Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55 results about "Flame speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

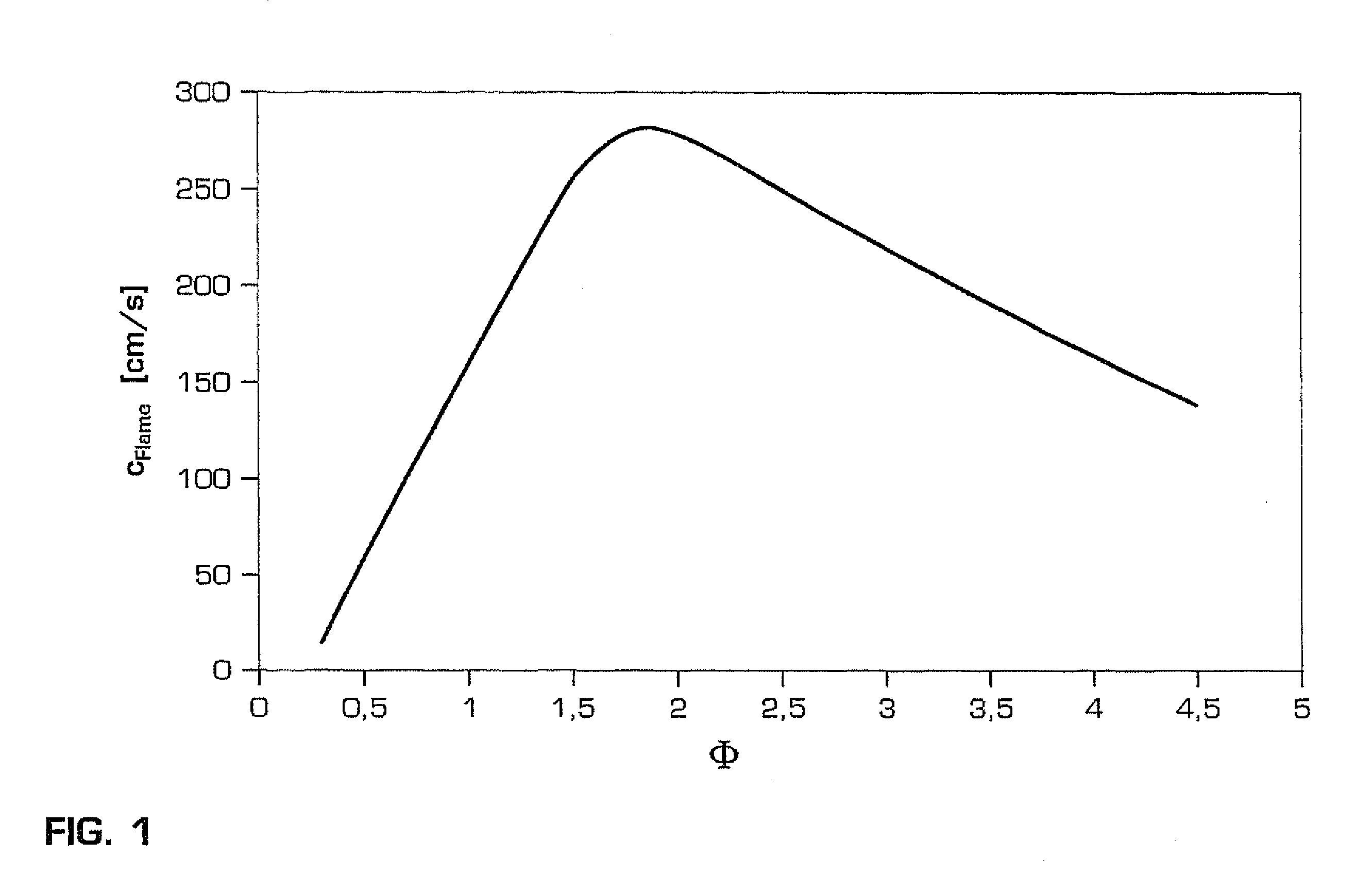

The flame speed is the measured rate of expansion of the flame front in a combustion reaction. Whereas flame velocity is generally used for a fuel, a related term is explosive velocity, which is the same relationship measured for an explosive. Combustion engineers differentiate between the laminar flame speed and turbulent flame speed. Flame speed is typically measured in m/s, cm/s, etc.

