Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Screw in smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

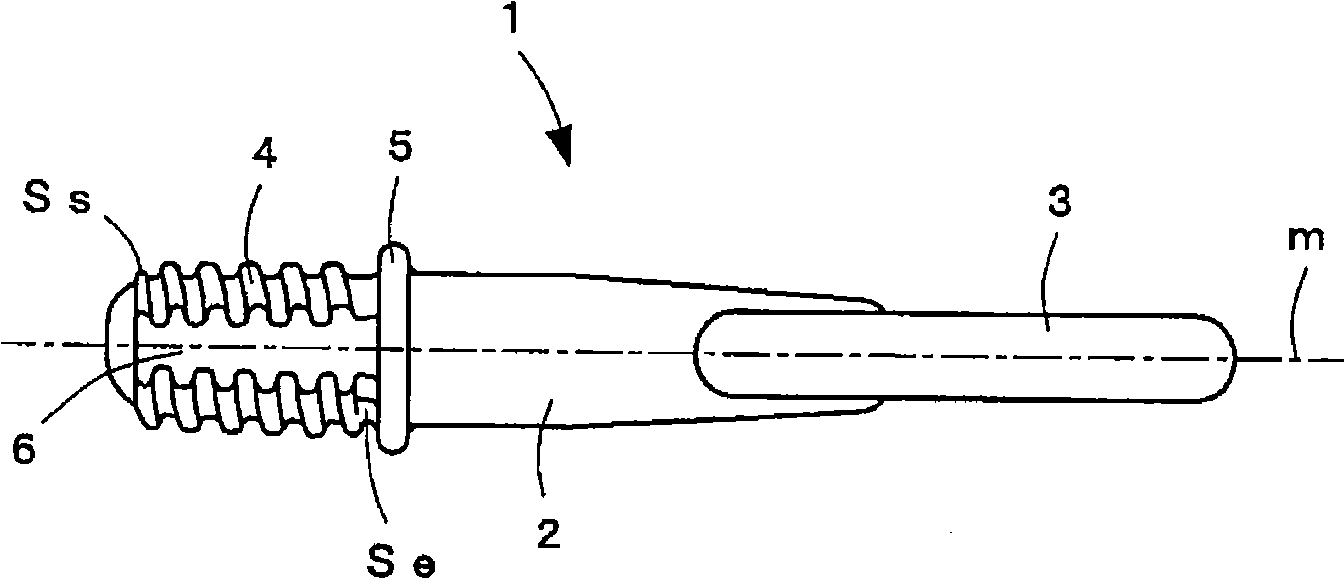

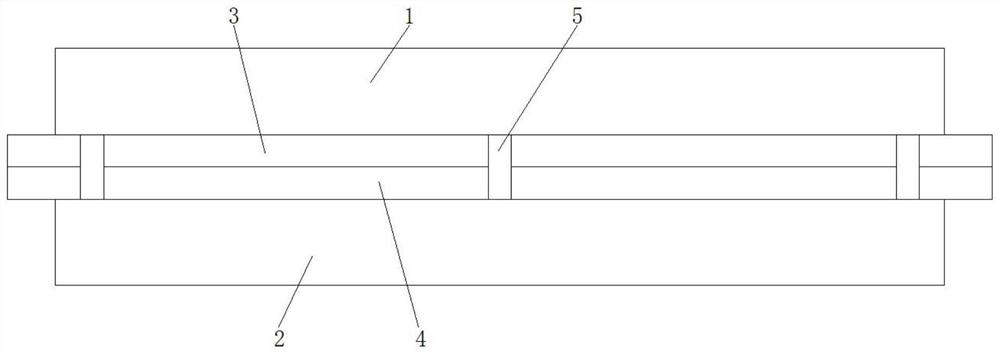

Towing device for vehicle, method of manufacturing towing hook for vehicle, and method of manufacturing connection member for vehicle

InactiveCN101547801AAvoid slackEnsure safetyMetal-working apparatusBoltsMechanical engineeringTowing

Provided are a towing device for a vehicle, a method of manufacturing a towing hook for a vehicle, and a method of manufacturing a connection member for a vehicle. The towing device is suitable for a towing device for an automobile, allows a hook part of the towing hook to be attached to a connection member on the automobile side in a specified direction, prevents lateral swing and looseness of the towing hook caused by vibration and external force during towing operation, provides reliability and safety of towing operation, enables smooth attachment of the towing hook to the connection member, allows the towing hook and the connection member to be increased in the strength and to be reduced in the size and weight, and can be easy processed and manufactured at low cost. The towing device for a vehicle includes the connection member having a female screw part and attachable to the vehicle side, and also includes the towing hook (1) having at one end a male screw part engageable with the female screw part and at the other end a hook part (3) to which a towing member (W) can be attached. The position of the hook part (3) after the male screw part is fastened to the connection member can be set to a predetermined allowable angular position (Theta).

