Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

822results about "Shaft sinking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

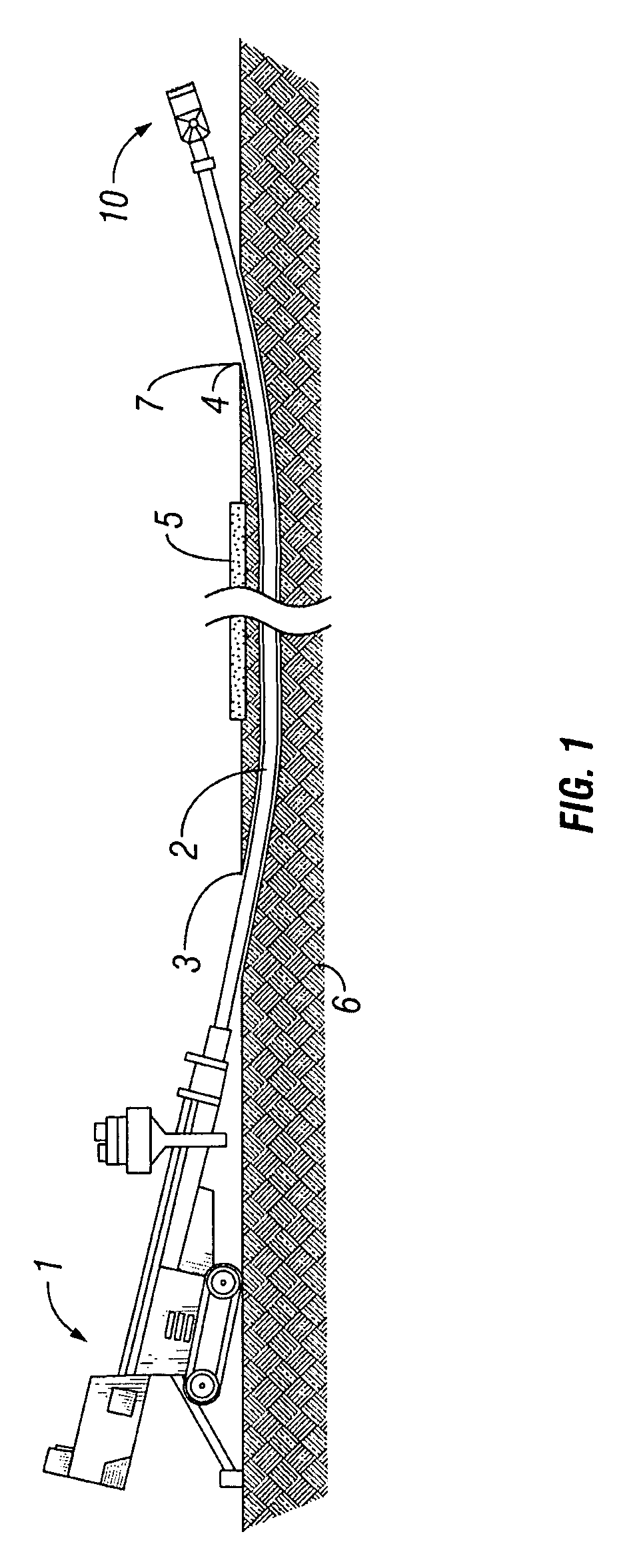

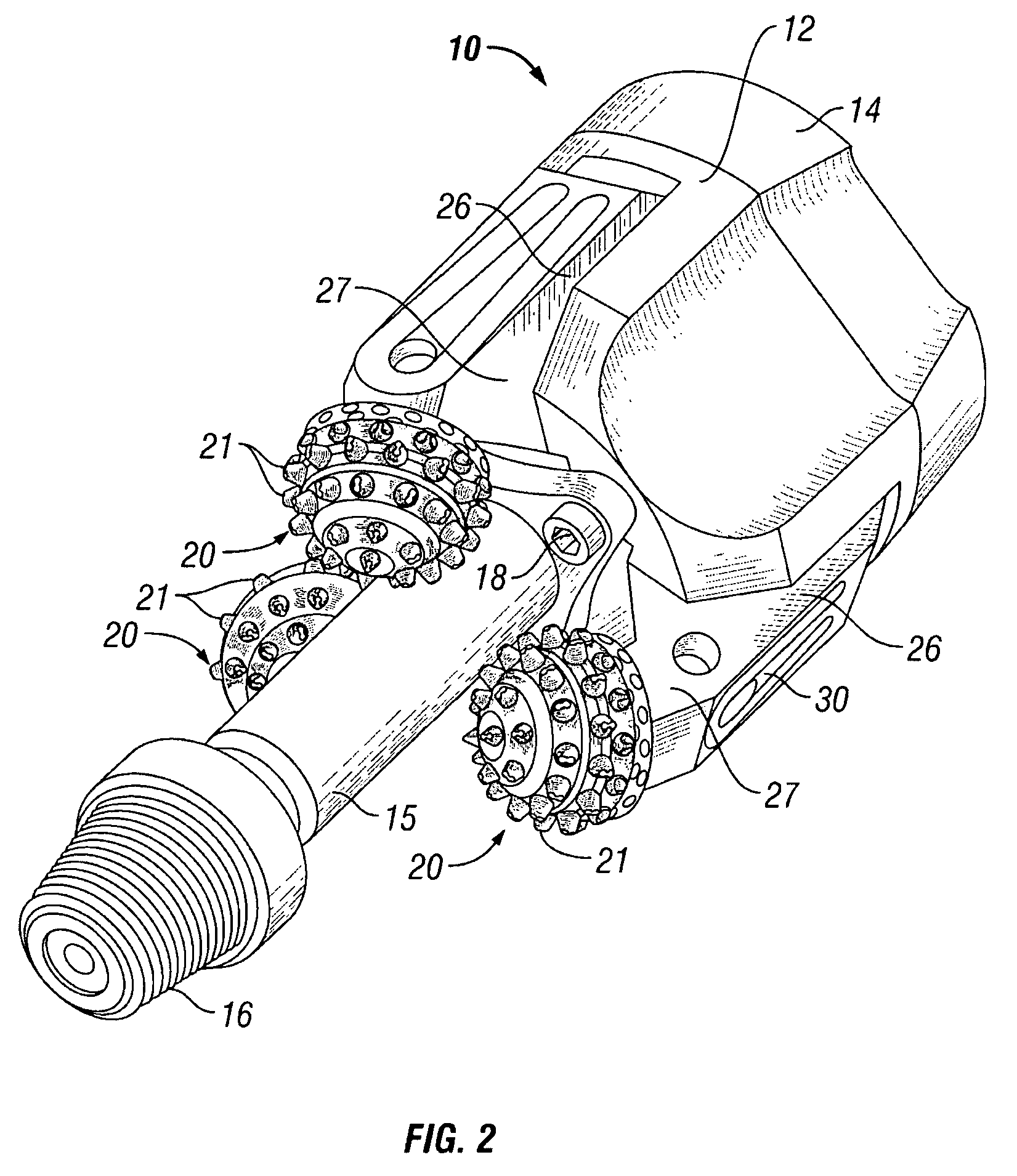

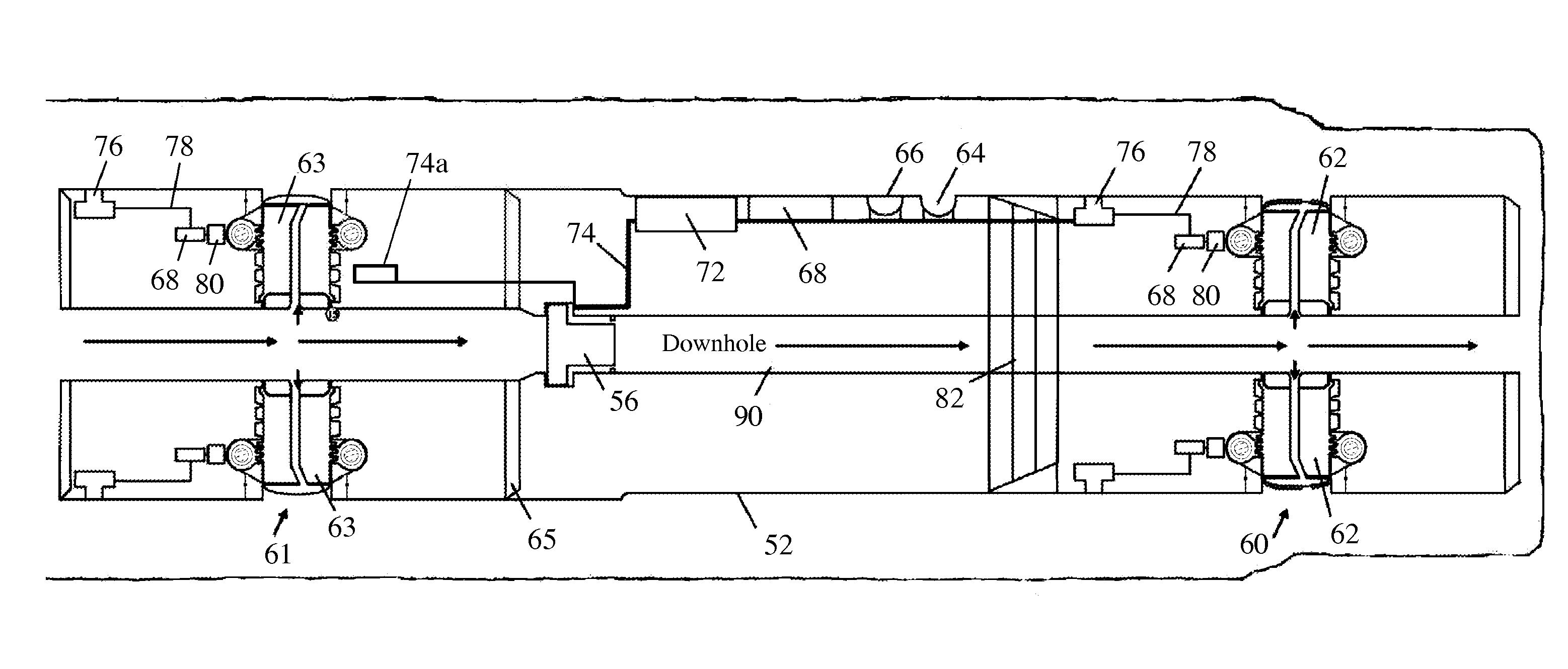

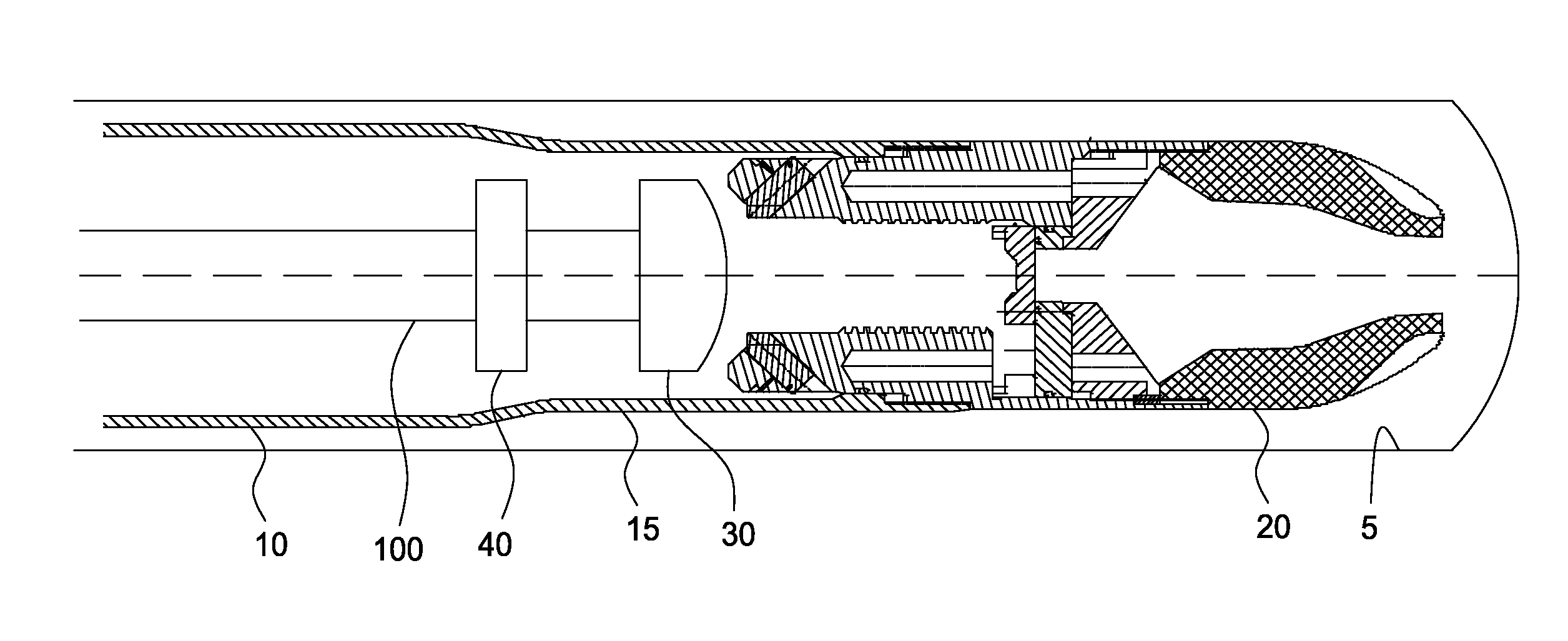

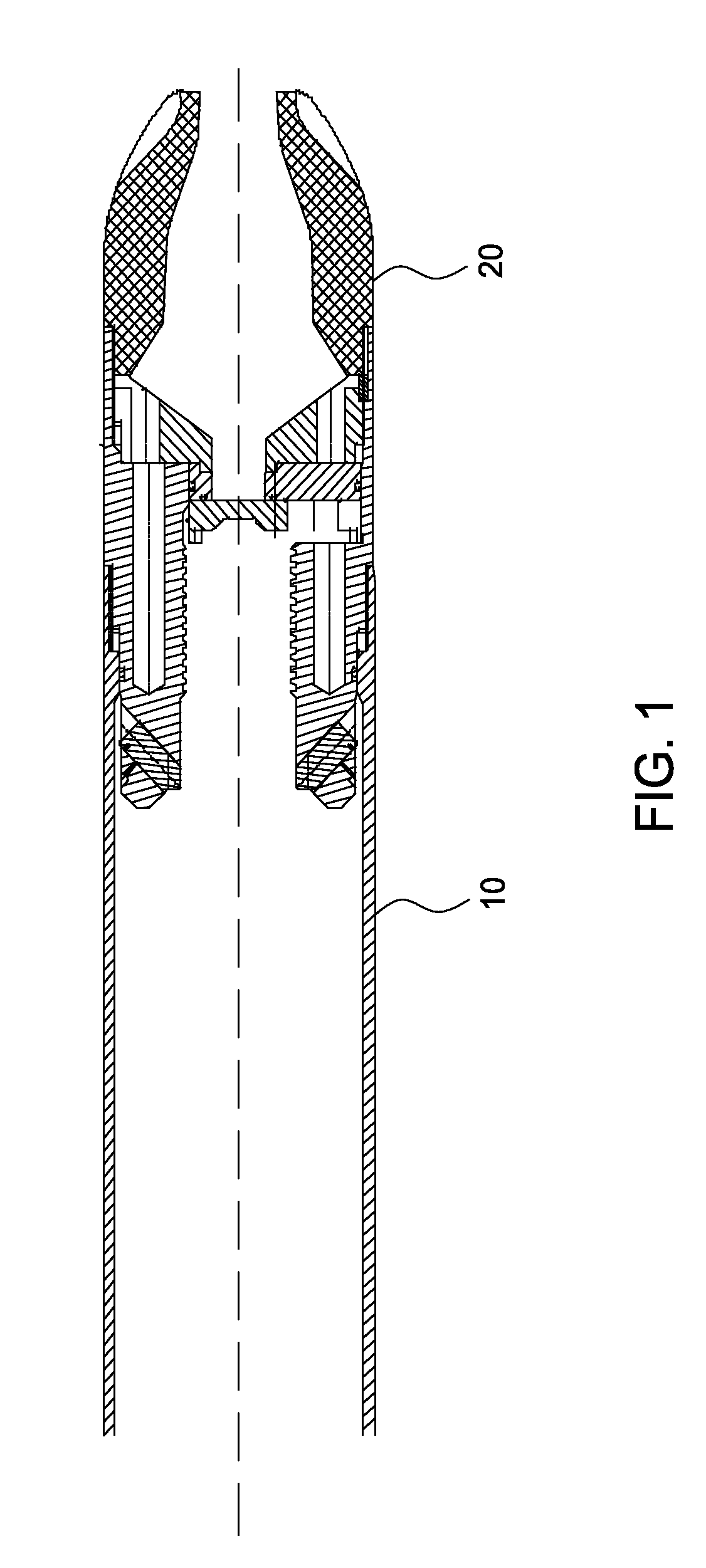

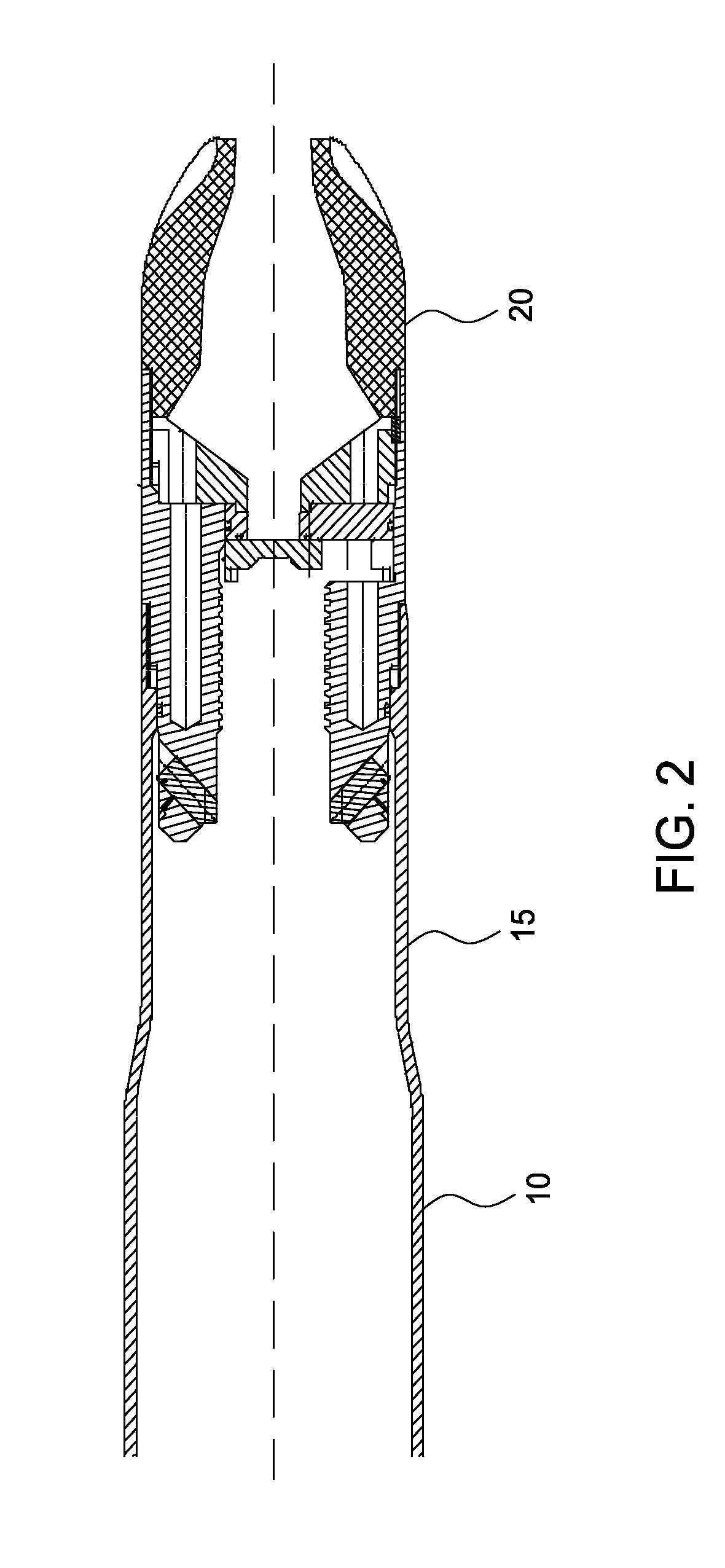

Expansion and sensing tool

ActiveUS20110247878A1Enter exactlyImprove drilling efficiencyBiocideDrill bitsEngineeringOil and natural gas

