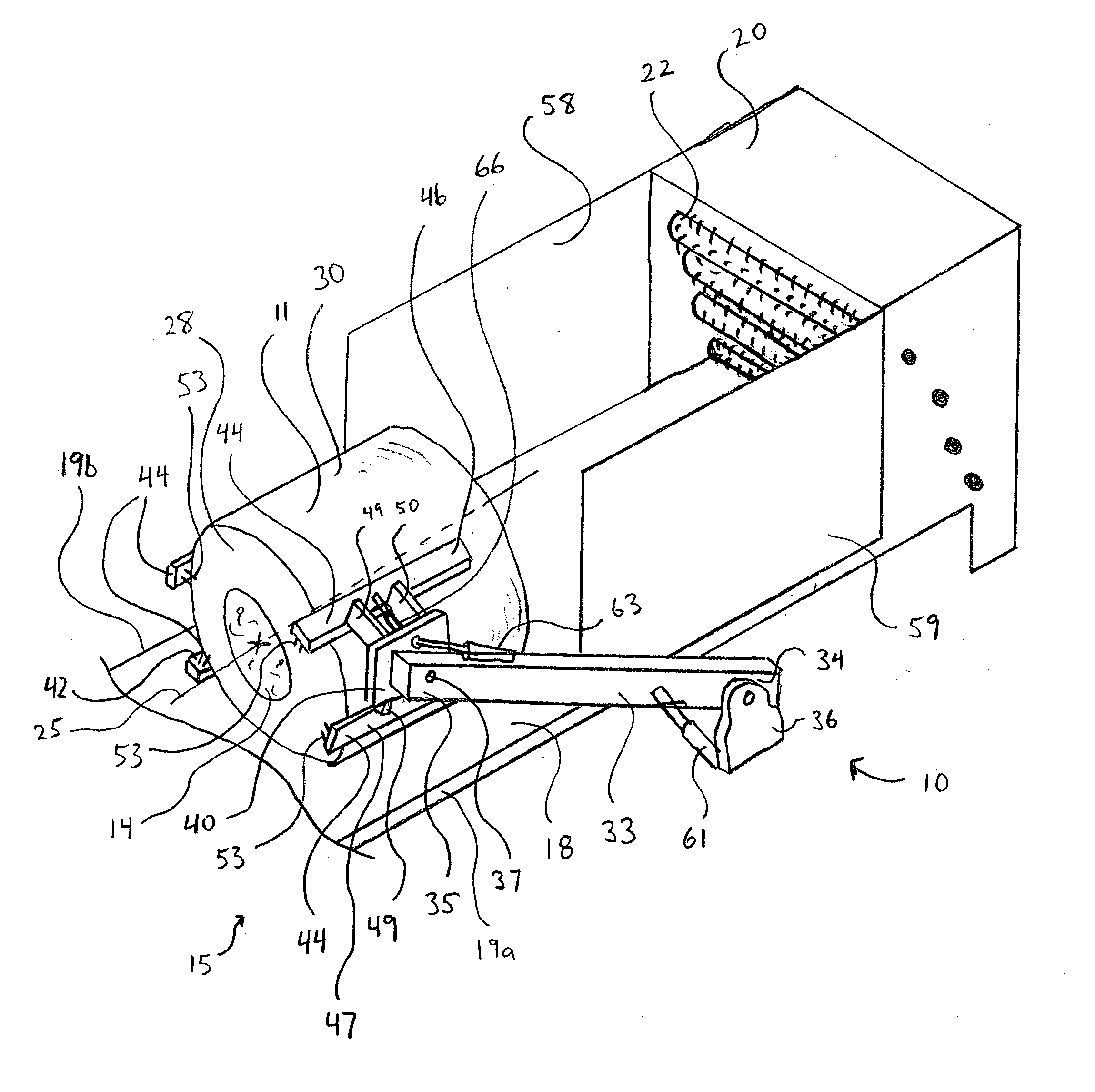

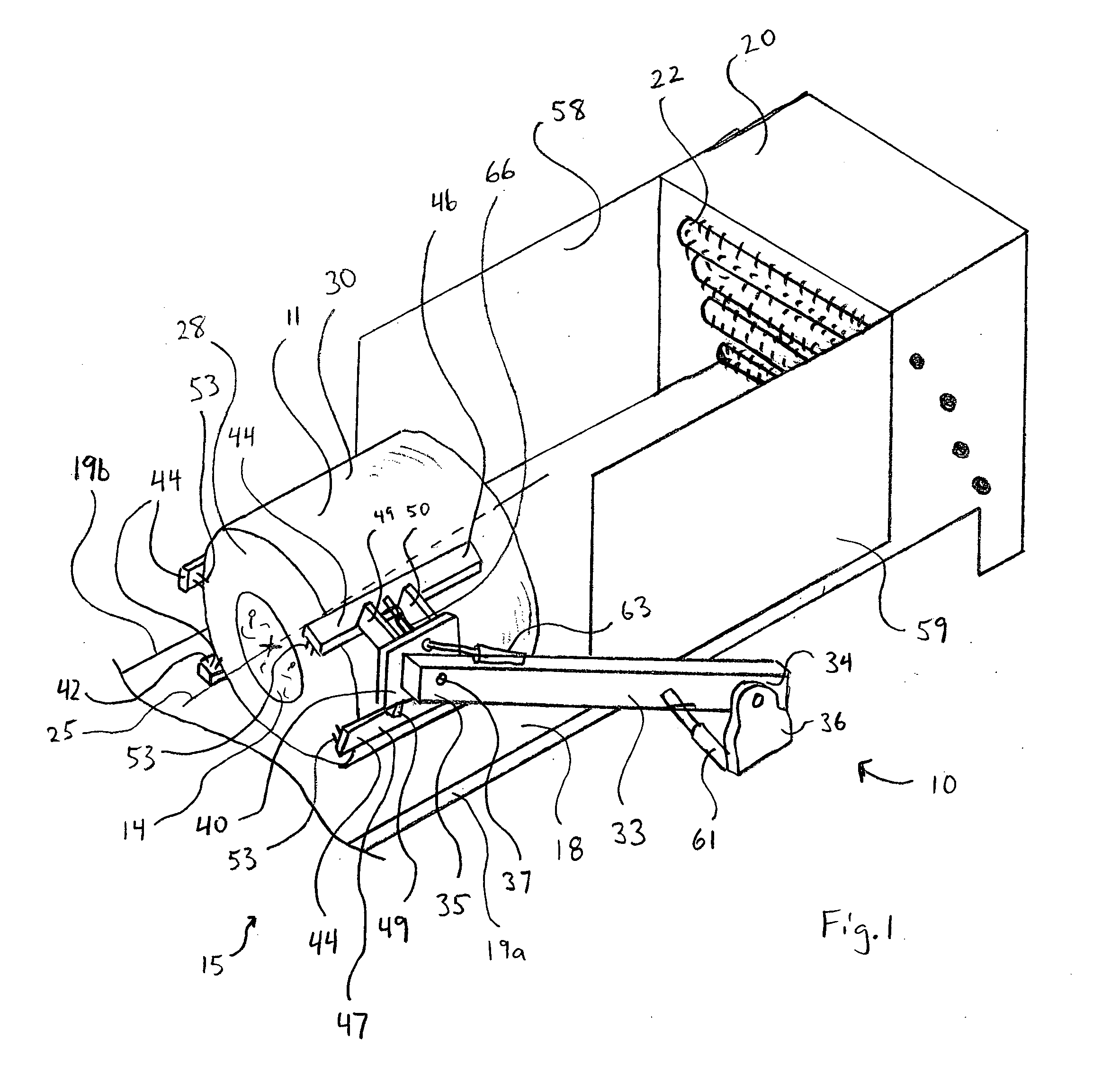

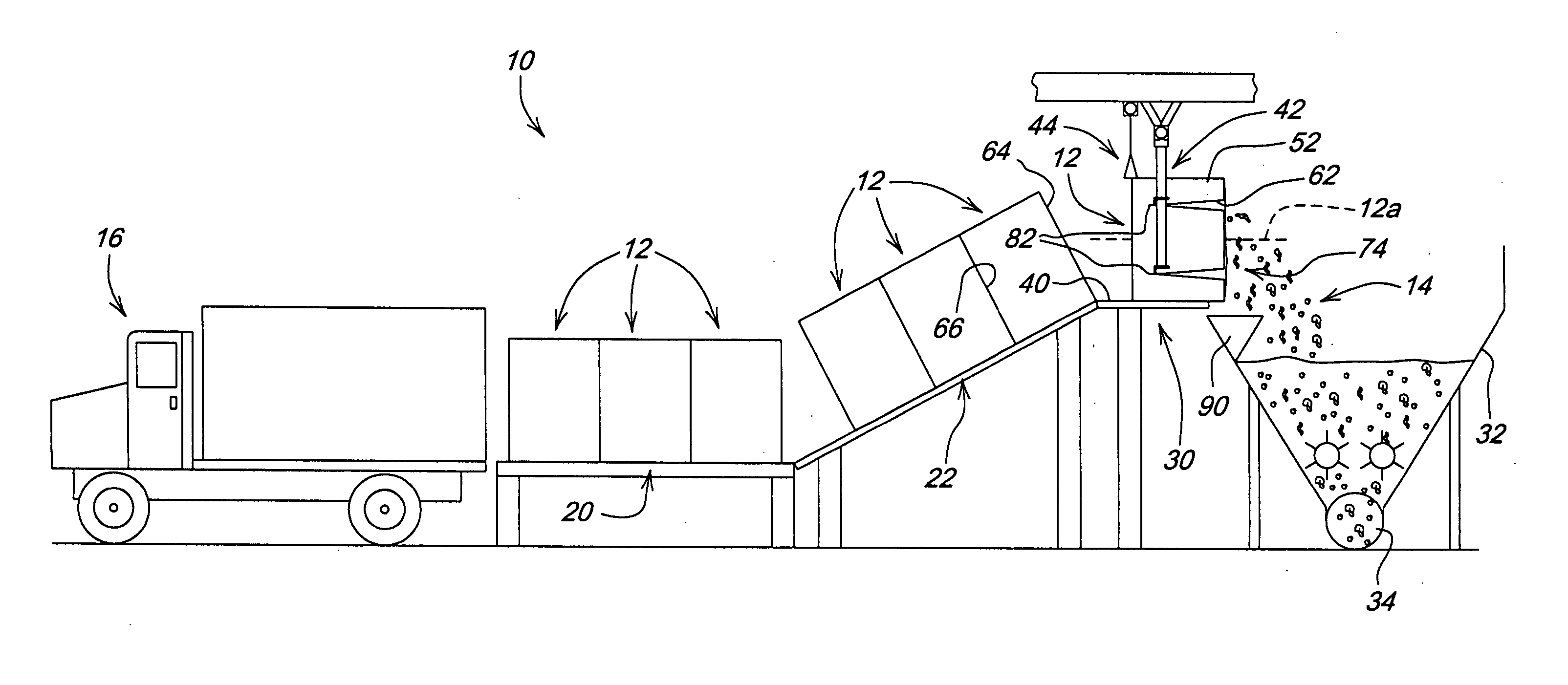

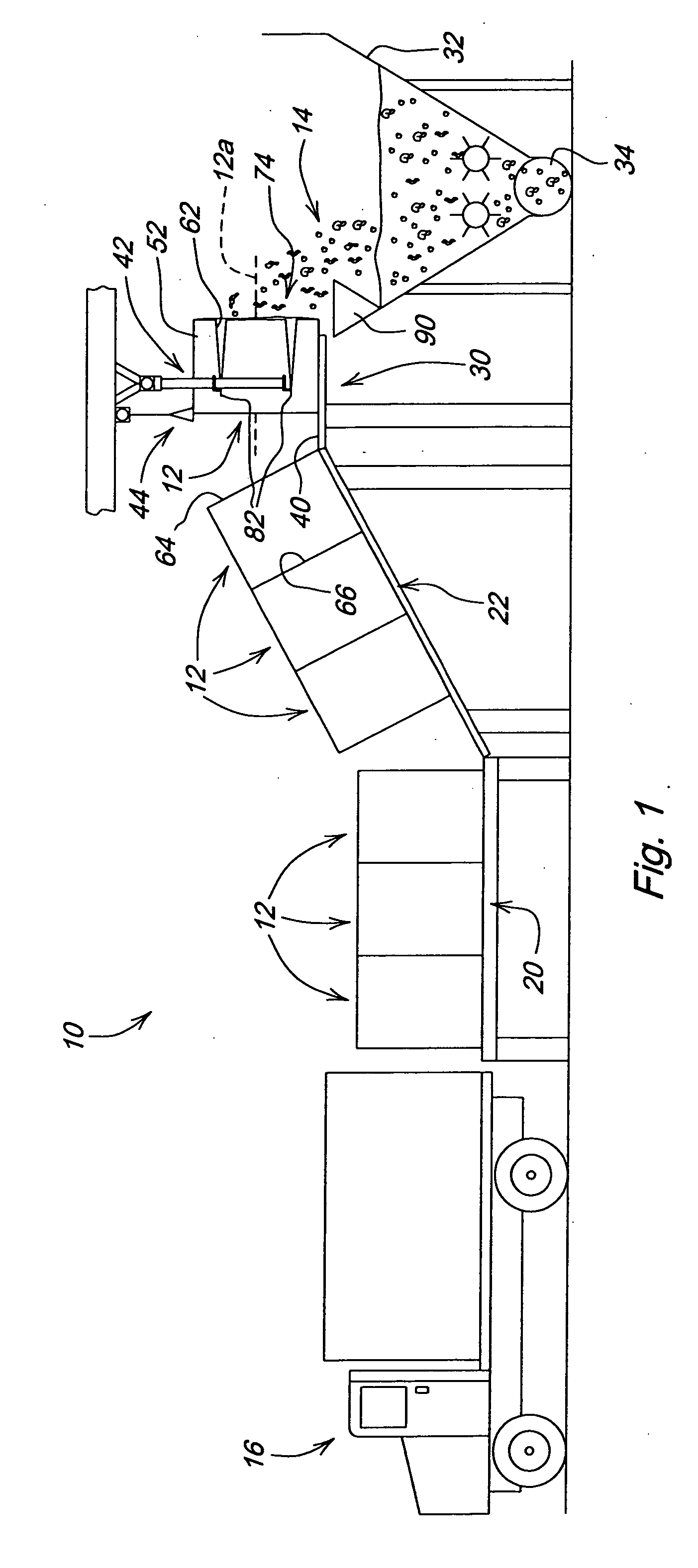

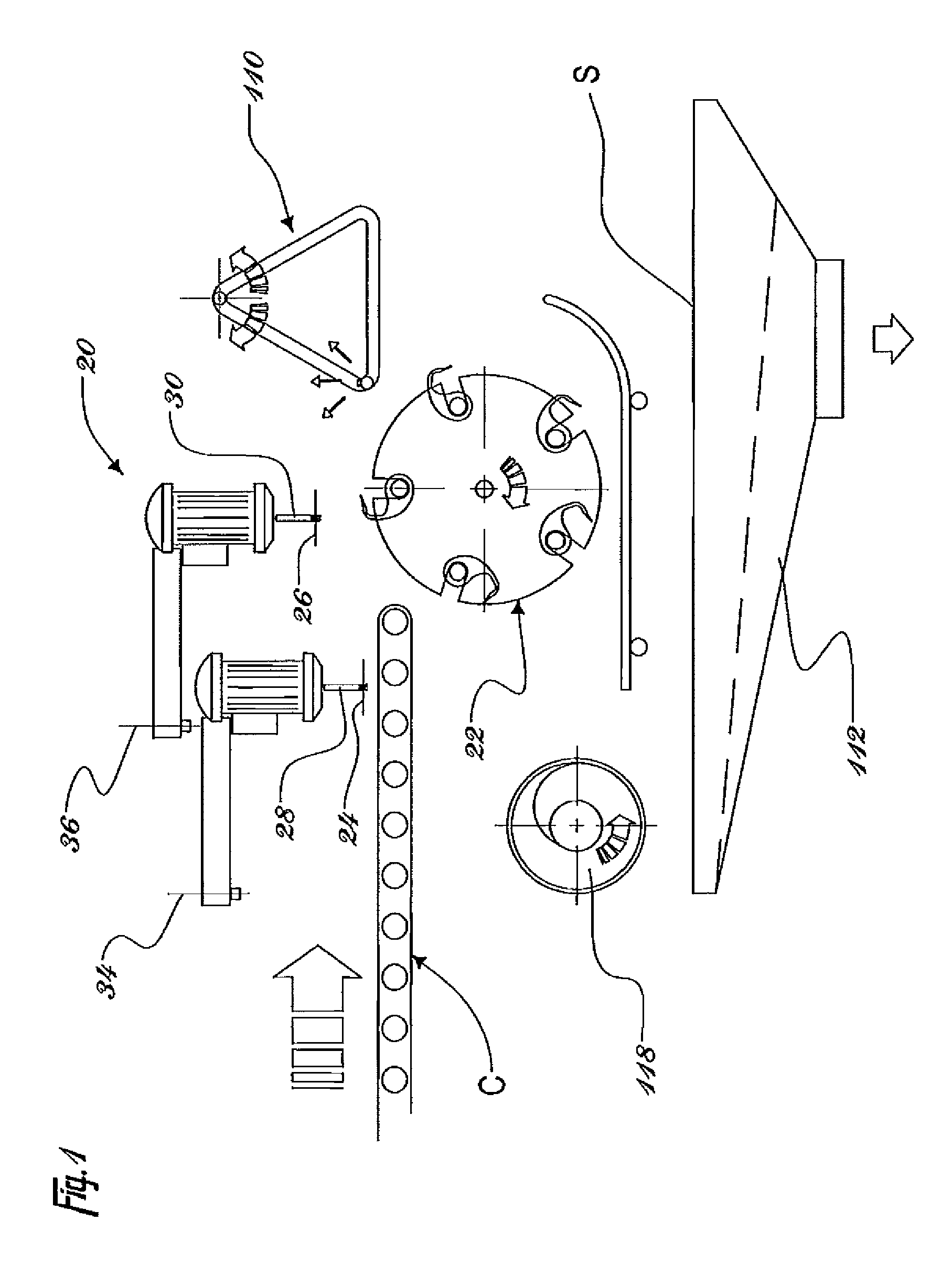

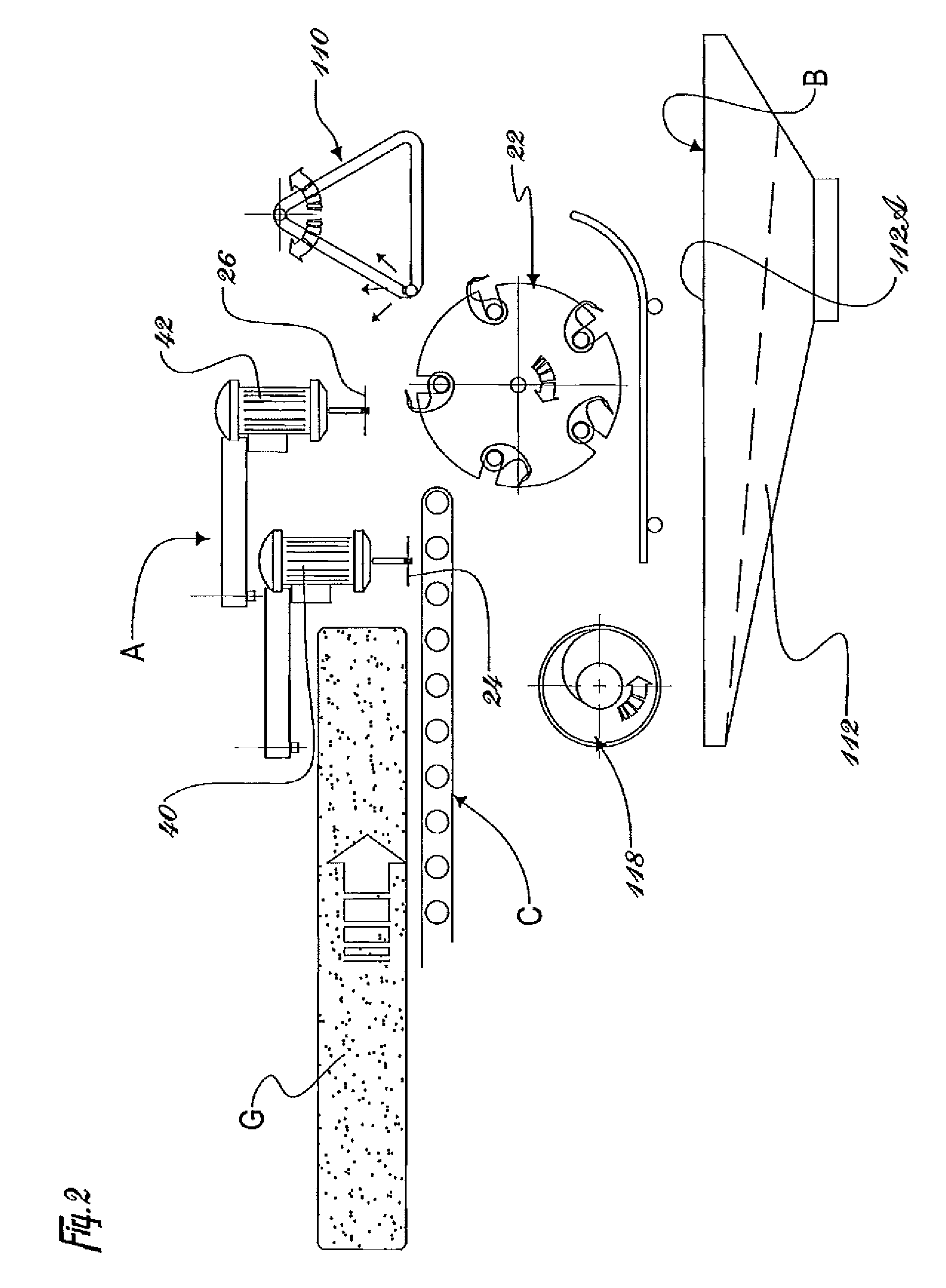

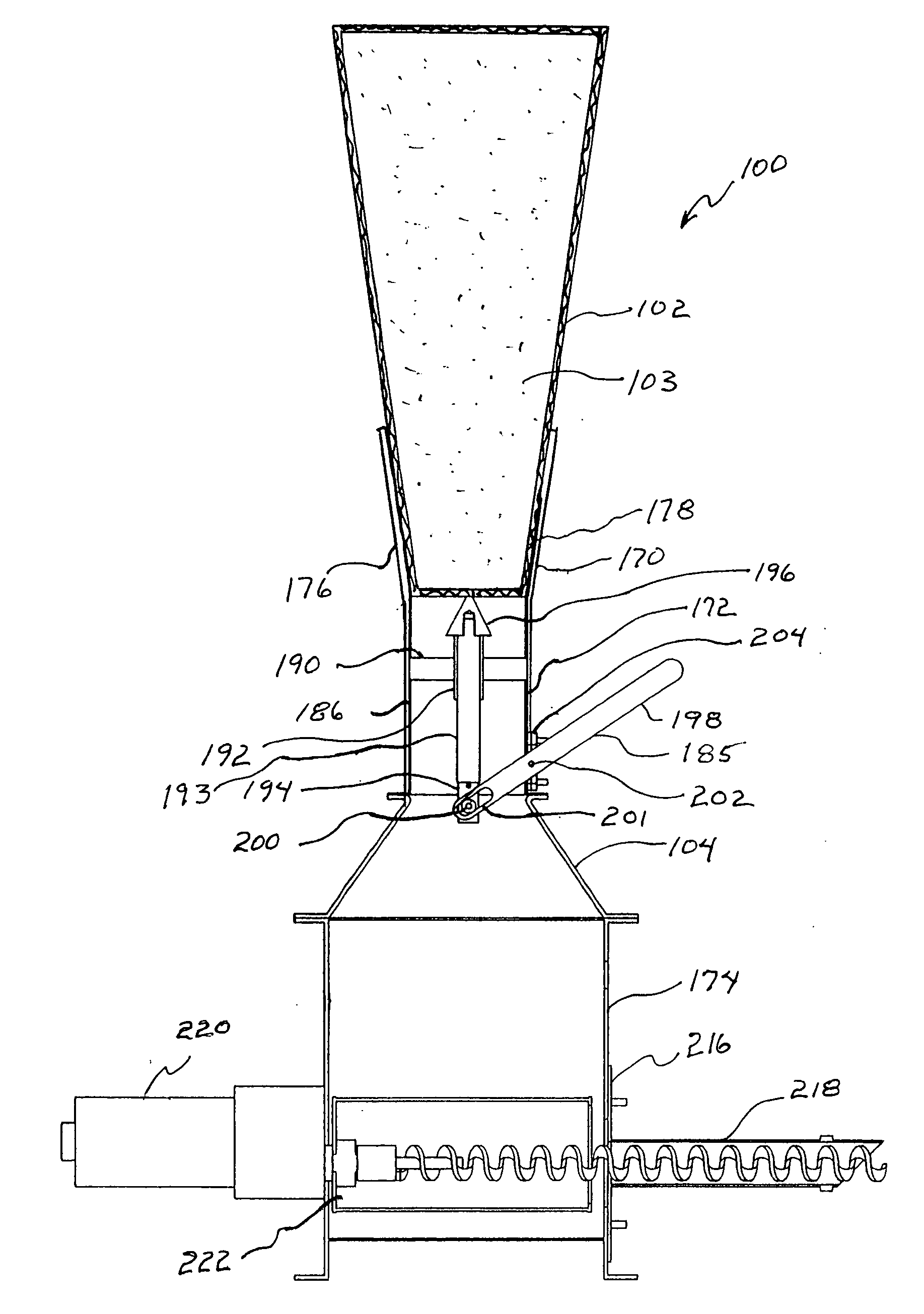

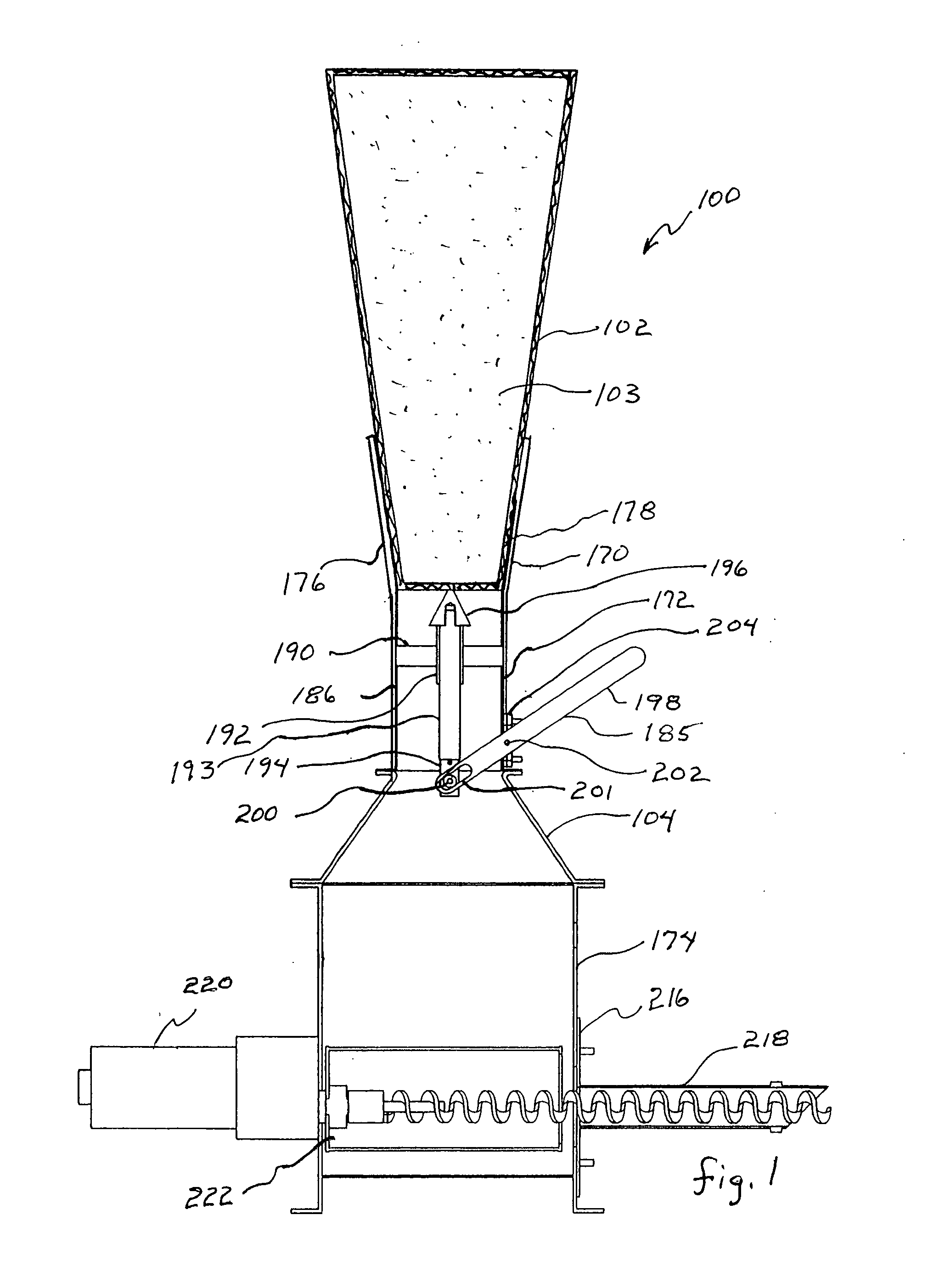

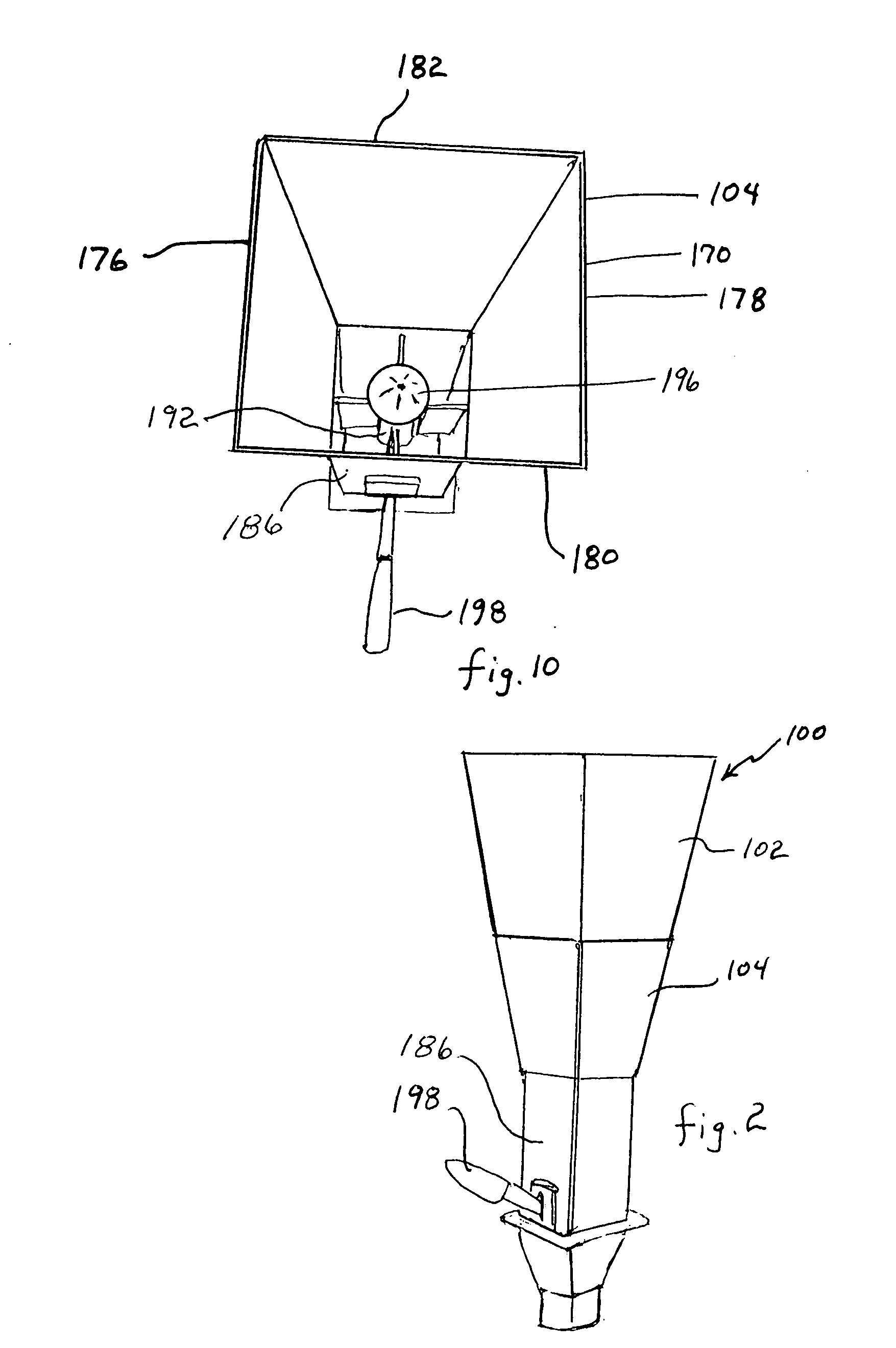

Seed cotton handling system

InactiveUS7165928B2Effective conveying and wrap cutting systemEconomical and easy to useLoadersLifting devicesHandling systemCantilever

Owner:DEERE & CO

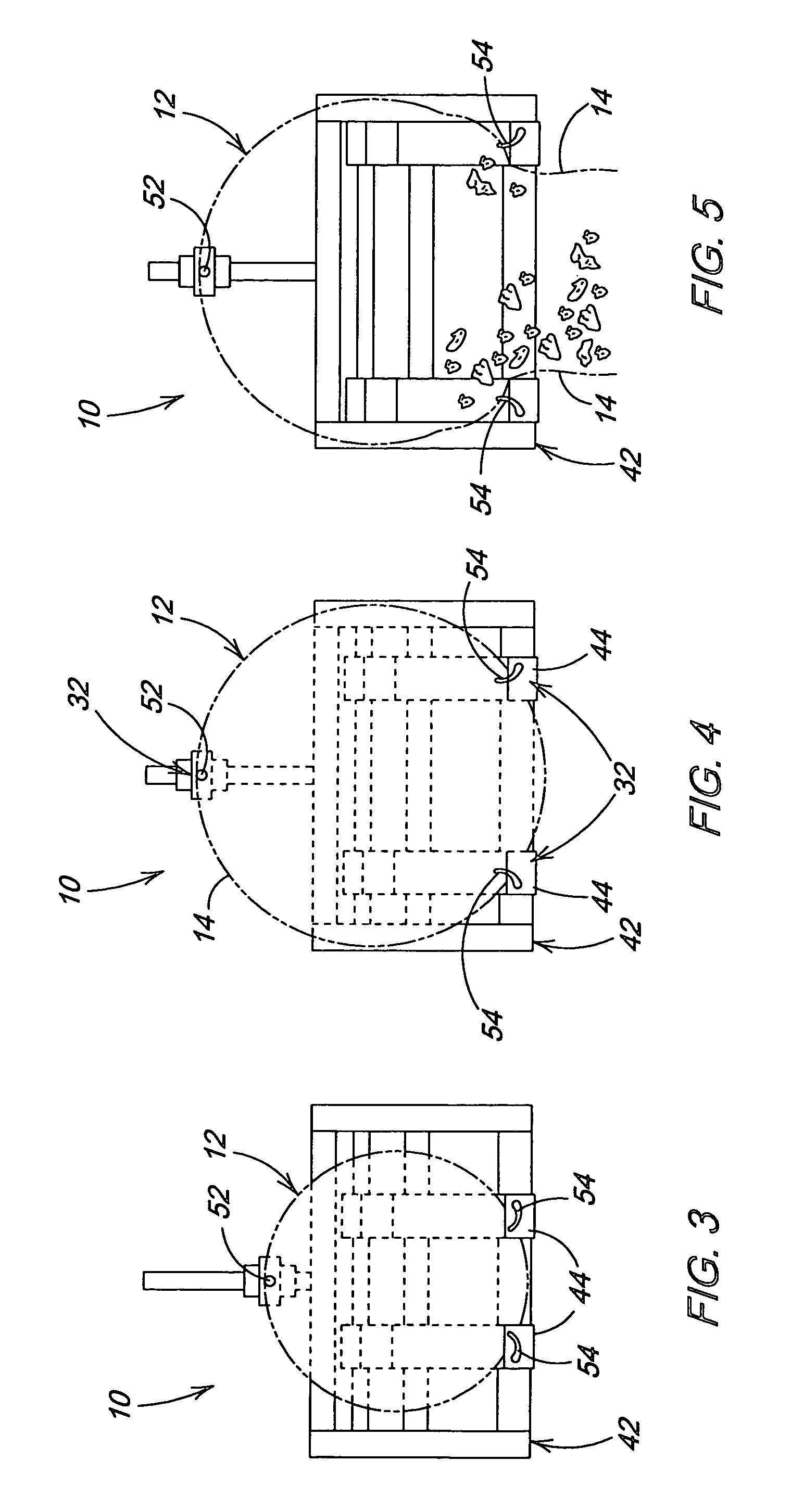

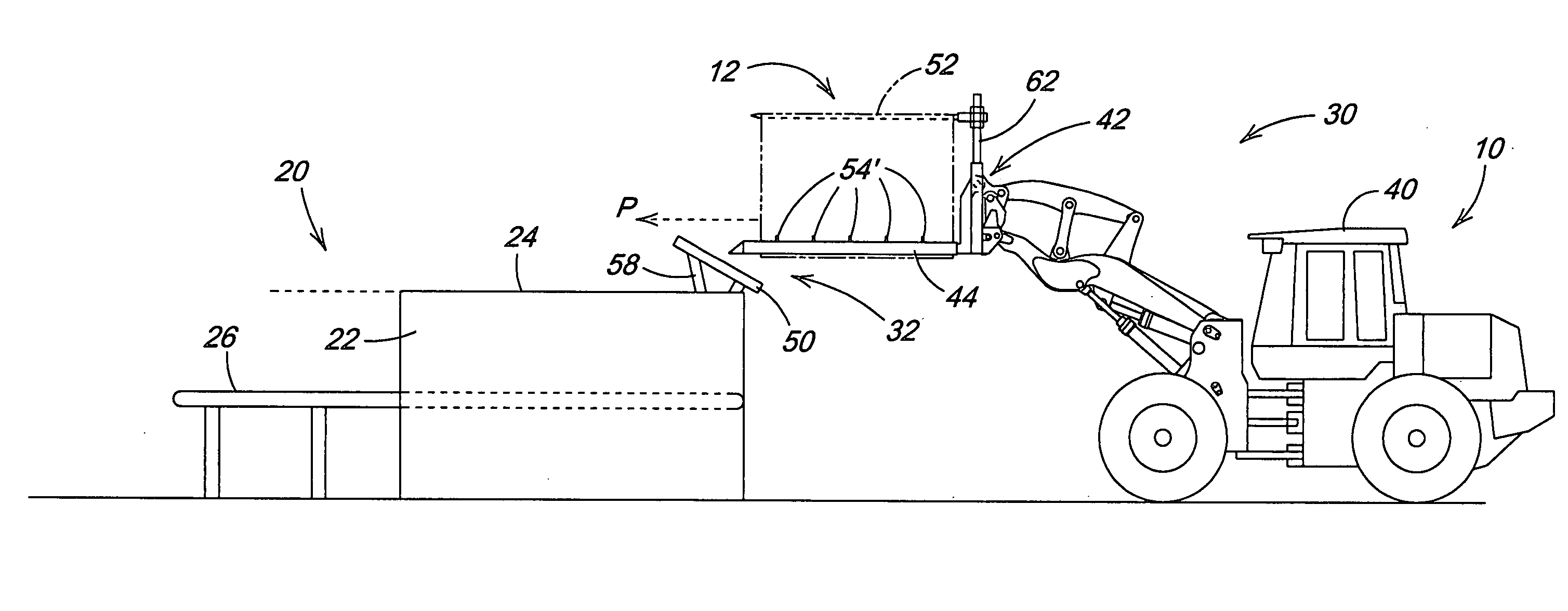

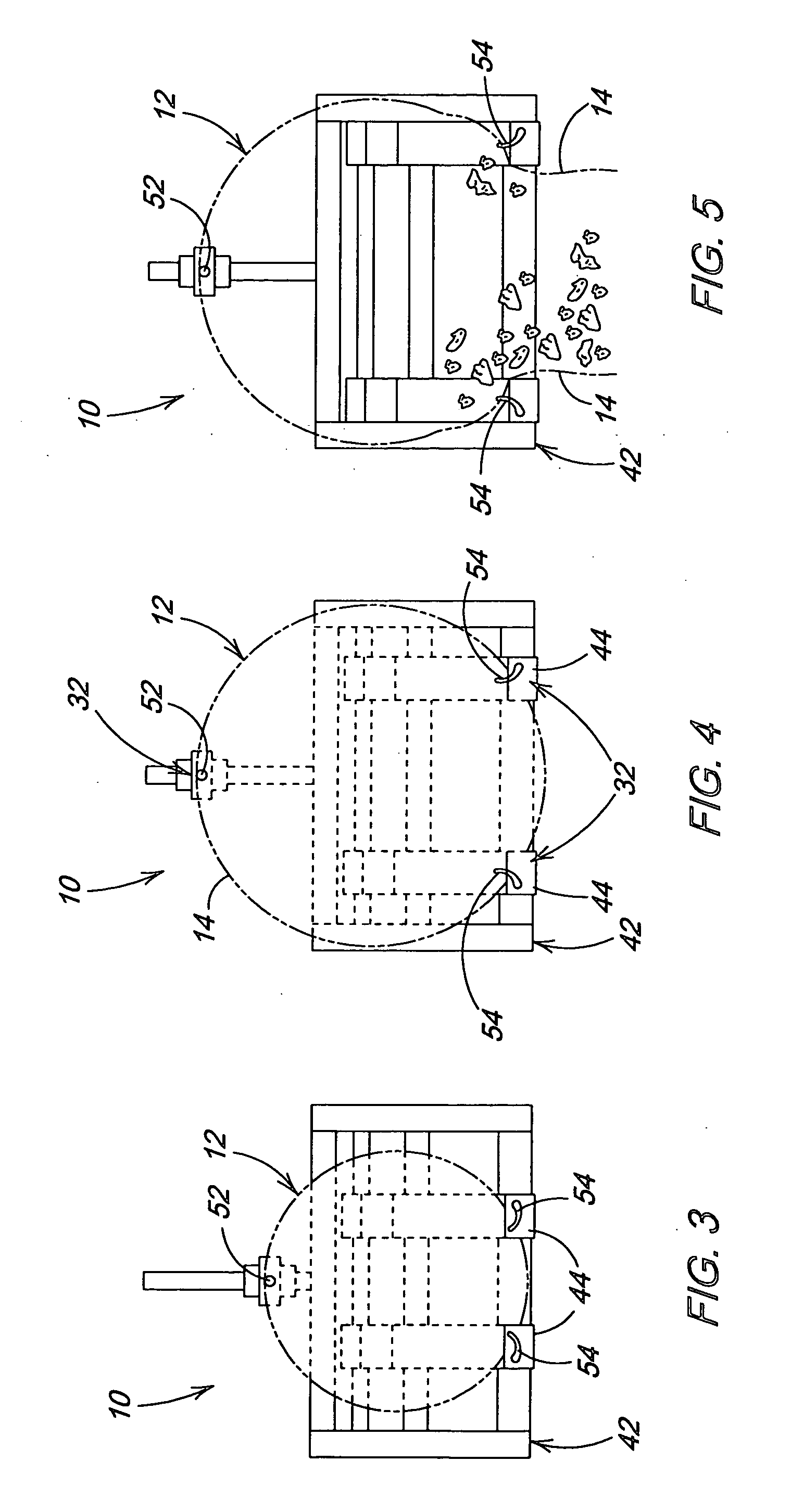

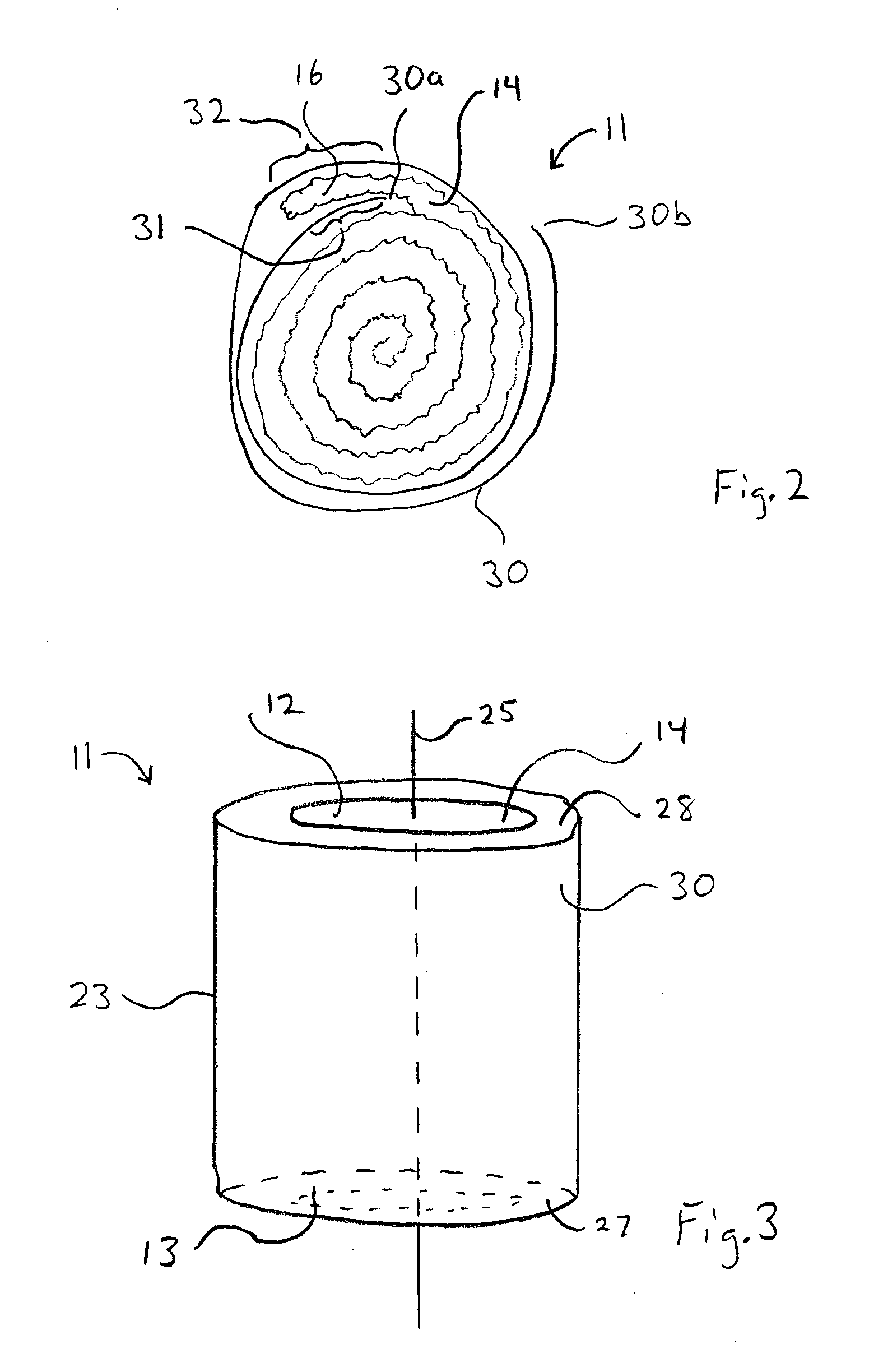

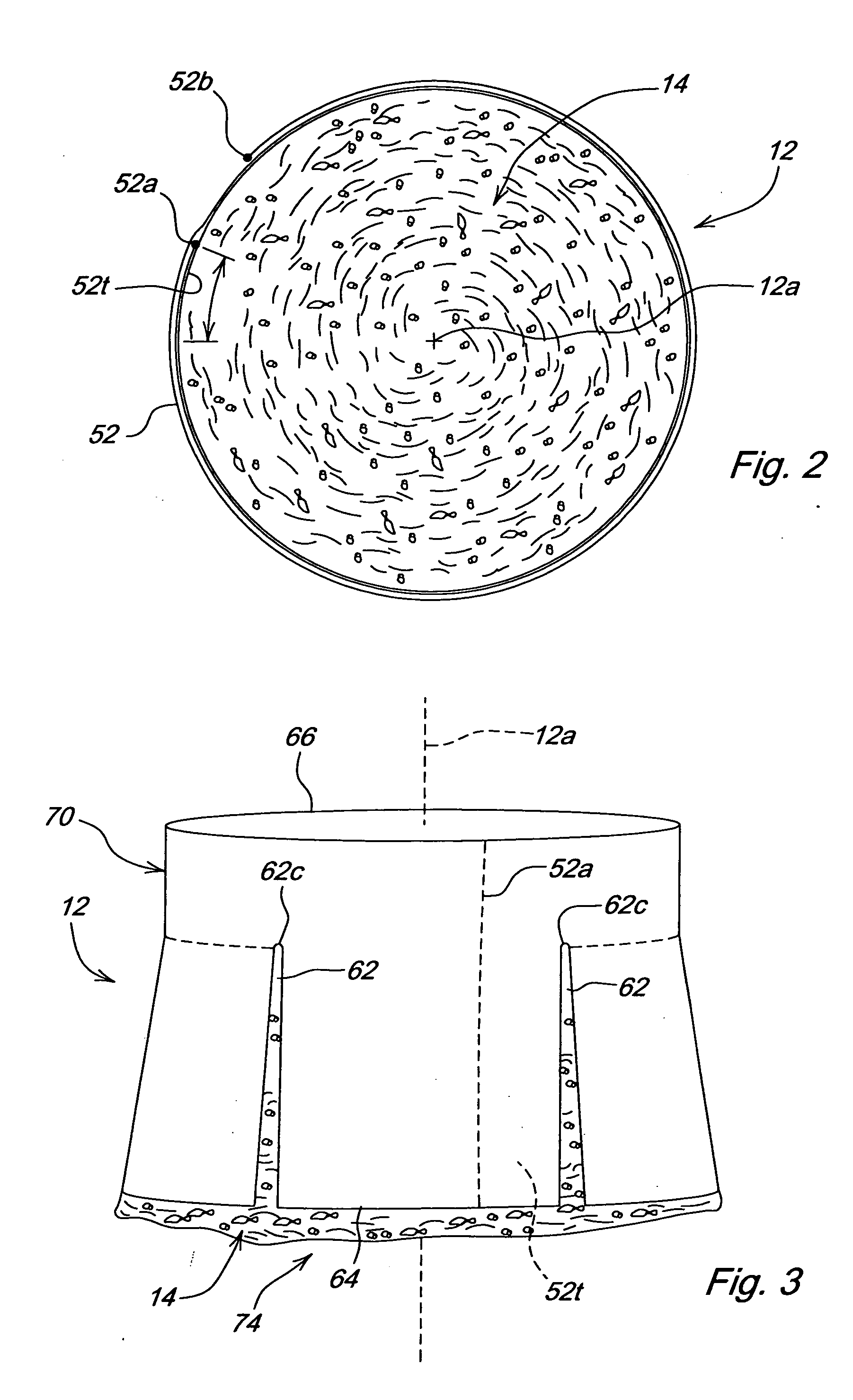

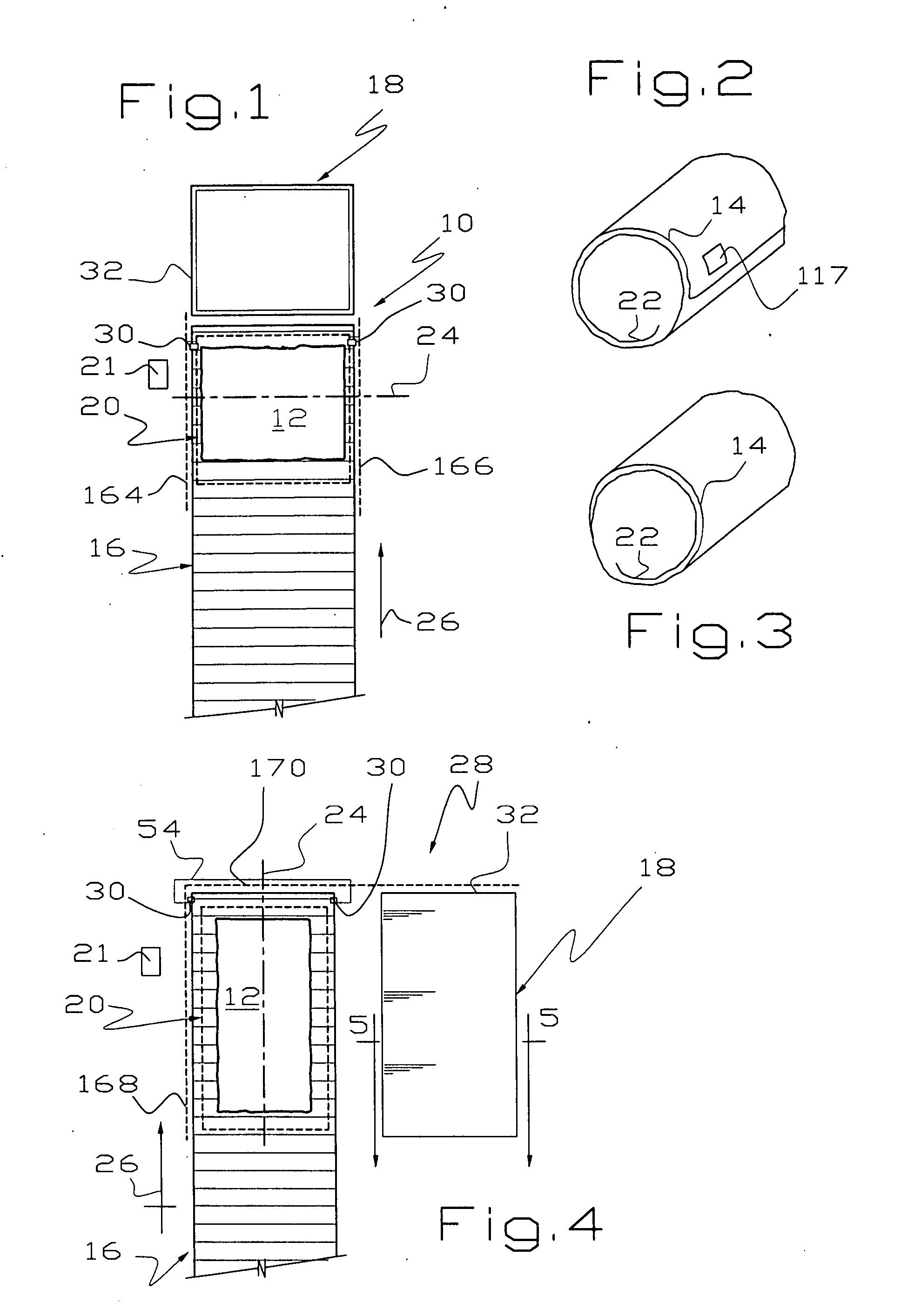

Technique for removing a cover from cylindrical modules

In one embodiment, a system for removing a plastic wrap from a cylindrical module includes a conveyor transporting the cylindrical module toward a disperser with the cylindrical axis of the module parallel to the direction of conveyor movement. In another embodiment, the disperser is a travelling head disperser thereby providing relative movement between the modules and the disperser. The direction of the wrap around the module is determined and the cover is removed during rotation of the module, either by unwrapping the plastic or by slitting the plastic and then rotating the module. The equipment used to handle a cylindrical module is moved out of the path of movement of a conventional rectangular module so an installation can handle both rectangular and wrapped cylindrical modules.

