Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "The process is easy to operate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

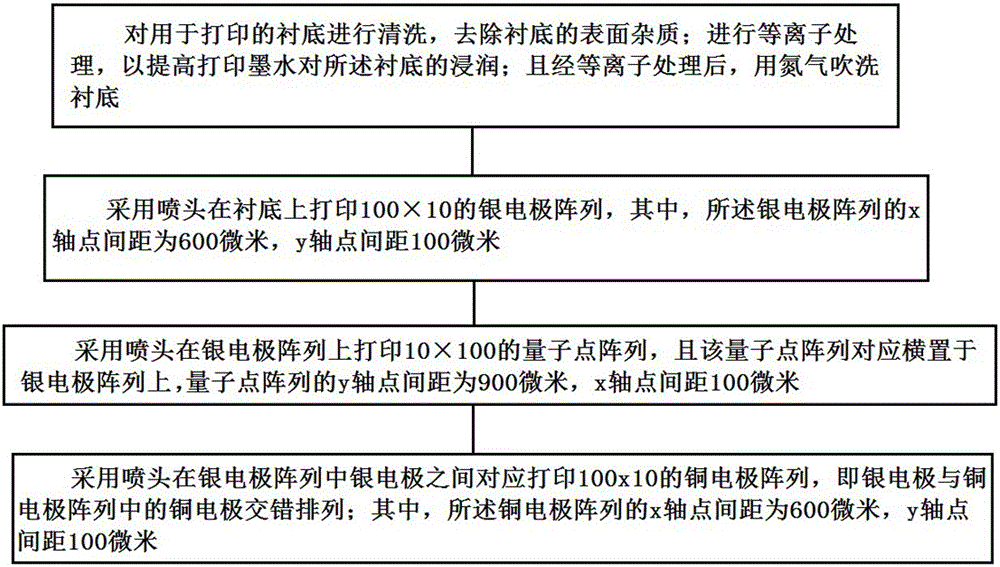

Method for preparing quantum dot photodetection array device based on ink-jet printing technology

InactiveCN104993022AImprove controllabilityScalable productionFinal product manufactureSemiconductor devicesComputer printingInk printer

The invention relates to a method for preparing a quantum dot photodetection array device based on ink-jet printing technology. The method is characterized by carrying out plasma and chloroform processing on a substrate; then, printing a metal electrode array and a quantum dot array on the substrate through an ink-jet printer with metal electrode ink and quantum dot ink respectively; and finally, carrying out current and voltage test in the dark and any monochromatic light source environment. The method for preparing the quantum dot photodetection array device based on the ink-jet printing technology is simple in preparation technology, and can carry out large-scale production; and the photodetection device adopts quantum dots, so that the photodetection device has a better photosensitive characteristic for any excitation light source.

Owner:FUZHOU UNIV

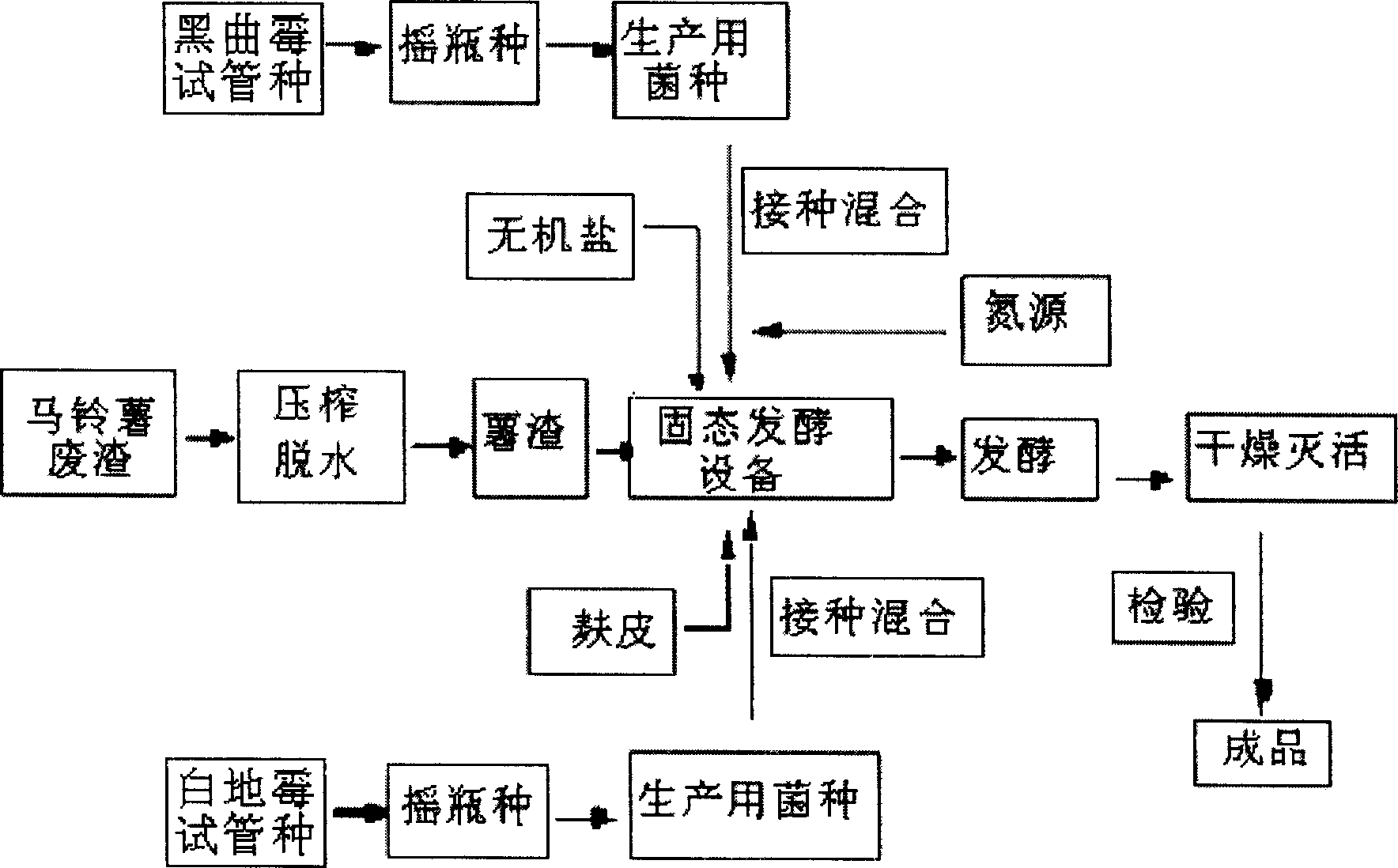

Method for preparing protein feed by solid fermenting potato slag

ActiveCN1899079ALow degree of mechanizationLess investmentAnimal feeding stuffVegetable proteins working-upMetabolitePotato starch

