Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Easily formed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

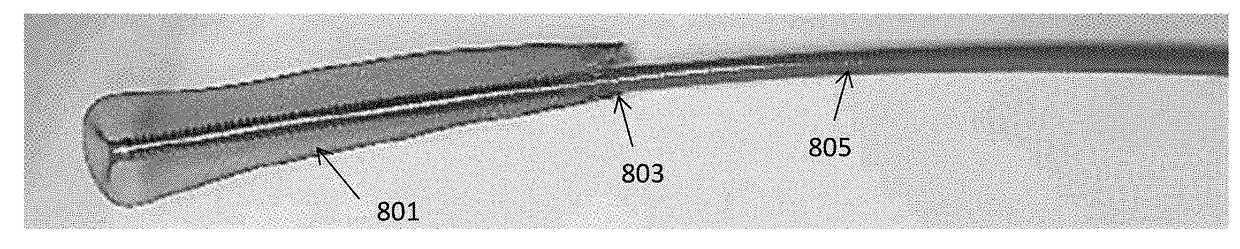

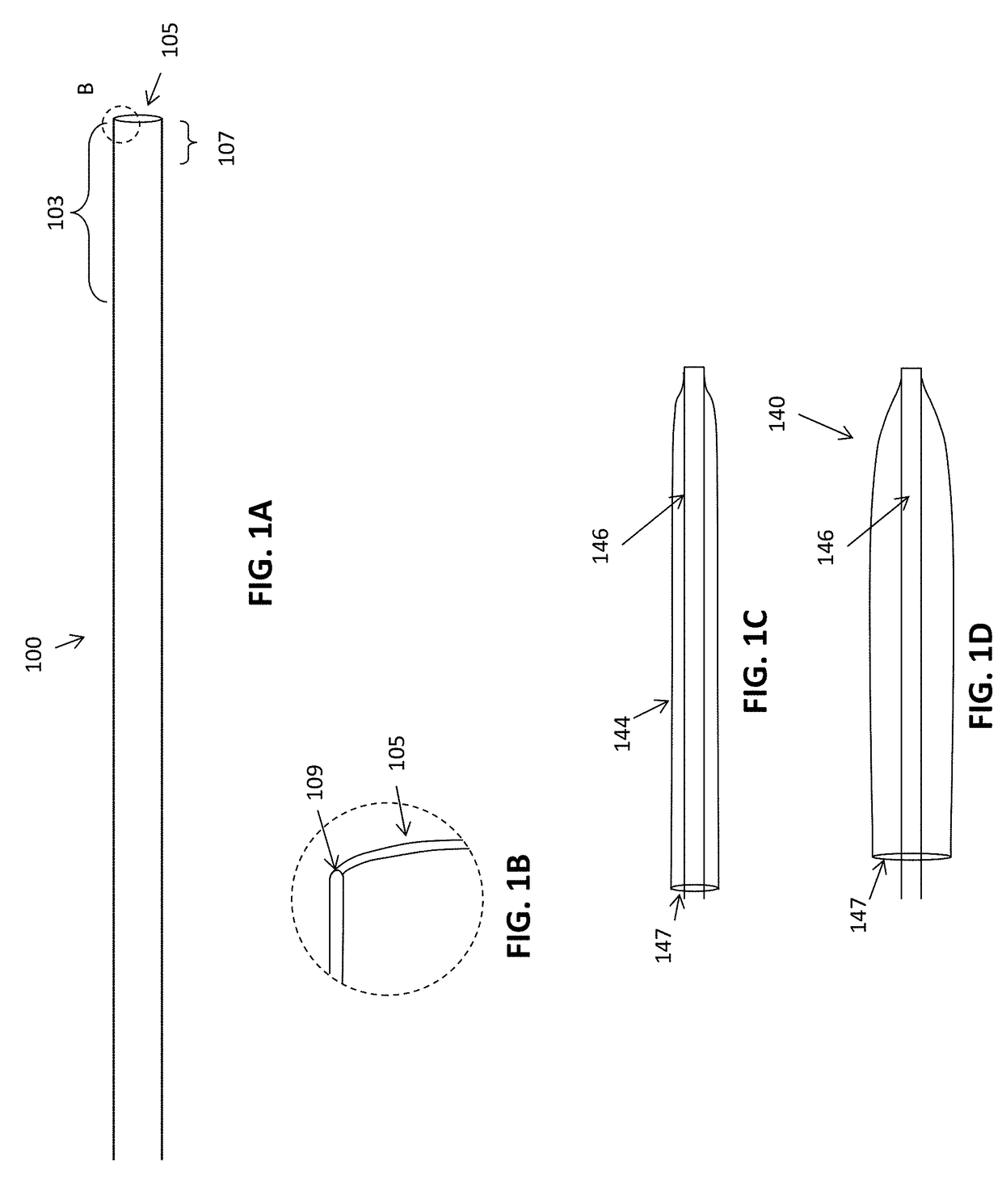

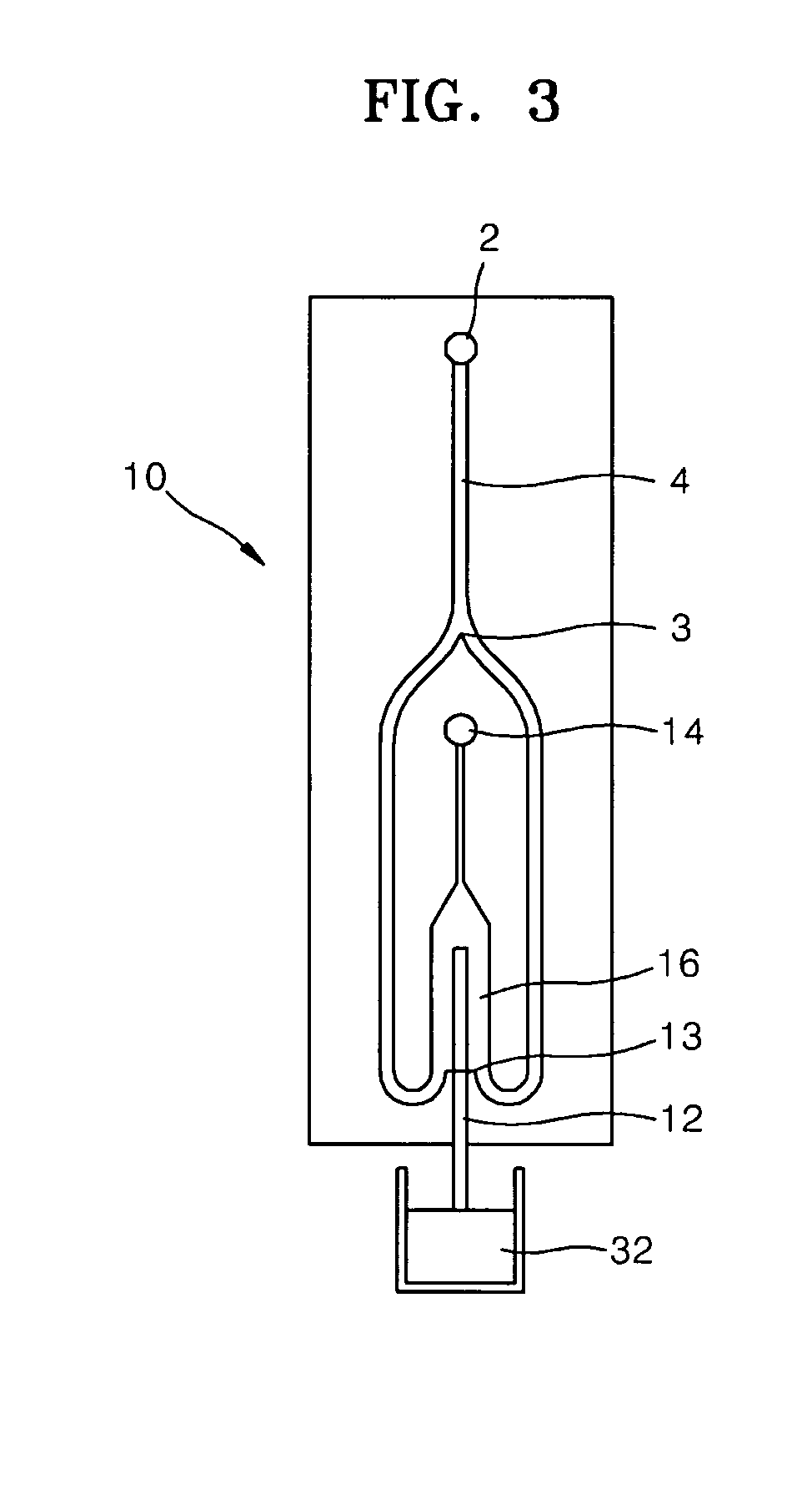

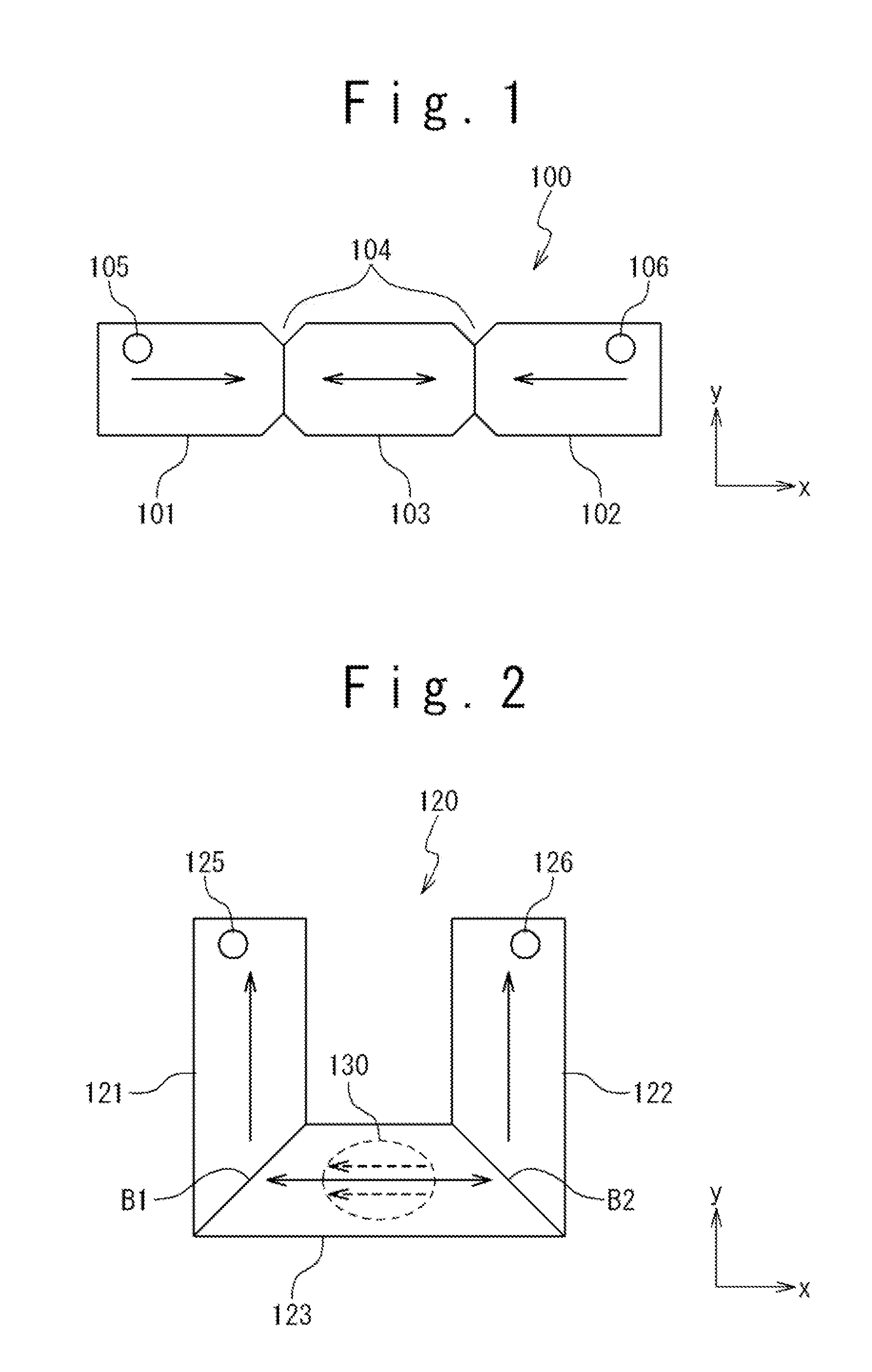

Inverting thrombectomy apparatuses and methods

Rolling tractor tube mechanical thrombectomy apparatuses that may be deployed from out of a catheter in situ are described herein. These apparatuses may be delivered out of a catheter from a collapsed delivery configuration within the catheter to a deployed configuration out of the catheter, in which the same catheter is re-inserted between a tubular tractor and an elongate puller. In particular, any of these methods and apparatuses may be adapted to work with a tractor tube having an open end that is biased open, including using an annular bias.

Owner:STRYKER CORP

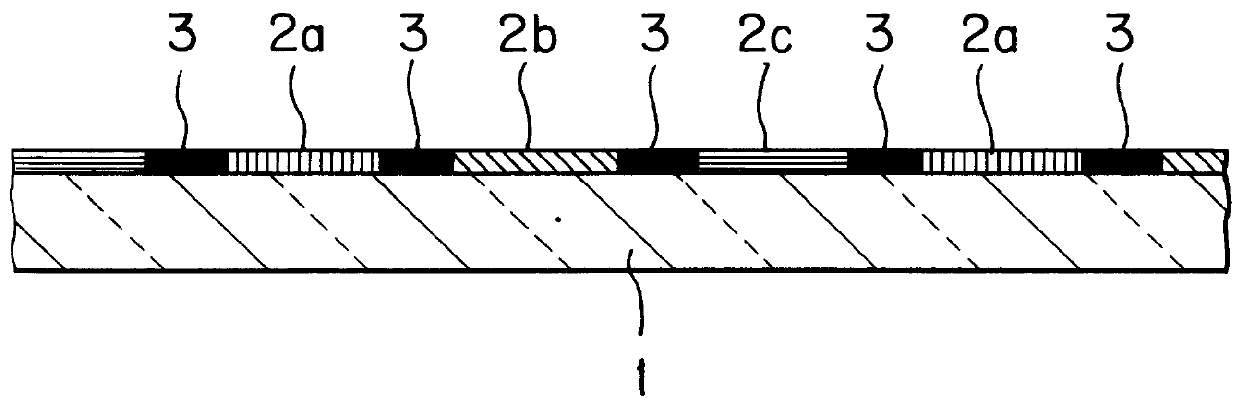

Transparent colored conductive film

InactiveUS6013983AHigh accuracyEasily formedIncadescent screens/filtersAlternating current plasma display panelsOxideOptoelectronics

A transparent colored conductive film is provided which can serve as both a color filter and a transparent electrode. Further, there are provided a composition for a transparent colored conductive film, comprising a metallic compound convertible to an oxide upon heating, a black or color inorganic pigment, and a liquid medium, a method for forming a transparent colored conductive film using the composition, and a display device having the transparent colored conductive film.

Owner:DAI NIPPON PRINTING CO LTD

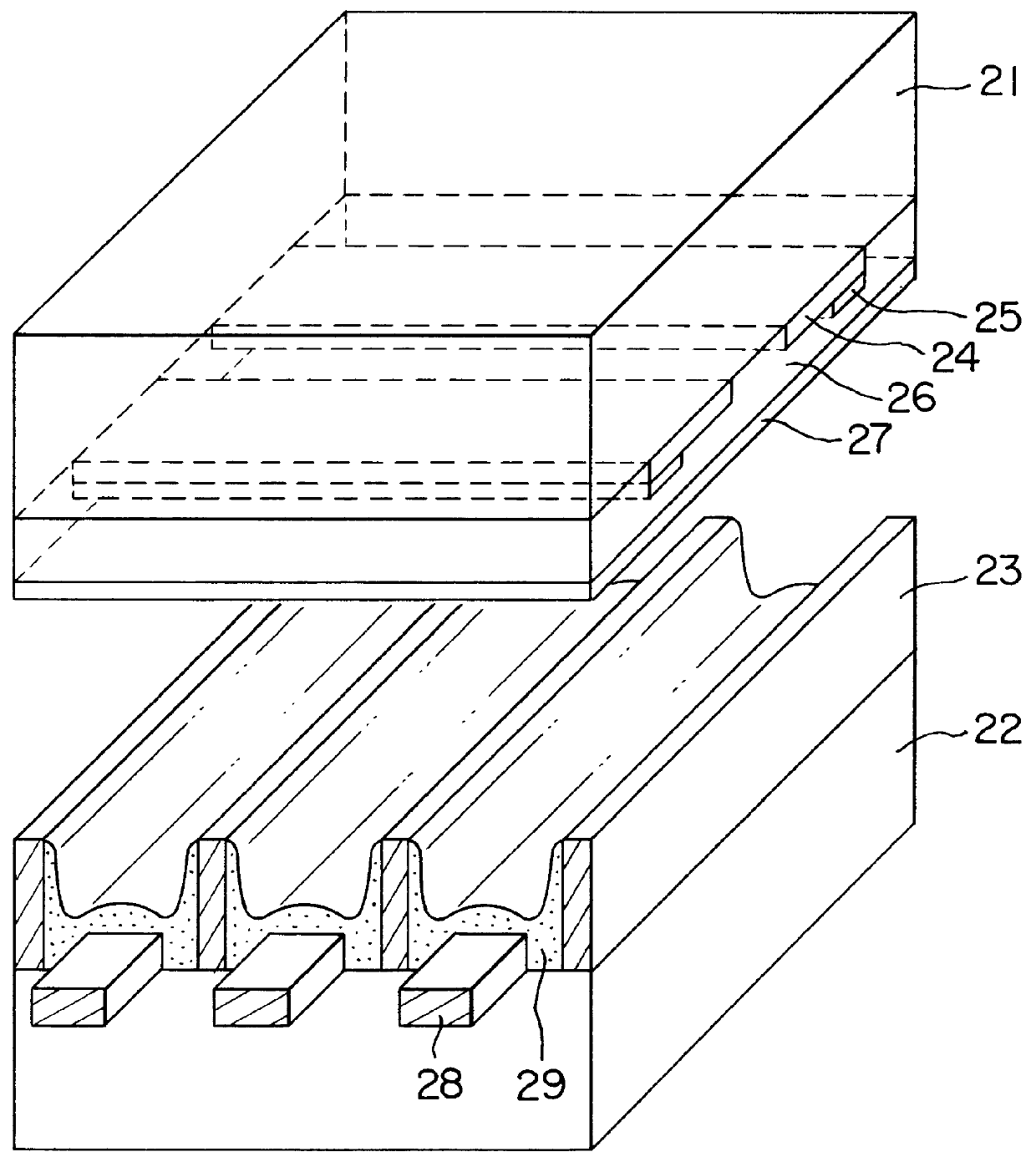

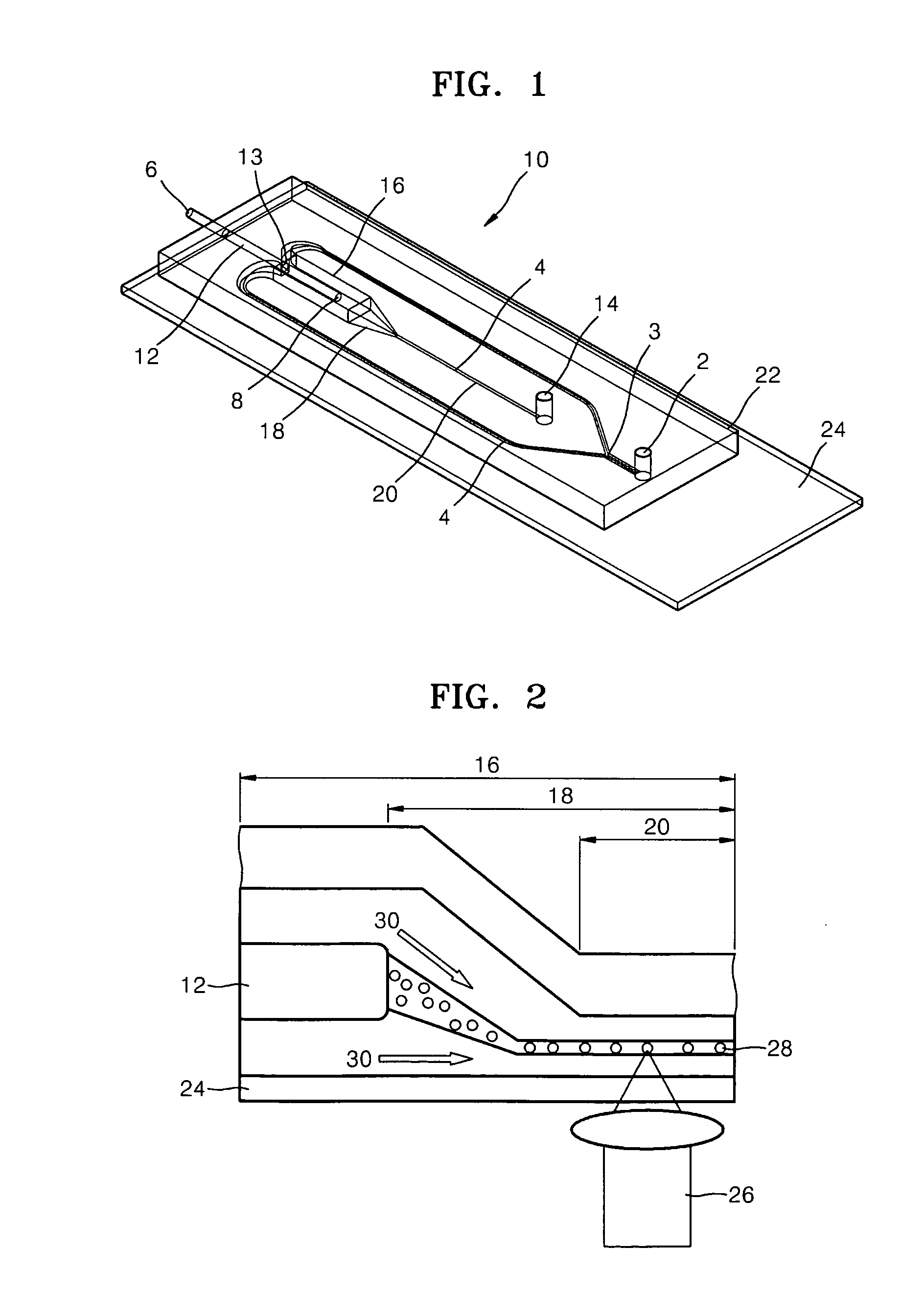

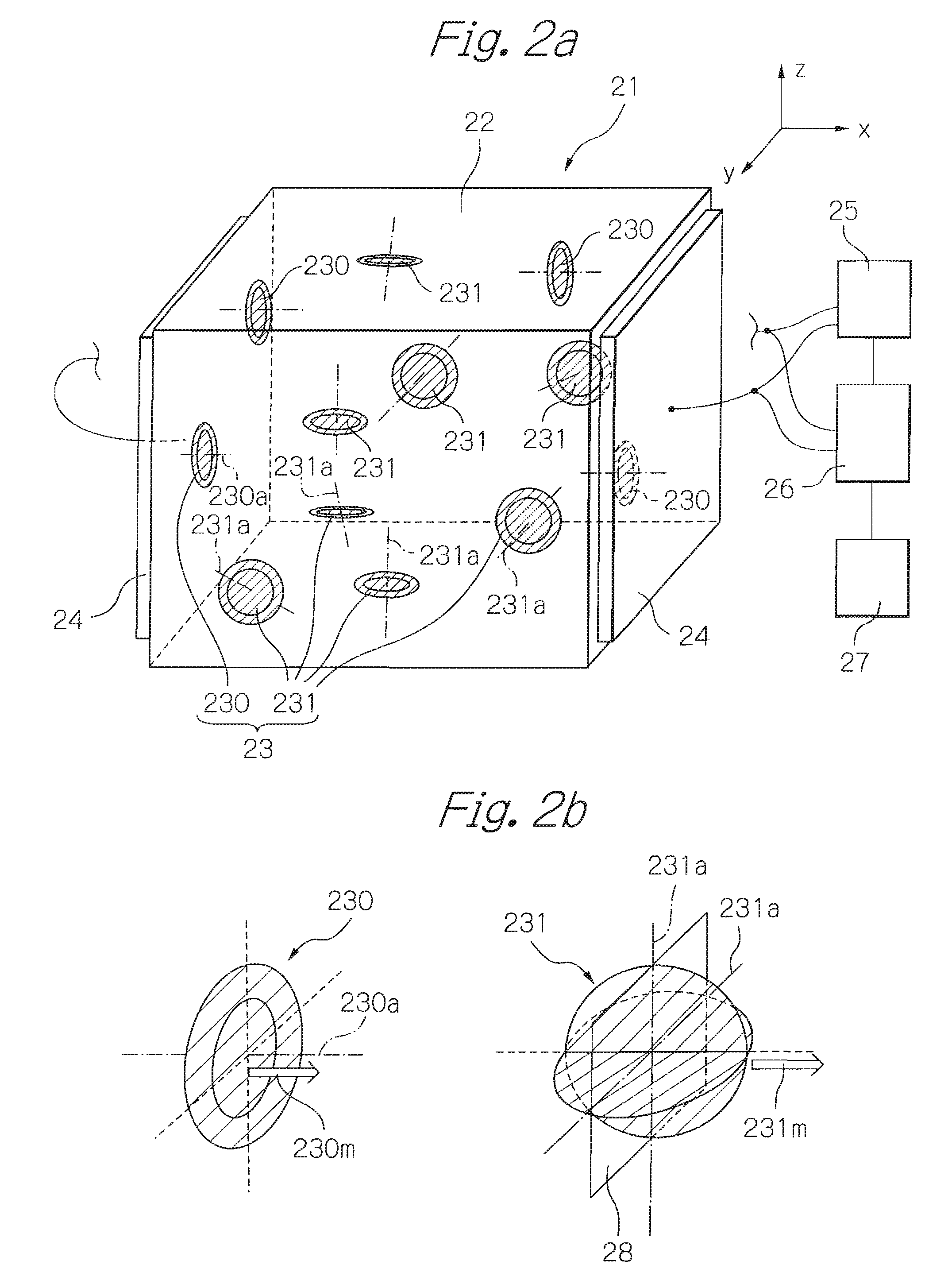

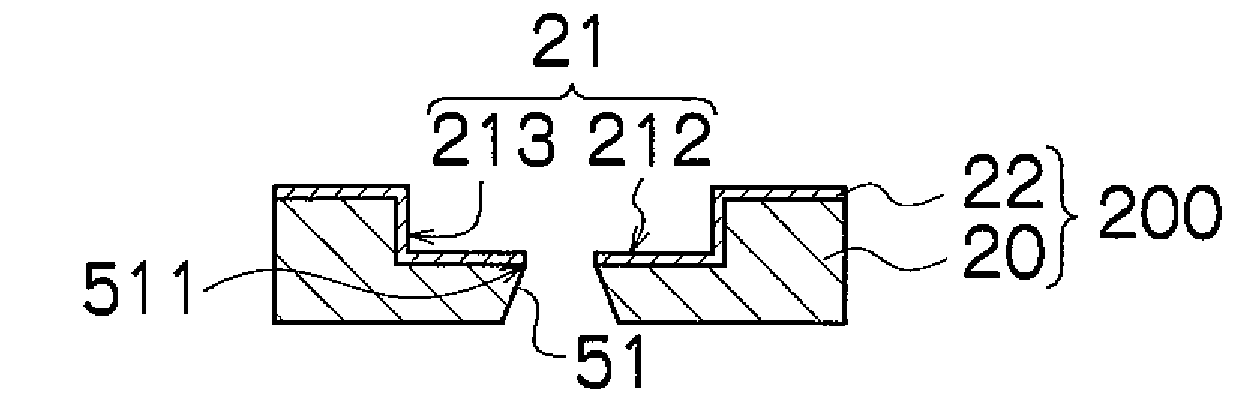

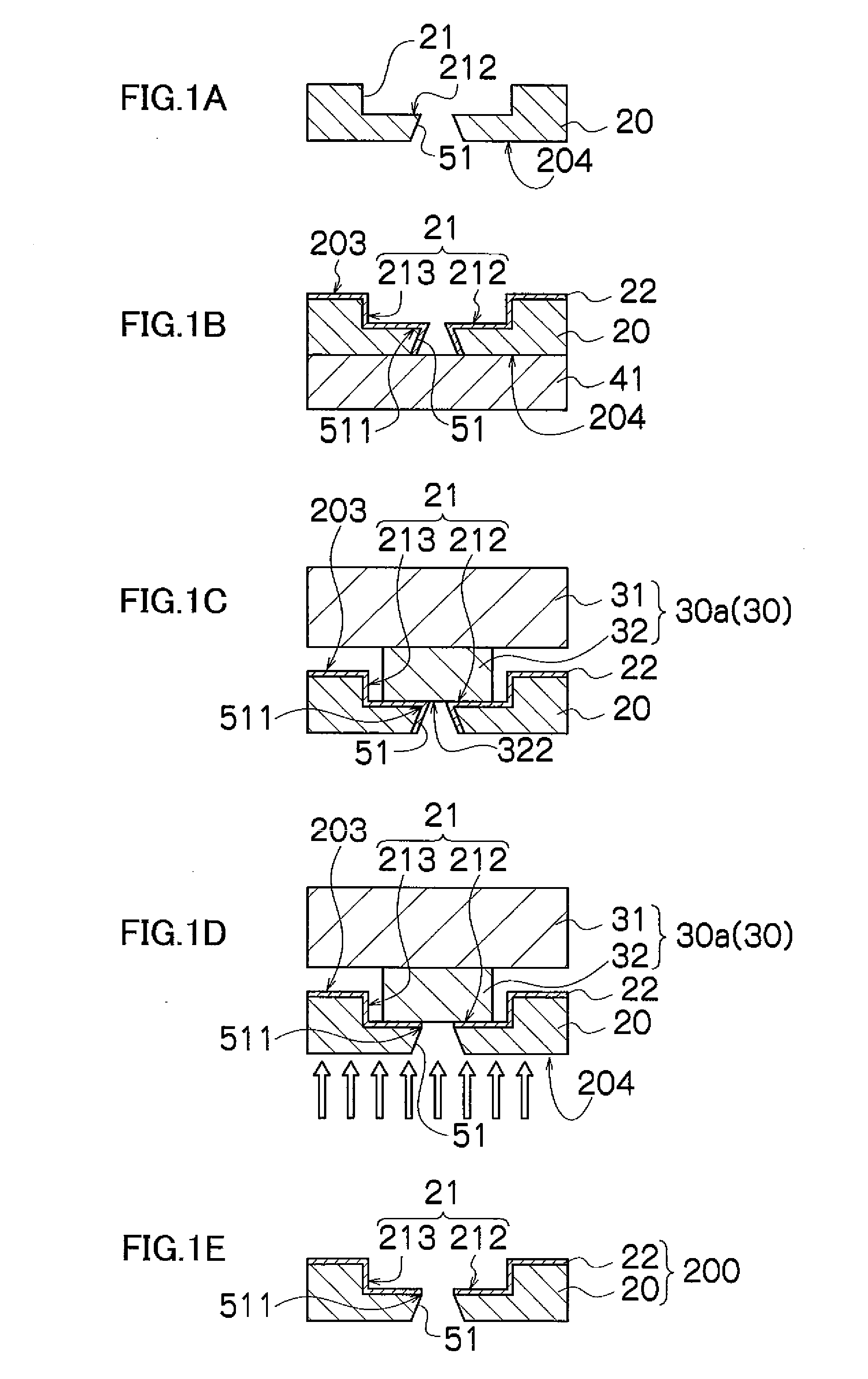

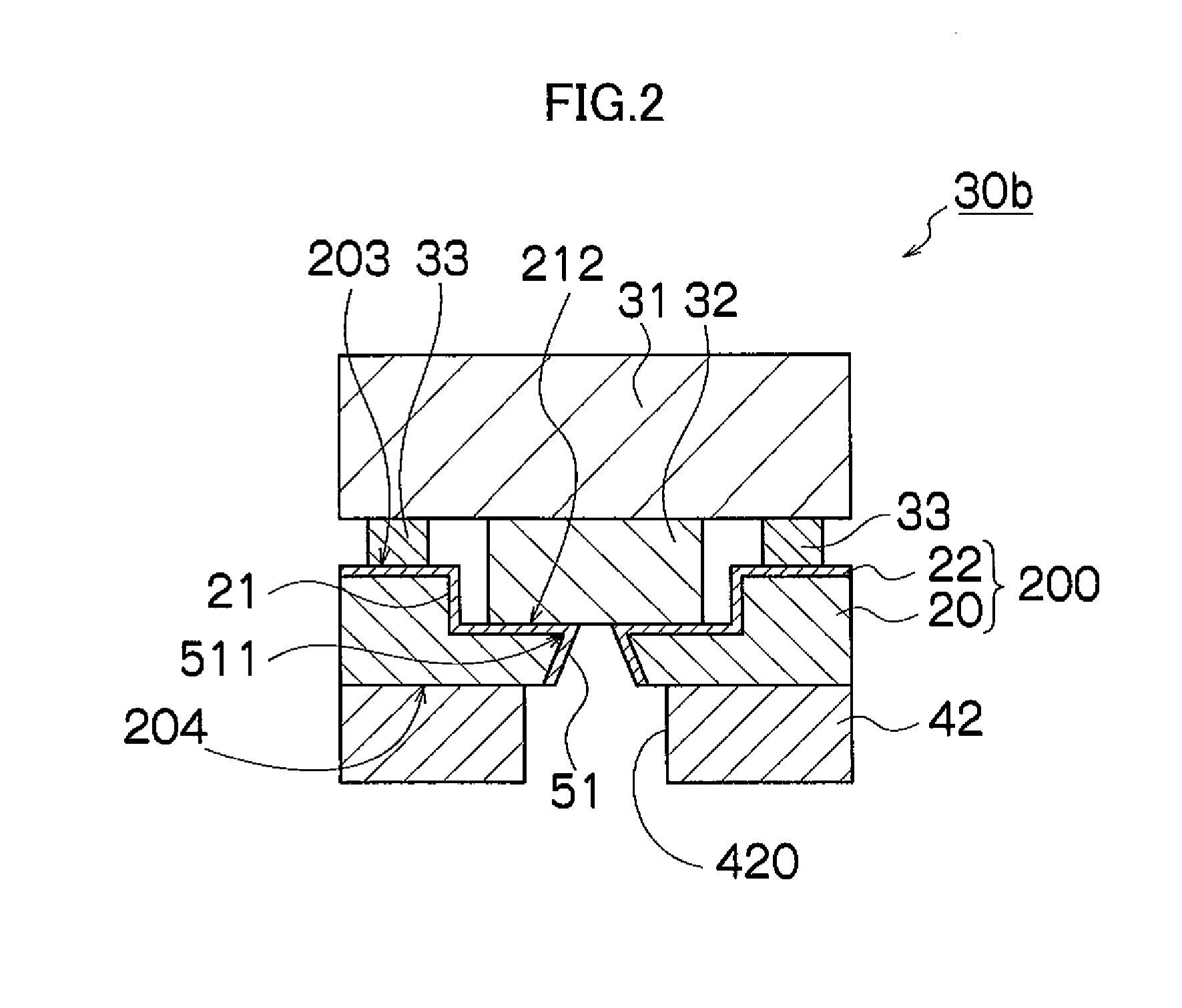

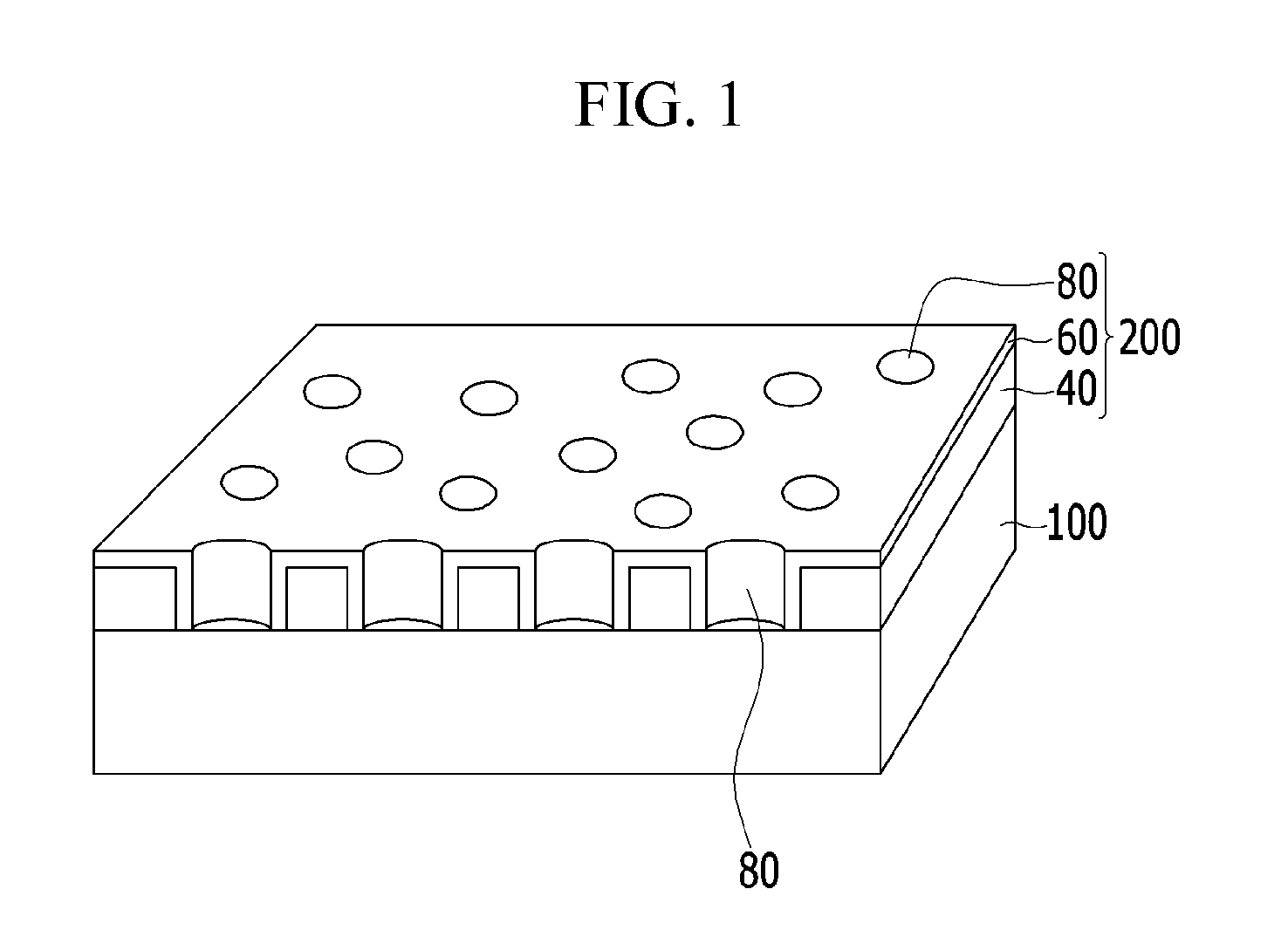

Apparatus for focusing and detecting particles in sample and method of manufacturing the same