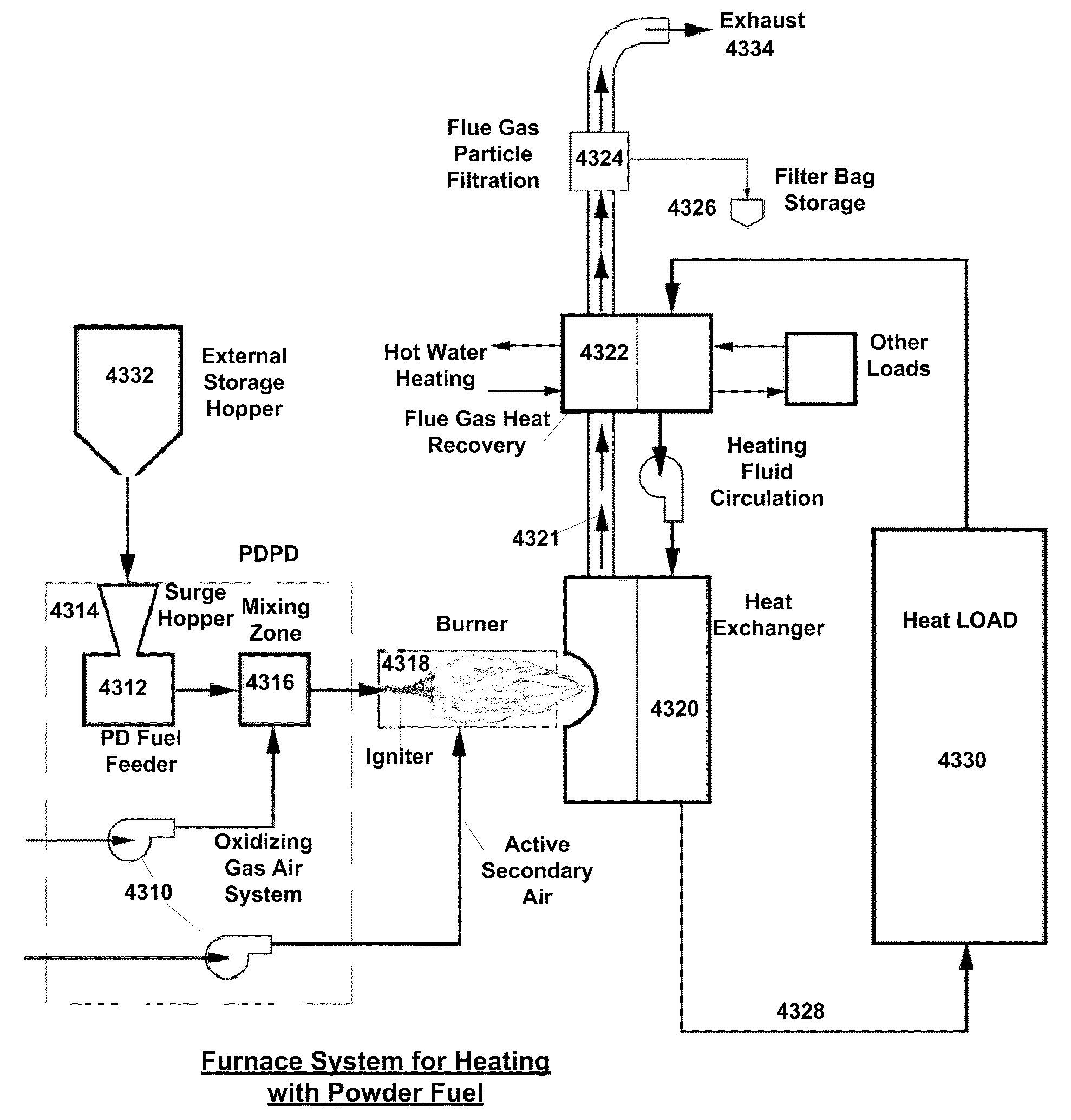

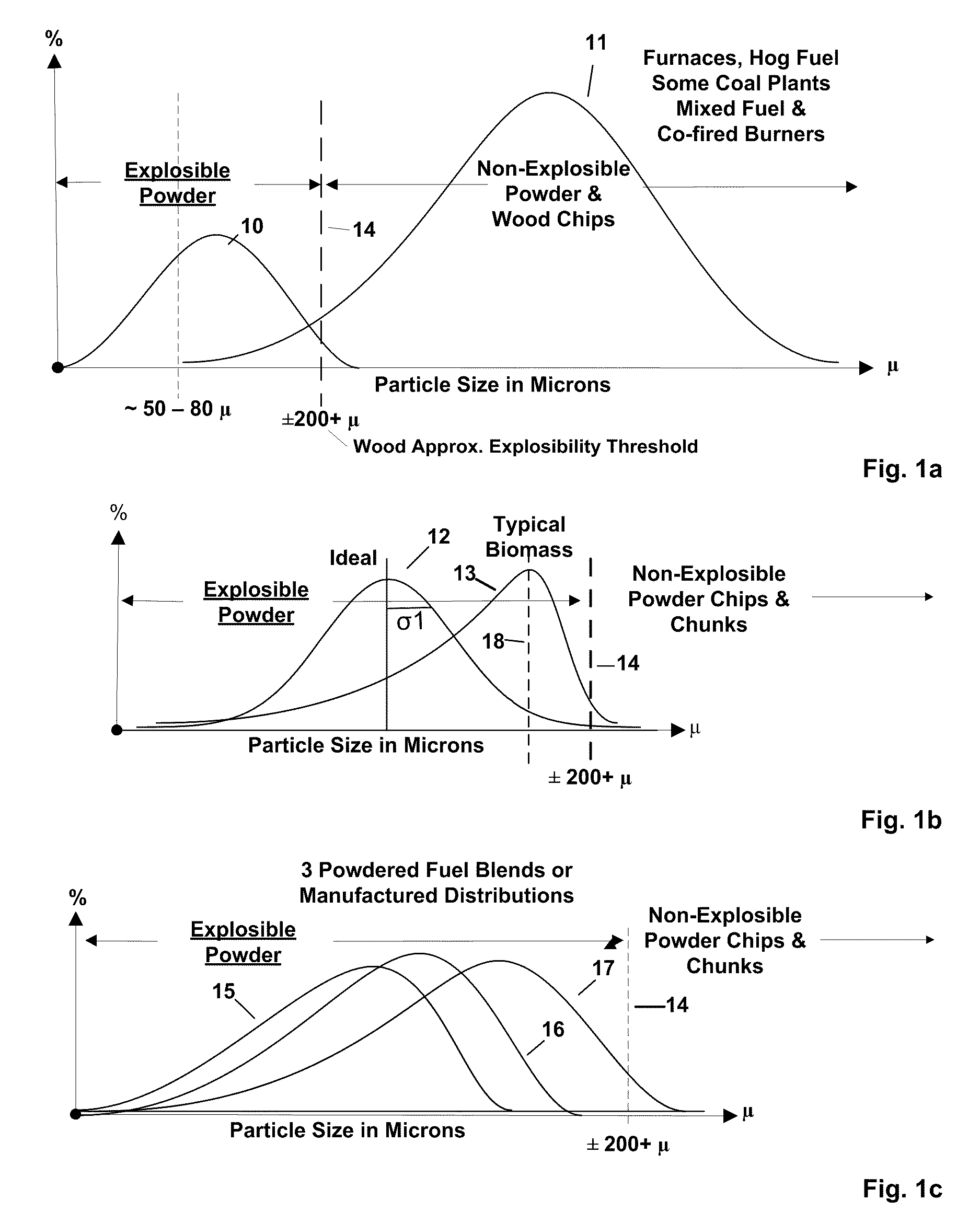

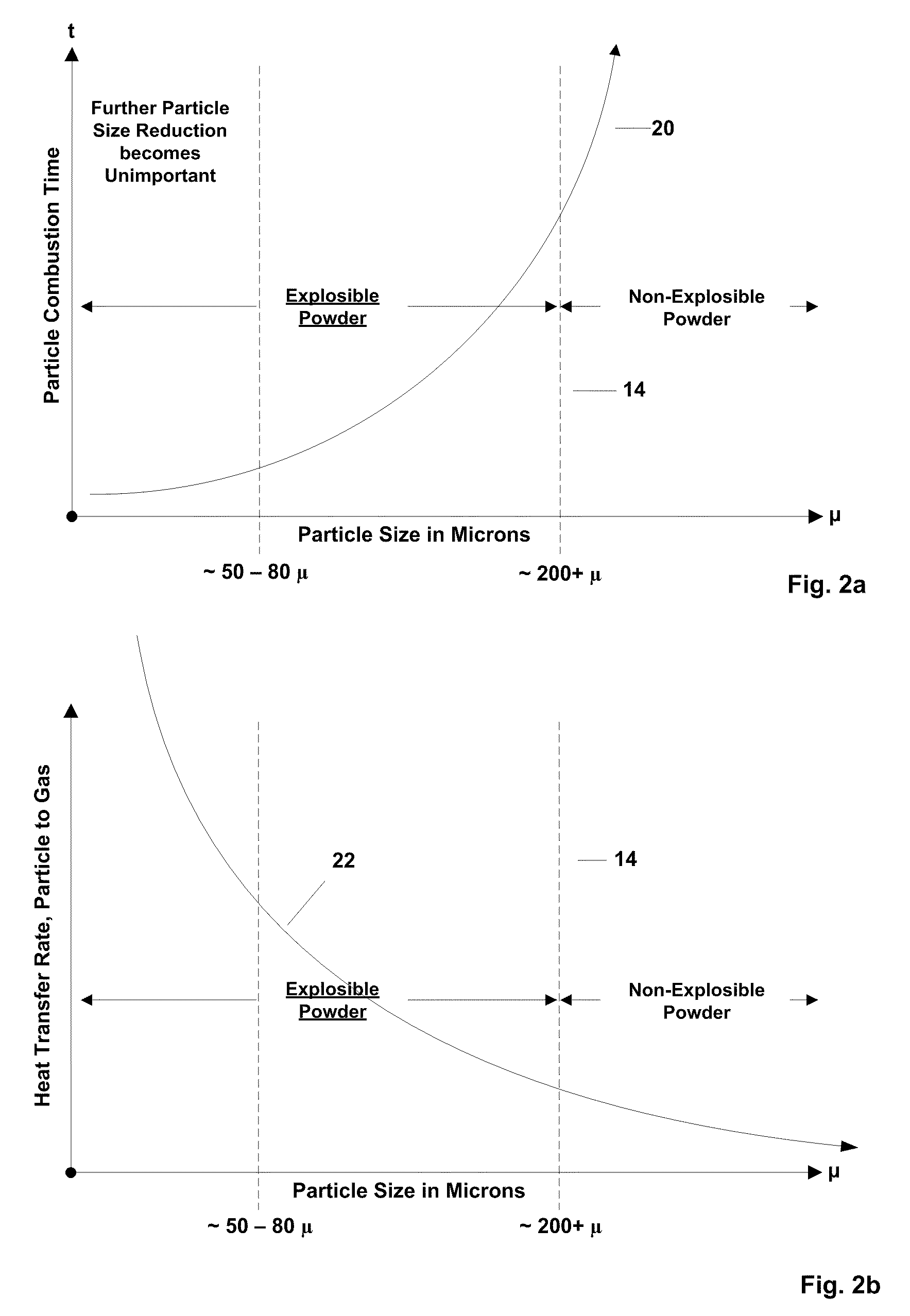

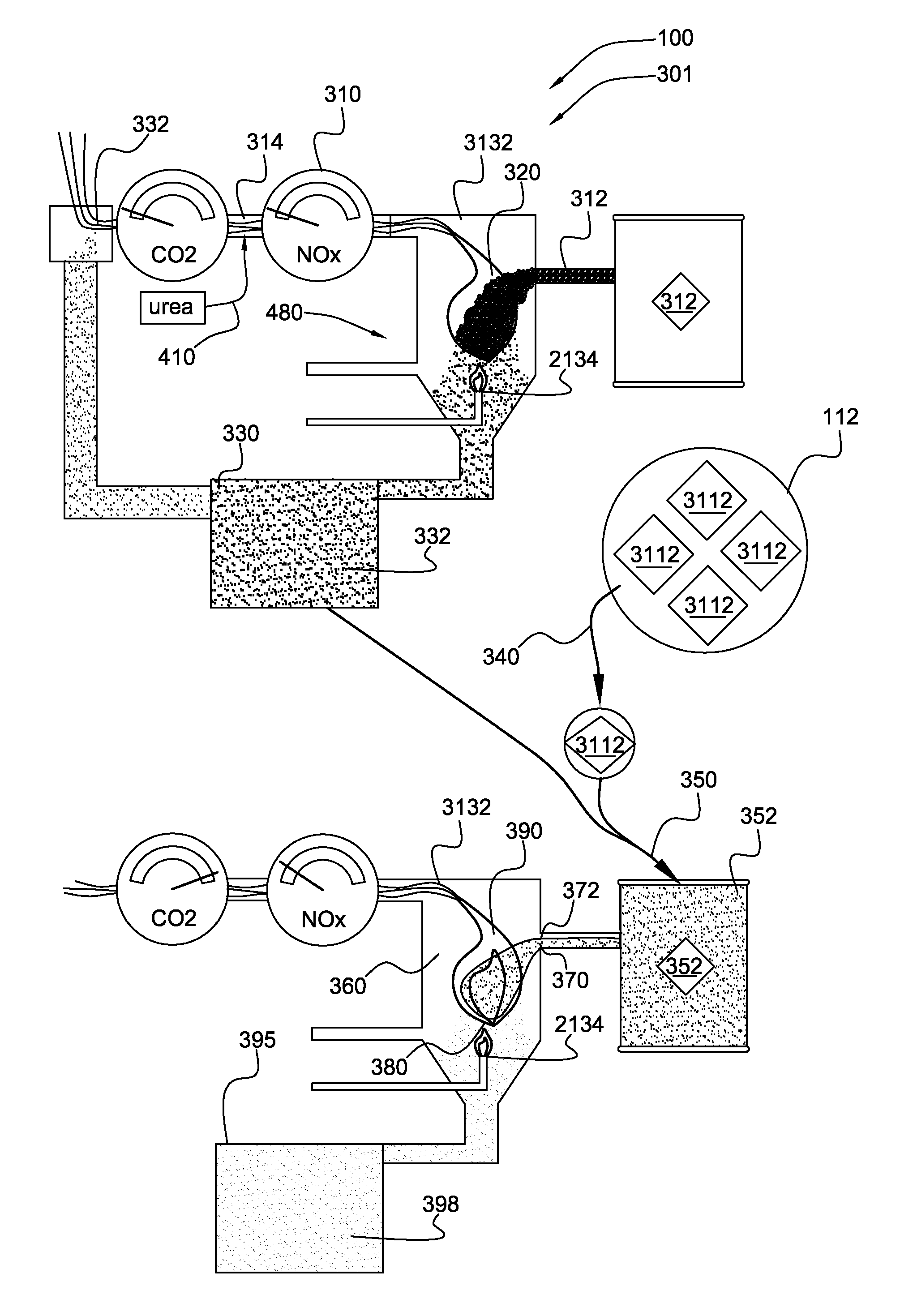

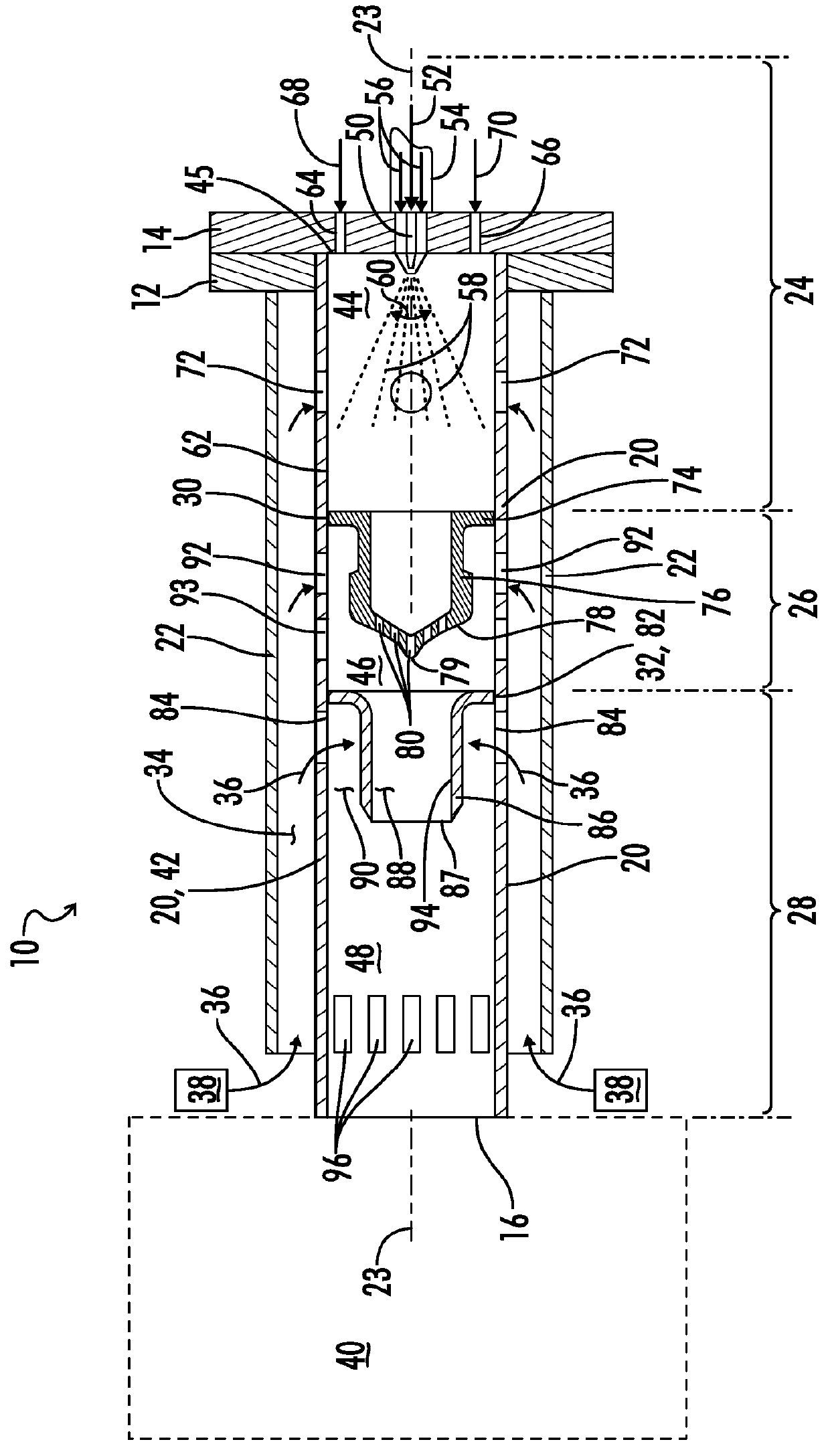

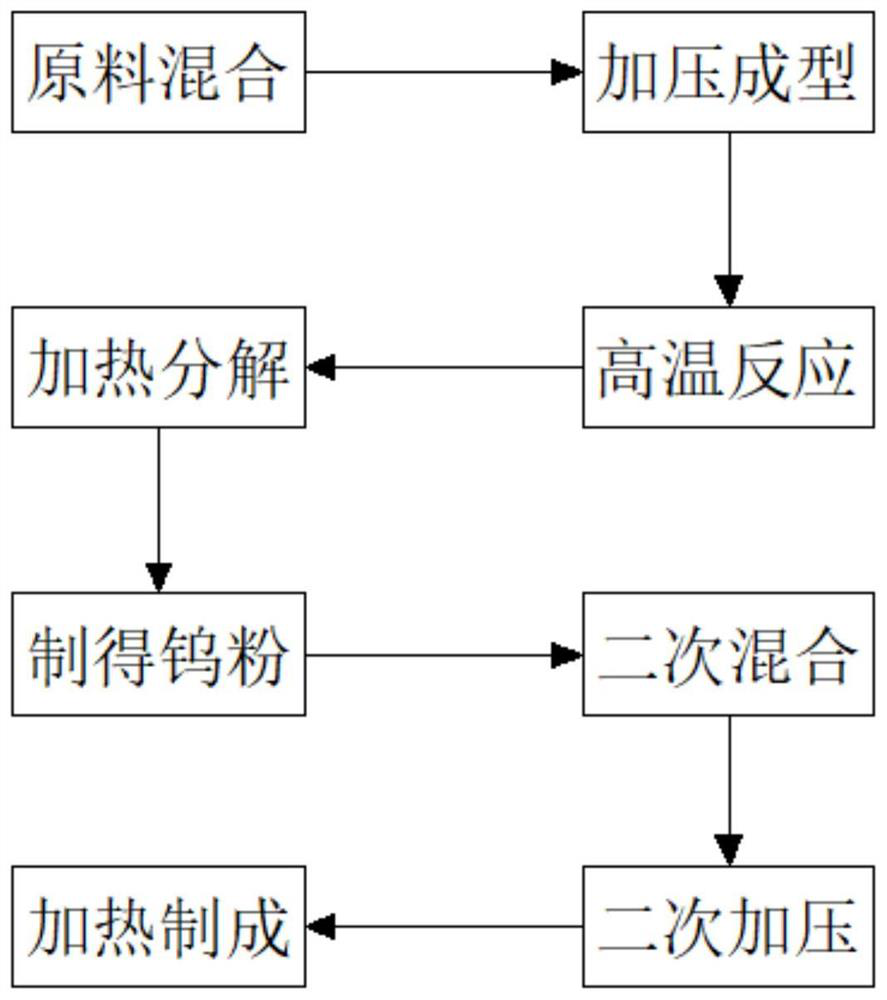

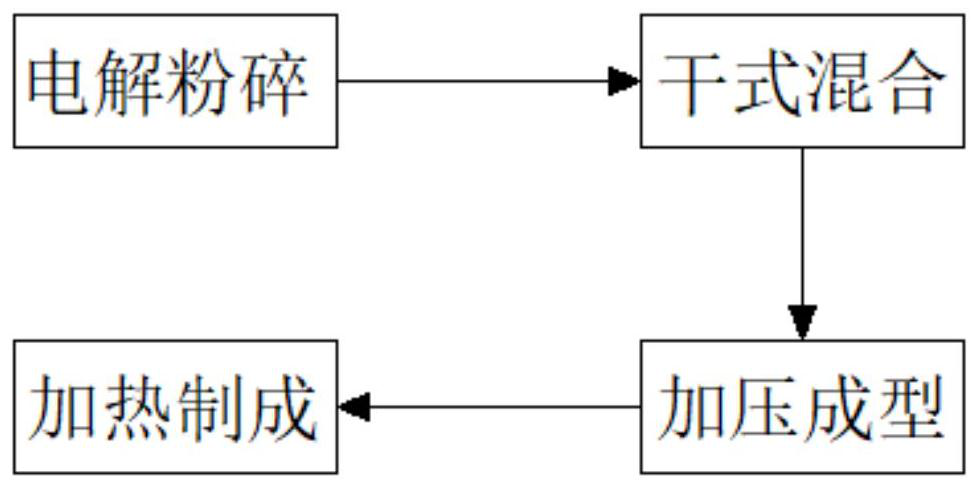

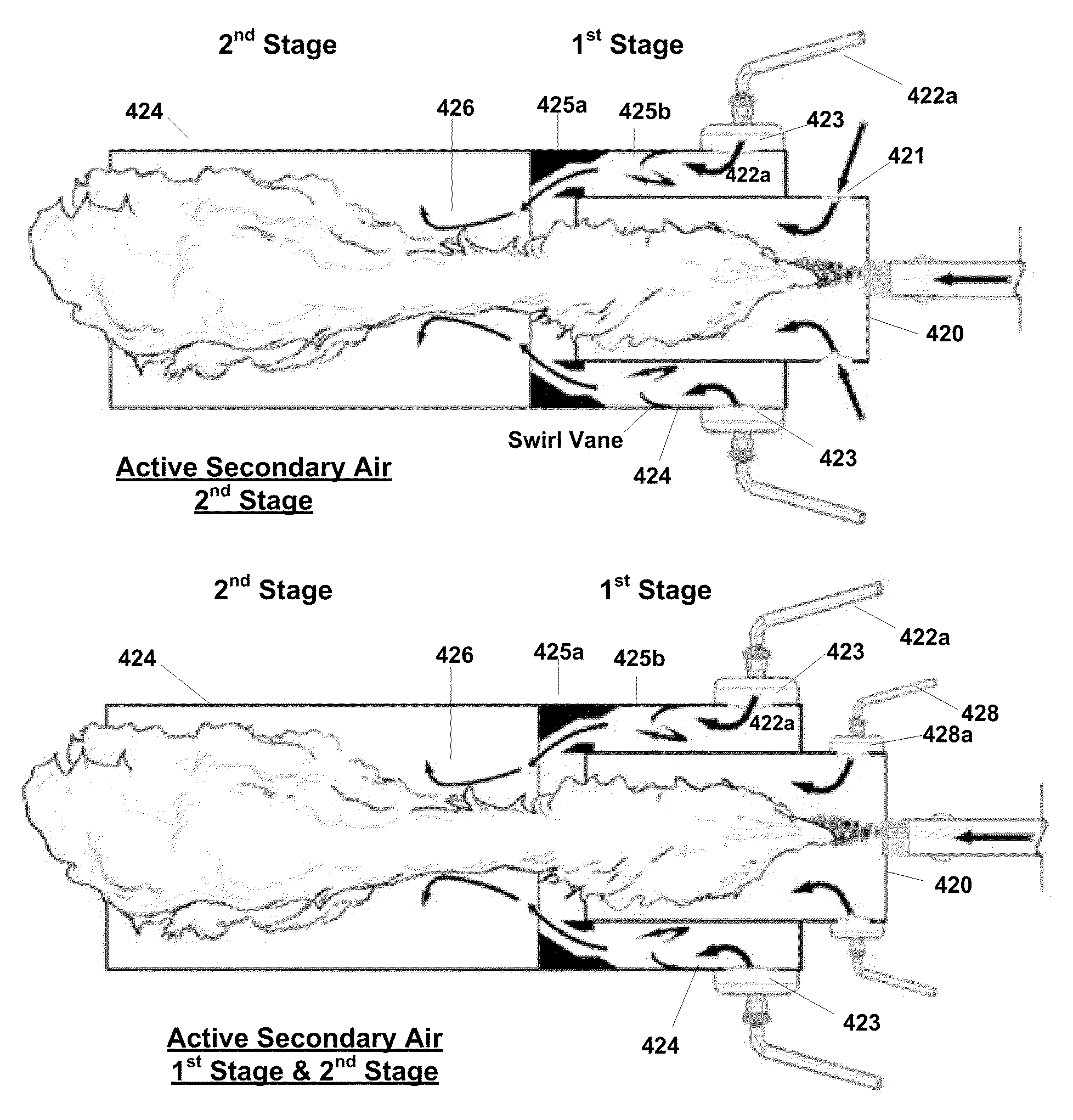

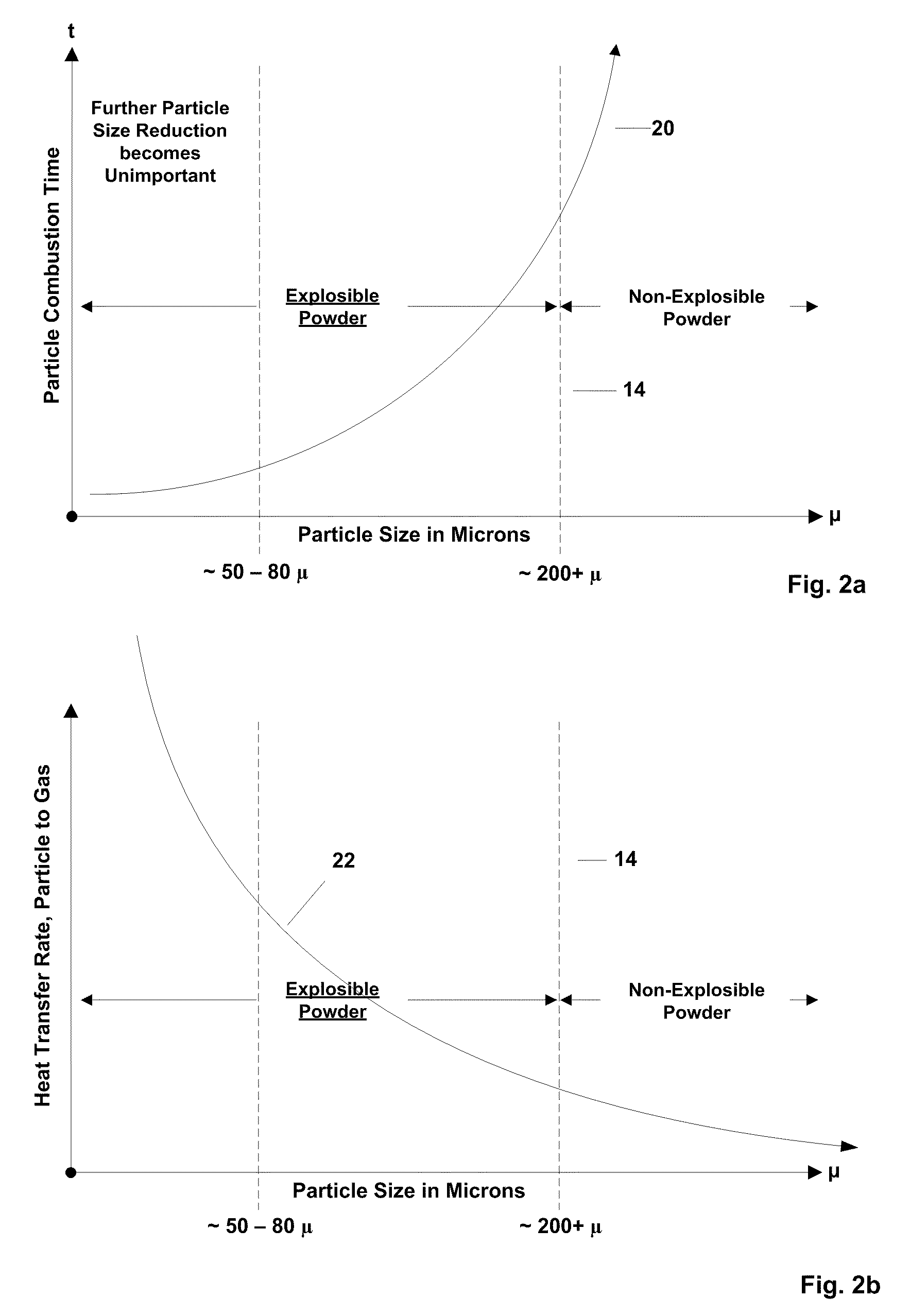

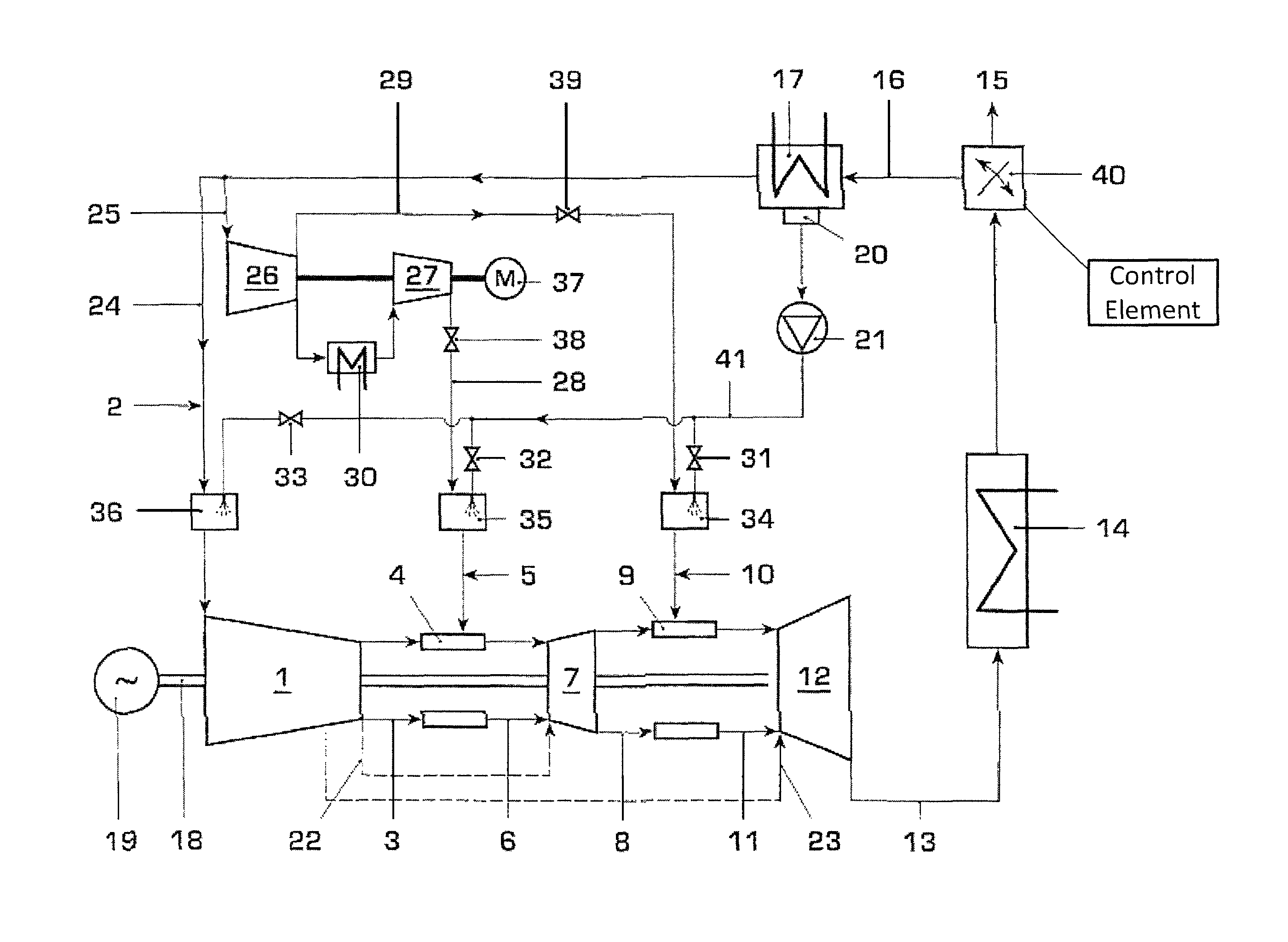

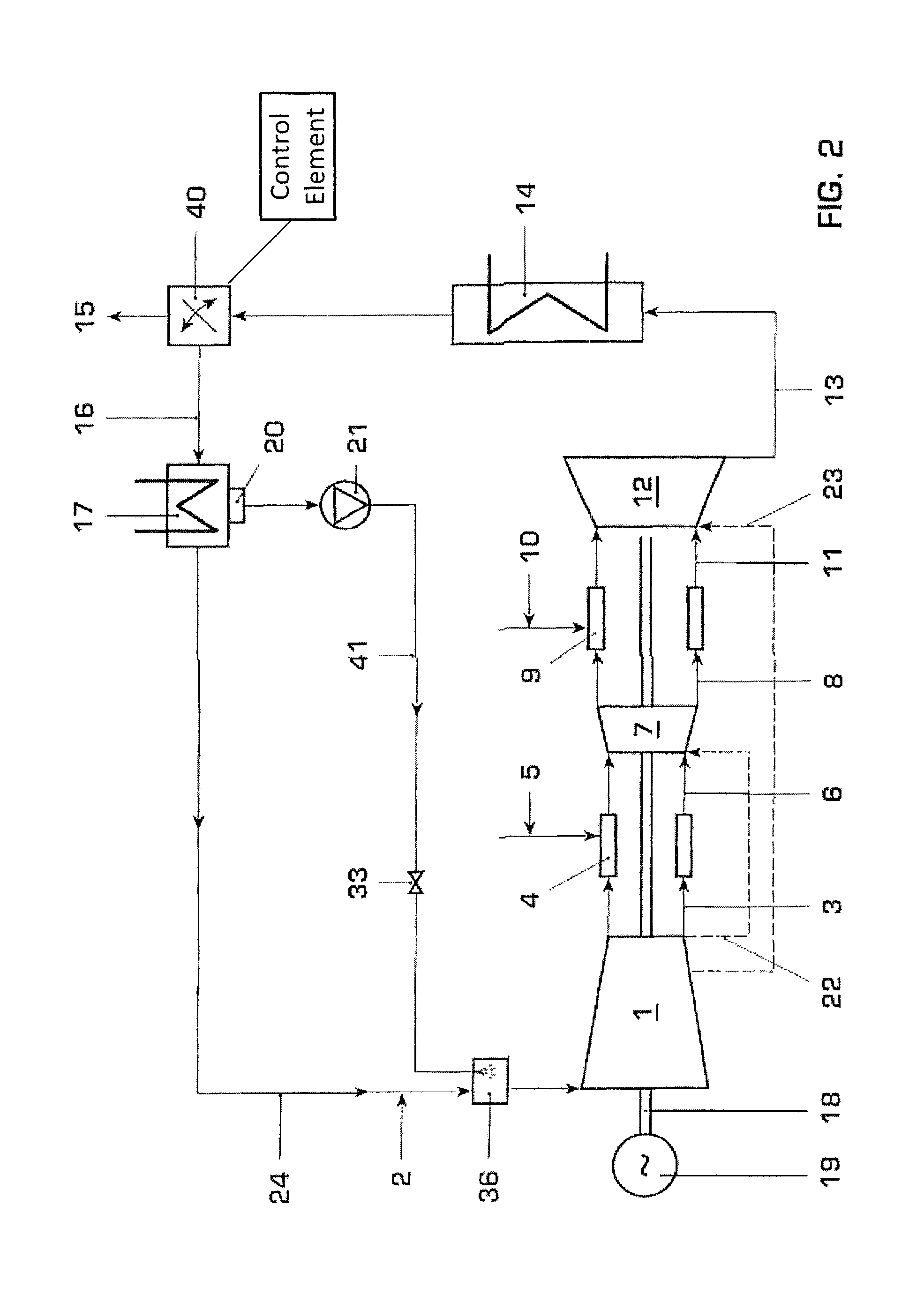

Powdered fuel conversion systems and methods

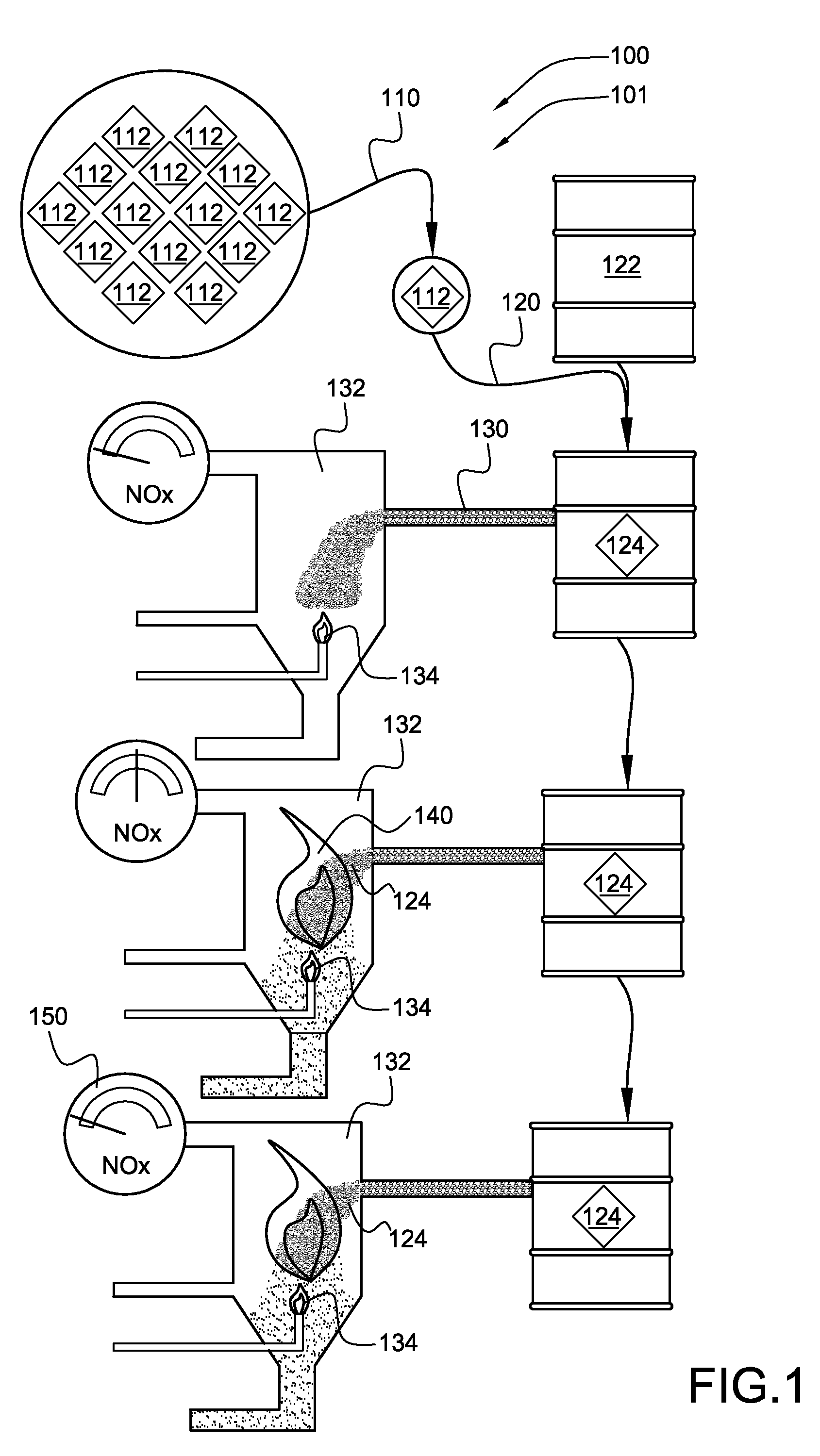

The burner preferably exclusively burns substantially explosible solid fuels and preferably has instant ON-OFF thermostat control, wastes no energy preheating the enclosure or external air supply, achieves stable combustion the moment the powder-air mix is ignited in our burner, is used in the upward vertical mode except for oil burner retrofits, burns a solid fuel in a single-phase regime as if it were a vaporized liquid or gas, is designed to complete combustion within the burner housing itself rather than in a large, high temperature furnace enclosure which it feeds, has an ultra-short residence time requirement, is a recycle consuming burner with self-contained management of initially unburned particles, is much smaller, simpler and lower cost, has a wider dynamic range / turndown ratio, is more efficient in combustion completeness and thermal efficiency, and operates with air-fuel mix approximately at the flame speed.