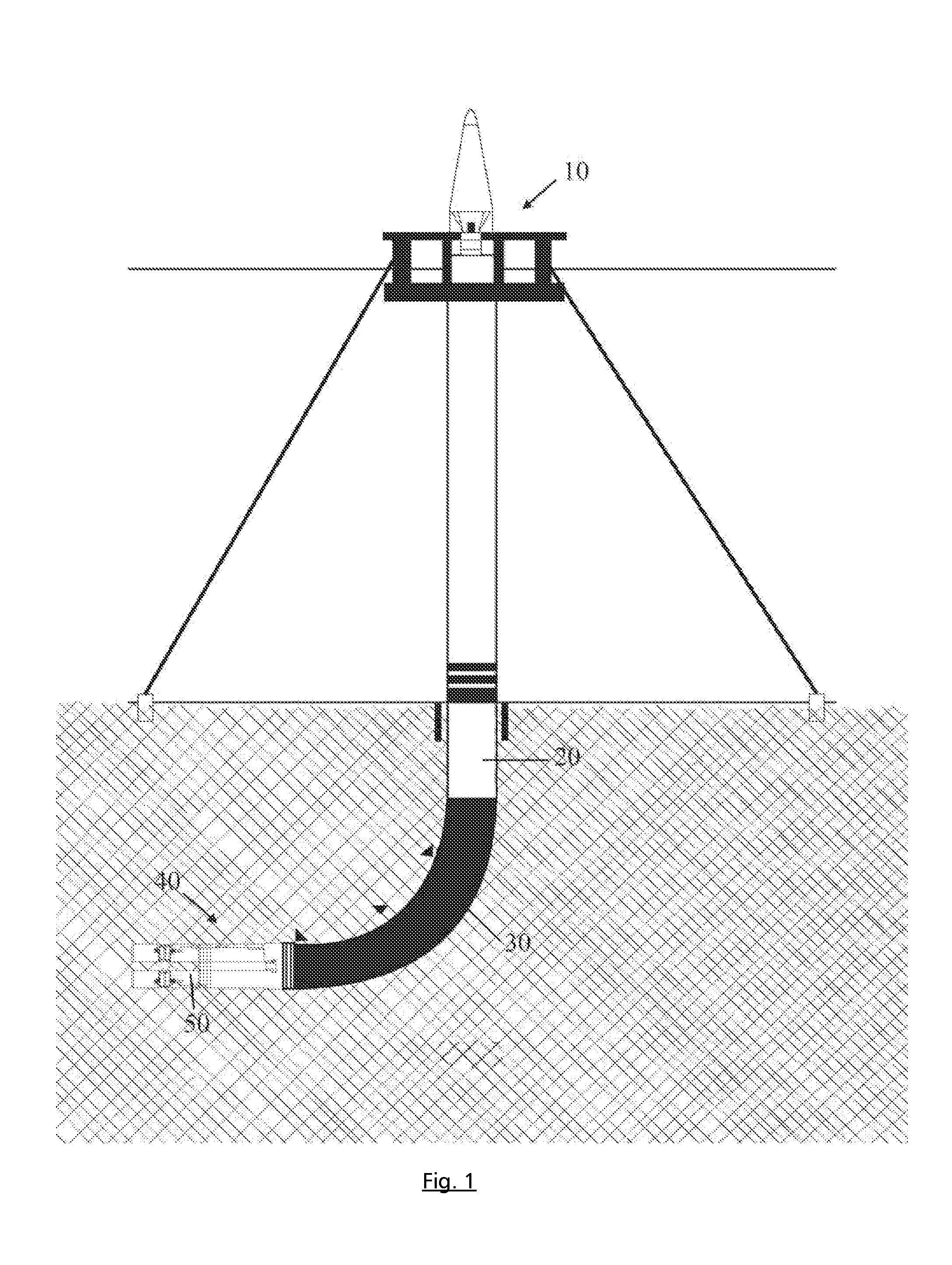

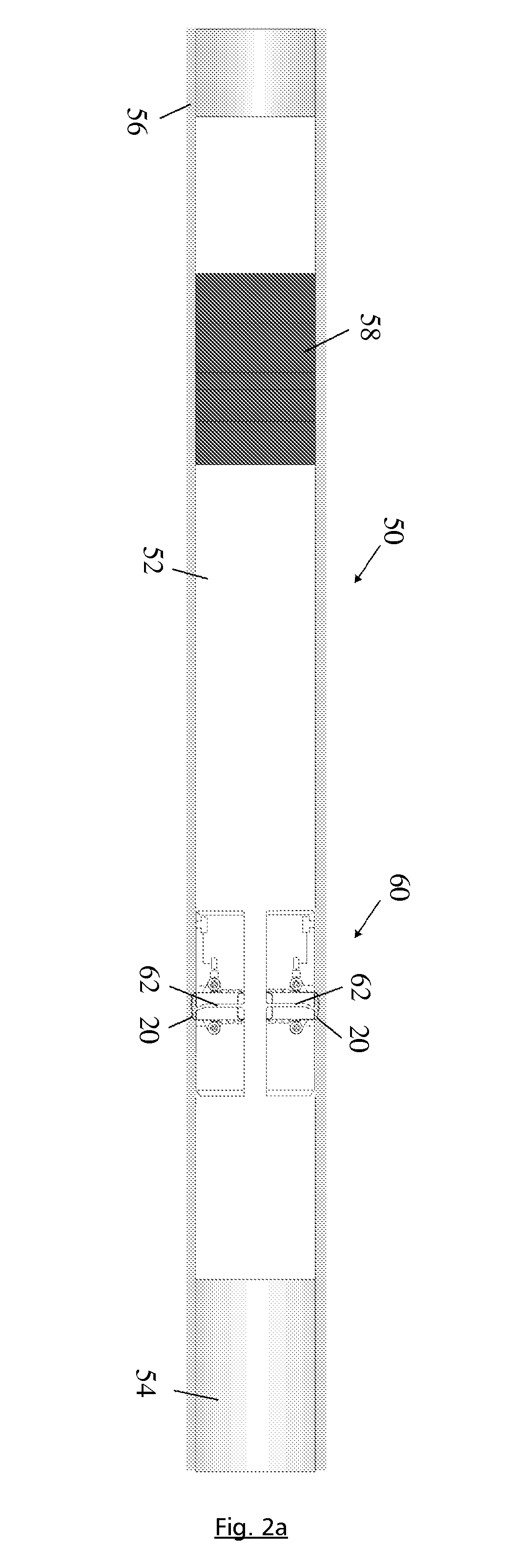

An expansion and sensing tool (50) comprising a tool body, cutter blocks and sensors with means for attachment to a drilling support and rotation which permits simultaneous underreaming and measurement of the diameter of a wellbore (40) drilled by an oil and gas rig (10) and characterized by radially extendable cutter blocks (62) incorporating positional sensors (80) adapted to measure the position of the cutter block relative to the tool, and vibration sensor means (76) to measure vibration and underreaming dynamics wellbore dimension in real-time, all of which are inter-linked by a means of communication using receivers, sensors and microprocessors to deliver a desired wellbore depth by simultaneously comparing and correlating measured vibration data and optimizing underreaming parameters. The tool may be optionally configured with calliper or stabilizer means directly or indirectly connected to the underreamer.