Owner:STOVER EQUIP

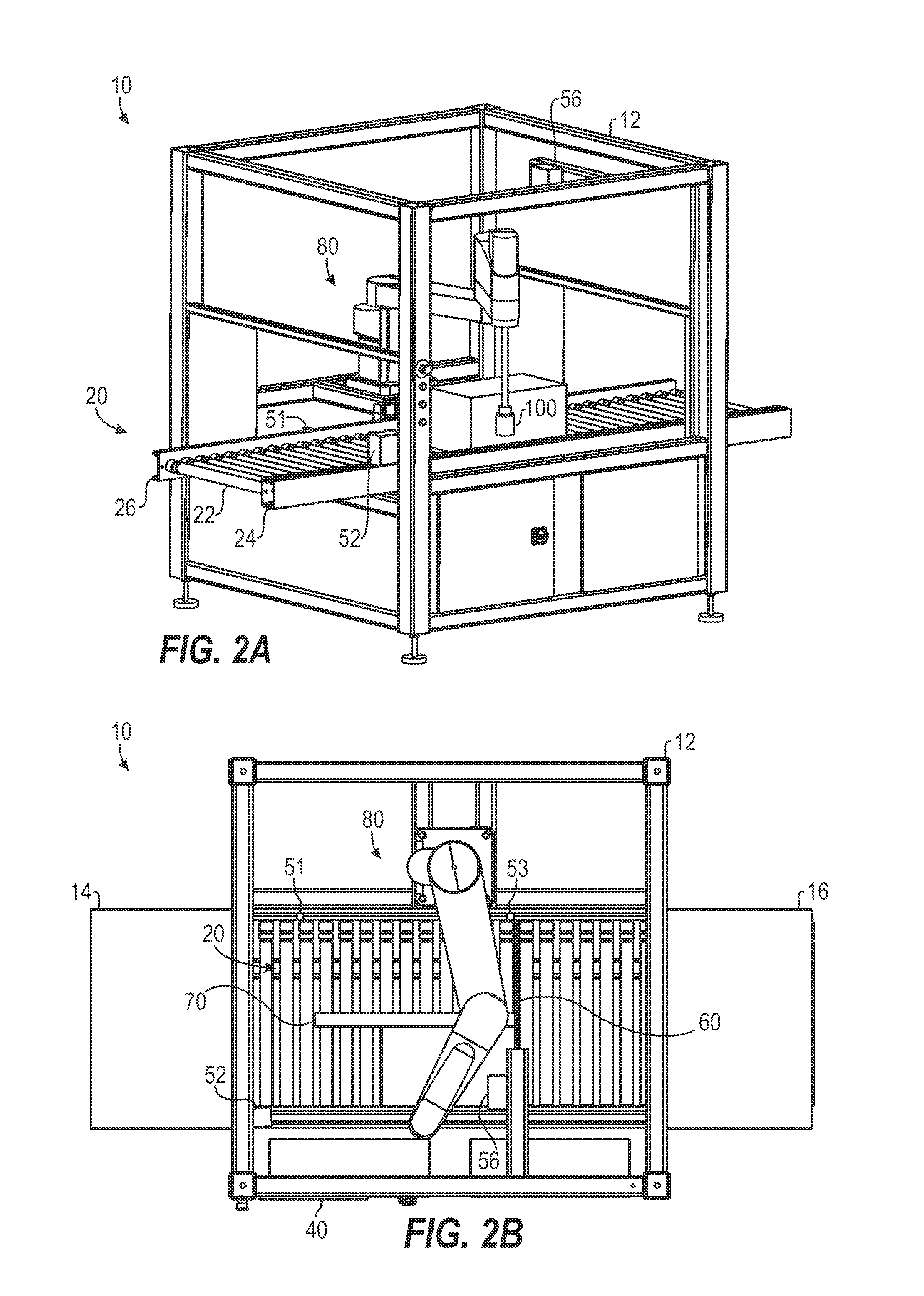

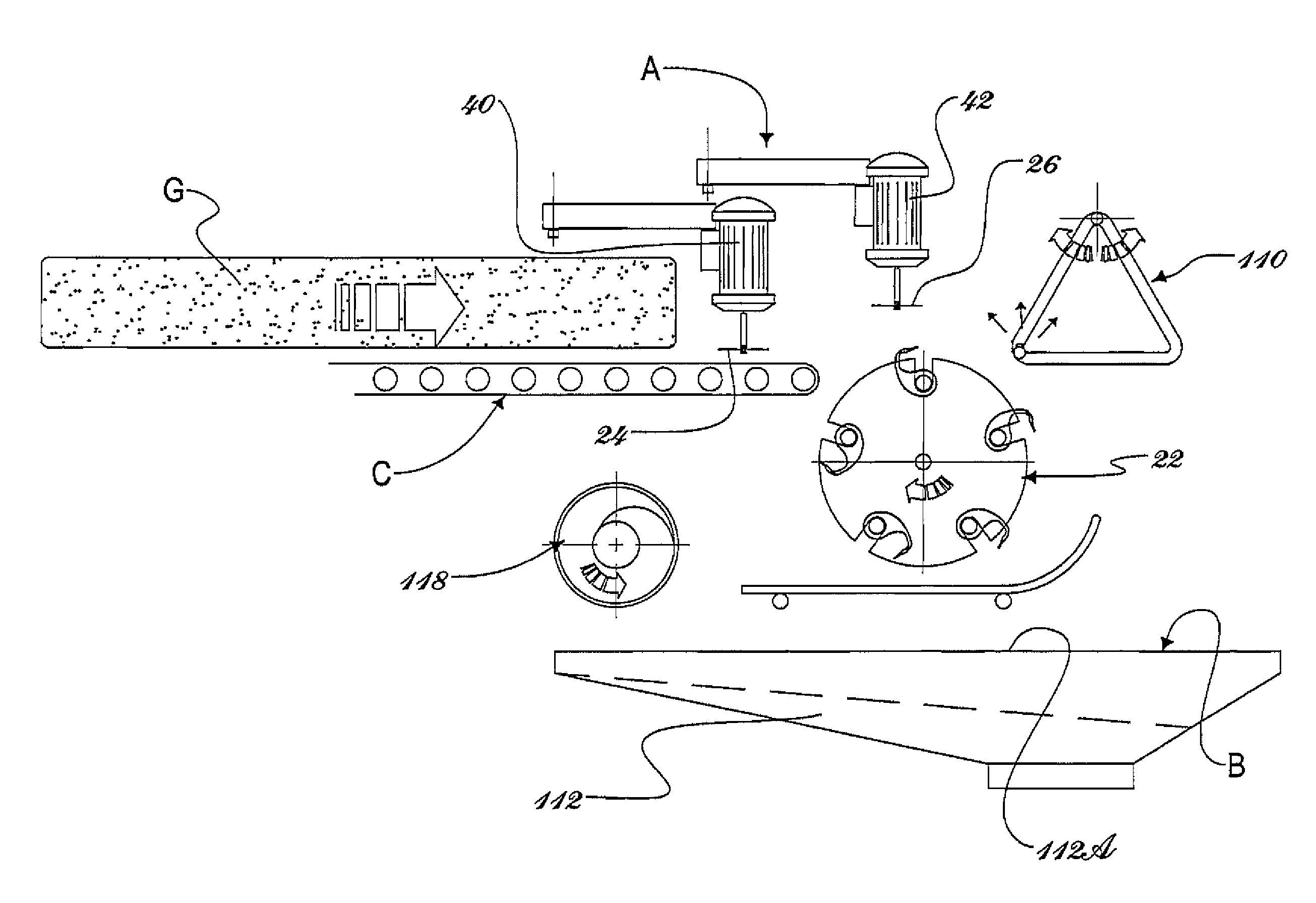

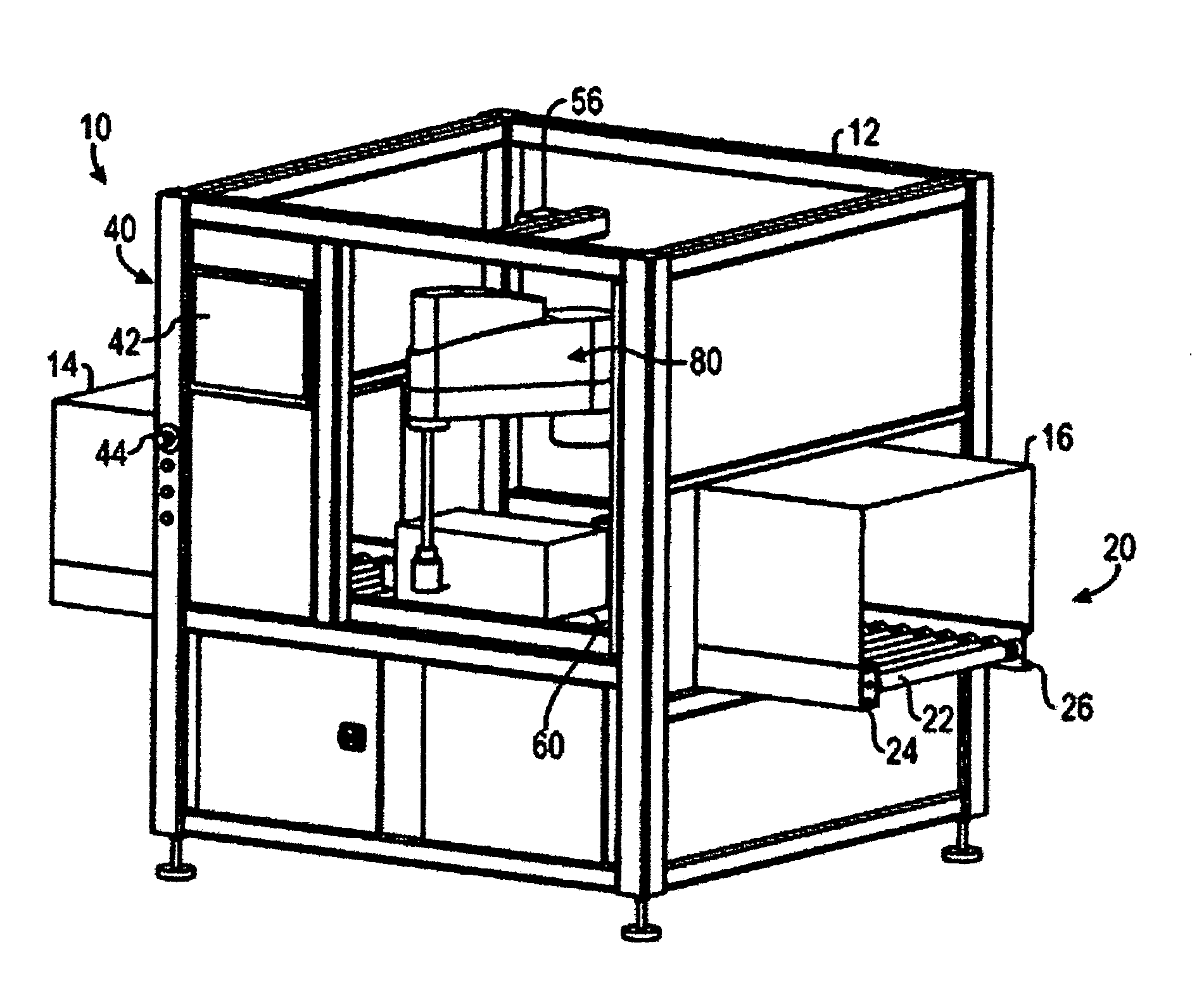

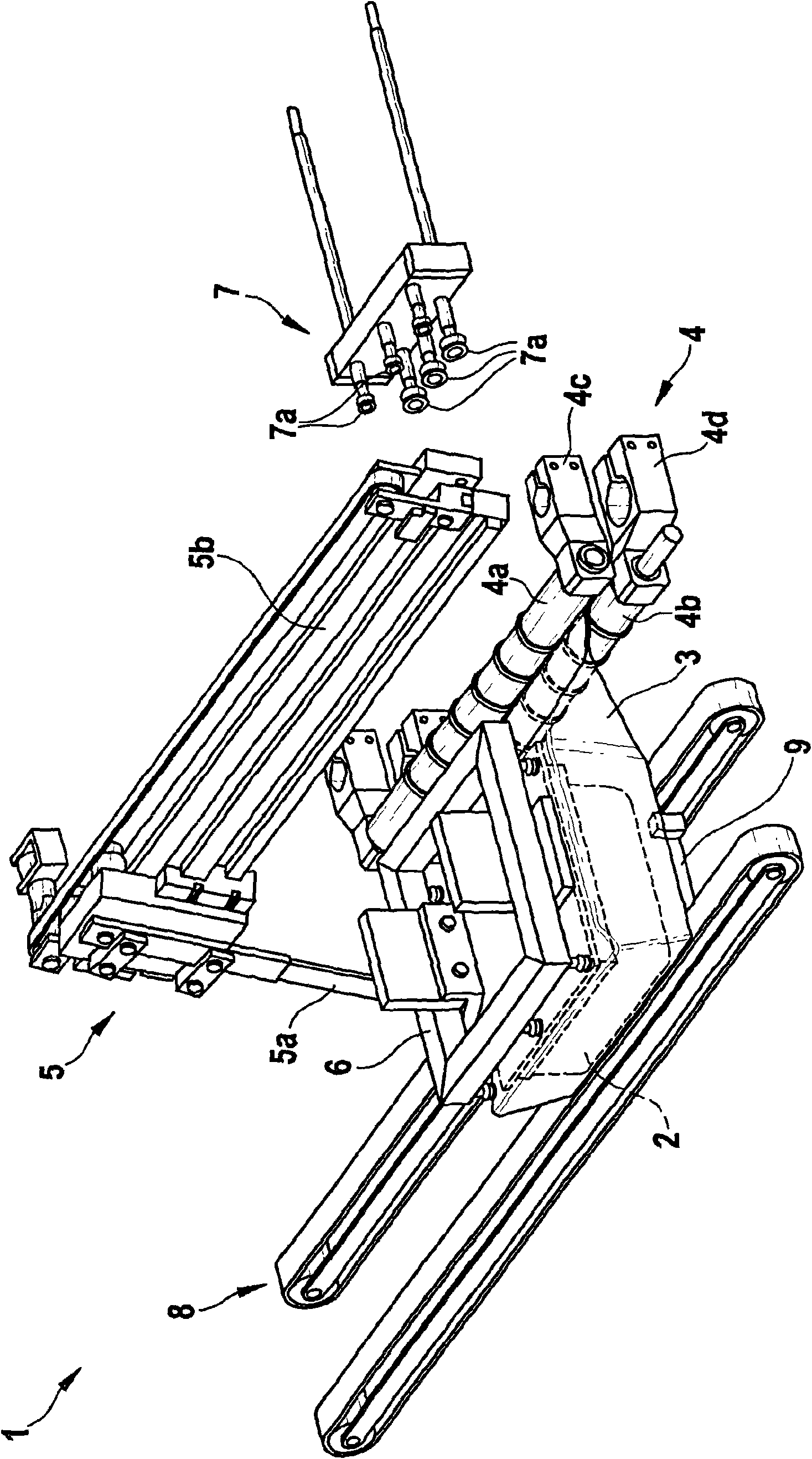

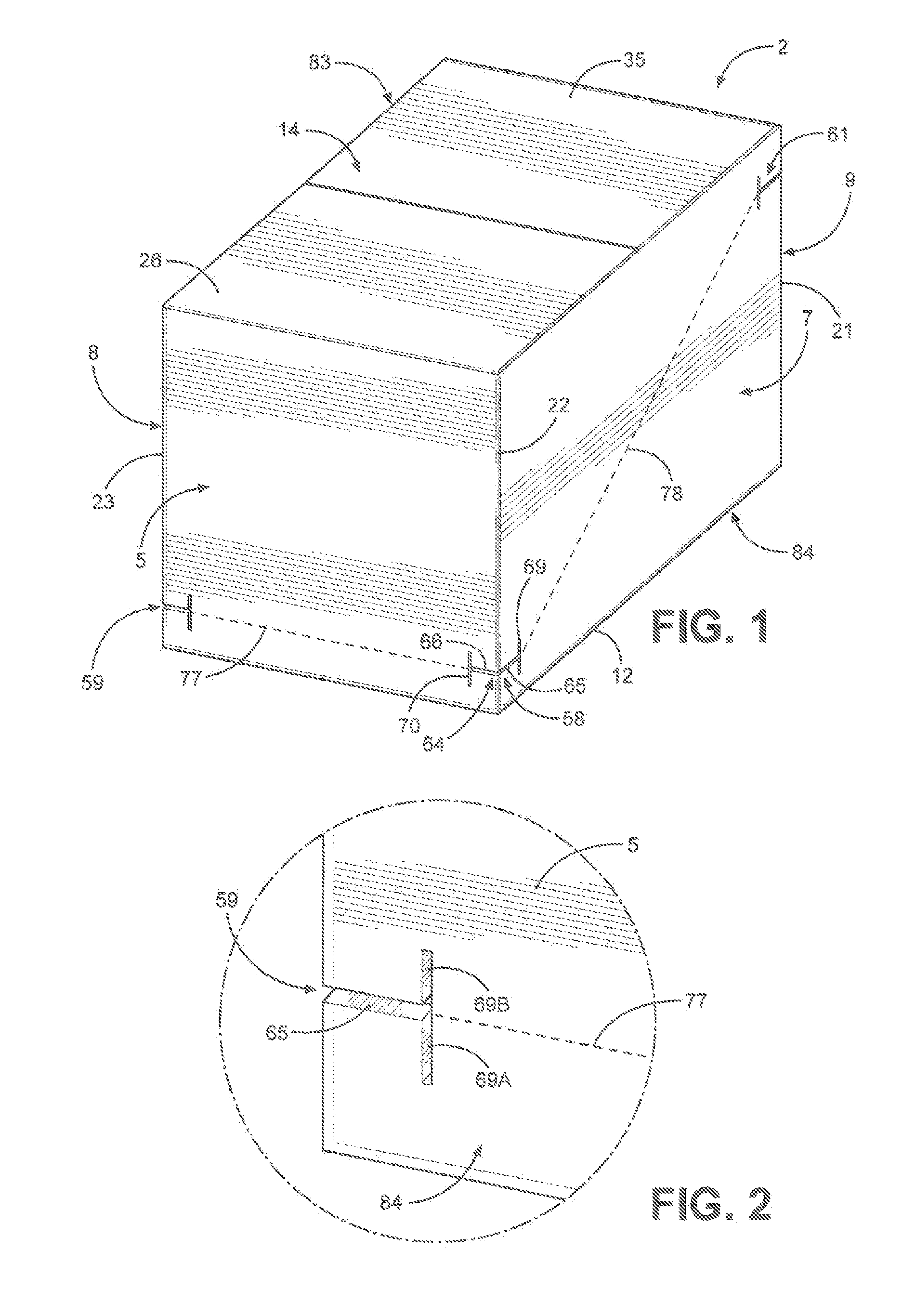

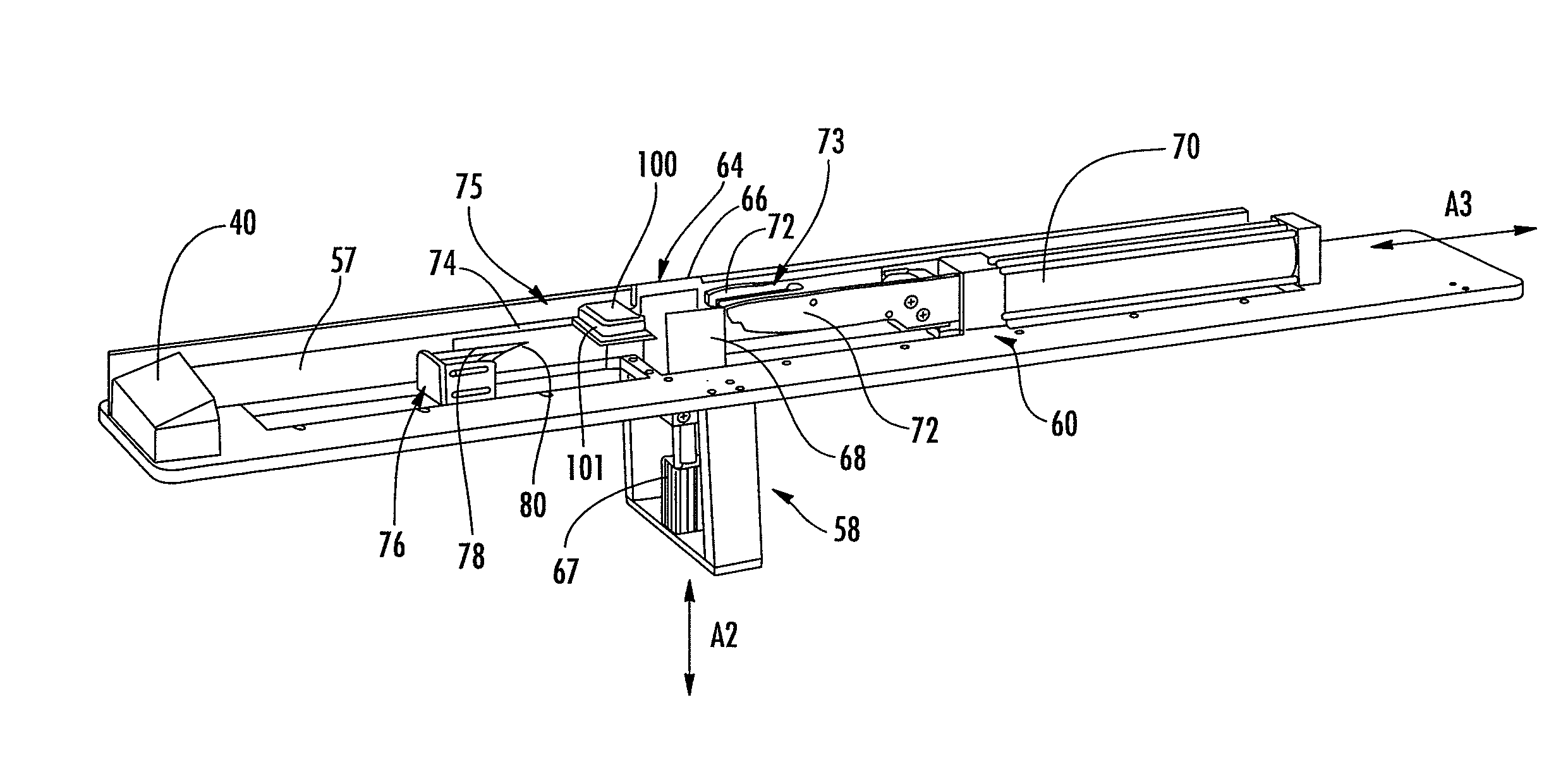

Automated box opening apparatus

ActiveUS7720567B2Prolong lifeProgramme-controlled manipulatorBox making operationsRobotic armEngineering

An apparatus includes a conveyor, a programmable motion device, and a controller. The conveyor preferably includes actuatable rollers, and the programmable motion device is preferably a robotic arm. The controller operates the conveyor, a stopping rail, and a positioning rail to move and position a box in a cutting position relative to the robotic arm. The controller determines three dimension of the box and translates a programmed cut pattern to those determined dimensions. Based on the determined dimensions, the controller then operates the robotic arm to perform the programmed cut pattern in the box with the cutting element. The cutting element preferably has square blade so that each of the four blades can be used to cut a side of the box without having to rotate the cutting element during operation.