Owner:MCKNIGHT JAMES K +2

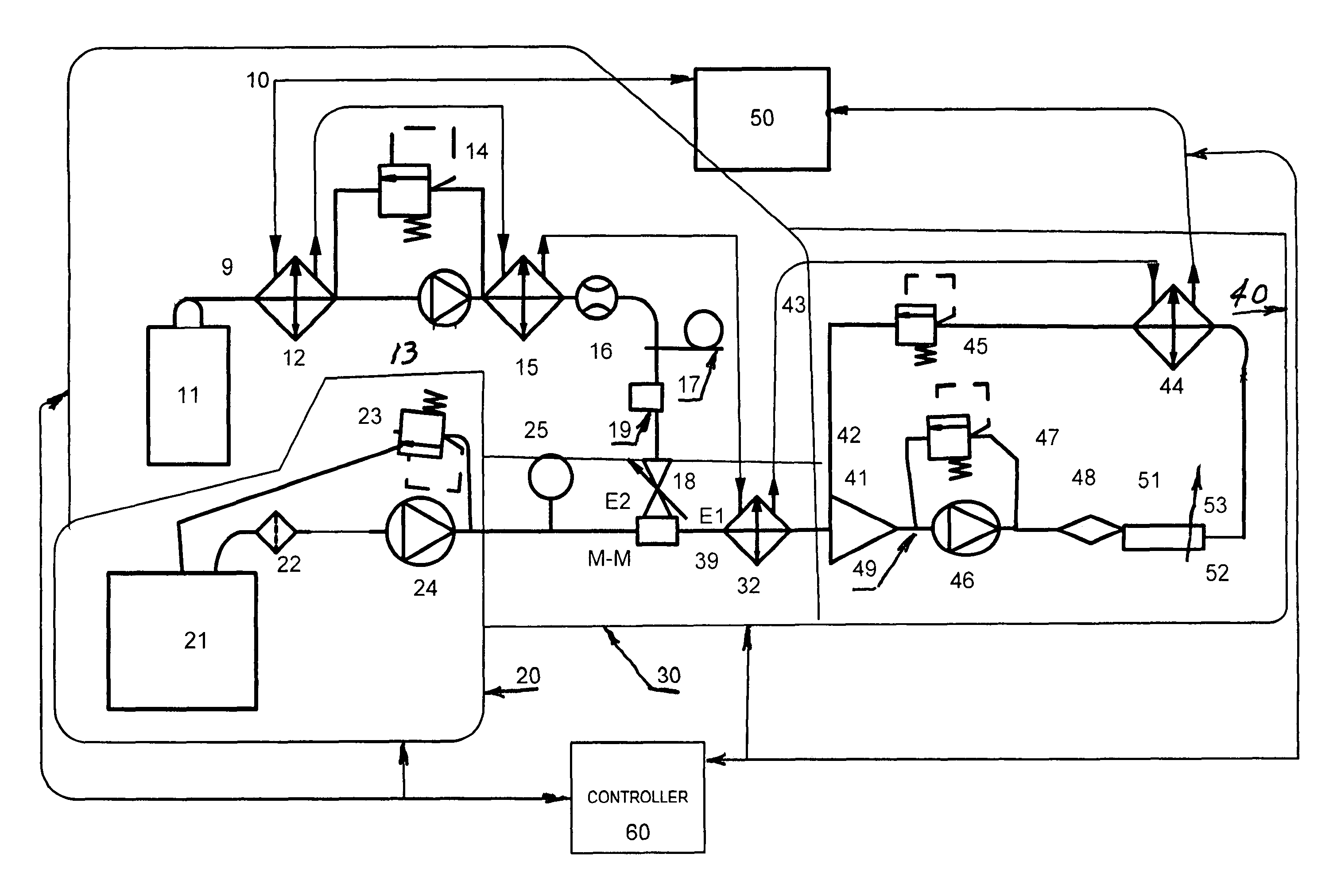

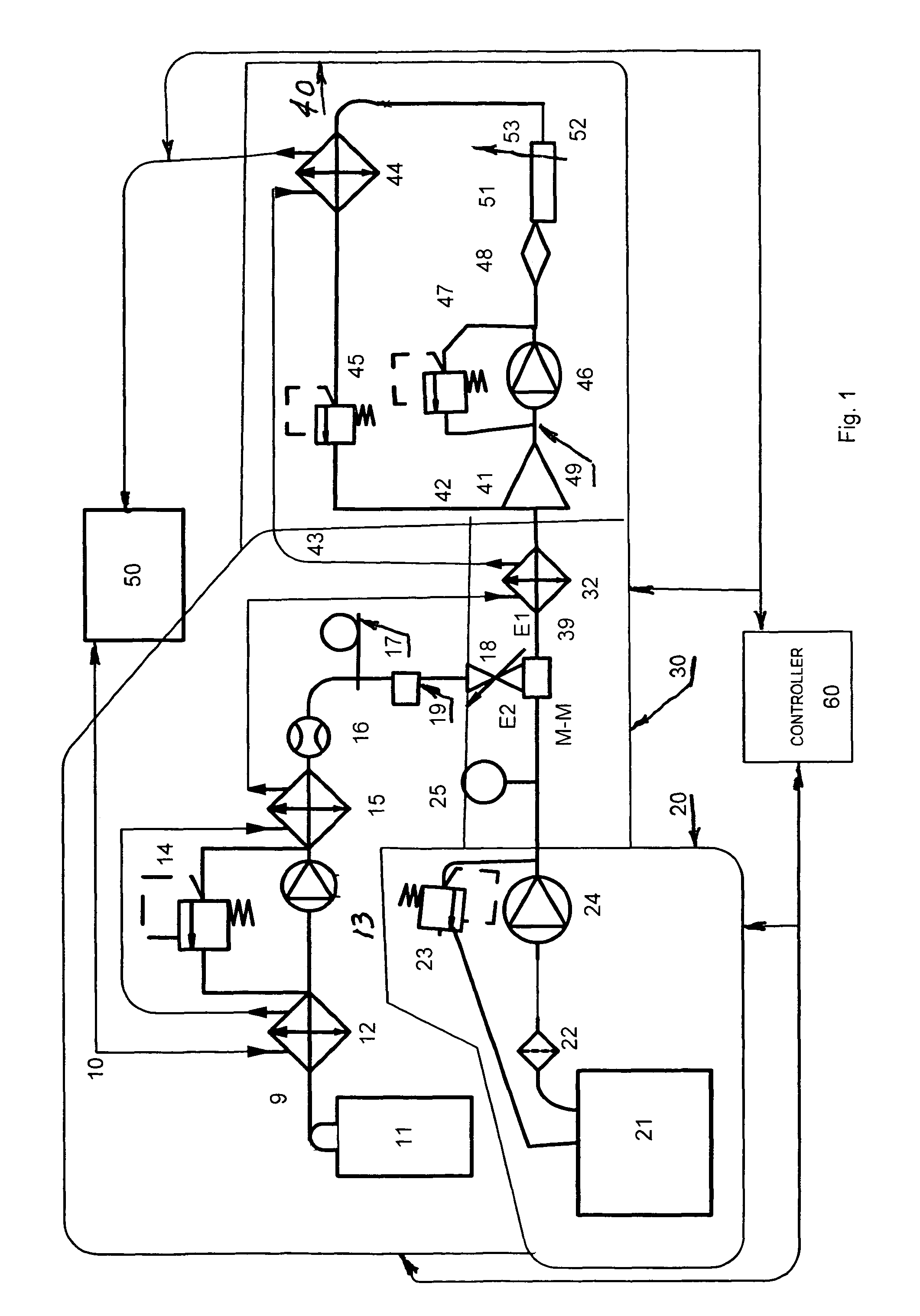

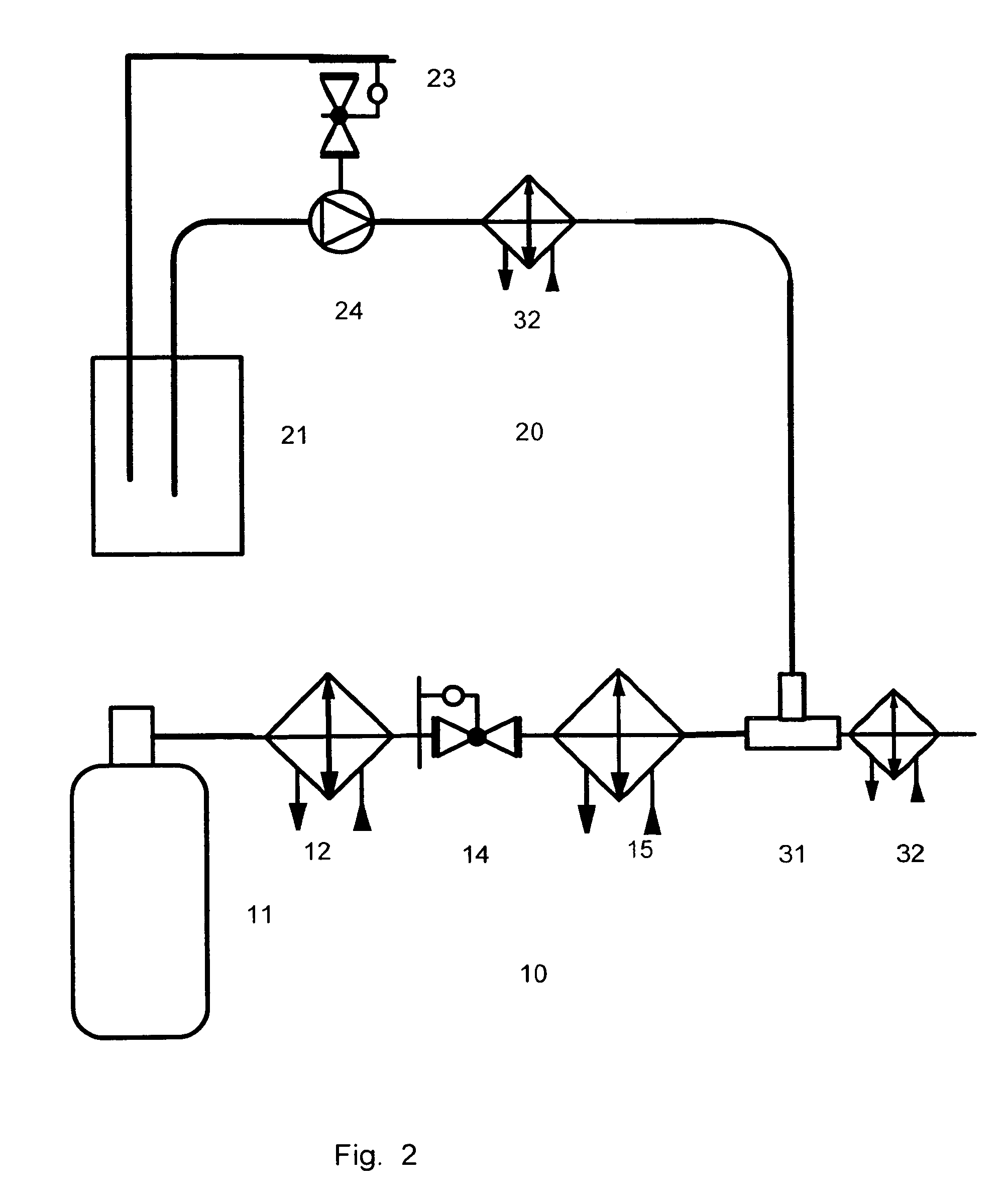

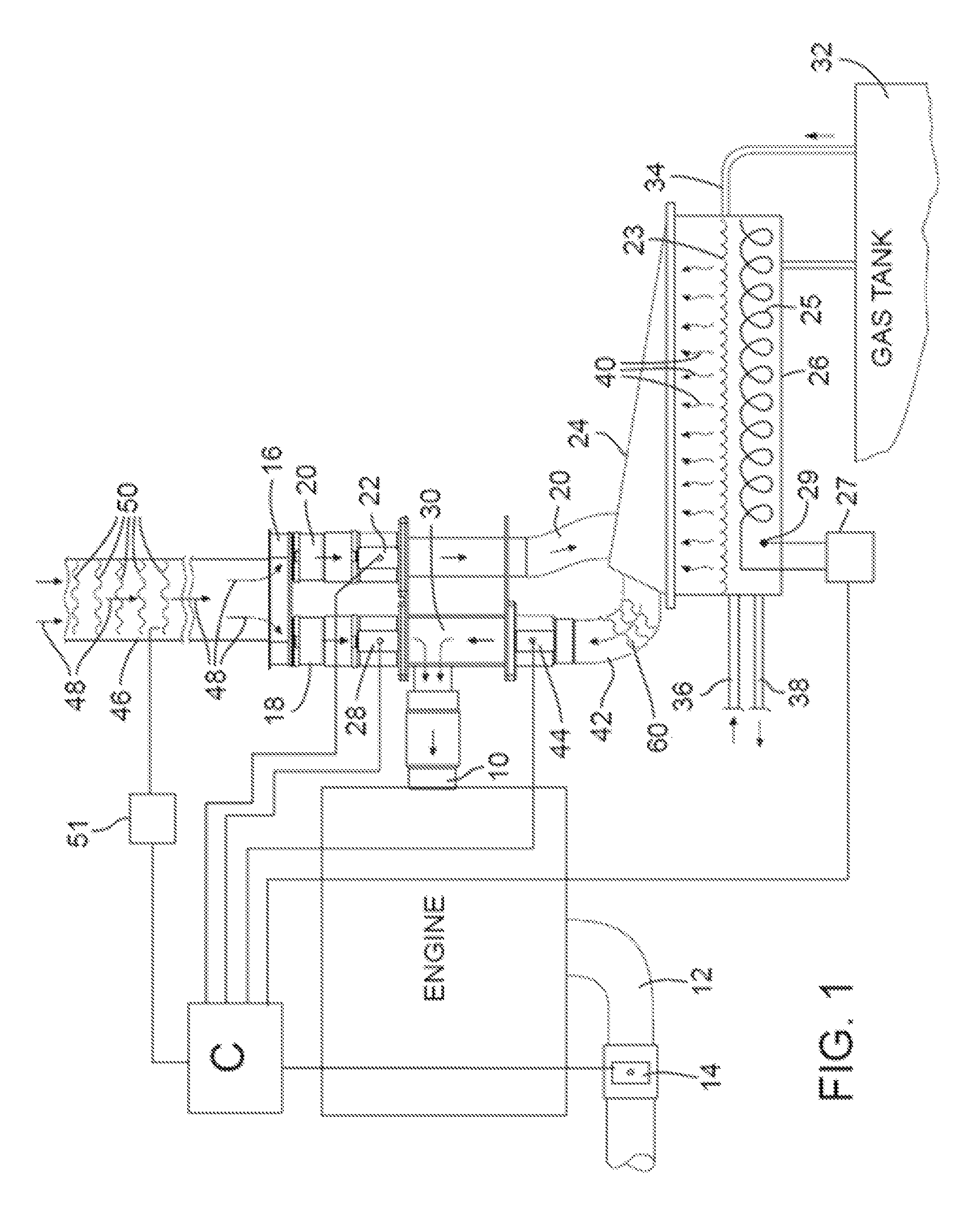

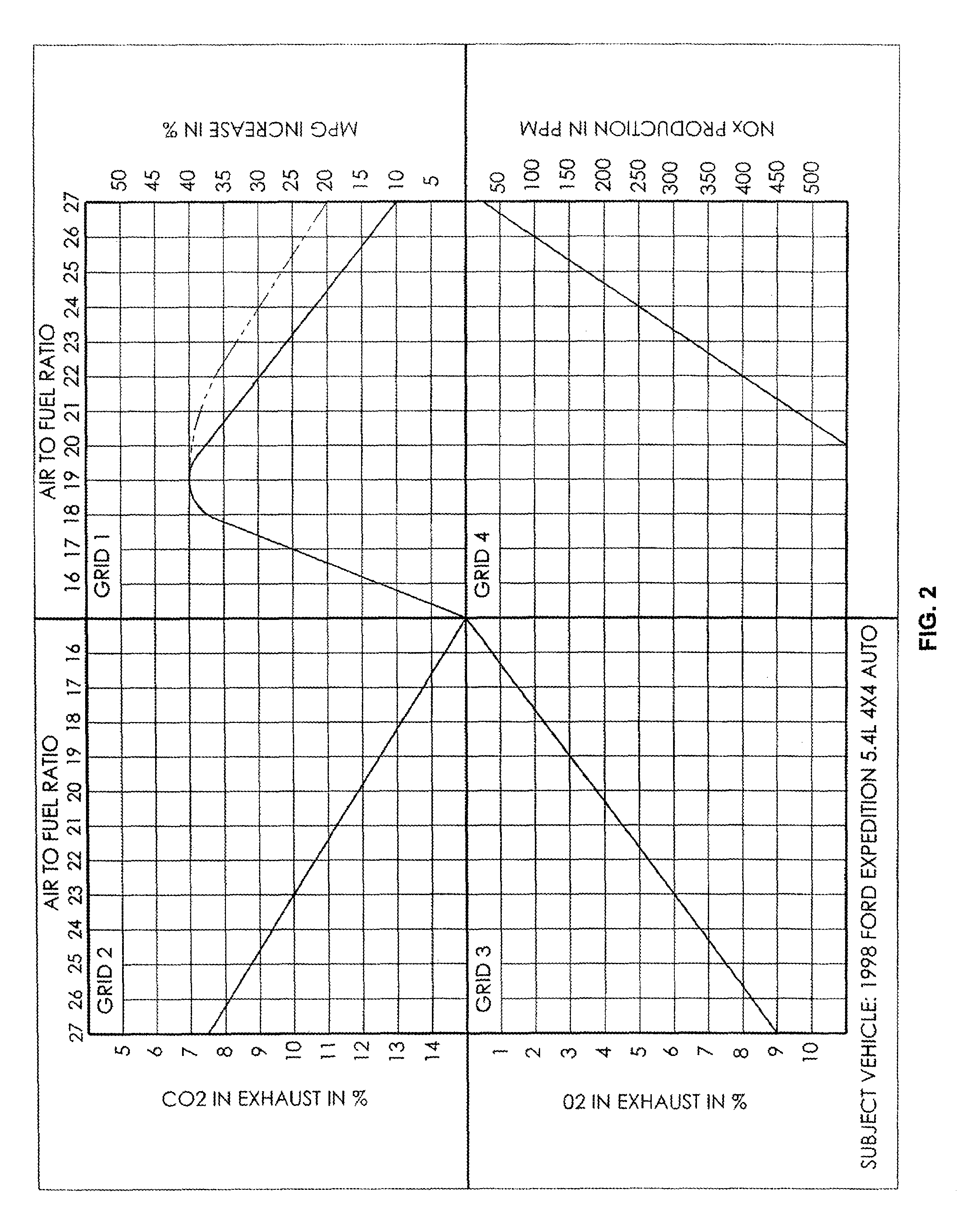

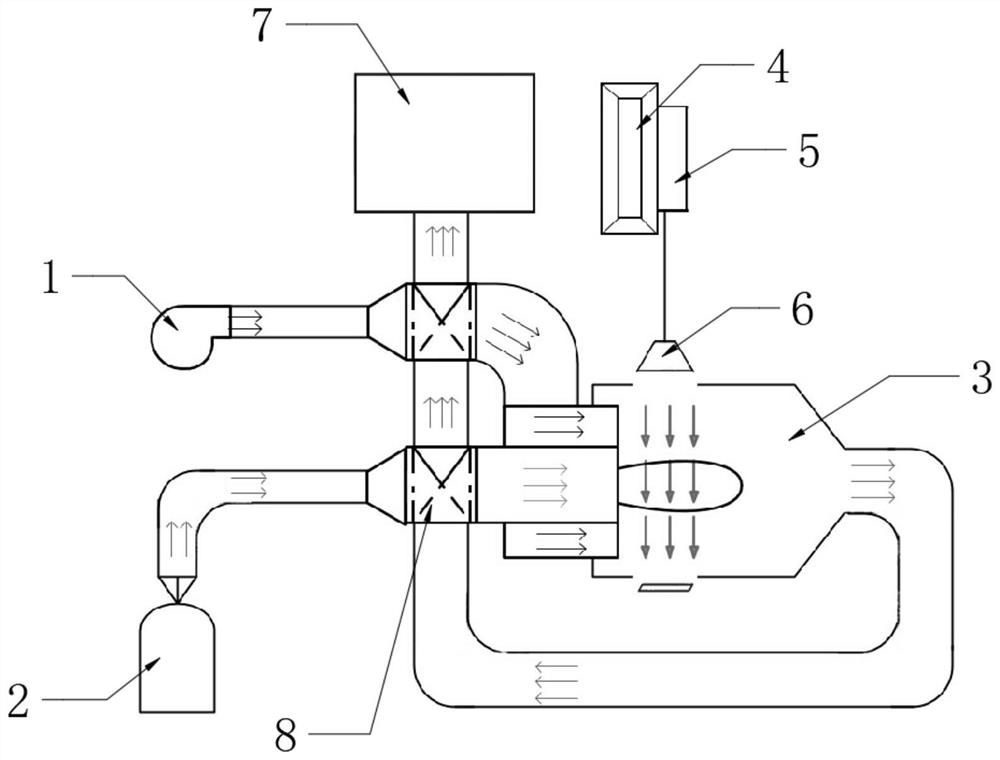

On demand hydrogen enhancement system for internal and external combustion engine

InactiveUS20100206721A1Increased flame speedImprove performanceCellsInternal combustion piston enginesExternal combustion engineInternal combustion engine

The objective of this invention, on demand hydrogen enhancement system for internal and external combustion engine, is to develop a continuous non pressurized water electrolyzer from clean water (not pure water or distil water) generator system. The mixed hydrogen gas and oxygen gas called “Oxyhydrogen”. Oxyhydrogen use as catalyse for internal and external combustion engine to increase fuel flame speed. It can use with variety fuels such as Ethanol, Methanol, Gasohol, Gasoline, Diesel, Bio Diesel, LPG, CNG, and LNG. This system can reduce fuel consumption, increase fuel efficiency, increase torque, reduce emissions, and reduce engine temperatures. The system required no cooling fan and electrolytic solution circulating pump. The system has less heat loss and very low electrical consumption. Oxyhydrogen will produce on demand as the engine RPM and load of generator. The control unit detects signal frequency from the alternator. Gas production rate low at low RPM and use less current and gas production will high at high RPM and use higher current. This can save lot of energy for the electrolysis process. In the past, water electrolysis use direct current (D.C.). In this invention the inventor uses D.C. with Frequency Modulate (FM) pulse width modulator (PWM) instead of Amplitude Modulator (AM) to control the electrolyzer (FMPWM). This circuit had current detector for automatic current adjustment and over current protection.

Owner:SNIDVONGS SURAVUT

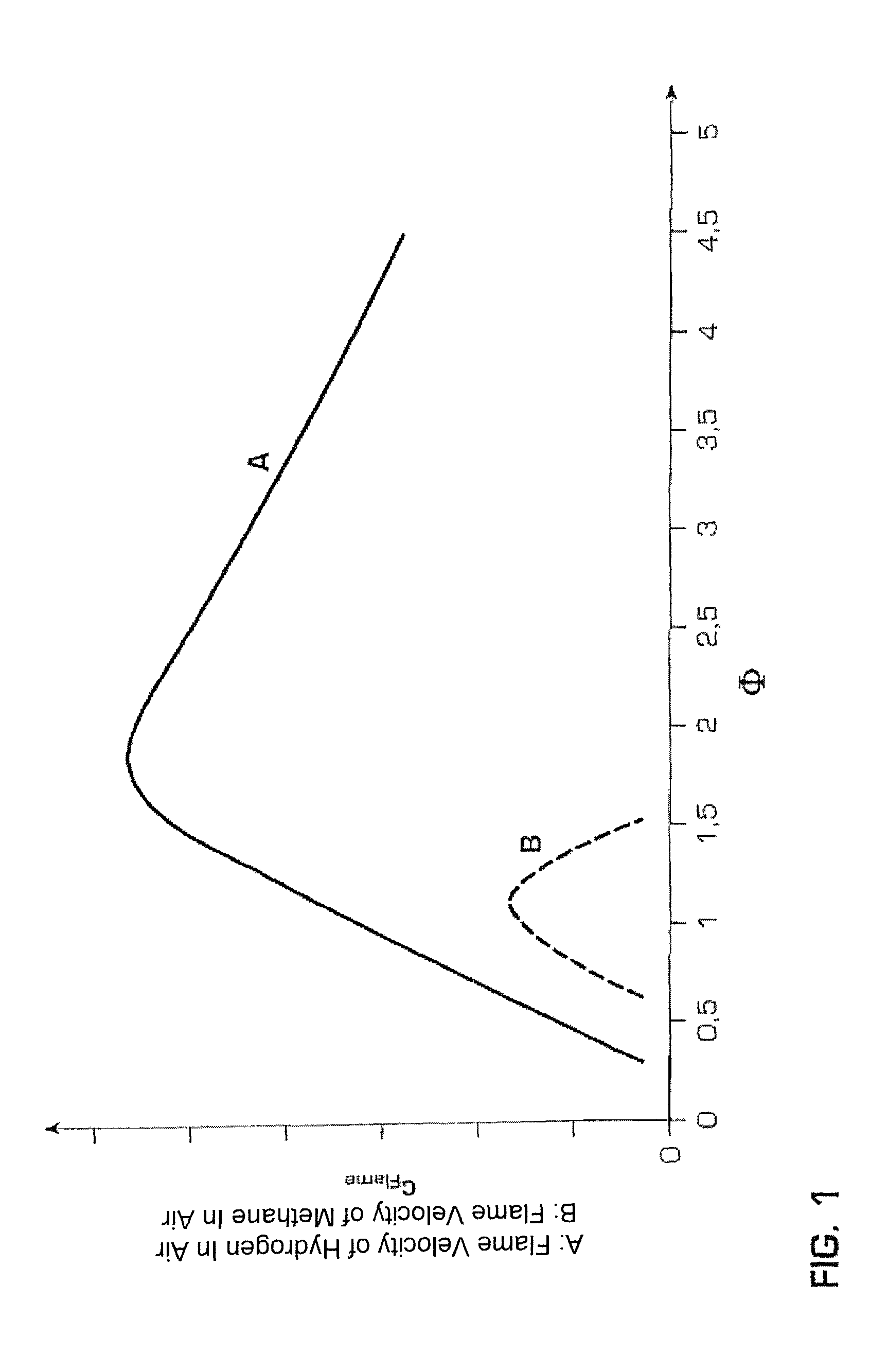

Gas turbine with water injection

ActiveUS20100146984A1Reduce burnShorten speedContinuous combustion chamberGaseous fuel feeder/distributionHydrogenCombustor

Reliable, low-NOx-emission operation of a gas turbine plant with hydrogen-rich fuel gas, and a gas turbine plant with a device for water injection into hydrogen-rich fuels in a gas turbine, involves suitable water injection (21), a water-fuel gas mist, i.e., a fuel gas in which fine water droplets are suspended, is created in the fuel gas feed line (15). This mist is introduced into the burners (20) of the gas turbine. As a result of the water-fuel gas mist, four effects are combined for ignition delay and reduction of the flame velocity of hydrogen-rich fuel gas. When using a water-fuel gas mist, the water, in a directed manner, reaches the region in the burner (20) in which it directly has the greatest possible effect upon the flame or the flame velocity.

Owner:ANSALDO ENERGIA SWITZERLAND AG

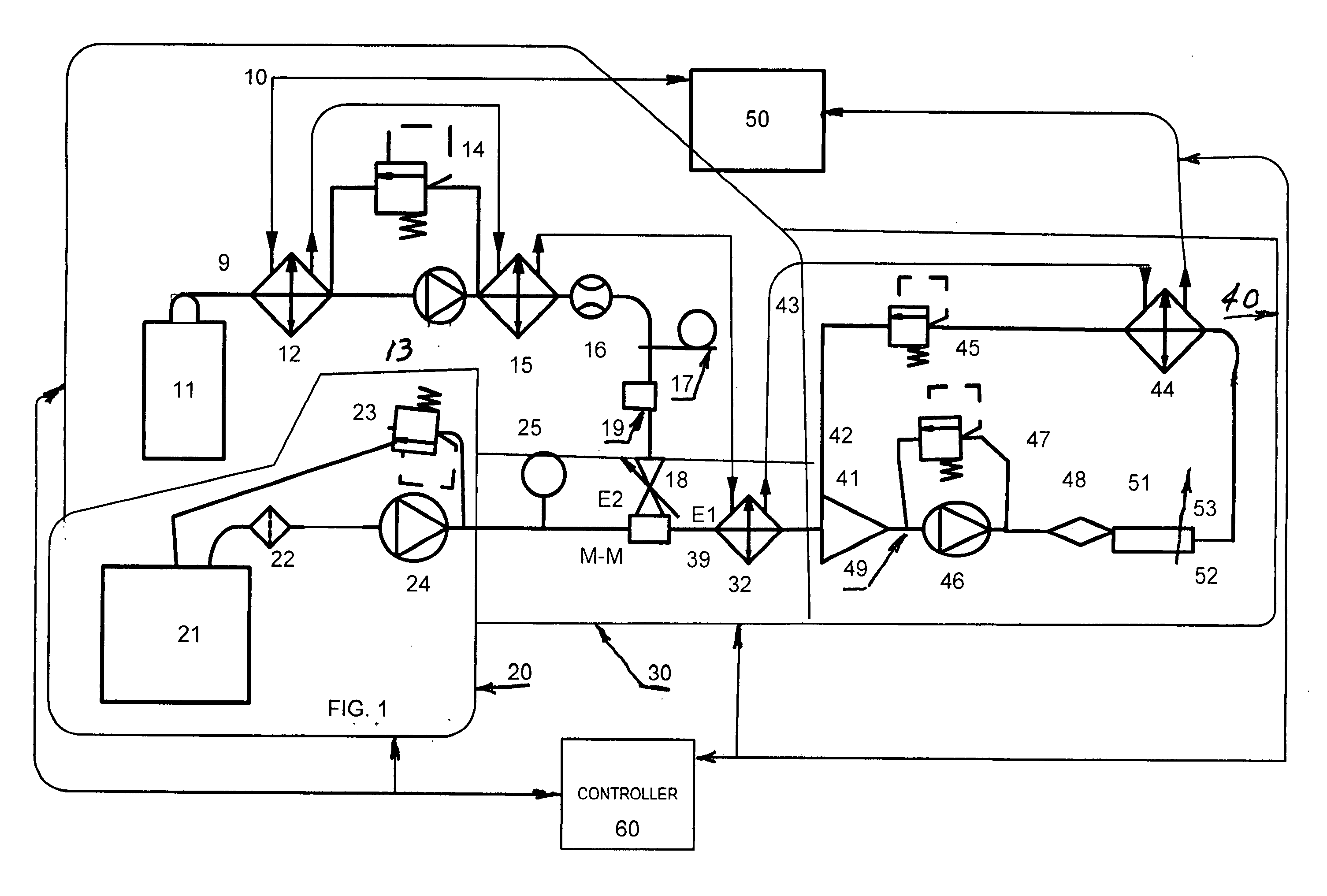

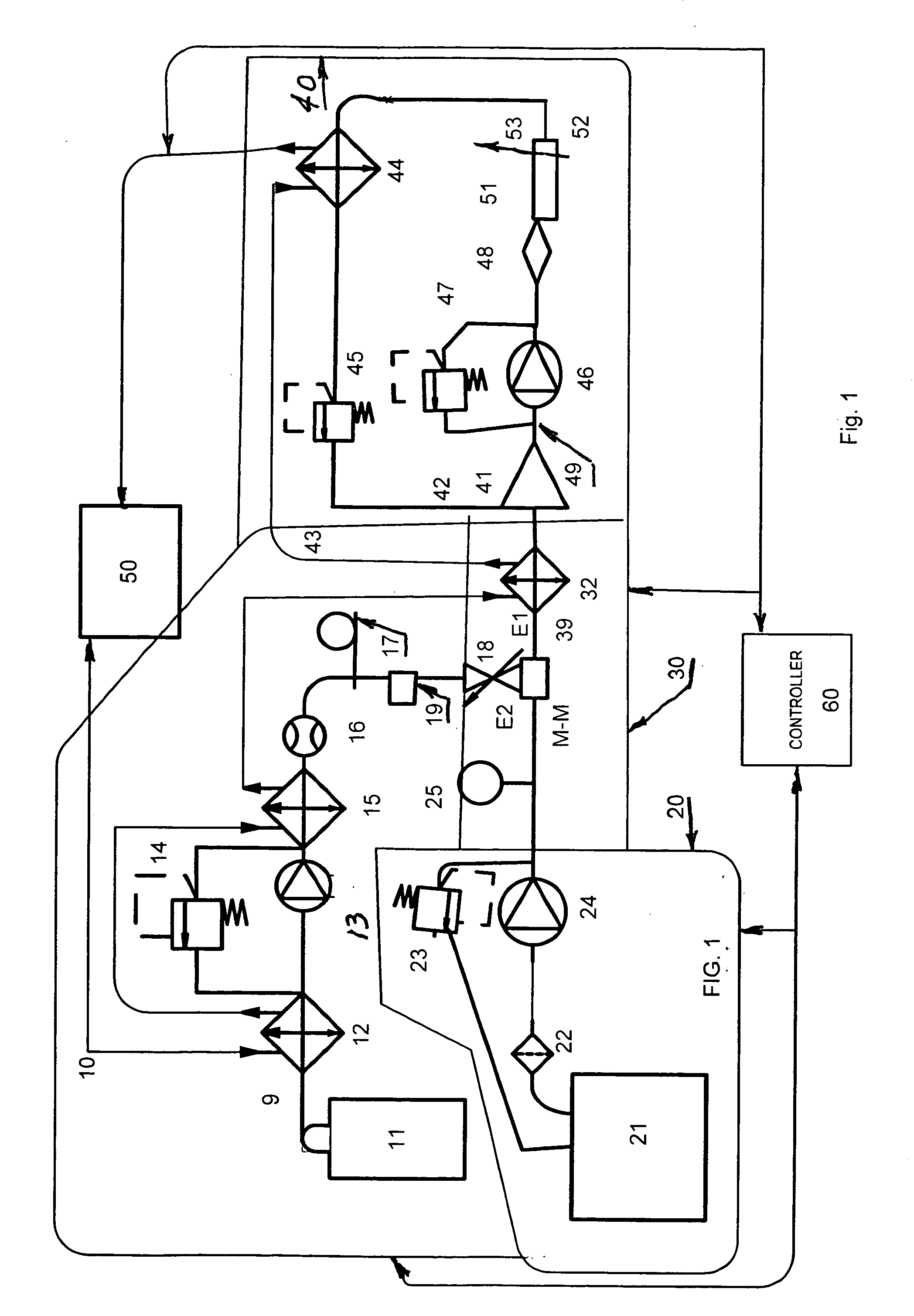

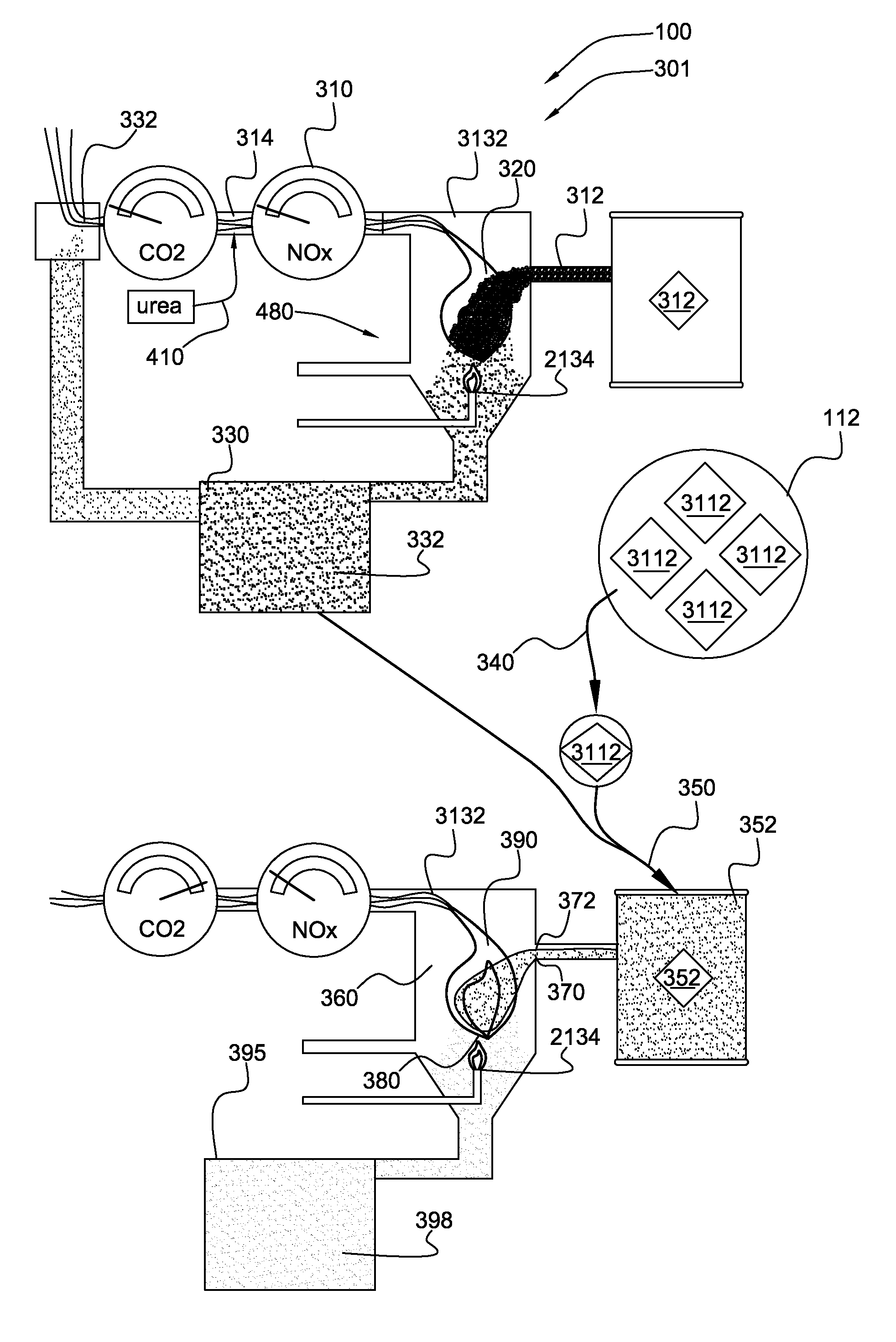

Fuel system and method for burning liquid ammonia in engines and boilers

ActiveUS20100288211A1Easy to igniteImprove combustion characteristicsElectrical controlControlling ratio of multiple fluid flowsCombustion chamberEngineering

A process and apparatus is provided for burning liquid ammonia in an energy device such as a diesel engine, boiler or gas turbine. In particular, the process and apparatus include mixing a renewable fuel with a low flame speed and high ignition temperature, e.g., ammonia, with a combustible liquid fossil or bio-fuel and supplying the mixture into a closed fuel loop where part is efficiently burned in an engine combustion chamber, and part is used to cool the engine and returned by the loop for mixture with fresh incoming fuel mixture. The invention provides for the mixing and emulsifying in such a way that vapour lock is avoided. In the loop, the mixture is emulsified into a disperse distribution of fuel droplets such that upon injection of a portion into the combustion chamber, the renewable fuel in an emulsified droplet evaporates, mixes with the air and forms a small combustion cell surrounding the liquid fuel droplet. The fuel droplet burns and then serves as an ignition kernel for the gas mixture in the small combustion cell producing efficient and rapid combustion of the renewable fuel. The fuel loop allows the fuel system to automatically scale for engines varying in power output from 1 to 35,000 horsepower.

Owner:CAHN RICHARD C +1

Method for carrying out high velocity oxy-fuel spraying on surface of roller of lithium battery pole piece rolling machine

InactiveCN105441857AImprove fatigue resistanceIncreased microhardnessMolten spray coatingCombustion chamberInner bound

The invention relates to a method for carrying out high velocity oxy-fuel spraying on the surface of a roller of a lithium battery pole piece rolling machine. The method of adding hydrogen into fuel and decreasing the diameter of a combustion chamber is adopted. By means of adding the hydrogen, the heat enthalpy value and the speed of the flame are increased. By means of adding of the hydrogen, tungsten carbide particles can be reduced and protected, and burning losses and decarburization are avoided. To further increase the speed of the flame, the diameter of an outlet of the combustion chamber is decreased by 2 mm-5 mm, the pressure of the combustion chamber is increased, and the speed of the flame is further increased. Due to adding of the hydrogen, burning losses and decarburization of the tungsten carbide particles can be reduced, the heat enthalpy value of the flame is increased, the tungsten carbide particles are heated more evenly, a coating can have higher tenacity and compactness, and the binding force of the coating is improved. By means of the method, the speed of the flame is increased, and the aim of increasing the particle spraying speed is achieved; and tungsten carbide particles at a higher speed impact on a base body, the binding force of the coating and the base body is improved, the inner binding force of the coating is increased by means of subsequent higher-speed particle impact, and therefore the binding force of the whole coating is increased.

