Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85 results about "Vapor lock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vapor lock is a problem caused by liquid fuel changing state to gas while still in the fuel delivery system of gasoline-fueled internal combustion engines. This disrupts the operation of the fuel pump, causing loss of feed pressure to the carburetor or fuel injection system, resulting in transient loss of power or complete stalling. Restarting the engine from this state may be difficult.

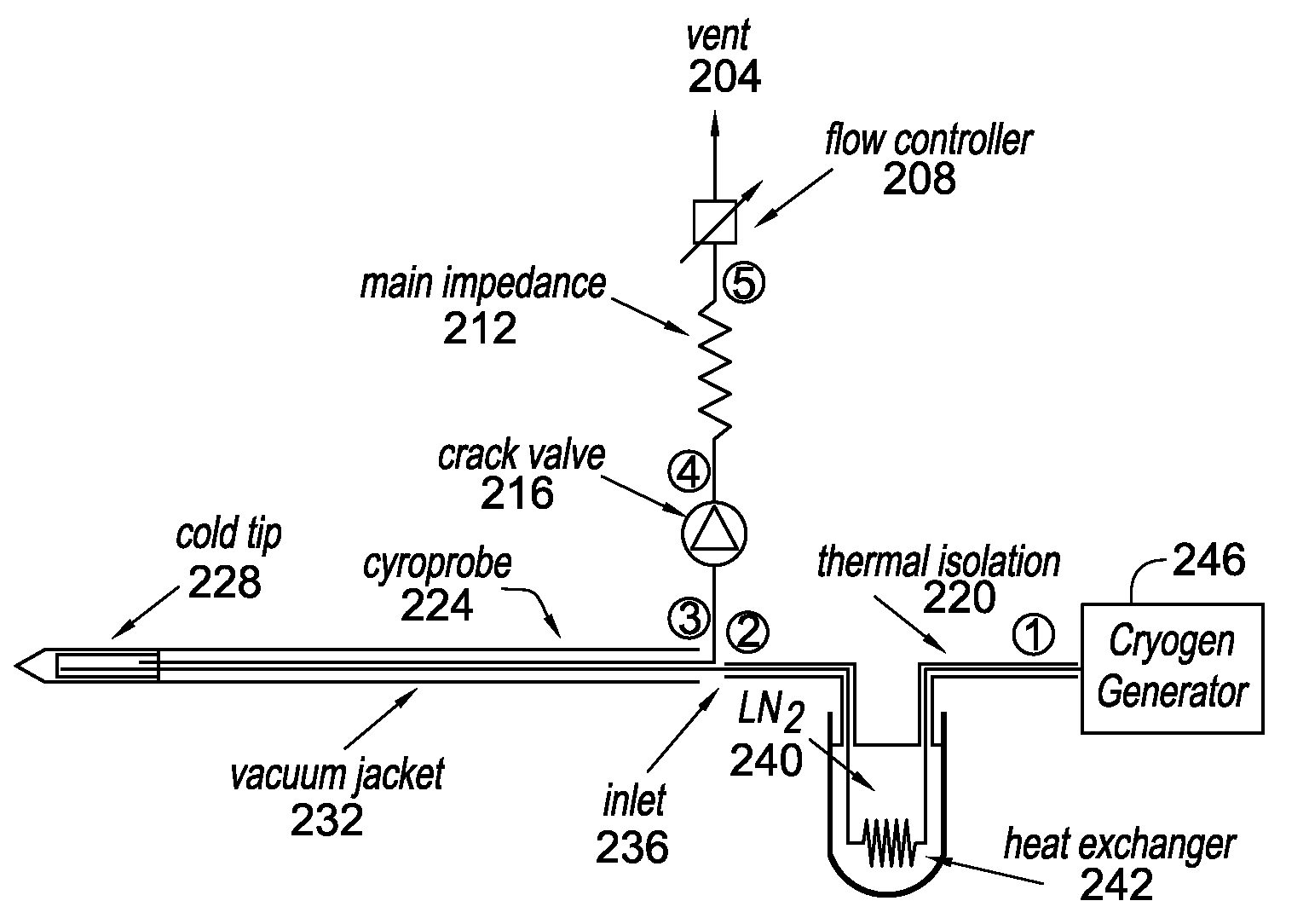

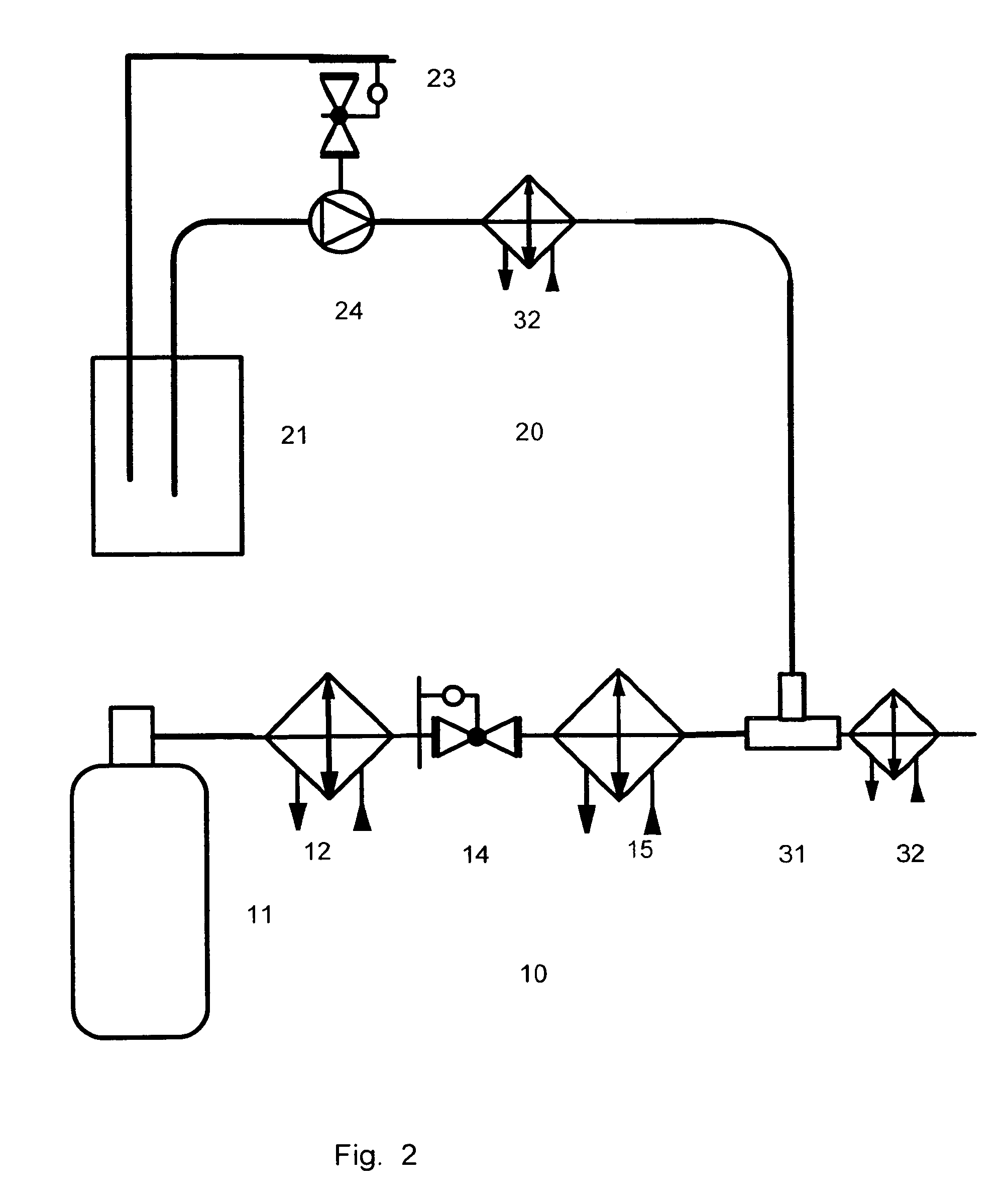

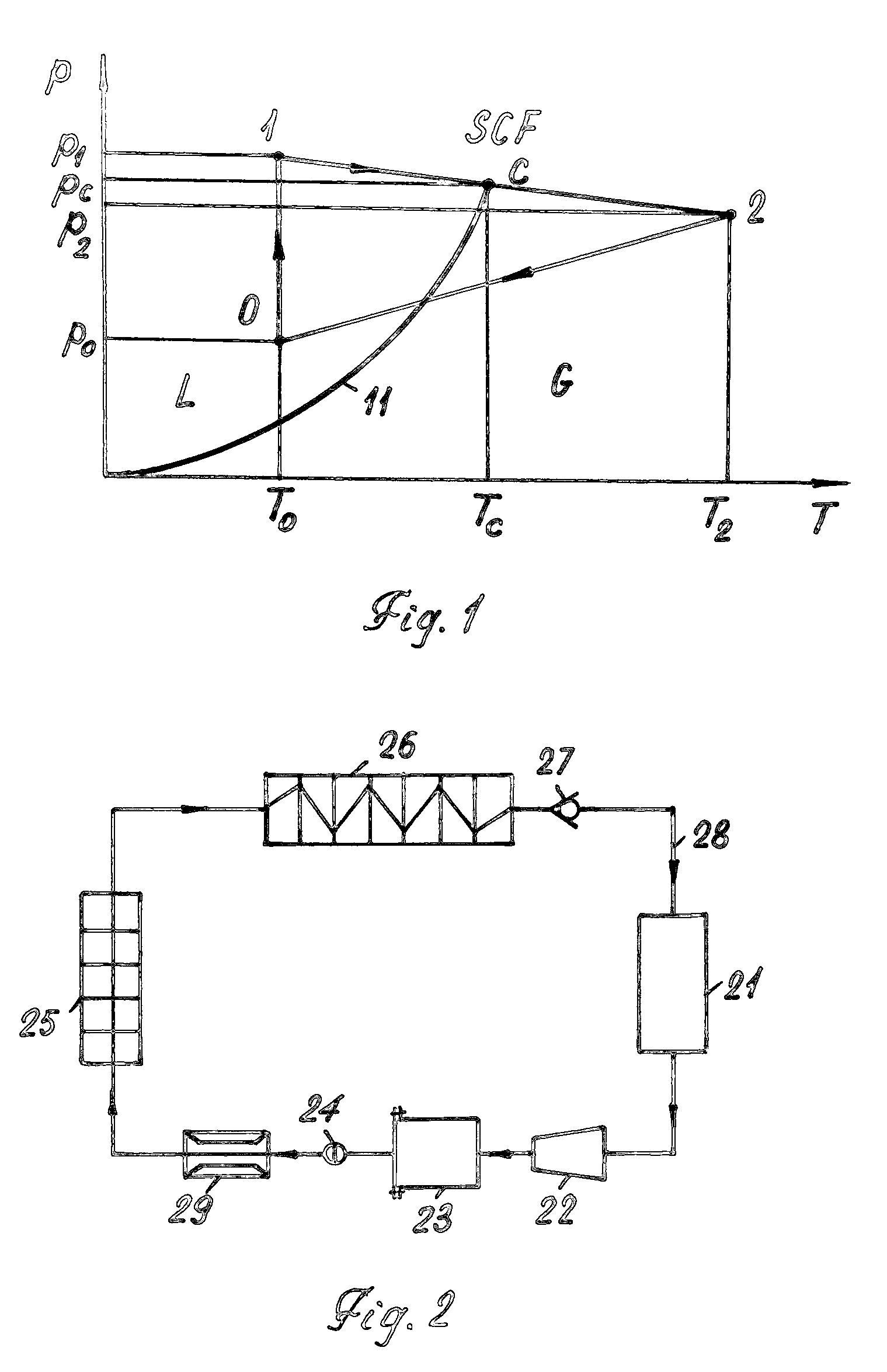

Methods and systems for cryogenic cooling

ActiveUS20050261753A1Increase pressurePrevents vapor lockDiagnosticsCompression machinesEngineeringVapor lock

