Pathological hard tissue slicing system

A hard tissue, pathological technology, applied in the field of pathological experiments, can solve the problems of pathologist's operation error, instability, and increased scrapping rate of diseased tissue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

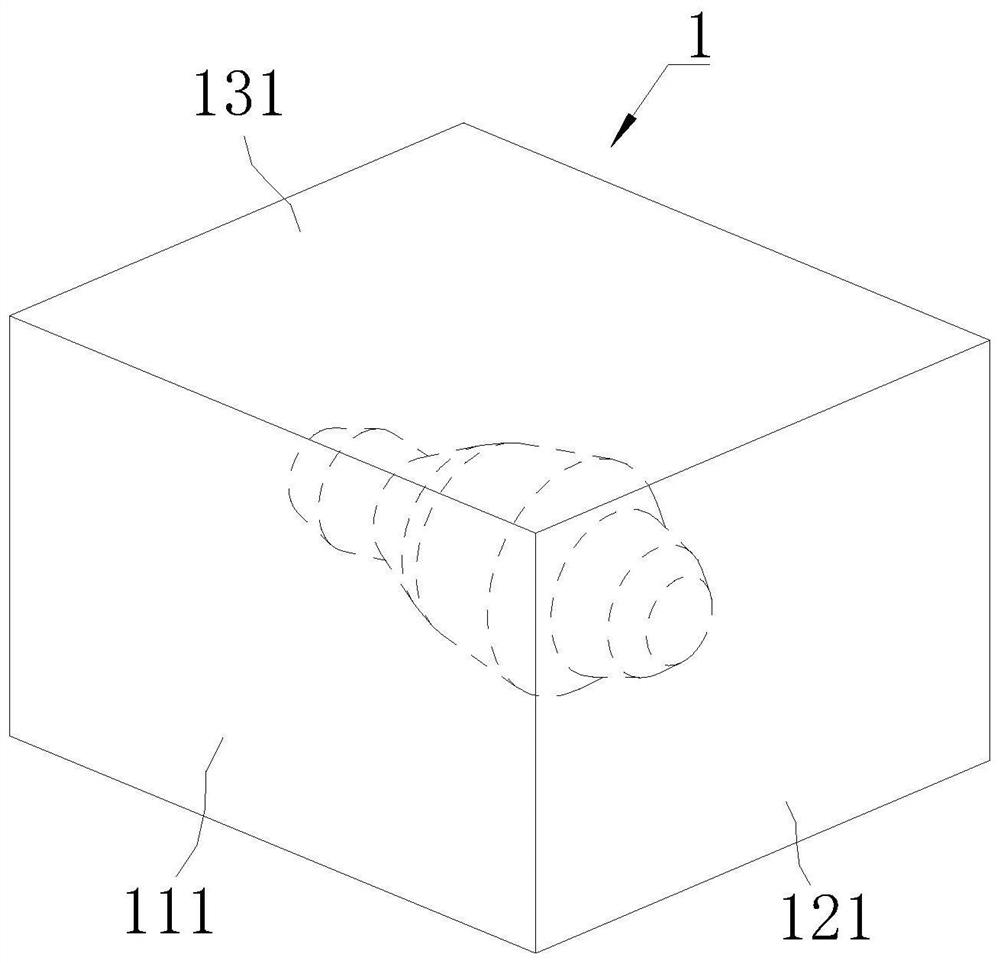

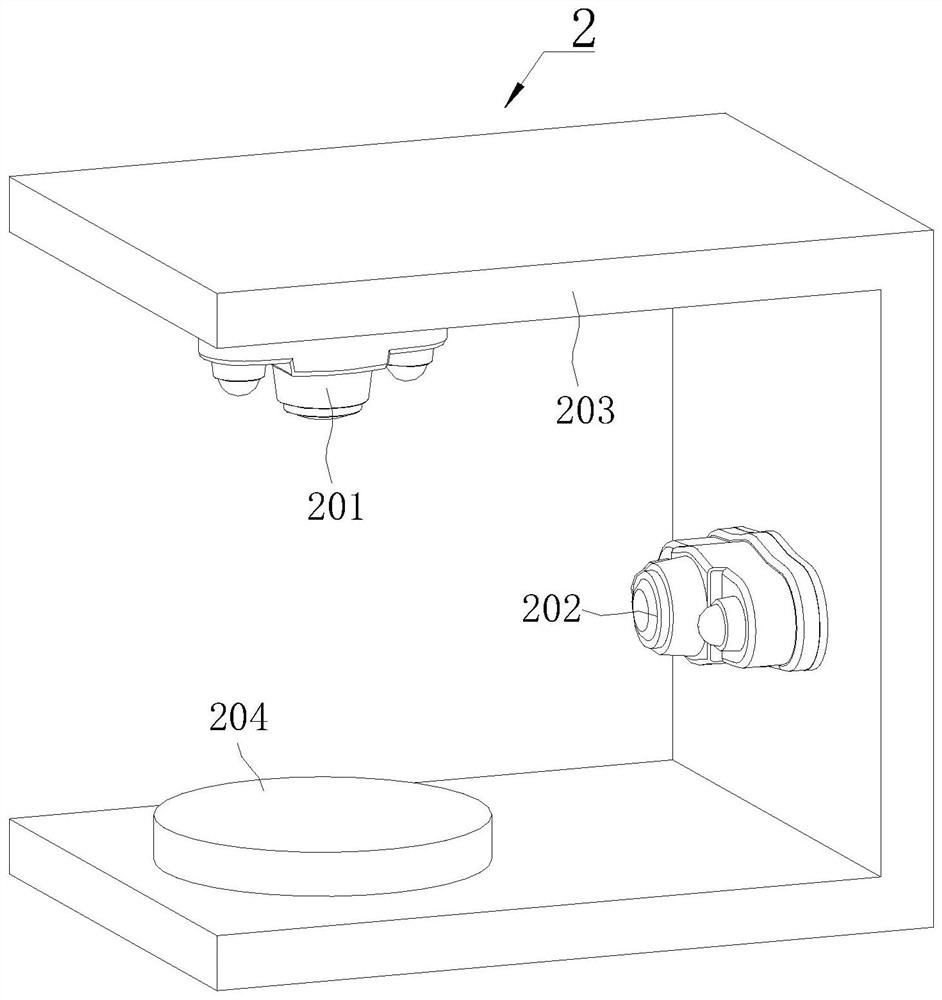

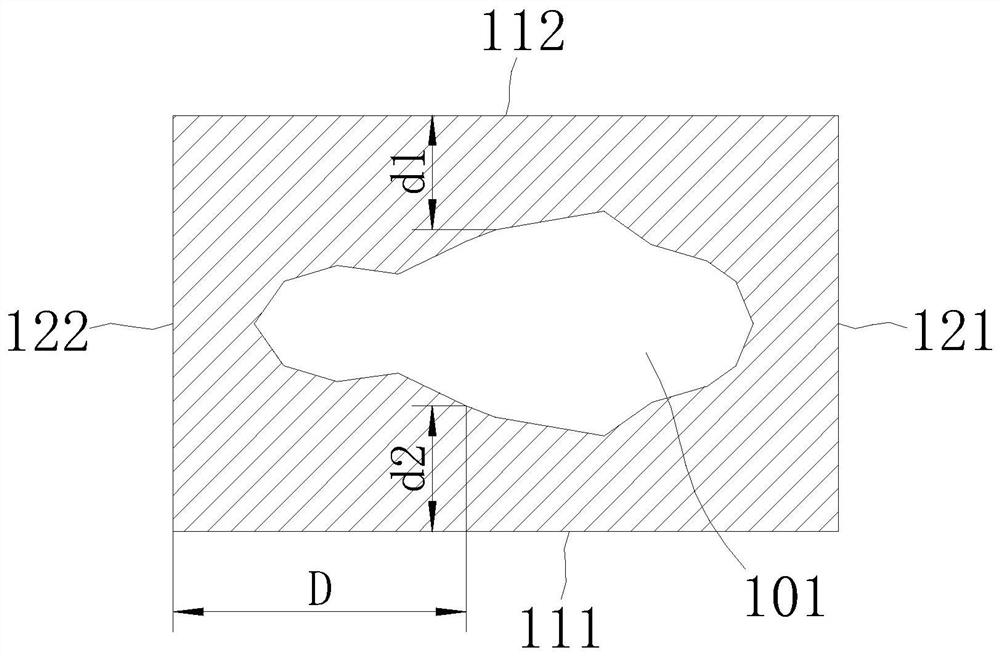

[0050] Specific embodiment one: please refer to Figure 1-8 A pathological hard tissue slicing system, used for slicing a wax block 1 embedded with pathological tissue 101, the wax block 1 is a light-transmitting cuboid or cube. The wax block 1 includes a left side 111 and a right side 112 which are mutually symmetrical planes, a front side 121 and a rear side 122 which are mutually symmetrical planes, an upper side 131 and a lower side 132 which are mutually symmetrical planes. The slicing system includes a distance-fixing unit 2, a clamping unit 3, a monitoring camera 4, a cutting unit 5 and a control unit.

[0051] The distance-fixing unit 2, the clamping unit 3, the monitoring camera 4 and the cutting unit 5 are all controlled by the control unit.

[0052] The distance-fixing unit 2 collects distance information on the wax block 1 through the upper camera 201 and the side camera 202 to determine the maximum section position of the pathological tissue 101 .

[0053] The d...

specific Embodiment 2

