Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

201results about How to "Little change in viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery slurry, preparation method of the lithium ion battery slurry, and lithium ion battery

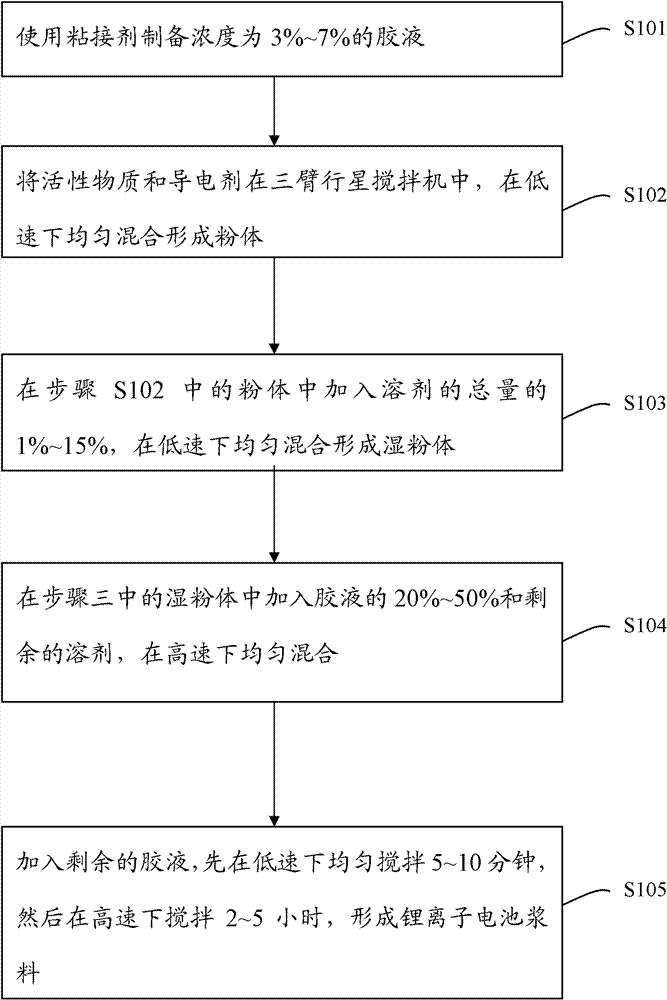

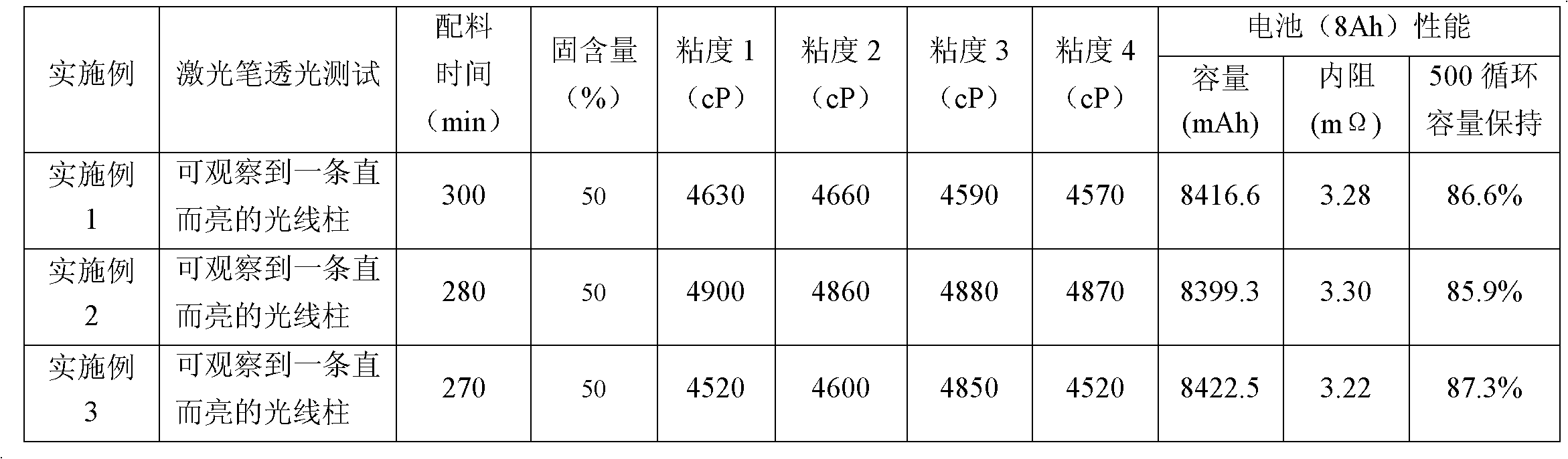

The invention discloses a preparation method of lithium ion battery slurry. The preparation method comprises the following steps of 1, preparing a glue solution having a concentration of 3 to 7% by an adhesive, 2, putting one or more active substances and one or more conducting additives into a three-arm planetary stirrer, and uniformly mixing the mixture into powder at a low speed, 3, adding 1 to 15% of a solvent into the powder obtained by the step 2, and uniformly mixing the mixture into wet powder at a low speed, wherein a ratio of the total mass of the solvent to the mass of the powder is in a range of (55: 4) to (50: 50), 4, adding 20 to 50% of the glue solution and the rest of the solvent into the wet powder, and uniformly mixing at a high speed, and 5, adding the rest of the glue solution into the mixture obtained by the step 4, uniformly stirring at a low speed for 5 to 10 minutes, and then stirring at a high speed for 2 to 5 hours to obtain the lithium ion battery slurry. The invention also discloses the lithium ion battery slurry and a battery pole piece prepared by the preparation method, and a lithium ion battery.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

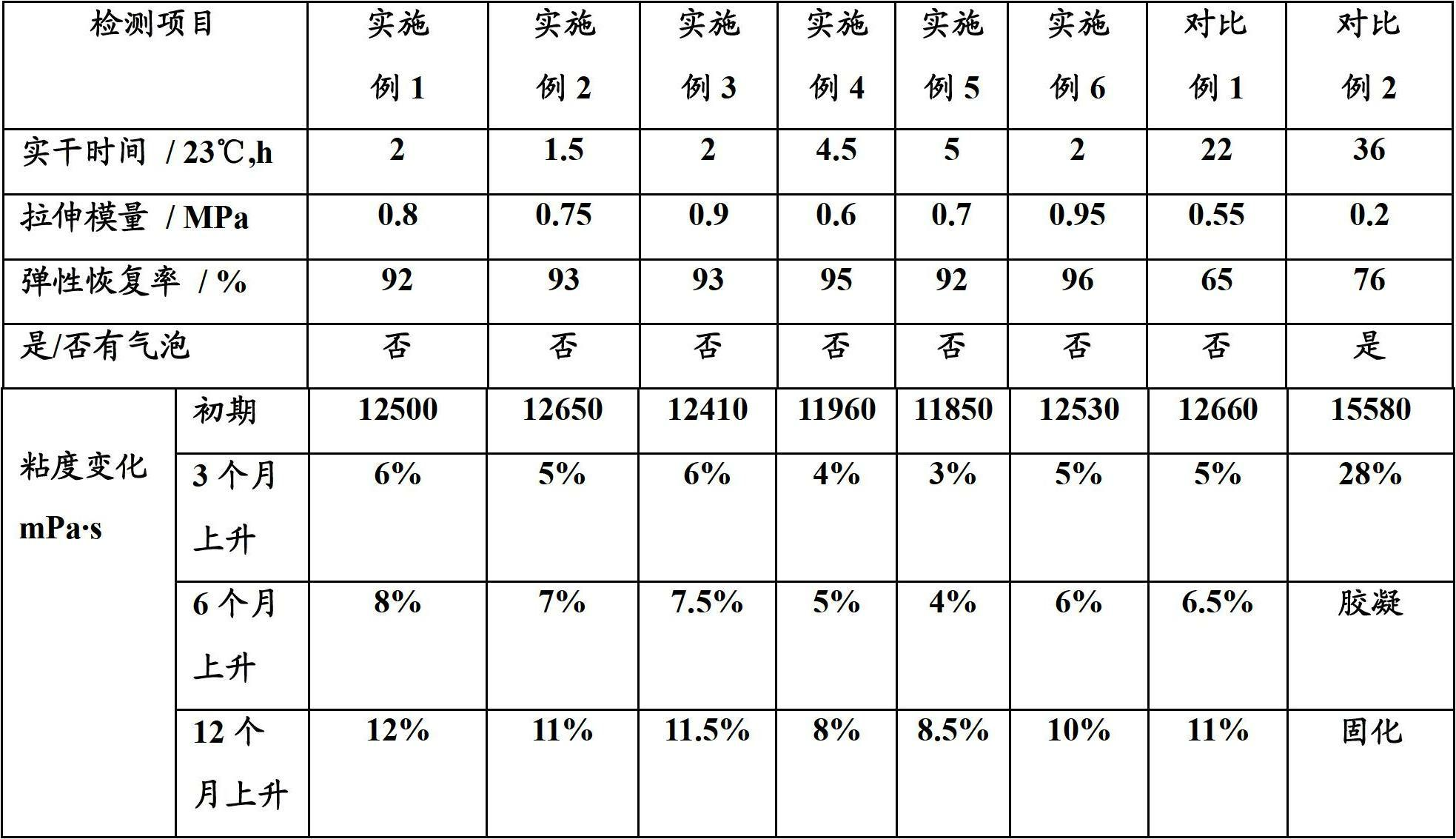

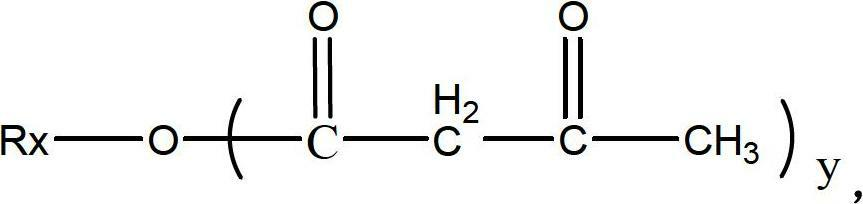

Single-component polyurethane sealant capable of quickly curing moisture and preparation method thereof

ActiveCN102690626AFast curingWon't foamNon-macromolecular adhesive additivesOther chemical processesAcetoacetatesCyclodextrin

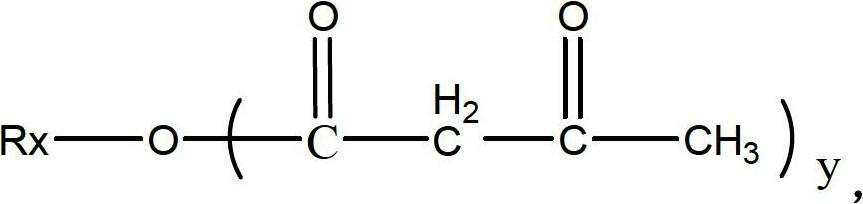

The invention relates to a single-component polyurethane sealant capable of quickly curing moisture and a preparation method thereof. The polyurethane sealant comprises the following raw materials in percentage by weight: 10 to 20 percent of polyisocyanate monomer, 20 to 45 percent of polyether polyol, 1 to 10 percent of acetoacetic ester sealed end polyether prepolymer, 5 to 20 percent of plasticizer, 25 to 40 percent of modified mineral powder, 1 to 5 percent of latent curing agent, 0.1 to 2 percent of cyclodextrin wrapped environment-friendly catalyst, 0.1 to 1 percent of defoaming agent and 0.1 to 1 percent of water-removing agent, wherein the water-removing agent is one or more of mono-isocyanate compound or functionalized silane compound. The single-component polyurethane sealant avoids bubble fundamentally, can be quickly cured, is stable in storage, and can be applied to construction on damp interfaces.