The present invention is protein feed and its preparation process with potato slag. Protein feed is prepared with waste potato slag from starch production, and through squeezing to dewater, adding certain amount of supplementary material, inoculating certain amount of microbe seed and solid fermentation. The said preparation process is simple, and has high yield, low investment, low power consumption and other advantages. Thus obtained feed product has the fermented product, including microbe, metabolite and substrate utilized fully, and possesses the active components maintained, high amino acid content and high nutritious value.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

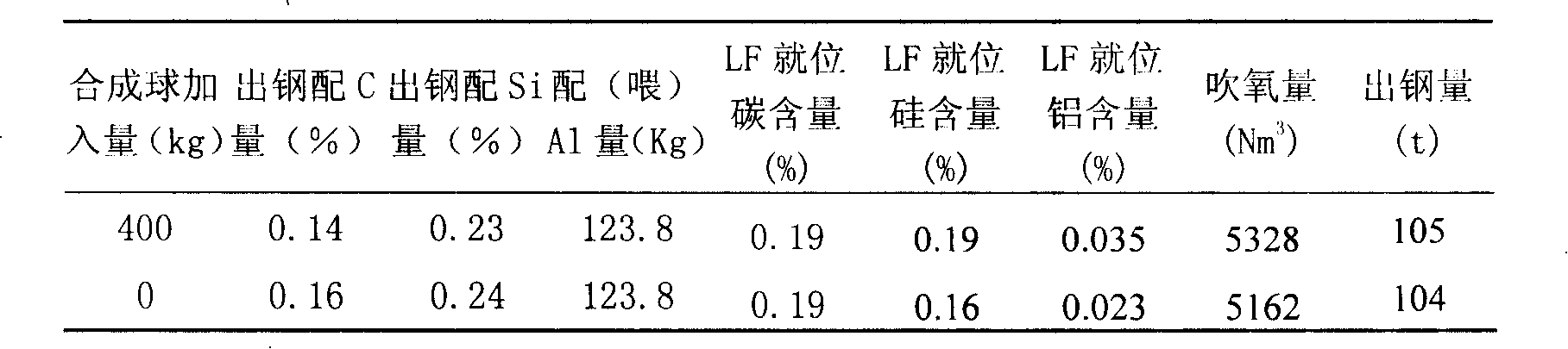

Pre-deoxidation recarburization process for arc furnace steel-smelting molten steel with slag

The invention relates to a pre-deoxidation and carburization craft of molten steel with slag in the electric-arc steelmaking furnace, comprising the following steps: (1) charging; (2) electrifying melting; (3) oxygen blowing to boost melting; (4) oxidation refining; (5) temperature measuring and sampling; (6) addition of deoxidizer (7) tapping. The pre-deoxidation and carburization craft of molten steel with slag in the electric-arc steelmaking furnace solves the problems in the prior art of high oxidation of molten steel in the electric-arc steelmaking furnace and low carbon content. The pre-deoxidation and carburization craft of molten steel with slag in the electric-arc steelmaking furnace has the advantages that: 1. the craft has easy operation and obvious effect. The carbon content of the steel in the electric furnace is increased, the oxygen content in molten steel is decreased and over-oxidation of the molten steel is avoided. 2. the addition of deoxidizer used for the molten steel outside the furnace is reduced, impurities content in steel is reduced and yielding rate the of the alloy is enhanced.

