Weak cyclone stagnation gas burner

A burner and stagnation technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as unstable combustion of extreme lean fuel, and achieve the effects of simple and reliable structure, improved life, and wide fuel adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention provides a weak-swirl stagnant gas burner, and the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

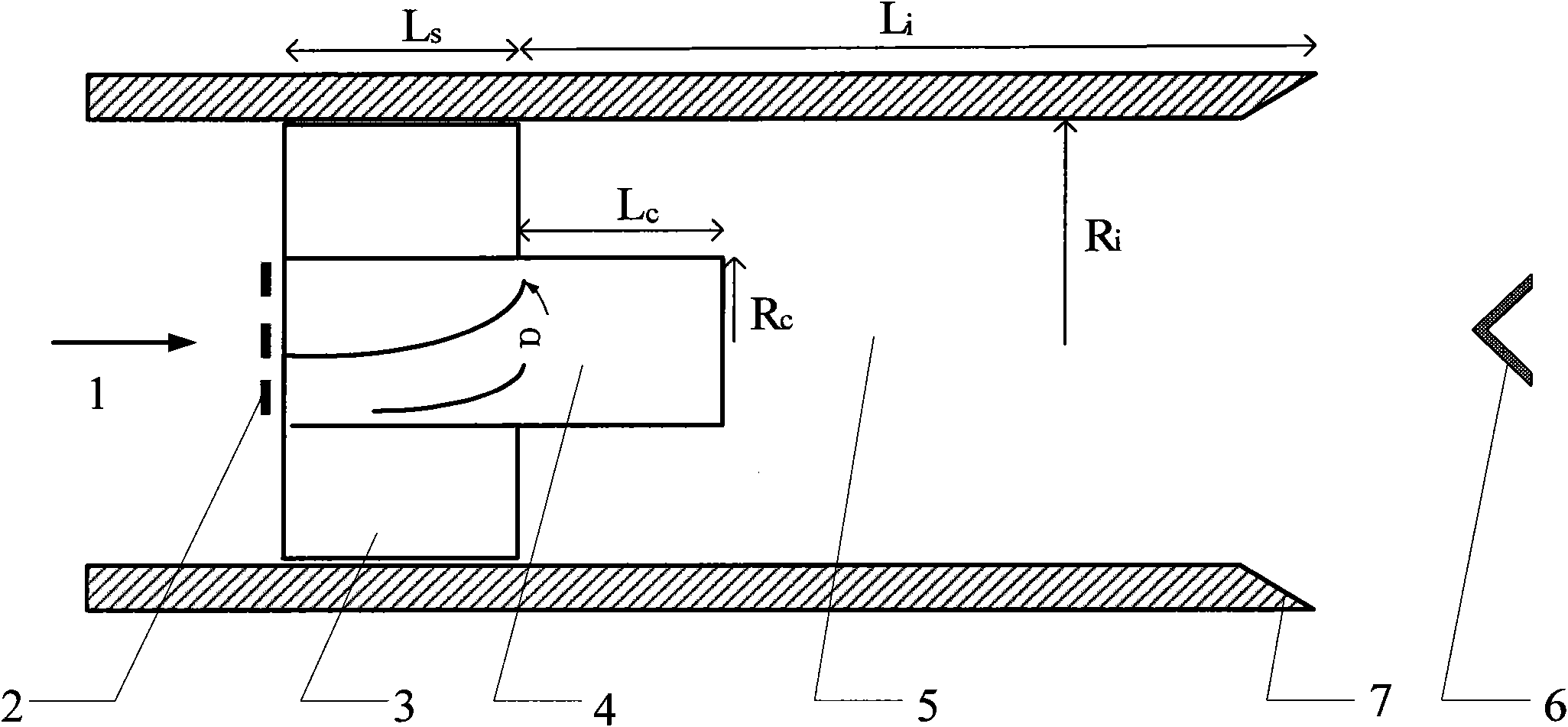

[0034] Such as figure 1 As shown, a DC center pipe 4 and a swirl device 3 are placed inside the burner, and a flow regulating hole network 2 is set at the premixed gas inlet 1 in front of the swirl device 3. Behind the DC center pipe 4 is a swirl development section 5 and Gas nozzle 7, a blunt body 6 is set at the gas nozzle 7; the premixed gas in the burner is divided into two channels, namely the swirl device 3 and the direct current center tube 4, and the mixed gas passes through the swirl development section 5 at the combustion outlet 7 diverges to form a weak swirl field, and forms a stagnant flame under the action of the blunt body 6, which plays a role in stabilizing the flame. The angle of gas nozzle 7 is 45 °.