Owner:CORNERSTONE AUTOMATION SYST +1

Seed cotton handling system

Wrapped cotton bales transported from a cotton harvest area to a receiver at the gin are moved intact to a position generally above a receiver upstream of the ginning equipment. As the bales are supported and conveyed, knife or similar cutting structure severs a portion of the wrap allowing egress of the cotton from the wrap into the receiver. Wrap removal structure prevents the wrap from entering the ginning equipment. In one embodiment of the invention, the wrap is conveyed to a wrap processor after the cotton falls into the receiver. The bale handler can include transversely adjustable cantilever supports to tension wrap for efficient cutting.

Owner:DEERE & CO

Cylindrical module unwrapping device and method

InactiveUS20090202327A1Avoid pollutionEasy to disassembleOverturning articlesPackaging bottlesFiberEngineering

Owner:CHEROKEE FABTION

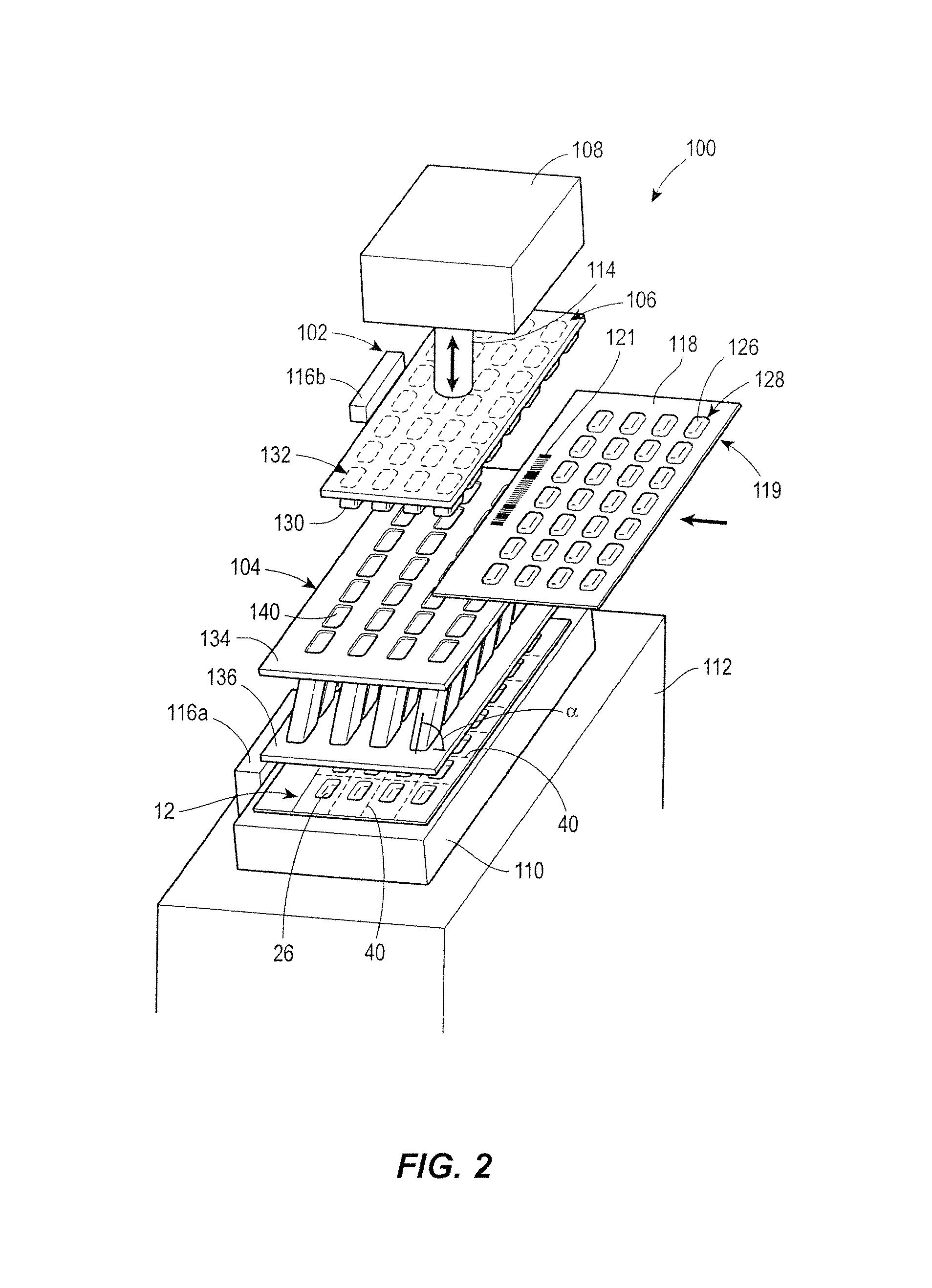

Method and system for verification of contents of a multi-cell, multi-product blister pack

ActiveUS7946101B1Control speedDigital data processing detailsPharmaceutical containersEngineeringBlister pack

A method of transferring a plurality of tablets of a product from a first blister card comprising a first plurality of blisters to a second blister card comprising a second plurality of blisters includes discharging the plurality of tablets from the first plurality of blisters of the first blister card. Then, each of the plurality of tablets are guided along one of a plurality of passageways defined by a transfer fixture positioned between the first blister card and the second blister card. Finally, the plurality of tablets are received in the second plurality of blisters of the second blister card. The method includes monitoring the deposit of product to the blister card and verifying the contents of the blister card.

