Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Entire tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

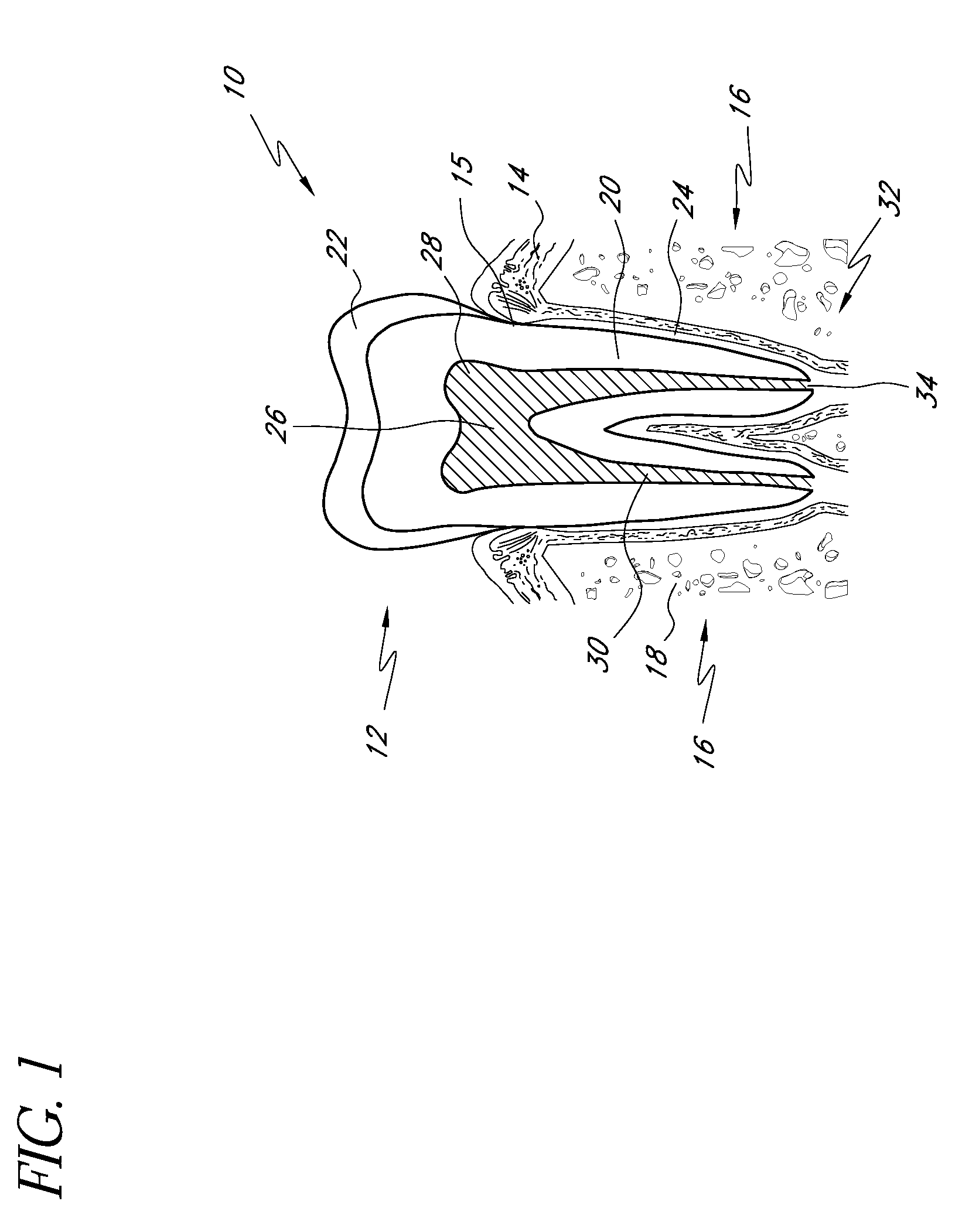

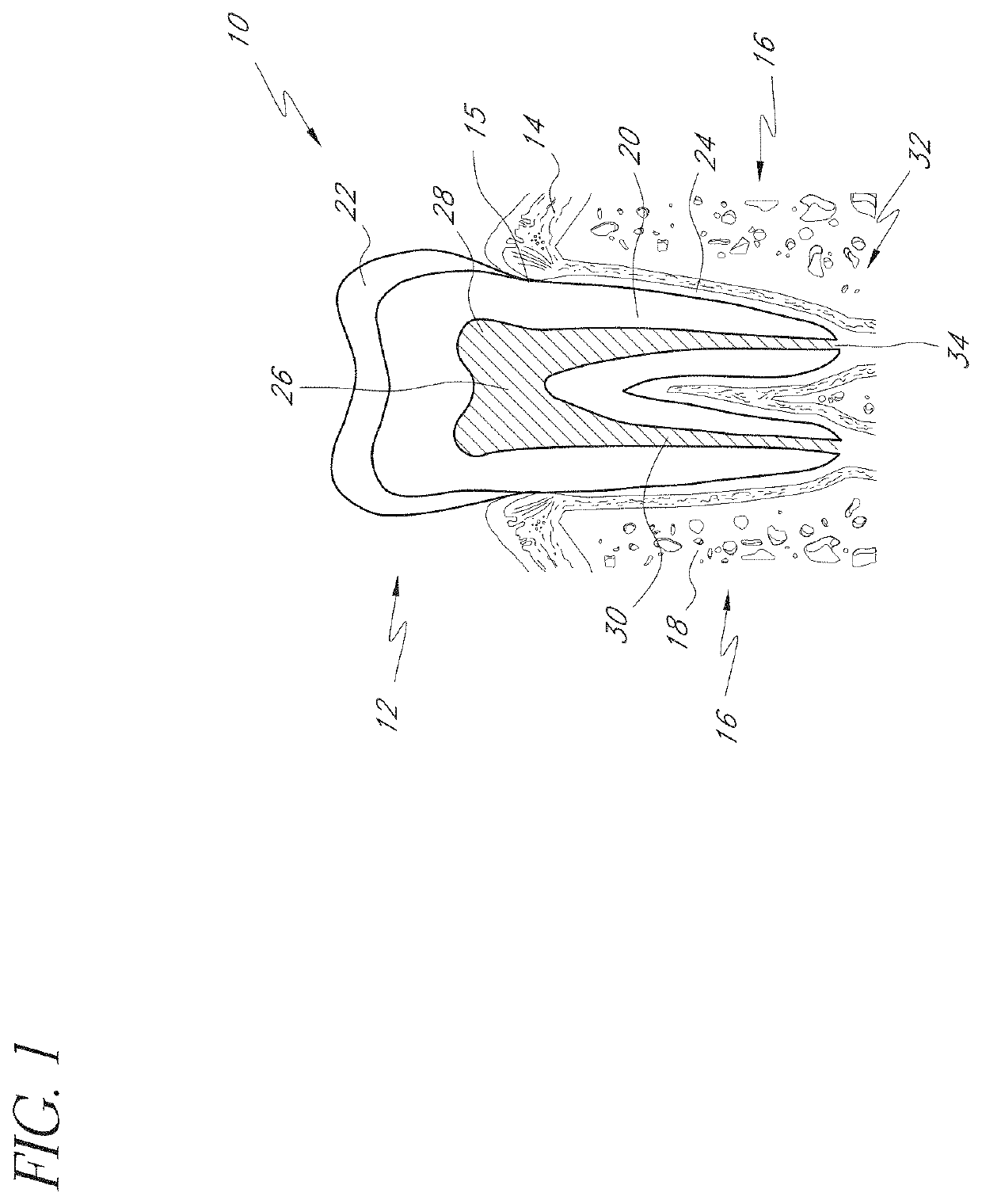

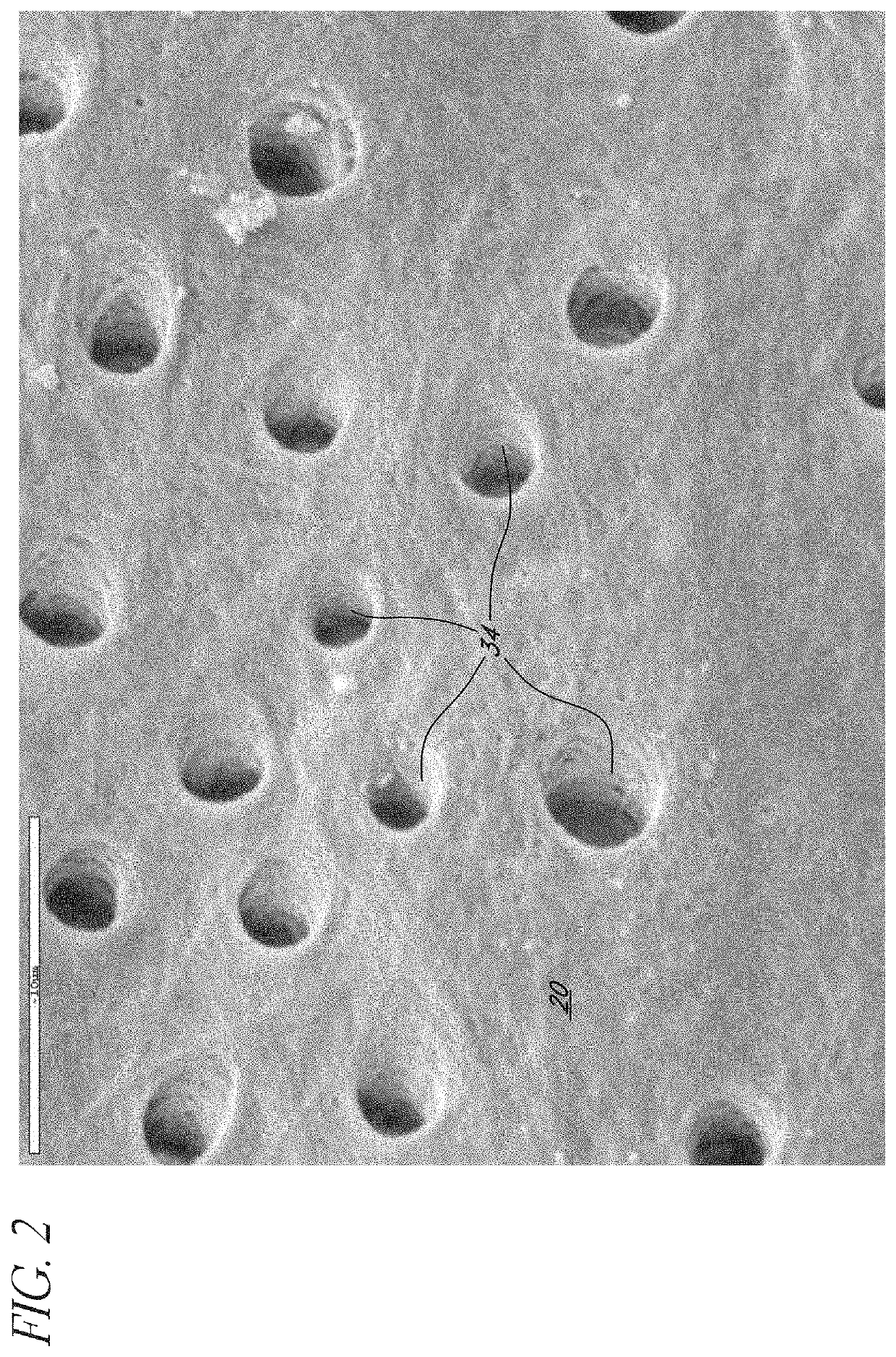

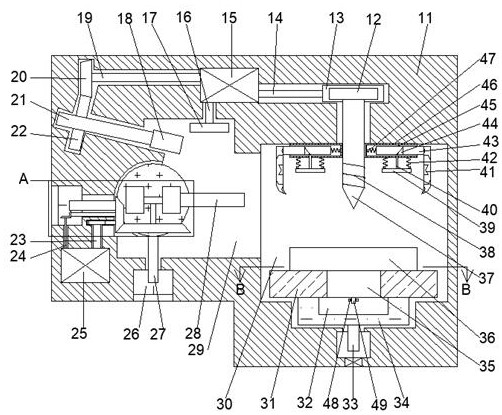

Apparatus and methods for treating root canals of teeth

Apparatus and methods for endodontic treatment of teeth provide effective cleaning of organic material (such as pulp and diseased tissue) from the root canal system. In an embodiment, a compressor system generates high pressure liquid (e.g., water) that flows through an orifice to produce a high-velocity collimated jet of liquid. The high-velocity jet is directed toward a surface of a tooth, for example, an exposed dentinal surface, and impingement of the jet onto the surface generates an acoustic wave that propagates throughout the tooth. The acoustic wave effectively detaches organic material from dentinal surfaces and tubules. The detached organic material is flushed from the root canal system by the liquid jet and / or by additional irrigation.