Owner:TIANJIN PIPE GROUP CORP

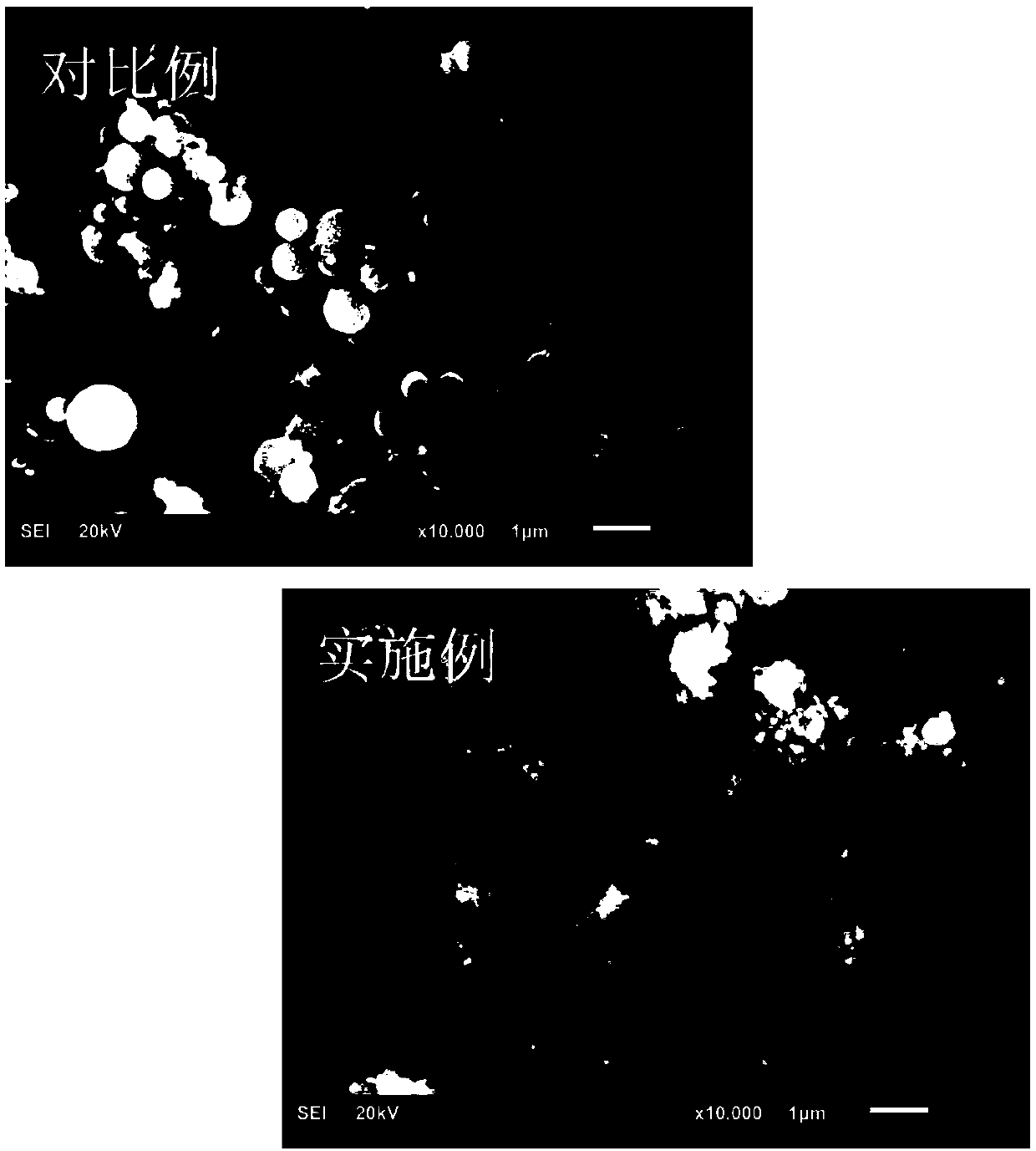

Positive electrode of solid electrolyte and solid state battery

ActiveCN108878960ASimple processThe process is easy to operateSolid electrolytesCell electrodesSolid-state batteryNanometre

The invention relates to a positive electrode of a solid electrolyte and a solid state battery. The positive electrode of the solid electrolyte comprises a positive electrode piece and a conductive ceramic composite coating, wherein the positive electrode piece is coated with a positive electrode active material layer, and the outer surface of the positive electrode active material layer is coatedwith the conductive ceramic composite coating. The thickness of the conductive ceramic composite coating is 1-50 [mu]m. The conductive ceramic composite coating comprises organic polymer, lithium salt, nano inorganic solid electrolyte, macromolecule grafted modified ceramic, a binding agent and a wetting agent. Based on the total weight of the conductive ceramic composite coating, the content ofthe organic polymer is 5-80wt%, the content of the lithium salt is 5-50wt%, the content of the nano inorganic solid electrolyte is 10-85wt%, the content of the macromolecule grafted modified ceramic is 1-20wt%, the content of the binding agent is 1-12wt%, and the content of the wetting agent is 0.1-0.5wt%.

Owner:NINGDE ZHUOGAO NEW MATERIAL TECH CO LTD

Metal slide fastener and manufacturing technology and metal slide fastener surface gold paint seal treatment machinery

InactiveCN101263948AThe process is easy to operateImprove processing qualitySlide fastenersPretreated surfacesEpoxyManufacturing technology

The invention relates to a metal zipper, the manufacture technology and a sealing and treating machine for the oil on the surface of the metal zipper, belonging to the technical field of daily necessities. A layer of oil is covered on the surface of the metal zipper; the oil comprises double-component epoxy resin varnish, epoxy curing agent and epoxide diluent with the weight ratio of 1:1 to 1.5:2.5 to 3.5. The metal zipper has the functions of rusting prevention, color losing resistance and anti-oxidizing discoloration with the advantages of good rigidity, friction resistance, scratch resistance and chemical corrosion resistance.

Owner:JIANGSU CMZ ZIPPER SCI & TECH CO LTD

Hydrolysis method for preparing rutile titanium dioxide

InactiveCN102502809AQuality improvementPigment performance is goodTitanium dioxideBoiling pointTitanium

The invention provides a hydrolysis method for preparing rutile titanium dioxide. The hydrolysis method comprises the following steps of: adding a crystal seed into titanium liquid under full stirring to form a hydrolysis system, wherein the ratio of the crystal seed to the titanium liquid is 1.0 to 5.0 percent according to the mass ratio of titanium dioxide in the crystal seed to titanium dioxide in the titanium liquid; heating the hydrolysis system to a first boiling point, and stopping heating and stirring after the color of the hydrolysis system is grayed to ensure that particles formed in the hydrolysis system are cured; and starting stirring, and continuously heating the hydrolysis system to ensure that the hydrolysis system is slightly boiled until hydrolysis is finished. The hydrolysis method has the advantages that: the process is easy and convenient to operate, cost is saved, and the like; and the rutile titanium dioxide with stable quality and high pigment performance can be prepared after metatitanic acid obtained through hydrolysis is subjected to subsequent treatment.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +1

Synthesis method of tourmaline

InactiveCN101654254AUniform particle sizeThe preparation method is mildAluminium silicatesSlurryBoron

The invention discloses a synthesis method of tourmaline. The method comprises the following steps: preparing a homogeneous solution with sodium, magnesium, aluminum, silicon, boron and other elementsat constant temperature, then adding precipitant sodium hydroxide to ensure the solution to reach a certain pH value, obtaining precipitate slurry, and then performing subsequent cleaning, filtrating, drying and calcining processes to prepare tourmaline powder. The method of the invention can be used to obtain the powder containing tourmaline directly, the conditions of the whole preparation method are mild, the method is easy to realize and the cost is low. The precipitate product can be dispersed and calcined to obtain nanometer tourmaline powder which can be conveniently used in fields such as medical treatment and health care, environmental protection, construction and the like.

Owner:SHANDONG UNIV

Production process for extracting yolk lecithin

InactiveCN102010439AThe process is easy to operateGood repeatabilityTransportation and packagingMixingSolventChemistry

The invention relates to a production process for extracting yolk lecithin, comprising the following concrete steps of: stirring and extracting yolk powder by using alcohol or acetone for two times at the temperature of 40-80 DEG C; merging extracts; carrying out vacuum concentration under the condition of controlling the temperature to be lower than 70 DEG C; adding water to continue concentrate to make the solvent residual be less than 5 percent; cooling concentrated solution and then adding activated carbon for decoloration; cooling and settling and then filtering to obtain filtrate; concentrating the filtrate to recover alcohol; freezing and drying the concentrated solution; and finally freezing and drying. The process has simplicity and convenience in operation, good repeatability, low production cost and stable product quality, reduces the consumption of the organic solvent and reduces the environmental pollution; the solvent has low residual quantity and does not contain toxic and harmful solvents; the yolk lecithin content of the product is as high as 70-95 percent. The yolk lecithin can be independently used as an emulsifier to be applied to emulsions, sweets, instant products, dairy products and the like.