Owner:WALGREEN CO

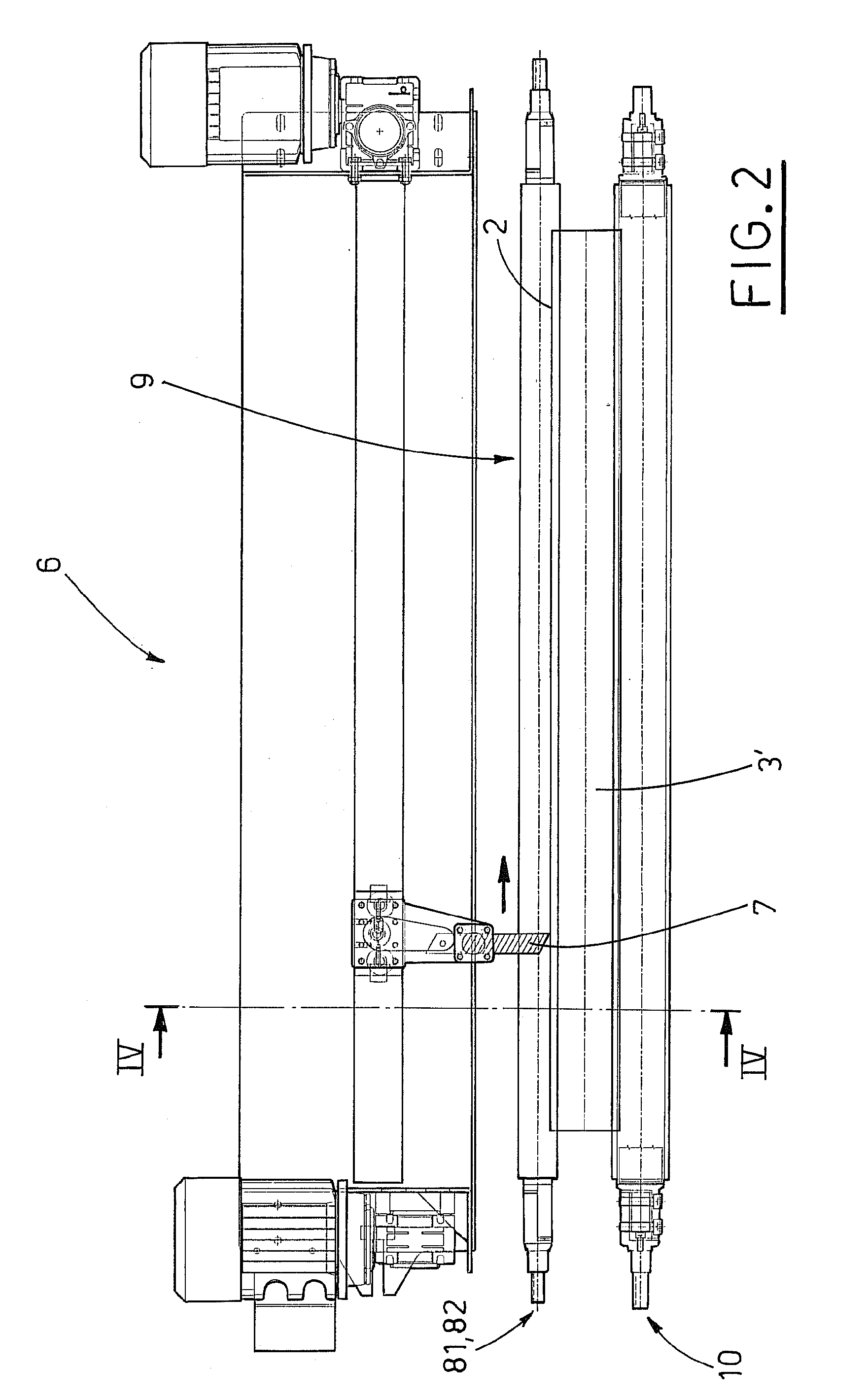

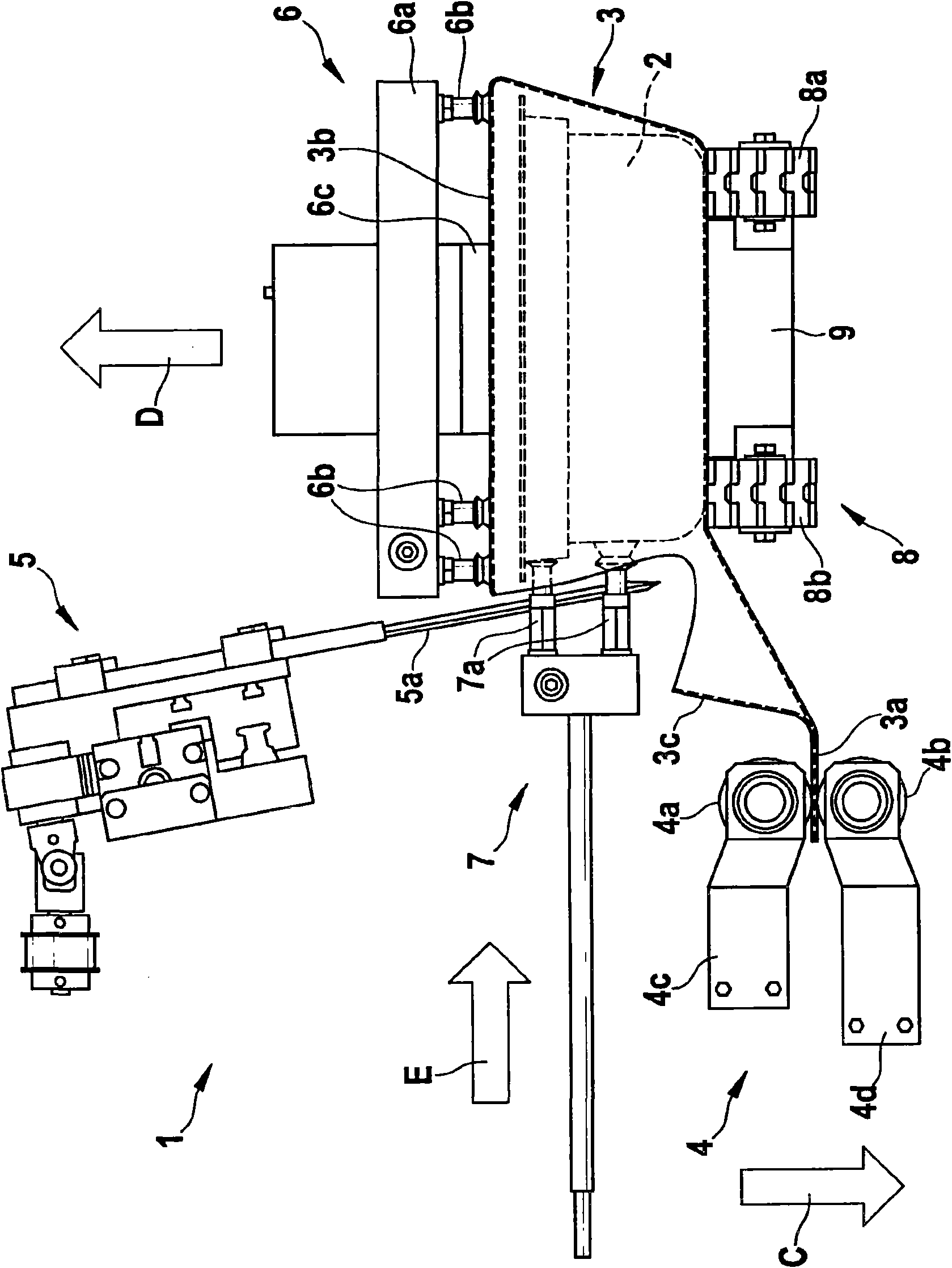

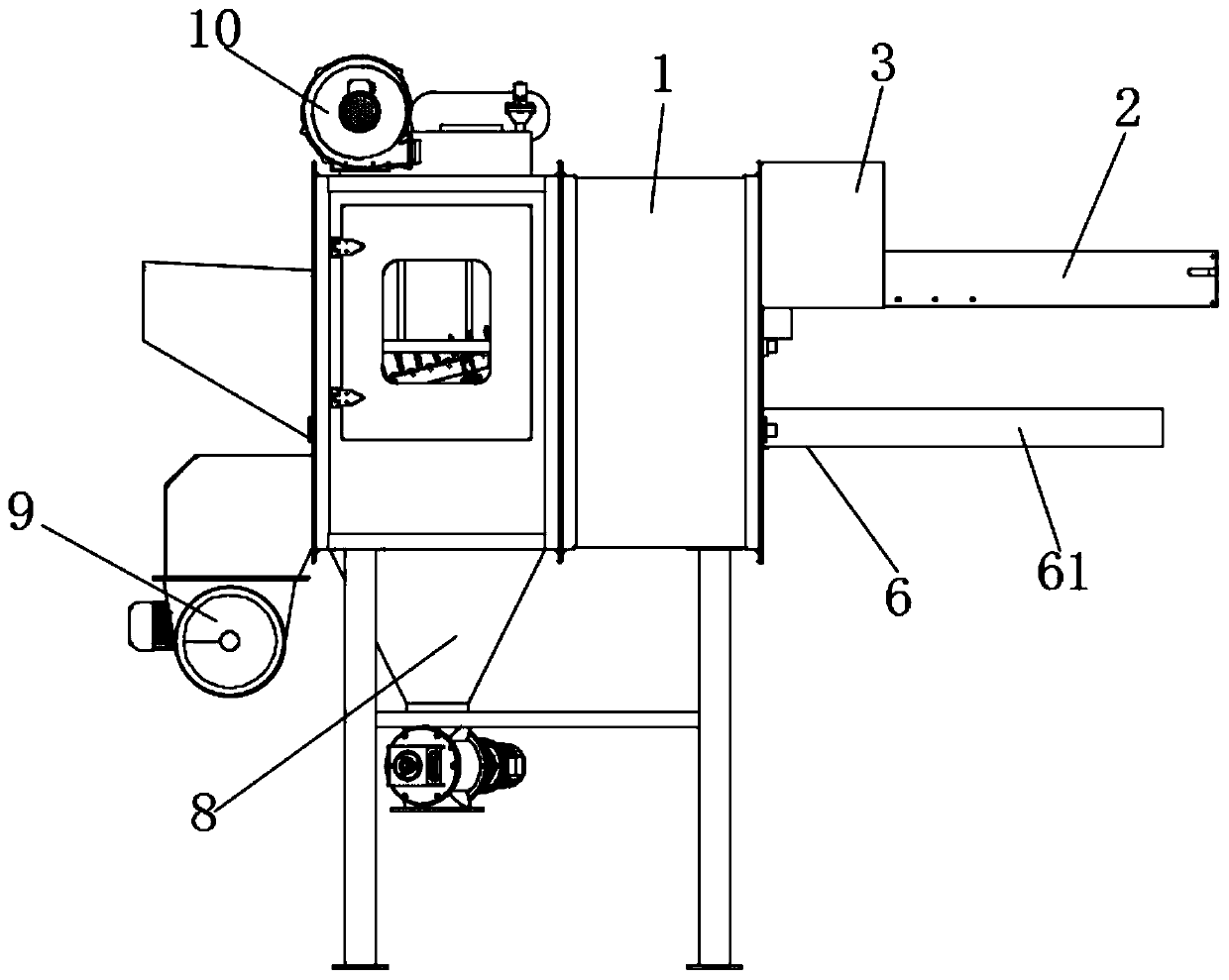

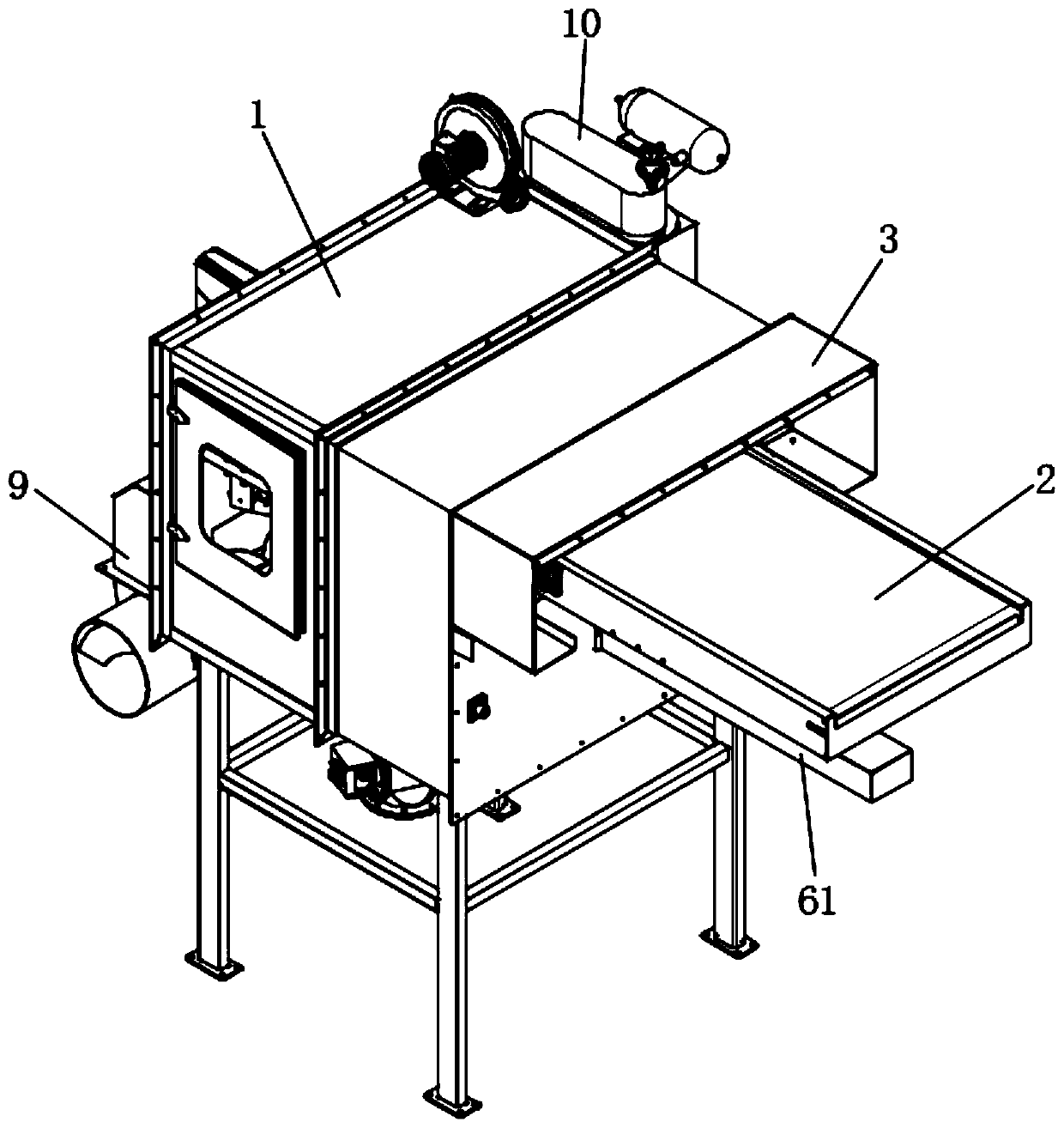

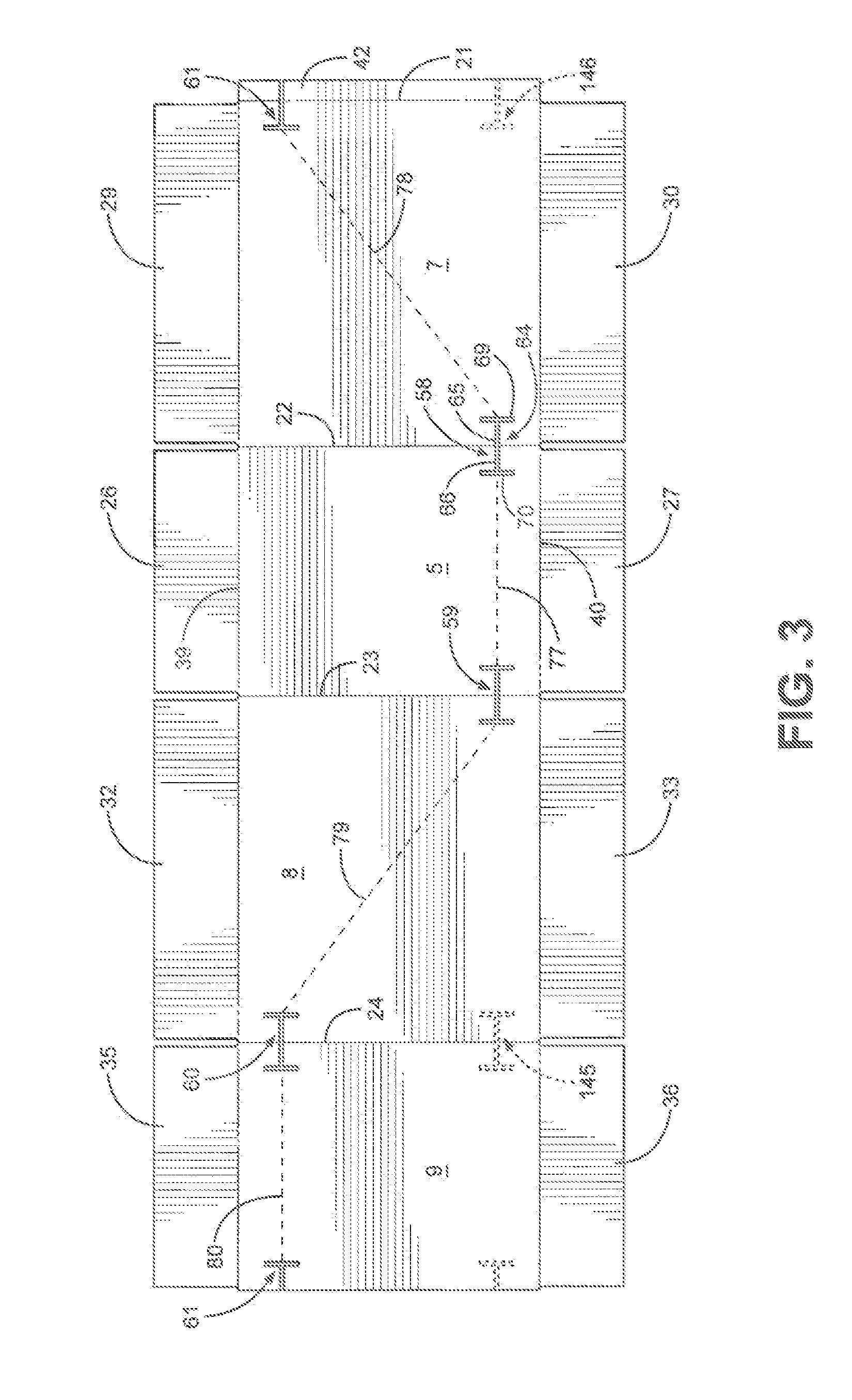

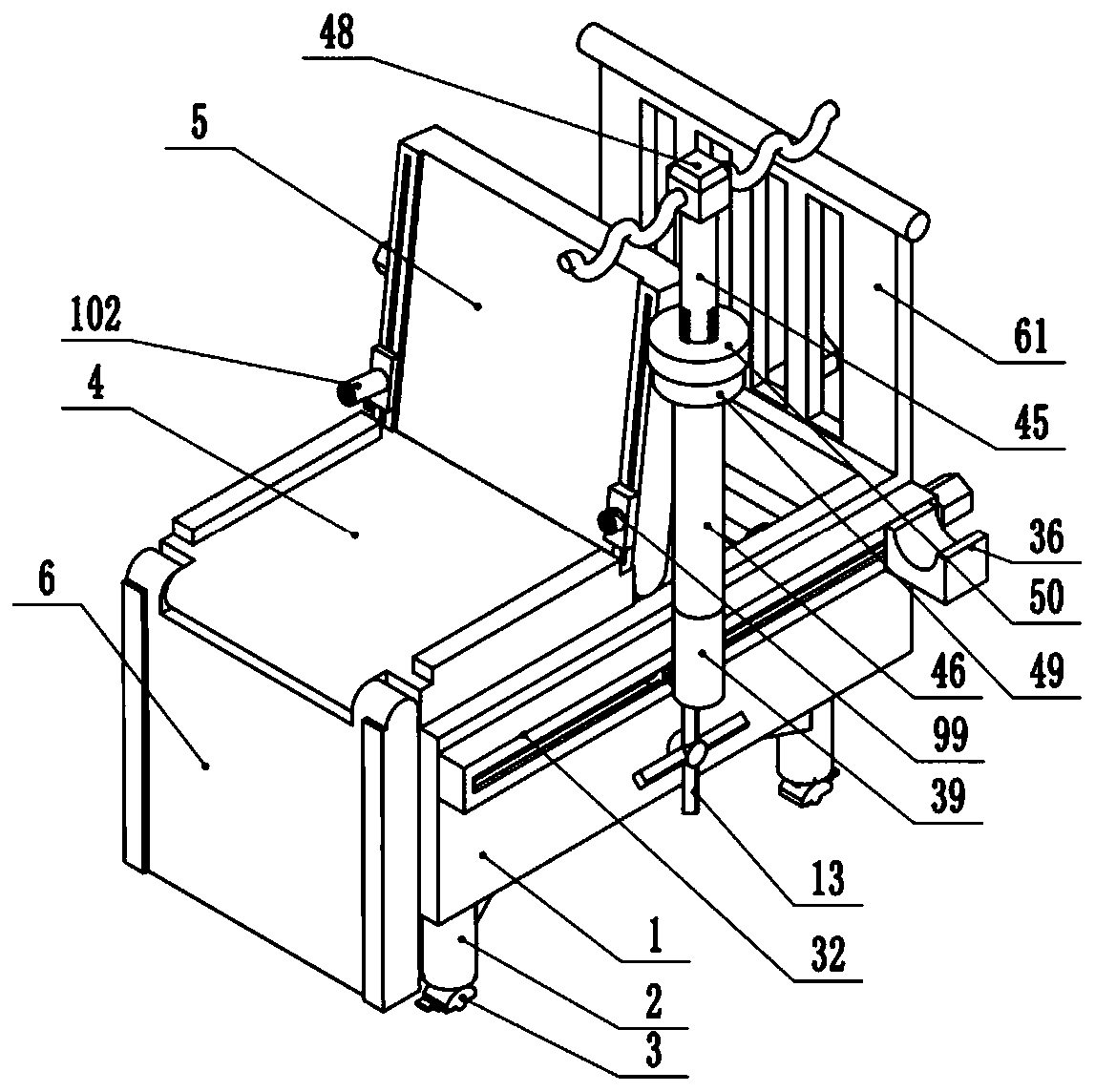

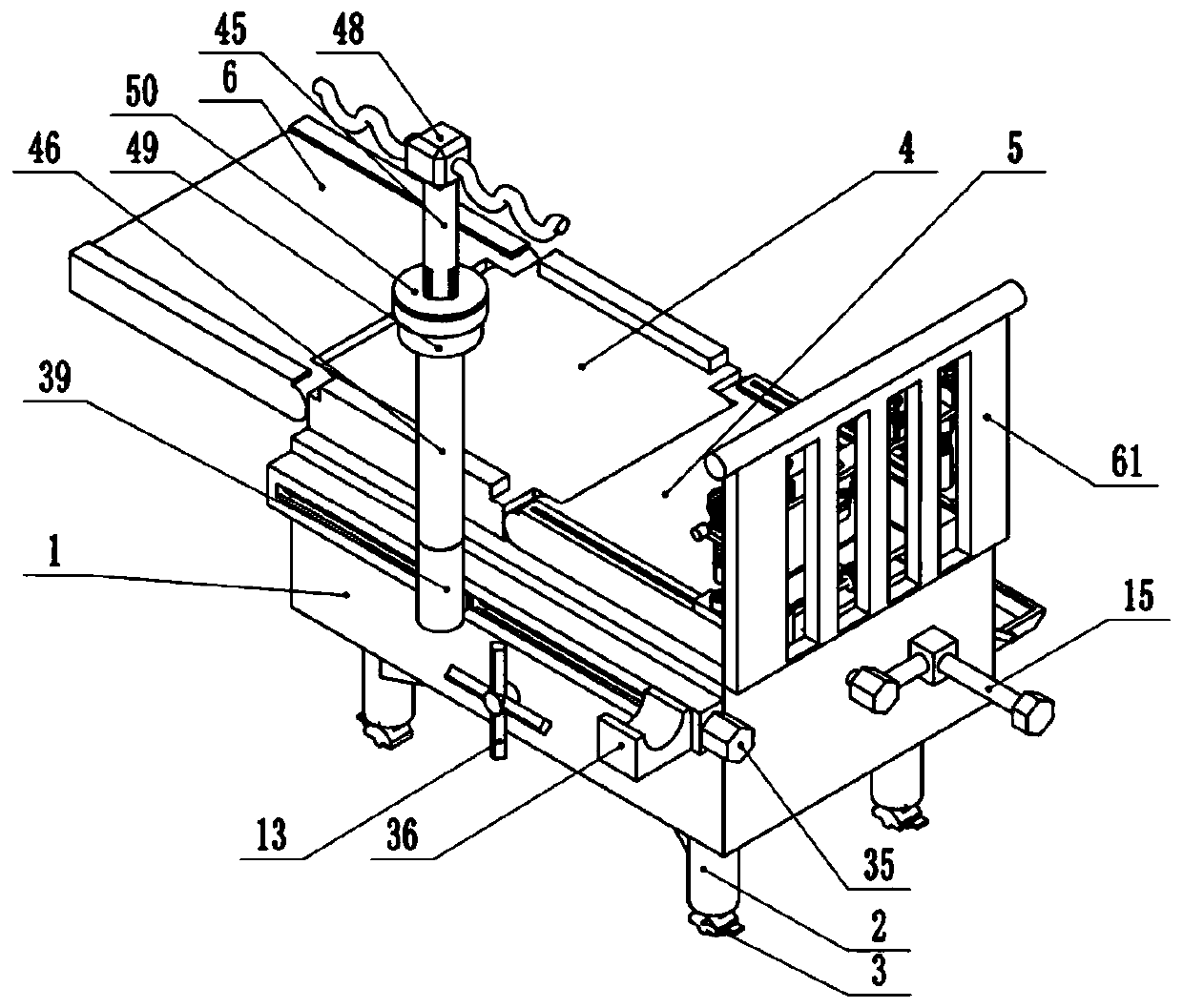

Machine For Cutting Products Paper Wrapping, In Particular Of Stacks Of Covers

InactiveUS20100218458A1Regular and effective cuttingInhibition formationMetal working apparatusUnpacking by cuttingStructural engineeringKnife blades

Machine for cutting the paper wrapping (2) which wraps and holds together in a packing (3) at least a stack of axial-symmetrical products (4) and / or at least an extended product (4), comprising a casing (5) for containing and protecting the moving parts, which contains a cutting station (T), comprising cutting means (6), comprising in turn at least a blade (7), and means (8) for folding in longitudinal direction, substantially uniformly and towards outside a portion (9) of the side surface of the paper wrapping (2) of a packing (3′), which is disposed in the cutting station (T), said portion (9) of the side surface having a length substantially corresponding to the longitudinal extension of the same packing (3, 3′); said machine (1) comprising also moving means (61) of said blade (7) for positioning the same at the folded portion (9) of the surface of the paper wrapping (2) and for translating it along the folded portion (9) itself, so that it is longitudinally cut.

Owner:CORIMA INT

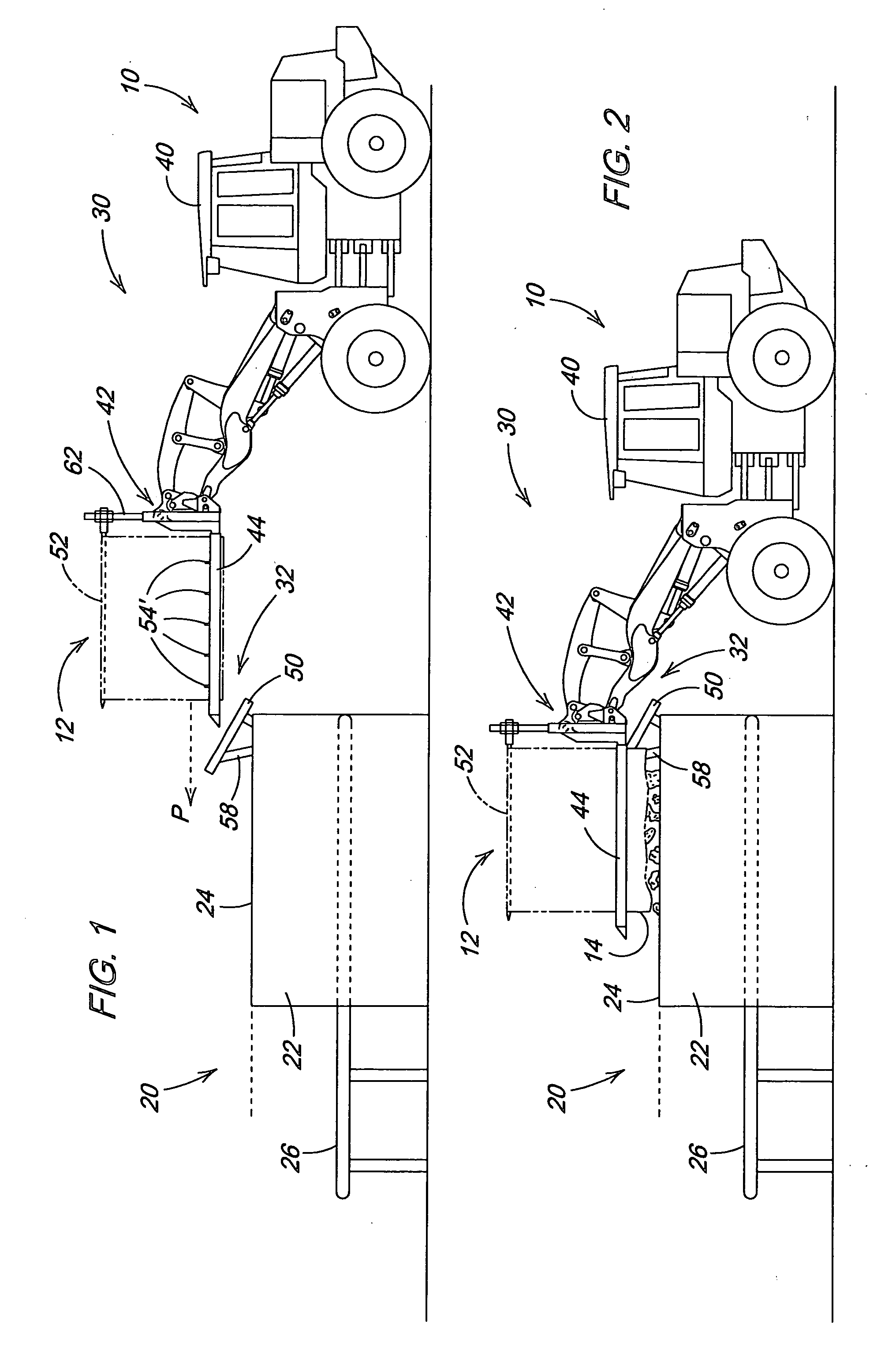

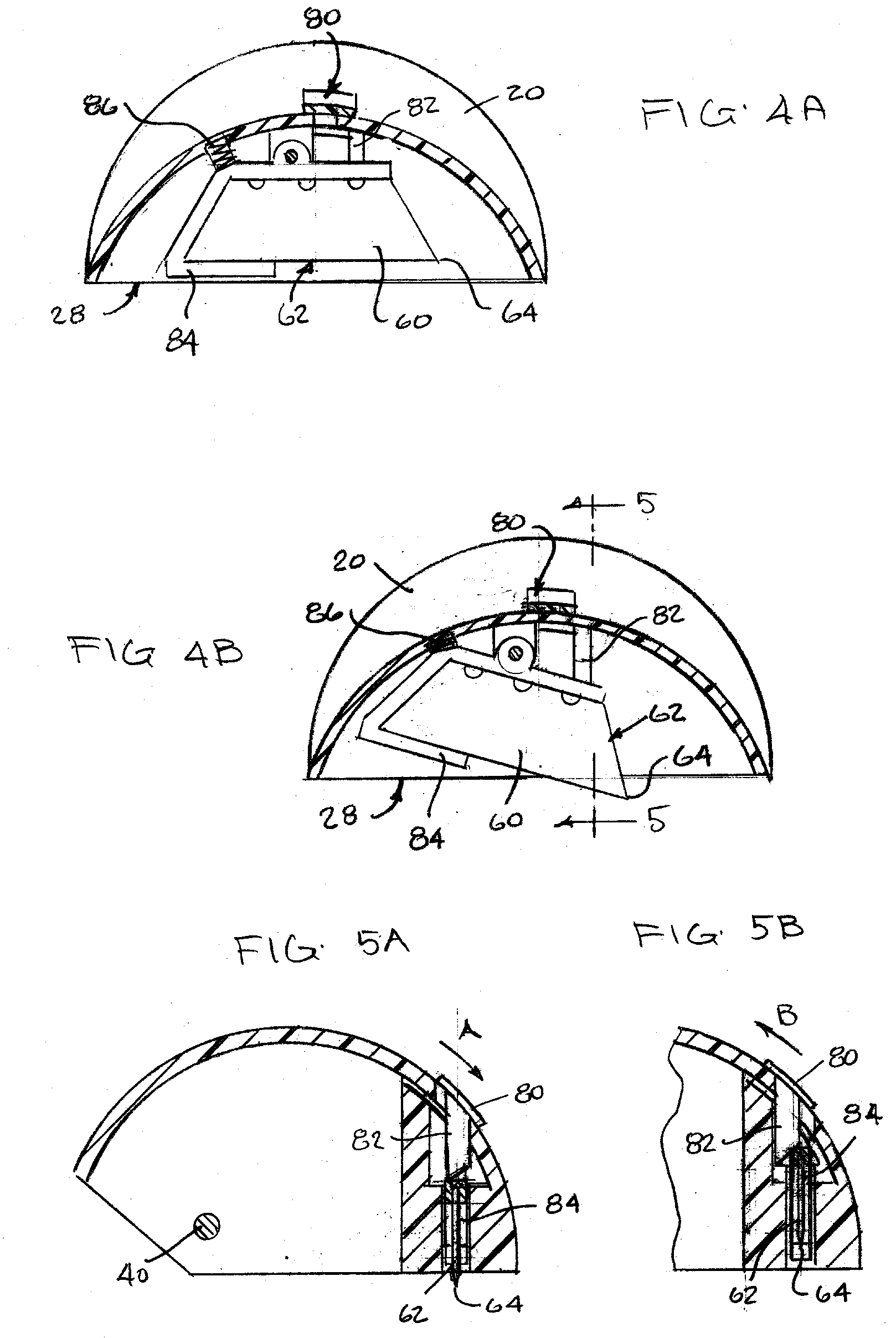

Module wrap removal

InactiveUS20060191241A1Eliminates wrap material contaminationEasy to disassembleOpening closed containersBottle/container closureControl mannerEngineering

A system wherein plastic wrap on round bales of cotton is partially slit starting at one end of the bale and continuing to a location offset from the opposite end of the bale. One or more partial lengthwise slits allow the cotton to fall into a gin input hopper in a controlled manner and maintain the entire wrap, including any non-adhered inner tail remnants, attached to an intact circumferential wrapper portion at the end of the bale opposite the slit end. The non-slit wrapper end portion is pulled from end of the bale, and the remaining cotton material drops into the receptacle free of contamination by any wrap material.