Owner:FALTEC CO LTD

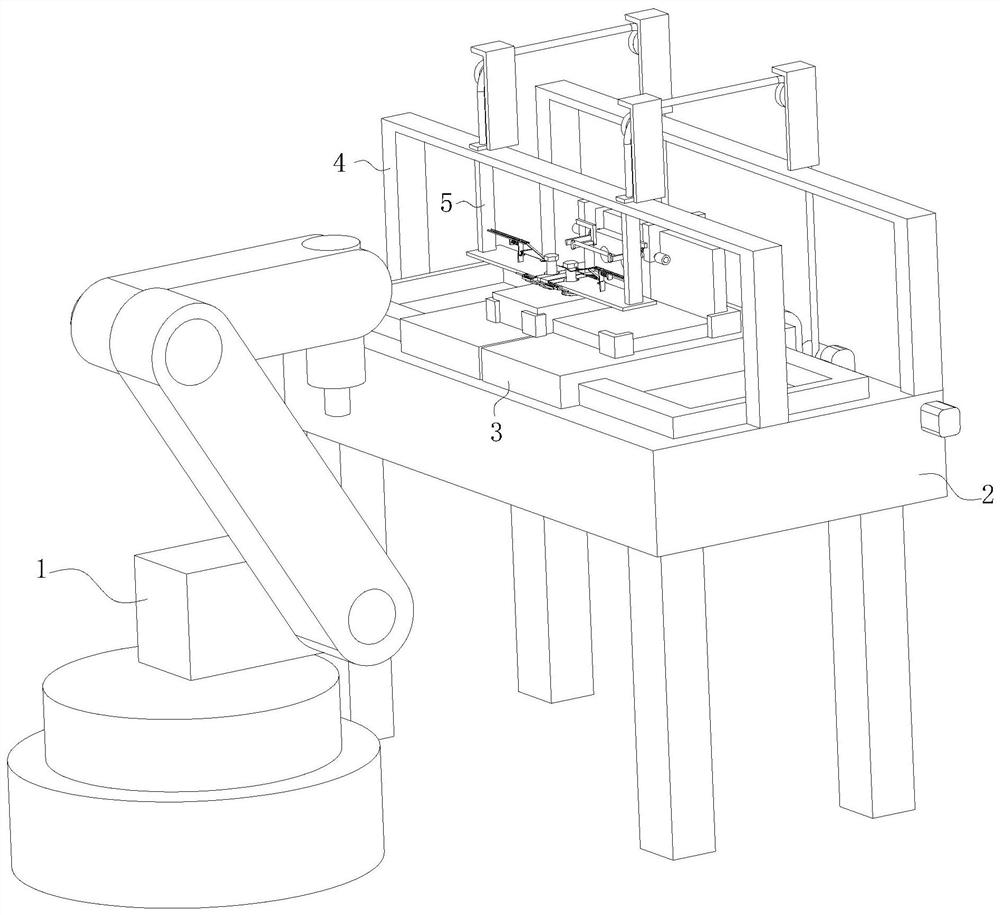

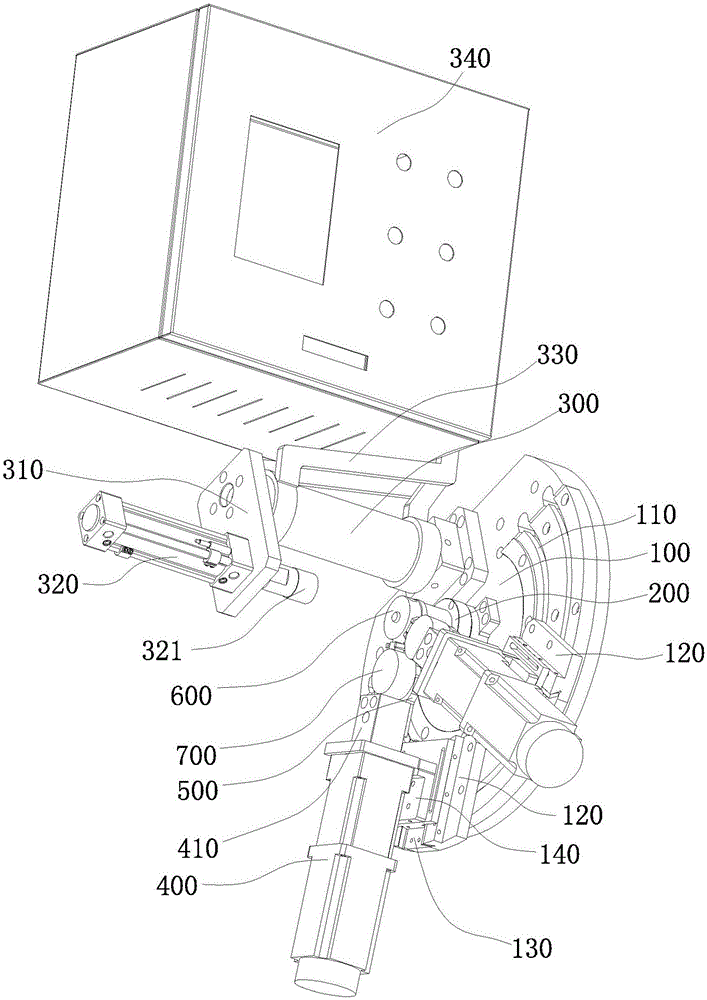

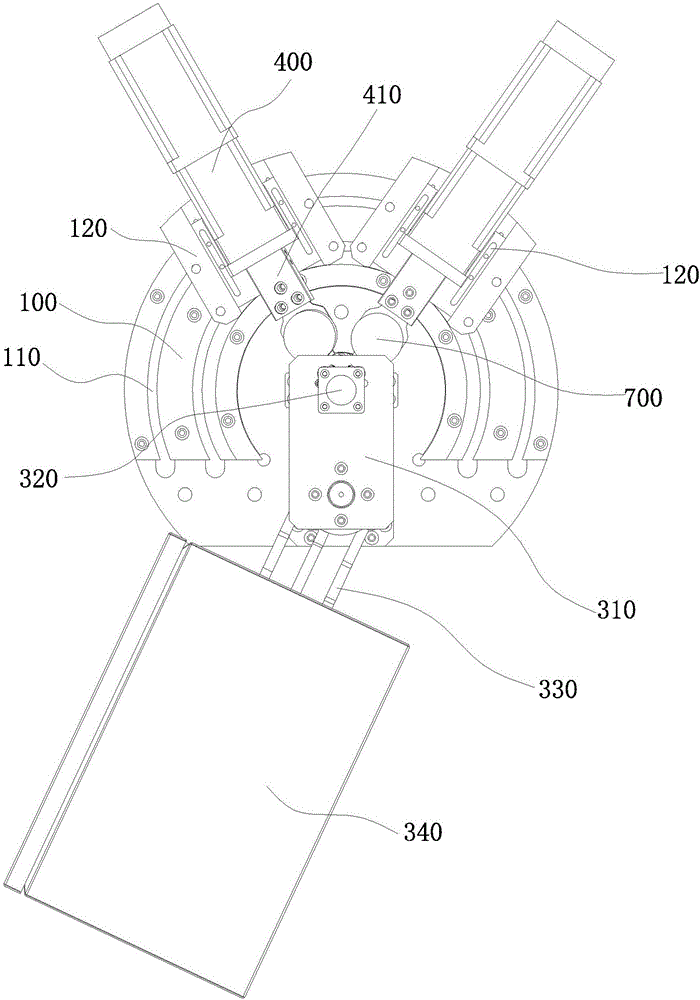

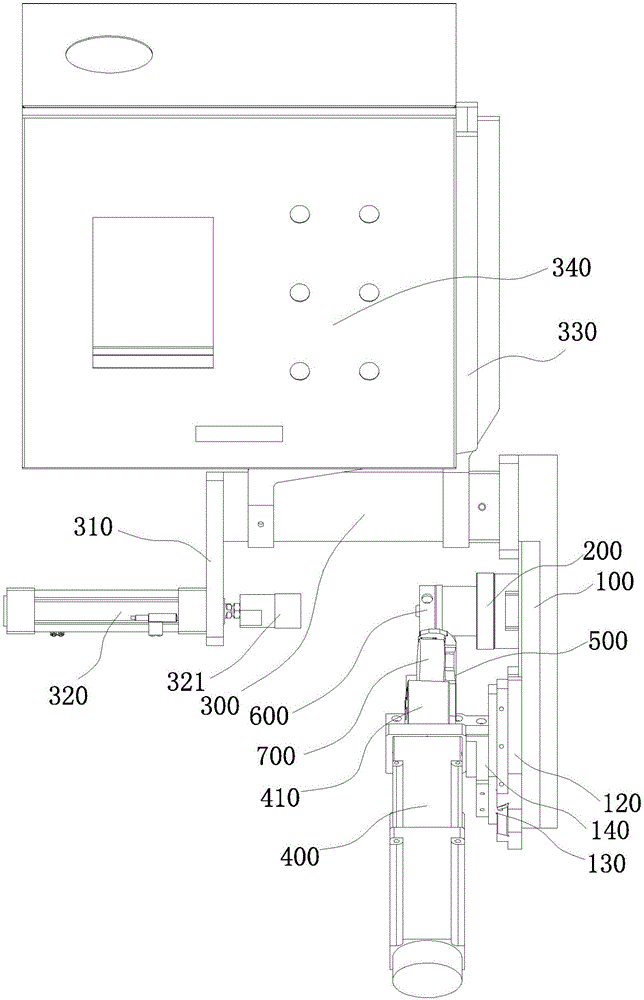

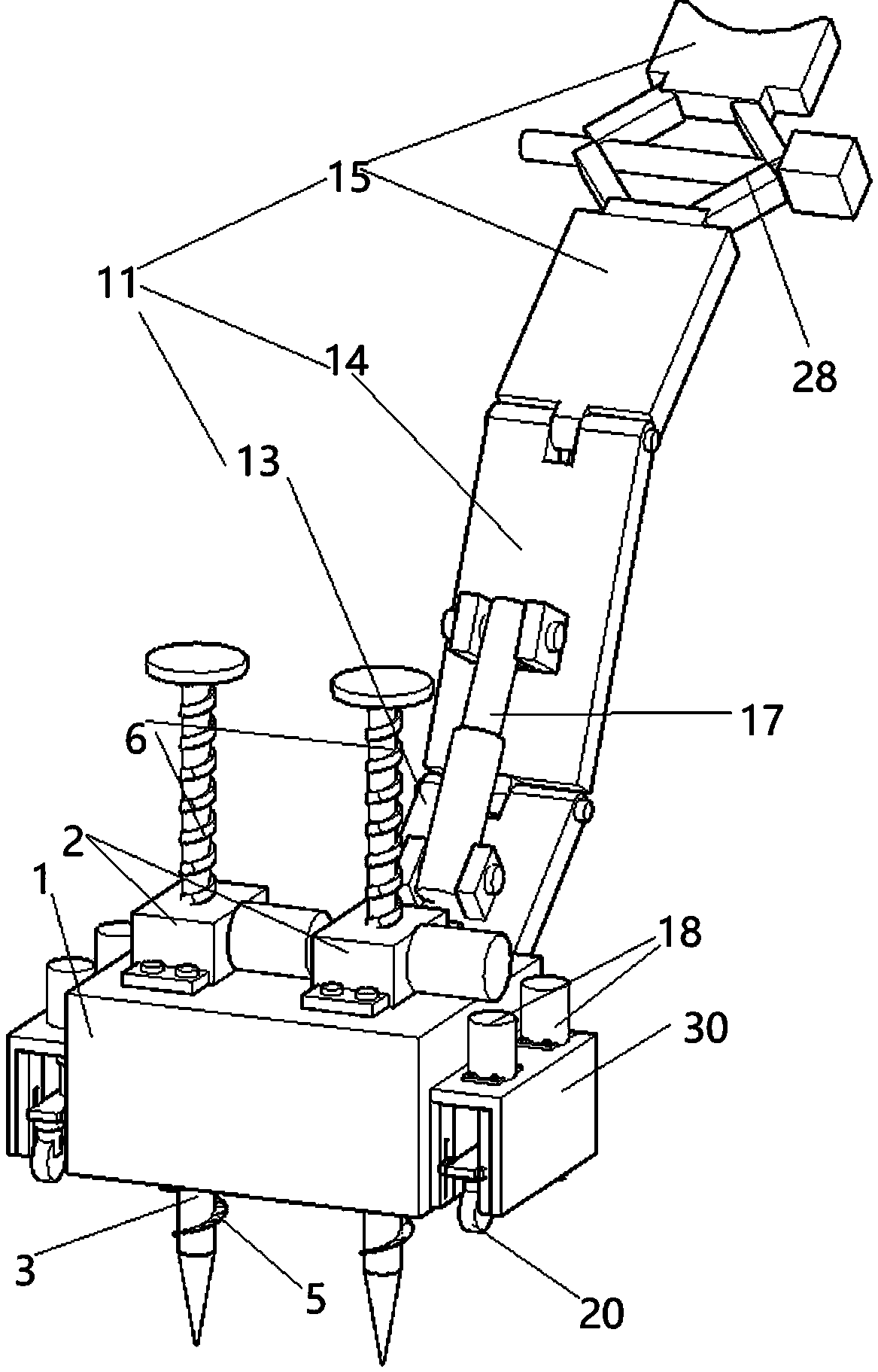

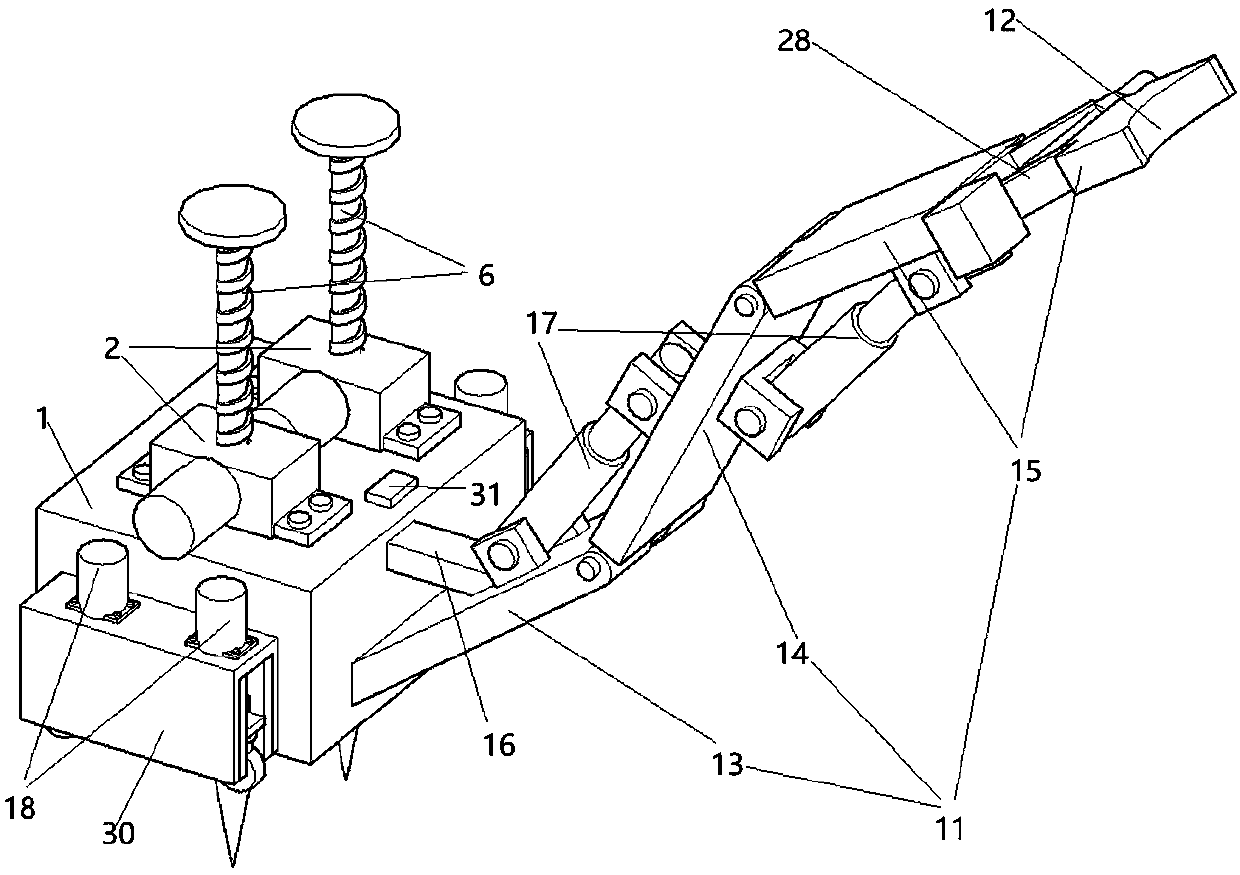

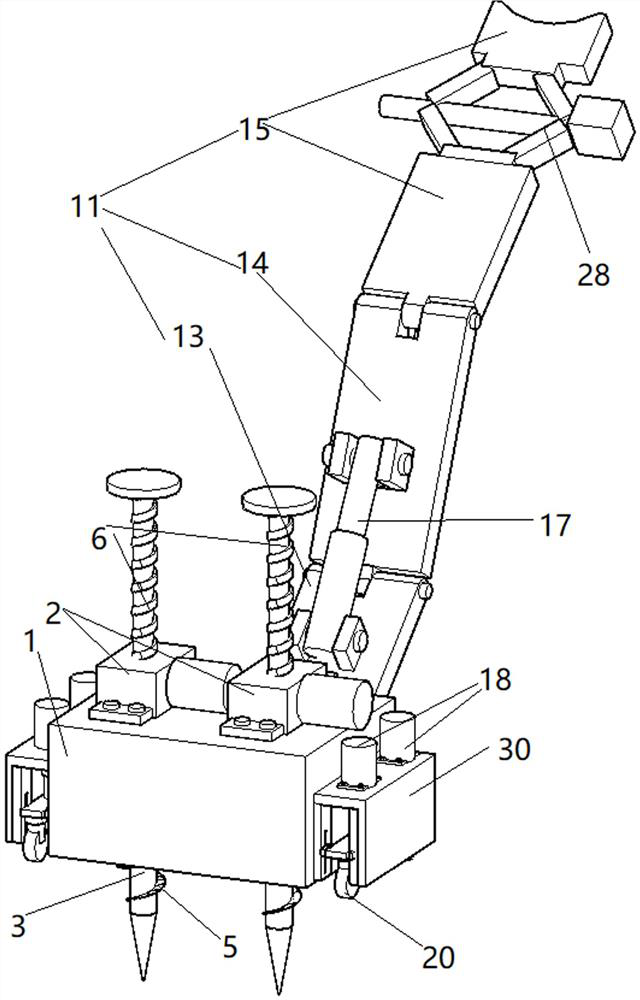

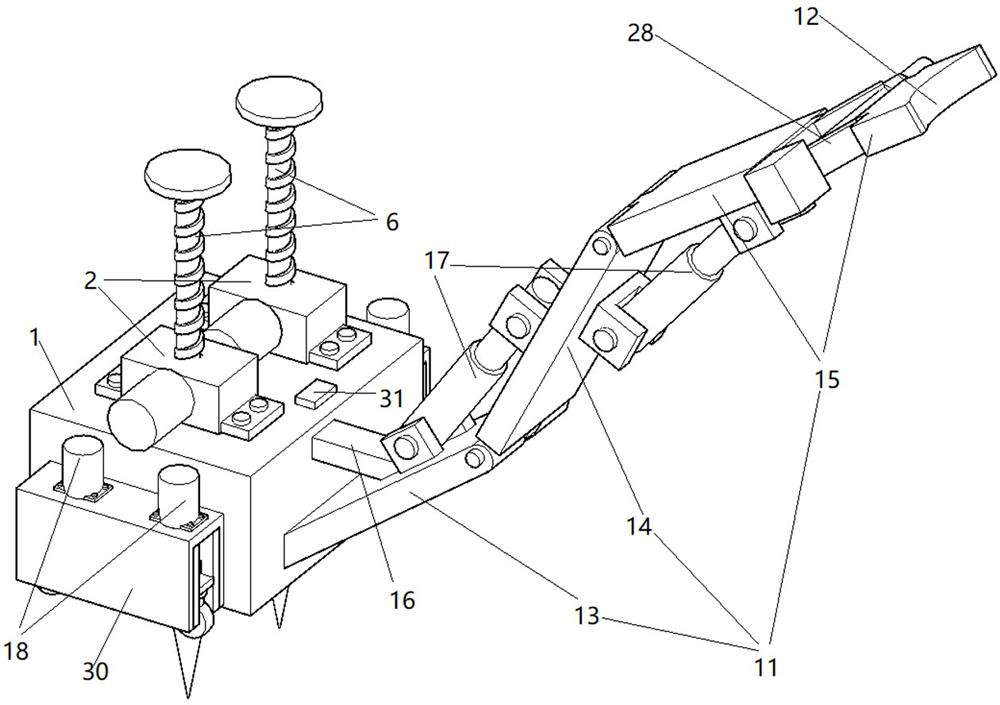

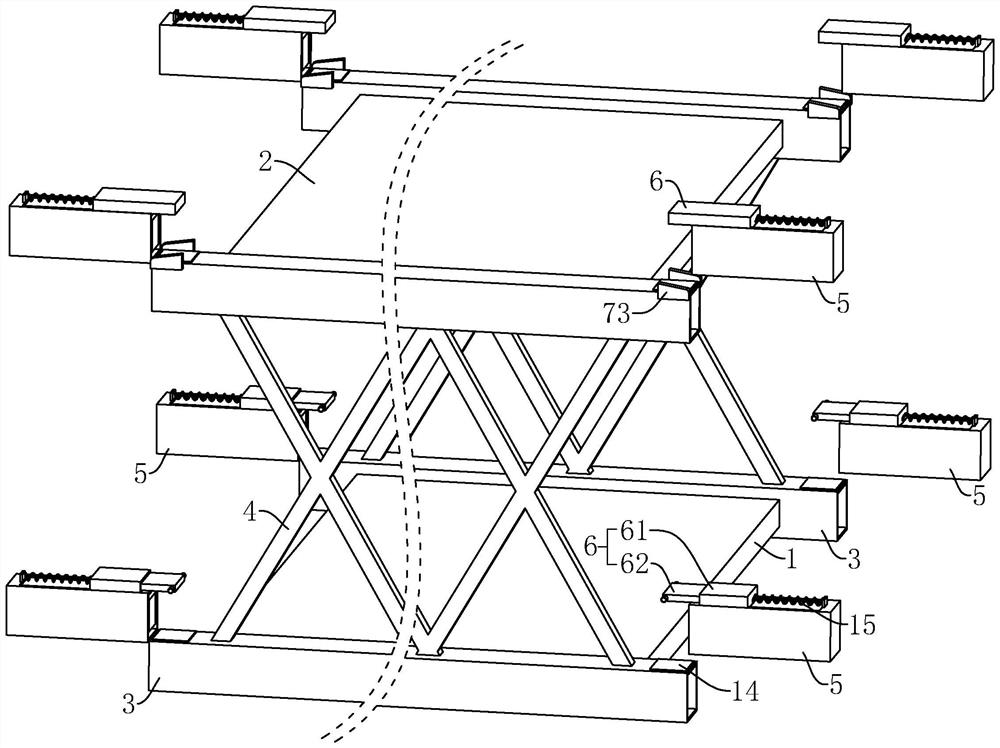

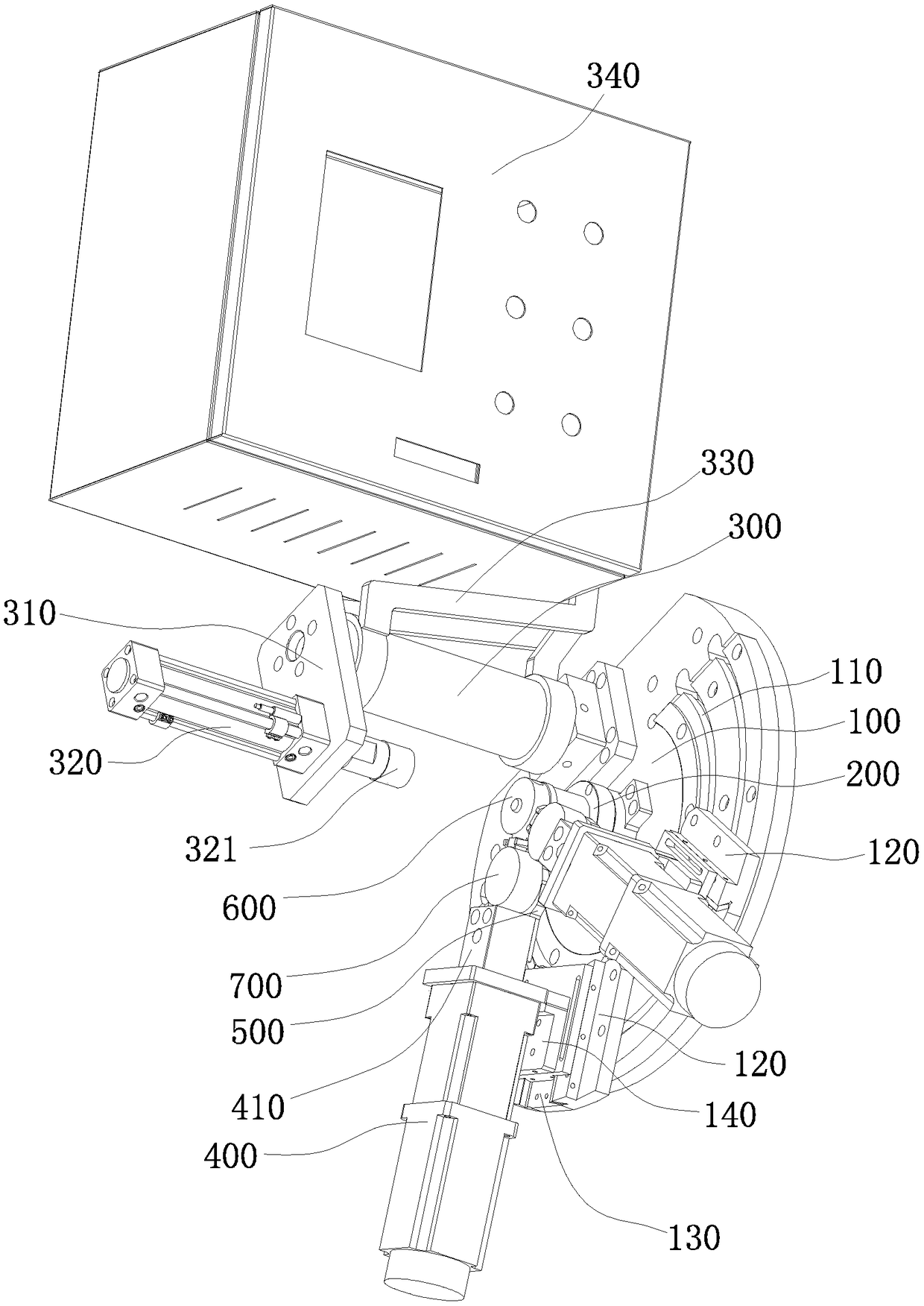

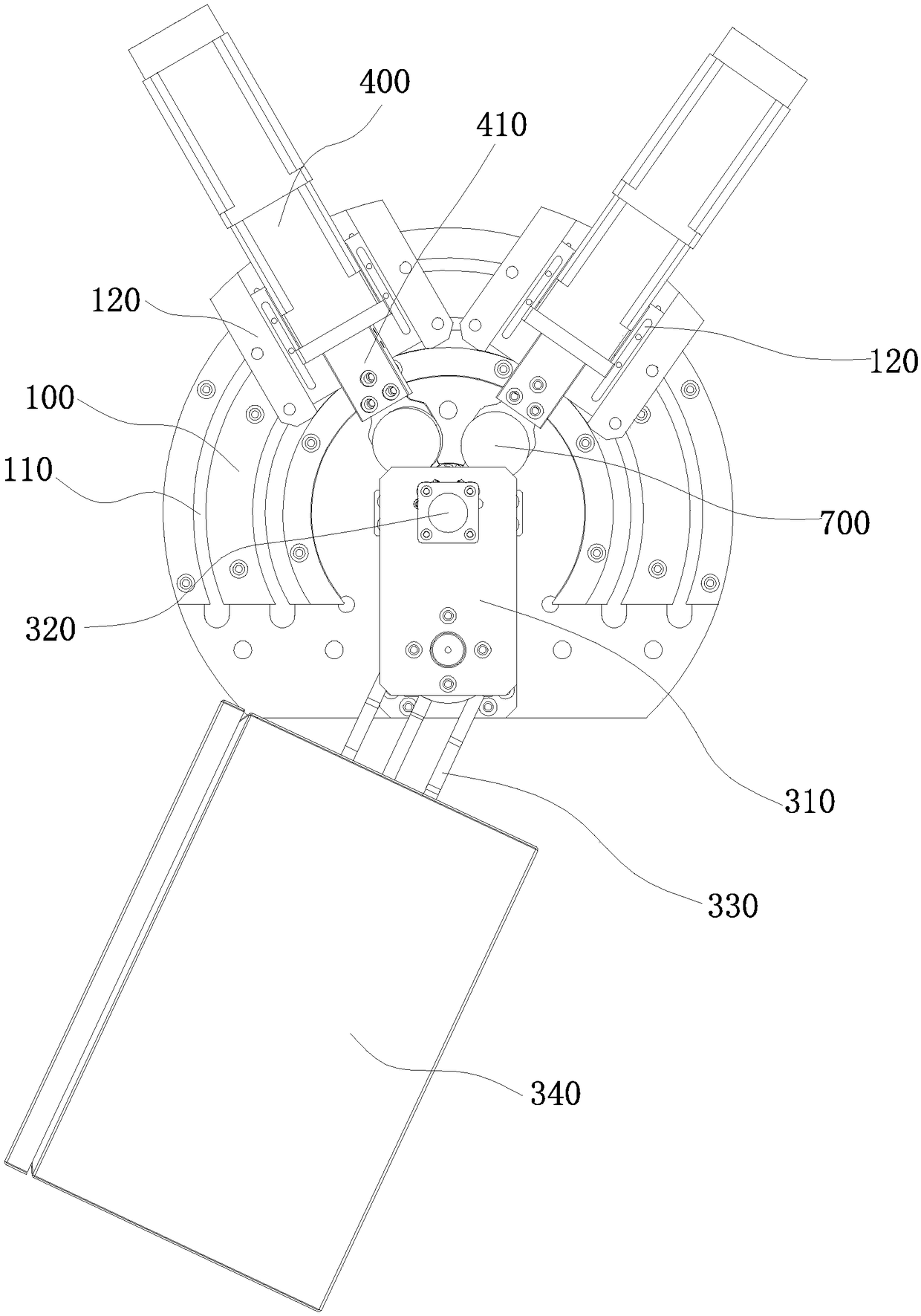

Precise six-degree-of-freedom assembly robot

InactiveCN113182832AEnsure safetyAvoid workpiece damageMetal working apparatusControl engineeringStructural engineering

The invention discloses a precise six-degree-of-freedom assembly robot, and belongs to the technical field of six-degree-of-freedom assembly robots. The precise six-degree-of-freedom assembly robot comprises a six-axis robot and an assembly table, wherein the six-axis robot is located on the front side of the assembly table; two symmetrically-arranged shelving plates are slidably connected to the top of the assembly table; and a driving mechanism used for driving the two shelving plates to move towards the middle of the assembly table simultaneously is connected to the top of the assembly table. When the six-axis robot is used for fastening a bolt every time, the bolt is guided through a through groove formed by a first connecting plate and a second connecting plate, so that the bolt can be smoothly aligned with a threaded hole of a workpiece every time, the bolt does not need to be clamped by the six-axis robot for thread fastening, the situation that the bolt cannot be aligned with the threaded hole of the workpiece and the workpiece is damaged due to track change caused by deviation or fixing looseness in operation of the six-axis robot is avoided, and the working safety is guaranteed.