Owner:SMART REAMER DRILLING SYST LTD

Vertical shaft construction method under unfavorable geological condition

The invention discloses a vertical shaft construction method under a unfavorable geological condition, comprising the following construction steps of: 1, pouring cover-weight concrete at a position wherein a well head of a vertical shaft is; 2, arranging two circles of advance consolidation grouting holes in the cover-weight concrete and arranging anchor bar bundles in the grouting holes, wherein the depths of the grouting holes are the same as the depth of the vertical shaft and the depths of the anchor bar bundles are the same as the depths of the grouting holes; 3, drilling pilot holes from top to bottom of the vertical shaft by utilizing a raise-boring machine; 4, drilling pilot shafts from bottom to top of the vertical shaft by utilizing the raise-boring machine; 5, carrying out advance support before expanding excavation; 6, carrying out hole drilling , blasting and the expanding excavation from top to bottom on the vertical shaft; and 7, carrying out reinforced support after the expanding excavation. By means of the vertical shaft construction method disclosed by the invention, the problems of the excavation of the light-section deep vertical shaft under the unfavorable geological condition are solved; and through the advance consolidation before the pilot hole construction, the advance support of small pipes before the expanding excavation and the steel support and bolt-spray support after the excavation, the influences of hole collapsing during the pilot shaft excavating and collapse after the expanding excavation on the construction are effectively eliminated.

