Electrode mixture paste for sodium secondary cell, positive electrode for sodium secondary cell, and sodium secondary cell

A sodium secondary battery and electrode technology, applied in the field of electrode composite material slurry, can solve problems such as difficulty in coating the current collector, reduced fluidity of electrode composite material slurry, etc., and achieve good adhesion and viscosity changes. Small, stable coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

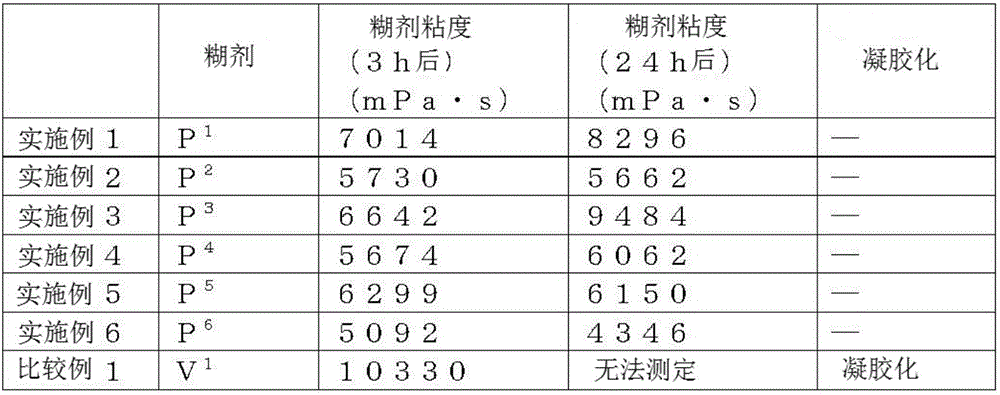

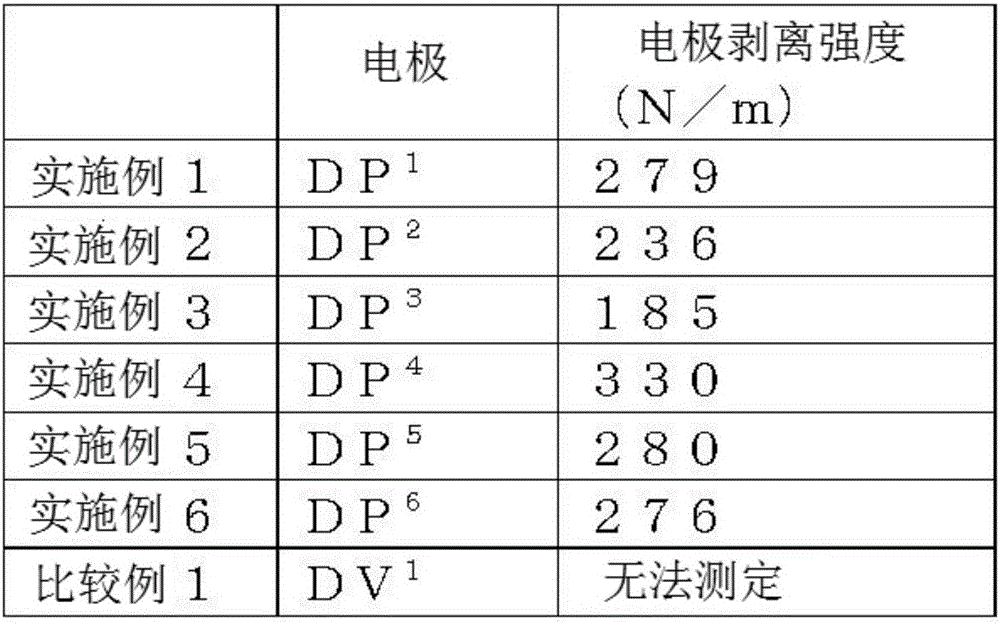

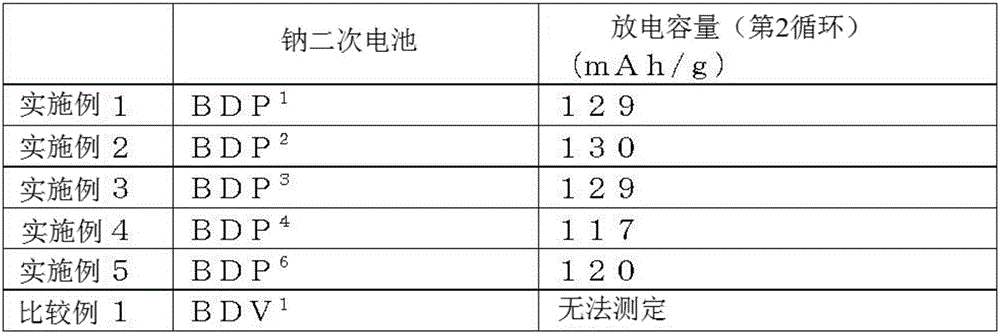

[0104] Hereinafter, the present invention will be described in more detail through examples. In addition, various evaluations of a composite metal oxide were performed by the following measurement.

[0105] 1. Powder X-ray Diffraction Determination of Composite Metal Oxide

[0106] The powder X-ray diffraction measurement of a composite metal oxide was performed using RINT2500TTR model manufactured by Rigaku Corporation. The measurement is performed by filling a special jig containing composite metal oxides, using a CuKα ray source, and performing the measurement at a diffraction angle 2θ=10 to 90° to obtain a powder X-ray diffraction pattern.

[0107] 2. Composition analysis of composite metal oxides

[0108] After dissolving the powder in hydrochloric acid, measurement was performed using an inductively coupled plasma emission analysis method (manufactured by SII, SPS3000, hereinafter may be referred to as ICP-AES.).

manufacture example 1

[0109] (electrode active material A 1 manufacturing)

[0110] In a beaker made of polypropylene, 44.88 g of potassium hydroxide was added to 300 ml of distilled water and dissolved by stirring to completely dissolve potassium hydroxide to prepare an aqueous potassium hydroxide solution (precipitating agent). Separately, in a separate polypropylene beaker, 21.21 g of iron (II) chloride tetrahydrate, 19.02 g of nickel (II) chloride hexahydrate, and manganese (II) chloride tetrahydrate were added to 300 ml of distilled water. 15.83 g was dissolved by stirring to obtain an aqueous solution containing iron-nickel-manganese. Stirring the above-mentioned precipitating agent, the above-mentioned aqueous solution containing iron-nickel-manganese was added dropwise thereto to obtain a slurry in which a precipitate was formed. Then, this slurry was filtered, washed with distilled water, and dried at 100° C. to obtain a precipitate. The precipitate, sodium carbonate, and calcium hydro...

Embodiment 1

[0114] (electrode compound slurry P 1 manufacturing)

[0115] Electrode material paste P 1 In the manufacture of, use the A of manufacturing example 1 as electrode active material 1 , using acetylene black (HS100, manufactured by Denkai Kogyo Co., Ltd.) as the conductive material, PVdF#7305 solution (PVdF:NMP=5:95, manufactured by KUREHA Corporation) as the binder, and an acid with an arity of 2 or more NMP solution using K 1 . follow A 1 : HS100: PVdF = 90: 5: 5 (weight ratio) method of weighing. to which according to A 1 : Oxalic acid = 100: 0.5 (weight ratio) way to add K 1 , using a bead mill disperser (trade name: Dispermat, manufactured by VMA-GETZMANN) to stir and mix, thus obtaining electrode composite slurry P 1 . The spin conditions were 3000 rpm for 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com