InactiveUS20080311005A1Easily formedEasy to manufactureAnalysis using chemical indicatorsLamination ancillary operationsBiomedical engineering

Owner:SAMSUNG ELECTRONICS CO LTD

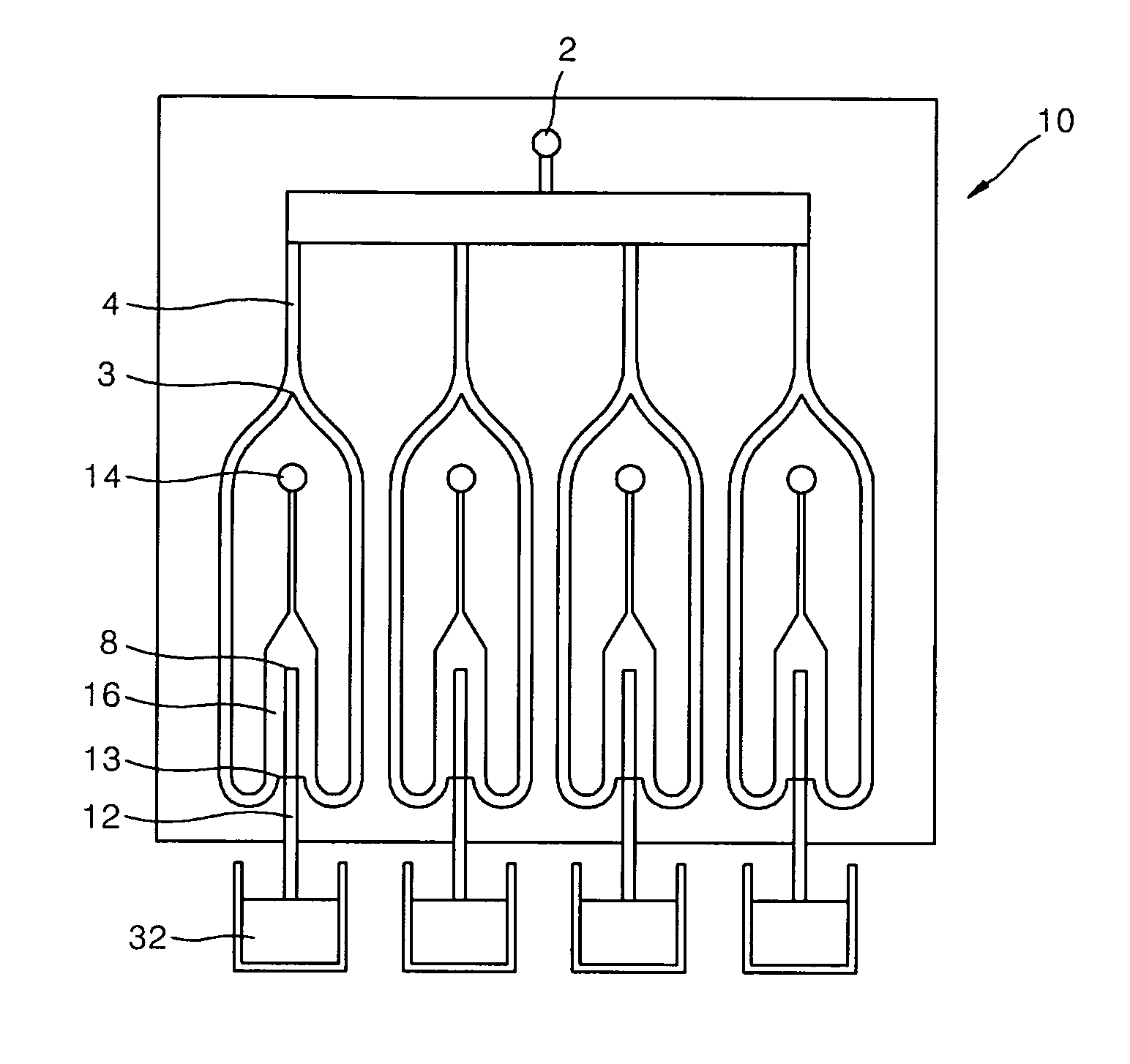

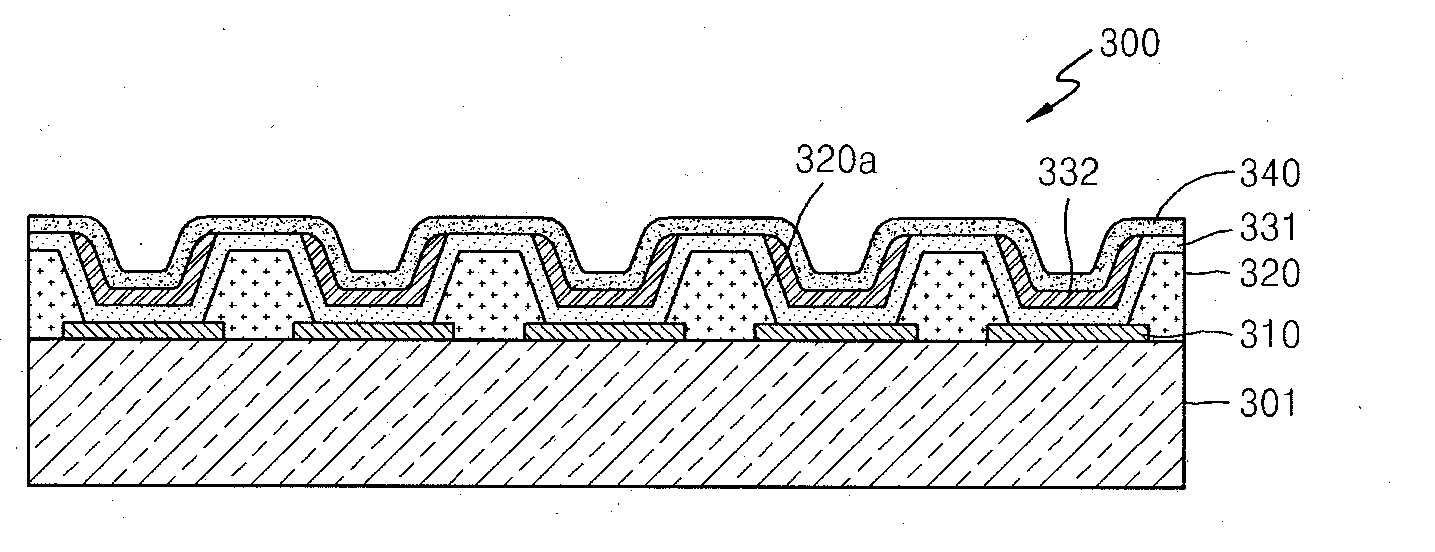

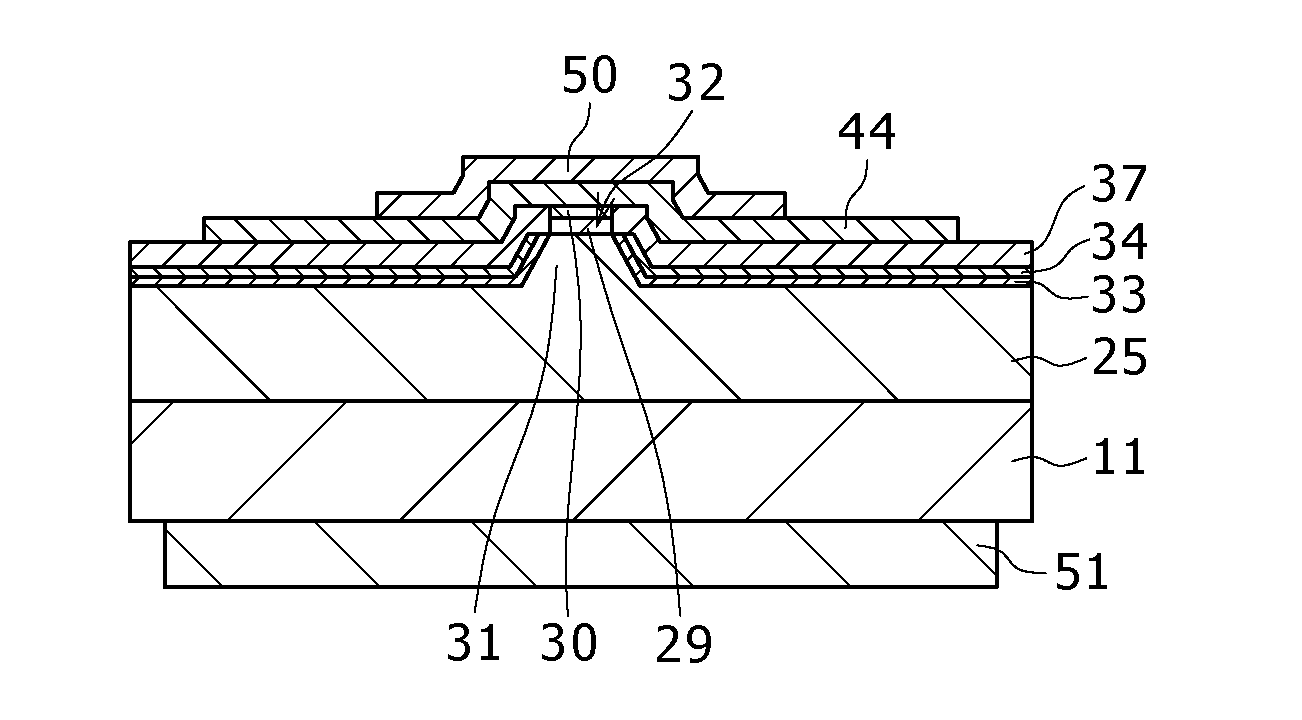

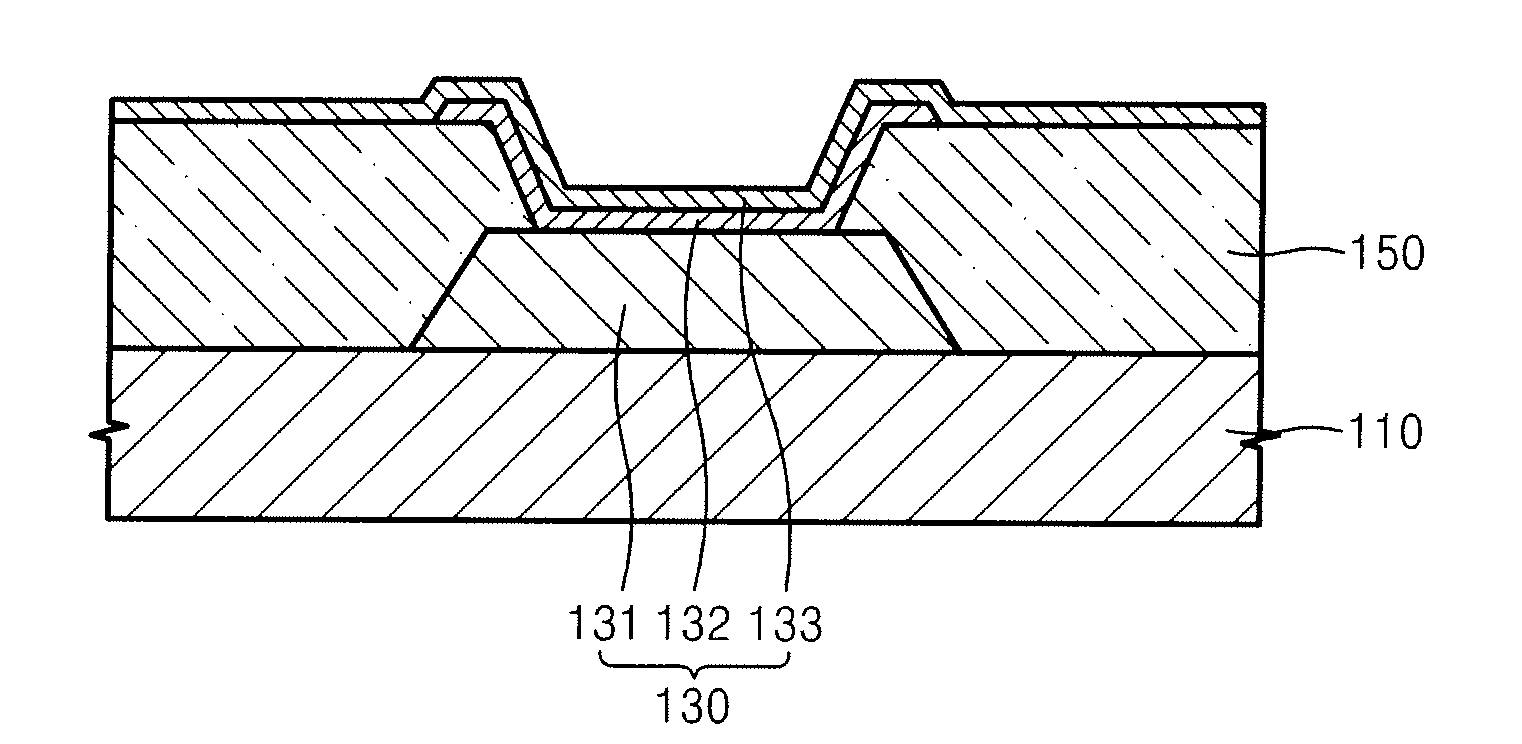

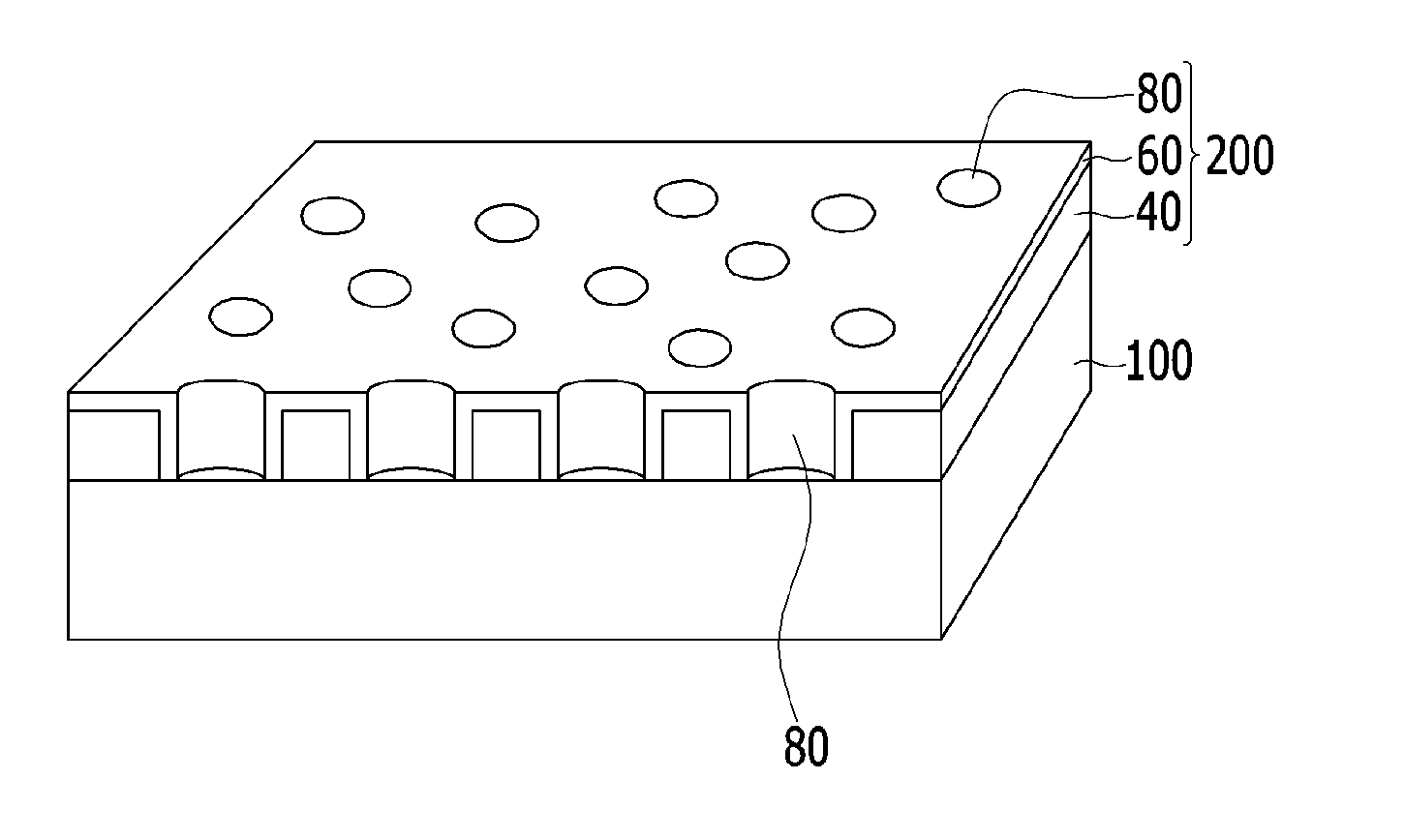

Method of manufacturing organic light emitting display apparatus, surface treatment device for organic light emitting display apparatus, and organic light emitting display apparatus

ActiveUS20110127507A1Easily formedWell formedElectroluminescent light sourcesSolid-state devicesOptoelectronicsLaser

Provided are a method of manufacturing an organic light emitting display apparatus, a surface treatment device for an organic light emitting display apparatus, and an organic light emitting display apparatus. To easily form organic emissive layers, the method includes: forming a first electrode on a substrate; forming on the first electrode a pixel defining layer having openings that expose predetermined portions of the first electrode; forming a charge carrying layer on the pixel defining layer and the first electrode exposed through the openings; hydrophobically treating portions of a surface of the charge carrying layer selectively, wherein the portions do not correspond to the openings, using a laser; forming organic emissive layers on the charge carrying layer; and forming a second electrode on the organic emissive layers so as to be electrically connected with the organic emissive layers.

Owner:SAMSUNG DISPLAY CO LTD

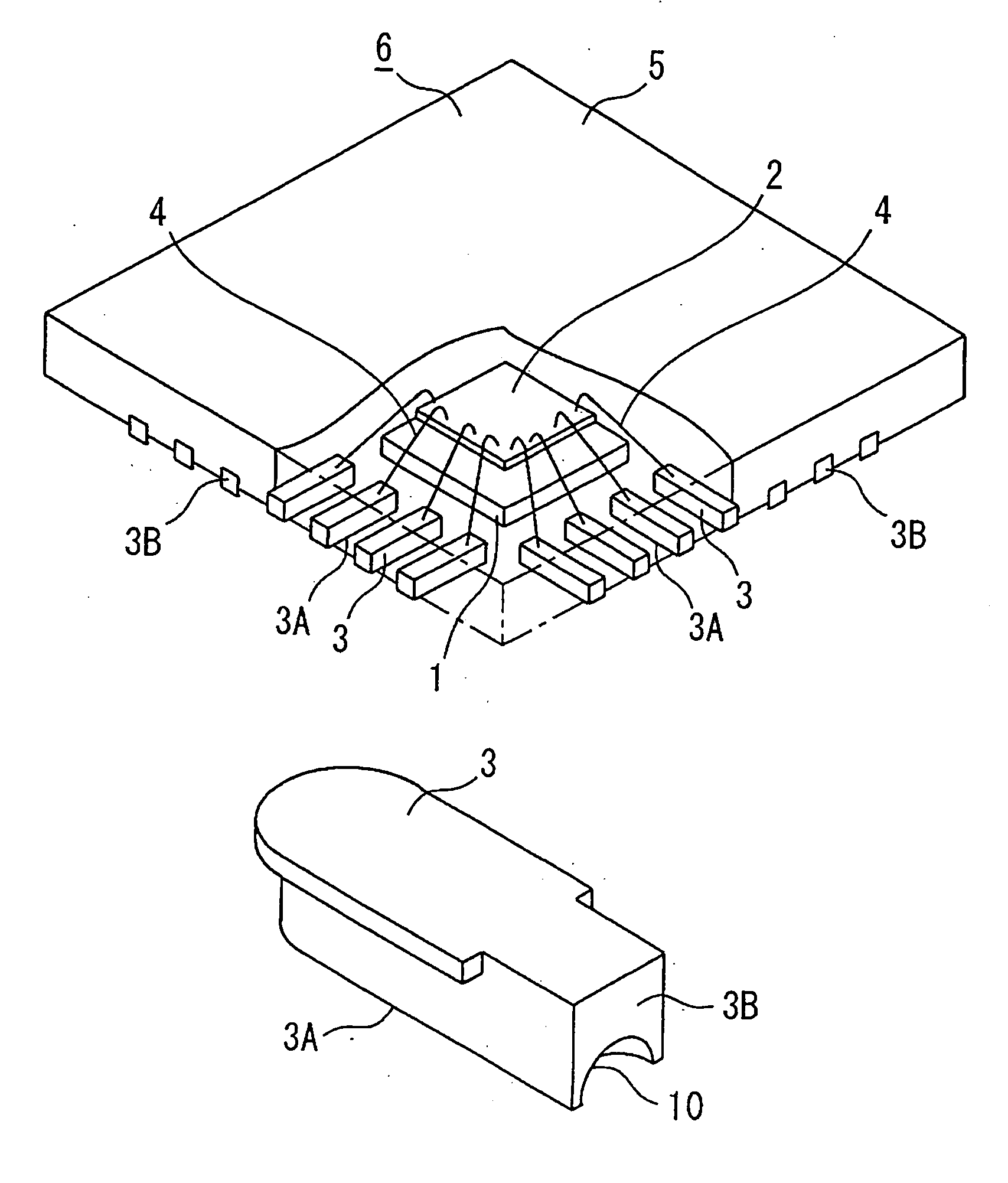

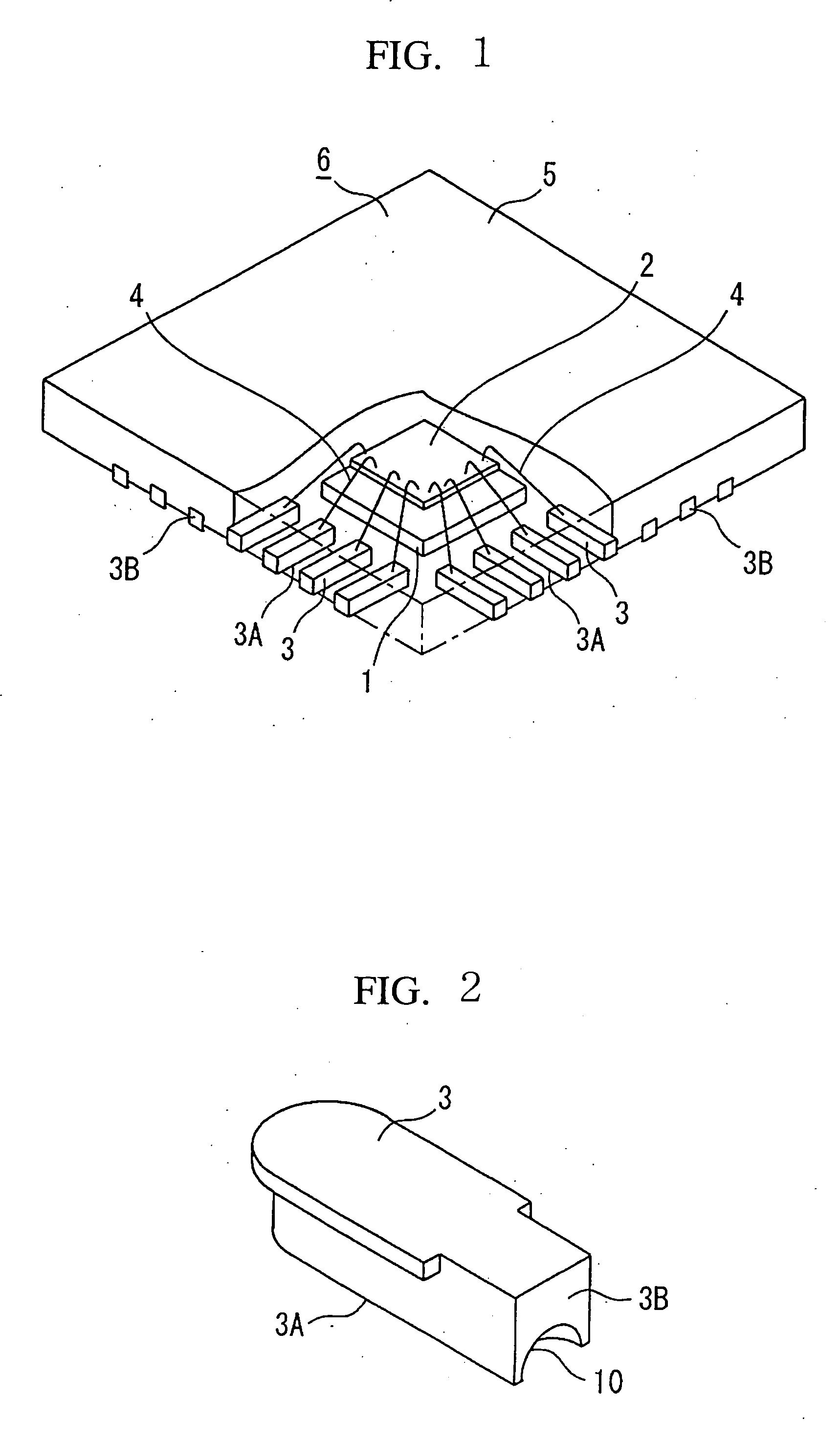

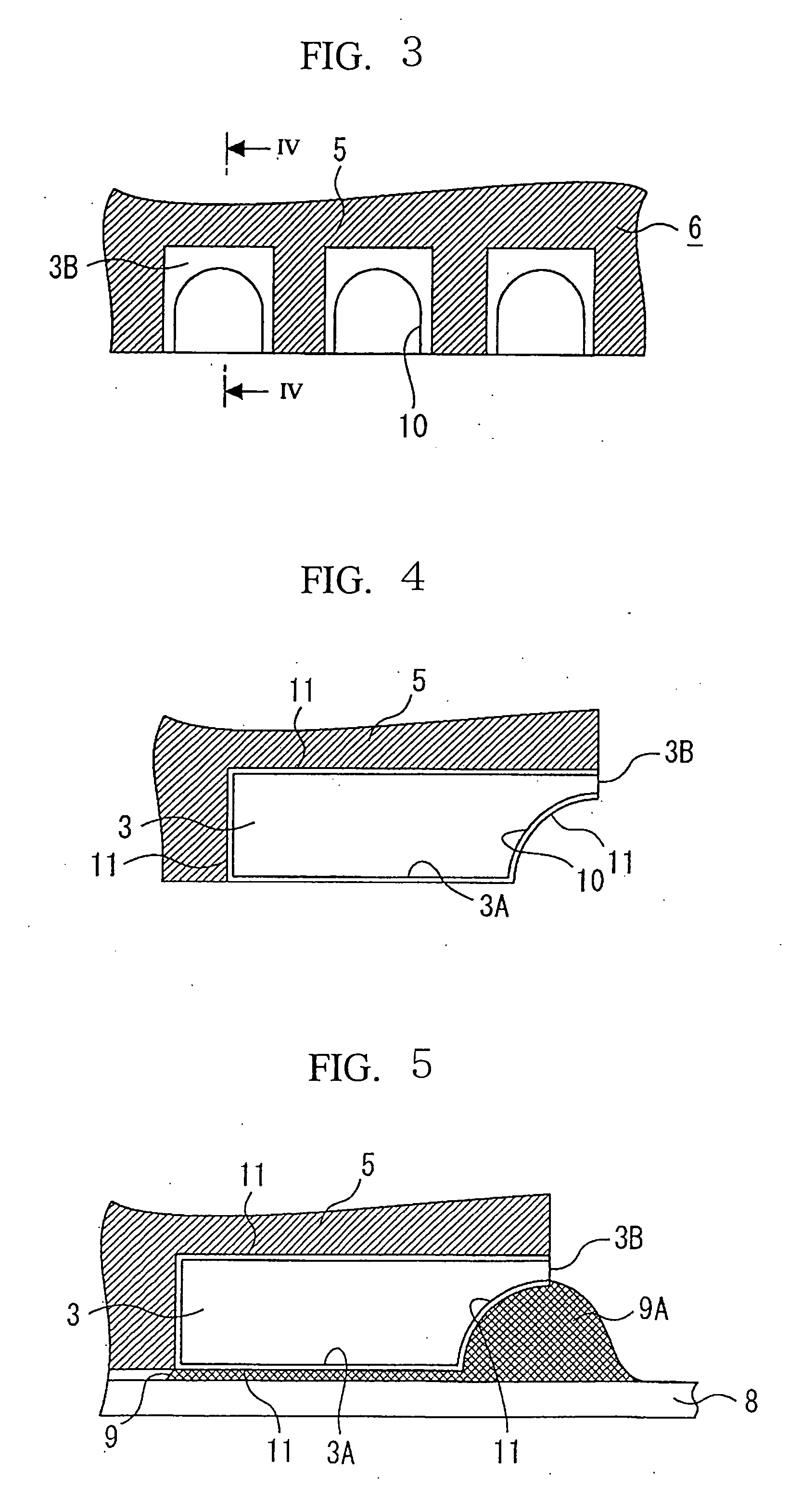

Electronic component package

InactiveUS20060043566A1Easily formedEasy to checkSemiconductor/solid-state device detailsSolid-state devicesEngineeringMetallic Lead

An electronic component package includes an electronic component substrate disposed on a dice pad, a plurality of leads disposed around the dice pad, wires connecting the leads and signal pads of the electronic component substrate, and a molding resin for sealing the dice pad, the electronic component substrate, and the wires such that the bottom surfaces and one end surfaces of the leads are exposed, wherein the one end surfaces of the leads do not protrude out of the molding resin, and recessions that open at the one end surfaces are formed in the bottom surfaces of the leads.

Owner:MITSUBISHI ELECTRIC CORP

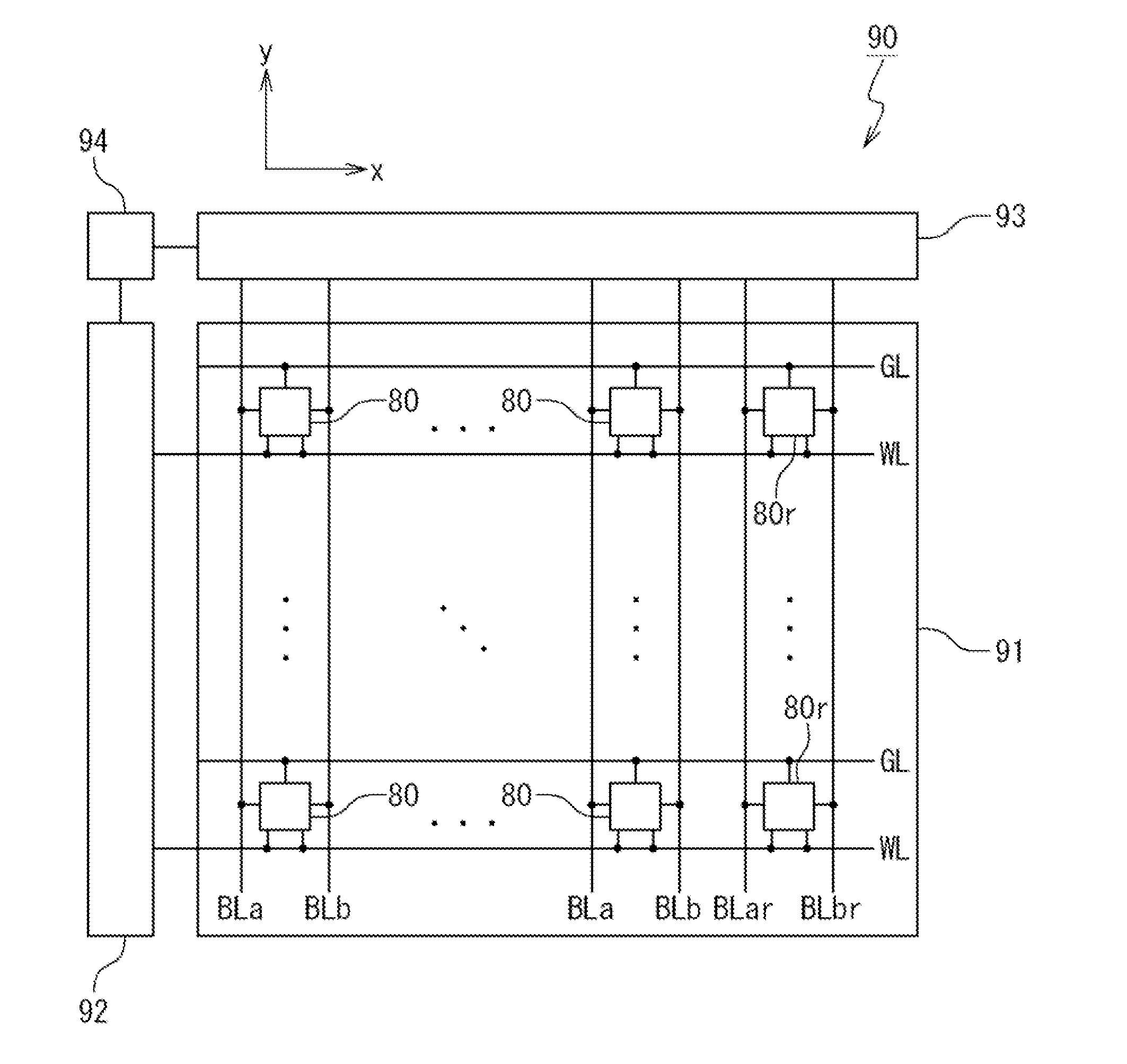

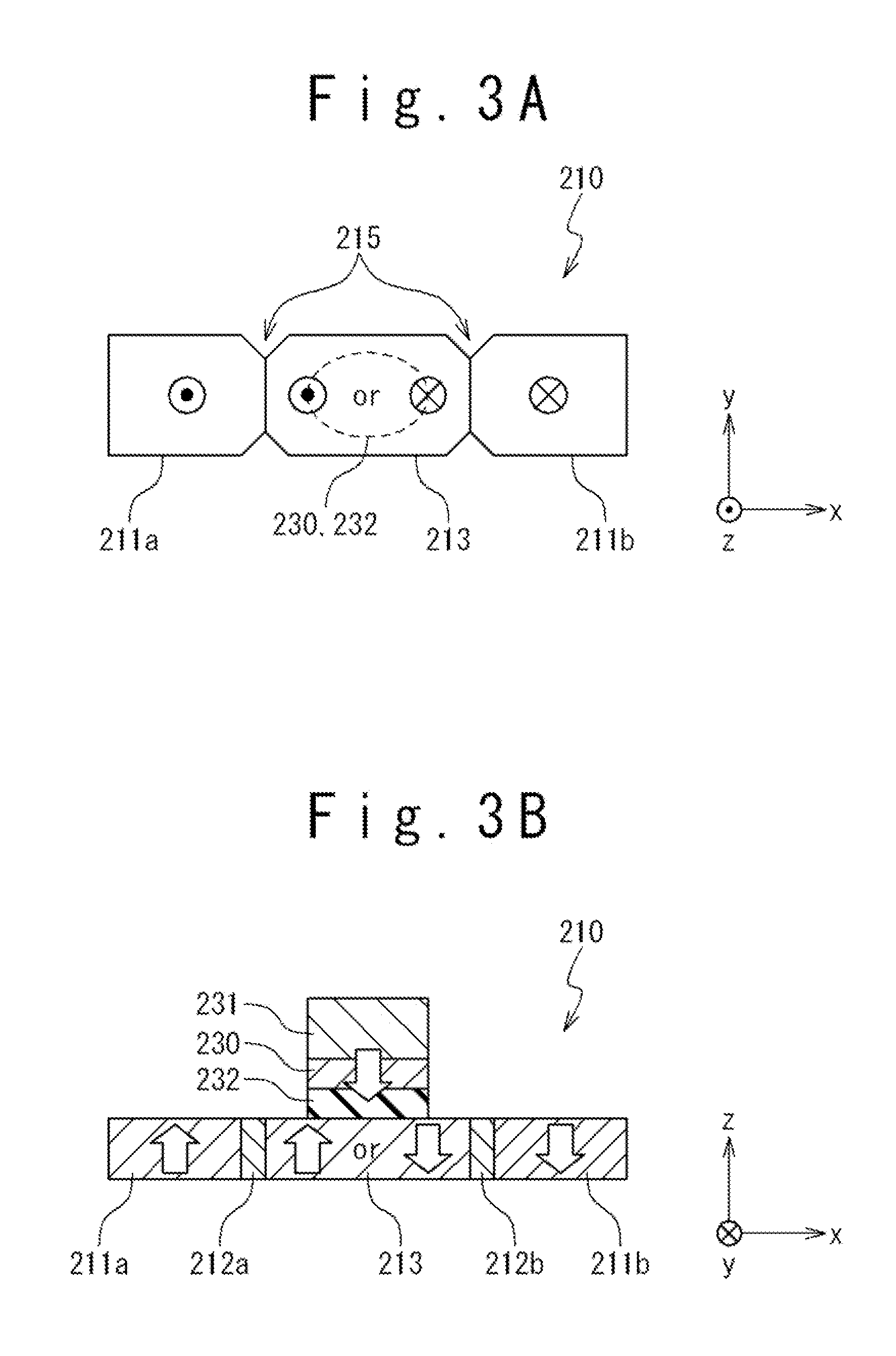

Magnetic memory element and magnetic random access memory

ActiveUS20110267879A1Easily formedWell formedMagnetic-field-controlled resistorsSolid-state devicesNuclear magnetic resonancePerpendicular magnetic anisotropy

A magnetic memory cell includes: a magnetization recording layer; and a magnetic tunneling junction section. The magnetization recording layer includes a ferromagnetic layer with perpendicular magnetic anisotropy. The magnetic tunneling junction section is used for reading information in the magnetization recording layer. The magnetization recording layer includes two domain wall moving areas.