Owner:XUZHOU JIYUAN PHARMA

Protein separating and purifying method

InactiveCN1749267AThe process is easy to operateLow input and operating costsPeptide preparation methodsCELL DEBRISChemistry

The protein separating and purifying method includes twice extraction in polymer / salt double water phase system, and chromatographic separation with anionic exchange resin to obtain protein of molecular weight 10,000-30,000. The method can eliminate great amount of impurity and cell segment simultaneously, has the features of maintaining protein activity, short phase separating time, no residue of organic solvent, easy engineering amplification and control operation, and can eliminate endotoxin to affect product quality. The method of the present invention is especially suitable for the separation and purification of hepatocytokine.

Owner:王玉亭

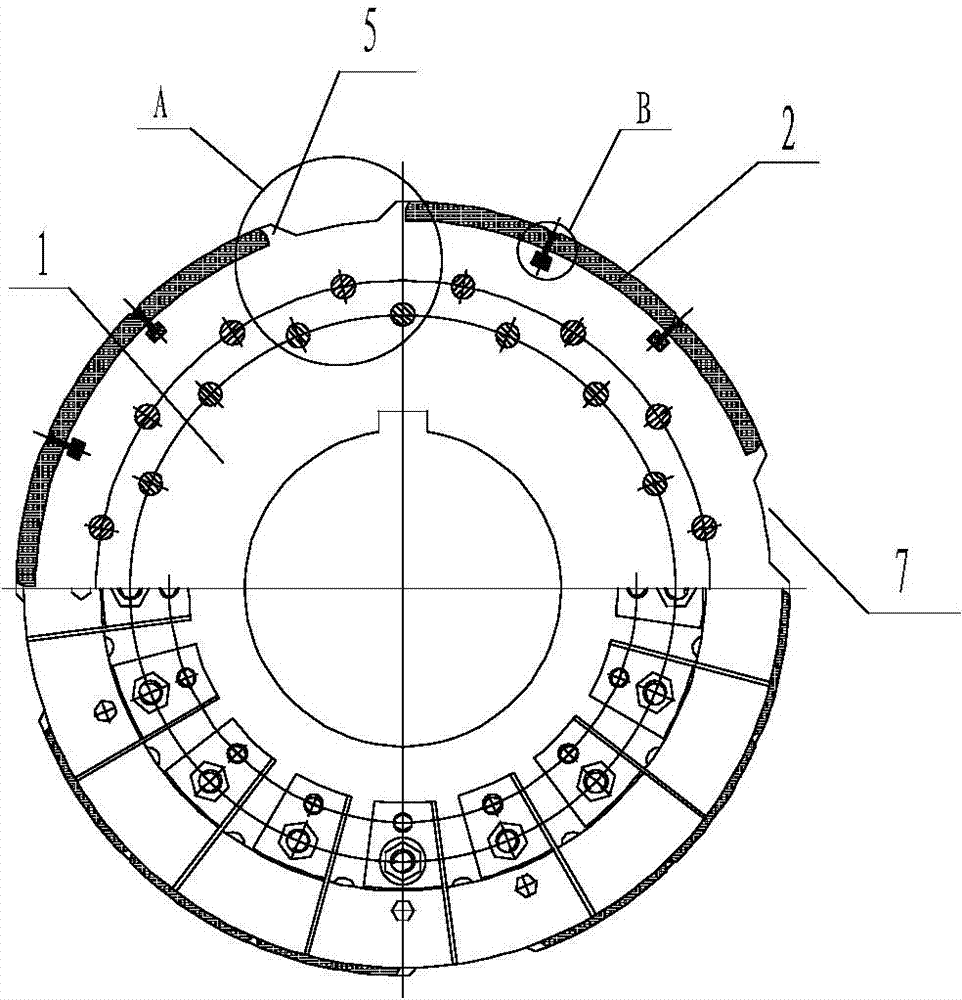

Middle-large size high speed rare-earth permanent magnet motor magnetic steel locking structure

ActiveCN104518589AEasy to fixSolve the problem of splicing fixedMagnetic circuit rotating partsSurface mountingElectric machine

The invention discloses a middle-large size high speed rare-earth permanent magnet motor rotor structure comprising a rotor core and magnetic poles attached on an outer surface of the rotor core; an outer periphery of the rotor core is provided with a plurality of flanges extending in an axial direction and used for positioning the magnetic poles in a radial direction and the periphery direction; T type slots are arranged between the flanges; each magnetic pole is formed by splicing a plurality of small magnetic steels on the surface of the rotor core in the axial direction and the periphery direction; the spliced magnetic pole is clamped between two adjacent flanges; the magnetic steels are clamped by a wedge nested in the T type slot; two end faces of the rotor core are provided with stop plates used for positioning the magnetic poles in the axial direction. The magnetic poles of the rare-earth permanent magnet motor are fixed in the radial direction and the periphery direction by the flanges arranged on the outer surface of the rotor core and T type slots and wedges between the flanges; the stop plate can fix the magnetic poles in the axial direction; the magnetic pole spliced by small magnetic steels is stable and firm in a whole; the T type slots and wedges are arranged to well solve the middle-large size motor surface mounting type magnetic steel splicing fixation problems.

Owner:安徽明腾永磁机电设备有限公司

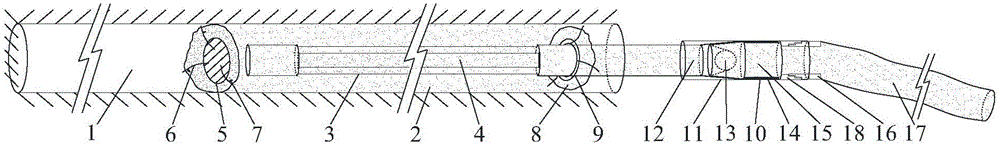

Flexible plastic quick grouting hole sealing device and method

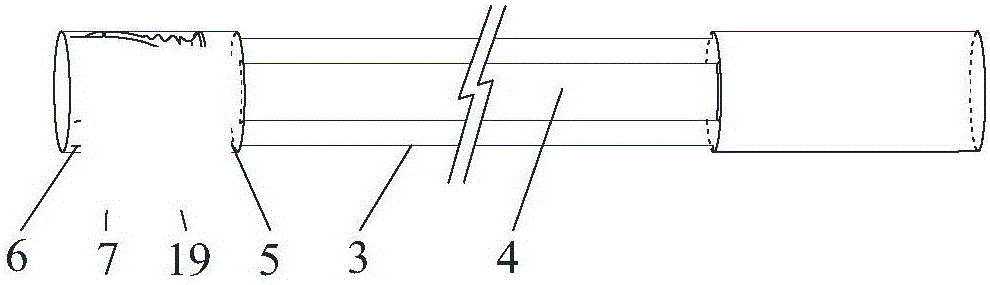

ActiveCN106401522ARaise the initial pressureFlexibleDrilling rodsWell/borehole valve arrangementsSlurryMechanical engineering

