Device for measuring knocking combustion pressure in millimeter-level circular tube

A technology of detonation combustion and magnitude, which is applied in the direction of measuring devices, measuring rapid changes, instruments, etc., can solve problems such as ignition failure, incomplete experiments, neglect of correlation, etc., and achieve the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

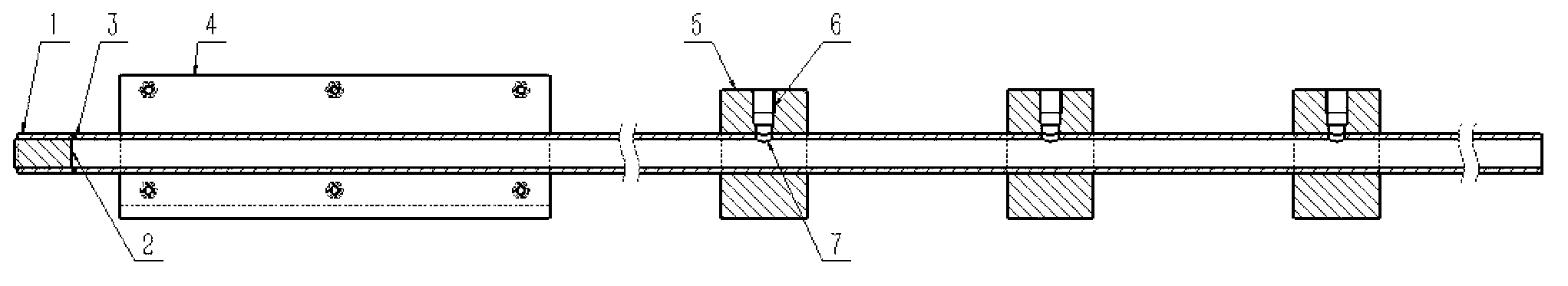

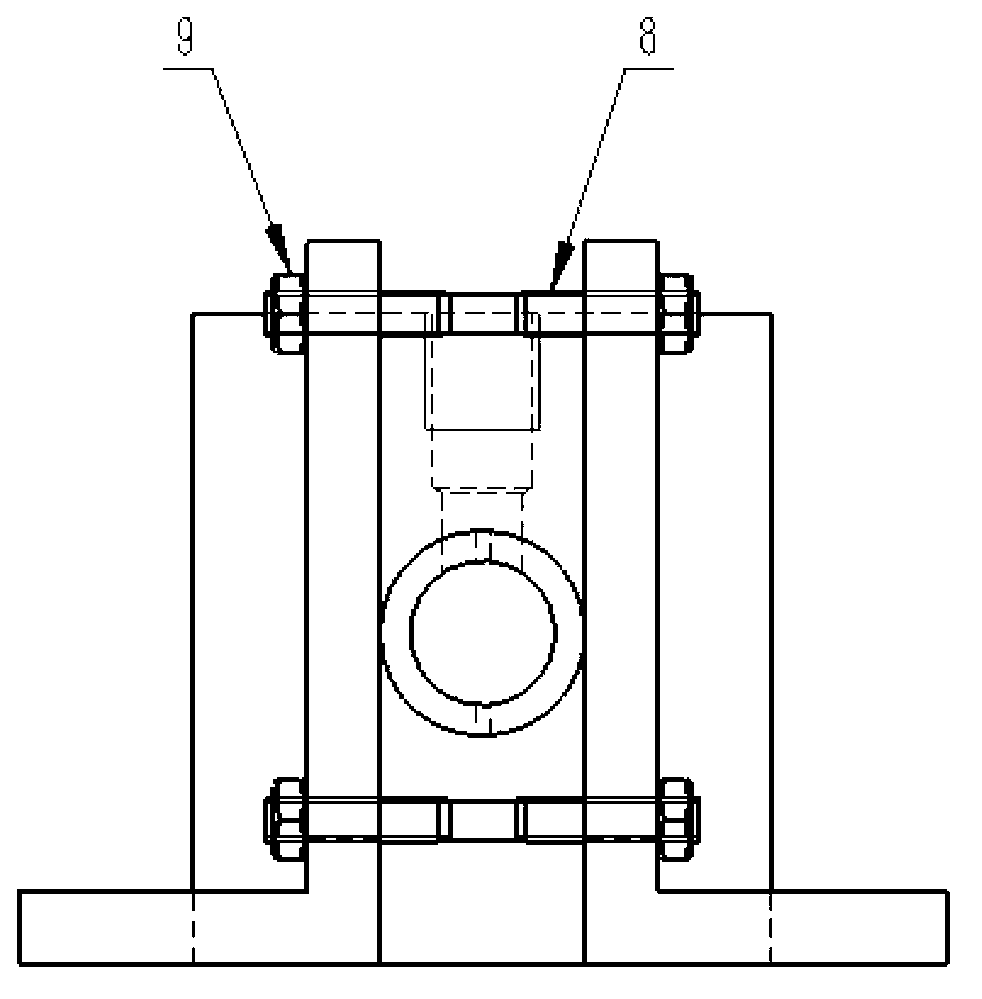

[0024] Refer to attached figure 1 , the device for measuring the detonation combustion pressure in a millimeter-scale circular tube in this embodiment includes a millimeter-scale transparent detonation tube 1, a splint 4, a sensor mounting seat 5 and a sensor. The detonation tube 1, splint 4 and sensor mount 5 are all made of plexiglass, so as to observe the flame propagation mode and measure the flame speed while measuring the pressure, and at the same time, it can play an insulating role and avoid the interference of electric sparks.

