Large-standard high-speed resin heavy duty grinding wheel for grinding steel billet

A heavy-duty, grinding wheel technology, used in abrasives, grinding devices, grinding/polishing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

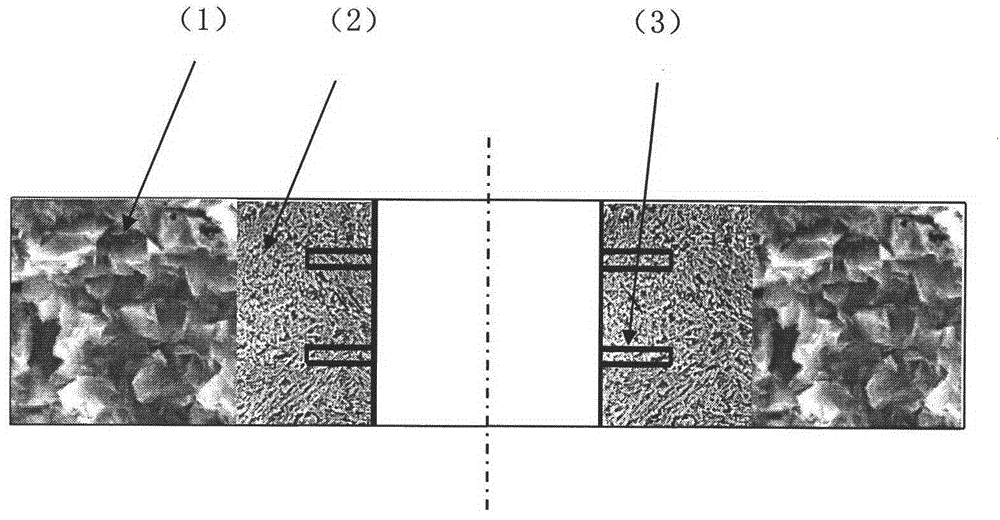

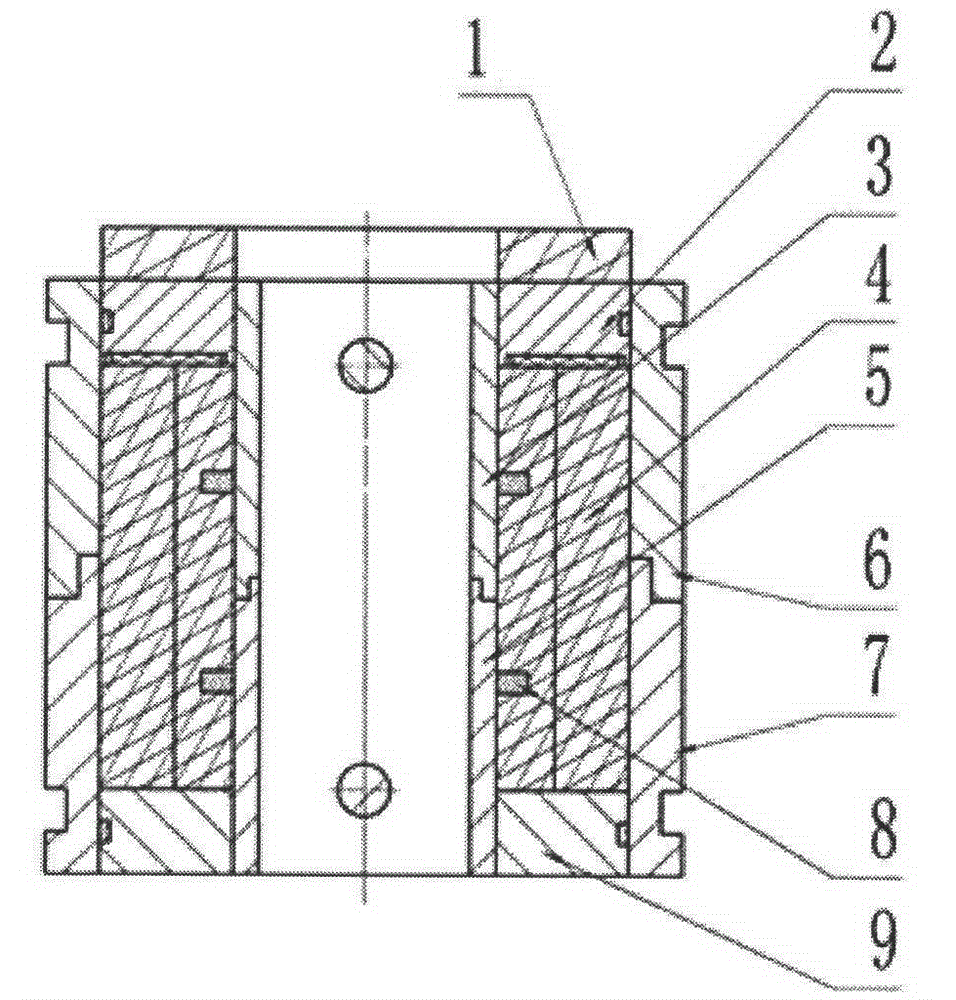

Image

Examples

preparation example

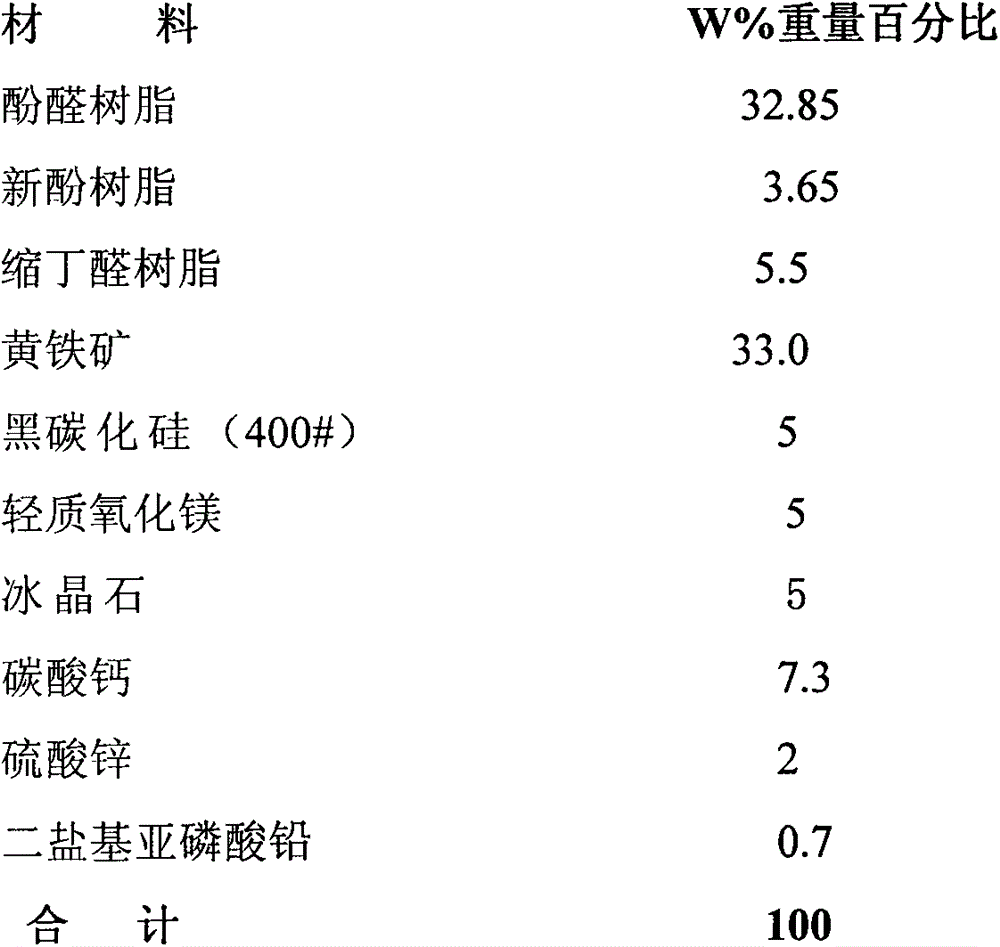

[0100] The following introduces the preparation examples of four specifications of the finished product specifications (grinding wheel diameter × thickness × aperture) 610 × 75 × 203, 760 × 75 × 2037, 760 × 125 × 203, 915 × 125 × 305 (mm), grinding stainless steel Material, the abrasive selection in the marginal material formula: zirconium corundum or alumina sintered corundum.

[0101] The following table is the different organizational ranges and the unit weight of the feeding materials in the design of the above four commonly used specification grinding wheels involved in the present invention:

[0102]

[0103] 1) Mixing process

[0104] Abrasives, binders, wetting agents, and fillers are mechanically stirred according to the prescribed quantity and procedure according to the formulation process, and evenly coated on the abrasives to make them a qualified molding material with good molding performance and qualified molding performance. It is composed of outer grinding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com