Owner:SONENDO

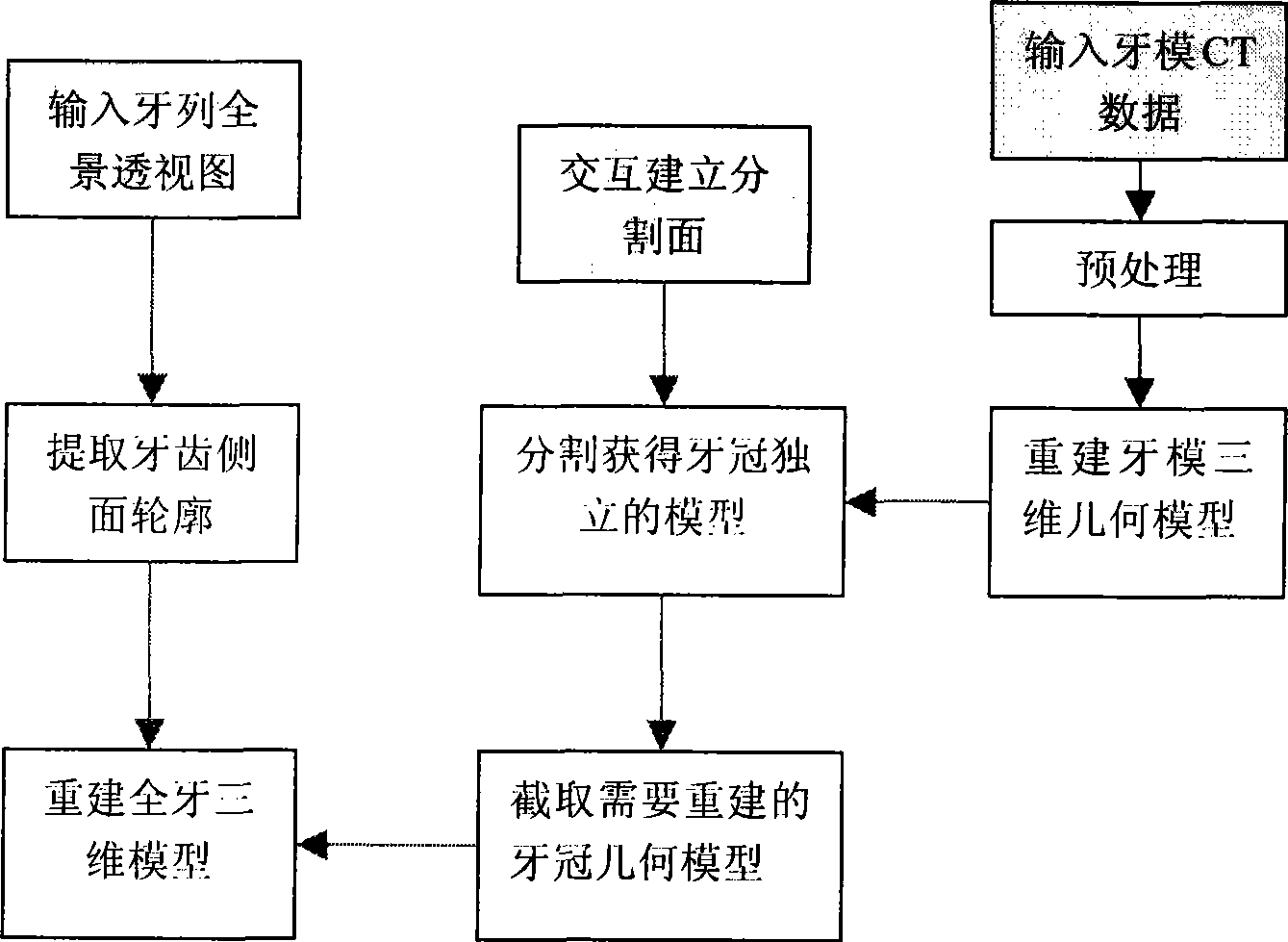

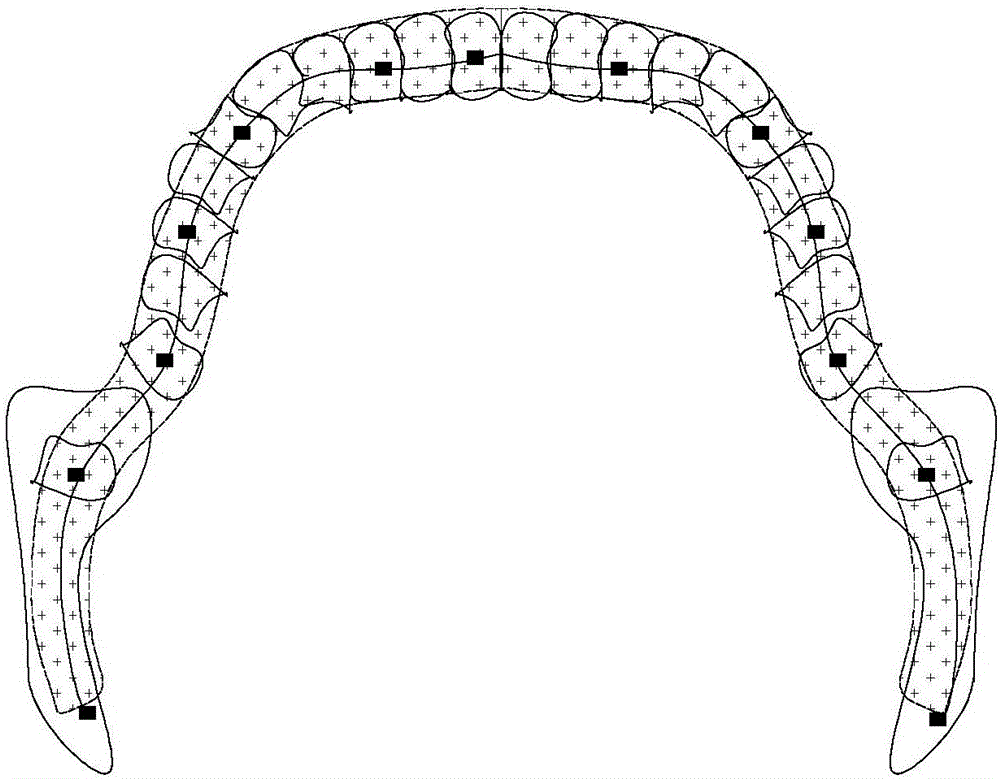

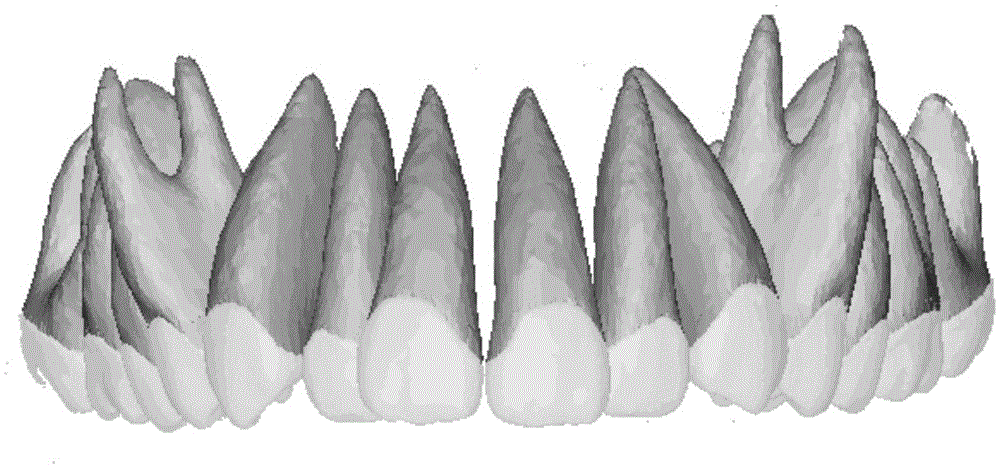

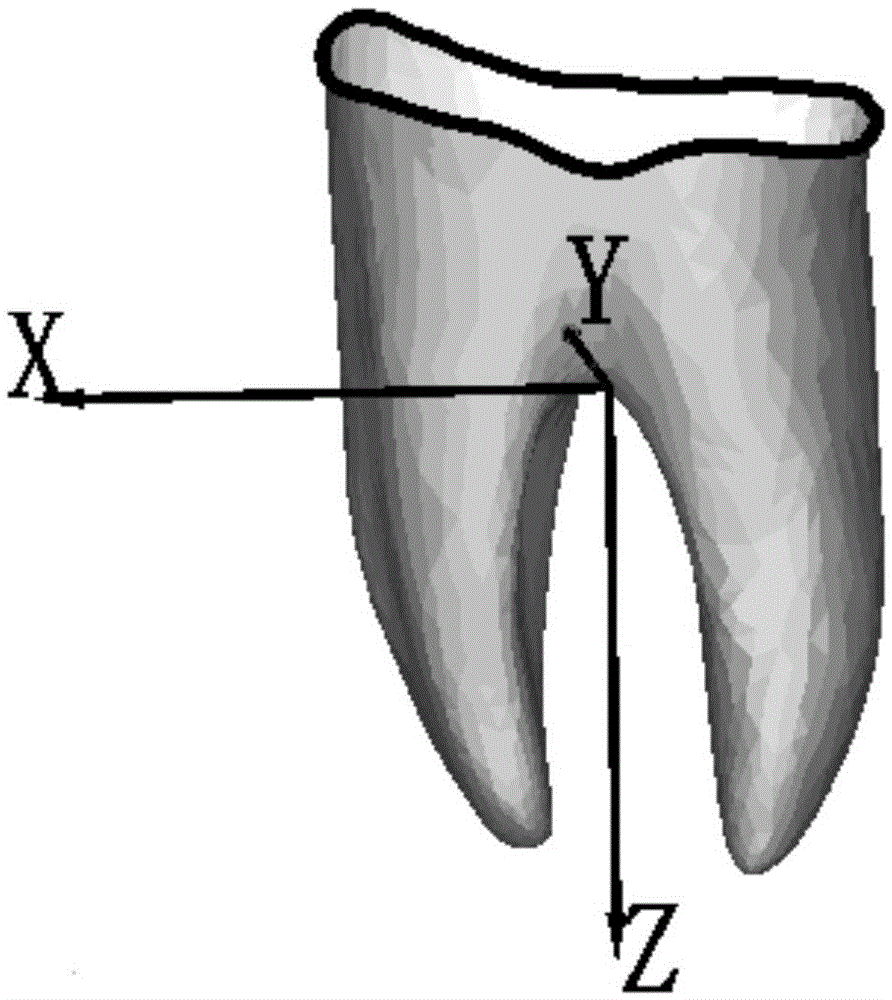

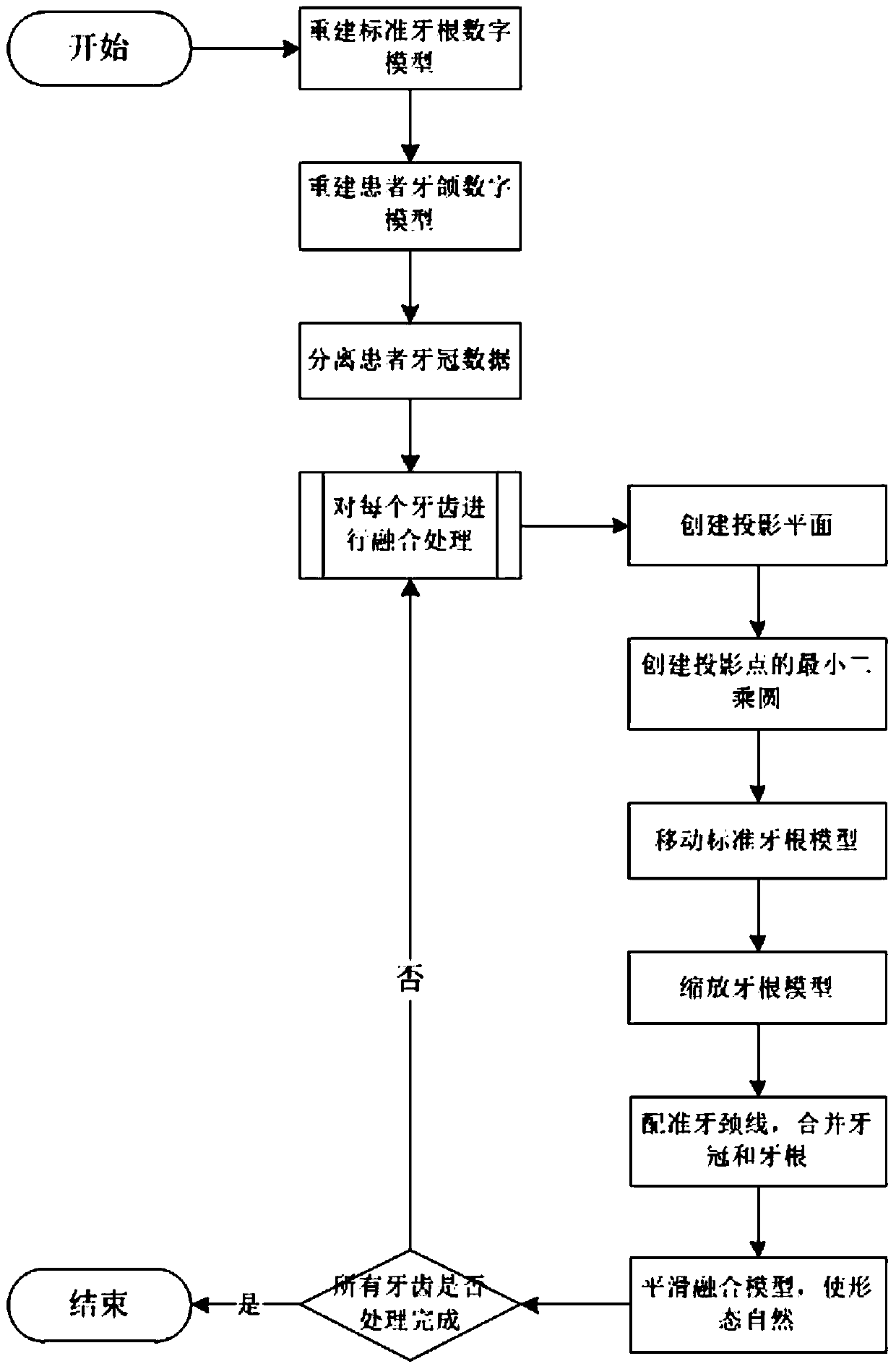

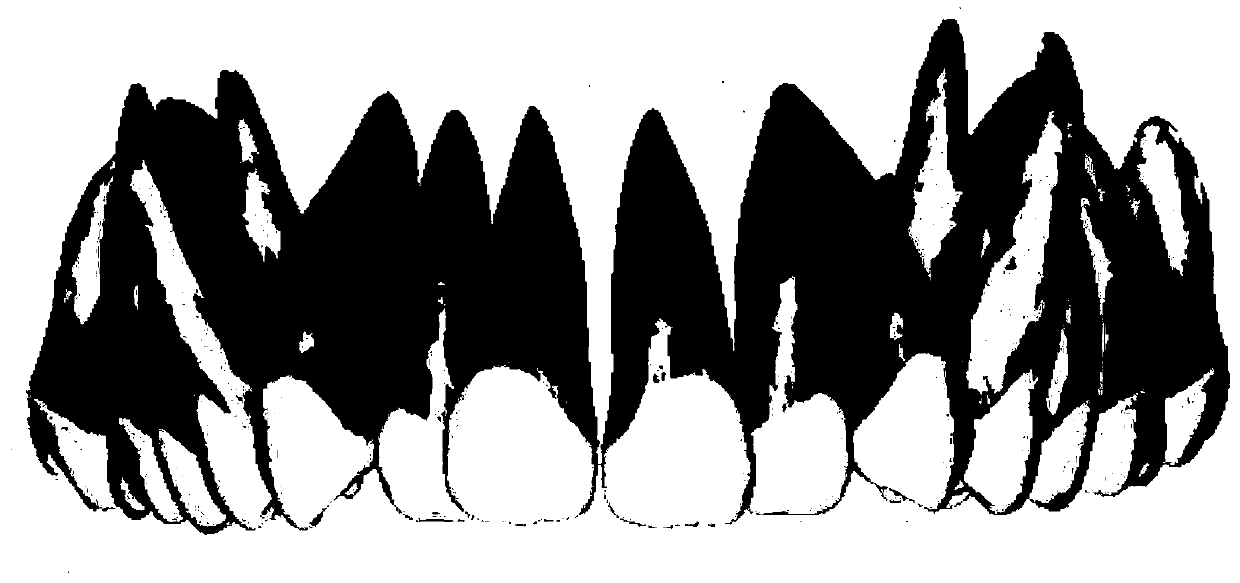

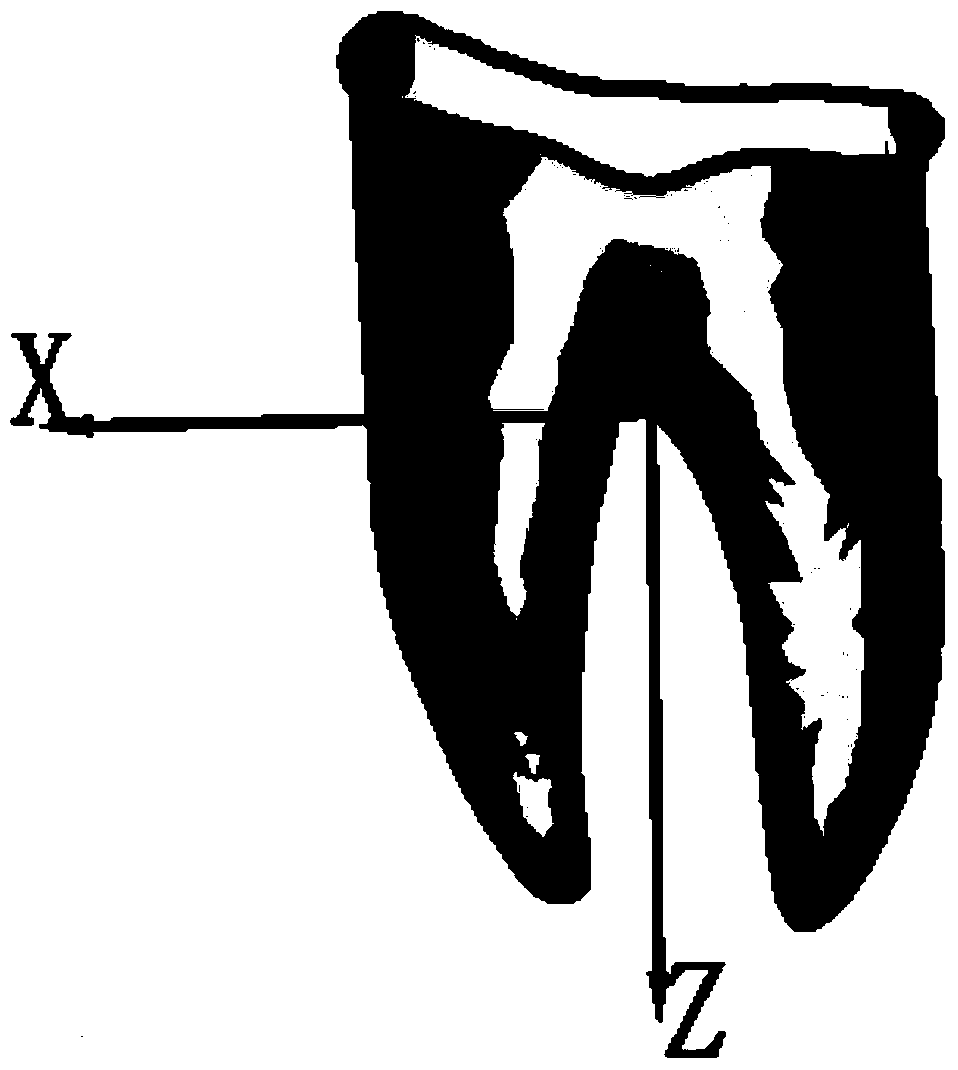

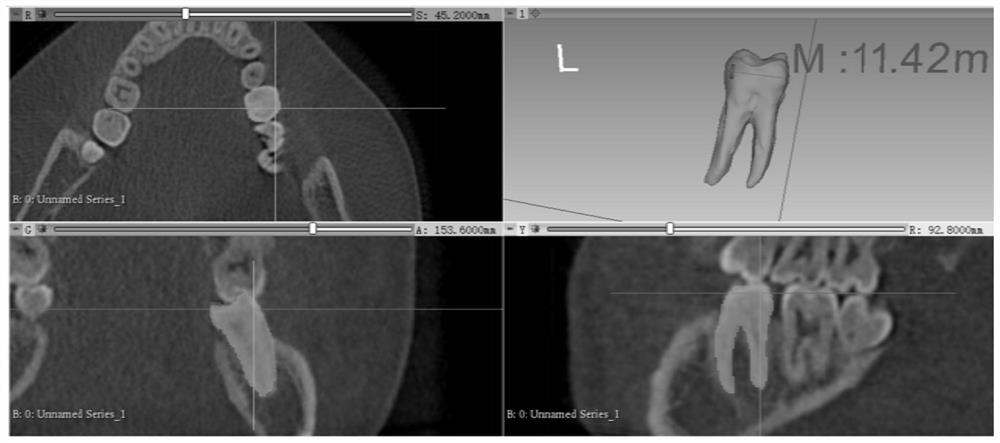

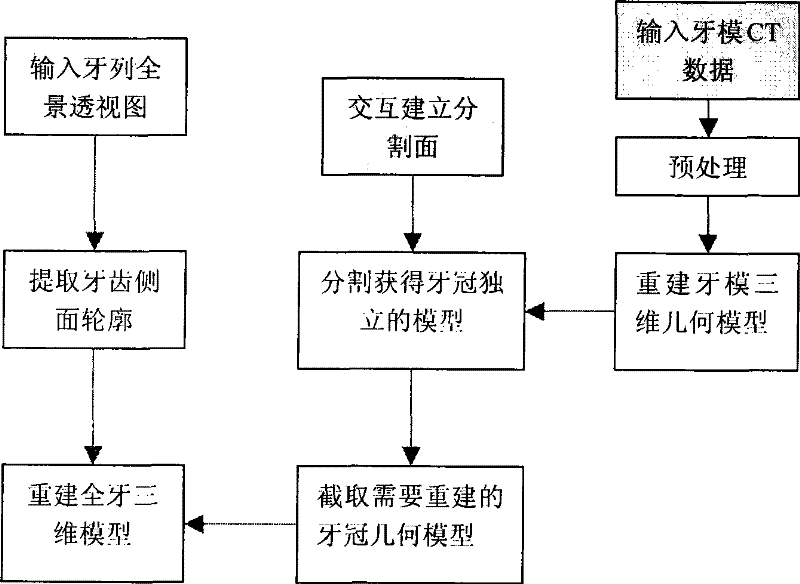

Method for reconstructing three dimensional model of complete teeth through CT data of dentognathic gypsum model and dentognathic panoramic perspective view

The invention provides a method for reconstructing a three-dimensional model of an entire tooth through the CT data of a plaster model of jaw and the panoramic drawing of the jaw. The method adopts the following steps: a cone beam CT (CBCT) specially used for the oral cavity is used for scanning the plaster model of the jaw to obtain the CT data of the plaster model of the jaw; three-dimensional reconstruction is performed to the CT data of the plaster model of the jaw to obtain the three-dimensional geometric model of the jaw; the three-dimensional geometric model of the jaw is extracted; the information on the side contour of the tooth is extracted and the three-dimensional geometric model of the radix dentis is generated in combination with the model of the corona dentis; and the three-dimensional model of the entire tooth is formed by combining the three-dimensional geometric models of the corona dentis and the radix dentis. The invention has the advantages that the three-dimensional geometric digit model of the entire tooth can be generated on the basis of the two-dimensional information of the side contour of the tooth on the panoramic drawing and according to the three-dimensional geometric information of the corona dentis part in the CT data. The method can be applied to every tooth in the panoramic drawing to generate the jaw model with accurate dentition, and can be applied to orthodontics and computer simulated tooth arrangement.

Owner:ZHEJIANG UNIV

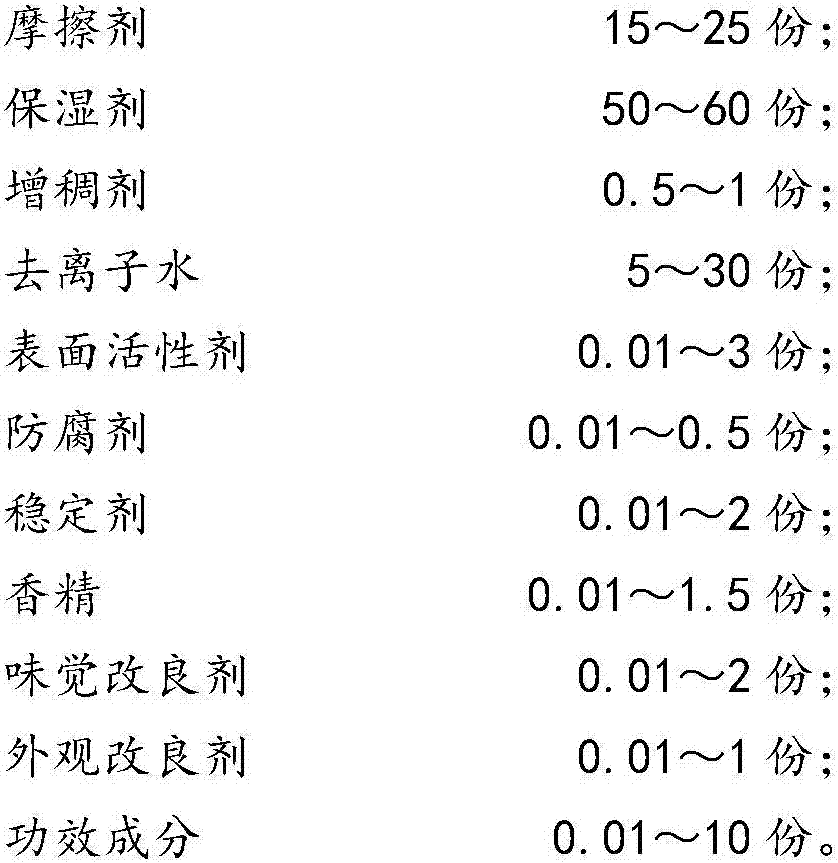

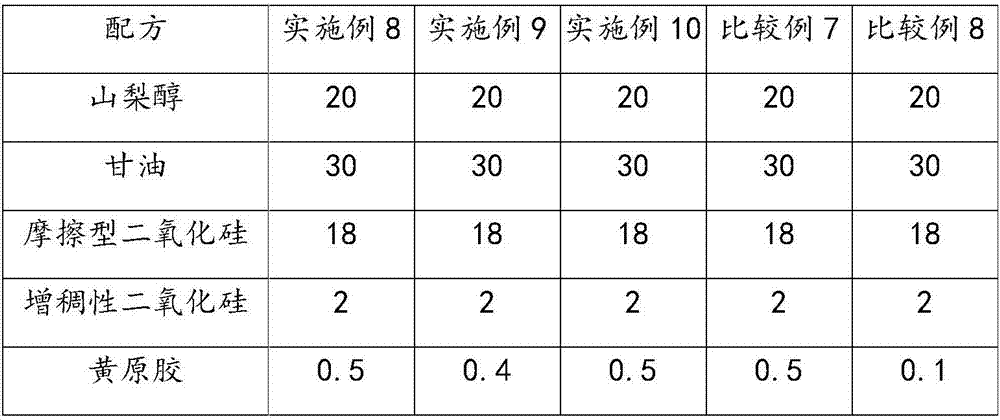

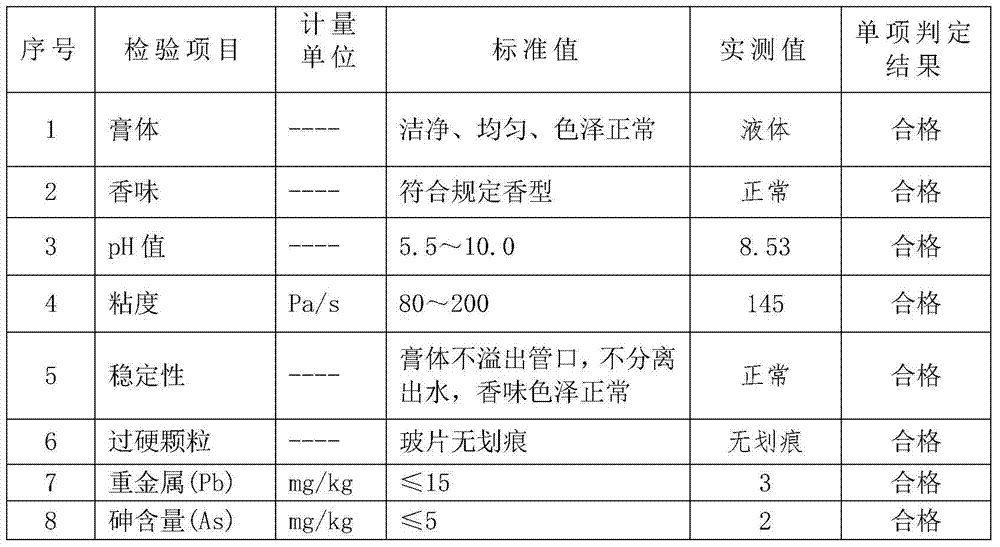

Toothpaste suitable for pump-type packing material and preparation method thereof

ActiveCN106890103APump out smoothlyLittle change in viscosityCosmetic preparationsToilet preparationsPreservativeToothpaste

The invention discloses a toothpaste suitable for a pump-type packing material and a preparation method thereof. According to a formula, the toothpaste is prepared from, by weight, 15-25parts offriction agent, 50-60 parts of moisturizer, 0. 5-1 part of thickening agent, 5-30 parts of deionized water, 0.01-3 parts of surfactant, 0.01-0.5 part of preservative, 0.01-2 parts of stabilizer, 0.01-1.5 parts of extract, 0.01-2 parts of taste modifier, 0.01-1part of appearance modifier and 0.01-10 parts of functional component. The toothpaste has good shear thinning specificity and thixotropy, can be easily discharged after pressing and pumping, is kept in a paste shape on a toothbrush and can be rapidly dispersed in the oral cavity, the effectively components in the product can smoothly reach the whole surface of the oral cavity and rapidly penetrate into gaps of teeth to cover the whole teeth, and the phenomenon that the toothpaste is dry or cannot be extruded out does not occur as time goes on.

