Unpackingg device for multi-purpose bottle package and unpacking method thereof

A bottle package and application technology, applied in the field of unpacking equipment, can solve the problem of not being able to dismantle different bottle packaging materials, achieve the effect of improving versatility and automation, and saving equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

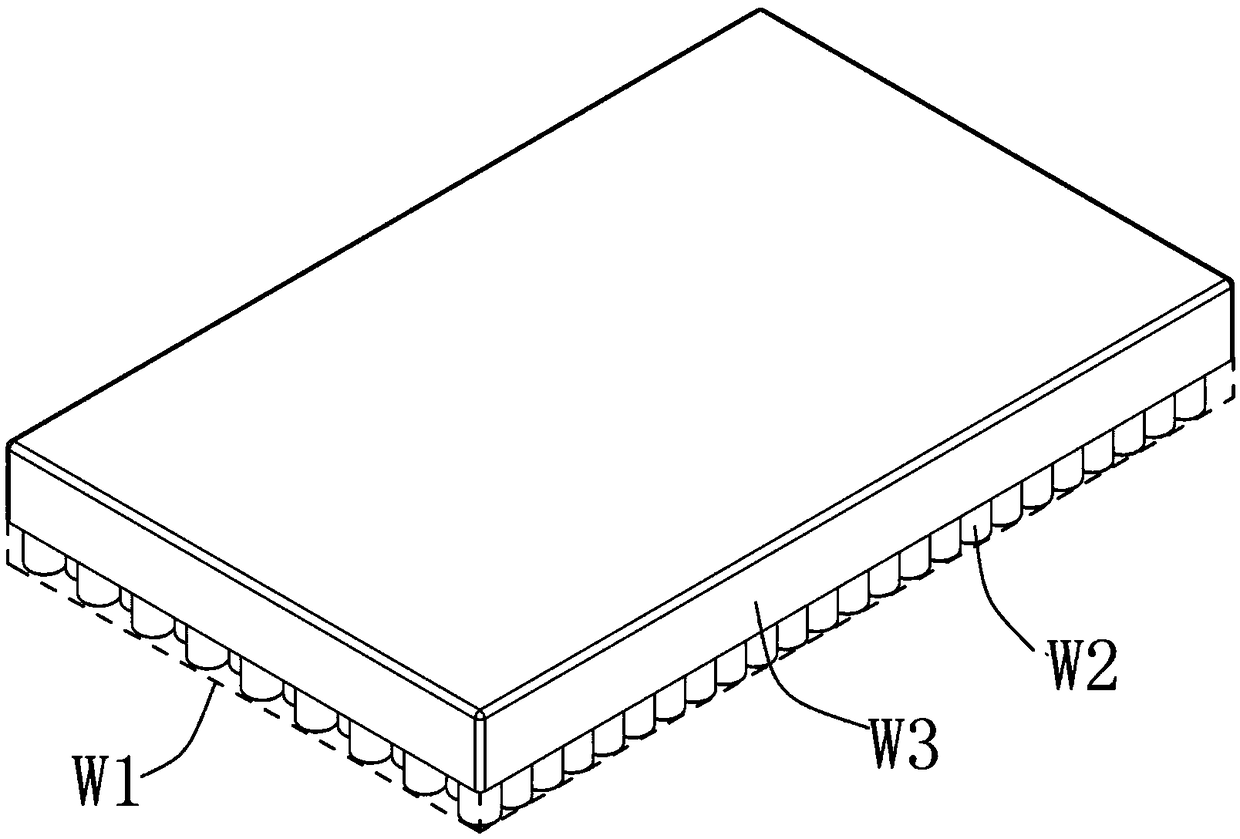

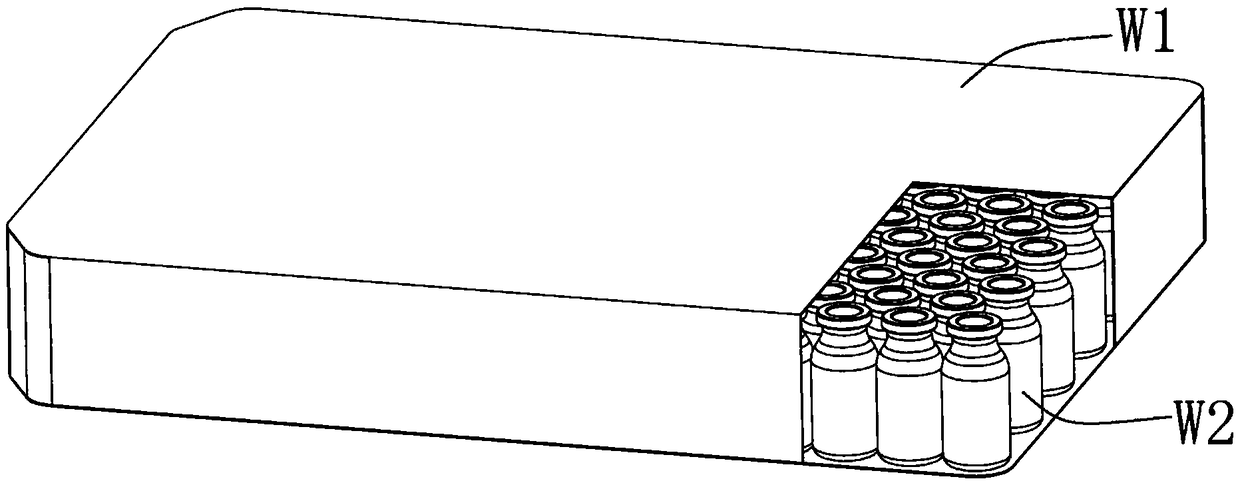

[0076] This embodiment 1 proposes an unpacking device suitable for multi-purpose bottle packs, which is used to unpack two kinds of packaged bottle packaging materials. One is the paper-supported plastic film bottle packaging material, such as figure 1 As shown, many container bottles W2 are arranged in a matrix, and a paper holder W3 is provided at the end of the container bottle W2 near the mouth of the bottle, and then the container bottle W2 and the paper holder are fixed by a heat-shrinkable plastic packaging film (hereinafter referred to as the packaging film W1). W3 is used for wrapping, and the other is the all-plastic film bottle packaging material, without setting the paper support W3, and directly setting the packaging film W1 on the outside of the container bottle W2 for wrapping.