Owner:北京瓢虫星球信息技术有限公司

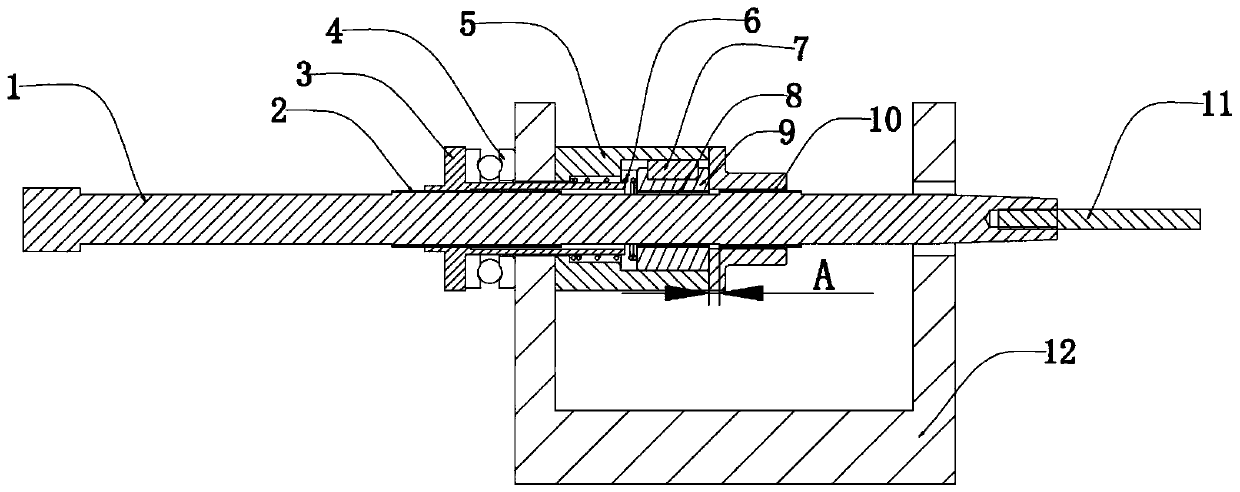

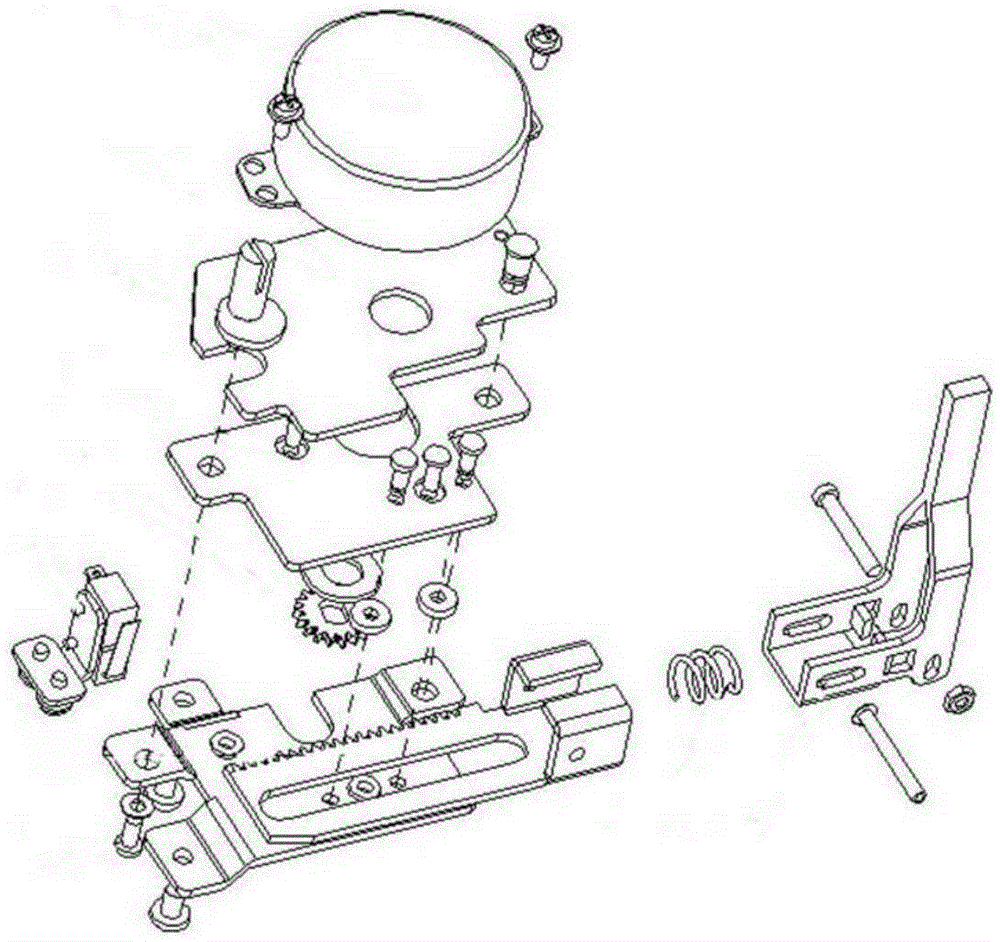

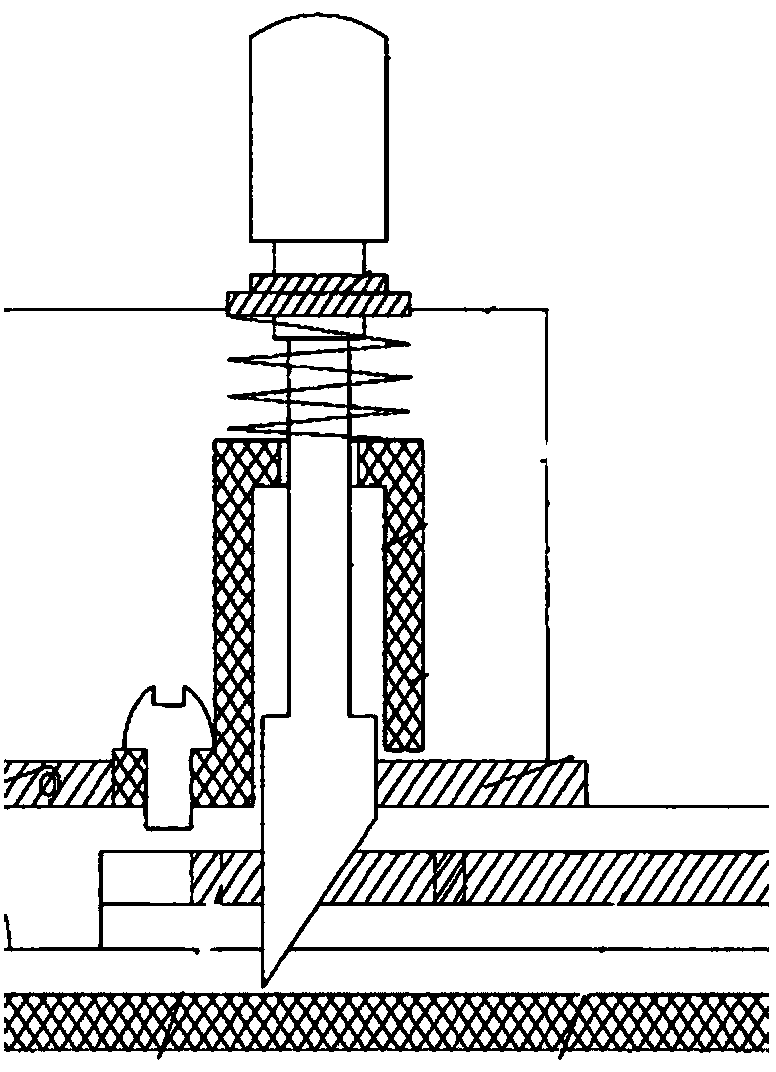

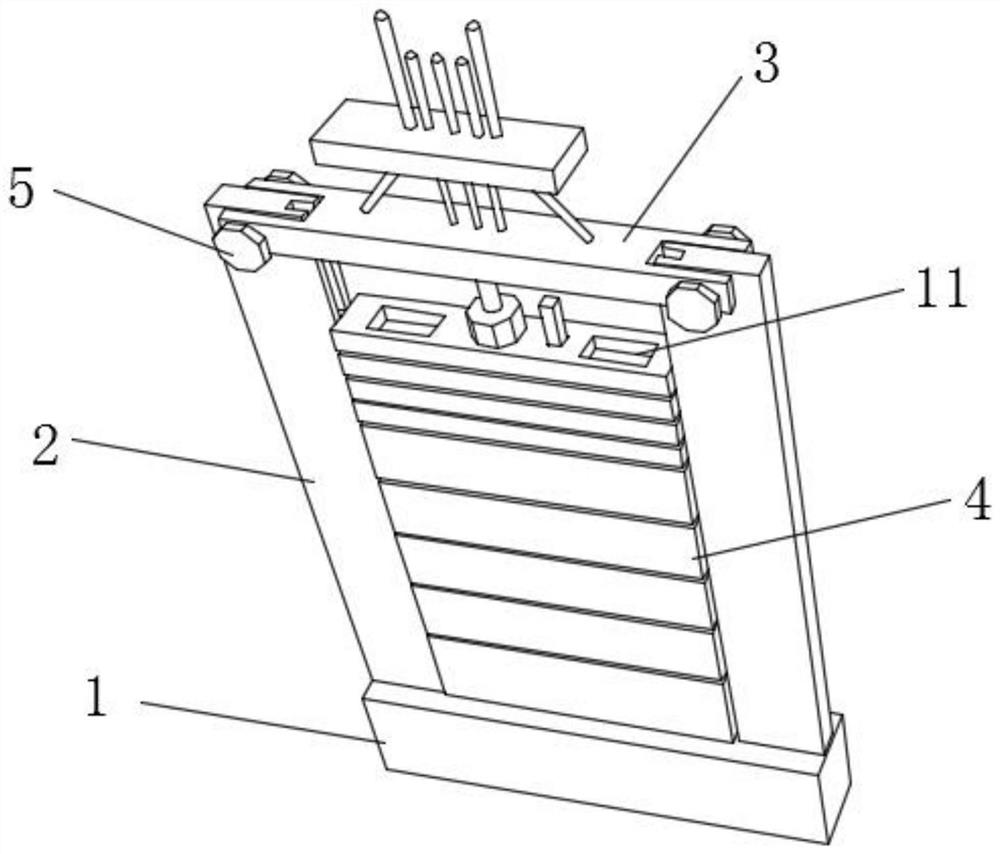

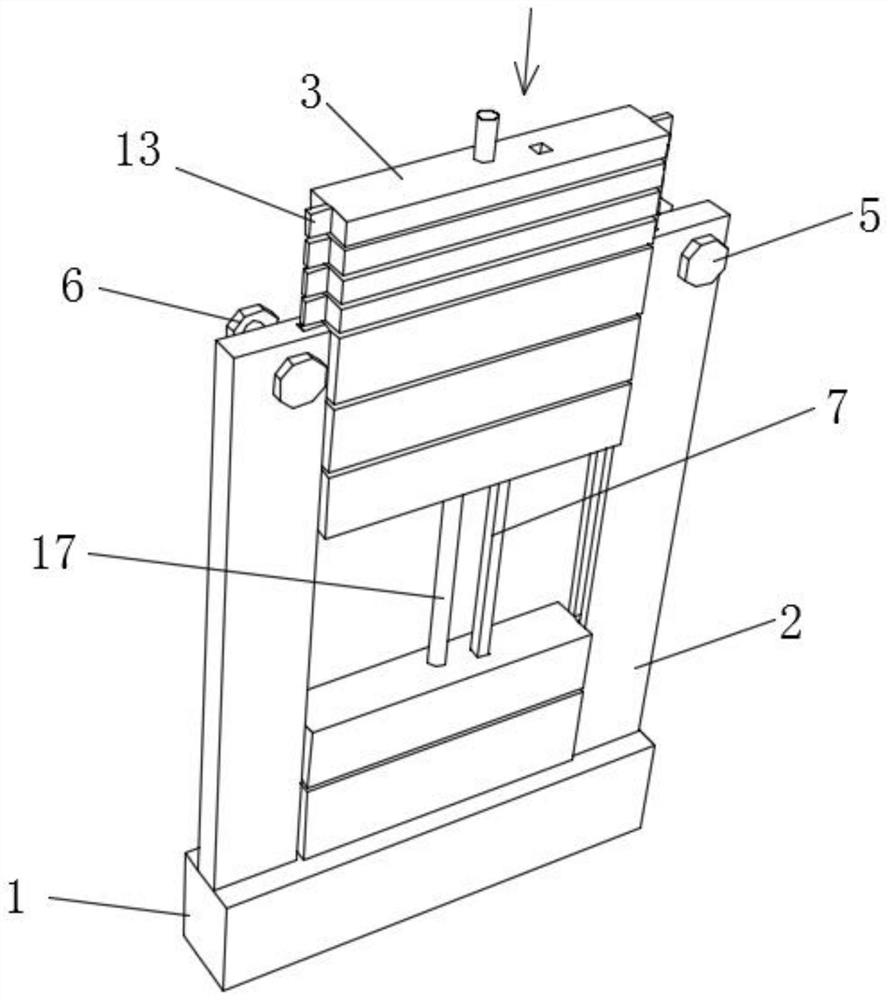

Screwing assembly machine for pressure gauge

ActiveCN106217015AIncrease productivityReduce manufacturing costMetal working apparatusEngineeringPiston rod

The invention provides a screwing assembly machine for a pressure gauge. The screwing assembly machine comprises a base mounting plate, a gauge stand fixture, an upright post, a gear motor and a gauge head fixture, wherein the gauge stand fixture is fixed to the base mounting plate and is used for fixing a gauge stand of the pressure gauge; one end of the upright post is fixed to the base mounting plate; an upper vertical plate is arranged on the other end of the upright post; a compaction cylinder is arranged on the upper vertical plate; a piston rod of the compaction cylinder is positioned right above the gauge stand fixture; the gear motor is arranged on the base mounting plate; a rotating head is in linkage connection on a rotating shaft of the gear motor; and the gauge head fixture is arranged on the rotating head and aligns to the gauge stand fixture. The screwing assembly machine has the beneficial effects that the pressure gauge can be automatically screwed on the gauge stand, so that the production efficiency is improved, and the production cost is reduced.