Owner:广州舒客实业有限公司

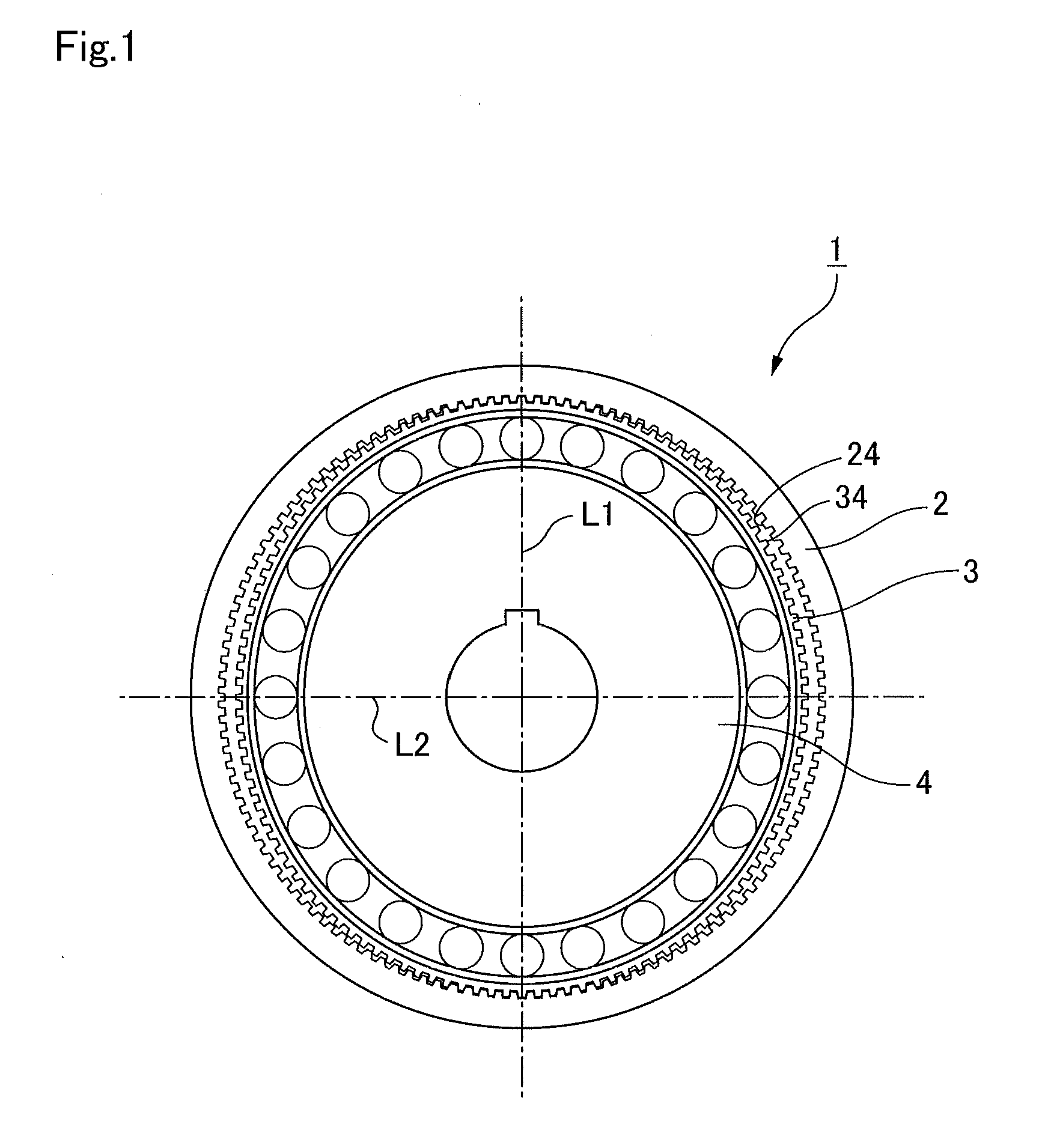

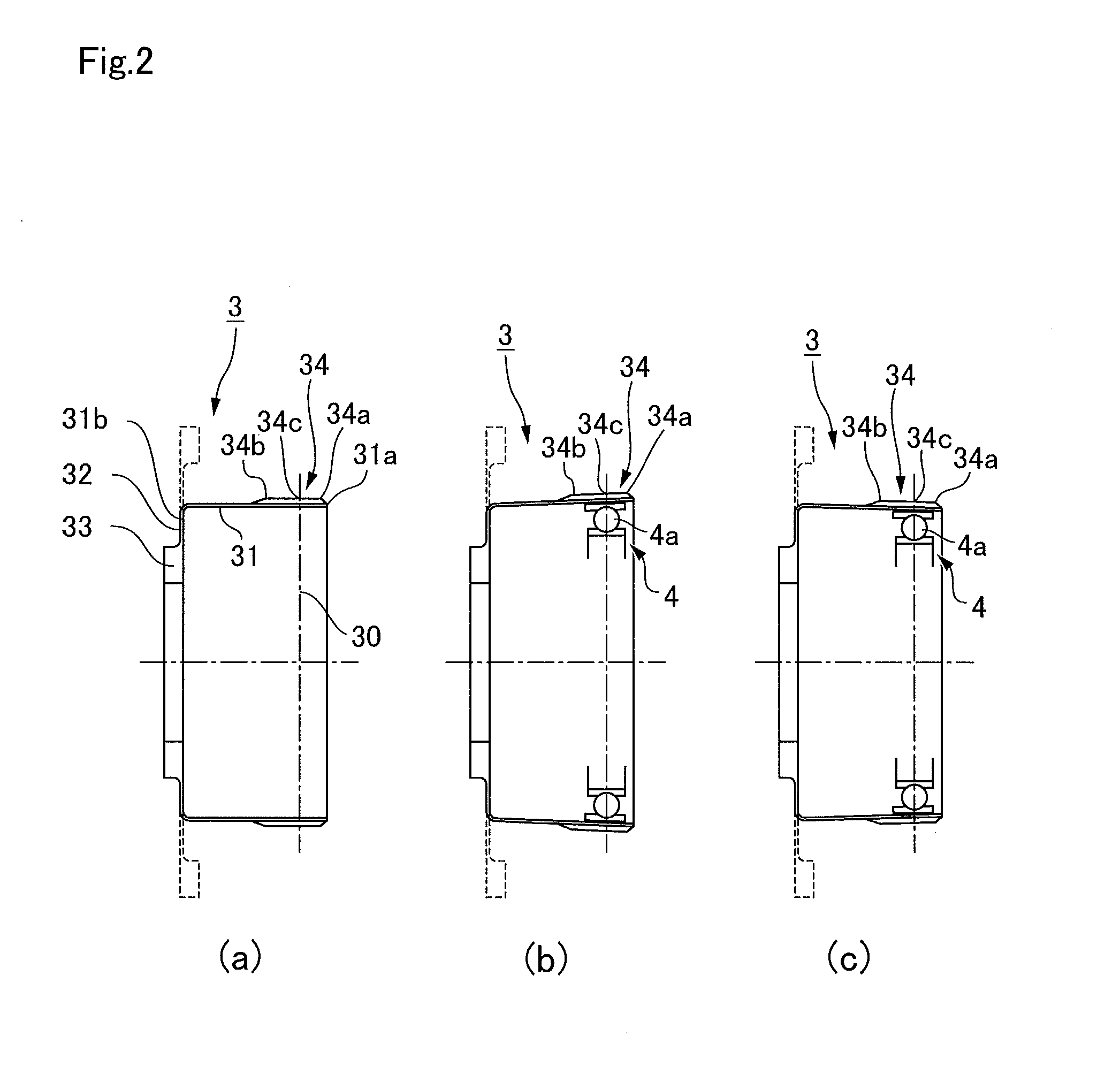

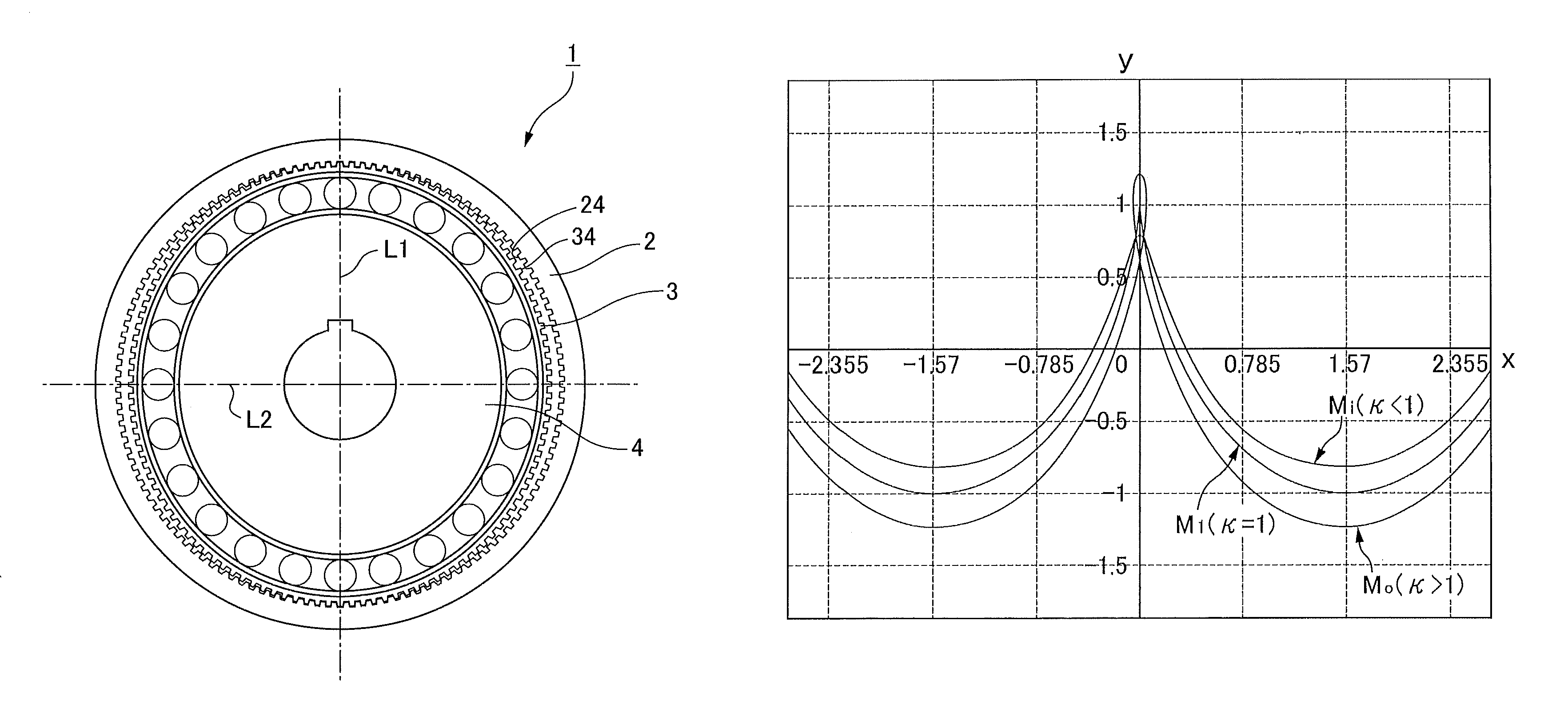

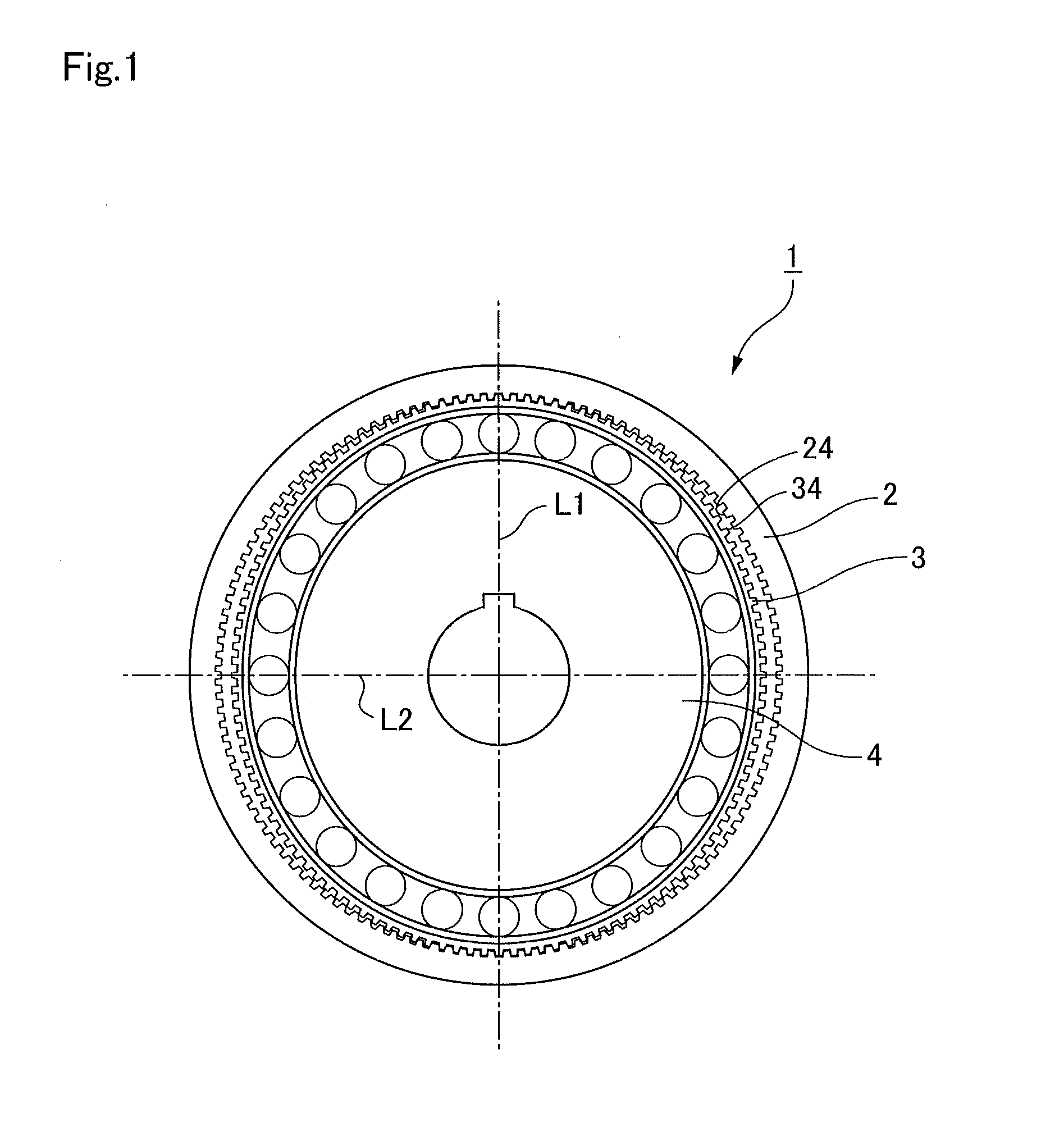

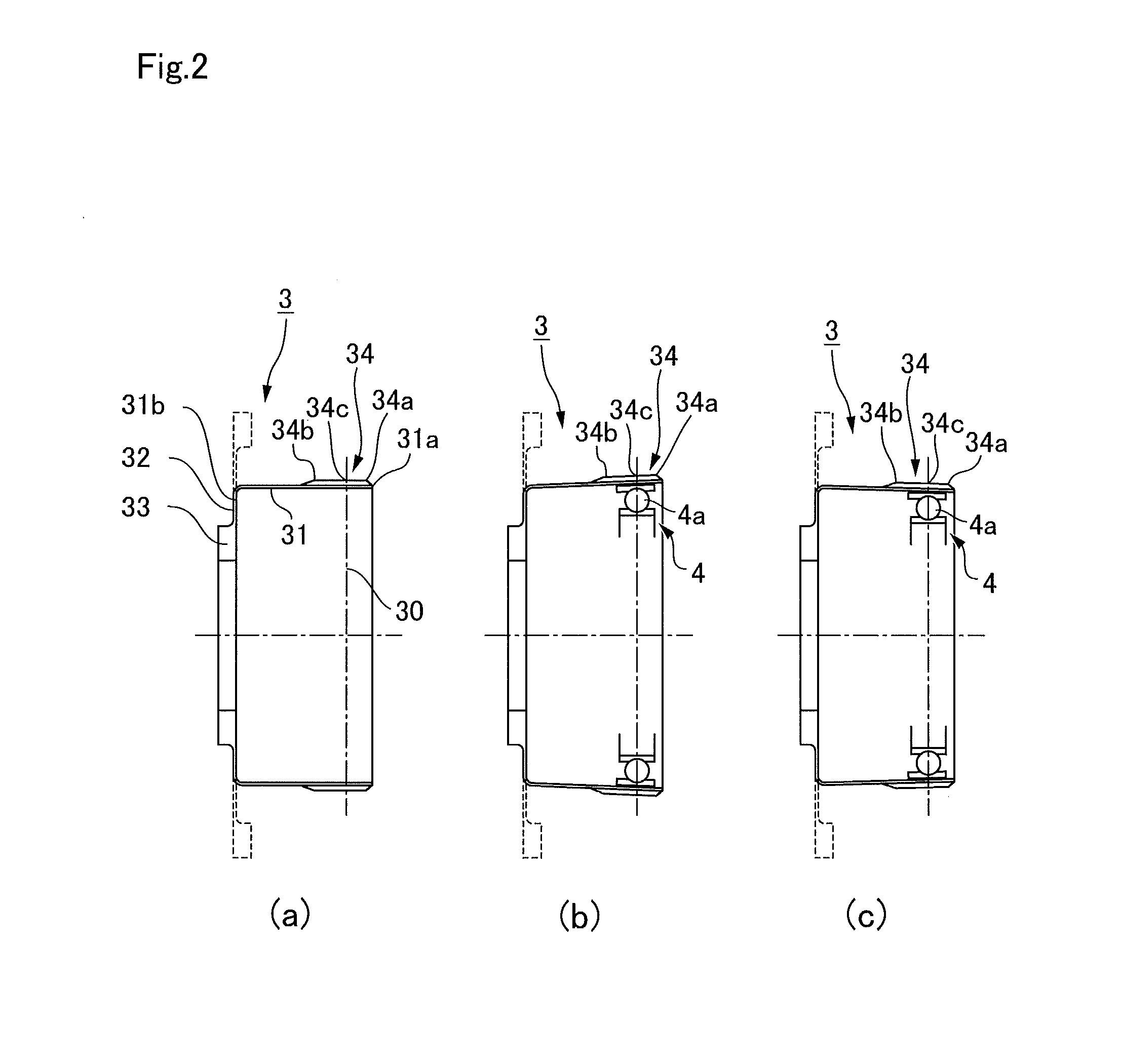

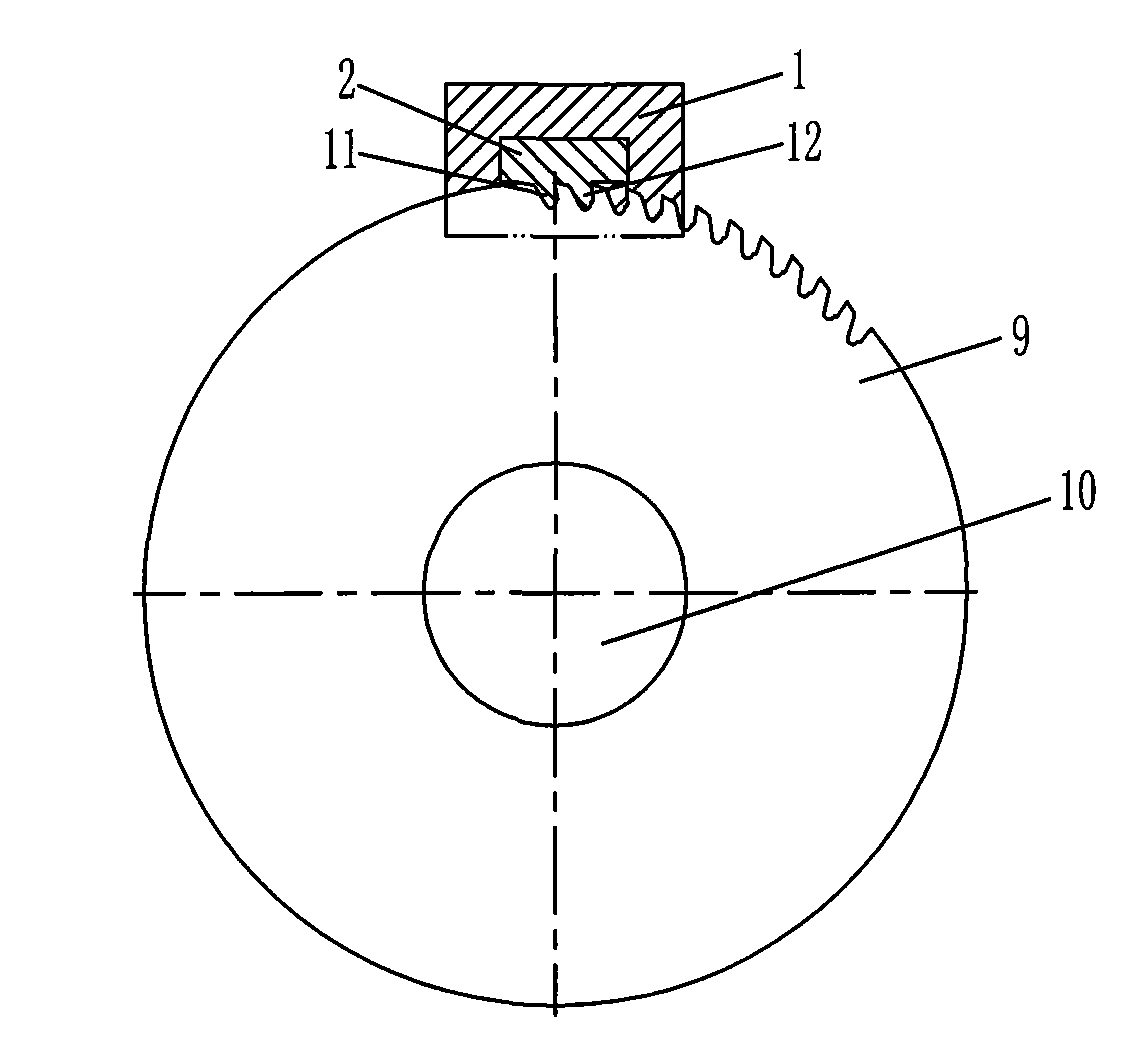

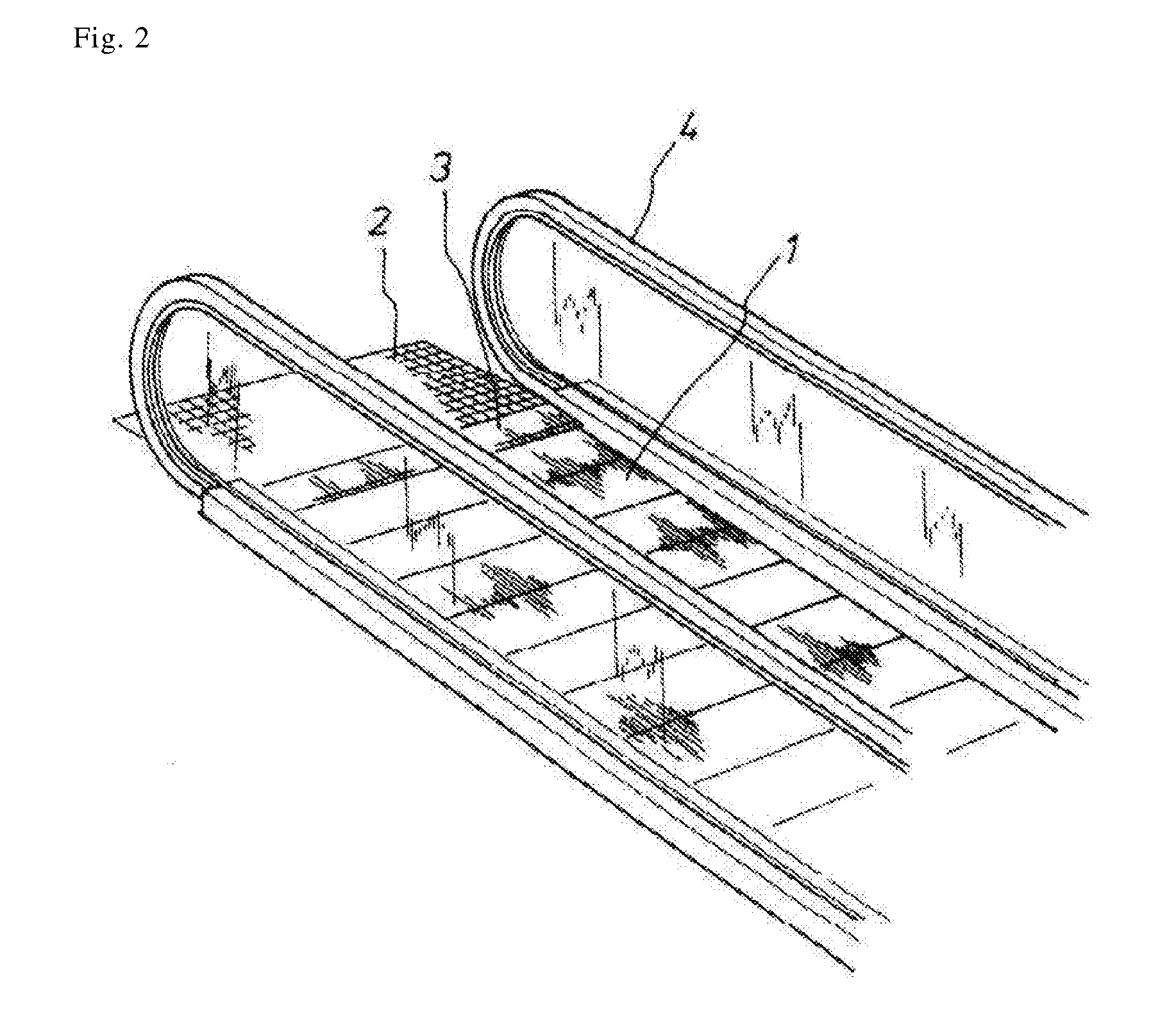

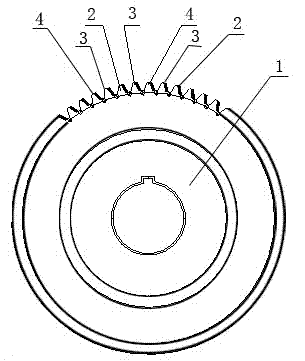

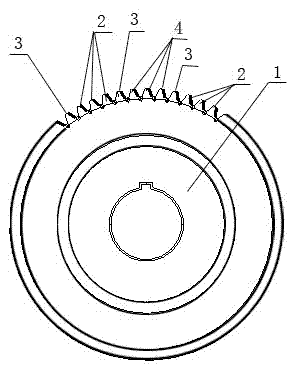

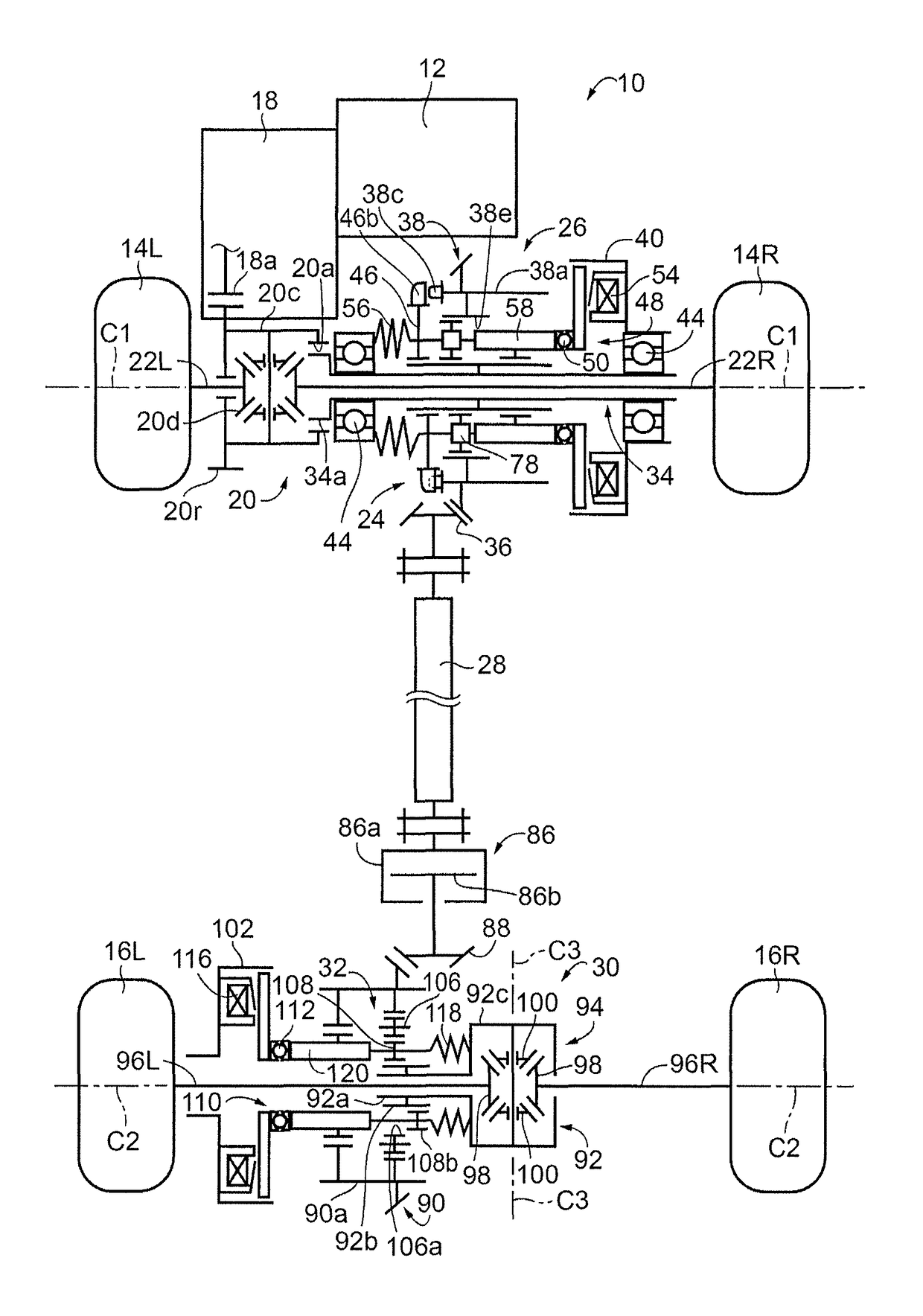

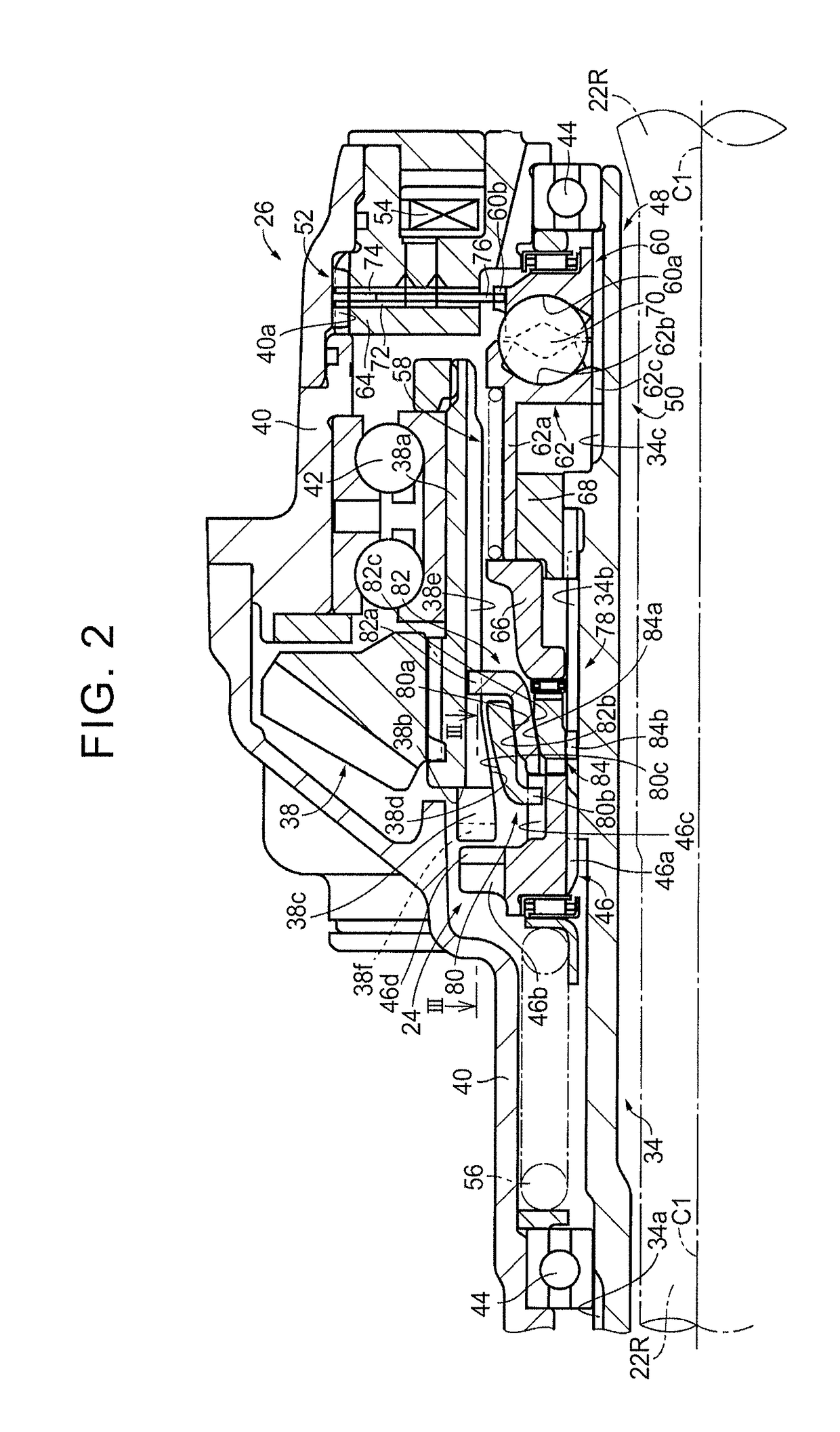

Wave gear device having three-dimensional continuous contact tooth profile

ActiveUS20120285283A1Effective engagementHigh torquePortable liftingGearing elementsEngineeringEntire tooth

In a wave gear device, similarity curve tooth profiles for defining the tooth-face tooth profile of each of a flexible externally toothed gear and a rigid internally toothed gear is determined from the movement trajectory, relative to a tooth of the rigid internally toothed gear, of a tooth of the flexible externally toothed gear at a main cross-section at which the deflection factor is κ=1. Tooth profile curves, which have been subjected to profile shifting corresponding to the difference between the deflection factor κo (>1) of the opening-end cross-section of the flexible externally toothed gear and the deflection factor κ of the main cross-section, are determined from the similarity curves; and the tooth profile curves are used to form the tooth-face tooth profile portions of the two gears. High-gear-tooth compound tooth profiles, defined from the tooth-face tooth profile portions, straight-line tooth profile portions continuing from the tooth-face tooth profile portions, and appropriate tooth-flank tooth profile portions for avoiding interference are used as tooth profiles of the internal teeth and the external teeth. Also, taking coning of the flexible externally toothed gear into account, negative profile shifting is applied from an opening-end cross-section to an inner-end cross-section of the flexible externally toothed gear, and rational meshing between the two gears is obtained along the entire tooth trace.