Owner:GUANGDONG INST OF NEW MATERIALS +1

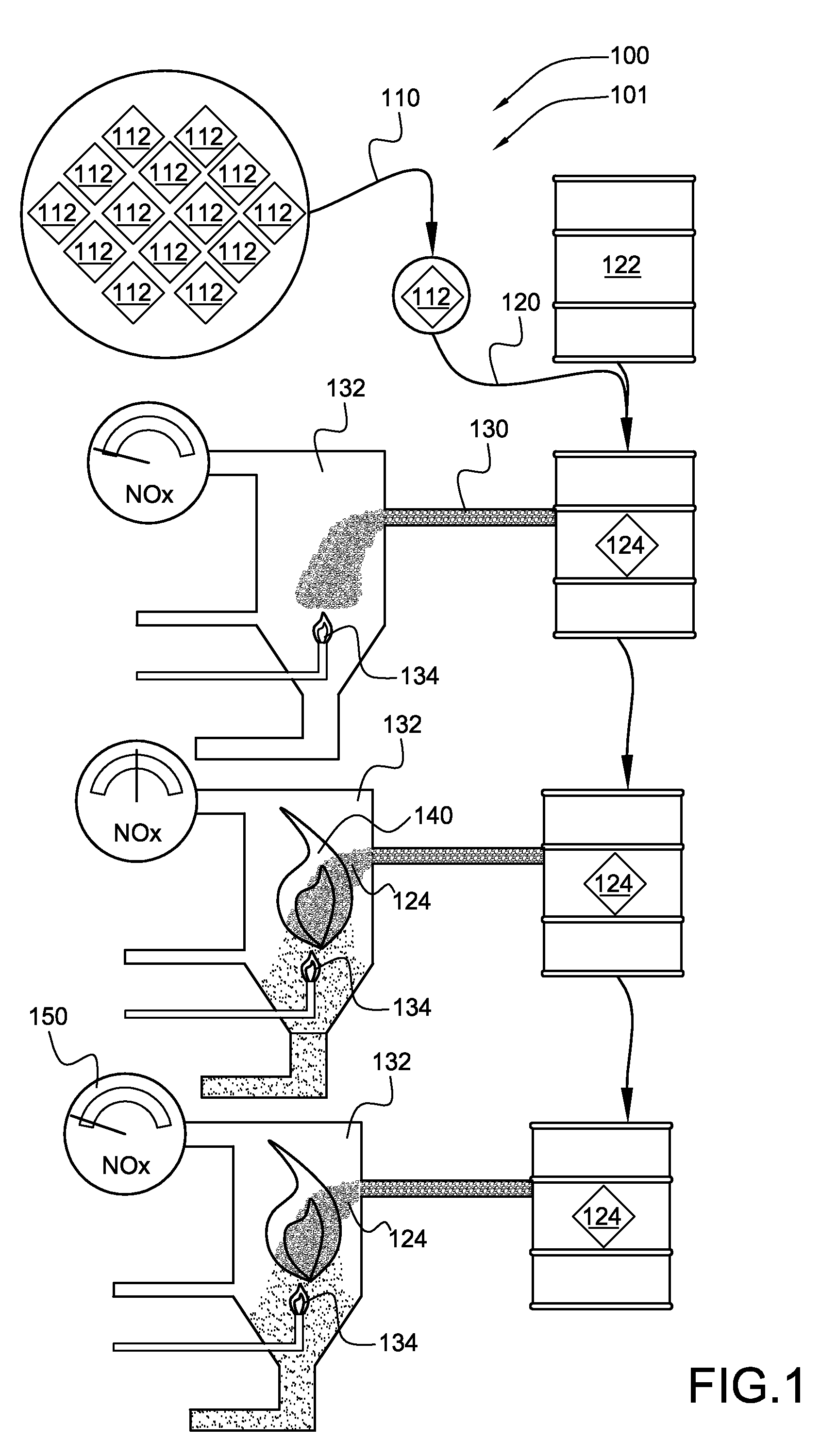

Combustion stabilization systems

InactiveUS20070281253A1Improve flame stabilityMinimize NOx emissionBurnersLiquid carbonaceous fuelsCombustorEngineering

Systems for stabilizing combustion while minimizing NOx generation by using high-flame-speed additives to stabilize the flame front in combustors operating at relatively low temperatures and / or under oxygen constraints. The system is adapted for use in coal-fired boilers, oil-fired boilers, and gas turbine engines. The methods stabilize the flame front to permit stable combustion under an expanded range of part-load conditions. The system provides substantially complete combustion of coal in coal boilers resulting in ash saleable for use in concrete manufacturing.

Owner:TOQAN MAJED

Fuel system and method for burning liquid ammonia in engines and boilers

ActiveUS8495974B2Avoid cavitationEnhance ignition and combustion characteristicElectrical controlControlling ratio of multiple fluid flowsCombustion chamberLiquid fuel

A process and apparatus is provided for burning liquid ammonia in an energy device such as a diesel engine, boiler or gas turbine. In particular, the process and apparatus include mixing a renewable fuel with a low flame speed and high ignition temperature, e.g., ammonia, with a combustible liquid fossil or bio-fuel and supplying the mixture into a closed fuel loop where part is efficiently burned in an engine combustion chamber, and part is used to cool the engine and returned by the loop for mixture with fresh incoming fuel mixture. The invention provides for the mixing and emulsifying in such a way that vapor lock is avoided. In the loop, the mixture is emulsified into a disperse distribution of fuel droplets such that upon injection of a portion into the combustion chamber, the renewable fuel in an emulsified droplet evaporates, mixes with the air and forms a small combustion cell surrounding the liquid fuel droplet. The fuel droplet burns and then serves as an ignition kernel for the gas mixture in the small combustion cell producing efficient and rapid combustion of the renewable fuel. The fuel loop allows the fuel system to automatically scale for engines varying in power output from 1 to 35,000 horsepower.

Owner:CAHN RICHARD C +1

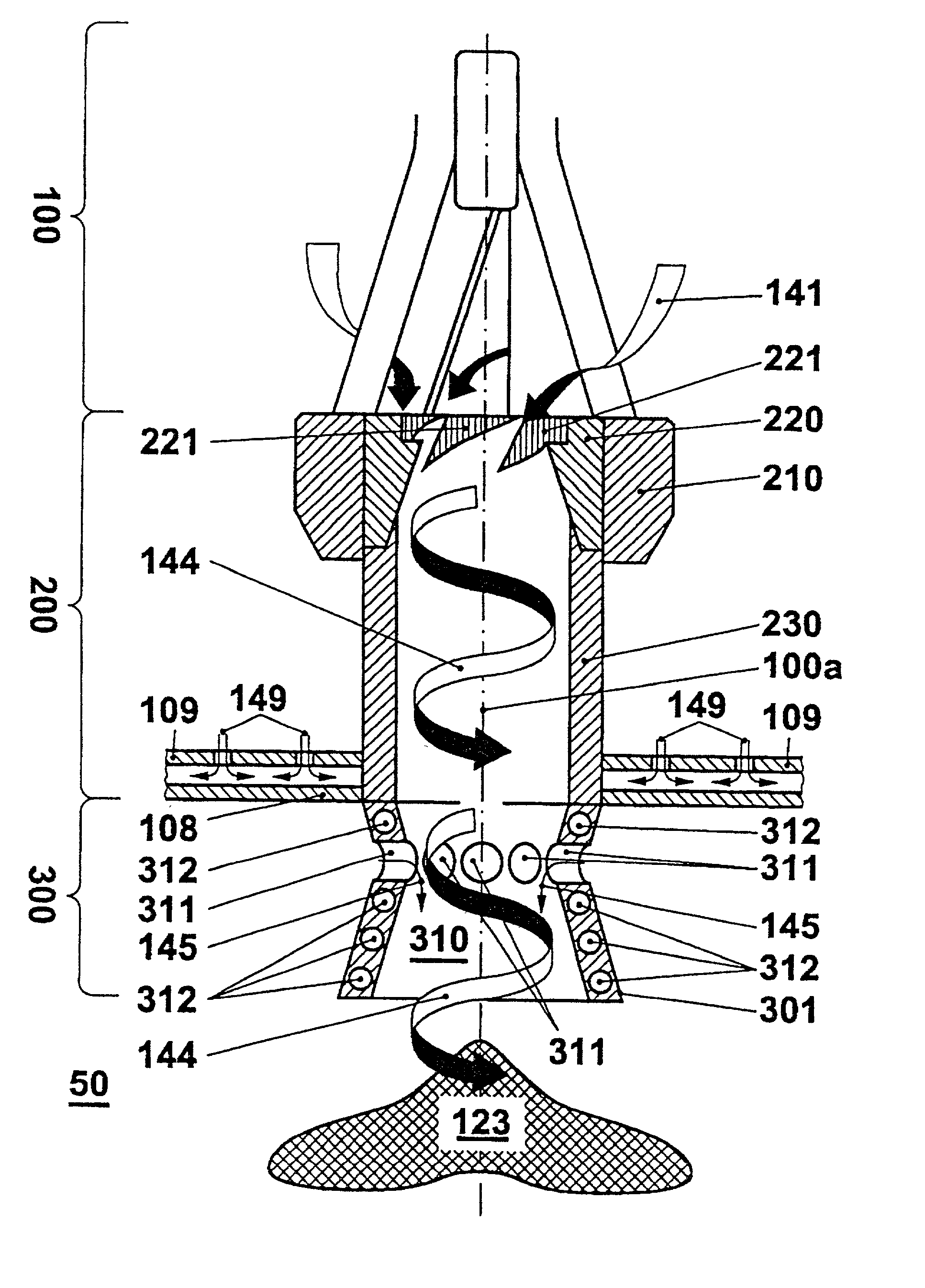

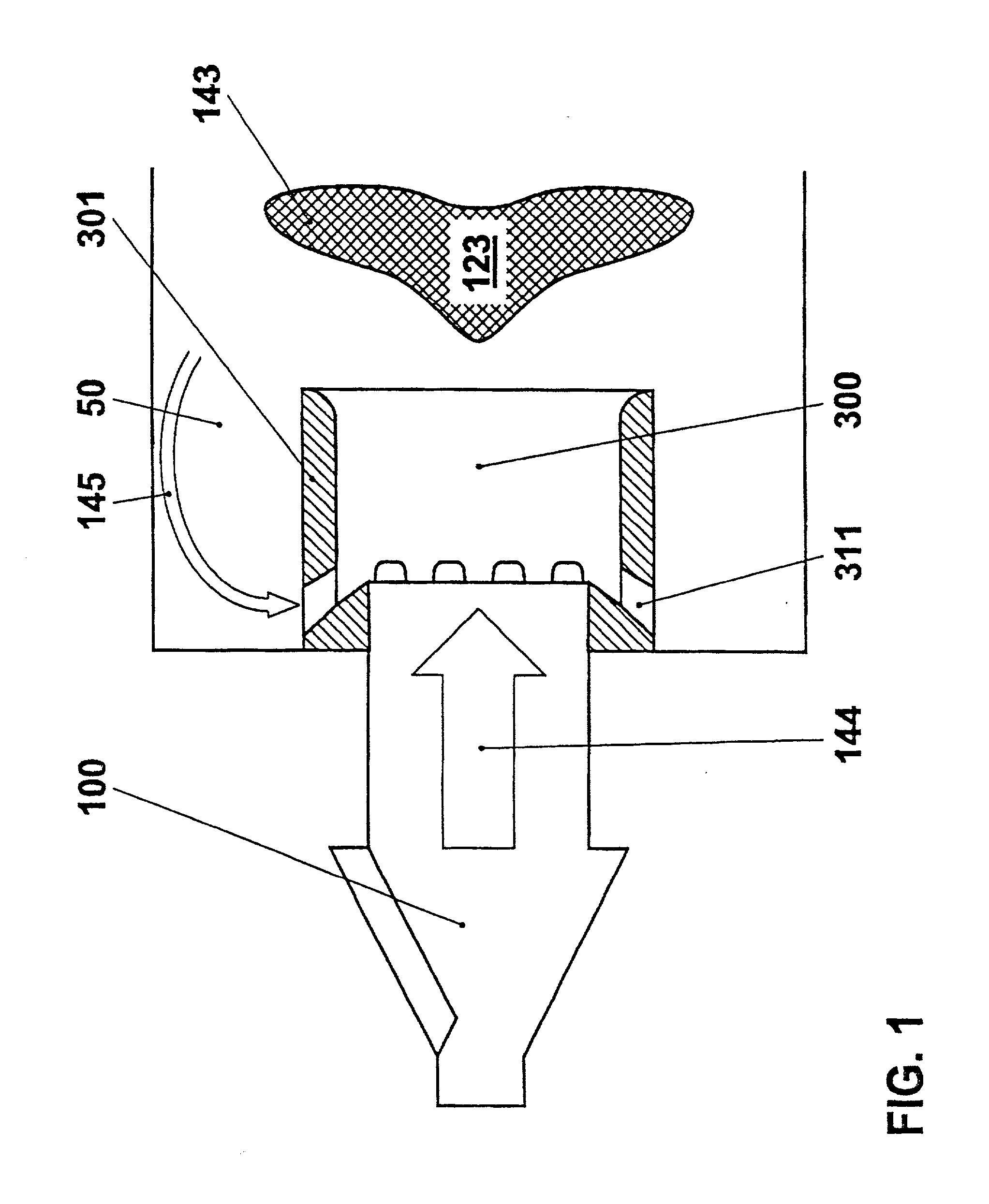

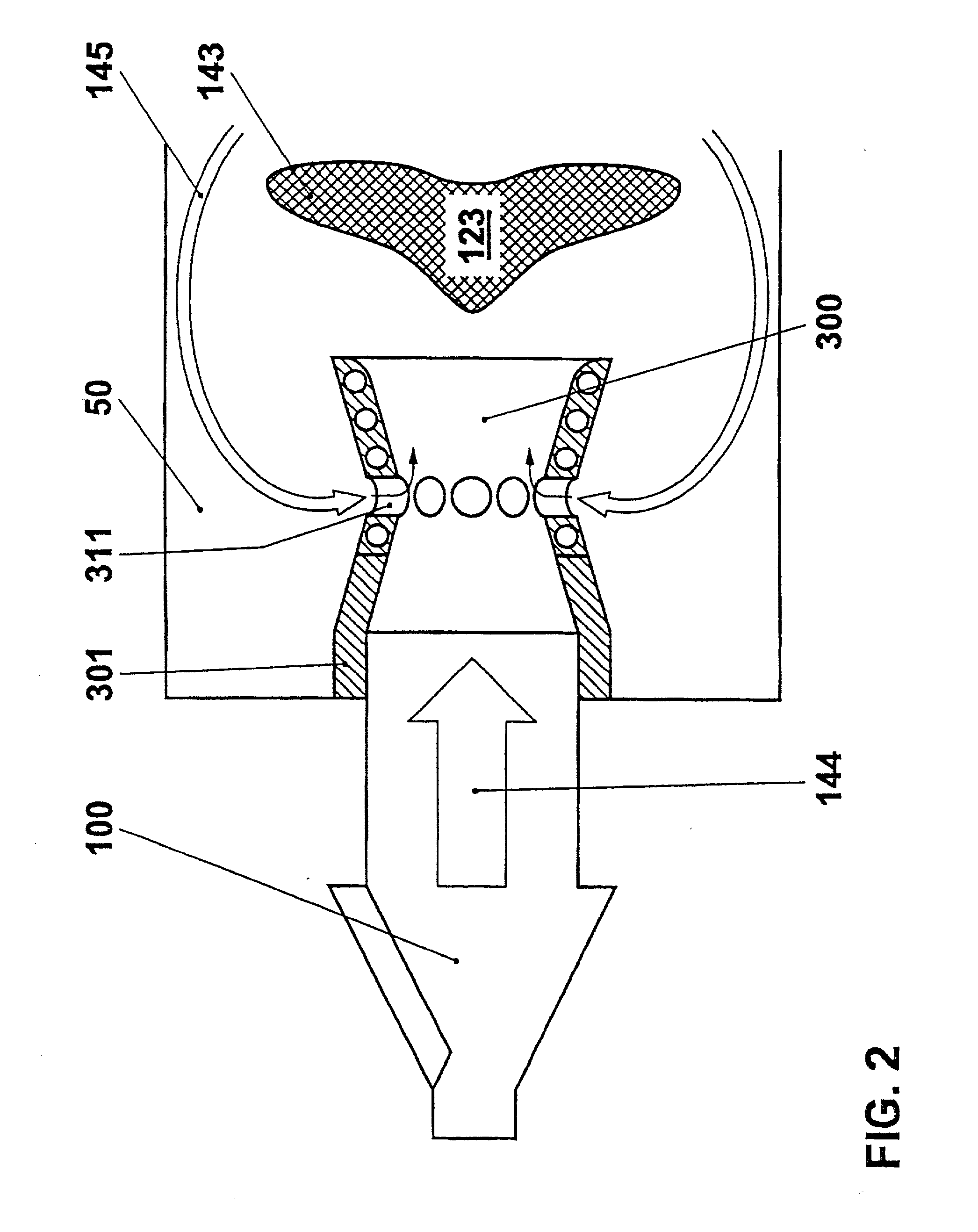

Burner with high flame stability

InactiveUS20020172905A1Improve flame stabilityReduce pressureGas turbine plantsBurner material specificationsCombustorCombustion chamber

The invention relates to a premix burner with high flame stability for use in a heat producer, preferably in the combustion chamber of a gas turbine. Modem lean operated premix burners make possible very low pollutant emissions, but sometimes operate very close to the extinction limit. To increase the stability of the lean premix combustion by increasing the distance between the flame temperature and the extinction limit temperature, it is proposed according to the invention to arrange a downstream combustion gas mixing section (300) for the burner, which mixing section (300) projects at least partially into the combustion chamber (50) and enables combustion gases from the combustion chamber (50) access to the fuel / air mixture (144) by means of combustion gas inlet openings (311). The added combustion gases (145) are mixed with the fuel / air mixture (144), and in this manner increase its temperature. This increase in temperature results in a significant increase in the flame speed, as a consequence of which the extent of the flame front (123) and the extinction limit temperature of the burner decrease.

Owner:ANSALDO ENERGIA SWITZERLAND AG

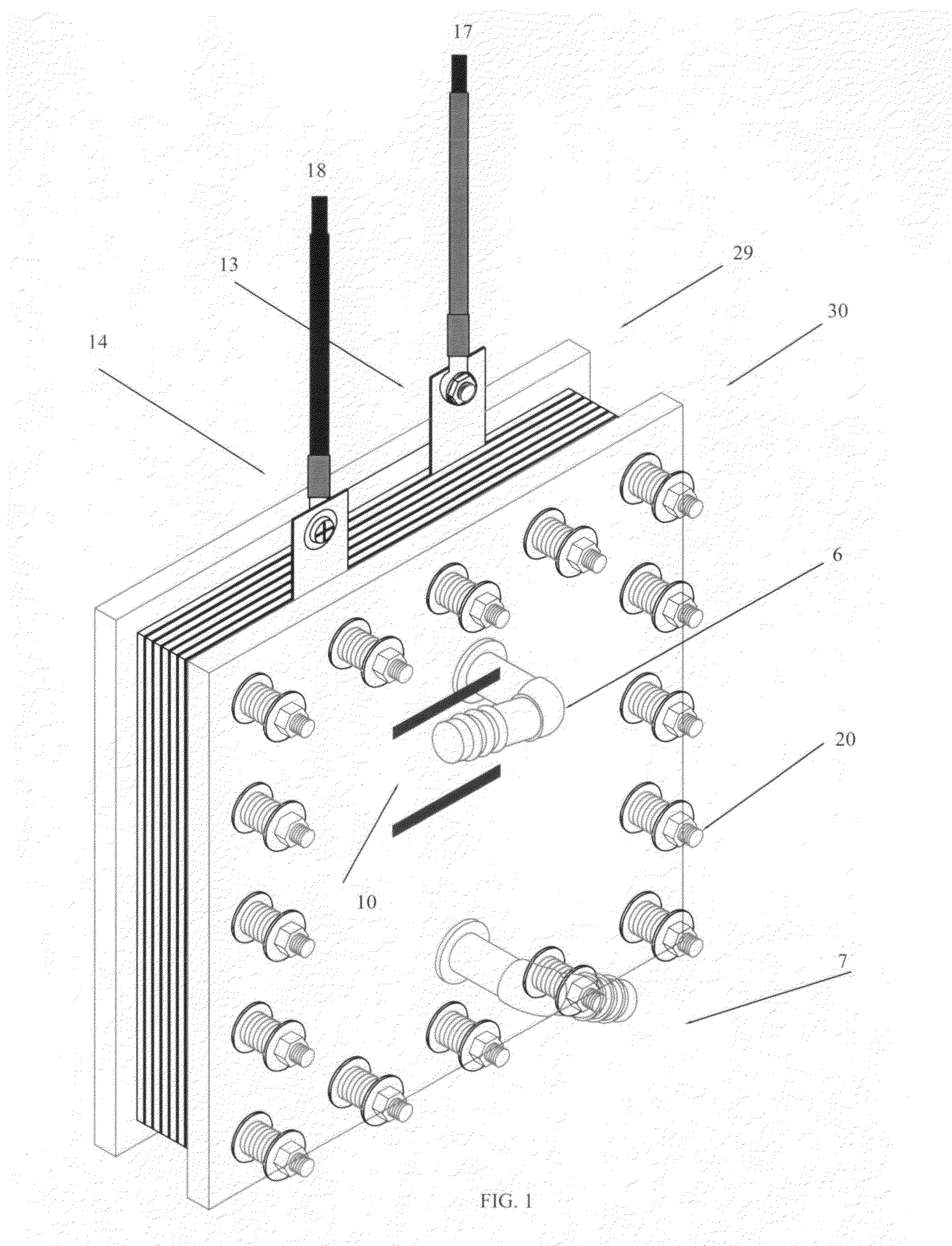

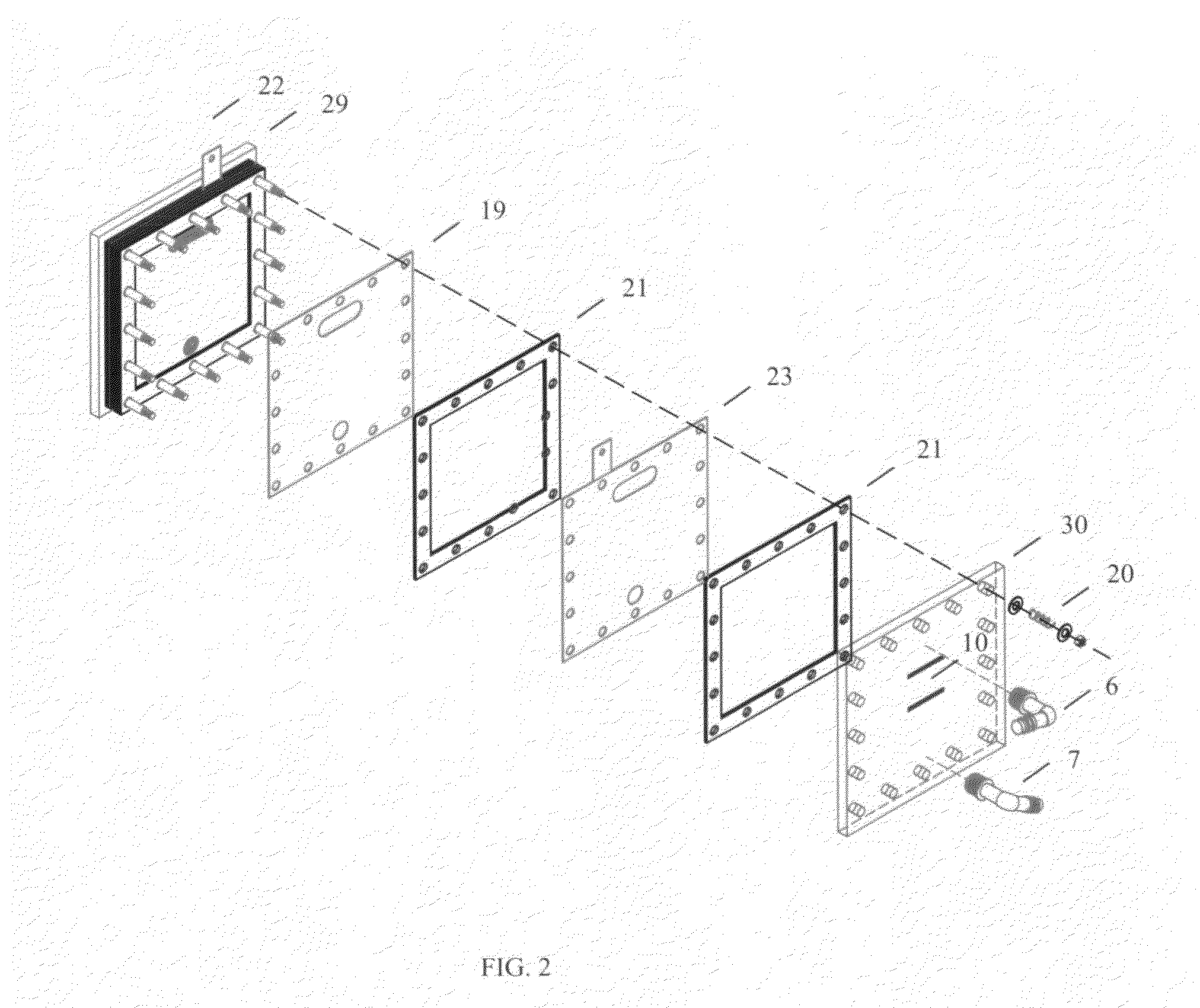

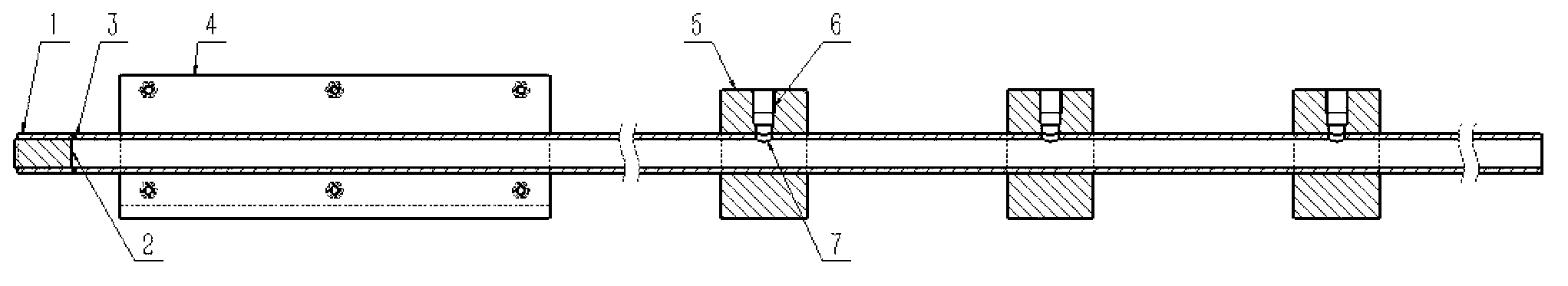

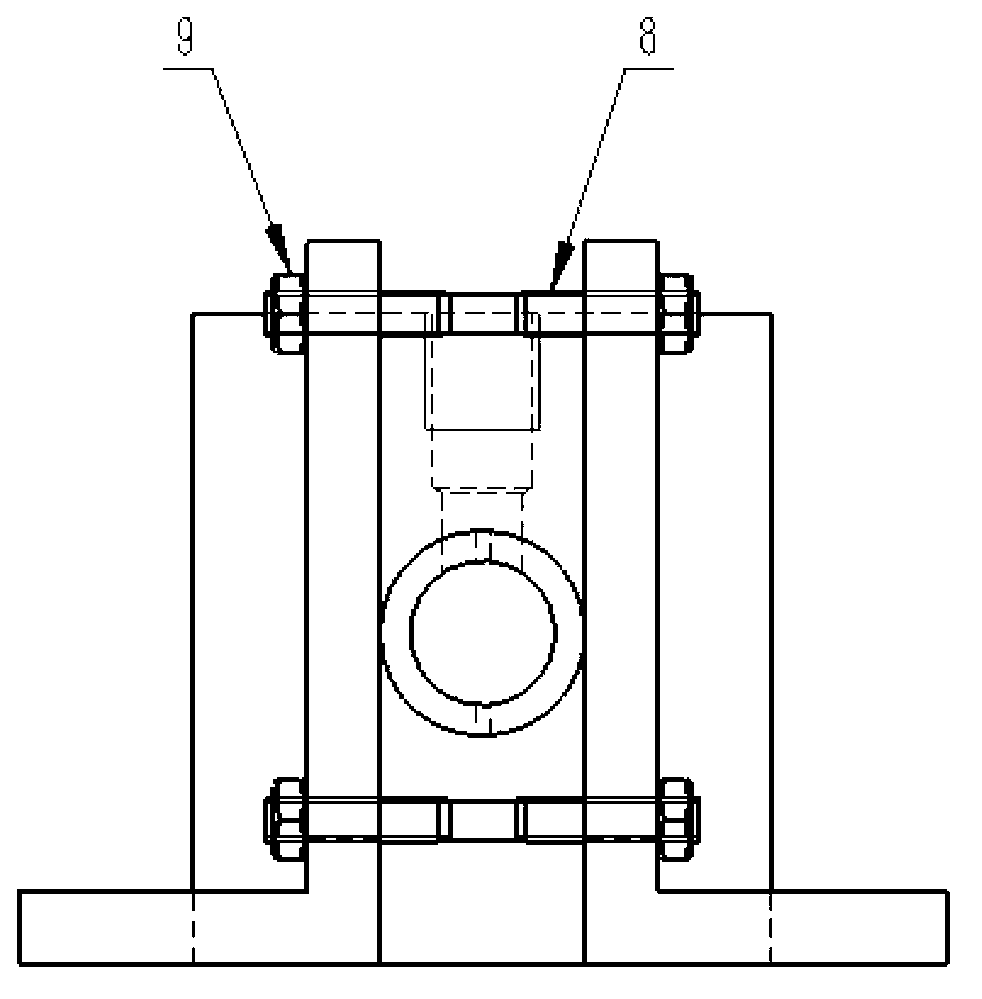

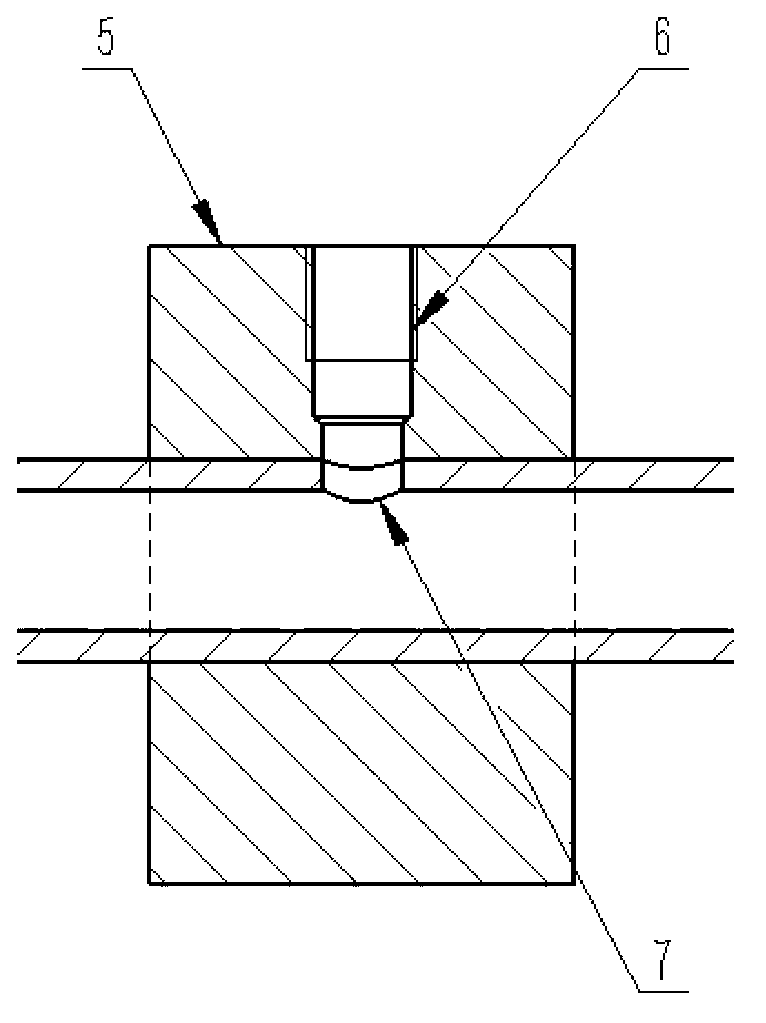

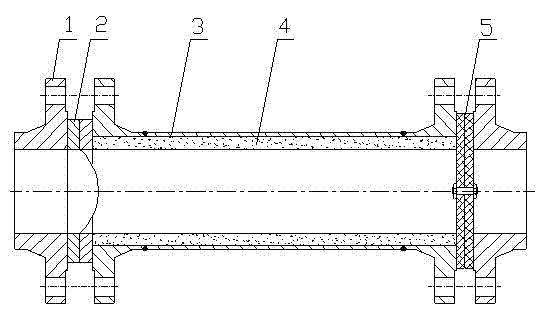

Device for measuring knocking combustion pressure in millimeter-level circular tube

InactiveCN103292954AAvoid interferencePlay an insulating roleRapid change measurementFlame propagationEngineering

The invention provides a device for measuring knocking combustion pressure in a millimeter-level circular tube. The device comprises a knocking tube, a clamping plate, a sensor mounting seat and a sensor. The clamping plate fixes and supports the front side of the knocking plate. The sensor mounting seat is arranged at the position where a flame forms knockings. A through hole is formed in a tube wall, and the through hole in the tube wall and a sensor mounting hole in the sensor mounting seat are coaxial. When the outer diameter of the knocking tube is larger than the diameter of the measuring end of the sensor, the hole diameter of the through hole in the tube wall is equal to the diameter of the measuring end of the sensor, and the measuring end face of the sensor is flush with the inner wall of the knocking tube. When the outer diameter of the knocking tube is not larger than the diameter of the measuring end of the sensor, the hole diameter of the through hole in the tube wall is smaller than the diameter of the measuring end of the sensor, and the measuring end face of the sensor is tangent to the circular face of the inner wall of the transparent knocking tube. The knocking tube, the clamping plate and the sensor mounting seat in the device are all made of organic glass, pressure can be measured, and a flame propagation mode can be observed and flame speed can be measured simultaneously. Meanwhile, the function of insulation can be achieved, and the interference of electric sparks is avoided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

System for improving fuel utilization

InactiveUS7631637B2Improve engine performanceAvoid condensationInternal combustion piston enginesGaseous engine fuelsFractionationLiquid fuel

A vapor fuel air mixture supply system for a combustion engine, whereby the mixture of air and fuel vapor is elevated in temperature prior to combustion. The liquid fuel may be vaporized in a fractionation process and further heated to enhance flame speed combustion and improve efficiency of the system.