Owner:宁波创二代机械科技有限公司

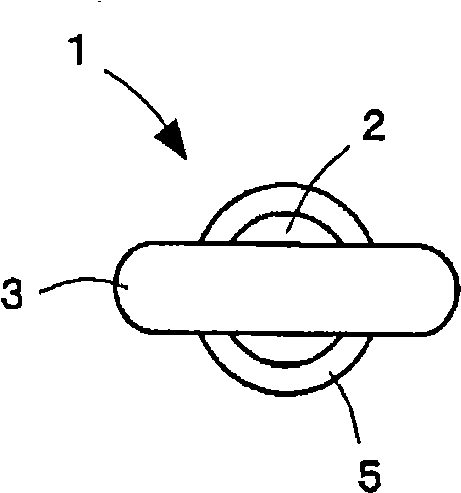

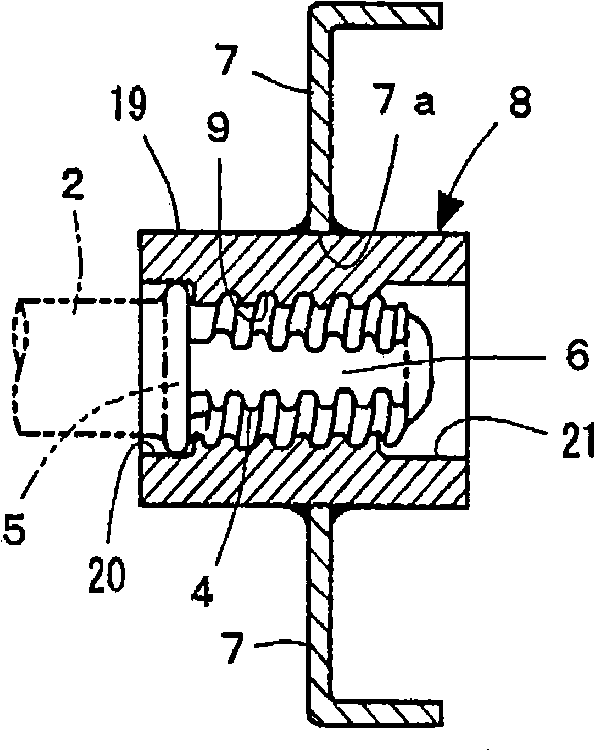

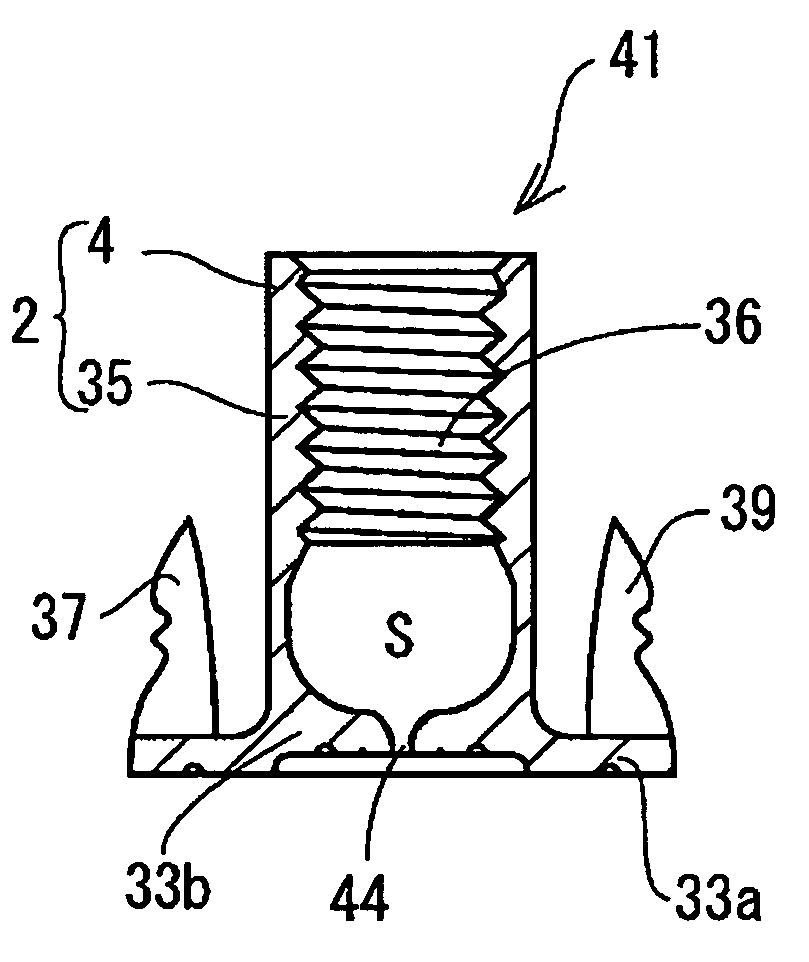

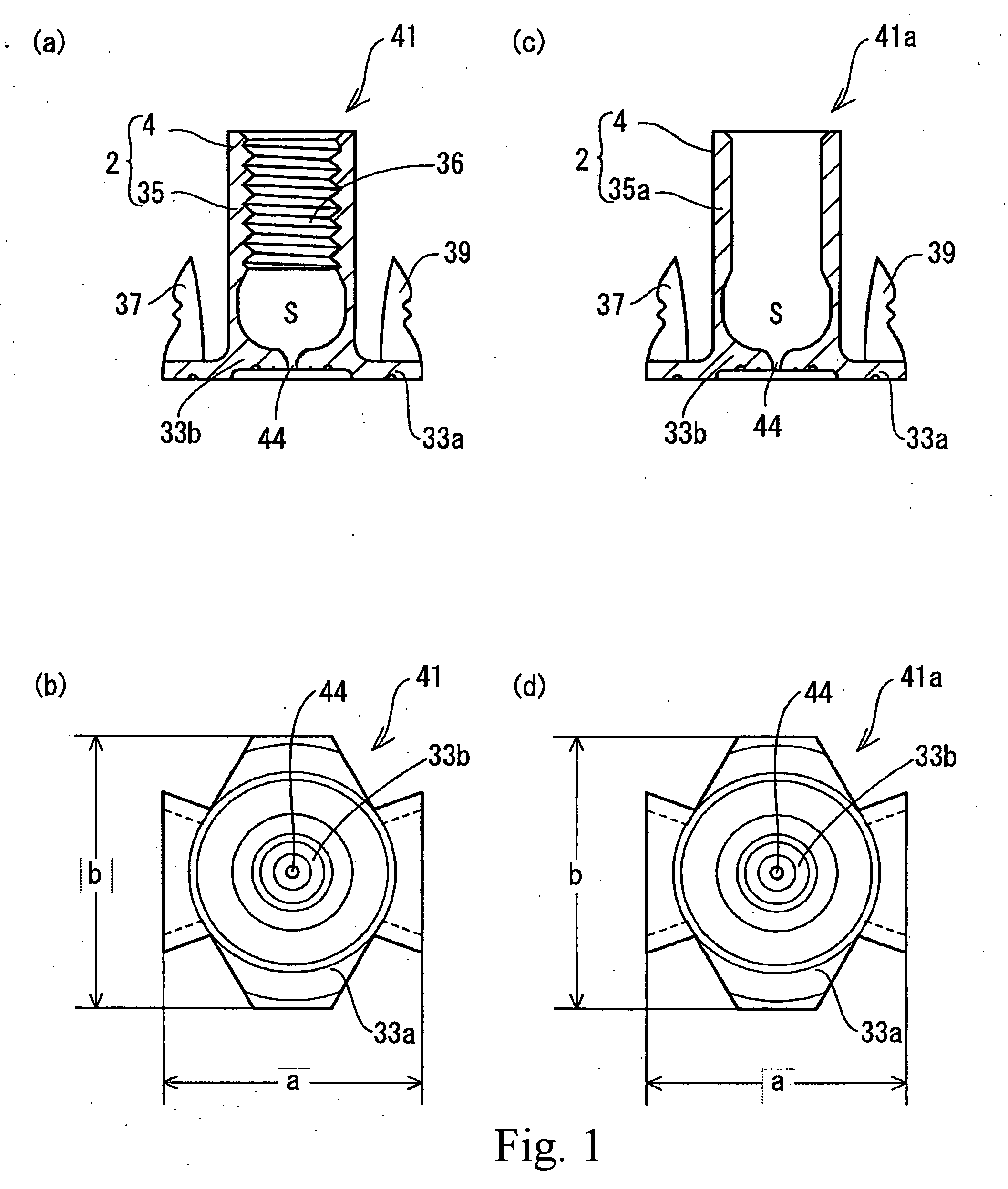

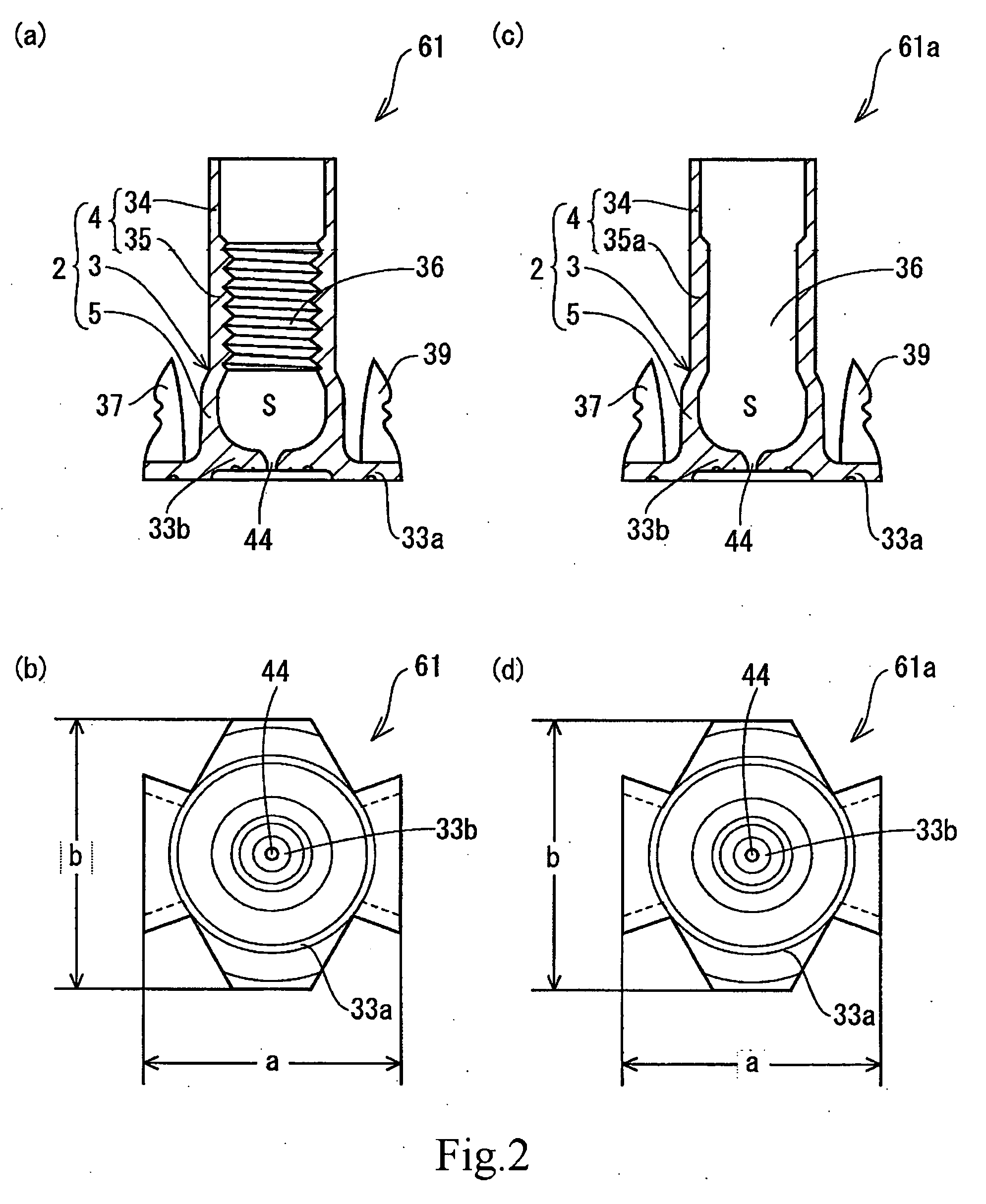

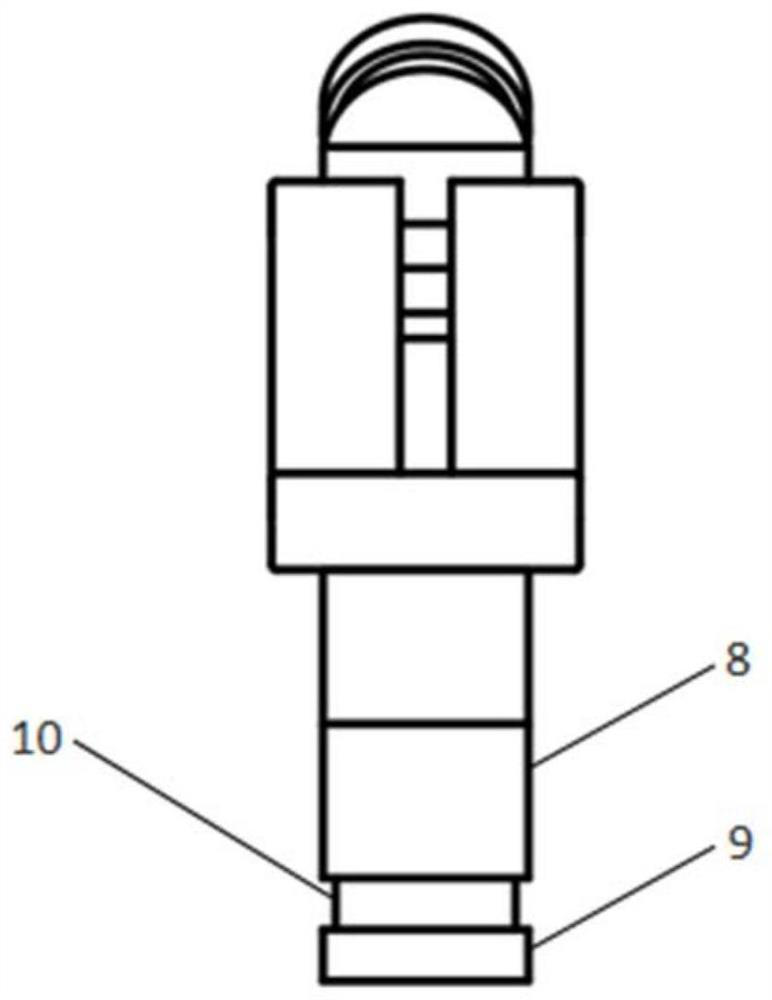

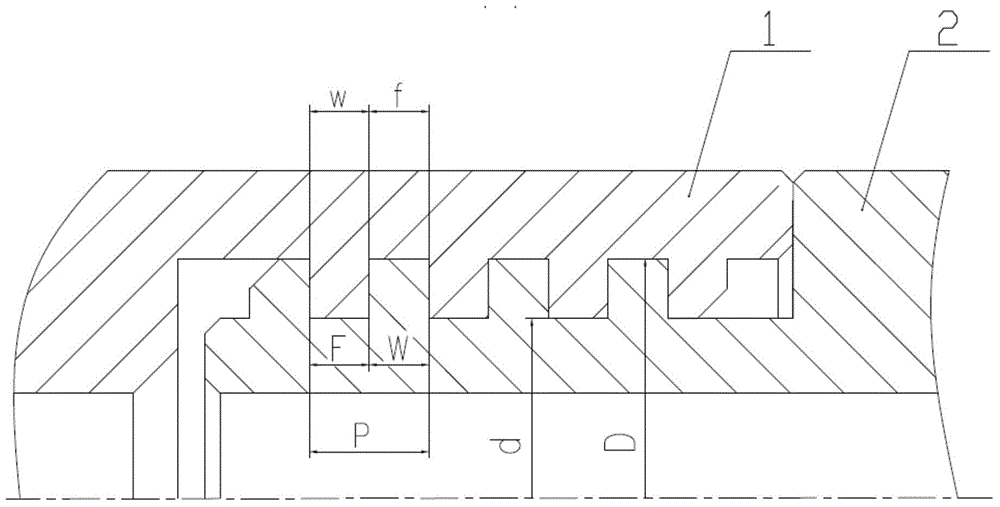

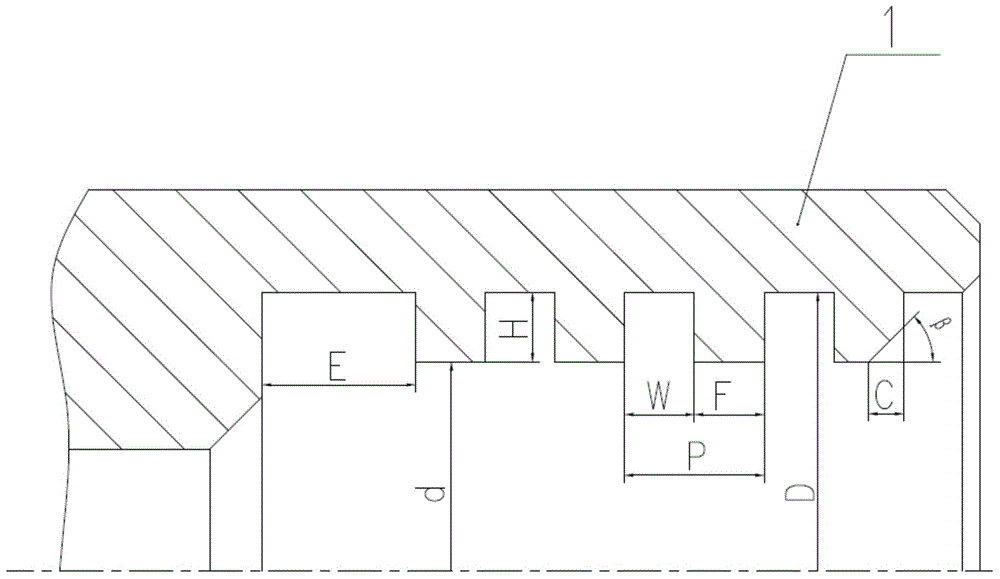

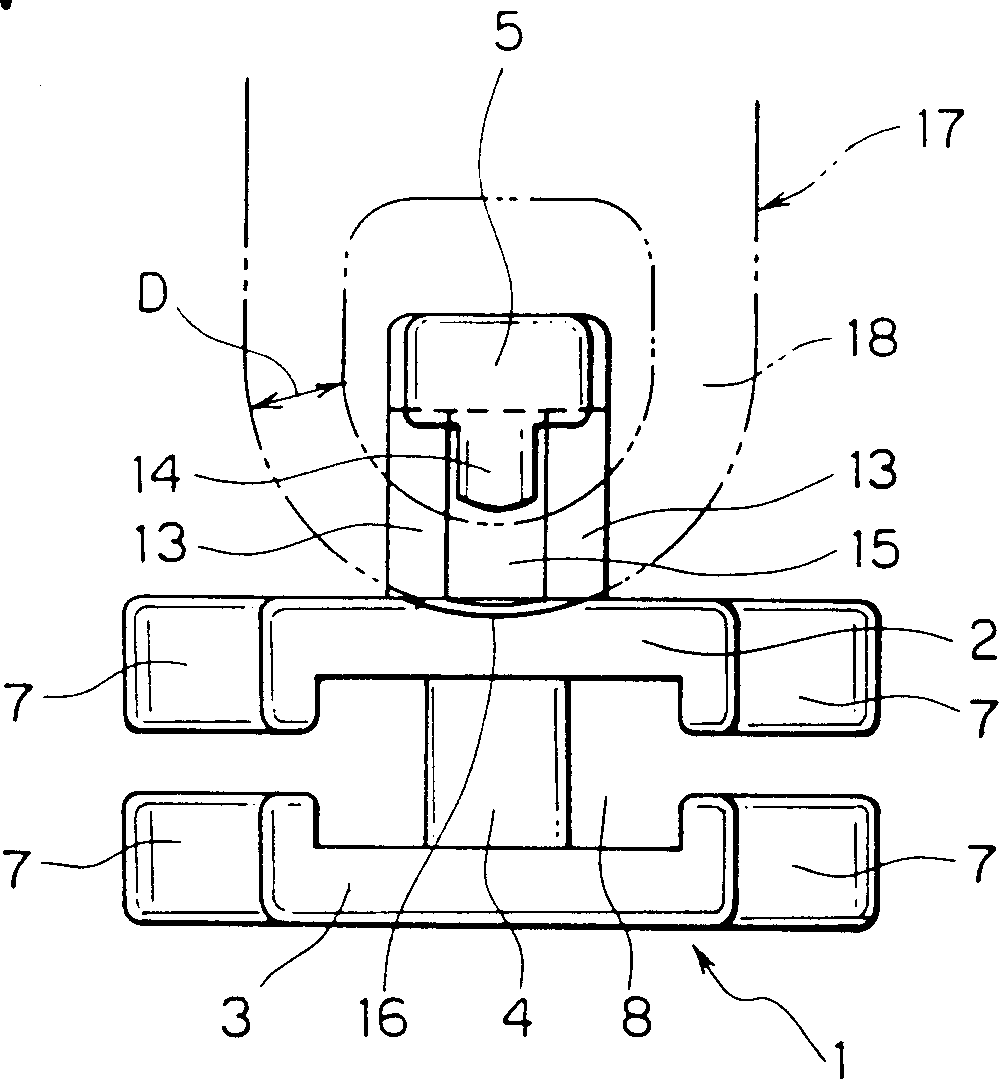

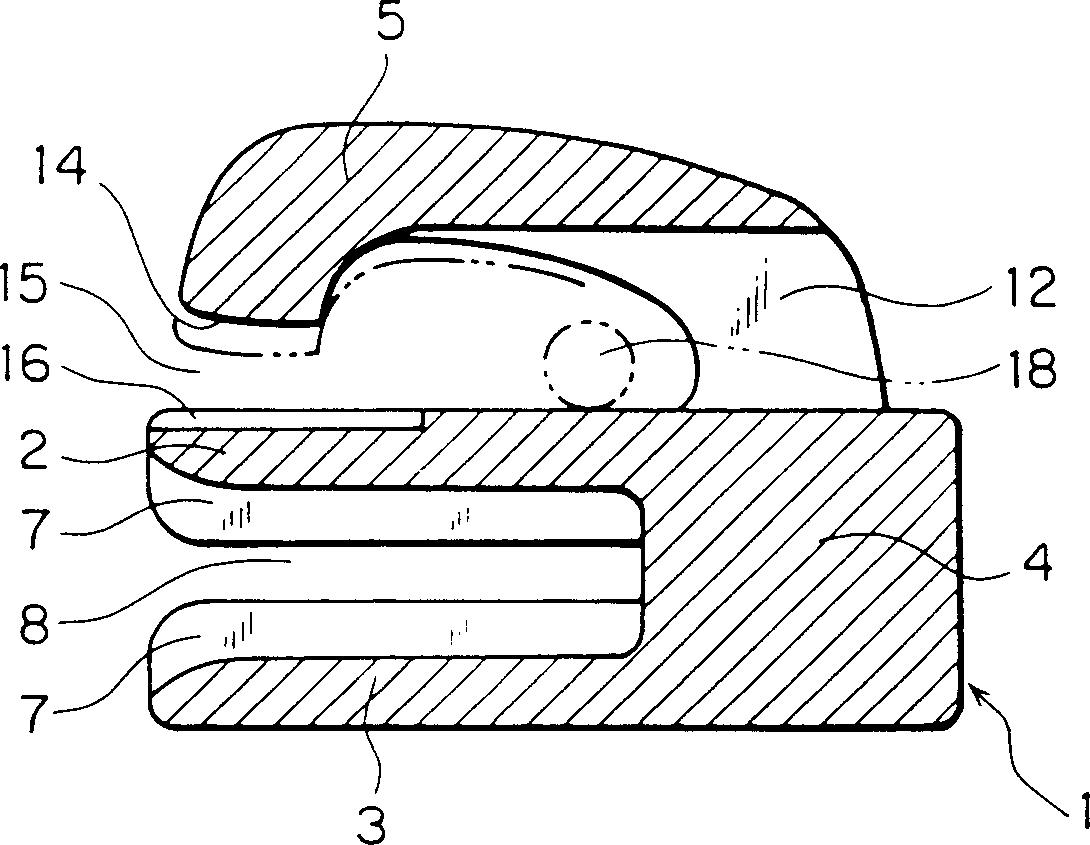

T-nut

There is provided a T-nut having a tubular shank 2, an external flange portion 33a extending outwardly from a first end of the shank 2, and an internal flange portion 33b extending inwardly opposite to the external flange portion 33a of the tubular shank 2, all of which are integrally formed from a metal plate by pressing. A hole 44 is formed at the vicinity of the center part of the internal flange portion 33b. This hole 44 allows the oil to enter the inside of the tubular shank to the extent that the oil is served as a lubricant.

Owner:NAGAYAMA ELECTRONICS IND

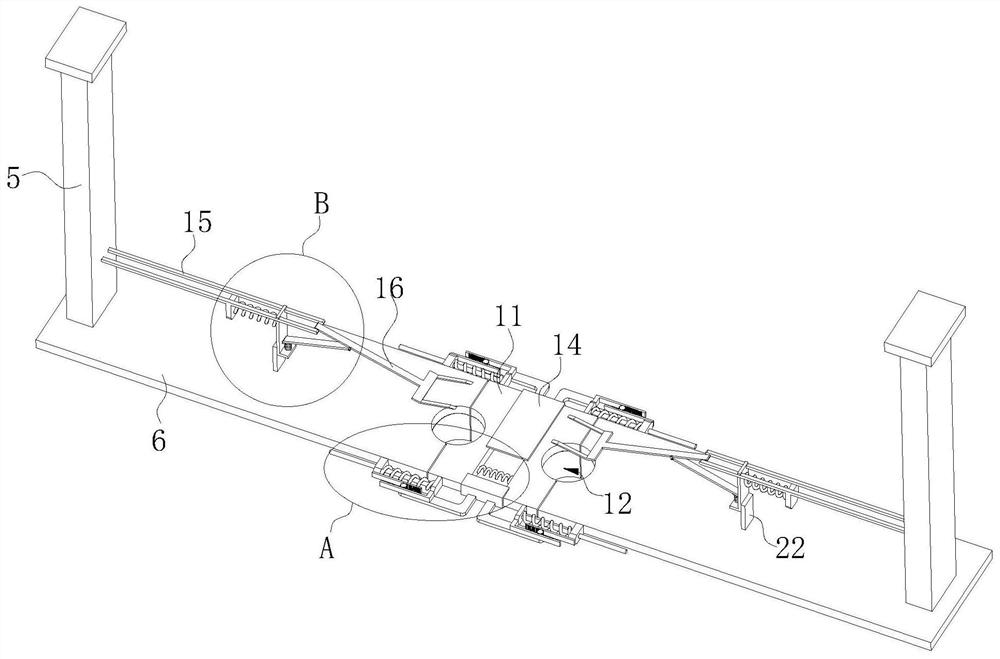

Tension relax device and tension relax method

InactiveCN110076905AFully automatedAvoid manual secondary adjustmentCeramic shaping apparatusEngineeringRebar

The invention discloses a tension relax device and tension relax method, and belongs to the technical field of rail transit infrastructure construction devices, the tension relax device comprises a tension-pull rod and a guide seat, wherein the tension-pull rod is provided with a first end and a second end; the first end is an operation end, and the first end can be connected with an operation piece to be tension relax; the second end is connected with a driving device and can drive the tension-pull rod to rotate through the driving device; the tension-pull rod is provided with first threads along the direction from the first end to the second end; the guide seat is internally provided with an inner cavity penetrating through the two ends, the tension-pull rod penetrates through the innercavity, at least a part of the inner cavity wall of the inner cavity is provided with second threads, and the second threads are in threaded connection with the first threads; after the tension-pull rod is separated from steel bar, the first threads of the tension-pull rod is in threaded connection with a retraction nut, so that the tension-pull rod can be continuously retracted out of the inner side surface of the die, so that the manual secondary adjustment of the tension-pull rod is avoided, so that the automation of the tension relax action is realized, the production efficiency is improved, and the production cost is reduced.

Owner:HIMILE MECHANICAL MFG

Ultralong hollow spiral grouting anchor rod connection piece

The invention provides an ultralong hollow spiral grouting anchor rod connection piece which is used for connecting anchor rods of ultralong supports. A front end anchor rod body and a front end connection piece are welded, a tail end anchor rod body and a tail end connection piece are welded, a grouting hole is respectively drilled at the centers of the front end connection piece and the tail end connection piece, and a grout vent hole is reserved at the tail end of the tail end anchor rod body. The connection piece is high and reliable in strength, high pressure grout can smoothly flow through the grout vent hole, and a spiral anchor rod and the connection piece can be smoothly screwed into a coal roadway anchor hole.

Owner:张延策

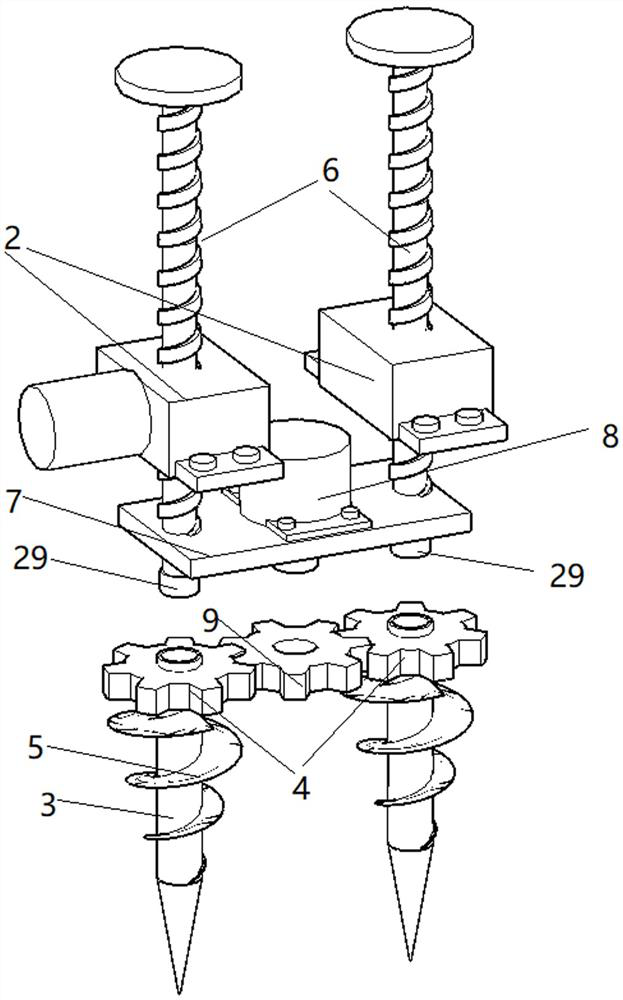

Telegraph pole support

The invention discloses a telegraph pole support. The telegraph pole support comprises a fixing box, wherein a spiral elevator is arranged on the fixing box and comprises a screw rod perpendicular tothe ground; the lower end of the screw rod is positioned in the fixing box; the bottom end face of the screw rod is rotationally connected with a connecting rod; a first gear is arranged at the upperportion of the connecting rod; a spiral blade is arranged at the middle portion of the connecting rod; the bottom end of the connecting rod is conical; an installing plate is arranged on the screw rod; a motor is arranged on the installing plate; a second gear engaged with the first gear is arranged on an output shaft of the motor; a first through hole allowing the spiral blade to penetrate is formed in a bottom plate of the fixing box; a first folding rod is arranged on the side face of the fixing box; an arc groove is formed in one end portion of the folding rod; and a telegraph pole is in tight contact with the inner concave face of the arc groove. The spiral blade is screwed into the ground to provide a fixing point for the folding rod, supporting is firm, use is convenient, and practicability is high.