Owner:HARMONIC DRIVE SYST IND CO LTD

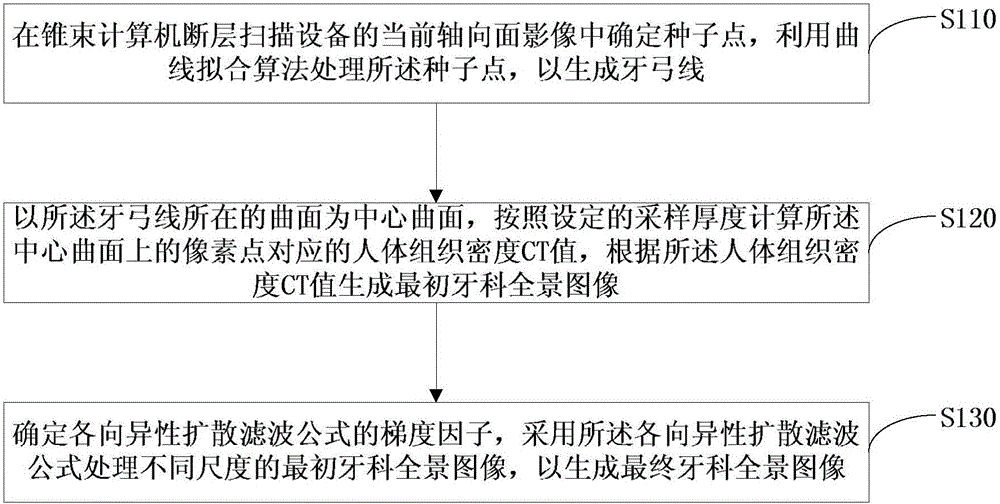

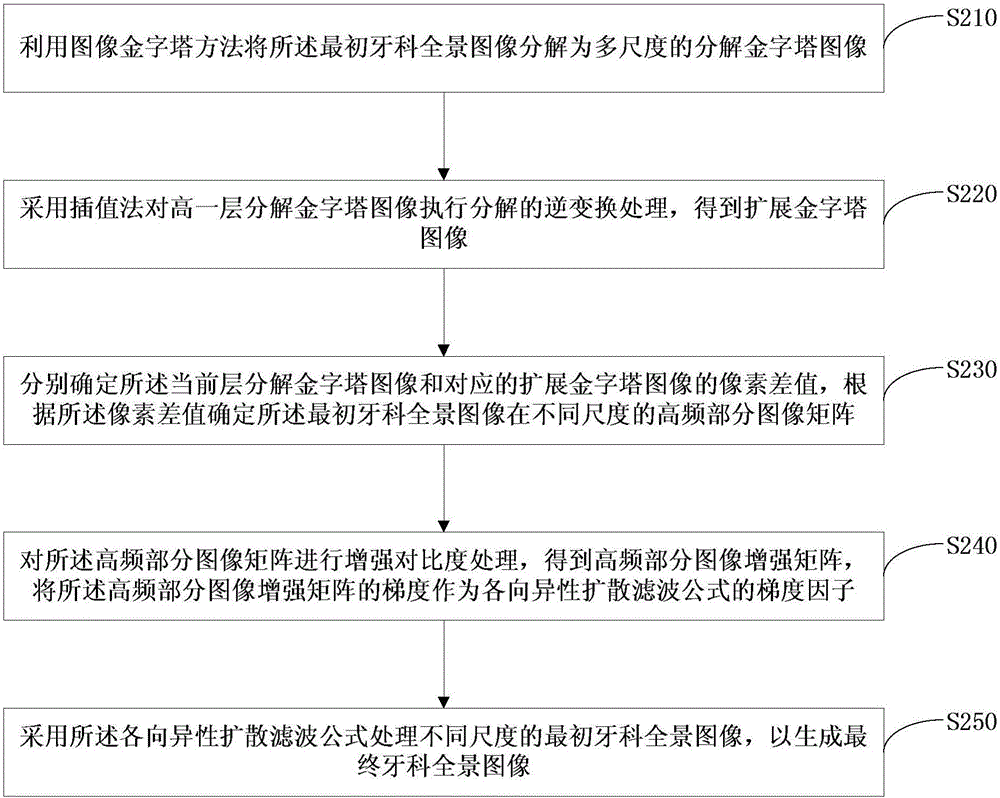

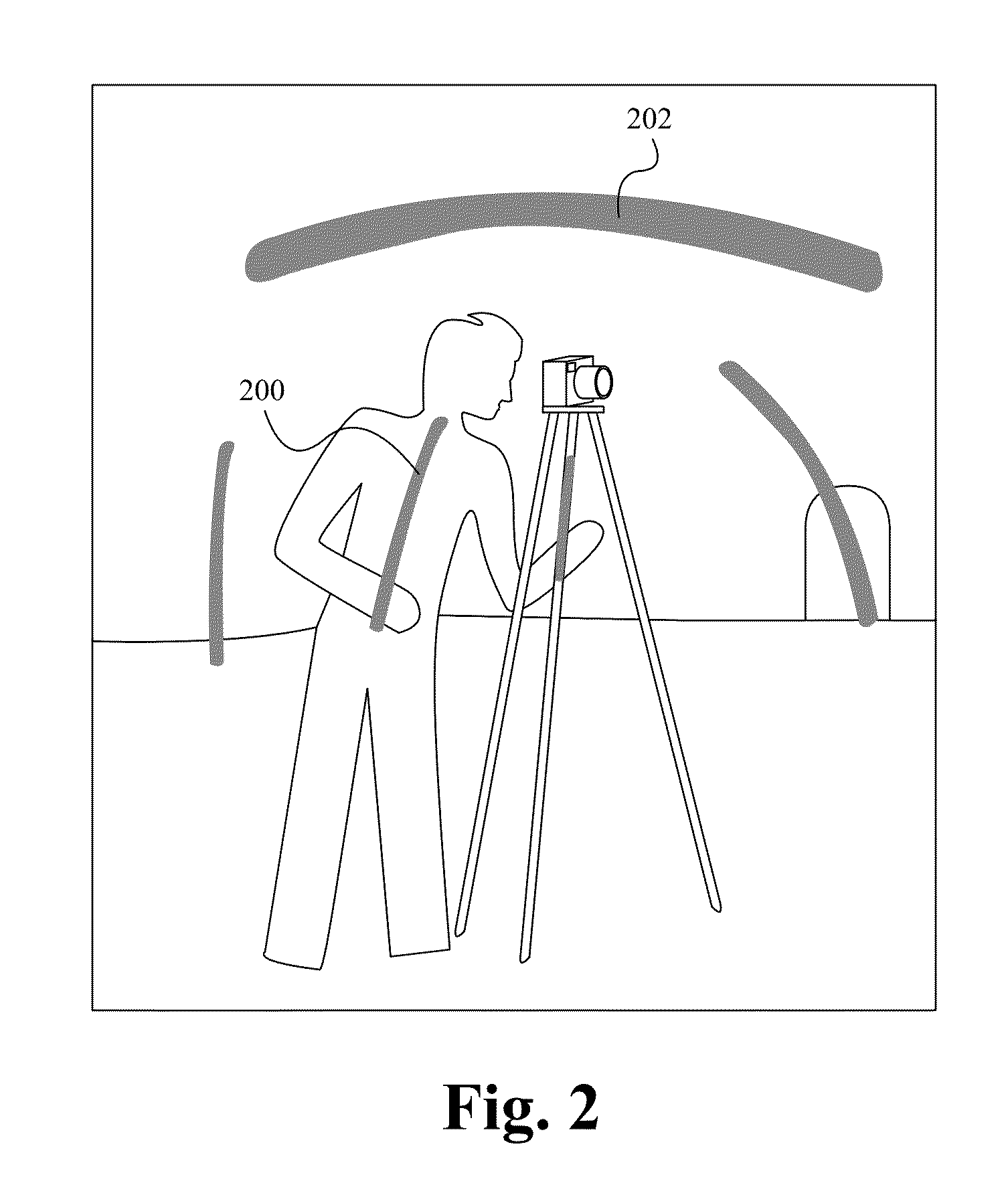

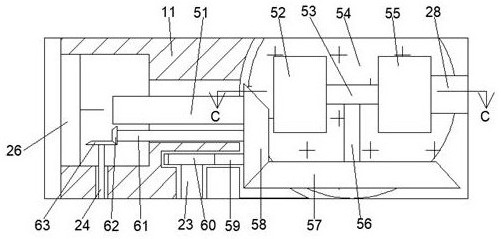

Method and device for generating dental panoramic image on the basis of CBCT image

The invention discloses a method and device for generating a dental panoramic image on the basis of a CBCT image. The method comprises steps of: determining a seed point in a current axial surface image of a CBCT apparatus, processing the seed point by using a curve fitting algorithm to generate a dental arch line; using a curve surface where the dental arch line is located as a central curve surface, computing body tissue density CT values corresponding to the pixels in the central curve surface according to a set sampling thickness, and generating initial dental panoramic images according to the body tissue density CT values; and determining the gradient factor of an anisotropic diffusion filter formula and processing the initial dental panoramic images with different scales by using the anisotropic diffusion filter formula to generate an final dental panoramic image. The method and device achieve a purpose of obtaining the two-dimensional panoramic image of the entire teeth by using the image processing algorithm on the basis of CBCT three-dimensional data.

Owner:FUSSEN TECH CO LTD

Wave gear device having three-dimensional continuous contact tooth profile

In a wave gear device, similarity curve tooth profiles for defining the tooth-face tooth profile of each of a flexible externally toothed gear and a rigid internally toothed gear is determined from the movement trajectory, relative to a tooth of the rigid internally toothed gear, of a tooth of the flexible externally toothed gear at a main cross-section at which the deflection factor is κ=1. Tooth profile curves, which have been subjected to profile shifting corresponding to the difference between the deflection factor κo (>1) of the opening-end cross-section of the flexible externally toothed gear and the deflection factor κ of the main cross-section, are determined from the similarity curves; and the tooth profile curves are used to form the tooth-face tooth profile portions of the two gears. High-gear-tooth compound tooth profiles, defined from the tooth-face tooth profile portions, straight-line tooth profile portions continuing from the tooth-face tooth profile portions, and appropriate tooth-flank tooth profile portions for avoiding interference are used as tooth profiles of the internal teeth and the external teeth. Also, taking coning of the flexible externally toothed gear into account, negative profile shifting is applied from an opening-end cross-section to an inner-end cross-section of the flexible externally toothed gear, and rational meshing between the two gears is obtained along the entire tooth trace.

Owner:HARMONIC DRIVE SYST IND CO LTD

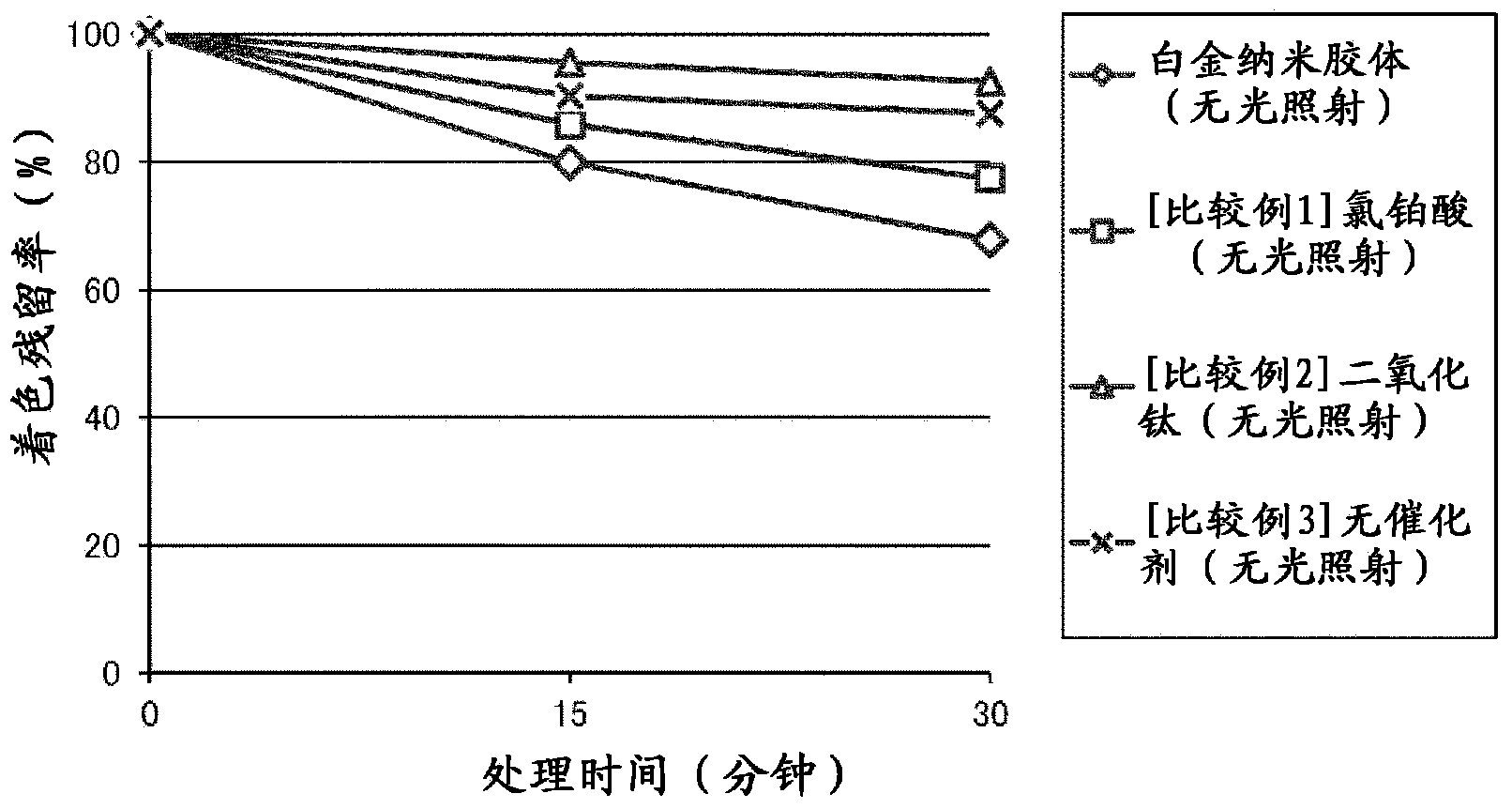

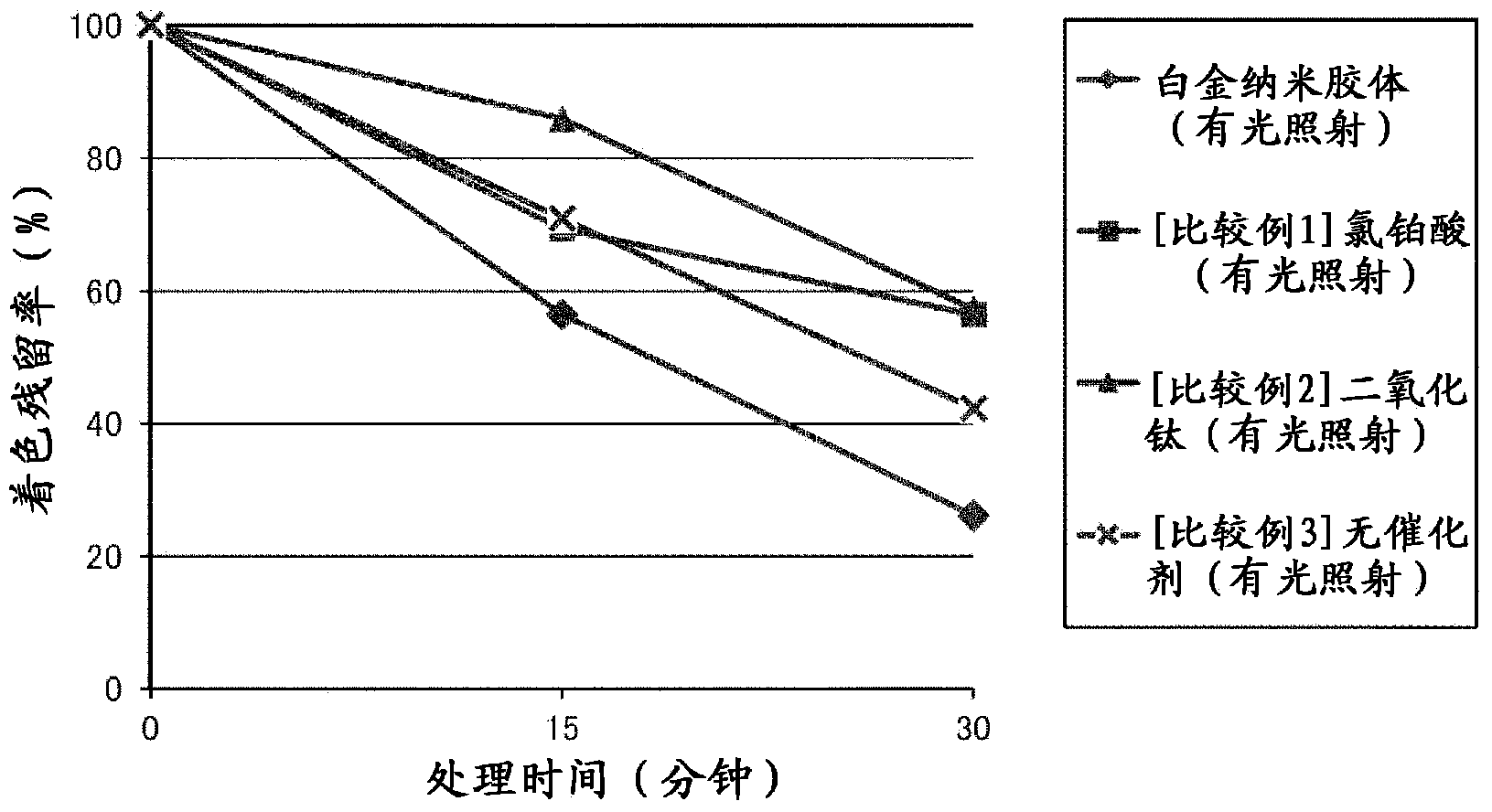

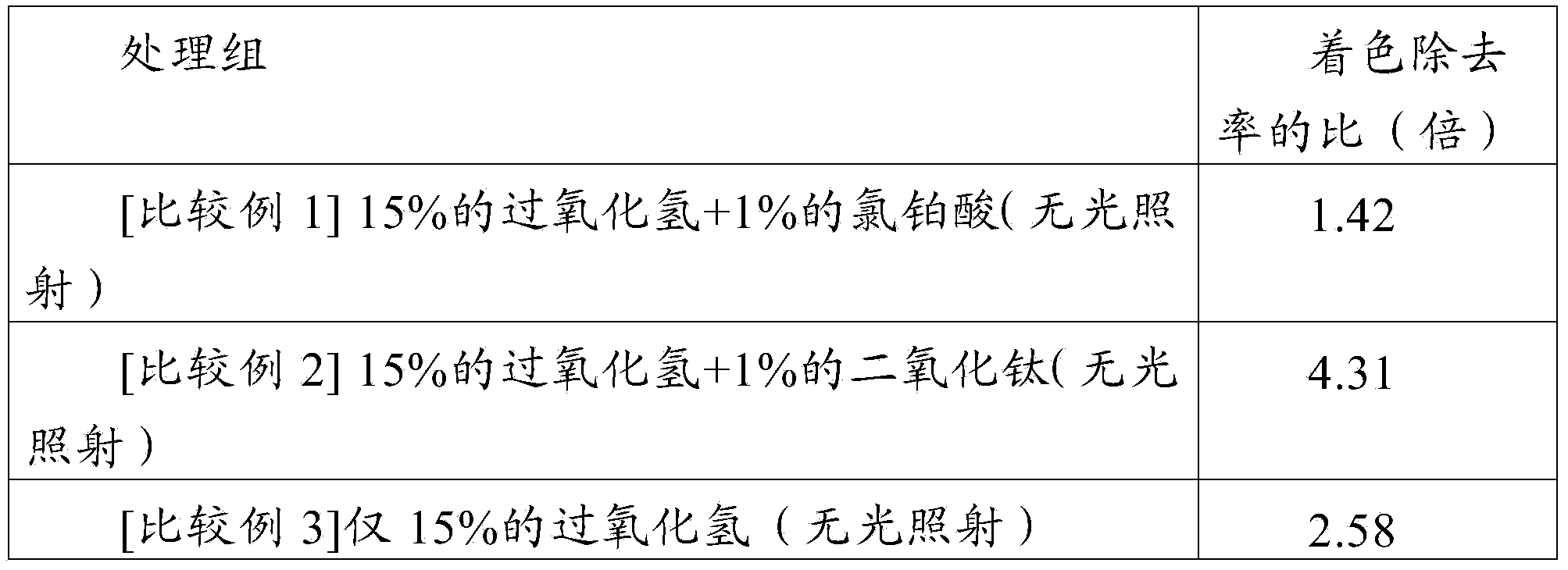

Tooth whitening composition containing colloidal platinum

InactiveCN103619309AImprove bleaching effectCosmetic preparationsToilet preparationsPhoto irradiationColloid

[Problem] The purpose of the present invention is to provide an oral composition that enables a high level of whitening effectiveness to be obtained over the entire application area of the oral composition. [Solution] The present inventors discovered that a tooth whitening composition with a high level of whitening effectiveness over the entire tooth whitening composition application area can be obtained by including colloidal platinum as a platinum catalyst in a peroxide-containing oral composition. The present inventors also discovered that whitening effectiveness can be enhanced by application of a tooth whitening composition comprising colloidal platinum to the surface of the teeth followed by photo-irradiation of the application site.

Owner:REGENETISS

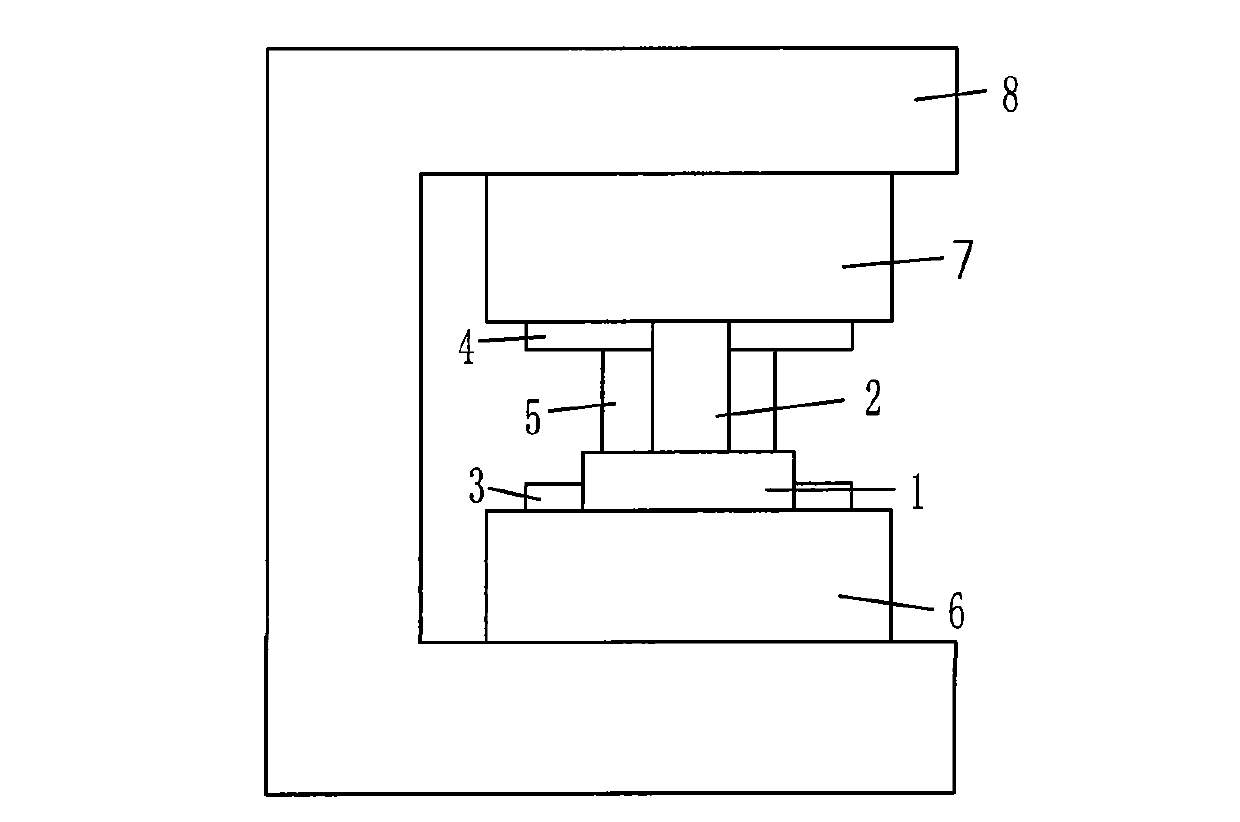

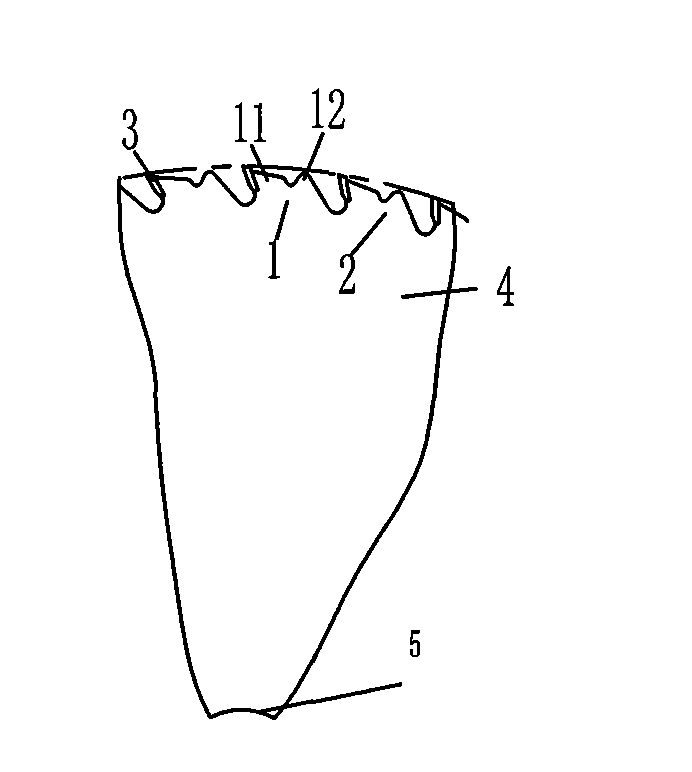

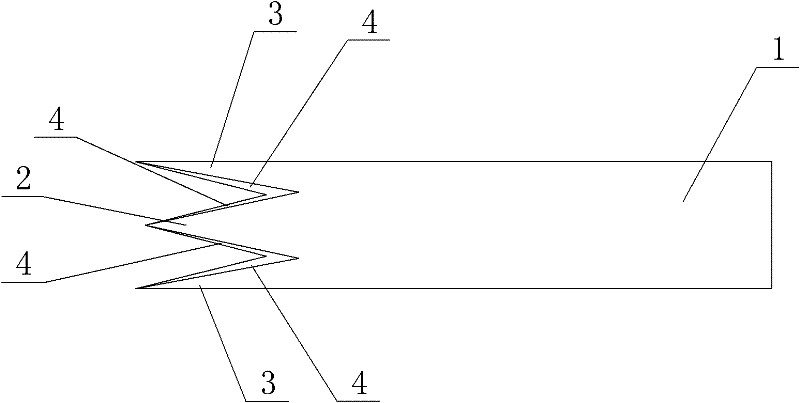

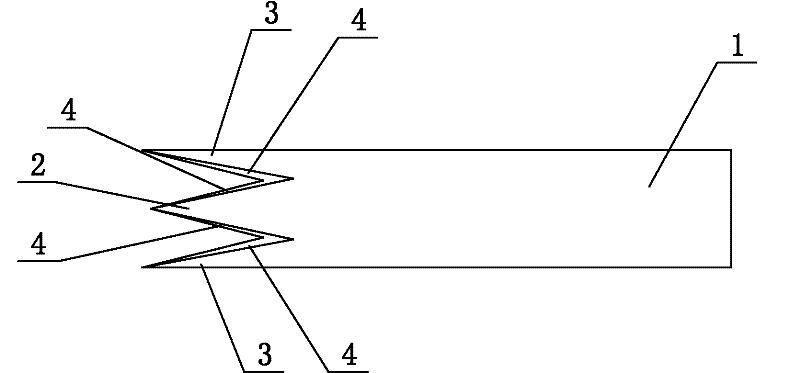

Tooth punching die for saw blade substrate

InactiveCN102019314ASolve processing defectsIntegrity guaranteedShaping toolsMetal sawing tool makingPunchingEngineering

The invention discloses a tooth punching die for a saw blade substrate. The tooth punching die comprises an upper die carrier and a lower die carrier, wherein a female die is fixed on the lower die carrier through a female die fixing plate; a male die is fixed on the upper die carrier through a male die fixing plate; a discharging device is fixed on the male die fixing plate; the male die and the female die are provided with a rough punching tooth and a fine punching tooth; and the size of the rough punching tooth is smaller than that of the fine punching tooth. In the tooth punching die for the saw blade substrate, a single tooth of the conventional die is replaced by double teeth, a tooth at the front operation end is the rough punching tooth while a tooth at the back operation end is the fine punching tooth, and the size of the rough punching tooth is slightly smaller than that of the fine punching tooth. When a double-tooth die is used for tooth punching, rough tooth punching and fine tooth punching are actually performed on the same tooth on the same die and rough punching is performed firstly. After a tooth index is selected by an indexing device, fine punching is performed on one roughly-punched tooth type and rough punching is performed on the other tooth type at the same time, so that tooth punching processing of the entire tooth type is finished, the completeness of the tooth type is ensured and the defects of tooth punching processing of the conventional die are overcome.