Owner:苏州中材非金属矿工业设计研究院有限公司 +1

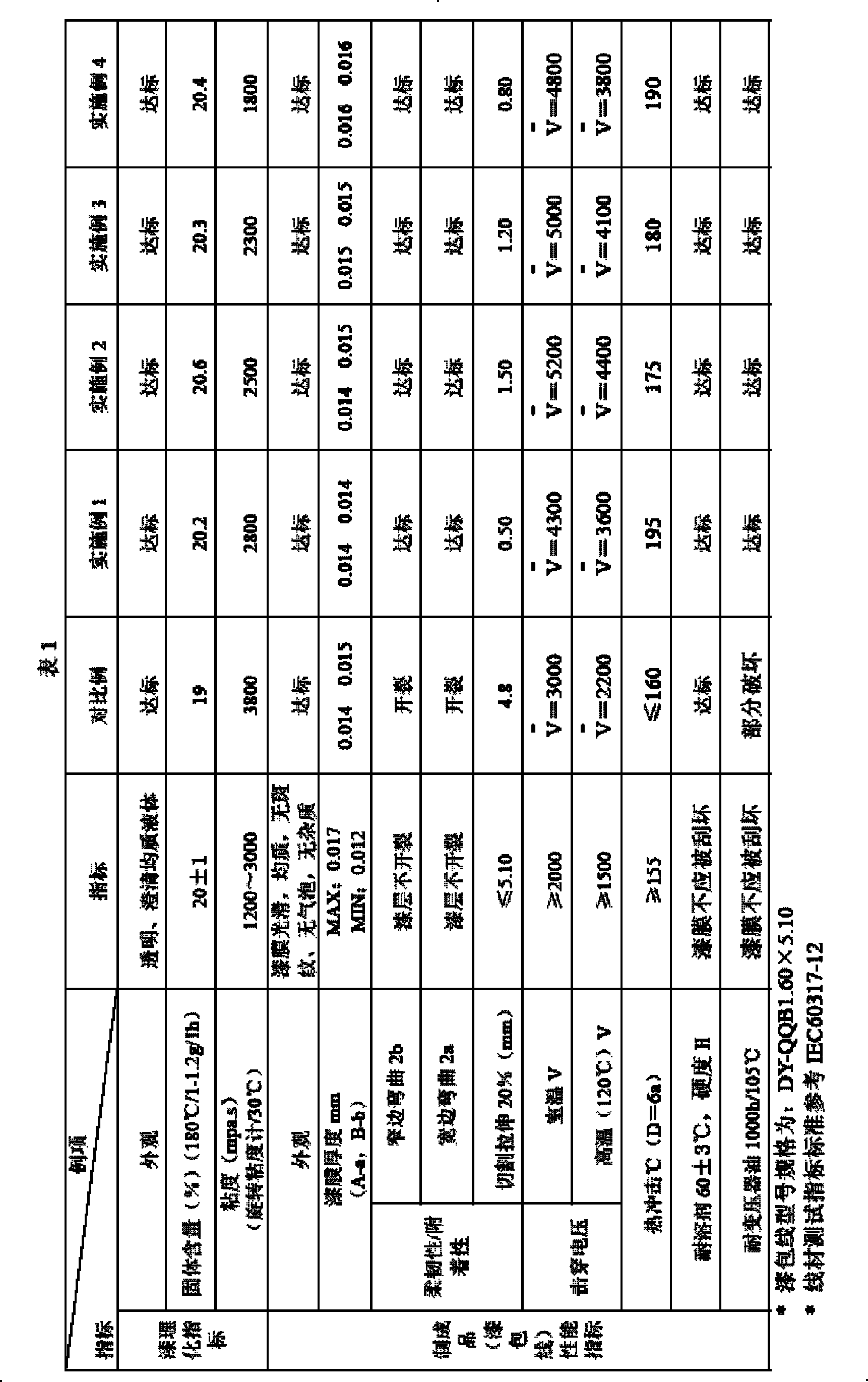

Preparation method of heat resistant acetal wire enamel

InactiveCN101891994AAvoid Solvent OdorsStrong process adaptabilityEpoxy resin coatingsHot stampingMelamine resin

The invention relates to acetal wire enamel meeting the heat level of 155 DEG C and above, which has good coating film and conductor adhesion. The heat resistant acetal wire enamel comprises the following components: 280-310 parts of methylphenol, 390-450 parts of dimethylbenzene, 100-160 parts of butanol, 100-125 parts of polyvinyl acetal resins, 57-65 parts of novolac epoxy resins, 28-34 parts of organic silicon resins, 4-7 parts of melamine resins and 0.08-0.15 of leveling agents by mole. The method has the following advantages: 1. in the subsequent wire enamel baking process, the process is easy to control, the molecular weight is uniform and the consistency is good; 2. the peculiar smell generated under normal temperature and during baking is reduced; 3. the product is stable in storage; 4. the coating processability is good and the prepared product has bright, clean and uniform surface; and 5. the heat resistance class of the prepared product is not less than 155 DEG C (F class), the hot stamping temperature thereof is not less than 180 DEG C and the cut-through temperature thereof is not less than 240 DEG C; and the prepared product has excellent medium resistance and excellent adhesion.

Owner:溧阳市佳禾电子材料有限公司

Emulsified asphalt waterproof coating for road bridge and preparation method thereof

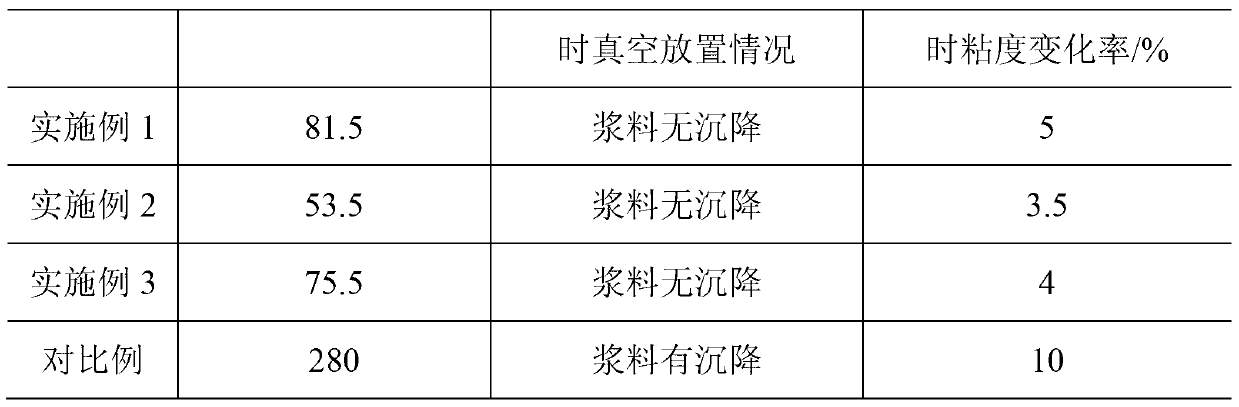

ActiveCN108285743AGood storage stabilityLittle change in viscosityBituminous coatingsEmulsionFoaming agent

The invention discloses an emulsified asphalt waterproof coating for a road bridge and a preparation method thereof. The emulsified asphalt waterproof coating for the road bridge comprises the following components in parts by weight: 3-18 parts of water, 5-50 parts of a fine powder, 0.01-0.1 part of a pH regulating agent, 0.01-0.1 part of hydroxymethyl celluloses, 0.1-1 part of a dispersing agent,0.05-0.5 part of a wetting agent, 0.005-0.2 part of a de-foaming agent, 0.5-5 part of adhesion aid, 0.8-1.5 parts of film forming aid, 0.5-10 parts of fast drying aid, 0.05-0.5 part of a stabilizingagent, 0.3-1.5 parts of a thickening agent, 30-70 parts of emulsified asphalt, 5-30 parts of an acrylic emulsion and 2-30 parts of high polymer latex. The prepared emulsified asphalt waterproof coating for the road bridge is high storage stability, high in product drying speed and stronger in adhesion to a substrate.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Method for preparing low-chromatic number isocyanate and isocyanate prepared by same

ActiveCN102718683AGood stabilityLittle change in viscosityIsocyanic acid derivatives purification/separationChemistryIsocyanate compound

The invention relates to a method for preparing low-chromatic number isocyanate containing a carbodiimide and / or uretonimine group capable of being stored in a liquid state and the isocyanate containing the carbodiimide and / or uretonimine group capable of being stored in the liquid state prepared by the method. The method comprises the following steps of: a) reacting an isocyanate group of the raw material isocyanate under the action of a cyclopentene phosphine catalyst to obtain isocyanate reaction liquid partially catalyzed by carbodiimide; and b) adding an anhydride terminating agent into the reaction liquid obtained from the step a) and terminate carbodiimide reaction. The liquid isocyanate prepared by the method has the advantages of low chromatic number and good storage stability.

Owner:WANHUA CHEM GRP +1

High concentration silica slurry

InactiveUS7192461B2High silica concentrationLow viscosityPigmenting treatmentSilicaSolventHigh concentration

A high concentration silica slurry can be used for polishing of substrates, such as semiconductor materials. The slurry contains a silica powder dispersed in an solvent. The silica slurry has a silica concentration of more than 50% by weight and a viscosity of less than 1000 mPa·s, wherein the silica powder has a ratio DL / DT of less than 1.3, wherein DL is an average particle size of the silica powder measured by a laser diffraction particle size distribution method and DT is an average primary particle size of the silica powder measured by a TEM photography observation, and wherein the silica powder has an average primary particle size of from 0.08 μm to 0.8 μm.

Owner:NIPPON AEROSIL

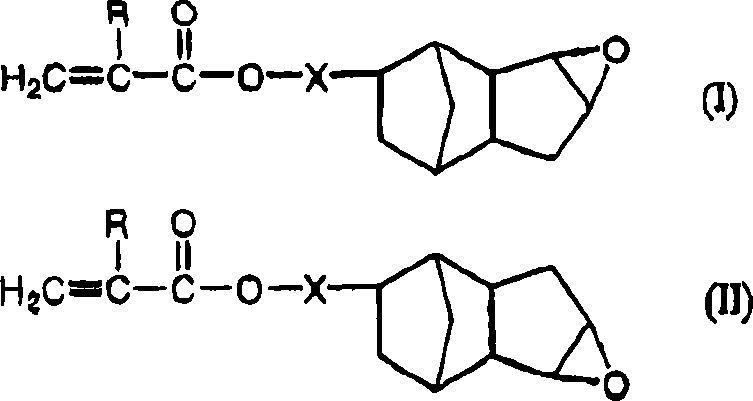

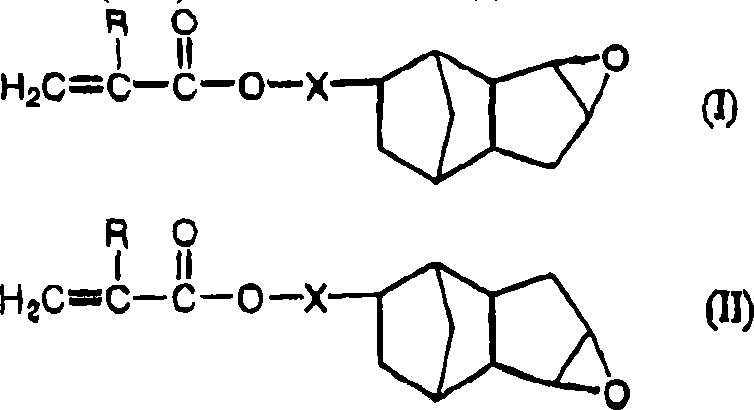

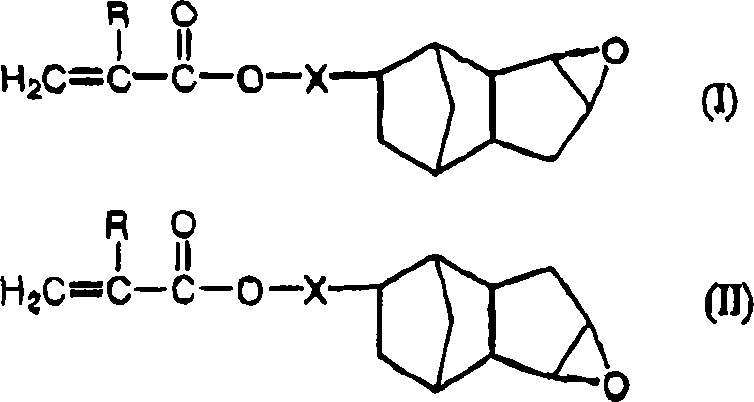

Coloring photosensitive resin composition

ActiveCN101100543ALittle change in viscosityGood solvent resistancePhotosensitive materials for photomechanical apparatusNon-linear opticsDouble bondSolvent

The present invention discloses a coloring photosensitive resin composition, which comprises substrate resin (A), coloring agent (B), photopolymerization compound (C), initiators for photopolymerization (D) and impregnant (E), wherein the substrate resin (A) comprises a structure unit obtaining from a monomer (A1) which is arranged with carbon-carbon double bonds and aliphatic polycyclic epoxides, and a structure unit obtaining at least from one monomer (A2) of unsaturated carboxylate and unsaturated carboxyl anhydride.

