Cutting and fusing device and elastic band manufacturing machine

A tape and cutter technology, used in textiles and papermaking, metal processing, cutting of textile materials, etc., can solve the problems of insufficient quality of the belt, unstable force of the raw material of the tape, and inability to cut the raw material of the tape completely. Achieve stable processing and consistent cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

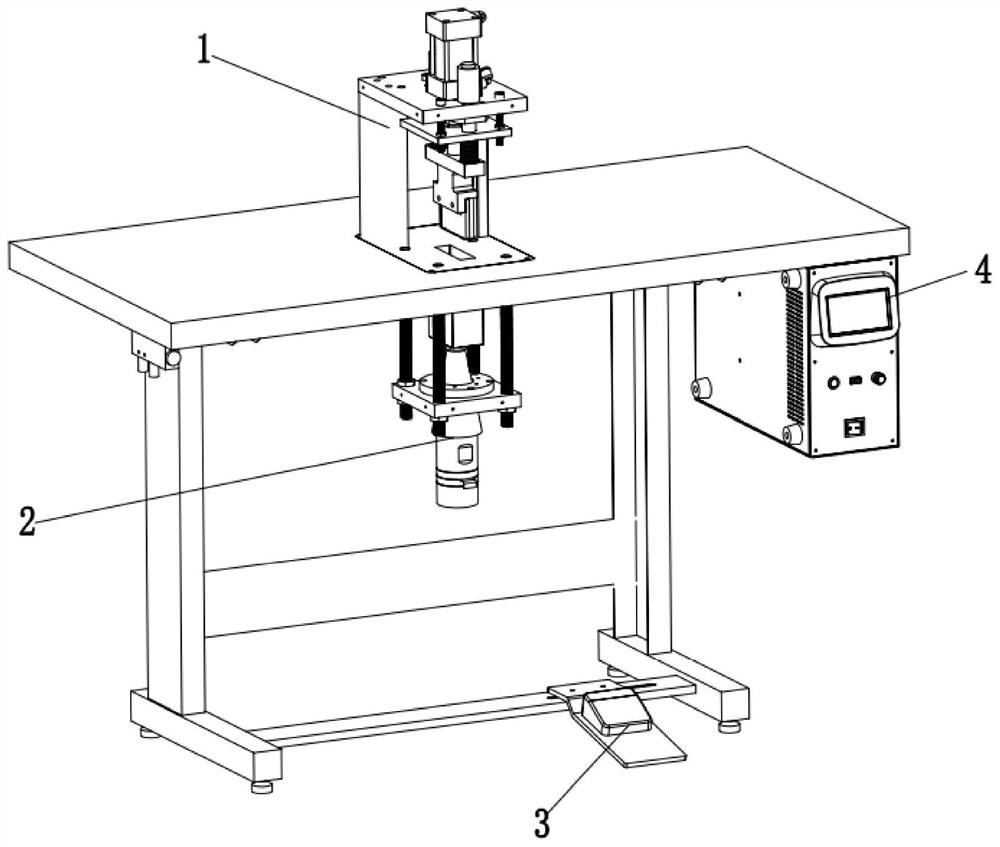

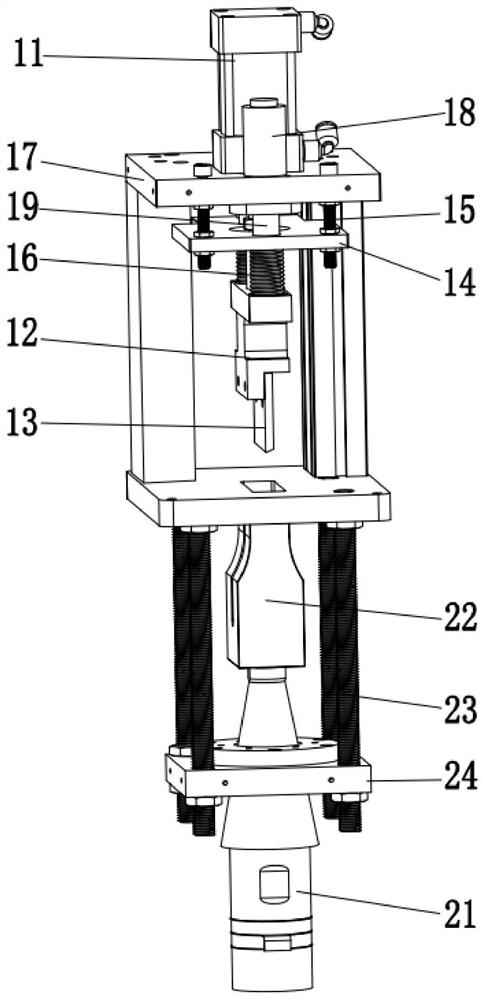

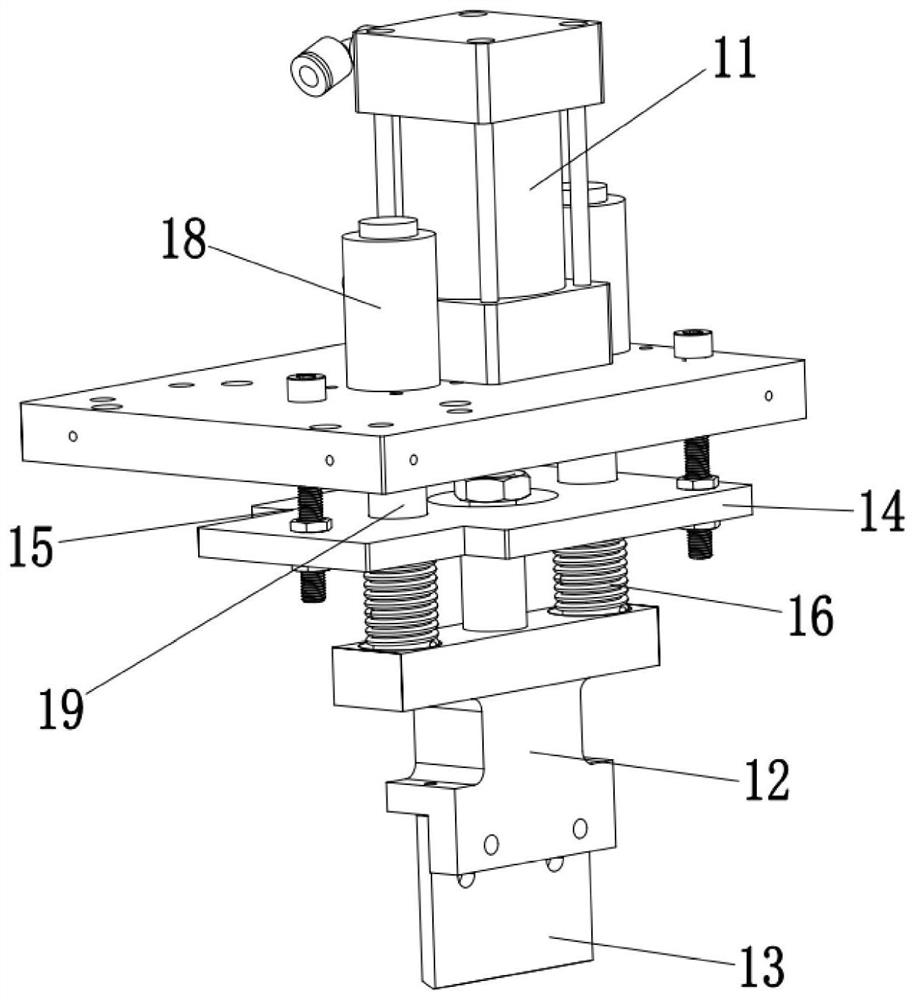

[0029]Such asfigure 1 As shown, this embodiment provides a cutting and fusing device for cutting and fusing a cloth belt. The cloth belt can be the waistband of underwear or other clothing. The cutting and fusing device includes an ultrasonic vibration component 2, a cutting component 1, a control component and an elastic component. Wherein, the ultrasonic vibration assembly 2 and the cutting assembly 1 are arranged oppositely, the ultrasonic vibration assembly 2 can be up and the cutting assembly 1 is down; or the ultrasonic vibration assembly 2 can be down and the cutting assembly 1 is up, and there is no position limitation. In this embodiment, the cutting assembly 1 is on the top, and the ultrasonic vibration assembly 2 is on the bottom. The control component is connected to the cutting component 1, and the control component is used to control the cutting component 1 to move away from the ultrasonic vibration component 2. The control assembly can be connected to the cutting asse...

Embodiment 2

[0046]This embodiment provides an elastic band manufacturing machine, including the above-mentioned cutting and fusing device. The elastic belt manufacturing machine can also be equipped with a material preparation device, a belt pulling device and a control device. The material preparation device is used to manufacture the material preparation device of the cloth belt, and the material preparation device is used to attach the rubber rope and the cloth together to form a whole elastic belt. The strapping device is used to stretch the ready elastic strap to a certain length, and the length can be set by the control device, for example, it can be set to a length of 20cm, 30cm or 40cm. The cutting and fusing device is used to cut and fuse the stretched elastic band to form a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com