Owner:国网河南省电力公司桐柏县供电公司

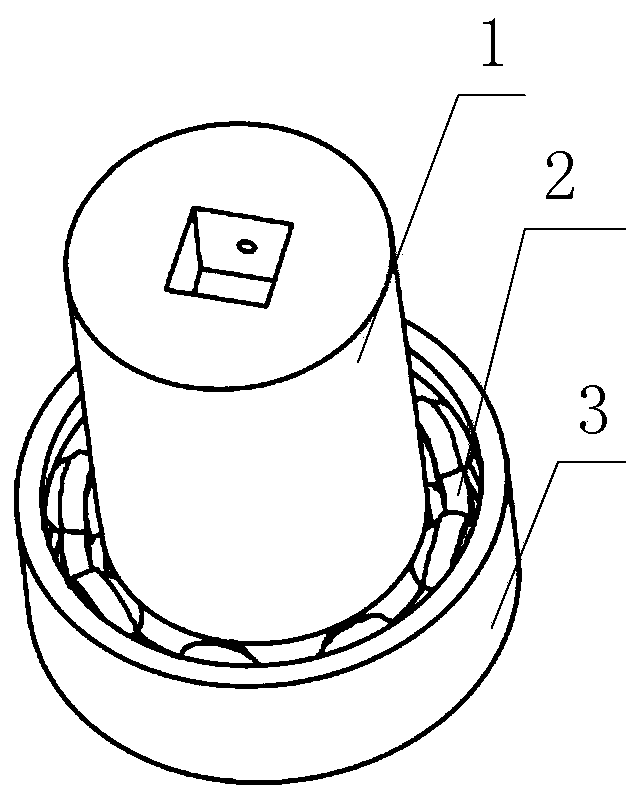

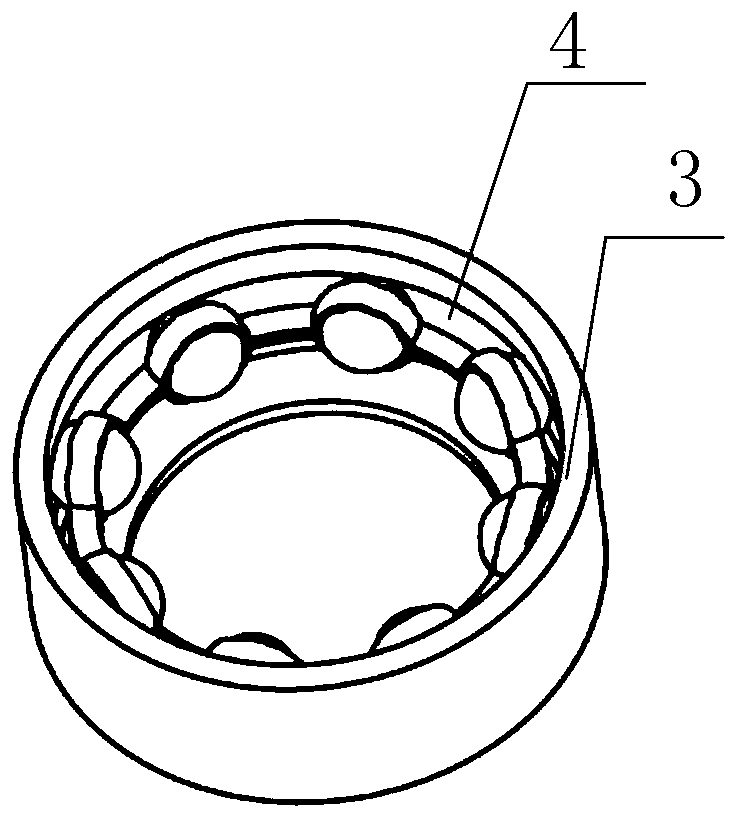

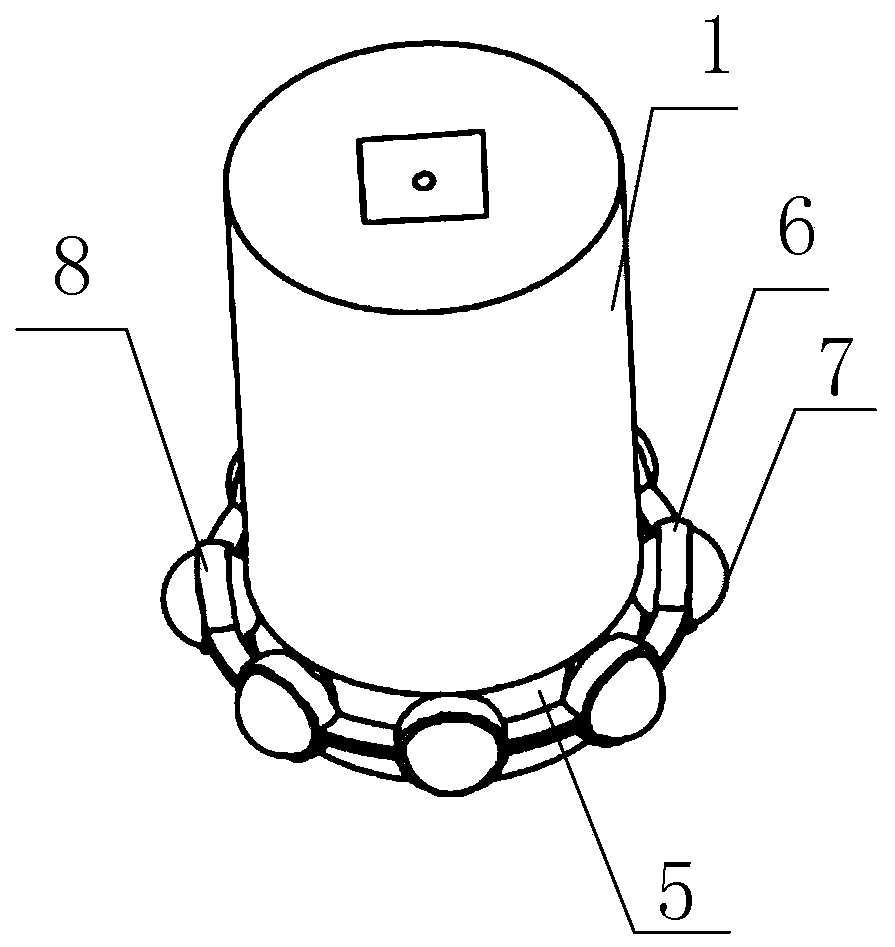

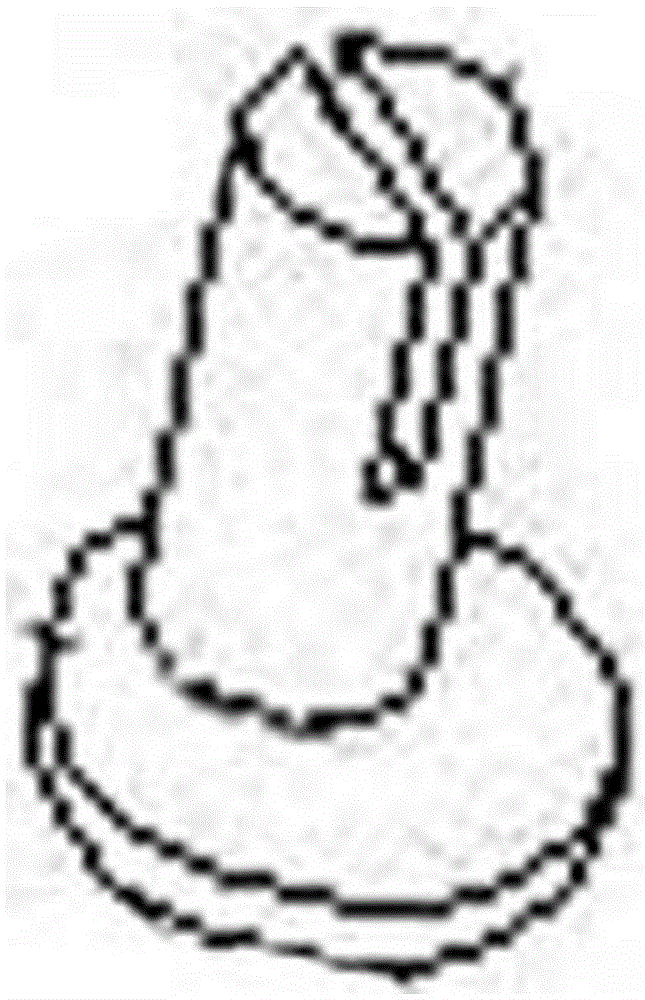

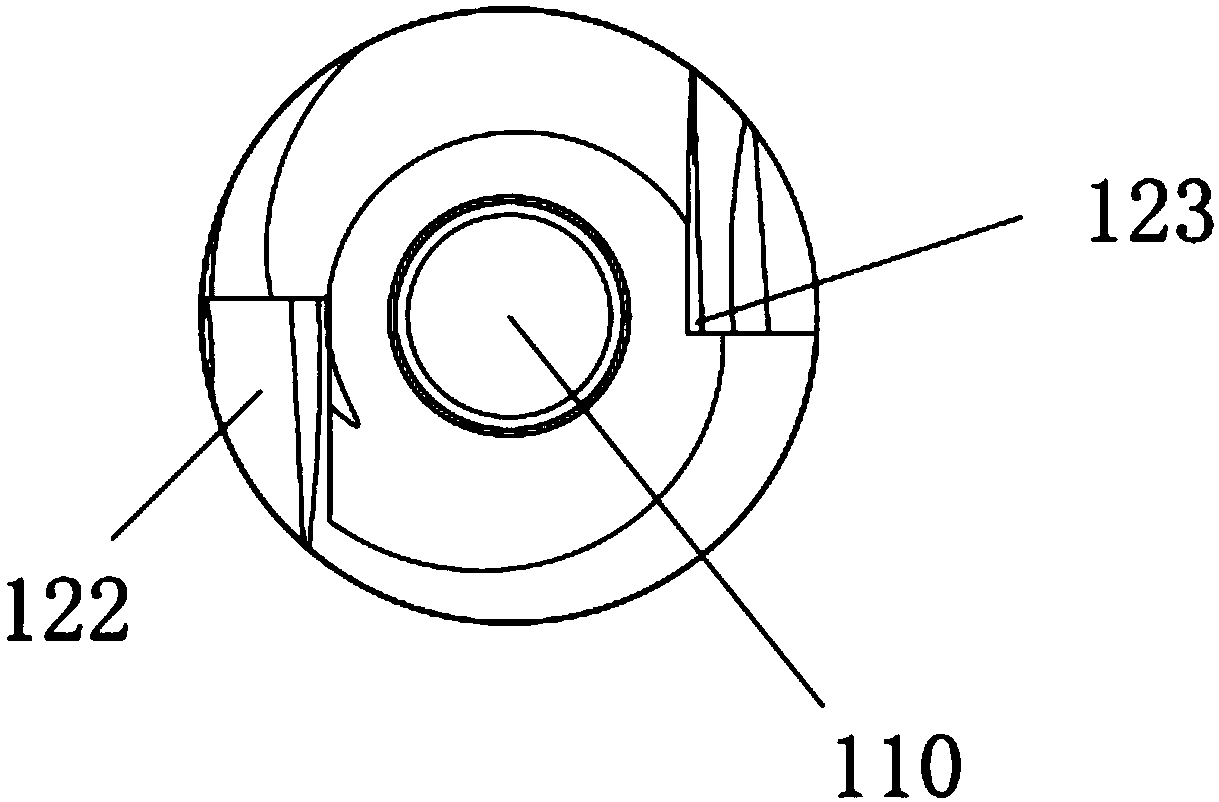

Fastening sleeve capable of preventing connection part from being scratched

InactiveCN109895011AScrew in smoothlyAvoid surface damageSpannersWrenchesFriction reductionMechanical engineering

The invention discloses a fastening sleeve capable of preventing a connection part from being scratched. An anti-friction ring is arranged around the outer side of a sleeve body of the fastening sleeve; the front end of the anti-friction ring is in an arc shape; mutual rotation can be performed between the outer side of the arc shape and an outer lining; and thus the surface friction between the connection part and the sleeve is transferred to the spherical surface friction of the arc surface and the inner wall of the outer lining, the frictional force is reduced, thus the connection part is screwed in more smoothly through the sleeve, meanwhile the sleeve body can be prevented from making direct contact with the connection part, the surface damage to a connected part is directly and completely eliminated during bolt assembling, the rusting problem, caused by the damage, of the connected part is completely eliminated, and the attractive appearance and practicability of a product are guaranteed.

Owner:SHAANXI HEAVY DUTY AUTOMOBILE

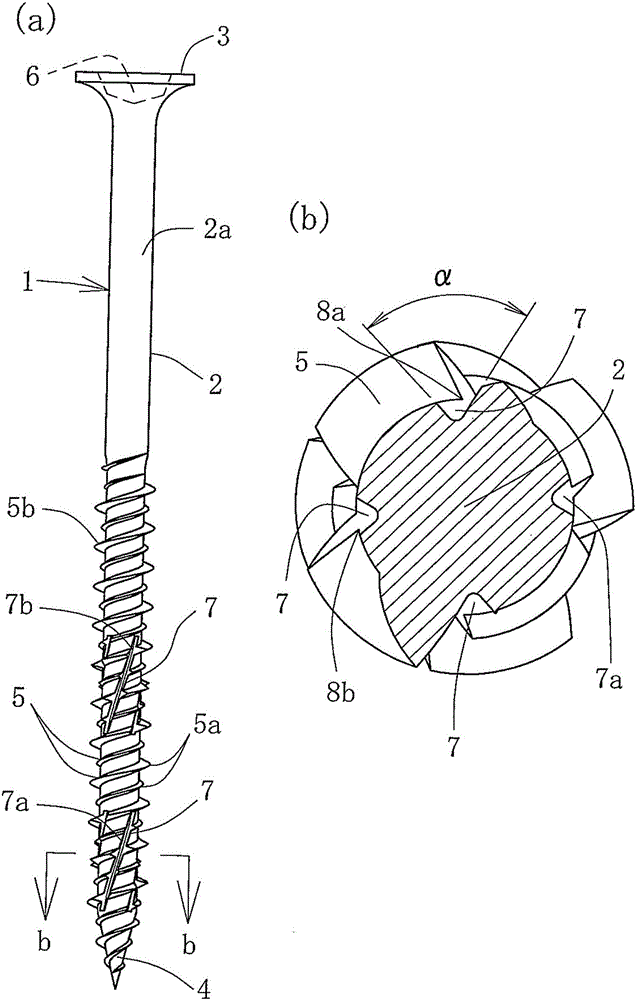

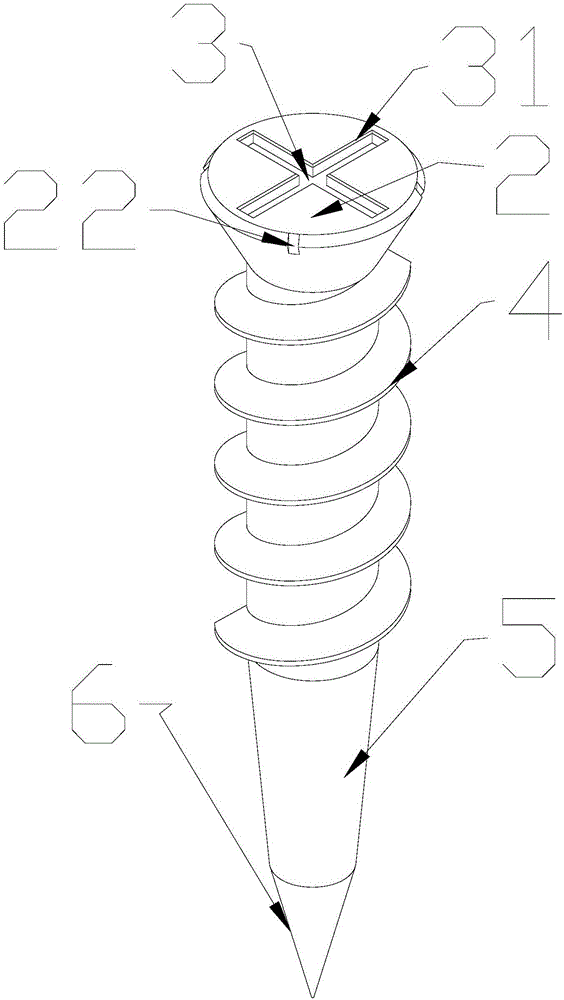

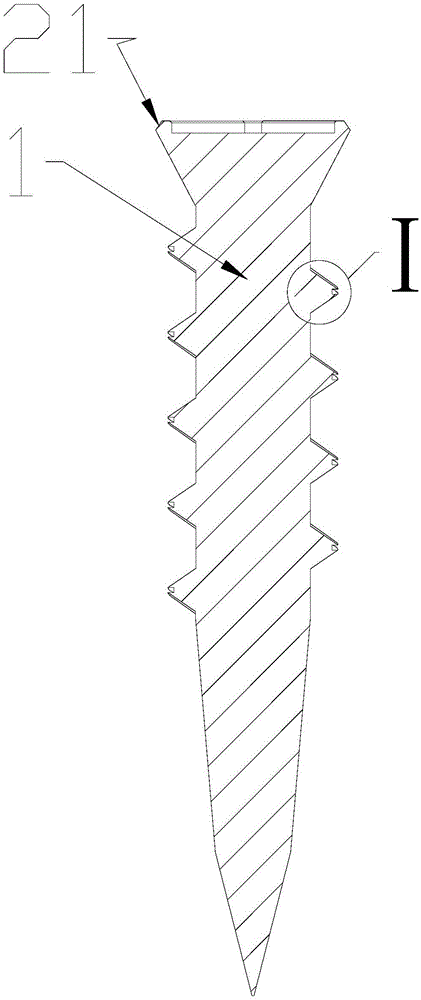

Wood screw

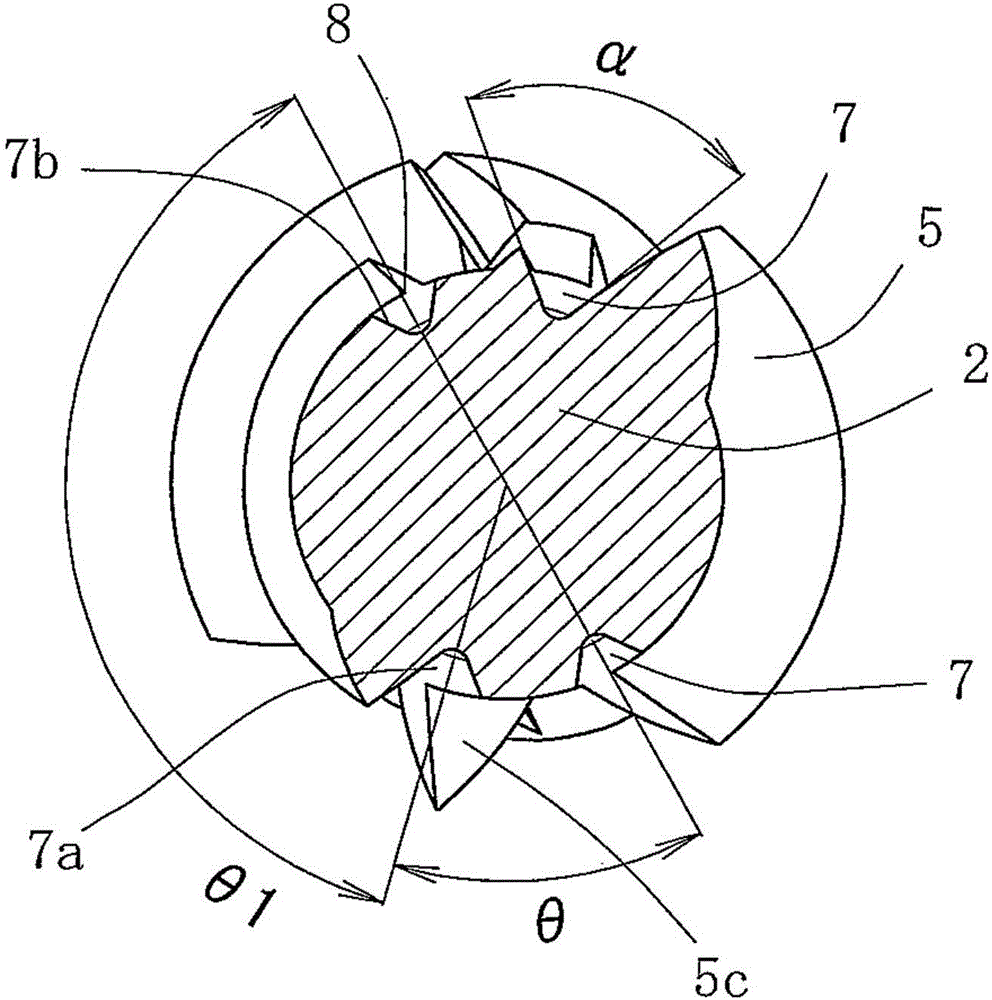

The invention provides a wood screw which cannot damage tightening performance in fastening state and can restrain the reduction of pulling resistance strenth after tightening. The wood screw (1) comprises a head (3) on one side of a shaft (2) and comprises a front end (4) on the other side, screw thread (5) spreads from the front end (4) of the shaft (2), cutting grooves (7) are respectively arranged with intervals on a plurality of axial positions along the shaft (2) and on the screw thread (5) of the shaft (2), the cutting grooves (2) have lengths which can make a plurality of scread threads (5) to be cut and are deeper than grooves of the scread threads (5), and grooveless screw thread (5a) are left between the ends of the cutting grooves (7) abutted along the axial direction of the shaft (2).

Owner:WAKAI & CO LTD

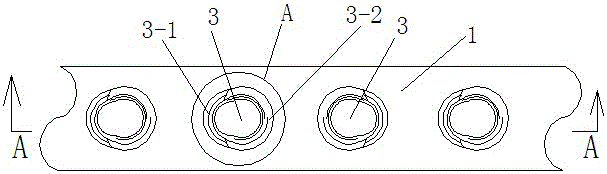

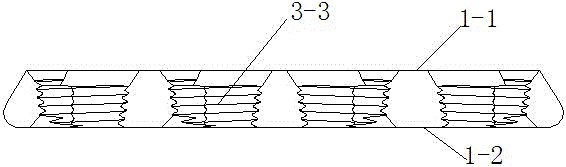

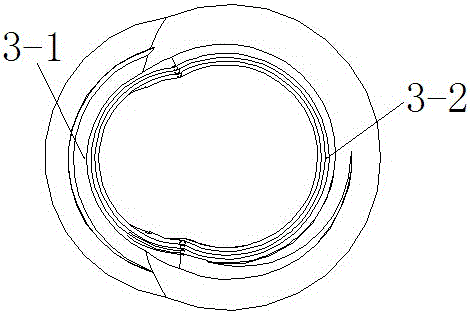

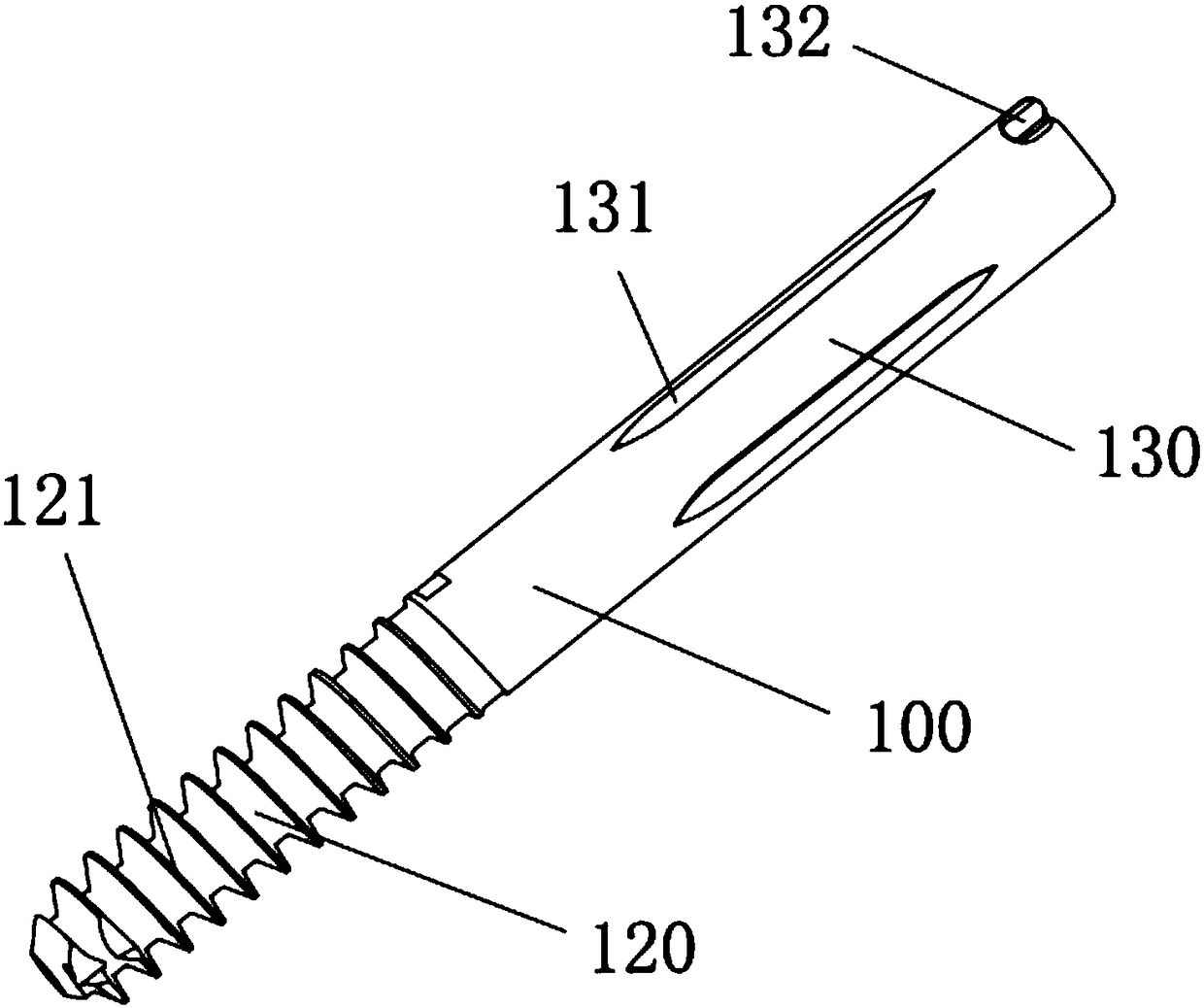

Spiral pressurization lock-in synchronism bone plate and application method thereof

The invention provides a spiral pressurization lock-in synchronism bone plate and an application method thereof. The bone plate comprises a bone plate body (1) and screws (2), wherein the bone plate body (1) is provided with a top surface (1-1) and a bottom surface (1-2) used for being connected with bones, a group of pressurization through holes (3) are formed in the bone plate body (1), the pressurization through holes (3) are connected with the top surface (1-1) and the bottom surface (1-2), an initial end (3-1) of the pressurization is arranged at one side of each pressurization through hole (3), a terminate end (3-2) of the pressurization is arranged at the other side of each pressurization through hole (3), integrally-continuous threads (3-3) are arranged on the inner walls of one or more pressurization through holes (3), each integrally-continuous thread (3-3) extends from the corresponding initial end (3-1) to the corresponding terminate end (3-2), and a thread (2-2) corresponding to the corresponding integrally-continuous thread (3-3) is arranged on the head portion (2-1) of each screw (2). According to the spiral pressurization lock-in synchronism bone plate and the application method thereof, in the pressurization and locking processes, no forced squeezing damage is caused, the mixed buckling phenomenon does not exist, no metal filing is generated, and time and labor are saved.