Owner:SINOHYDRO BUREAU 5

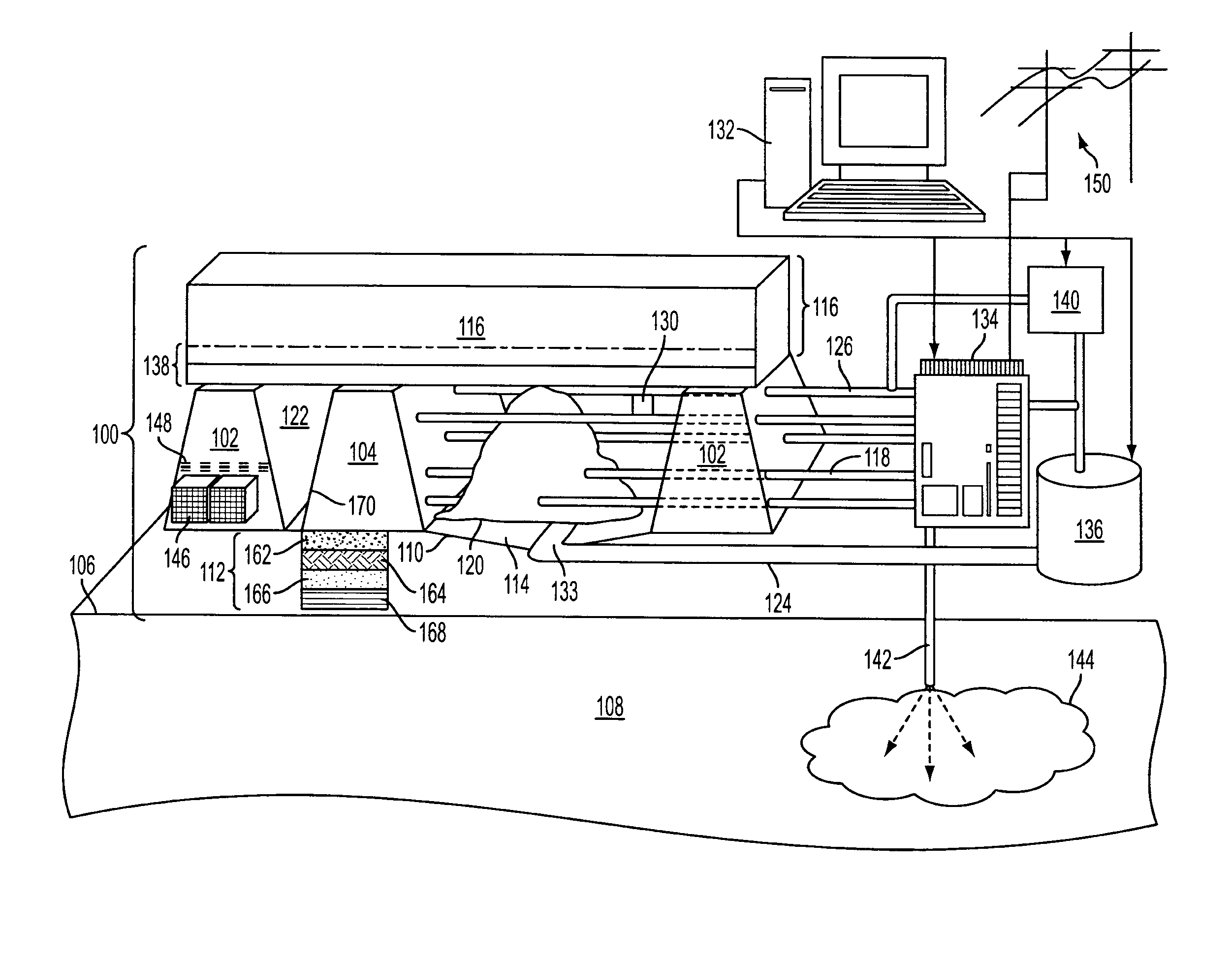

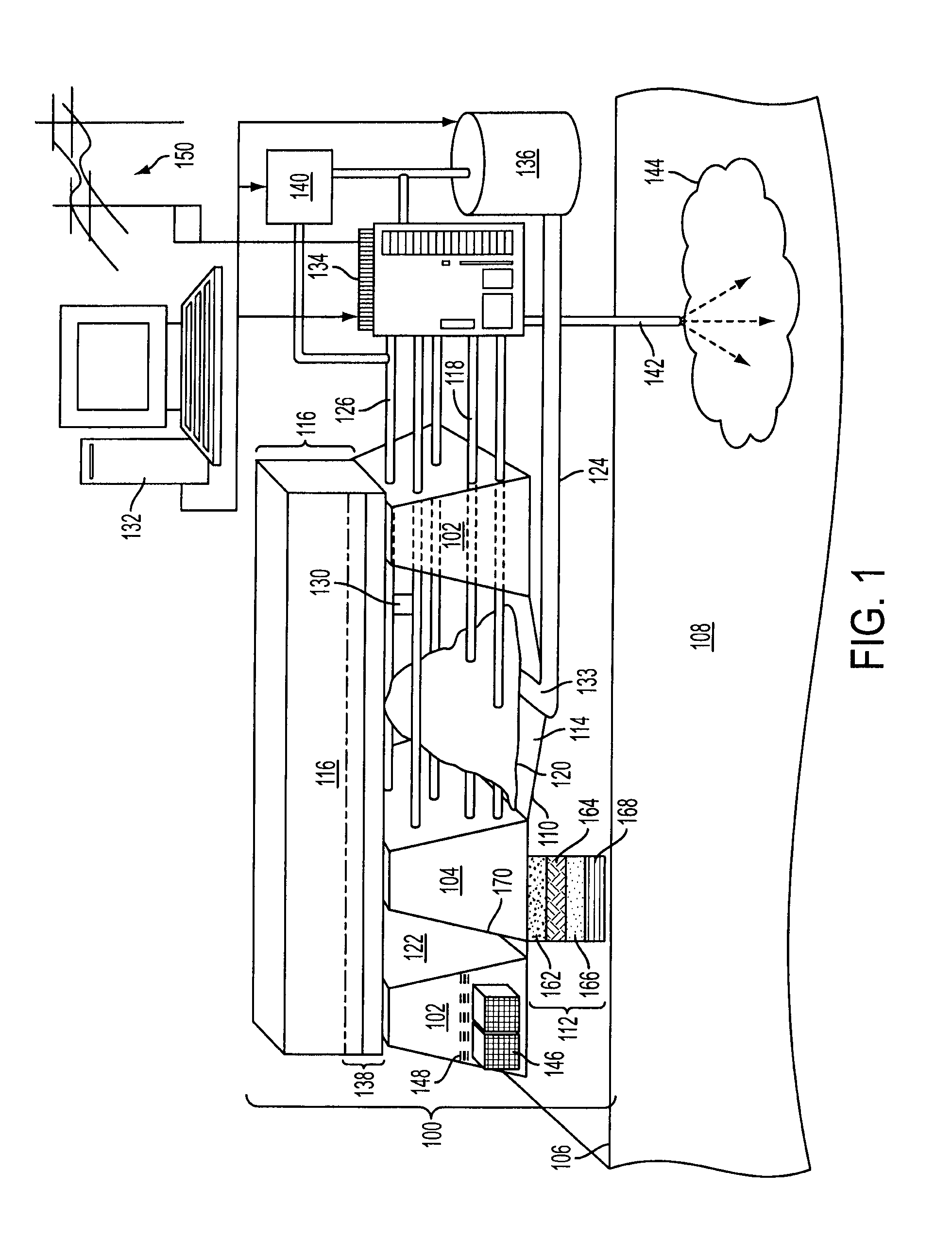

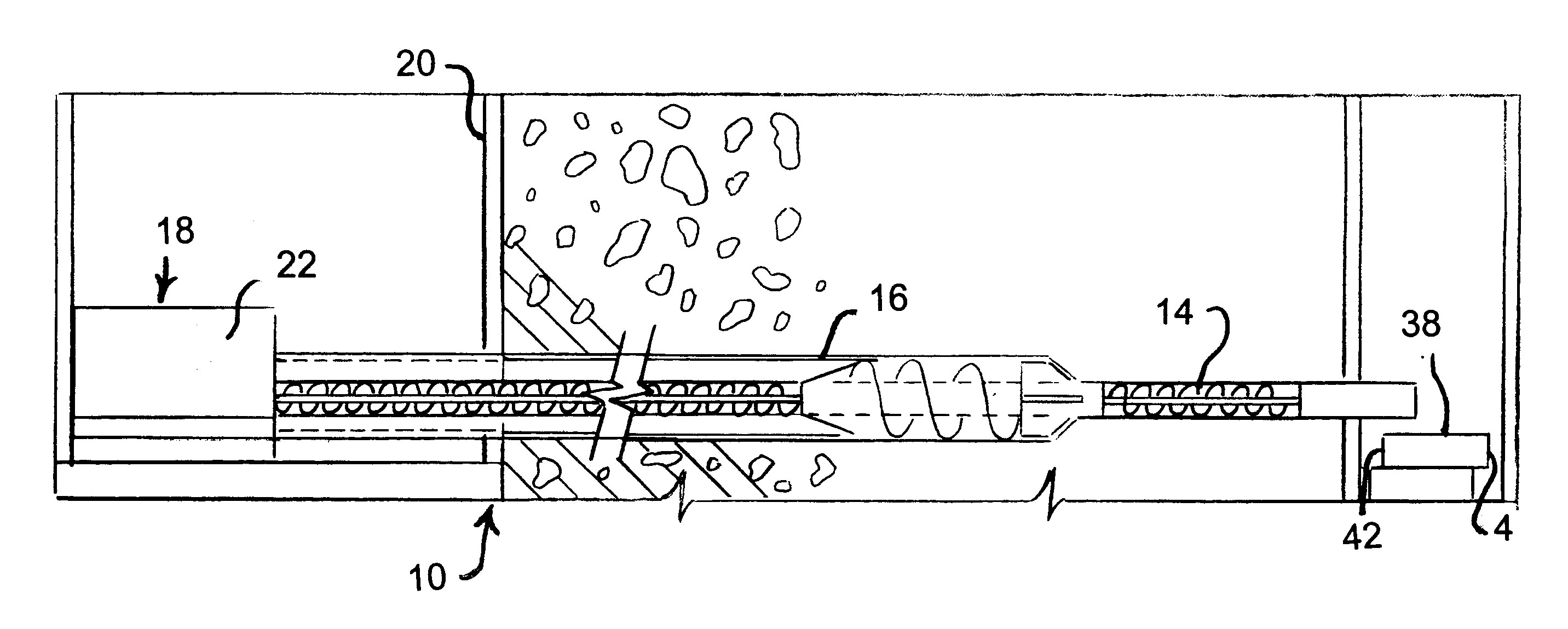

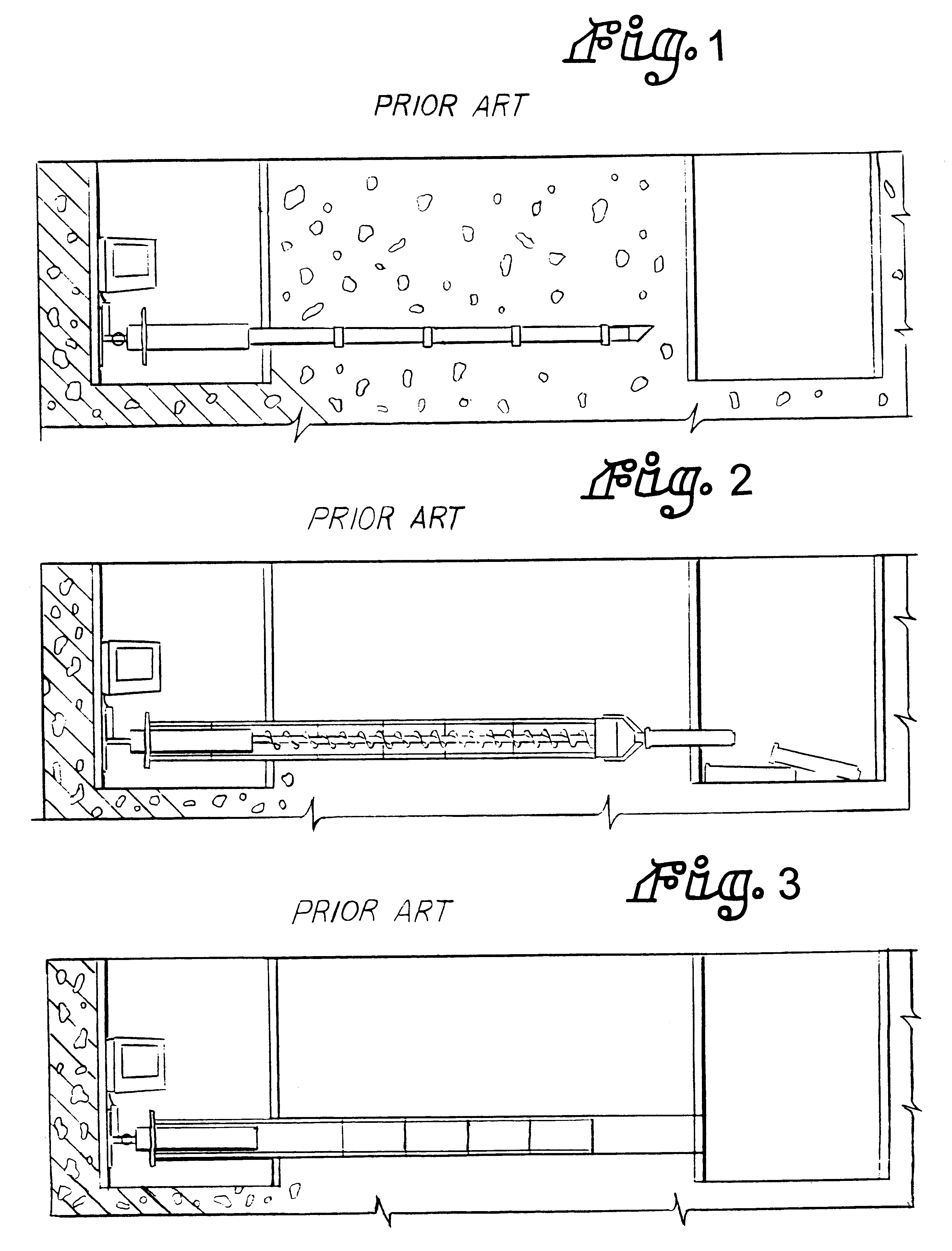