Owner:HEIXUANFENG SAW IND

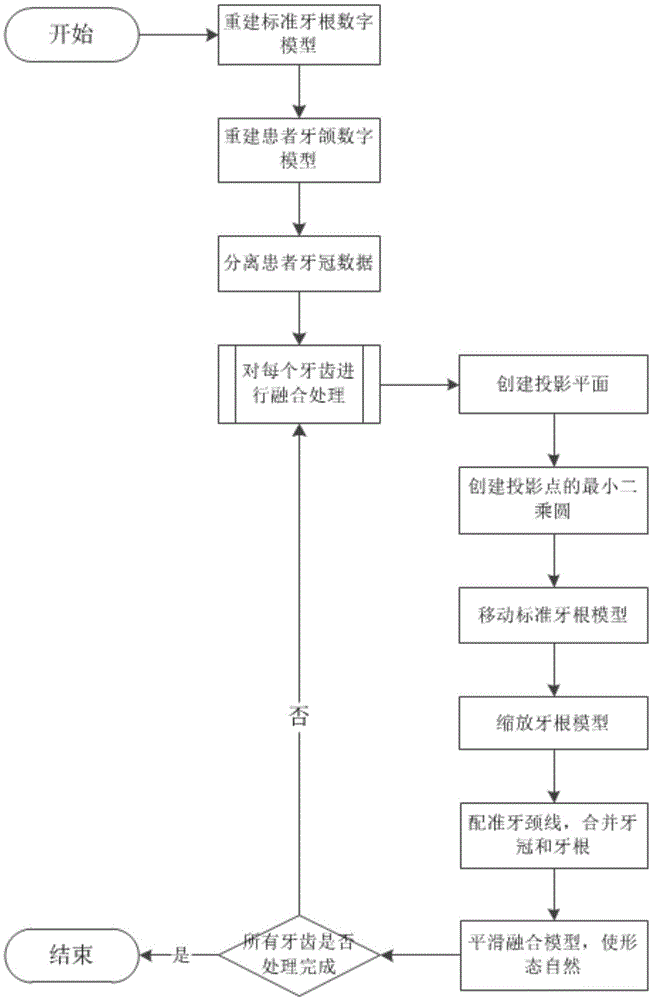

Method for reconstructing tooth root of patient

The invention discloses a method for reconstructing tooth root of a patient. The method comprises steps of scanning a standard tooth model and reconstructing a standard tooth digital model, wherein the standard tooth digital model comprises crown data and root data, and acquiring the root data of the standard tooth digital model; reconstructing a jaw digital model of the patient and acquiring the crown data from the jaw digital model of the patient; and promoting fusion between the root data of the standard tooth digital model and the crown data of the patient, wherein in the tooth model that fusion is completed, each tooth crown is aligned and integrated with matching tooth root on corresponding position so as to present the natural state of the entire teeth. The method disclosed by the invention has the advantages of being able to acquire the tooth root location information of the patient and improve the success rate of a correction scheme.

Owner:杭州一牙数字口腔有限公司

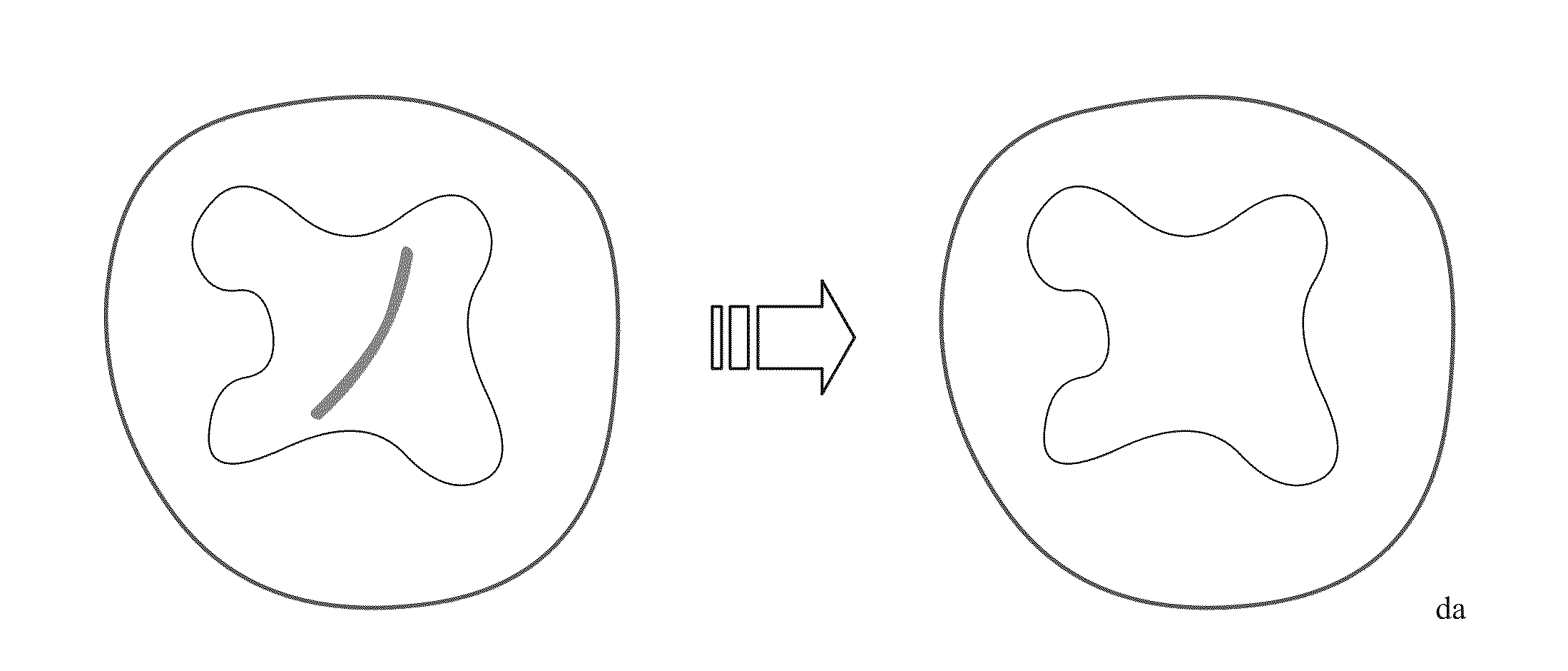

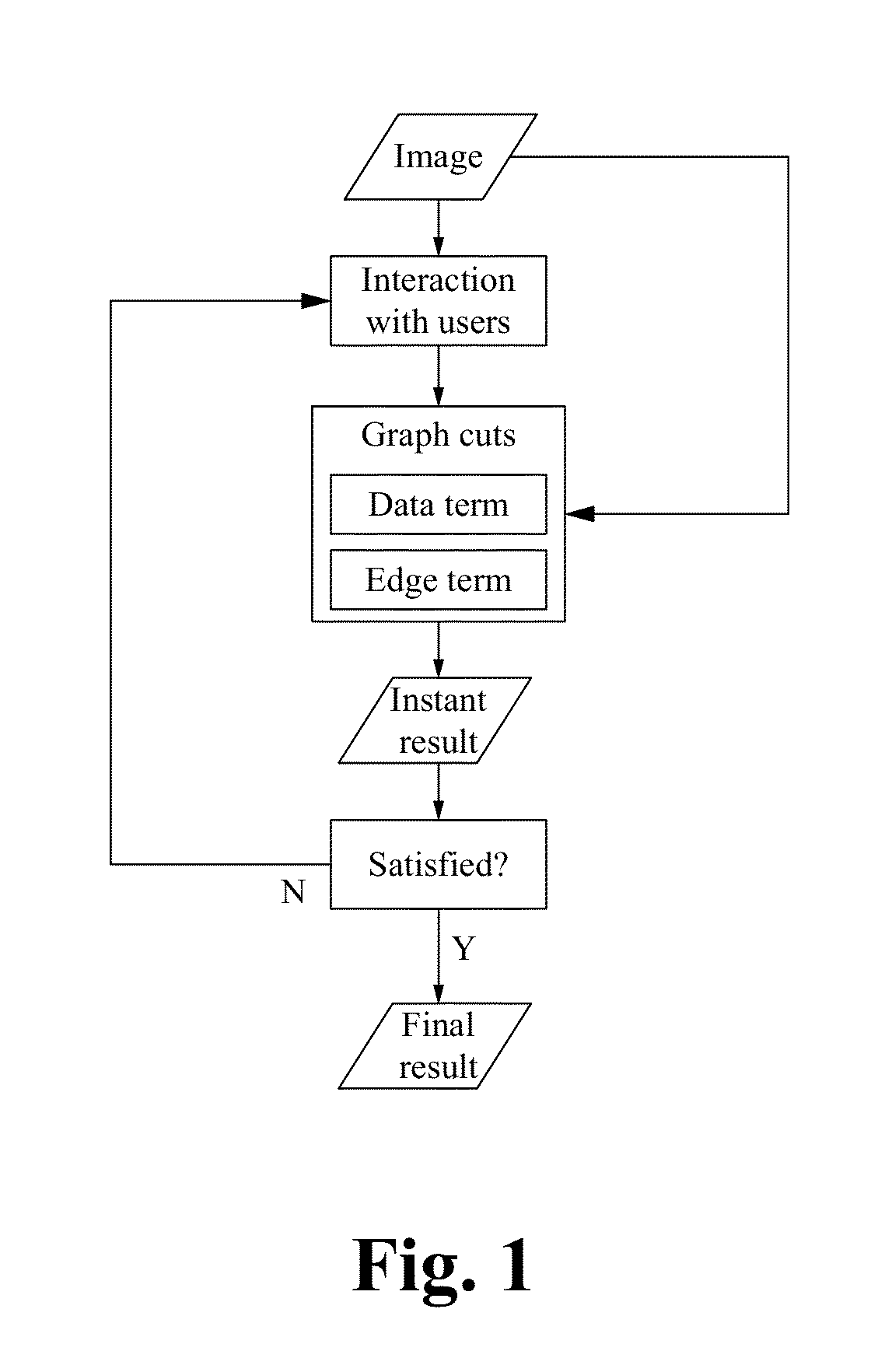

Graph cuts-based interactive segmentation of teeth in 3-d ct volumetric data

ActiveUS20130243289A1Increase in imaging regionSatisfied with the resultImage enhancementImage analysisGraphicsBone tissue

An interactive segmentation framework for 3-D teeth CT volumetric data enables a user to segment an entire dental region or individual teeth depending upon the types of user input. Graph cuts-based interactive segmentation utilizes a user's scribbles which are collected on several 2-D representative CT slices and are expanded on those slices. Then, a 3-D distance transform is applied to the entire CT volume based on the expanded scribbles. Bony tissue enhancement is added before feeding 3-D CT raw image data into the graph cuts pipeline. The segmented teeth area is able to be directly utilized to reconstruct a 3-D virtual teeth model.

