Lean oil heat intensified firing actuating apparatus of pulverized coal boiler

A technology of pulverized coal boiler and starting device, which is applied in the directions of burner, combustion method, combustion type, etc., to achieve the effects of fast combustion speed, strong wind resistance and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

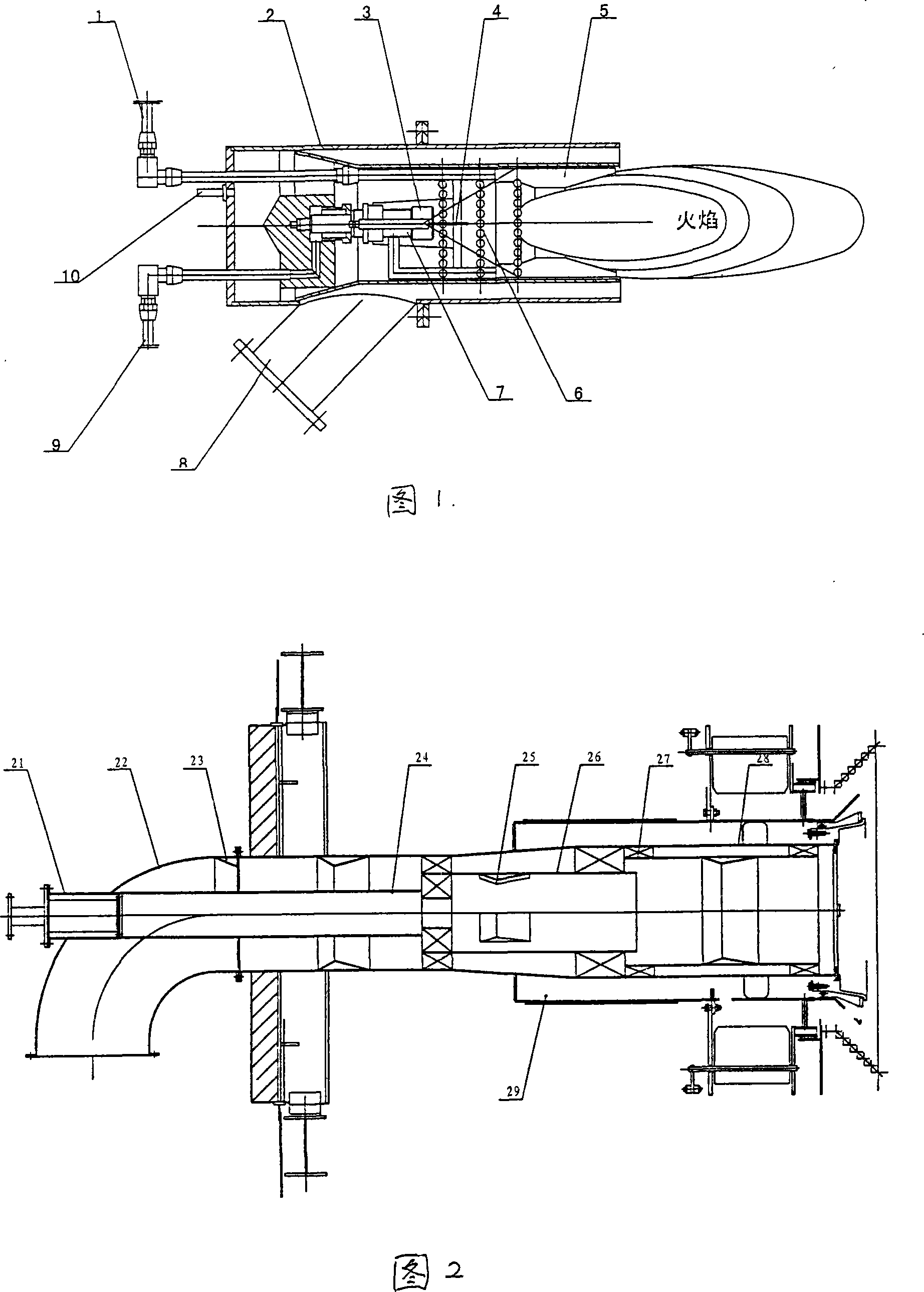

[0012] In Fig. 1, the oil-lean thermally enhanced oil burner 21 has a barrel-shaped double-layer casing 2, one end of the casing 2 is closed, and the other end is open. At the closed end, the oil inlet pipe 1 and the compressed air inlet pipe 9 penetrate the end. The walls are respectively inserted into the housing in parallel and fixed, and the compressed air inlet pipe 9 bends into the housing 2, and is sequentially connected with the lean oil gun 7, the air atomizer 3 and the electric igniter 4 installed axially at the center, and the air mist In front of the carburetor 3, there are air film air chambers 6 and oil-intensified preheating chambers 5 with 2-3 stages of porous sleeve structure; on the side of the closed end of the casing 2, there is an oblique air inlet pipe 8 connected, The air inlet pipe 8 is connected to the channel between the double-layer shells 2, forming a Venturi tube with an axial flow structure to supply air and support combustion; the combustion proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com