Owner:DEERE & CO

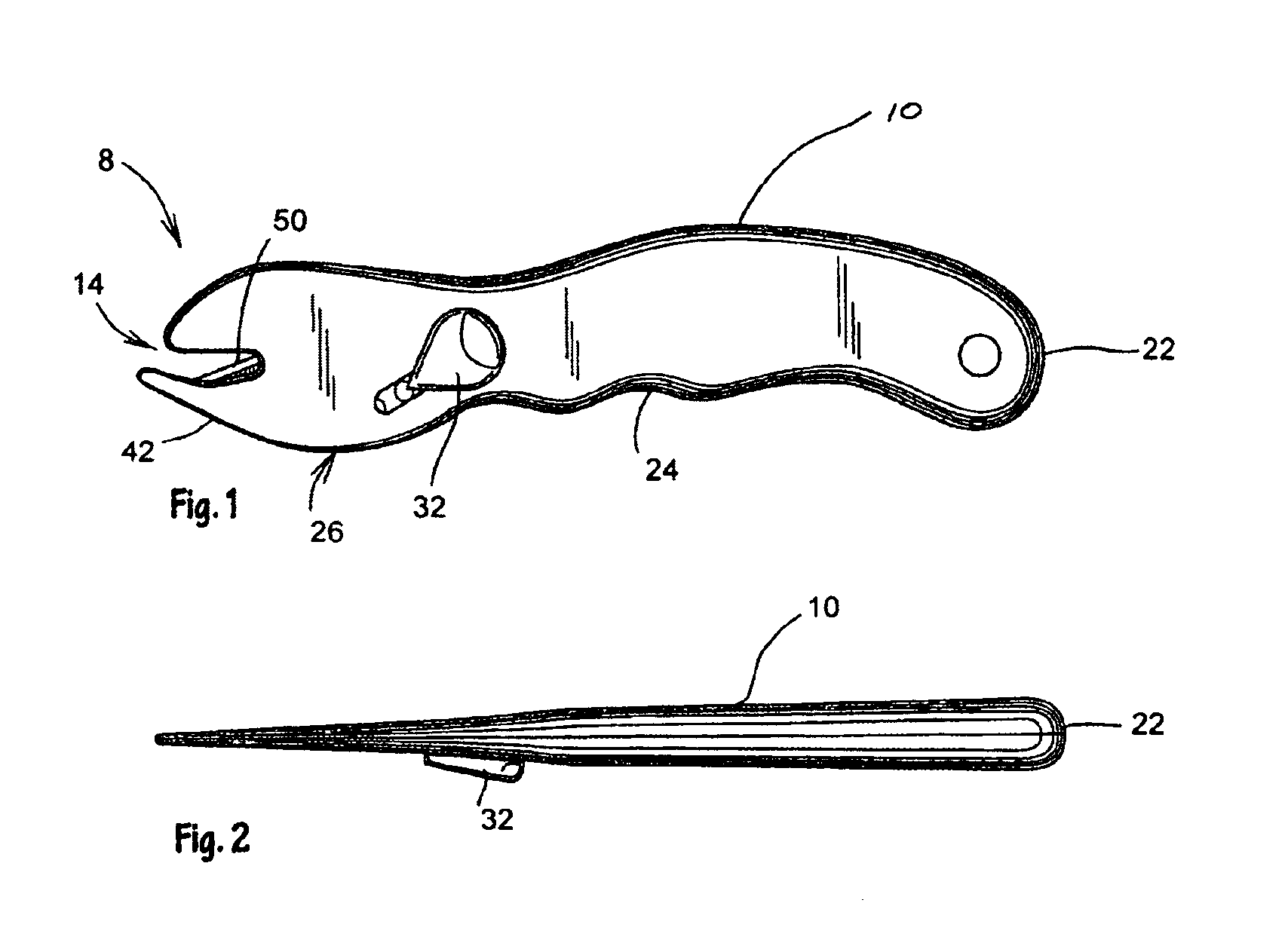

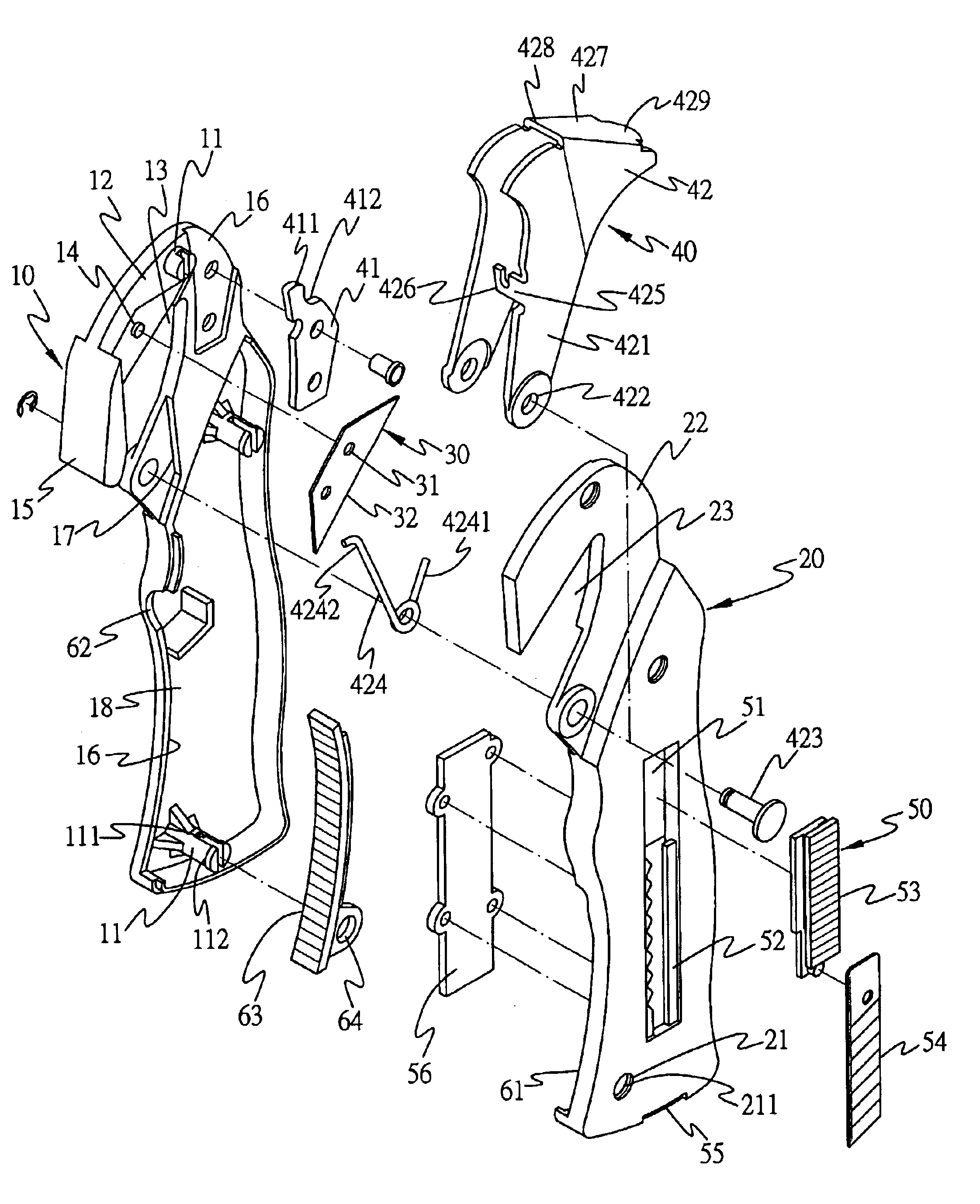

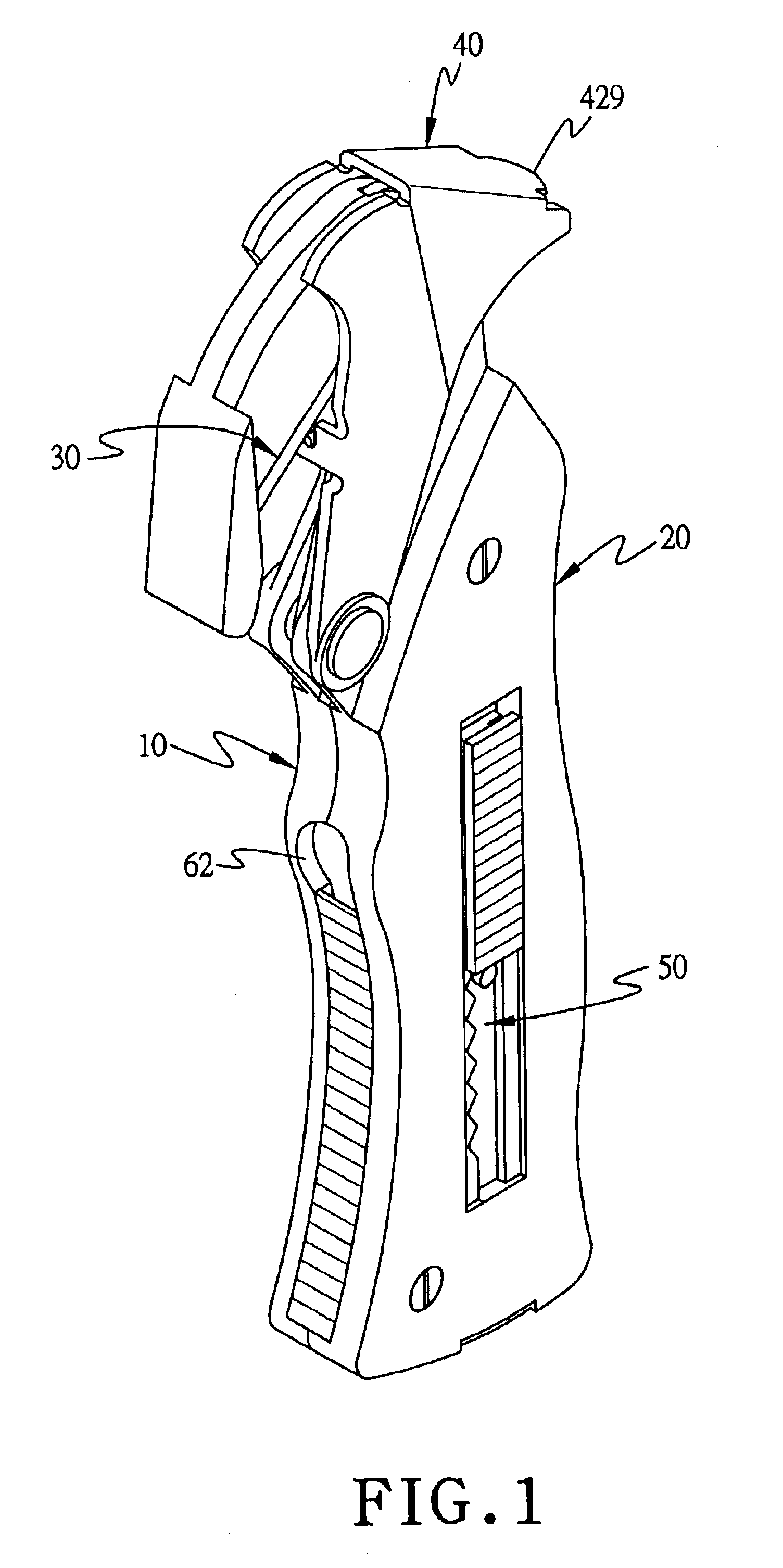

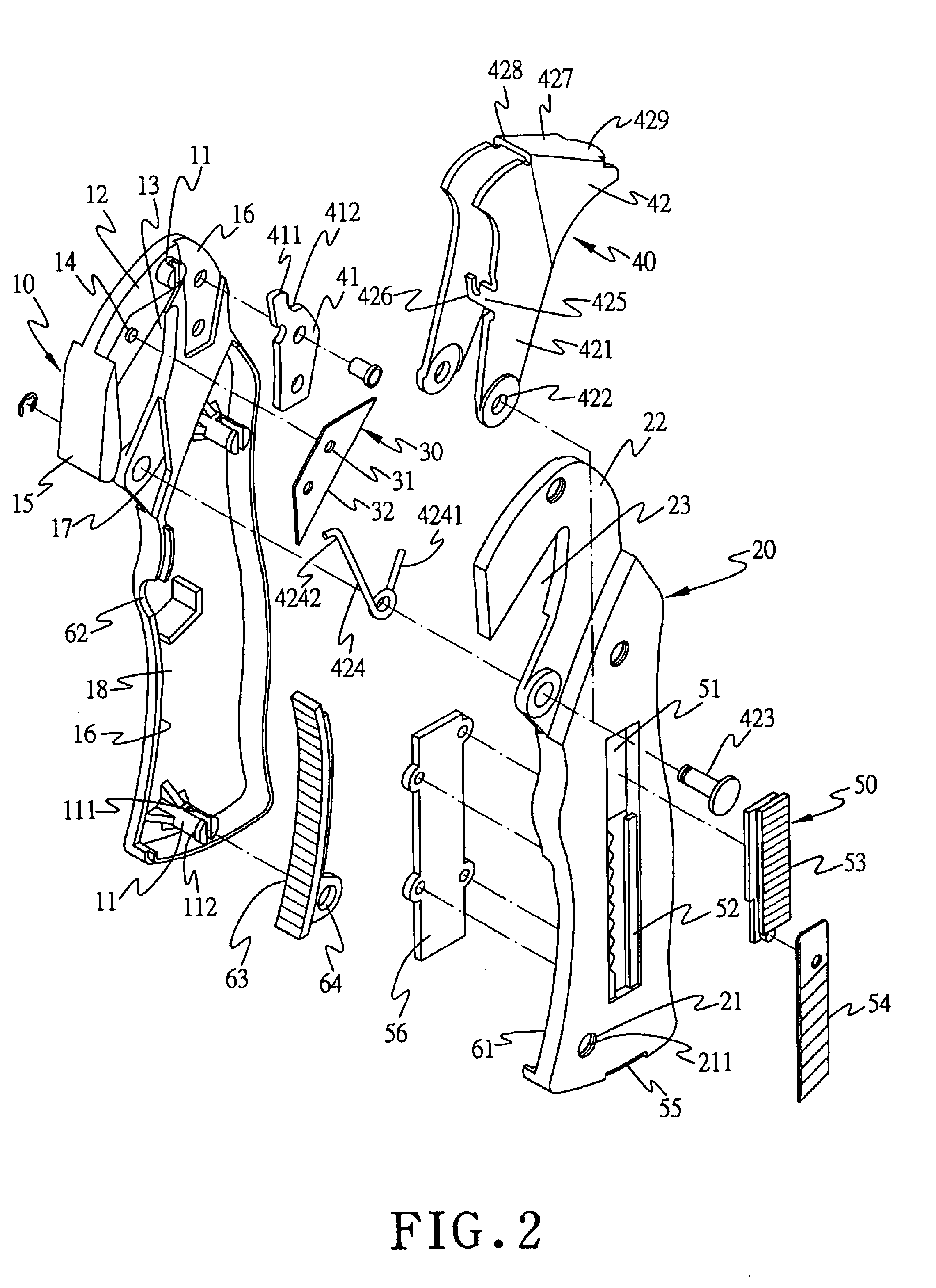

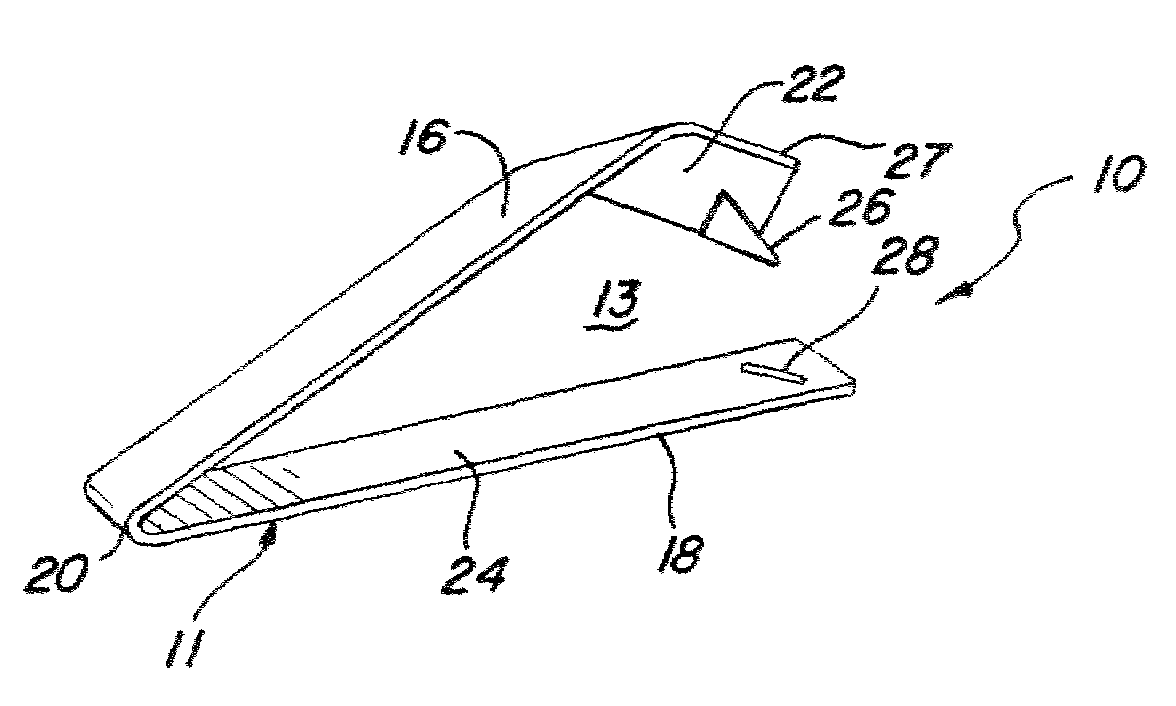

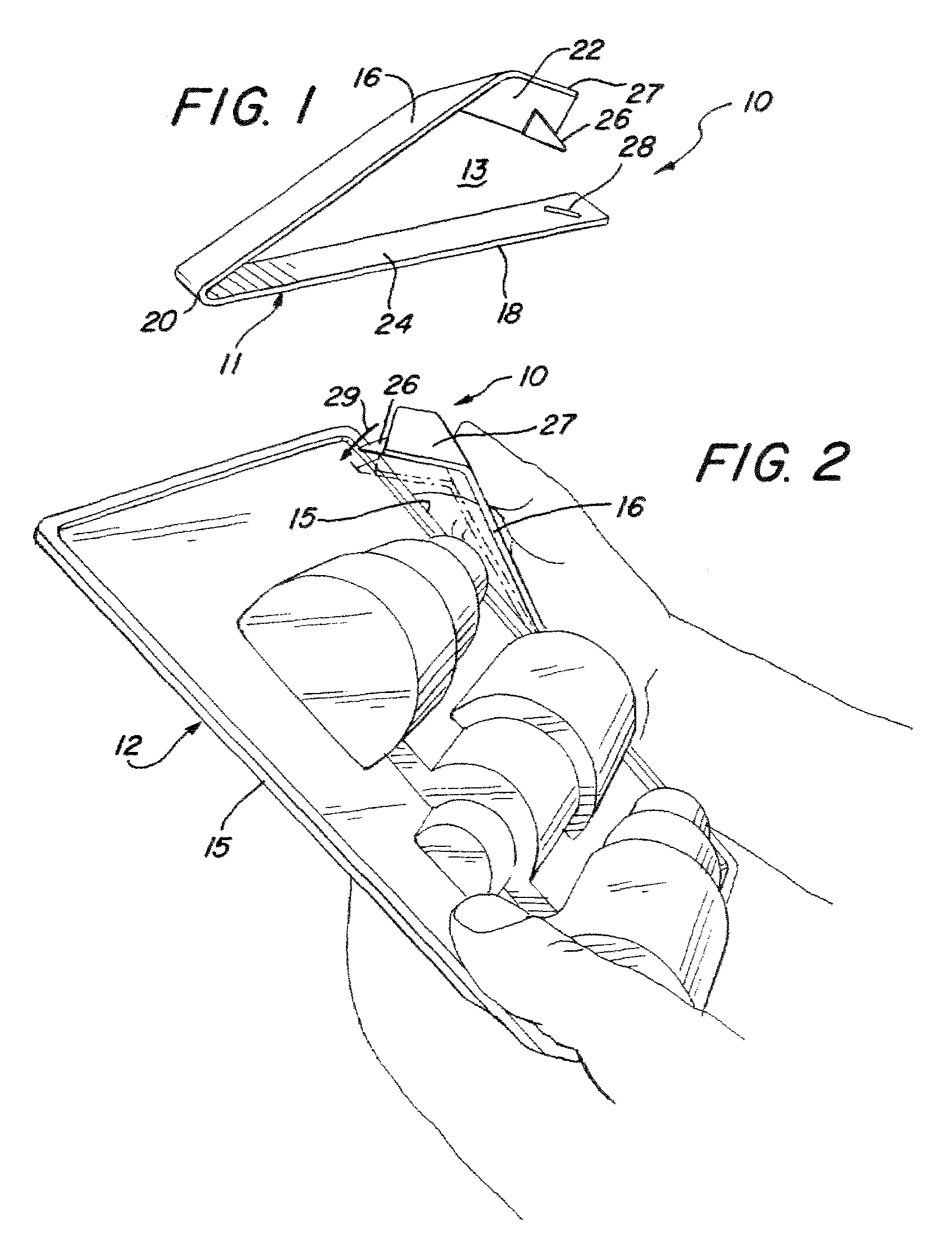

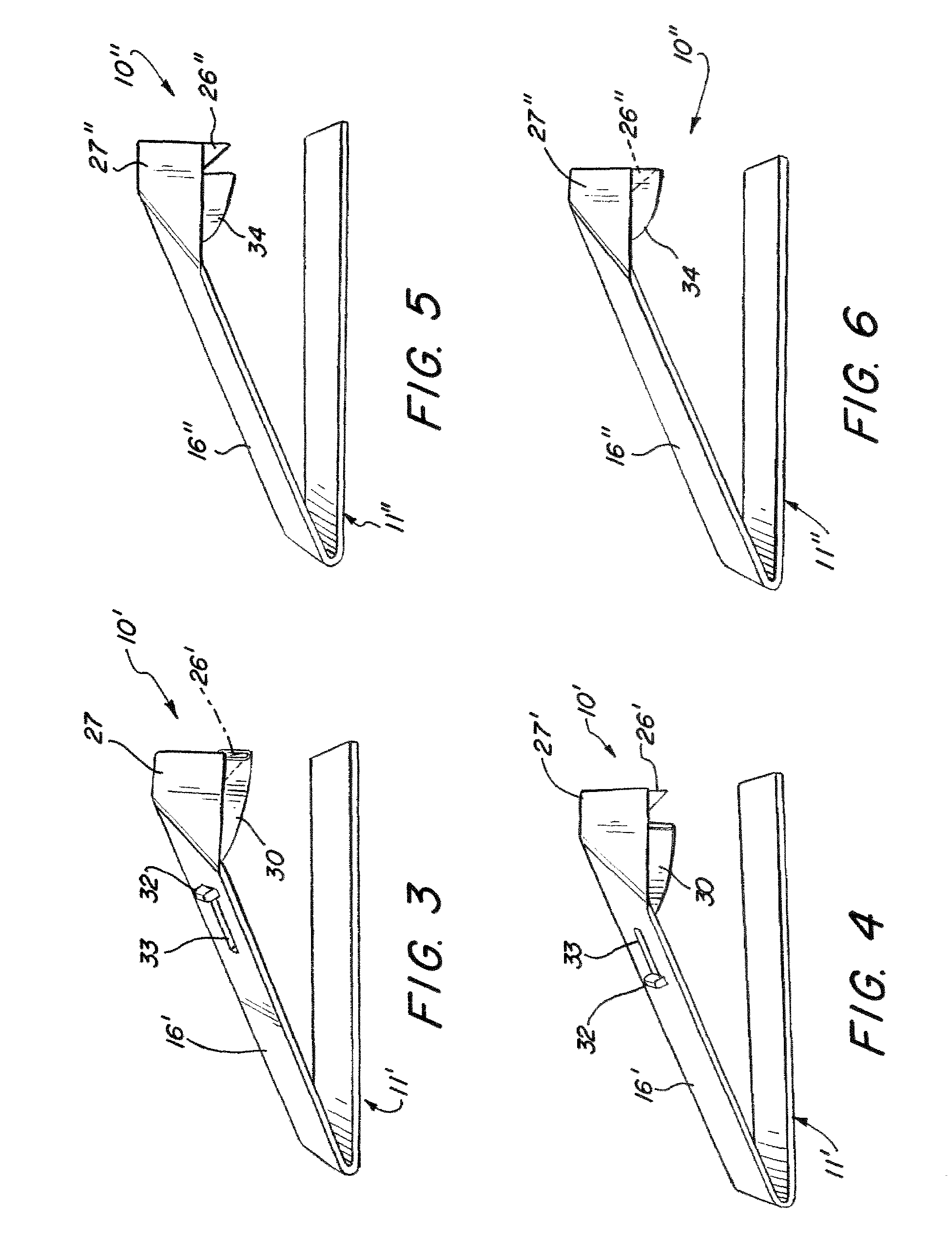

Cutting tool

A cutting tool includes a housing having a first end with a first edge and a second end. A handle extends from the second end of the housing. The housing has a slideable blade with a cutting position and a retracted position inside the housing. A finger portion is cantilevered from the first end of the housing. The finger portion and the first edge define an elongated opening having a juncture end at the first end of the housing. A cutting edge is embedded at the juncture end. The cutting edge is shaped, sized and orientated to facilitate forward slitting of heavy plastic sheet. The slideable blade slides axially along a track. A biasing means repositions the slideable blade from the cutting position to the retracted position.

Owner:PERLMUTTER THOMAS +1

Automatic bag slitter, and method of use thereof

ActiveUS8197174B1Easy maintenanceEnhancing bag separationBags openingPackaging bottlesLitterEngineering

The automatic bag opening and slitting machine has a spike star wheels assembly comprising either of one or a combination of star wheels or cylindroid drum like object. The star wheels assembly is provided with spikes which convey a bag, impaled on the spikes when in an extended position, and extends beneath rotary cutting disks driven by two independent pneumatic or electric motors, that may make a continuous cut around three sides of the bag, so that after cutting thereof, the bag comprises two halves joined only at the rear or trailing side of the bag. These two bag halves are unfolded as one half of the bag engaged by the spikes is drawn around the upstream end of the star wheels assembly, while the other half slides over the rocker arm / bag separation bar / slide guide bar, thus emptying the powder / granular content of the bag into a hopper and releasing the emptied bag by retraction of the spikes from the bag for collection therebelow into a chute, for disposal into an endless screw which extrudes the bag into a compaction tube. The compacted bags are thereafter pushed into a waste plastic bag for refuse disposal.

Owner:LUXME HLDG

Automated Box Opening Apparatus

ActiveUS20070162174A1Prolong lifeProgramme-controlled manipulatorBox making operationsRobotic armEngineering

An apparatus includes a conveyor, a programmable motion device, and a controller. The conveyor preferably includes actuatable rollers, and the programmable motion device is preferably a robotic arm. The controller operates the conveyor, a stopping rail, and a positioning rail to move and position a box in a cutting position relative to the robotic arm. The controller determines three dimension of the box and translates a programmed cut pattern to those determined dimensions. Based on the determined dimensions, the controller then operates the robotic arm to perform the programmed cut pattern in the box with the cutting element. The cutting element preferably has square blade so that each of the four blades can be used to cut a side of the box without having to rotate the cutting element during operation.

Owner:CORNERSTONE AUTOMATION SYST +1

Piercing member for container access device

Owner:BECTON DICKINSON & CO LTD

Dispensing system

InactiveUS20050232731A1Easily and fully dischargeEliminating and greatly reducing and potentialBulk conveyorsStorage devicesEngineeringMechanical engineering

A sealable container and a dispenser suitable for use with the sealable container are disclosed. The sealable container comprises a plurality of generally tapering sides and a sealable structure disposed at each end of the container. The dispenser includes a hopper and an opening assembly. The hopper is configured for a contacting substantially parallel relation with the generally tapering sides of the sealable container, when the sealable container is disposed in the hopper. The opening assembly includes an opener, which punctures, then withdraws from, the sealable structure.

Owner:LUND VIRGIL D

Device and method for removing a sterile object from a sterile packaging

ActiveCN101687559APreferred extension constructFast and reliable clampingBags openingUnpacking by cuttingEngineeringMechanical engineering

The invention relates to a device for removing a sterile object (2) from a sterile packaging (3), having a clamp device (4) which clamps a first subarea (3a) of the sterile packaging (3), a cutting device (5) for cutting the sterile packaging (3) in such a manner that a slit is produced in the sterile packaging (3), a holding device (6) which holds a second subarea (3b) of the sterile packaging (3), and a removal device (7) to remove the object (2) from the sterile packaging (3) through the slit. The invention also relates to a method for removing a sterile object.

Owner:SYNTEGON TECHNOLOGY GMBH

Cardboard box unpacking device

A cardboard box unpacking device has a blade positioned in a slanting blade groove fo a main body and a covering body for cutting off plastic packaging strap tensioned on a cardboard box, a staple removing device provided at the upper rear side of the main body for removing staples from the cardboard box and a telescopic blade device disposed at the lower portion of the covering body for culling off adhesive tape adhered to the cardboard box.

Owner:YU CHEN HSIU MAN

Clean full-automatic bale breaking method and structure

The invention discloses a clean full-automatic bale breaking method and structure, and belongs to the field of bale breakers. The clean full-automatic bale breaking structure comprises a bale breakerhousing bracket, a bag feeding belt conveyor and a bag feeding guide shell, wherein the bag feeding belt conveyor is arranged on the right side of the bale breaker housing bracket. Through the bag feeding belt conveyor, a sliding conveyor and the bag feeding guide shell, a material bag which requires bale breaking is conveyed to the interior of the bale breaker housing bracket; through the interaction between a swinging mechanism as well as a bag breaking and waste bag pushing mechanism, the original material bag is broken and separated; through a separating grid, a pure material drops into acollecting silo, so that the material wasting phenomenon can be avoided; the broken bag enters a waste bag collecting device; through a dust removing system, no dust leaks during the bag breaking process and the material separating process; the structure is simple, the operation is simple and the occupied area is small; during the bale breaking process, only one person is needed to put the material bag on the belt conveyor; the degree of automation is high; and the circumstance of dust leakage is prevented during the bale breaking process.

Owner:常州沃斯曼自动化科技有限公司

Plastic package opener

InactiveUS7730620B1Easy to operate manuallyEasily and safely openedOpening closed containersBottle/container closureMemory retentionPlastic packaging

A plastic package opener having a body with a generally “V” shaped configured is formed from a memory retention material, by angled first and second legs held together by a portion of material. A sharp edge or blade member is held to an interior surface of one of the legs at an angle to the terminal ends of the legs. A movable blade cover may be provided for safety. A plastic package to be opened is inserted between the open ends of the legs and the blade member brought against the plastic package by squeezing the two legs together and directed across the surface of the plastic package to sever the plastic package and open the same for removal of an item or items held therein.

