Halogen-free and lead-free solder paste and preparation method

A technology of halogen-free lead-free solder paste and lead electronics, which is applied in the field of electronic soldering materials, can solve the problems that the quality of solder paste cannot meet the requirements, the active temperature and activity of flux components are not good, and achieve the best ICT test performance, contact Excellent denaturing performance and less corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

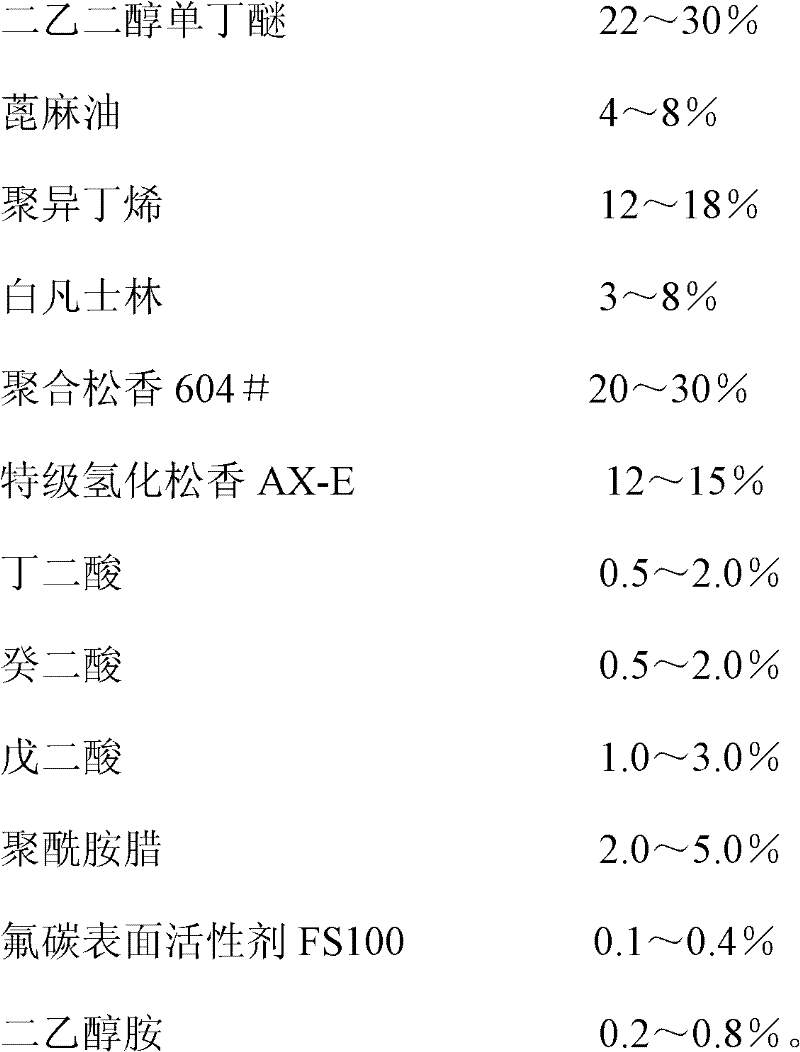

Method used

Image

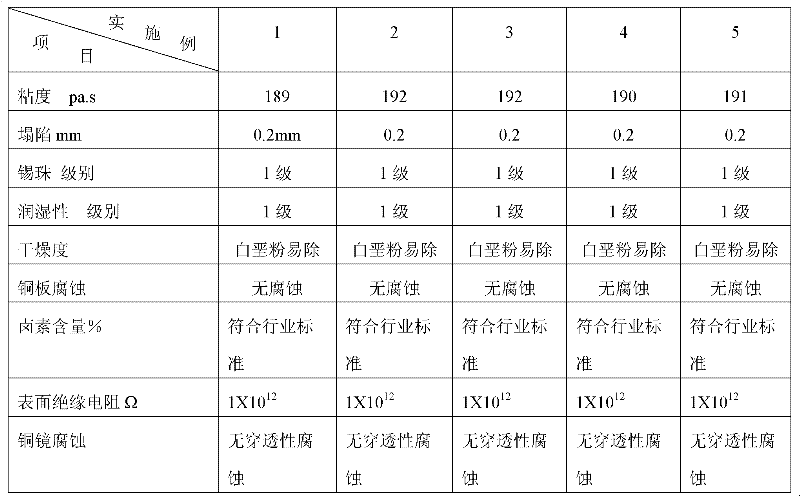

Examples

Embodiment 1

[0028] Take 30g of diethylene glycol monobutyl ether, 7g of castor oil, and 13g of polyisobutylene and add them into a temperature-controlled emulsifier for heating, stir at a temperature of 120°C at a speed of 200r / min for 10 minutes, and then add 7.0g of white petrolatum , 20g of polymerized rosin 604#, 14g of special-grade hydrogenated rosin AX-E were added in turn and stirred at a speed of 800r / min for 10 minutes to obtain a mixed solution, cooled to 100°C, and 1.0g of succinic acid, 1.0 g of sebacic acid and 2.0 g of glutaric acid were stirred at a speed of 1000 r / min for 10 minutes to obtain a secondary mixed solution, cooled to a temperature of 70 ° C, and 4.0 g of polyamide wax was added and stirred at a speed of 1200 r / min for 10 minutes to obtain Cool the mixed solution three times to 55°C, add 0.4g fluorocarbon surfactant FS100 and 0.6g diethanolamine in turn, stir at 1200r / min for 5 minutes, then evacuate to a vacuum value of 0.06MPa while stirring, until the temper...

Embodiment 2

