Shearing tool for insulation paper of rotor slot of miniature motor

A micro-motor and rotor slot technology, applied in laying solid insulation and other directions, can solve the problems of high labor intensity and low labor efficiency, and achieve the effect of shortening process time, reducing production cost and improving labor productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

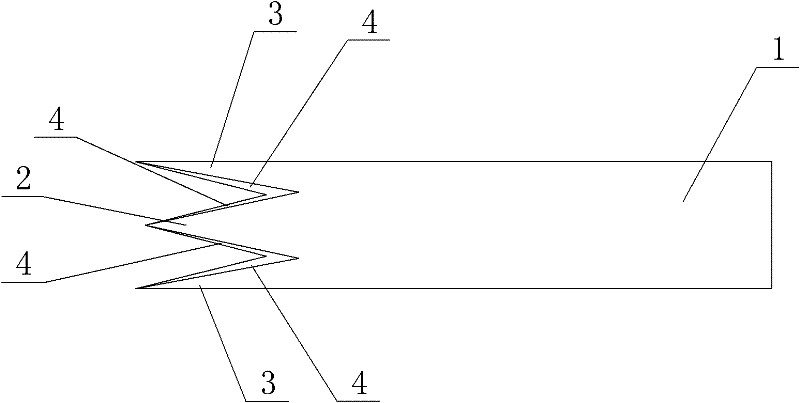

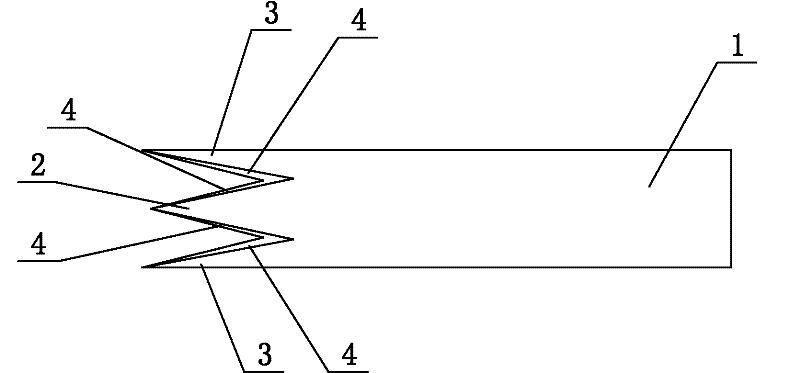

[0013] Please refer to figure 1 as shown, figure 1 It is a side view of the cutter for cutting insulating paper in the rotor slot of the micro-motor of the present invention.

[0014] In this embodiment, a micro motor rotor slot insulating paper shearing tool includes a knife handle 1 and a knife head, the knife head is arranged at one end of the knife handle 1, the knife handle 1 is a rectangular flat structure, and the knife head It is a zigzag structure with a total of three teeth, the middle is a whole tooth 2 with a cutting edge 4, the two sides of the whole tooth 2 are half teeth 3, and the two half teeth 3 are symmetrical along the middle whole tooth 2, and The inner sides of the two half-tooths 2 are provided with cutting edges 4, and the dedendum width of the full-toothed teeth 2 is equal to the arc length of the outer circle between two adjacent slots of the rotor.

[0015] The length from the tooth tip to the tooth root of the whole tooth 2 and the half tooth 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com