The invention discloses a flexible plastic quick grouting hole sealing device and method. The device is mainly composed of an umbrella buckle type plugging device, a slotting flexible plastic grouting pipeline and a double-cone pipe connector device. The initial grout pressure in pipes is positively stored in a sealed mode through the differential flow of grout fed into and discharged out of the grouting pipes, and the processes of automatic pushing out, spreading and plugging of a convex angle umbrella buckle are completed. A flexible plastic pipe capable of being coiled is adopted to be inserted into a drill hole at a time, and the primary quick hole sealing operation requirement is met. According to the flexible plastic quick grouting hole sealing device and method, the process of traditional hole sealing operation is simplified, operation is convenient and quick, the cost is low, and the device and the method are novel hole sealing device and method which have wide application and popularization value.

Owner:CHINA UNIV OF MINING & TECH

LED package component, substrate and wafer level packaging method thereof

InactiveCN104576888ASimple coating processThe process is easy to operateSemiconductor devicesPhysicsFluorescence

The invention provides a substrate used for LED chip wafer level packaging, a packaging method and an LED package component. The substrate comprises a first substrate and a second substrate, a cut-through concave hole is formed in the first substrate, the side wall of the concave hole is a slope, the width of an opening formed at the bottom of the concave hole is smaller than that of an opening formed at the top of the concave hole, and a light-reflecting layer overlaps the side wall of the concave hole; the top of the second substrate bonds with the bottom of the first substrate, at least two through holes are formed in the surface, corresponding to the concave hole position on the first substrate, of the second substrate, and the through holes are filled with metal; another light-reflecting layer overlaps the top surface of the second substrate, the light-reflecting layer of the second substrate and the light-reflecting layer portion corresponding to the concave hole position on the first substrate are separated into two light-reflecting layer areas, an eutectic bonding layer overlaps the surface of each light-reflecting layer area, and the eutectic bonding layer on the surface of each light-reflecting layer area corresponds to at least one through hole position on the second substrate. By means of the substrate, the coating technology of the fluorescent layer is greatly simplified.

Owner:HKUST LED FPD TECH R&D CENT AT FOSHAN

Method for preparing oxide ceramic target material green body

PendingCN108046767ASimple moldThe process is easy to operateMouldsSlip casting mouldsOxide ceramicOxide

The invention discloses a method for preparing an oxide ceramic target material green body. Oxide slurry is obtained by utilizing a vacuum ball milling process, then grouting and forming are performed, a sintering process is also performed, and a drying process of the oxide target material green body can also be performed before the sintering process, wherein the vacuum degree of the vacuum ball milling process is 10Pa or lower, and the ball milling time is 48-72h. The oxide ceramic target material green body prepared by the method disclosed by the invention is large in size and simple in process, and high-density oxide target material green body with different shapes such as a cylindrical shape and a flat plate shape can be prepared.

Owner:ZHENGZHOU UNIV

Colored paint/ink cured on tyre by using ultraviolet light and preparation method thereof

ActiveCN103740171AExcellent performanceThe process is easy to operateInksCoatingsSolventPhotoinitiator

The invention relates to a colored paint / ink cured on a tyre by using ultraviolet light and a preparation method thereof. The colored paint / ink comprises the following components in parts by weight: 8-18 parts of acrylics, 0.8-2 parts of resin, 8-16 parts of solvent, 0.5-3 parts of rubber, 0.01-0.12 part of dispersing agent, 4-8 parts of color paste, 0.03-0.1 part of flatting agent and 0.15-1 part of photoinitiator. The preparation method comprises the steps of stirring the solvent and rubber in a closed mixing stirrer until the rubber is completely dissolved into transparent liquid; transferring the transparent liquid into a dispersing stirrer; adding the acrylics, the resin and the dispersing agent and stirring; and adding the color paste, the flatting agent and the photoinitiator according to the component ratio, stirring and discharging. According to the colored paint / ink provided by the invention, UV (ultraviolet) irradiates the tyre, so that one-time curing formation is realized, and a film forming object has excellent performance on the tyre of the automobile; and meanwhile, the preparation method has the characteristics of simple process operation and high output.

Owner:江苏久瑞高能电子有限公司

Process for preparing test tube brush type silicon carbide

The preparation process of test tube brush shaped silicon carbide includes the following steps: setting silicon inside graphite crucible, distributing polyacrylonitrile-base carbon fiber on the crucible and covering with one graphite crucible in the same size to increase contact between carbon fiber and silicon vapor; setting the crucible without direct contact between the Si powder and carbon fiber inside vacuum high temperature sintering furnace under Ar atmosphere, heating in the temperature raising rate of 10-30deg.c / min to 1450-1650deg.c and maintaining for 3-9 hr; and turning off the power supply after finishing reaction while maintaining circular cooling water until cooling completely to obtain grey silicon carbide.

Owner:ZHEJIANG SCI-TECH UNIV

Method for determining isolated soy protein digestibility in vitro

InactiveCN102329853AThe process is easy to operateEasy to manage and controlMicrobiological testing/measurementBiological testingAnimal scienceIsolated Soy Protein

The invention provides a method for determining isolated soy protein digestibility in vitro. The method includes the following steps: preparing the aqueous solution of isolated soy protein as a sample; using one or more varieties of enzymes to simulate the environment of the human gastrointestinal tract to digest the sample in vitro; stopping the process of digestion, and obtaining a sample to be determined; and determining the in-vitro digestibility of the sample to be determined. The method has the advantages of energy saving, environment-friendliness, safety, high efficiency and the like, and is easy to operate.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

Preparation method of PBO

A preparation method of PBO which comprises the following steps: dispersing and mixing the following raw materials: 4,6-diamino-1,3-resorcinol hydrochlorate or phosphate, terephthalic acid, polyphosphoric acid and phosphorus pentoxide at the temperature of 60 to 150 DEG C; degassing under a vacuum circumstance; carrying out polymerization reaction of the mixture in a capillary microfluid reaction space of which the pipe diameter is 1 to 10 mm by passing the mixture through at least three reaction zones in a warmer and warmer manner, wherein the temperature range of 100 to 200 DEG C, the temperature difference of adjacent reaction zones is equal to or higher than 40 DEG C, and the intrinsic viscosity of the obtained PBO end product is 20 to 30 dl / g. Through high efficiency and uniform heat transmission and mass transfer, the temperature in the polymerization reaction system is uniform, the controllability is higher, and polymerization reaction can be carried out and fulfilled efficiently; under the premise of the same polymer molecular weight, the polymerization reaction time can be shortened to several hours, or even dozens of minutes; both the production efficiency and heat efficiency are greatly improved.