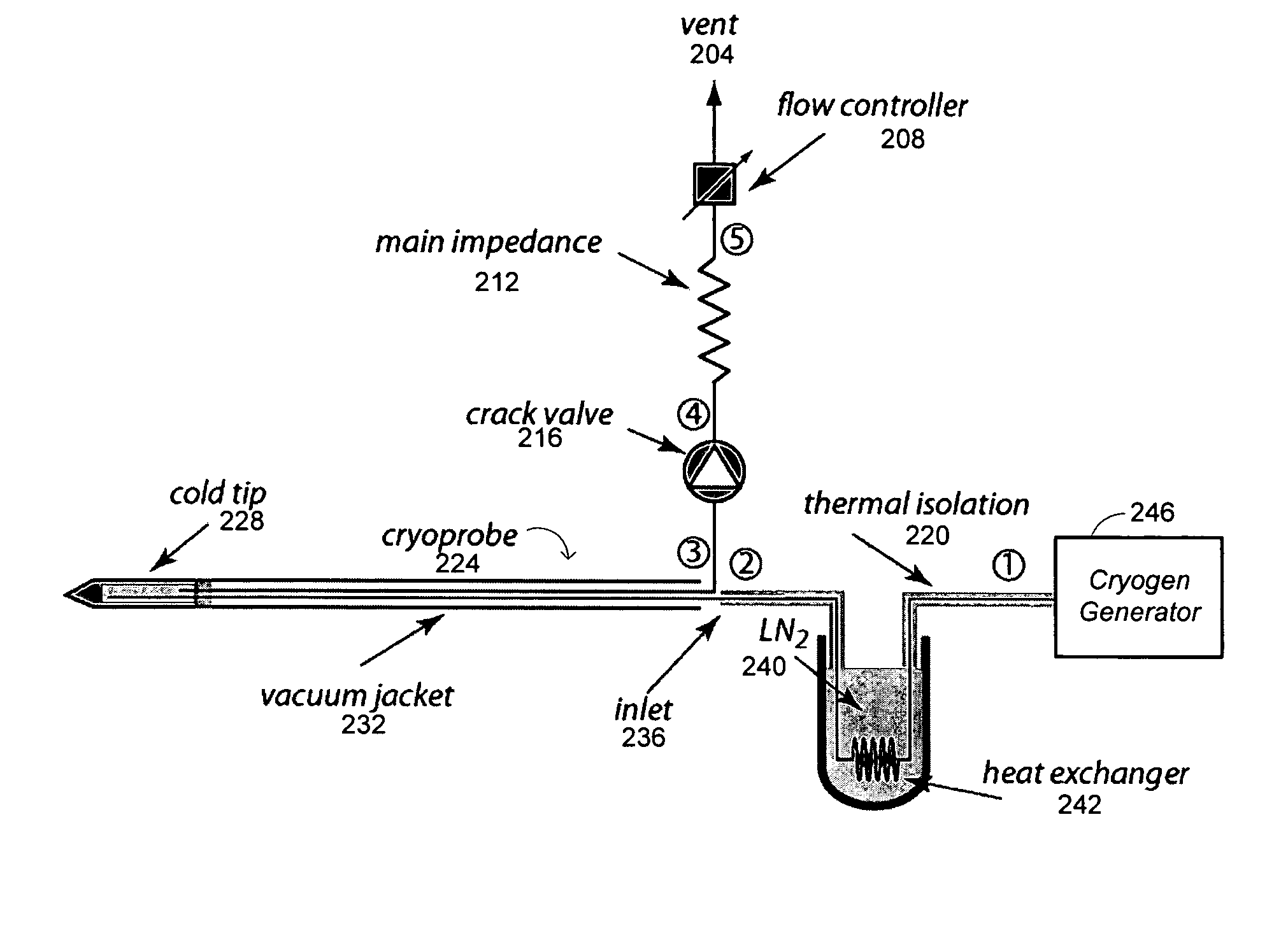

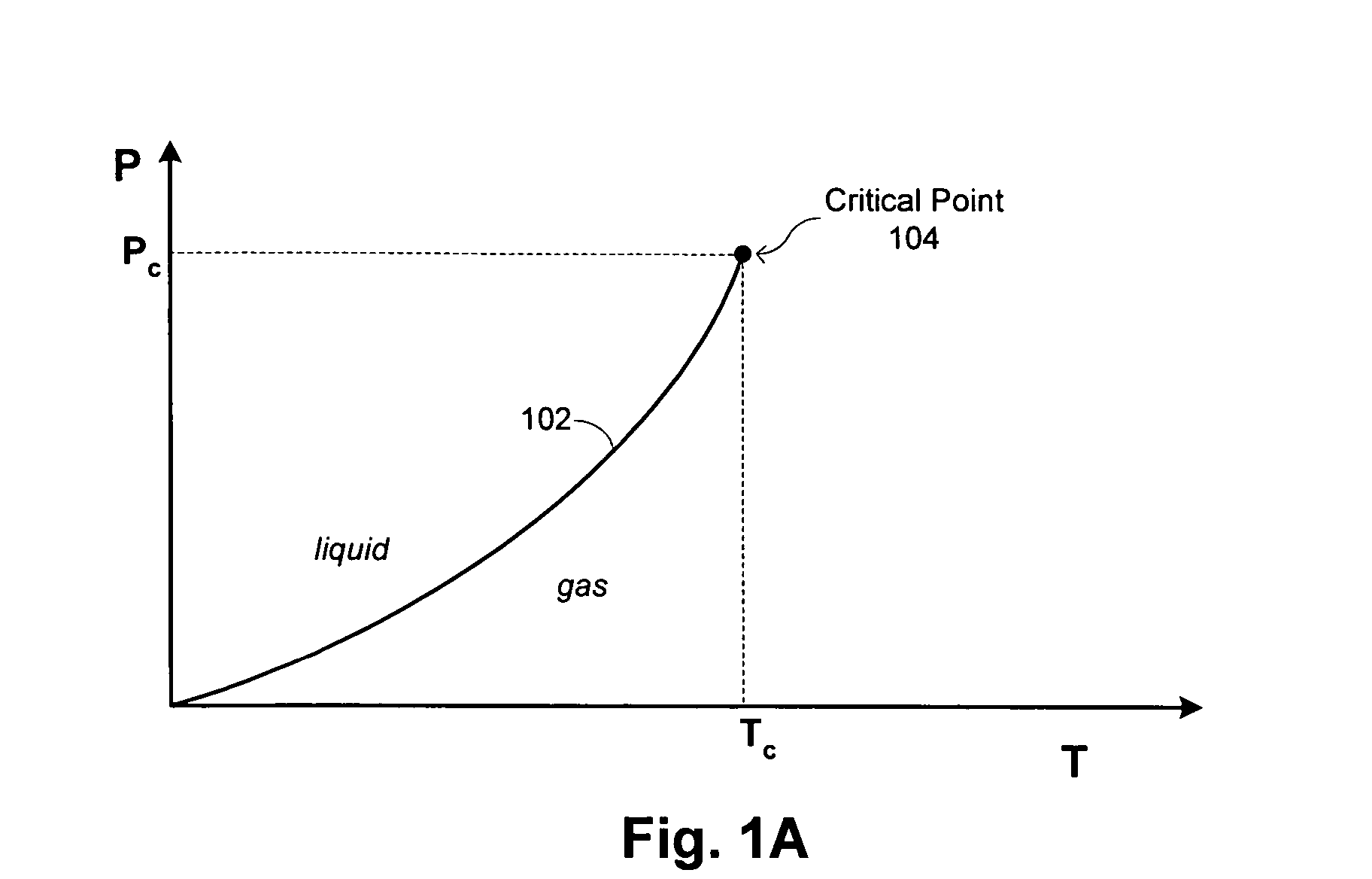

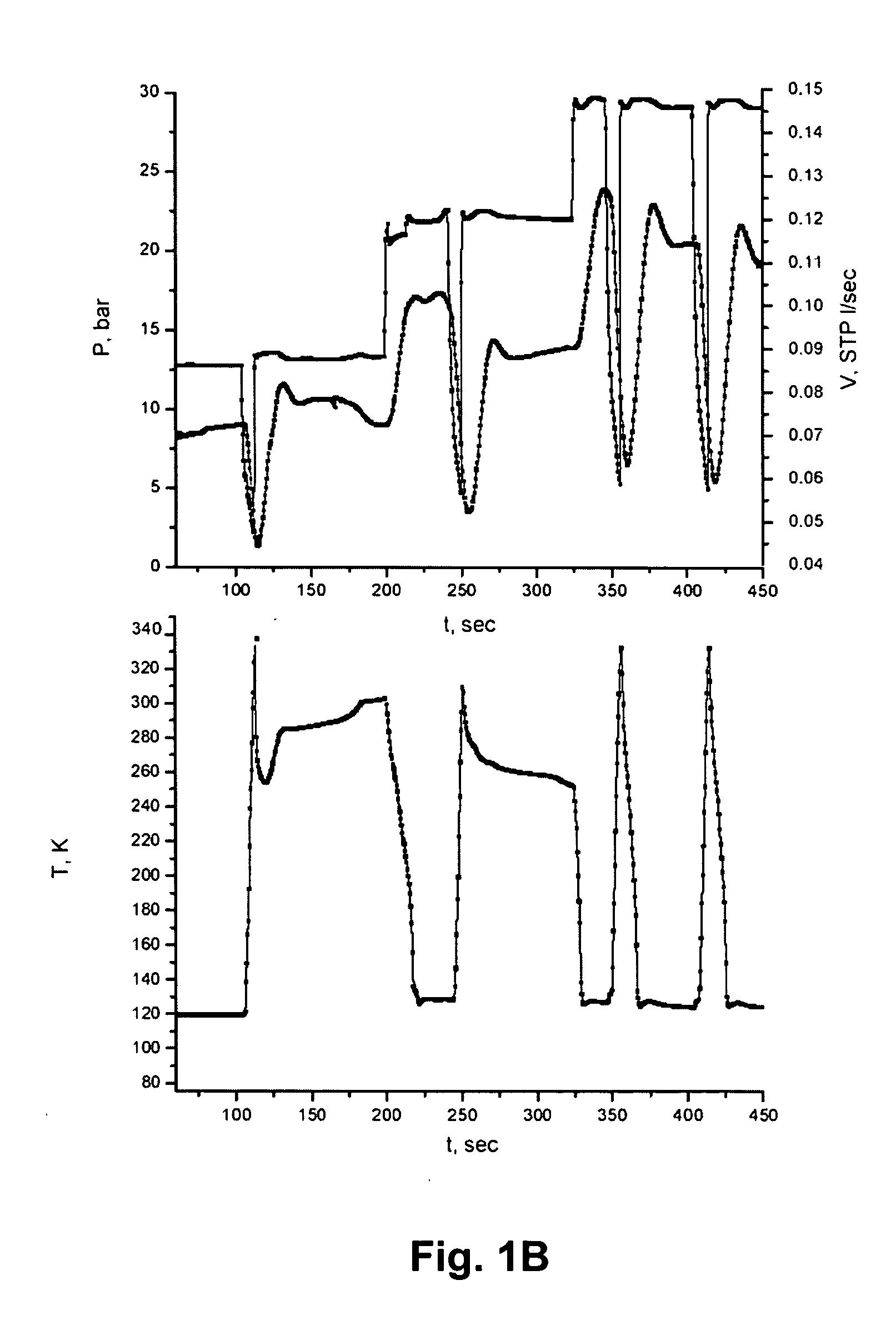

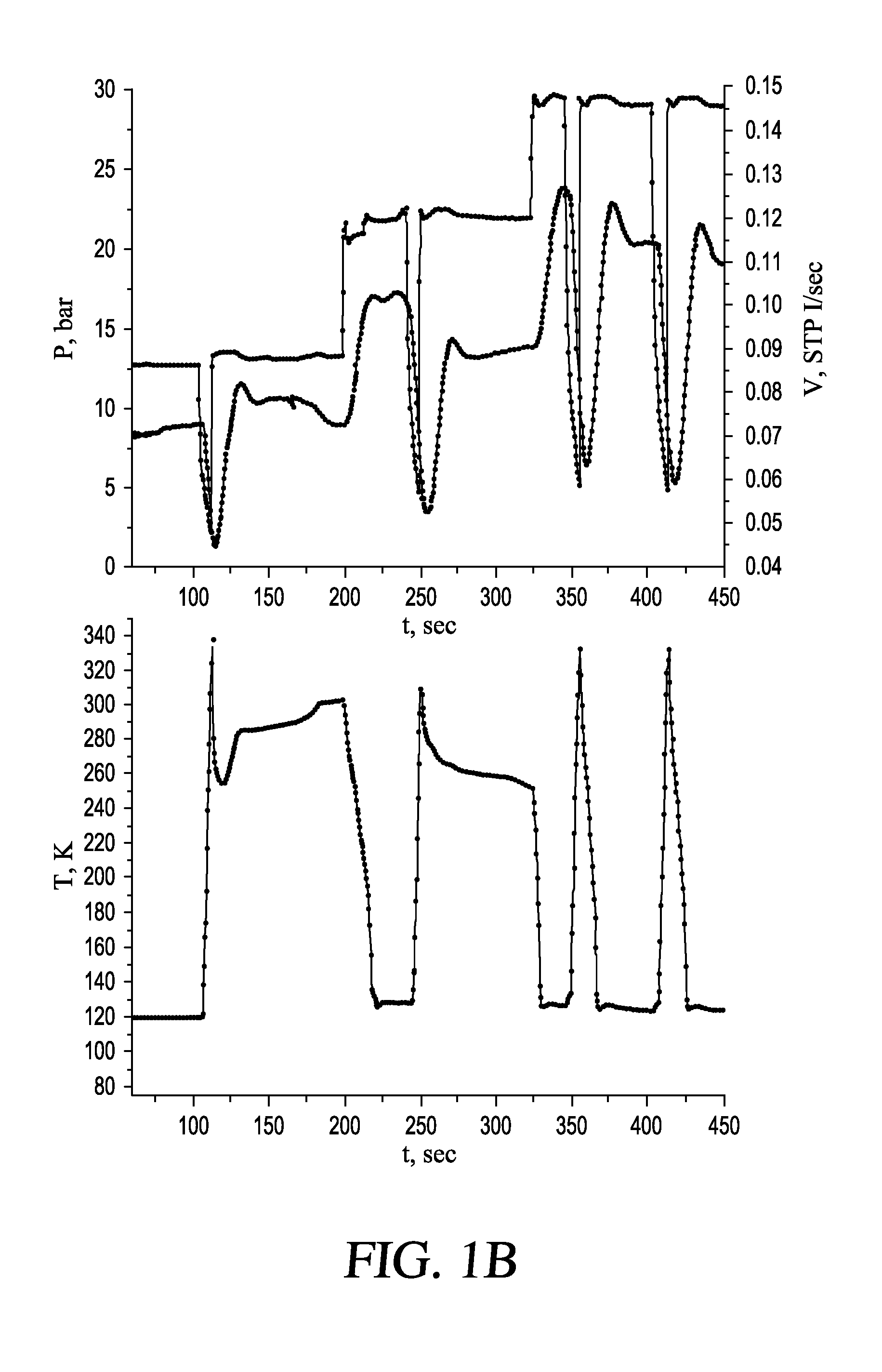

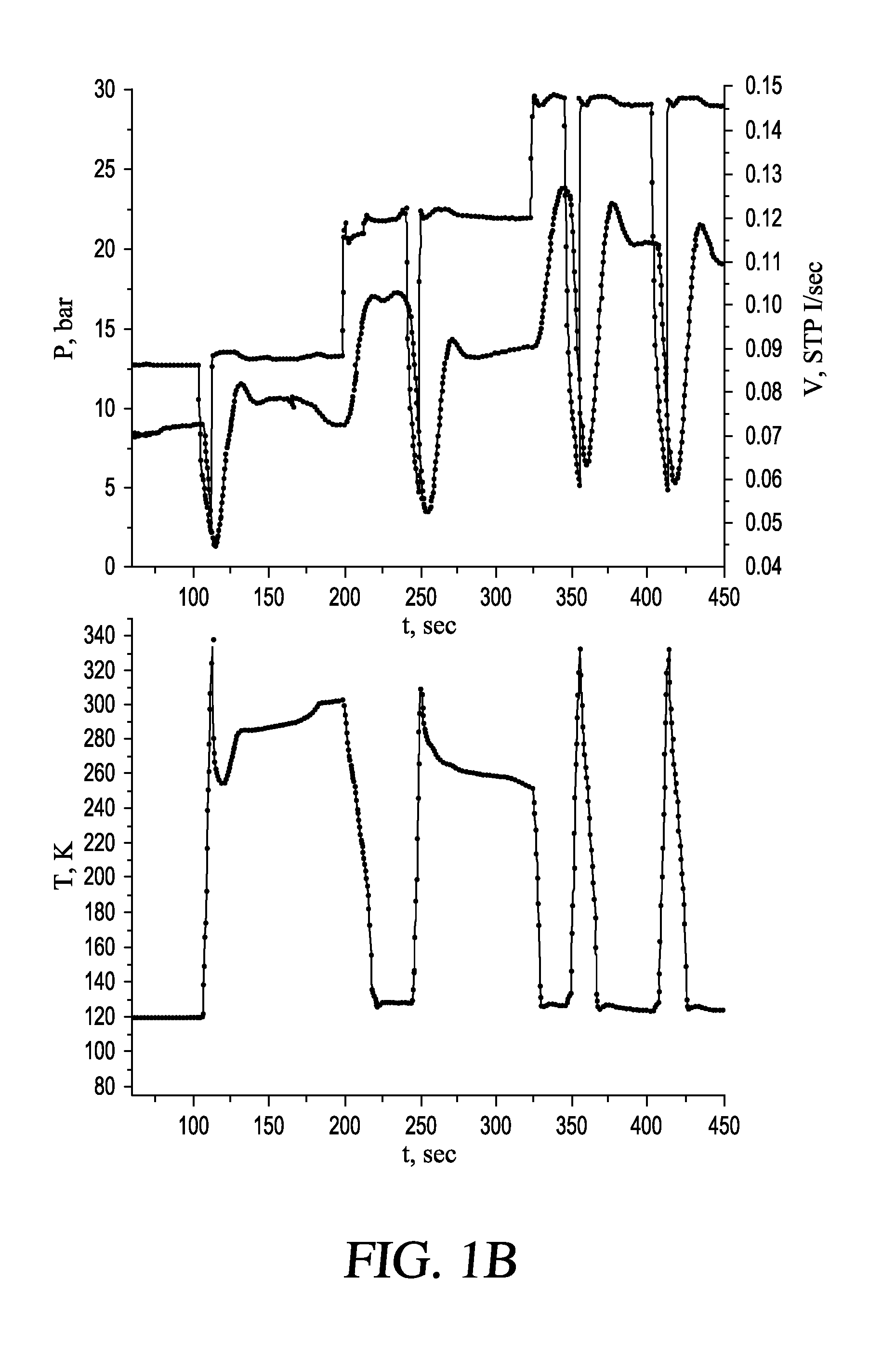

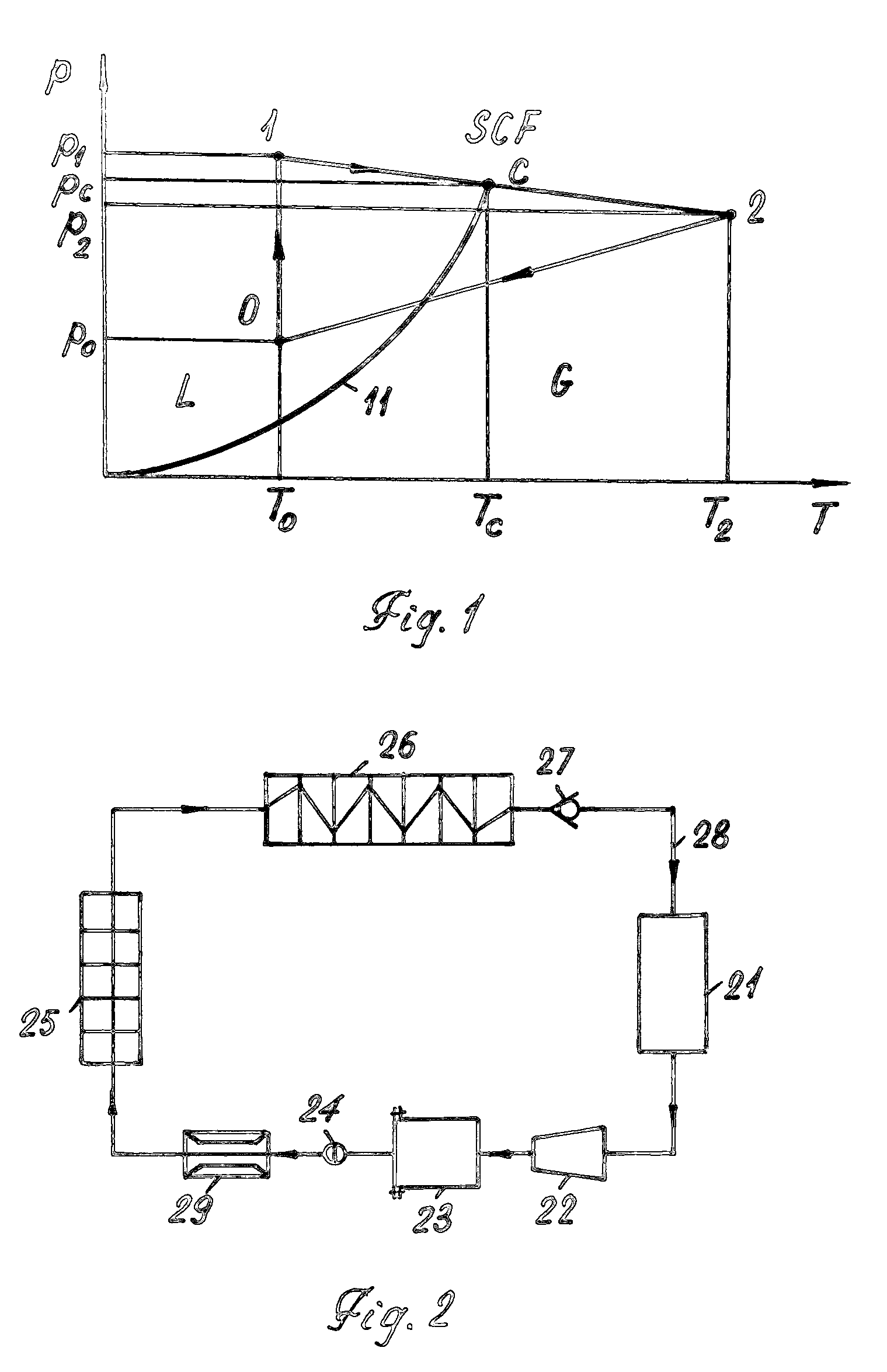

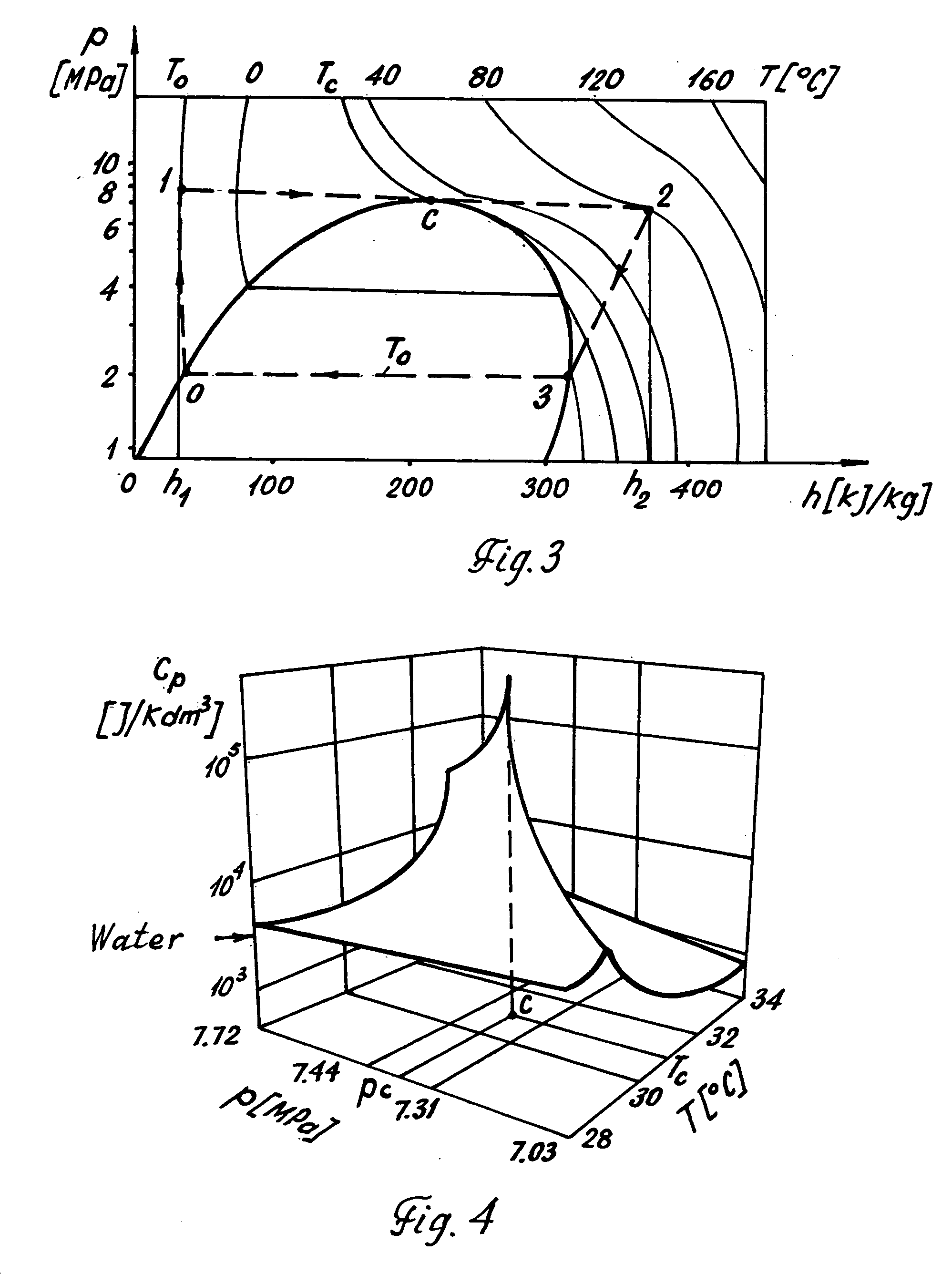

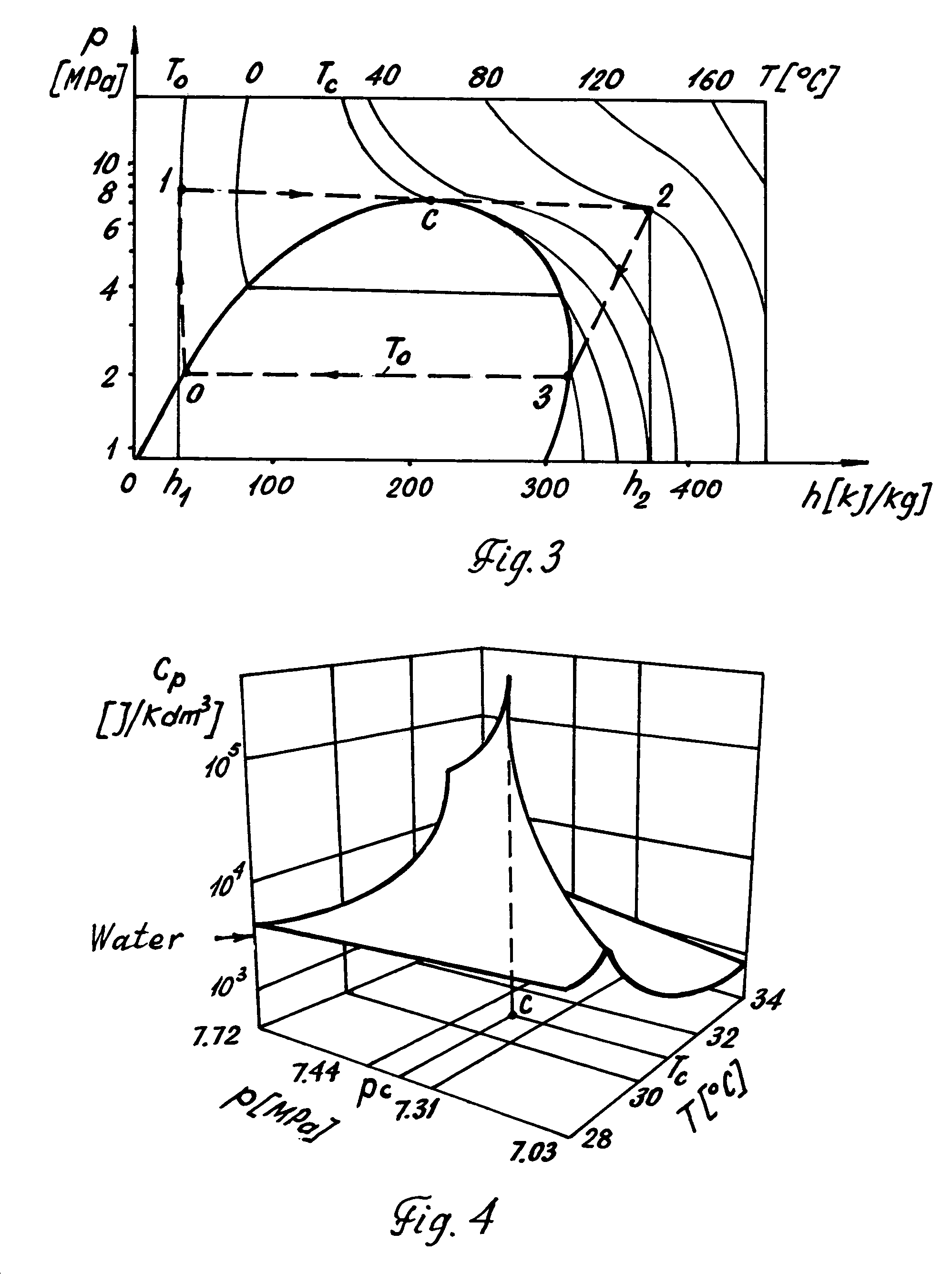

Methods and systems are provided for cooling an object with a cryogen having a critical point defined by a critical-point pressure and a critical-point temperature. A pressure of the cryogen is raised above a pressure value determined to provide the cryogen at a reduced molar volume that prevents vapor lock. Thereafter, the cryogen is placed in thermal communication with the object to increase a temperature of the cryogen along a thermodynamic path that maintains the pressure greater than the critical-point pressure for a duration that the cryogen and object are in thermal communication.

Owner:ADAGIO MEDICAL

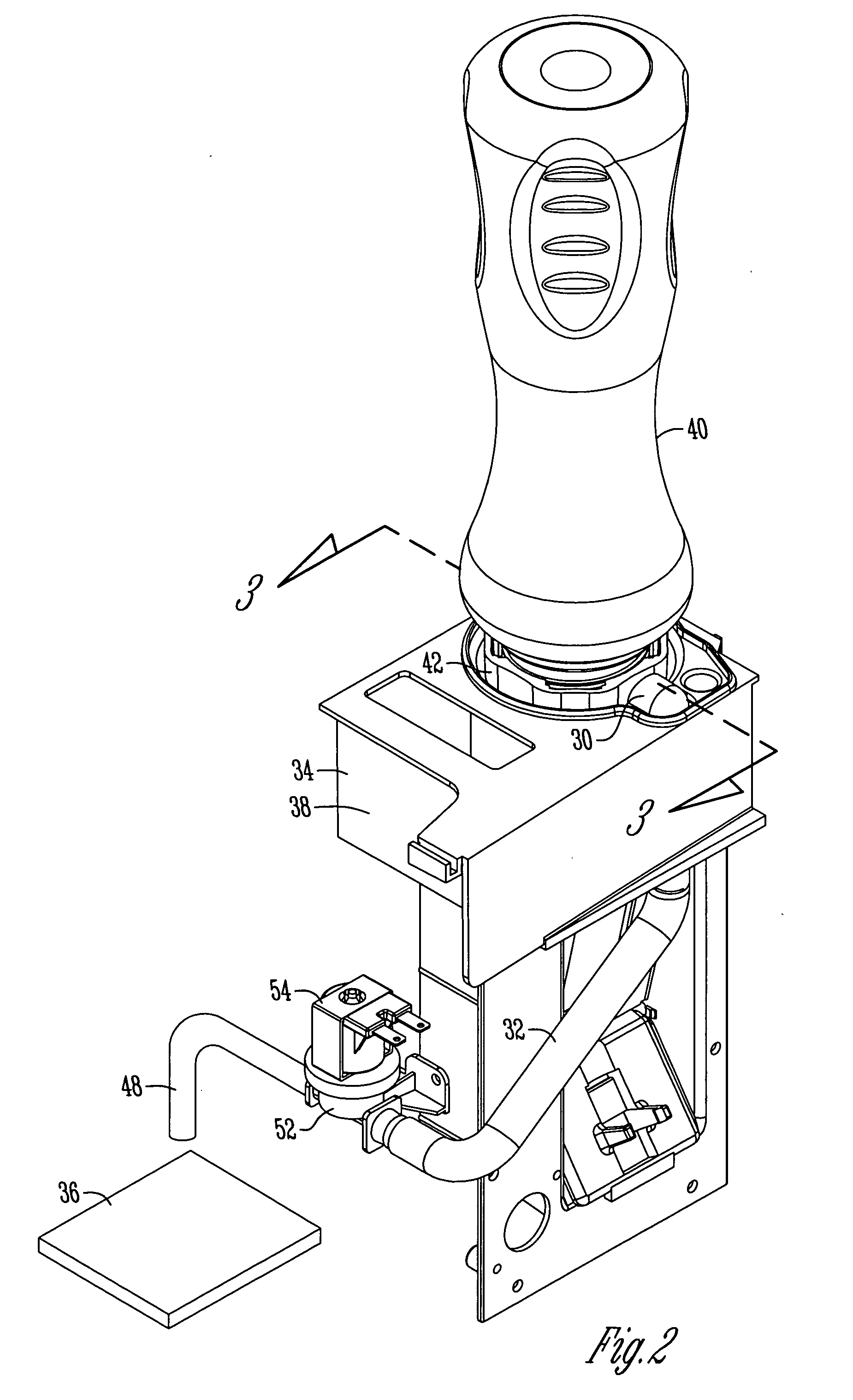

Sump pump system

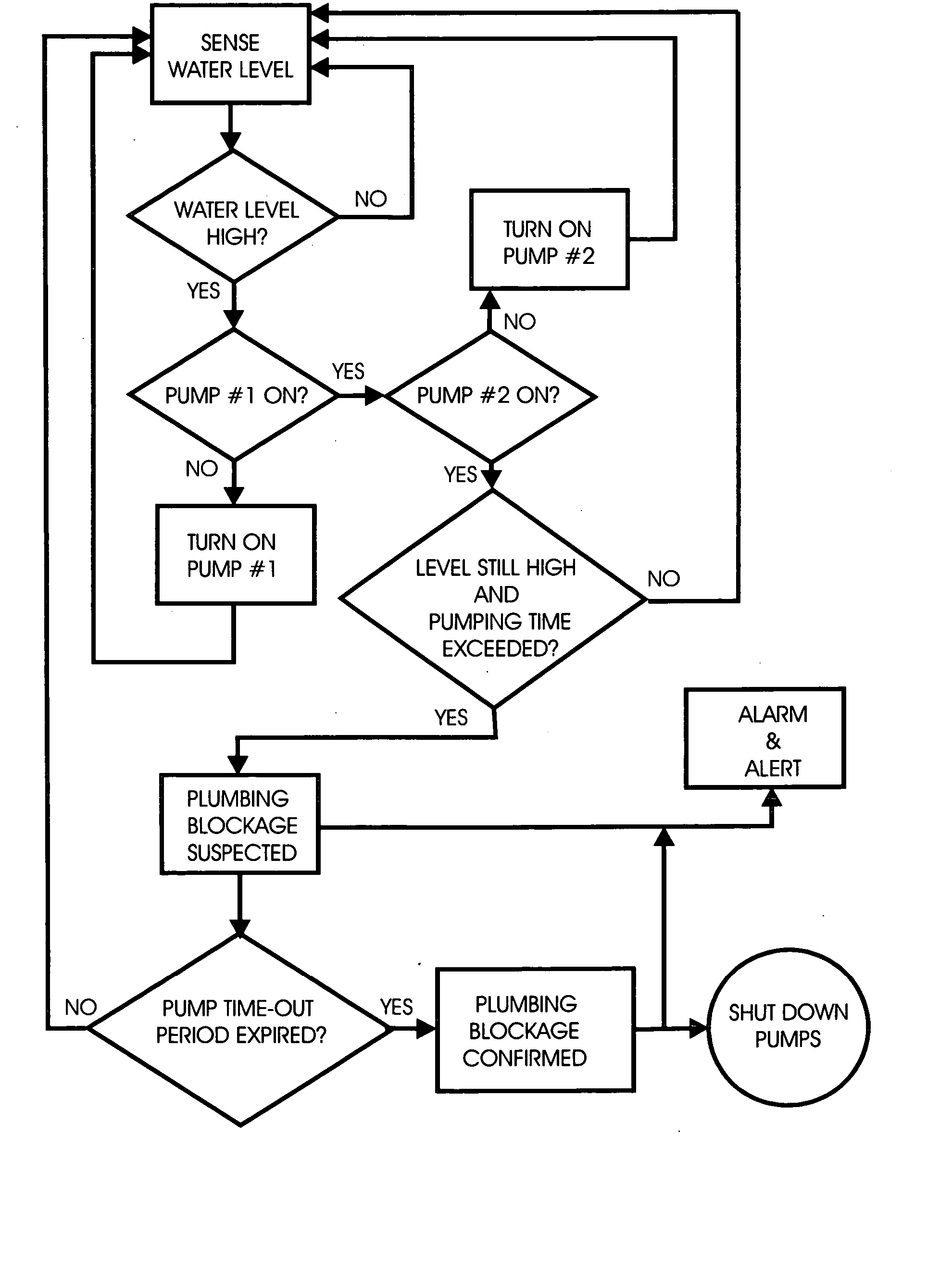

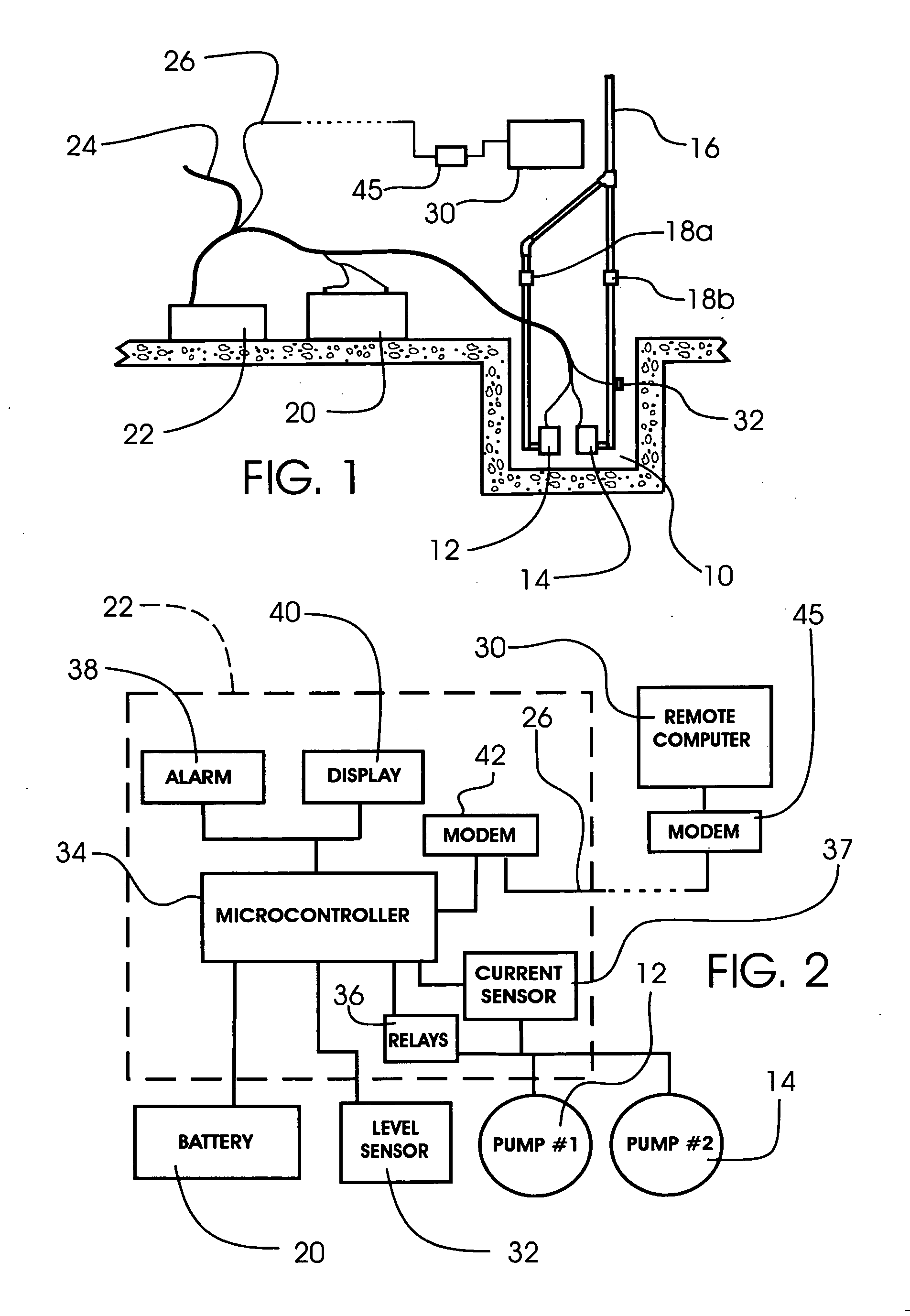

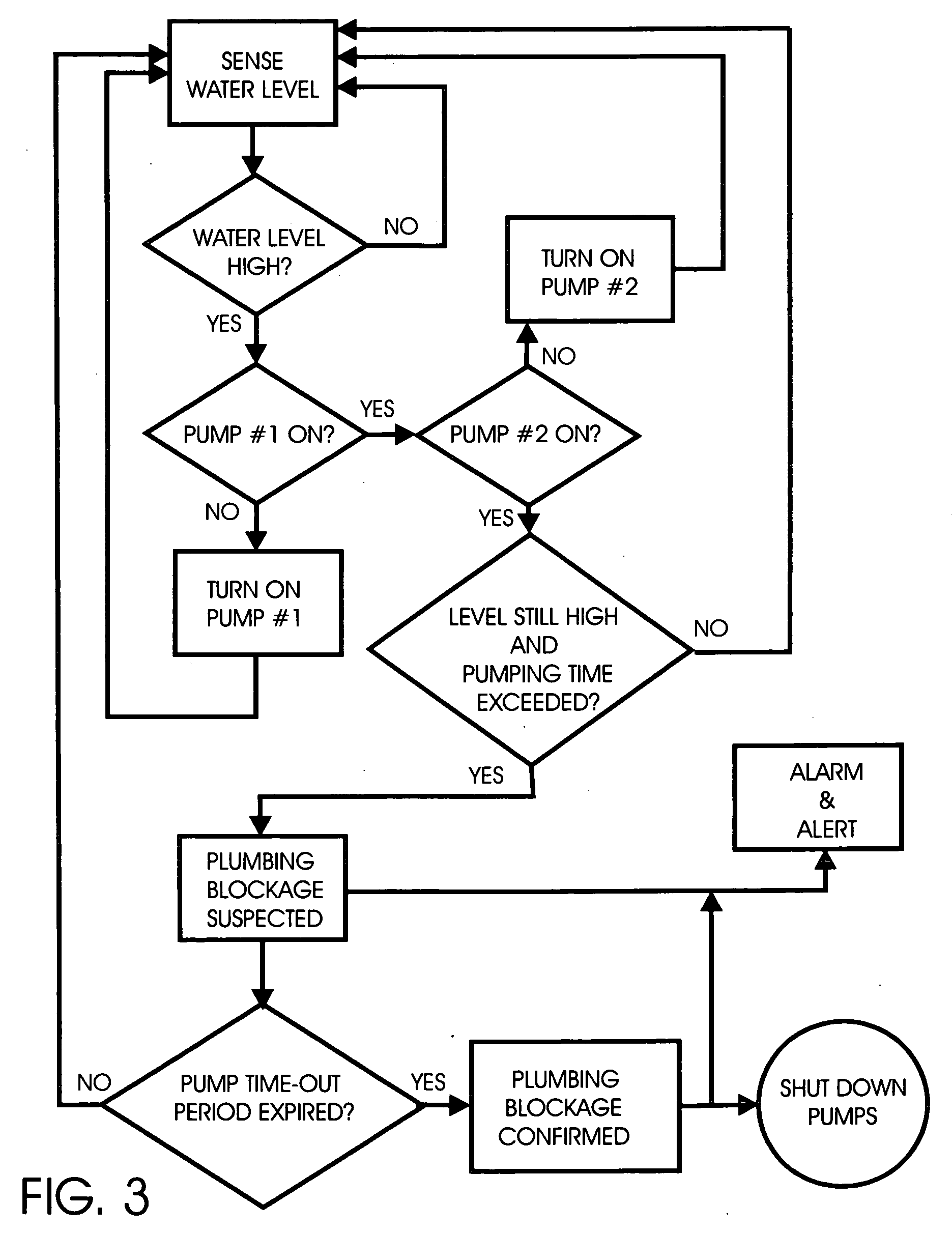

A programmed microcontroller based sump pump system includes multiple pumps that can be employed with one as a primary pump and one as a back-up, or can be employed in combination to increase the discharge rate. The microcontroller monitors the back-up battery condition, and computes and displays the battery life; monitors the system for clogs or vapor locks in the discharge piping; switches to an emergency periodic pumping mode of operation, when needed; and notifies the user by phone or e-mail of a system malfunction.

Owner:GIERKE DANIEL

Methods and systems for cryogenic cooling

InactiveUS7921657B2Reduce the temperatureCompression machines with non-reversible cycleTherapyEngineeringVapor lock

Methods and systems are provided for cooling an object with a cryogen having a critical point defined by a critical-point pressure and a critical-point temperature. A pressure of the cryogen is raised above a pressure value determined to provide the cryogen at a reduced molar volume that prevents vapor lock. Thereafter, the cryogen is placed in thermal communication with the object to increase a temperature of the cryogen along a thermodynamic path that maintains the pressure greater than the critical-point pressure for a duration that the cryogen and object are in thermal communication.

