Photoelectric glass cutting machine

A photoelectric glass and cutting machine technology, applied in glass cutting devices, glass production, glass manufacturing equipment, etc., can solve the problems of fast wear of synchronous belts, high noise, large transmission gap between gears and racks, etc., to achieve uniform cutting force, The effect of low noise and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

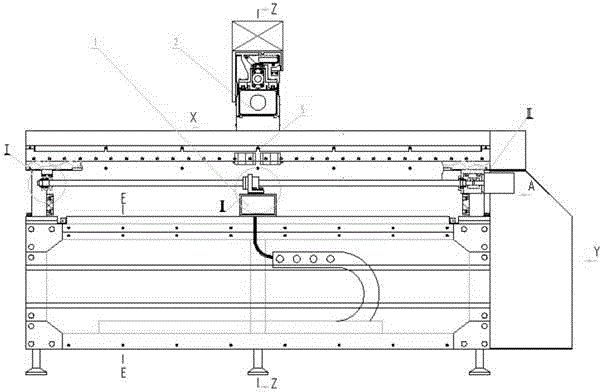

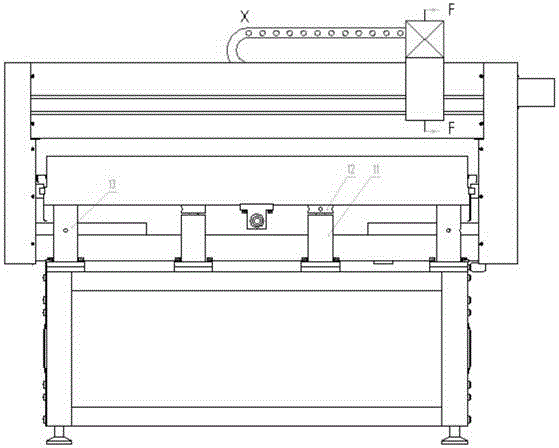

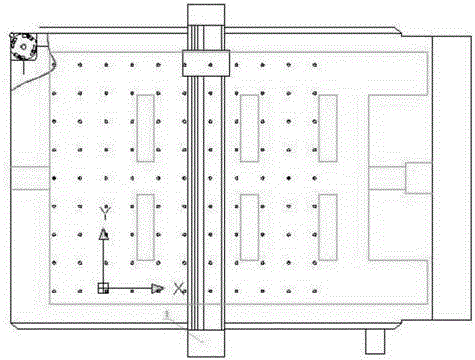

[0022] Such as Figure 1 to Figure 12 As shown, a photoelectric glass cutting machine includes a base 8 made of square tube material, main supports 13 are installed at both ends of the base, a middle support 11 is installed in the middle, and adjustable feet are installed under the base 8 7. The main support 13 is connected to the table 4, the middle support 11 is connected to the base 8, and the adjustment plate 12 is installed on the middle support 11 to make the table 4 flat, and the guide rail 30 is installed on the table 4 , the left middle connecting seat 24 and the right middle connecting seat 34 are installed on the guide rail 30, the left middle connecting seat 24 is connected to the left lower connecting seat 27, and the right middle connecting seat 34 is connected to the right lower connecting seat 37, so The top of the left middle connecting seat 24 is connected with the left upper connecting seat 23, and the right middle connecting seat 34 is connected with the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com