Owner:ANASTASI CHRIS +1

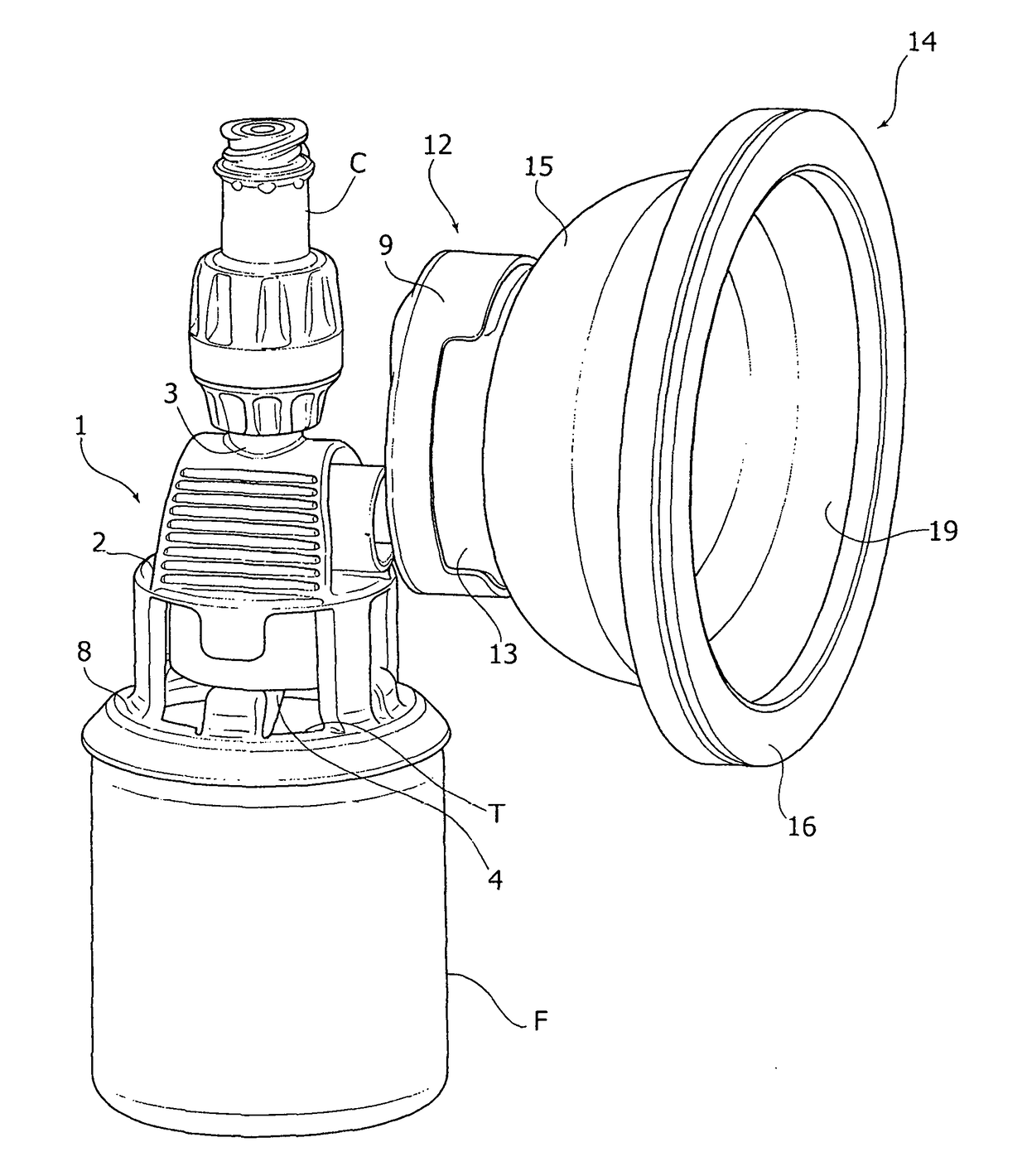

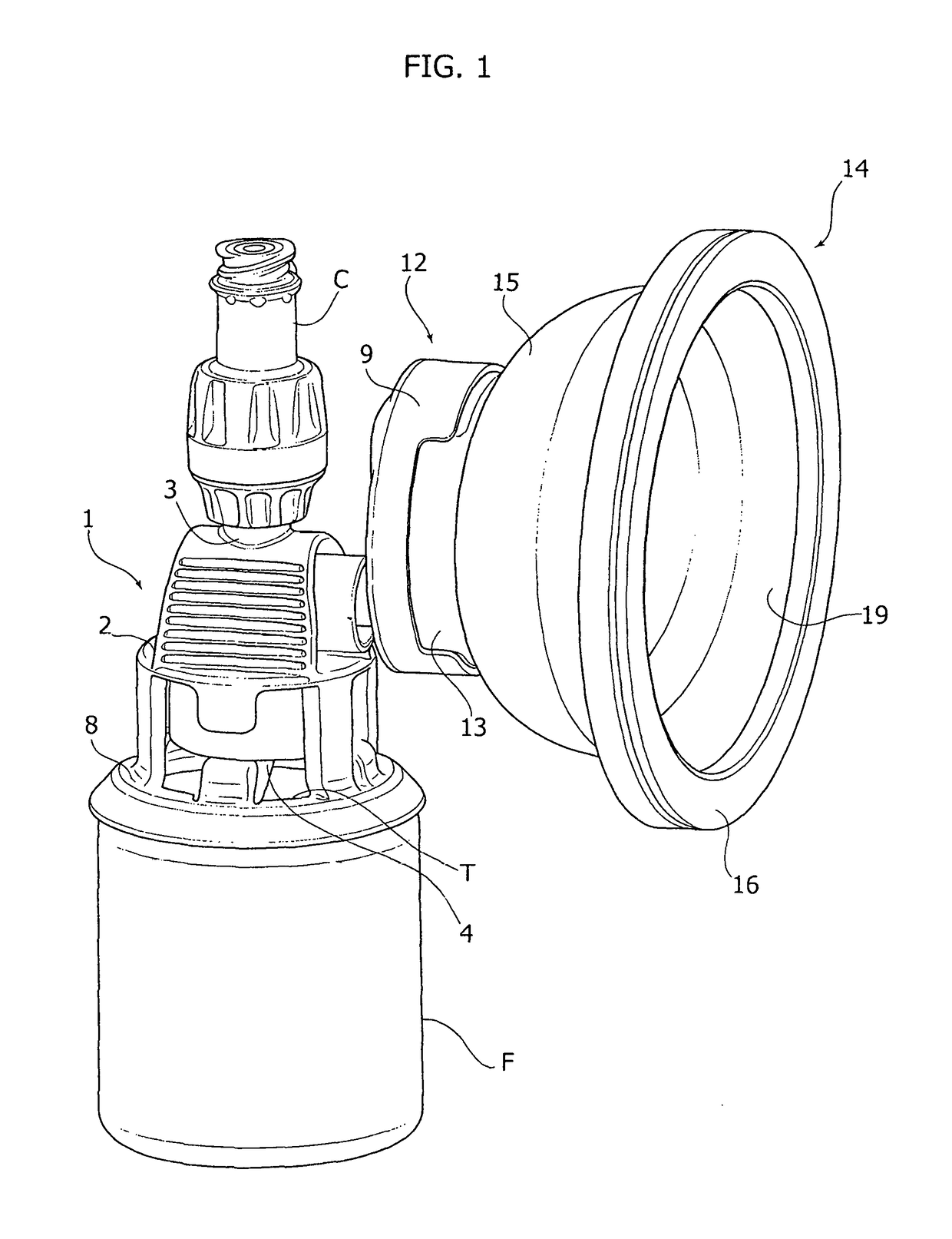

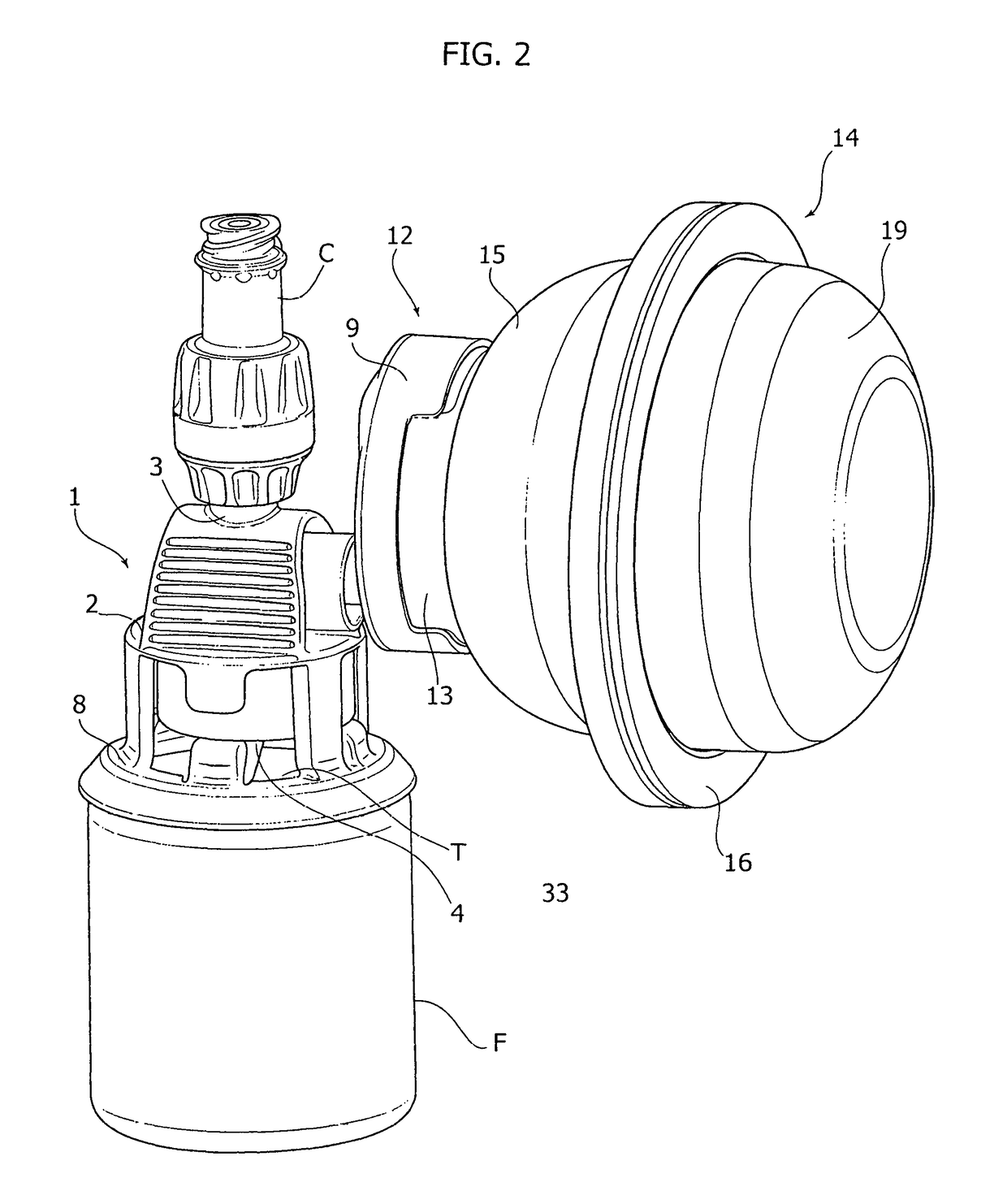

Access device for containers of fluidizable substances

ActiveUS10016339B2Improve securityEffective barrierPharmaceutical containersMedical packagingEngineeringCheck valve

An access device for containers of fluidizable substances includes a body provided with a hollow spike designed to be inserted into a container of a substance to fluidize and having an axial fluid passage and an axial passage for venting of the container, an expandable chamber connected to the venting passage of the spike through a lateral passage of the body, a first check valve enabling one-way communication from the lateral passage to the expandable chamber, a second check valve enabling one-way communication from a vent opening to the venting passage of the spike. A double impermeable filtering membrane is interposed between the first check valve and the second check valve.

Owner:IND BORLA

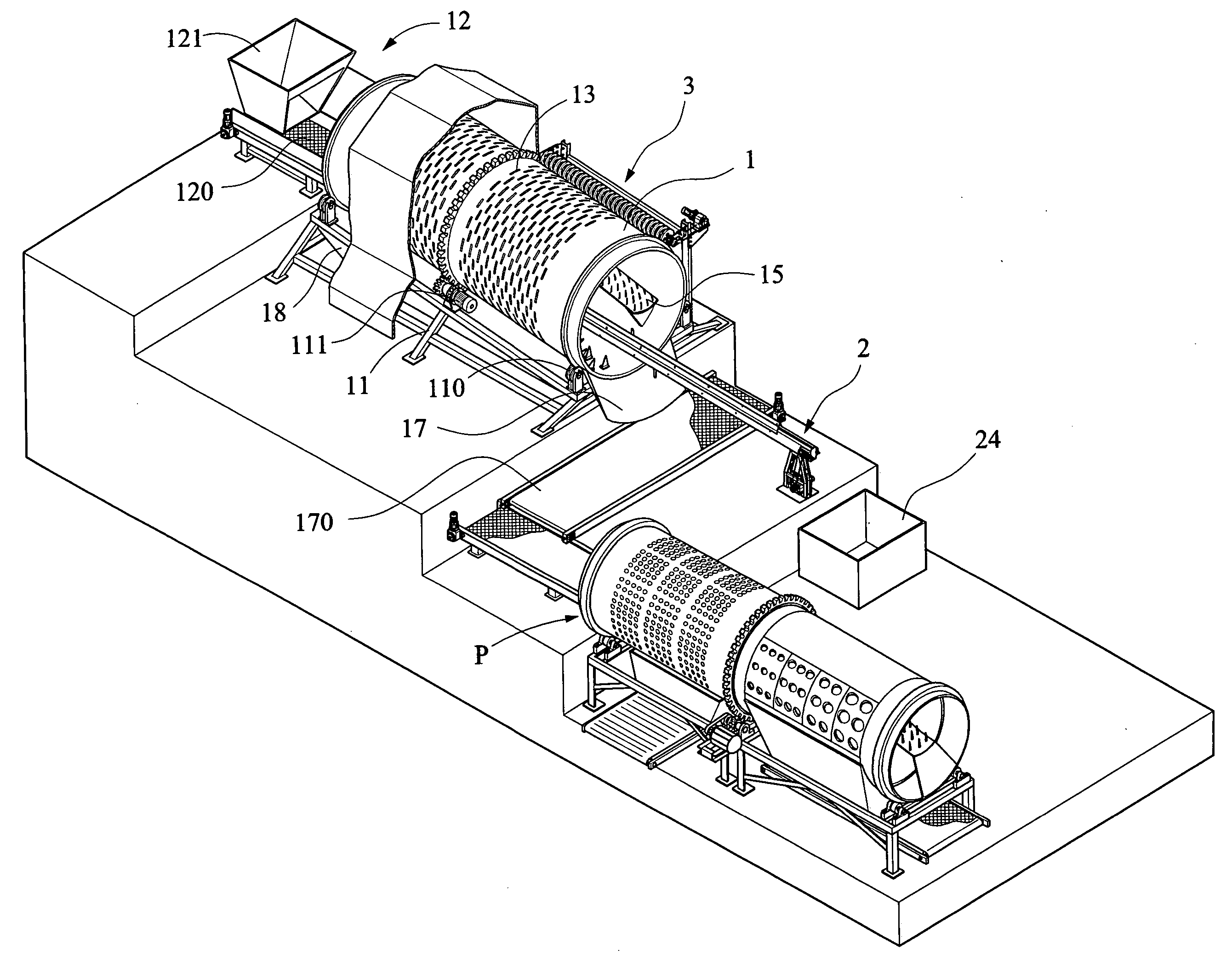

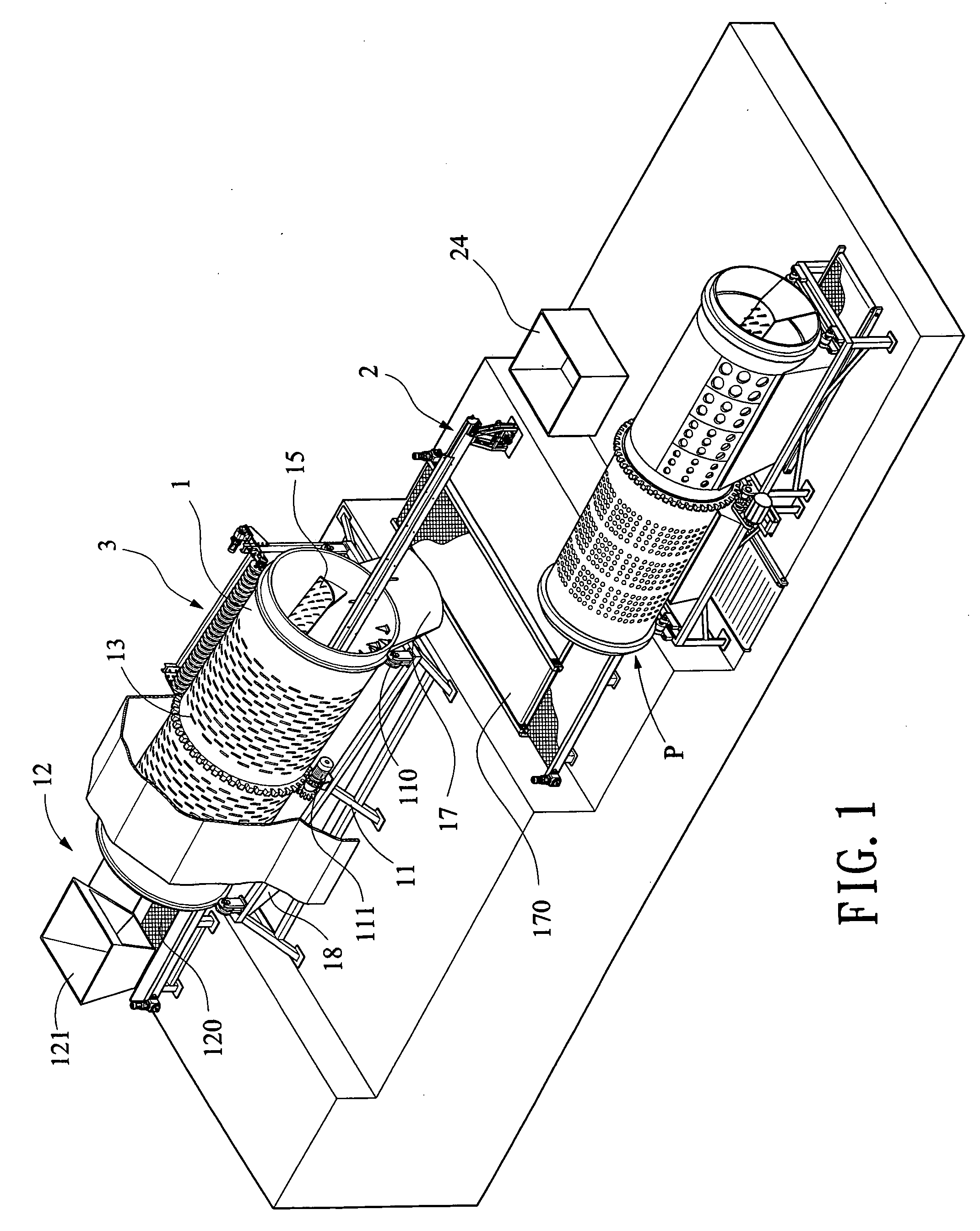

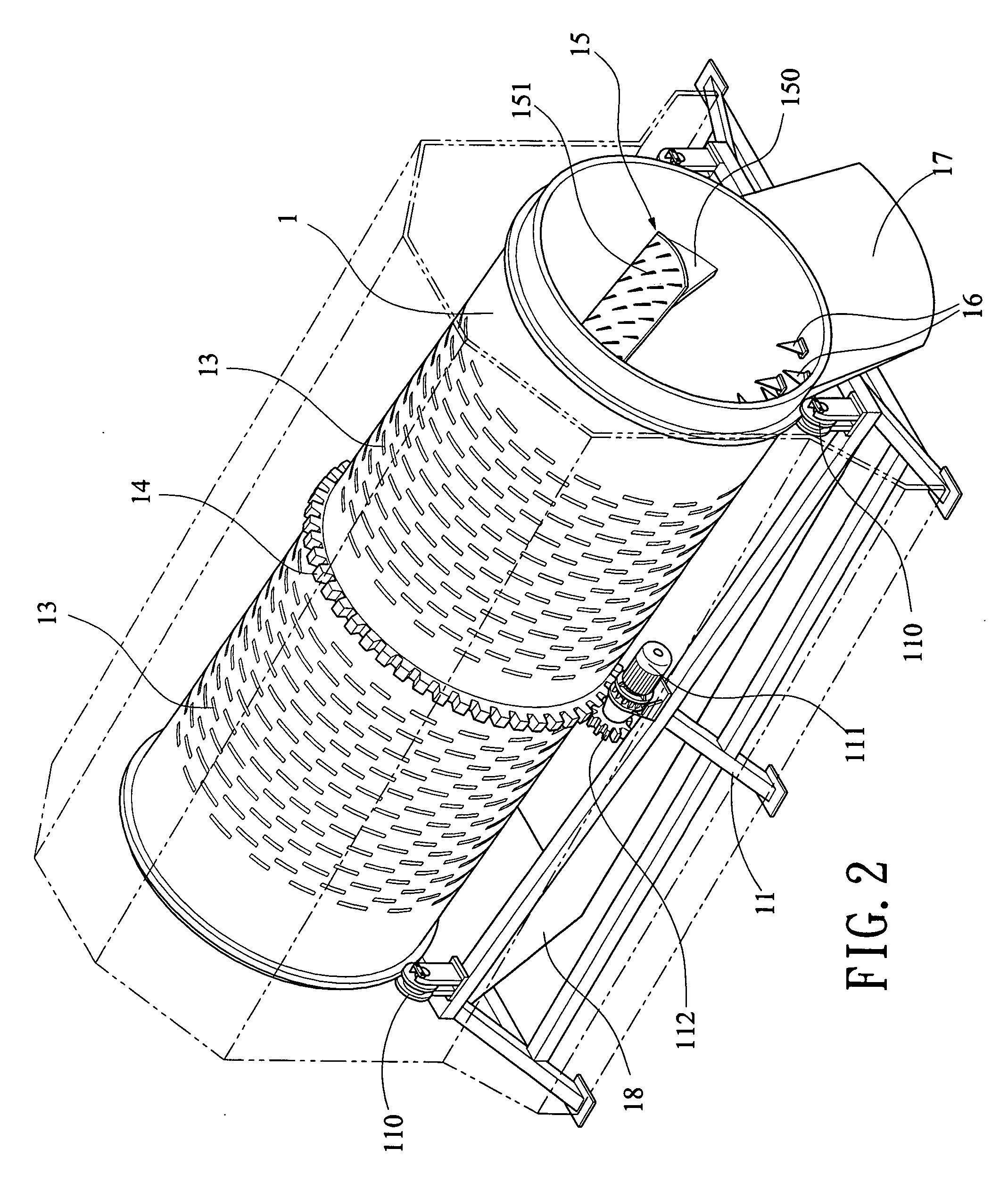

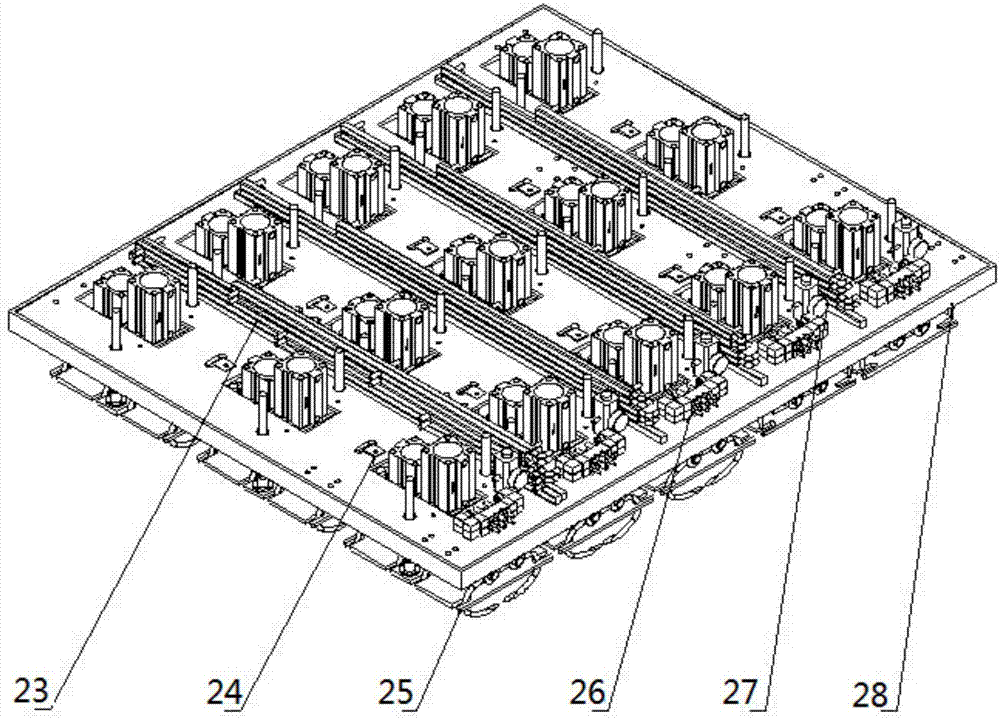

Apparatus for piercing garbage bags and collecting nonrigid, elongate objects and powder

Provided is an apparatus comprising a screen assembly for sifting powder including a rear feeding device, a first conveyor adapted to convey garbage bags from the feeding device to the screen assembly, an inclined board extended downwardly from a front end of the screen assembly, and a second conveyor provided below the board, the second conveyor being adapted to convey materials leaving the screen assembly to a subsequent station for processing; and a nonrigid, elongate object collection assembly extended from the rear of the screen assembly through the screen assembly to a point in front of the screen assembly, the object collection assembly including an elongate housing of rectangular section, a gable roof provided on the housing, a lengthwise gap provided on a top of the gable roof, and a container provided below a front end thereof for collecting nonrigid, elongate objects dropped therefrom.

Owner:WST INT HLDG

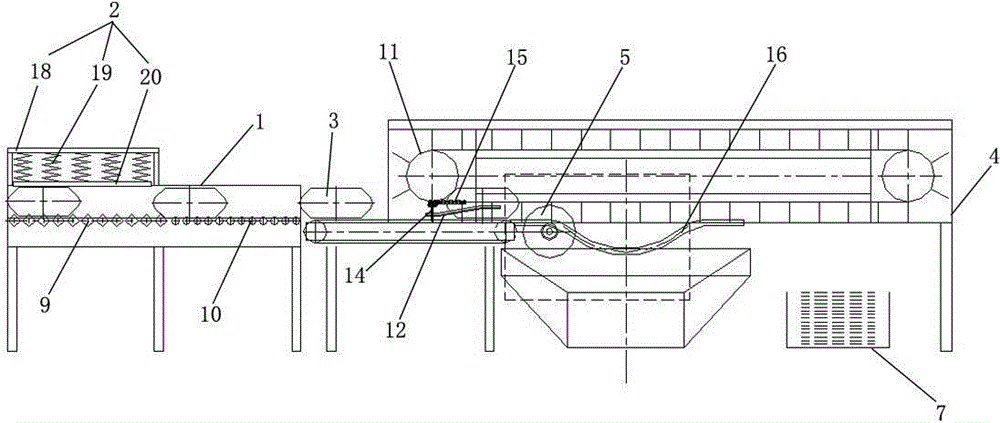

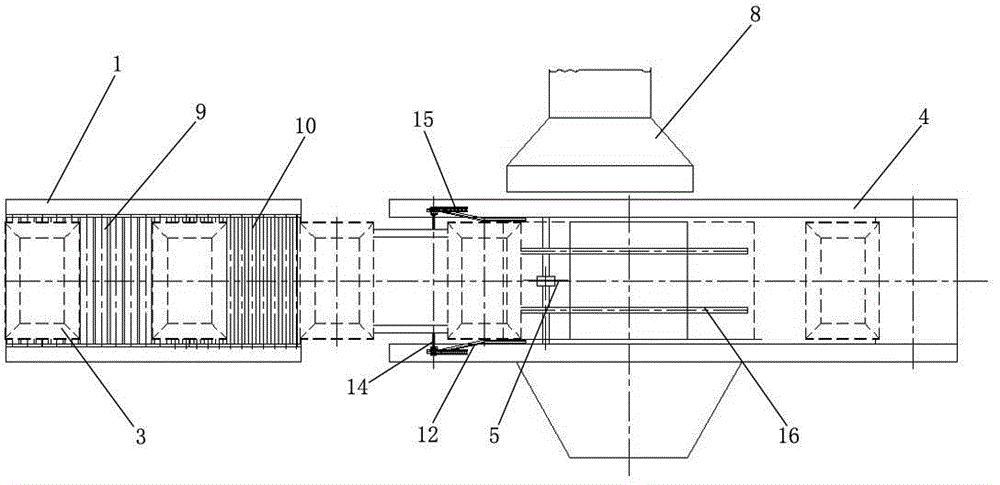

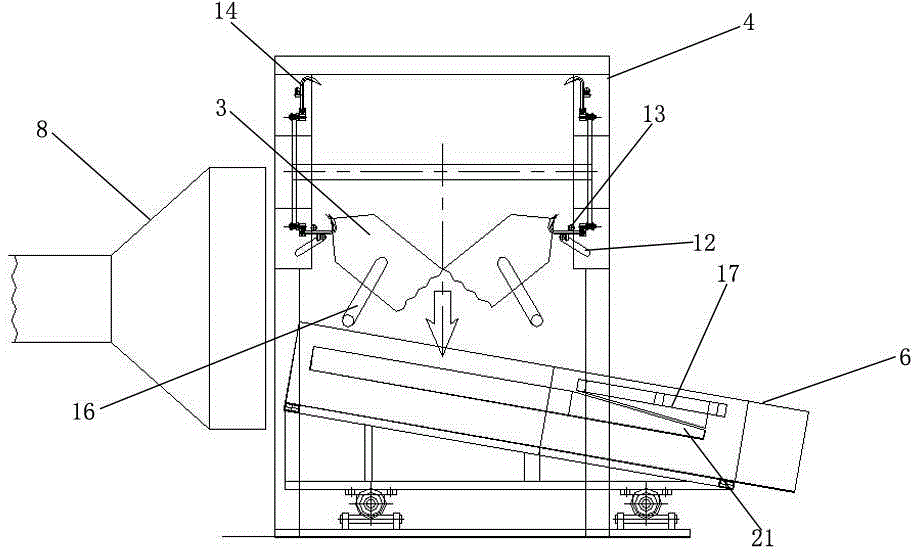

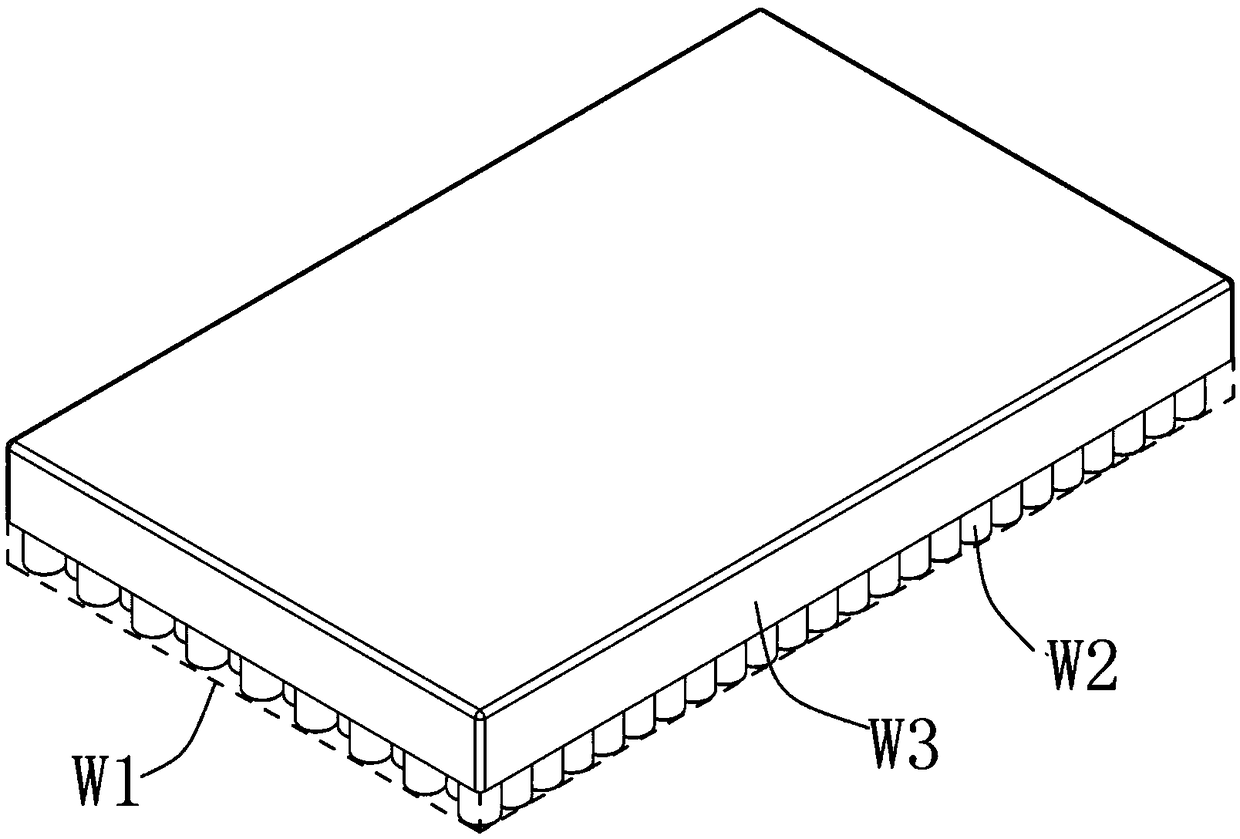

Novel intelligent unpacking system

InactiveCN106927091AReduce consumptionIncrease productivityConveyor partsUnpacking by cuttingControl systemMaterial transport

The invention discloses a novel intelligent unpacking system. The novel intelligent unpacking system comprises a loading station, a bag pressing station, an unpacking station, a chipping separation station, a bag collection station and a control system, wherein the loading station comprises two material transport devices, one material transport device places material bags onto the bag pressing station, and the other material transport device rapidly conveys the material bags to the unpacking station and the bag collection station from the bag pressing station; primary crushing is carried out on hardened blocks in the material bags at the bag pressing station; the bottoms of the material bags are cut at the unpacking station, and then the material bags are beat through the reciprocating rectilinear movement of a swing lever to guarantee thorough shaking-off for materials in the material bags, and secondary crushing is carried out on the materials in a hopper; then the materials are conveyed to the chipping separation station through a conveying device; chippings are eliminated from the materials at the chipping separation station; the material bags are collected and arranged at the bag collection station; and the control system controls the loading station, the bag pressing station, the unpacking station, the chipping separation station and the bag collection station.