Owner:ADAGIO MEDICAL

Methods and systems for cryogenic cooling

ActiveUS20080173028A1Reduce the temperatureCompression machines with non-reversible cycleTherapyEngineeringVapor lock

Owner:ADAGIO MEDICAL

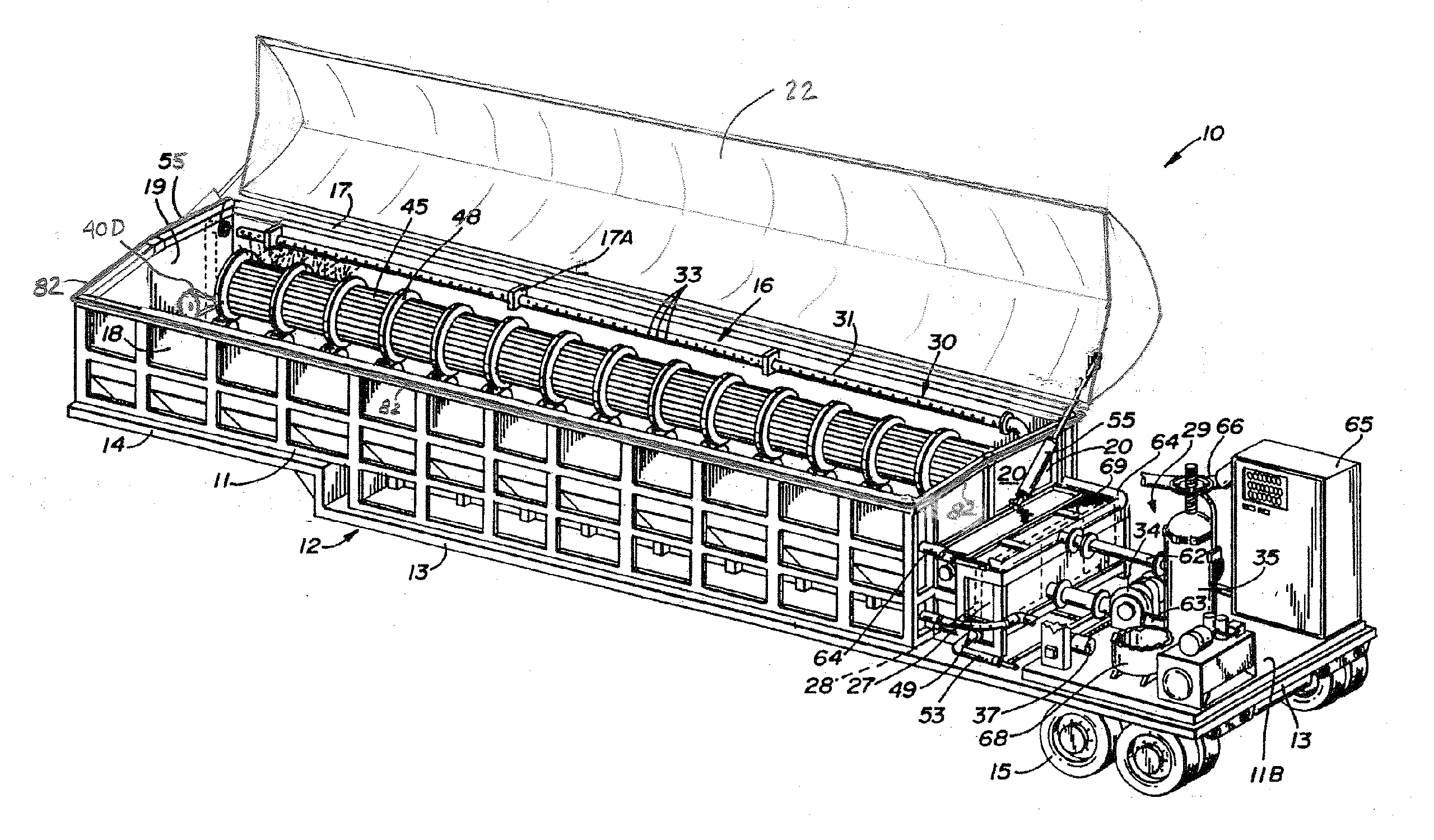

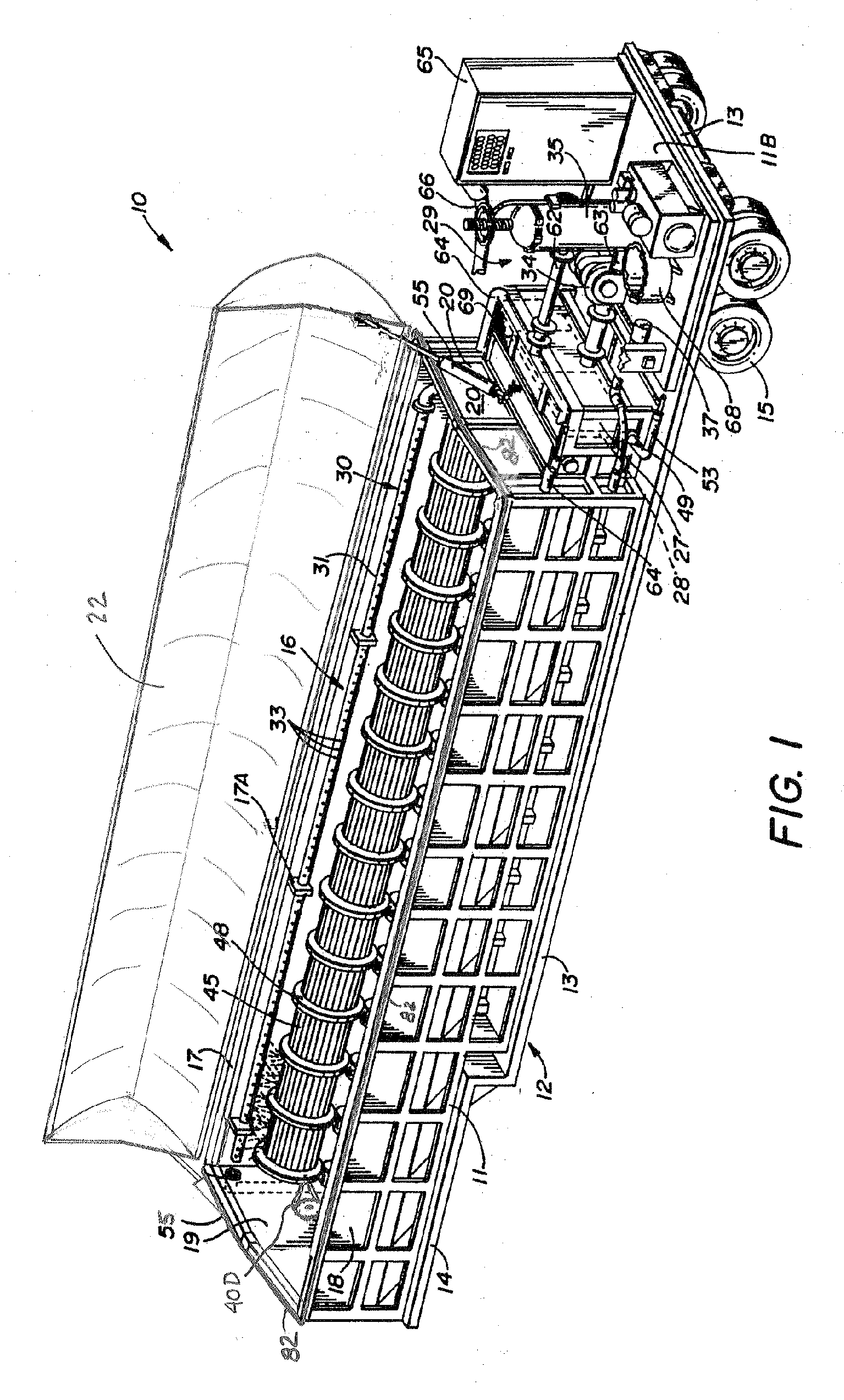

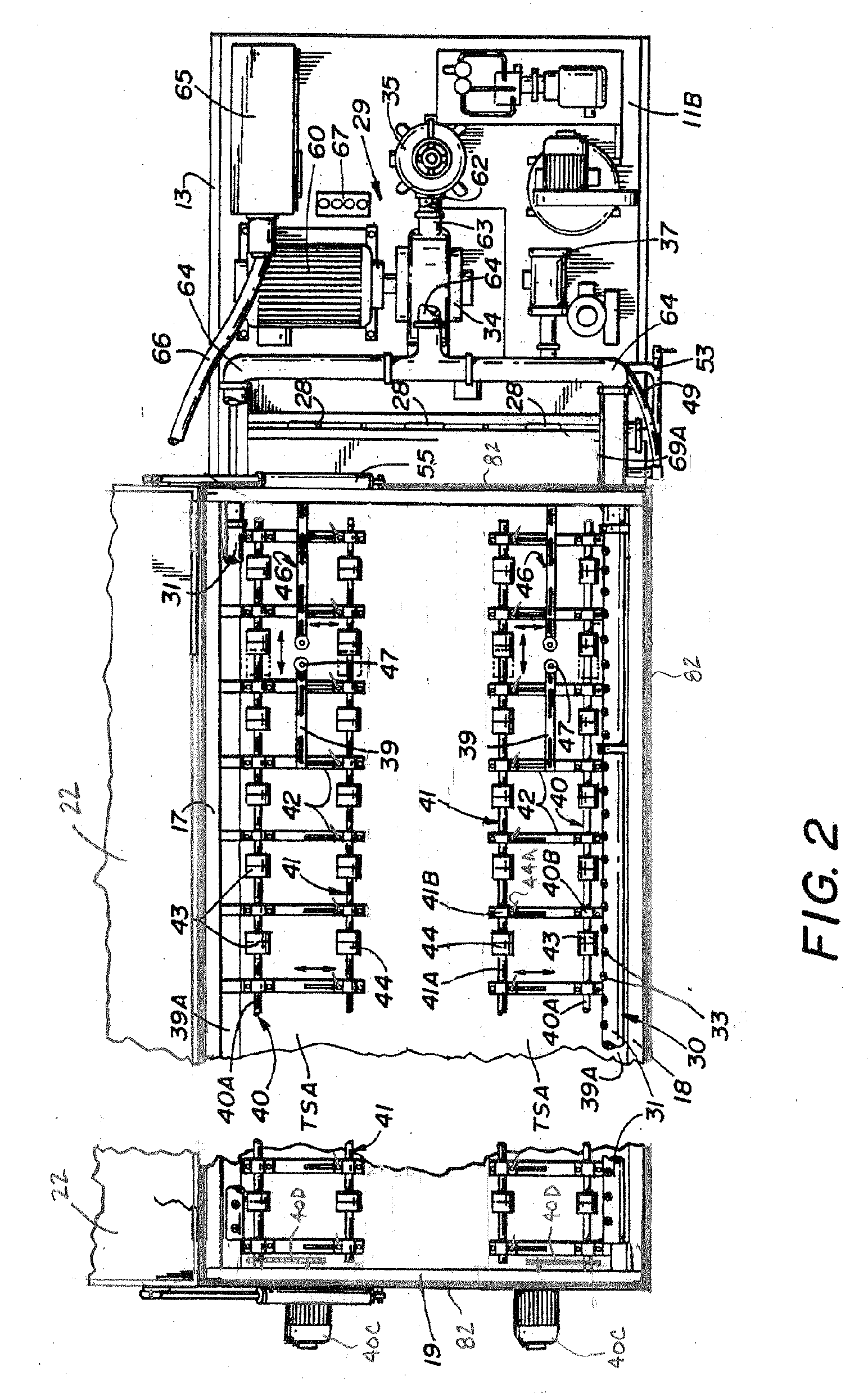

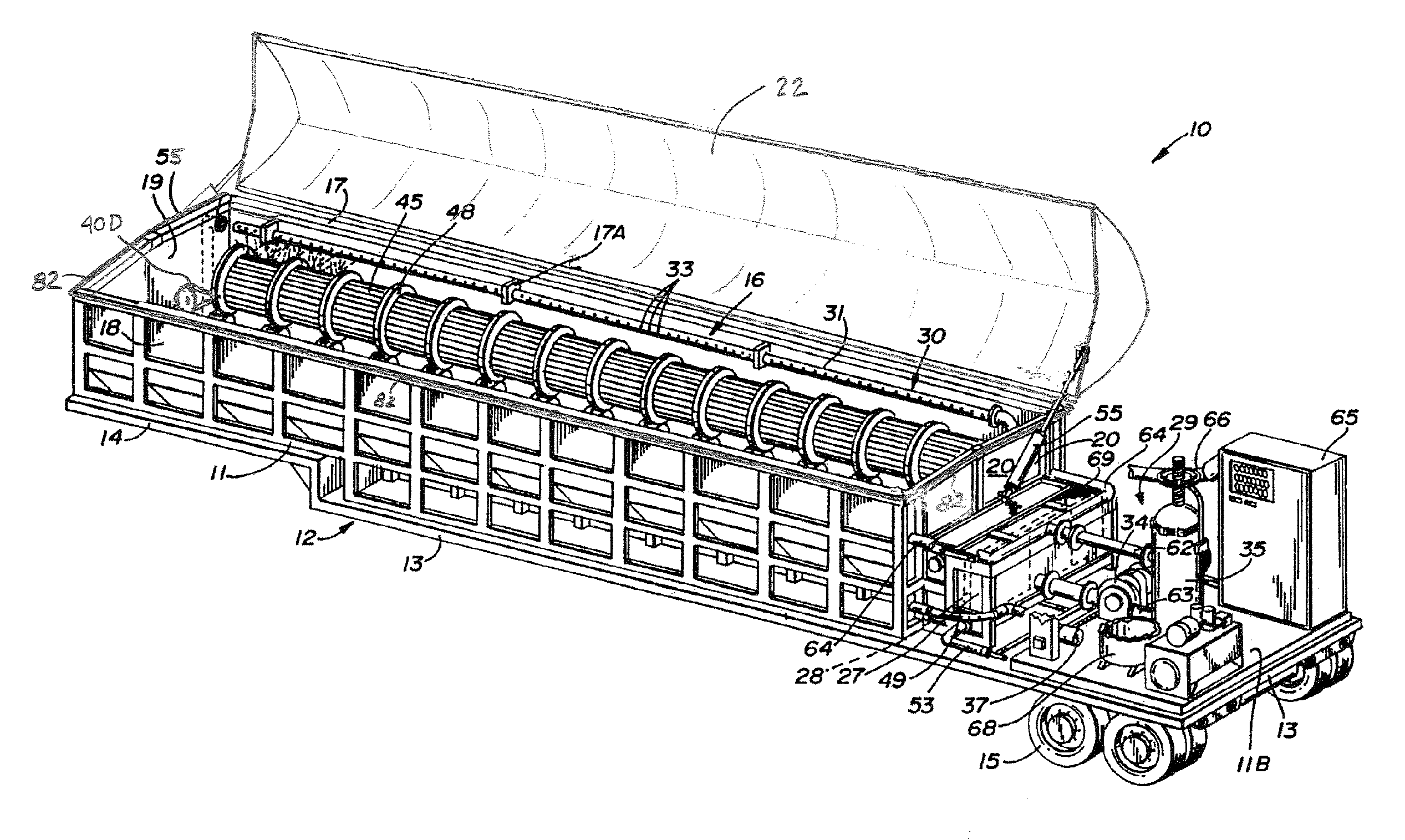

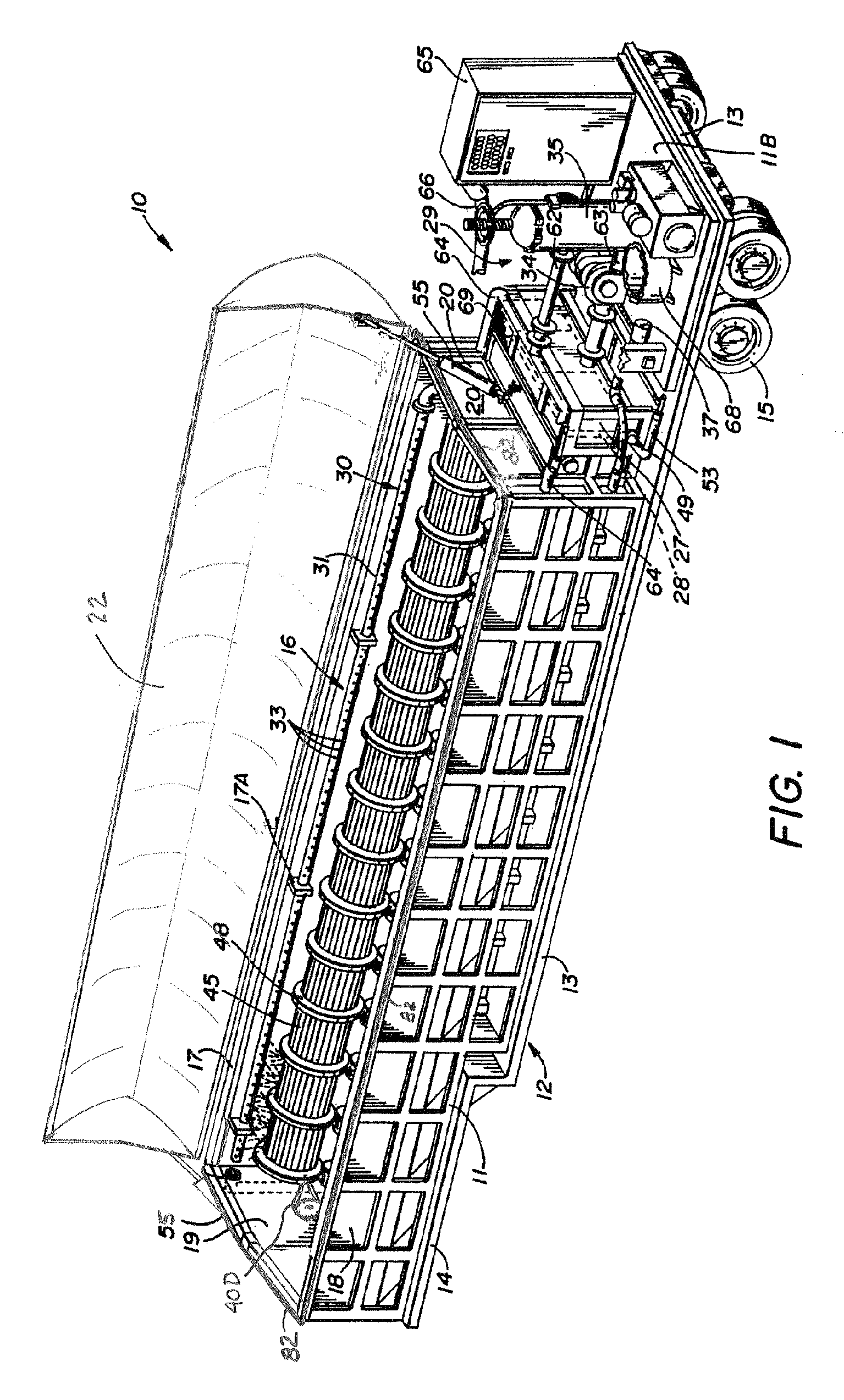

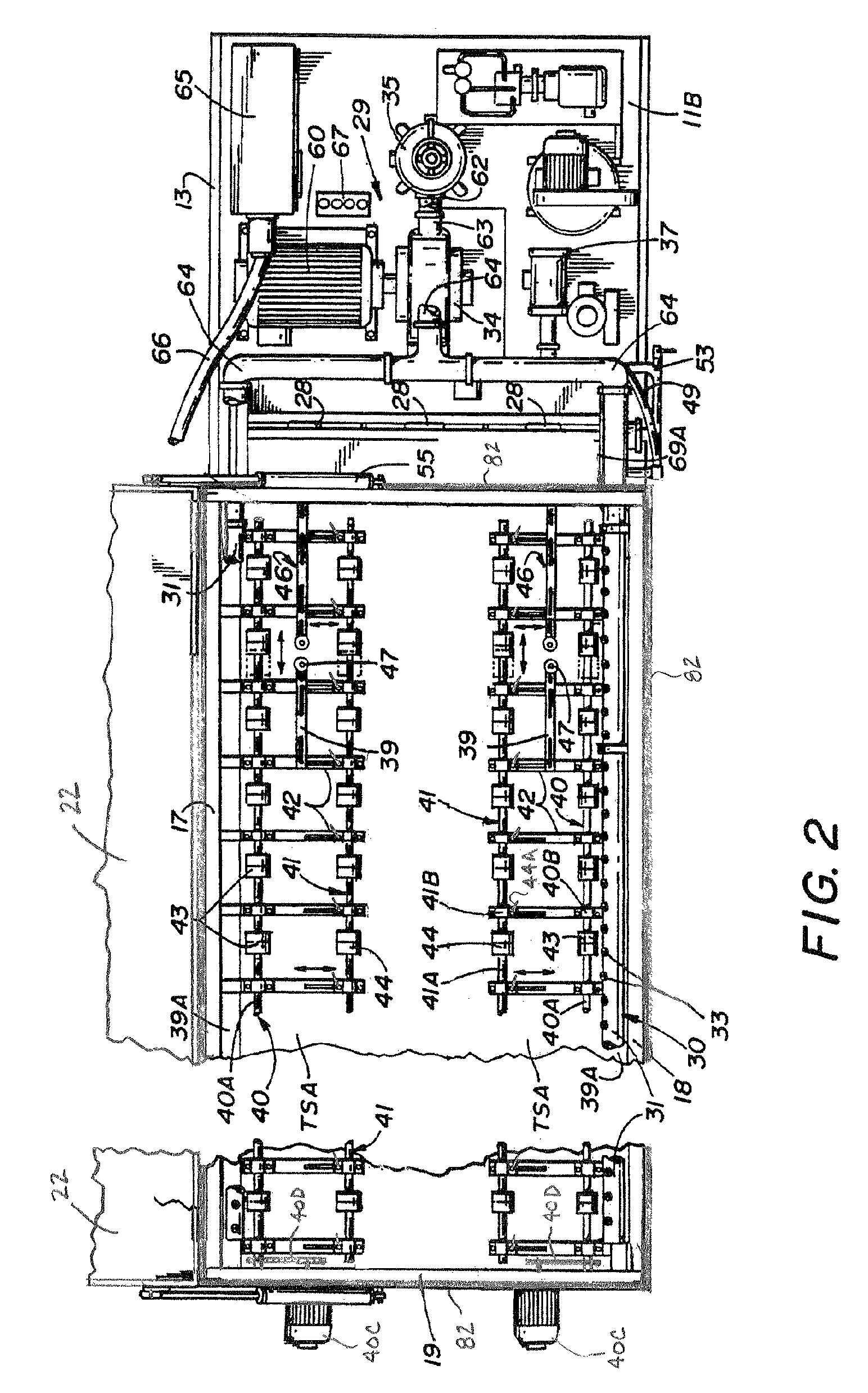

Method and system for cleaning heat exchanger tube bundles

InactiveUS20060185691A1Overcome problemsHollow article cleaningCleaning using toolsEngineeringOxygen

A method and system utilizing a mobile cleaning unit for providing cleaning of heat exchanger tube bundles. The mobile cleaning unit utilizes a pressurized seal positioned about top door of the cleaning enclosure to provide a fluid and vapor lock of the cleaning enclosure. An oxygen purging system of the cleaning enclosure, the cleaning fluid reservoir, and the control panels provides additional safety. The mobile cleaning unit can use cleaning fluid produced at the facility site and return the cleaning fluid to the facility site for reprocessing after the heat exchanger tube bundles are cleaned.

Owner:NAT HEAT EXCHANGE CLEANING CORP

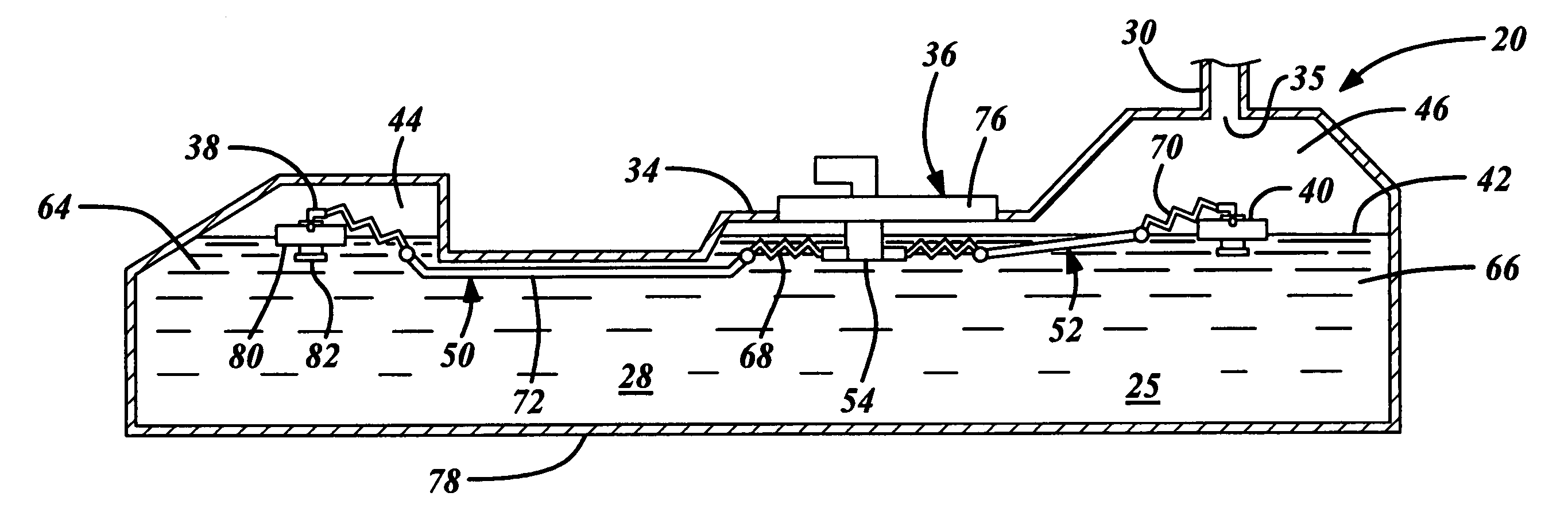

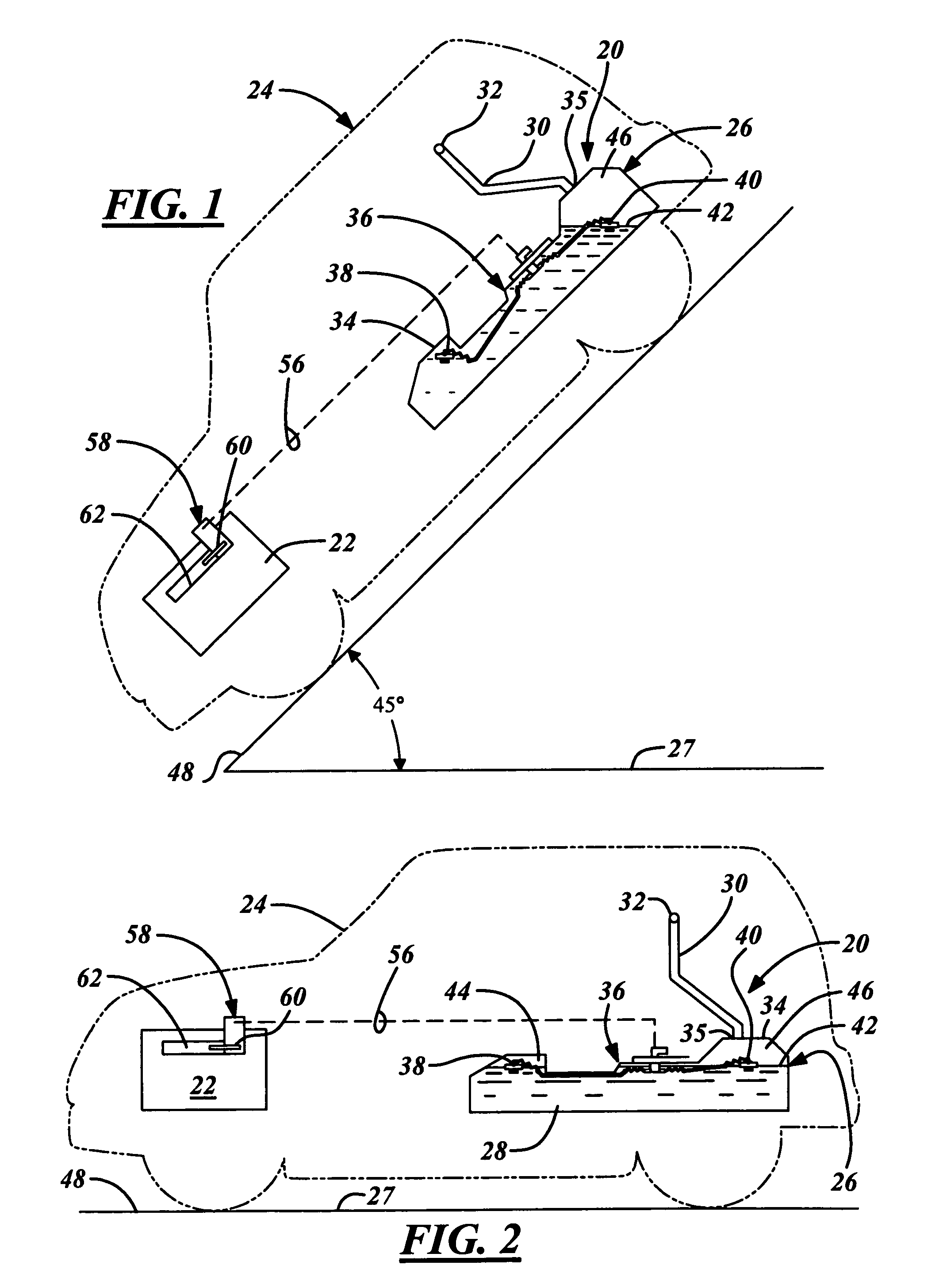

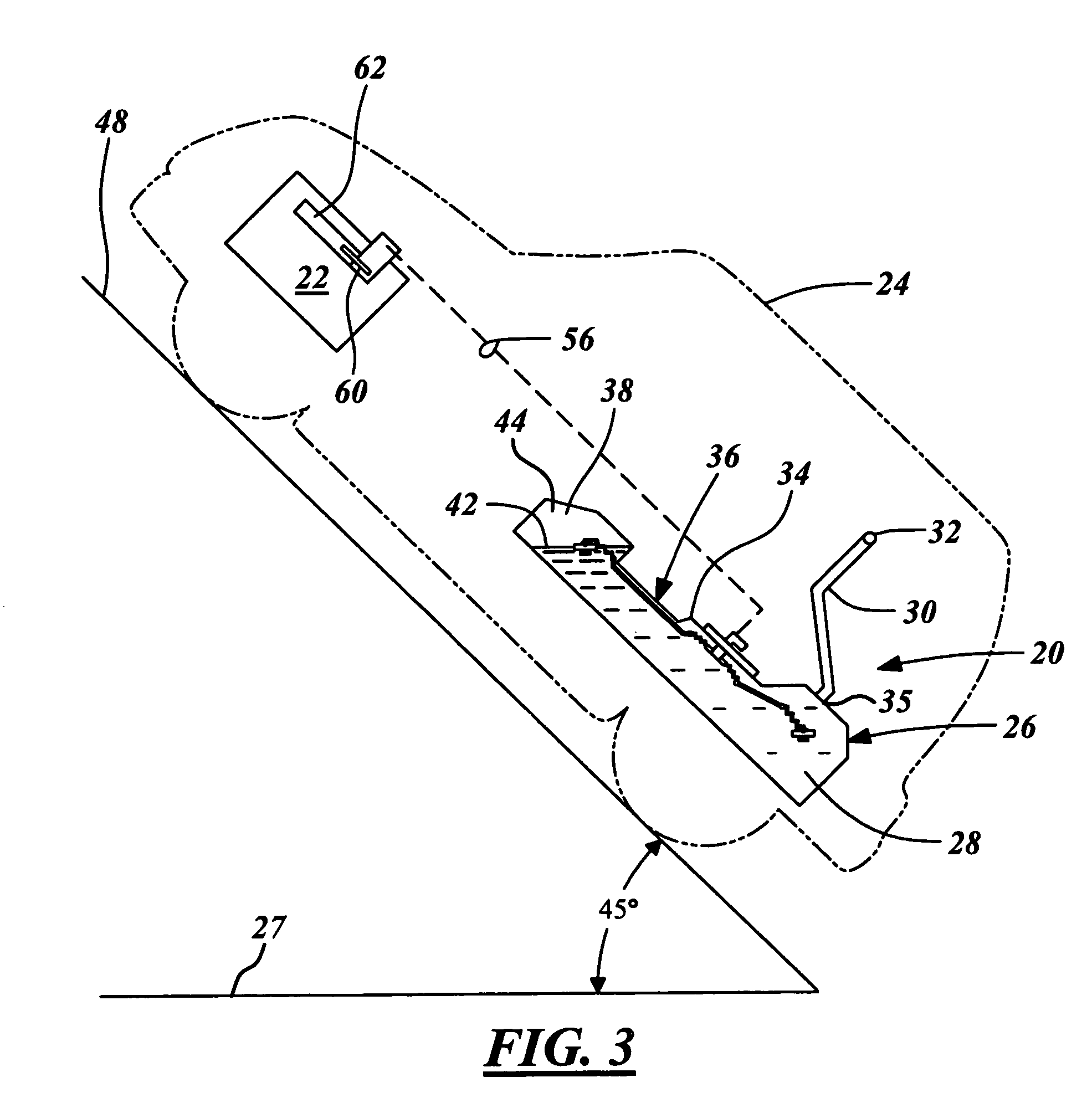

Fuel storage system for a vehicle

InactiveUS7520293B2Good flexibilityLight weightOperating means/releasing devices for valvesLarge containersExhaust valveSurface level

A fuel storage system for a transportation or recreational vehicle has a fuel tank that carries a vapor assembly that seeks out vapor pockets and controllably removes fuel vapor from the tank without releasing hydrocarbons to the surrounding environment. Preferably, a vent manifold attaches to a flange that sealably covers an access hole of the tank. At least one flexible tentacle extends from the manifold in the tank to a respective vapor vent valve that floats upon the surface of fuel at a vapor dome. When freely floating, the vent valve is open thus communicates the vapor dome through the tentacle and preferably with a filtering carbon canister. As fuel surface levels change or the vehicle tilts, changing the vapor dome size or location in the tank, the floating vapor vent valve is free to move generally with the vapor dome and as permitted by the flexibility of the trailing tentacle. With tank orientations where the vapor vent valve falls below the surface of fuel, the vent valve automatically closes to prevent flooding of the respective tentacle and remote vapor canister.