Owner:四川宝利丰科技有限公司

Method for separating and recovering V and Cr from V-Cr waste material

InactiveCN103352124AThe process is simpleThe process is easy to operateProcess efficiency improvementIon exchangeWaste material

The invention provides a method for separating and recovering V and Cr from a V-Cr waste material. The process flow of the method comprises the following steps: 1, carrying out two-stage acid dipping; 2, carrying out acidity adjustment oxidation; 3, carrying out ion exchange adsorption, desorbing for V removal, and transiting ion exchange resin; 4, carrying out purification and V precipitation; and 5, carrying out purification and Cr precipitation: removing impurities from a Cr-containing solution which is a raffinate flowed through the third-stage ion exchange resin, and purifying Cr. The method has the advantages of simplification, convenient operation, low energy consumption, realization of the recovery rate of 90% or more, and no pollution to the environment because of no generation of hexavalent Cr in the whole process. The method is an optimally-designed industrial operating method, and is in favor of the industrialized popularization enforcement.

Owner:全喆 +2

Non-dissolving antibacterial cellulose acetate and preparation method and application thereof

ActiveCN107177004AGood chemical stabilityHigh antibacterial efficiencySemi-permeable membranesNon solventHydrogen

The invention discloses non-dissolving antibacterial cellulose acetate and a preparation method and application thereof; the non-dissolving antibacterial cellulose acetate is prepared by substituting hydrogen on part of hydroxyl groups in cellulose acetate by bromoacetyl groups. The preparation method comprises: 1) dissolving the cellulose acetate; 2) dropwise adding bromoacetyl under quick stirring to ensure the temperature of a reaction system is kept at 0-5 DEG C; 3) allowing reacting at 20-35 DEG C under quick stirring; 4) adding deionized water to precipitate out cellulose acetate, and drying to obtain the non-dissolving antibacterial cellulose acetate. An antibacterial reverse osmosis membrane is prepared by dissolving the non-dissolving antibacterial cellulose acetate in a solvent, adding a non-solvent to obtain a casting liquid, scraping, and solidifying. According to the technical scheme provided by the application, bromo-alkyl antibacterial groups are grafted to cellulose acetate to obtain the non-dissolving antibacterial cellulose acetate having good chemical stability and good antibacterial efficiency, and a reverse osmosis membrane made with the non-dissolving antibacterial cellulose acetate has good antibacterial property.

Owner:TIANJIN POLYTECHNIC UNIV

Method for recovering copper, lead and zinc from ultra-fine complicated cyanidation tailings

ActiveCN104646185AThe process is easy to operateProduction indicators are stableFlotationSodium carbonateOre concentrate

The invention provides a method for recovering copper, lead and zinc from ultra-fine complicated cyanidation tailings, and belongs to the technical field of mineral processing. The method comprises the following steps that (1) the ultra-fine complicated cyanidation tailings are concentrated through a thickener, and water and sodium carbonate are added and are stirred to be made into primary ore pulp; (2) the primary ore pulp is conveyed to a flotation machine unit, once-coarse once-fine twice-sweeping flotation flow process is adopted for recovering lead; the tailings obtained through secondary sweeping flotation are lead sweeping flotation tailings; (3) the lead sweeping flotation tailings are concentrated, then, water is added, and secondary ore pulp is prepared; the secondary ore pulp is conveyed to the flotation machine unit, once-coarse twice-fine and twice-sweeping flotation flow process is adopted for recovering copper, and the tailings obtained through secondary sweeping flotation are copper sweeping flotation tailings; (4) the copper sweeping tailings are concentrated, then, water is added, and tertiary ore pulp is obtained, and the pH value is regulated; once-coarse three-time-fine and twice-sweeping flotation flow process is adopted for recovering zinc; concentrates obtained through tertiary concentration are zinc concretes. The method provided by the invention has the advantages that the operation in the technical process is simple, the production index is stable, in addition, the recovery and the use of production tailing water are realized, and the environment pollution is reduced.