Owner:山东康盛医疗器械股份有限公司

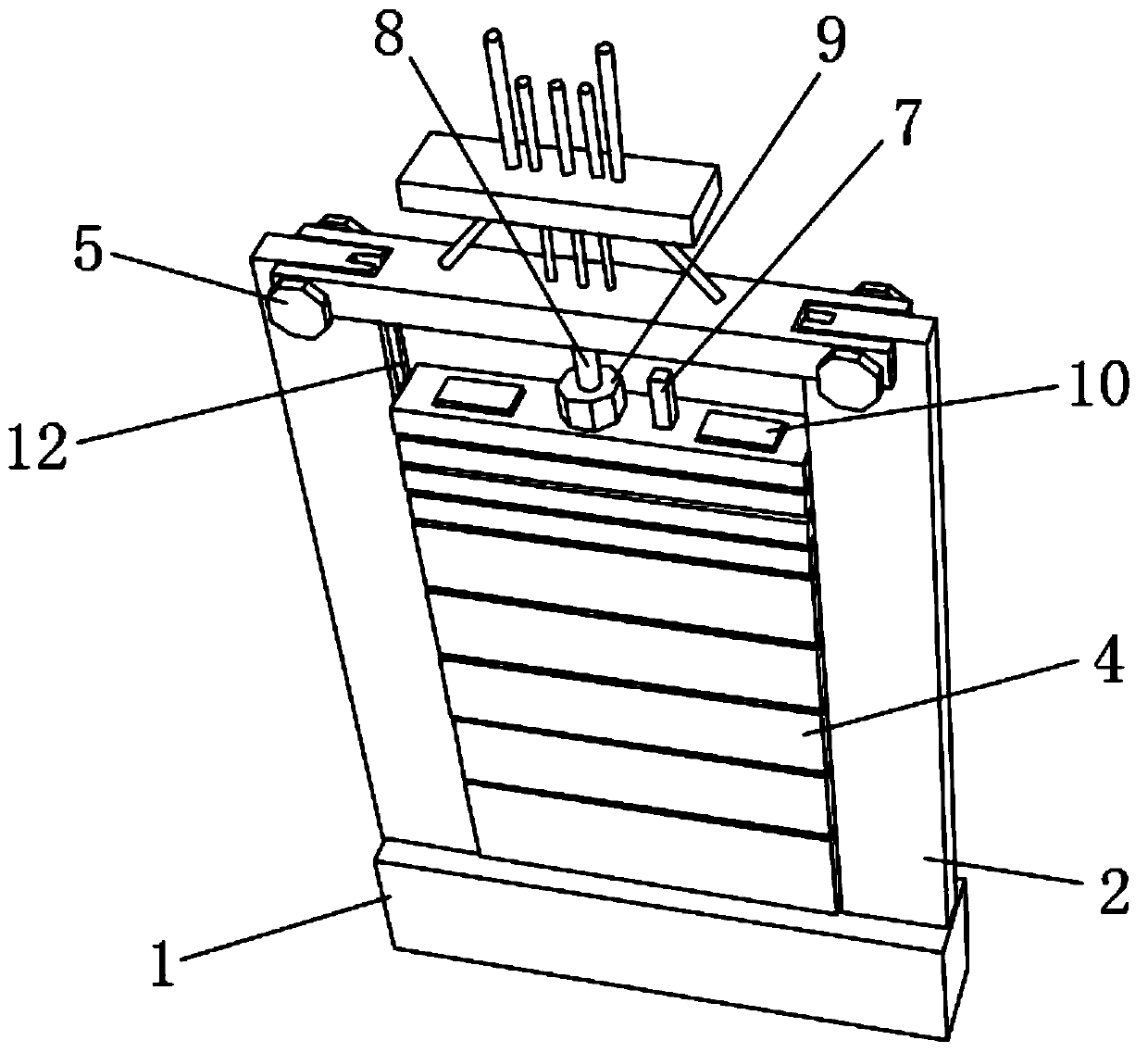

Novel hobbing fixture for shaft gear with internal spline

The invention provides a novel hobbing fixture for a shaft gear with an internal spline. The hobbing fixture comprises a base and a positioning rod integrally formed with the base; the end, far away from the base, of the positioning rod is provided with a first thread, a first positioning sleeve is connected to the step portion formed between the base and the positioning rod, a second positioning sleeve symmetrical to the first positioning sleeve is arranged in the mode of penetrating through the positioning rod, and a positioning nut is connected to the base in a threaded mode and is in threaded fit with the outer wall of the first positioning sleeve. The novel hobbing fixture for the shaft gear with the internal spline is a fixture designed for hobbing of the gear with the internal spline, spline connection pitch cercle meshing is steady when the fixture is in a using state, the condition that eccentricity is generated when hobbing is conducted is prevented, the problems such as noise and early failure of a bearing are effectively avoided, and the qualification rate is increased.

Owner:TIANJIN TAIWEI GEAR

Preparation method of diamond-coated dental implant

PendingCN111839770ASmooth implantationEffectively disperse stressDental implantsOsseointegrationDentistry

The invention discloses a diamond-coated dental implant. The diamond coated dental implant includes: an implant including an upper layer portion, a middle layer portion and a lower layer portion, a base table of which the bottom end is provided with a screw rod, wherein the screw rod is spirally assembled in a groove body preset in the implant, and at least two clamping columns which are assembledin column grooves preset in the surface of the lower layer part in an inserting manner, wherein one end of each clamping column extends into the groove body. The technical key points are as follows that: the diamond film layer is designed on the surface of the implant, so that the hardness of the implant can be remarkably improved, the implant can be screwed in, the surface friction force is reduced, the screwing-in process is smoother, the damage to tissues during screwing-in is reduced, cell protein adhesion can be remarkably promoted, and the osseointegration is enhanced at the same time,the clamping column is designed on the surface of the implant, and the clamping column can be extruded in the process of mounting the base station, so that the whole implant has a barb function, and the stability of the whole implant after being assembled is remarkably improved.

Owner:苏州卡彭新材料科技有限公司

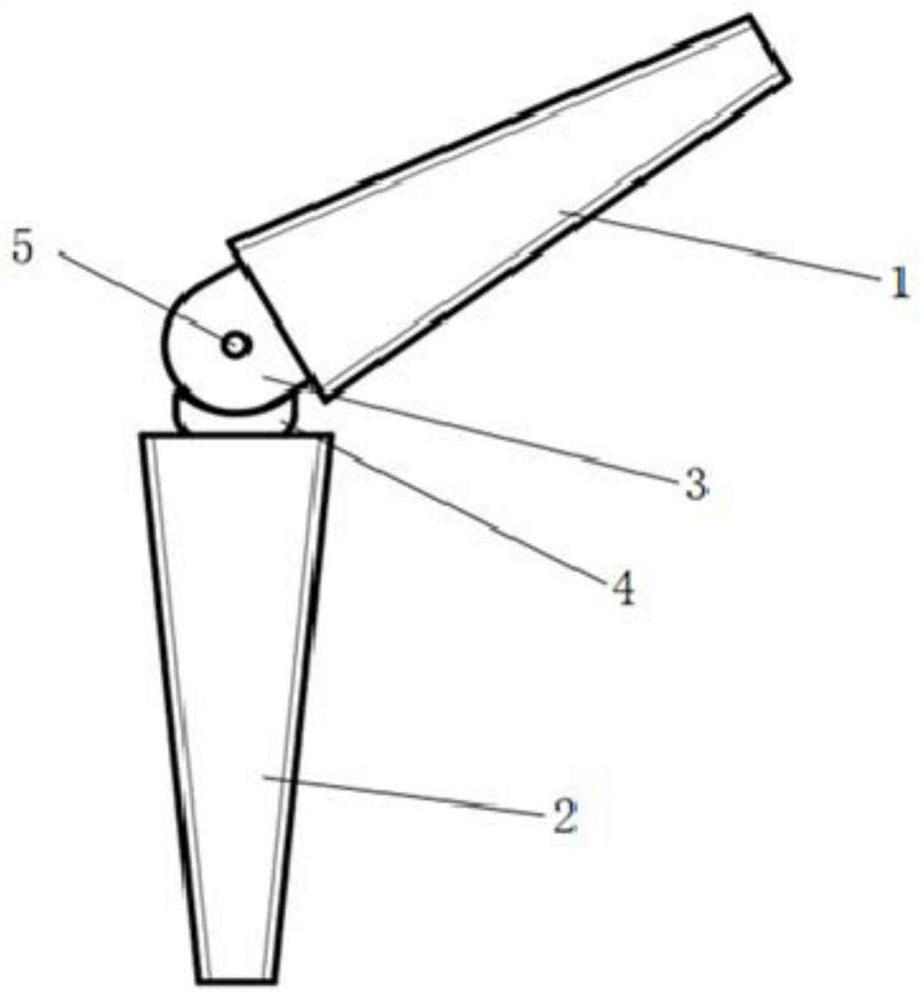

Hinge type interphalangeal joint prosthesis

PendingCN113425469AEasy to fixAvoid high stressFinger jointsAnkle jointsEngineeringInterphalangeal Joint

The invention relates to the technical field of medical prostheses, and provides a hinge type interphalangeal joint prosthesis. The hinge type interphalangeal joint prosthesis comprises a near-end broach, a far-end broach, a phalanx head, a phalanx platform and a rotating screw, wherein the phalanx platform is inserted into the phalanx head and is hinged to the phalanx head through the rotating screw; a cylindrical main body structure is arranged on the phalanx platform and the tail part of the far end of the phalanx head; a square outline and a circular outline at the tail end are arranged on the cylindrical main body structure; a transition groove is formed between the square outline and the circular outline at the tail end; and a rubber ring is in sleeving to the transition groove. The hinge type interphalangeal joint prosthesis has the beneficial effects that the rubber ring between the phalanx platform and the far-end broach and the rubber ring between the phalanx head and the near-end broach have certain elasticity, large stress can be avoided when the finger is in a bent state or is subjected to external force, and an effect of a buffer strip is performed; and in addition, the square outline can increase a limiting effect, and the round outline can facilitate fixation of the rubber rings in the broaches.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

An electric pole bracket

The invention discloses a utility pole support, which comprises a fixing box, on which a screw jack is arranged, and the screw jack includes a screw perpendicular to the ground, the lower end of the screw is located in the fixing box, and the bottom end surface of the screw is Rotate and connect the connecting rod, the upper part of the connecting rod is provided with a gear one, the middle part of the connecting rod is provided with a spiral blade, the bottom end of the connecting rod is conical, the screw rod is provided with a mounting plate, and the motor is provided on the mounting plate. The output shaft of the motor is provided with a gear 2 that engages with the gear 1, a through hole 1 is provided on the bottom plate of the fixed box for the helical blade to pass through, a folding rod 1 is provided on the side of the fixed box, and an arc is provided at the end of the folding rod. The utility pole is in close contact with the inner concave surface of the arc-shaped groove, and the spiral blade of the present invention is screwed into the ground to provide a fixed point for the folding pole, with firm support, convenient use and strong practicability.

Owner:国网河南省电力公司桐柏县供电公司

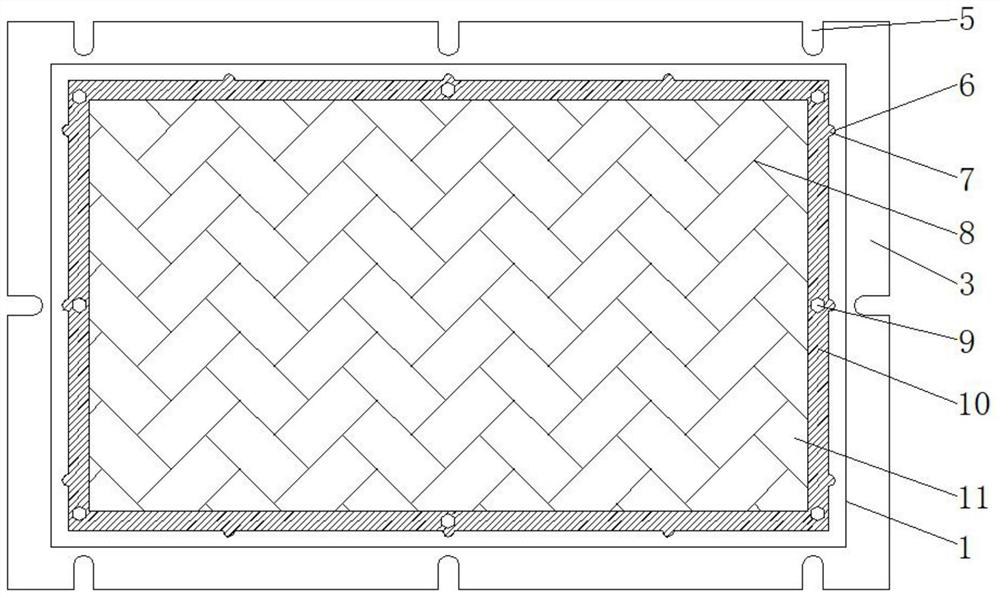

Ceramsite light partition wall board machining mold

InactiveCN112192723AReduce manufacturing costPlay a limiting roleMouldsMould fastening meansEngineeringGrain structure

The invention relates to the technical field of light partition wall board machining, and discloses a ceramsite light partition wall board machining mold. The ceramsite light partition wall board machining mold comprises an upper mold and a lower mold, the upper mold is arranged over the lower mold in a covering mode, and the upper mold and the lower mold are internally provided with a grain structure and a pouring structure; the grain structure comprises first grains, bolts, an annular frame, a grain board, screw holes, a block groove, a first magnet, an annular board, a second magnet, a clamping block and second grains; and the block groove is formed in the middle of the inner side surface of the upper mold, the first magnet is fixedly embedded into the position, in the block groove, ofthe interior of the upper mold, and the first magnet is transversely embedded into the block groove. According to the ceramsite light partition wall board machining mold, the block groove and the detachable annular frame are arranged in the upper mold, the grain board with the different first grains can be fixed into the upper mold, when different light wall boards are machined, the grains on onesides of the wall boards can be changed only by replacing the grain board, mold replacing is not needed for machining, and the production cost is reduced.

Owner:至大(上海)环保科技有限公司

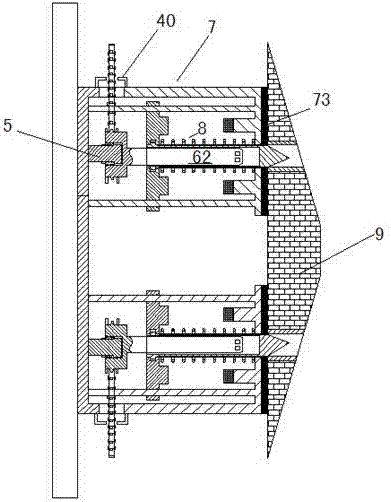

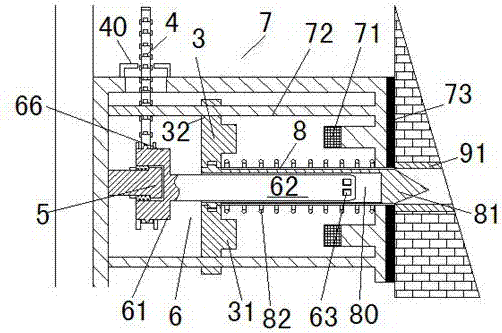

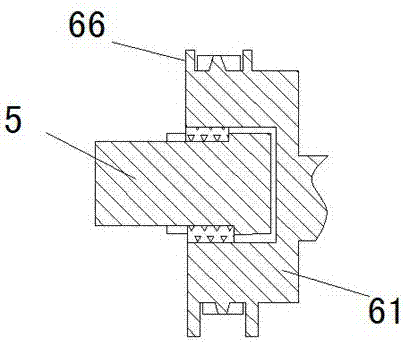

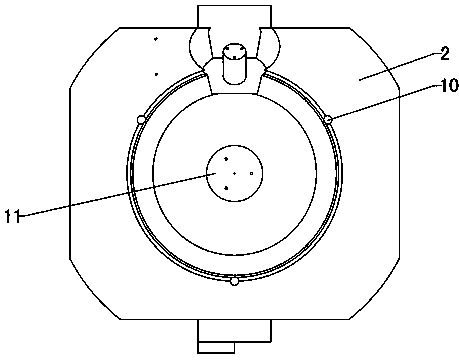

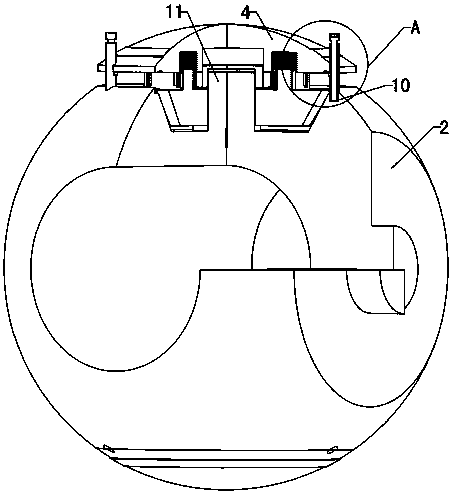

Improved type fire extinguisher storage box fixing frame

InactiveCN106994213AEffective operation with top pressureEnsure the way forwardFire rescueThreaded pipeFixed frame

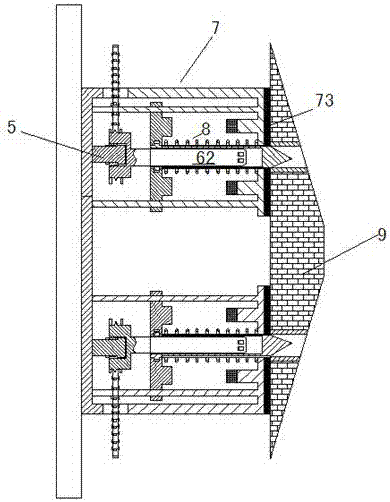

The invention discloses an improved type fire extinguisher storage box fixing frame. The fixing frame comprises a rack (7) and in-shell screwing and fixing assembling parts located in the upper end and the lower end of the rack (7), each in-shell screwing and fixing assembling part comprises a thread convex tongue part (8) entering a thread pipe sleeve (91) fixed into a wall (9) in a thread manner, a pushing slippage portion (3) connected with the thread convex tongue part (8) through a bearing, a drive sliding rod (62) capable of entering an inner sliding groove (80) in the thread convex tongue part (8) in a slippage manner, and a suspension joint shaft (5) fixedly connected with the rack (7) and capable of being borne on a rotating disc pipe sleeve (61) fixedly connected with the drive sliding rod (62) in a twisted manner.

Owner:广州迪然安全检测技术有限公司

Large-span corridor between unequal-height high-rise buildings

ActiveCN114293653AEliminate frequent observation stepsReduce workloadBuilding constructionsClassical mechanicsEngineering

The invention relates to the field of corridors, in particular to a large-span corridor between unequal-height high-rise buildings, which comprises a bottom plate layer, a top plate layer, chord pipes, web members and preassembled pipes, elastic plates for the chord pipes to abut against are arranged on the preassembled pipes, and avoiding mechanisms for avoiding the elastic plates when the chord pipes on the top plate layer approach are arranged on the four lower preassembled pipes. The elastic plate can be reset again after successful avoidance; a connecting rod and a first elastic piece are arranged in the preassembling pipe; a positioning groove is formed in the upper surface of the connecting rod, a through hole communicated with the elastic plate and the positioning groove is formed in the preassembling pipe, a positioning rod which penetrates through the through hole and is inserted into the positioning groove is arranged on the elastic plate, and the positioning rod is used for positioning the connecting rod in the preassembling pipe; and the positioning rod is separated from the positioning groove. According to the scheme, the step that workers frequently observe butt joint of the preassembled pipe and the chord pipe is omitted, and the workload and potential safety hazards of the workers are reduced.

