EPS package foam forming technology

A foam molding and process technology, applied in the field of foam molding process, can solve the problems of products prone to raspberries, all small bumps in appearance, and collapsed appearance of products, avoiding long-term work and handling, avoiding water velocity impact collapse, guaranteeing The effect of appearance finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

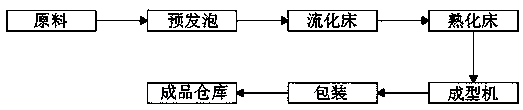

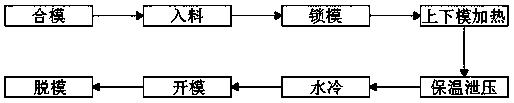

[0028] The present invention provides such Figure 1-2 A kind of EPS packaging foam molding process shown, comprises the following steps:

[0029] (1) Selection of raw materials: select ultra-fine foam particle raw materials with a diameter of 0.4~0.6mm;

[0030] (2) Pre-foaming: The raw materials need to be weighed before the pre-foaming work: pour the raw materials into the hopper, and send them into the pre-weighing hopper through the rotating screw. The computer chip detects the feeding amount through the infrared position sensor. When it reaches the upper Within a limited time, the rotating screw stops and the feeding ends. At this time, the stirring motor of the foaming machine is turned on, the warehouse door is closed, and the steam main valve is opened. When the temperature in the barrel reaches 100 degrees, the pre-weighing hopper starts to discharge the material to the weighing pan, and the weighing is obtained. To weigh the exact value, weigh continuously during t...

Embodiment 2

[0037] The present invention provides such Figure 1-2 A kind of EPS packaging foam molding process shown, comprises the following steps:

[0038] (1) Selection of raw materials: select ultra-fine foam particle raw materials with a diameter of 0.4~0.6mm;

[0039] (2) Pre-foaming: The raw materials need to be weighed before the pre-foaming work: pour the raw materials into the hopper, and send them into the pre-weighing hopper through the rotating screw. The computer chip detects the feeding amount through the infrared position sensor. When it reaches the upper Within a limited time, the rotating screw stops and the feeding ends. At this time, the stirring motor of the foaming machine is turned on, the warehouse door is closed, and the steam main valve is opened. When the temperature in the barrel reaches 100 degrees, the pre-weighing hopper starts to discharge the material to the weighing pan, and the weighing is obtained. To weigh the exact value, weigh continuously during t...

Embodiment 3

[0046] The present invention provides such Figure 1-2 A kind of EPS packaging foam molding process shown, comprises the following steps:

[0047] (1) Selection of raw materials: select ultra-fine foam particle raw materials with a diameter of 0.4~0.6mm;

[0048] (2) Pre-foaming: The raw materials need to be weighed before the pre-foaming work: pour the raw materials into the hopper, and send them into the pre-weighing hopper through the rotating screw. The computer chip detects the feeding amount through the infrared position sensor. When it reaches the upper Within a limited time, the rotating screw stops and the feeding ends. At this time, the stirring motor of the foaming machine is turned on, the warehouse door is closed, and the steam main valve is opened. When the temperature in the barrel reaches 100 degrees, the pre-weighing hopper starts to discharge the material to the weighing pan, and the weighing is obtained. To weigh the exact value, weigh continuously during t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com