Owner:VAPOR FUEL TECH

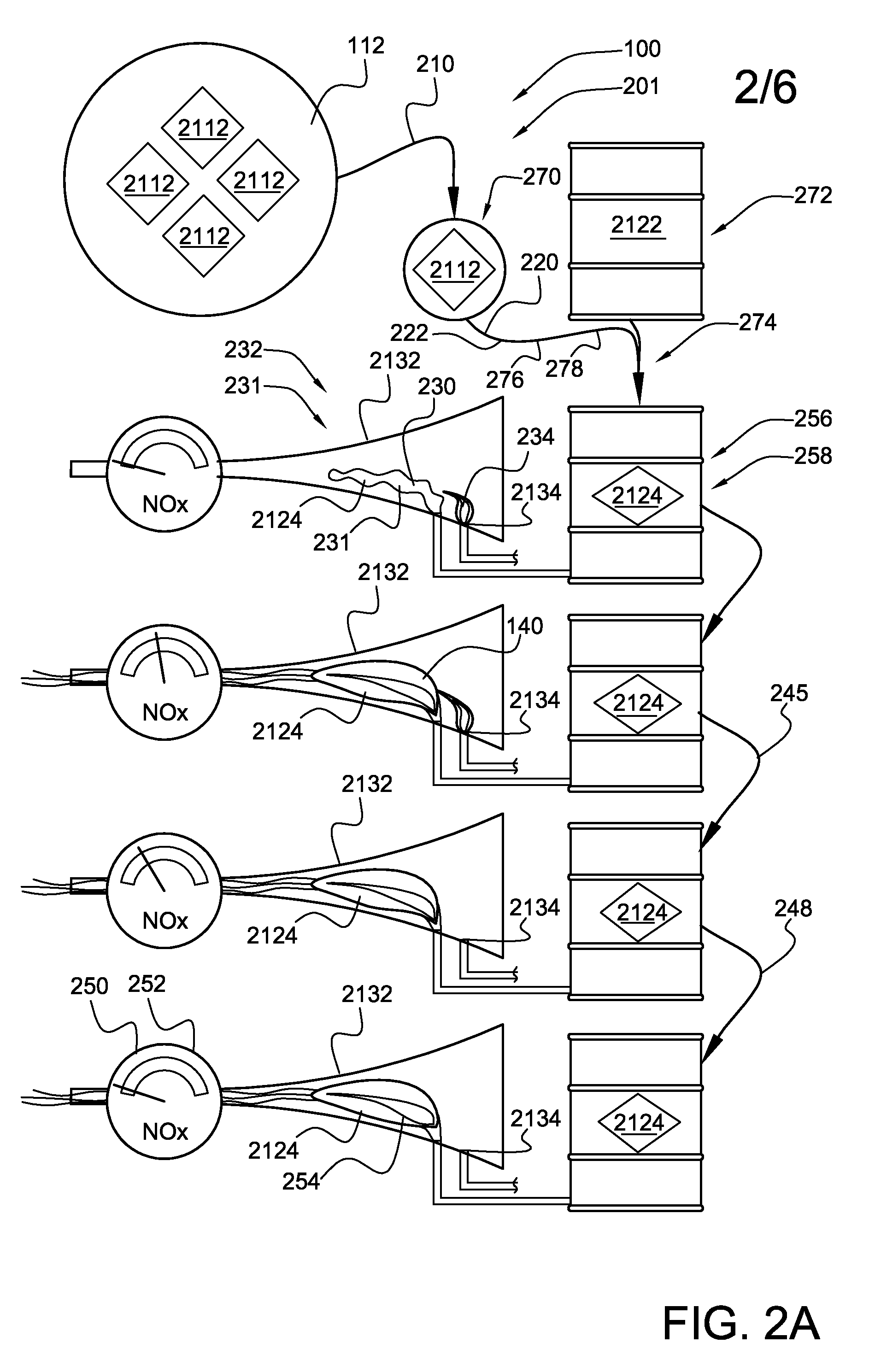

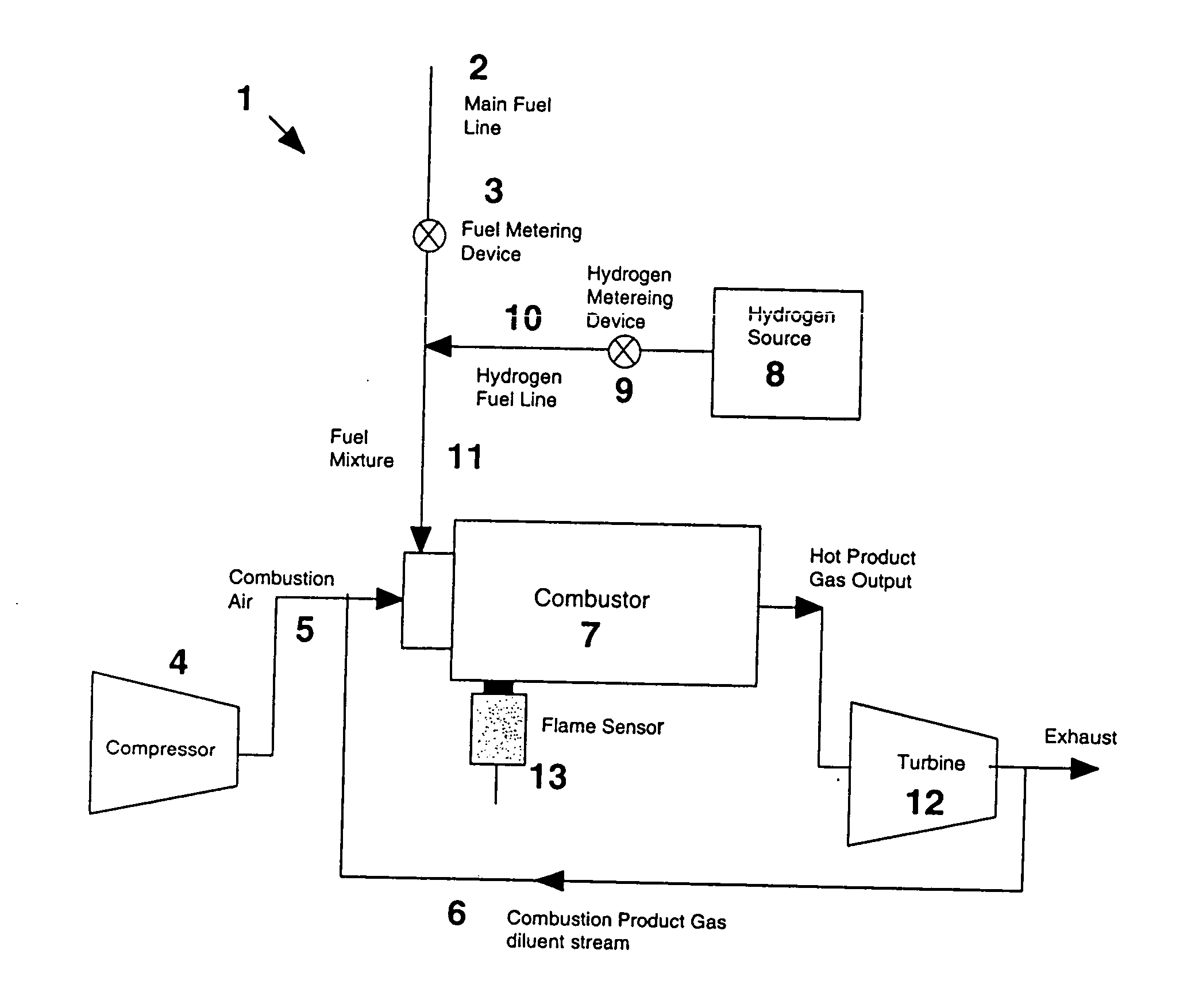

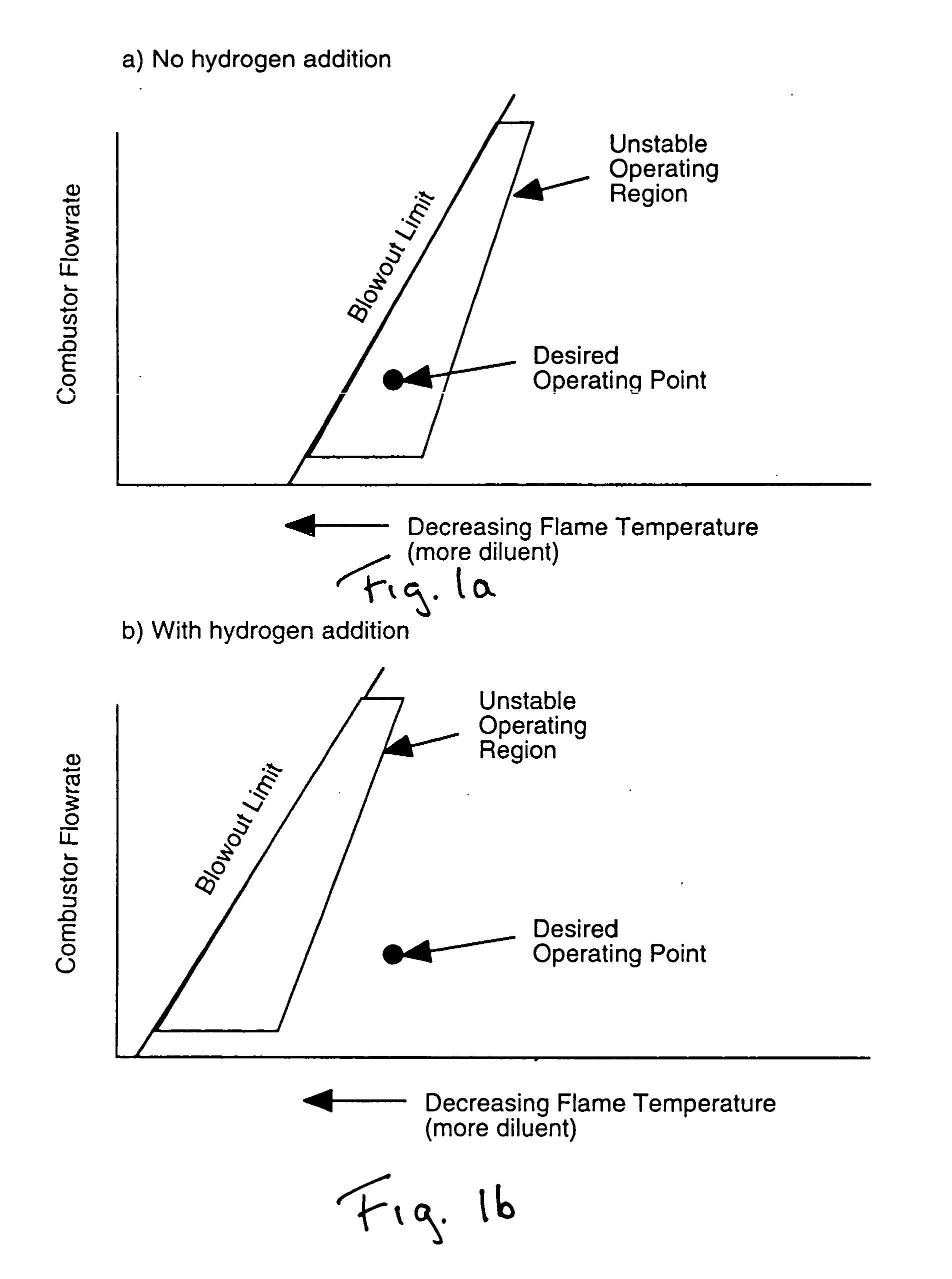

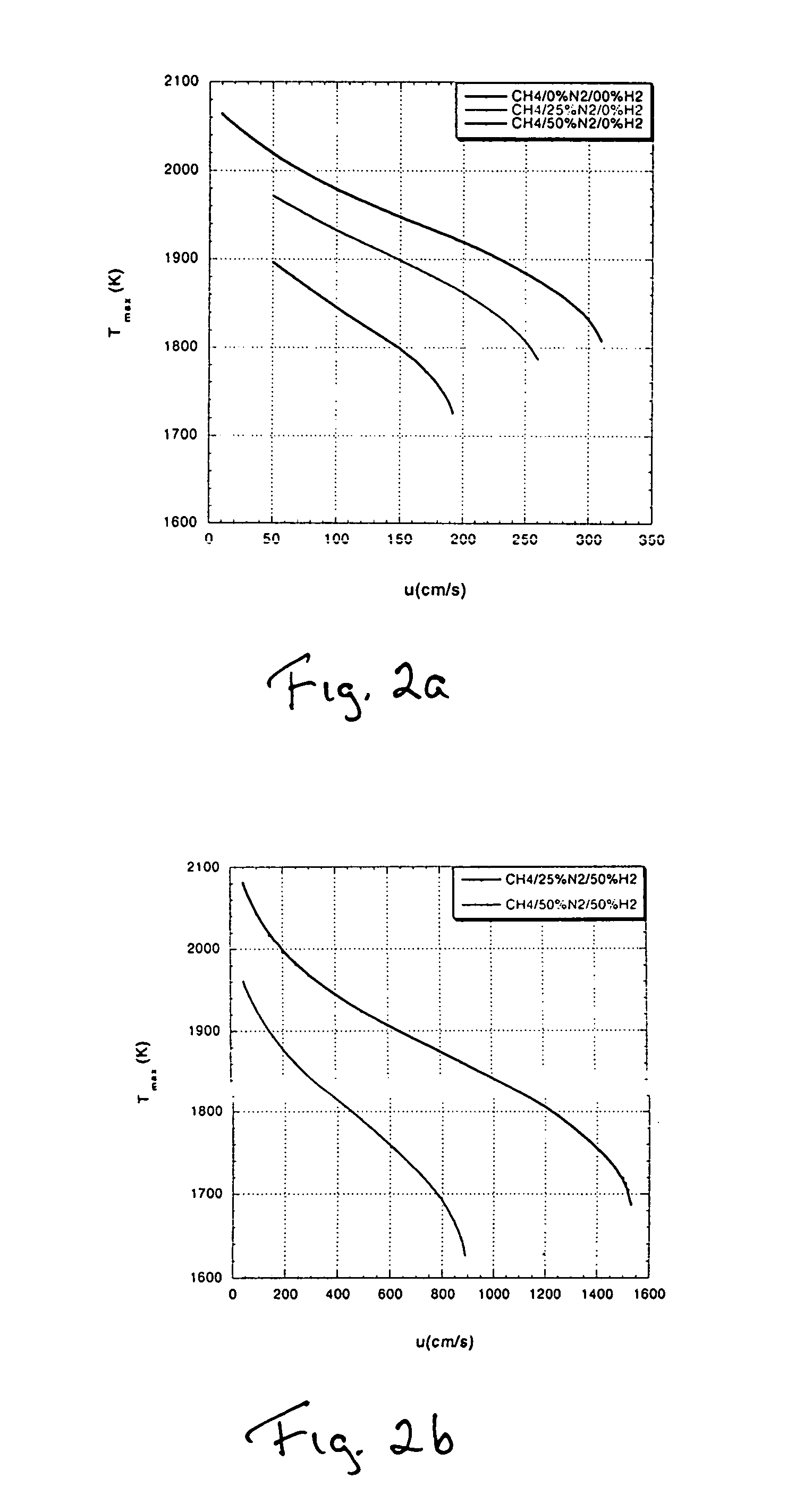

Method for control of NOX emissions from combustors using fuel dilution

InactiveUS20070031768A1Easy to installLow costInternal combustion piston enginesExhaust apparatusCombustion chamberWater vapor

A method of controlling NOx emission from combustors. The method involves the controlled addition of a diluent such as nitrogen or water vapor, to a base fuel to reduce the flame temperature, thereby reducing NOx production. At the same time, a gas capable of enhancing flame stability and improving low temperature combustion characteristics, such as hydrogen, is added to the fuel mixture. The base fuel can be natural gas for use in industrial and power generation gas turbines and other burners. However, the method described herein is equally applicable to other common fuels such as coal gas, biomass-derived fuels and other common hydrocarbon fuels. The unique combustion characteristics associated with the use of hydrogen, particularly faster flame speed, higher reaction rates, and increased resistance to fluid-mechanical strain, alter the burner combustion characteristics sufficiently to allow operation at the desired lower temperature conditions resulting from diluent addition, without the onset of unstable combustion that can arise at lower combustor operating temperatures.

Owner:SANDIA NATIOANL LAB

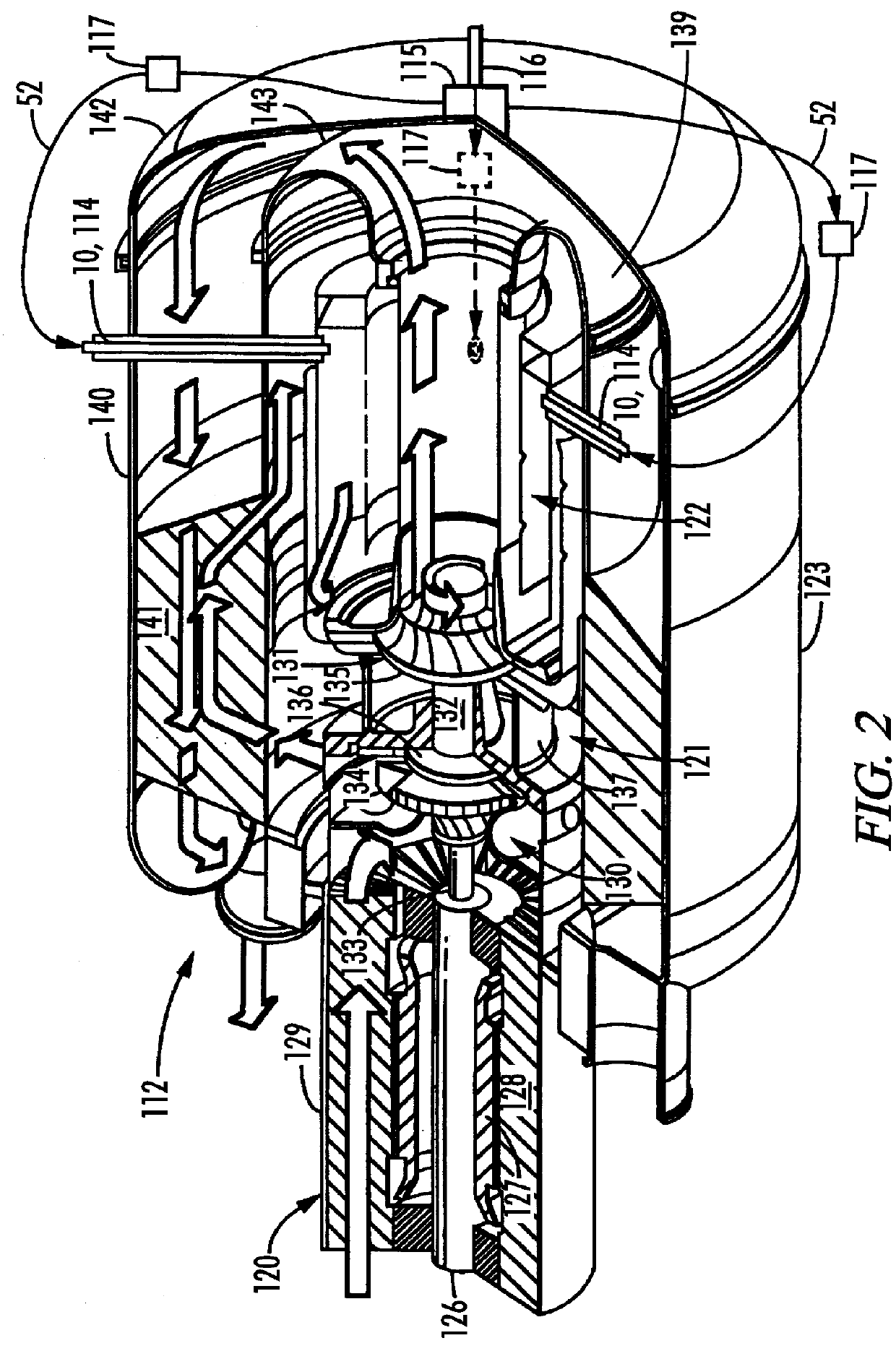

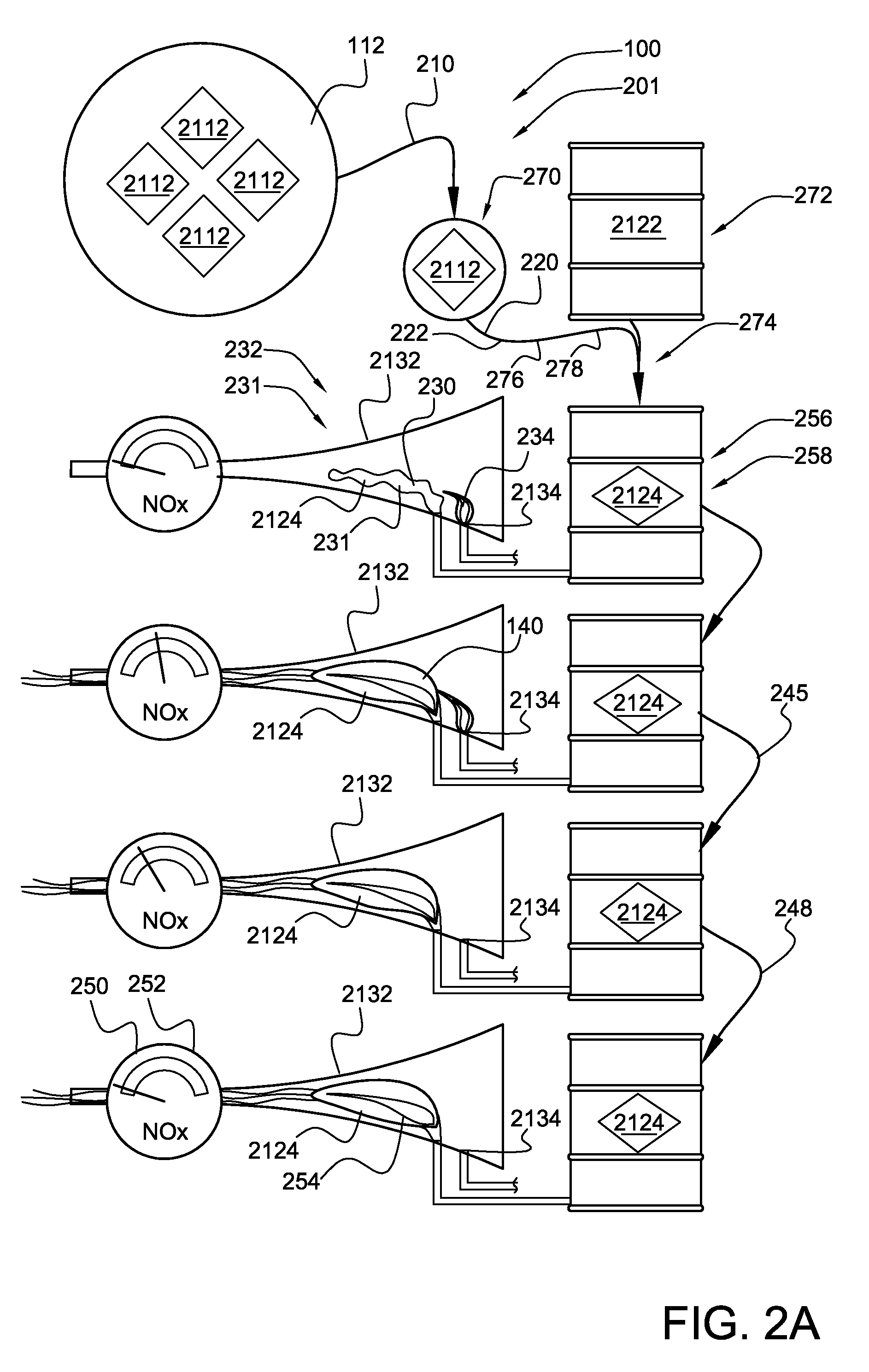

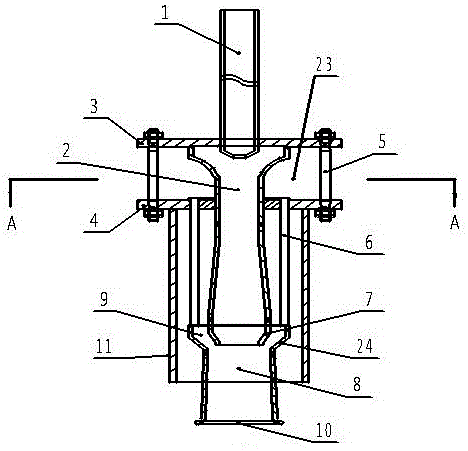

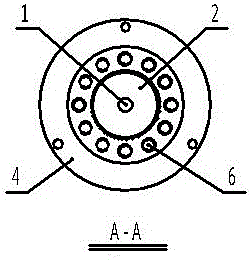

Fuel Injector For High Flame Speed Fuel Combustion

ActiveUS20160033135A1Avoid layeringIncrease flow rateBurnersContinuous combustion chamberCombustionNuclear engineering

A multiple fuel capable, pre-mixed, low emission injector is provided which is particularly suited for burning high flame speed fuels. The fuel injector includes an injector body having a preliminary pre-mixing chamber, an intermediate pre-mixing chamber and a final pre-mixing chamber. A fuel distributor separates the preliminary pre-mixing chamber from the intermediate pre-mixing chamber. A guide vane separates the intermediate pre-mixing chamber from the final pre-mixing chamber.

Owner:CAPSTONE TURBINE

Combustion stabilization systems

Owner:TOQAN MAJED

Inner bore supersonic speed flame gun for liquid fuel

The invention discloses an inner bore supersonic speed flame gun for a liquid fuel. The flame gun comprises a gun housing, a gun barrel, an oxygen conveying pipeline, a fuel conveying pipeline, an ignition line pipeline, a fuel spray nozzle, a stabilizer, a combustion chamber, a high-temperature high-pressure gas gathering section, an elbow connector, a power feeding needle, a gas compressing throat, a flame diffusion section, a nozzle, a bottom water outlet of the combustion chamber, a sparking plug and a cooling water inlet pipeline; the combustion chamber is located in the gun barrel, the fuel spray nozzle is arranged in a position where the fuel conveying pipeline and the stabilizer are connected, the sparking plug is arranged in a position where the ignition line pipeline is connected to the stabilizer, the stabilizer is arranged at one end of the combustion chamber while the elbow connector is arranged at the other end, the high-temperature high-pressure gas gathering section, the gas compression throat and the flame diffusion section are successively arranged in the through pipeline after the combustion chamber is connected to the elbow connector, and the nozzle is arranged at the tail end of the flame diffusion section; the power feeding port is located in the middle position of the elbow connector. The inner bore supersonic speed flame gun disclosed by the invention can effectively improve the flame speed and the bonding strength of the coating and reduce the porosity.

