Fastening sleeve capable of preventing connection part from being scratched

A technology for fastening sleeves and connectors, which is applied to wrenches, wrenches, screwdrivers, etc., can solve problems such as increased product rework costs and sales costs, no protective devices, product quality damage, etc., to ensure aesthetics and practicality, and eliminate Effect of surface damage and friction reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

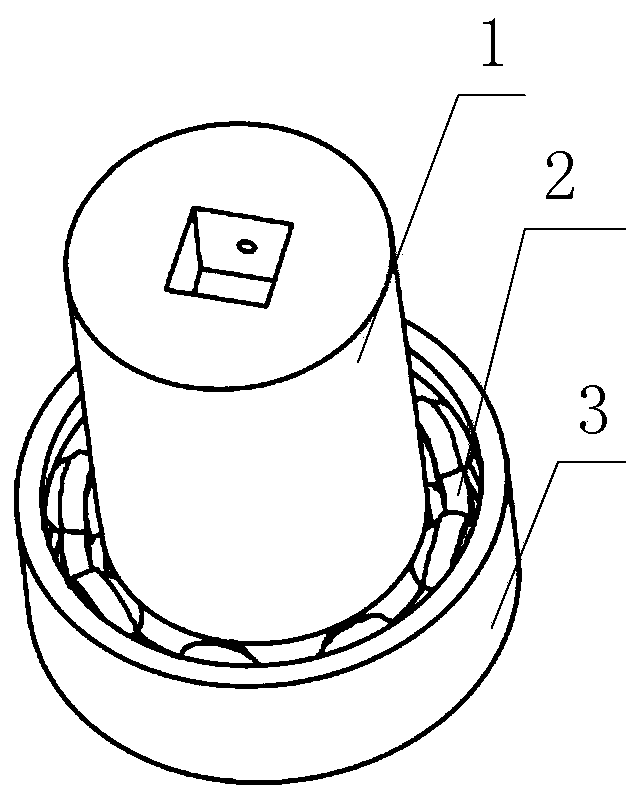

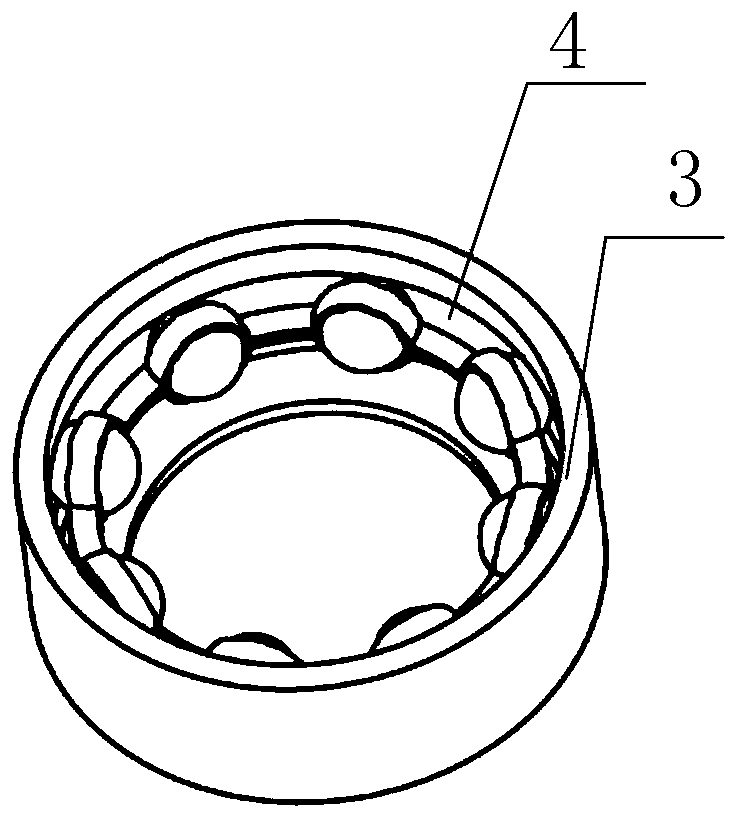

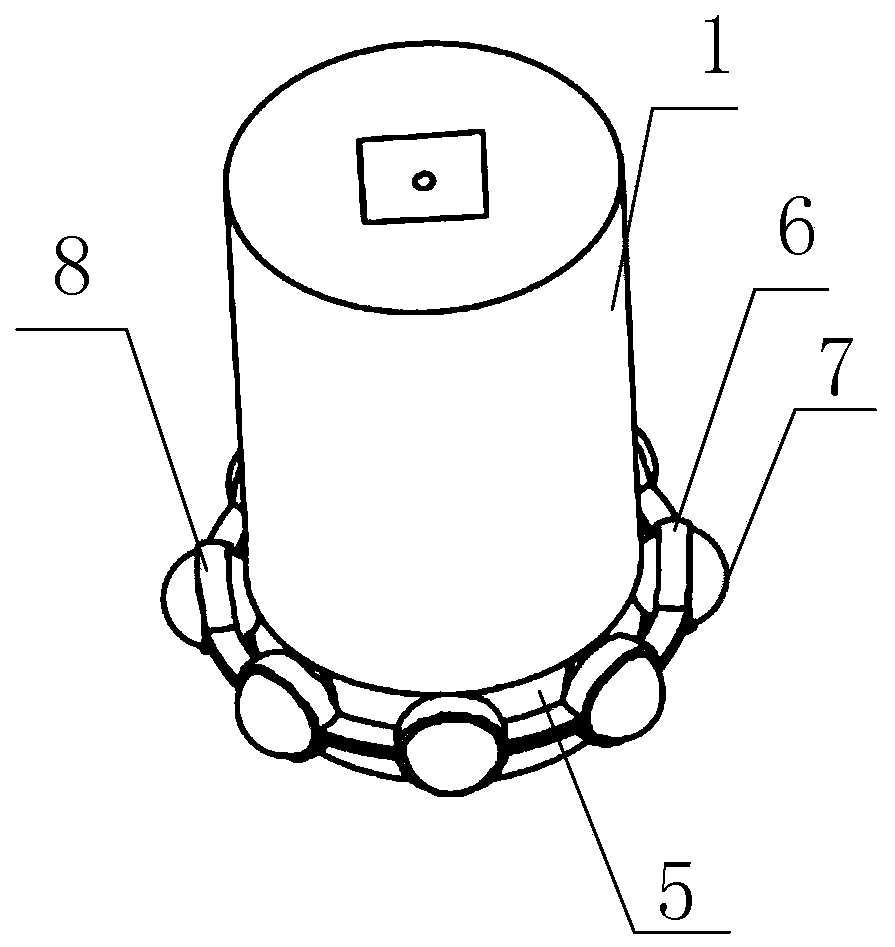

[0042] see figure 1 , figure 2 , image 3 with Figure 4 , the anti-friction ring 2 is a ball ring belt 6; when the anti-friction ring 2 is a ball ring belt 6, the ball ring belt 6 is composed of a ball 7 and a ball connecting device 8; the ball connecting device 8 is equally provided with several holes 9 , the axis of the hole 9 is perpendicular to the axis of the sleeve body 1, the ball 7 is installed in the hole 9, the two ends of the ball 7 along the axial direction of the hole 9, one end is in contact with the sleeve body 1, and the other end is in contact with the inner groove 4. Preferably, the ball connection device 8 is divided into upper and lower parts, including an upper strap 10 and a lower strap 11. The upper strap 10 and the lower strap 11 have the same structure and are symmetrical in mirror image. Circular ring, the opening position of the circular rings of the two hoops, the sizes of the circular rings are all the same, and the opening directions of the c...

Embodiment 2

[0047] see Image 6 with Figure 7 , the anti-friction ring 2 can be an annular protrusion. When the anti-friction ring 2 is an annular protrusion, the annular protrusion is fixedly arranged on the inner wall of the outer lining 3 and arranged along the circumferential direction of the outer lining 3; the annular protrusion The cross-section of the ring-shaped protrusion is arc-shaped, and the outer side of the ring-shaped protrusion is in contact with the outer groove 5. The arc of the ring-shaped protrusion is the same as that of the outer groove 5, ensuring that the outer lining 3 can be snapped into the outer groove 5 during assembly. In the outer groove 5, a small round hole is opened to inject lubricant; in this embodiment, the outer lining 3 is also installed on the annular protrusion 12 by heating and pressing; the final fastening sleeve is as follows Figure 9 shown.

[0048] work process:

[0049] The input end of the air trigger is connected to the top interface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com