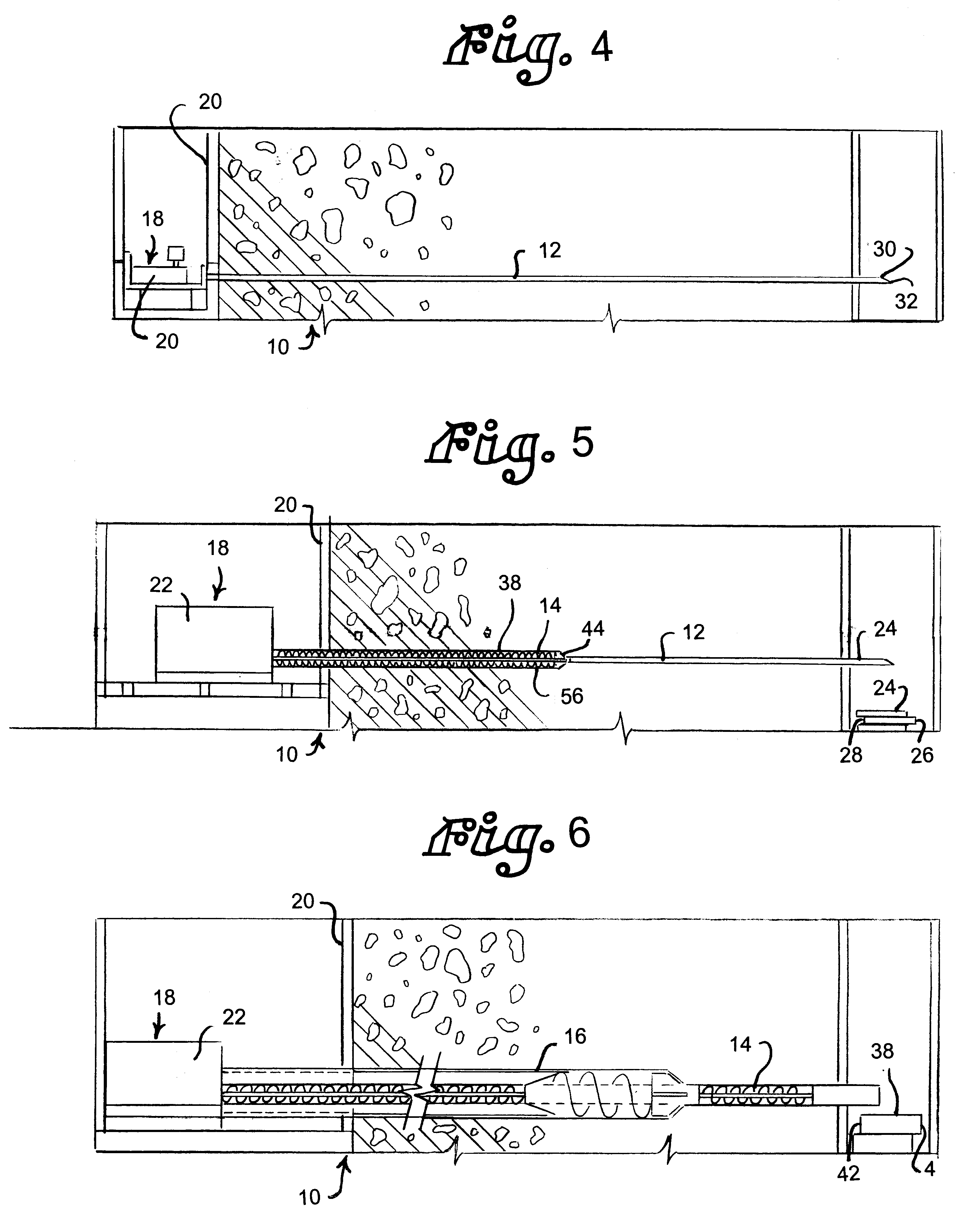

Methods of recovering hydrocarbons from hydrocarbonaceous material with reduced non-carbonaceous leachate and co2 and associated systems

