Burdening technology for slurry used by nanometer ferrous phosphate lithium ion battery

A lithium iron phosphate, lithium ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as the inability to fix solid content ingredients, the speed cannot achieve the dispersion effect, and the production quality is affected, and is conducive to automation. Continuous production, excellent electrochemical performance, and the effect of shortening batching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Nano-lithium ferrous phosphate (with a particle size range of 1-100nm) is used as the positive electrode material, superfine carbon powder (SuperP) is used as the conductive agent, polyvinylidene fluoride (PVDF) is used as the binder, and nitrogen-methylpyrrolidone (NMP) is used as the Solvent, nano-lithium ferrous phosphate: superfine carbon powder: polyvinylidene fluoride: nitrogen methyl pyrrolidone The mass ratio is 94:3:3:100, and the solid content is fixed at 50% (that is: lithium ferrous phosphate, super The mass ratio of fine carbon powder, polyvinylidene fluoride and nitrogen methyl pyrrolidone is 100:100), and the positive electrode slurry of lithium ion battery is prepared.

[0023] The slurry preparation process is as follows:

[0024] (1) Mix and stir the binder and 40% (mass fraction) solvent for 120 minutes according to the conventional method to make a glue with a solid content of about 7% (that is: the mass content of the binder in the solvent is 7%), ...