Owner:NEC CORP

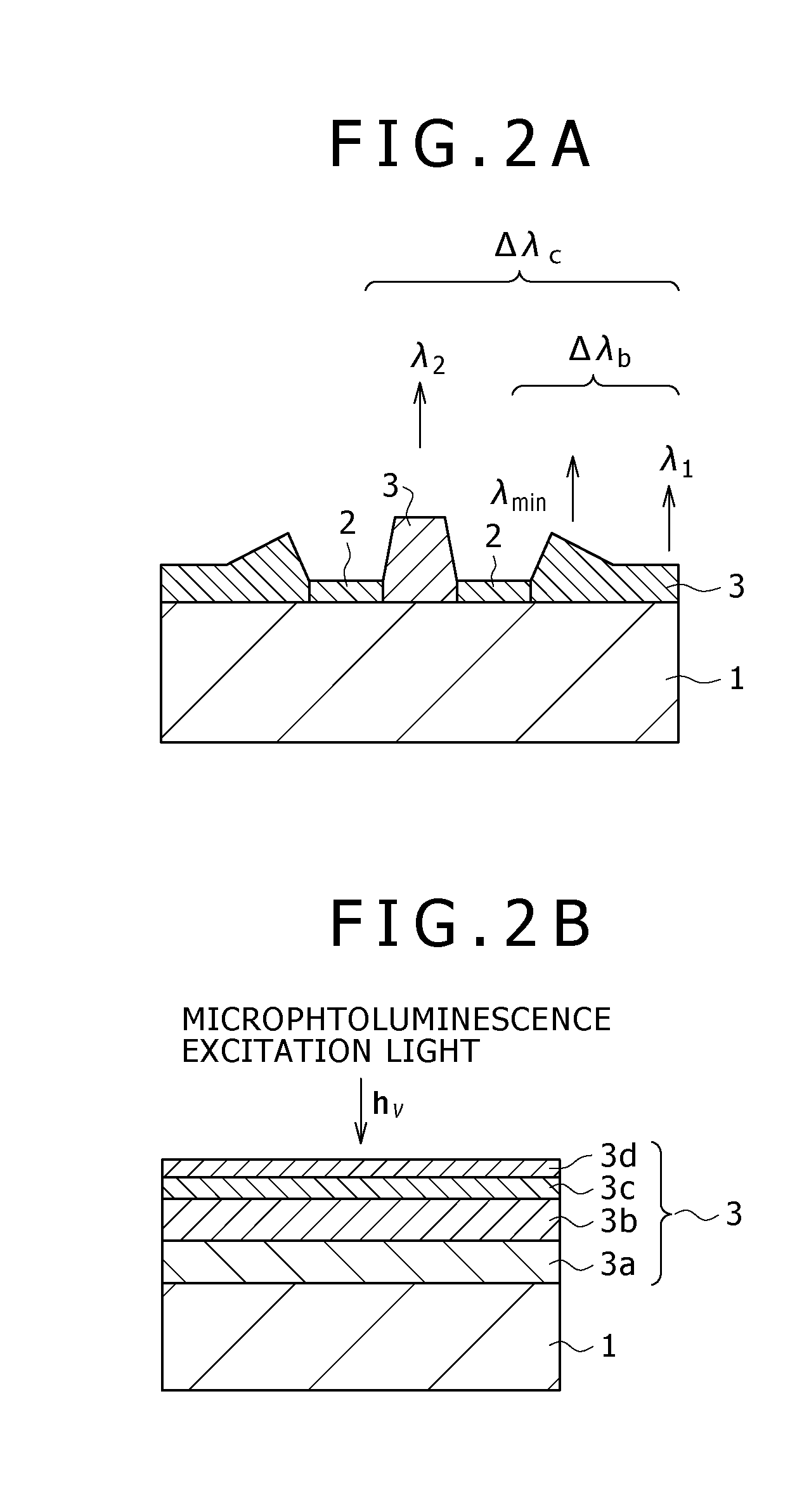

Method of manufacturing semiconductor laser, semiconductor laser, optical pickup, optical disk device, method of manufacturing semiconductor device, semiconductor device, and method of growing nitride type group iii-v compound semiconductor layer

ActiveUS20080240190A1Prevent light absorption and local heat generationEasily formedOptical wave guidanceLaser detailsSemiconductor laser theoryOptical pickup

A method of manufacturing a semiconductor laser having an end face window structure, by growing over a substrate a nitride type Group III-V compound semiconductor layer including an active layer including a nitride type Group III-V compound semiconductor containing at least In and Ga, the method includes the steps of: forming a mask including an insulating film over the substrate, at least in the vicinity of the position of forming the end face window structure; and growing the nitride type Group III-V compound semiconductor layer including the active layer over a part, not covered with the mask, of the substrate.

Owner:SONY CORP

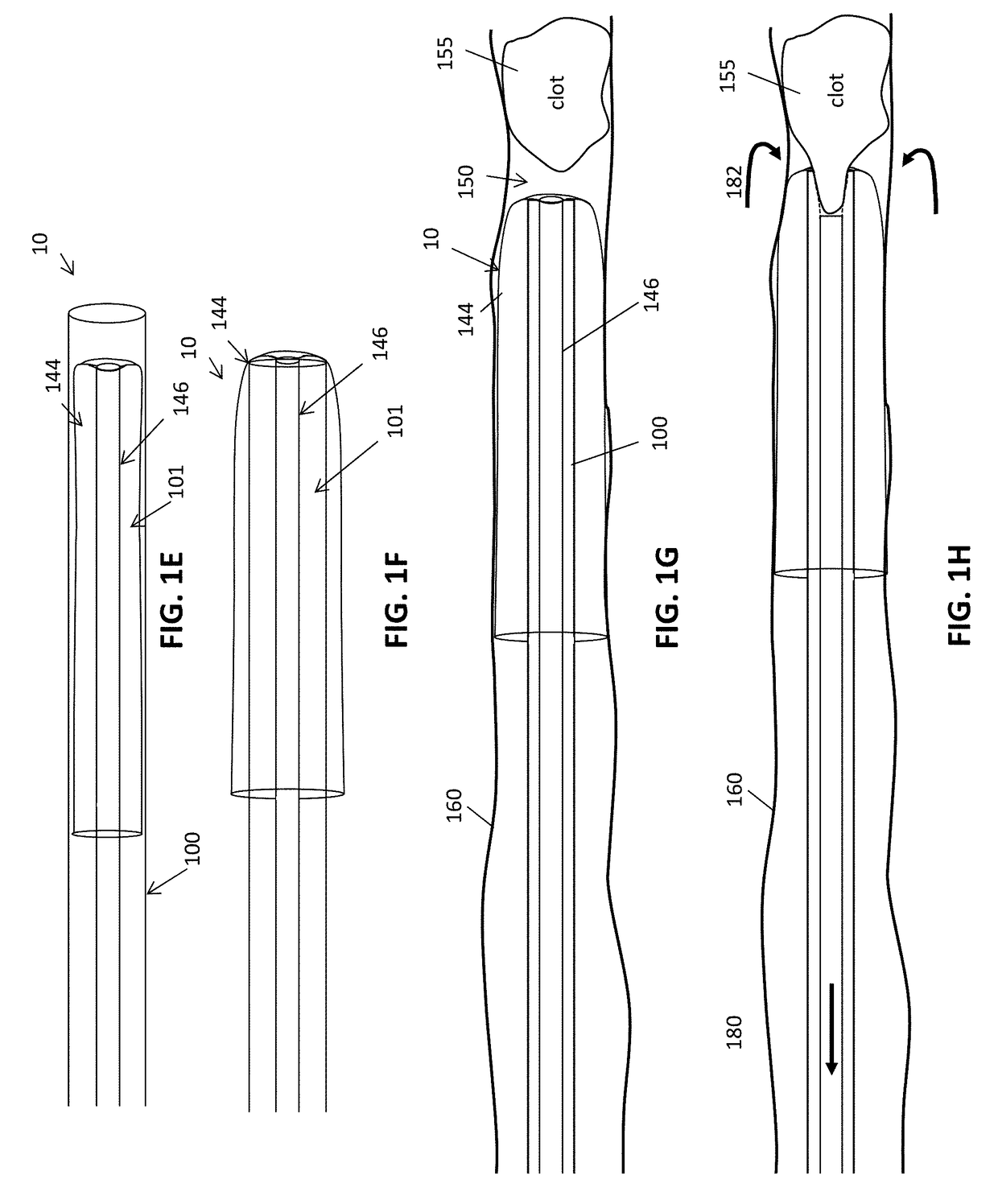

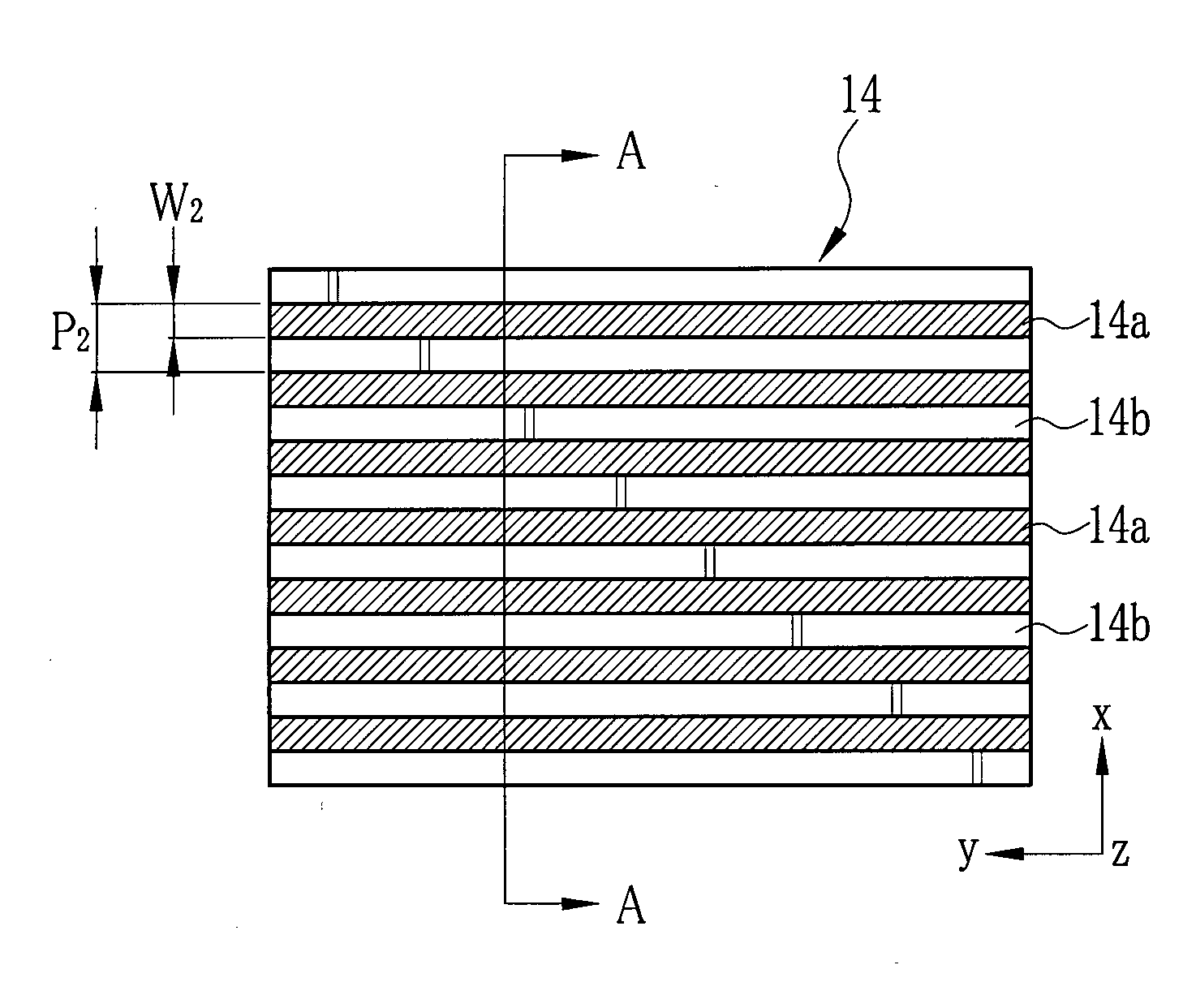

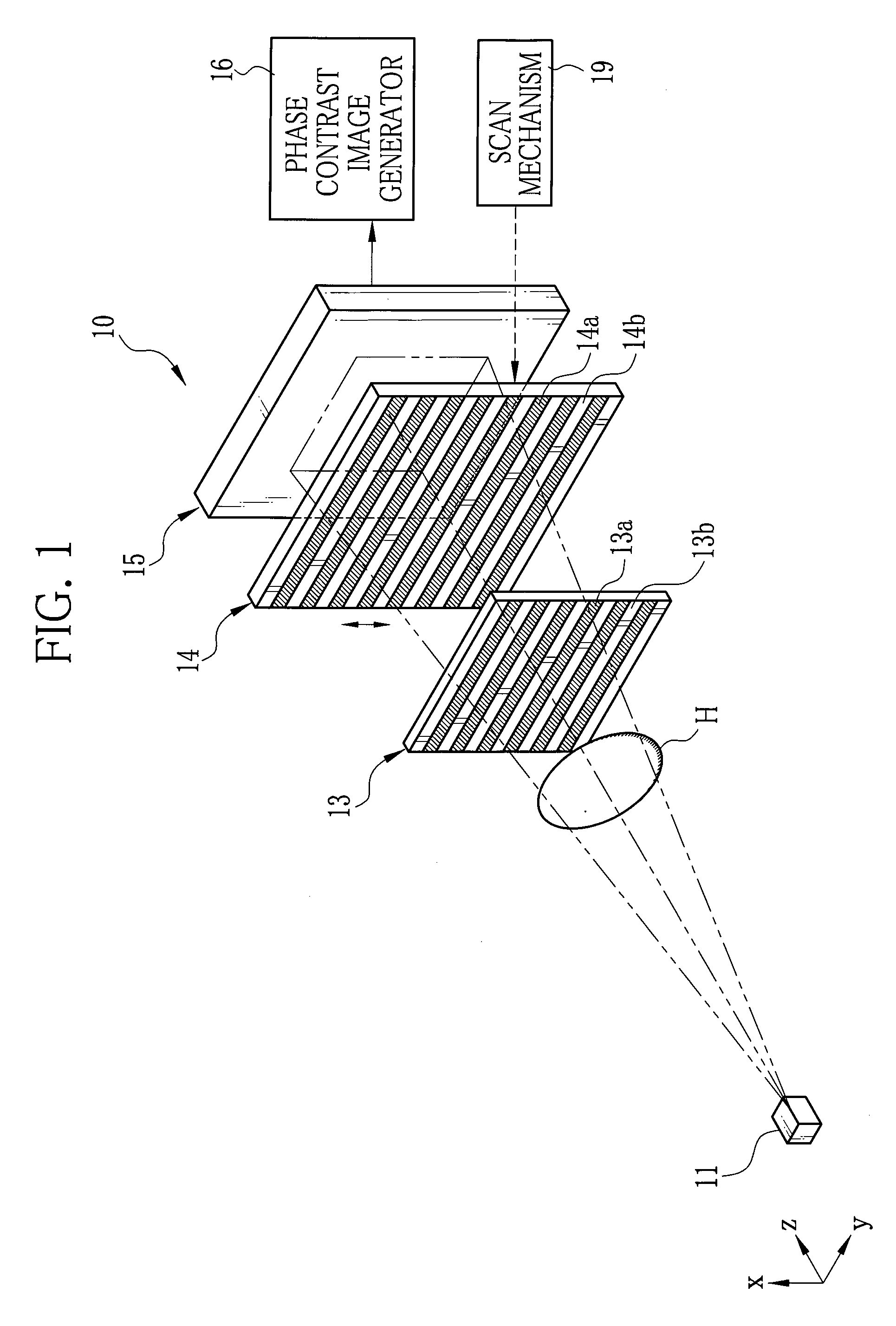

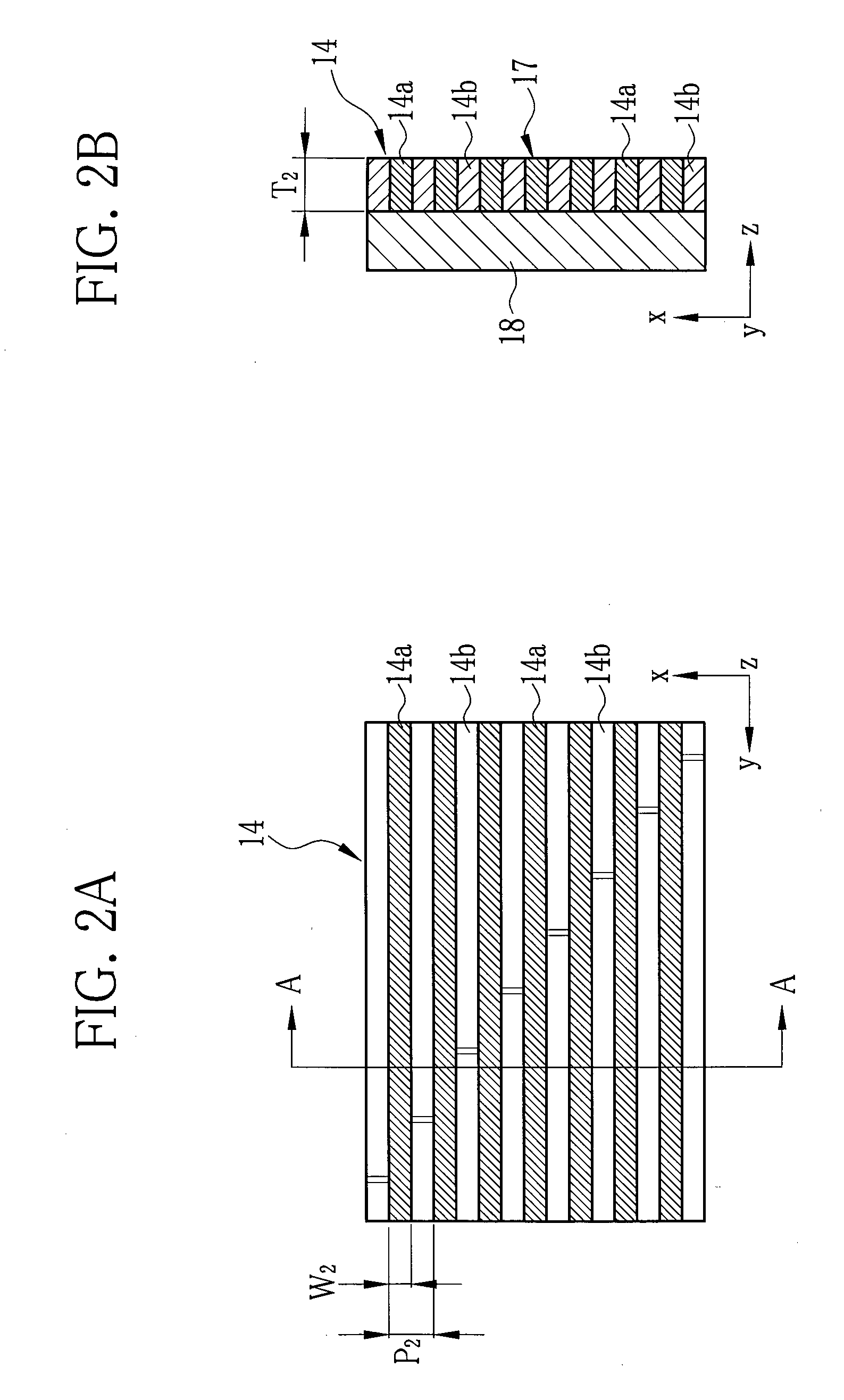

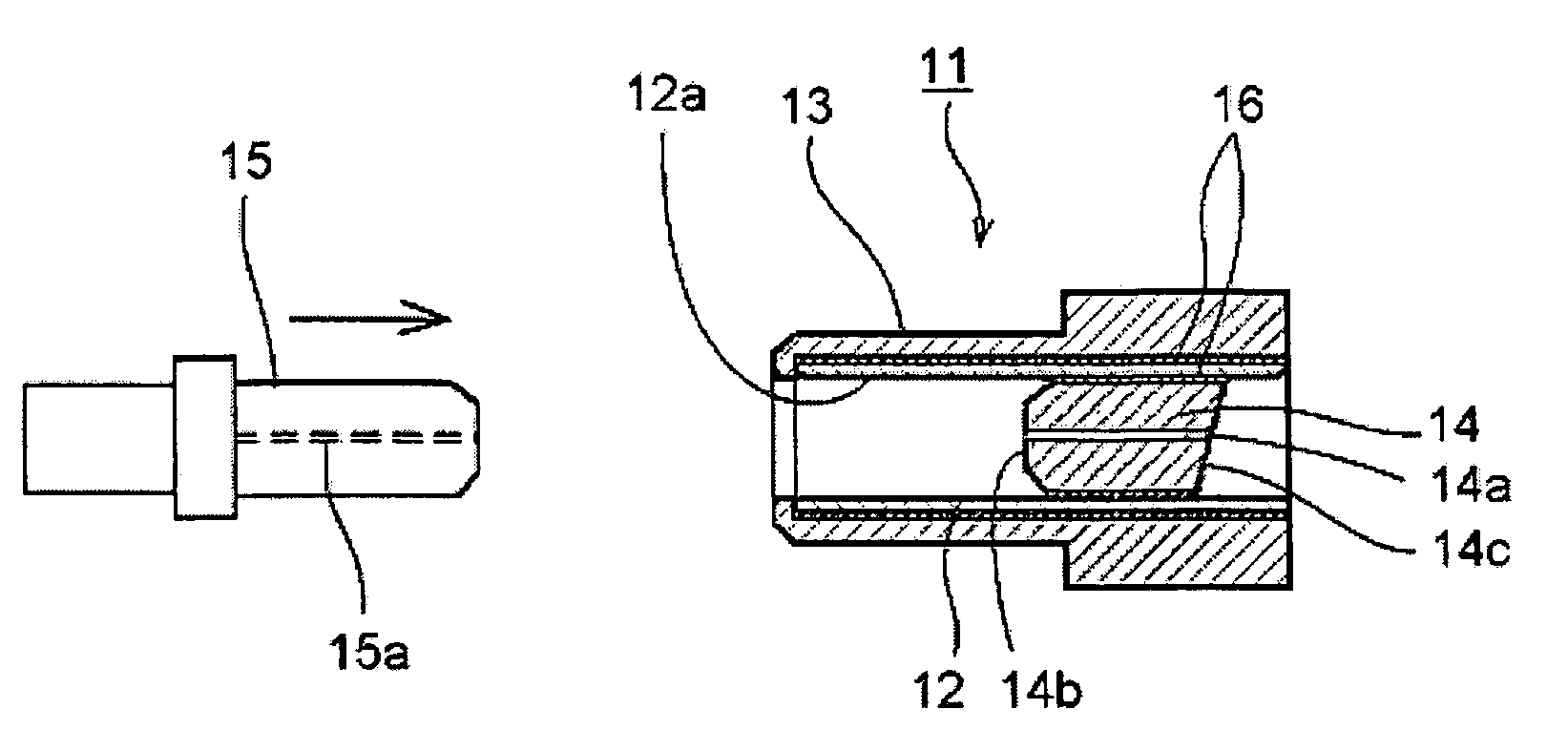

Grid for radiation imaging and method for producing the same

InactiveUS20120307976A1Easily formedImprove overall strengthImaging devicesHandling using diffraction/refraction/reflectionPhotolithographyElectroplating

A conductive substrate (18) and an etching substrate (20) are bonded to each other. An etch mask (25) is formed on the etching substrate (20) using a photolithography technique. On the etching substrate (20), grooves (20a) and X-ray transmitting sections (14b) are formed by dry etching using Bosch process. The grooves (20a) are filled with Au (27) by an electroplating method using the conductive substrate (18) as an electrode. Thus, X-ray absorbing sections (14a) are formed.

Owner:FUJIFILM CORP

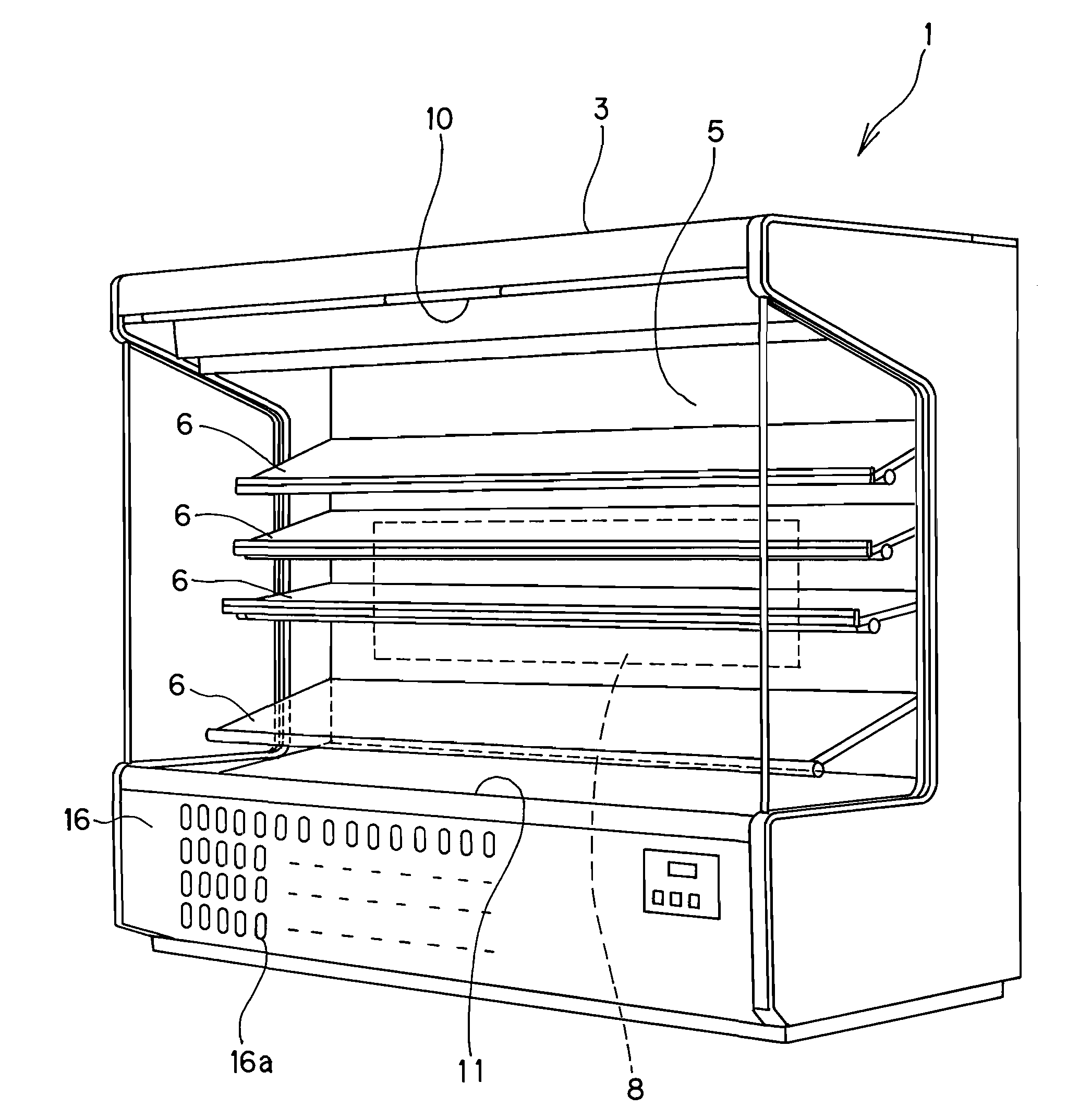

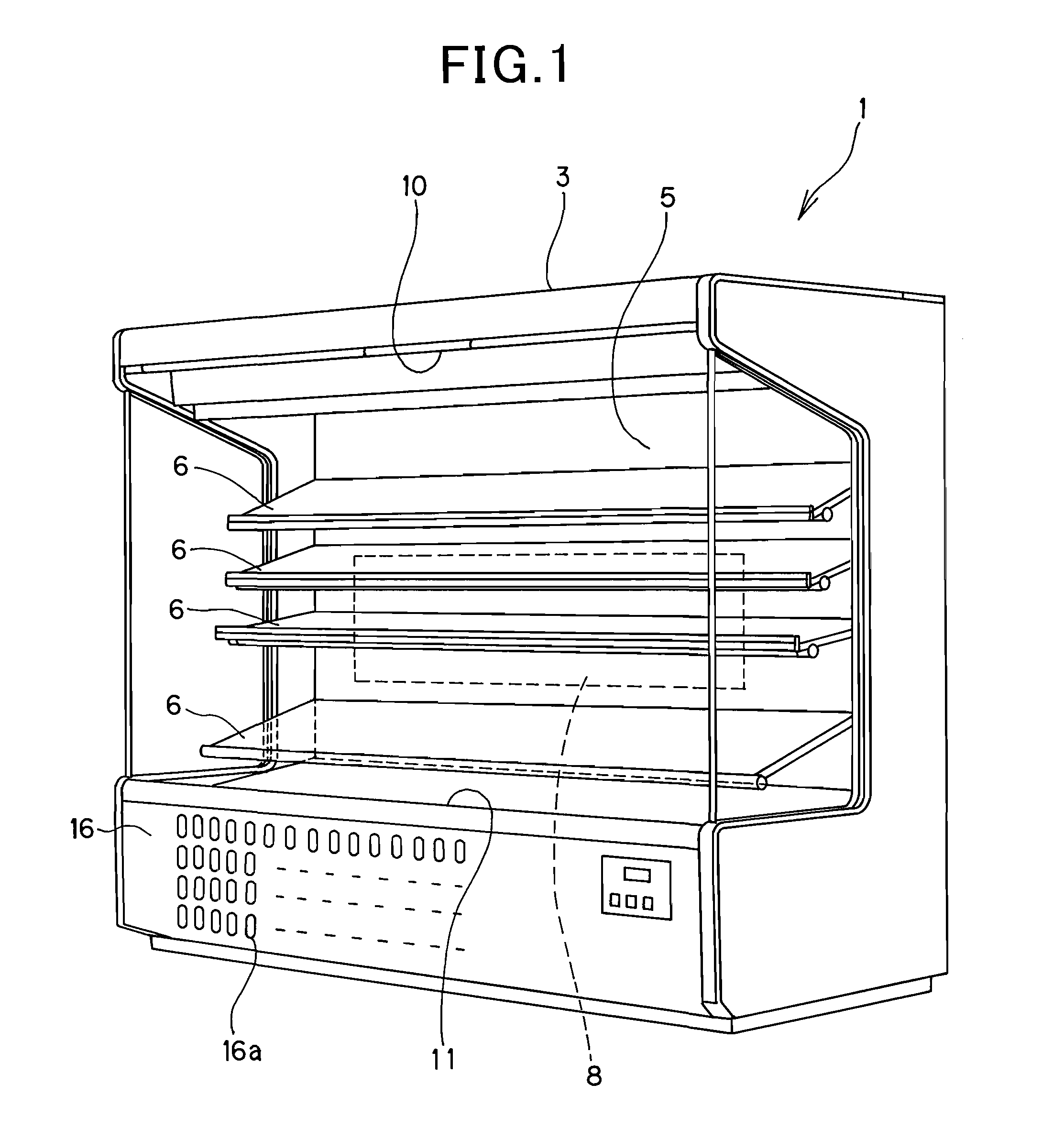

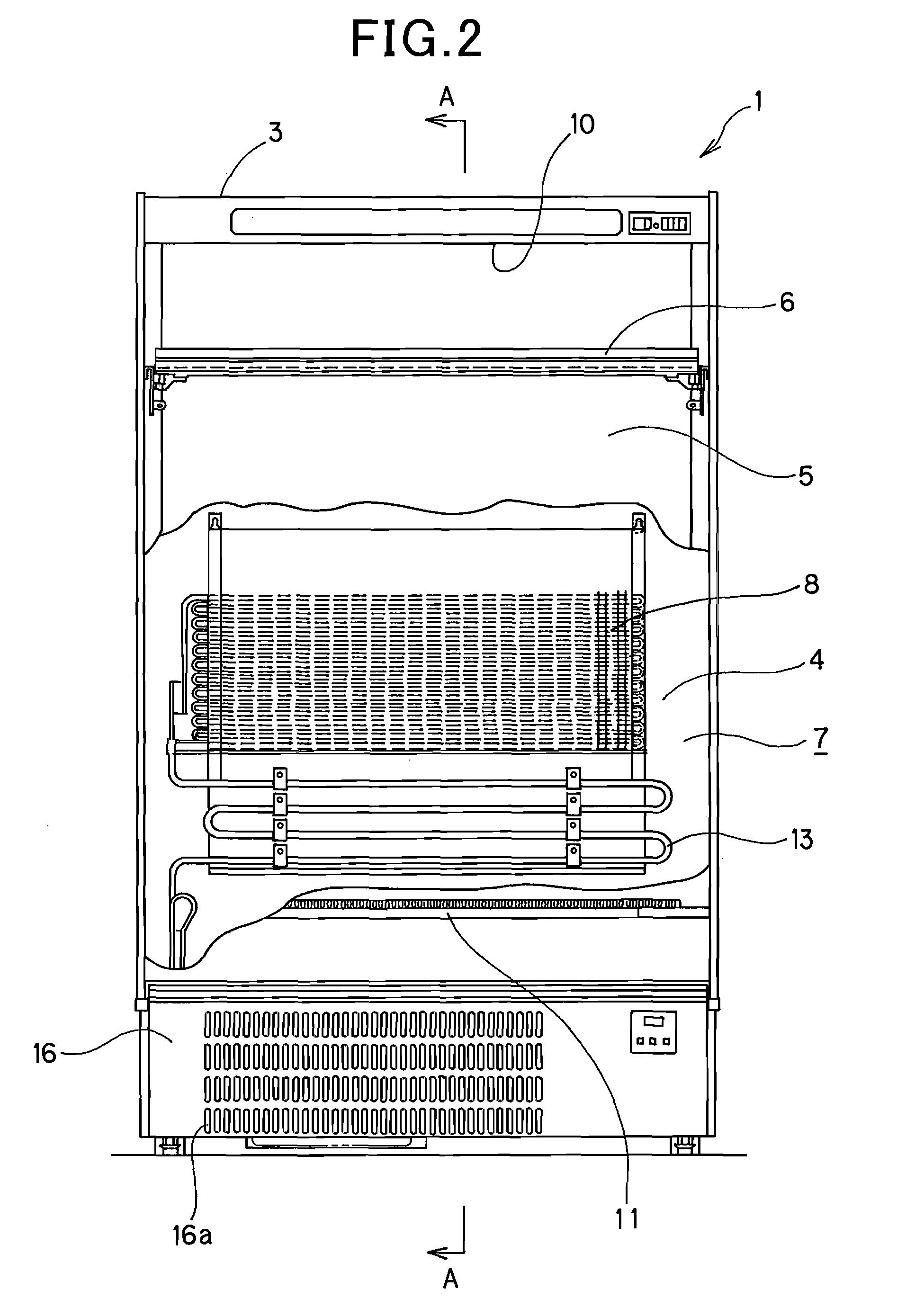

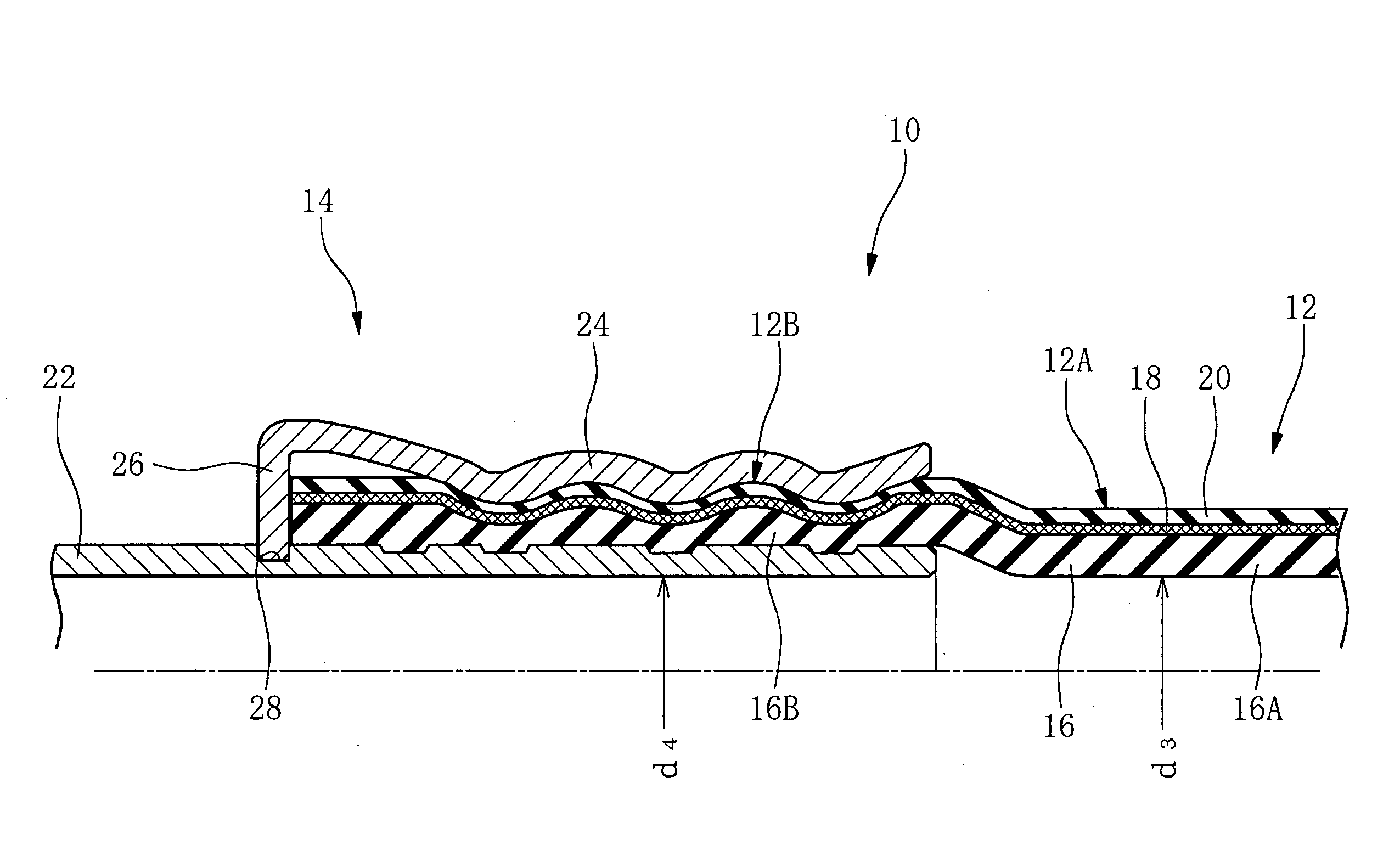

Showcase

ActiveUS20080115920A1Reduce number of stepEasily formedShow cabinetsEvaporators/condensersEngineeringTubing types

A showcase having a fin-and-tube type cooler which comprises plural planar fins and a refrigerant pipe penetrating through the plural planar fins and cools air to be fed toward display racks, wherein the plural planar fins comprise long fins arranged in parallel to an air flow direction along which air flows through the cooler, and short fins that are shorter in length in the air flowing direction than the long fins and arranged between respective adjacent long fins at the downstream side of the cooler with respect to the air flowing direction. Furthermore, the refrigerant pipe comprises first U-shaped hair pins each having two straight pipe portions and second U-shaped hair pins each having two straight pipe portions, the pitch between the two straight pipe portions of each second U-shaped hair pin is set to the double of the pitch between the two straight pipe portions of each first U-shaped hair pin, and the first and second U-shaped hair pins penetrate through the hole portions formed in the plural planar fins so as to be disposed in a predetermined arrangement style.