Owner:BEIJING CONSTR ENG GRP CO LTD

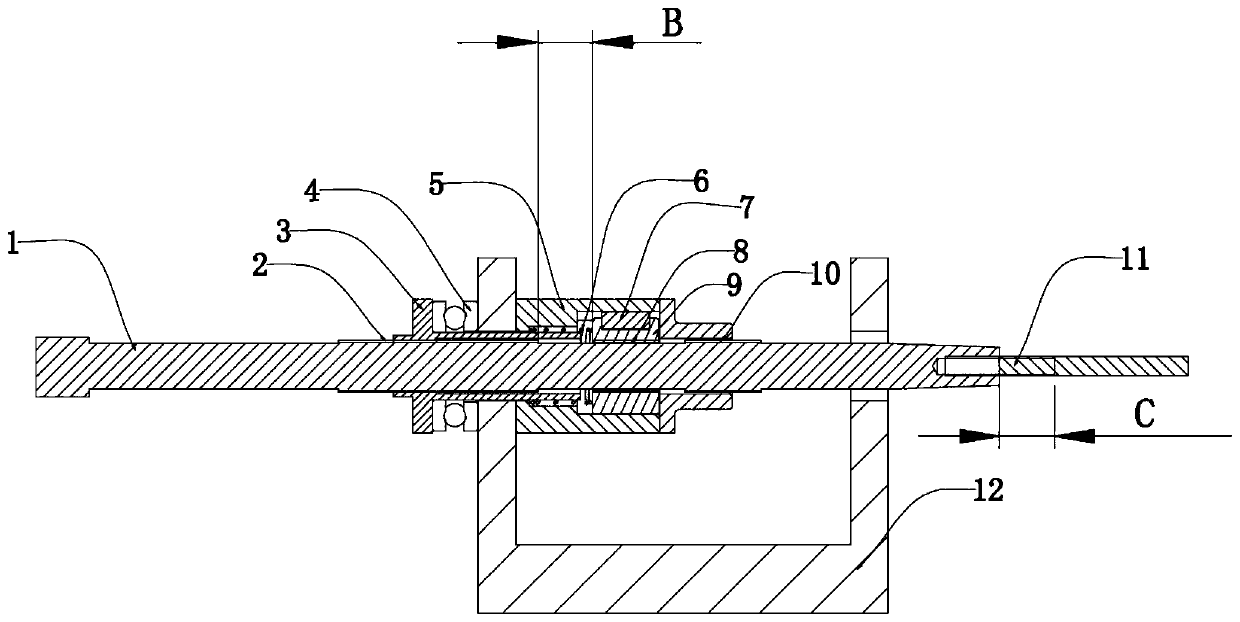

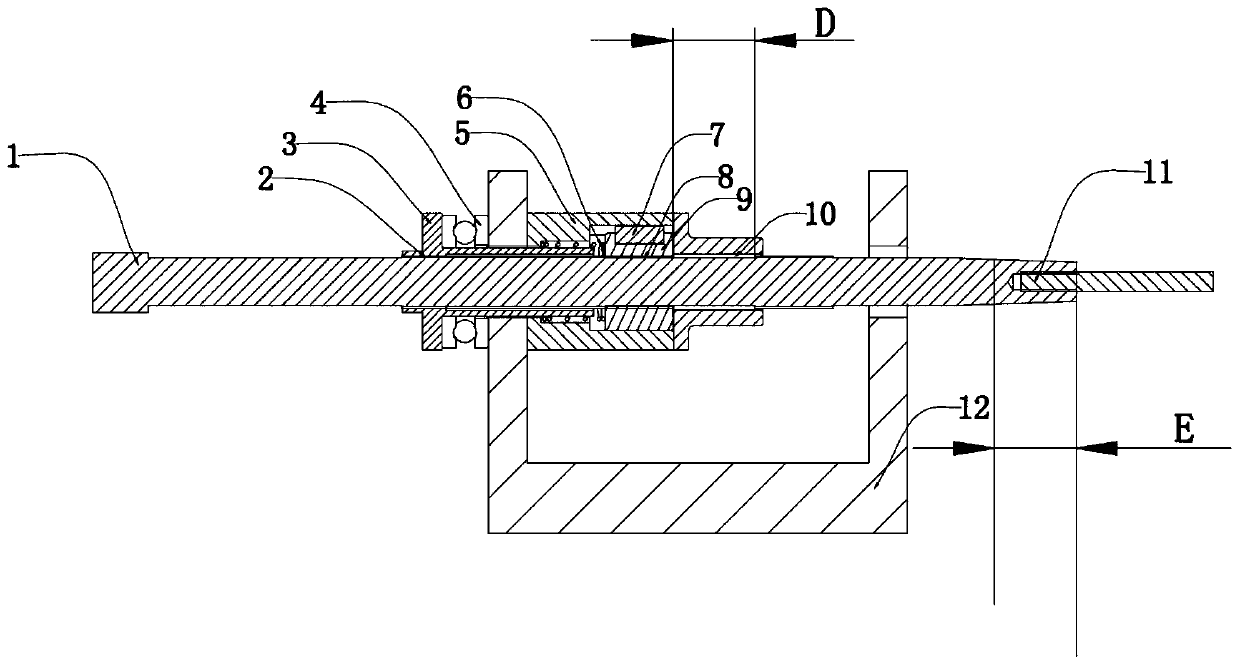

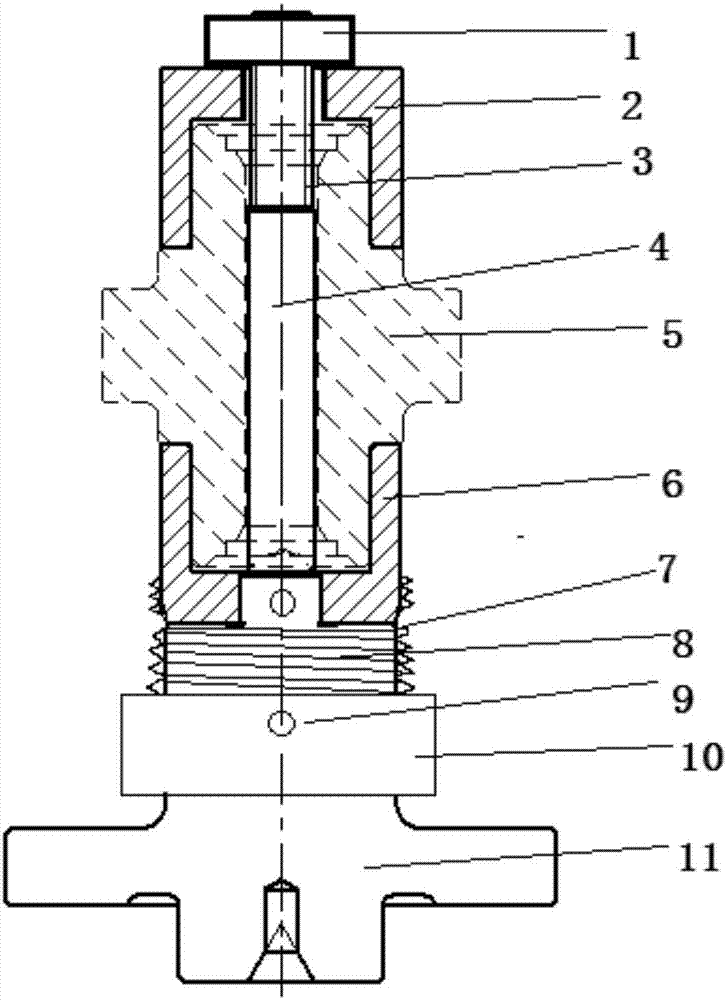

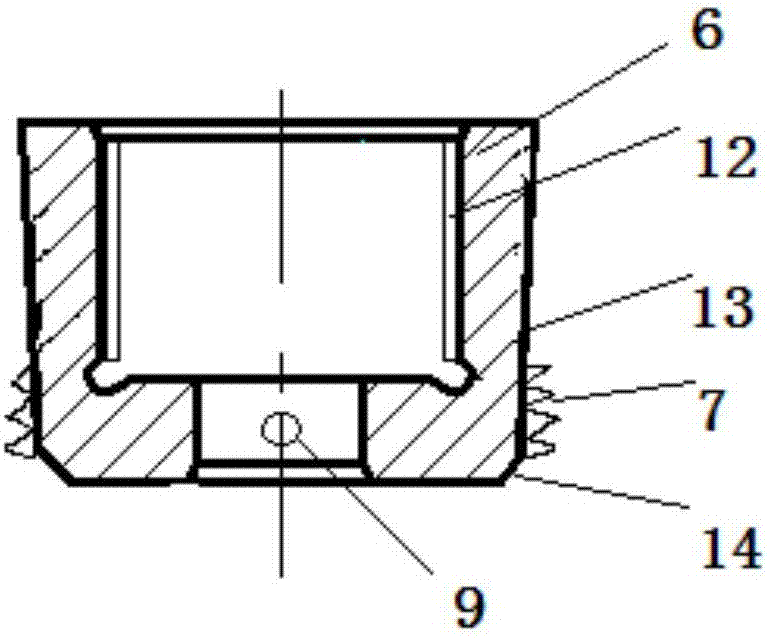

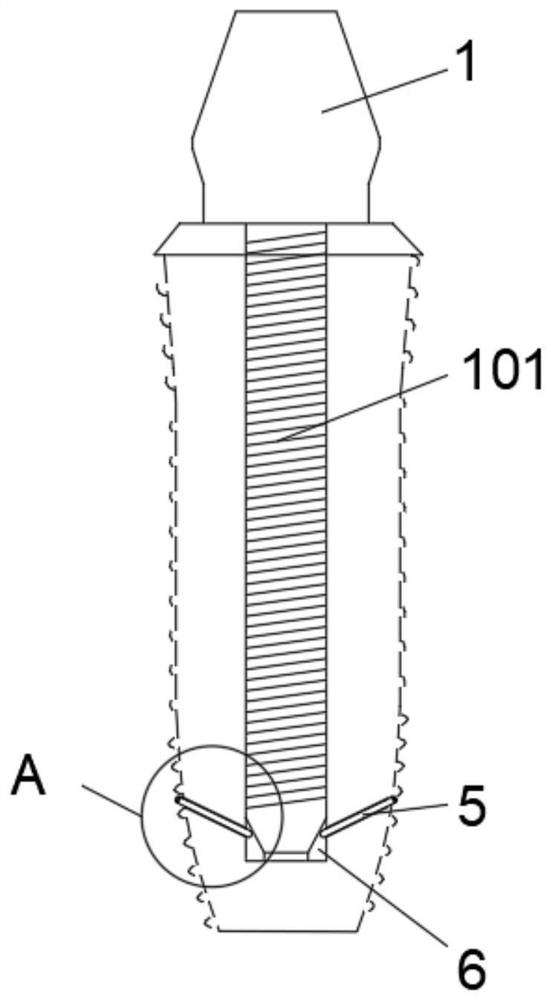

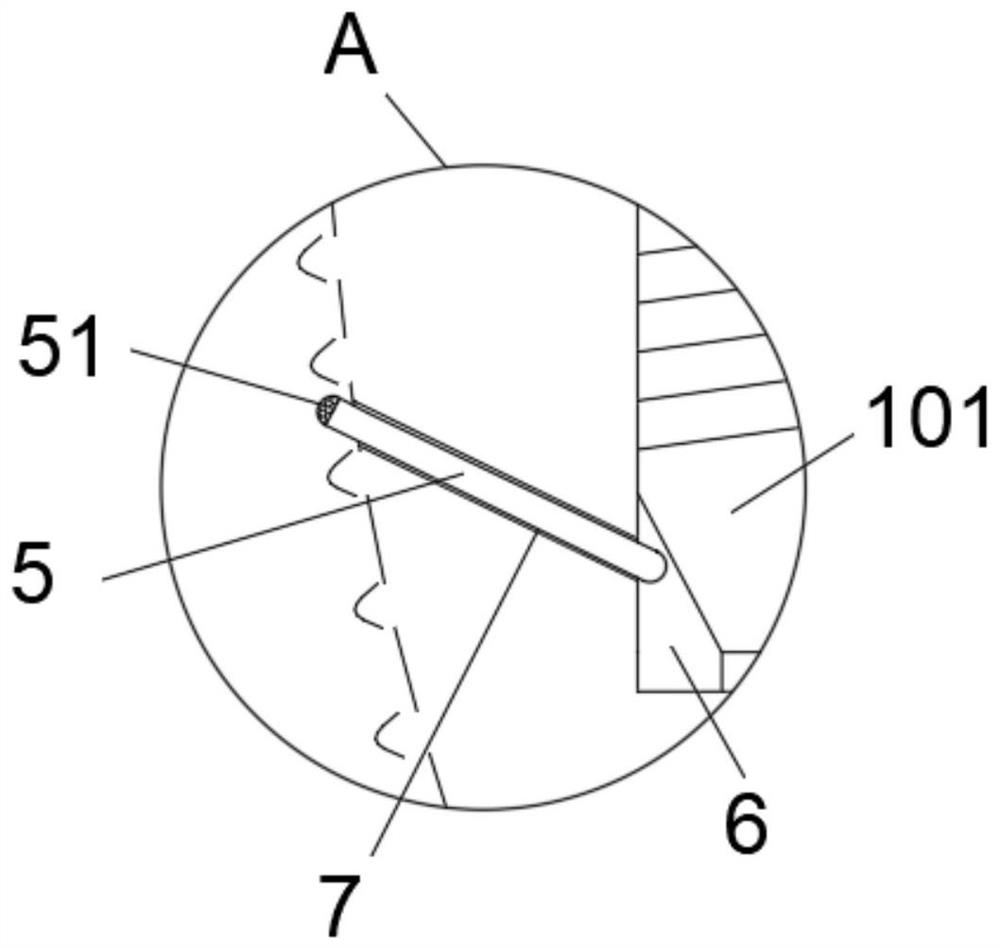

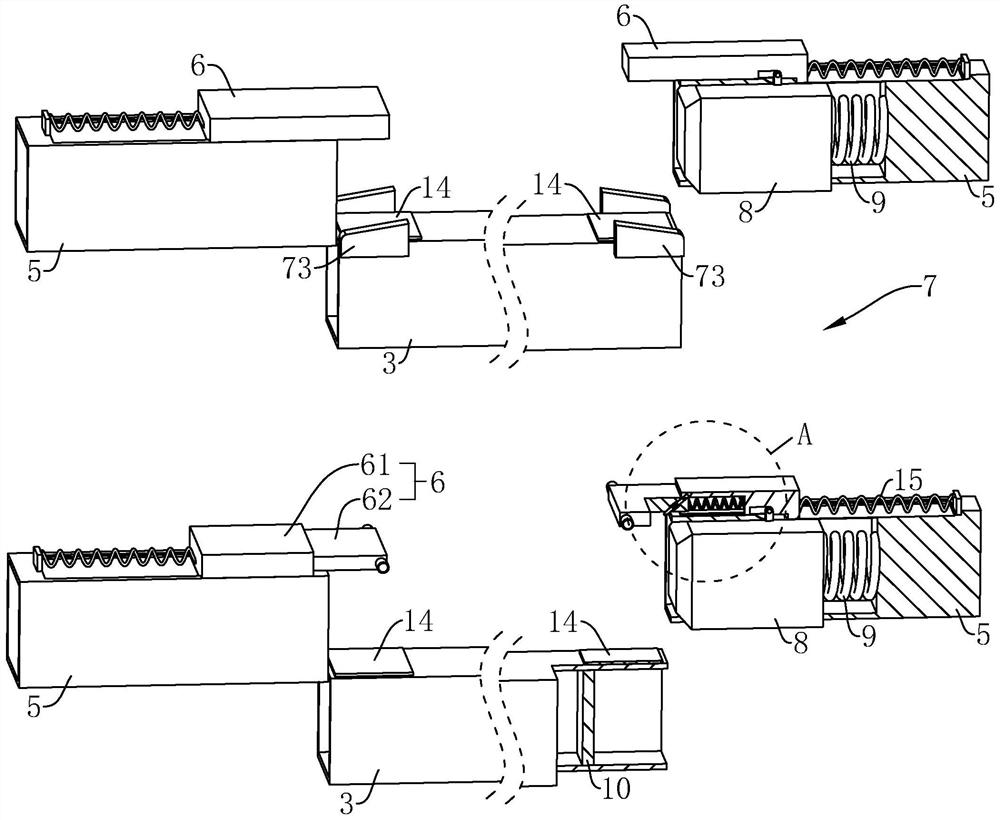

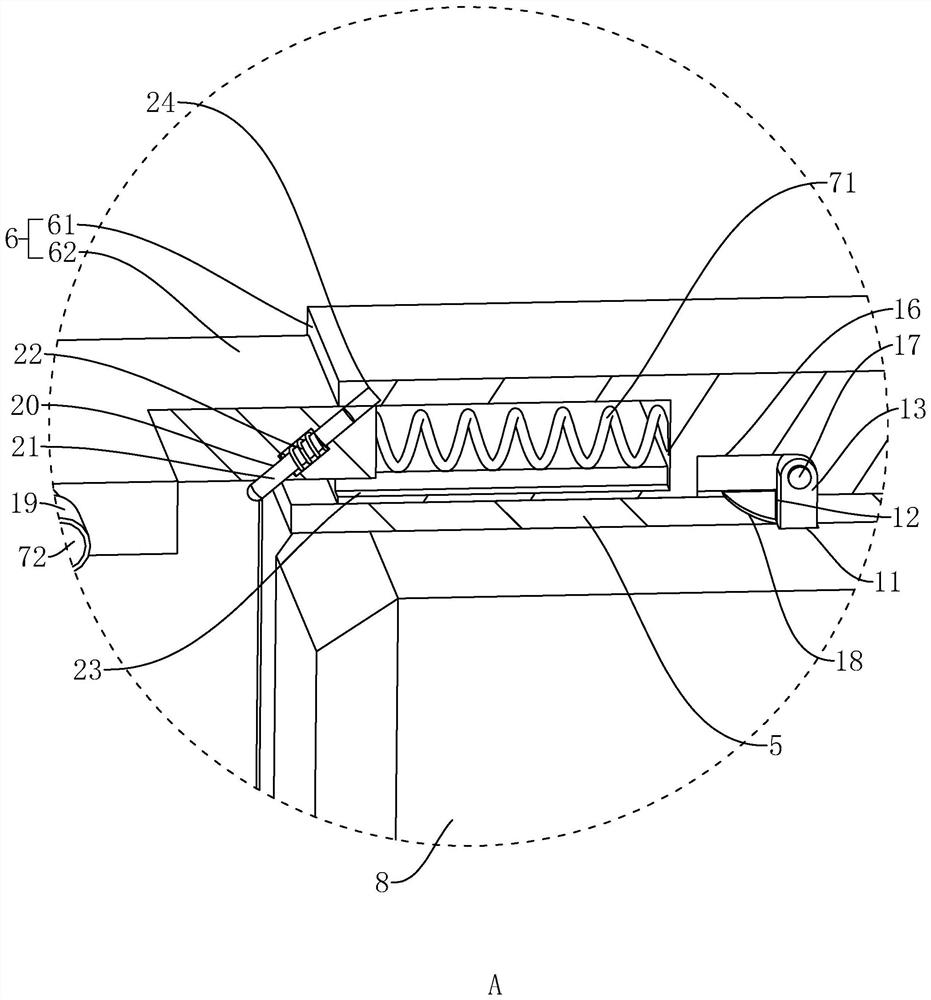

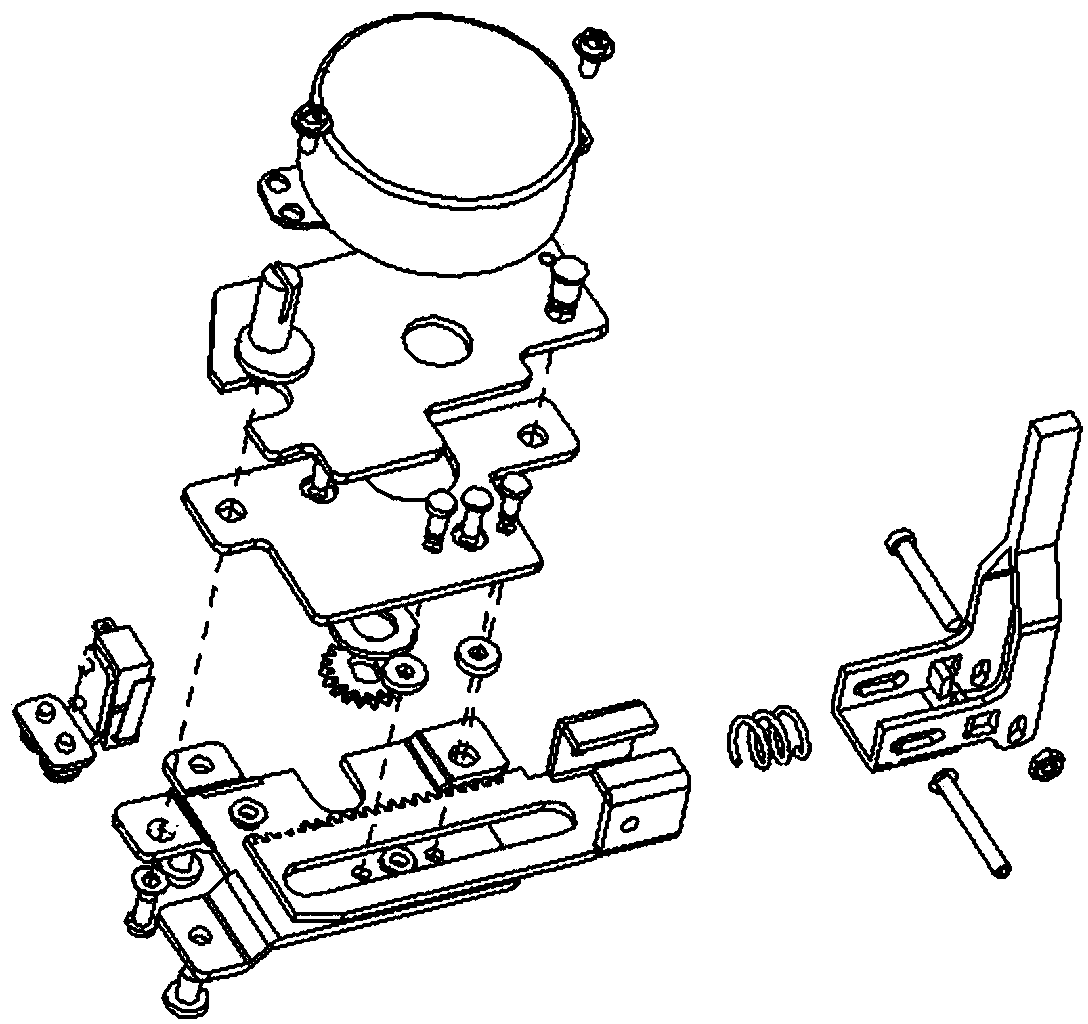

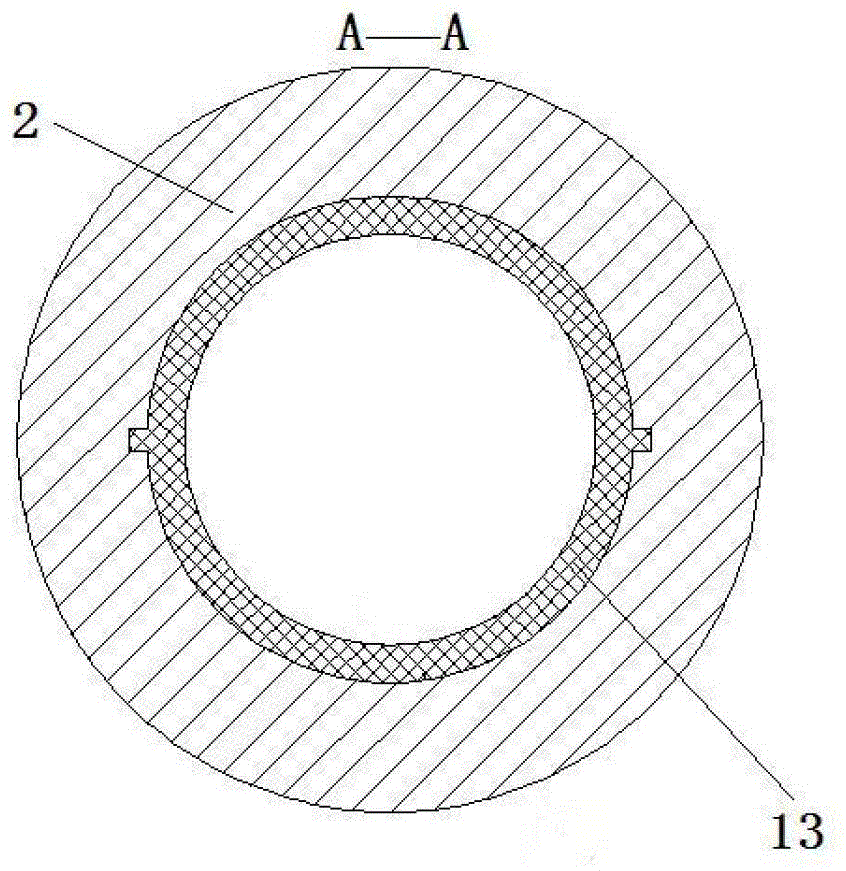

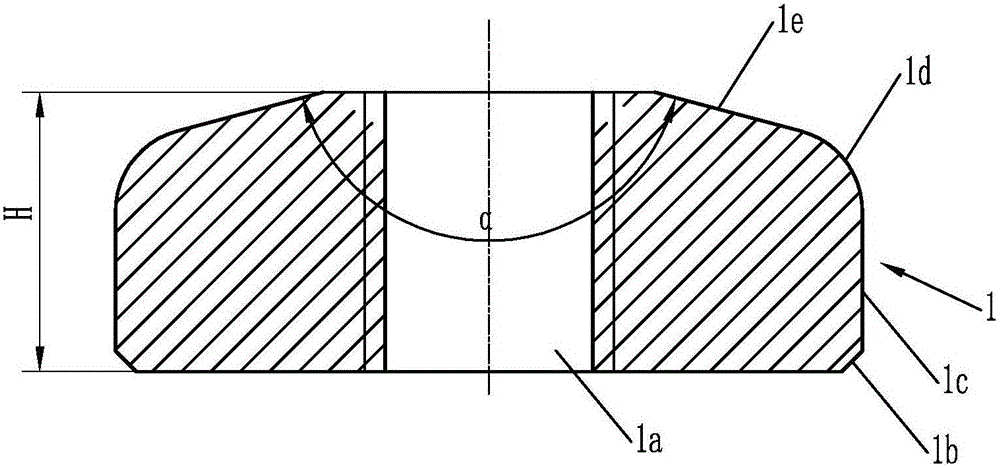

A forced sealing ball valve, valve ball assembly tooling and assembly method

ActiveCN108036073BScrew in smoothlyGuaranteed positional relationshipPlug valvesLoad-engaging elementsGear wheelEngineering

The invention relates to a forced seal ball valve and ball valve assembly fixture and an assembly method, and belongs to the technical field of seal valves. The force seal ball valve and valve ball assembly fixture includes a vertical guide pin and a limiting support, and the outside of the guide pin is provided with the limiting support. The assembly method includes the following steps of 1) forming positioning holes; 2) mounting double-screw bolt gears (1); 3) installing a pin roller mechanism in a sleeve mode; 4) installing a positioning fixture and pointing the limiting support toward theaxis direction of a double-screw bolt gear shaft (11); 5), lifting valve clacks (4), and contacting the bottom surfaces of the valve clacks (4) with the limiting support arranged on the guide pin; 6),vertically screwing the valve clacks (4) in; 7), fully screwing the valve clacks in until the valve clacks are tightened with a valve ball base (2), taking out the guide pin, and placing a limiting pin in a guide pin hole. It takes only several minutes or even tens of seconds to assemble a seal valve using the assembly method, which saves a lot of assembly time, assembly process is simple and easy to operate, and a lot of production costs are saved.