[0025] The front end of the transparent detonation tube is closed by the detonation tube plug 2. The material of the detonation tube plug 2 is polytetrafluoroethylene, and an ignition pinhole is opened at the end of the detonation tube close to the detonation tube plug, and the ignition needle extends into the The ignition pin holes ignite in the detonation tube.

[0026] The splint fixes and supports the front side of the transparent detonat...

Embodiment 2

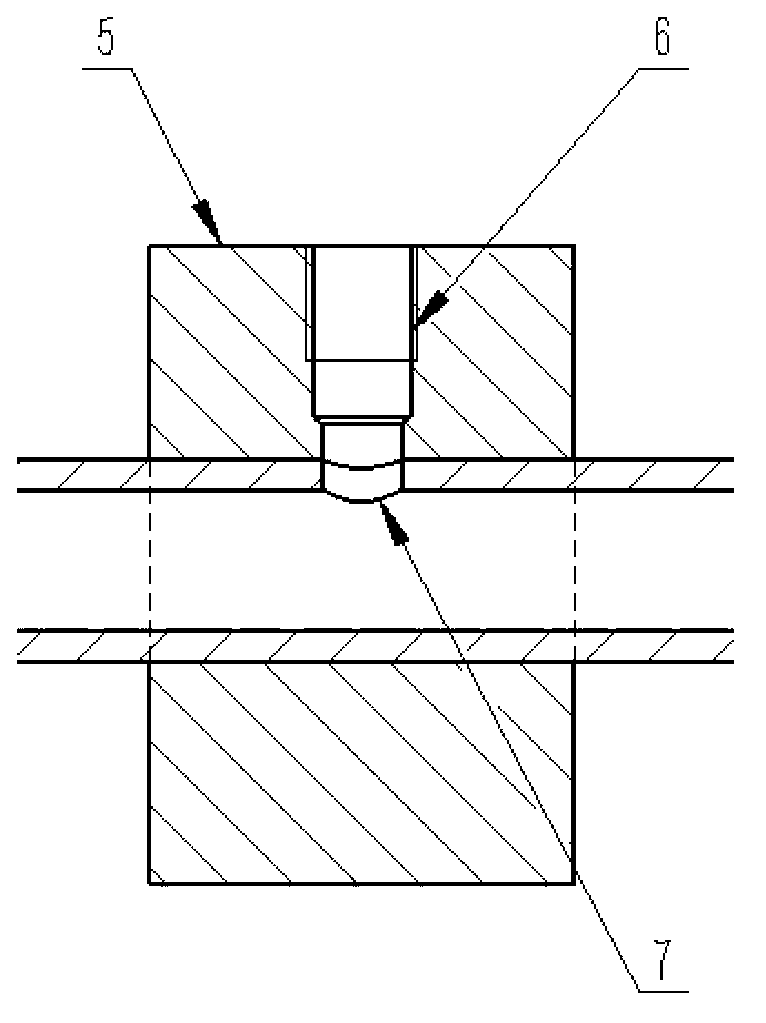

[0033] Refer to attached figure 1 , 2 , 5, and 6, but the outer diameters of the detonation tube 1 used in this embodiment are 4mm and 5mm respectively; Sensor, this design embodies the principles of material saving and convenience. When using a detonation tube of a certain size, you only need to place the corresponding side up to measure. Since the outer diameter of the detonation tube 1 is smaller than the diameter of the measuring end of the sensor, the diameter of the tube wall through hole 7 is smaller than the outer diameter of the detonation tube 1, and the measured pressure waveform is as follows: Figure 8 As shown, the peak pressure of P1 is 1.074MPa, and that of P2 is 0.833MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com