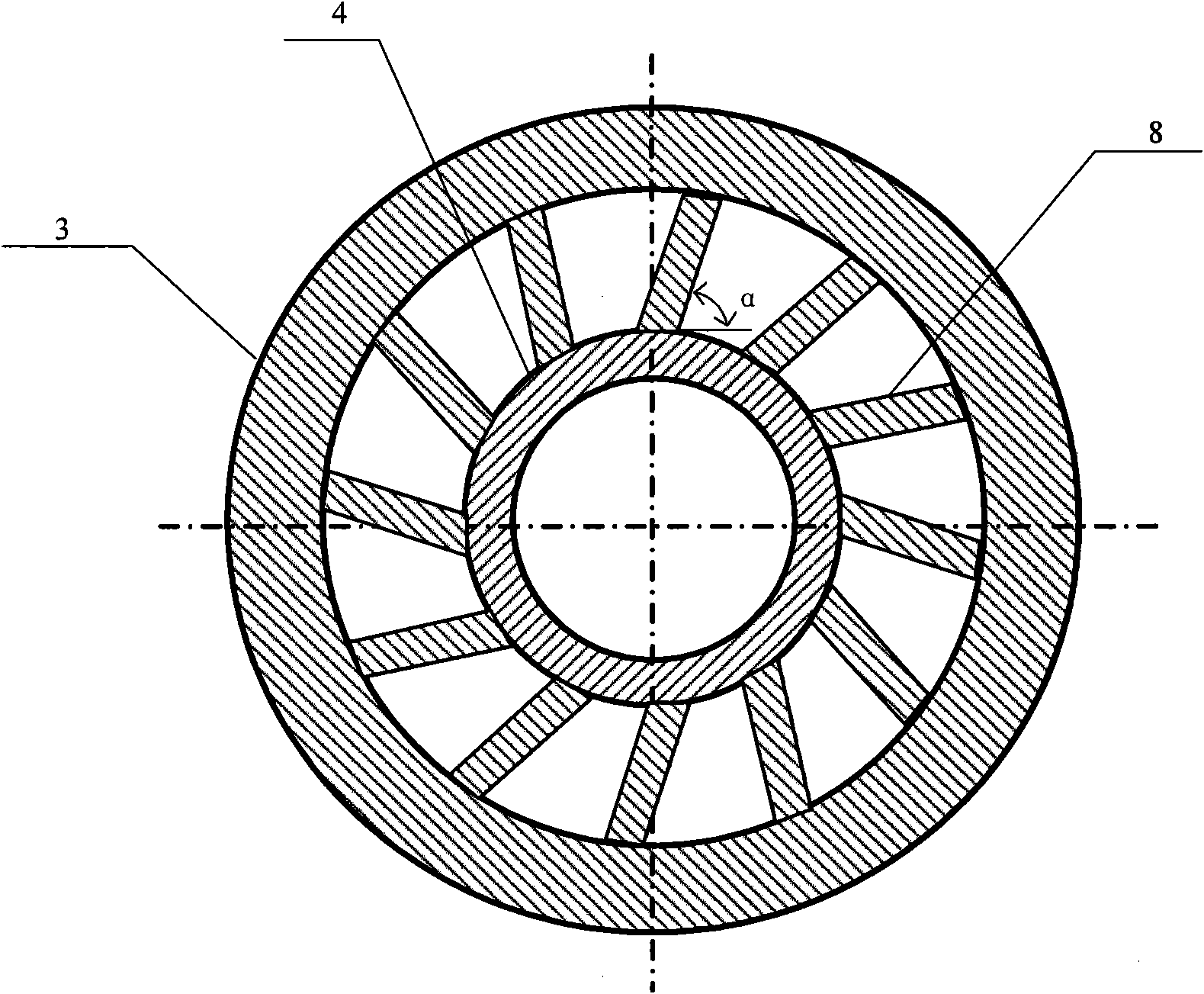

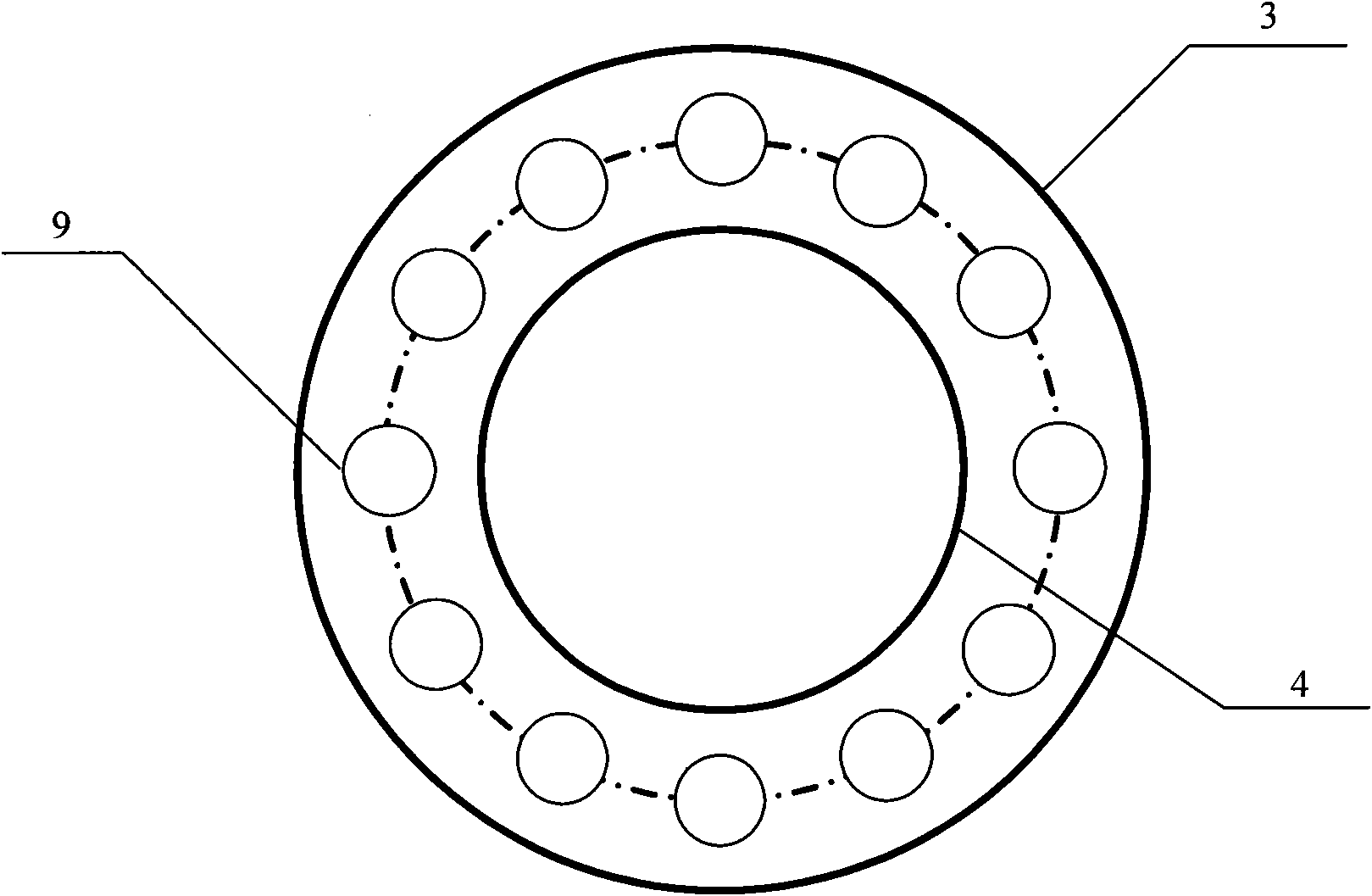

[0035] The implementation of the swirl device 3 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com