Owner:SONY CORP

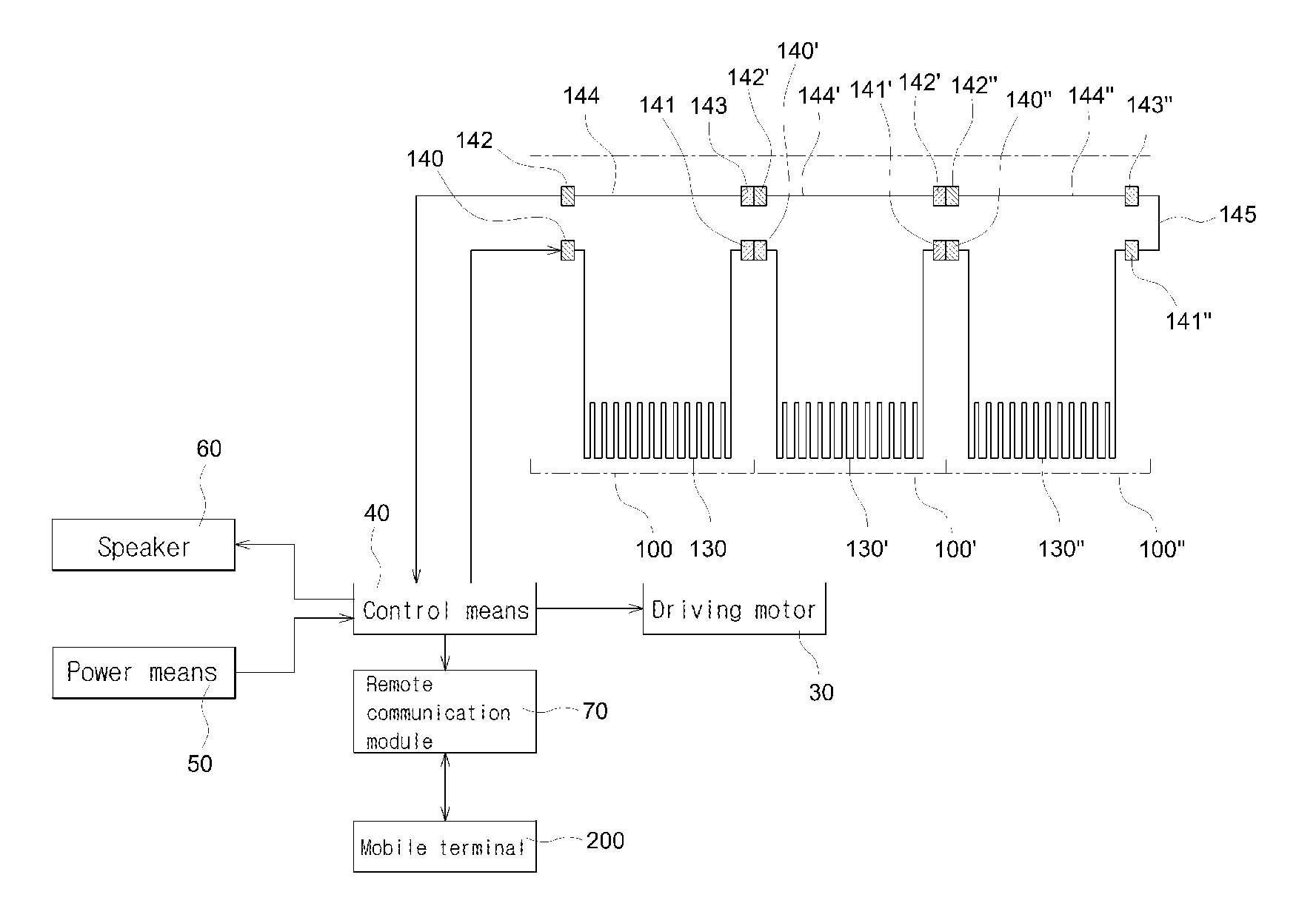

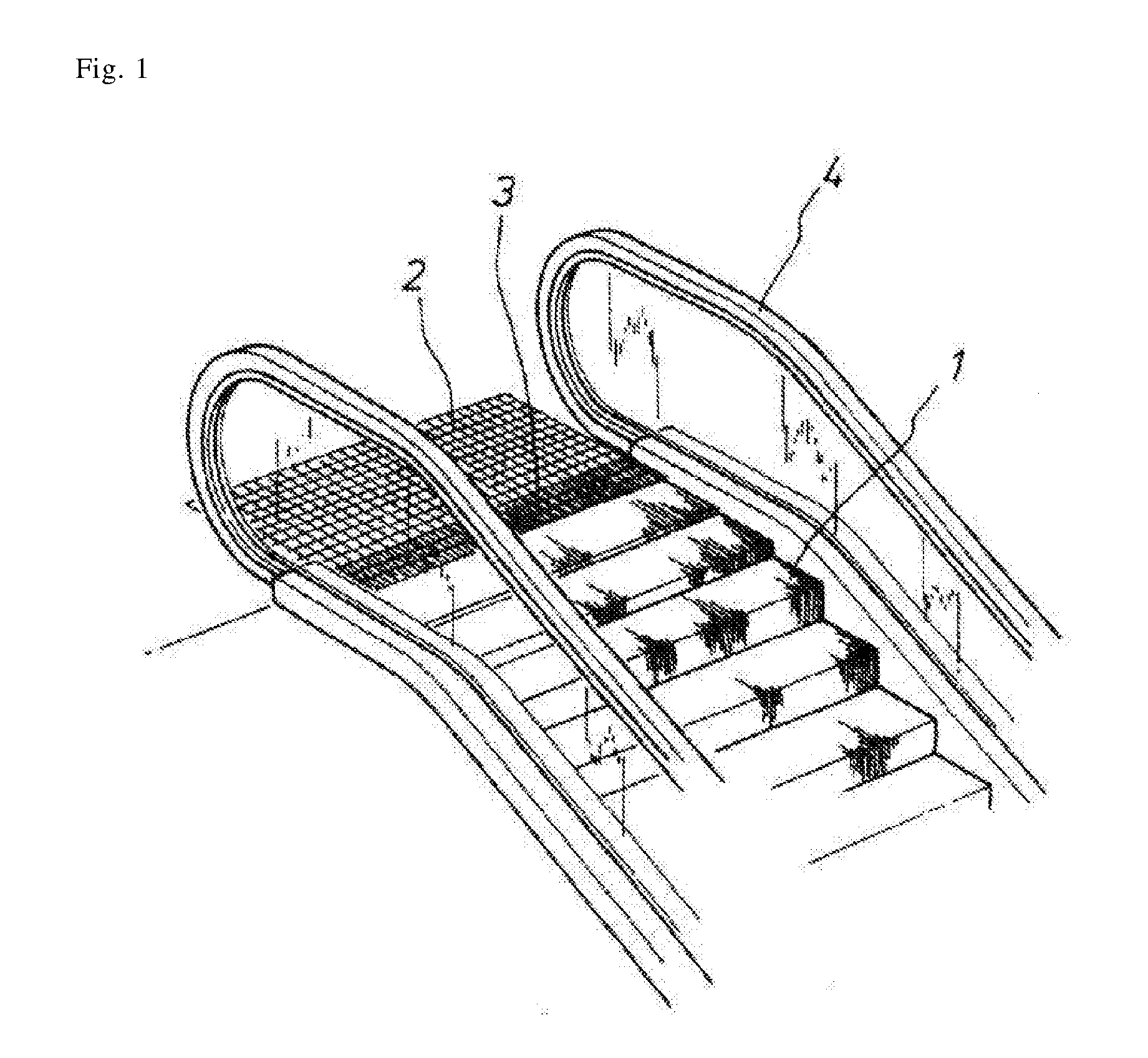

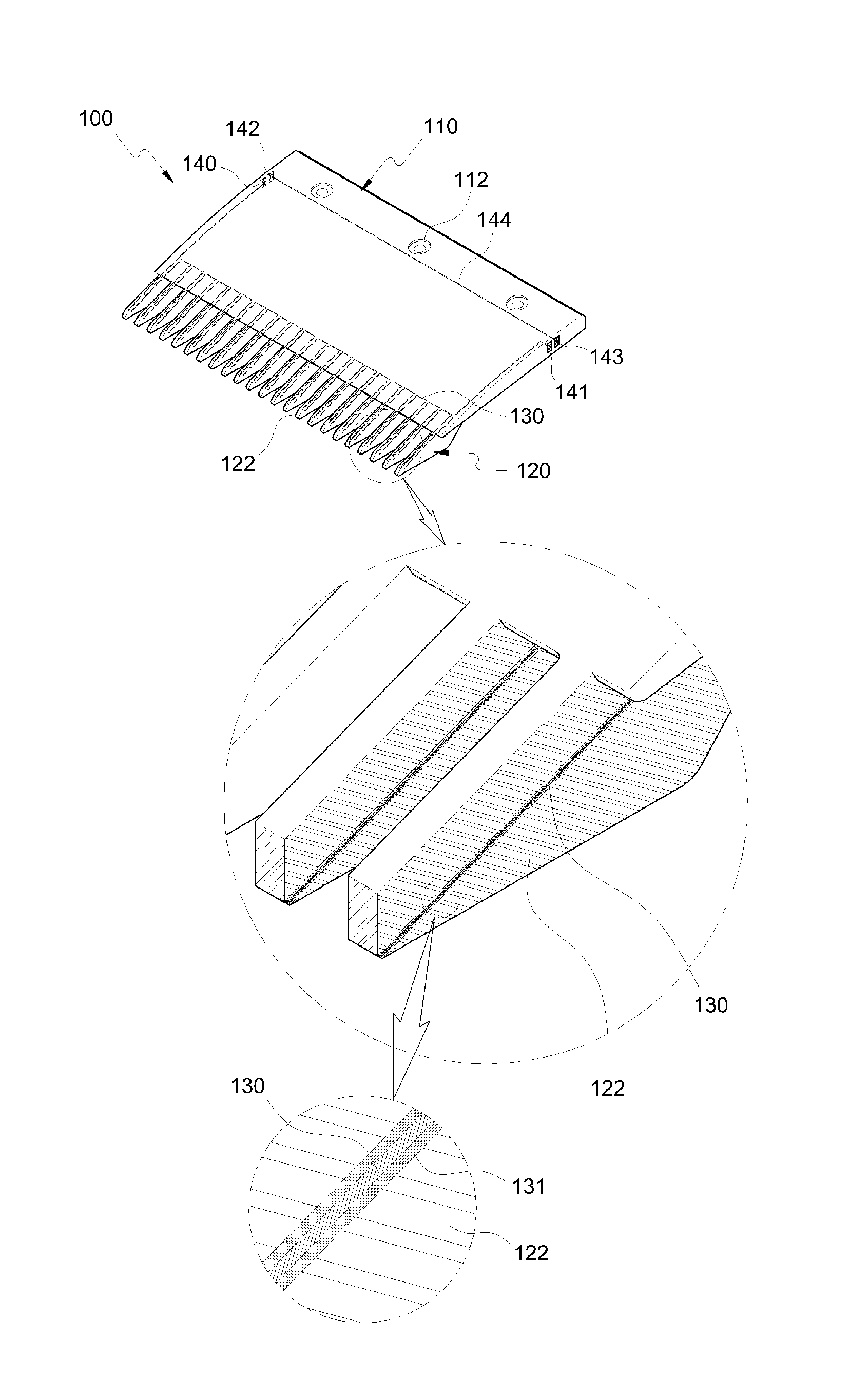

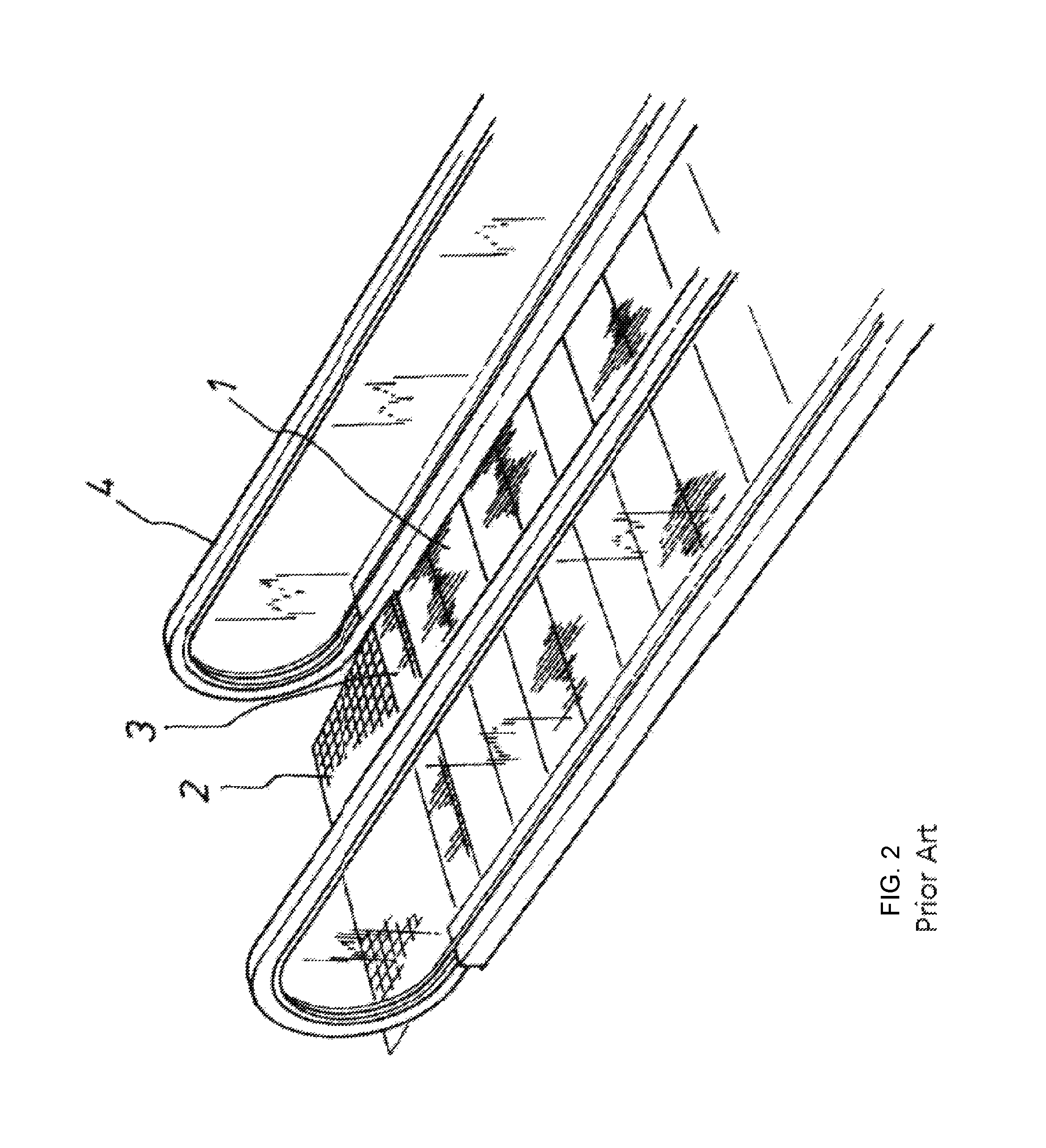

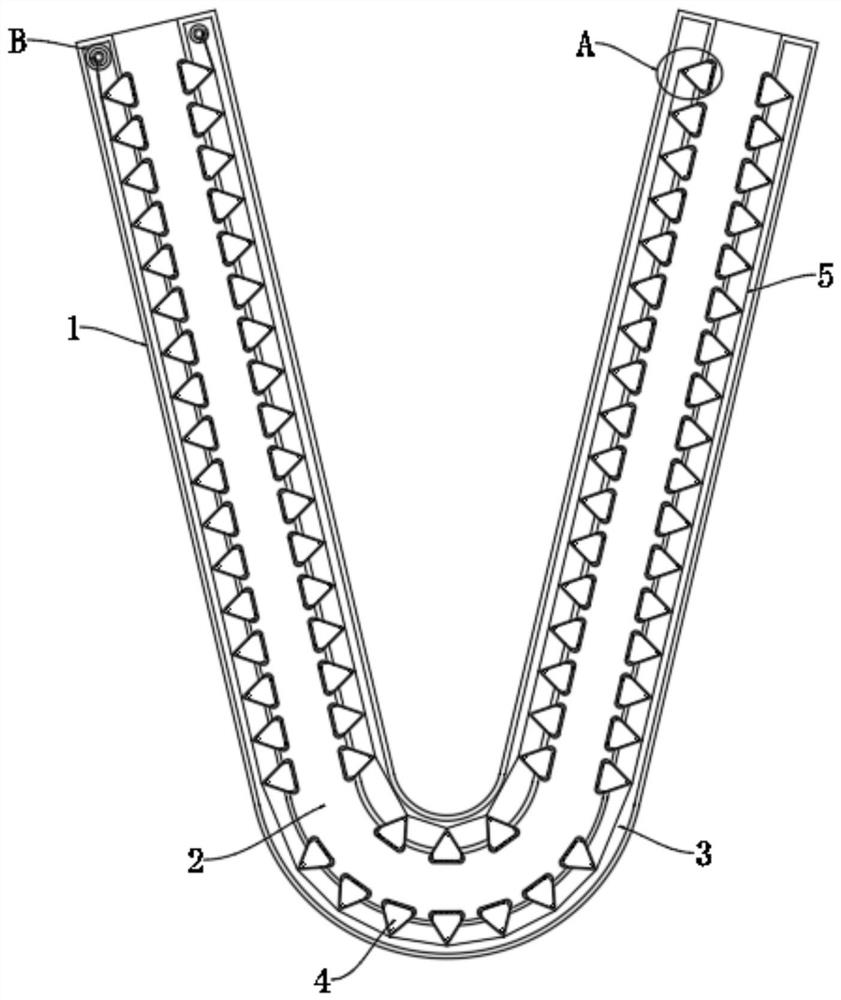

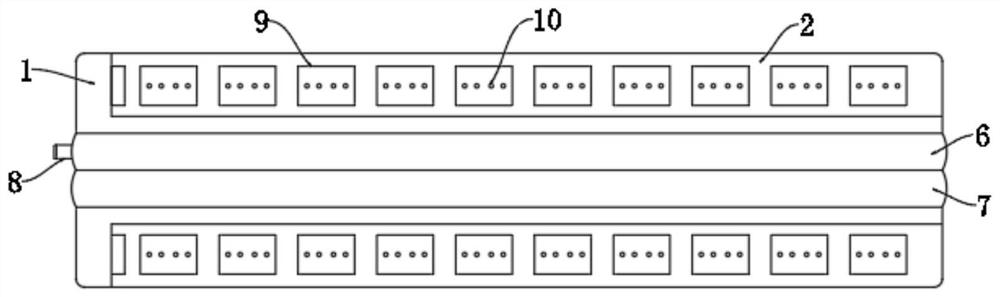

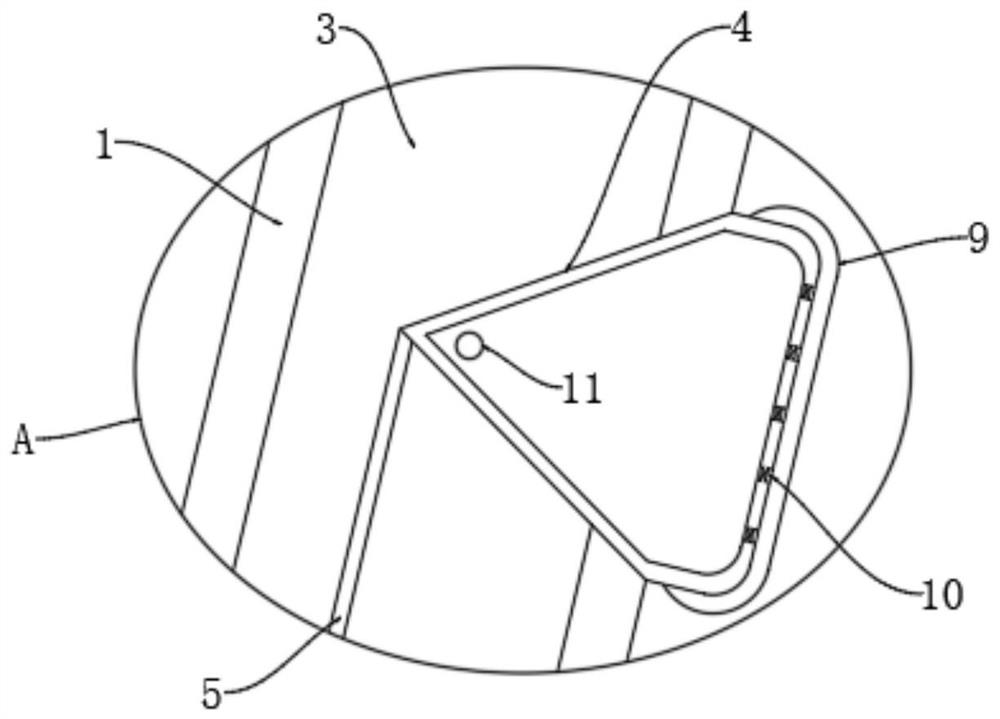

Safety comb plate of escalator

InactiveUS20160145078A1Damage detection is simpleSimple configurationConveyorsControl devices for conveyorsEntire toothDamage detection

A comb plate is provided that can be monitored whether entire teeth are damaged by continuously installing one detection line in order to detect damage of teeth of a comb plate fixed to the front of a landing plate of an escalator and that has a simple configuration for damage detection and that can minimize a cost for monitoring the teeth by using only one detection line while monitoring the entire of a plurality of comb teeth provided in the comb plate.

Owner:MIJUHITEC

Method for processing middle convex gear by adopting shaving cutter and modified shaving cutter

InactiveCN102476263AGood base joint accuracyImprove noiseGear teeth manufacturing toolsGear teethHobbingInvolute

The invention discloses a method for processing a middle convex gear and a modified shaving cutter. The method comprises a gear blank rough machining procedure, a thermally treating procedure, a gear blank finish machining procedure, a gear hobbing procedure before shaving and a shaving procedure, wherein in the shaving procedure, the modified saving cutter with three kinds of cutter teeth is used for processing the middle convex gear; the modified shaving cutter consists of three kinds of cutter teeth, i.e., normal cutter teeth of a standard shaving cutter, cutter teeth formed by reducing the entire tooth profile tooth thickness of the normal cutter teeth of the standard shaving cutter, and cutter teeth formed by thinning the entire tooth profile tooth socket of the normal cutter teeth of the standard shaving cutter; the three kinds of cutter teeth are distributed alternatively at intervals on the shaving cutter; and the tooth profiles of the three kinds of cutter teeth are standard involutes. In the invention, the shaving cutter is used for processing the middle convex gear, and an ideal convex tooth profile can be obtained by selecting a reasonable thinning way and a reasonable thinning amount for the cutter teeth of the shaving cutter; and the tooth profiles of the three kinds of cutter teeth are standard involutes, so that a processed gear base pitch has high accuracy, and gear noise is remarkably lowered.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

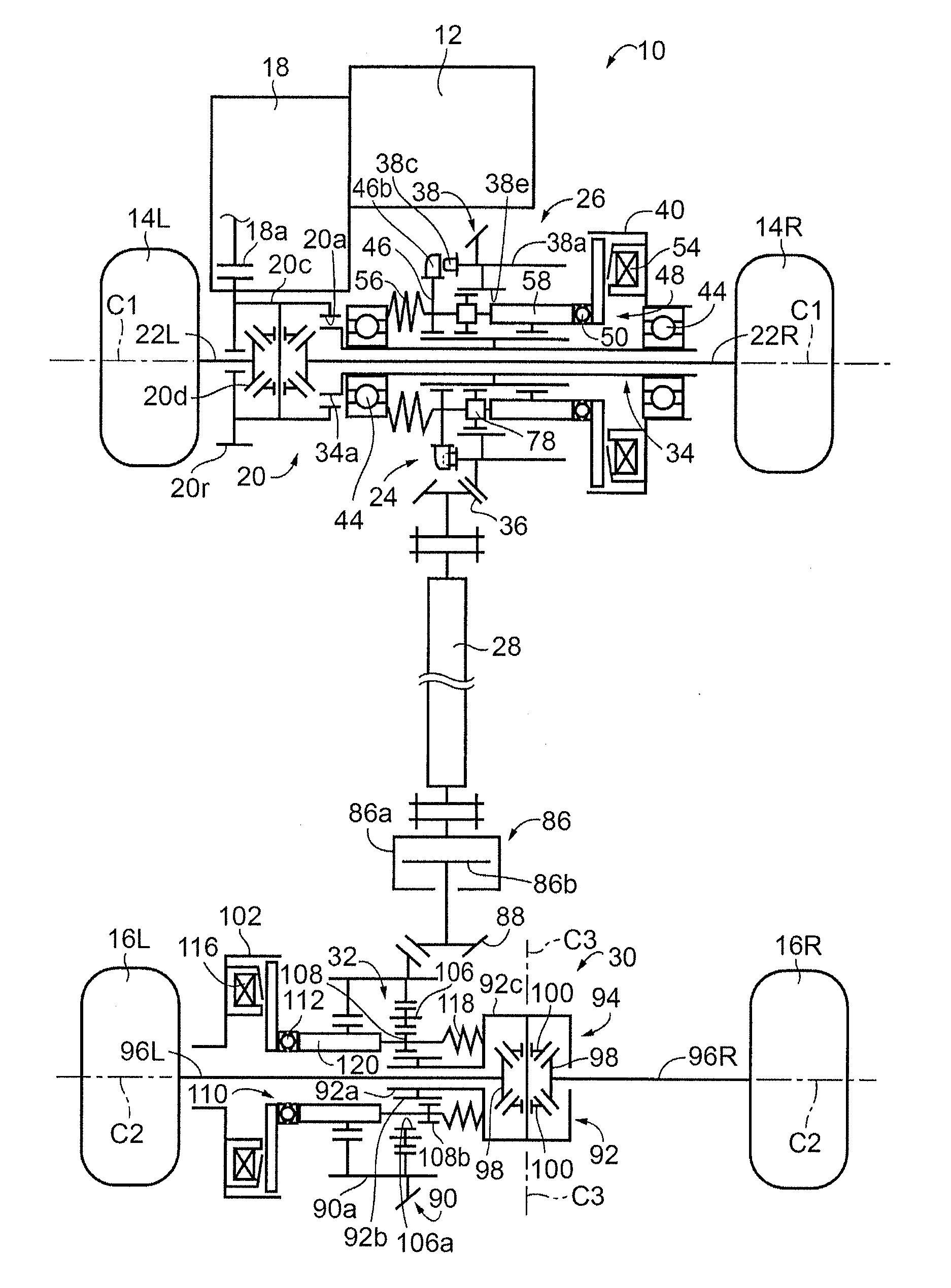

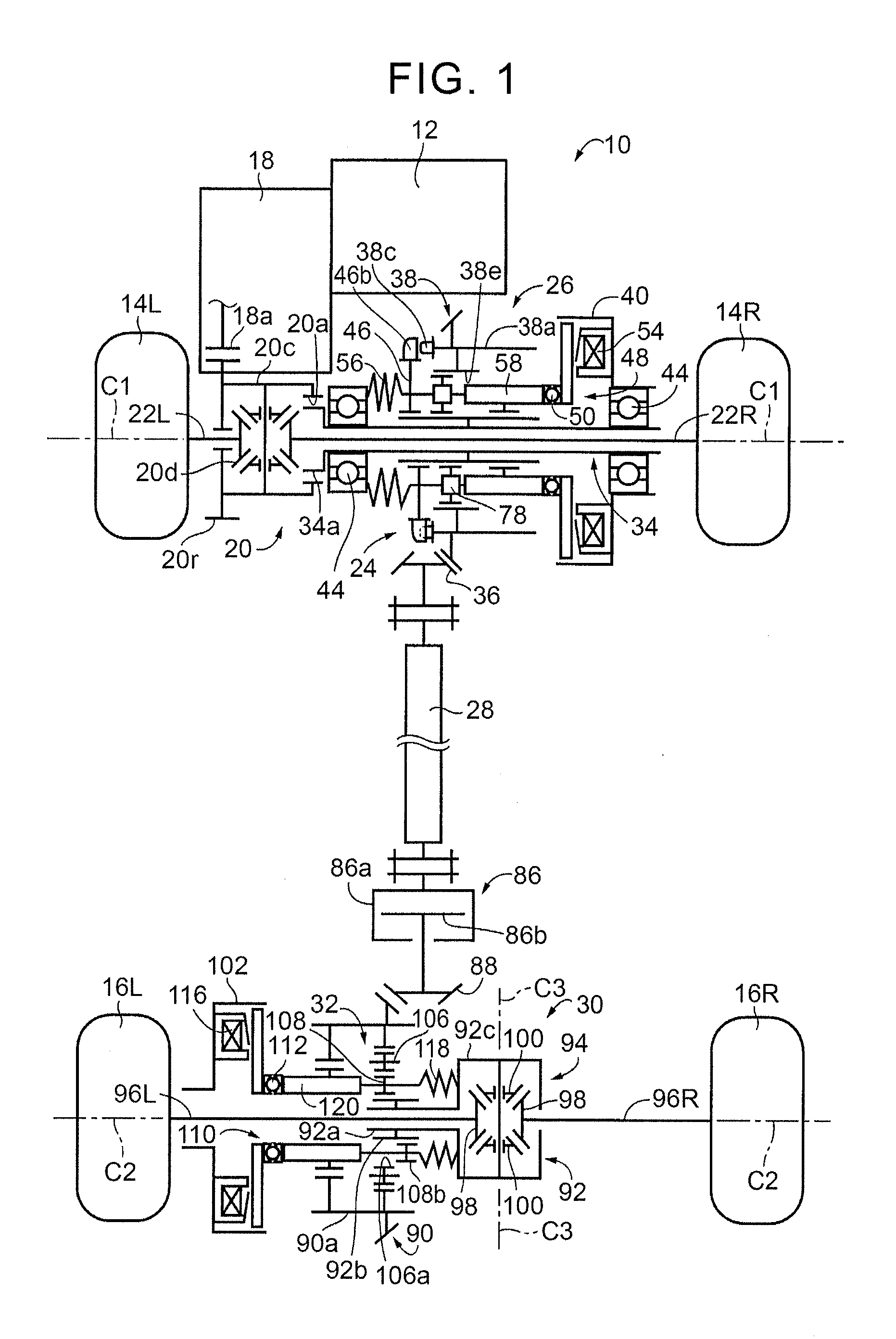

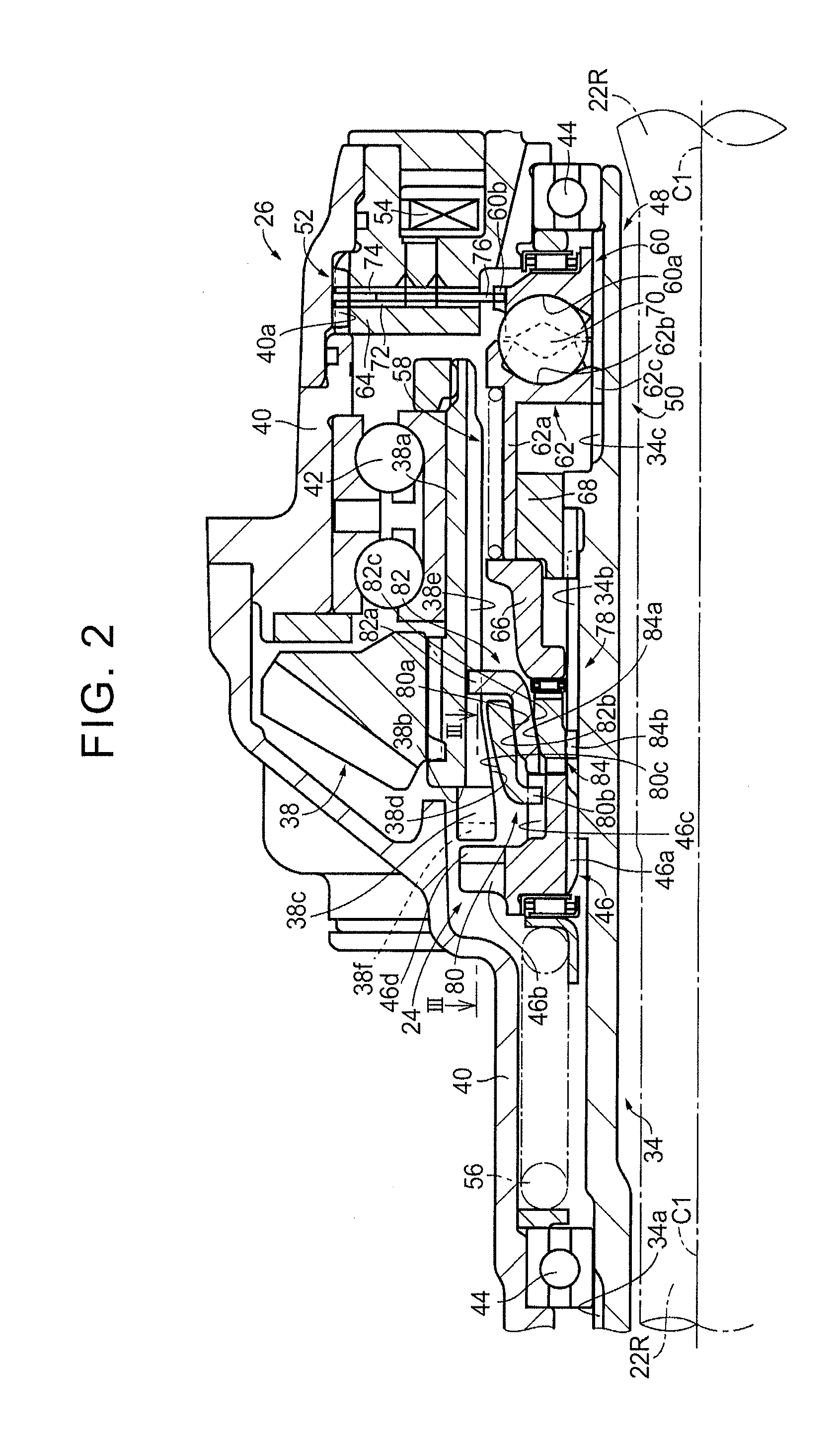

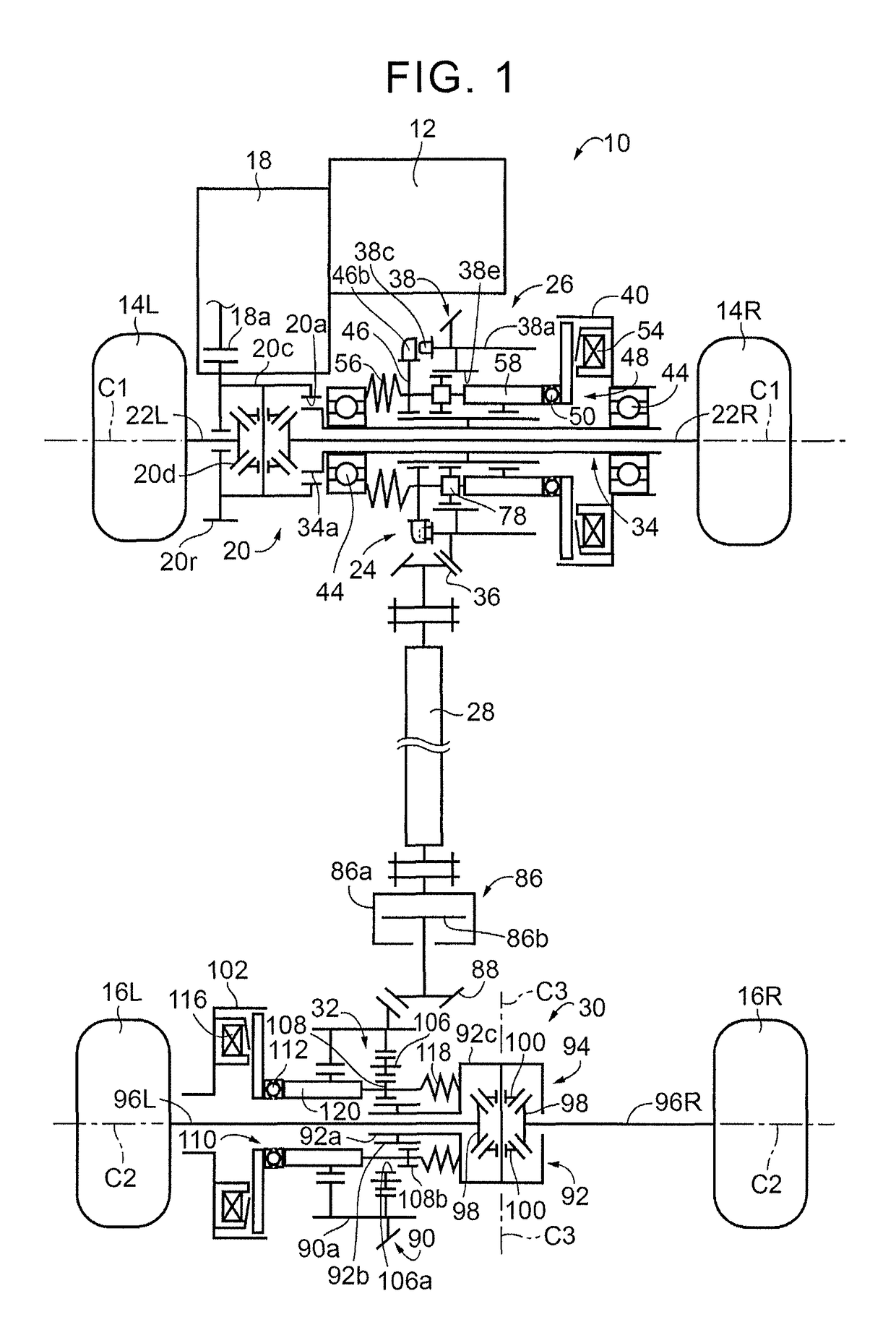

Four-wheel-drive vehicle

ActiveUS20160303966A1Prevent jumpingShorten the switching timeMagnetically actuated clutchesVehicle sub-unit featuresRotational axisEngineering

A four-wheel-drive vehicle includes a driving source, main driving wheels, auxiliary driving wheels, a power transmitting member, a first mesh clutch, and a second mesh clutch. Meshing teeth on the driving source side of the first mesh clutch each have, along an entire tooth width thereof, an inclined surface in which a length in a rotational axis direction increases in a direction in which the meshing teeth on the driving source side rotate when the four-wheel-drive vehicle is traveling forward. The meshing teeth on the power transmitting member side of the first mesh clutch each have, along an entire tooth width thereof, an inclined surface in which a length in a rotational axis direction decreases in a direction in which the meshing teeth on the driving source side rotate when the four-wheel-drive vehicle is traveling forward.