Owner:TI GRP AUTOMOTIVE SYST LLC

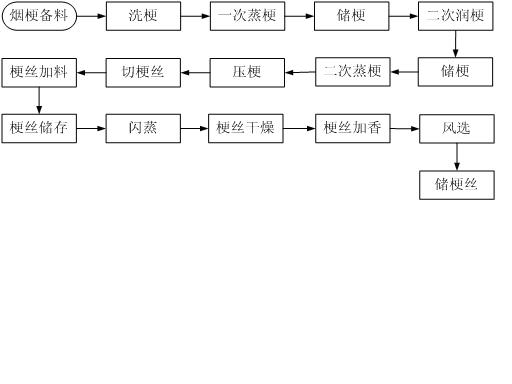

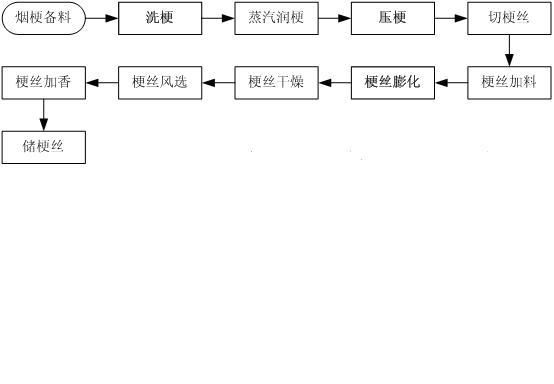

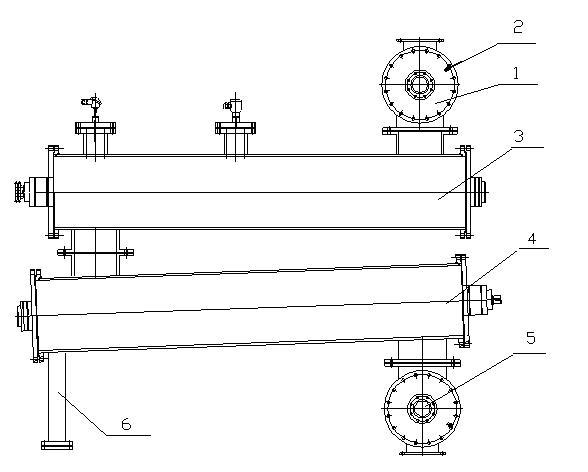

Steam stalk moistening method and equipment for implementing same

ActiveCN101862021AEnough pressureSufficient temperatureTobacco preparationPretreatment methodPulp and paper industry

The invention provides a tobacco stalk pre-processing method and tobacco stalk pre-processing equipment which can shorten the water permeability time of the tobacco stalk, ensure consistent moisture of the soaked tobacco stalk, save the storage process of the moistening of the tobacco stalk and simplify the process flow. The method comprises the following steps of: feeding a tobacco stalk material into a screw conveyer which is filled with steam and keeps proper pressure and proper temperature; continuously feeding the tobacco stalk material into the screw conveyer through a feeding vapor lock; continuously discharging the tobacco stalk material through a discharging vapor lock; and increasing the moisture and the temperature of the tobacco stalk to meet the requirements of the stalk pressing and cutting process on the discharging temperature and the moisture. The equipment comprises a bearing screw conveyer with a steam inlet and a water drainage port; a feed port and a discharge port of the screw conveyer are provided with the feeding vapor lock and the discharging vapor lock respectively; and the feeding vapor lock is provided with a water replenishing port. The water permeability of the tobacco stalk is improved by increasing the pressure and the temperature of the moistening environment of the tobacco stalk, so that the method and the equipment shorten the water permeability time of the tobacco stalks, quickly realize the pre-processing effect of the moistening of the tobacco stalk, save the storage process of the moistening of the tobacco stalk and greatly simplify the process flow of the stalk processing.

Owner:ZHISI HLDG GRP

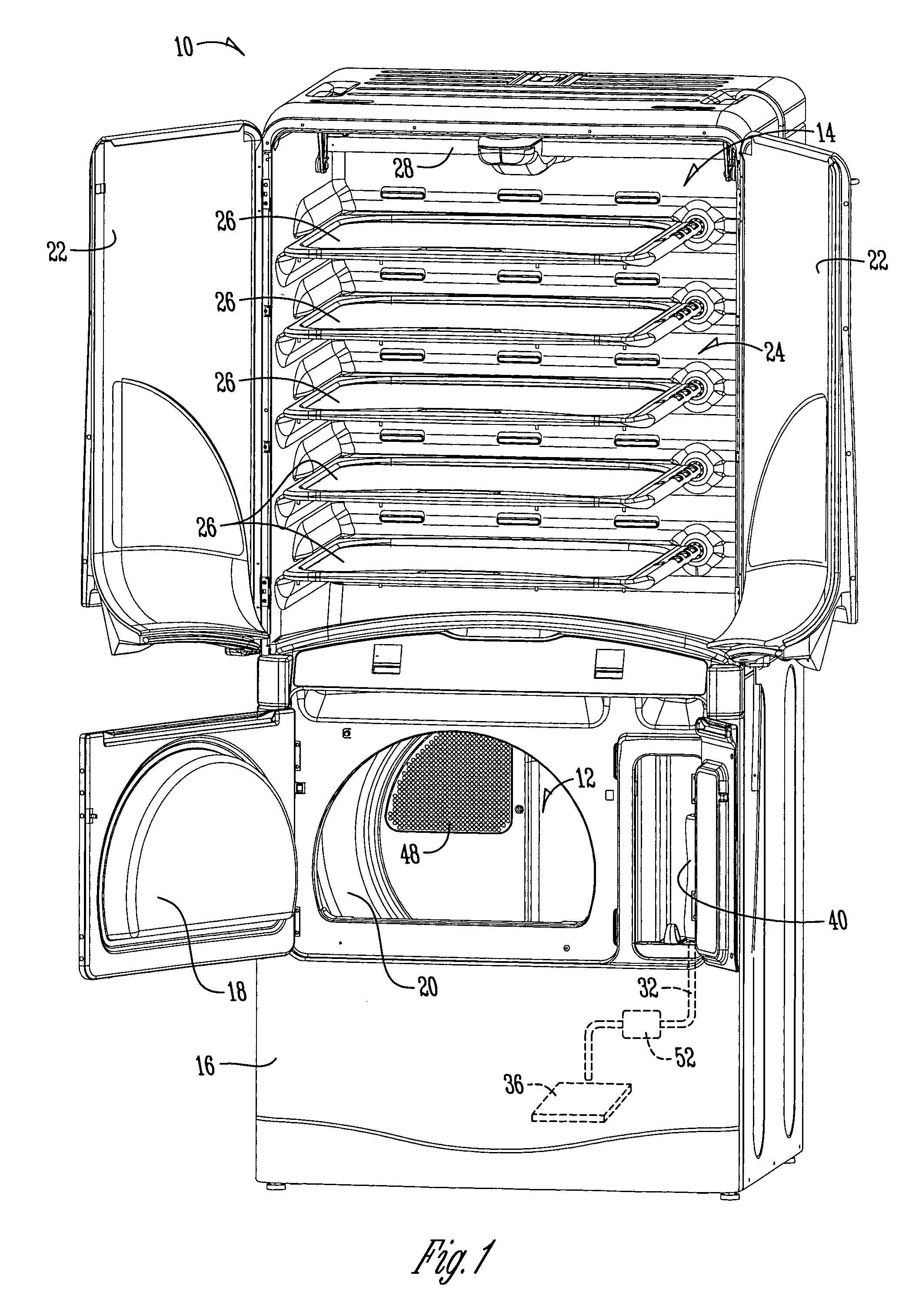

Filter vent for drying cabinet

InactiveUS20050278983A1Avoid cloggingPrevent vapor lockDrying gas arrangementsIroning apparatusVapor lockWater reservoir

A filter vent device is provided for a cabinet dryer having a steam generator for supplying steam to the drying chamber. A water reservoir supplies water to the steam generator via a water hose. The filter vent device is disposed in the water reservoir or tank and includes a water passage with a filter to prevent foreign particles or matter from passing into the hose, thereby preventing clogging. The filter vent device also includes an air passage to allow the escape of air from the water hose, thereby preventing vapor lock. The filter vent device is removably mounted in the water reservoir or tank and has a one-piece construction.

Owner:MAYTAG

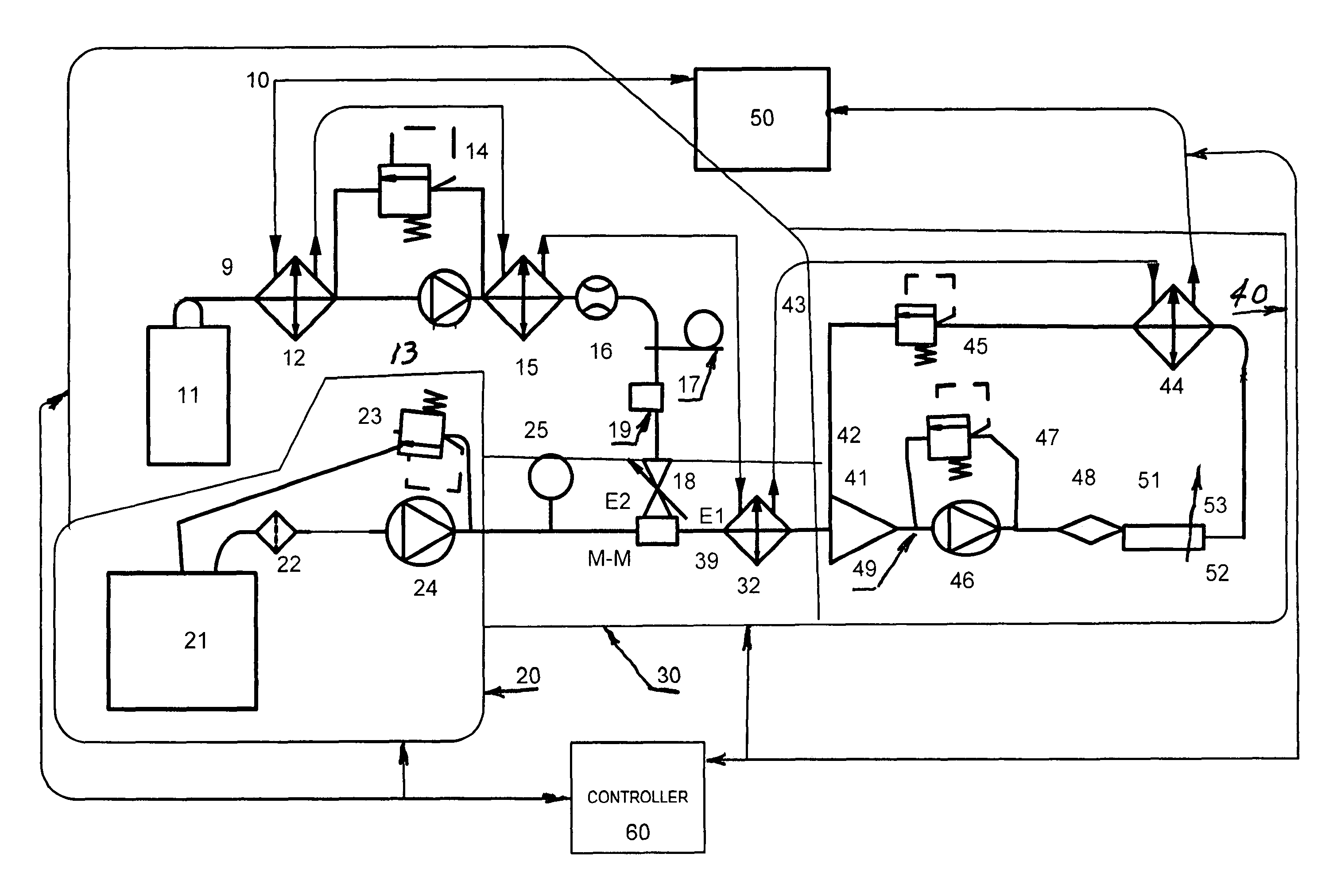

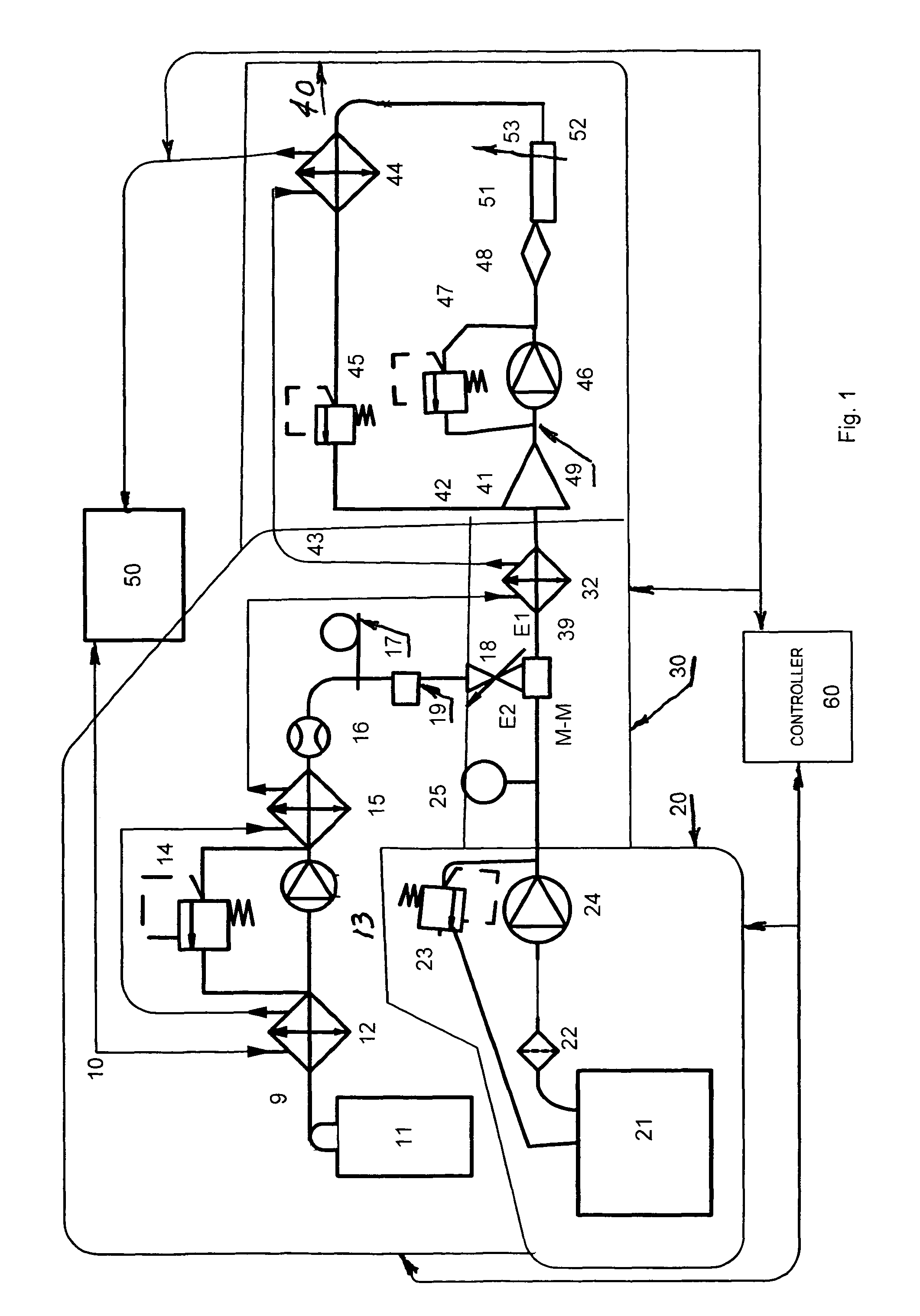

Fuel system and method for burning liquid ammonia in engines and boilers

ActiveUS8495974B2Avoid cavitationEnhance ignition and combustion characteristicElectrical controlControlling ratio of multiple fluid flowsCombustion chamberLiquid fuel

A process and apparatus is provided for burning liquid ammonia in an energy device such as a diesel engine, boiler or gas turbine. In particular, the process and apparatus include mixing a renewable fuel with a low flame speed and high ignition temperature, e.g., ammonia, with a combustible liquid fossil or bio-fuel and supplying the mixture into a closed fuel loop where part is efficiently burned in an engine combustion chamber, and part is used to cool the engine and returned by the loop for mixture with fresh incoming fuel mixture. The invention provides for the mixing and emulsifying in such a way that vapor lock is avoided. In the loop, the mixture is emulsified into a disperse distribution of fuel droplets such that upon injection of a portion into the combustion chamber, the renewable fuel in an emulsified droplet evaporates, mixes with the air and forms a small combustion cell surrounding the liquid fuel droplet. The fuel droplet burns and then serves as an ignition kernel for the gas mixture in the small combustion cell producing efficient and rapid combustion of the renewable fuel. The fuel loop allows the fuel system to automatically scale for engines varying in power output from 1 to 35,000 horsepower.

Owner:CAHN RICHARD C +1

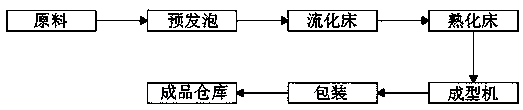

EPS package foam forming technology

The invention discloses an EPS package foam forming technology. The EPS package foam forming technology comprises the following steps of first, carrying out material selection; second, carrying out pre-foaming; third, carrying out fluidization; fourth, carrying out curing; fifth, carrying out forming; six, carrying out packaging; and seventh, obtaining a finished product. According to the EPS package foam forming technology, a mold designed according to the technology is used for mold forming work, and according to a traditional mold, because of a vapor lock, a vapor lock hole is prone to being blocked when ultrafine raw materials are in use; the smooth finish of the appearance of a product is guaranteed; during demolding work after forming is completed, air blowing and an ejector rod areused in cooperation, a water-free demolding technology without the vapor lock is adopted, at the moment of demolding, air blowing is carried out on a lower mold to enable the product to move towards an upper mold, and after the upper mold is opened to some extent, the product is sent downwards through the ejector rod of a material gun, and a blow-out valve acts at the time to blow the product outof the mold; and in this way, it can be avoided that the surface of the product is poor in flatness because of sinking after being impacted by water with a high-speed, and the process of transferringthe product to a drying room for drying is omitted.

Owner:江西维力科技有限公司

Biodiesel

InactiveCN101469282AIncrease motivationImprove antiknock performanceBiofuelsLiquid carbonaceous fuelsAlkaneDetonation

The invention relates to a biodiesel, which is finally prepared by the processes of mixing and stirring diesel oil, solvent oil, gasoline, alkane, rapeseed oil, hogwash oil, acidated oil, palm oil, vegetable oil and animal oil, can achieve synchronous combustion and outburst, can greatly improve the power and the anti-knock property of an engine without the phenomenon of detonation, can ensure that the engine is easy to start in winter, is not easy to generate vapor lock in summer, give full play to the power, does not erode vehicle machine members in the use process, can clean and maintain the engine without disassembly and eliminate carbon deposited in the engine, prolong the service life of the engine, can be burnt more sufficiently due to the high oxygen content simultaneously with far less air (oxygen) than the common diesel oil in burning, does not generate black smoke, has low tail gas emission which is more than 40 percent lower than that of the common diesel oil, and is a high cleanliness fuel worthy of the name.

Owner:史国兴

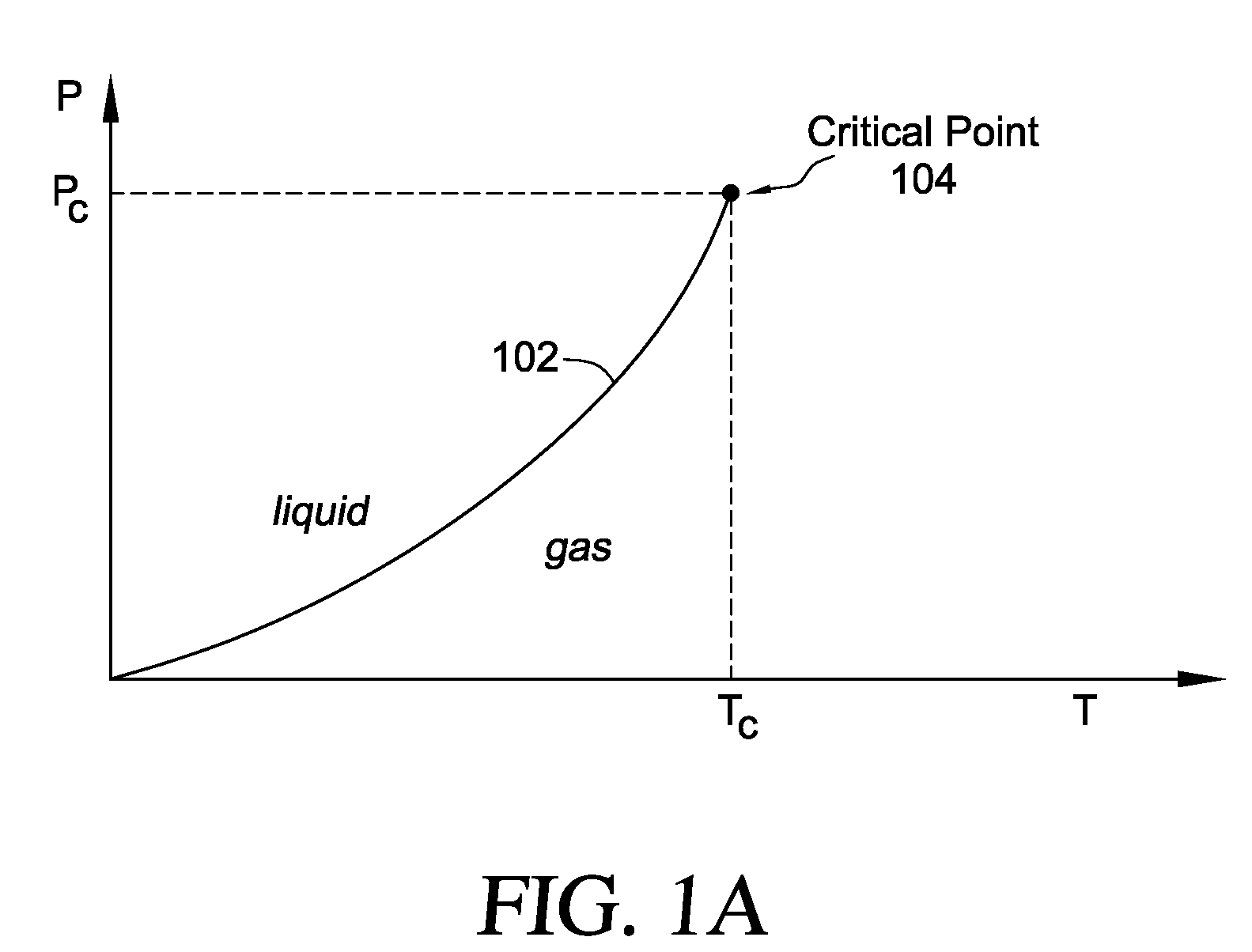

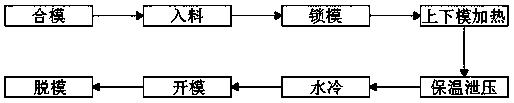

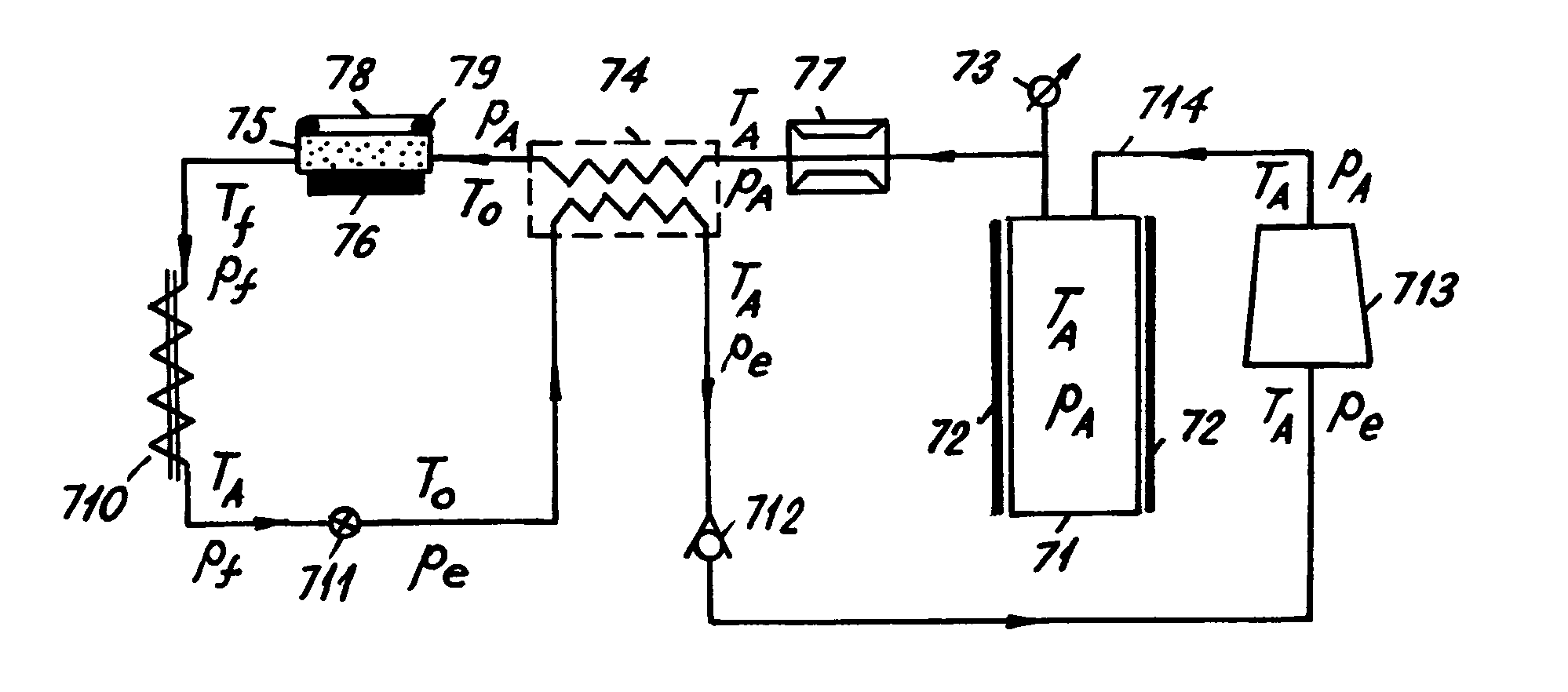

Cooling methods and systems using supercritical fluids

InactiveUS20090113903A1Most efficientReliable absorptionCompression machinesHeat-exchange elementsEngineeringVapor lock

The methods and systems using supercritical fluids for cooling of objects with high thermal emissions are disclosed. The unique thermodynamic properties of supercritical fluids combined with microchannel cooling technology allow effective absorption of the waste heat and exclude “vapor lock”, “boiling crisis”, and other deficiencies of conventional two-phase liquid cooling.

