Low-pollution combustion chamber adopting fuel-grading and three-stage cyclone air inlet

A combustor, low-pollution technology, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problem of increasing the complexity of the fuel and air mixing device at the head of the combustion chamber, poor fuel atomization effect in the duty area, CO and Increased UHC emissions and other issues to achieve the effect of broadening the stable working range, suppressing the formation of local hot spots, and increasing the intake air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the technical solutions, implementation methods and advantages of the present invention more clear and detailed, the present invention will be further described in detail below in conjunction with the attached schematic diagrams and specific examples.

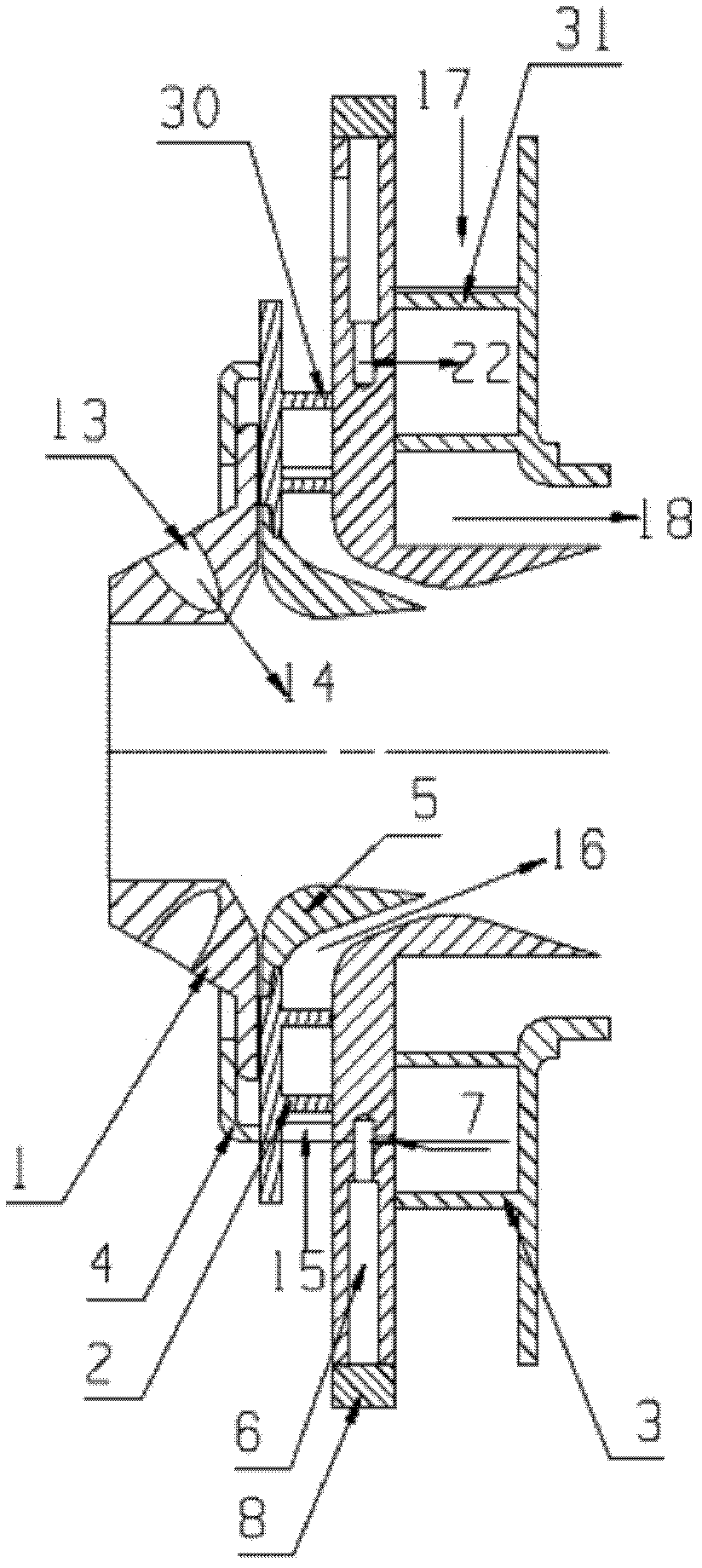

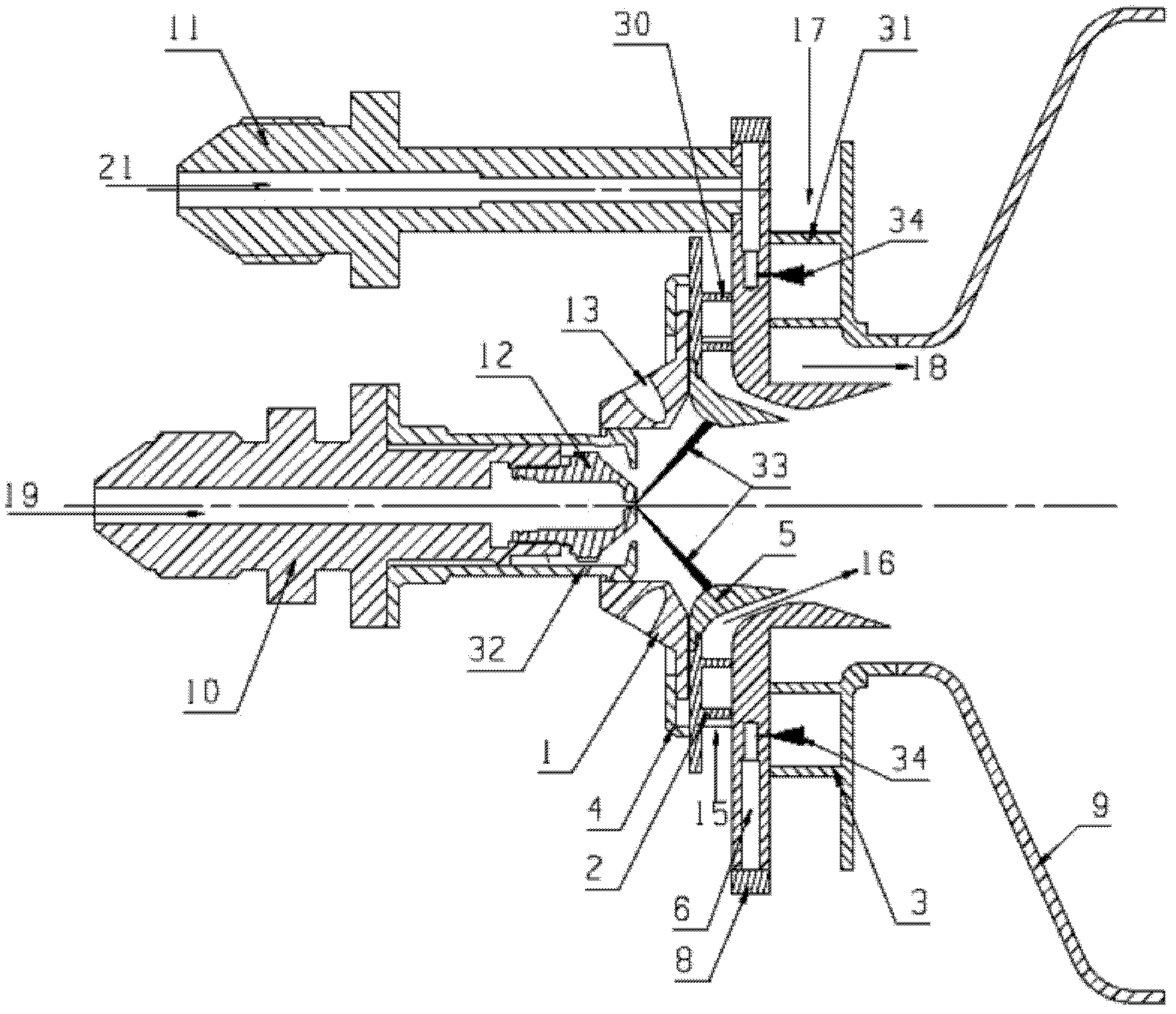

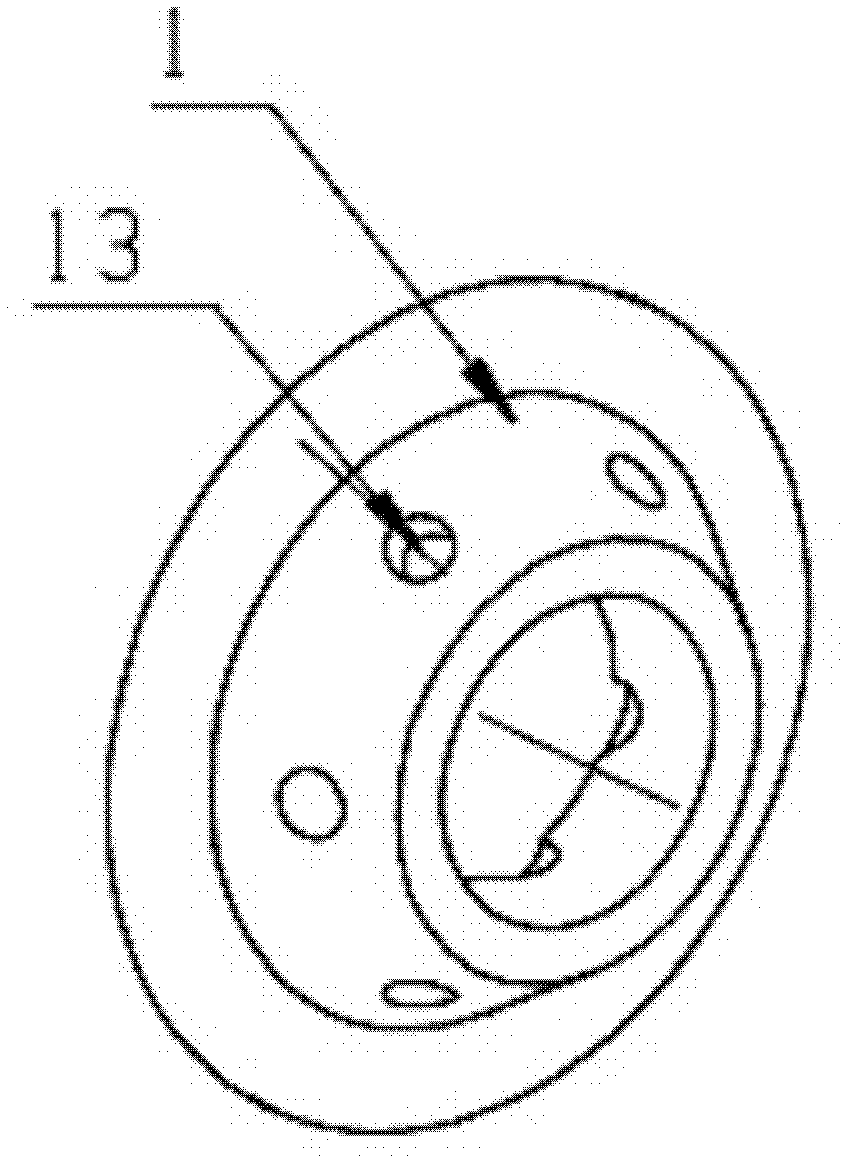

[0054] The principle of the invention is a low-pollution combustion chamber that adopts the three-stage swirl air intake of fuel oil classification: the fuel oil and the air participating in the combustion enter the combustion chamber in a graded manner, and this classification scheme is conducive to the full mixing of fuel oil and air. mix. The fuel enters the duty-level nozzle and the main combustion-level multi-point nozzle in two ways, and the air participating in the combustion enters the head of the flame tube from the third-level swirler respectively. The fuel coming in from the central duty nozzle and the inner two-stage swirling air form a duty stage. When the engine is in a low load state such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com