Owner:SANYO ELECTRIC CO LTD

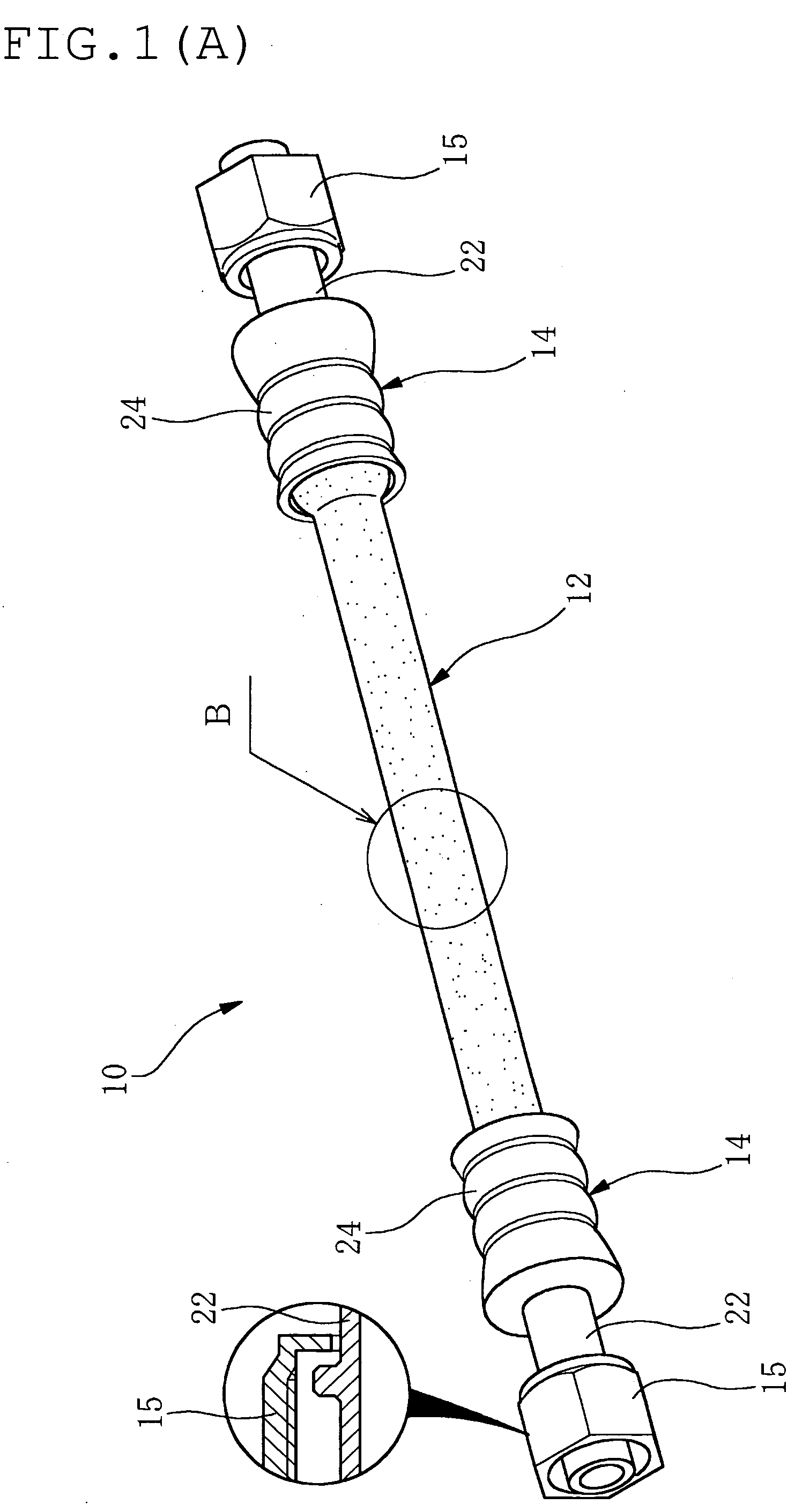

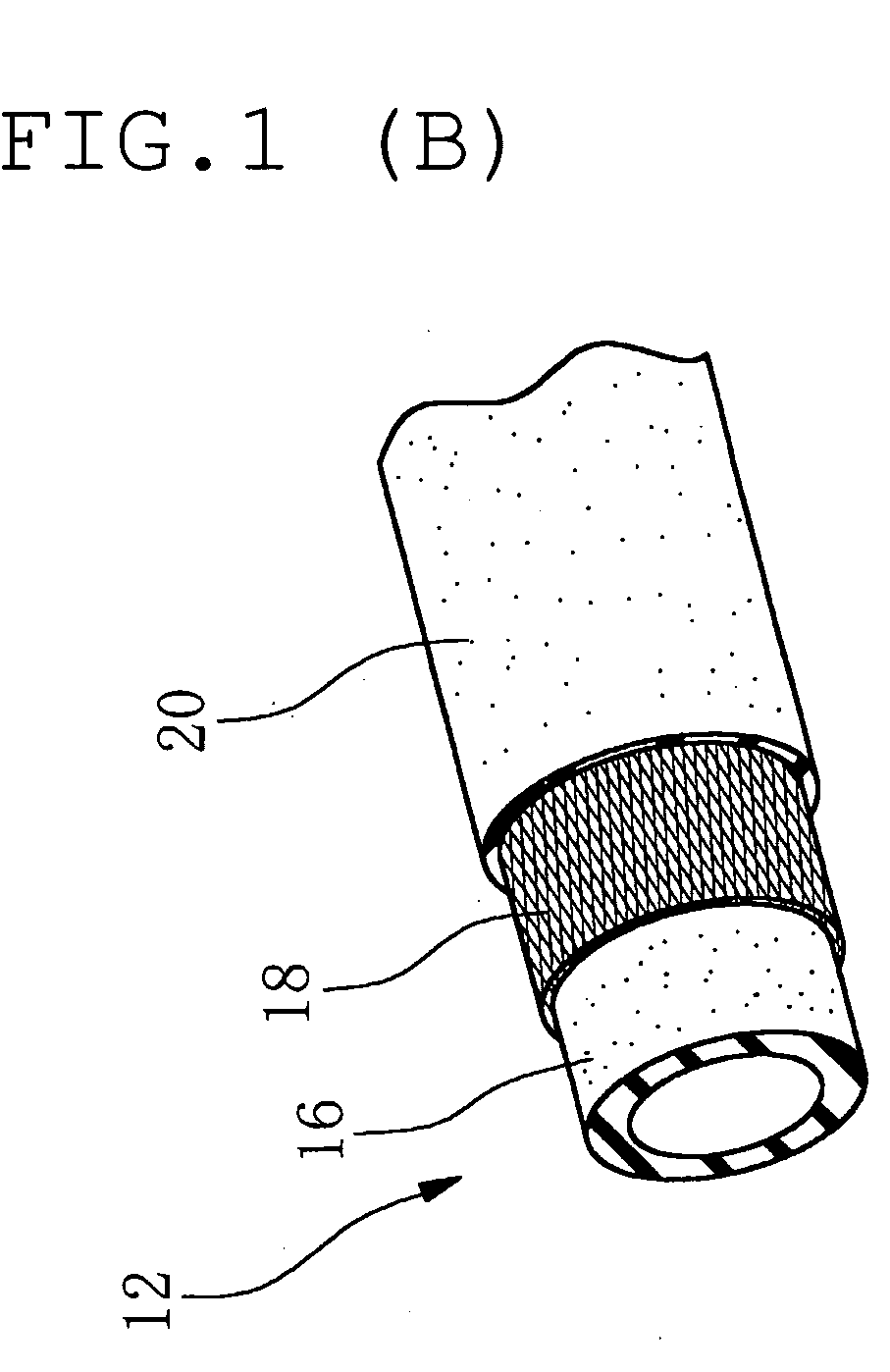

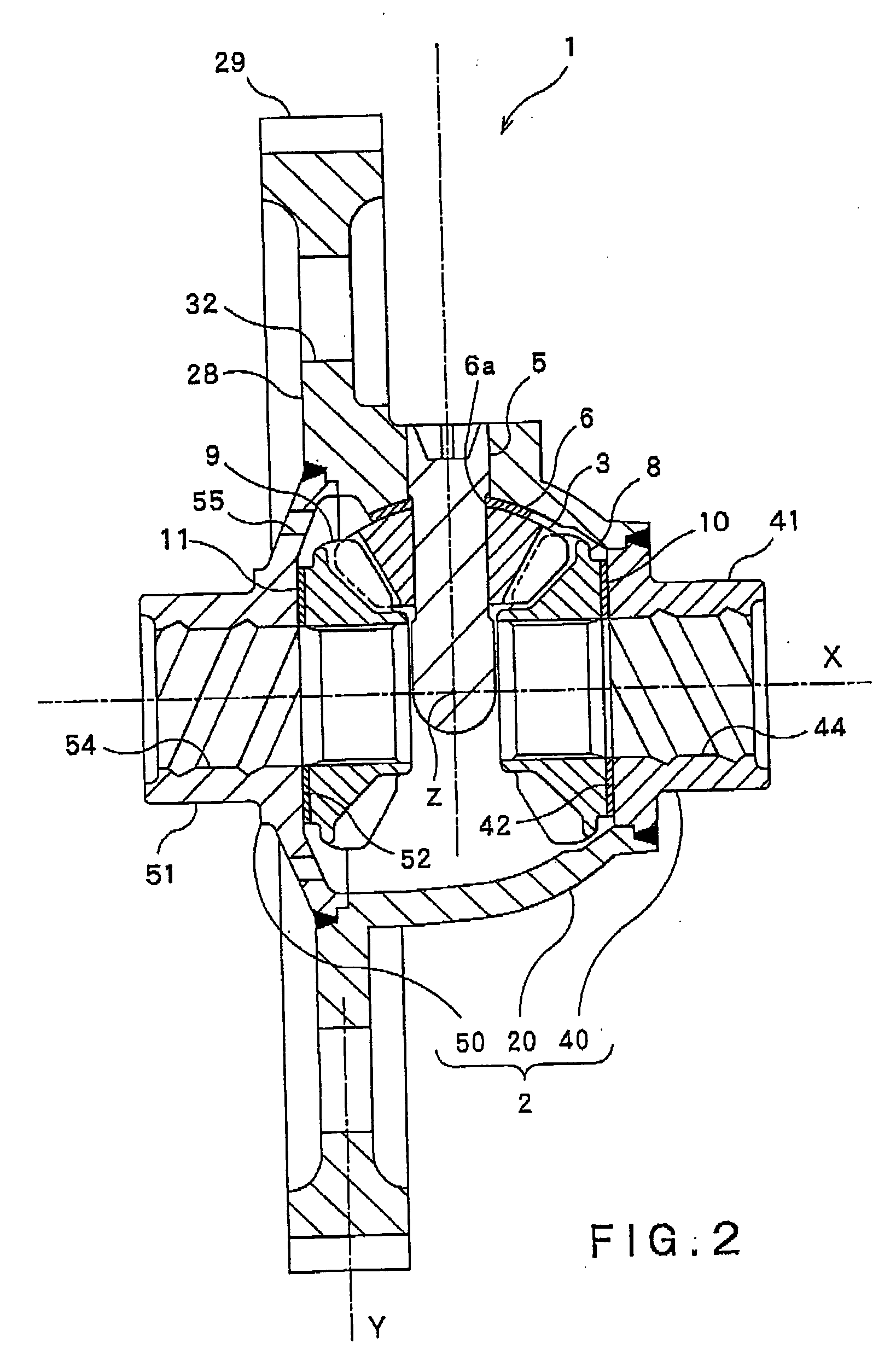

Pressure resistant vibration absorbing hose

A pressure resistant vibration absorbing hose has a hose body including an inner surface rubber layer, a reinforcing layer and an outer surface rubber layer and a joint fitting including a rigid insert pipe and a socket fitting. The joint fitting is attached to a swaged portion of an axial end portion of the hose body by securely swaging the socket fitting thereto. The inner surface rubber layer is formed by molding such that a swaged portion thereof is larger than a main portion thereof in diameter and a wall thickness of the swaged portion is equal to or larger than a wall thickness of the main portion, and after that, the reinforcing layer and the outer surface rubber layer are laminated to construct the hose body.

Owner:DENSO CORP +1

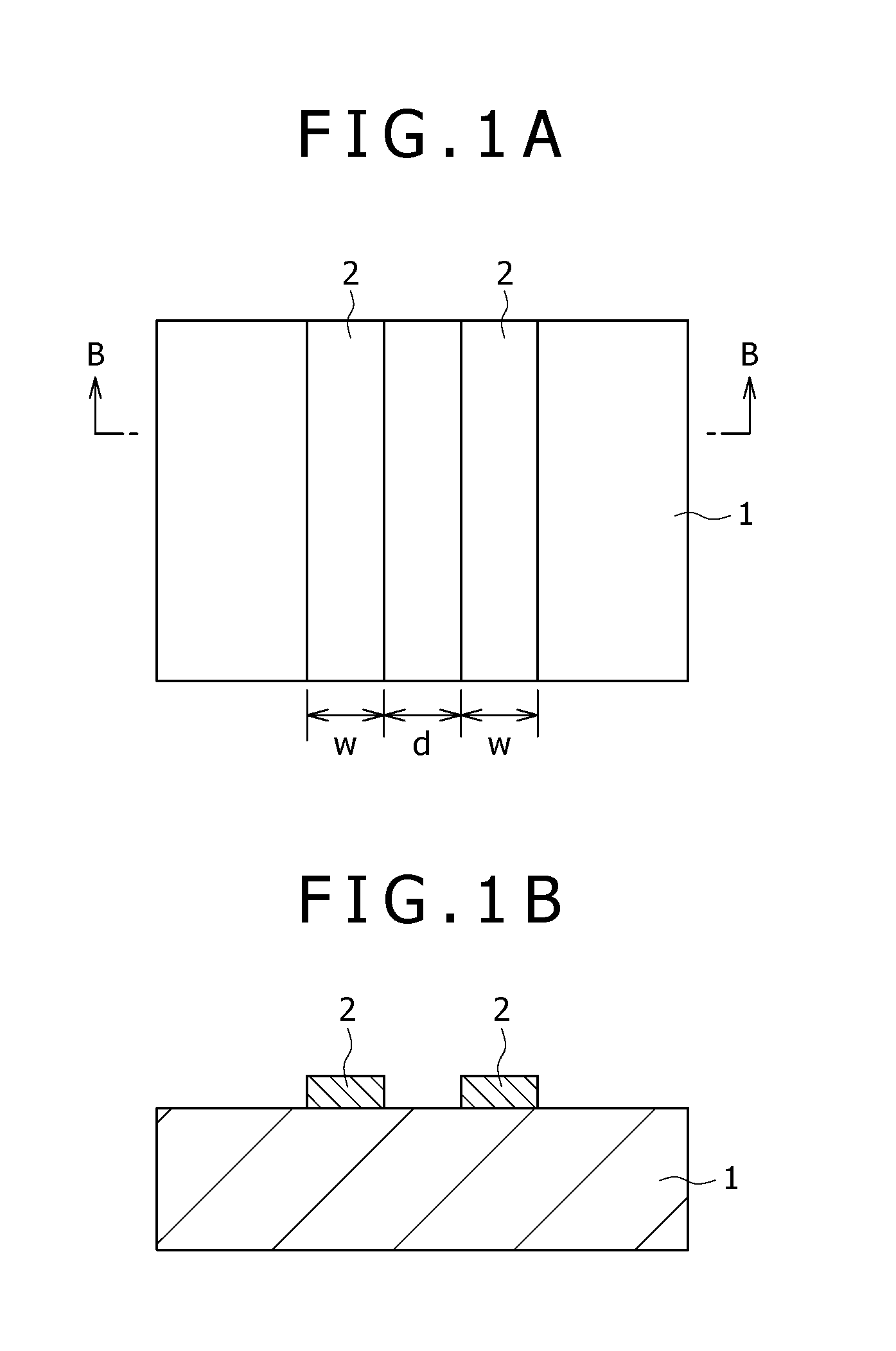

Method for manufacturing silicon substrate having textured structure

ActiveUS20140349485A1Easily formedEasy to removeNanoinformaticsPhotomechanical apparatusSubstrate surfaceSilicon

The present invention provides a method for manufacturing a silicon substrate having texture structure, by which, in comparison with conventional methods, it is possible to reduce manufacturing step and form easily regular texture structure on silicon substrate surface. The method of the present invention comprises the steps of: (A) forming a pattern on the silicon substrate using a resin-comprising composition; (B) irradiating an etching gas to the silicon substrate surface other than the pattern portion; and (C) processing the silicon substrate irradiated with the etching gas with an alkaline etching fluid to form concave structure under the pattern portion. Furthermore, the present invention provides a resin-comprising composition usable in the method, in particular, a composition comprising photo-curable resin.

Owner:TOKUYAMA CORP

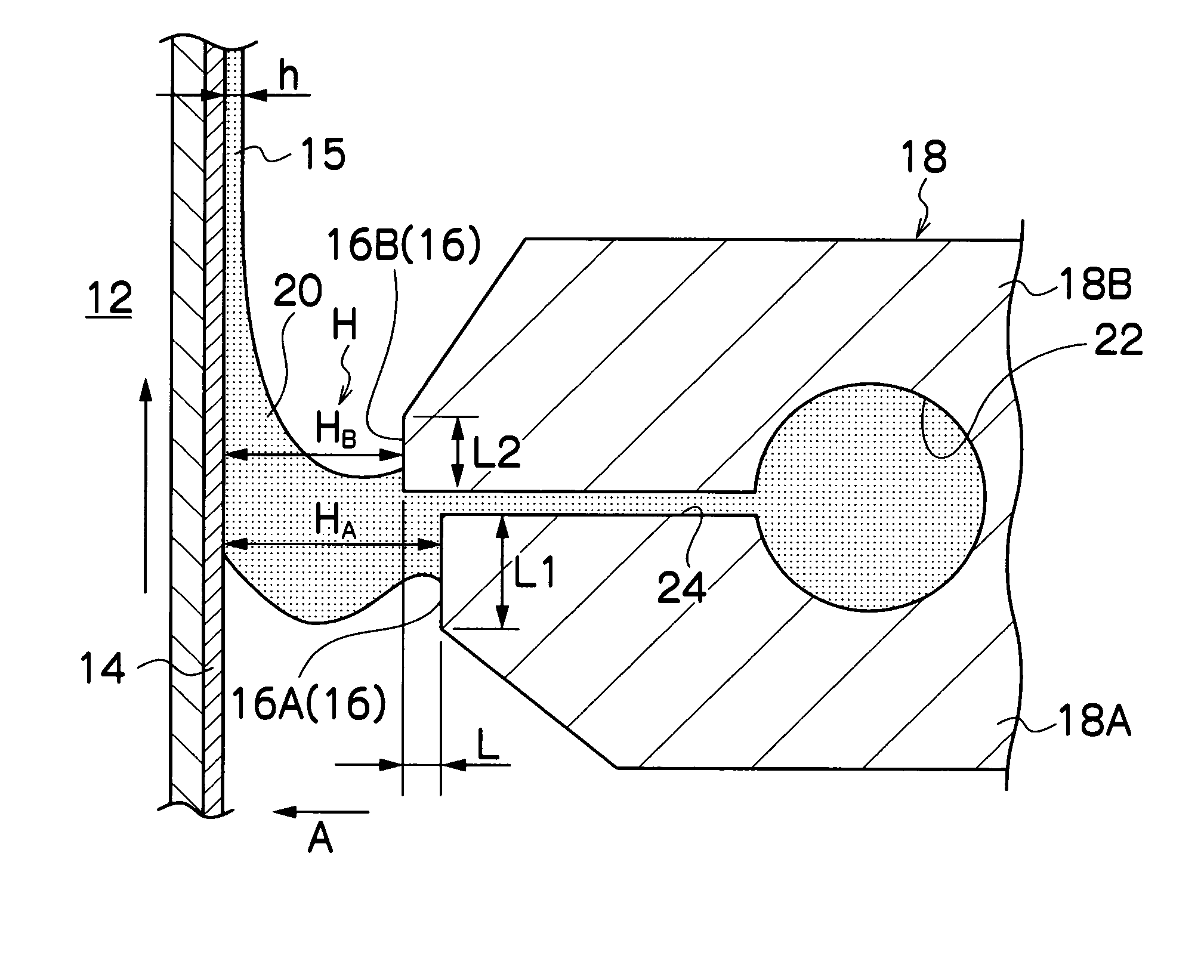

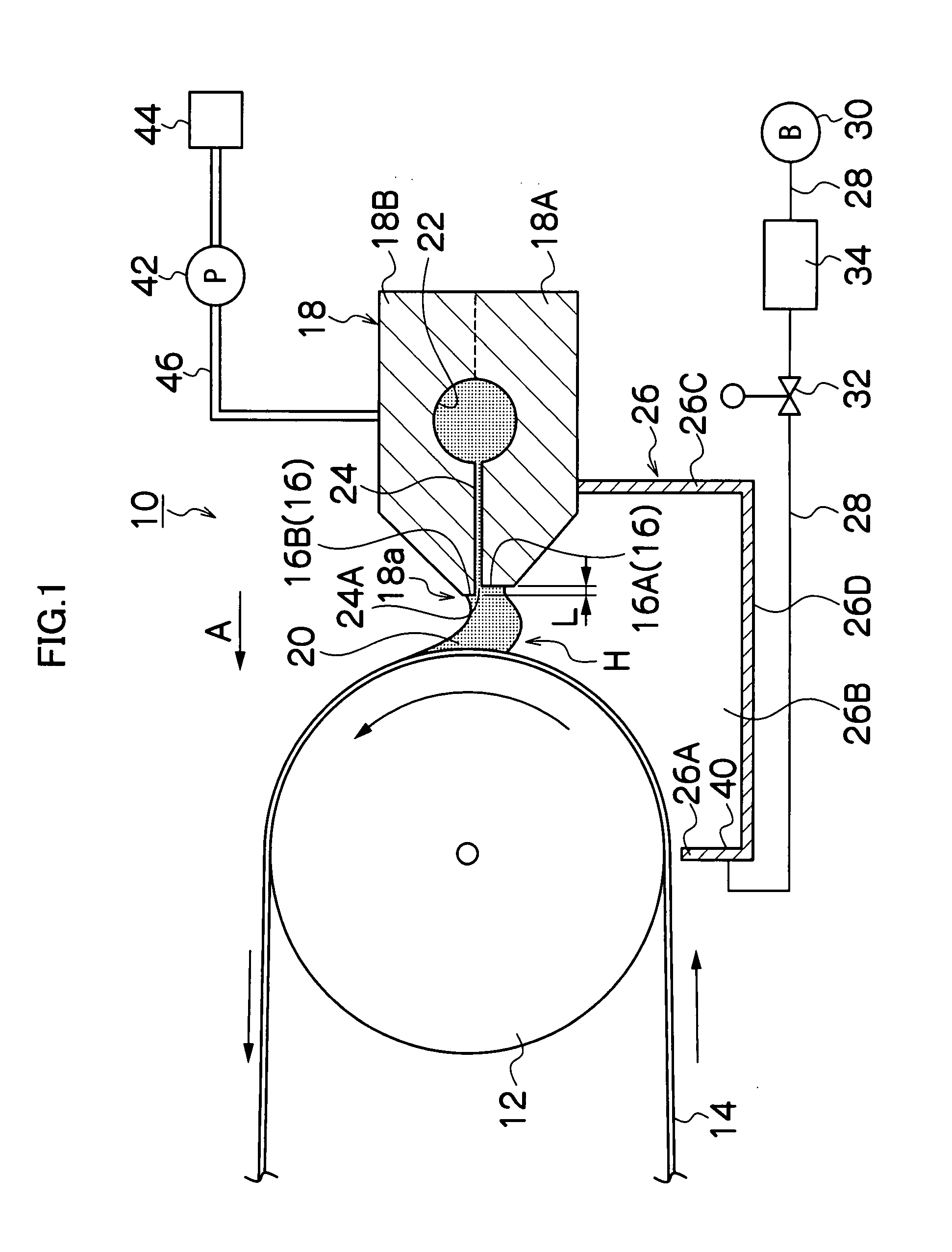

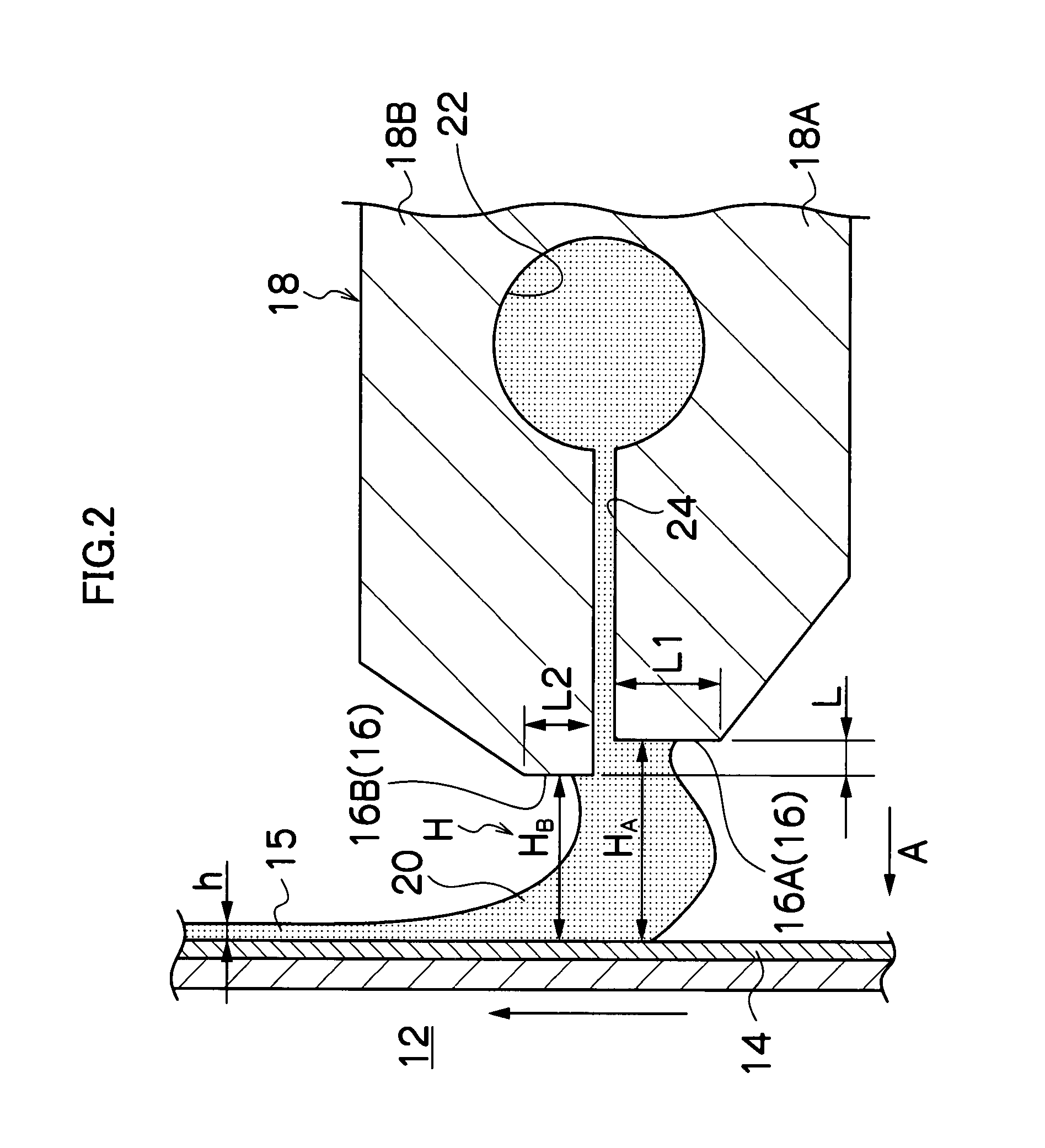

Method and apparatus for applying coating solution

The present invention provides a method for applying a coating solution by discharging a coating solution from a slit provided at a tip of a slot-die toward a surface of a web fitted onto a backup roller, the method comprising: a stand-by step of staying the slot-die at a stand-by position having a larger clearance between the slot-die and the web than that of a standard coating process; and a two-stage moving operation including a first moving step in which the slot die is moved to a coating initiation position having a smaller clearance than that of the standard coating process to initiate application of a coating solution, and a second moving step in which the slot die is moved away from the coating initiation position to a standard coating position having the clearance of the standard coating process to perform constant application of the coating solution.

Owner:FUJIFILM CORP

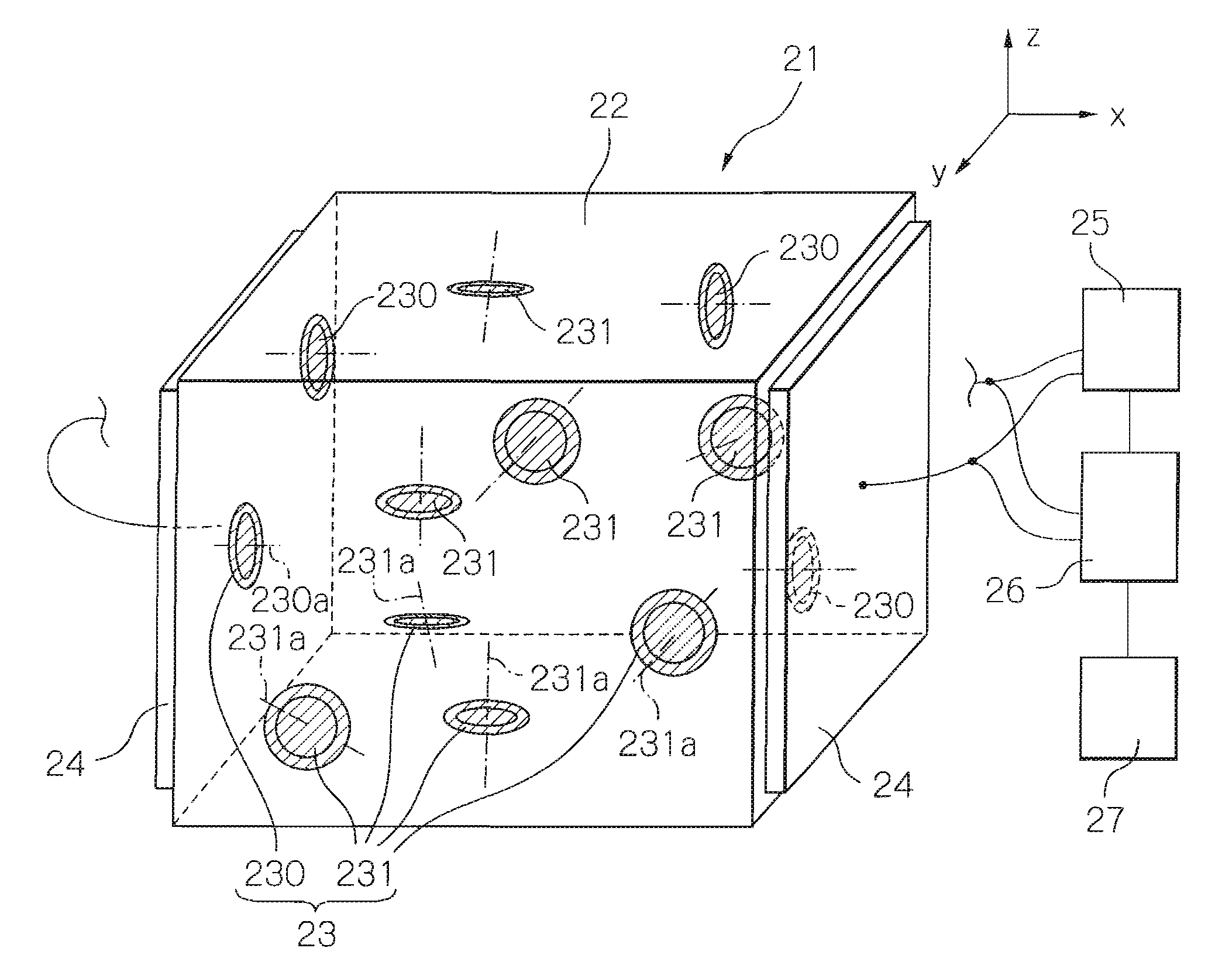

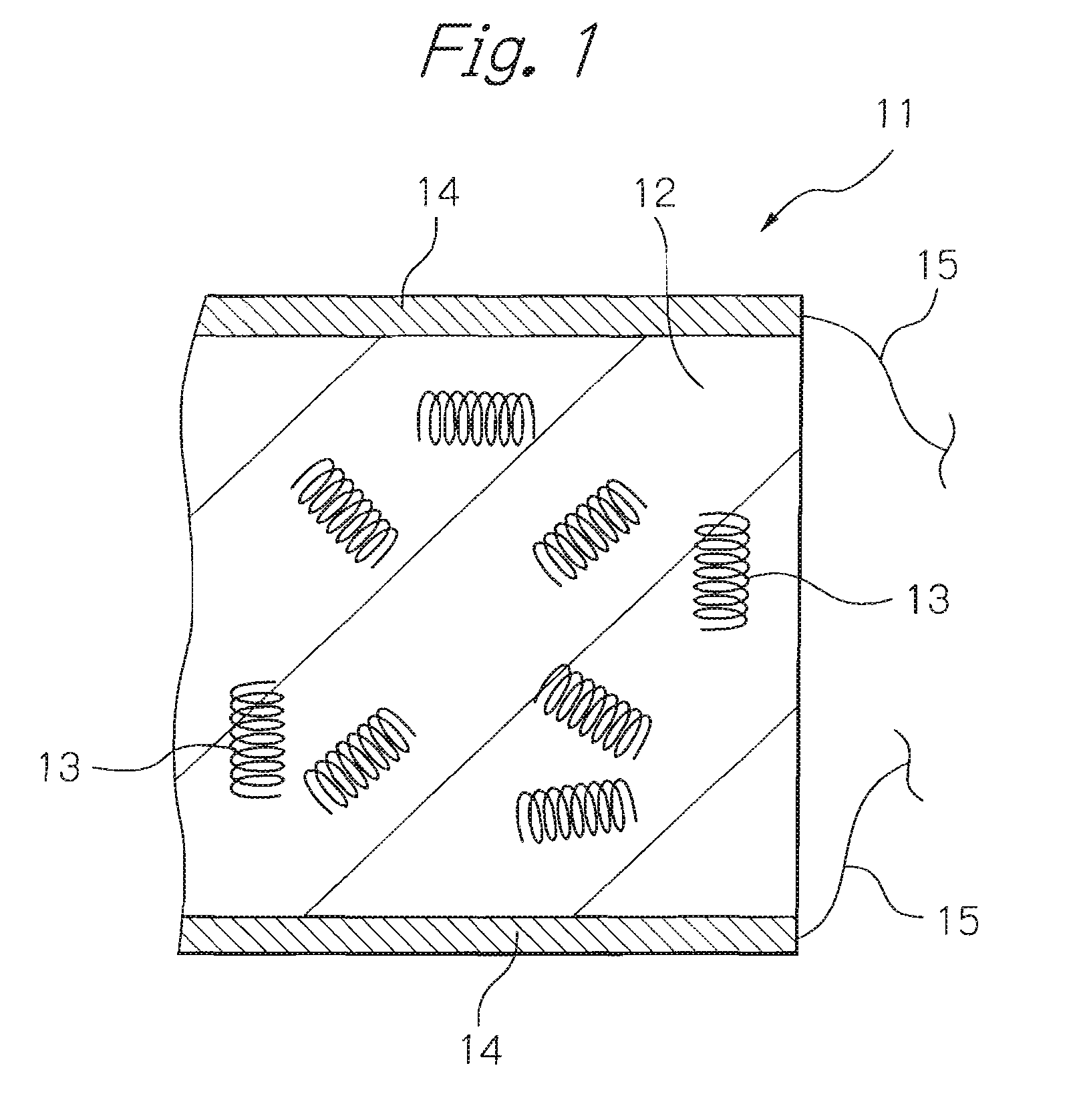

Tactile sensor utilizing microcoils with spiral shape

InactiveUS20090045820A1Easily formedLess variationResistance/reactance/impedenceForce measurementSpiral coilTactile sensor

Provided is a material for tactile sensor, which is easy to be formed, and in which the shape, size and orientation of coils dispersed in the medium are sufficiently controlled. The tactile-sensitive material comprises a medium and a plurality of micro coils dispersed in the medium and constituting a LCR resonance circuit, and wherein each of the plurality of micro coils comprises at least one spiral coil portion, and coil axes of the plurality of micro coils are aligned along at least one direction and / or directed in at least one plane. When a tactile stress is applied to the tactile-sensitive material, the C component is varied significantly, which contributes to the improvement in sensitivity of the tactile sensor. Further, by providing a core at the coil center, the sensitivity is more improved.