Owner:CRYOMECHANICS

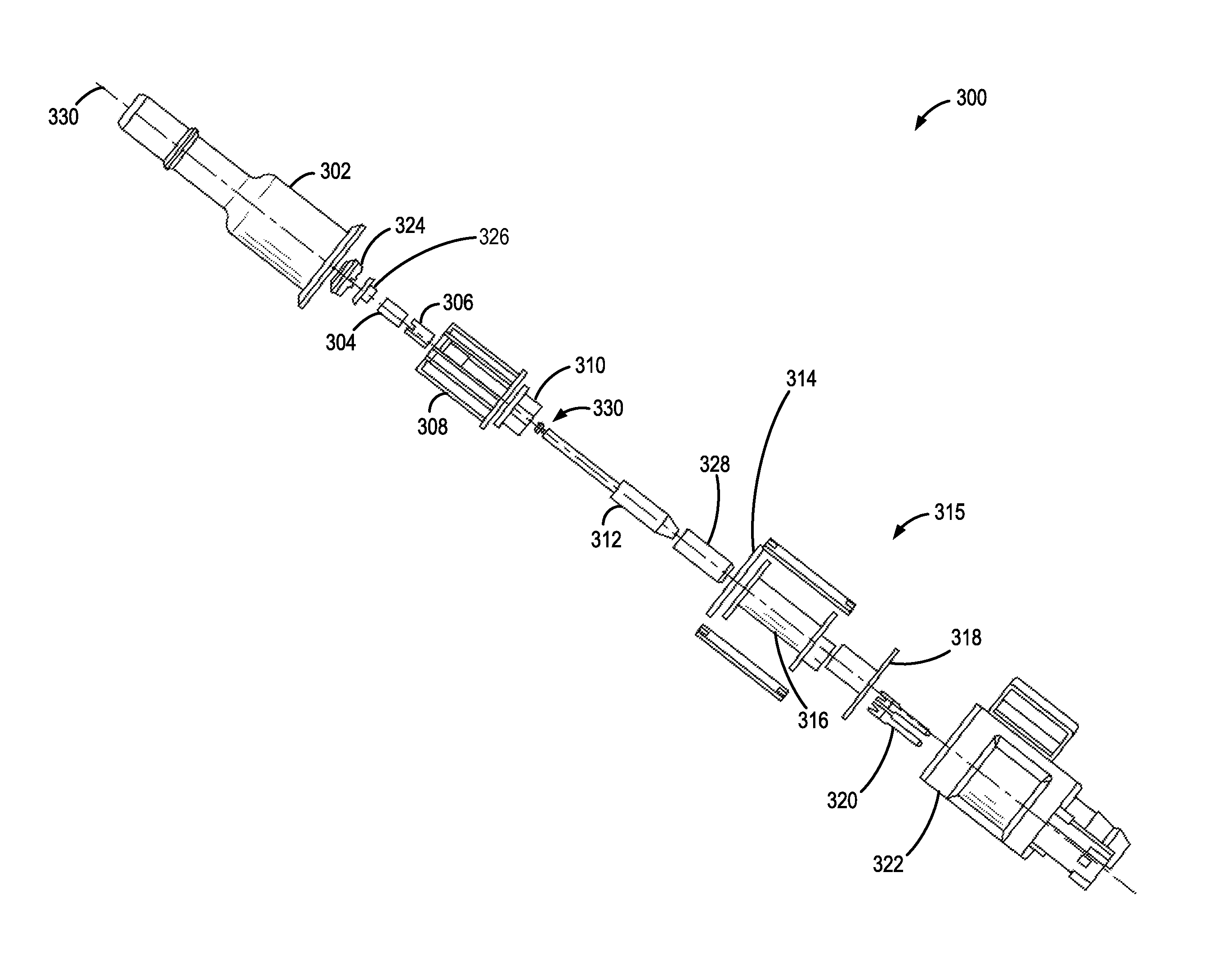

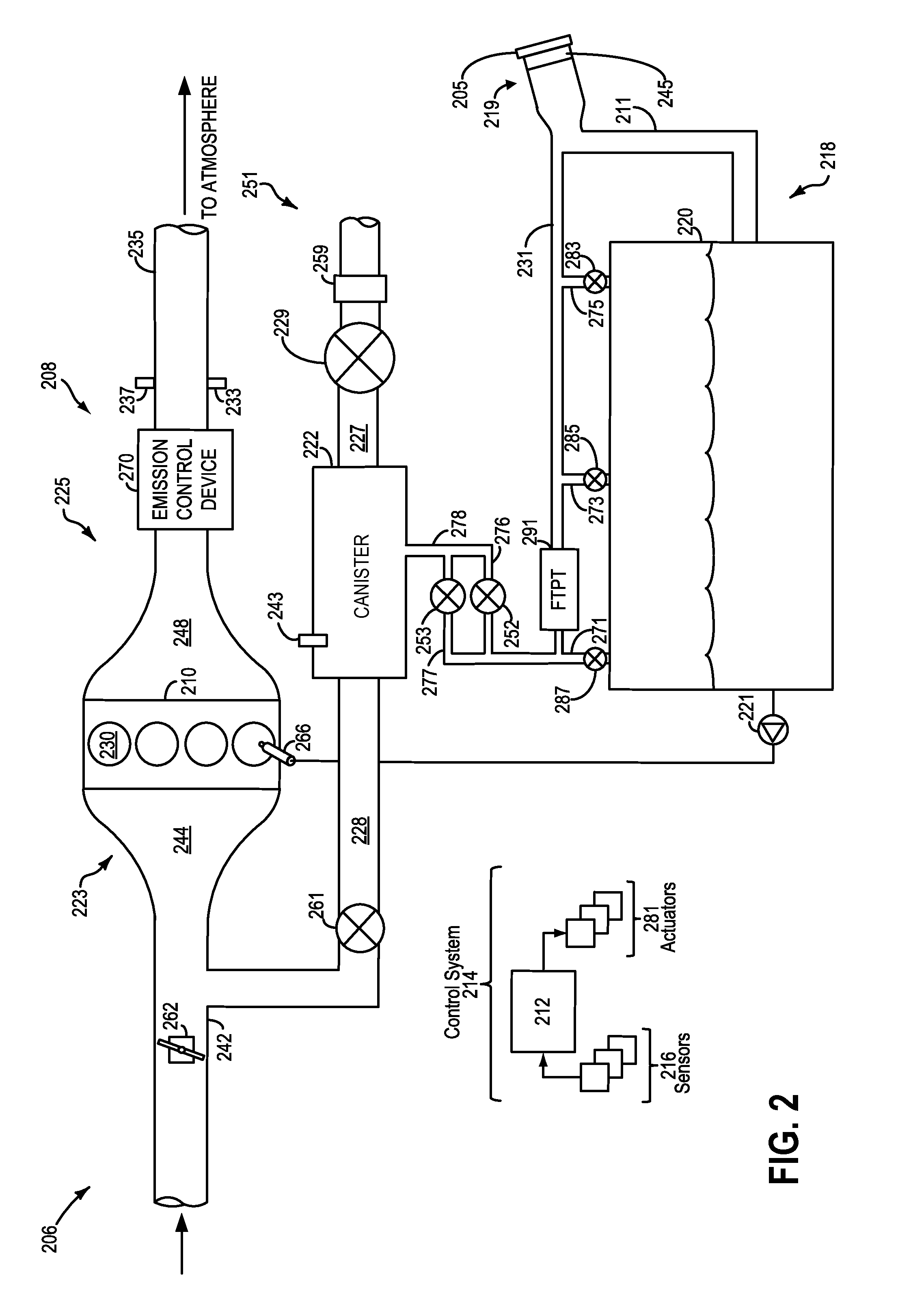

Systems and methods for depressurizing a fuel tank

ActiveUS20160298579A1Reduce releaseReduce tank pressureOperating means/releasing devices for valvesNon-fuel substance addition to fuelEngineeringPressure threshold

Methods and systems are provided for depressurizing a fuel tank prior to refueling the fuel tank. One example method includes adjusting a latchable refueling valve to a latched open position to enable vapor flow from the fuel tank to a vapor canister at a first rate, and responsive to fuel tank pressure being higher than a first pressure threshold after a pre-determined duration at the latched open position, modifying the latchable refueling valve to an unlatched open position. The unlatched open position of the latchable refueling valve enables a second flow rate for fuel vapors, the second flow rate higher than the first flow rate at the latched open position.

Owner:FORD GLOBAL TECH LLC

Component oil capable of reducing saturated vapor pressure of methanol gasoline

InactiveCN101760258ALow saturated vapor pressureCorrect positive deviationLiquid carbonaceous fuelsFuel additivesCatalytic reformingNaphtha

The invention discloses component oil capable of reducing saturated vapor pressure of methanol gasoline, which is prepared from 20 to 25 percent of No.120 solvent oil, 20 to 25 percent of No.200 solvent oil, 5 to 10 percent of methylbenzene, 3 to 5 percent of dimethylbenzene, 20 to 30 percent of heavy naphtha and 20 to 25 percent of catalytic reformed gasoline. The component oil is mainly used for blending with traditional national standard No.90 and No.93 gasoline to prepare low proportional methanol gasoline with the methanol content of 10 to 30 percent, so that the positive deviation of the saturated vapor pressure of the low proportional methanol gasoline is rectified, the saturated vapor pressure of the low proportional methanol gasoline is effectively reduced, the vapor pressure is ensured to be not high when the national standard No.90 and No.93 gasoline are doped with the low proportional methanol, a 'vapor lock' phenomenon cannot happen in high temperature weather, and an engine can normally work.

Owner:山西华顿实业有限公司

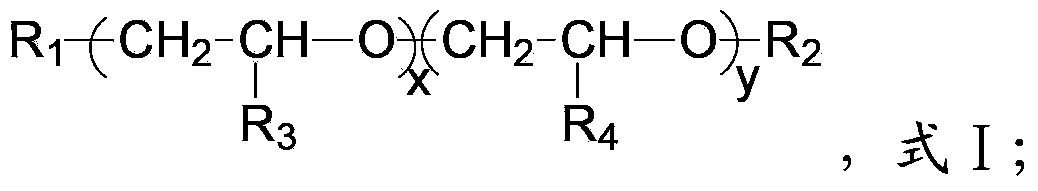

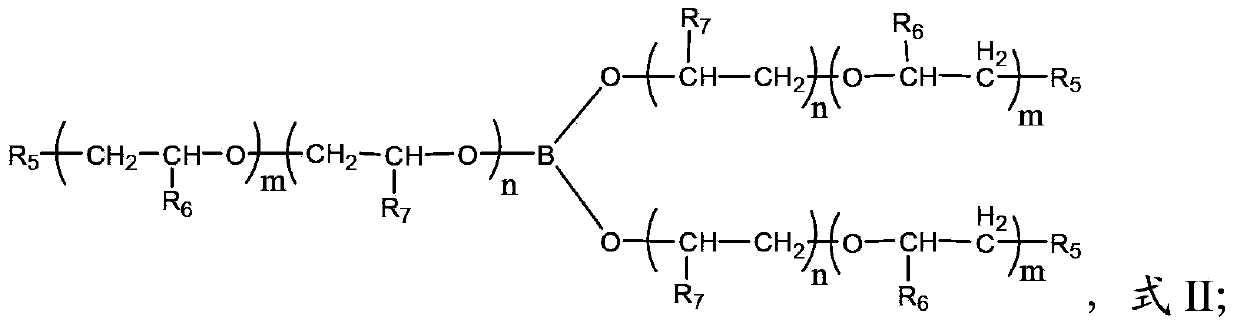

Motor-vehicle brake-fluid composition and preparation method thereof

The invention provides a motor-vehicle brake-fluid composition. The composition comprises: 49 wt%-59 wt% of polyalkylene glycol ether, 40 wt%-50 wt% of polyalkylene glycol ether orthoborate, 0.1 wt%-3.0 wt% of an antioxidant, 0.01 wt%-0.5 wt% of a metal deactivator, 0.1 wt%-3.0 wt% of a corrosion inhibitor, and 0.0005 wt%-0.05 wt% of an anti-foaming agent. The prepared motor-vehicle brake-fluid composition provided by the invention has no vapor lock under a high-temperature condition, and has excellent flowing performance under a low-temperature condition; and all performances of the composition meet or exceed the indexes of GB12981-2021HZY6, and the composition is capable of transmitting brake energy normally under an extremely low-temperature condition.

Owner:CHINA PETROLEUM & CHEM CORP

Methanol gasoline for vehicles

InactiveCN103361128AGood miscibilityPrevent oxidation and corrosionLiquid carbonaceous fuelsSolventCleansing Agents

The invention relates to methanol gasoline for vehicles. The methanol gasoline for the vehicles comprises the following raw materials: by volume ratio, 15-100 of methanol, 0-85 of gasoline, 1-2 of an additive. The additive comprises the following components: by volume ratio, 4-10 of a cosolvent, 50-70 of an antiknock agent, 5-20 of a lubricant, 1-10 of a preservative, 3-15 of a cleaning agent, 1-8 of a combustion improver and 1-8 of an anti-vapor-lock agent. The methanol gasoline for the vehicles has good mutual solubility due to the addition of the cosolvent. Due to the addition of the antiknock agent, the lubricant, the preservative, the cleaning agent, the combustion improver and the anti-vapor-lock agent, the methanol gasoline for the vehicles can prevent oxidation corrosion of metal parts and wearing of cylinders, and has the advantages of strong dynamic property, full combustion, high antiknock property, no vapor lock and the like. Because the main raw materials are the gasoline and the methanol and cost of the raw materials is low, the methanol gasoline for the vehicles is convenient for industrial production.

Owner:深圳欧醇化国际新能源科技有限公司

Enthalpy extractor for hydrocarbon vapors

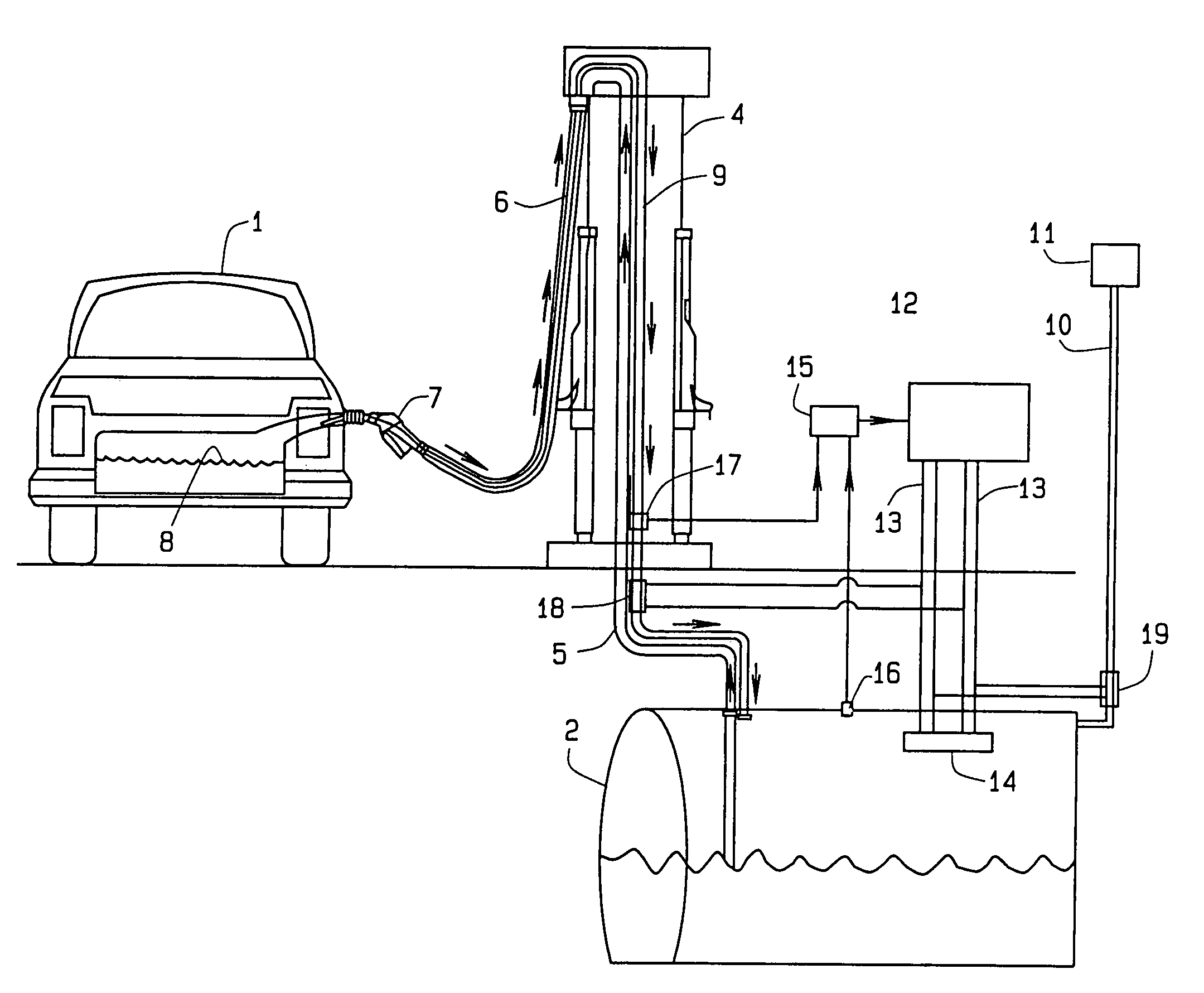

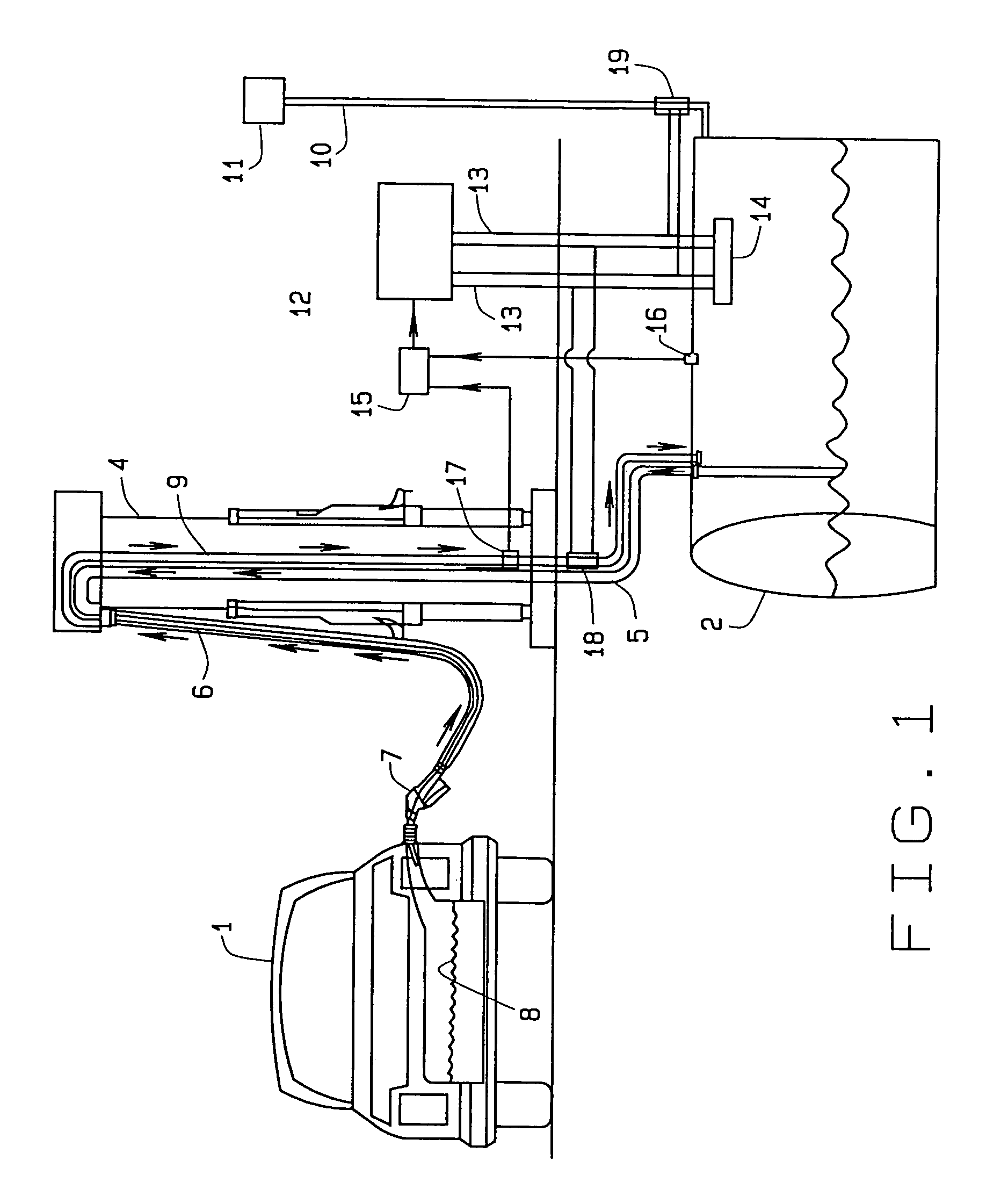

InactiveUS7000651B2Reduce chanceKeep the pressureLiquid transferring devicesSolid materialPressure reductionUnderground storage tank

A fuel storage tank vapor cooler to effect pressure reduction, in a fuel dispensing system, including the application of a refrigeration unit, that operates under the effects of a control unit, sensitive to vapor pressures, and vapor flow, to initiate the operations of the refrigeration unit, and effecting, through a properly located heat exchanger, a reduction in the temperature of the stored vapors, and thereby reducing its incident pressure. Such heat exchangers may be located either within the vapor storage area of the underground storage tank, the heat exchanger may locate in cooperation with the vapor return line, to the underground storage tank, or it may be located within the vent line from the storage tank, to chill the vapors and thereby provide for a reduction in their pressure. Such heat exchangers may be used in combination, or individually, whatever is determined to obtain the results as desired from the system of this invention.