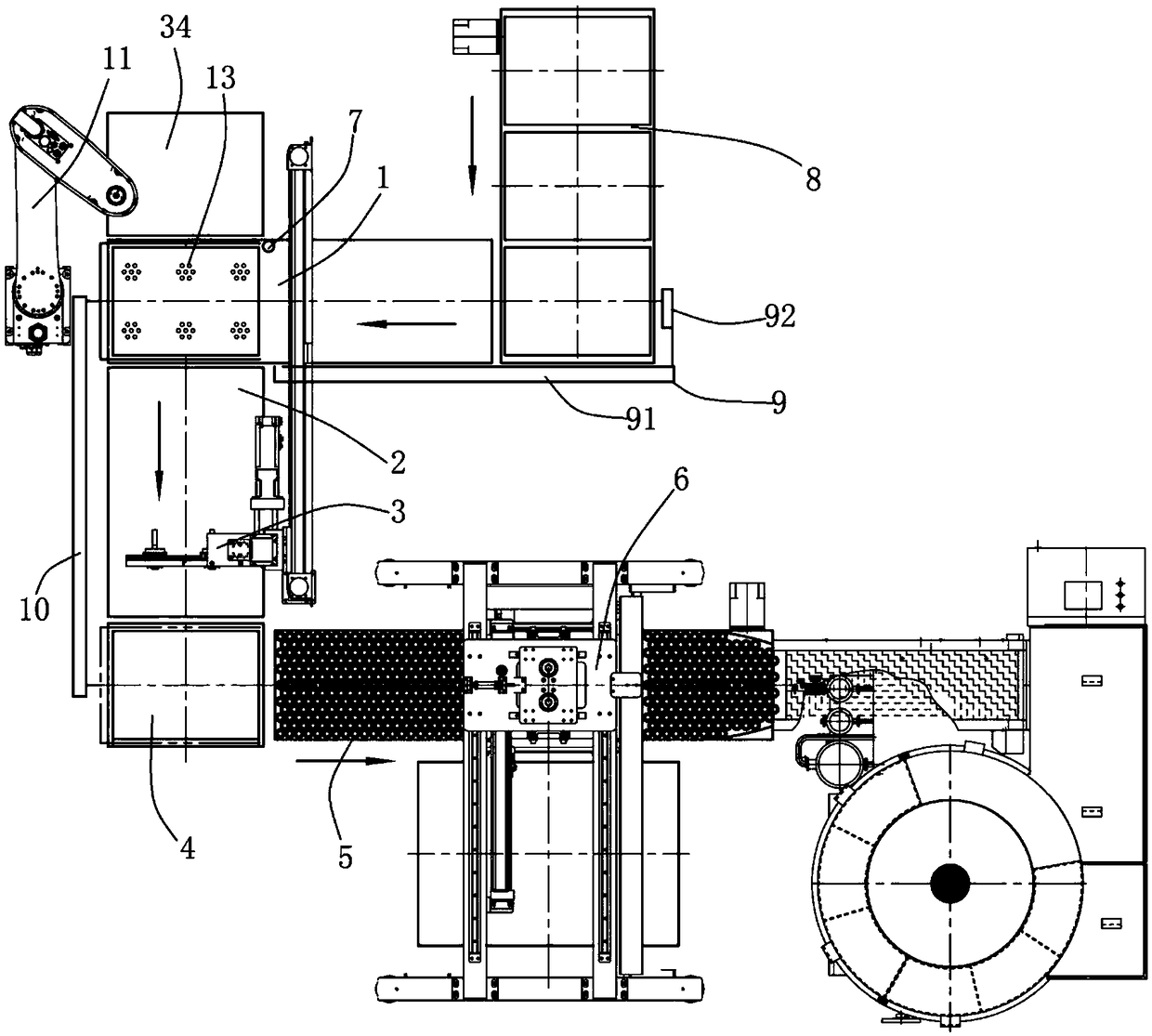

[0077] Please refer to Figure 3 to Figure 11 , the present invention is applicable to the unpacking equipment of multi-purpose bottle bag, comprises:

[0078] A film cutting platform ...

Embodiment 2

[0111] This embodiment 2 proposes an unpacking method suitable for multiple-purpose bottle packs, which is used to remove the packaging film W1 of the all-plastic film bottle packaging material, including the following steps:

[0112] 1. Entering the bottle

[0113] 1. Put the bottle packaging material W into the packaging material conveying track 8, and the packaging material conveying track 8 drives the bottle packaging material W to move to the end of the track and reach the side of the film cutting platform 1;

[0114] 2. The packaging material pushing mechanism 9 pushes the bottle packaging material W onto the film cutting platform 1 .

[0115] 2. At the film cutting station:

[0116] 1. The framing mechanism 10 positions the bottle packaging material W, and the first vacuum suction cup 13 on the film cutting platform 1 absorbs and fixes the bottom film of the bottle packaging material W;

[0117] 2. The film cutting tool 12 is driven by the film cutting manipulator 11,...

Embodiment 3

[0131]This embodiment three proposes a kind of unpacking method that is applicable to multi-purpose bottle bag, is used for removing the packaging film and the paper holder of paper holder plastic film bottle packing material, comprises the following steps:

[0132] 1. Entering the bottle

[0133] 1. Put the bottle packaging material W into the packaging material conveying track 8, and the packaging material conveying track 8 drives the bottle packaging material W to move to the end of the track and reach the side of the film cutting platform 1;

[0134] 2. The packaging material pushing mechanism 9 pushes the bottle packaging material to the film cutting platform 1.

[0135] 2. At the film cutting station:

[0136] 1. The framing mechanism 10 positions the bottle packaging material W, and the first vacuum suction cup 13 on the film cutting platform 1 absorbs and fixes the bottom film of the bottle packaging material W;

[0137] 2. Driven by the film cutting manipulator 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com