Owner:TDK CORPARATION

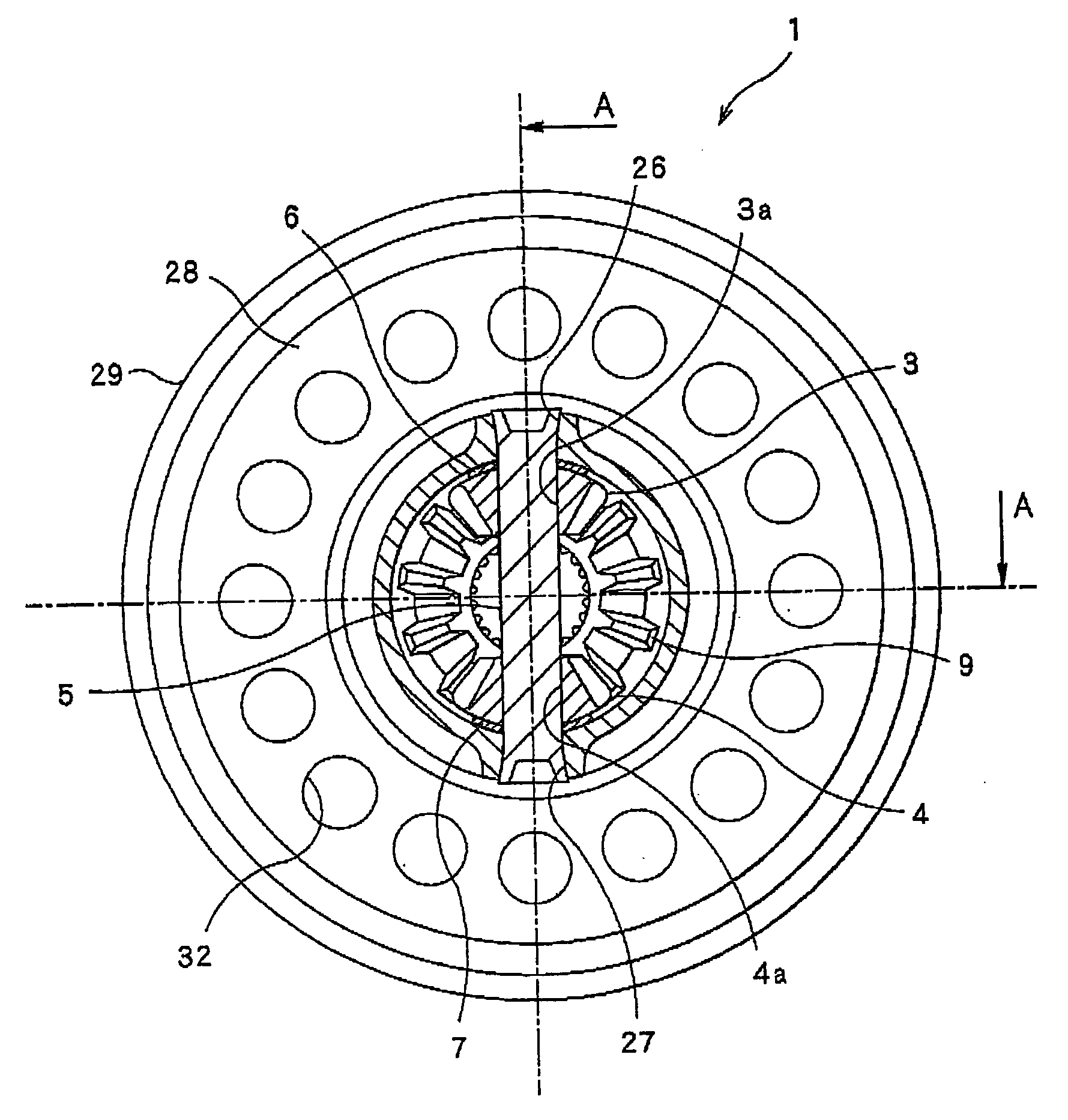

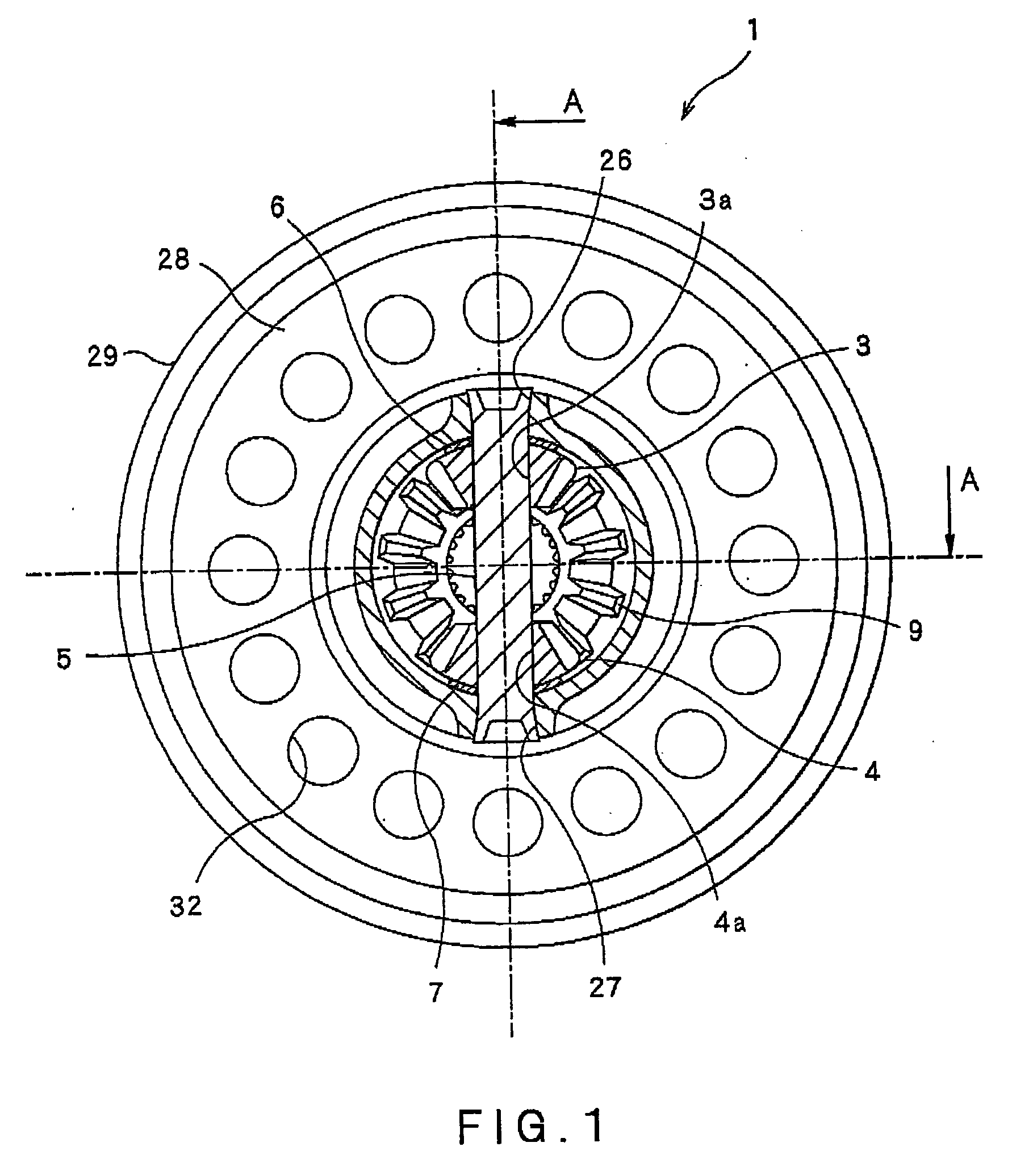

Differential gear

InactiveUS20090215573A1Good precisionEasily formedMetal-working apparatusGear wheelsEngineeringDrive shaft

A differential case includes a first boss part into which a first drive shaft is inserted, and a second boss part into which a second drive shaft opposed to the first drive shaft is inserted. The differential case is composed of: a first case body extending from pinion-shaft assembling parts on which a pinion shaft is assembled, to a ring gear; a second case body having the first boss part; and a third case body having the third boss part. The first case body is integrally formed by forging. The second case body is integrally formed by forging. The third case body is integrally formed by forging. The first case body and the second case body are joined to each other by welding. The first case body and the third case body are joined to each other by welding.

Owner:MUSA PRECISION IND CO LTD

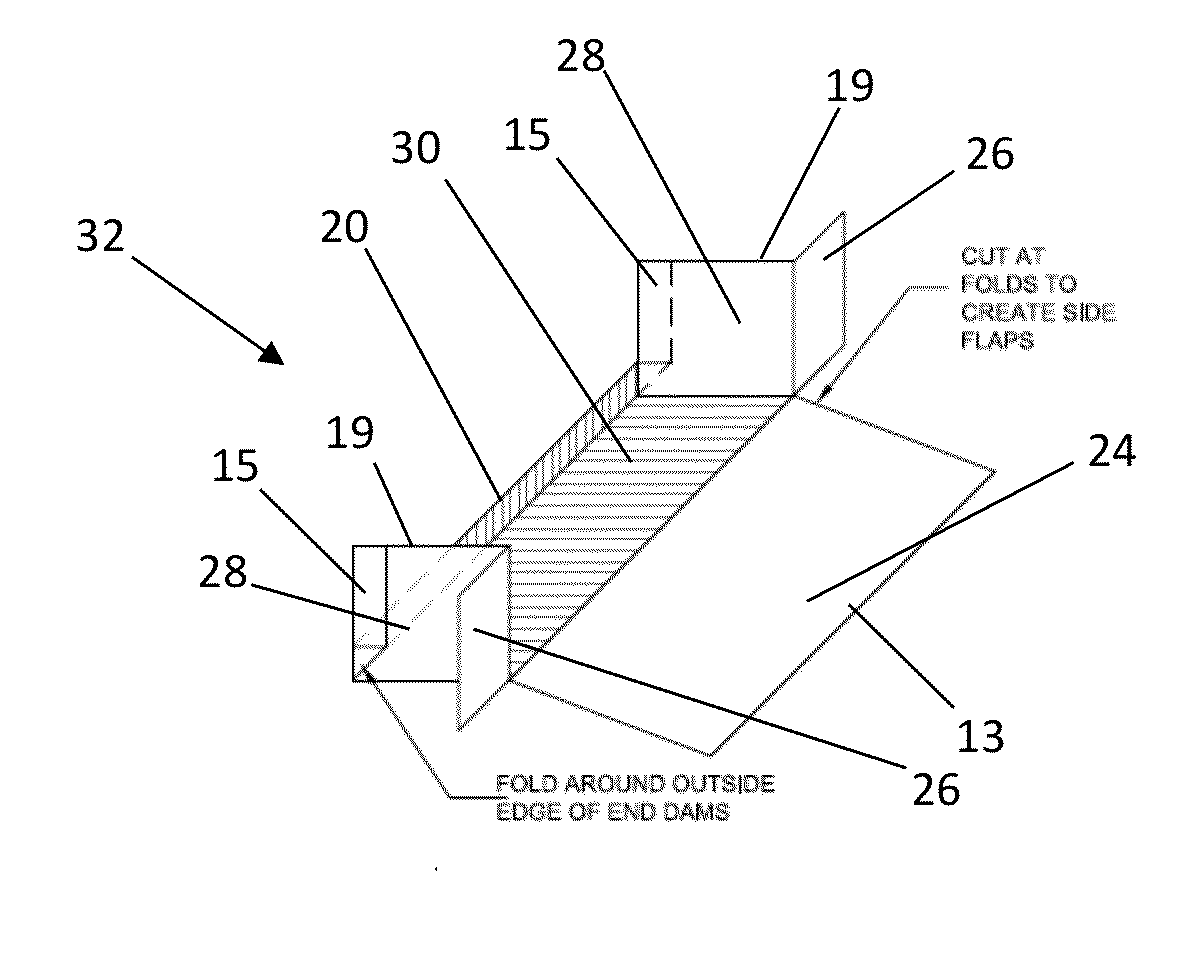

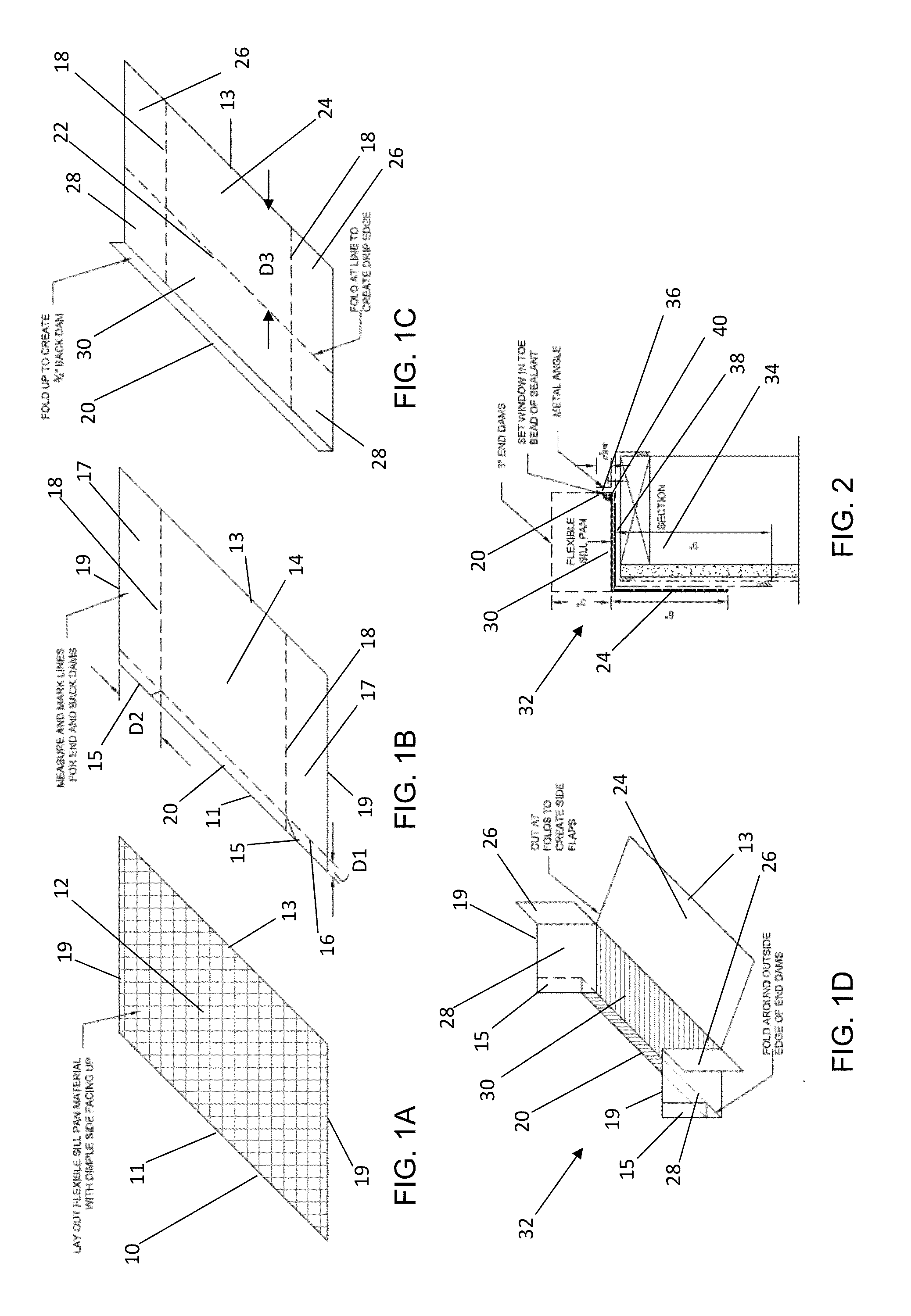

Sill pan

A method for forming a sill pan is provided that includes the measurement of a width and length of an opening sill to be sealed. A piece of flexible sill pan material is cut based on the measured opening sill. Fold lines and cuts are created in the piece to form the sill pan. The resulting sill pan is readily formed to have at least one attribute of self-adherence, draining without shims, nail hole self-sealing, and provision of dams without resort to frame cutting.

Owner:SOCOTEC CONSULTING INC

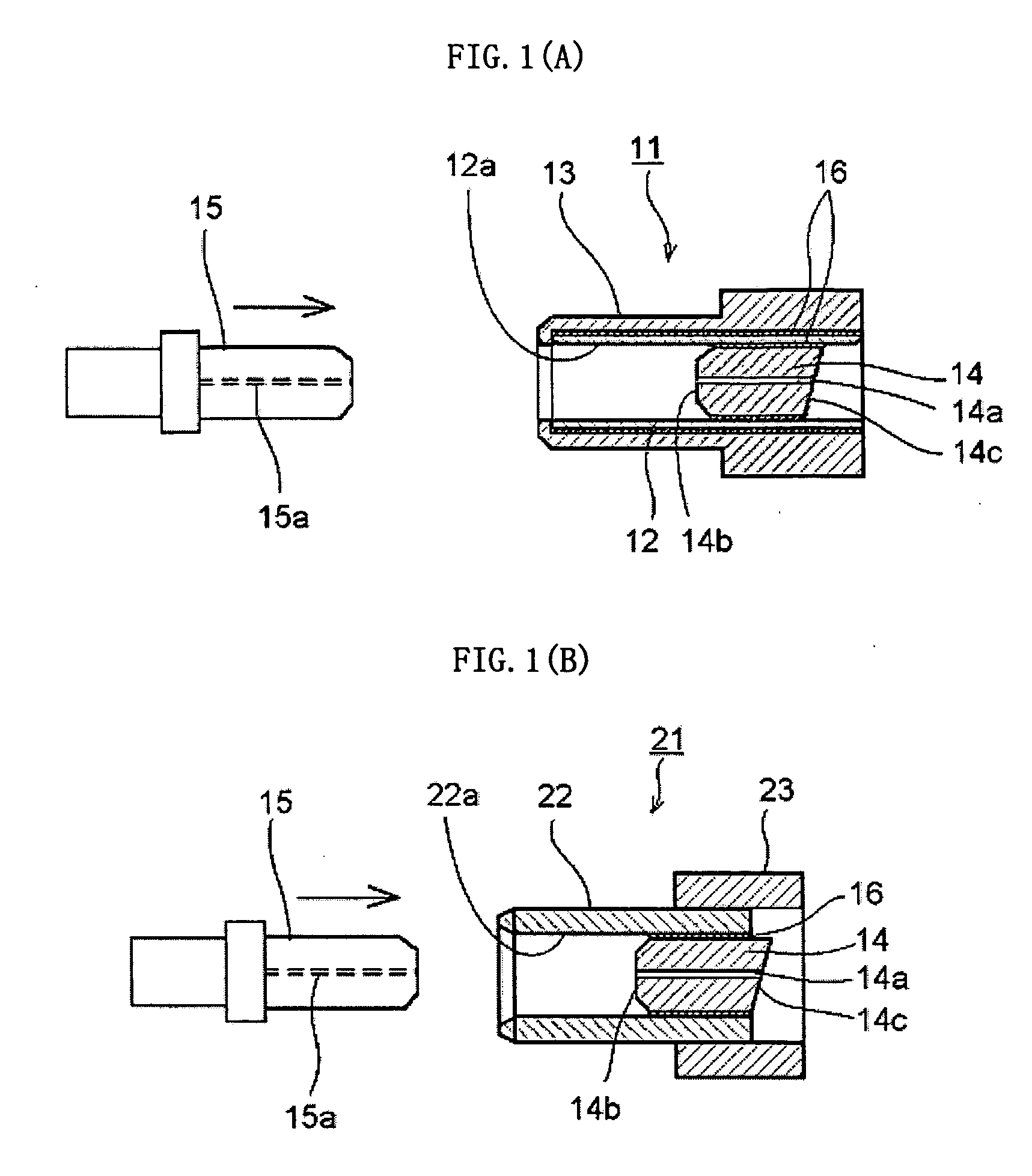

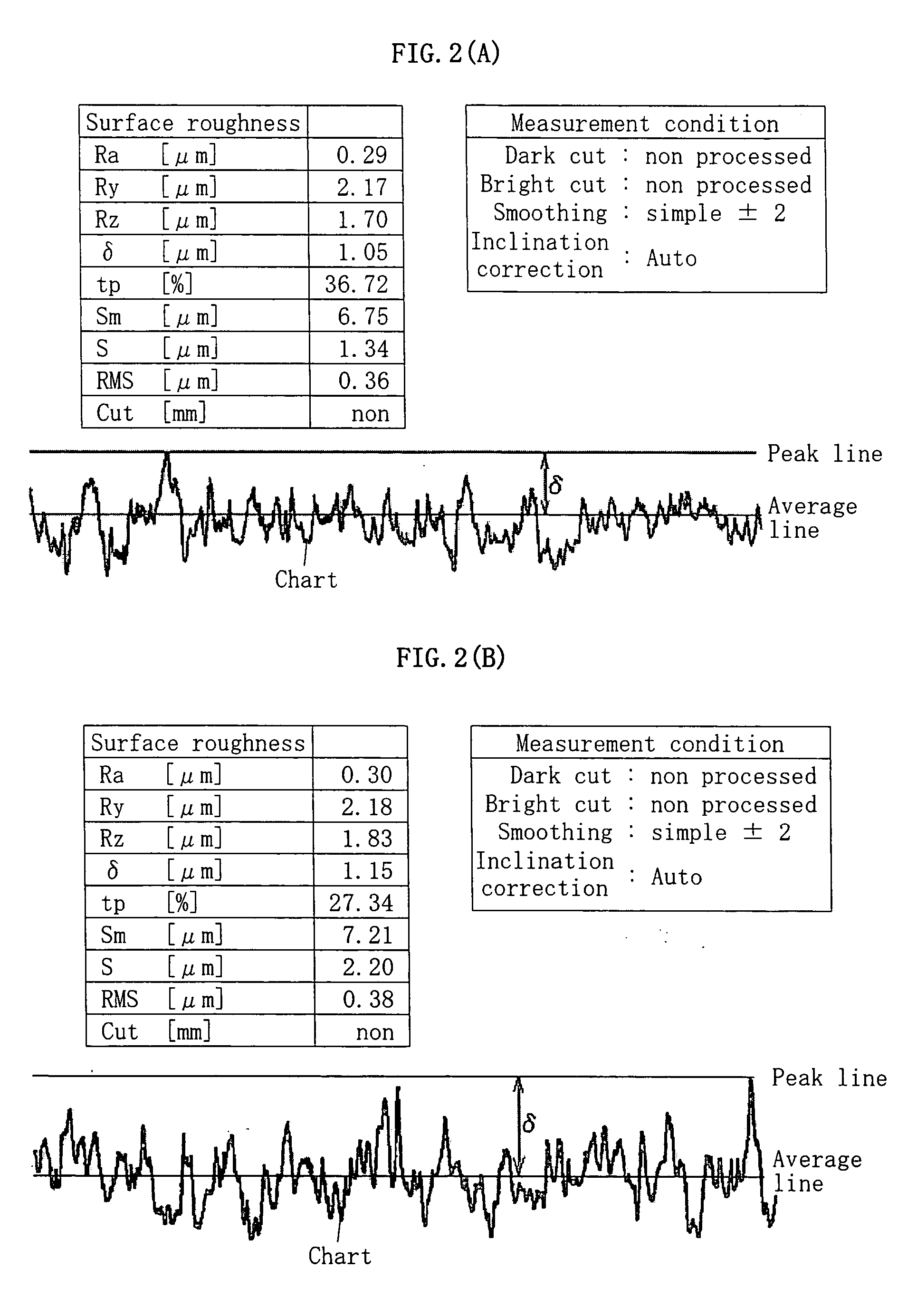

Optical receptacle

An optical receptacle comprises a precision sleeve, a stub with an optical fiber fixed to one end of an inner hole of the precision sleeve through an adhesive, and a sleeve holder fixed to an outer periphery of the precision sleeve by press-fitting or through the adhesive. An outer periphery of the stub with an optical fiber and / or the inner hole of the precision sleeve has a surface roughness Ra value of 0.1 μm or more and 0.5 μm or less.

Owner:NIPPON ELECTRIC GLASS CO LTD

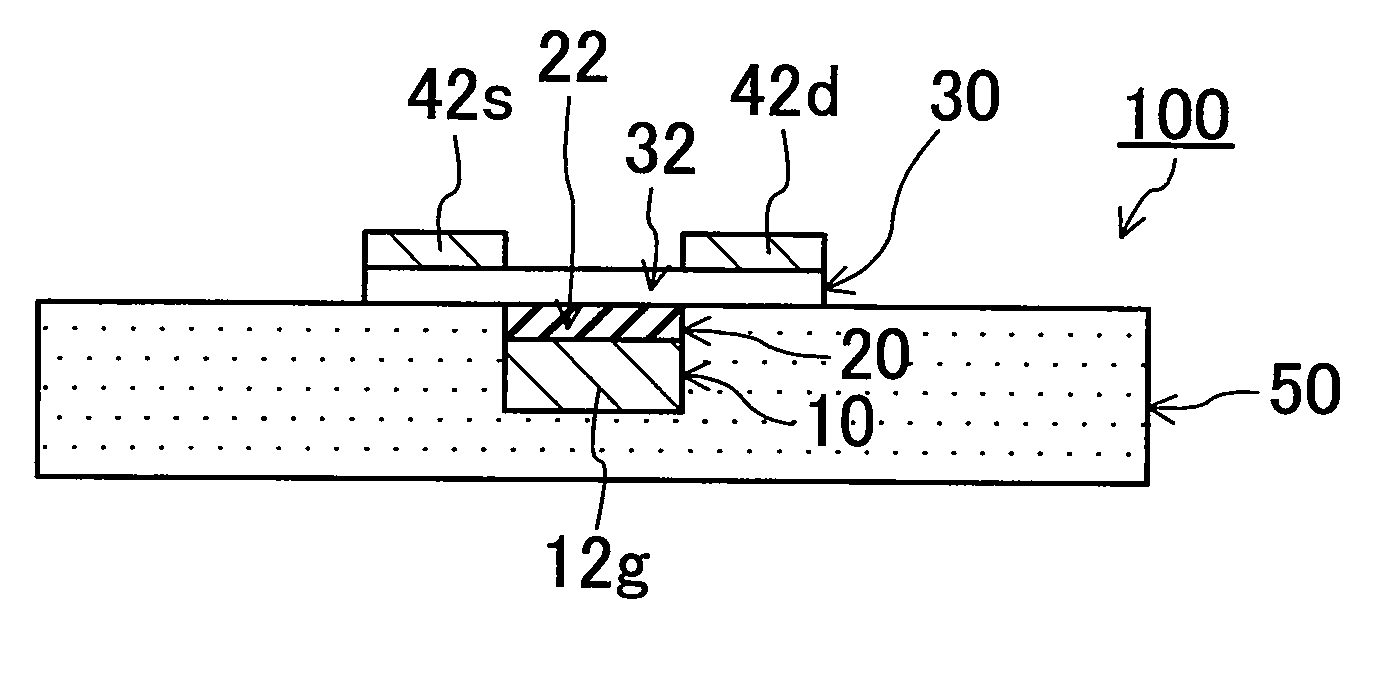

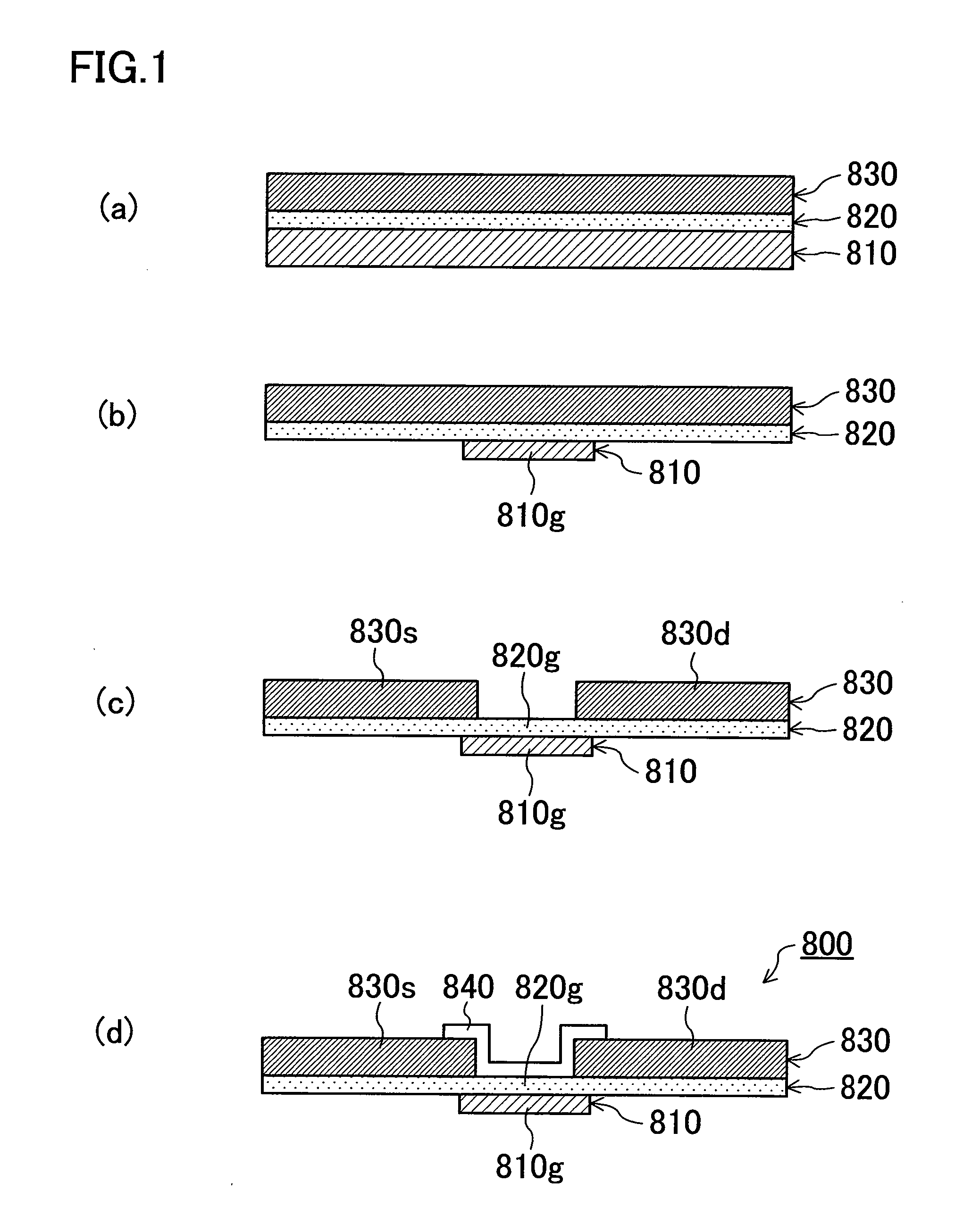

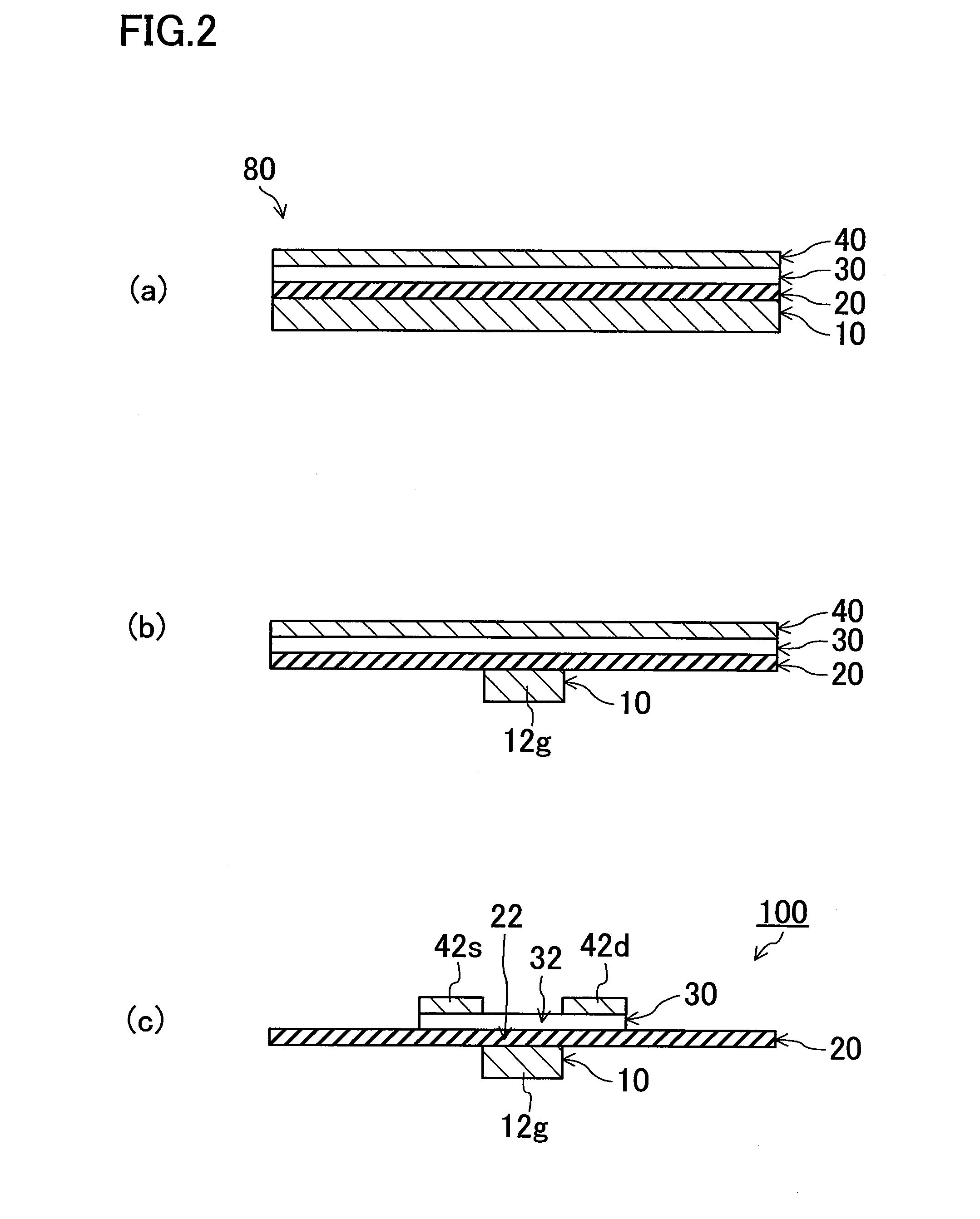

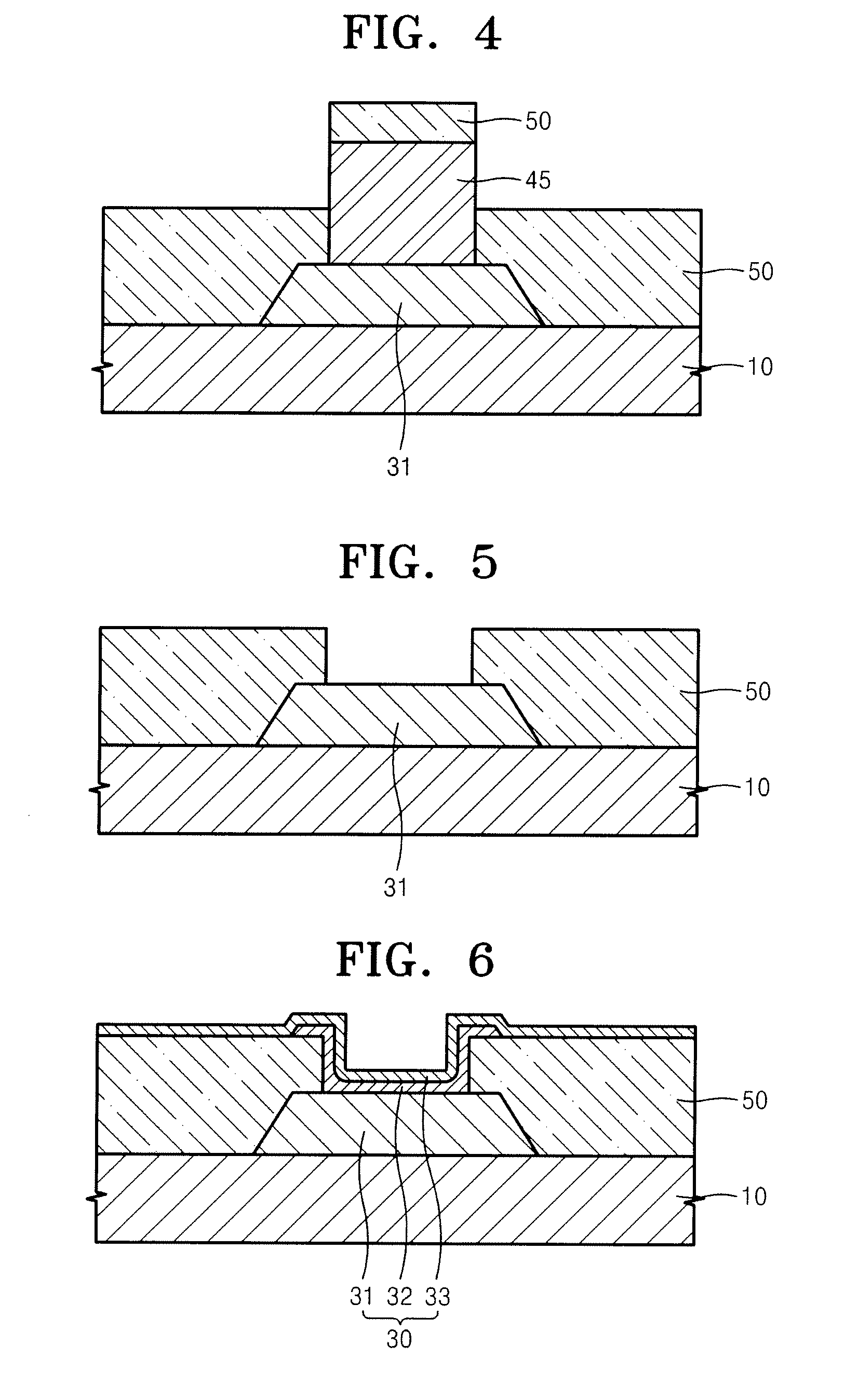

Method for fabricating flexible semiconductor device and layered film used therefore

A method for fabricating a flexible semiconductor device includes: preparing a layered film 80 including a first metal layer 10, an inorganic insulating layer 20, a semiconductor layer 30, and a second metal layer 40 which are sequentially formed; etching the first metal layer 10 to form a gate electrode 12g; compression bonding a resin layer 50 to a surface of the layered film 80 provided with the gate electrode 12g to allow the gate electrode 12g to be embedded in the resin layer 50; and etching the second metal layer 40 to form a source electrode 42s and a drain electrode 42d, wherein the inorganic insulating layer 20 on the gate electrode 12g functions as a gate insulating film 22, and the semiconductor layer 30 between the source electrode 42s and drain electrode 42d on the inorganic insulating layer 20 functions as a channel 32.