Owner:SUMITOMO CHEM CO LTD

Coating composition and optical diffusion film

ActiveCN102925036AImprove stabilityLittle change in viscosityDiffusing elementsPolyurea/polyurethane coatingsCelluloseUltraviolet

The invention relates to a coating composition and an optical diffusion barrier. The coating composition contains the following components in parts by weight: 40-70 parts of thermosetting resin or ultraviolet curing resin, 50-180 parts of diffusion particle, 2.0-10 parts of cross-linking agent or photoinitiator, 0.10-2 parts of leveling agent, 10-60 parts of cellulose ester and 100-300 parts of solvent. The coating composition has the advantages of high stability, and no aggregation or precipitation among particles; and the viscosity variation of the coating composition is slight. The coating of the optical diffusion film containing the coating composition is uniform, the coating surface does not have the defects of lines, white spots, liquor lines, transparent spots and the like, and thus, the optical diffusion film can satisfy the demands for backlight modules.

Owner:昆山乐凯锦富光电科技有限公司

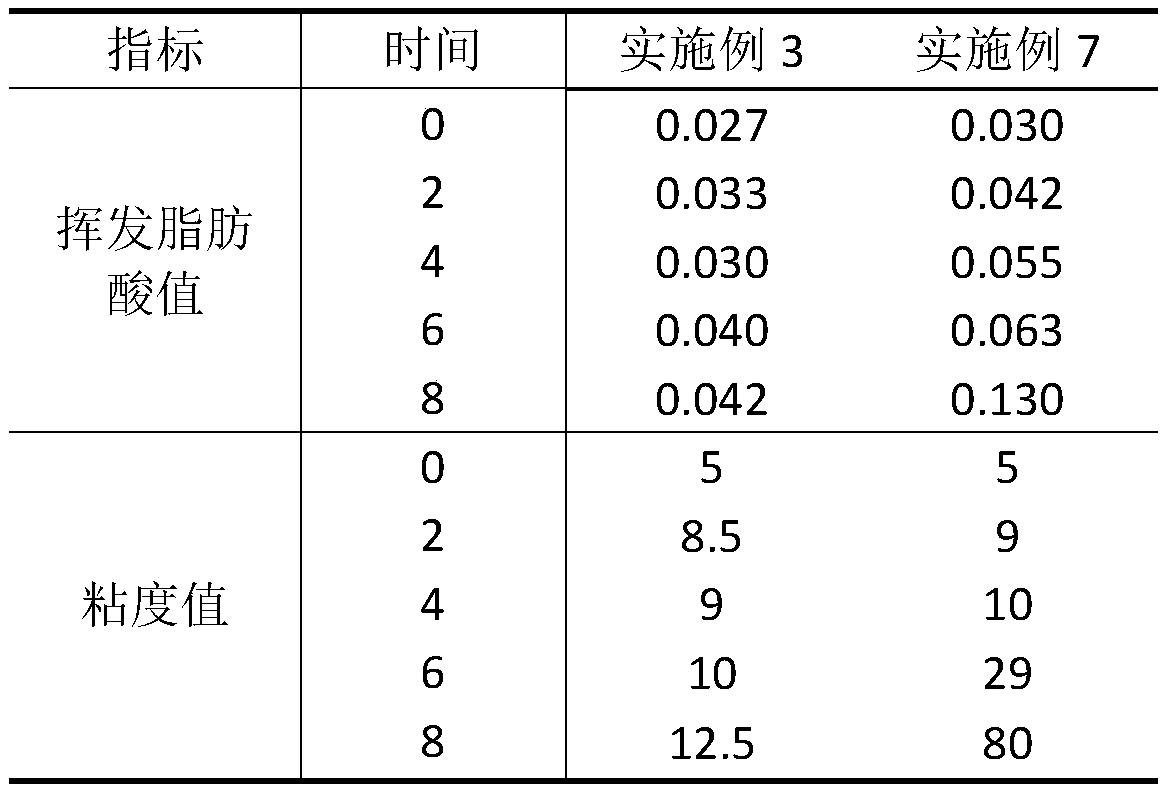

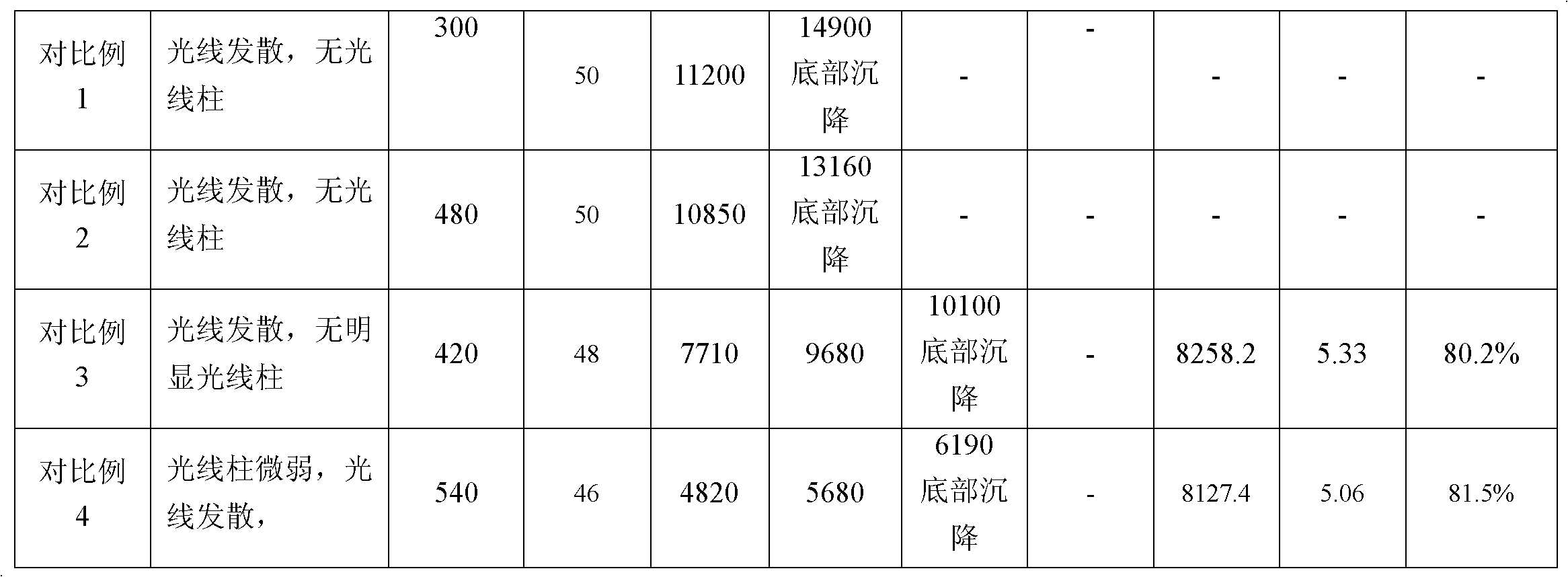

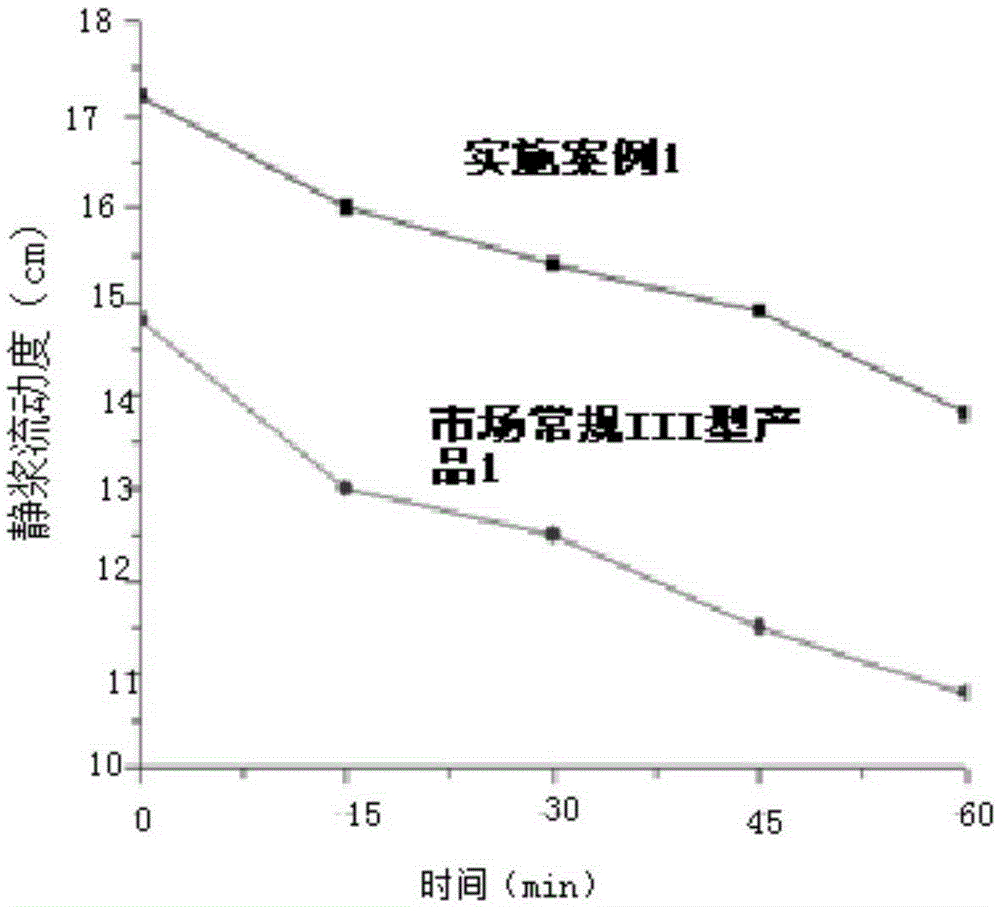

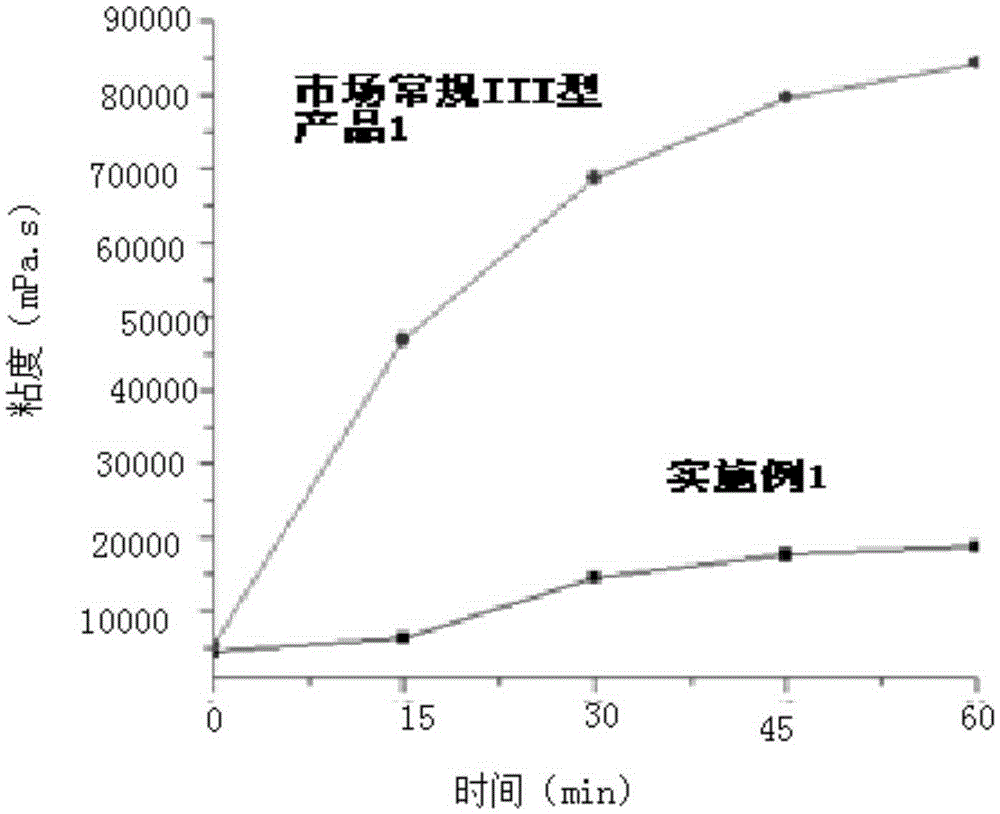

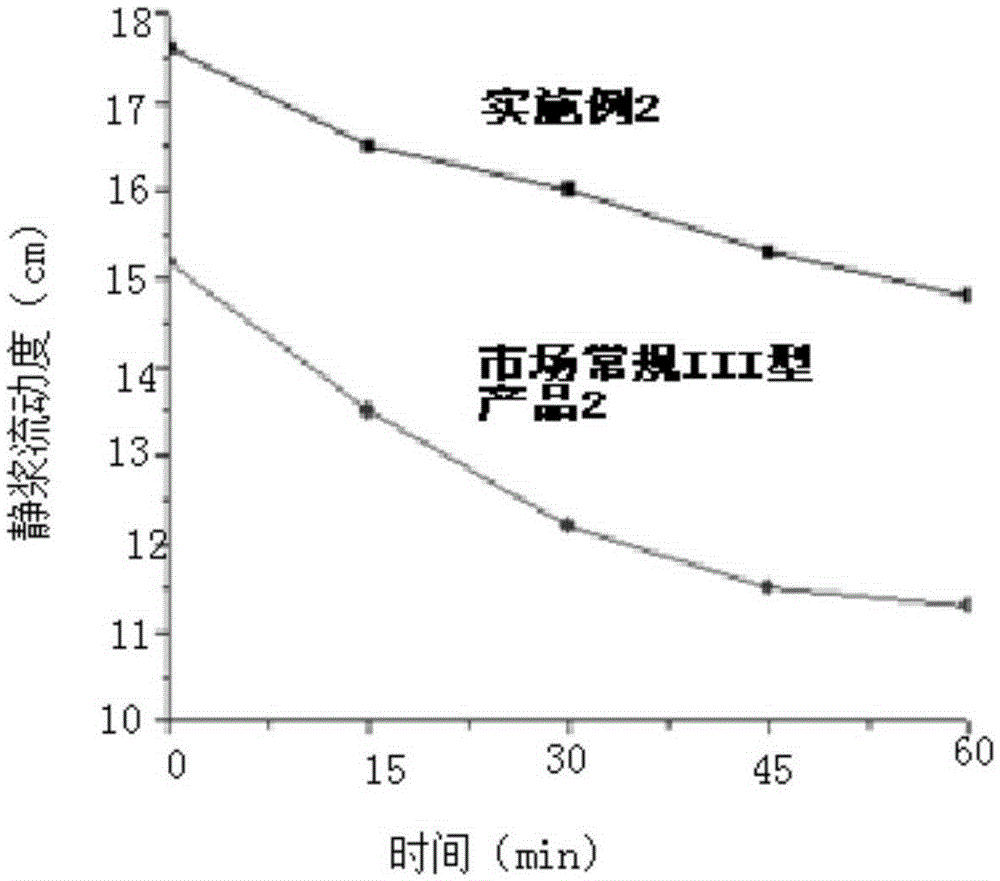

Type II polymer cement waterproof coating and preparation method thereof

The present invention discloses a type II polymer cement waterproof coating and a preparation method thereof. The type II polymer cement waterproof coating comprises liquid material and powder material, the ratio of liquid material to powder material is 1: 1.2 by mass. A liquid material formulation includes the following ingredients by weight percentage: 75-85% of VAE emulsion, 3.5-10% of plasticizer, 0.05-0.25% of starch ethers, 0.83-1.18% of mixed acetic acid esters and 10-14% of water; a powder material formulation includes the following ingredients by weight percentage: 25-35% of cement, 15-25% of quartz powder, 45-55% of wollastonite powder and 0.05-0.2% of water reducing agent. The type II polymer cement waterproof coating of the present invention is free of sags in building elevation construction, is not liable to crack in rough surface construction, and performs well in bonding with a base layer and the like.

Owner:SHANGHAI ORIENTAL YUHONG WATERPROOF TECH

Lead-Free Solder Alloy

ActiveUS20140141273A1Excellent drop impact resistanceGood thermal cycle performanceSolid-state devicesWelding/cutting media/materialsDrop impactThermal fatigue

By using a solder alloy consisting essentially of 0.2-1.2 mass % of Ag, 0.6-0.9 mass % of Cu, 1.2-3.0 mass % of Bi, 0.02-1.0 mass % of Sb, 0.01-2.0 mass % of In, and a remainder of Sn, it is possible to obtain portable devices having excellent resistance to drop impact and excellent heat cycle properties without developing thermal fatigue even when used in a high-temperature environment such as inside a vehicle heated by the sun or in a low-temperature environment such as outdoors in snowy weather.

Owner:SENJU METAL IND CO LTD

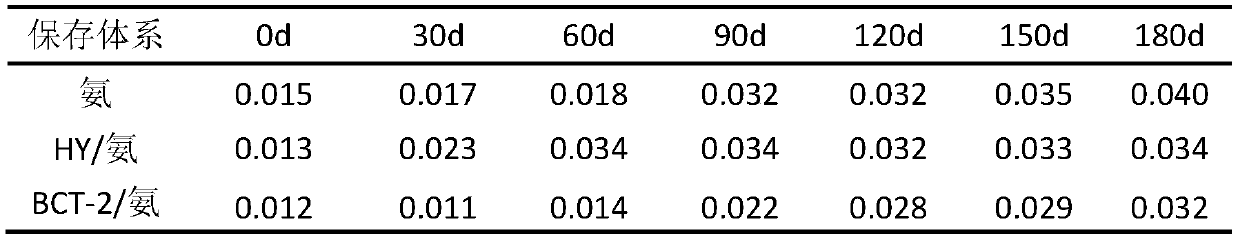

Application of low-ammonia or zero-ammonia latex in natural latex foamed product

The invention relates to the field of rubber products, and concretely relates to an application of low-ammonia or zero-ammonia latex in a natural latex foamed product. The invention also provides thenatural latex foamed product. The natural latex foamed product is prepared from, by weight, 100 parts of the latex, 2-3 parts of a vulcanizing agent, 0.5-3 parts of a foaming agent, 0.5-1.5 parts of agelling agent, 3-5 parts of an activator, 3-12 parts of an assistant and 20-100 parts of a filler. The natural latex foamed product has the advantages of excellent foam stability, uniform cell size,structured and stable hole structure and few internal defects, and produced sponge products have the advantages of large permanent compression set, low tensile strength, low elongation at break, and significantly improved resilience rate.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