Owner:ZIBO VOTAISI PETROCHEM EQUIP CO LTD

Novel fire extinguisher storage box fixing frame

InactiveCN106994214AEffective operation with top pressureEnsure the way forwardFire rescueFixed frameThreaded pipe

The invention discloses a novel fire extinguisher storage box fixing frame. The fixing frame comprises a rack (7) and in-shell screwing and fixing assembling parts located in the upper end and the lower end of the rack (7), each in-shell screwing and fixing assembling part comprises a thread convex tongue part (8) entering a thread pipe sleeve (91) fixed into a wall (9) in a thread manner, a pushing slippage portion (3) connected with the thread convex tongue part (8) through a bearing, a drive sliding rod (62) capable of entering an inner sliding groove (80) in the thread convex tongue part (8) in a slippage manner, and a suspension joint shaft (5) fixedly connected with the rack (7) and capable of being borne on a rotating disc pipe sleeve (61) fixedly connected with the drive sliding rod (62) in a twisted manner.

Owner:广州迪然安全检测技术有限公司

Manual and electric conversion knob of circuit breaker reclosing mechanism

ActiveCN103426696BEasy to convertSimple structureProtective switch operating/release mechanismsEngineeringCircuit breaker

The invention discloses a manual and electric switching knob of a breaker reclosing mechanism. The manual and electric switching knob comprises a handle (1) and a cylinder (2), the handle (1) is used for allowing an operator to grip and apply external force, the cylinder (2) is in linkage with the handle (1) to be driven by the handle (1) to rotate, and a spiral rail (4) extending along an axial direction of the cylinder (2) is formed in an outer wall (3) of the cylinder (2). The spiral rail (4) can be matched with a double-rack plate of the reclosing mechanism to realize switching among different working modes of the double-rack plate, and accordingly the reclosing mechanism can conveniently switch electric opening and closing and manual opening and closing of a breaker. Meanwhile, the switching knob is simple in structure and easy to process.

Owner:DELIXI ELECTRIC

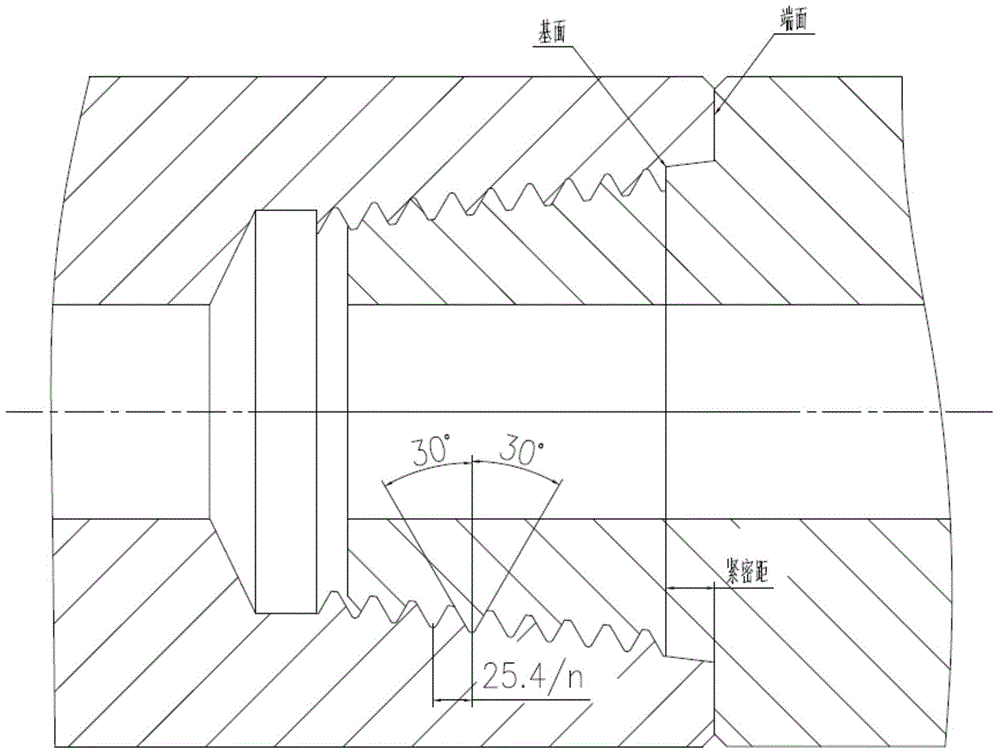

Connection thread between drilling tool systems of blasthole drill

InactiveCN105715215AGood self-lockingScrew in smoothlyDrilling rodsDrilling casingsManufacturing cost reductionFeeler gauge

The invention relates to a connection thread between drilling tool systems of a blasthole drill, and aims to solve the problem of processing of special inch tapered threads of an existing slender-shaft drilling rod: a lengthened lathe with a tilted profiling device is used for processing the thread, and the thread is required to be checked with a special thread ring or feeler gauge, but a general numeric control machine tool cannot be used for processing the thread, so that a certain difficulty in the processing of the thread and inconvenience in user maintenance are caused. The connection thread between the drilling tool systems of the blasthole drill comprises internal and external threads. The connection thread adopts a cylindrical single-line rectangular thread for connection, only has a large diameter and a small diameter without a medium diameter, and is a concave-convex straight tooth with a rectangular axial section taking a tooth shape; the tooth side surface of the connection thread is a working engagement sliding face with a smooth surface; the connection thread adopts small-diameter centered clearance fit. The processing bottleneck of the slender-shaft drilling rod is solved; furthermore, the production period is shortened, and the manufacturing cost is reduced; the precision of the rectangular straight tooth shape is easy to guarantee.

Owner:中钢集团衡阳机械有限公司

Practical cross recessed screw

The invention discloses a practical cross recessed screw which comprises a screw body, a screw head, a cross recess, an external thread, a first conical surface and a second conical surface. The upper portion of the screw body is connected with the screw head. The screw head is a circular truncated cone body, and a first chamfer is formed in the circular side line of the upper end face of the screw head. Four side grooves which are evenly distributed in the circumferential direction are formed in the first chamfer. The cross recess is formed in the end, away from the screw body, of the screw head. The external thread is arranged on the partial outer surface of the screw body, and tracking grooves are formed in the outer edge of the external thread. A first conical surface is arranged on the screw body and located below the external thread, and the first conical surface and the screw body are provided with a second conical surface. According to the practical cross recessed screw, the total length of the first conical surface and the second conical surface is designed to be one half of the length of the screw body, so that a longer pressing-in distance is achieved when the screw enters media at the beginning, and subsequent screwing-in of the screw is better facilitated; second chamfers are formed in intersection lines of the cross recess and the top head end face, and therefore the cross recess cannot be damaged when a hammer is used for knocking the screw.

Owner:HAIYAN HAITANG STANDARD PARTS FACTORY

Zipper head and casting die for compression casting same

InactiveCN1139346CFirmly connectedPrevent prolapseSlide fastenersDomestic articlesDie castingEngineering

In a die-casting slide fastener slider having a plastically deformable, cantilevered pull-tab attaching lug (5) on a slider body (1), the lug (5) projects from an upper end of a guide post (4) over an upper wing (2) toward a rear end (11) of the upper wing (2) and terminates in a downward end projection (14) spaced from the upper wing (2) by a gap (15) through which an attachment ring (18) of a pull tab (17) is threaded. The lug (5) has a longitudinal hollow (12) through its base to facilitate plastically deforming the lug (5) to reduce the size of the gap (15) after threading. In this structure, since first and second slide cores (22, 23) of a mold for die-casting the slide fastener slider can be inserted from the front and rear sides, it is possible to mold the lug (5) without generating any parting line on its overall appearance.

Owner:YKK CORP

Manual and electric switching knob of breaker reclosing mechanism

ActiveCN103426696AEasy to convertSimple structureProtective switch operating/release mechanismsEngineeringCircuit breaker

The invention discloses a manual and electric switching knob of a breaker reclosing mechanism. The manual and electric switching knob comprises a handle (1) and a cylinder (2), the handle (1) is used for allowing an operator to grip and apply external force, the cylinder (2) is in linkage with the handle (1) to be driven by the handle (1) to rotate, and a spiral rail (4) extending along an axial direction of the cylinder (2) is formed in an outer wall (3) of the cylinder (2). The spiral rail (4) can be matched with a double-rack plate of the reclosing mechanism to realize switching among different working modes of the double-rack plate, and accordingly the reclosing mechanism can conveniently switch electric opening and closing and manual opening and closing of a breaker. Meanwhile, the switching knob is simple in structure and easy to process.

Owner:DELIXI ELECTRIC

A pressure gauge tightening assembly machine

ActiveCN106217015BIncrease productivityReduce manufacturing costMetal working apparatusEngineeringPiston rod

The invention provides a screwing assembly machine for a pressure gauge. The screwing assembly machine comprises a base mounting plate, a gauge stand fixture, an upright post, a gear motor and a gauge head fixture, wherein the gauge stand fixture is fixed to the base mounting plate and is used for fixing a gauge stand of the pressure gauge; one end of the upright post is fixed to the base mounting plate; an upper vertical plate is arranged on the other end of the upright post; a compaction cylinder is arranged on the upper vertical plate; a piston rod of the compaction cylinder is positioned right above the gauge stand fixture; the gear motor is arranged on the base mounting plate; a rotating head is in linkage connection on a rotating shaft of the gear motor; and the gauge head fixture is arranged on the rotating head and aligns to the gauge stand fixture. The screwing assembly machine has the beneficial effects that the pressure gauge can be automatically screwed on the gauge stand, so that the production efficiency is improved, and the production cost is reduced.

Owner:宁波创二代机械科技有限公司

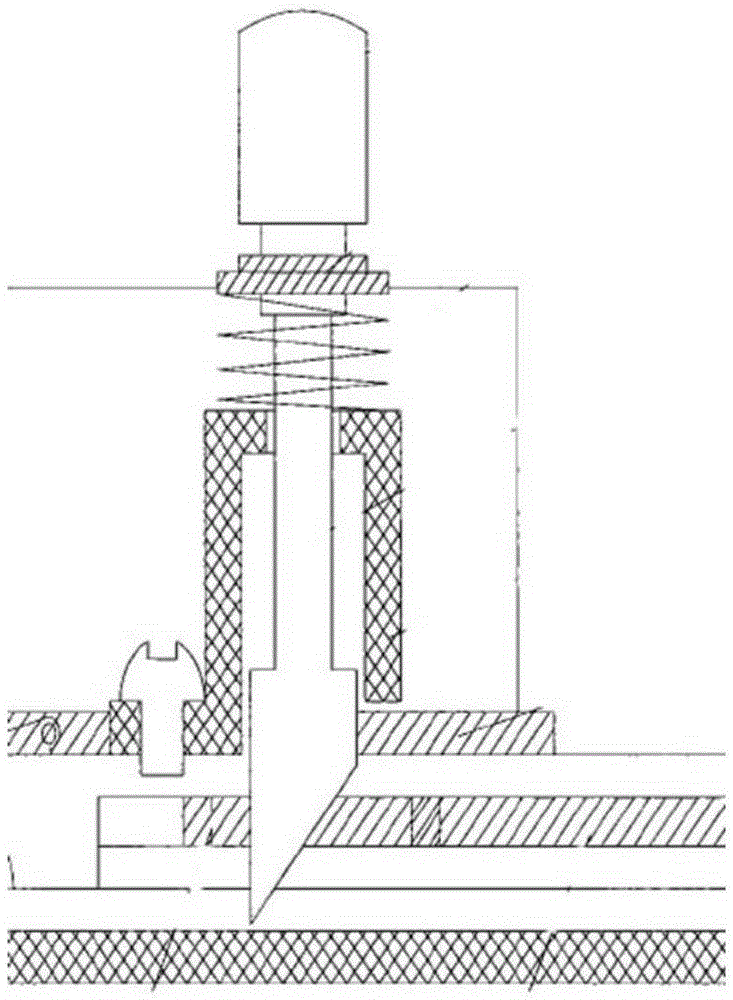

Threaded type tension nail

The invention discloses a threaded type tension nail which comprises a body. A through center hole is formed in the axis of the body, the body comprises a threaded portion and a rod, the threaded portion and the rod are axially integrally formed, a plurality elongated grooves are axially uniformly formed in the outer surface of the rod, the widths of the elongated grooves are gradually increased from the rod to the threaded portion, tips are formed at two ends of each elongated groove, threads with equal crest widths are formed on the outer surface of the threaded portion, the end surface, which is far away from the rod, of the threaded portion is flat, and two V-shaped cutting edges are formed at the front end of each thread. The threaded type tension nail has the advantages that the threaded type tension nail can be smoothly screwed into bones and is good in bone pullout strength and applicable to young patients or patients with good bone quality, and conditions such as nail withdrawal can be prevented.

Owner:SHUANGYANG MEDICAL INSTR SUZHOU

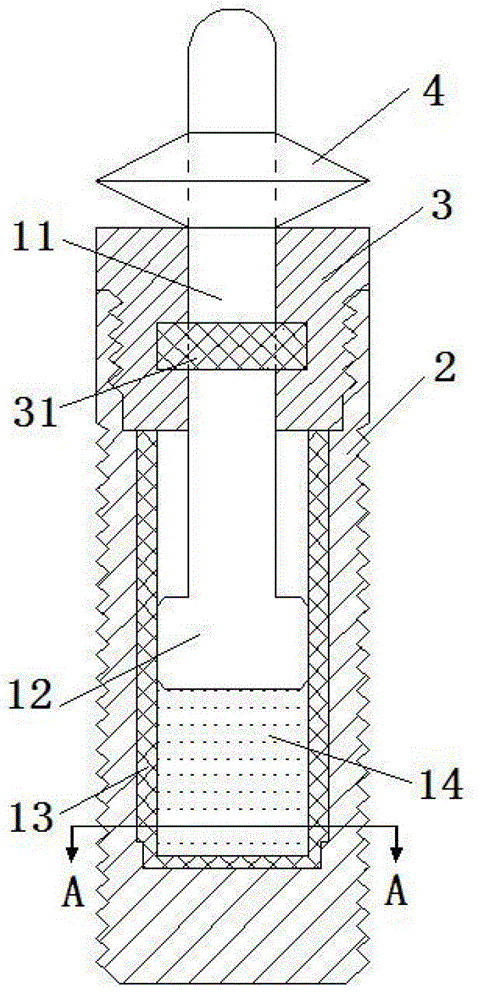

Dental implants with vibration damping and anti-rotation

InactiveCN102764161BReduce radial vibrationAvoid bone resorptionDental implantsDental implantPiston rod

The invention discloses a dental implant with functions of reducing vibration and preventing rotation, which comprises a buffering and vibration reduction part and an implant part. The buffering and vibration reduction part comprises a piston rod and an airtight cavity; the lower end of the piston rod is provided with a piston; the piston is plugged into the airtight cavity; air is sealed in the airtight cavity; the piston rod and the airtight cavity which are connected are arranged in the implant part; and the outer wall of the airtight cavity is matched with the inner wall of the implant part. The invention provides the artificial dental implant which can be used for effectively buffering the impact and the vibration on teeth, which are generated in the chewing process, dispersing an occlusion load and avoiding the bone adsorption of alveolar bone so as to improve the stability of the implant and also has the characteristics that the dental implant is prevented from rotating, is tightly sealed, is rapid and convenient to assemble, has high strength and the like.

Owner:LANZHOU UNIVERSITY

Vehicle frame connector on shock absorber

InactiveCN105035243AEffectively blockAvoid enteringAxle suspensionsShock absorbersVehicle frameEngineering

The invention discloses a vehicle frame connector on a shock absorber. A body of the connector is of a rotary body structure. An inner threaded hole is formed in the center of the body in the axial direction and is a through hole. The inner threaded hole is used for being connected with a screw rod. The bottom face of the body is connected with the lower end of a cylindrical section through a chamfered section. The upper end of the cylindrical section is connected with the lower end of a conical section through a circular arc section. The circular arc section is in smooth transition connection with the cylindrical section and the conical section. The conical section is of a big-end-down structure. The upper end of the conical section is directly connected with the lower end of the small cylindrical section. The upper end of the small cylindrical section is directly connected with the top face of the body. The height of the small cylindrical section ranges from 0.6 mm to 1 mm. According to the vehicle frame connector on the shock absorber, the upper end of the body is adjusted to be the small cylindrical section, and the height design of the small cylindrical section is reasonable; the outer circular face of the small cylindrical section is fixedly welded to a vehicle frame during welding, and the small cylindrical section can effectively block welding slag and prevent the welding slag from entering the inner threaded hole, so that the inner threaded hole is prevented from being damaged, and the screw rod can be smoothly screwed into the inner threaded hole.

Owner:重庆川东减震制造有限公司

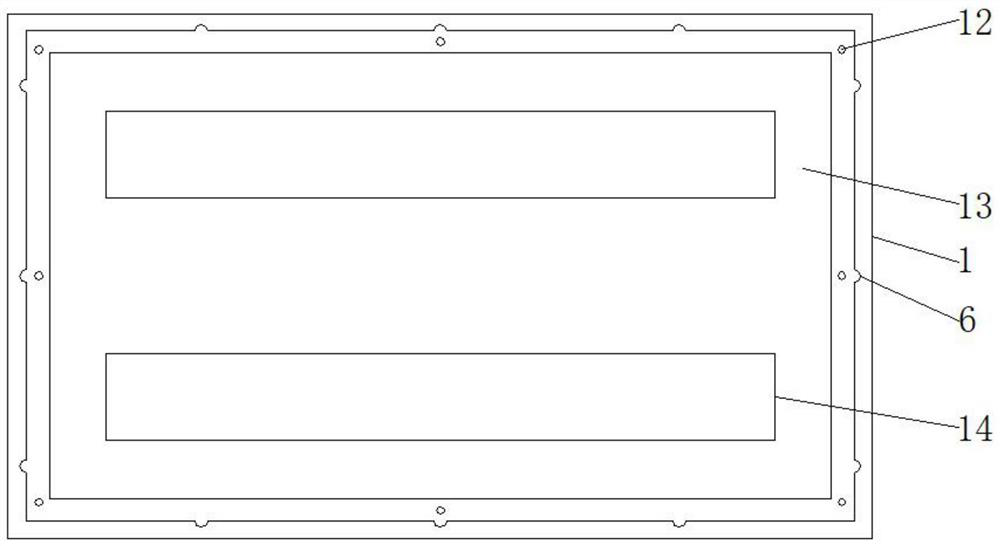

An elevator counterweight device with associated counterweights and belts

ActiveCN110054068BGuaranteed stabilityNot easy to be injuredMine liftsControl engineeringControl theory

The invention discloses an elevator counterweight device with associated counterweights taken out, which belongs to the field of elevator counterweights. A counterweights associated type taken out elevator counterweight device includes a counterweight frame and a counterweight group. The weight group is located inside the counterweight frame. The counterweight frame includes a counterweight frame seat, a counterweight frame top and a pair of counterweight frame sides. A pair of counterweight frame sides are fixedly connected to the left and right ends of the counterweight frame seat. The center of the weight block is drilled from top to bottom with a center jack, and the center of the upper end of the counterweight frame seat is connected with a center column. If necessary, take out multiple counterweights at one time. During the process of taking out and transporting, the relative stability of multiple counterweights can be guaranteed, and it is not easy to slip and hurt the handling personnel, which improves safety and can be reinstalled at one time, greatly shortening the The disassembly and installation time is reduced, the operation efficiency is improved, and the elevator maintenance process is accelerated.

Owner:南通通途机电制造有限公司

Counter weight block joint type taking-out type elevator counter weight device

The invention discloses a counter weight block joint type taking-out type elevator counter weight device, and belongs to the field of elevator counter weight devices. The counter weight block joint type taking-out type elevator counter weight device comprises a counter weight frame and a counter weight block set located on the inner side of the counter weight frame. The counter weight frame comprises a counter weight frame base, a counter weight frame roof and a pair of counter weight frame edges, wherein a pair of counter weight frame edges are fixedly connected to the left end and the rightend of the upper side of the counter weight frame base. Center inserting holes are chiseled in the center positions of the counter weight blocks from top to bottom, the center position of the upper end of the counter weight frame base is connected with a center stand column, and the upper end of the center stand column penetrates through the center inserting holes and is in threaded connection with a pressing type fastening nut. According to the scheme, the multiple counter weight blocks can be taken out at a time according to the actual operation requirements, in the taking-out and carrying process, relative stability of the multiple counter weight blocks can be guaranteed, slipping and carrying personnel crushing are not likely to happen, safety is improved, one-time reinstalling can beconducted, the dismounting and mounting time is greatly shortened, the operation efficiency is improved, and the elevator maintaining progress is accelerated.

Owner:南通通途机电制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com