Owner:HUSKY CORP

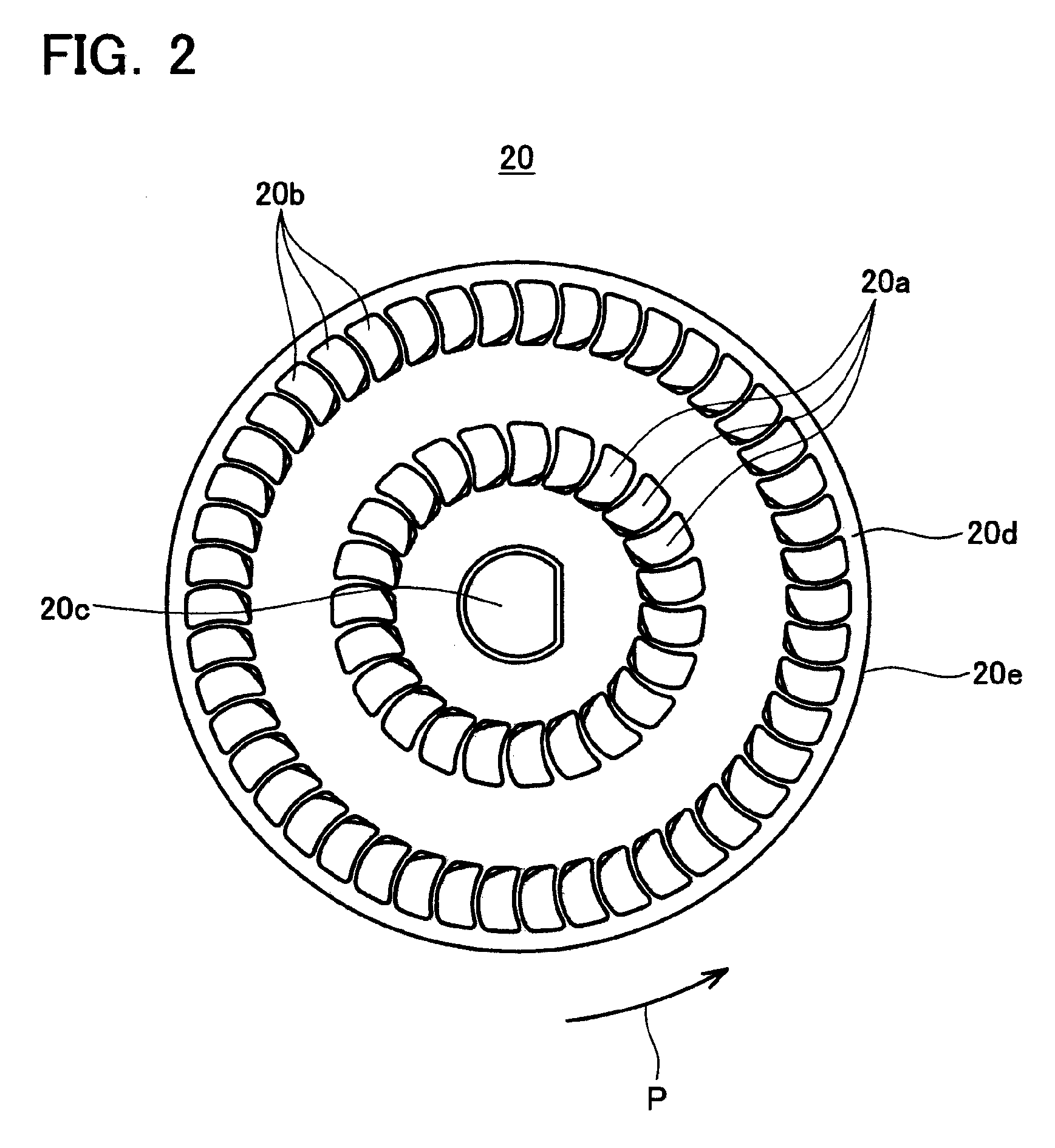

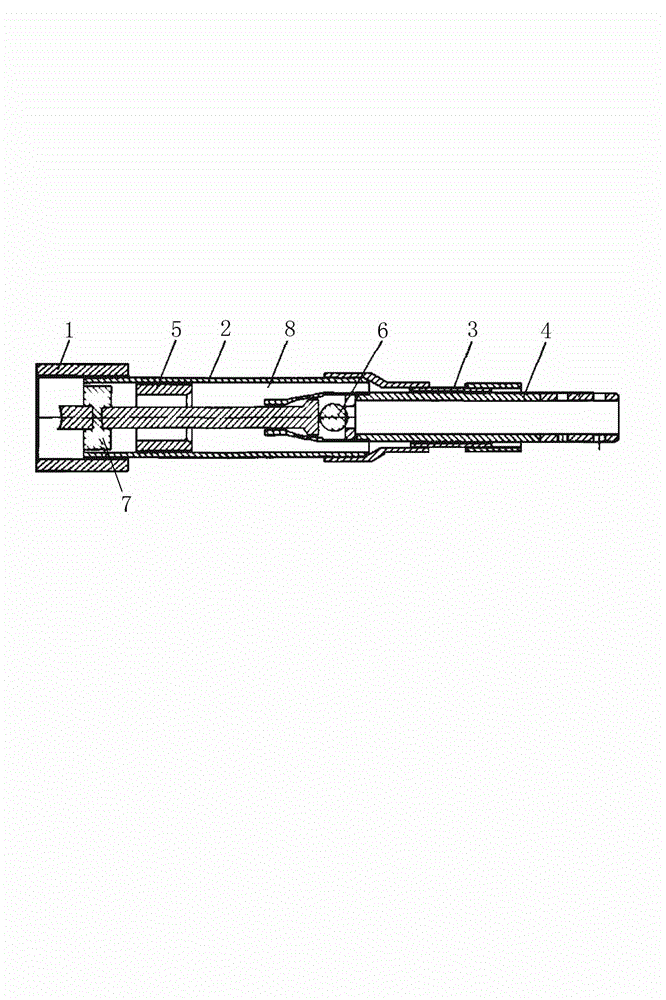

Fuel pump

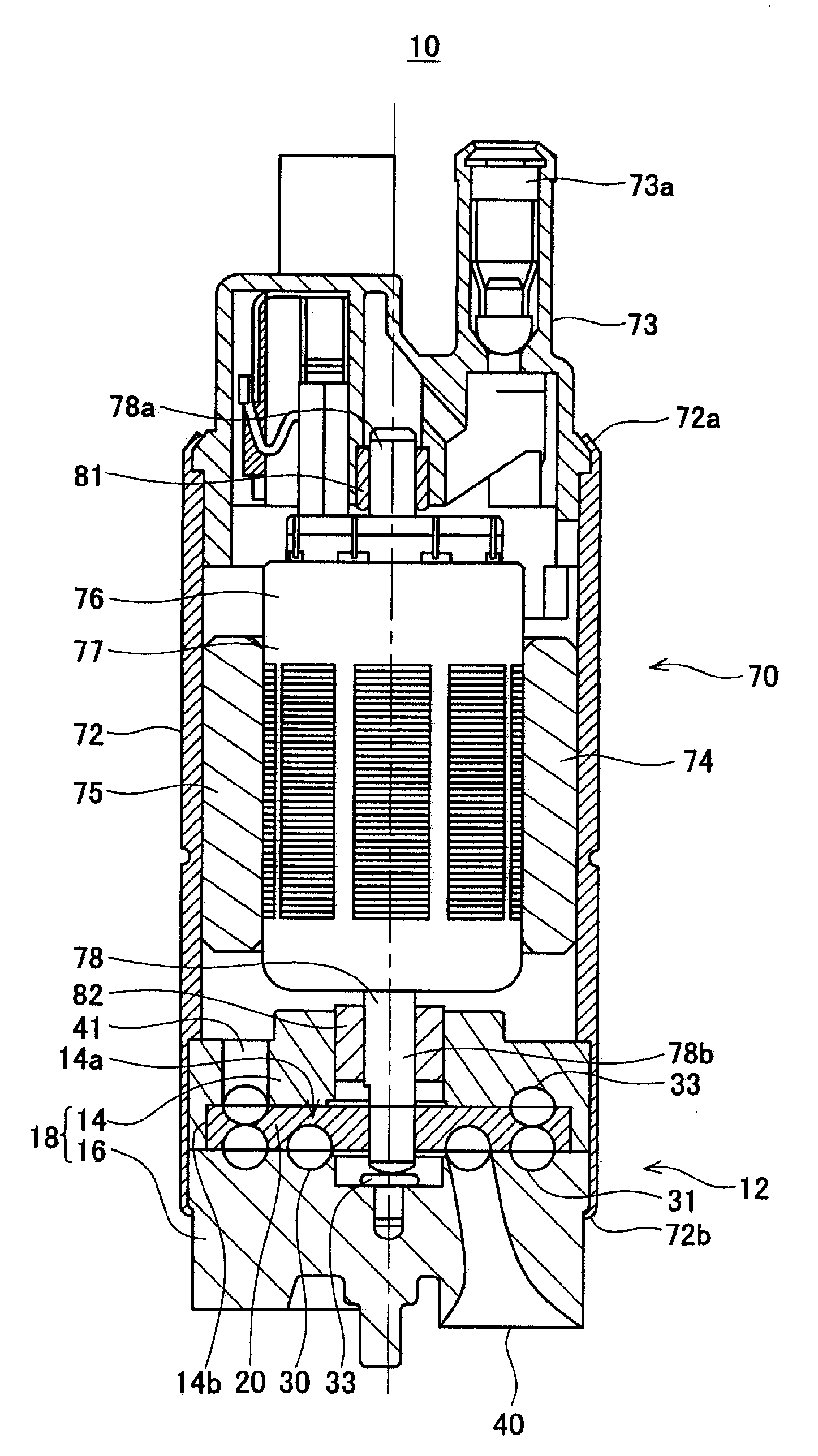

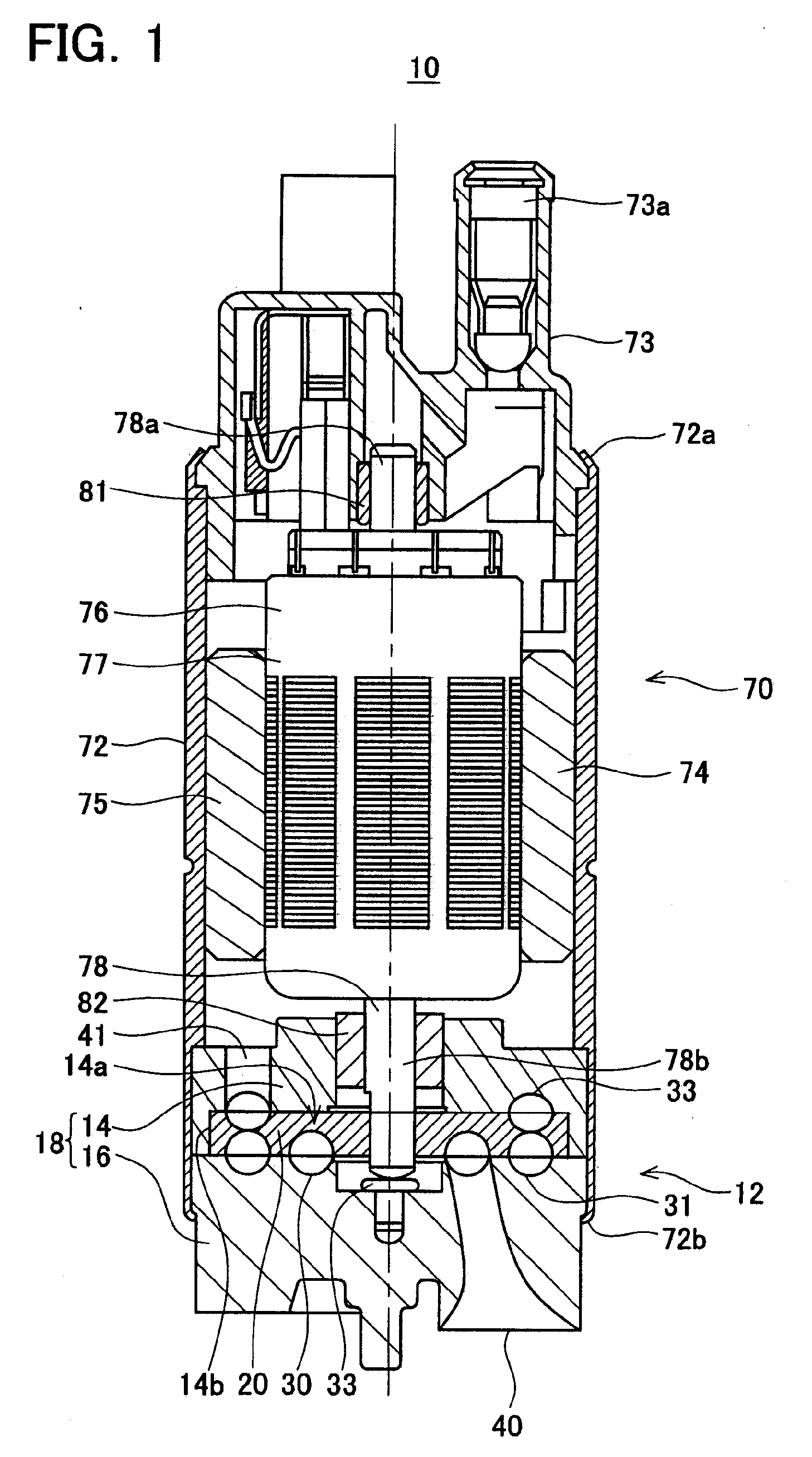

InactiveUS20070264117A1Reduces efficiency of pumpChange pressureCircumferential flow pumpsPump componentsImpellerVapor lock

A vapor lock in a fuel pump can be prevented by reducing the formation of vapor within the fuel. A first group of concavities may be formed in an inner circumferential region of an intake side face of an impeller, and a second group of concavities may be formed concentrically in a region outside of the first group of concavities. A third group of concavities that communicates with the second group of concavities may be formed in a discharge side face of the impeller. The impeller is housed within a casing. A first groove that faces the first group of concavities and a second groove that faces the second group of concavities may be formed in the face of the casing that faces the intake side face of the impeller. A third groove that faces the third group of concavities may be formed in the face of the casing that faces the discharge side face of the impeller.

Owner:AISAN IND CO LTD

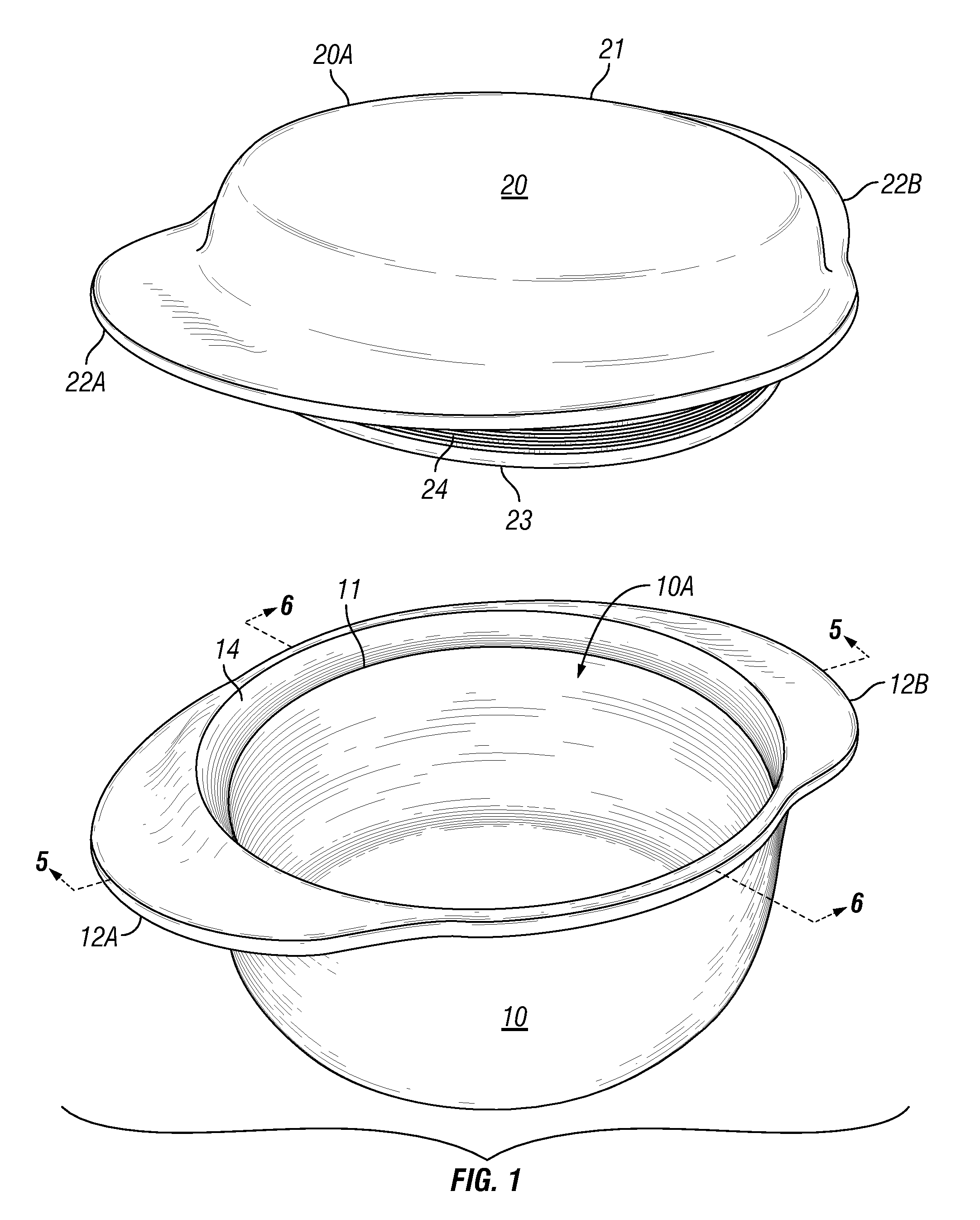

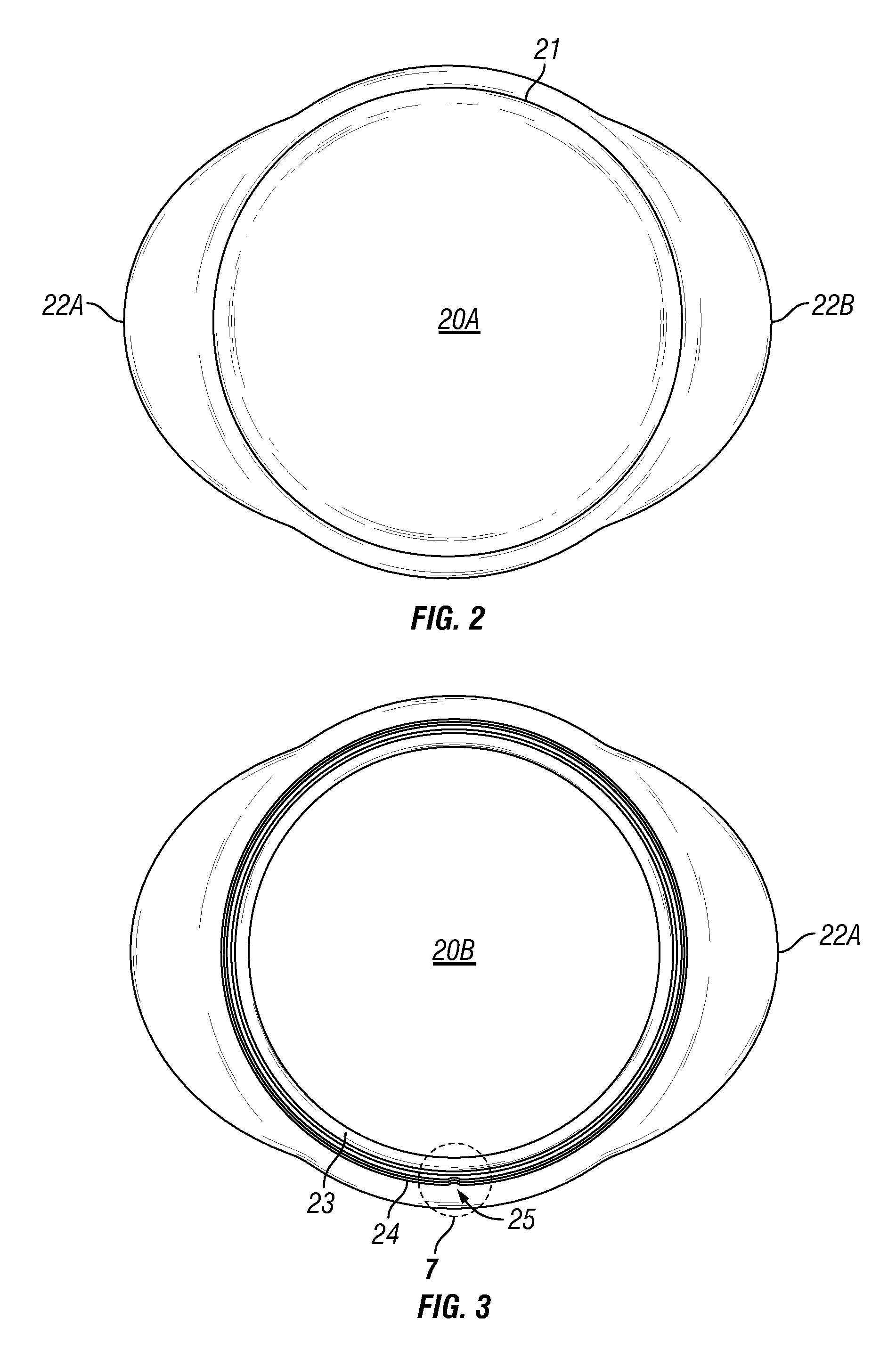

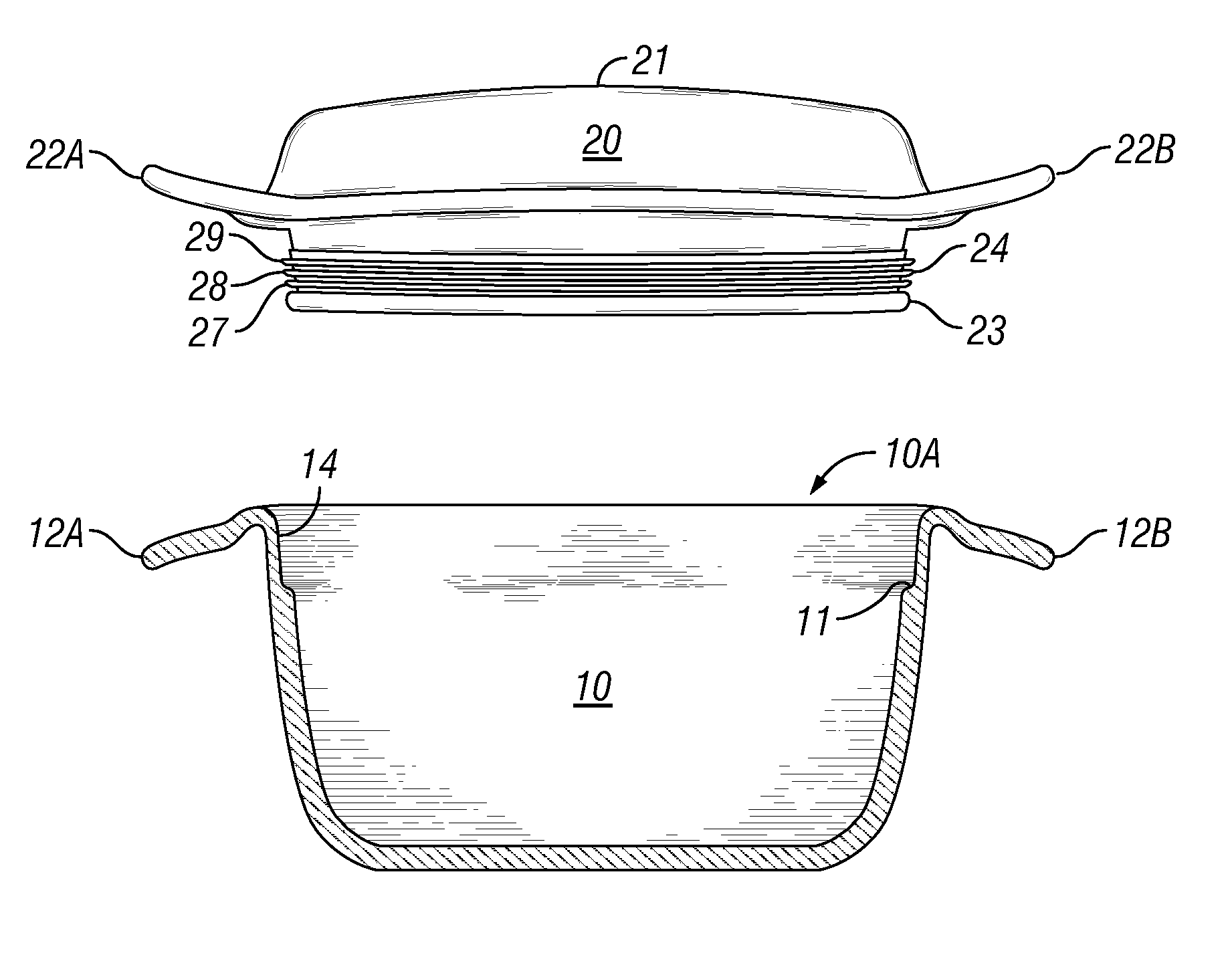

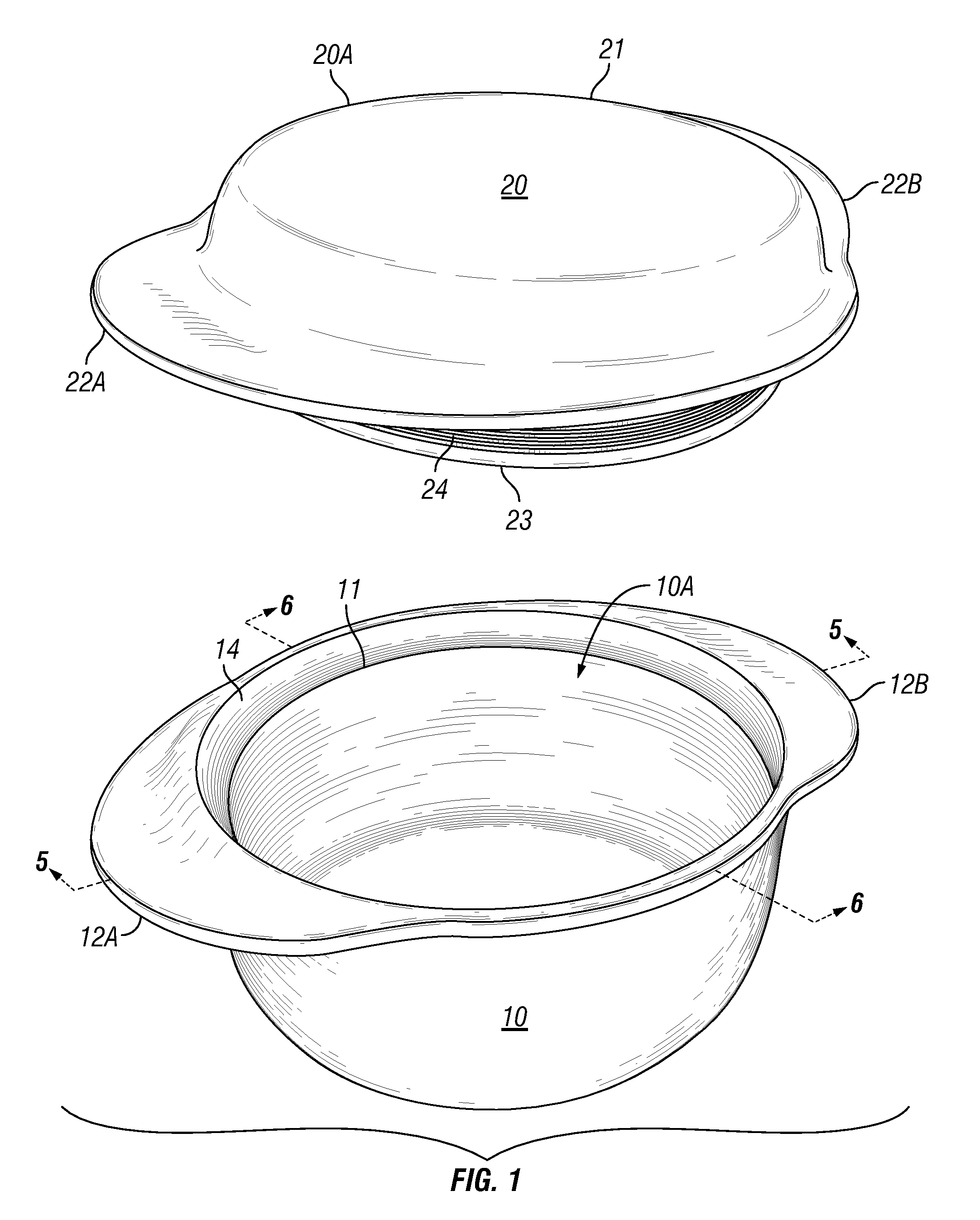

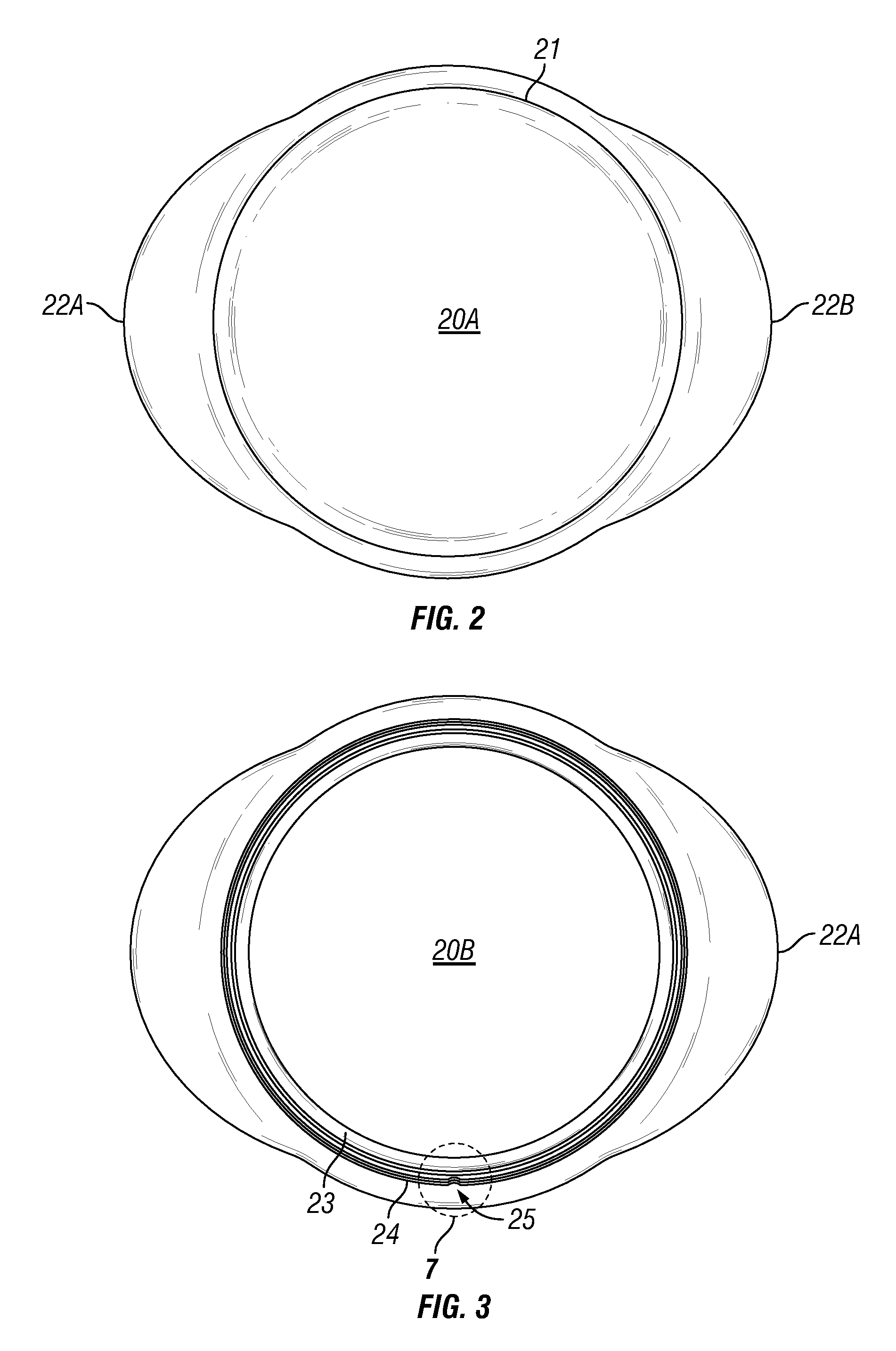

Food container apparatus and method of using same

ActiveUS20100200075A1Promote sportsRelieve stressCooking-vessel materialsCooking-vessel lids/coversMicrowave ovenRoom temperature

A food container system and method of using same is provided for heating, storing or cooling food placed within a container. The container system facilitates heating of food without dehydration of the food, and it permits cooling of the food, such as, for example, cooling in a refrigerator or cooling at room temperature after removal from a heating oven or microwave, without vapor lock preventing or making difficult the removal of a lid from a container in which the food is heated or cooled. The system comprises, in one aspect, a ceramic lid and a ceramic container to receive the lid, and a seal having a channel there through and disposed intermediate the ceramic lid and the ceramic container. In one aspect, the seal may comprise a heat-resistant silicon material. In one aspect, the same container system may be used, for example, to heat a food placed in the container, to serve the food at a dining table, and to store the food, or the remaining unconsumed portion of the food, in a refrigerator for later reheating and consumption.

