Ternary nitric acid nano-molten salt heat transfer and storage medium, preparation method and application thereof

A heat storage medium and molten salt technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of poor thermal stability of calcium nitrate, high upper limit working temperature, and reduce heat preservation energy consumption, etc., to broaden the working temperature range , Overcome the effect of small heat of solution and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-25

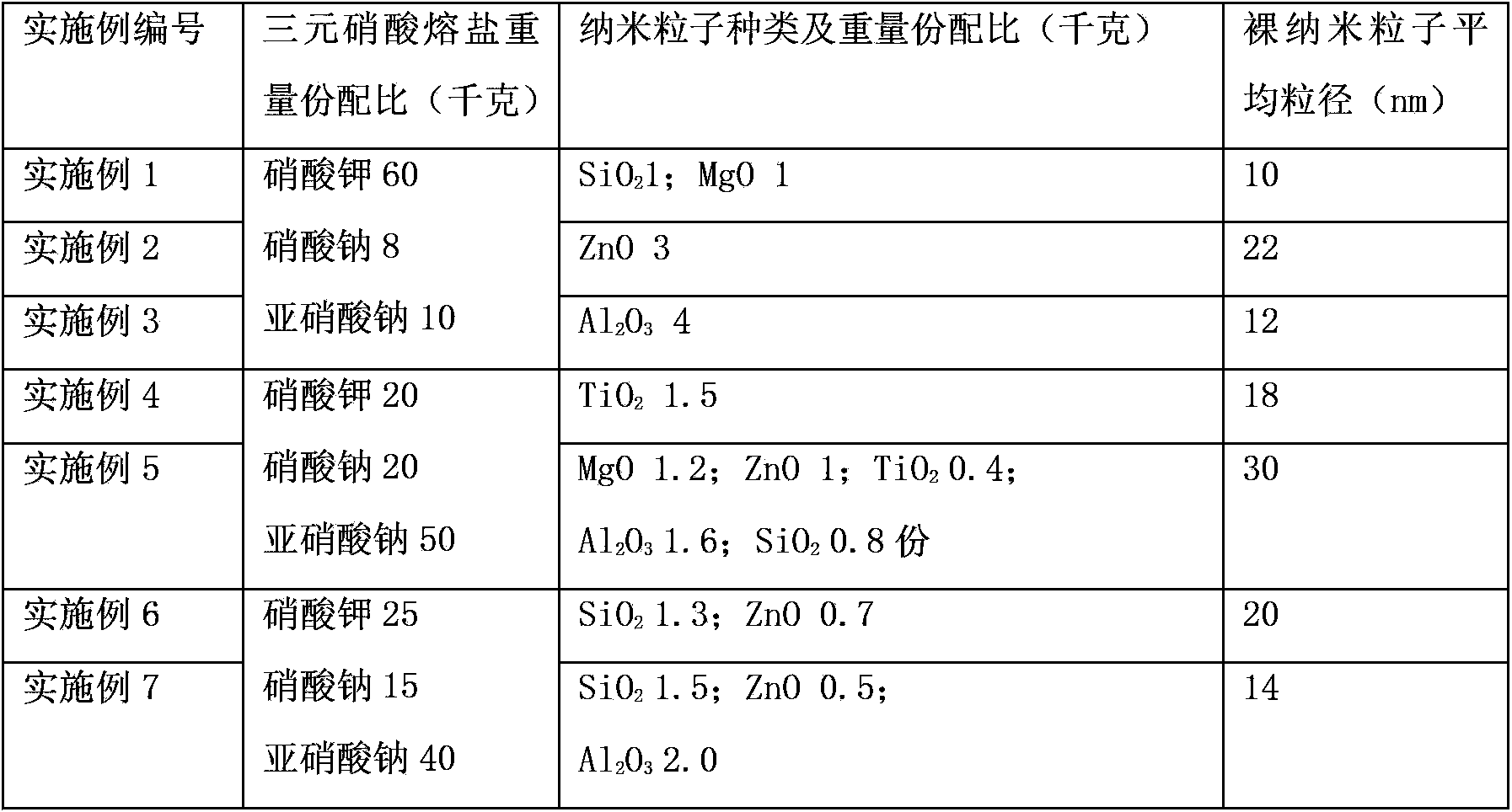