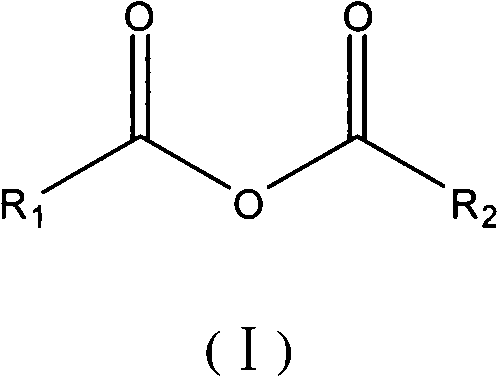

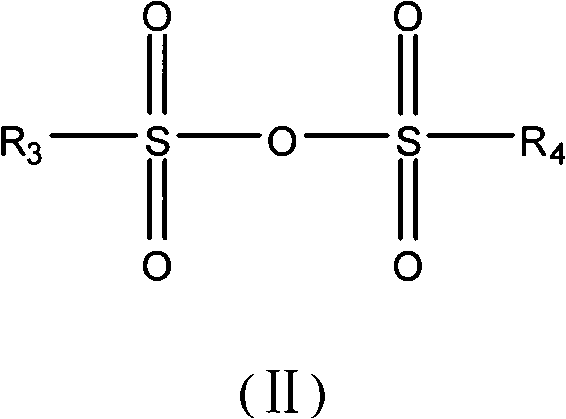

Light color modified isocyanate mixture and preparation method thereof

ActiveCN107879951AGood storage stability at room temperatureGroup content decreasedIsocyanic acid derivatives purification/separationHigh temperature storageSilanes

The invention relates to a light color modified isocyanate mixture and a preparation method thereof. The method comprises the following steps: (a) carrying out reaction on isocyanate groups of the rawmaterial isocyanate in the presence of phosphorus-heterocycle catalysts, and finally obtaining a modified isocyanate reaction solution containing carbodiimide and / or uretonimine derivatives; and (b)adding a terminating agent compounded from halogenated silane organic matters and sulfonic anhydrides into the reaction solution obtained in the step a so as to terminate the carbodiimide reaction. The modified isocyanate prepared by the method has the characteristics of normal-temperature liquid and normal temperature and high temperature storage stability and low color number.

Owner:WANHUA CHEM GRP CO LTD

Electrolyte resistant antipermeation synthetic printing thickener and its preparation method and application

This invention discloses an ionization resistant, impervious composite printing thickener and its manufacturing method and application, which is got through co polymerization of such unsaturated acids as a-alkyl acrylic acid polyoxyethylene ester, acrylic acid, methacrylic acid and such unsaturated monomers as acrylamide and butyl acrylate in mixed solution of water and solvent naphtha by antiphase latex. When the thickener in this invention is applied in pigment printing color paste, it assumes advantages of high thickening ability, strong ionization resistance and no oozing, and besides it can be applied in thickening white coat, black coat and color paste, the prepared printing color paste not oozing or gelling.

Owner:SICHUAN TEXTILE SCI RES INST +1

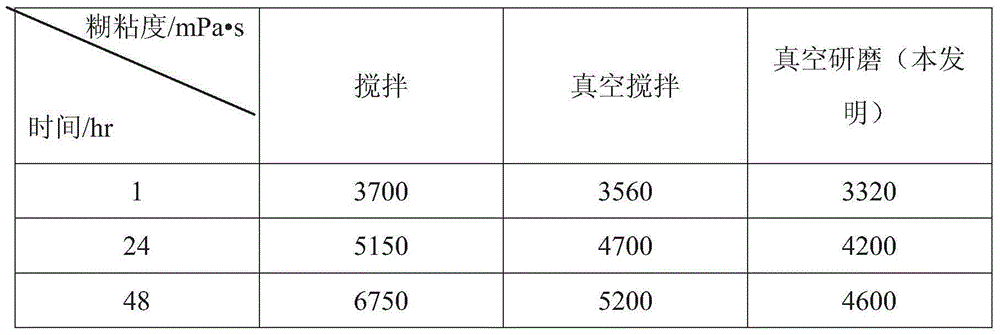

Preparation method of paste material of PVC paste resin

InactiveCN104673138ALittle change in viscosityAccelerated agingNon-macromolecular adhesive additivesPolymer sciencePlasticizer

The invention provides a preparation method of a paste material of PVC paste resin. The preparation method is technically characterized by comprising the following steps: firstly weighing PVC paste resin, a plasticizer and a stabilizer in parts by weight, sequentially adding into a mortar, and manually dispersing the materials at normal temperature with a brayer for 3-10min, thus finishing the first plastification process; regulating the rotating speed of a vacuum grinder to 50-130rpm, dispersing the materials in the mortar at normal temperature with the brayer, and starting a vacuum pump at the same time for grinding in vacuum for 10min, thus finishing the second plastification process and obtaining a finished product; weighing a certain amount of the finished product paste material, putting into a test cup, putting the test cup into a 30 DEG C thermostatic water bath, standing still at a constant temperature for 1hr, and then testing the viscosity. Through vacuum grinding, the stability of the paste material is improved, and then the disintegration of secondary particles of the PVC paste resin can be accelerated, so that the paste material of PVC paste resin with relatively stable time-dependent behavior can be obtained.

