Preparation method of ZTA nano composite powder

A nano-composite and powder technology, which is applied in the field of large-scale and rapid ZTA nano-composite powder preparation, can solve the problems of complicated ZTA nano-composite powder technological process, unfavorable large-scale industrial production, long process cycle, etc. The effect of industrial large-scale continuous production, environmental protection, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

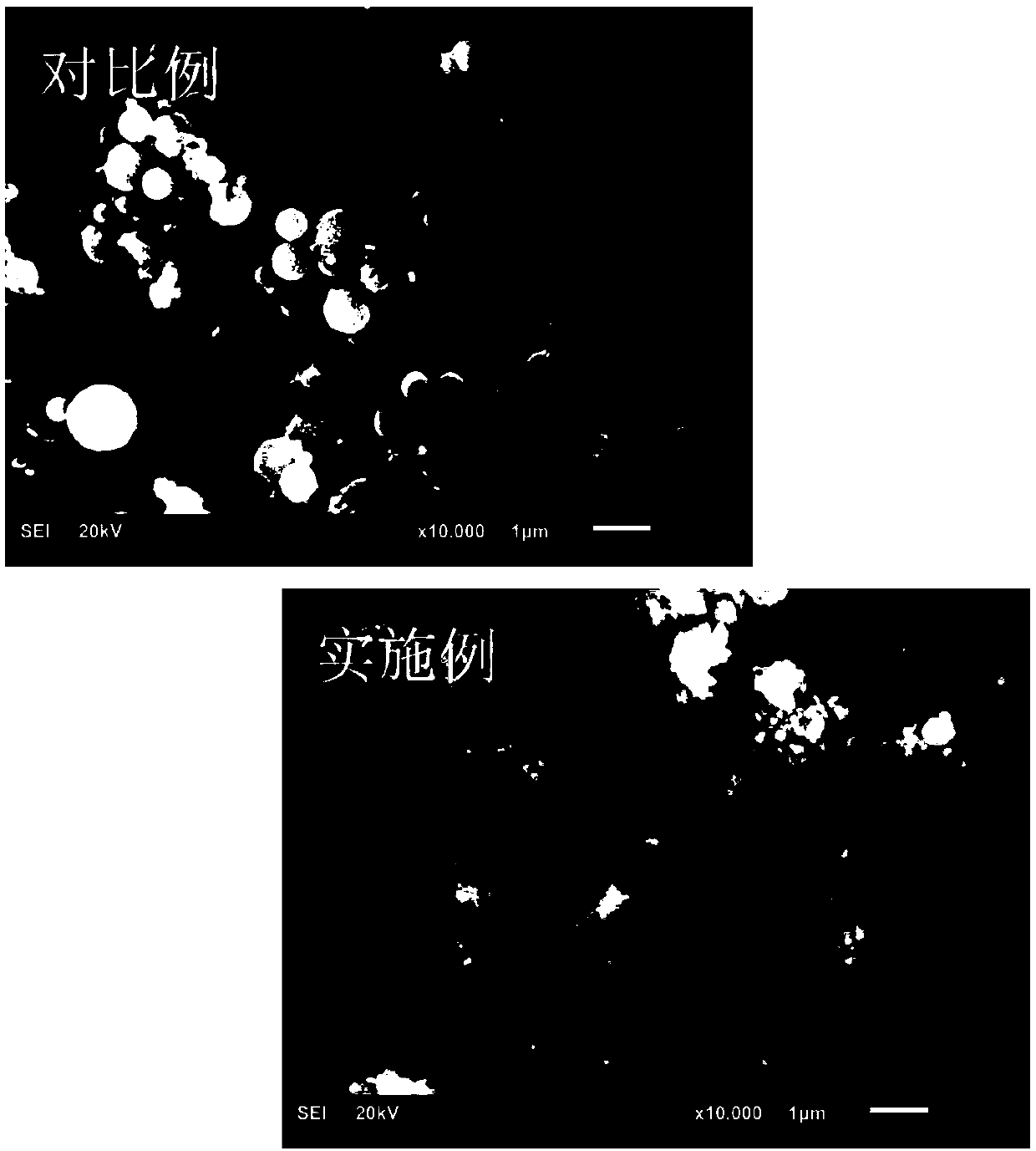

[0028] Such as Figure 1 to Figure 3 as shown, figure 1 It is the graph of the powder morphology change before and after the addition of the additive of the present invention; the powder of the comparative example is seriously agglomerated, ZrO2 is unevenly distributed, the powder particles of the embodiment are fine, and the agglomeration is relatively light, and ZrO2 is distributed on the surface of the spherical particle and uniformly dispersed;

[0029] figure 2 It is a diagram of the composition change of the powder sintered sample before and after the addition of the additive of the present invention; t-ZrO2 increases obviously, which is conducive to improving the strength and toughness of the material;

[0030] image 3 It is a graph showing the change in mechanical properties of the sintered sample before and after adding the additive of the present invention. The addition of Al improves the dispersion of ZrO2 in the powder, and the ZrO2 grains are finer after sint...

Embodiment 2

[0044] The difference between embodiment 2 and embodiment 1 is:

[0045] A kind of preparation method of ZTA nanocomposite powder of the present invention, comprises the steps:

[0046] In step (1), the raw material spherical Al 2 o 3 , ZrO 2 , MgO, and additive powder are premixed according to the proportioning configuration; the raw material powder includes the following components according to mass percentage:

[0047] 15%≤ZrO 2 ≤30%,

[0048] MgO 0.25,

[0049] 0.5%≤Al≤5%,

[0050] The balance is additive powder.

[0051] In step (2), the ball milling balls are agate balls, and the premixed powder and agate balls are put into the nylon ball milling tank according to the ball-to-material ratio of 4:1, and absolute ethanol is used as the ball milling medium, and the amount of absolute ethanol added is Submerged 1.2cm above the level of ball milling balls in the nylon tank, and added process control agent;

[0052] In step (3), the ball milling speed is 45 rpm, and t...

Embodiment 3

[0054] The difference between embodiment 3 and embodiment 1 is: the preparation method of a kind of ZTA nanocomposite powder of the present invention, comprises the steps:

[0055] In step (1), the raw material spherical Al 2 o 3 , ZrO 2 , MgO, and additive powder are premixed according to the proportioning configuration; the raw material powder includes the following components according to mass percentage:

[0056] 15%≤ZrO 2 ≤30%,

[0057] MgO 0.25,

[0058] 0.5%≤Al≤5%,

[0059] The balance is additive powder;

[0060] The additive powder is Al powder, its purity is ≥99.5%, and the particle size of Al powder is ≤Al 2 o 3 Powder size.

[0061] In step (2), the ball milling balls are agate balls, and the premixed powder and agate balls are put into the nylon ball milling tank according to the ball-to-material ratio of 4.5:1, and absolute ethanol is used as the ball milling medium, and the addition of absolute ethanol is Submerge 2cm of the ball milling ball level in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com