Owner:山东森烨生态工程有限公司

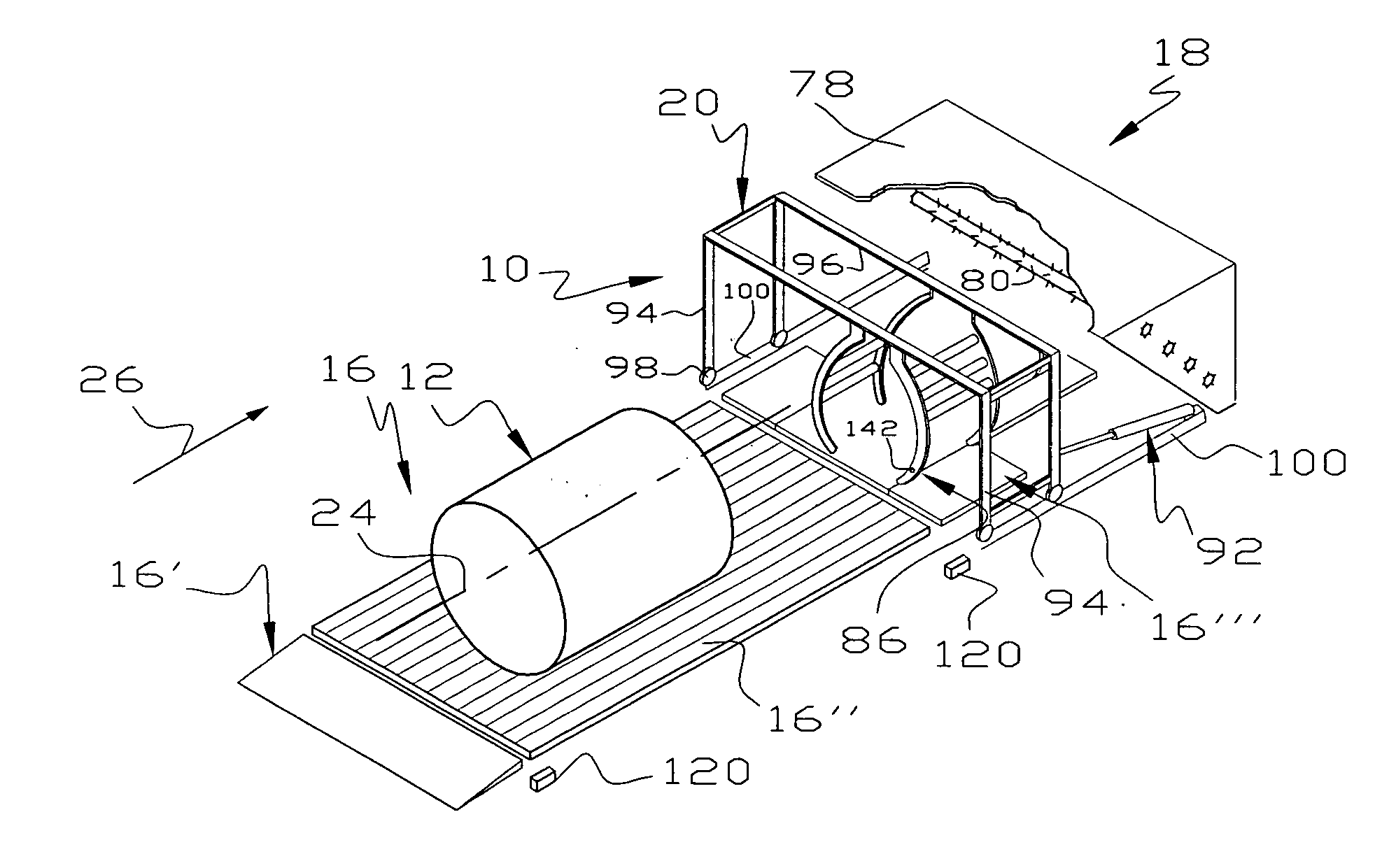

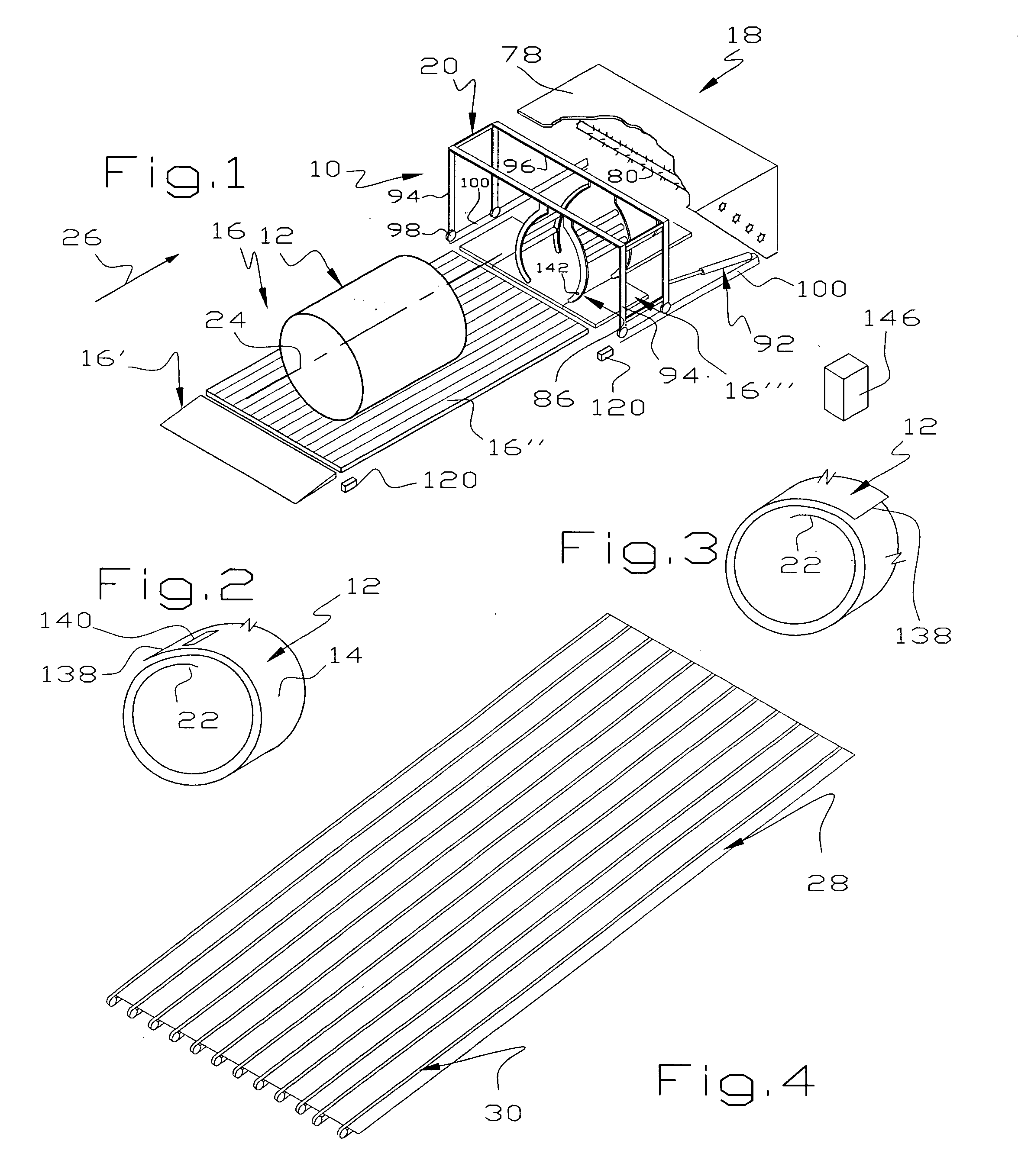

Digesting cylindrical modules

A conveyor delivers a series of cylindrical wrapped fibrous modules to a station where the module is lifted off the conveyor and an operation conducted on the module. One operation is to find a tail, or unattached segment, of the cover. Another operation is to remove the cover, by slitting and then unwinding it. The cover is delivered to a storage area and the contents of the module are delivered into a hopper, or in some embodiments, into a disperser. In some embodiments, a grabber moves the slit cover from adjacent a slitting position to a storage area and includes a guide wheel for moving a conveyor up and down in response to the configuration of the round module. In one embodiments, the plastic cover is removed manually by workers guiding the plastic wrap as it is unrolled by the unrolling device.

Owner:STOVER EQUIP

Shipping and display container

A packaging container, adapted to be cut to establish a display container for products stored therein, is formed with corner slits having a primary slit portion extending around a respective corner of the container, as well as secondary slit portions which extend at non-linear angles to the primary slit portion. Between the corner slits, the container can be provided with cut lines to act as a guide for a cutting instrument used to separate the container into top and bottom sections, with the bottom section establishing the display container. With the inclusion of the corner slits, the cutting instrument need not make any cuts through the corners. In addition, cuts made between the corner slits need not be perfectly aligned between respective primary slit portions due to the existence of the secondary slit portions.

Owner:GENERAL MILLS INC

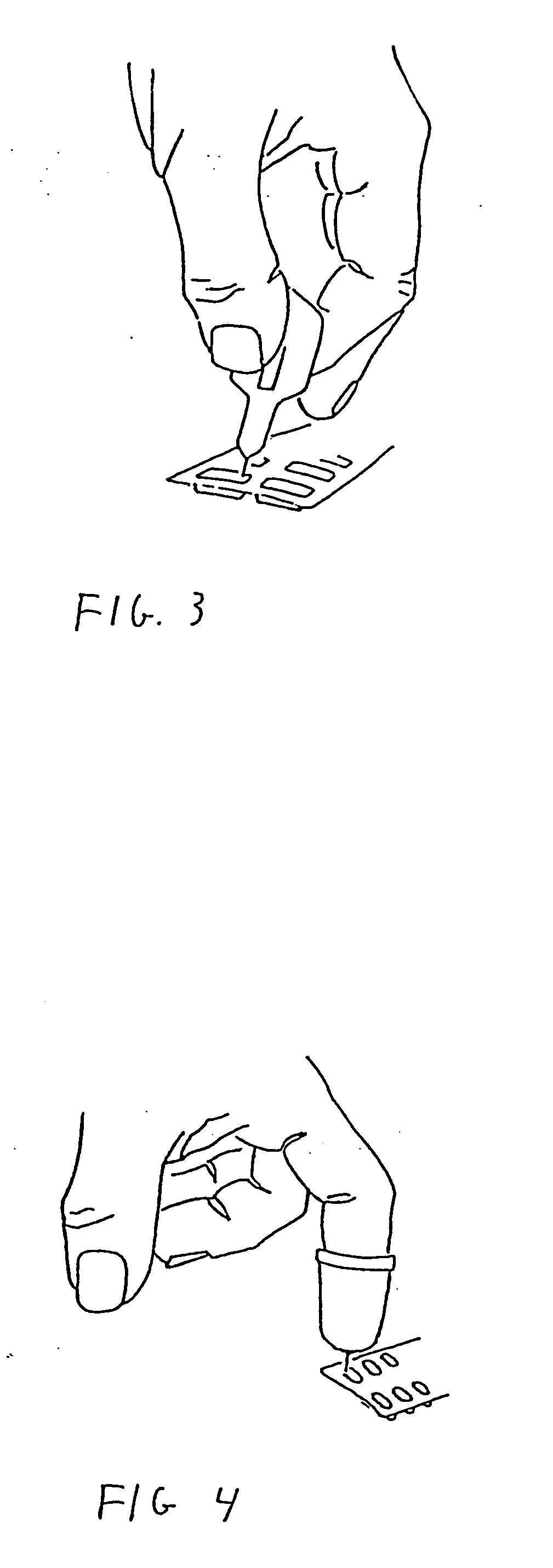

Clam Shell and Blister Package Opening Device and Method for Using Same

InactiveUS20050102838A1Reduce frictionPortable power-driven toolsMetal working apparatusEngineeringHand held devices

Opening a blister or clam shell package with a continuous linear cut includes positioning the package between jaws, at least one of which includes a cutting surface, moving the jaws to a compressed position in which the cutting surface penetrates the package, and sliding the jaws relative to the package while maintaining the jaws in the compressed position. Several handheld devices to implement the method are described, including variations in which the handheld device has fixed jaws and in which the device is an appliance. Devices include at least one bearing surface which reduces the risk of cutting users and things other than the package to be opened.

Owner:LEASON DAVID

Automatic and continuous bag-breaking and unloading device

ActiveCN104960717ACompact front and backPractical and reliable mechanical structureUnpacking by cuttingButt jointEngineering

The invention discloses an automatic and continuous bag-breaking and unloading device. The automatic and continuous bag-breaking and unloading device comprises a bag reshaping area, a belt conveyer and a bag-breaking unloading area which are arranged on the front, middle and rear sections respectively. The bag-breaking reshaping area comprises a vibration machine frame and a spring supporting frame, wherein the spring supporting frame is arranged above the vibration machine frame in an erected mode; the vibration machine frame is provided with a transmission roller mechanism; a floating interval where bags pass in a reshaping mode is kept between the spring supporting frame and the transmission roller mechanism; the front portion of the belt conveyer is in butt joint with the transmission roller mechanism, and the rear portion of the belt conveyer is in butt joint with the bag-breaking unloading area; the bag-breaking unloading area comprises a rack, a hook mechanism, a cutter, a vibration sieving mechanism, an empty bag collecting frame and a dustproof mechanism. The automatic and continuous bag-breaking and unloading device is simple and compact in structure, integrates the integration and reshaping procedure and the bag-breaking unloading procedure, realizes an automatic and continuous production mode of bag reshaping and bag-breaking unloading, is economical and durable, and is not prone to having faults after being operated for a long time.

Owner:HANGZHOU WAHAHA GROUP

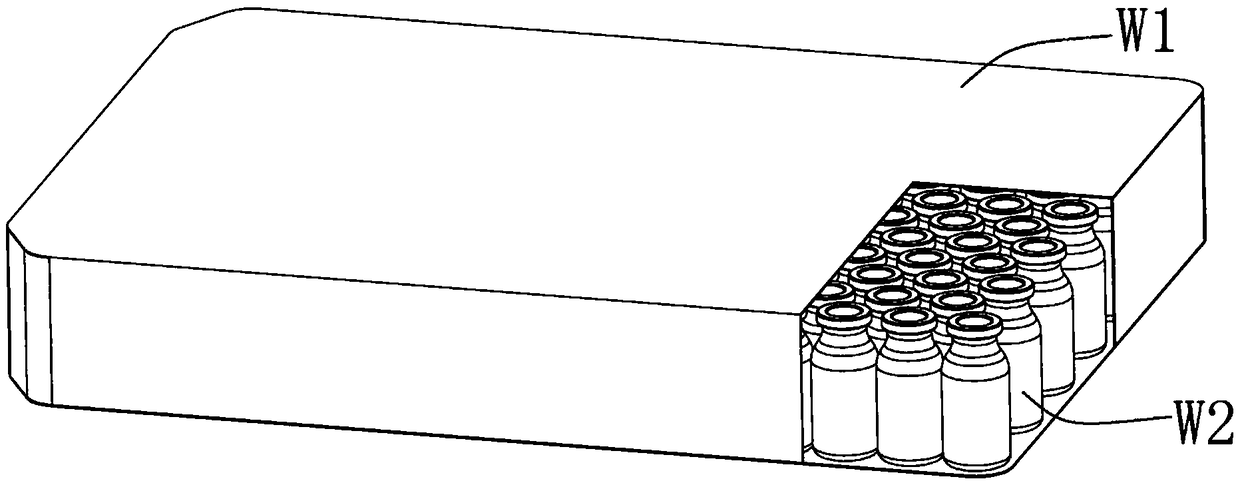

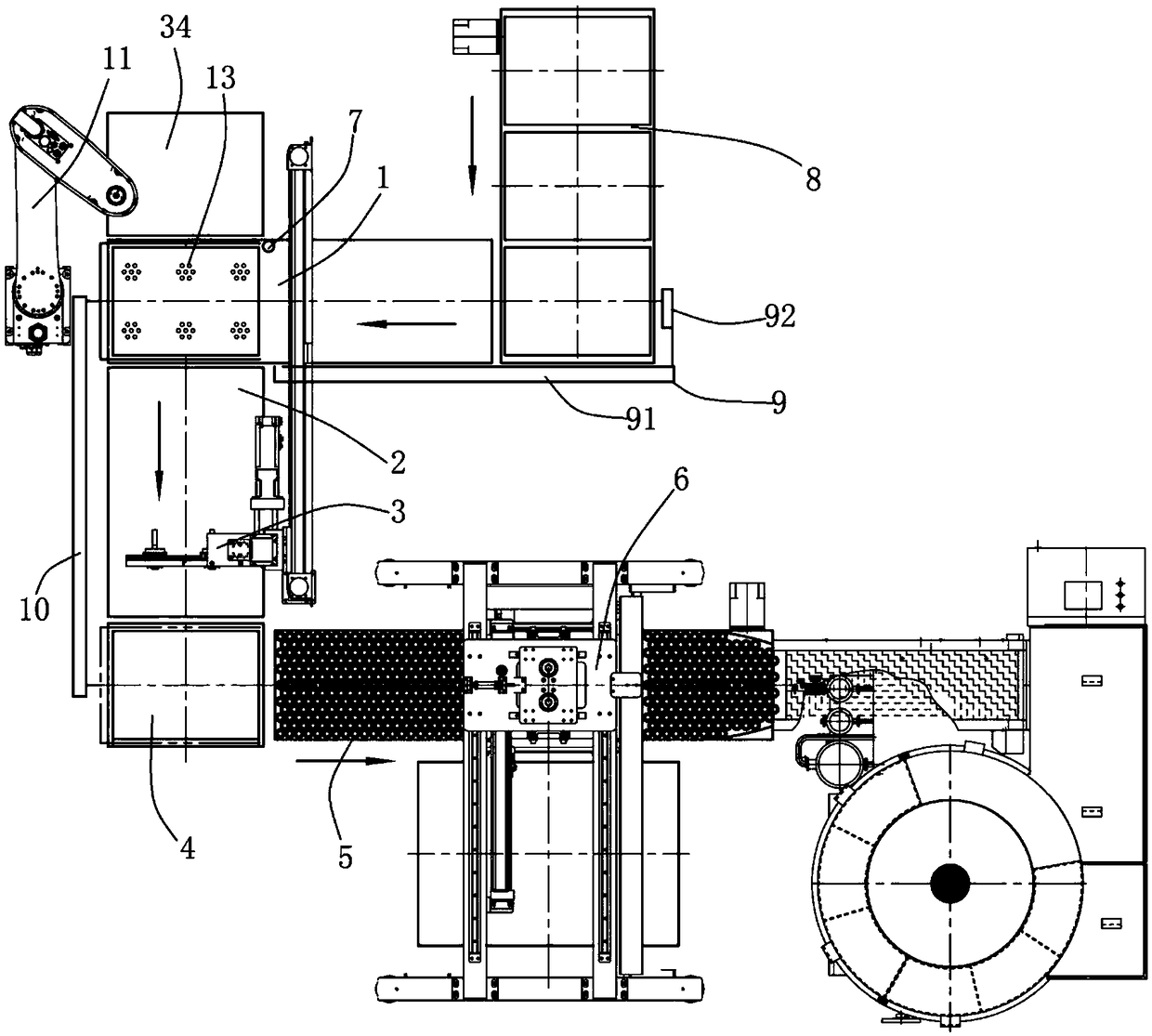

Unpackingg device for multi-purpose bottle package and unpacking method thereof

ActiveCN108860870ASolve the costAddress operational complexityUnpacking by cuttingButt jointEngineering

The invention discloses an unpacking device suitable for a multi-purpose bottle package. The unpacking device comprises a film cutting platform, a conveying platform, a film clamping platform, a plastic and film separating mechanism, a bottle conveying track, and a tray taking mechanism, wherein a first vacuum suction cup is arranged on the film cutting platform, and a film cutting manipulator isarranged at one side of the film cutting platform; the film cutting manipulator is provided with a film cutting cutter, and is used for performing annular four-sided cutting or three-sided cutting ofa packaging film on a bottle packaging material, and the starting end of the conveying platform butts up to the film cutting platform; the film clamping mechanism is arranged at one side, away from the film cutting manipulator, of the conveying platform, and is used for clamping a top film of the bottle packaging material of which the three sides are cut, and the input end of the plastic and filmseparating mechanism is in butt joint with the tail end of the conveying platform, and is used for separating a bottom film of the bottle packaging material of which the four sides are annularly cut and the three sides are cut from the bottom of a container bottle; the bottle conveying track is in butt joint with the output end of the plastic and film separating mechanism, and the tray taking mechanism is arranged above the bottle conveying track, and is used for taking a paper tray and the top film at the top of the bottle packaging material of which the four sides are annularly cut. The unpacking device can be used for unpacking the packaging film of the whole plastic film bottle packaging material, and can also be used for unpacking the packaging film and the paper tray of the paper tray plastic film bottle packaging material.

Owner:TRUKING TECH LTD

Blister knife

InactiveUS20050210682A1Reduce penetrationAvoid unintended cutsThrusting weaponsWeapon componentsBlister packBlisters

A device for opening blister packs without annular depressions around the blisters serving as guidance trails is provided comprising a handle and a cutter having a suitable transverse dimension and form of cross section at the position of the intended cutting, making it suitable for cutting the foil of the type used in blister packs, and for opening any pack or container wrapped in a foil or any other cutable material or tape used for packaging as such. A preferred cutter is having cutter formed essentially as a rod and further provided with a point in order to facilitate penetration of foils. The device may be provided with means for protection of the cutter in order to avoid unintended cuts during storage and transport. The handle of the device may be shaped in order to facilitate the use by elderly and / or patients suffering from a rheumatic disease. The device is versatile and simple to use and may provide a relief of a long felt problem for nurses and other medical staffs, elder patients and in particular patients suffering from a rheumatic disease.

Owner:BARTHOLIN HENRIK

Device for assisting treatment of sepsis

The invention provides a device for assisting treatment of sepsis. The device comprises a bed body, wherein a first bed board is fixedly connected on the left side of the upper end of the bed body; asecond bed board is hinged at the right end of the first bed board, and a third bed board is hinged at the left end of the first bed board; a lifting device is arranged at the lower end of the insideof the bed body; a turnover device which can be used for controlling over turning of the second bed board and the third bed board is arranged at the upper end of the inside of the bed body; a cross beam which can move left and right along the second bed board; and a clamping block is arranged on the cross beam, and an arc opening plate is arranged under the center position of the cross beam. According to the device, the mouth of a patient can be opened through the opening plate, and a tracheal catheter can be conveniently inserted into the trachea when mechanical ventilation is performed on the patient, and unsmooth ventilation caused by the fact that the patient bites into the catheter under an unconscious situation can be prevented; the catheter can be fixed through the clamping block during ventilation, an existing mode of sticking the catheter onto the patient face with a medical adhesive tape is replaced, the fixing soundness of the catheter can be reinforced, and the device can be turned from the form of a hospital bed to the form of a hospital chair to facilitate movement.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Method of handling clamshell containers containing a particulate aliquot

A method for handling package assemblies in an automated aliquot and / or dispersal processes is provided. Embodiments of the present invention include, but are not limited to, a method of handling a package assembly containing a particulate aliquot (such as a selected type of agricultural seed) that includes first and second portions which cooperate to contain the aliquot, the method including receiving the package assembly in a package assembly handling device, and applying a force to the package assembly using the package assembly handling device so that the first and second portions at least partially separate in response to the force.

Owner:PIONEER HI BRED INT INC

Unwrapping stretch film from a palletized load

ActiveUS7343722B1Cost effectiveProjector film strip handlingFilament handlingEngineeringMechanical engineering

An apparatus for unwrapping stretch film from a palletized load. The unwrapping apparatus can also include a spooler unit for collecting the film after the film has been cut by the cutting unit. The spooler unit can include a roller guide having two roller members which can be selectively positioned in one of an open position or a closed position. The spooler unit can include a stripper plate, one or more spooler forks, and a shuttle pin. The shuttle pin can be movable within a channel of the stripper plate to rotate within close proximity of one spooler fork during rotation of the spooler unit.

Owner:TASK AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com