ActiveUS20080190816A1Avoid insufficient heatingInhibition formationThermal non-catalytic crackingUnderground chambersLeachateMaterials science

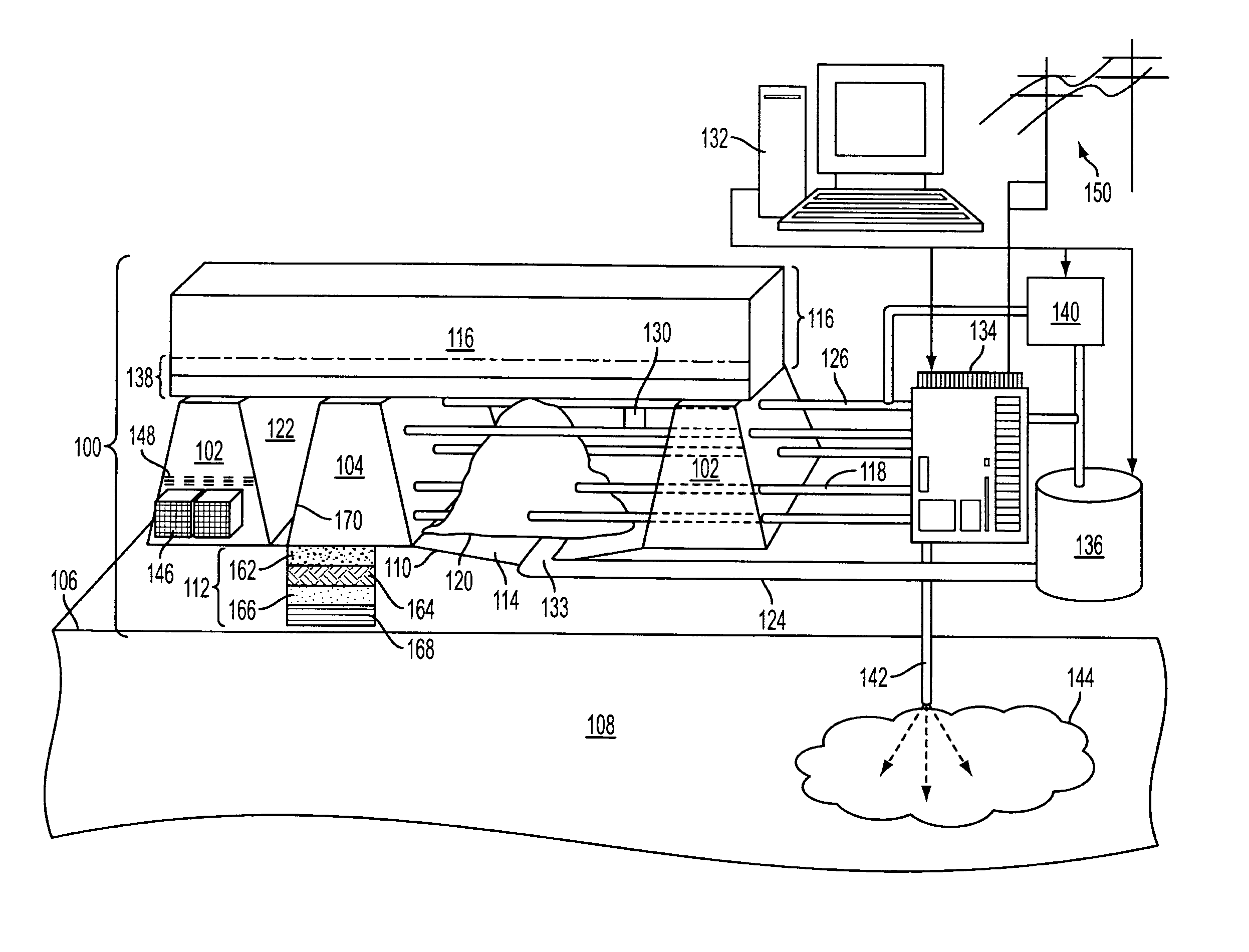

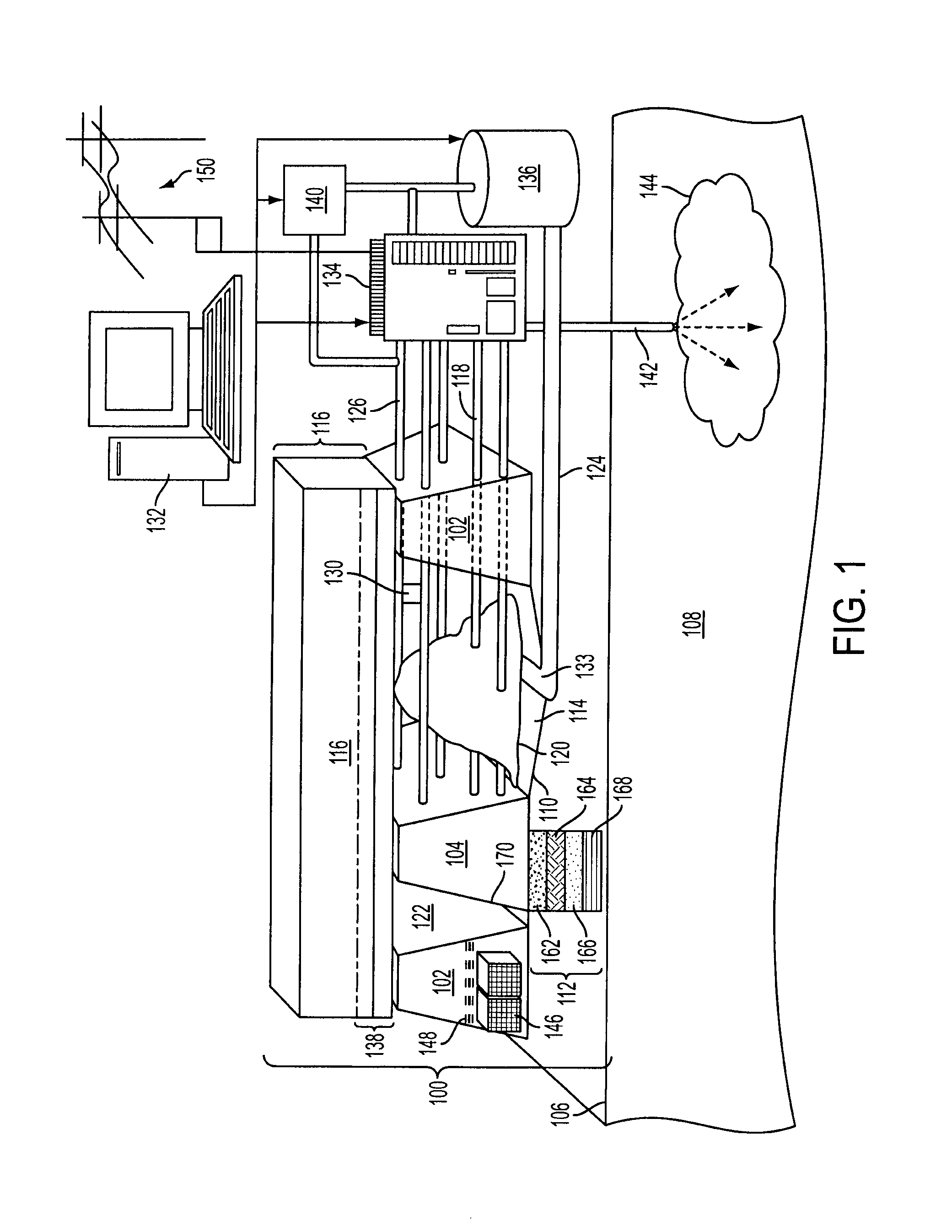

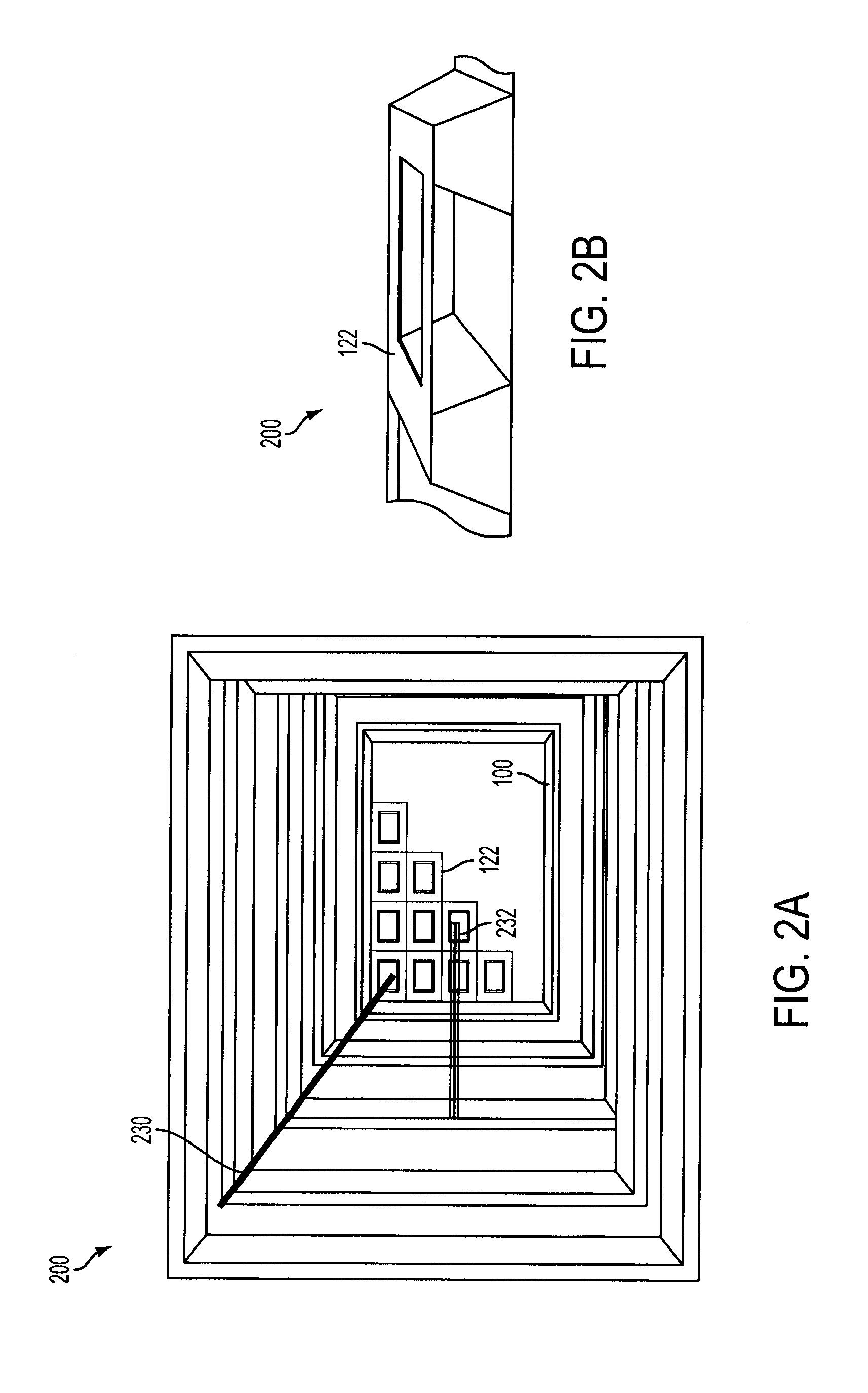

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a stationary permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom within a temperature range which is sufficient to substantially avoid formation of carbon dioxide or non-hydrocarbon leachates. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