Embodiment 2

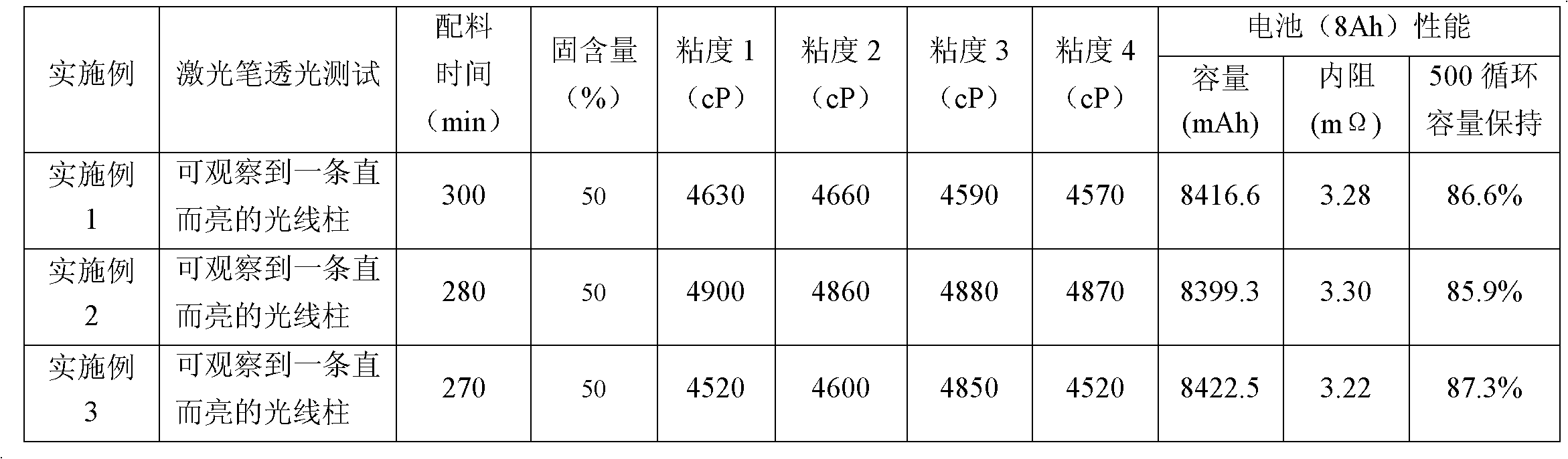

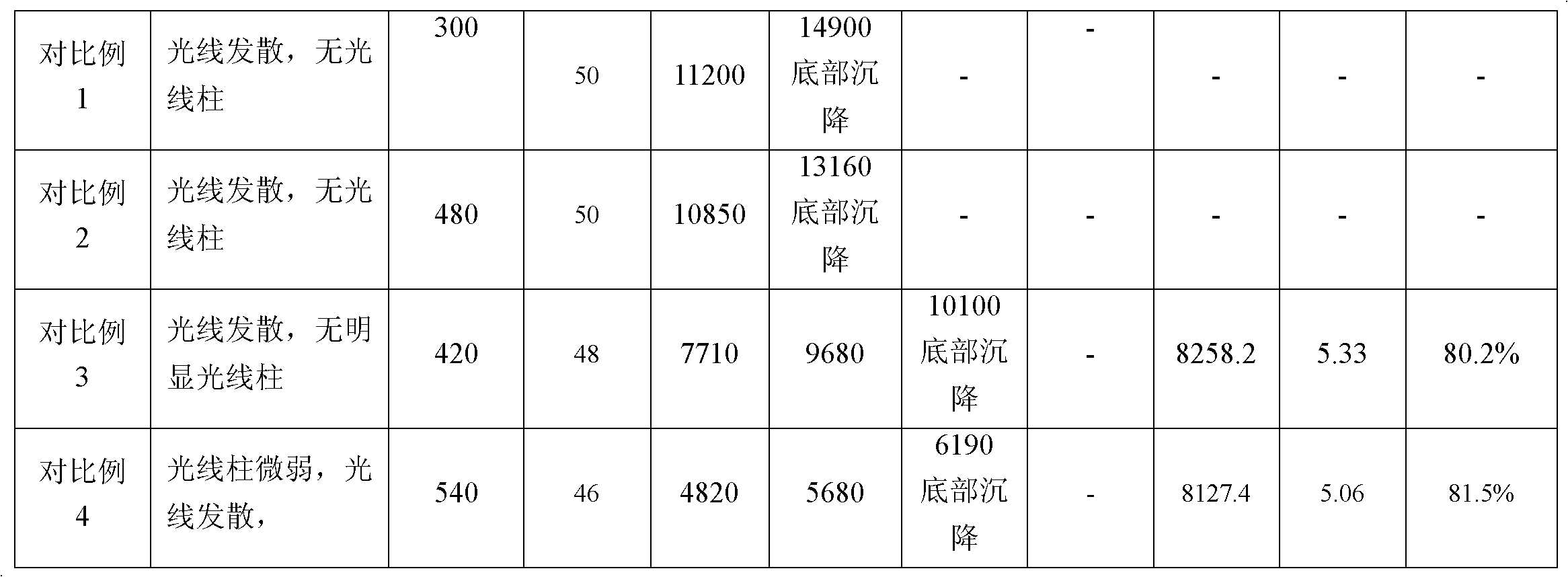

[0032] Completely make the preliminary slurry according to the conditions of Example 1, the preliminary slurry is stirred and dispersed reciprocally between the mixing tank and the disperser for 70min; the linear speed of the disperser is 40m / s, and then defoaming, filtering, iron removal process to make slurry. Use a 500ml transparent glass cup to take the slurry, irradiate the slurry with a laser pointer, and observe through light transmission. A straight and bright beam of light can be observed in the solution, indicating that the dispersion is very uniform.

[0033] The viscosity of the slurry was tested to obtain a viscosity of 1, and the viscosity was tested after being left open for 24 hours in an environment with a dew point of -50°C, and the viscosity was measured to be 2, and the viscosity was tested after 48 hours, and the viscosity was obtained after 7 days. The obtained test results are listed in Table 1. It can be seen from Table 1 that the slurry has little chan...

Embodiment 3

[0036] Completely make the preliminary slurry according to the conditions of Example 1, the preliminary slurry is stirred and dispersed reciprocally between the mixing tank and the disperser for 60min; the linear speed of the disperser is 45m / s, and then defoaming, filtering, iron removal process to make slurry. Use a 500ml transparent glass cup to take the slurry, irradiate the slurry with a laser pointer, and observe through light transmission. A straight and bright beam of light can be observed in the solution, indicating that the dispersion is very uniform.

[0037] The viscosity of the slurry was tested to obtain a viscosity of 1, and the viscosity was tested after being left open for 24 hours in an environment with a dew point of -50°C, and the viscosity was measured to be 2, and the viscosity was tested after 48 hours, and the viscosity was obtained after 7 days. The obtained test results are listed in Table 1. It can be seen from Table 1 that the slurry has little chan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com