Owner:ZHENGZHOU LIJIA THERMAL SPRAYING MACHINERY CO LTD

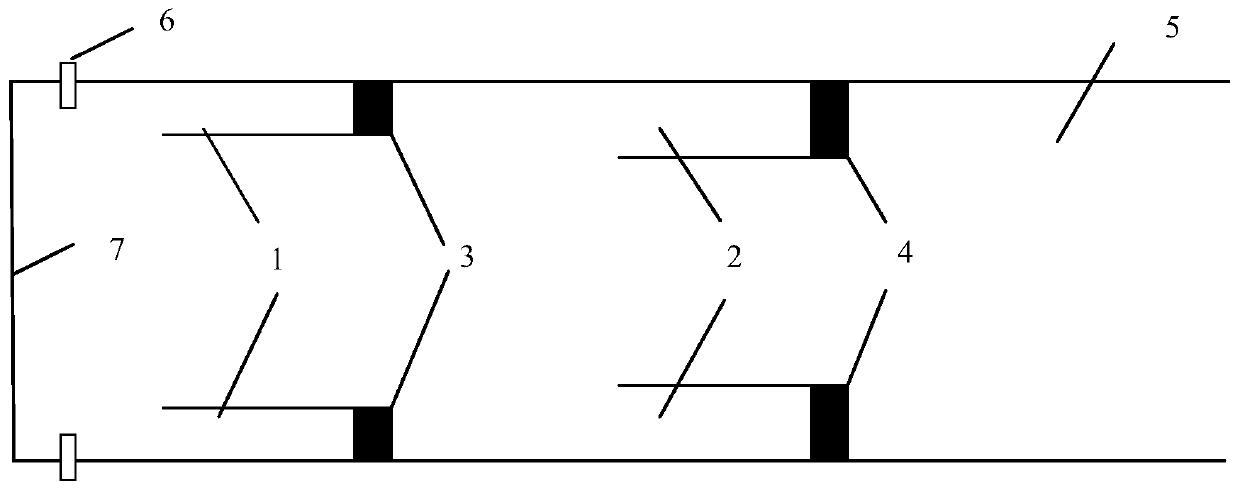

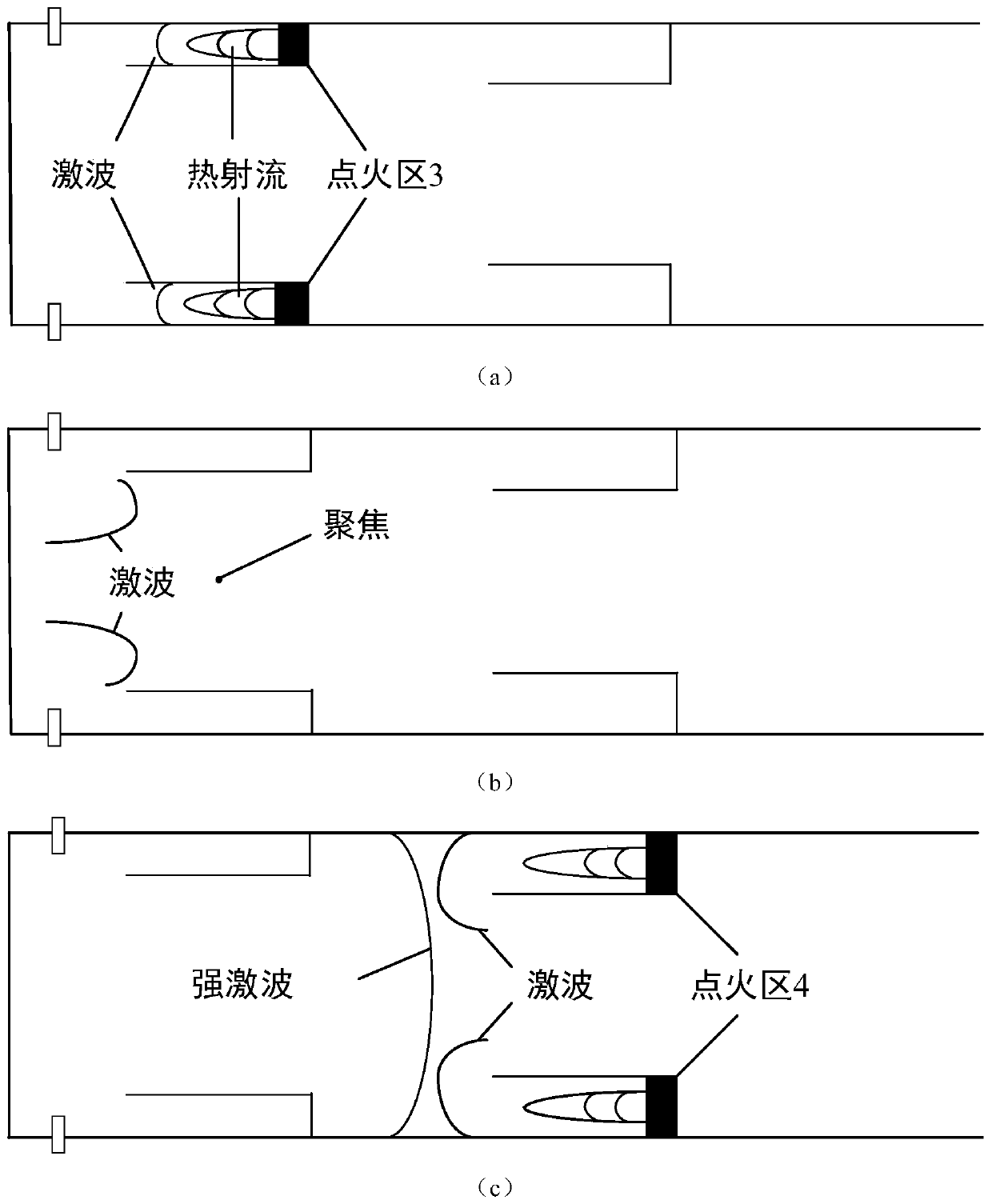

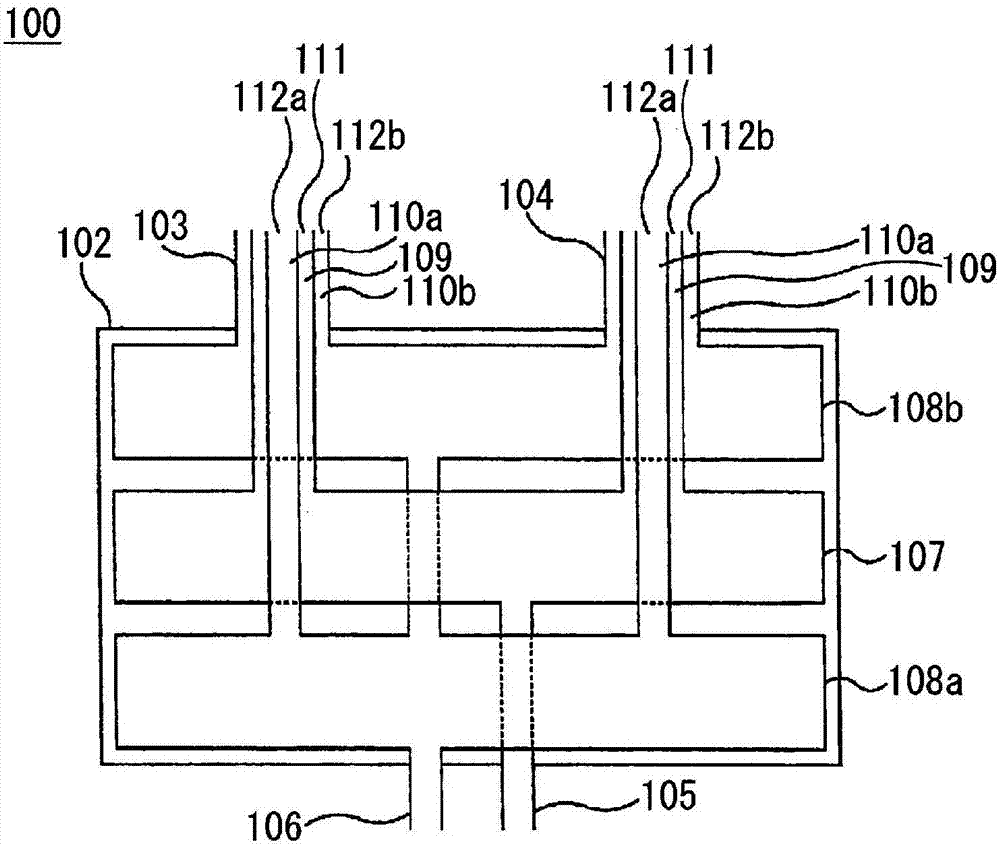

Pulse detonation engine combustor and ignition method thereof

ActiveCN110131071AIncrease working frequencyImprove convenienceIntermittent jet plantsRocket engine plantsShock waveCombustion chamber

The invention provides a pulse detonation engine combustor and an ignition method thereof. A large-size main detonation chamber is divided into a plurality of small-size zones, firstly the main detonation chamber is filled with air and fuel, then ignition is conducted with low energy in the first line of zone close to the left end wall of the detonation chamber, flame is accelerated to form hot jet flow large in energy and containing a large number of active groups in the small-size zone, and the hot jet flow enters the main detonation chamber; afterwards the jet flow collides with the left end wall face to cause shock focusing, flame speed is increased, and shock-wave strength is enhanced; and then through corresponding sequential control, mixed fuel in the second line of zone far away from the left end wall face is ignited with low energy, jet flow formed in the zone enters the main detonation chamber, and ignition energy is increased again. Compared with common ignition, the pulse detonation engine combustor and the ignition method thereof organically combine multipoint ignition, jet flow ignition, obstacle reinforcement turbulent flow, shock reflection focusing, small pipelineacceleration and other principles and methods, detonation waves can be generated in a shorter time and distance, and thus time and distance of DDT are shortened.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

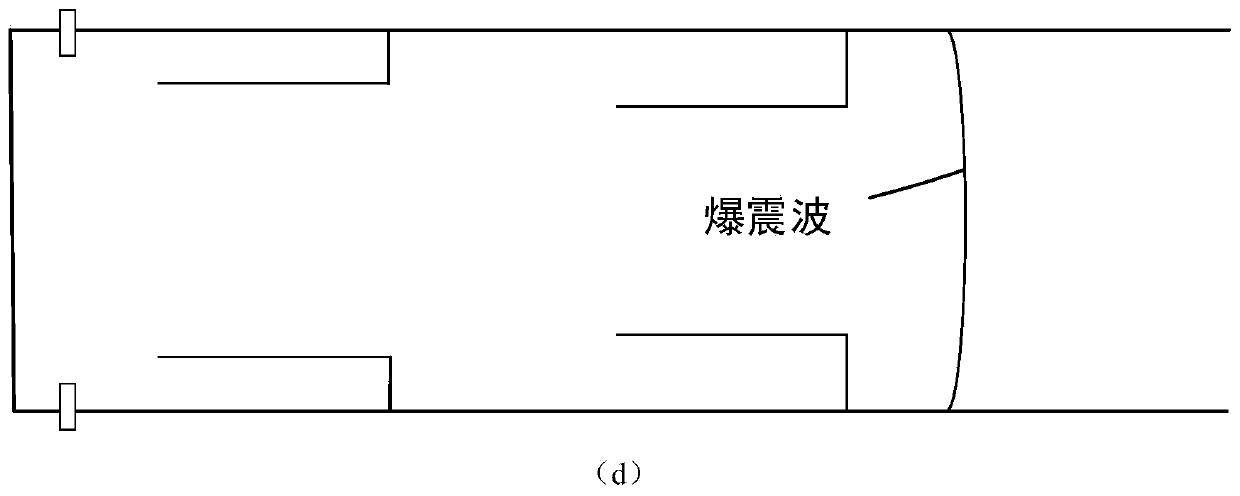

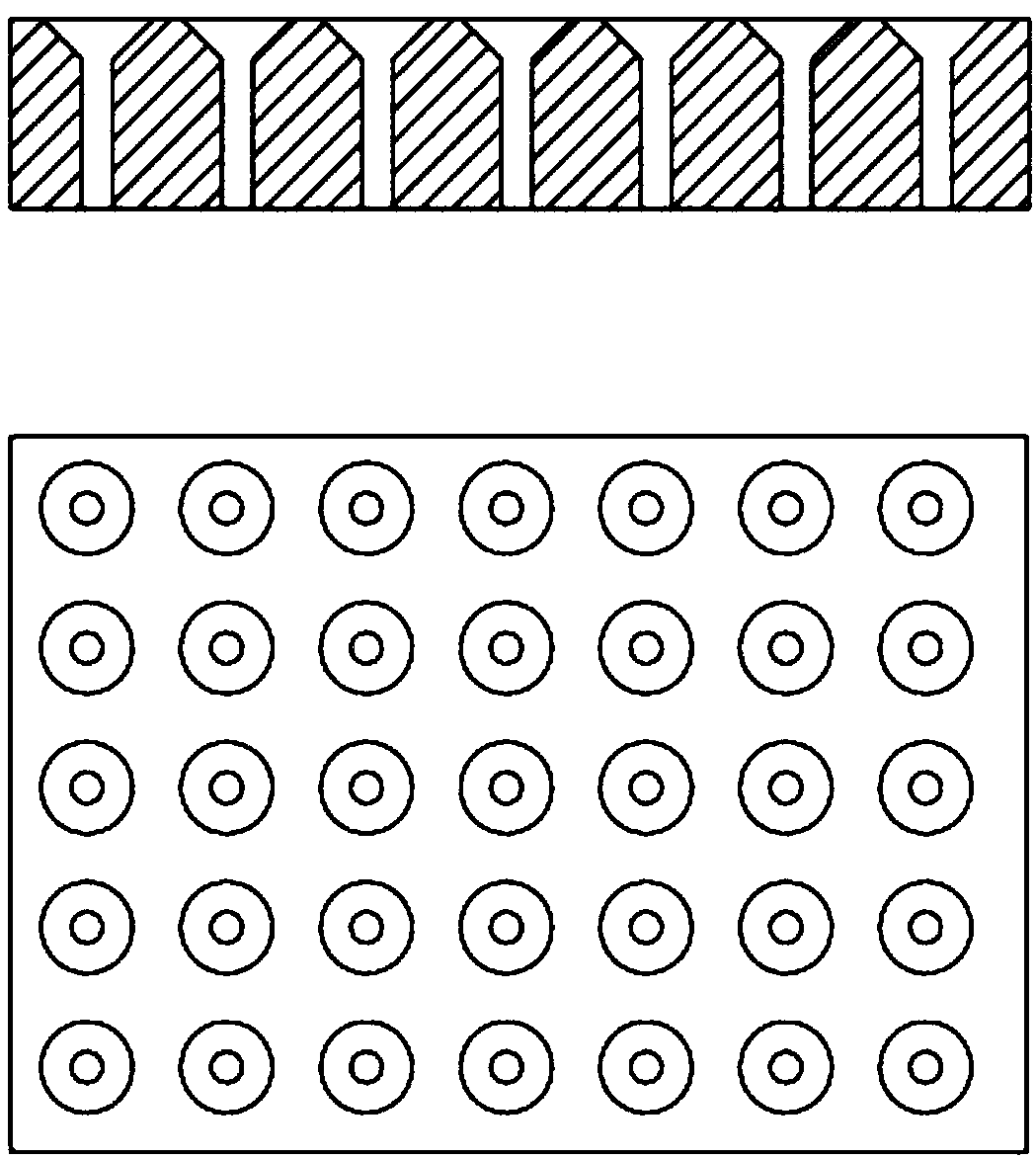

Variable-hole-diameter porous ceramic burning plate

InactiveCN108954311ABurner safety arrangementsBurner material specificationsPollutant emissionsQuenching

The invention discloses a variable-hole-diameter porous ceramic burning plate. A plurality of small holes are evenly and densely distributed in the gas inlet face of the variable-hole-diameter porousceramic burning plate, the diameter of the holes in the gas inlet face is less than the hole diameter of the gas outlet face, the hole sections can be in various shapes, the hole diameter going deep into a certain thickness range of the burning plate is invariant, then the hole diameter is gradually increased and can be increased in a V shape, a curved shape or a step shape, and all the holes penetrate through the burning plate vertically. The gas outlet face serves as a burning face. The hole diameter of the gas inlet face is less than the quenching distance required by wall surface quenchingof adopted fuel gas on a ceramic body, the hole diameter of the gas outlet face approaches to the quenching distance during quenching, and the minimum hole depth is greater than two times of the quenching distance. When various fuel gas is compatible, the gas inlet hole diameter is calculated in the minimum quenching distance, and the thickness is calculated in the maximum value. The hole diameter increasing area can be coated with a catalyst to promote rapider and more full burning, and the infrared conversion rate is increased. According to the variable-hole-diameter porous ceramic burningplate, burning stability can be improved, the flame speed can be increased, the burning ultimate range is expanded, and the pollutant discharging concentration is decreased.

Owner:SHENZHEN YUANJIANG SCI & TECH CO LTD

Additive for combustion enhancement of liquid hydrocarbon fuels

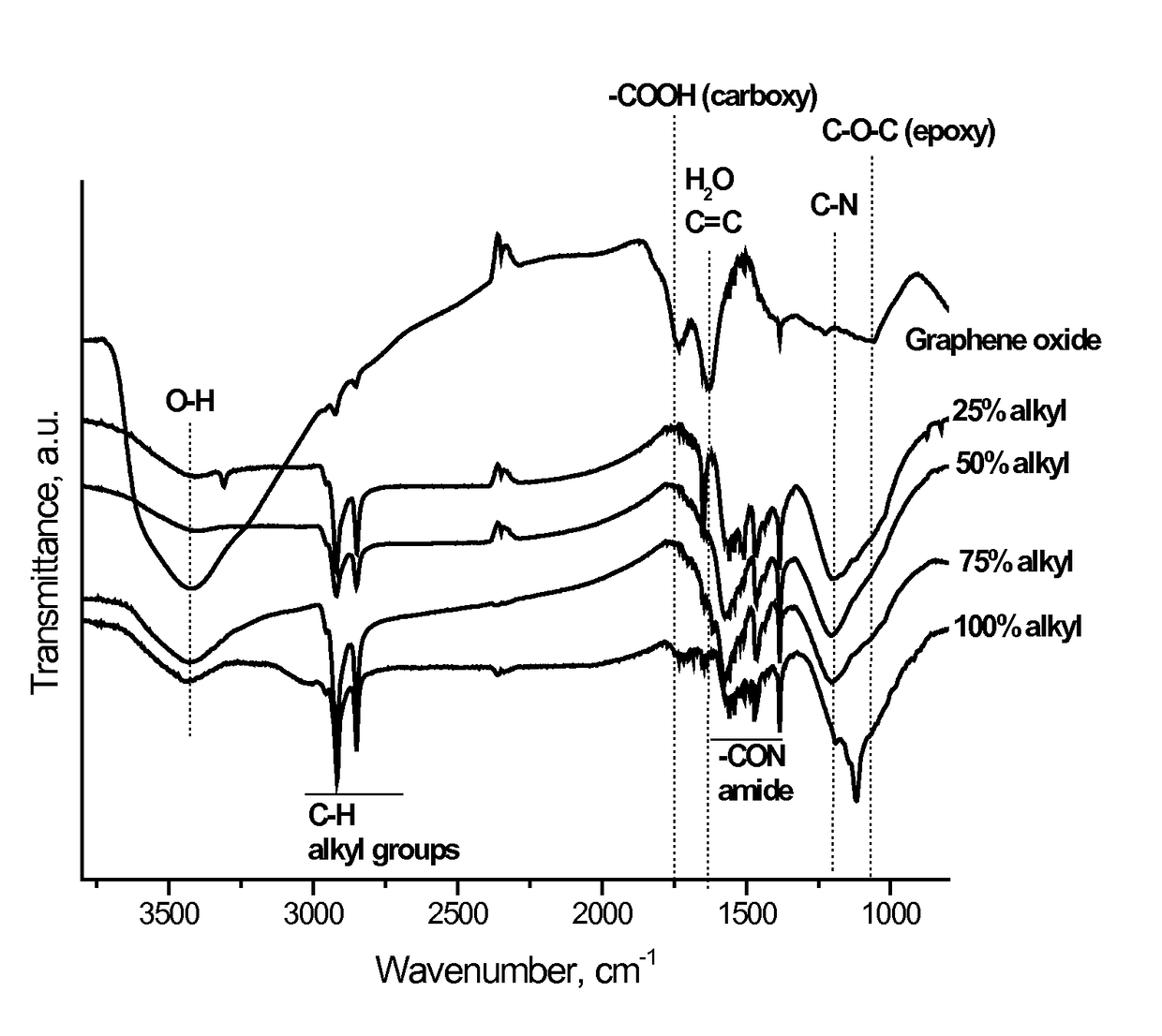

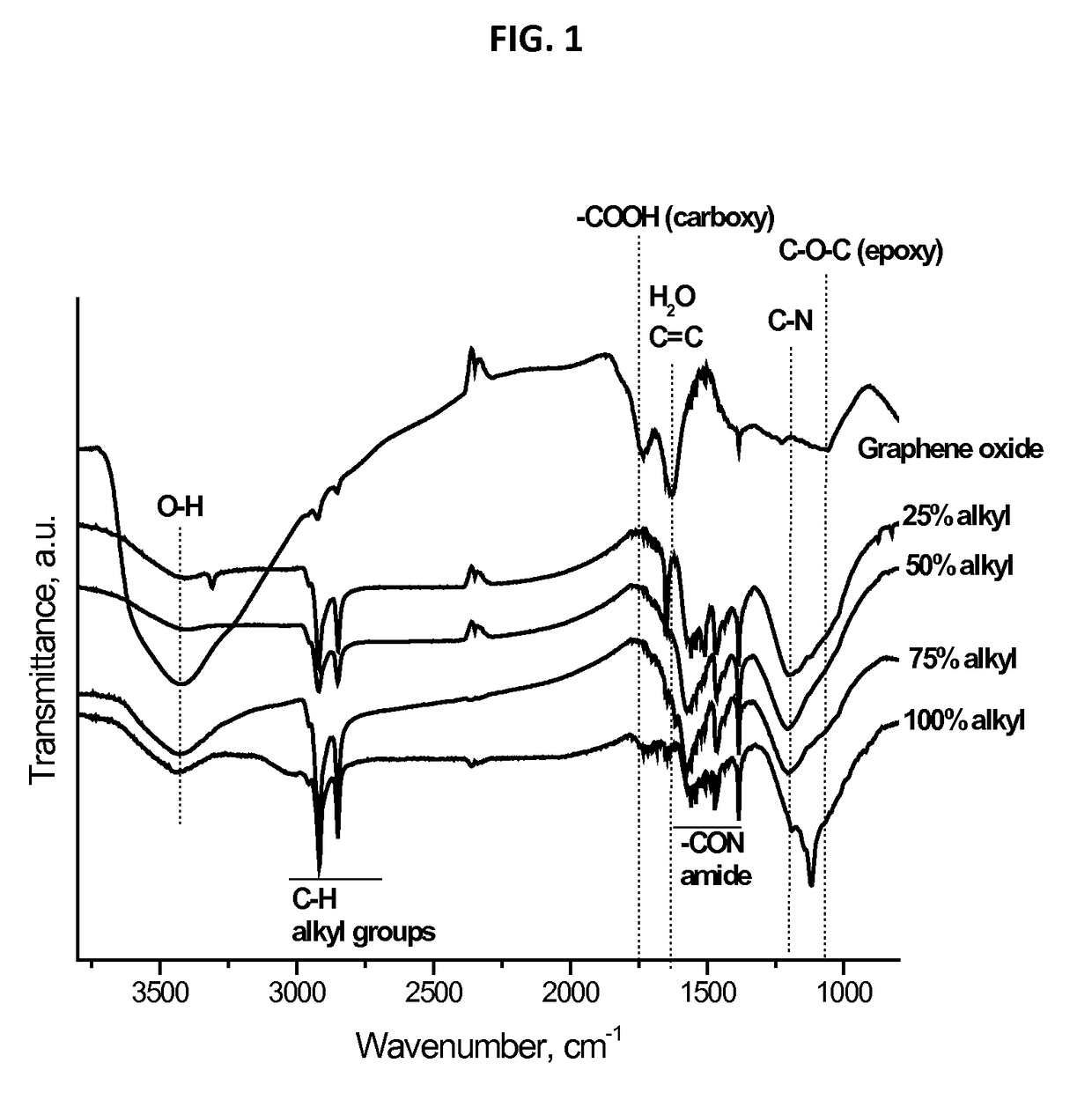

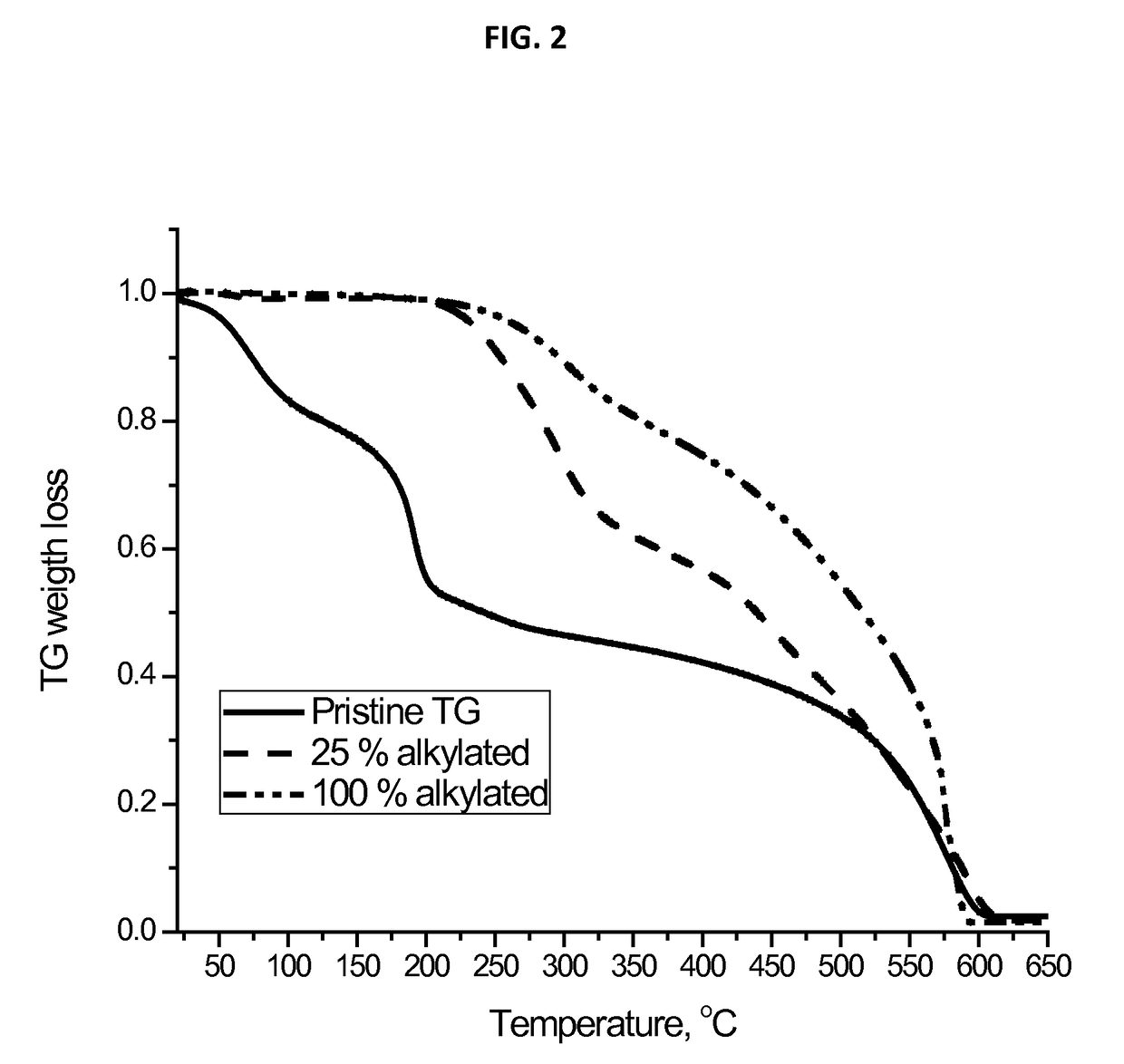

ActiveUS10017706B1Increase energy densityUseful characteristicLighting and heating apparatusLiquid carbonaceous fuelsLiquid hydrocarbonsGraphitic carbon

A stabilized composition comprising a liquid hydrocarbon fuel, such as JP-8, and a fuel additive, wherein the fuel additive comprises a graphitic carbon compound functionalized with a plurality of alkyl groups, wherein at least one alkyl group at each site of alkyl functionalization on the graphitic carbon compound has 8 or more carbon atoms, for example, poly(octadecyl)-graphene oxide. A method of increasing the energy density of a liquid hydrocarbon fuel involving adding to the fuel one or more alkyl-functionalized graphitic carbon compounds. The stabilized composition is useful for enhancing the properties of combustion processes, including energy density, thrust, flame speed, or a combination thereof, without introducing undesirable combustion effects, emissions, or combustion signature.