Owner:SHENYANG CHEM IND CO LTD

Method of catalyzing esterification of carboxylic acid and expoxy compound

InactiveCN1425642AImprove catalytic selectivityNo ring-opening self-polymerization reactionOrganic compound preparationCarboxylic acid esters preparationEpoxyReaction temperature

The present invention rlates to the method of catalyzing esterification of carboxylic acid and epoxy compound with acetylacetone-based metal complex as catalyst in the reaction temperature of 70-140 deg.c. The said method can catalyze esterification, alone or corporated, of saturated or unsaturated carboxylic acid and epoxy compound in which catalytic efficiency and selectivity without promoting the ring-opening polymerization of epoxy radical. The said method can wide application foreground in industrial production.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

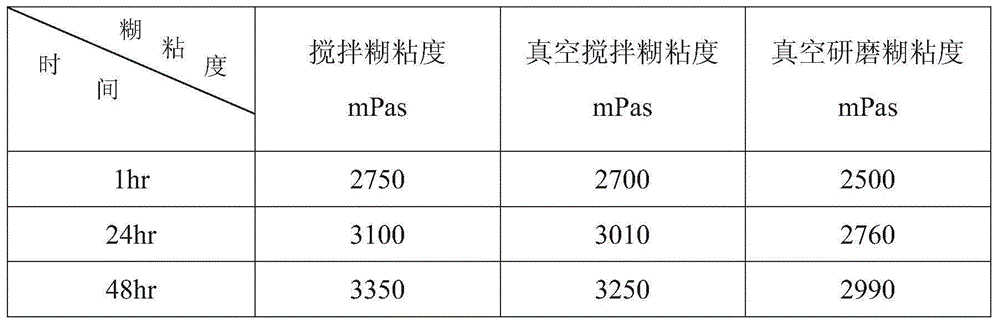

Li-ion positive electrode slurry and preparation method thereof

InactiveCN103346318AEvenly dispersedSolve the defect of easy reunionCell electrodesLithium iron phosphatePyrrolidinones

The invention provides a Li-ion positive electrode slurry and a preparation method thereof. The preparation method comprises the following steps of: mixing lithium iron phosphate and dry inorganic conductive agent powder, wherein uniform mixing is judged by randomly sampling and measuring the resistance value of the powder, and is considered to be achieved when the difference of the resistance value of each sample powder is less than 5%; then adding PVDF (Polyvinylidene Fluoride) colloidal fluid into the mixture step by step; finally regulating the viscosity of the slurry by utilizing 1-Methyl-2-pyrrolidinone, thereby obtaining the Li-ion positive electrode slurry. The viscosity of the Li-ion positive electrode slurry is 3000-5000cps, and the Li-ion positive electrode slurry comprises 1-methyl-2-pyrrolidinone, as well as lithium iron phosphate, polyvinylidene fluoride and the inorganic conductive agent which are at a mass ratio of (85-95):(3-8):(2-10). According to the preparation method, whether the inorganic conductive agent is uniformly dispersed in lithium iron phosphate is determined by a method of randomly sampling dry powder, mixing samples and measuring the resistance values, and meanwhile, the PVDF colloidal fluid is added step by step in a substep slurry preparation process, so that the conventional thought of firstly mixing solid materials and adding the colloidal fluid in one step in a slurry preparation process in the field is broken through, and a favorable slurry preparation effect is achieved.

Owner:IRICO

Preparation method and usage method of low-viscosity flame-retardant heat-conducting solvent-free polyurethane electronic-pouring sealant

ActiveCN107216846AImprove flame retardant performanceLow viscosityNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsPolymer scienceIn situ polymerization

The invention discloses a preparation method and a usage method of a low-viscosity flame-retardant heat-conducting solvent-free polyurethane electronic-pouring sealant. The electronic-pouring sealant comprises a component A and a component B, wherein the component A is prepared by means of the following process: adding 100 parts of castor oil, 5 to 15 parts of flame retardant, 1 to 5 parts of high heat conductive insulation composite powder and 0.05 to 3 parts of an anti-foaming agent into a reaction kettle in parts by mass, performing uniform mixing and vacuum dehydration, then adding 0.05 to 0.3 part of a catalyst, and performing uniform mixing to obtain the component A; and the component B is liquefied diphenylmethylene diisocyanate. In the invention, a high heat conductive insulation composite powder heat conduction technology, a polyurethane in-situ polymerization self-flame-retardant technology and a thermal sensitive catalyst asynchronous catalysis technology are adopted, the product viscosity is smaller than 6000mPa.s, the heat conduction coefficient is greater than 1.85W / MK, the volume resistivity is greater than 4.2*10<12>omega.m, and the flame retardant property can be up to the American FMVSS302 standard.

Owner:SHAANXI UNIV OF SCI & TECH

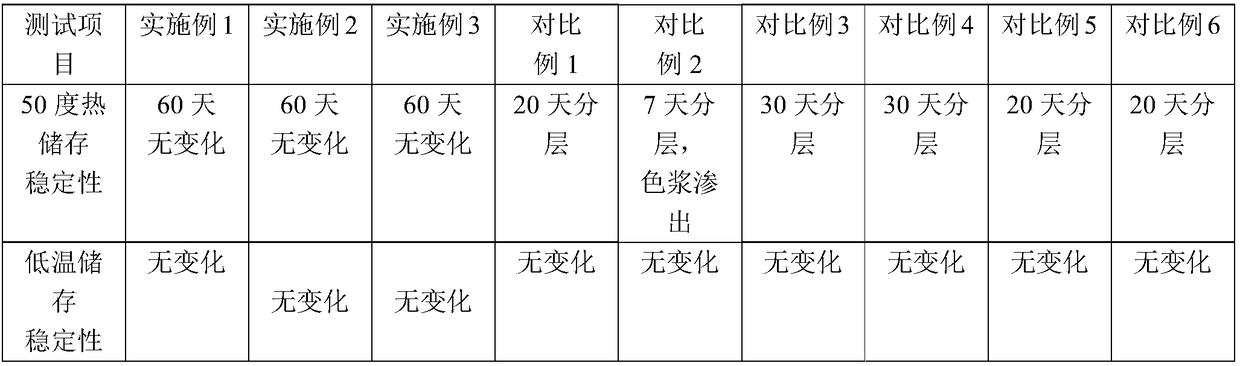

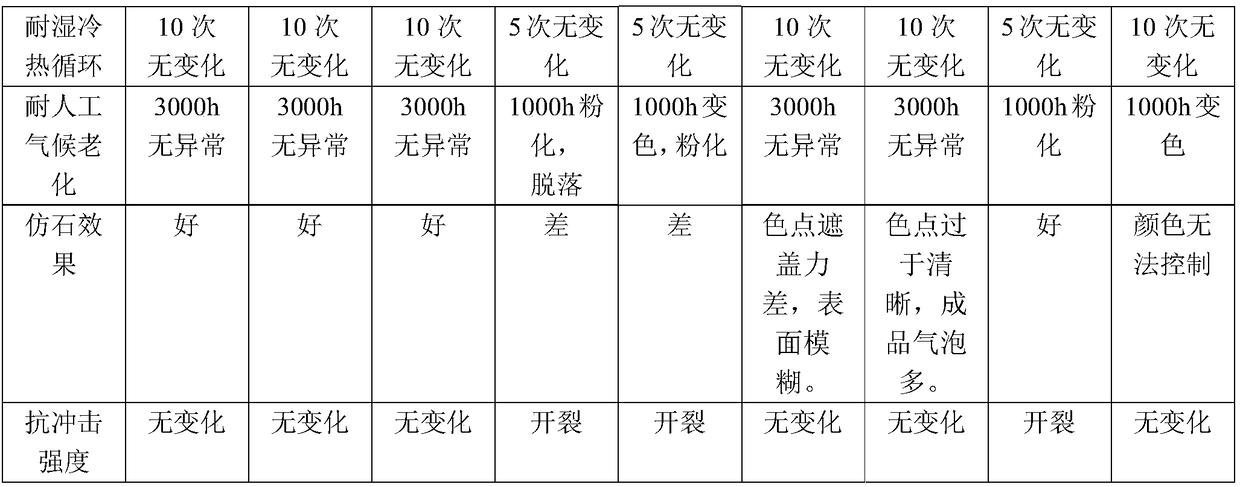

Stone-imitating coating and preparation method thereof

The invention provides a stone-imitating coating and a preparation method thereof. The stone-imitating coating includes, by weight, 300-500 parts of deionized water, 2-3 parts of a sterilizing agent,2-5 parts of cellulose, 1-2 parts of a dispersant, 2-4 parts of a defoaming agent, 7-10 parts of a film forming additive, 7-10 parts of propylene glycol, 1-3 parts of a pH regulator, 150-200 parts ofa binder, 2-4 parts of a thickener, 300-500 parts of sintered colored sand, and 5-15 parts of protective glue. The sintered colored sand is made from quartz sands in 40-120 meshes, toner percentage being 0.8-1.2%. By using the sintered colored sand instead of calcium carbonate sand, regulating raw material ratio and optimizing process parameters, the coating has excellent performance, good stability and good anti-aging effect. The preparation method has simple process and can achieve industrial large-scale production; the product brings excellent economic benefit to enterprises and has extensive prospect.

Owner:上海贝塔建筑科技有限公司

Method for applying paper-making process reconstituted tobacco filler

ActiveCN106235374ALittle change in viscosityEnsure stabilityTobacco preparationChemistryTobacco product

A method for applying paper-making process reconstituted tobacco filler comprises the following steps that 1, a reconstituted tobacco coating solution is prepared; 2, calcium carbonate, alumina, talcum powder, bentonite, an assistant guar gum, chitosan, gelatin and vinyl acetate are mixed to be uniform according to a certain proportion; 3, a mixture obtained after the filler and the assistant are mixed is added into the coating solution and dispersed to be uniform; 4, a reconstituted tobacco product substrate is coated with the coating solution, and the finished reconstituted tobacco is obtained through drying and slitting. Starting from paper-making process reconstituted tobacco production, a filler application technical scheme is systematically provided, the prepared reconstituted tobacco product is close to natural tobacco, the viscosity change of the coating solution in the reconstituted tobacco production process is small, the stability of the coating rate is guaranteed, the running stability and the filler utilization rate of a reconstituted tobacco production line are improved, and the production cost is reduced. The method cannot bring negative influences to the sensory quality of the product.

Owner:HENAN CIGARETTE IND TOBACCO SLICE

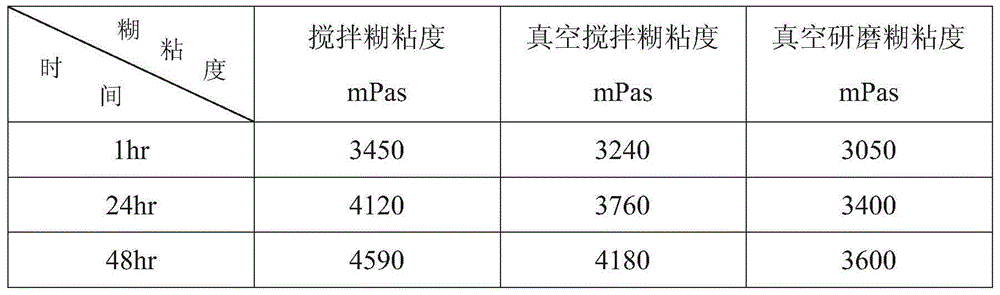

Burdening technology for slurry used by nanometer ferrous phosphate lithium ion battery

The invention relates to a burdening technology for slurry used by a nanometer ferrous phosphate lithium ion battery. Nanometer ferrous phosphate lithium ion, conductive agent, binder and N-methyl pyrrolidone are prepared into primary slurry; the primary slurry is stirred and dispersed for 60-90 minutes in a reciprocating mode between a stirring pot and a dispersion machine to obtain the slurry used by the nanometer ferrous phosphate lithium ion battery; and the linear velocity of the dispersion machine is 35-45m / s. The slurry prepared with the burdening technology disclosed by the invention can be evenly dispersed. The viscosity of the slurry slightly changes with the extending of placing time, and performance is stable. The lithium ion battery prepared by the slurry has the advantages of excellent electrochemistry performance, high retention rate of capacity-grading volumes and low resistance.