[0030] Take 23.8g of diethylene glycol monobutyl ether, 8g of castor oil, and 12g of polyisobutylene, add them into a temperature-controlled emulsifier and heat them, stir at 125°C at a speed of 200r / min for 5 minutes, and then add 8.0g of white Petroleum jelly, 20g of polymerized rosin 604#, 15g of special-grade hydrogenated rosin AX-E were added sequentially and stirred at a speed of 800r / min for another 5 minutes to obtain a mixed solution, cooled to 105°C, and 2.0g of succinic acid, 2.0 g of sebacic acid and 3.0 g of glutaric acid were stirred at a speed of 1000 r / min for 5 minutes, and the temperature of the secondary mixed solution was lowered to 75 ° C, and 5.0 g of polyamide wax was added and stirred at a speed of 1200 r / min for 5 minutes. The temperature of the mixed solution obtained three times was lowered to 50°C, and 0.4g of fluorocarbon surfactant FS100 and 0.8g of diethanolamine were added in sequence, and then stirred at a speed of 1200r / min for 5 minutes, and t...

Embodiment 3

[0032]Take 26.3g of diethylene glycol monobutyl ether, 6g of castor oil, and 15g of polyisobutylene into a temperature-controlled emulsifier for heating, stir at 120°C at a speed of 200r / min for 10 minutes, and then add 5.0g of white Petroleum jelly, 25g of polymerized rosin 604#, 14g of special-grade hydrogenated rosin AX-E were added sequentially and stirred for another 10 minutes at a speed of 800r / min to obtain a primary mixed solution, which was cooled to 100°C, and 1.0g of succinic acid, 1.0 g of sebacic acid and 2.0 g of glutaric acid were stirred at a speed of 1000 r / min for 10 minutes to obtain a secondary mixed solution cooled to a temperature of 70 ° C, and 4.0 g of polyamide wax was added and stirred at a speed of 1200 r / min for 10 minutes to obtain The temperature of the three mixed solutions was lowered to 50°C, and 0.2g of fluorocarbon surfactant FS100 and 0.5g of diethanolamine were added in sequence, and then stirred at a speed of 1200r / min for 10 minutes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com