Owner:TOYOTA JIDOSHA KK

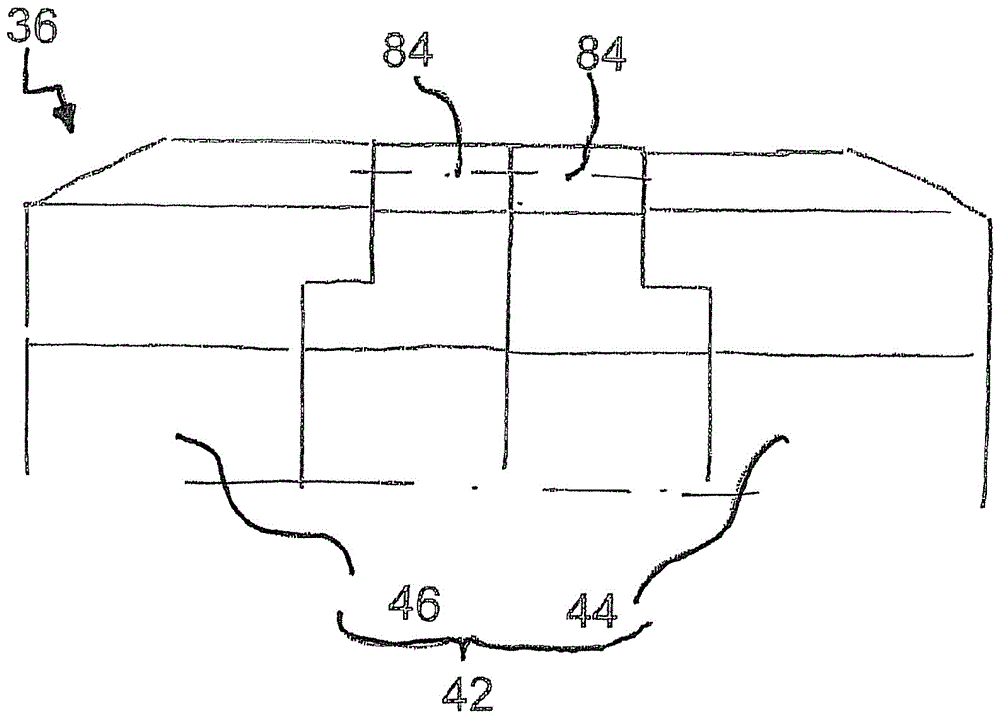

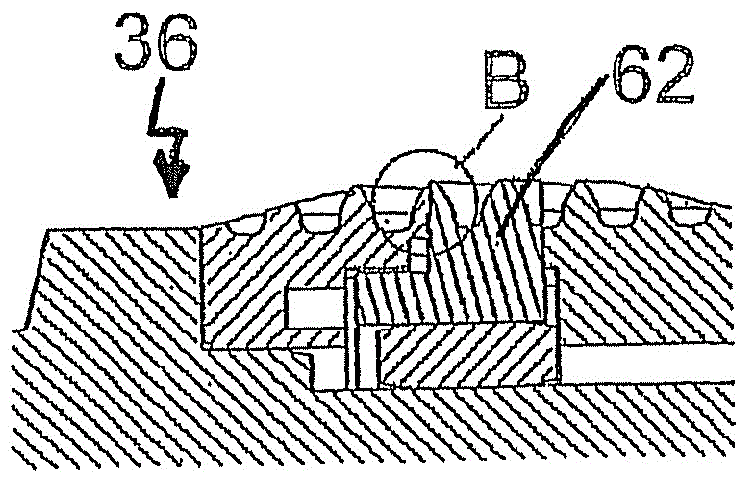

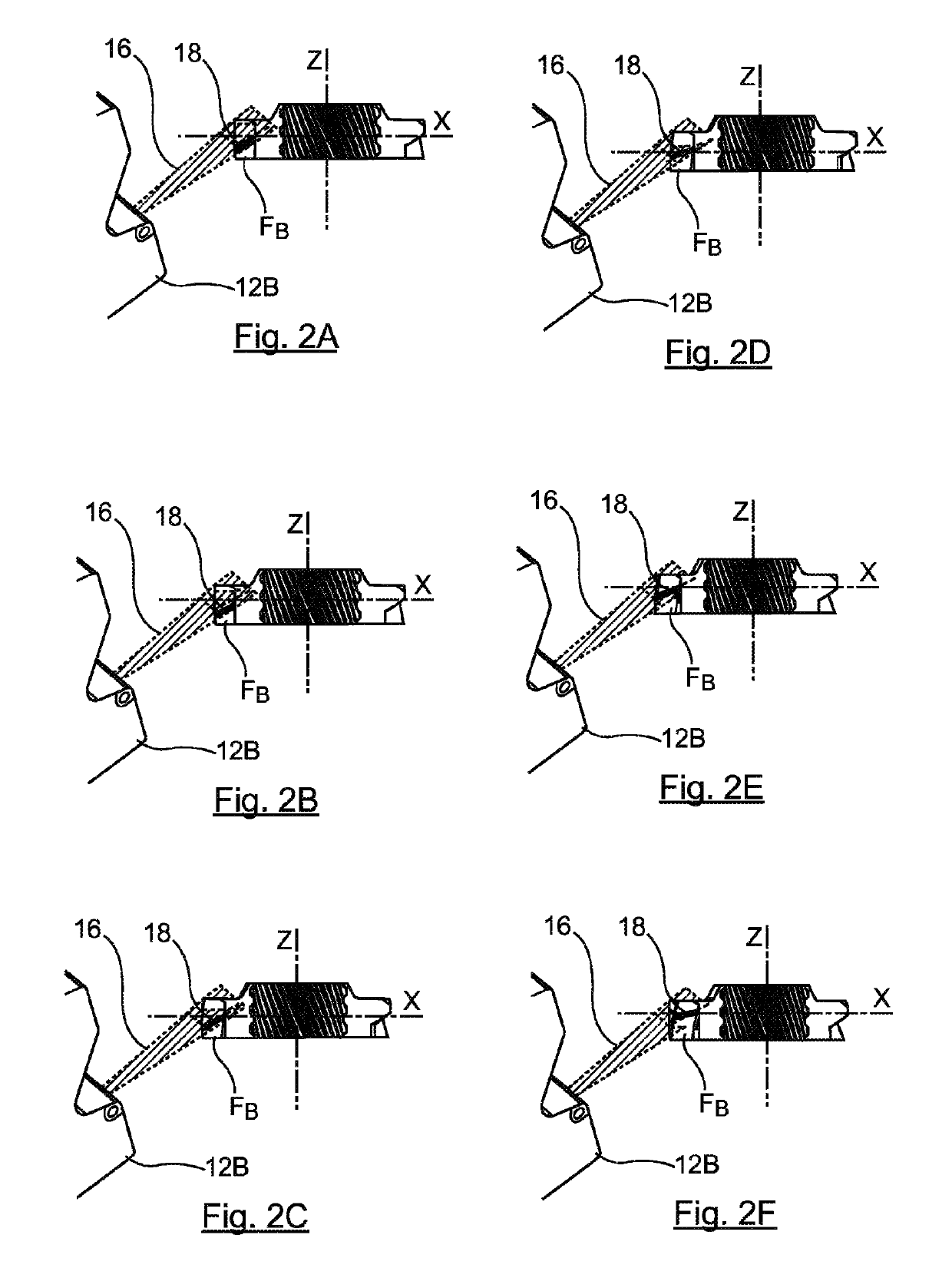

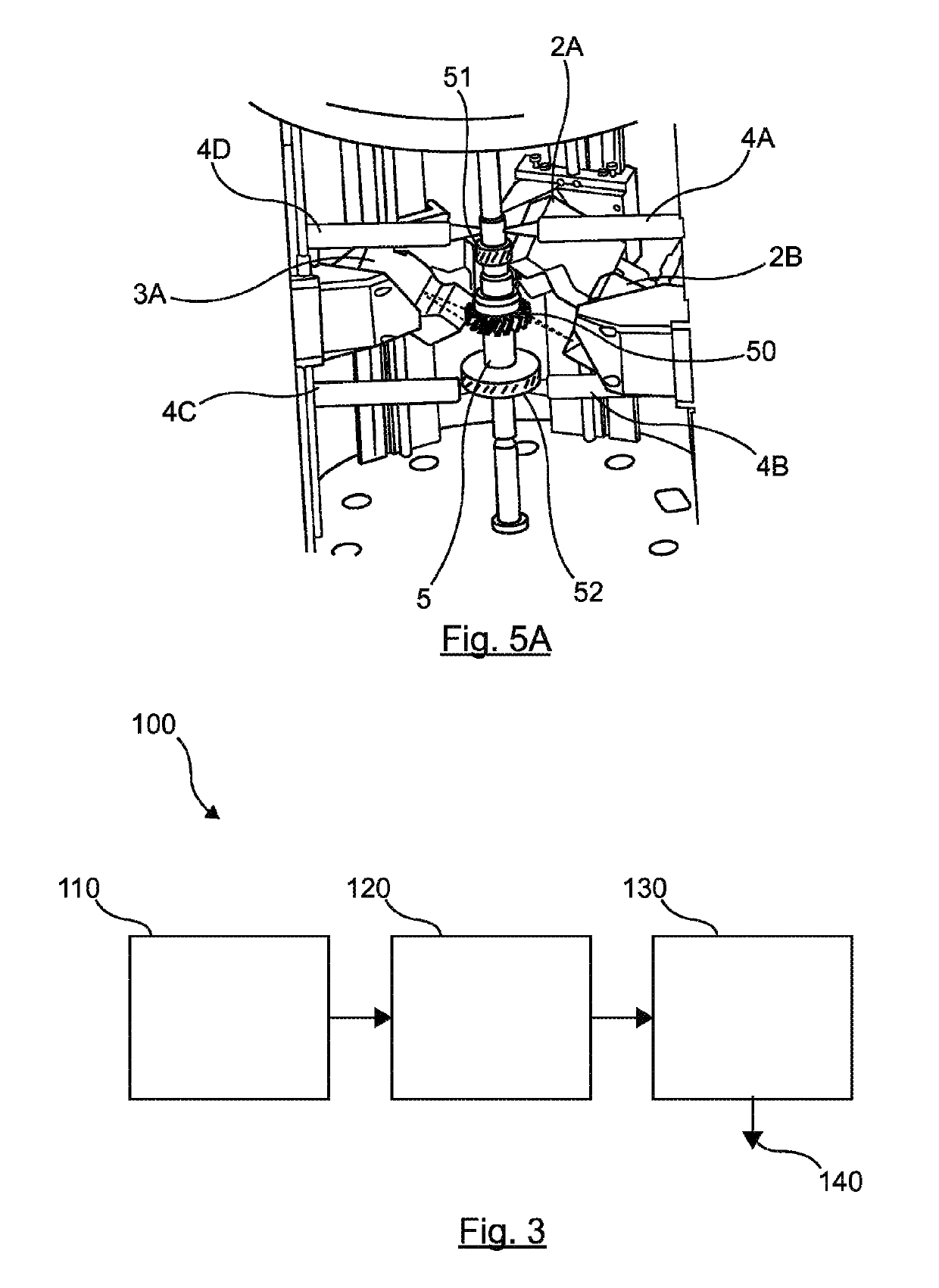

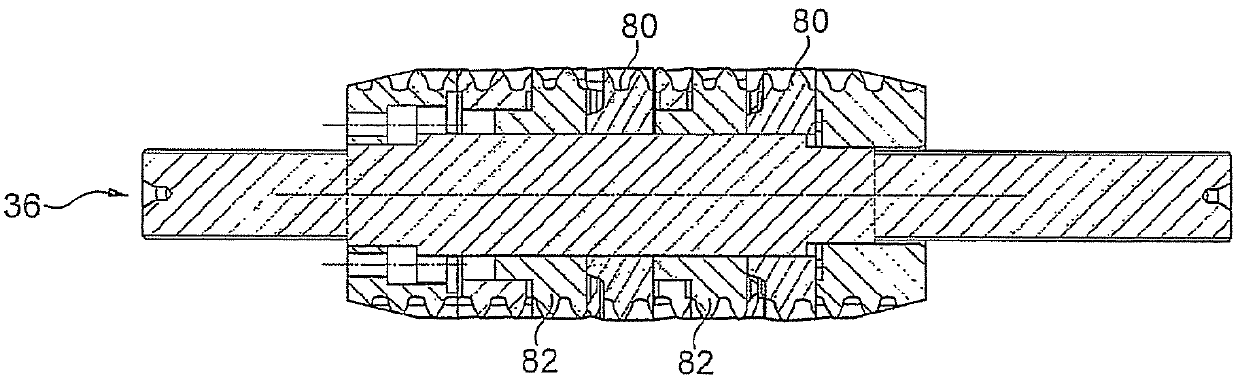

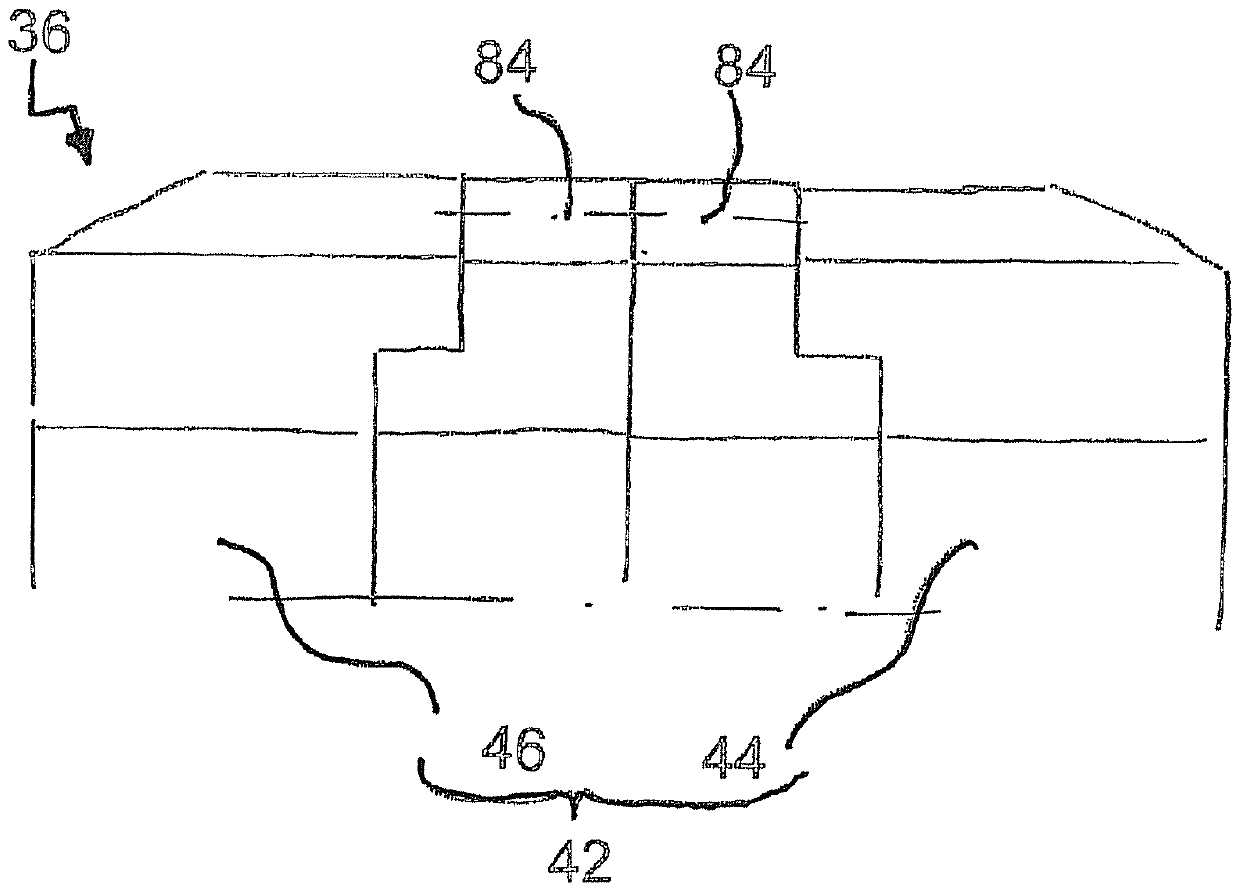

Method and device for producing gear together with clamping means

ActiveCN106163694AEase of mass productionReduce manufacturing costGear wheelsEngineeringEntire tooth

The invention relates to a method for producing at least one gear, in particular a helically toothed gear, wherein the gear is produced from a gear blank (20, 38, 50, 52, 62, 72, 80, 82, 84) pressed and sintered with an oversize in the region of the set of teeth (18), wherein the gear blank (20, 38, 50, 52, 62, 72, 80, 82, 84) has two opposite end faces and a circumference. In the method, the gear blank (20, 38, 50, 52, 62, 72, 80, 82, 84) is clamped in a clamping means (42). The gear blank (20, 38, 50, 52, 62, 72, 80, 82, 84) is compressed in the region of the oversize by means of the engagement of at least one circumferential tool (10, 28) having a set of mating teeth (12, 26) that engages with the set of teeth (18) of the gear blank (20, 38, 50, 52, 62, 72, 80, 82, 84), wherein the gear blank (20, 38, 50, 52, 62, 72, 80, 82, 84) is radially clamped over the circumference by the clamping means (42) at both end faces during the compression of the gear blank, wherein each individual tooth (56, 66) of the set of teeth (18) of the gear blank (20, 38, 50, 52, 62, 72, 80, 82, 84) is supported by the clamping means (42) substantially over the entire tooth height. In this way, the quality of the set of teeth can be improved. The invention further relates to a device and to a clamping means.

Owner:GKN POWDER METALLURGY ENG GMBH

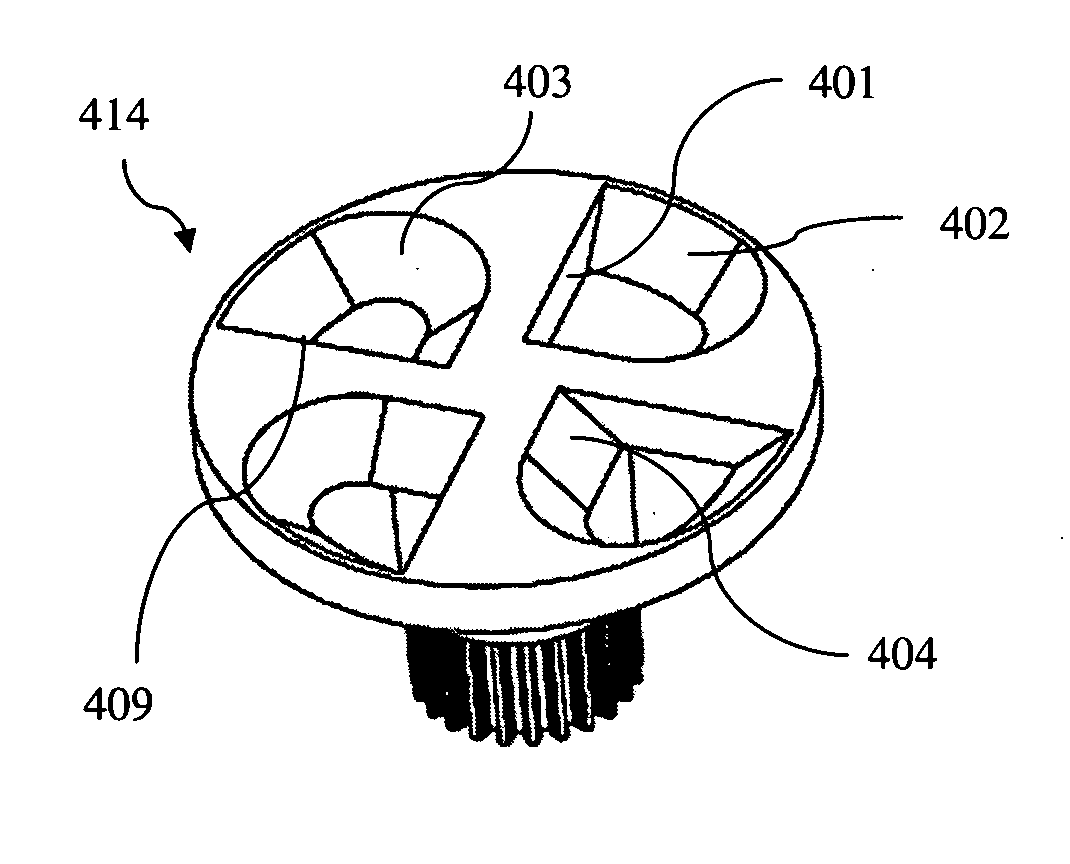

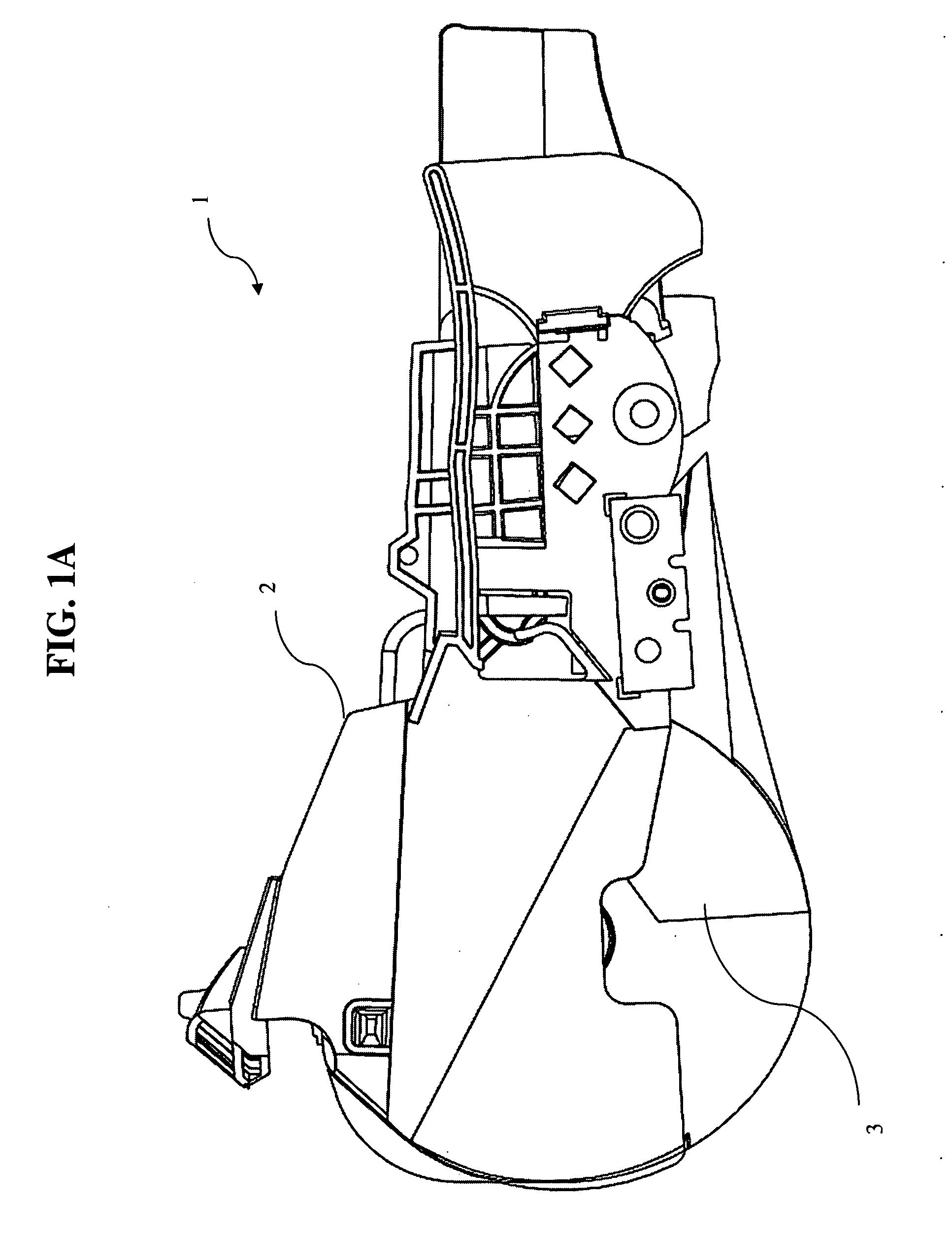

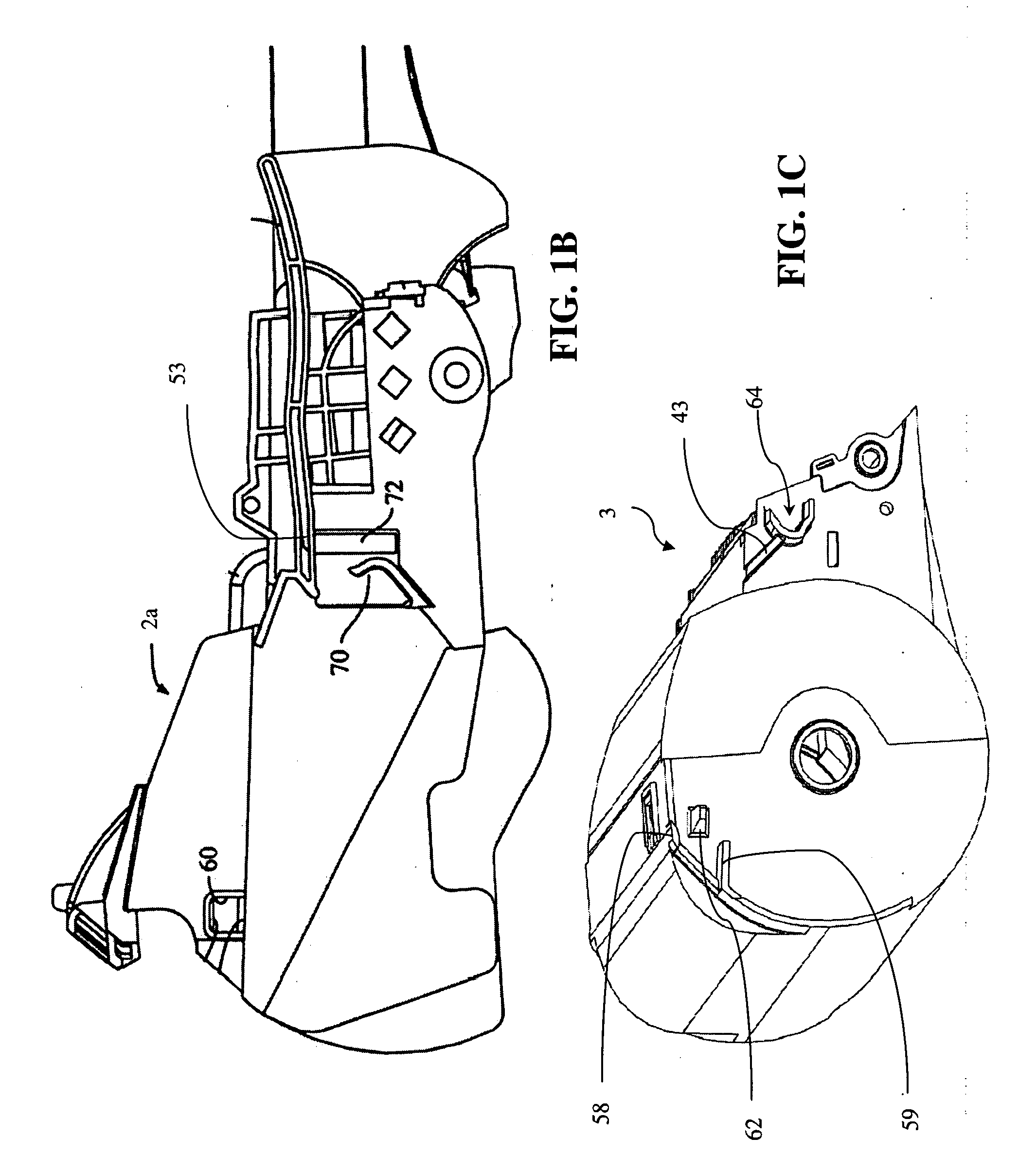

Imaging Cartridge Drive Having Entire Tooth Engagement

InactiveUS20080152383A1Easy constructionReduce in quantityElectrographic process apparatusLeading edgeEngineering

Provided is an improved drive mechanism for an imaging machine. A tapered surface is disposed outboard of the drive dog seat whereby a tooth of the imaging machine drive mechanism is centered and directed into the drive dog seat. The leading edge of the drive dog seat contacts the base of the imaging machine drive mechanism thus making full contact between the drive dog seat and the imaging machine drive mechanism tooth.

Owner:MILLER STEVEN

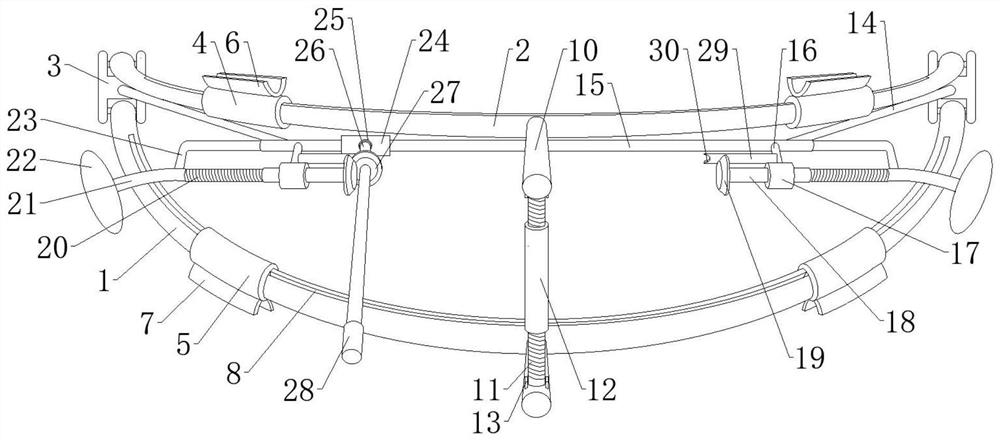

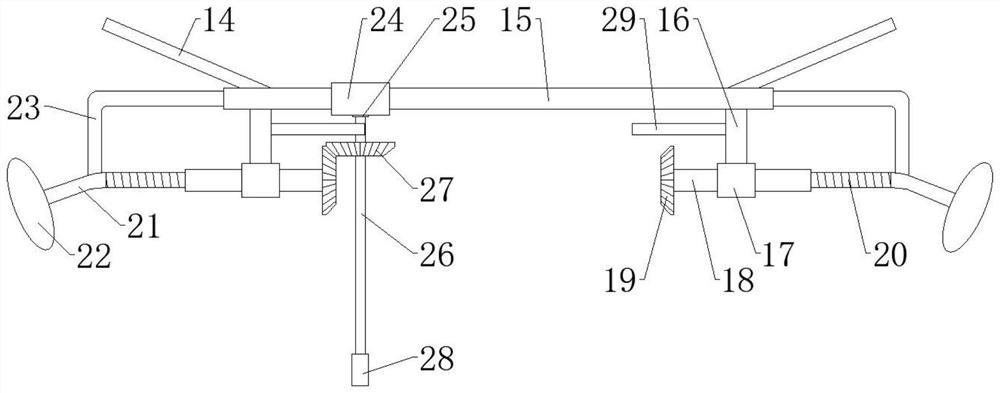

Stable anti-injury oral cavity repair supporting device and adjusting method thereof

The invention discloses a stable anti-injury oral cavity repair supporting device and an adjusting method thereof, and relates to the technical field of medical instruments. The stable anti-injury oral cavity repair supporting device comprises an upper tooth supporting ring and a lower tooth supporting ring; and the rear ends of the left and right sides of the upper tooth supporting ring and the lower tooth supporting ring are hinged to two H-shaped connecting blocks. According to the stable anti-injury oral cavity repair supporting device and the adjusting method thereof, two first sliding sleeves and two second sliding sleeves are arranged on the upper tooth supporting ring and the lower tooth supporting ring in a sliding mode correspondingly, so that the two first sliding sleeves and the two second sliding sleeves slide on the upper tooth supporting ring and the lower tooth supporting ring correspondingly; and therefore, two upper tooth sockets on the upper side and two lower toothsockets on the lower side can be driven to slide on the upper tooth supporting ring and the lower tooth supporting ring respectively, the upper tooth sockets and the lower tooth sockets can be in buttjoint with different portions of teeth on the upper side and the lower side in the oral cavity, the upper tooth sockets and the lower tooth sockets can be prevented from wrapping the whole teeth, andoperation of doctors is more convenient.