Owner:HUNAN FENGYUAN YESHINE KINGCO NEW ENERGY

Easily-coating type flexible waterproof slurry and preparation method thereof

ActiveCN105236885AImprove adhesionGuaranteed performance and waterproof effectBonding strengthPolyvinyl alcohol

An easily-coating type flexible waterproof slurry and a preparation method thereof are disclosed and belong to the technical field of waterproof coatings. The slurry comprises a composition A and a composition B, and mainly comprises the following compositions: some kinds of a polymer emulsion, an antifoaming agent, a dispersant, quartz powder, quartz sand, ash concrete and polyvinyl alcohol. The composition A comprises 80-90 parts by weight of the polymer emulsion, 1-3 parts by weight of the antifoaming agent, 0.3-0.5 part by weight of the dispersant, 0.1-1 part by weight of an antiseptic, and 1-2 parts by weight of a mildew inhibitor. The composition B comprises 40-60 parts by weight of ash concrete, 30-45 parts by weight of quartz sand, 10-15 parts by weight of quartz powder, 0.02-0.05 part by weight of polyvinyl alcohol, and 0.5-1 part by weight of the water reducer. The easily-coating type flexible waterproof slurry possesses excellent construction performance, settlement resistance, bonding strength, waterproof effect and cracking resistant function.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH

High-covering black UV silkscreen printing ink

The invention discloses a high-covering black UV silkscreen printing ink. A preparation method for the high-covering black UV silkscreen printing ink comprises the following steps: preheating acrylate and then mixing the preheated acrylate with a part of active monomer; then adding a dispersant and carrying out primary dispersion; then successively adding pigment and a filling material and carrying out secondary dispersion; carrying out grinding to obtain color paste; mixing a phosphine oxide photoinitiator with residual active monomer; and adding the color paste, an organosilicon antifoaming agent and an organosilicon leveling agent and carrying out uniform dispersion so as to obtain the high-covering black UV silkscreen printing ink. The high-covering black UV silkscreen printing ink provided by the invention is reasonable in composition; all the components are in good compatibility; and the prepared printing ink has excellent comprehensive properties and good storage performance, and the viscosity of the printing ink is suitable for silkscreen printing. The printing ink does not need increase in the usage amounts of components like carbon black, prevents unfavorable influence of the components on the appearance and light shading performance of a product, and can meet light shading requirements of the product after only one printing and under the condition of a thickness of 7 to 8 micrometers, so unexpected technical effects are obtained.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

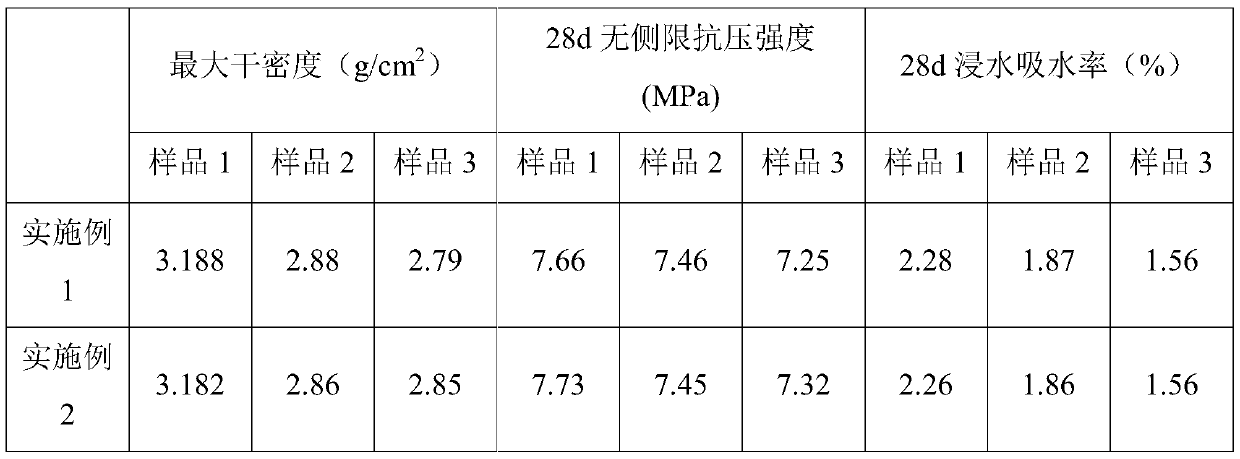

Environmentally friendly soil curing agent and preparation method

The invention discloses an environmentally friendly soil curing agent and a preparation method. The environmentally friendly soil curing agent comprises 30 parts of papermaking sludge, 15 parts of slag powder, 32 parts of sodium polyacrylate, 36 parts of glycerol, 26 parts of sulfonated oil, 18 parts of an exciting agent, 9 parts of an oxidant, 10 parts of a dispersant, 2 parts of a polymeric additive, 0.6 part of a surfactant, 4 parts of lignin fiber, 10 parts of amino silanol, and 3-6 parts of a water absorbing agent. The environmentally friendly soil curing agent of the invention can be processed in a wide range, the hardness of obtained cured soil is in a high range, the obtained cured soil has the advantages of high durability, strong permeability and good water resistance, and the curing agent has the advantages of low production cost, environmental protection and no pollution.

Owner:北京中科盛联集团有限公司

A use of a polyalkylmethacrylate polymer

InactiveCN101128571AImprove low temperature performanceWide temperature operating rangeLubricant compositionGas supplyPolymer

The present invention relates to the use of polyalkylmethacrylate polymers for improving the outgassing properties of functional fluids.

Owner:EVONIK OPERATIONS GMBH

High-performance conductive silver paste

ActiveCN109509568AReduce contact resistanceGood compatibilityNon-conductive material with dispersed conductive materialMicron scaleSilver paste

The invention provides a high-performance conductive silver paste, which comprises the following components in parts by weight: 15-50 parts of silver powder, 0.1-10 parts of nano-scale metal powder, 2-12 parts of resin, 38-83 parts of an organic solvent, 0.1-5 parts of a compound and 0-5 parts of an additive, wherein the granularity of the silver powder is 2-10 [mu]m; the granularity of the nano-scale metal powder is 1-1000nm; and the compound includes one or more of metal acid salt and unsaturated fatty acid compounds. In the high-performance conductive silver paste provided by the invention,the micron-scale silver powder and the nano-scale metal powder are used in a matched manner to serve as a conductive filler, the compound with specific components is contained at the same time, and the conductive silver paste is enabled to have good conductive performance under the comprehensive effect of the metal powder with different granularities and the compound with specific components.

Owner:TAIYUAN HYPERION NEW MATERIAL CO LTD

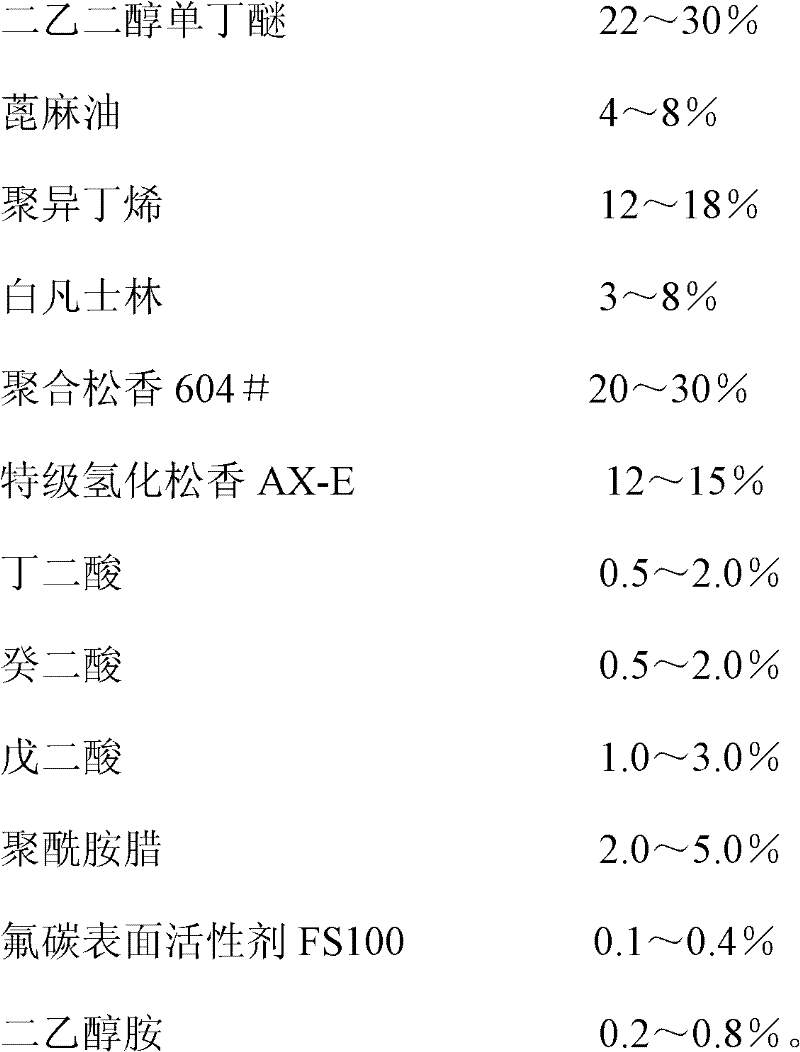

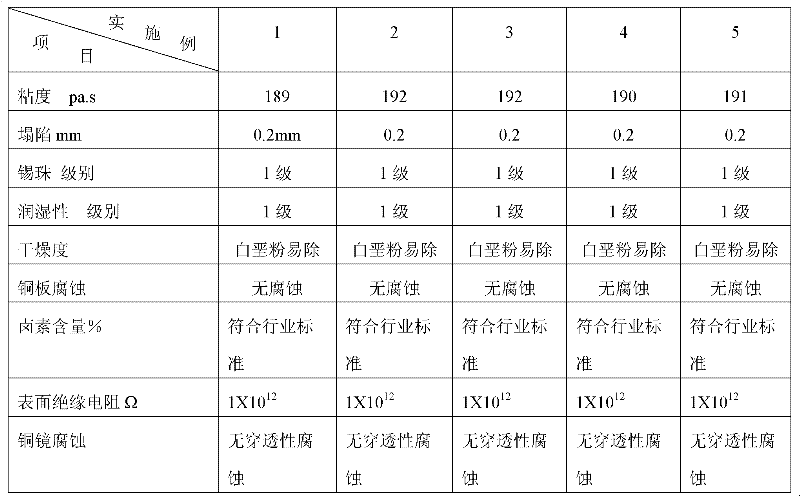

Halogen-free and lead-free solder paste and preparation method

ActiveCN102528329AImprove adhesionAdjustable viscosityWelding/cutting media/materialsSoldering mediaDiethylene glycol monobutyl etherGlutaric acid

The invention relates to a halogen-free and lead-free solder paste and a preparation method. The preparation method is characterized in that the method comprises the steps of adding diethylene glycol monobutyl ether, castor oil and polyisobutene in a temperature control emulsifying machine and mixing, then adding albolene, polymerized rosin and hydrogenated rosin and mixing again to obtain first mixing solution, reducing the temperature of the first mixing solution, adding succinic acid, sebacic acid and glutaric acid, and mixing again to obtain second mixing solution, reducing the temperature of the second mixing solution, adding polyamide wax and mixing again to obtain third mixing solution, reducing the temperature of the third mixing solution, adding a fluorocarbon surfactant and diethanol amine, then stirring and vacuuming until the temperature is restored to the room temperature, standing for 24h with low temperature, then adding lead-free electronic-grade tin alloyed powder Sn96.5Ag3.0Cu0.5, and stirring to obtain the halogen-free and lead-free solder paste. After being welded, the halogen-free and lead-free solder paste has the advantages and effects of fewer residues, extremely high surface insulation resistance, low corrosion, no needing of cleaning, good thixotropic property and electric conductivity, bright welding points after welding and incapability of collapsing easily.