Owner:PANASONIC CORP

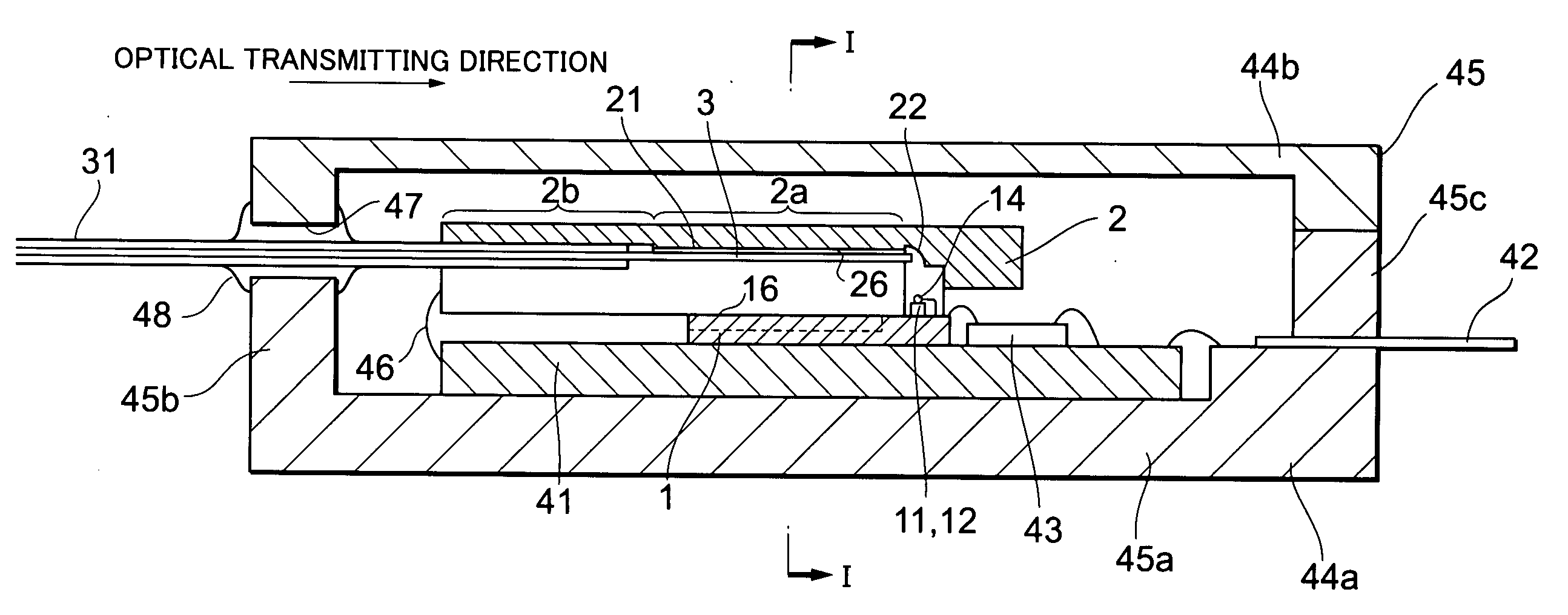

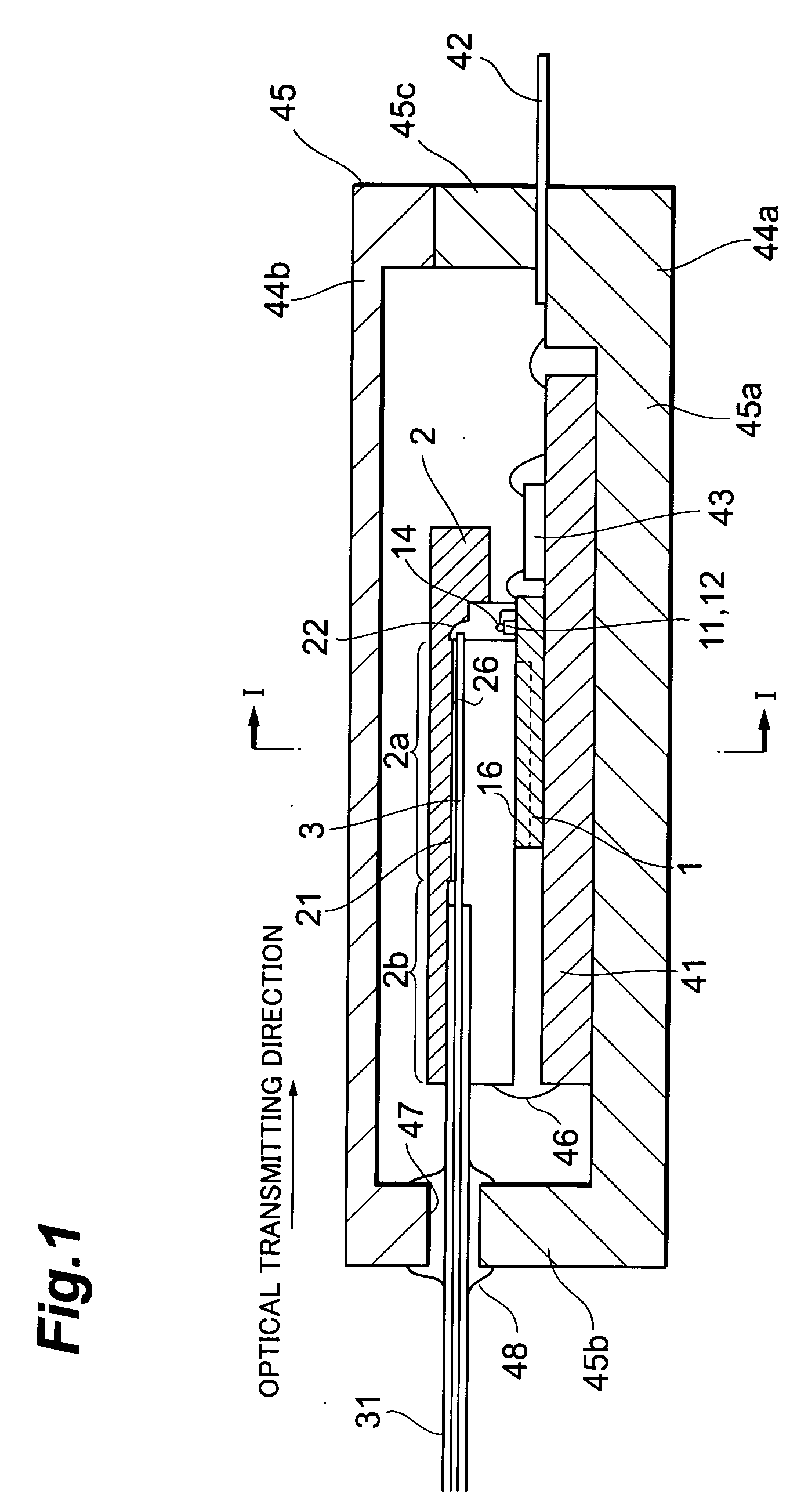

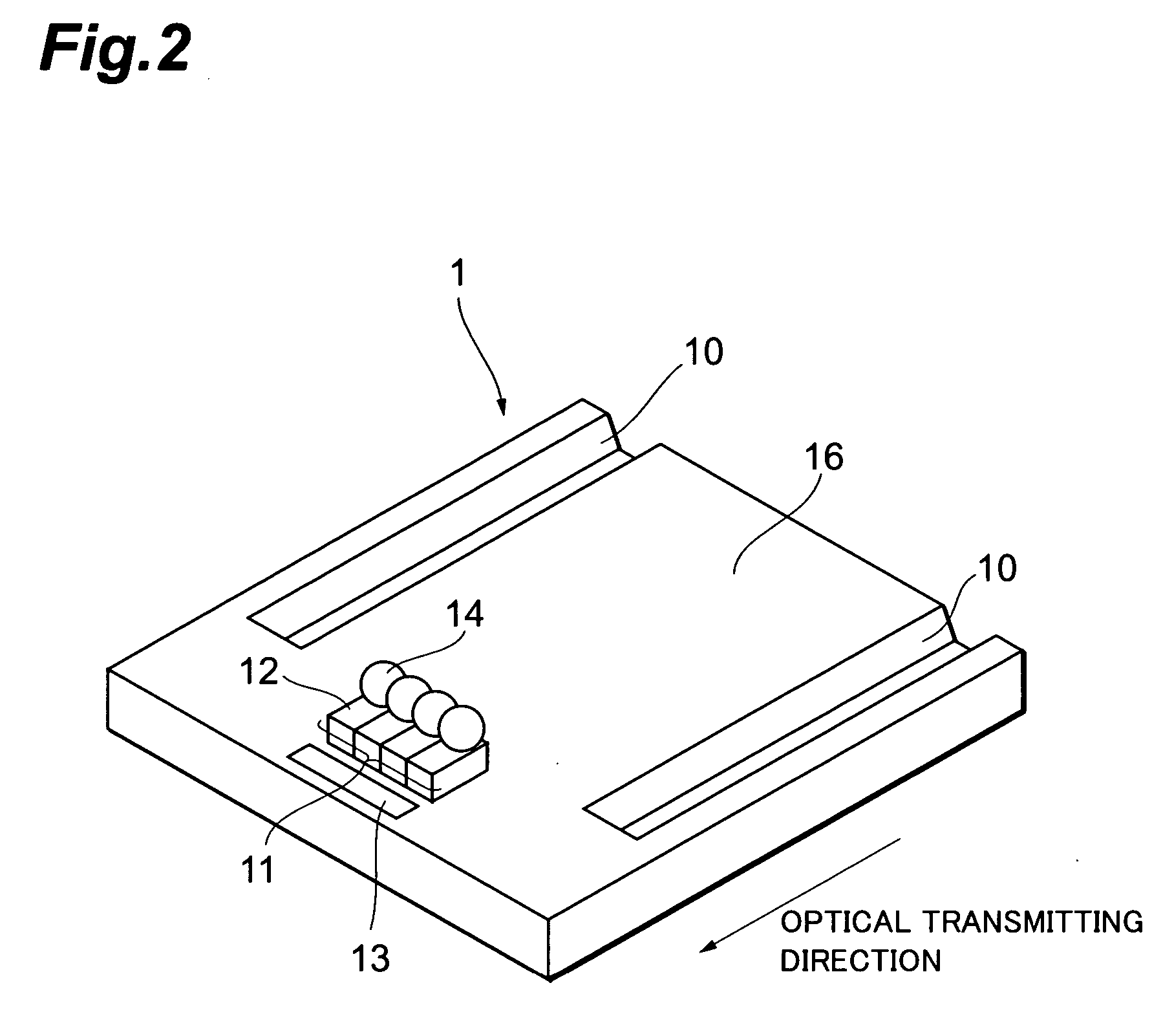

Optical module

An optical module comprises: a sub-mount 1, having four photodiodes 12 and two guide grooves 10 disposed on an optical element mounting surface 16; a fiber fixing member 2, having four V-grooves 21, four concave mirrors 22, and two guide rails 20 disposed on an optical fiber fixing surface 26; and four optical fibers 3, fixed to the fiber fixing member 2. With this optical module, the sub-mount 1 and fiber fixing member 2 are aligned and fixed by the fitting together of the guide grooves 10 and guide rails 20. A passive alignment type optical module that enables mass production and cost reduction is thus realized.

Owner:HAMAMATSU PHOTONICS KK

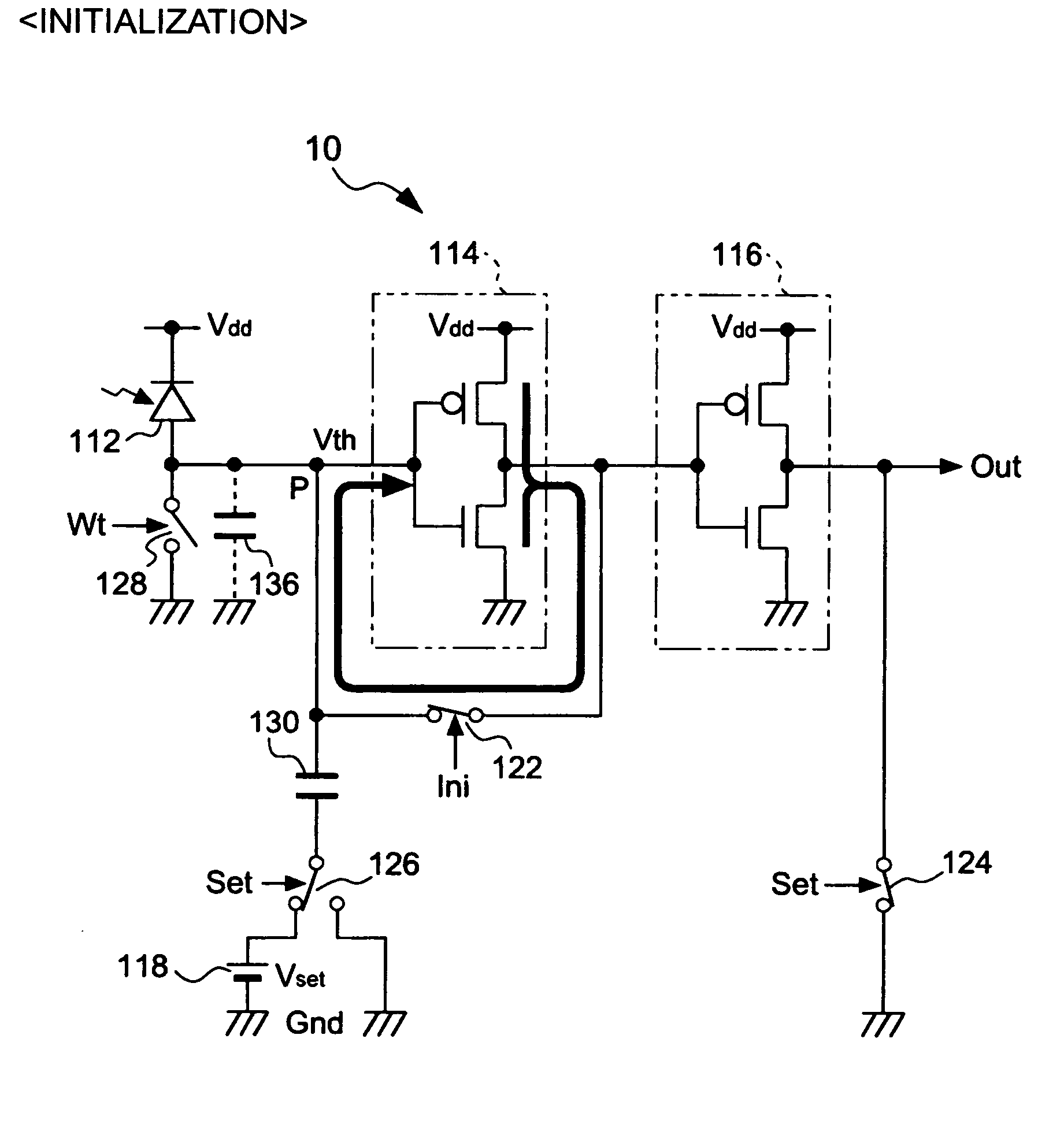

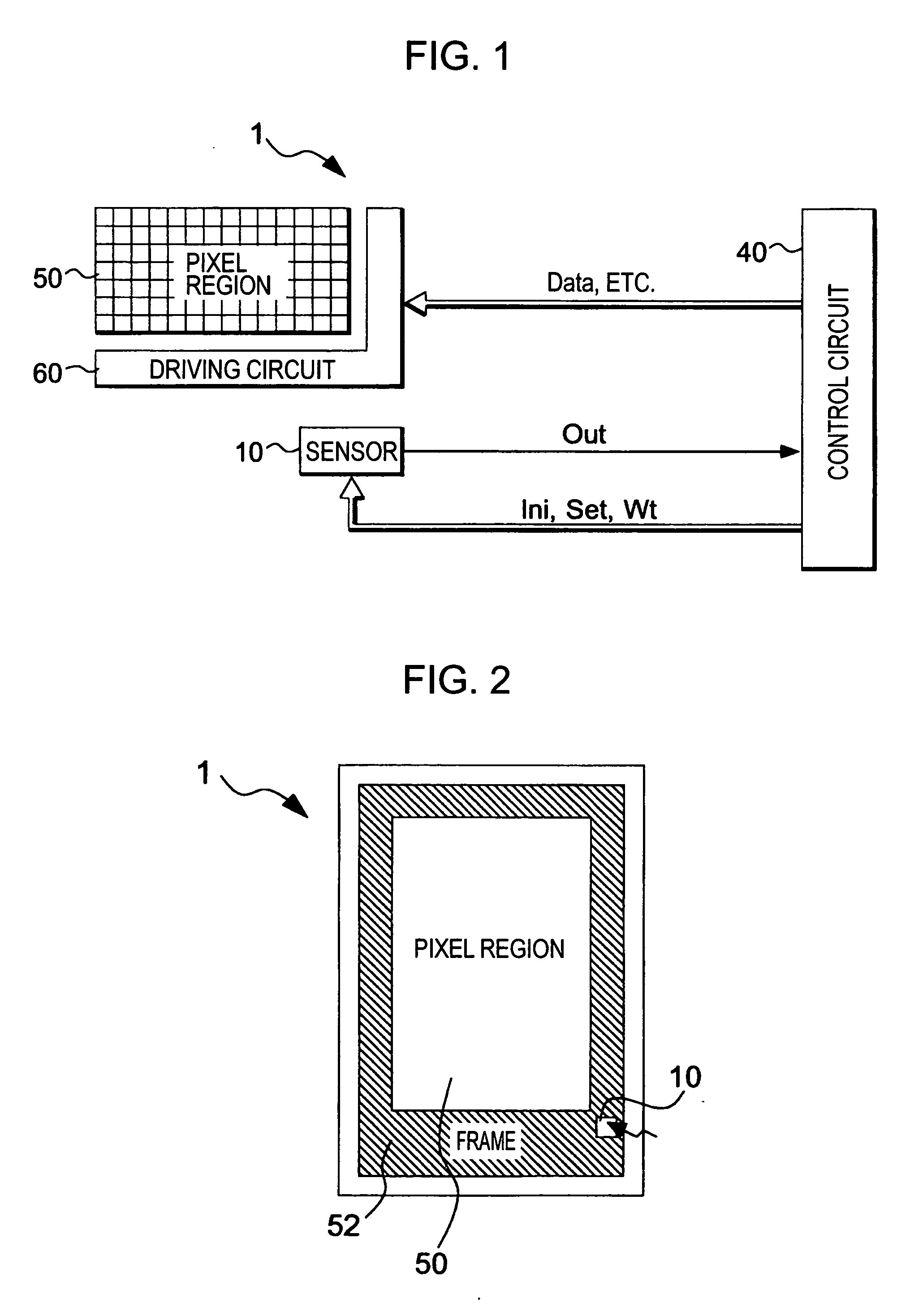

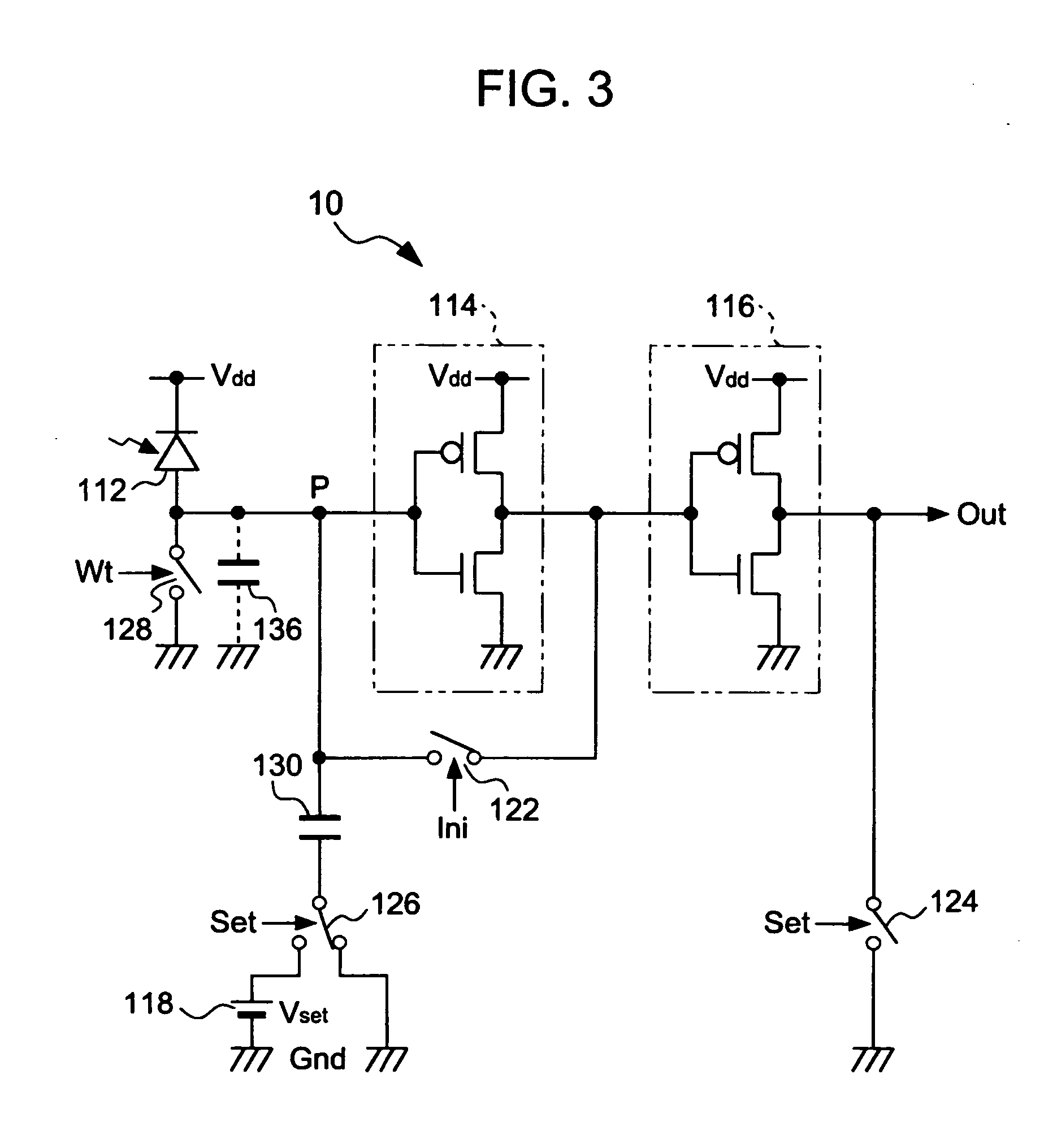

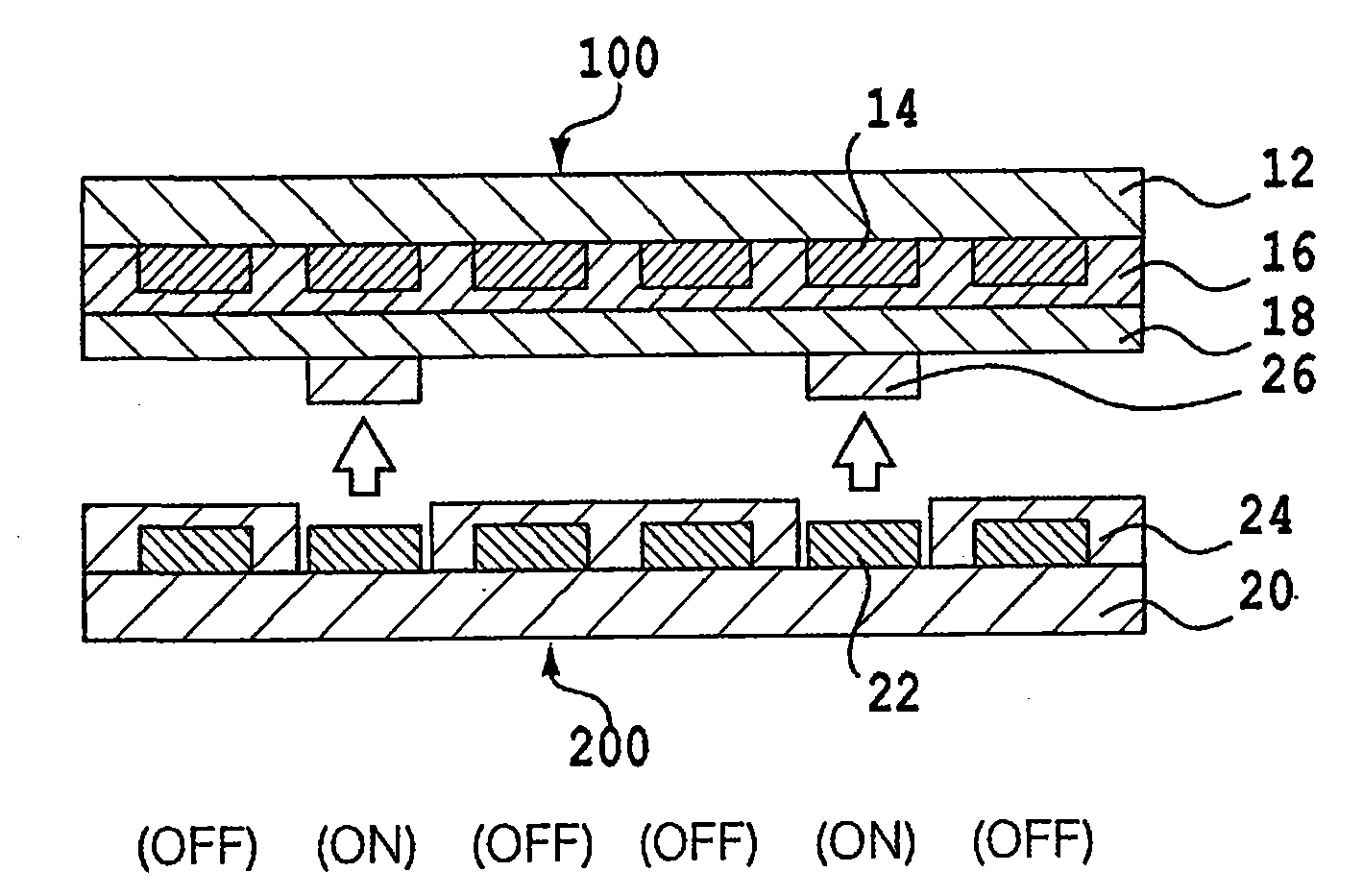

Optical sensor, output processing method of optical sensor, display device, and electronic apparatus

ActiveUS20050269486A1Easily formedWell formedPhotometry using reference valueStatic indicating devicesEngineeringVoltage

An optical sensor includes a light receiving element in which a current corresponding to the amount of received light flows between one end and the other end thereof, a comparator which compares a voltage at the one end of the light receiving element with a predetermined threshold voltage to output a logical signal based on the comparison result, an initialization circuit which initializes the voltage at the one end of the light receiving element to the threshold value or a voltage approximate to the threshold voltage before detecting the amount of the received light, and a voltage changing circuit which changes the voltage at the one end of the light receiving element by a predetermined voltage after completing the initialization. In the optical sensor, after changing the voltage by the voltage changing circuit, a period until the logical signal output from the comparator is logically inverted is expressed as a value corresponding to the amount of the received light.

Owner:138 EAST LCD ADVANCEMENTS LTD

Method for manufacturing patterned vapor-deposited film

InactiveUS20080226814A1Easily formedHigh resolutionFinal product manufactureVacuum evaporation coatingLaser scanningHeating element

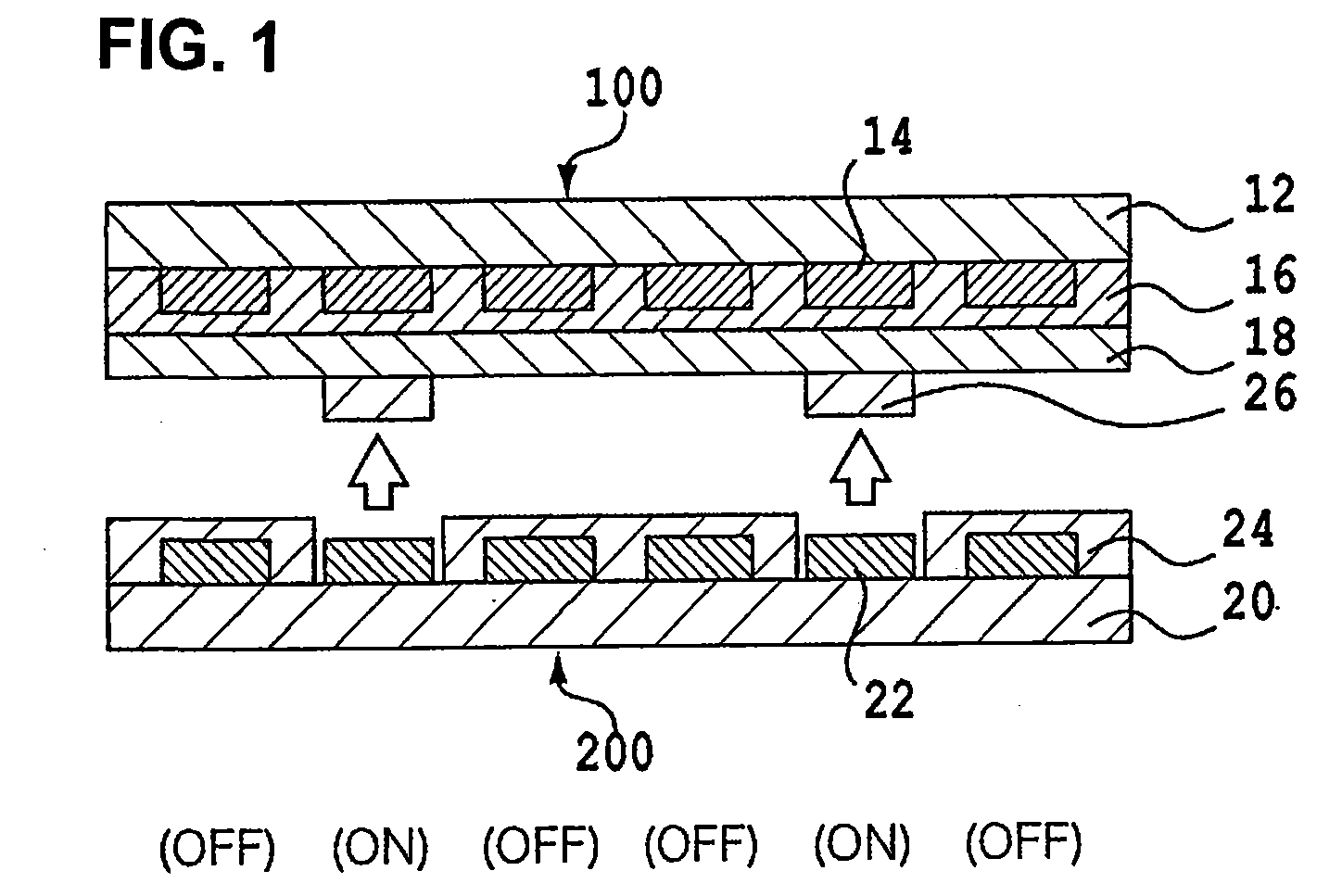

A method for manufacturing a vapor-deposited film having a high-resolution pattern, without using a metal mask that makes it difficult to realize high resolution or an expensive laser scanning device. A patterned vapor-deposited film is manufactured by a method including: preparing a deposition panel containing a substrate, a plurality of heating elements, and a deposition material layer formed on the plurality of heating elements, the deposition material layer forming the outermost surface; disposing the deposition panel and a device substrate so that the deposition material layer faces the device substrate; and causing at least some of the plurality of heating elements to generate heat, selectively evaporating the deposition material layer that is positioned on the heating elements that have generated heat, and vapor depositing on a surface of the device substrate to form a vapor-deposited film.

Owner:FUJI ELECTRIC HLDG CO LTD

Battery electrode production method

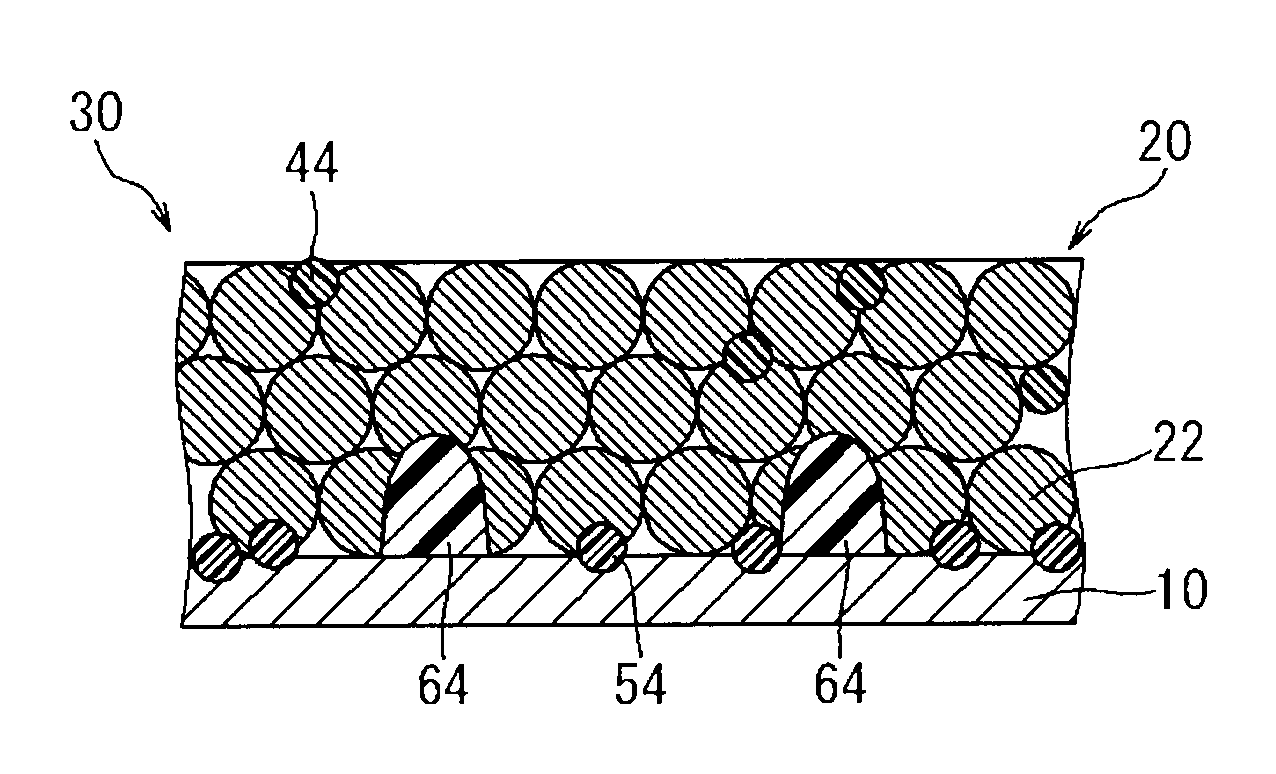

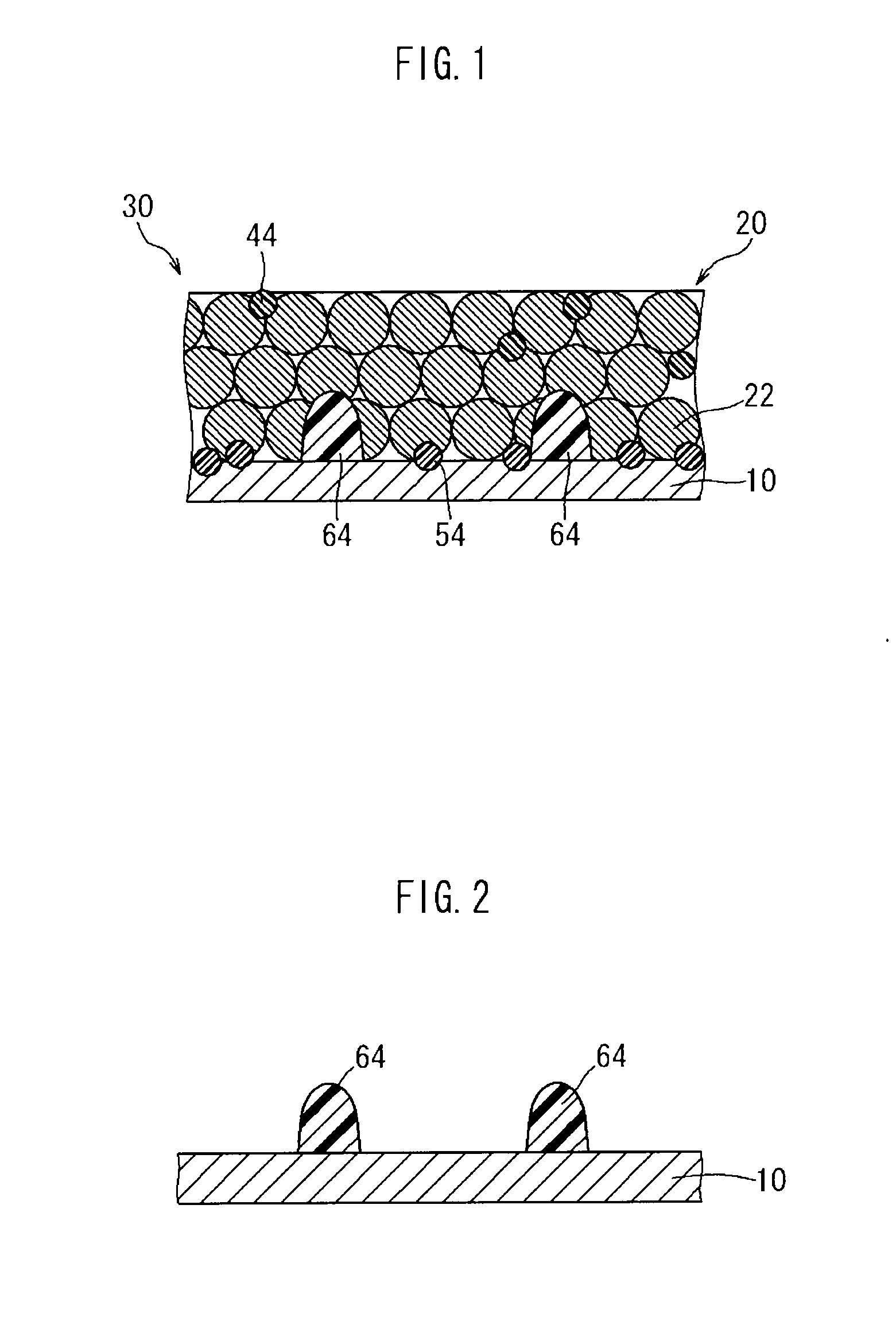

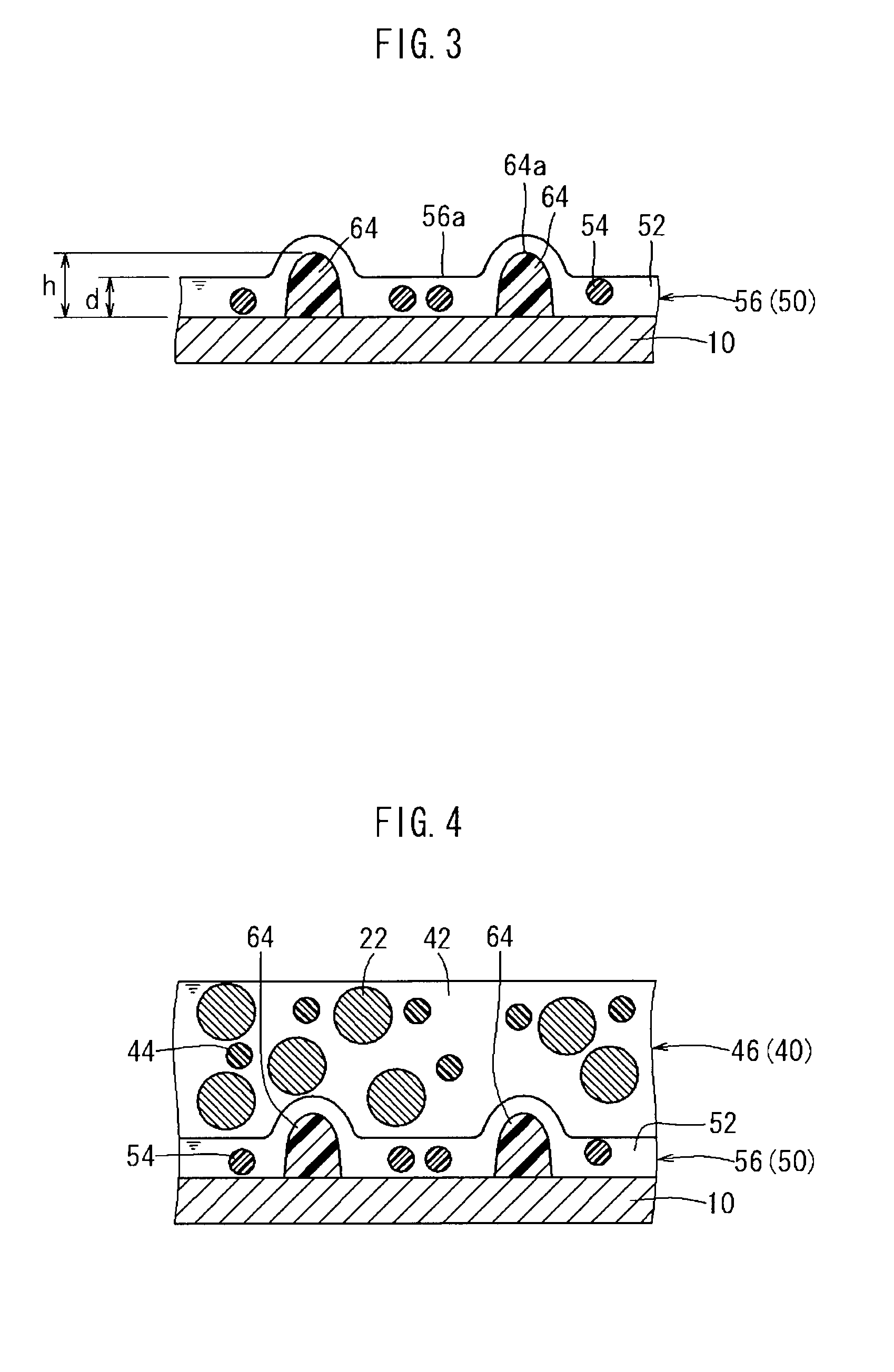

ActiveUS20130022864A1Easily formedEfficiently formedFinal product manufactureFilling tube/pocket electrodesCurrent collectorPolymer chemistry

The present invention provides a method for producing a battery electrode having a configuration in which a compound material layer containing an active material 22 and a binder 54 is retained on a current collector 10. This method includes a step of forming protrusions 64 composed of a polymer on a surface of the current collector 10, a step of forming a binder solution layer 56 by coating a binder solution 50 containing the binder 54 over the polymer protrusions 64 onto the current collector 10, a step of depositing the binder solution layer 56 and a compound material paste layer 46 on the current collector 10 by applying a compound material paste 40 containing the active material 22 over the binder solution layer 56, and a step of obtaining an electrode in which the compound material layer is formed on the current collector 10 by drying both the deposited binder solution layer 56 and compound material paste layer 46.