Owner:乳山市人民医院

Shearing tool for insulation paper of rotor slot of miniature motor

InactiveCN102420509AReduce manufacturing costReduce processing timeApplying solid insulationEngineeringMicromotor

The invention discloses a shearing tool for the insulation paper of a rotor slot of a miniature motor. The shearing tool comprises a tool holder and a tool bit. The tool bit has a zigzag structure with three teeth which comprises a middle entire tooth with cutting edges and two half teeth on the two sides of the entire tooth, wherein the two half teeth are symmetrical about the middle entire tooth; the inner sides of the two half teeth are provided with a cutting edge respectively; and the width of the tooth root of the entire tooth is equal to the length of a sandwiched arc of an outer circle between two adjacent slots of a rotor. When the shearing tool for the insulation paper of the rotor slot of the miniature motor is used, the two half teeth of the tool are arranged between the insulation paper and the outer circle of a rotor core respectively, the middle entire tooth is arranged on the outer circle of the rotor core, the tool holder applies a thrust to the tool, and the tool bit moves forwards along the outer circle of the rotor core to cut off the insulation paper at the two ends of the rotor slot at the same time. Compared with the prior art, the shearing tool shortens process time for removing the insulation paper of the rotor slot of the miniature motor to be 1 / 3 of original process time, improves labor productivity and decreases the production cost of an enterprise.

Owner:JIANGNAN YIFAN MOTOR

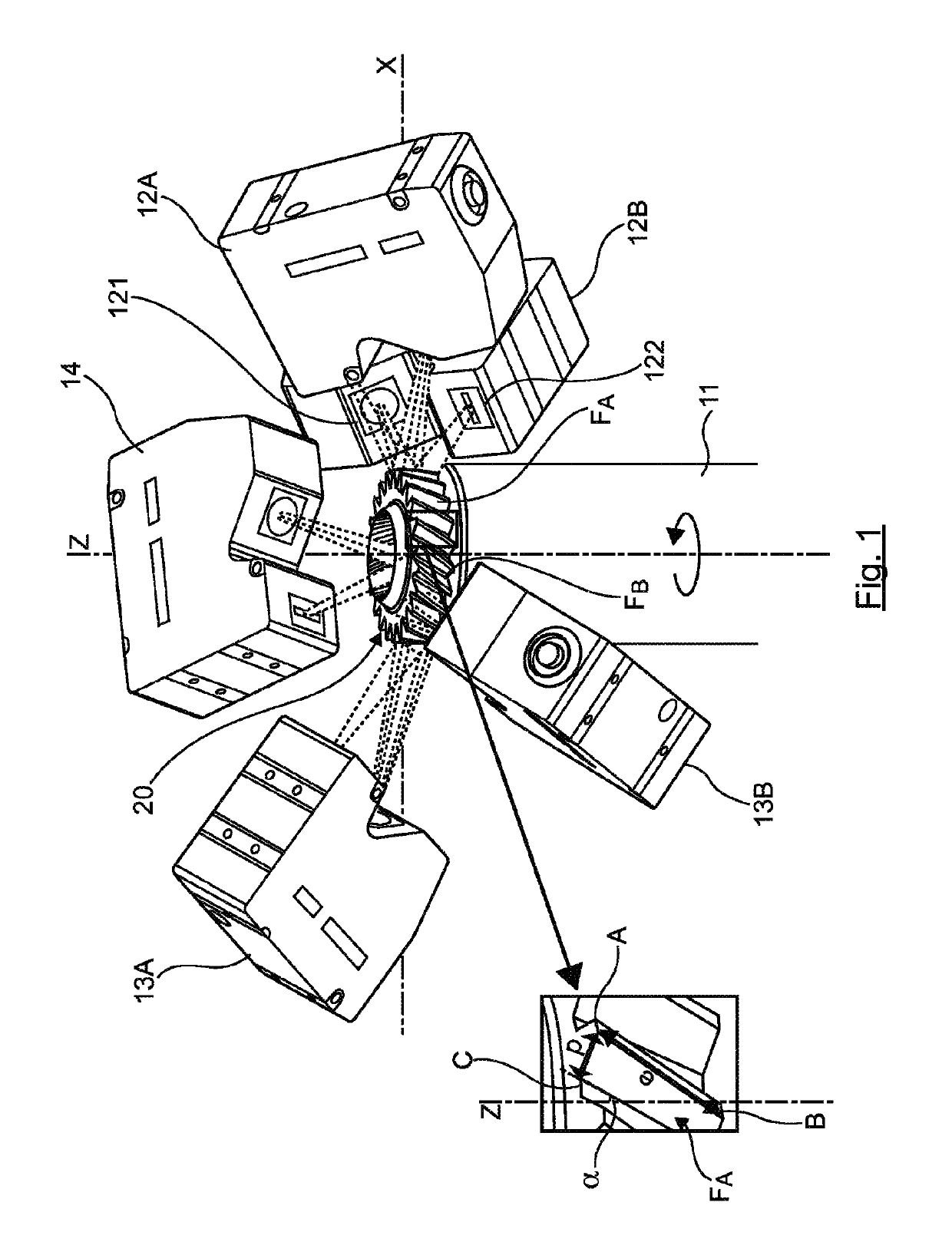

Device for the contactless three-dimensional inspection of a mechanical component with toothing

ActiveUS10724852B2Shorten the timeImprove simplicityCaliper-like sensorsUsing optical meansMechanical componentsEngineering

Owner:DWFRITZ AUTOMATION INC

Safety comb plate of escalator

A comb plate is provided that can be monitored whether entire teeth are damaged by continuously installing one detection line in order to detect damage of teeth of a comb plate fixed to the front of a landing plate of an escalator and that has a simple configuration for damage detection and that can minimize a cost for monitoring the teeth by using only one detection line while monitoring the entire of a plurality of comb teeth provided in the comb plate.

Owner:MIJUHITEC

A method of reconstructing a patient's tooth root

Owner:杭州一牙数字口腔有限公司

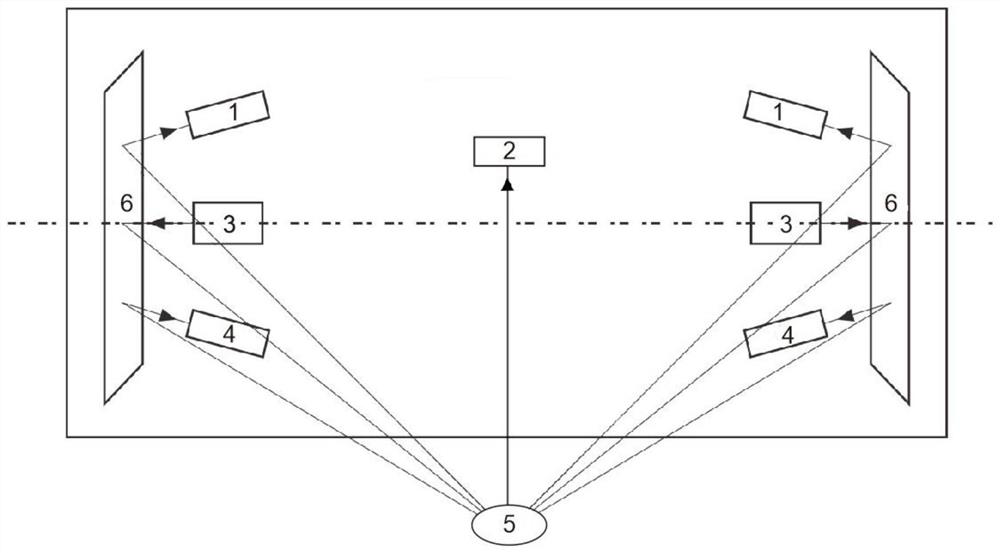

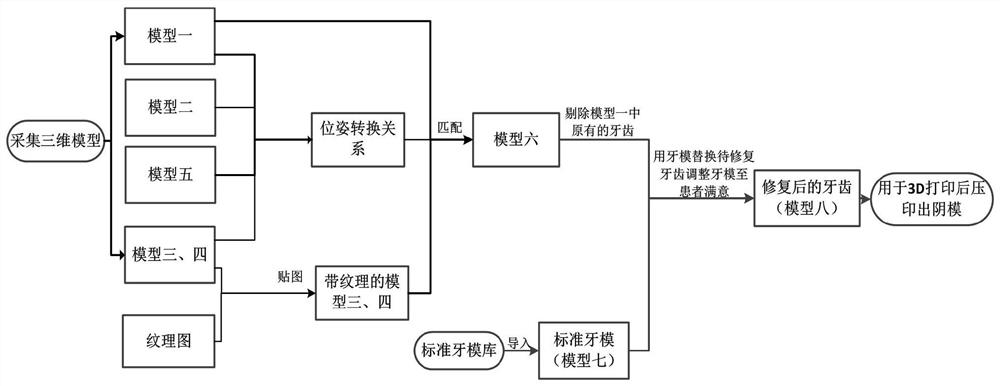

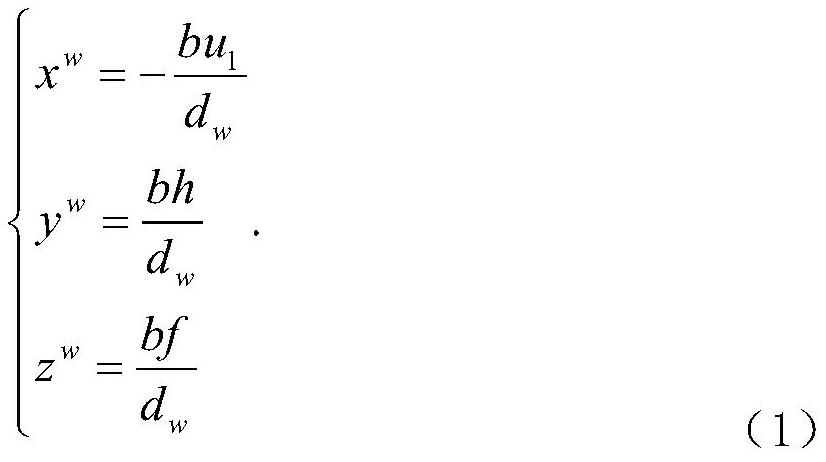

A dental restoration design method and device based on a three-dimensional scanning device

ActiveCN108062792BSpeed up the beauty design processImprove communication efficiencyImage enhancementImage analysisDental castEntire tooth

The invention discloses a dental restoration design method and device based on a three-dimensional scanning device. The three-dimensional scanning device quickly acquires a three-dimensional human face model and a patient's high-precision digital three-dimensional model of teeth. Through the matching relationship between the two models, it is registered into the mouth of the face model. At the same time, attach texture to the digital 3D model of teeth in various ways, and then take a single or multiple standard dental models to replace the single or multiple teeth to be repaired. Restoration design is carried out by adjusting standard dental model parameters, and at the same time display the three-dimensional model of the tooth after restoration to realize dental restoration design. The design parameters can be directly used to process and manufacture diagnostic veneers in dental aesthetic restoration, which saves the link of diagnostic wax-up in dental aesthetic restoration and speeds up the entire dental cosmetic design process. The digital smile design based on 3D can overcome many defects of 2D DSD and perfect the DSD design.

Owner:SUZHOU DEKA TESTING TECH CO LTD

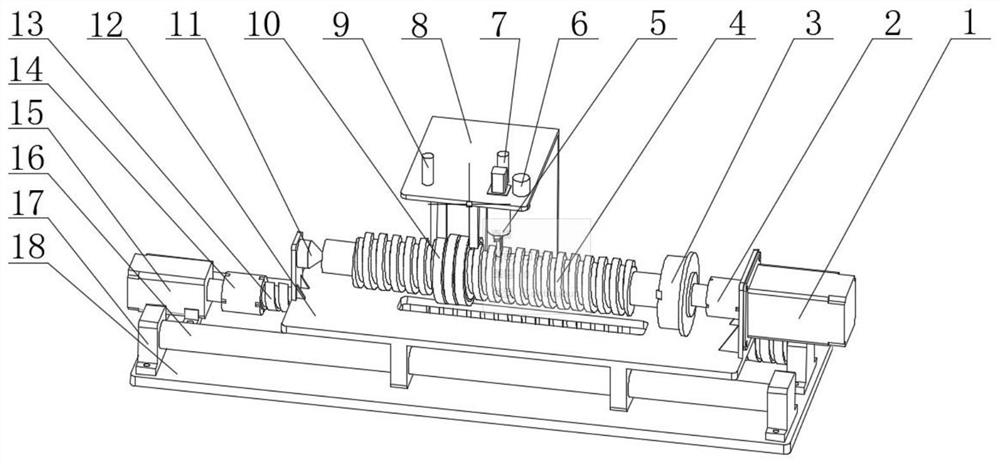

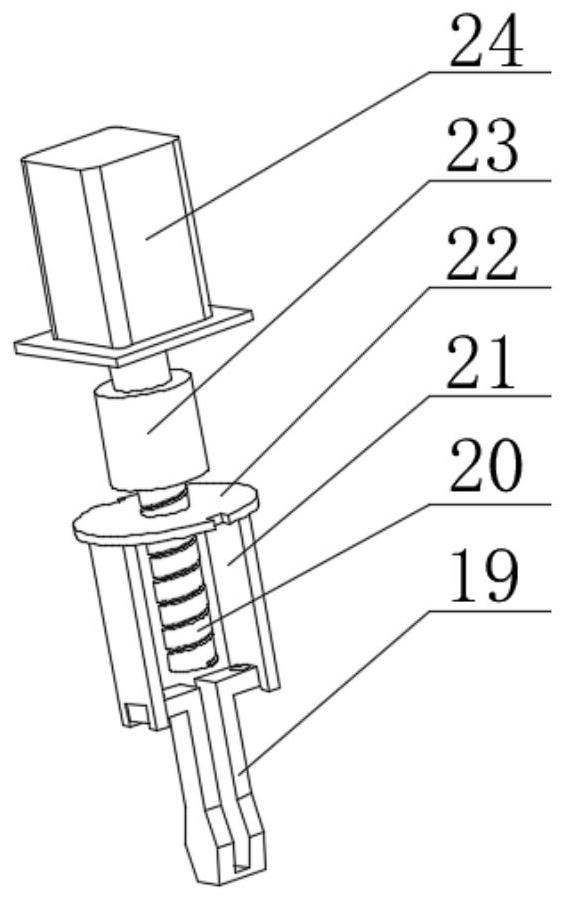

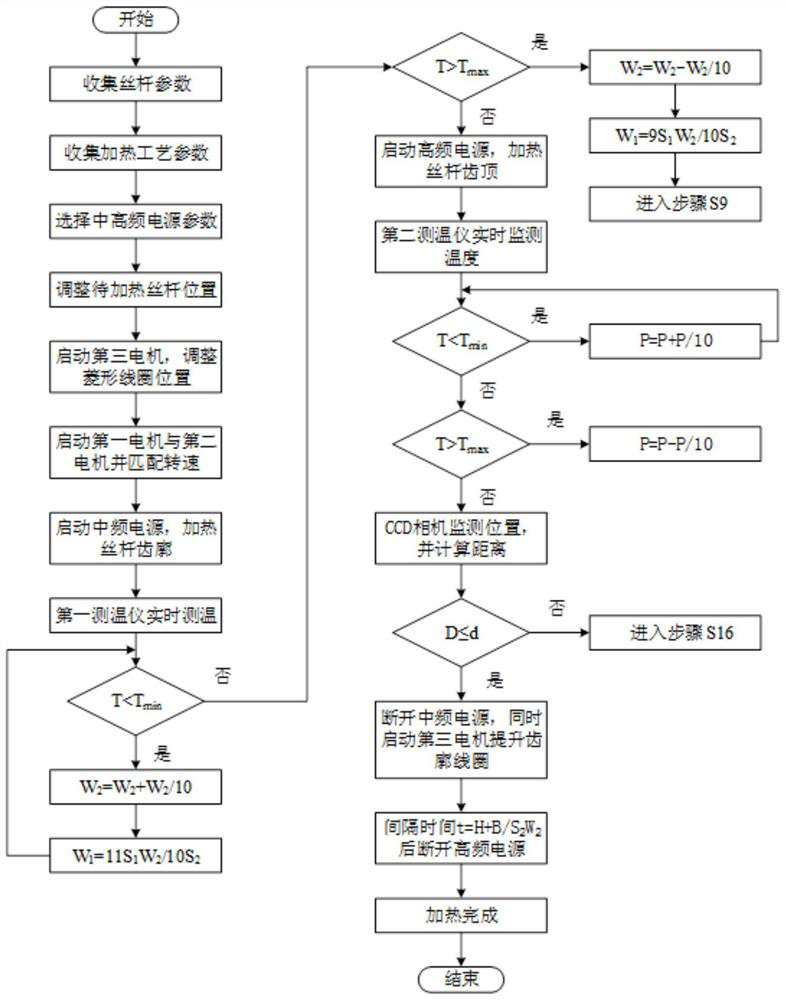

A large diameter and large pitch screw surface induction heating device and surface heating method

ActiveCN113832306BHeating evenlyAdjust the speed in real timeFurnace typesIncreasing energy efficiencyMotor speedHelical coil

Owner:常州市斯比泰机械制造有限公司

Method and device for manufacturing gears together with clamping mechanism

ActiveCN106163694BEase of mass productionReduce manufacturing costGear wheelsEngineeringEntire tooth

The invention relates to a method for producing at least one gear, in particular a helically toothed gear, wherein the gear is produced from a gear blank pressed and sintered with an oversize in the region of the set of teeth, wherein the gear blank has two opposite end faces and a circumference. In the method, the gear blank is clamped in a clamping means. The gear blank is compressed in the region of the oversize by means of the engagement of at least one circumferential tool having a set of mating teeth that engages with the set of teeth of the gear blank, wherein the gear blank is radially clamped over the circumference by the clamping means at both end faces during the compression of the gear blank, wherein each individual tooth of the set of teeth of the gear blank is supported by the clamping means substantially over the entire tooth height. In this way, the quality of the set of teeth can be improved. The invention further relates to a device and to a clamping means.

Owner:GKN POWDER METALLURGY ENG GMBH

Dental calculus removing device for pet dog

Owner:扬州金霞塑胶有限公司

A device for gear manufacturing

ActiveCN111872492BEffectively fixedShorten the timeOther manufacturing equipments/toolsGear-cutting machinesCircular discGear wheel

A device for gear manufacturing disclosed by the present invention includes a frame, and a drilling cavity with an opening to the left is arranged inside the frame, and a hydraulic telescopic rod is fixed at the lower end of the drilling cavity, and the hydraulic telescopic rod The upper end is fixed with a support column, and the support column is provided with an anti-touch cavity with an upward opening. The anti-touch cavity, the present invention can directly process a complete disc, and then complete the machining of the shaft hole and tooth profile of the entire tooth profile through mechanical transmission, and the clamping device provided can effectively fix the gear disc, It reduces the time for people to process and place the inner hole when processing the tooth shape, and improves the processing efficiency.

Owner:扬州进扬耐热钢有限公司

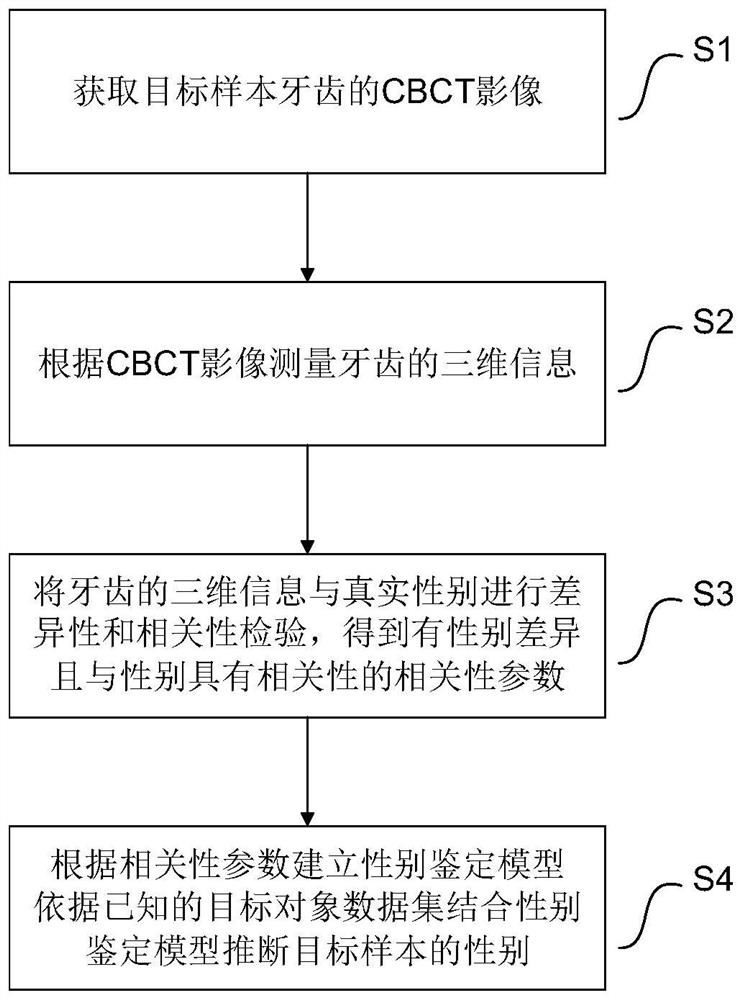

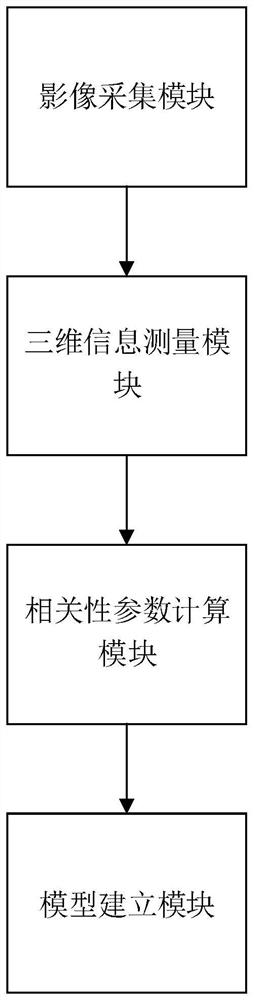

Tooth-based gender inference method, system and device and storage medium

PendingCN114343703AReduce the impactImprove accuracyComputerised tomographsTomographyCbct imagingEntire tooth

The invention discloses a tooth-based gender deduction method, system and device and a storage medium, and the method comprises the steps: obtaining a CBCT image (Cone-beam CT, CBCT) of a target sample tooth; measuring three-dimensional information of the teeth according to the CBCT image; performing difference and correlation test on the three-dimensional information of the teeth and the real gender to obtain correlation parameters with gender difference and gender correlation; and establishing a sex determination model according to the correlation parameters. According to the invention, data measurement based on CBCT is adopted, so that more tooth three-dimensional information can be obtained. According to the method, the tooth volume is adopted as an identification object, the three-dimensional form information of the whole tooth is segmented, the influence of information such as adjacent teeth is reduced to a certain extent, and the identification accuracy is improved.

Owner:西安交通大学口腔医院

Four-wheel-drive vehicle

ActiveUS9925870B2Shorten the switching timeImprove switch reliabilityGearingMagnetically actuated clutchesRotational axisEntire tooth

Owner:TOYOTA JIDOSHA KK

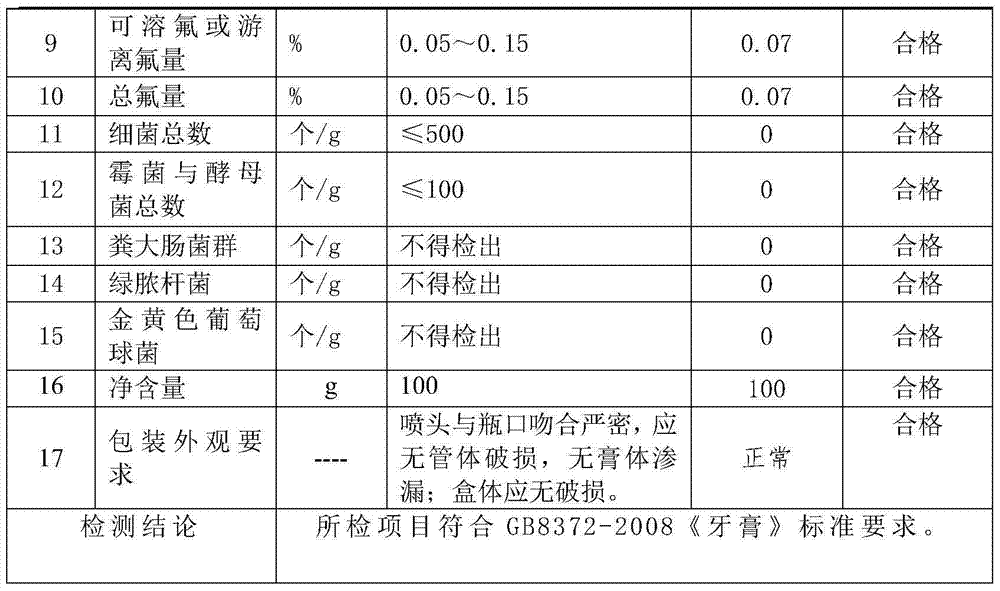

A kind of liquid toothpaste and preparation method thereof

ActiveCN104666185BGrowth inhibitionImprove bleedingAntibacterial agentsCosmetic preparationsBleeding gumBetaine

The invention belongs to the field of daily necessities, and specifically discloses a liquid toothpaste and a preparation method thereof. The liquid toothpaste is composed of xylitol, vitamin C, cetylpyridinium chloride, sodium fluoride, natural betaine, sodium phytate, traditional Chinese medicine extract, sodium lauryl sulfate, sodium lauroyl sarcosinate, glycerin, sorbitol , silicon dioxide, essence, cooling agent, preservative, sweetener, edible gum and water. The toothpaste exists in a liquid form, so that the active ingredients in the product can smoothly reach the various surfaces of the oral cavity and quickly penetrate into the crevices of the teeth, covering the entire teeth. It can effectively sterilize, inhibit bacterial growth, remove dental plaque, prevent caries, and can effectively improve gum and periodontal problems such as bleeding gums, gum pain, gum swelling, and bad breath, protect the oral cavity, and make teeth white and healthy.

Owner:CHENGDU ROSUN DISINFECTION PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com