Combustion feedforward and feedback composite optimization controlling method for pulverized coal fired boiler

A technology of feed-forward feedback and optimal control, applied in the field of control, can solve the problems of lack of clear physical meaning, recognition of operating personnel, difficulty in debugging and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

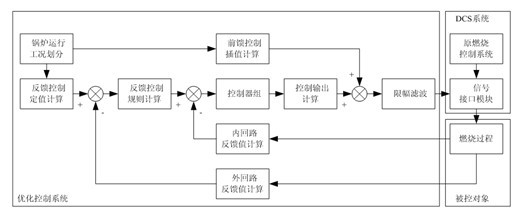

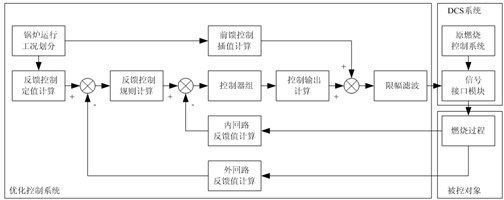

[0050] Attached below figure 1 And take a 600MW thermal power unit as an example to illustrate the overall technical scheme of boiler combustion feedforward feedback compound optimization control system. The optimization control system includes the following logic function modules:

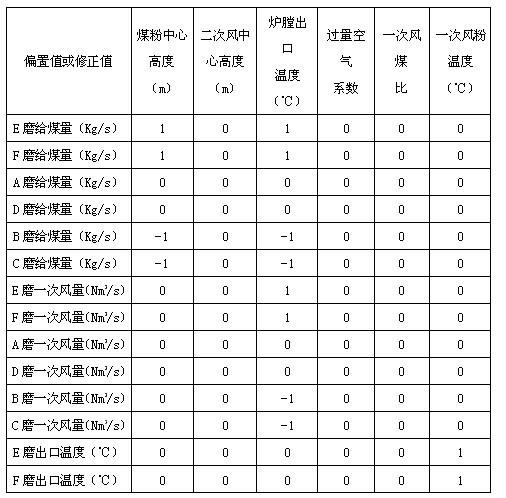

[0051] (1) The division module of boiler operating conditions. The operating conditions of the boiler are divided according to the 6 switching signals of the coal mill operating state and the 2 analog signals of the main steam flow rate and the total coal feeding amount of the boiler. In the range of 50%-100% load, coal mills may run 3, 4, 5, 6 units, considering the boiler operation regulations, the front and rear walls are opposed to each other and the combustion method does not appear to burn in separate layers or the front and rear walls have two or more layers of burners on the same side There are 8, 8, 6 and 1 total of 23 legal grinding operation combinations for single-wall combustion and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com