Owner:TOYOTA JIDOSHA KK

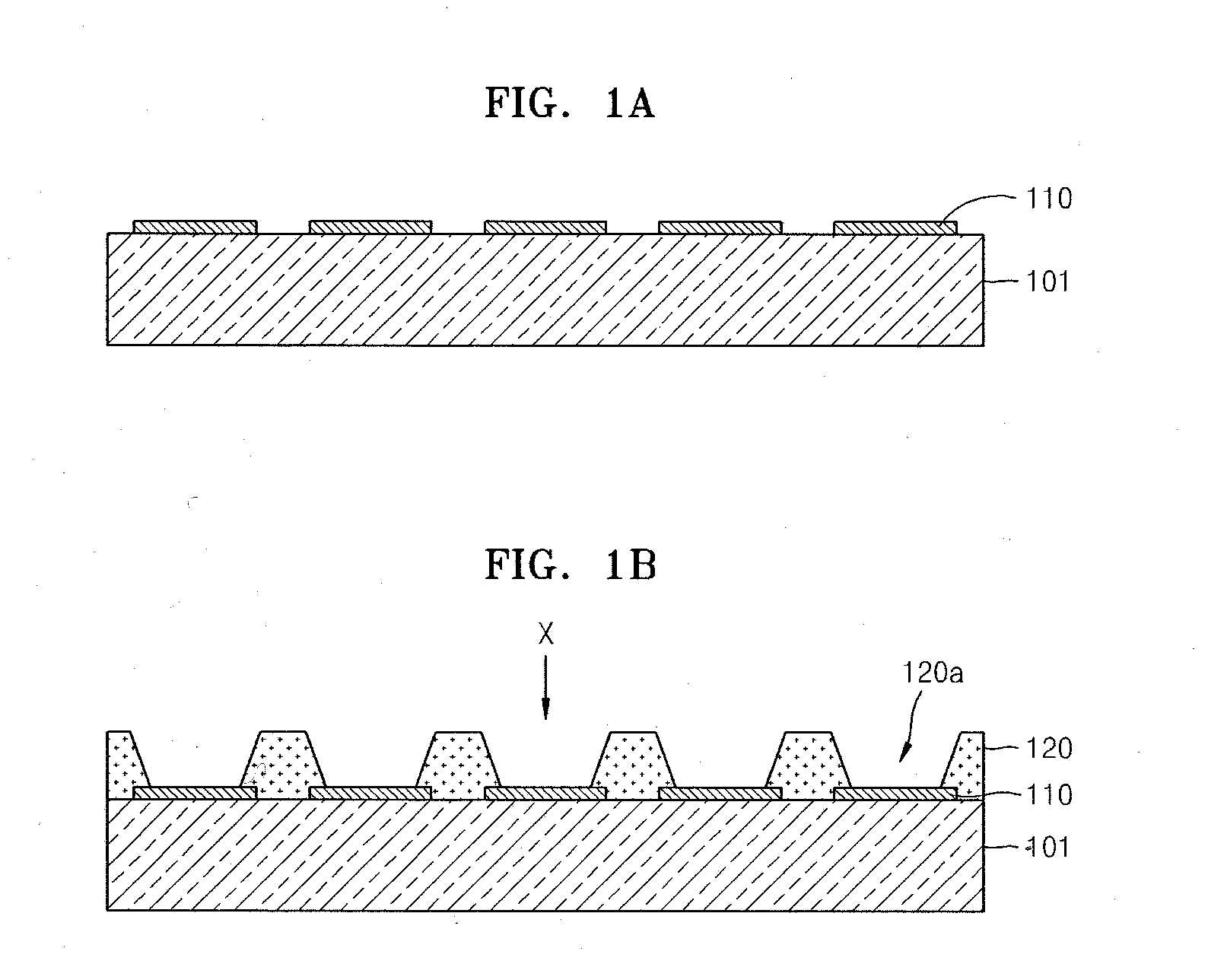

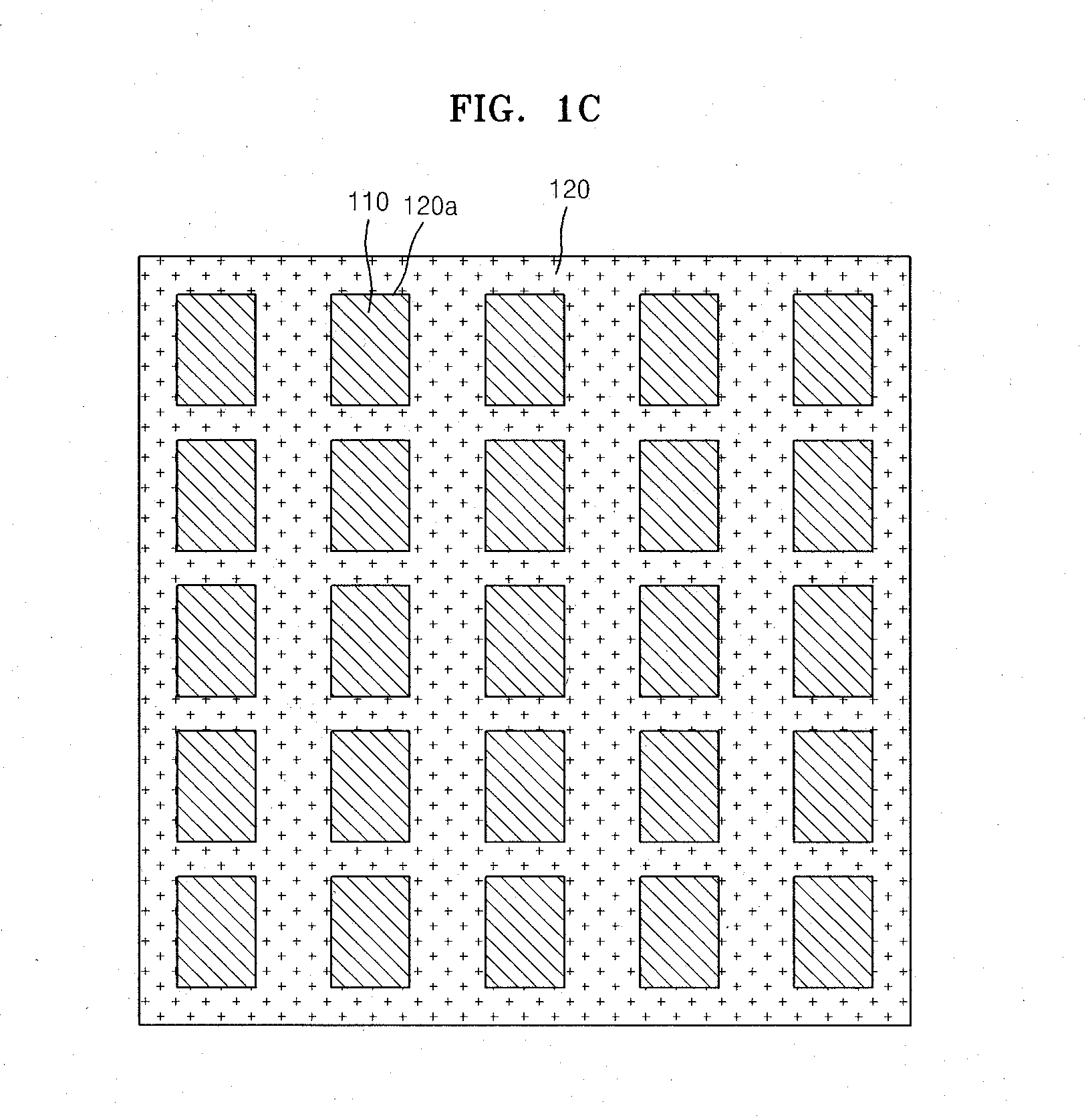

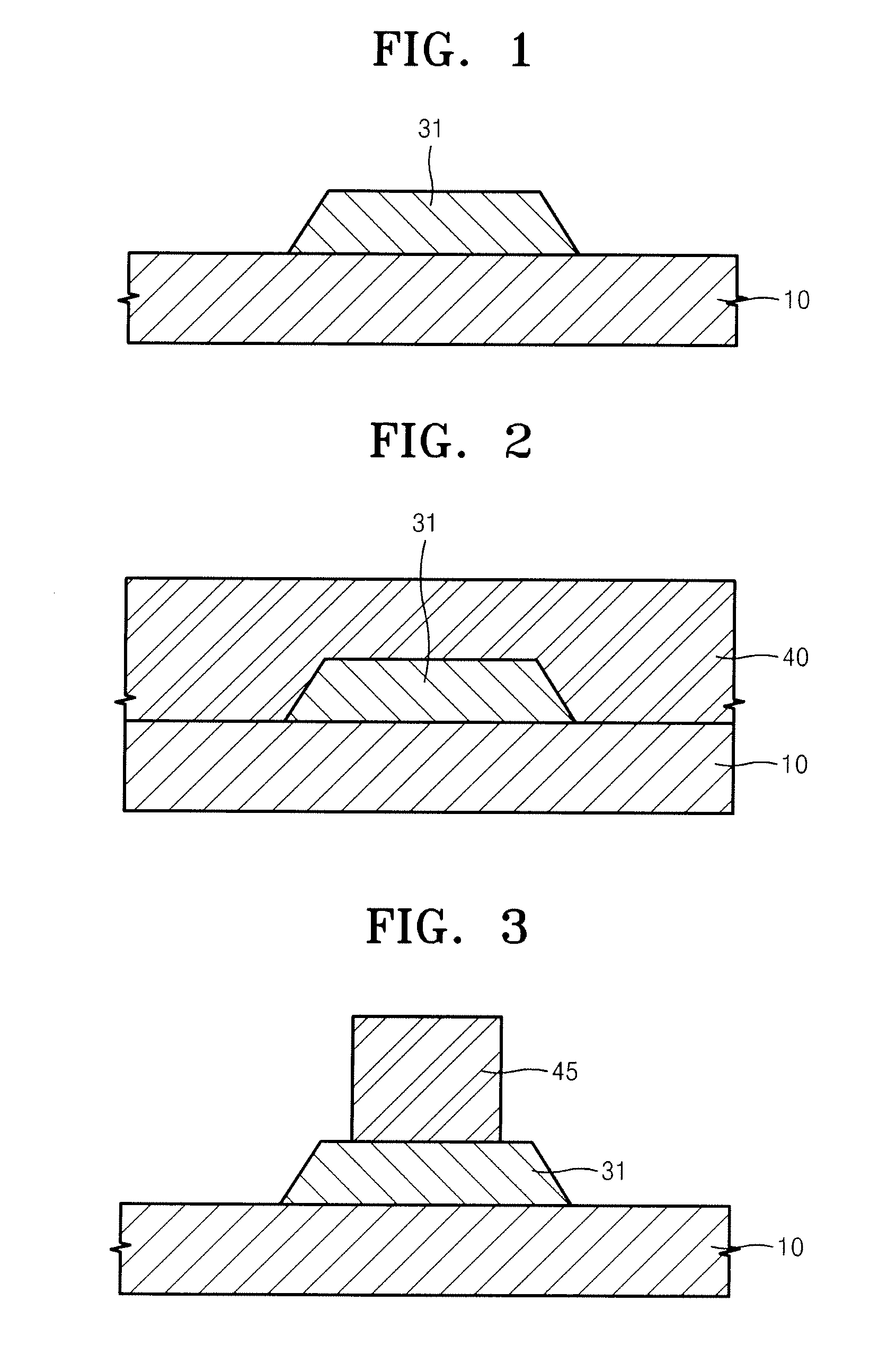

Method of manufacturing organic light emitting device

ActiveUS20100029028A1Easily formedWell formedSolid-state devicesSemiconductor/solid-state device manufacturingBlock layerPhotoresist

A method of manufacturing an organic light emitting device by which a pixel defining layer can be easily formed. The method includes: forming a first electrode on a substrate; forming a photoresist layer to cover the first electrode; patterning the photoresist layer and forming a blocking layer so that the blocking layer is on a side of the first electrode opposite to a side facing the substrate; forming a pixel defining layer on the substrate to cover side ends of the first electrode; removing the blocking layer and exposing the side of the first electrode contacting the blocking layer; forming an intermediate layer including an organic light emitting layer on the side of the first electrode that is exposed by removing the blocking layer; and forming a second electrode on the intermediate layer.

Owner:SAMSUNG DISPLAY CO LTD

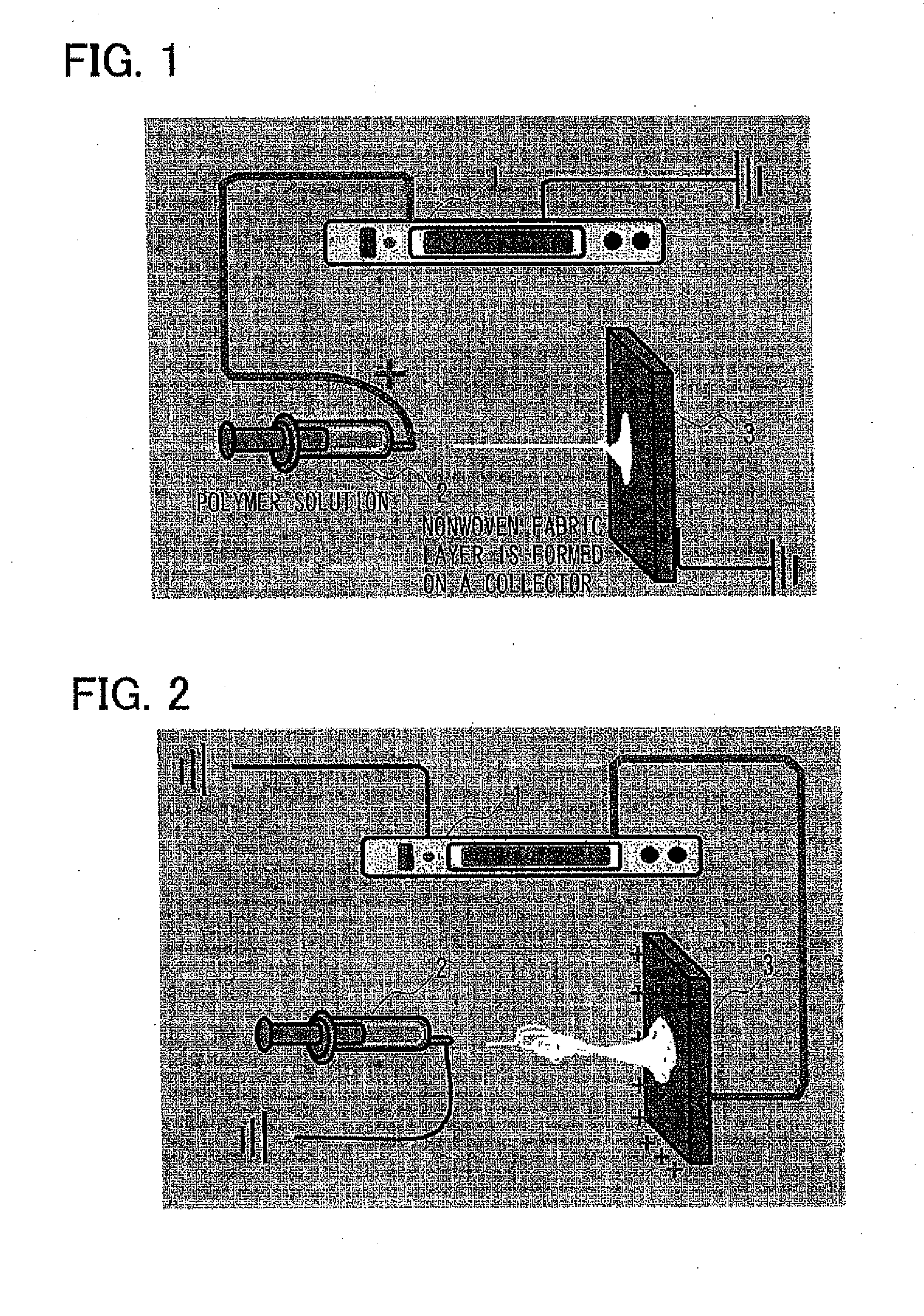

Fiber wadding for filling bone defects

ActiveUS20120136090A1Uniform dispersionEasily formedImpression capsSurgical adhesivesSiloxaneWadding

A fiber wadding for filling bone defects having a flocculent three-dimensional structure is disclosed. The fiber wadding includes a plurality of fibers that contain a biodegradable resin as a principal component and a siloxane. Outside diameter of the plurality of fibers of the wadding is from about 0.05 μm to about 30 μm. Bulk density of the fiber wadding is about 0.005-0.3 g / cm3.

Owner:NAGOYA INSTITUTE OF TECHNOLOGY +1

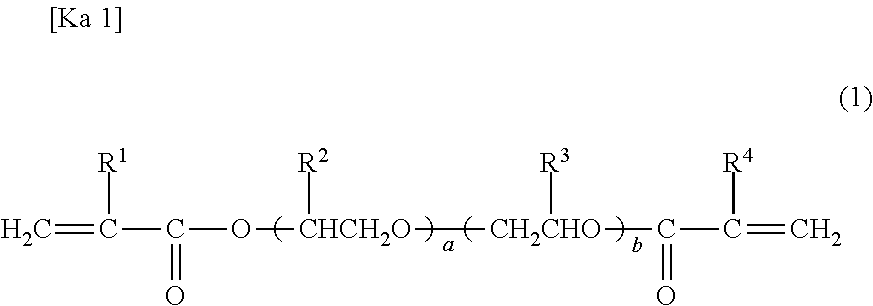

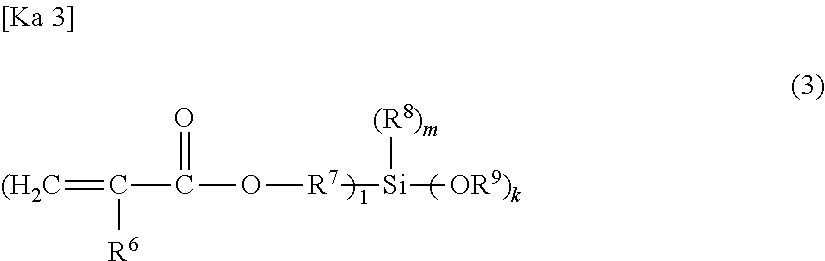

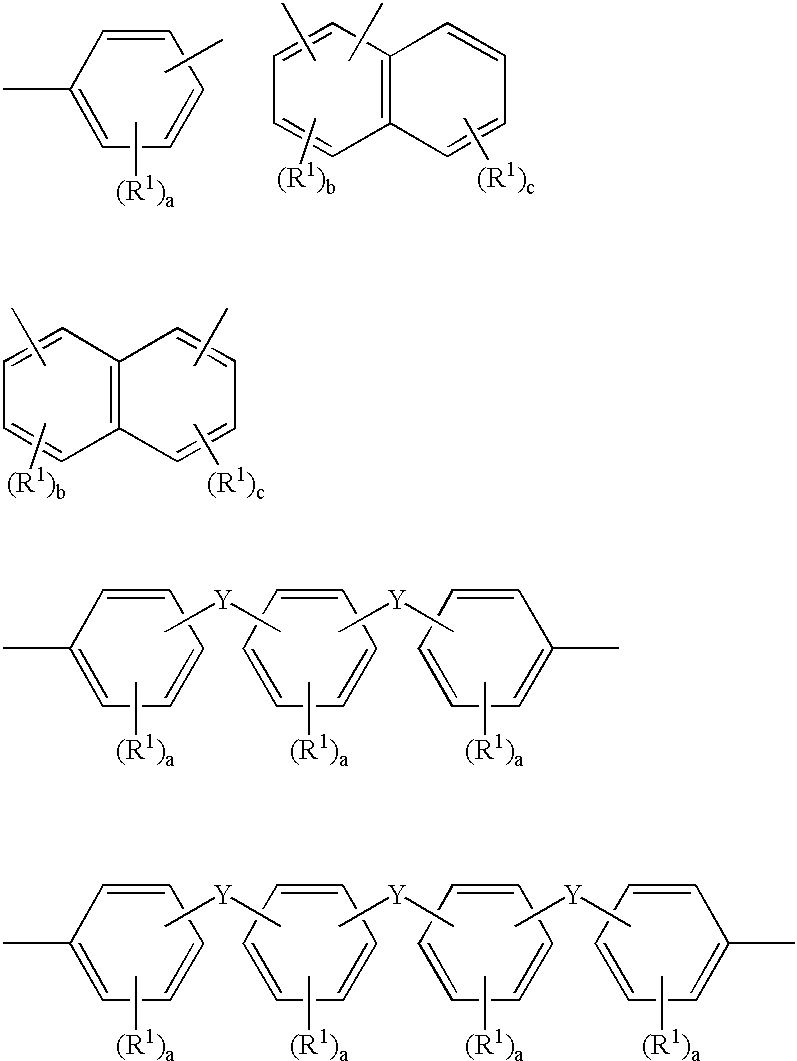

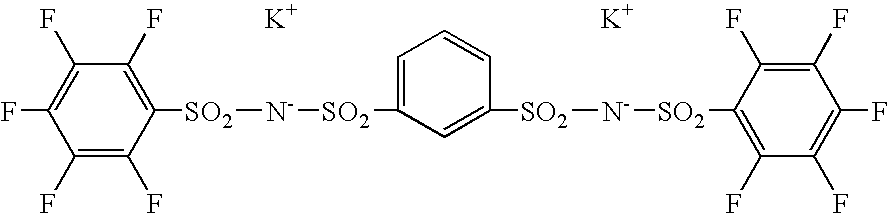

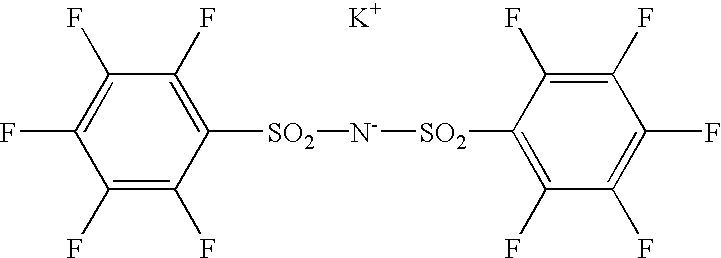

Polymer electrolyte and process for producing the same

InactiveUS6939646B2Excellent thermal resistanceEasily formedOrganic chemistryIon-exchanger regenerationSolventStructural unit

A polymer electrolyte having, in a main chain, a structural unit represented by the following formula (1):—[Ar1—(SO2—N−(X+)—SO2—Ar2)m—SO2—N−(X+)—SO2—Ar1—O]— (1)wherein Ar1 and Ar2 independently represent a divalent aromatic groups, m represents an integer of 0 to 3, and X+ represents an ion selected from hydrogen ion, an alkali metal ion and ammonium ion, which is excellent in proton conductivity, thermal resistance and strength. The polymer electrolyte is soluble in solvents and has excellent film forming property and recycling efficiency.

Owner:SUMITOMO CHEM CO LTD

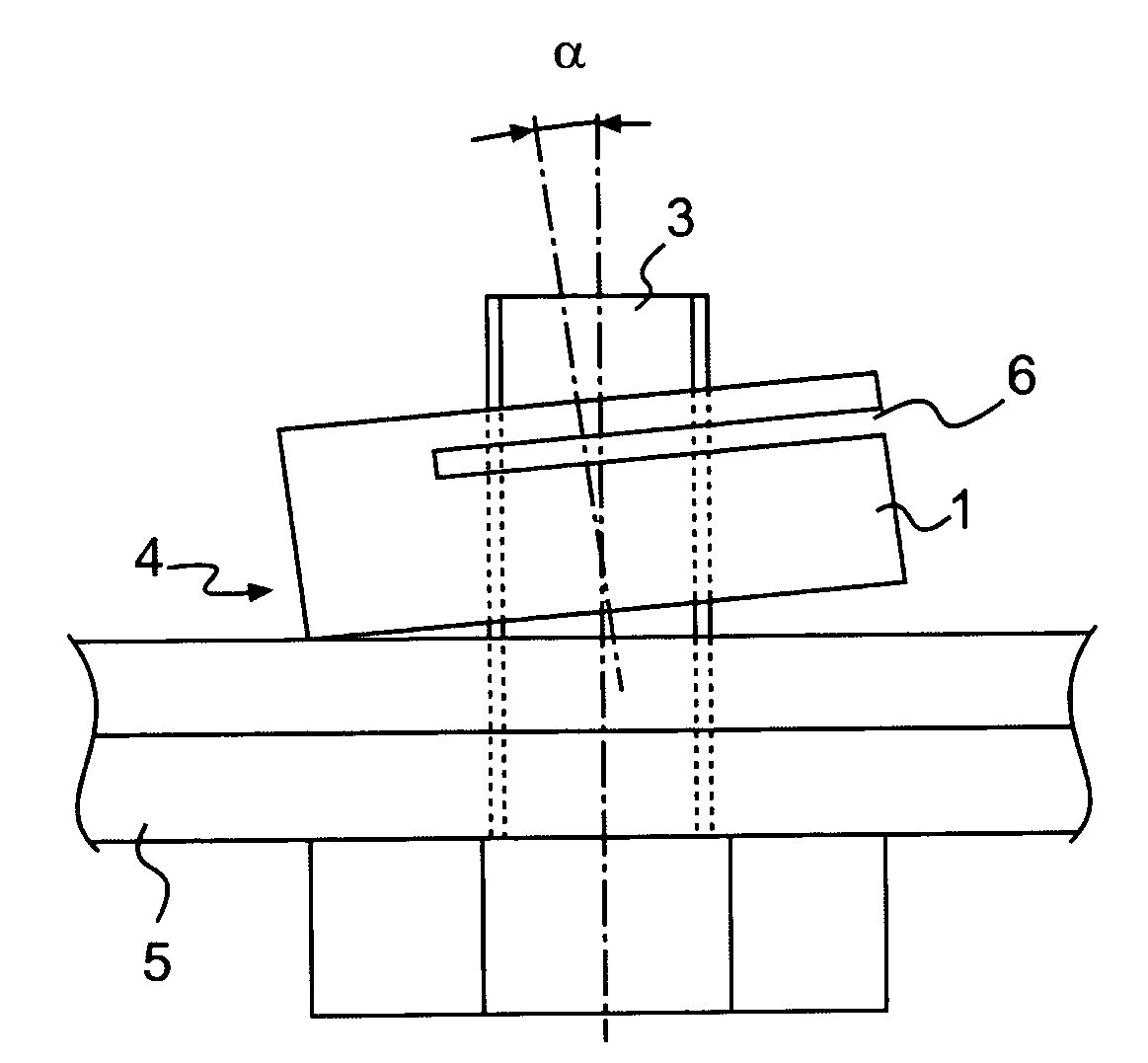

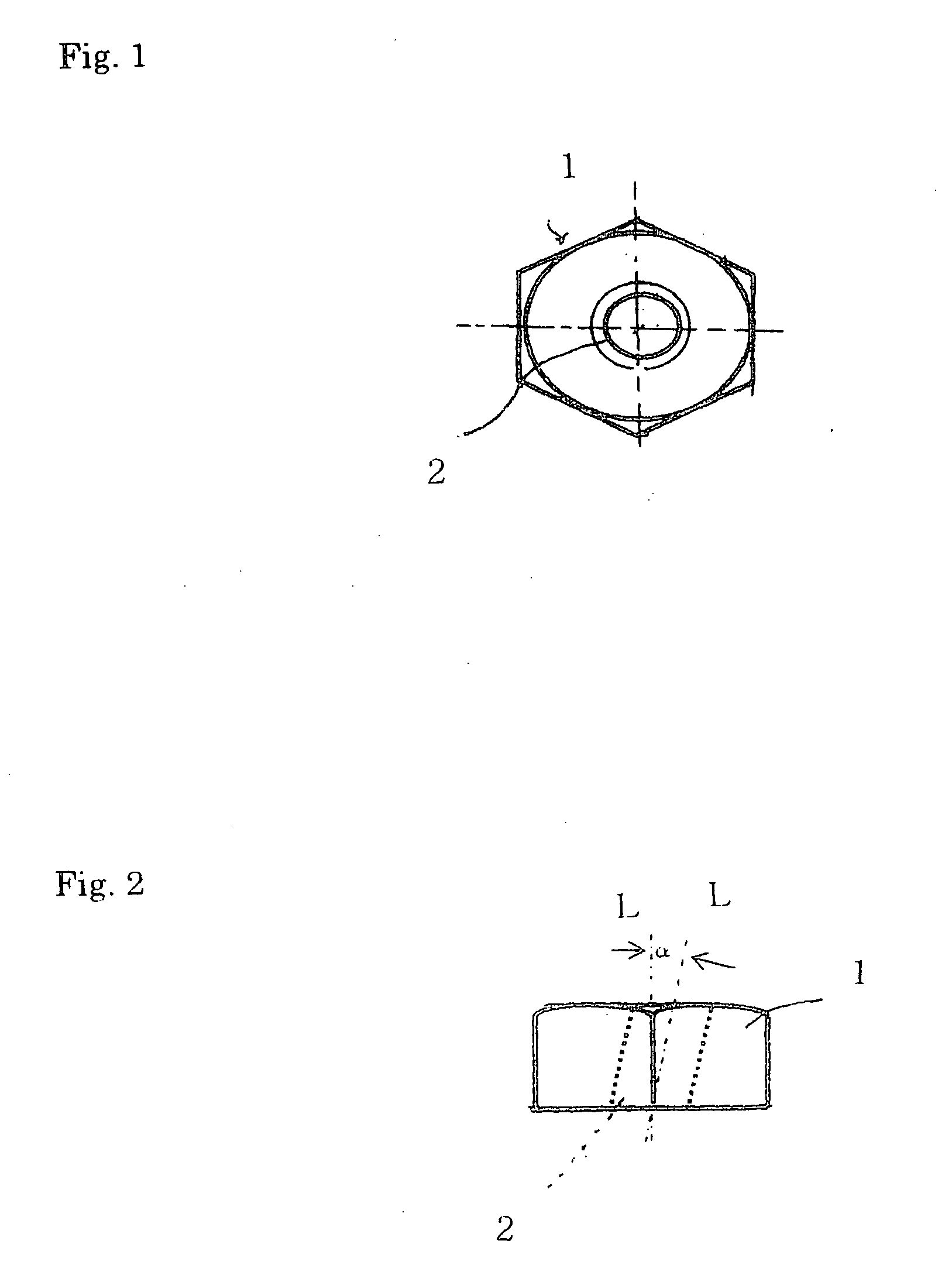

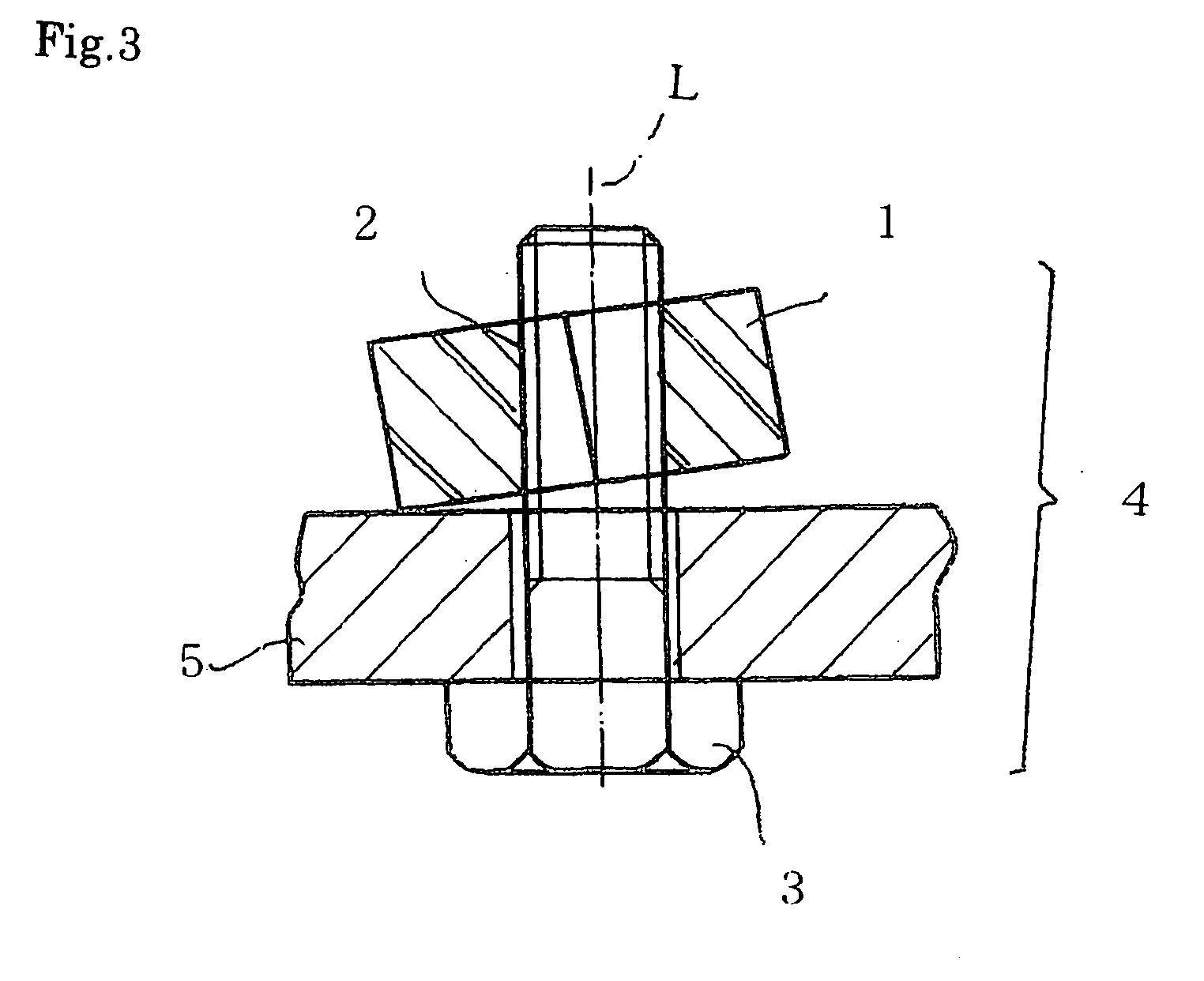

Method of a fastening a bolt and a nut and their fastening structure

A bolt and nut fastening structure and method include a nut and a bolt screwed onto the nut, an inner screw of the nut being provided to be inclined at a required angle against a central axis line of the nut, and the method of fastening the same. In an initial stage of fastening the bolt and the nut, axial force in the bolt is generated when a part of a bearing surface of the inner screw of the nut seats on a part of a screw of the bolt due to rotation of the nut. Then the axial force is also enlarged proportionally to an increase in rotation angle of the nut to enlarge the seating area.