Owner:惠州市斯泰尔科技有限公司

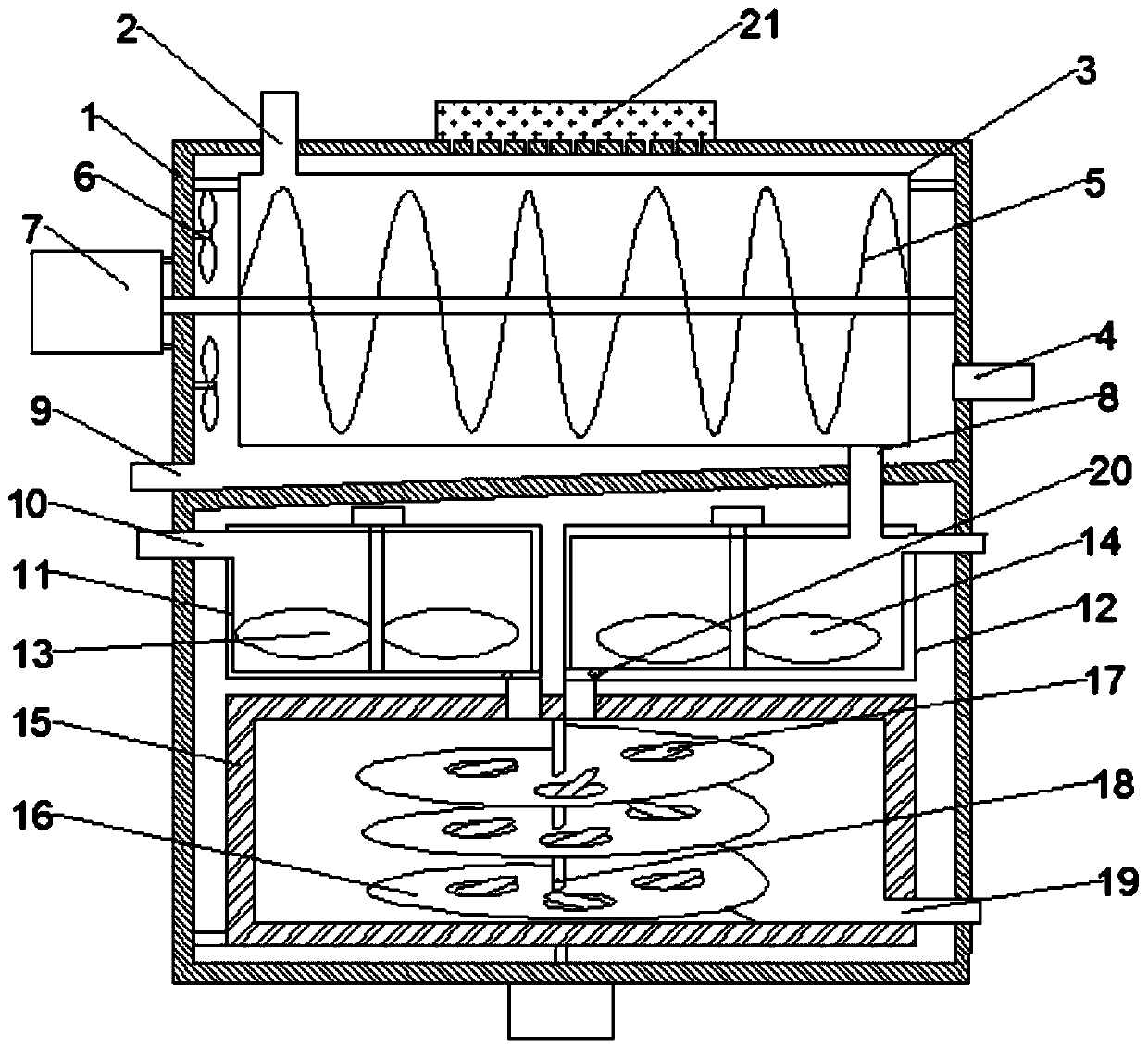

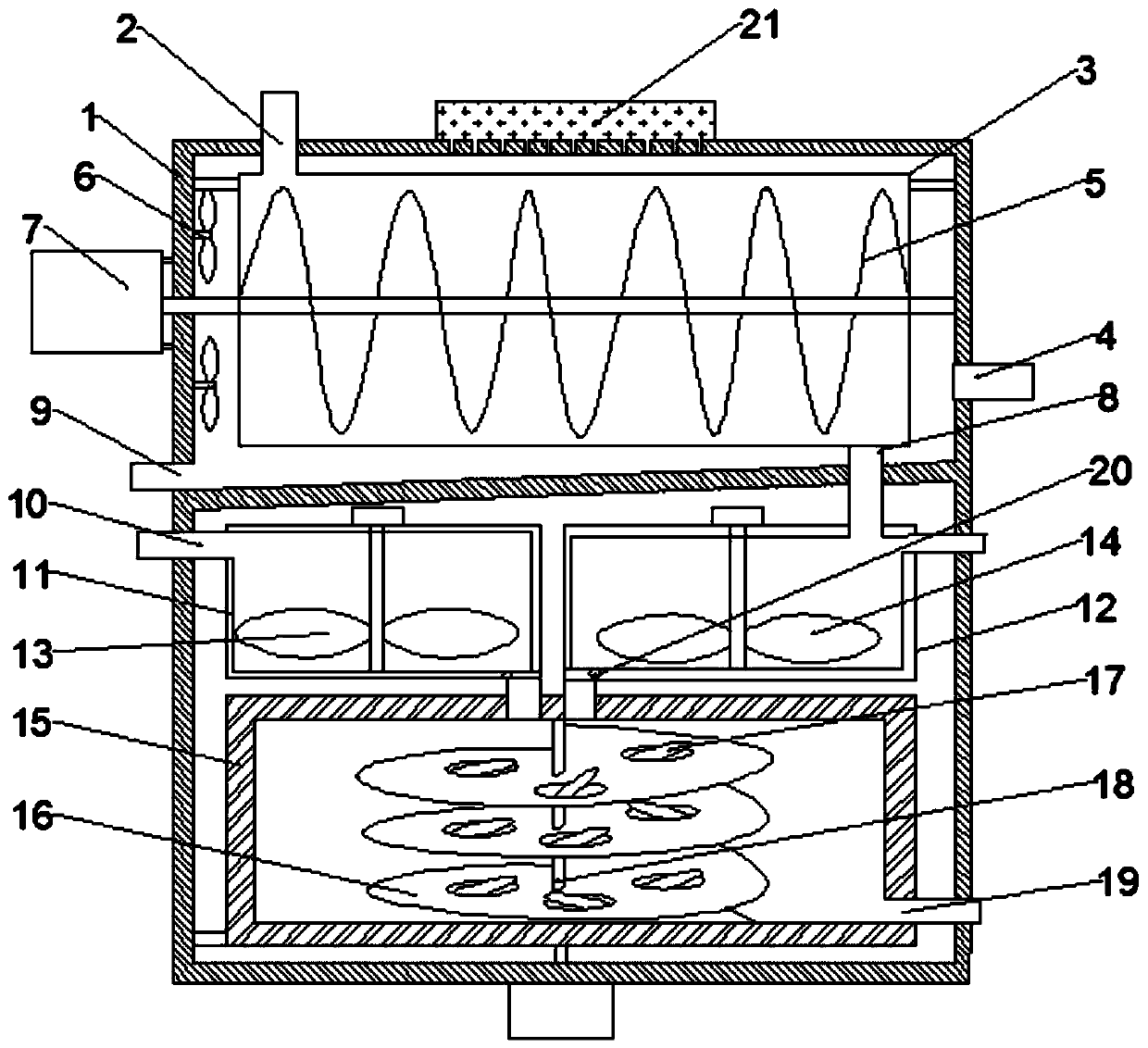

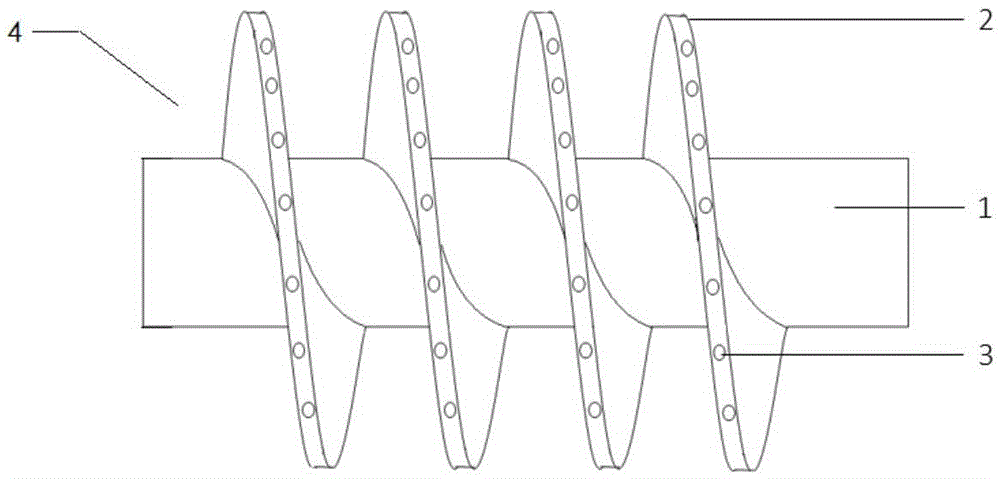

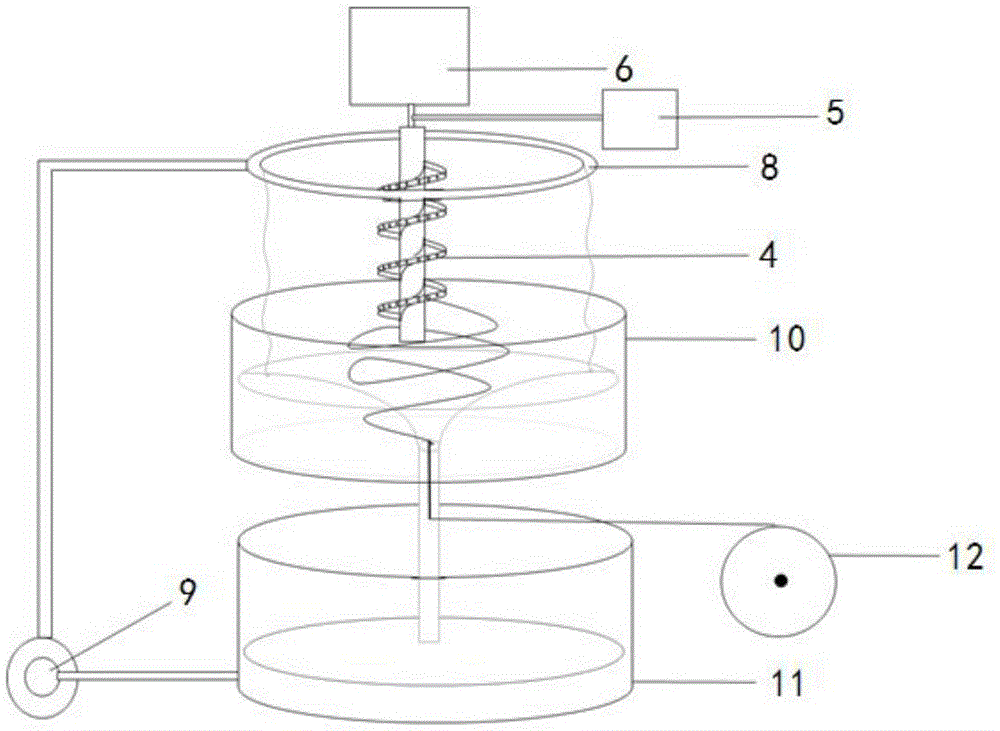

Centrifugal spiral spinning device

ActiveCN105648545AConducive to continuous industrializationImprove lateral uniformitySpinnerette packsNew-spun product collectionEdge surfaceSpiral blade

The invention discloses a centrifugal spiral spinning head and a centrifugal spiral spinning device employing the same. The centrifugal spiral spinning head comprises two parts, namely a hollow screw and a coaxial spiral blade which is connected with the hollow screw, wherein spinneret orifices are evenly formed in the outer edge surface of the spiral blade vertically to the axial direction; and when the screw rotates at a high speed, a feed liquid flows through the hollow screw under the action of centrifugal force, and is sprayed from the spinneret orifice in the tip of the spiral blade. According to the centrifugal spiral spinning device, the defects that existing centrifugal spinning equipment is complicated in structure, poor in air-tightness, and poor in spinning uniformity; and the actual requirements can be well met.