Owner:NORTHEASTERN UNIV

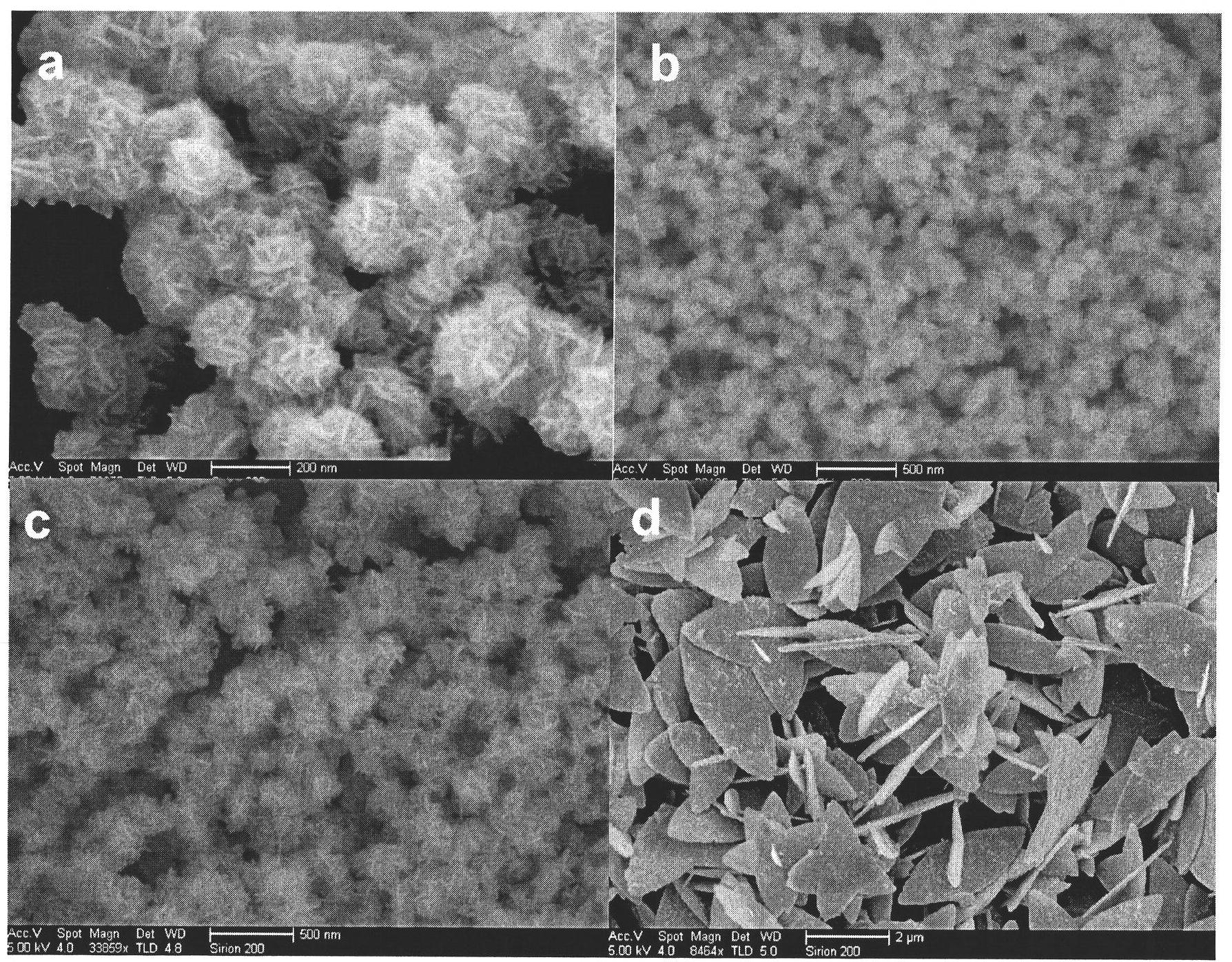

Method for preparing tungsten trioxide nano material

InactiveCN102211789AGood dispersionEffective control of morphologyNanostructure manufactureTungsten oxides/hydroxidesDistilled waterTungsten trioxide

The invention discloses a method for preparing a tungsten trioxide nano material. The method comprises the following steps of: placing a metal tungsten plate in deionized water or distilled water with stirring, irradiating the metal tungsten plate by using laser with wavelength of 532nm or 1,064 nm, the pulse width of between 5 and 15ns, repetition frequency of 1 to 20Hz and single pulse energy of 50 to 120mJ for at least 10 minutes to obtain tungstic acid colloidal solution and then performing aging treatment on the tungstic acid colloidal solution for at least 24 hours or adding acid into the tungstic acid colloidal solution to adjust the pH value of the tungstic acid colloidal solution to be -0.6 to 3.0 to obtain yellow precipitates, or placing the metal tungsten plate in the acid solution with the pH value of -0.6 to 3.0 with stirring, and irradiating the metal tungsten plate by using the laser with the wavelength of 532nm or 1,064 nm, the pulse width of between 5 and 15ns, repetition frequency of 1 to 20Hz and single pulse energy of 50 to 120mJ to obtain the yellow precipitates, then centrifuging and washing the yellow precipitates to obtain the tungstic acid; and placing thetungstic acid at the temperature of 480 to 520 DEG C, and annealing for at least one hour to obtain the tungsten trioxide nano material. The appearance and the size of the product can be effectively adjusted and controlled in a large range.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Welding technology for copper pipe and steel pipe

InactiveCN103920972AThe process is easy to operateEnvironmental protection is goodArc welding apparatusWelding/soldering/cutting articlesSteel tubeMachine tool

The invention discloses a welding technology for a copper pipe and a steel pipe. The copper pipe and the steel pipe are circular pipes. The technology comprises the steps that (1) the copper pipe and the steel pipe which are in insertion connection or butt connection are integrally fixed to a clamp body rotating on a machine tool at a constant speed; (2) the current of an argon arc welding gun is adjusted, the electric arc heating temperature of the argon arc welding gun is made to reach more than 1000 DEG C, the angle of the argon arc welding gun is adjusted, and the argon arc welding gun is made to be aligned with the portion where the copper pipe is combined with the steel pipe; (3) the argon arc welding gun is started to heat the circumference of the portion where the copper pipe is combined with the steel pipe when the copper pipe and the steel pipe rotate at the constant speed, after heating for 5 s, copper at the portion where the copper pipe is combined with the steel pipe is in the molten state, and steel at the portion where the copper pipe is combined with the steel pipe is in the semi-molten state, the copper and the steel naturally permeate each other and are blended, the copper pipe and the steel pipe are taken out to be cooled, and the copper pipe is tightly connected with the steel pipe. The welding technology is good in environment-friendly performance, easy and convenient to implement, low in cost and safe to use.

Owner:任少琳

Efficient recycling device and process for hollow particles in ash residues in ash storing yard and storage yard of power station

ActiveCN103752592AThe process is easy to operateLow running costSolid waste disposalSlurry pumpPower station

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Method of reducing heavy metals of cereals

ActiveCN103549234BThe process is easy to operateLow costFood homogenisationFood precipitationChemistryNational standard

The invention belongs to the technical field of deep processing of cereals such as rice, and relates to a method of reducing heavy metal residues of cereals such as rice polluted by heavy metals such as cadmium and lead and processing byproducts. The method comprises the following steps: by taking the heavy metal polluted cereals such as rice, wheat and corn and cereal processing byproducts such as rice bran and bran as raw materials, purifying, cleaning, soaking by a soaking liquid, defibrinating and settling and separating to obtain a supernate; carrying out pH regulation, settlement or membrane separation, washing, settlement and drying to obtain cereal proteins; carrying out washing, pH adjustment, filtration and drying on precipitate to obtain cereal starch or polysaccharide; or carrying out washing, pH adjustment, protease hydrolysis, washing, filtration and drying to obtain cereal starch or polysaccharide. The permissible content of heavy metals such as cadmium, lead, arsenic, mercury and nickel in products such as cereal proteins, cereal starch or polysaccharide prepared by the method provided by the invention satisfies the national standard.