[0083] Embodiment 2: Different from Embodiment 1, the cutting unit 5 includes a blade 501 and a cutting motor 502 . The output end of the cutting motor 502 is connected with the blade 501, and the output end of the cutting motor 502 can move vertically up and down, so that the blade 501 can cut part of the wax block 1 located outside the cutting end face. After the blade 501 completes a cycle of moving up and down, the movable top block 305 moves to the outside by a set distance, and the set distance is set by the control unit. Effectively reduce the setting of electrical components and reduce costs.

specific Embodiment 3

[0084] Embodiment 3: On the basis of Embodiment 1 or 2, the clamping unit 3 further includes writing brushes and crayons.

[0085] The writing brush is driven by the writing brush motor, and the writing brush motor is controlled by the control unit.

[0086] The crayon is driven by a crayon motor, which is controlled by a control unit.

[0087] During rough cutting, after the blade 501 completes a cycle of moving up and down, the control unit controls the operation of the brush motor to make the brush sweep the cut surface of the wax block 1, so that the paraffin burrs produced after rough cutting are swept away.

[0088] When finely cutting, after the blade 501 completes a cycle of moving up and down, the control unit controls the operation of the crayon motor, so that the crayon holds up the cut slices and puts them into the pool, waiting for the next step of dyeing process.

[0089] It effectively reduces the manual work and reduces the problem of chip rupture caused by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com