Owner:ECO WORLD

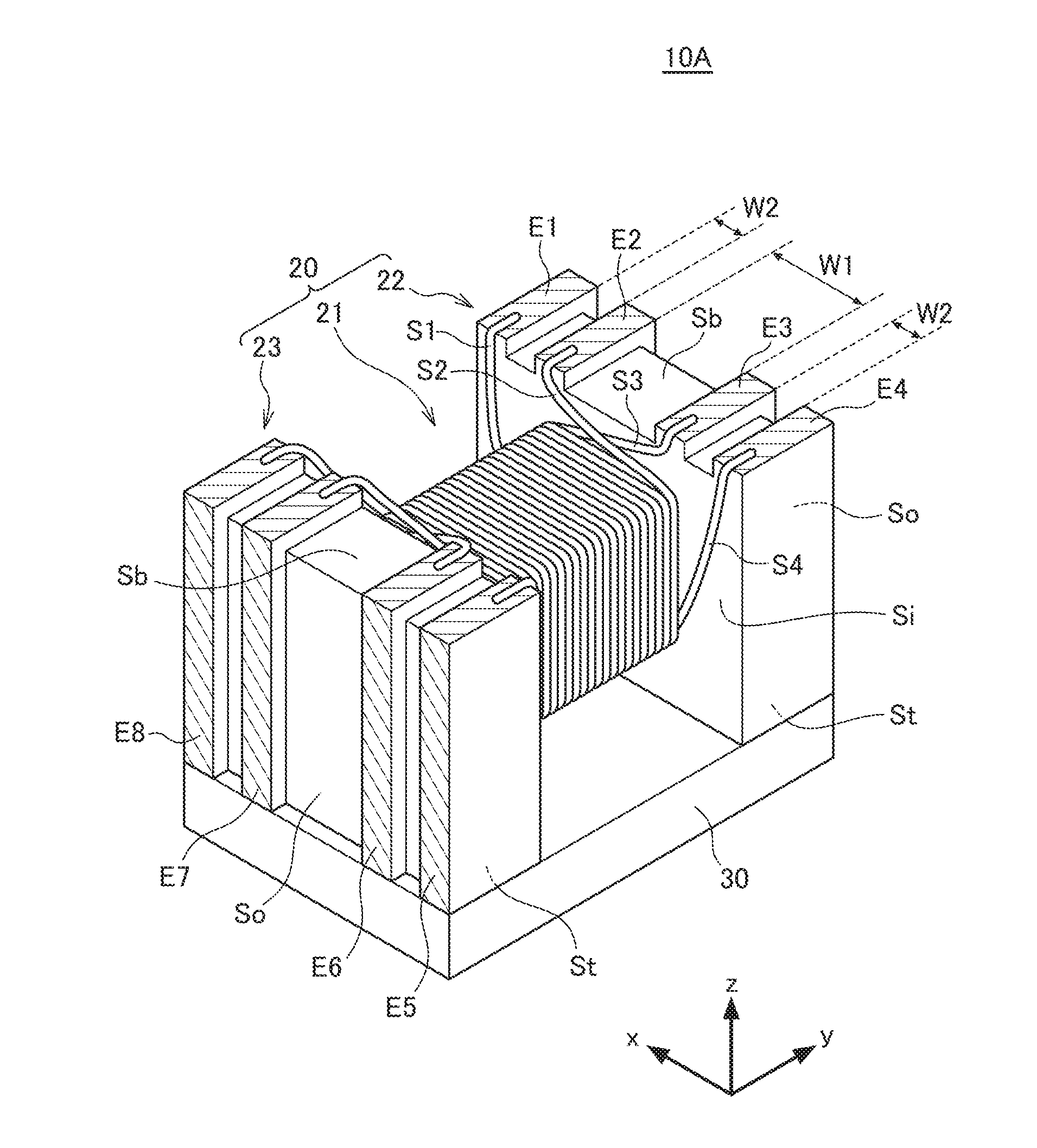

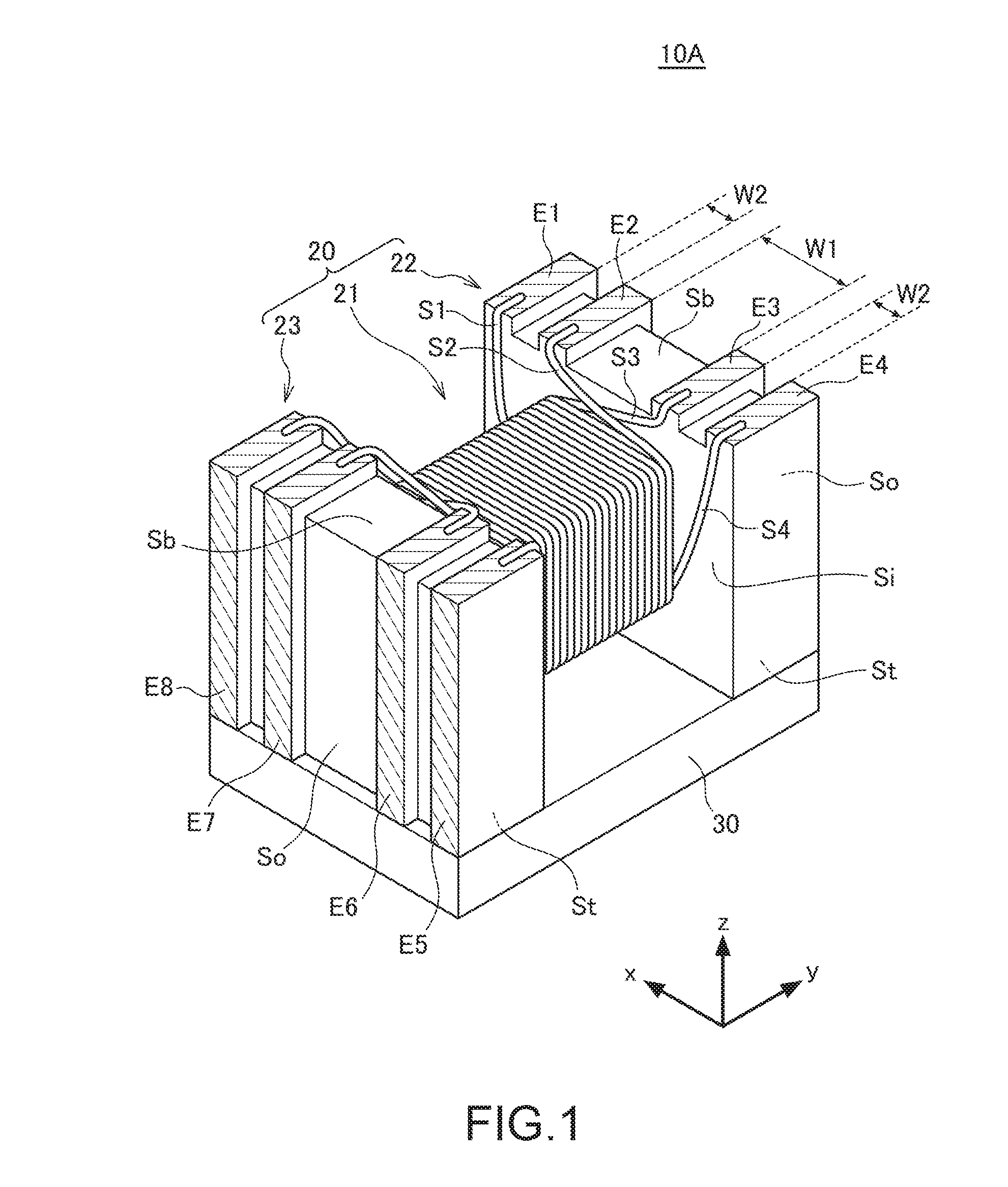

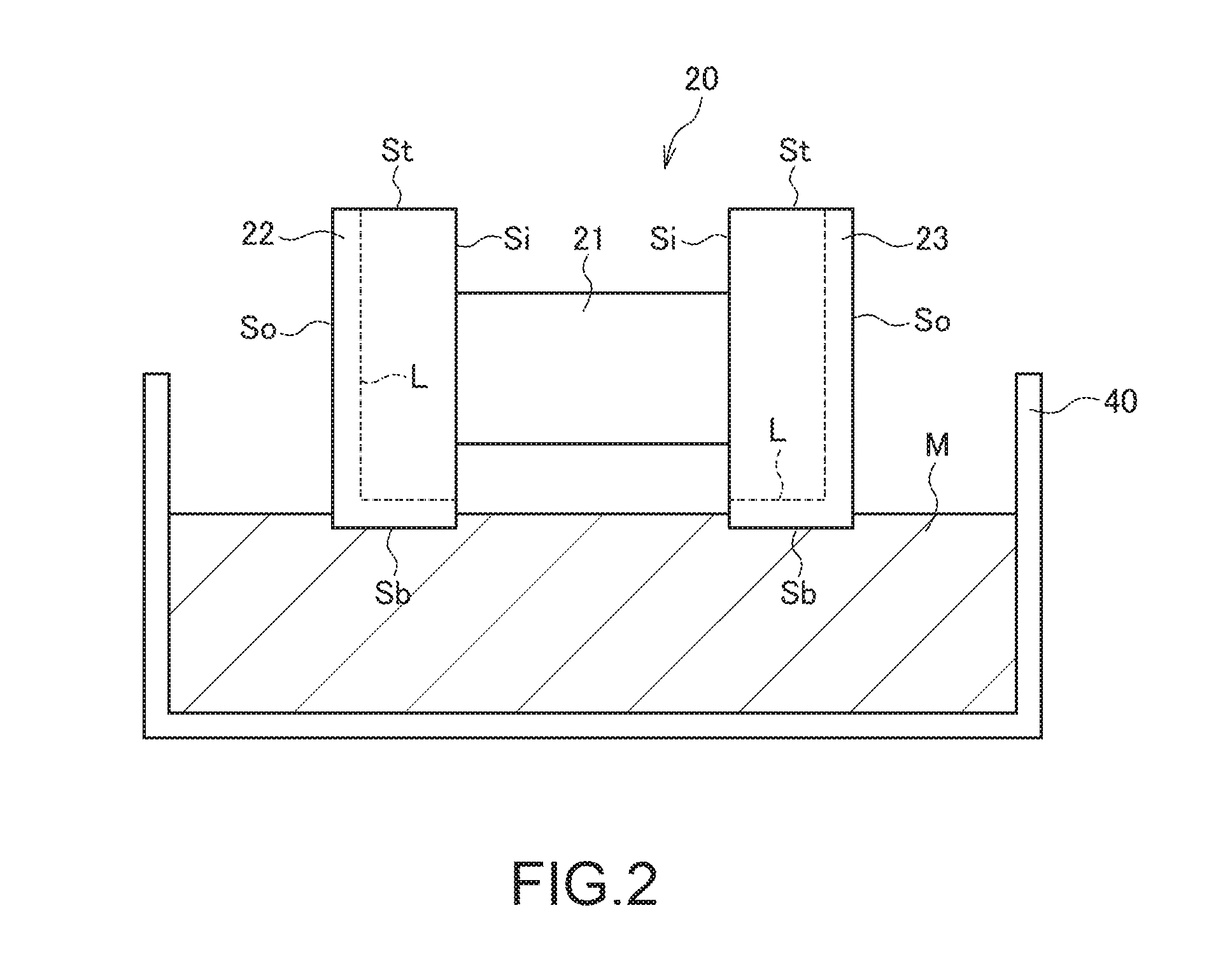

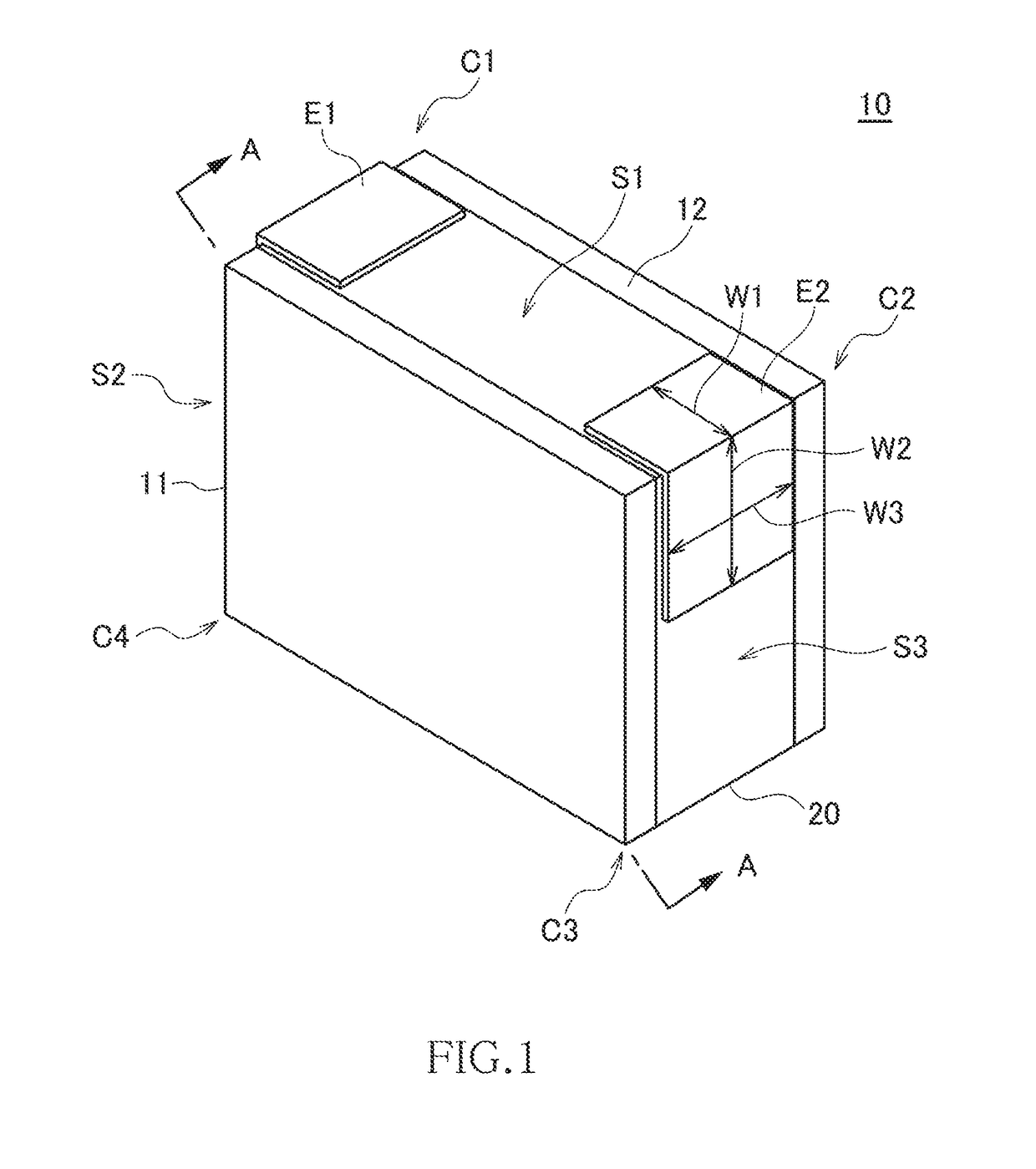

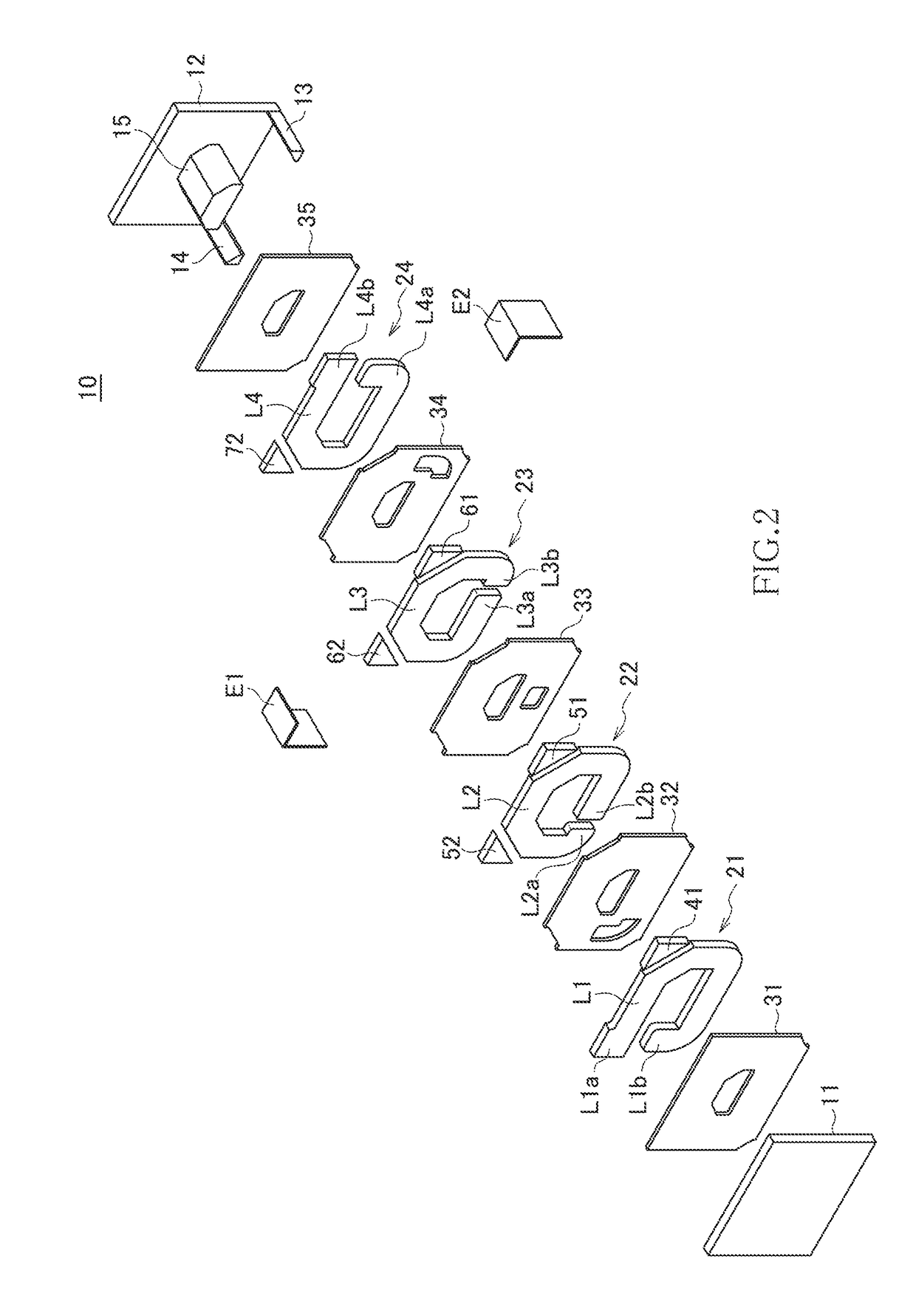

Coil component and manufacturing method thereof

ActiveUS20170011843A1Easily formedAvoid contactTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureElectrical and Electronics engineeringFlange

Disclosed herein is a coil component that includes a drum core including a pair of flange portions and a winding core portion positioned between the flange portions, a plurality of terminal electrodes formed on the flange portions, and a plurality of wires wound around the winding core portion, each end of the wires being electrically connected to an associated one of the terminal electrodes. Each of the flange portions has an inner side surface connected to the winding core portion and an outer side surface opposite to the inner side surface, the outer side surface has a plurality of ridges and at least one groove, and the terminal electrodes are formed on at least the ridges of the outer side surfaces such that the terminal electrodes are isolated from each other by the groove.

Owner:TDK CORPARATION

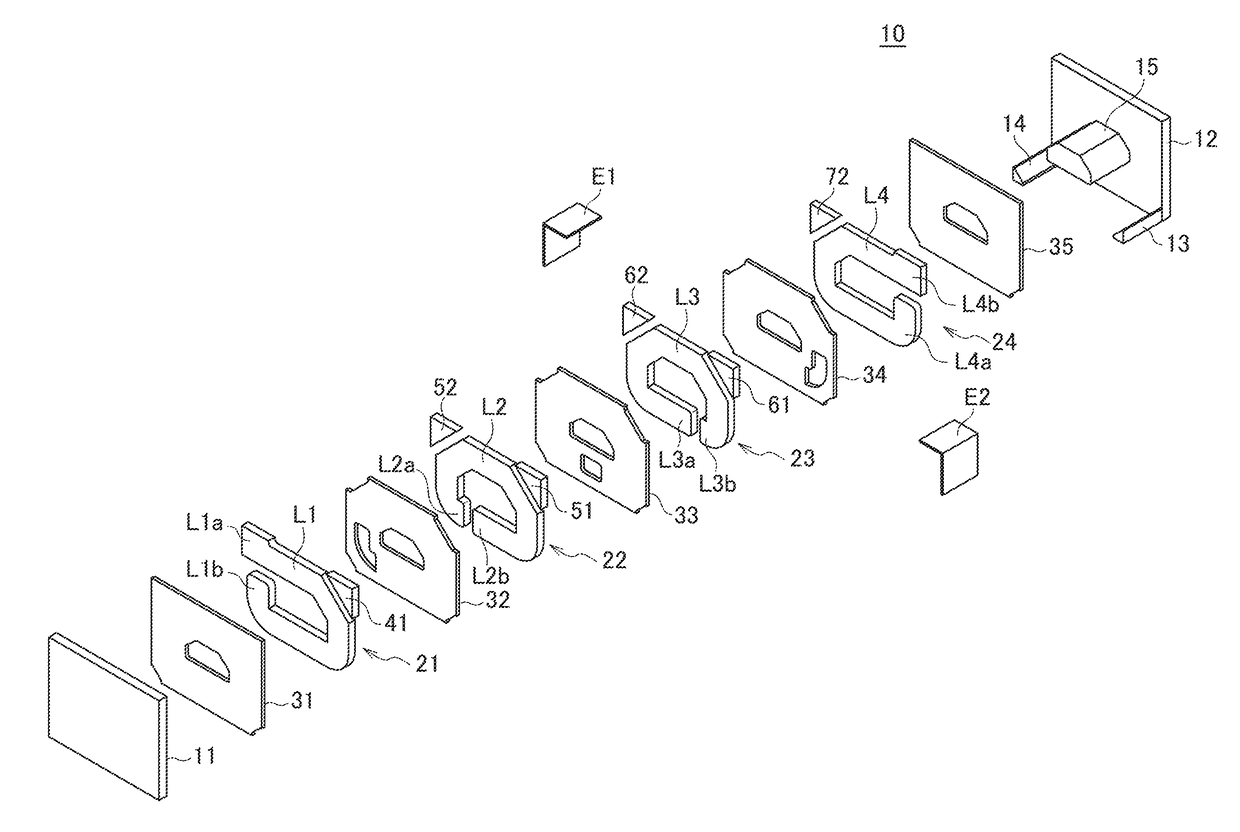

Coil component, manufacturing method thereof, and circuit board on which coil component are mounted

ActiveUS20170110234A1Easily formedReduce magnetic resistanceFinal product manufacturePrinted circuit aspectsElectrical conductorNon magnetic

Disclosed herein is a coil component that includes first and second magnetic members; a coil layer arranged between the first and second magnetic members, the coil layer including a plurality of conductor layers and a plurality of non-magnetic insulating layers, the conductor layers and the non-magnetic insulating layers being alternately laminated, the conductor layers being connected to each other via through holes formed in the non-magnetic insulating layers to form a coil pattern; a first external terminal covering one end of the coil pattern exposed to at least one of side surfaces of the coil layer without covering the first and second magnetic members; and a second external terminal covering other end of the coil pattern exposed to at least one of the side surfaces of the coil layer without covering the first and second magnetic members.

Owner:TDK CORPARATION

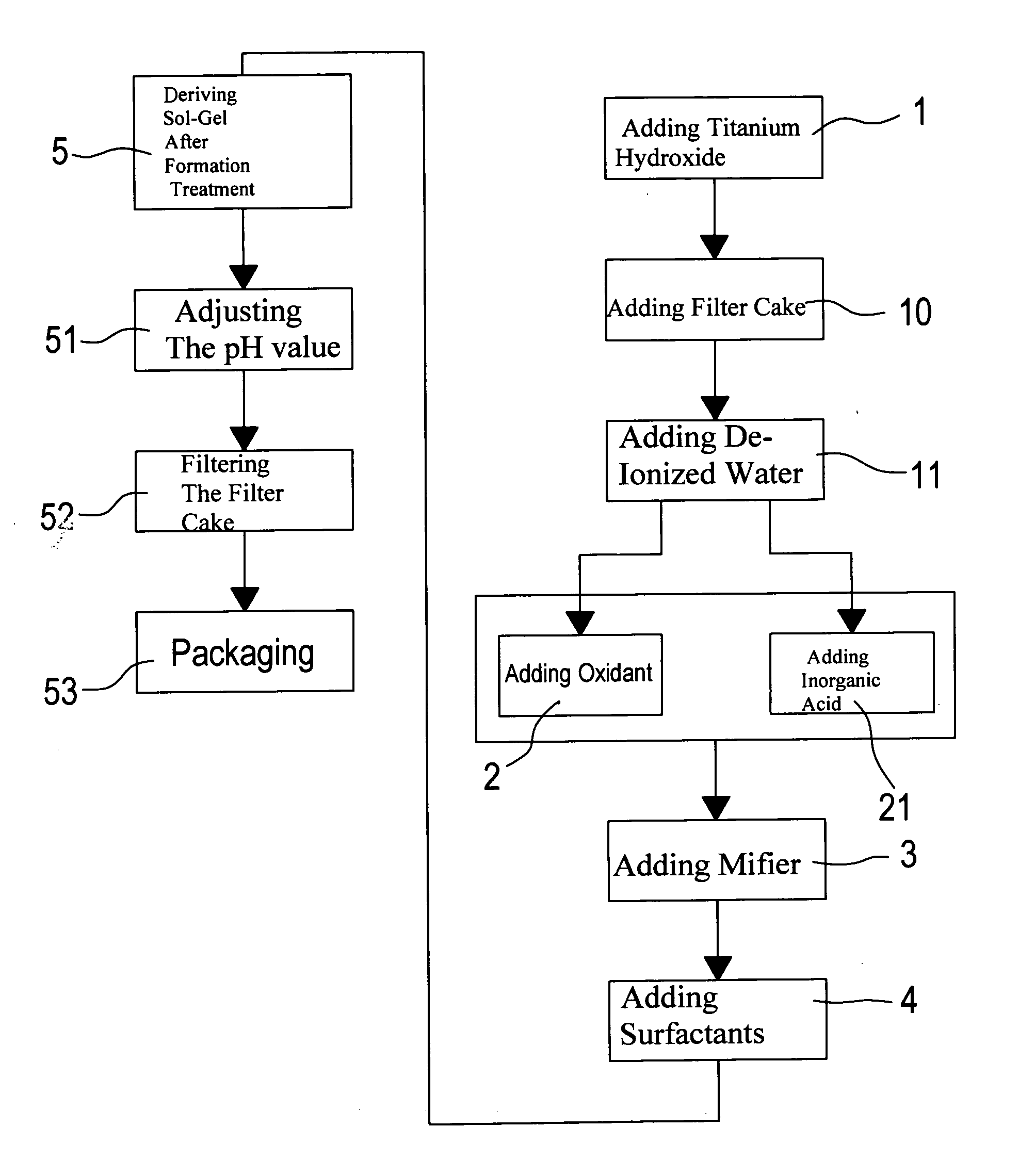

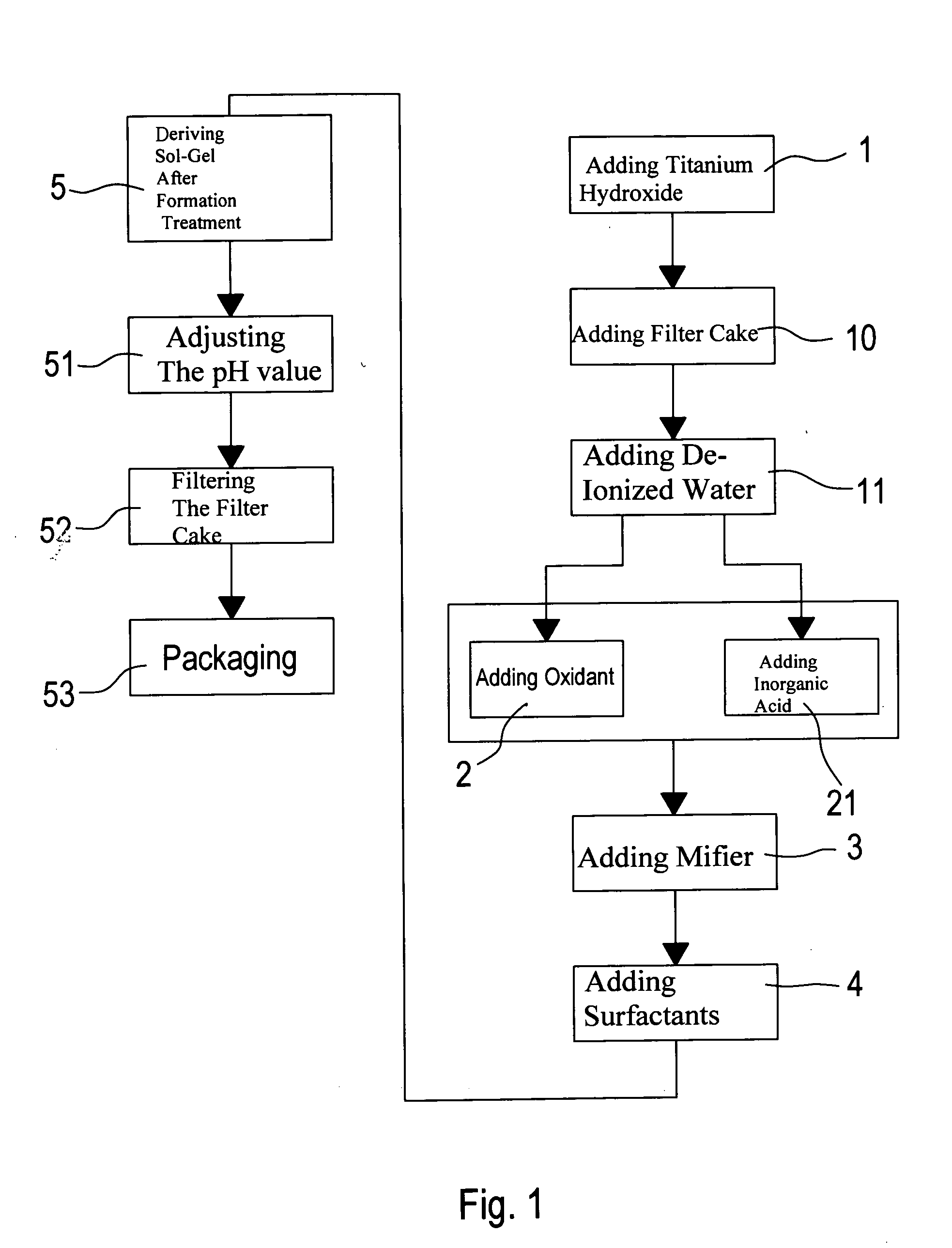

Method for synthesizing high adsorptive nanometer scale titanium dioxide solution

InactiveUS20050265917A1Highly adsorptiveEasily formedPigmenting treatmentMaterial nanotechnologyIonTitanium tetrachloride

A method for synthesizing high adsorptive nanometer scale titanium dioxide solution is disclosed. Titanium tetrachloride or titanium oxysulfate is dissolved and diluted in acid liquid and then ammonia water is used to change the pH value of the solution to be between 7 and 9 so as to generate titanium hydroxide. After washing or filtering, a form-transfer process is executed in predetermined condition. Clean titanic acid is agitated in de-ionized water and thus the titanic acid is uniformly mixed with de-ionized water; and then predetermined oxidant or inorganic acid, and modifier are added. Then a formation process is executed in a predetermined temperature and time so as to get a titanium dioxide sol-gel which can be applied to a surface of an object to be treated so as to form with film with preferred adsorption.

Owner:LIU WEN CHUAN

Method of manufacturing nozzle plate and method of manufacturing liquid ejection head

InactiveUS20080217290A1Easily formedHighly accurate lyophobic filmRecording apparatusDecorative surface effectsLiquid jetCounterbore

The method of manufacturing a nozzle plate includes: a lyophobic film forming step of preparing a nozzle plate having a recess-shaped counterbore section and a nozzle opened in a bottom surface of the counterbore section, and forming a lyophobic film on a surface of the nozzle plate including the bottom surface of the counterbore section of the nozzle plate and at least a portion of an inner wall of the nozzle; an abutting step of preparing a protective plate having a projecting section, and abutting a top surface of the projecting section of the protective plate against the bottom surface of the counterbore section of the nozzle plate in such a manner that the top surface of the projecting section of the protective plate makes tight contact with an opening edge of the nozzle on a liquid ejection side of the nozzle plate; a lyophobic film removing step of removing the lyophobic film from the inner wall of the nozzle of the nozzle plate by etching the nozzle plate from a liquid supply side which is opposite to a side of the nozzle plate that is abutted against the protective plate; and a separating step of separating the protective plate from the nozzle plate.

Owner:FUJIFILM CORP

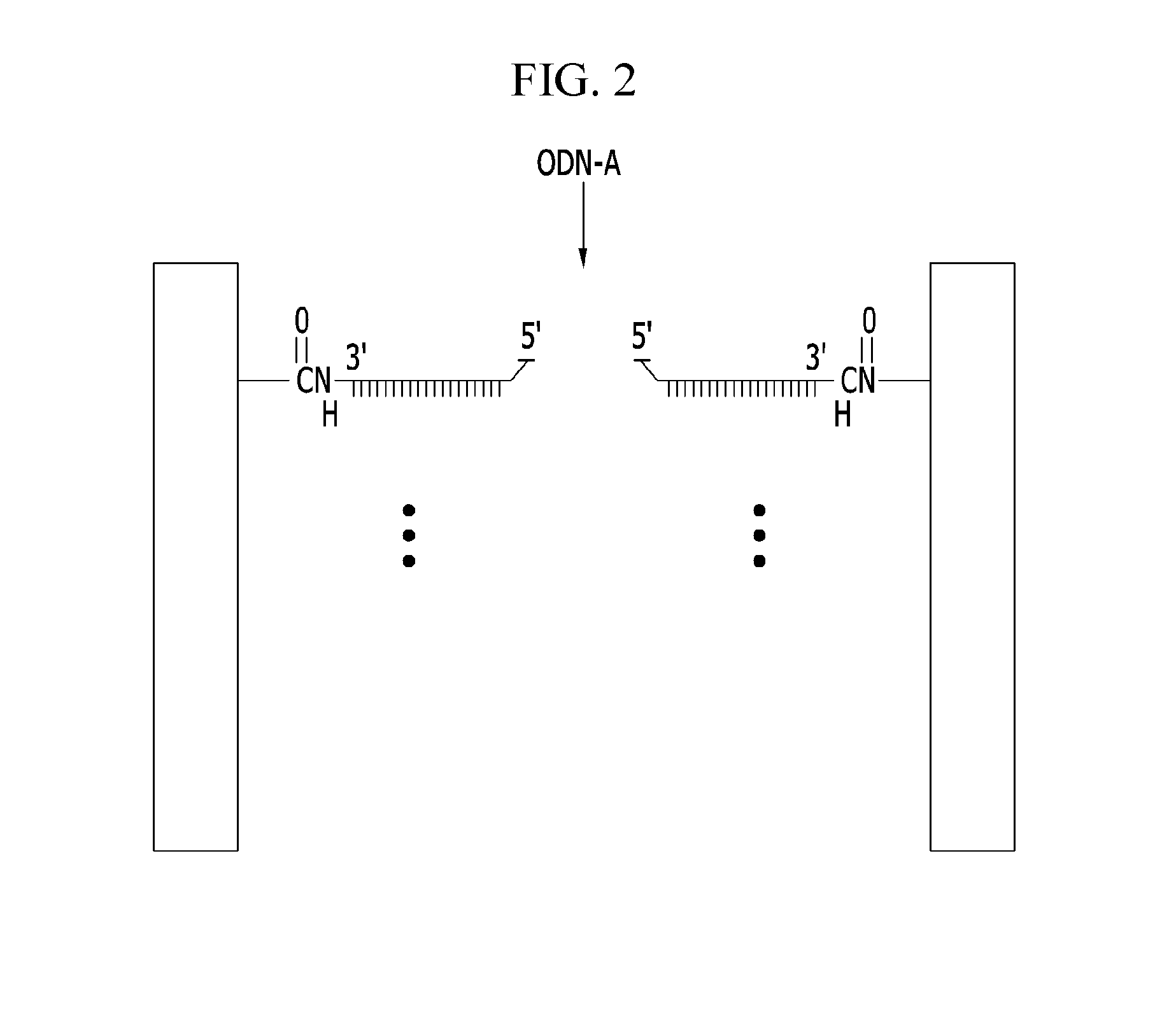

Membrane and method of fabricating the same

InactiveUS20130040127A1Easily formedThickness of membrane is slimMaterial nanotechnologyPaper/cardboard articlesChemistryNanopore

Owner:POSTECH ACAD IND FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com