Owner:HUAZHONG AGRICULTURAL UNIVERSITY

Control method for polyester melt conveying pressure and system thereof

ActiveCN101481827ADelivery pressure is stableGuaranteed uptimeSpinning head liquid feederFluid pressure control using electric meansPolyesterComputer module

The invention relates to a polyester melt delivery pressure control method and a system thereof, in particular to a polyester melt delivery pressure control method and a system thereof in polyester melt direct spinning. The polyester melt pressure control is divided into five control links which are polyester melt discharging pump flow control, final polyester melt filter back pressure control, melt discharging pump speed control, dicing cutter flow control and dicing cutter speed control, the polyester melt discharging pump flow control, the final polyester melt filter back pressure control and the dicing cutter flow control are controlled by a cascade control loop consisting of a main loop and a minor loop, the melt discharging pump speed control is controlled by a melt discharging pump speed PID control module 4 and a melt discharging pump speed PID control module 5 respectively, and the dicing cutter speed control is controlled by a dicing cutter speed PID control module 10 and a dicing cutter speed PID control module 13 respectively. The control method and the system thereof solve the problem of polyester melt delivery pressure fluctuation in the polyester melt direct spinning, and make up the deficiency that the prior art can only perform manual control.

Owner:JIANGSU HENGLI CHEM FIBER

Method for purifying recombinant human proinsulin

ActiveCN102532257AGuarantee process consistencyThe process is easy to operatePeptide preparation methodsEnzymeEnzyme digestion

The invention belongs to the field of biomedicine, and particularly relates to a method for purifying recombinant human proinsulin, in particular to a method for purifying recombinant human proinsulin by using macroporous absorbent resin and cation exchange resin. In the method, a recombinant human proinsuli plural liquid is adsorbed and concentrated through the macroporous absorbent resin, and is loaded onto the cation exchange resin for further purifying, so that the collected proinsulin has high yield and high purity, and can be directly applied to enzyme digestion to obtain insulin. The method is easy and convenient to operate, has high process cohesion, and is suitable for industrial production.

Owner:LUNAN PHARMA GROUP CORPORATION

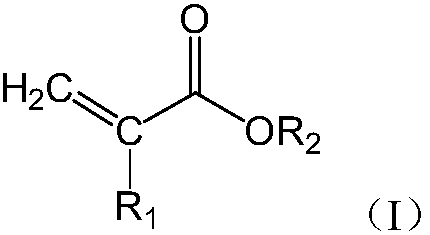

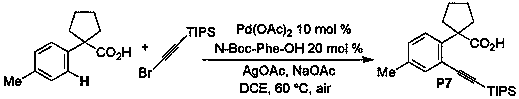

Phenylacetic acid type aryne preparation method

InactiveCN109553633AEasy to getFew reaction stepsSilicon organic compoundsPhenylacetic acidPalladium catalyst

The invention discloses a phenylacetic acid type aryne preparation method, wherein compounds represented by a structural formula I and a structural formula II are used as raw materials, the ortho-alkynylation reaction of the compound represented by the structural formula I is achieved in an organic solvent by adding a ligand and a palladium catalyst in the presence of an alkali and an oxidizing agent so as to obtain phenylacetic acid type aryne represented by a structural formula III. According to the present invention, the introducing of the external guiding group is not required during the synthesis so as to reduce the reaction steps; and the preparation method has advantages of simple and convenient process operation, easily-available raw materials, mild conditions, cost reducing and reduced requirements on equipment, and is suitable for industrial mass production. The formulas I, II and III are defined in the specification.

Owner:HUBEI UNIV

Processing method of boiled petasites tatewakianus

ActiveCN103976307AReduce iron oxide contentImprove darkeningFood ingredientsFood preparationCitric acidChemistry

The invention relates to a processing method of boiled petasites tatewakianus. The processing method comprises the step of adding petasites tatewakianus raw materials into a citric acid solution for sufficiently precooking for 7-12min, wherein the citric acid solution is prepared by adding 520-560g of citric acid into every 1000kg of water, the mass ratio of the petasites tatewakianus raw materials to the water in the citric acid solution is 1:5, the temperature of the citric acid solution is 95-100 DEG C, and the pH value is 3.9-4.3. The canned boiled petasites tatewakianu prepared by using the processing method of the boiled petasites tatewakianu, provided by the invention, has the advantages of petasites tatewakianus raw material blackening phenomenon improvement, petasites tatewakianus taste improvement, low petasites tatewakianus skin viscidity, high toughness as well as simplicity and easiness for peeling.

Owner:FUJIAN SANXIN FOOD STUFFS

Bulging process taking manual flat-press flat-die cutting machine as carrier

ActiveCN102166898AThe process is easy to operateReduce manufacturing costPattern printingEngineering

The invention belongs to a process for bulging after a packaging product is printed, in particular to a bulging process taking a manual flat-press flat-die cutting machine as a carrier, which is characterized by comprising the following steps of: (1) fixing the position of a negative plate; (2) fixing the position of a positive plate; (3) pressing in a combined mode; (4) pressing in a separated mode; (5) finely adjusting the bulging position; and (6) carrying out bulging operation. The bulging process provided by the invention is simple and convenient in operation, stable and reliable, and low in production cost. In the invention, a common flat-press flat-die cutting machine is used as a carrier, and a simple, convenient and feasible process is matched to realize a high-precision bulging process which can be realized by an automatic die cutting machine, thereby greatly lowering the production cost and improving the utilization ratio of equipment.

Owner:ZIBO TAIBAO FP PROD CO LTD

Preparation method of ZTA nano composite powder

The invention discloses a preparation method of ZTA nano composite powder. The preparation method comprises the following steps of: (1) weighing raw materials including spherical Al2O3, ZrO2, MgO andadditive powder according to proportions, and premixing the raw materials; (2) using an agate ball as a ball milling ball, putting the premixed powder and the agate ball into a nylon ball milling tankaccording to a ball-material ratio of 4-5:1, using anhydrous ethanol as a ball milling medium with the addition amount of 1-2cm above the horizontal plane of the ball milling ball in the nylon tank,and adding a process control agent; (3) carrying out ball milling with a horizontal ball mill, and controlling the ball milling rate and the ball milling time; and (4) carrying out ball-material separation with anhydrous ethanol after ball milling, drying the separated mixed solution, and sieving the powder after drying through a sieve of 80 meshes to obtain ZTA nano composite powder. The preparation method provided by the invention has the advantages of short process flow, simple and convenient process operation, low equipment requirement, low cost, less emission of three wastes, less harm toenvironment and human bodies, and convenience for popularization and industrial large-scale continuous production.

Owner:SOUTHWEST UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com