Owner:PRECISION COMBUSTION

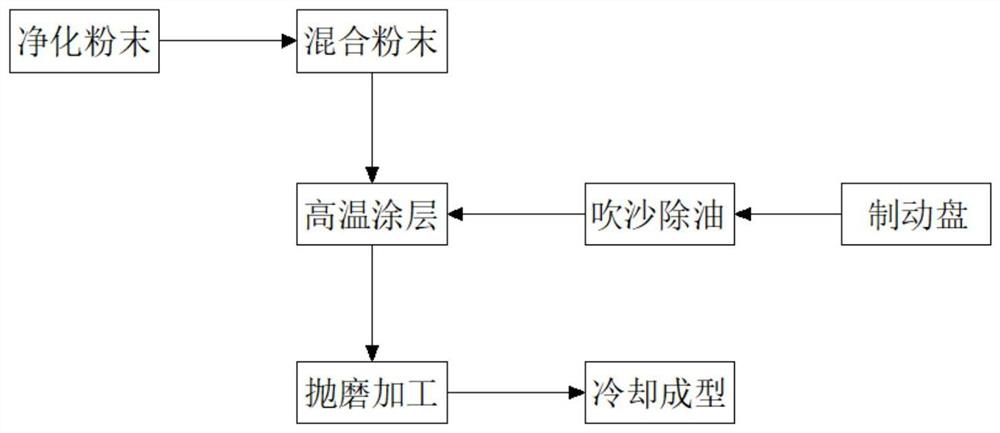

Manufacturing method of wear-resistant alloy coating of automobile brake disc

InactiveCN112593180AHigh bonding strengthQuality improvementMolten spray coatingMolten stateAlloy coating

The invention discloses a manufacturing method of a wear-resistant alloy coating of an automobile brake disc. The manufacturing method of the wear-resistant alloy coating of the automobile brake disccomprises the following raw materials: 25%-70% of tungsten carbide, 15%-70% of chromium carbide and a brake disc base material, and hypersonic flame is utilized. Through axially feeding powder to theflame, spraying particles can be heated to a molten or semi-molten state and accelerated to be up to 300-500 m / s, so that the compact high-quality coating with high bonding strength is obtained. The hypersonic flame speed is very high, but the temperature is relatively low and is about 3000 DEG C. For WC-Co series hard alloys, decomposition of WC in the spraying process can be effectively inhibited, and the coating is high in bonding strength and compact. The wear resistance is excellent, greatly exceeds that of a plasma spraying layer, is equivalent to that of an explosion spraying layer, andalso exceeds that of an electroplated hard chromium layer and a spray melting layer. The surface hardness is increased and can reach HV900-1200. The temperature resistance can reach 600-900 DEG C, the emission of brake dust is reduced by 90%, and the effect of no rusting can be achieved forever.

Owner:SUZHOU TONGMING MACHINERY

Powdered fuel conversion systems and methods

Owner:MCKNIGHT JAMES K +2

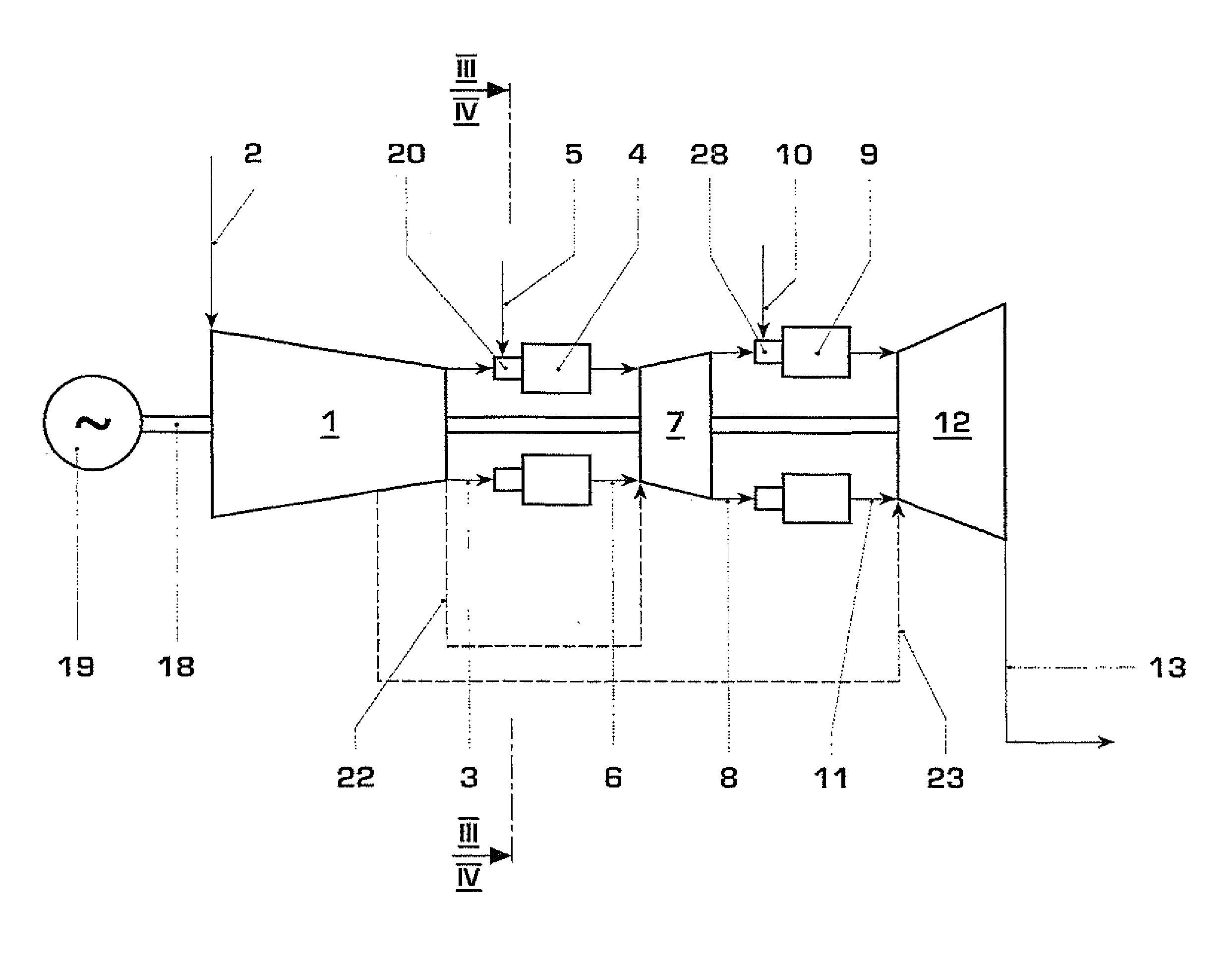

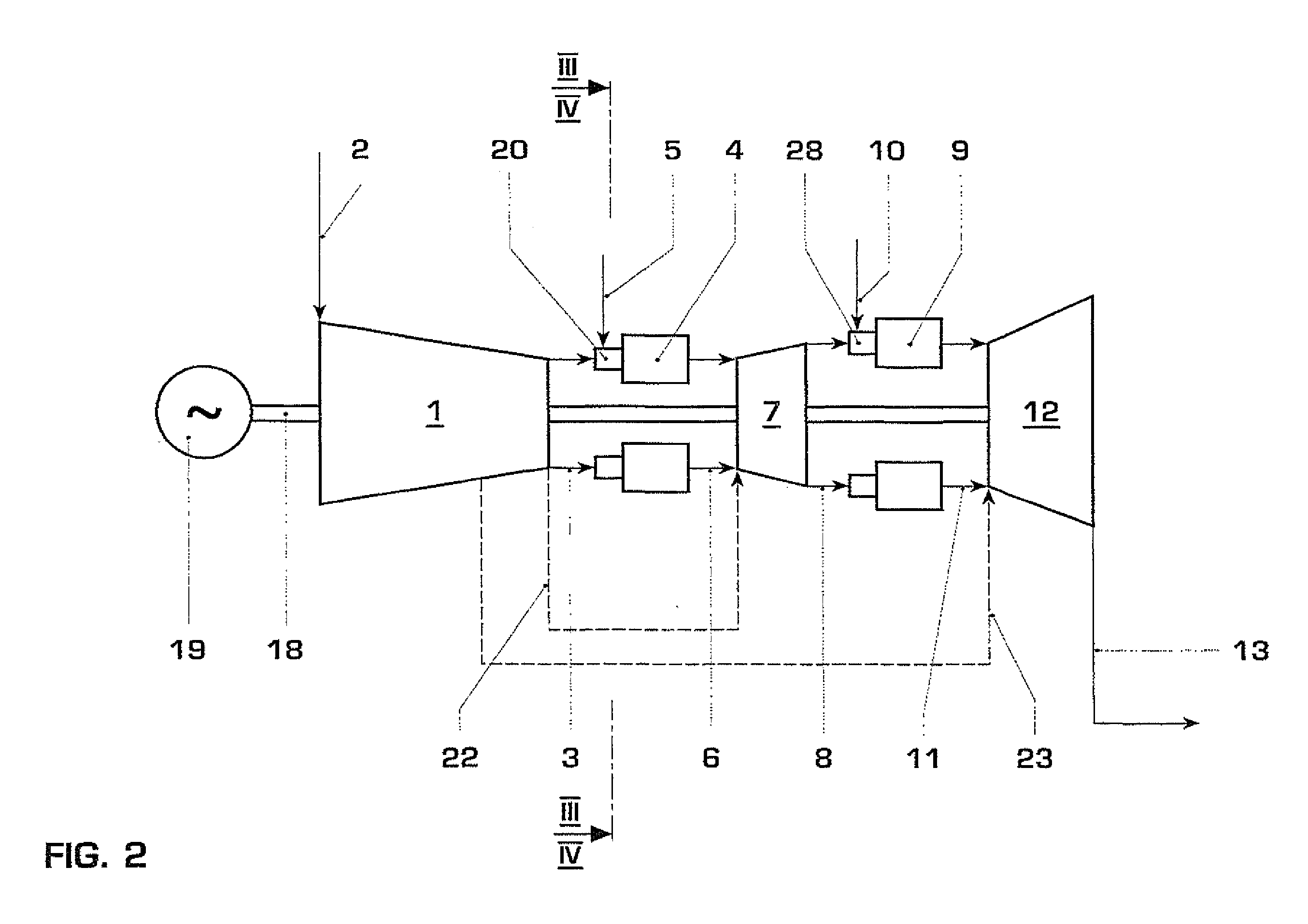

Gas turbine installation with flue gas recirculation dependent on oxygen content of a gas flow

A method and installation are disclosed which can, for example, provide for reliable, low-Nox-emission operation of a gas turbine installation with hydrogen-rich fuel gas. An exemplary gas turbine installation includes an arrangement for flue gas recirculation into a compressor inlet and for fuel gas dilution. Oxygen content in combustion air can be reduced by recirculation of recooled flue gas, and the fuel gas can be diluted with compressed flue gas. The oxygen reduction in the combustion air can lead to minimum residual oxygen in the flue gas which can be used for fuel gas dilution. As a result of the flue gas recirculation, water content in the combustion air can be increased by feedback of the water which results as a combustion product. The oxygen reduction, increased water content, and fuel dilution can reduce the flame velocity of hydrogen-rich fuel gases and enable a robust, reliable and low-emission combustion.

Owner:GENERAL ELECTRIC TECH GMBH

Deflagration overpressure relief device with wave adsorption and flame suppression functions

InactiveCN102954262AProtection securityExplosion sound weakenedValve members for absorbing fluid energyEqualizing valvesPhysical chemistryAluminum silicate

The invention relates to the technical field of chemical machinery and discloses a deflagration overpressure relief device with wave adsorption and flame suppression functions. The deflagration overpressure relief device is formed by pipe flanges, a rupture disk assembly, a relief pipeline, an aluminum silicate wool porous material and a fireproof corrugated plate; the rupture disk assembly is arranged at the joint of the pipe flanges; the aluminum silicate wool porous material is attached to the inner wall of the relief pipeline; and the fireproof corrugated plate is arranged at the tail end of the relief pipeline. In the emergency discharging process, a rupture disk is opened under a rated opening pressure; a discharged deflagration medium is subjected to effective wave adsorption, pressure reduction and noise reduction by the aluminum silicate wool porous material arranged on the inner wall of the pipeline so as to obviously inhibit the pressure, the flame speed and the voice strength; and then the discharged deflagration medium is subjected to fire retardance and flame suppression by the fireproof corrugated plate at the tail end. After the discharged material passes through the device, the flame and the pressure are inhibited in a combined manner and the safety of containers, equipment and people close to an outlet of the relief pipeline is effectively protected.

Owner:DALIAN UNIV OF TECH

Fire-proof exterior wall coating

InactiveCN104446266ADelayed ignitionImprove fire resistanceMelamine formaldehyde resinFire retardant

The invention discloses a fire-proof exterior wall coating. The fire-proof exterior wall coating is composed of base materials, curing agent, light stabilizer, fillings and fire retardant, wherein the base materials are silicate cement clinker, the curing agent is melamine-formaldehyde resin, the light stabilizer is carbon black, the fillings are perlite, and the fire retardant is aluminum hydroxide. Made from the base materials, the curing agent, the light stabilizer, the fillings and the fire retardant, the fire-proof exterior wall coating is flame-retardant or nonflammable, avoids direct contact between protected materials and air, retards fire catching of objects, reduces the flame speed and increases the fire-resistant limit of coated materials.

Owner:SUZHOU AOLAX BUILDING MATERIALS

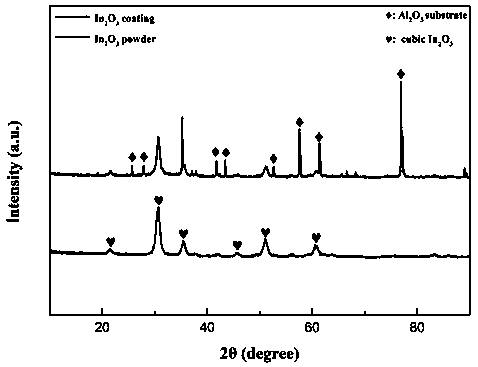

Preparation method of metal oxide suspension and method for spraying suspension to form high-specific-surface-area gas-sensitive coating under liquid material flame

InactiveCN109850934APromote meltingImprove work efficiencyLiquid surface applicatorsZinc oxides/hydroxidesRoom temperatureSpherical morphology

The invention discloses a preparation method of a metal oxide suspension capable of being applied to industrial production and a method for spraying the suspension to form a high-specific-surface-areagas-sensitive coating under a liquid material flame. The method utilizes a composite soft template method to synthesize a hollow spherical metal oxide suspension having hollow spherical morphology with a wall thickness thicker than that of a conventional hollow spherical morphology (structural strength of the hollow sphere is improved, and the intrinsic morphology after colliding with a substratecan be preserved), and the gas-sensitive coating is prepared by using the suspension as a liquid material and adopting a liquid material precursor flame spray (LPFS) technique with a milder flame speed and temperature. According to the method provided by the invention, the prepared gas-sensitive coating is a gas-sensitive coating having hollow spherical morphology, and has high sensitivity, faster response / recovery time and good long-term stability to a specific gas at under low temperature or even room temperature condition.

Owner:扬州睿德石油机械有限公司 +1

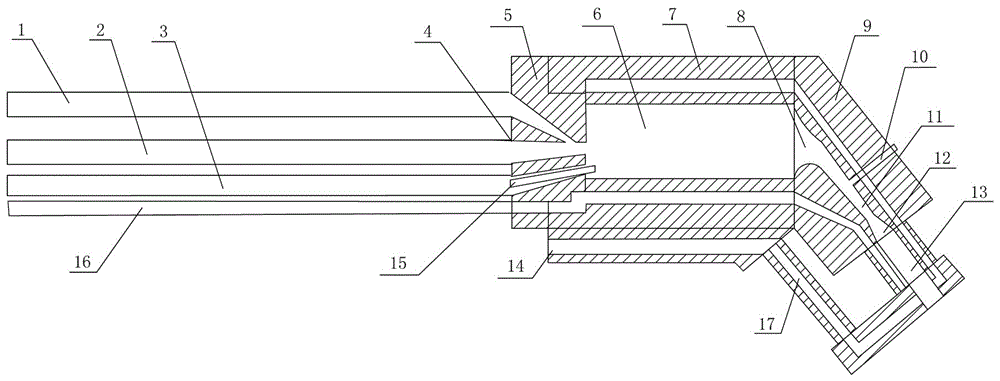

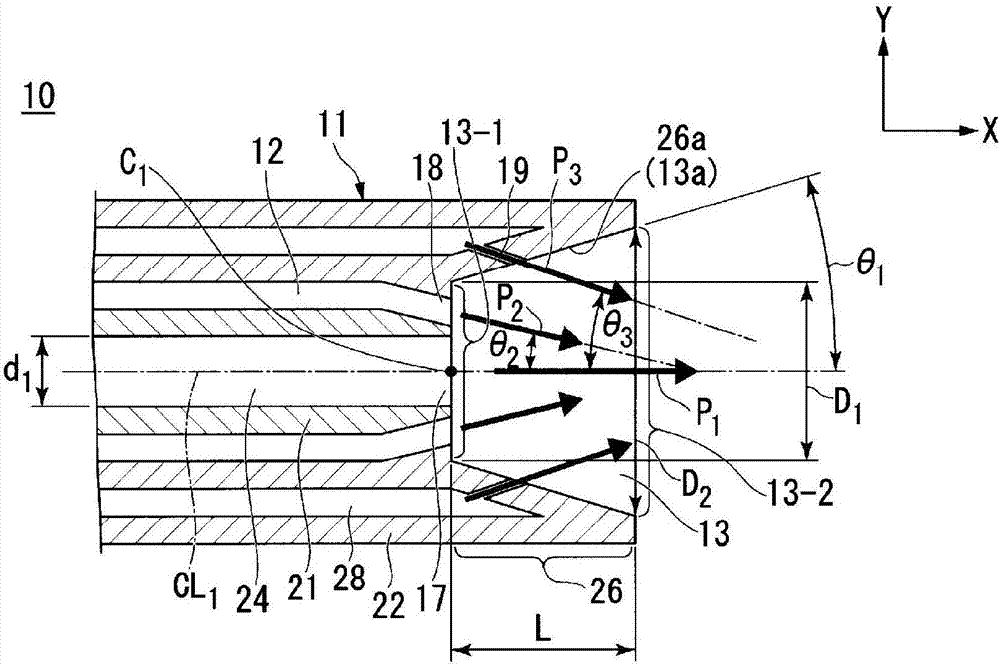

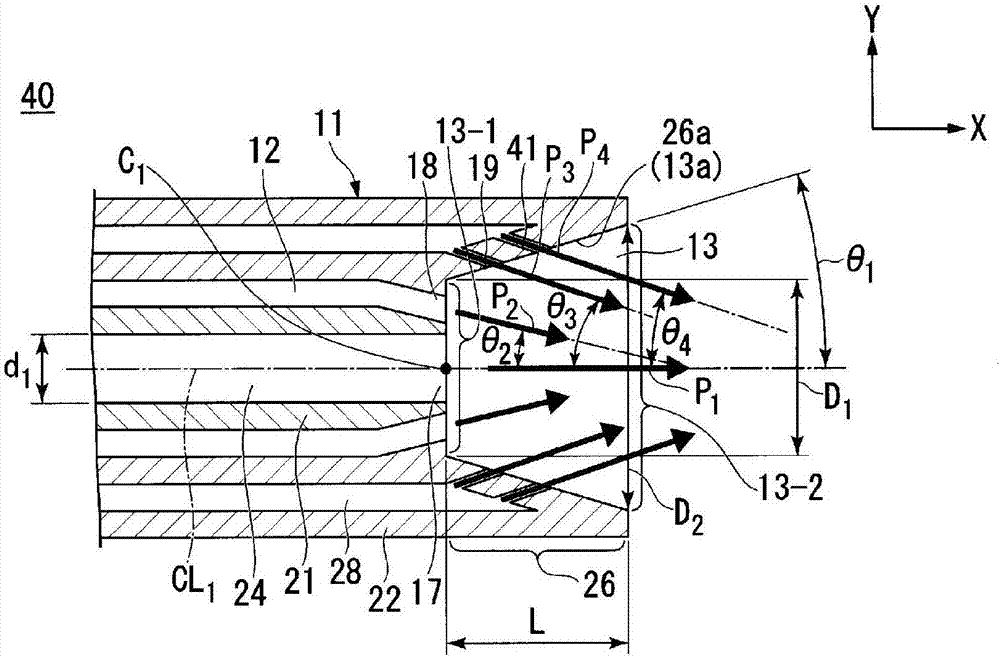

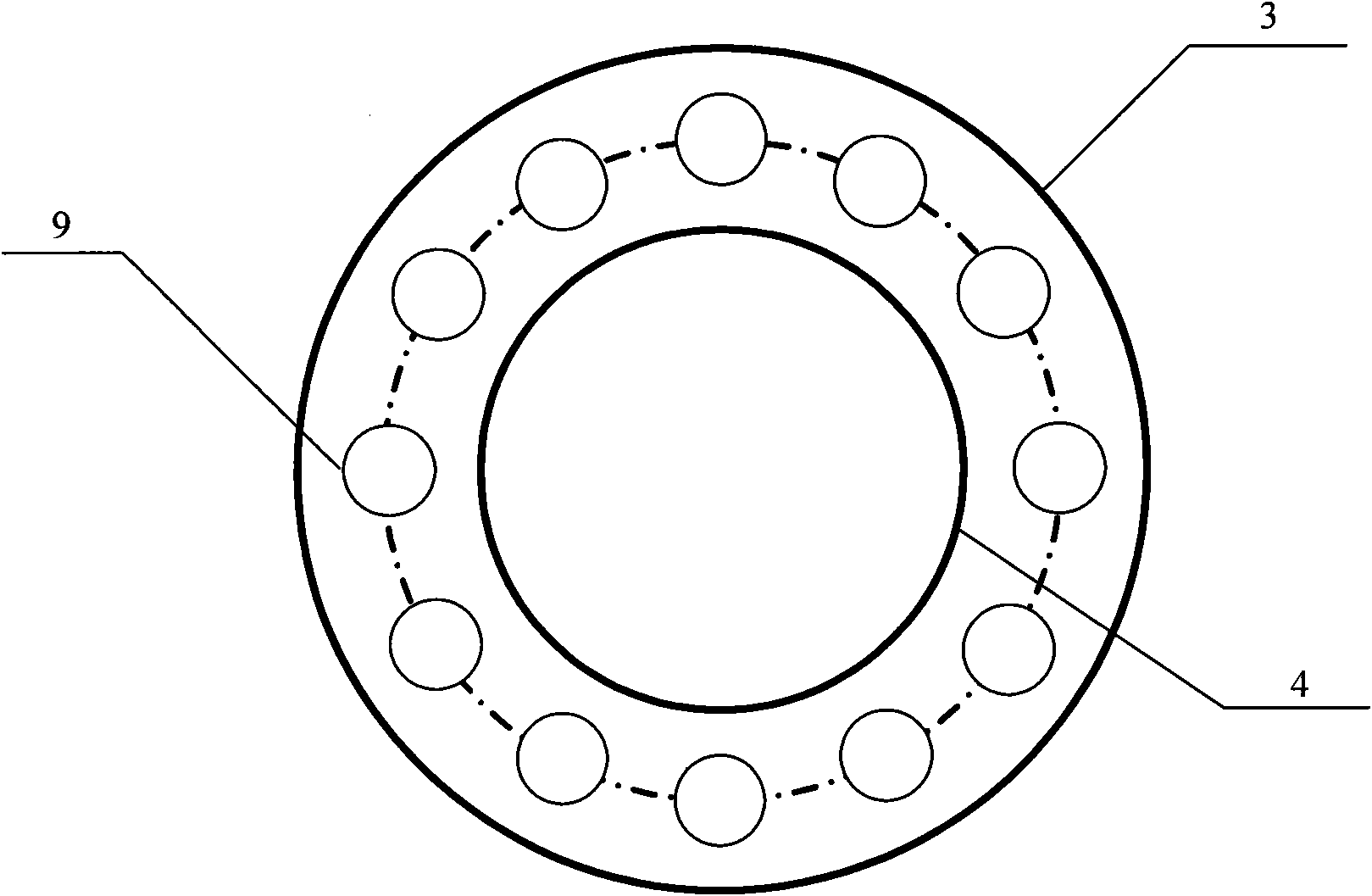

Gas fuel burner and method for heating gas fuel burner

InactiveCN107250669AHigh axial speed and high temperaturePrevent oxidationGaseous fuel burnerCombustorCombustion chamber

The present invention addresses the problem of providing a gas fuel burner and a method for heating the gas fuel burner that allows a high axial flame speed and a high temperature flame without losing combustion efficiency and that can suppress oxidation of the object to be heated and improve convection heat transfer efficiency. This gas fuel burner 10 comprises: a first oxidation agent ejecting port 17 that is disposed in the center C1 of a first circular face 13-1 constituting a combustion chamber 13 having a truncated cone shape that expands from the basal end toward the distal end of a burner body 11 and that ejects a first oxidation agent in the direction that the center axis CL1 of the burner body extends; a gas fuel ejecting port 18 that is disposed on the outside of the first oxidation agent ejecting port 17 and that ejects gas fuel in a direction intersecting the direction that the center axis CL1 extends; and a second oxidation agent ejecting port 19 that is disposed on a side face 13a of the combustion chamber 13 and that ejects a second oxidation agent in a direction intersecting the direction that the center axis CL1 extends.