Owner:LENTRADE

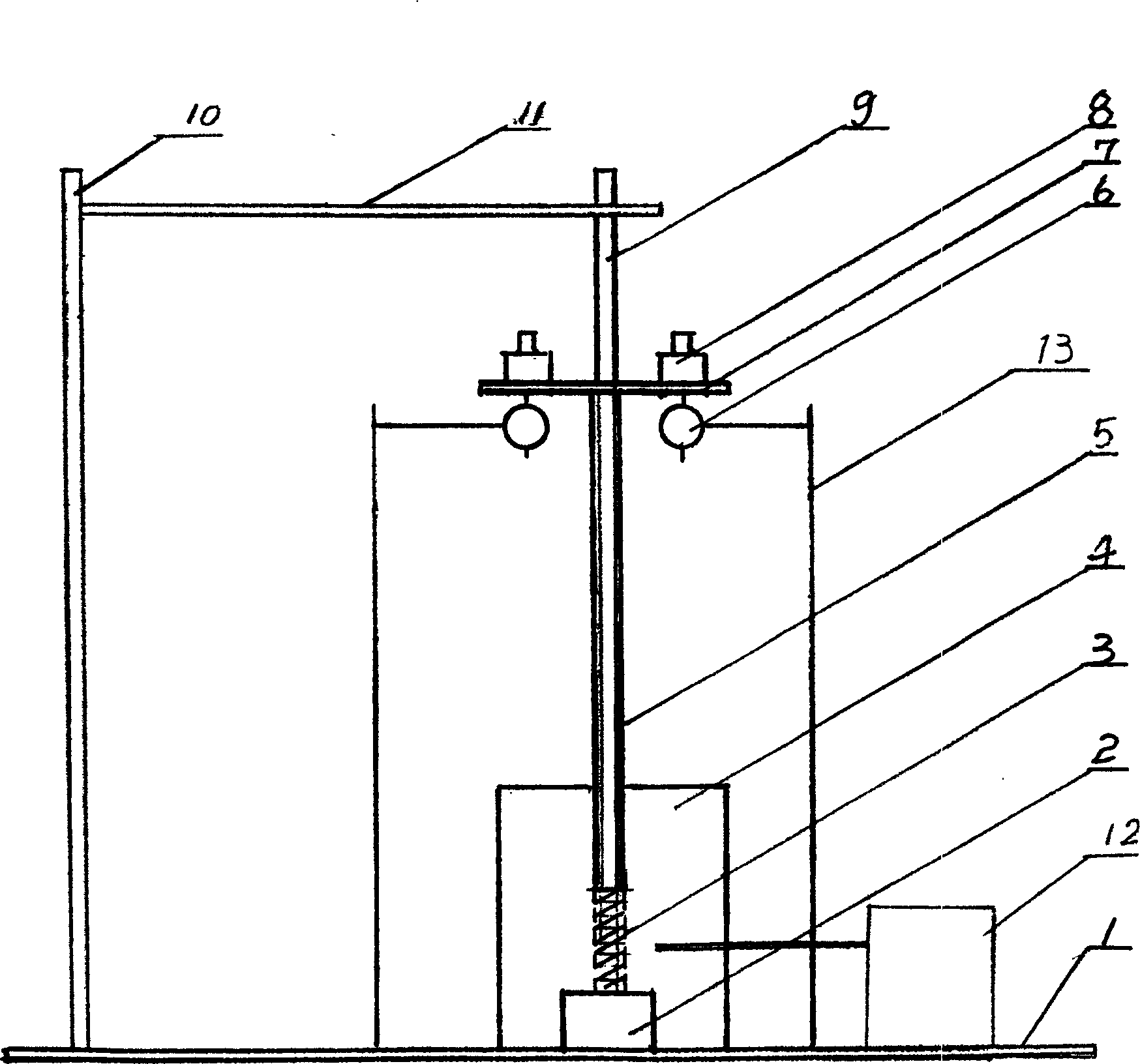

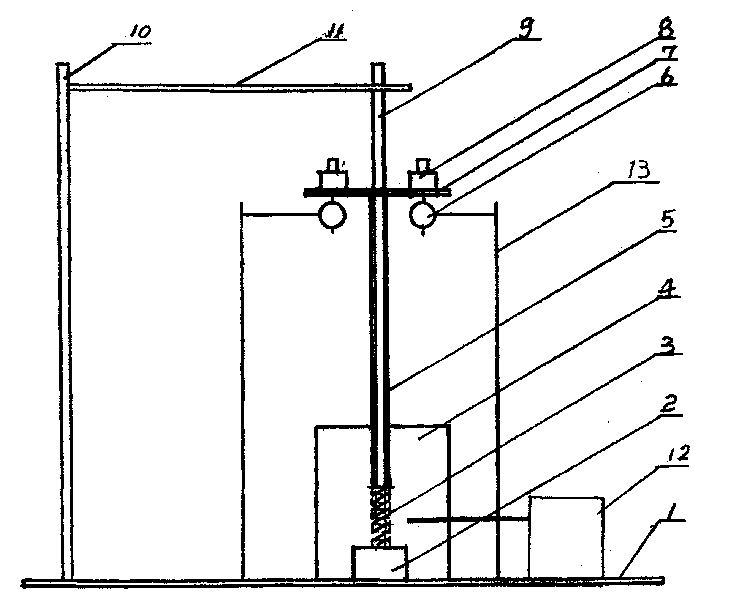

High temperature alloy spring for steam turbine steam locking and its processing method and detecting installation

InactiveCN1410688AImprove quality levelHigh thermal efficiencyLeakage preventionMachines/enginesQuality levelWorking temperature

The column type helical spring is made from Inconal X-750 (GH4145) alloy wire. The procedures for manufacturing the spring are as following: wrapping the semi-finished product of long coil of spring:cutting the long coil to single springs; washing the springs; carrying out the solid solution heat treatment; cutting end and adjusting the pitch, and carrying out the aging heat treatment. With the tests of rigidity and permangnet deformation in high temperature being completed, the finished springs are obtained. The device for testing rigidity of the spring includes the worktable, the electric stove and dial gauge etc. Testing indicates the performances of the spring: when the working temperature at 550 degree.C, the service life > or =25000 hr. The spring is easy to be assembled in the vapor lock.

Owner:DONGFANG TURBINE CO LTD

Food container apparatus and method of using same

ActiveUS8708184B2Promote sportsRelieve stressCooking-vessel materialsRemovable lids/coversMicrowaveRoom temperature

Owner:LENTRADE

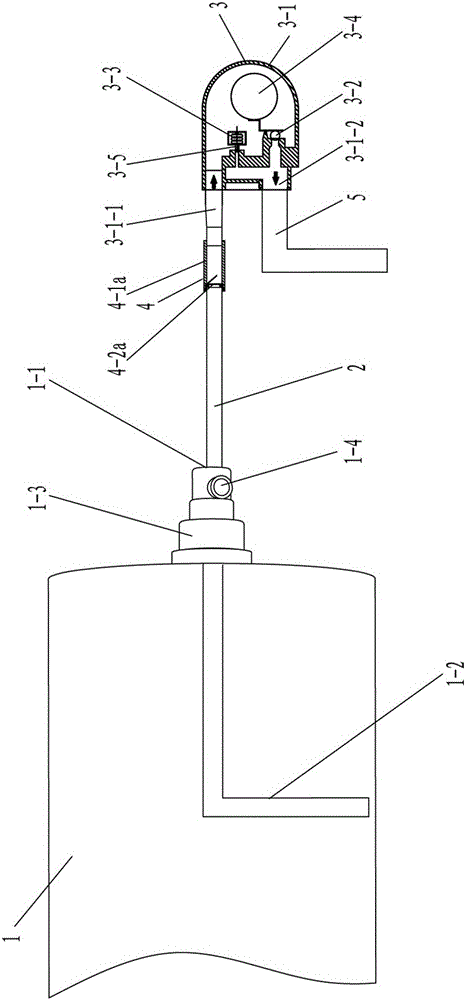

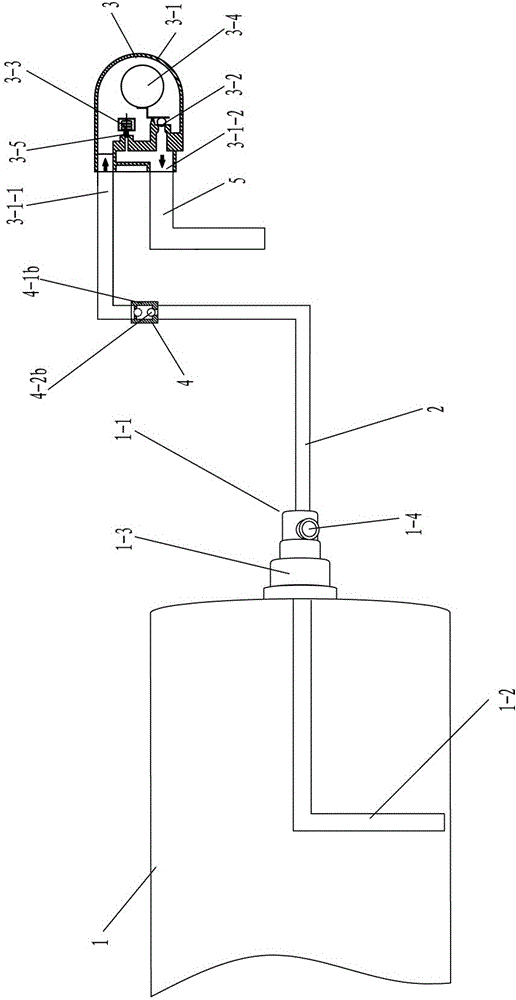

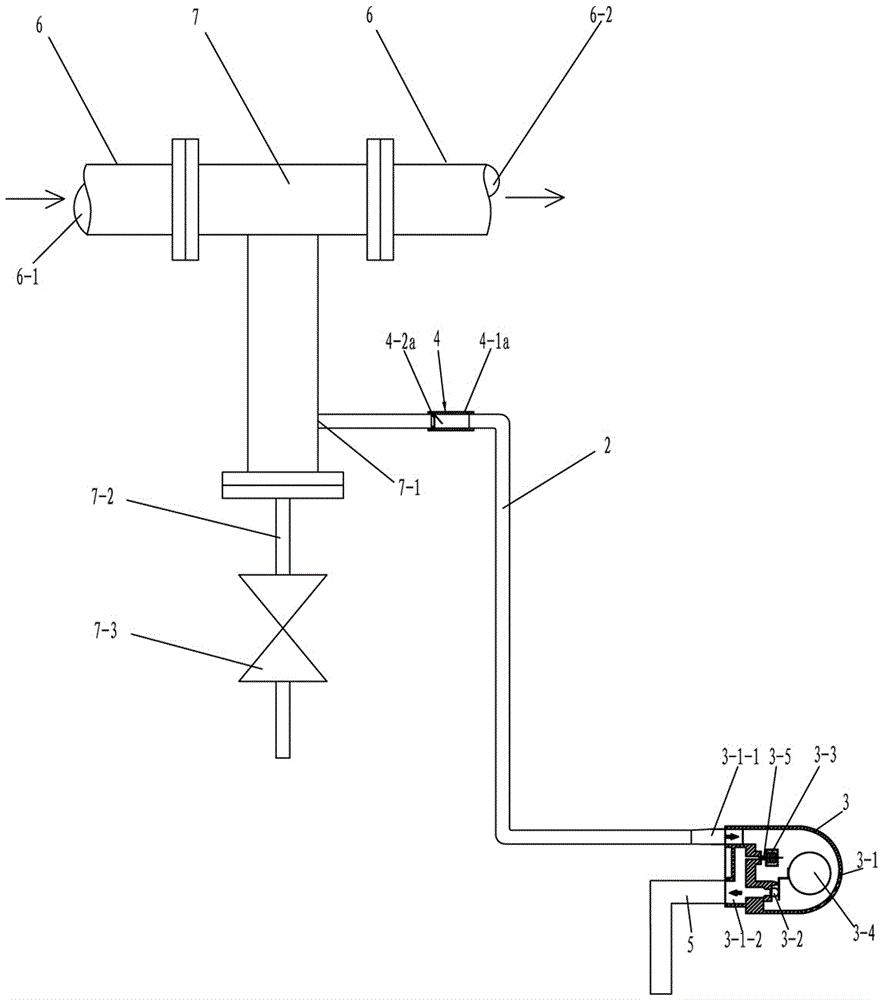

Steam lock relieving device of steam system drain valve

The invention relates to a steam lock relieving device of a steam system drain valve. The device comprises a steam drying cylinder, a siphon pipe, a steam rotating joint, a drain pipe and a drain valve; a steam rotating joint is mounted on the steam drying cylinder; one end of the steam rotating joint is connected with one end of the siphon pipe, and the other end is connected with one end of the drain pipe; one end of the drain pipe is communicated with the siphon pipe through the steam rotating joint, and the other end is communicated with a water inlet of the drain valve; the drain valve has a water outlet; and the steam rotating joint has a steam inlet. The device is characterized in that a steam lock relieving mechanism is arranged on a pipeline of the siphon pipe or the drain pipe. The device can automatically stop steam from flowing to the drain valve to lower the internal temperature of the drain valve in the non-drain period, and can automatically relieve the stop in the drain period to timely enable the drain valve to carry with the steam lock relieving device to relieve the steam lock so as to drain condensed water continuously generated in the steam drying cylinder.

Owner:常州宏大智慧科技有限公司

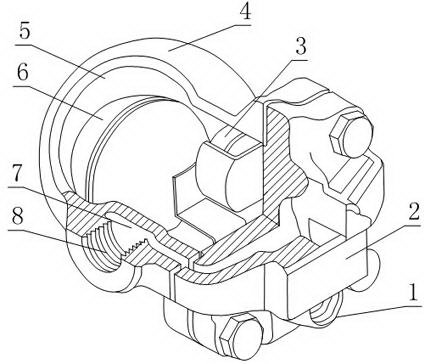

Valve assembly

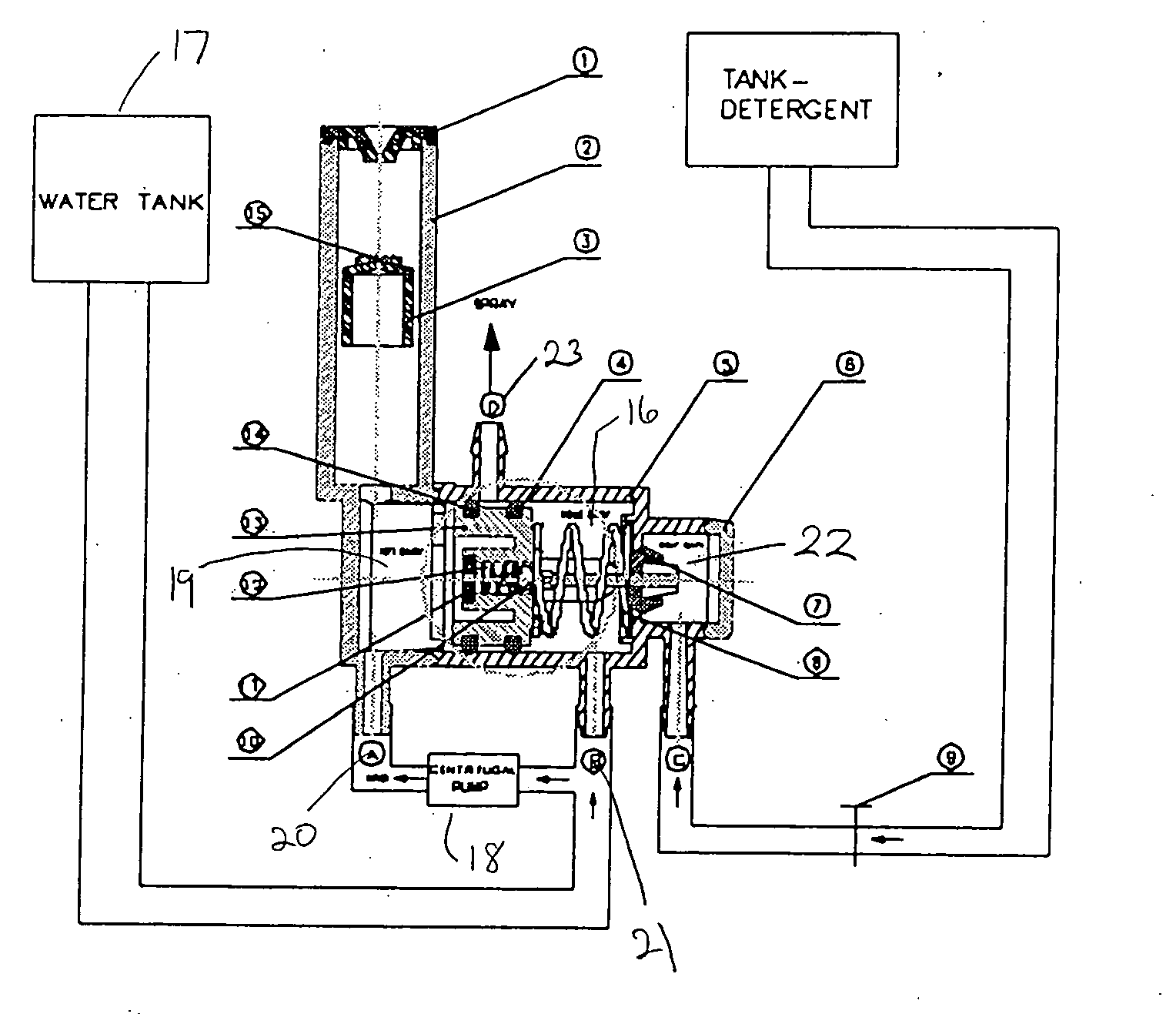

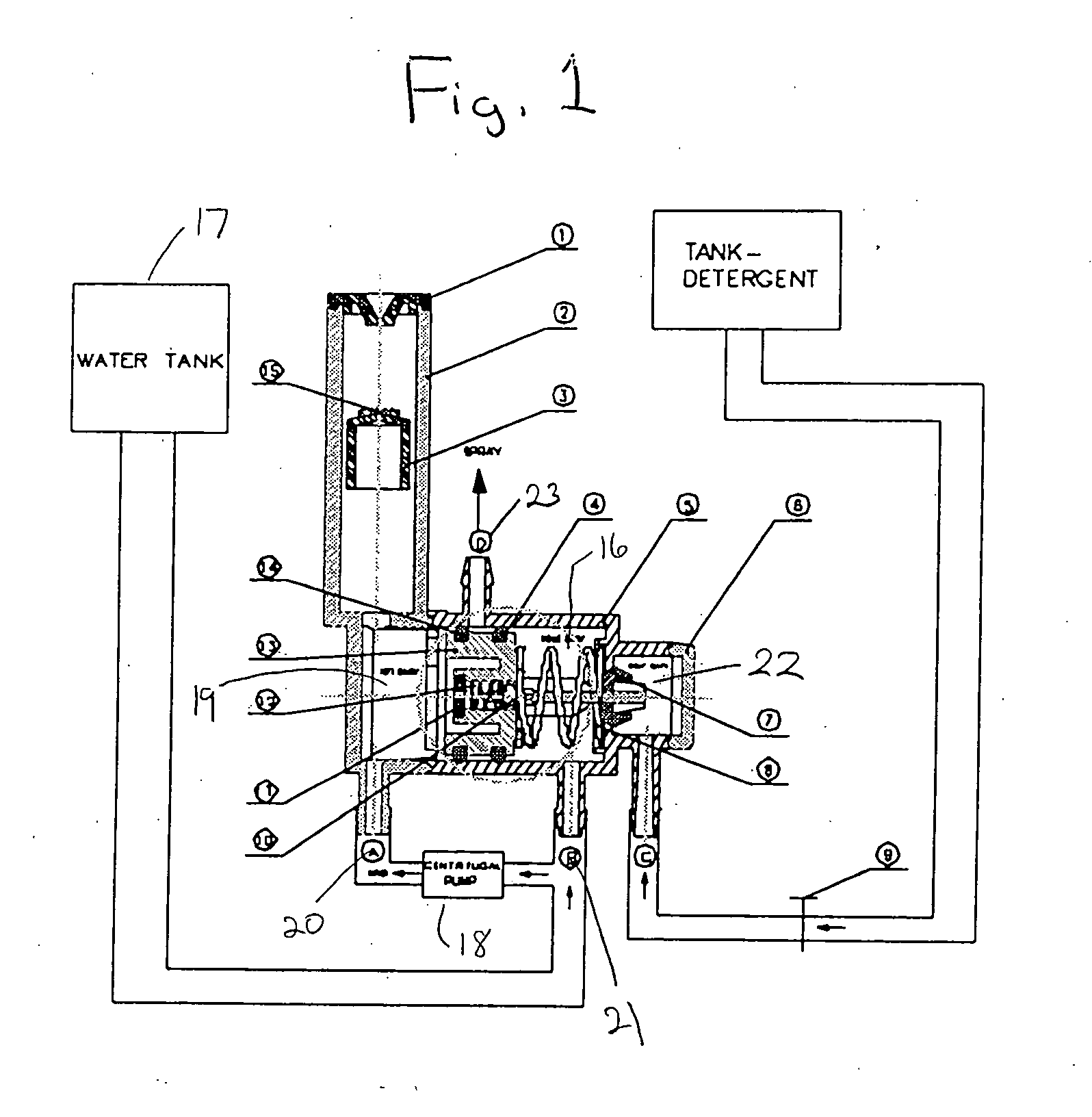

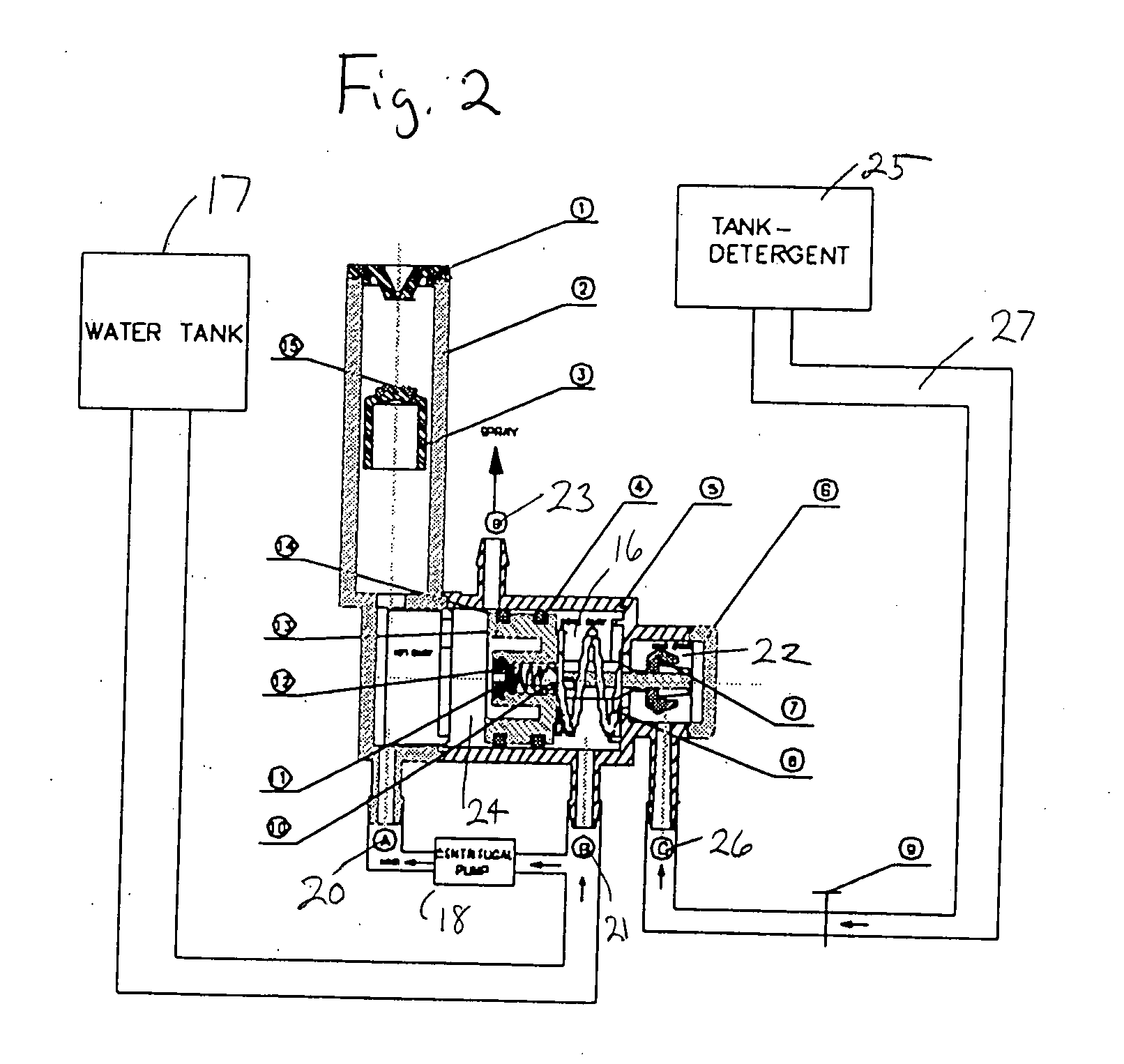

InactiveUS20050150073A1Good flexibilityEasy maintenanceCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention relates to a valve assembly for use in connection with carpet cleaning extraction machines and similar extraction cleaning devices. The invention allows the intake of liquid and the mixing of different liquids in a mixing chamber, such as clean water with detergent, and the discharge of a selected liquid without the formation of an air or vapor lock that would inhibit the discharge of the selected liquid. In particular, the invention prevents the formation of a vapor lock when water is being drawn into a chamber that would prevent the subsequent discharge or spraying of the liquid.

Owner:GT INVESTMENTS BVI

Oil well pump

InactiveCN103062021ASolve the problem of opening and closing lagImprove pump efficiencyFlexible member pumpsPump controlEngineeringPumpjack

The invention discloses an oil well pump controlled by two valves. The oil well pump comprises a pump head, a pump cylinder and a plunger cylinder. The pump head is fixed at one end of the pump cylinder; the plunger cylinder is fixed at the other end of the pump cylinder, and a part of the plunger cylinder extends to the interior of the pump cylinder; a plunger rod is movably arranged in the plunger cylinder; a travelling valve is further fixed in the pump cylinder and arranged between the plunger cylinder and the pump head; the plunger rod extends to the interior of the pump cylinder through the interior of the plunger cylinder and penetrates through the travelling valve; and a fixed valve and a travelling bonnet are arranged on the plunger rod respectively, the travelling bonnet is matched with the travelling valve, and the fixed vale is arranged in the plunger cylinder. By means of the oil well pump, the problems of the vapor lock and the start and stop lag of the oil well pump and a fixed valve ball are solved effectively, and the pump efficiency and the mechanical extraction efficiency of thickened oil pumping are improved.

Owner:SHAANXI ZHONGMING ENERGY INVESTMENT

Method and system for cleaning heat exchanger tube bundles

A method and system utilizing a mobile cleaning unit for providing cleaning of heat exchanger tube bundles. The mobile cleaning unit utilizes a pressurized seal positioned about top door of the cleaning enclosure to provide a fluid and vapor lock of the cleaning enclosure. An oxygen purging system of the cleaning enclosure, the cleaning fluid reservoir, and the control panels provides additional safety. The mobile cleaning unit can use cleaning fluid produced at the facility site and return the cleaning fluid to the facility site for reprocessing after the heat exchanger tube bundles are cleaned.