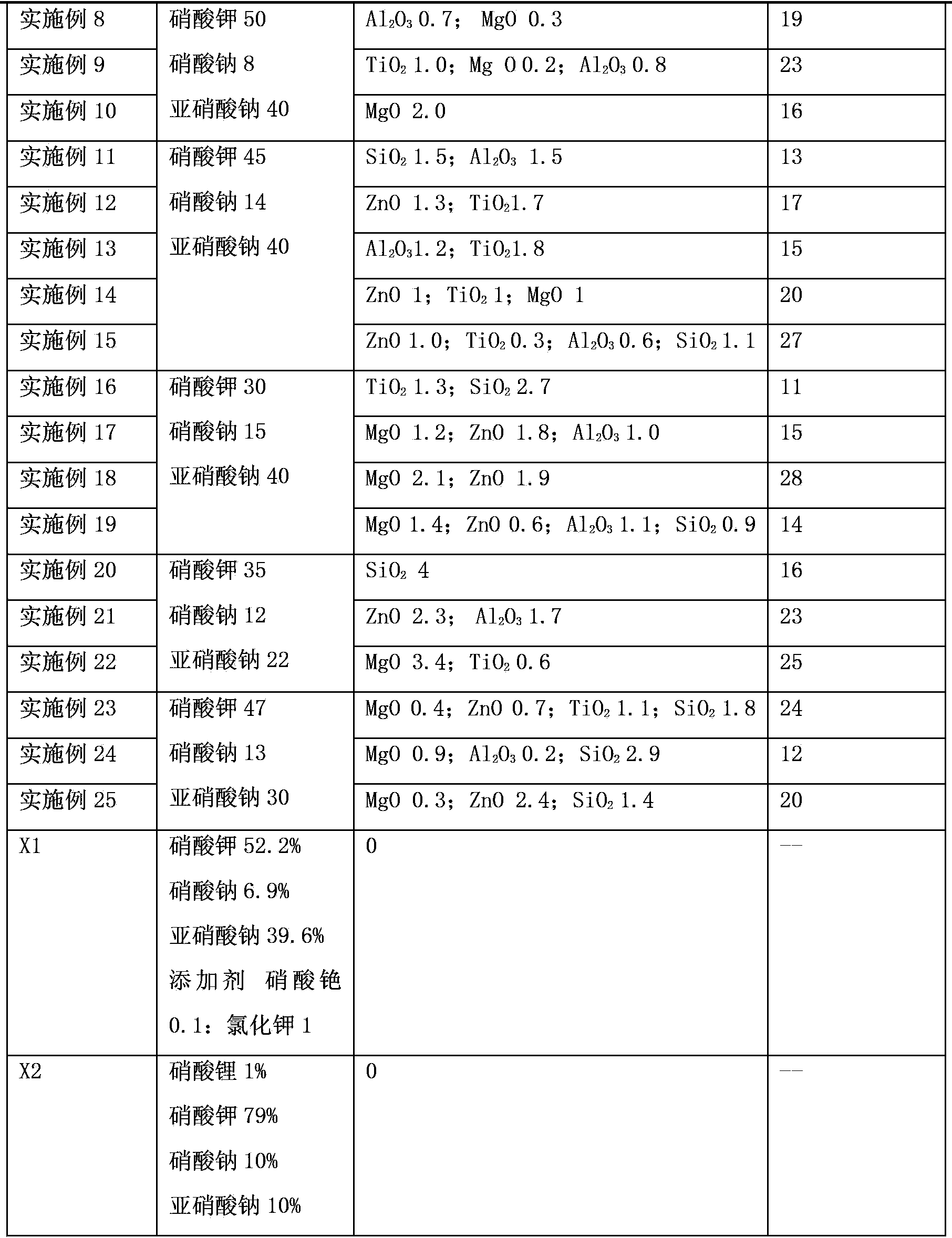

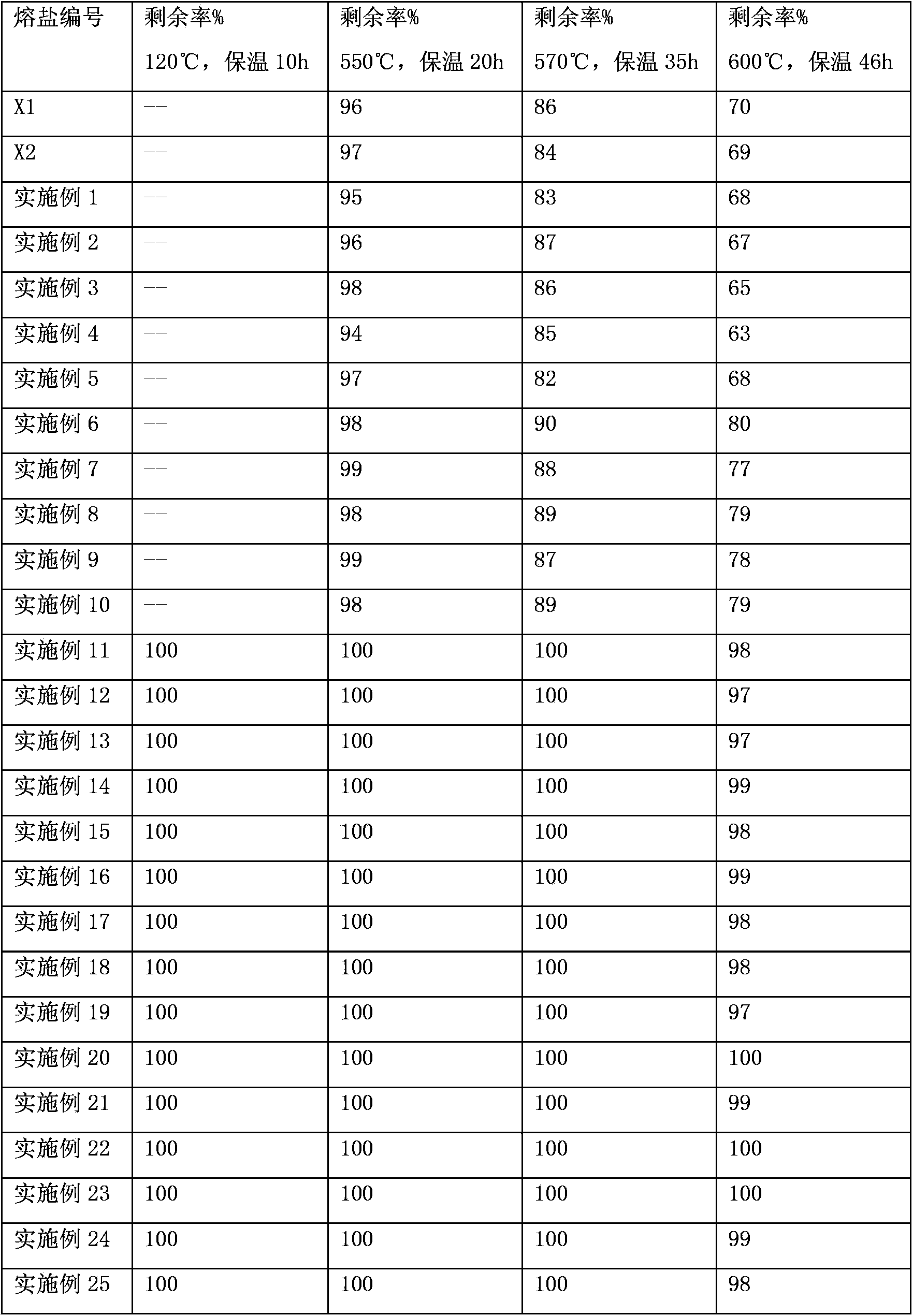

[0051] Examples 1-25 were obtained according to the above-mentioned preparation method. Table 1 shows the formulations of various examples of the present invention and the particle sizes of nanoparticles in the formulations, as well as the formulation (X1) of molten nitric acid salt obtained by adding the fourth component to molten salt of ternary nitric acid according to the prior art and quaternary nitric acid Recipe for Molten Salt (X2)

[0052] Among them, the Chinese invention patent with the application number of 200710027954.1 discloses a molten salt heat transfer heat storage medium and its preparation method, X1 is the nitric acid molten salt with additives obtained by the inventor according to the formula and preparation method described in Example 1 of the specification ;

[0053] The Chinese invention patent with application number 00111406.9 discloses a kind of (LiNO 3 -KNO 3 -NaNO 3 -NaNO 2 ) mixed molten salt and preparation method, X2 is the quaternary nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com