Owner:NIPPON SANSO CORP

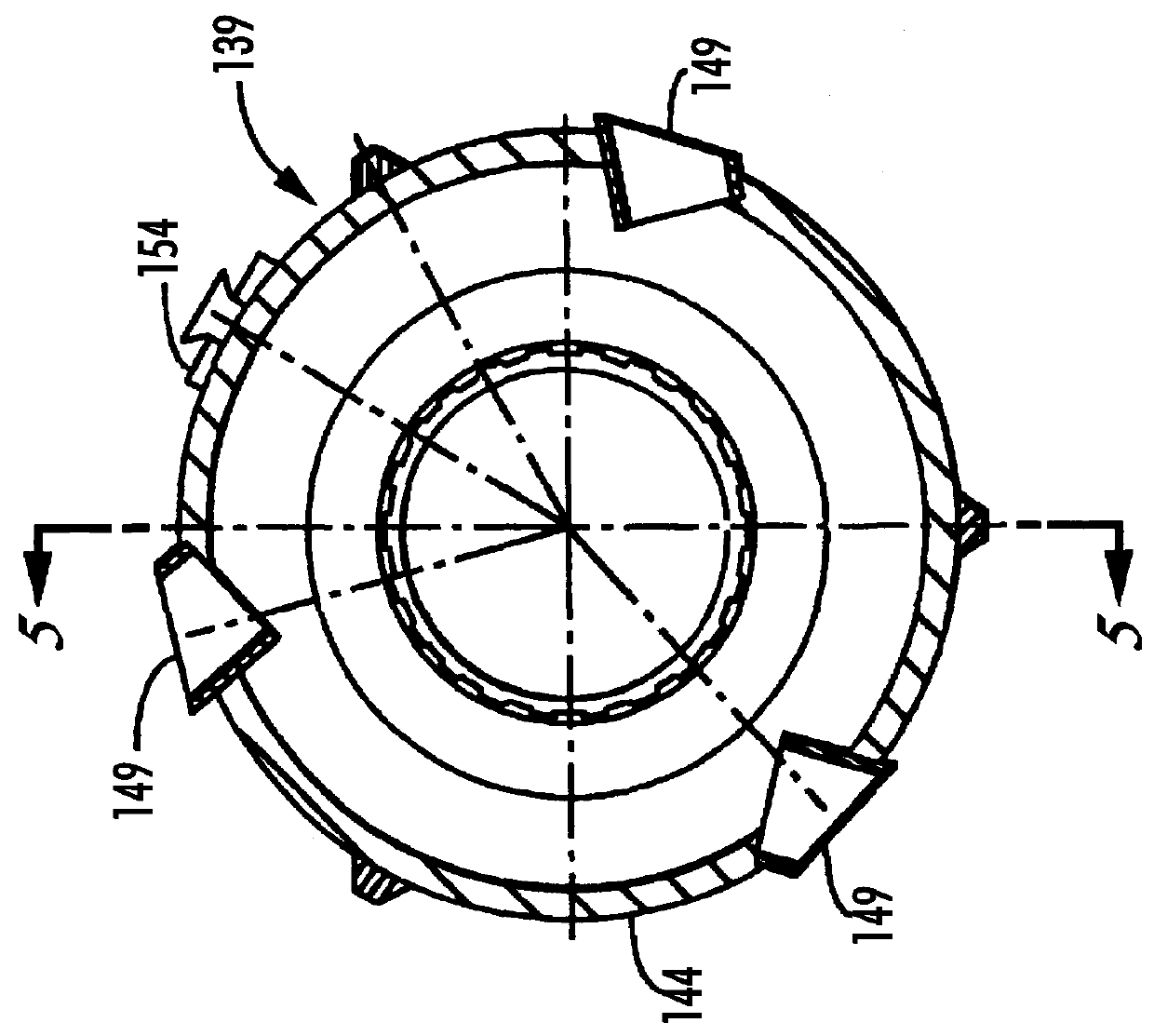

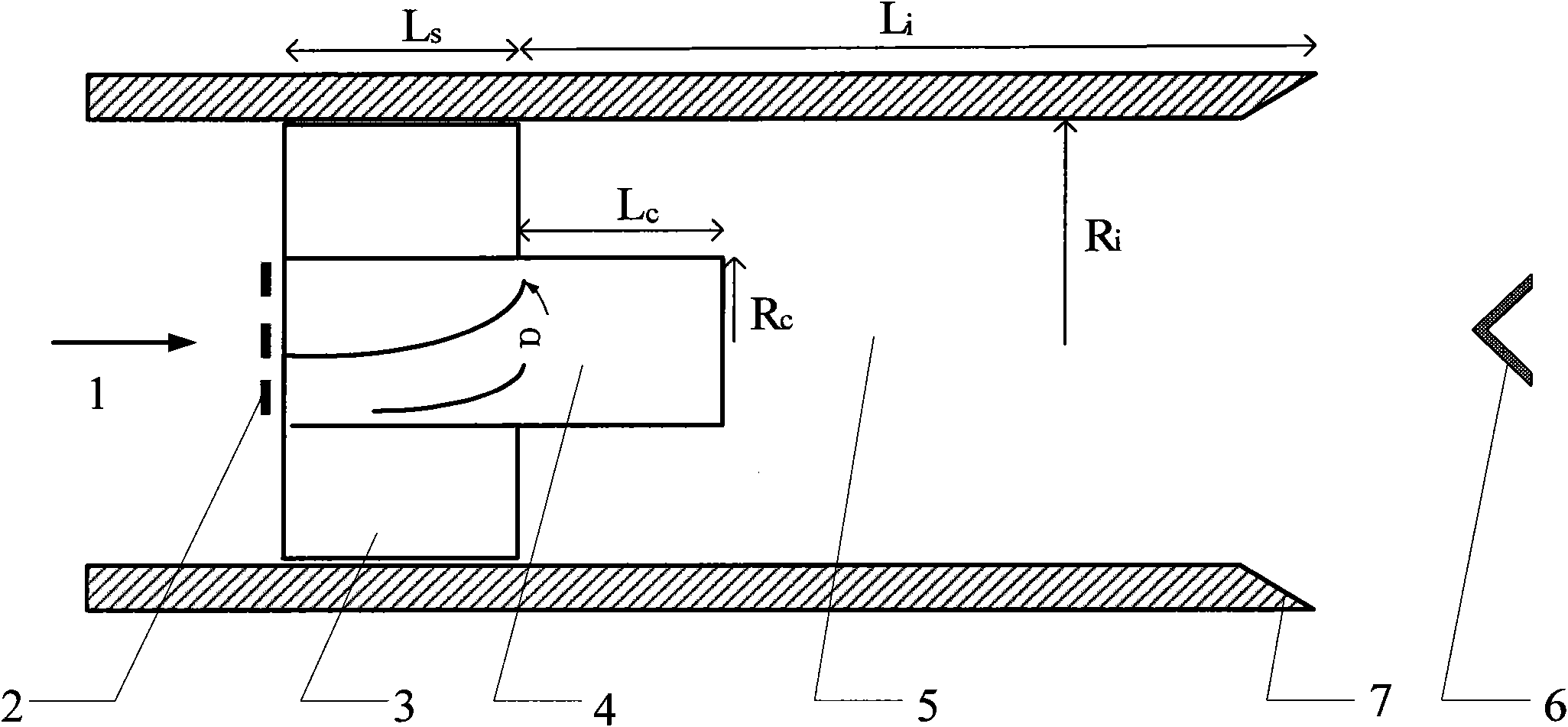

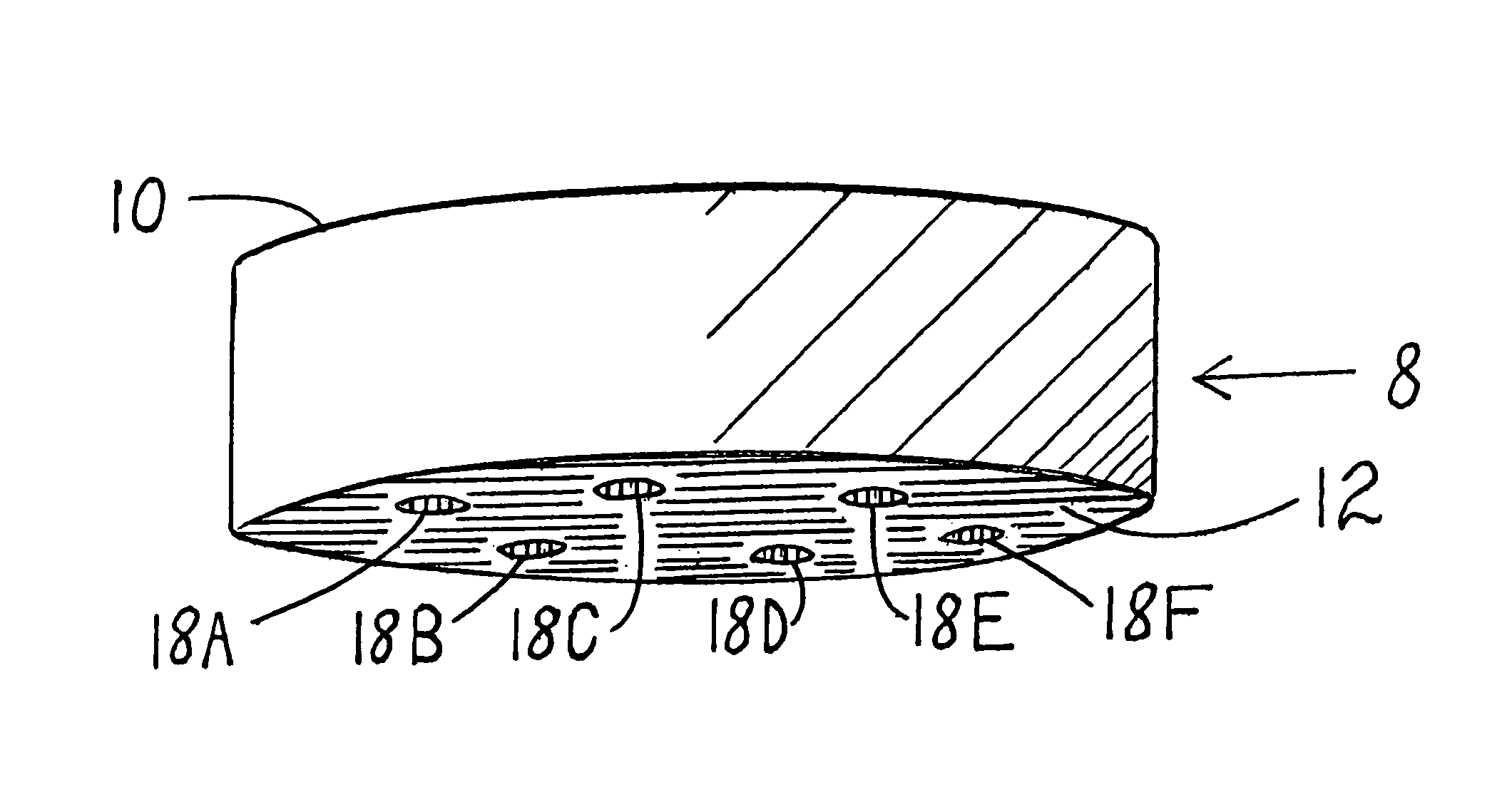

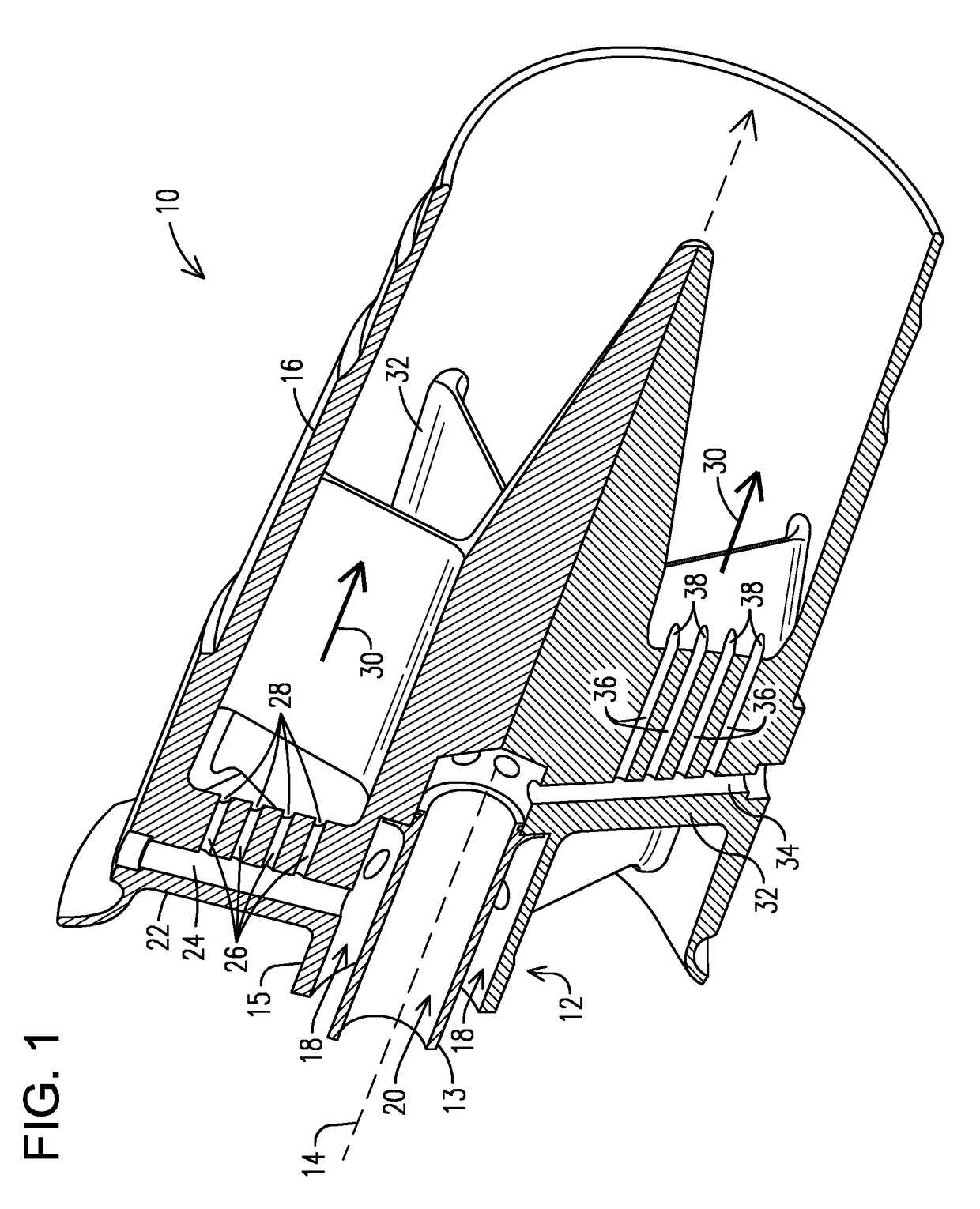

Fuel injector including a lobed mixer and vanes for injecting alternate fuels in a gas turbine

ActiveUS20170363291A1Increase heightIncreased flame speedContinuous combustion chamberGaseous fuel burnerEngineeringGas turbines

A fuel injector for injecting alternate fuels having a different energy density in a gas turbine is provided. A first fuel supply channel (18) may be fluidly coupled to a radial passage (22) in a plurality of vanes (20) that branches into passages (24) (e.g., axial passages) to inject a first fuel without jet in cross-flow injection. This may be effective to reduce flashback in fuels having a relatively high flame speed. A mixer (30) with lobes (32) for injection of a second fuel may be arranged at the downstream end of a fuel delivery tube (12). A fuel-routing structure (38) may be configured to route the second fuel within a respective lobe so that fuel injection of the second fuel takes place radially outwardly relative to a central region of the mixer. This may be conducive to an improved (e.g., a relatively more uniform) mixing of air and fuel.

Owner:SIEMENS ENERGY INC

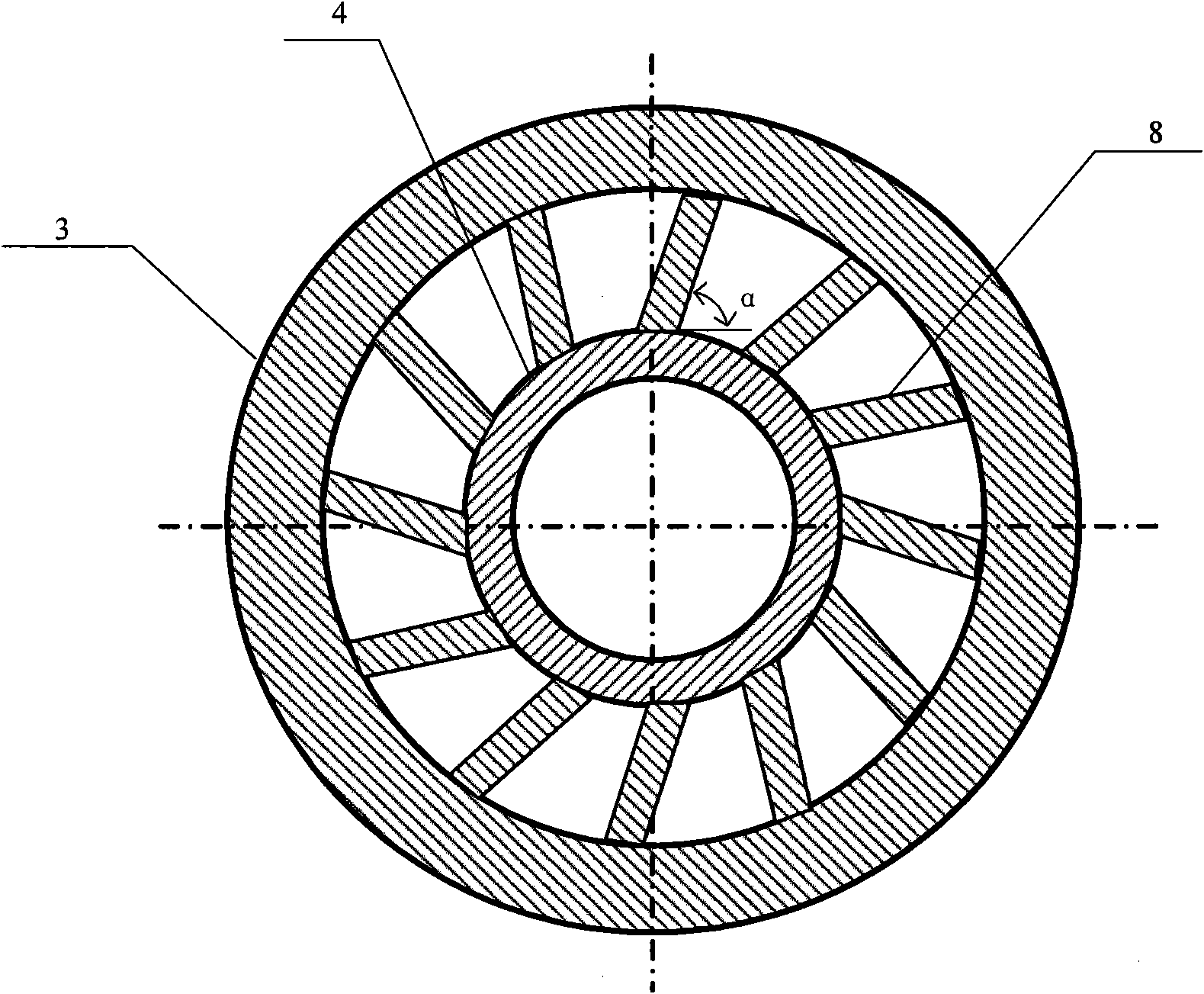

Weak cyclone stagnation gas burner

ActiveCN101846319AImprove combustion efficiencyThe overall structure is simple and reliableGaseous fuel burnerCycloneStagnation point

The invention belongs to the technical field of industrial combustion apparatus, and particularly relates to a weak cyclone stagnation gas burner. Two channels, namely a cyclone device and a direct flow central tube, for premixing gas are formed in the burner; the mixed gas passes through a cyclone development section and is diffused at a combustion outlet to form a weak cyclone field and form stagnation flames under the action of a blunt body arranged at a gas nozzle so as to play a role in stabilizing the flames. The burner can generate stable boosting flames, wherein stagnation points of free flames exist at the positions, on a central diffusion flow field of the gas nozzle, of which the average premixed gas speed and the turbulent flow combustion flame speed are equal to each other; and the extreme depleted fuel combustion makes NOX generated by the combustion less than 5 ppm, and the CO content in a flue gas be lowered to be less than 400 ppm. The weak cyclone stagnation gas burner has the advantages of wide fuel adaptability, simple and reliable structure, and suitability for combustion of industrial furnaces, reformers and gas turbines.

Owner:TSINGHUA UNIV

Low-nitrogen energy-saving combustion unit of combustor

ActiveCN105805743ASpeed up the flowUniform distribution of temperature fieldGaseous fuel burnerCombustorSpray nozzle

The invention discloses a low-nitrogen energy-saving combustion unit of a combustor. The low-nitrogen energy-saving combustion unit of the combustor comprises a cylindrical shell and a diffusion throat pipe mixing chamber. The front portion of the diffusion throat pipe mixing chamber is arranged in the cylindrical shell. The low-nitrogen energy-saving combustion unit of the combustor is characterized in that the front end of the diffusion throat pipe mixing chamber is conical, and a conical cover is installed in front of a conical shrinkable throat pipe; an annular gap air duct is formed between the outer wall of the conical shrinkable throat pipe and the inner wall of the conical cover; a secondary air pipe communicates with the annular gap air duct; and a conical combustion nozzle is fixed to the front end of the conical cover. By the adoption of the structure, gas can be combusted twice, and the speed of a flame sprayed out of the cylindrical combustion nozzle is high, so that sufficient stirring is achieved in a furnace, the temperature field distribution in the furnace is uniform, and the heat exchange rate is increased; and the energy can be saved by 10% or over by the adoption of the low-nitrogen energy-saving combustion unit. According to the low-nitrogen energy-saving combustion unit of the combustor, the discharge of oxynitride is lower than 40 mg / m<3> and is much lower than the national standard, and the energy saving and emission reduction effects are extremely remarkable.

Owner:北京中宇先创能源科技有限公司

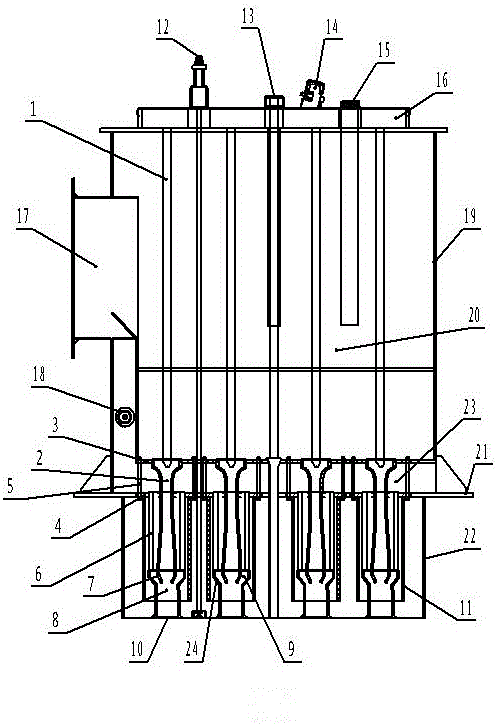

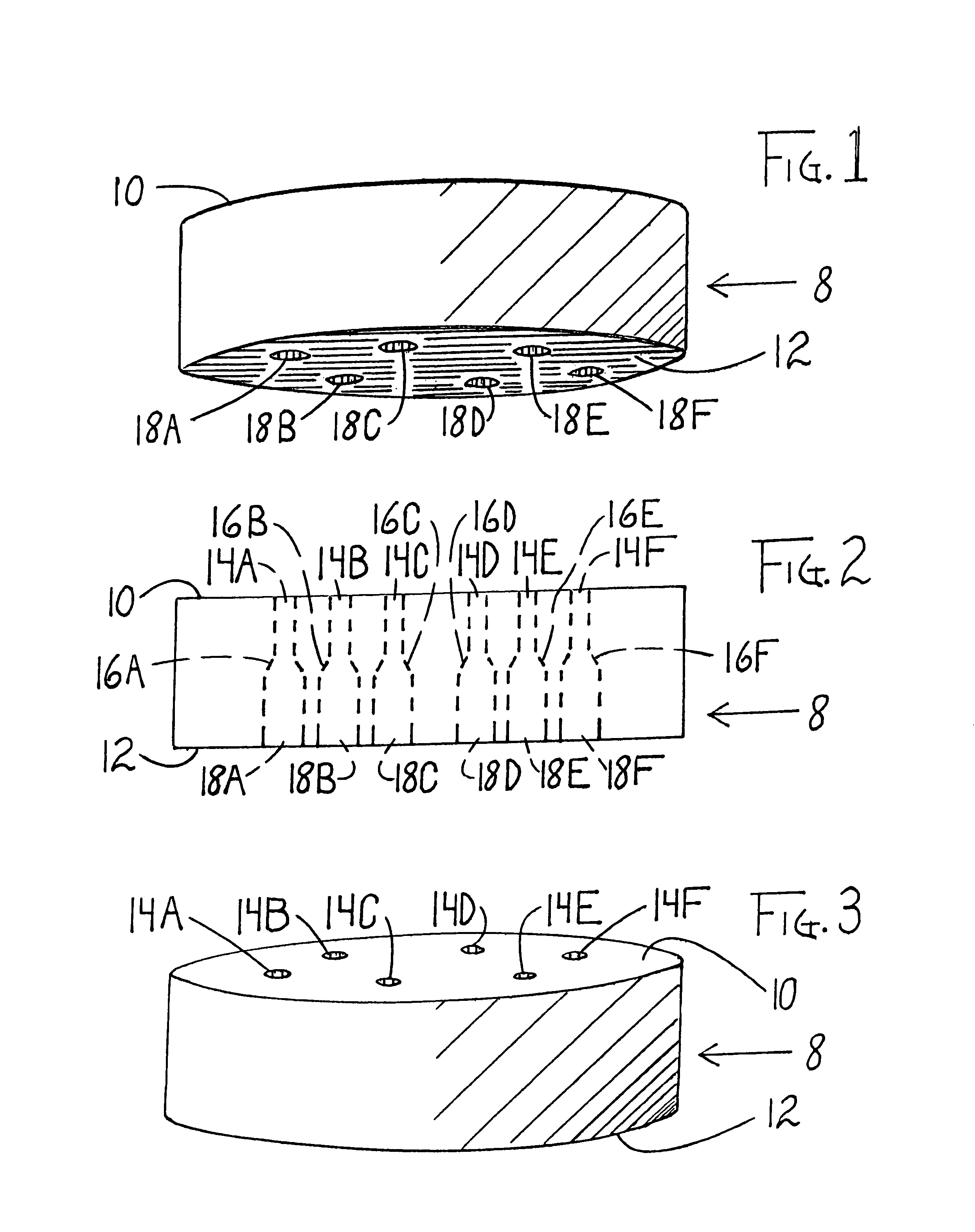

Fire kindler

One embodiment of a fire-kindler which produces a solitary flame cone comprised of pre-mixed air and fuel gases and an increased flame velocity. Comfortably portable in ones' back pocket, a conveniently accessible product of easy use. More reliable in and resistant to adverse outdoor conditions when igniting a woodfire. Comprised of a geometrically shaped plate of combustible material, body of fire-kindler 8 of FIGS. 1,2 and 3 has a multiplicity of air apertures 14A-16A18A, thru, 14F-16F-18F of FIG. 2 passing therethrough. Working co-operatively to produce a strong increased flame velocity in a more neutral solitary flame. Thus establishing a more intense heat output in a more persistently sturdy flame that remains more consistently focused among adverse winds. Thereby, increasing the application of heat and the speed and ease of firewood ignition.

Owner:MAYFIELD ROBERT NICHOLAS

Ultrasonic cooperative control preheating type ammonia combustion method and system

The invention is suitable for the technical field of ammonia combustion, and provides an ultrasonic cooperative control preheating type ammonia combustion method and system. A gas storage tank; the combustor is provided with an inner pipe and an outer pipe, an annular air passage is formed between the inner pipe and the outer pipe, and the combustor is connected with a flue gas treatment assembly used for recycling and treating flue gas; a preheating assembly; the ultrasonic assembly is arranged in the direction, perpendicular to the combustion jet flow, close to the burner nozzle and used for generating ultrasonic waves acting on flames; according to the invention, fuel preheating enhanced combustion and NOx emission reduction by ultrasonic excitation of flame are coupled, by combining the preheating assembly and the ultrasonic assembly, the ammonia gas fuel is subjected to preheating warming pretreatment and then is ignited, a new solution is provided for the problem of low combustibility of ammonia gas, stable combustion of the ammonia gas at the preheating temperature of 320 DEG C is realized, NOx emission is reduced, and the combustion efficiency is improved. And the flame speed and temperature are improved.

Owner:QINGDAO UNIV OF SCI & TECH

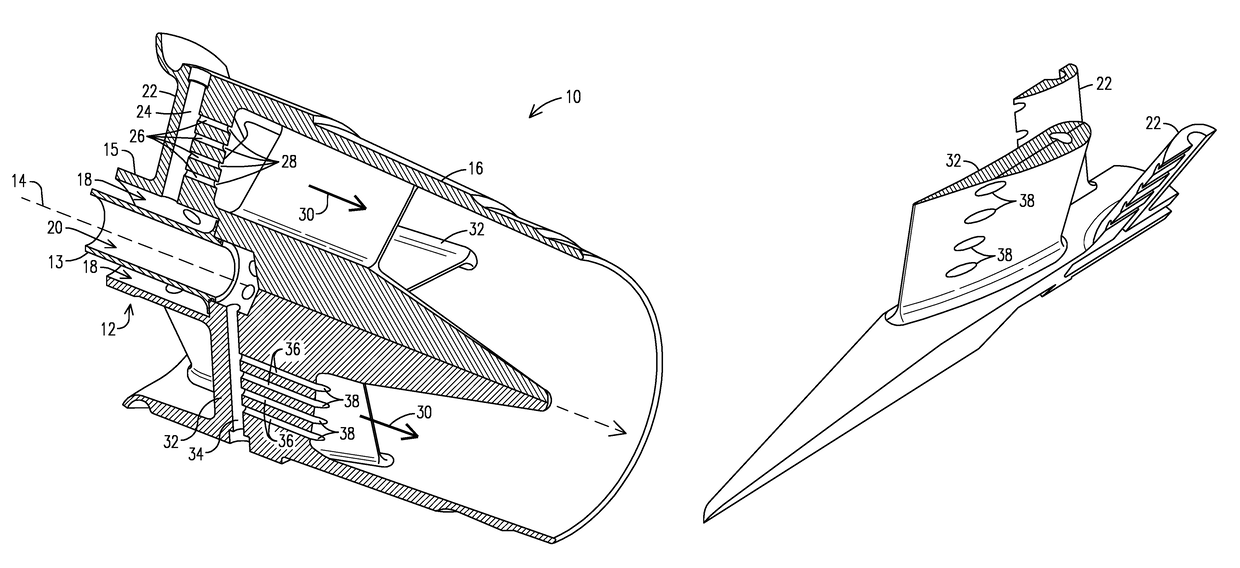

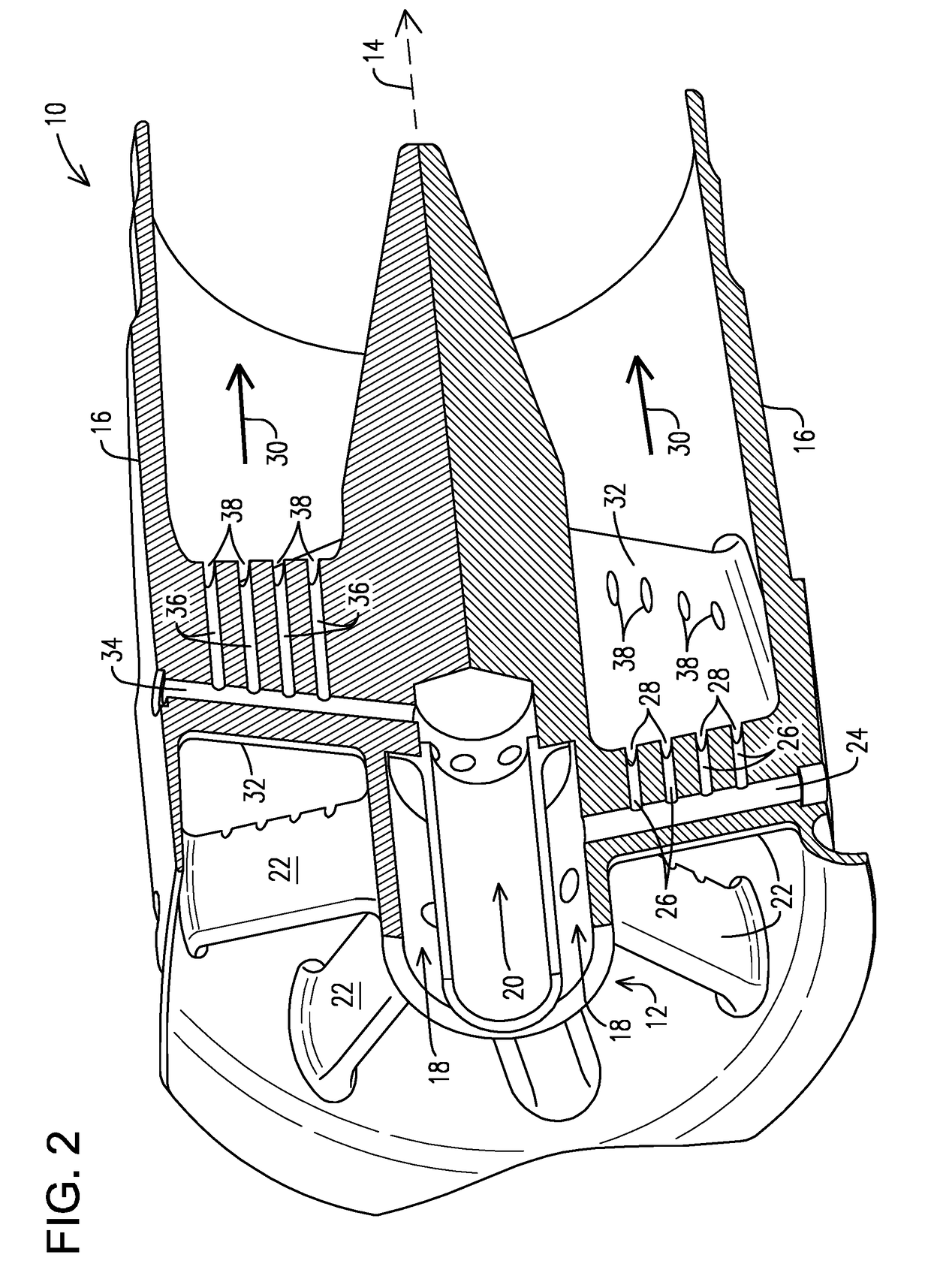

Fuel injector including tandem vanes for injecting alternate fuels in a gas turbine

A fuel injector for injecting fuels having a different energy density in a gas turbine is provided. A first fuel supply channel (18) and a second fuel supply channel (20) may be coaxially arranged in a fuel delivery structure (12). A first set of vanes 22 includes a radial passage (24) in fluid communication with the first channel (18) to receive a first fuel. Passage (24) branches into passages (26) each having an aperture (28) to inject the first fuel without jet in cross-flow injection. A second set of vanes (32) includes a radial passage (34) in fluid communication with the second channel (20) to receive a second fuel. Passage (34) branches into passages (36) each having an aperture (38) arranged to inject the second fuel also without jet in cross-flow injection. This arrangement may be effective to reduce flashback that otherwise may be encountered in fuels having a relatively high flame speed.

Owner:SIEMENS ENERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com