Owner:NAT HEAT EXCHANGE CLEANING CORP

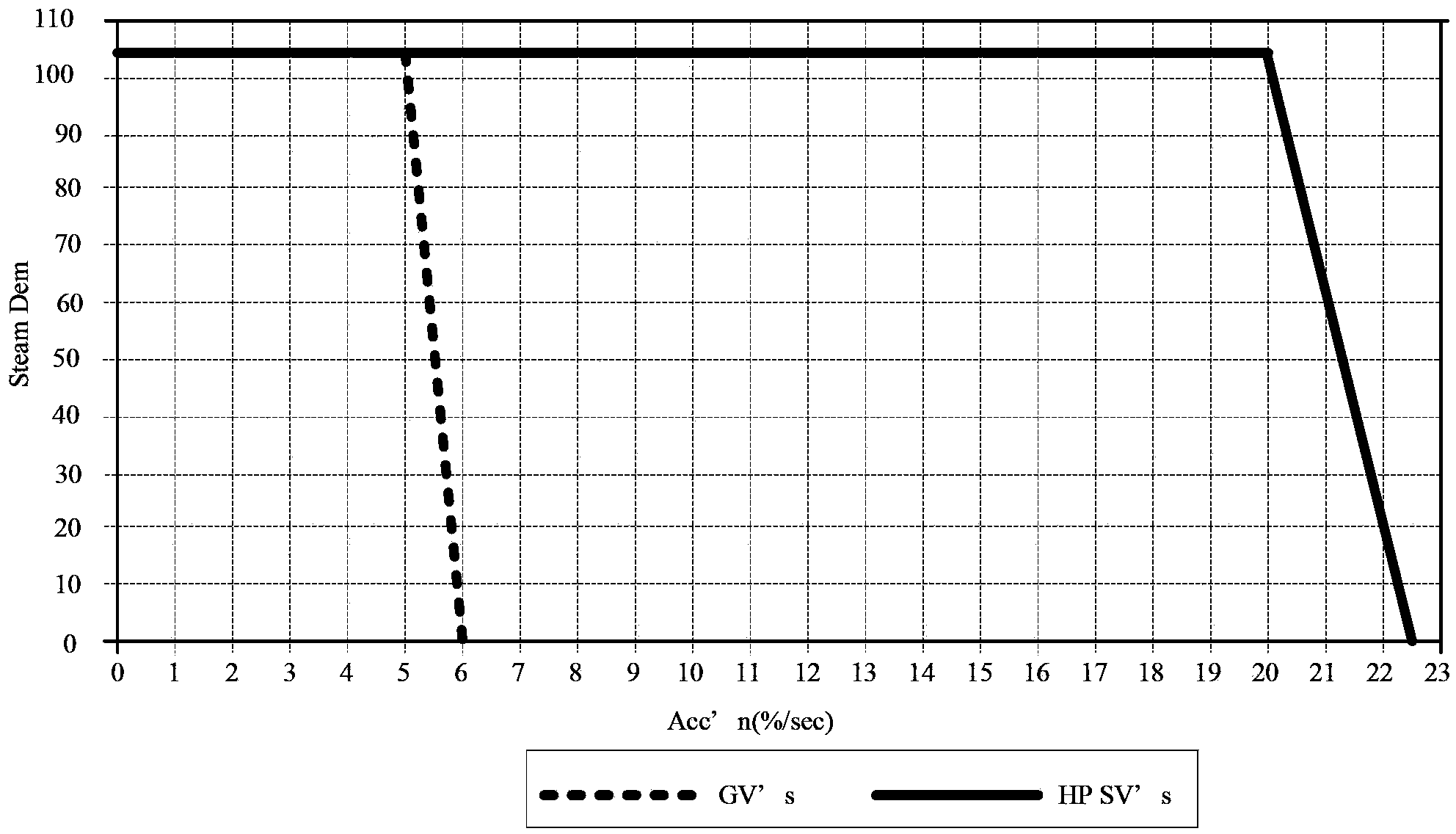

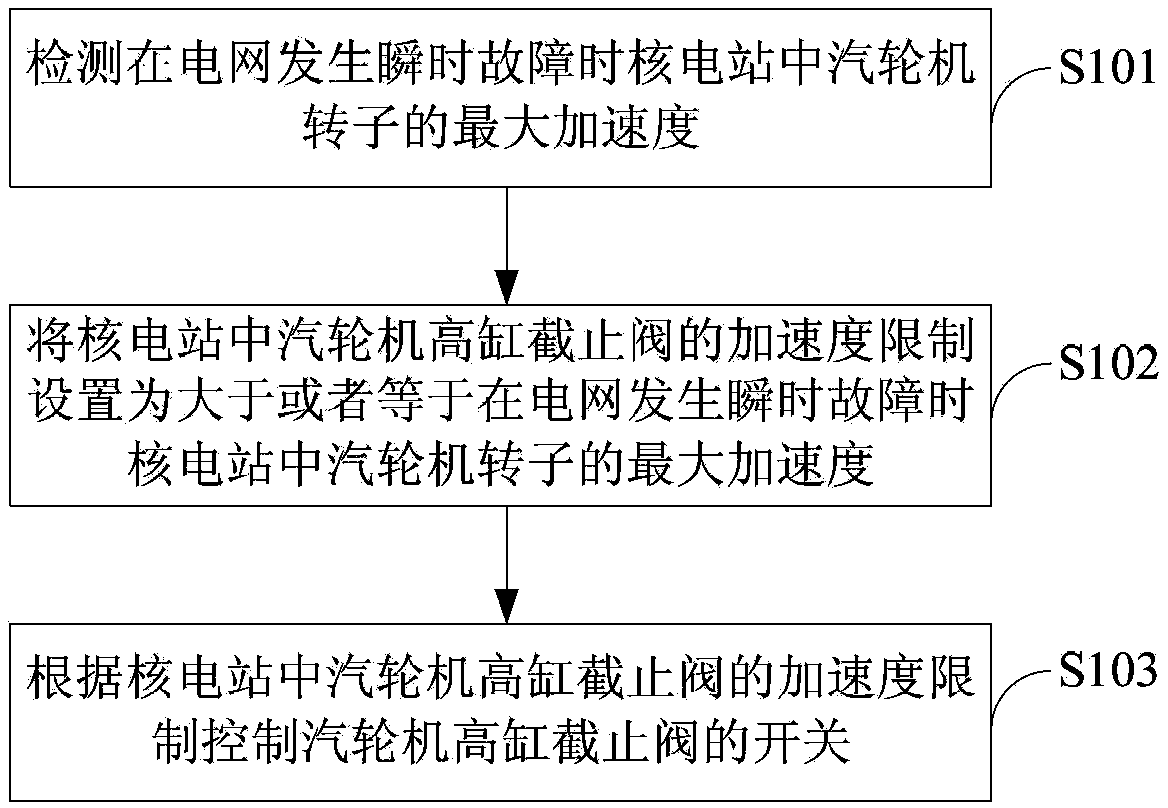

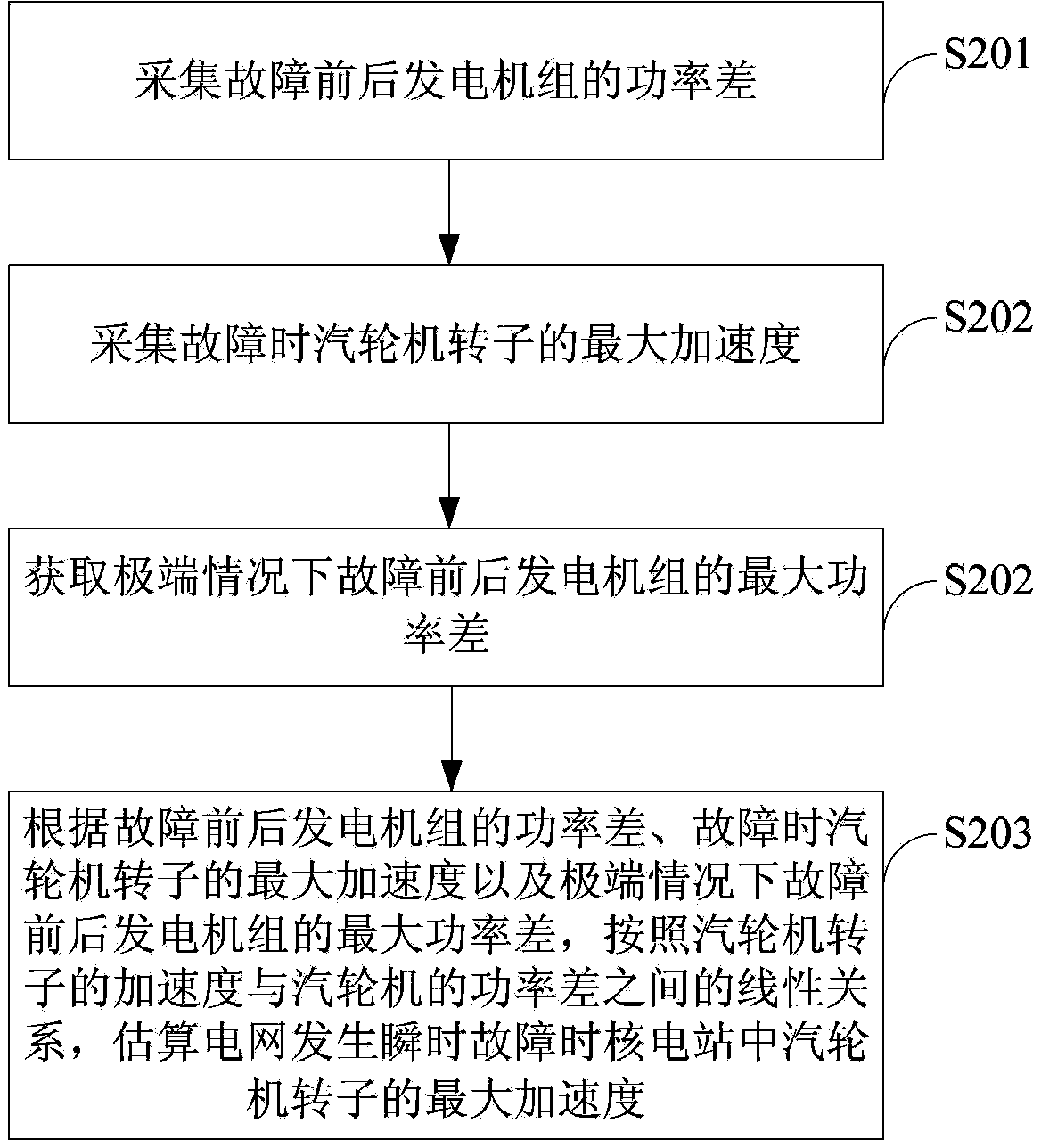

Method and device for preventing turbine control system of nuclear power station from generating disturbance

ActiveCN103806959AAvoid vapor lock failureMachines/enginesSafety/regulatory devicesNuclear powerNuclear engineering

The invention is suitable for the professional technical field of a million kilowatt level pressurized water rector nuclear power station and provides a method and a device for preventing a turbine control system of the nuclear power station from generating disturbance. The method comprises the steps of detecting the maximum acceleration of a rotor of the turbine in the nuclear power station when a power grid is subjected to a transient fault; setting the acceleration limitation of a high cylinder cutoff valve of the turbine in the nuclear power station to be larger than or equal to the maximum acceleration of the rotor of the turbine in the nuclear power station when the power grid is subjected to the transient fault; limiting a switch of the high cylinder cutoff valve of the turbine according to the acceleration of the high cylinder cutoff valve of the turbine in the nuclear power station. According to the method and the device for preventing the turbine control system of the nuclear system from generating disturbance, the high cylinder cutoff valve of the turbine is prevented from being subjected to the turbine locking phenomenon during the transient fault of the power grid.

Owner:LINGAO NUCLEAR POWER +1

Cooling methods and systems using supercritical fluids

InactiveUS8087256B2Most efficientReliable absorptionCompression machinesHeat-exchange elementsEngineeringVapor lock

The methods and systems using supercritical fluids for cooling of objects with high thermal emissions are disclosed. The unique thermodynamic properties of supercritical fluids combined with microchannel cooling technology allow effective absorption of the waste heat and exclude “vapor lock”, “boiling crisis”, and other deficiencies of conventional two-phase liquid cooling.

Owner:CRYOMECHANICS

Drain-off device for preventing generation of steam locking favorably

The invention discloses a drain-off device for preventing generation of steam locking favorably. The drain-off device comprises a left valve deck and a right valve deck. A condensate water accommodation chamber is arranged between the left valve deck and the right valve deck; an inlet tube and an outlet tube are arranged on the left valve deck and the right valve deck; a floating ball is arranged in the condensate water accommodation chamber. The drain-off device also comprises an emptier. The emptier comprises a thermal static metal piece, a sealing ball and a steam locking discharging runner; the front end and the back end of the steam locking discharging runner are connected with the condensate water accommodation chamber and the outlet tube respectively; the sealing ball is fixed on the thermal static metal piece, and directly faces the front end of the steam locking discharging runner; the section of the thermal static metal piece is a diamond; the sealing ball is positioned in the apex angle of the diamond. By applying the drain-off device, automatic discharging of non-condensable gas can be realized, and the service life is long.

Owner:CHENGDU KELIFU SCI & TECH

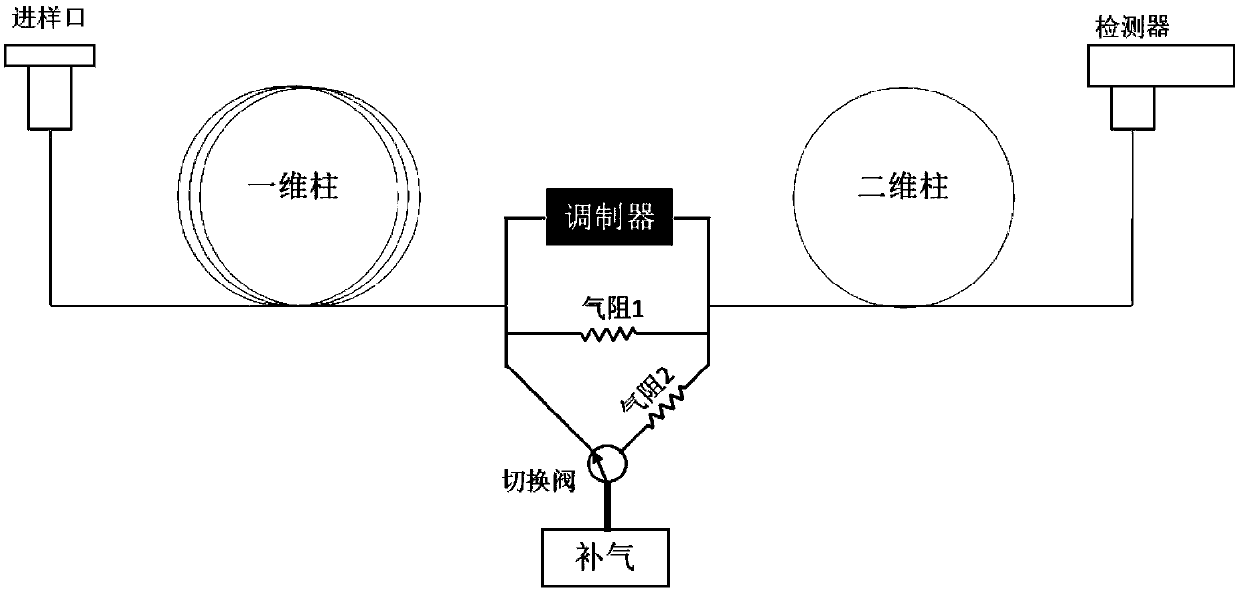

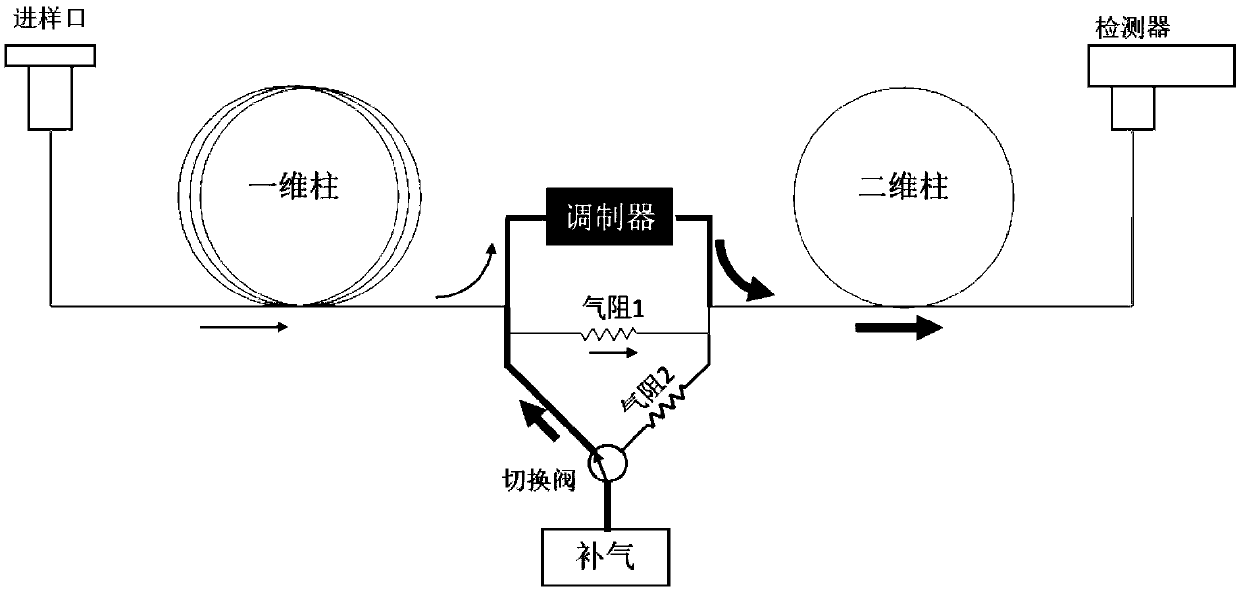

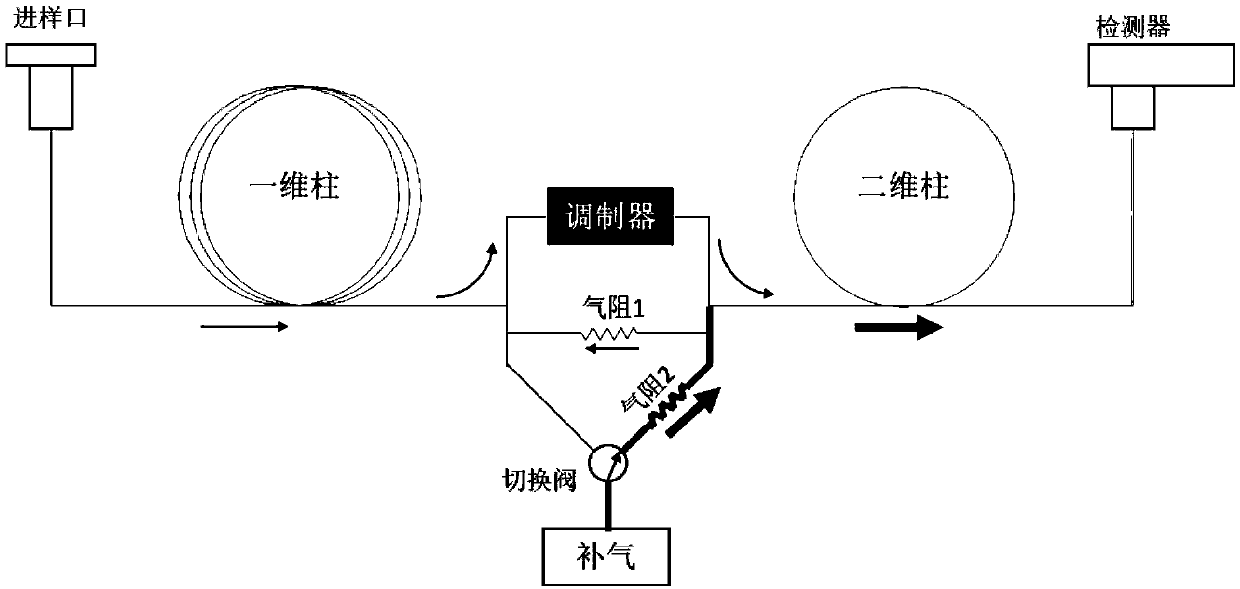

Comprehensive two-dimensional gas chromatograph and optimization modulation method thereof

The invention discloses a gas flow modulation device for a comprehensive two-dimensional gas chromatograph. The gas flow modulation device comprises a gas supplementation module, a switch valve, a first vapor lock and a second vapor lock, wherein a gas outlet of the gas supplementation module is connected to an intake of the switch valve through a pipeline; a first outlet of the switch valve is used for connecting an inlet of a modulator through a pipeline; a second outlet of the switch valve is connected with a first end of the second vapor lockthrough a pipeline; a second send of a second vapor lockis connected with an outlet of the modulator through a pipeline; a first end of the first vapor lockis connected with the inlet of the modulator through a pipeline; a second end of the first vapor lockis connected with the outlet of the modulator through a pipeline. Through the gas flow modulation device, the defects that a modulated two-dimensional initial peak width and a compound boiling spread, which can be modulated, are mutually contradictory and cannot be taken into consideration at the same time are overcome and not only is a wider compound boiling spread, which can be modulated, obtained but also a narrower two-dimensional initial peak width is obtained.

Owner:J&X ELECTRONICS TECH (SHANGHAI) CO LTD

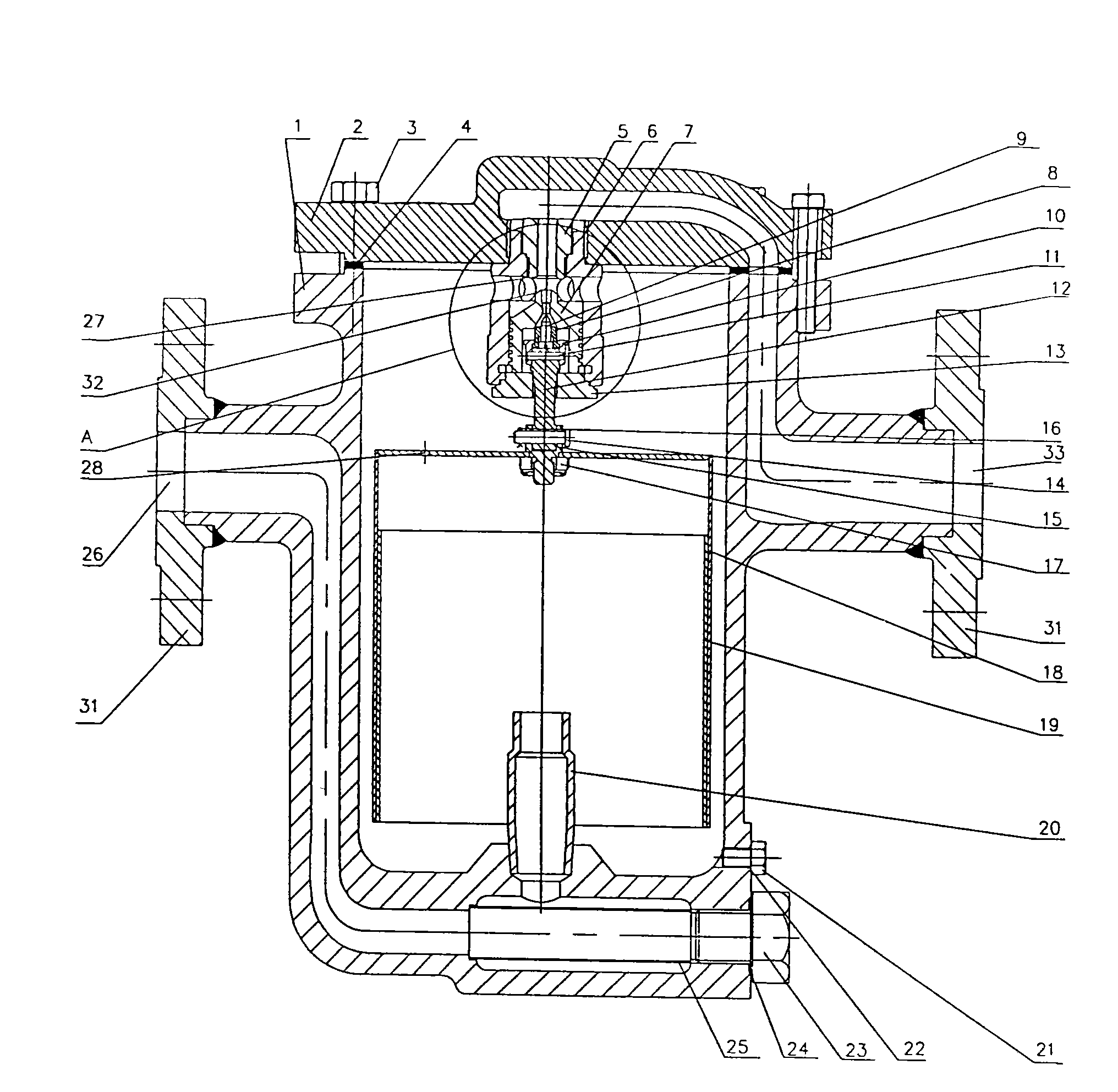

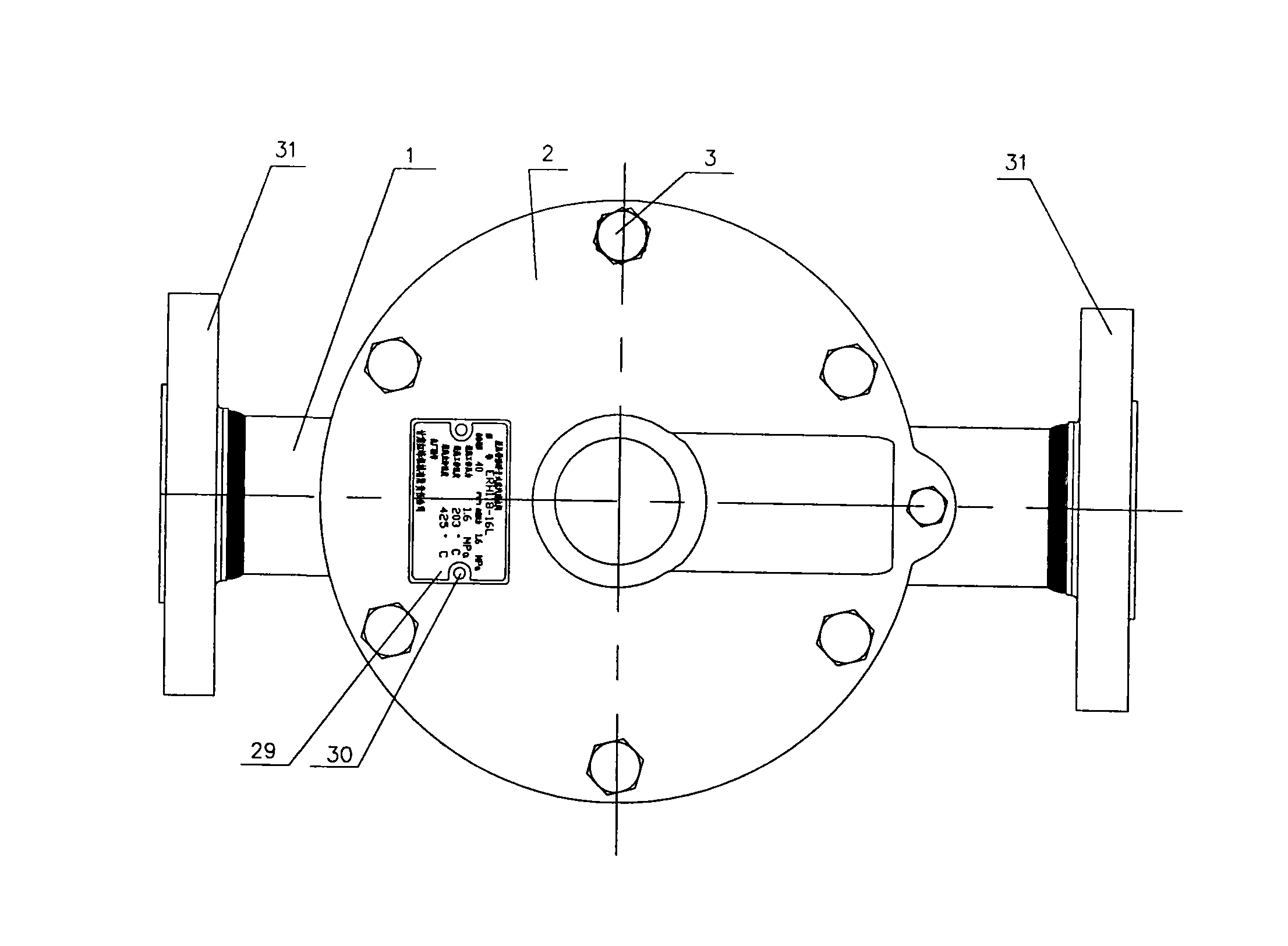

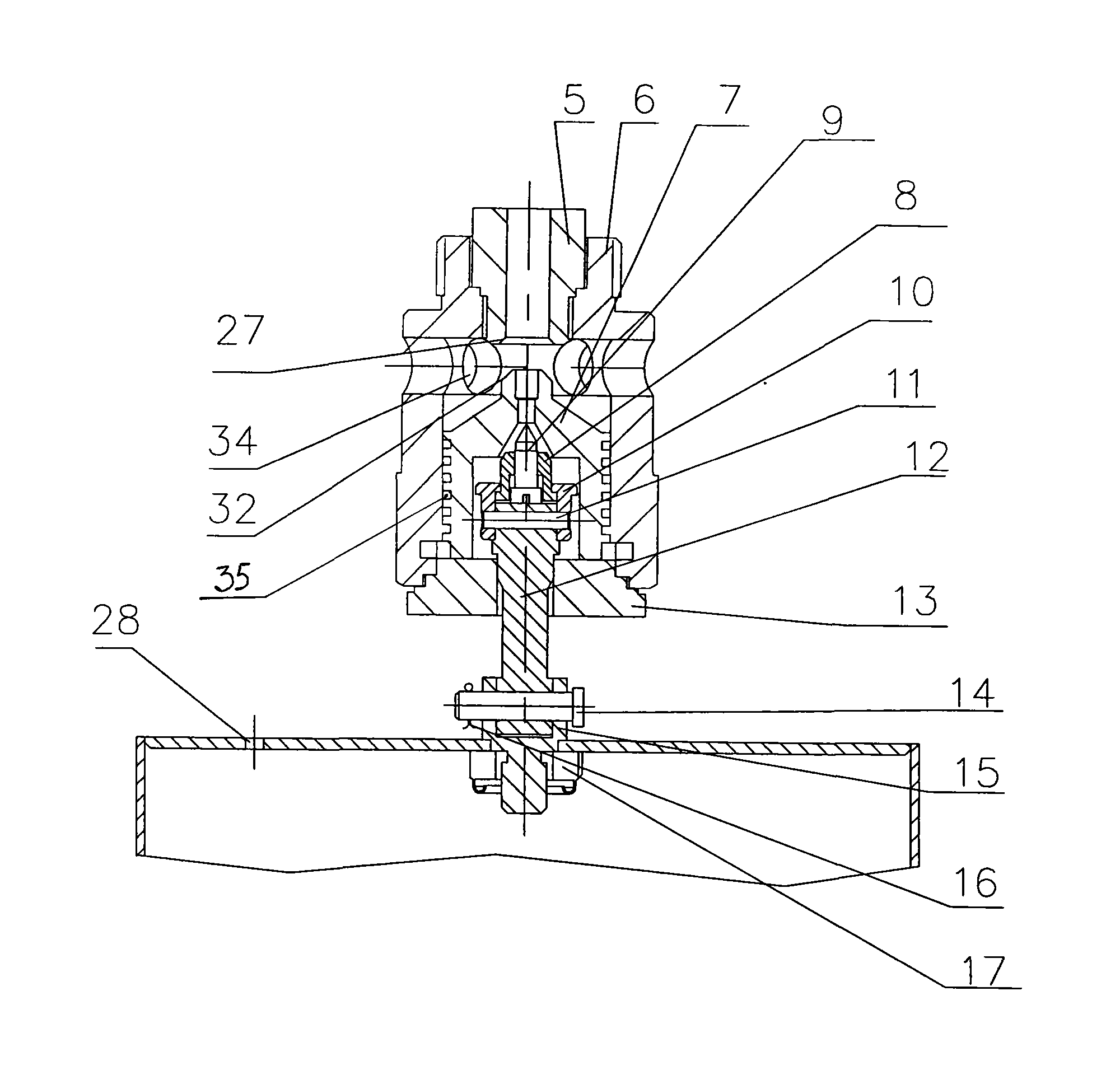

Piston bucket type low-pressure vapor drain valve

The invention relates to a piston bucket type low-pressure vapor drain valve. The drain valve is characterized in that: the left side and the right side of a valve body (1) are provided with an inlet hole (26) and an outlet hole (33) respectively; the valve body (1) is downwardly provided with a hole along the inlet hole (26), and upwardly provided with a hole along the outlet hole (33); and a valve cover (2) is provided with a hole, and the valve body (1) and the valve cover (2) which are castings in one-time cast forming. One end of a main valve seat control stand (6) is in threaded connection with a main valve seat (5) in a cavity, the external diameter of the main valve seat control stand (6) is in threaded connection with the valve cover (2), the other end of the main valve seat control stand (6) is in threaded connection with a connecting plate (13), and the joint between a connecting rod (12) and a guide cap (10) is arranged in the inner cavity of the main valve seat control stand (6). The other end of the connecting rod (12) is connected with a bucket (18). The drain valve has the advantages that: the condensation water can be drained in time, the vapor leakage loss is minimized, the loaded vapor leakage rate is less than 2 percent, the range of the operating pressure is wide, the water drainage is not affected after pressure change, the back pressure rate is more than 90 percent, the condensation water is easy to recover, the air blocking and the vapor locking phenomena can be eliminated, along with flexible action, reliability, little noise and long service life.

Owner:GANSU HONGFENG MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com