Owner:烟台森森环保科技有限公司

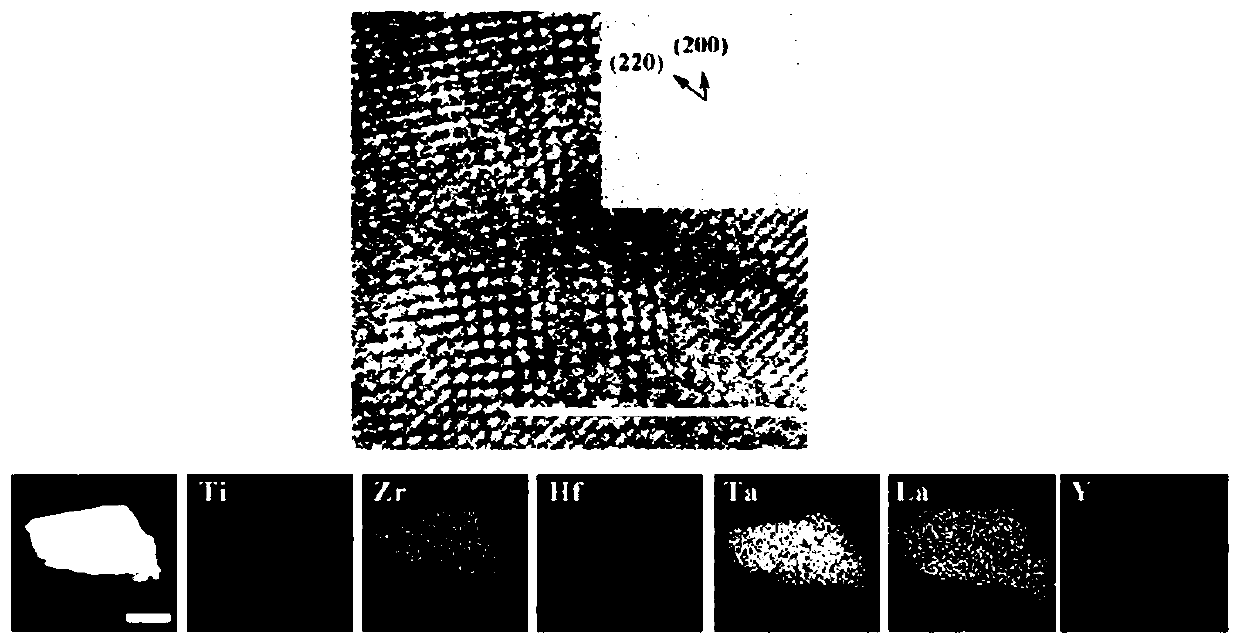

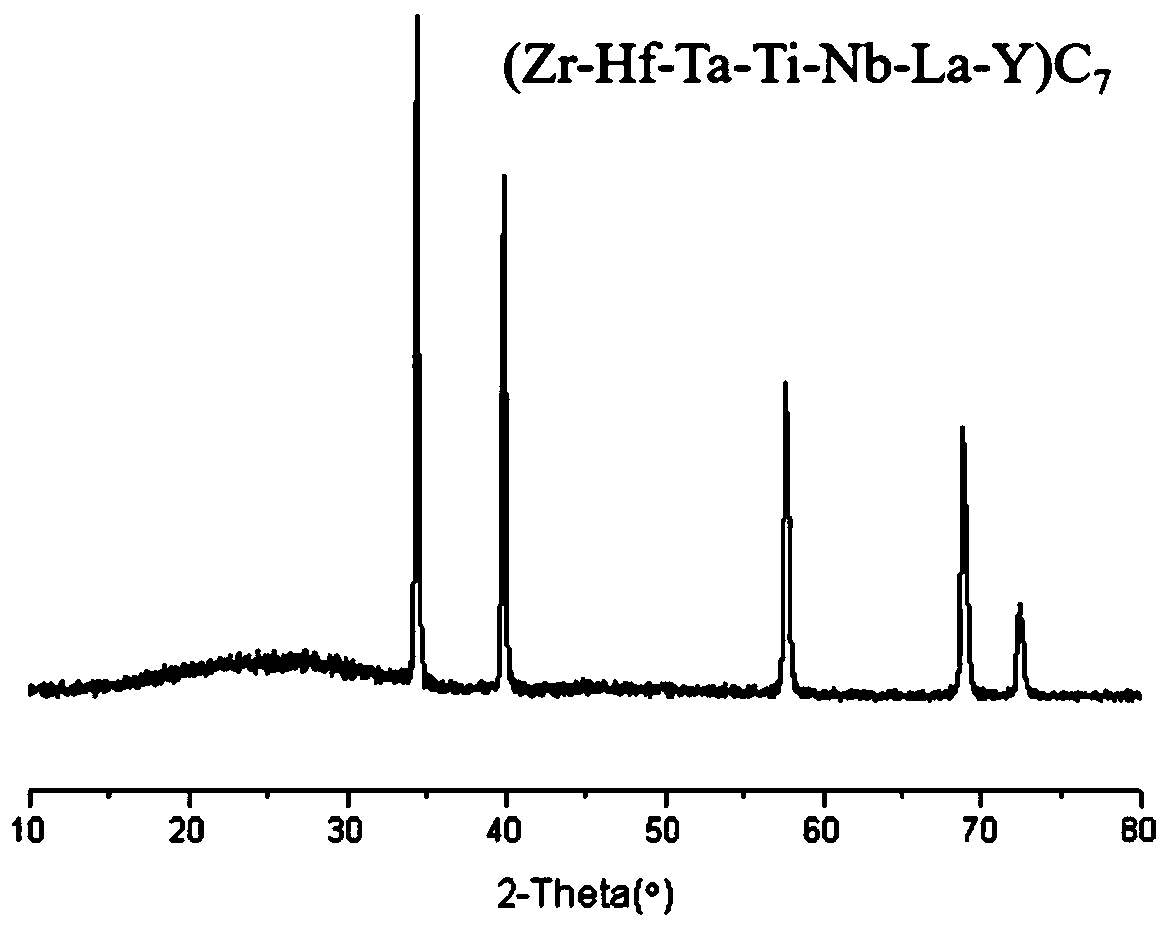

Carbide high-entropy ceramic precursor containing rare earth, high-entropy ceramic and preparation method

The invention discloses a carbide high-entropy ceramic precursor containing rare earth. The precursor comprises at least four transition metal elements and at least one rare earth metal element, and the precursor is dissolved in one or more of methanol, ethanol, isopropanol, n-propanol, n-butanol, isobutanol, ethylene glycol monomethyl ether or ethylene glycol ethyl ether. The precursor is prepared by respectively complexing a plurality of transition metal alkoxides, mixing the obtained complex with a compound containing rare earth elements, carrying out co-hydrolysis, and performing reactionwith a carbon source. According to the preparation method of the precursor, the ratio of all the raw materials in the step is finely adjusted, so that all the elements in the precursor are uniformly distributed at a molecular level, all the metal elements are subjected to short-range diffusion in the cracking process, and all the elements can be subjected to solid solution at a relatively low temperature. The preparation of the high-entropy ceramic is different from laser sintering and oxidation reduction in a traditional method, and the high-performance ceramic with a single crystalline phaseand with all elements in a molecular-level uniform distribution state is prepared on the basis of the precursor.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Glass lubricant used for hot extrusion of titanium alloy and zirconium alloy as well as preparation method thereof

ActiveCN107629832ALittle change in viscosityGood thermal barrier effectAdditivesSolubilitySoluble glass

The invention belongs to the field of a lubricant, and relates to the lubricant used for hot extrusion of a titanium alloy and a zirconium alloy as well as a preparation method thereof. The lubricantis composed of lubricant powder and soluble glass, the ratio of soluble glass to the mixed lubricant powder is 1:2-1:3, the lubricant powder comprises the following components: 60-80% of low-softeningpoint glass powder, 10-30% of SiO2 powder, 10-30% of NaCl powder, and the soluble glass with concentration being 1.0-1.1 mol / L. The lubricant has the advantage that the change of viscosity is small with temperature. The lubrication effect and thermal barrier effect are good, and cleaning is easy. The NaCl has water solubility, an extruding product attached with the lubricant is immersed into water, NaCl in the lubricant is dissolved in water, a porous structure is formed, and the lubricant is easily peeled from the surface of the product, and no pickling pollution is generated.

Owner:UNIV OF SCI & TECH BEIJING

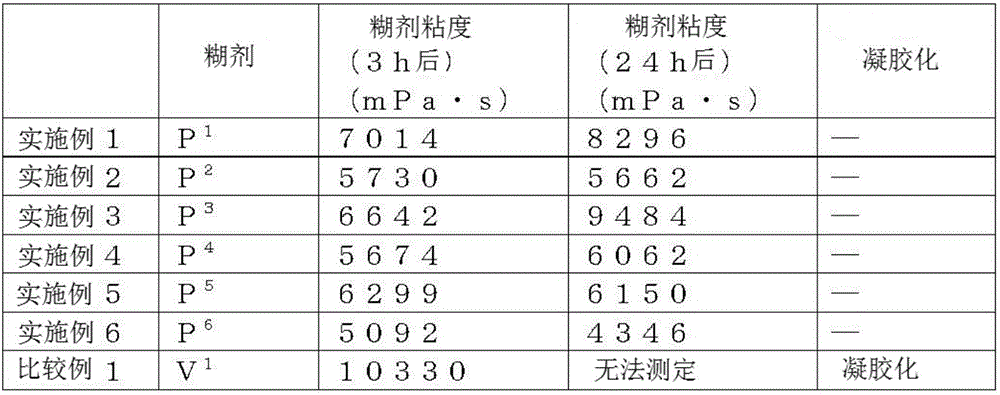

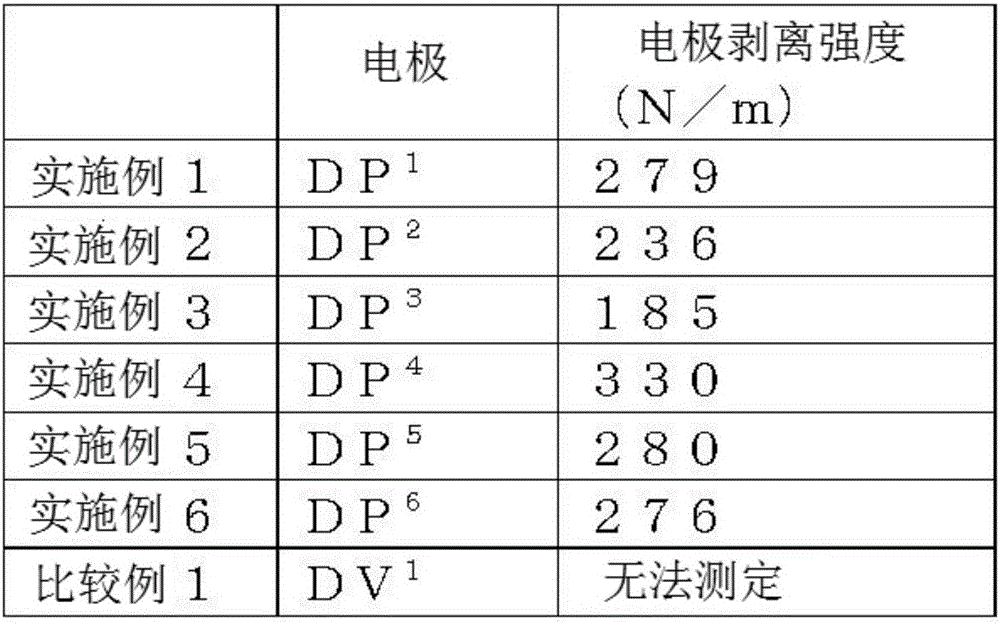

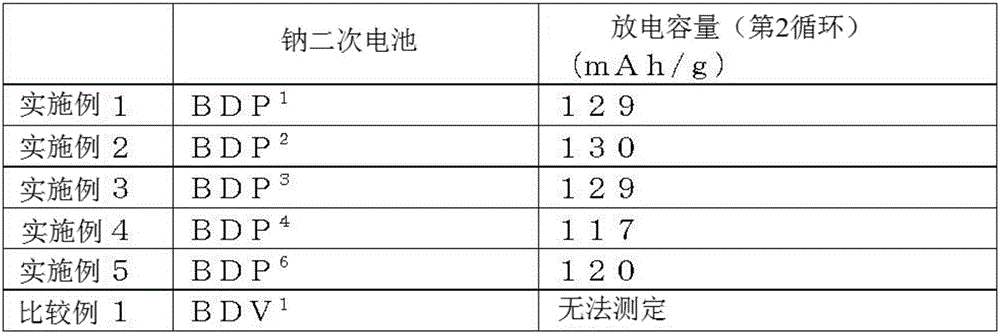

Electrode mixture paste for sodium secondary cell, positive electrode for sodium secondary cell, and sodium secondary cell

ActiveCN106104872AInhibit sheddingGood adhesionSecondary cellsPositive electrodesOrganic solventTemporal change

Provided is an electrode mixture paste for a sodium secondary cell containing a positive electrode active material that can be doped and dedoped using sodium ions, an electroconductive material, a binder, an organic solvent, and an acid having a valence of two or above, wherein the temporal change in viscosity is low even in the absence of a special facility.

Owner:SUMITOMO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com