Preparation method of diamond-coated dental implant

A technology for diamond coating and dental implants, applied in dentistry, dental implants, dental prosthetics, etc., can solve the problems of the implant stability not being further improved, the work efficiency not being significantly improved, and loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

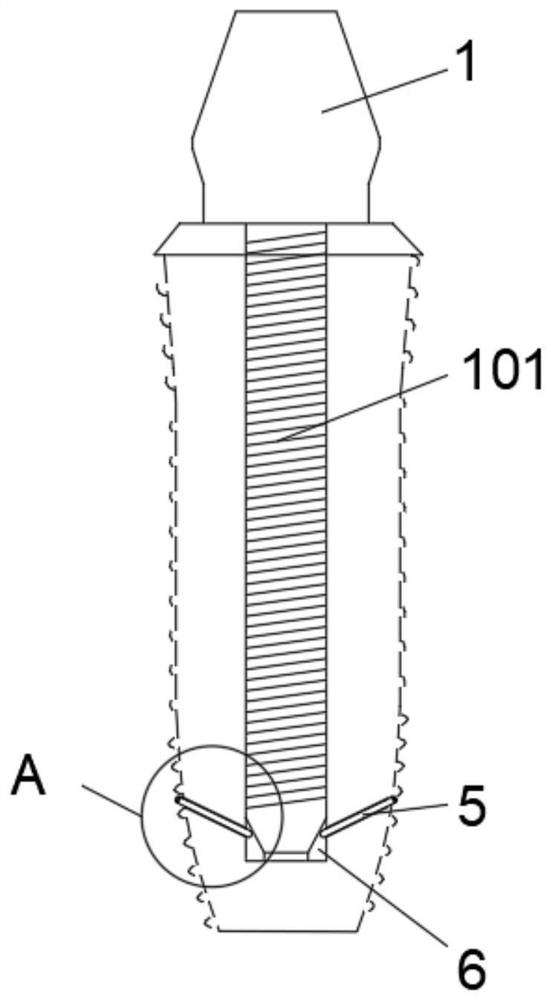

[0039] This embodiment provides a specific structure of a diamond-coated dental implant, such as Figure 1-3 Shown, a diamond-coated dental implant comprising:

[0040] An implant comprising an upper part 2, a middle part 3 and a lower part 4;

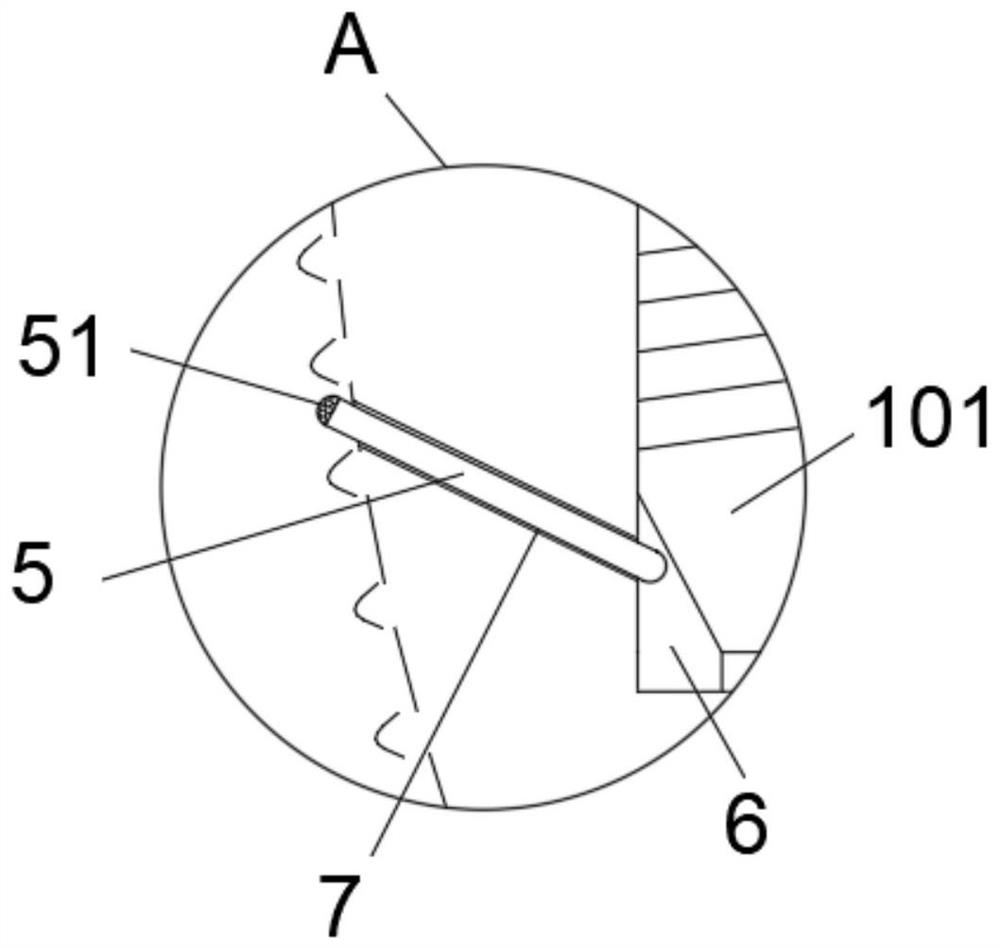

[0041] The abutment 1 has a screw 101 welded to its bottom, and the screw 101 is screw-fitted into the preset groove 6 inside the implant; and

[0042] At least two groups of posts 5 are plugged into the preset post grooves 7 on the surface of the lower part 4 , and one end of the posts 5 extends into the groove body 6 .

[0043] like figure 1 As shown, the upper part 2 and the lower part 4 are conical structures, the middle part 3 is a columnar structure, and the surface of the implant is coated with a diamond film layer.

[0044] In the implant mentioned above, the upper part 2 provides the function of bone expansion and initial stabilization, the middle part 3 can effectively disperse the stress, and the lower part 4 ensures the ...

Embodiment 2

[0049] The present embodiment provides a kind of preparation method of diamond-coated dental implant, comprises the steps:

[0050] Substrate pretreatment: use a grinder to grind and polish each part of the substrate to form a preliminary implant, abutment 1 and post 5;

[0051] Drilling treatment: use a drilling machine to open slots inside and on the surface of the implant, and finally form the slot body 6 and column slot 7;

[0052] Surface treatment: including but not limited to spin deposition method and acid etching sandblasting method, and chemical deposition method can also be used to coat the surface of the implant, and the surface coating treatment of titanium and titanium alloy implants, and form diamond film layer.

[0053] The specific process of substrate pretreatment is:

[0054] First, using powder metallurgy technology, Nb, Zr or Mo elements are added to medical pure titanium, and the ratio of each element to medical pure titanium is 0.01-0.2:1, thereby form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com