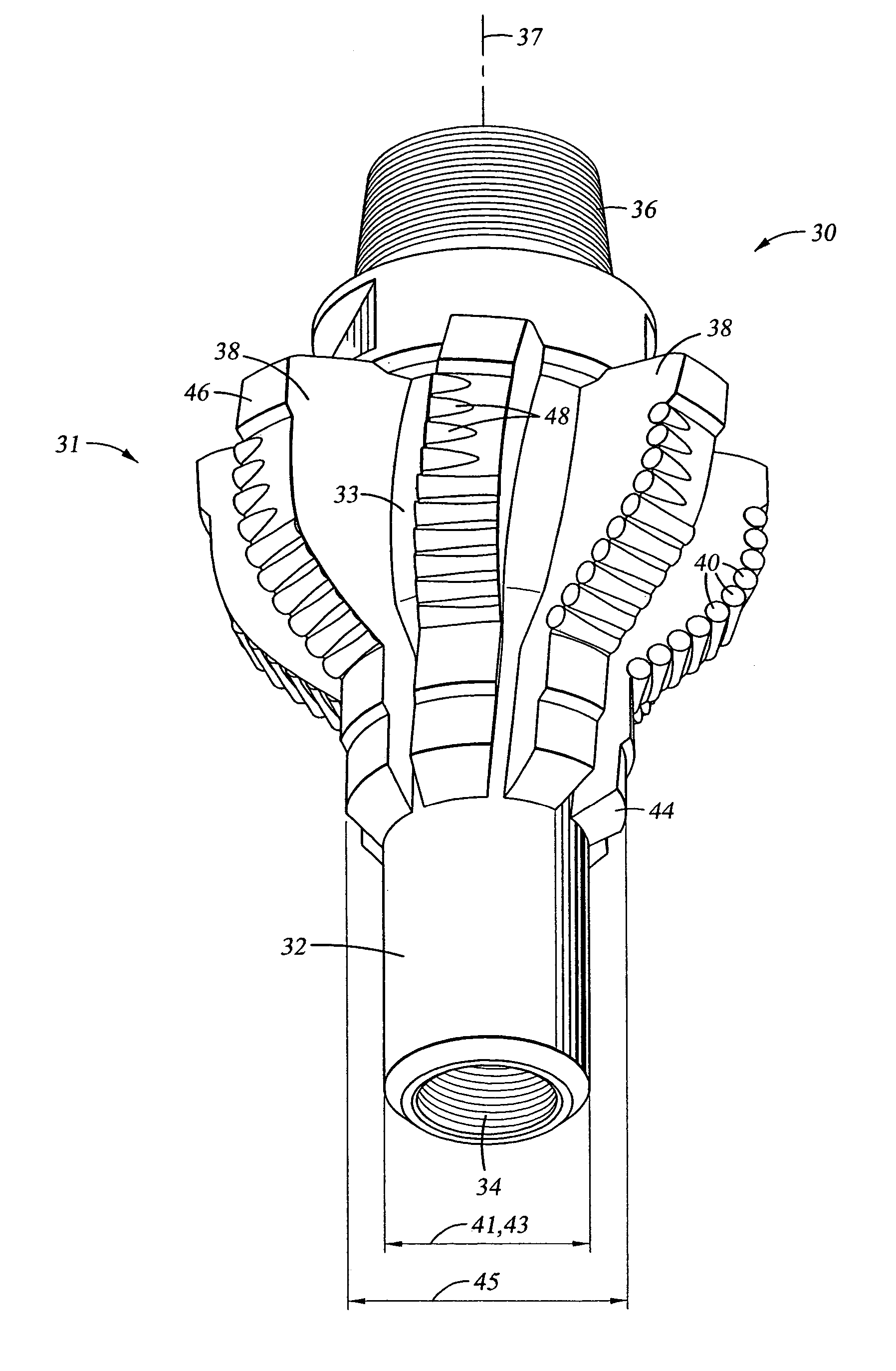

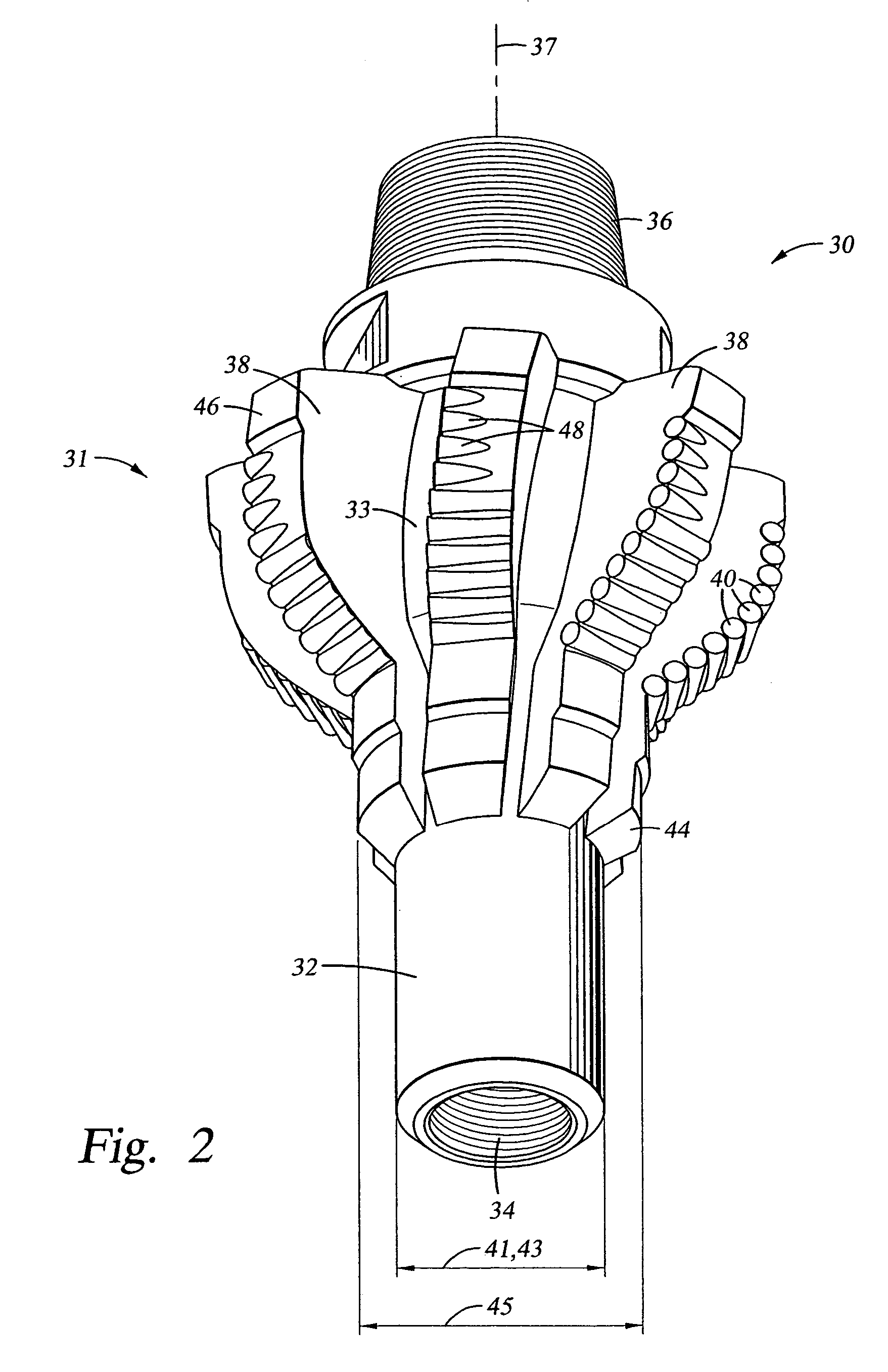

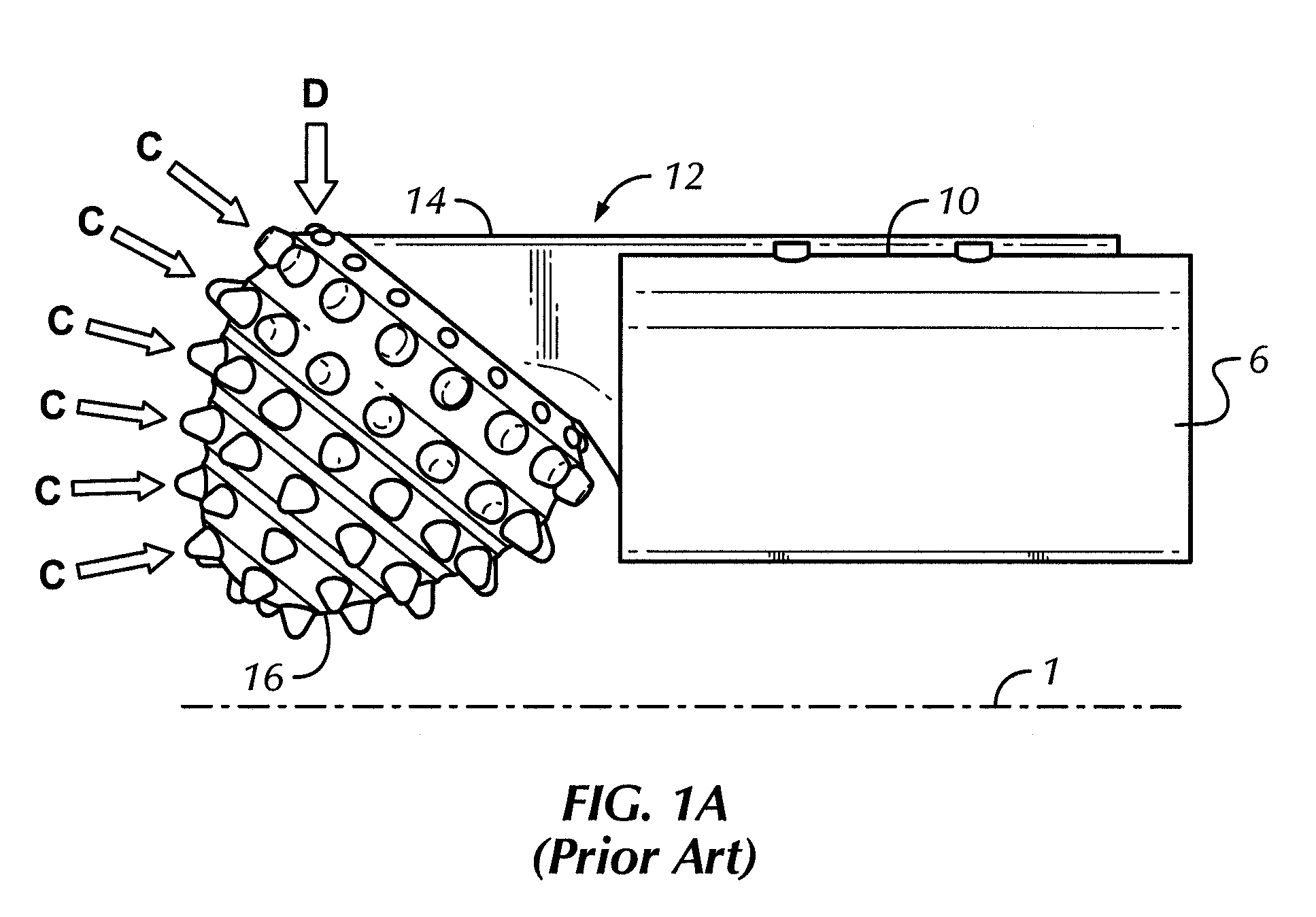

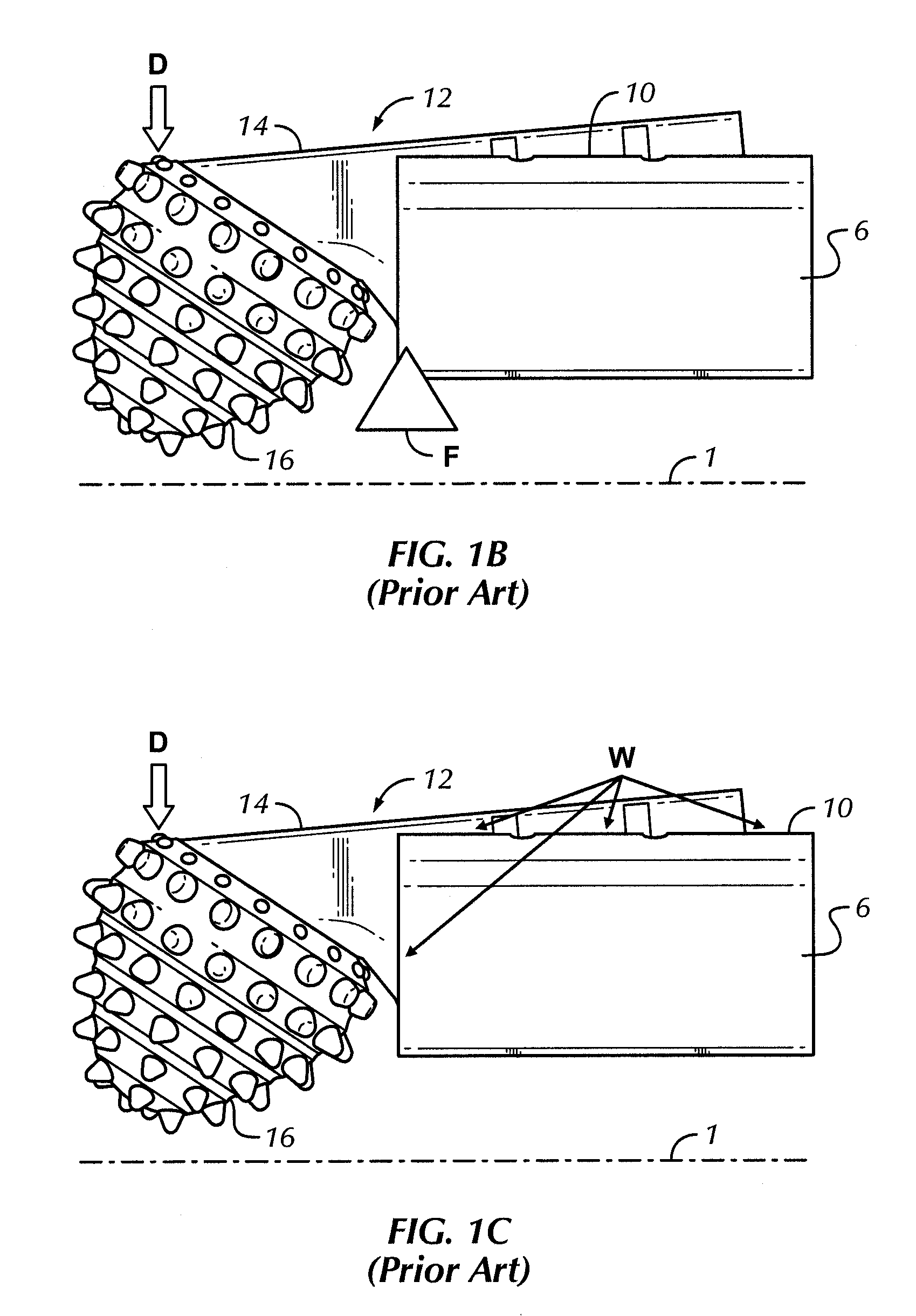

Fixed blade fixed cutter hole opener

A hole opener including a tool body having upper and lower ends. The upper and lower ends may be coupled to adjacent drilling tools. At least two blades are formed on the tool body and are arranged so that the hole opener is positioned concentric with a wellbore, and cutting elements are located on the blades. The at least two blades and the cutting elements are arranged to increase a diameter of a previously drilled wellbore.A hole opener including a tool body having upper and lower ends. The upper and lower ends may be coupled to adjacent drilling tools. At least two blades are formed on the tool body and are arranged so that the hole opener is positioned concentric with a wellbore, and cutting elements are located on the blades. The hole opener includes a pilot hole conditioning section. The pilot hole conditioning section includes at least two pilot blades formed on the tool body in a position axially ahead of the blades. The pilot blades include a taper at a downhole end and gage pads positioned at selected diameters. At least one cutting element is disposed on the pilot blades.

Owner:SMITH INT INC

Methods of recovering hydrocarbons from hydrocarbonaceous material using a constructed infrastructure having permeable walls and associated systems

ActiveUS20080190815A1Easy to produceLarge movementThermal non-catalytic crackingUnderground chambersHydrocotyle bowlesioidesEngineering

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a constructed permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume having substantially permeable side walls and a substantially impermeable cap. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom without contamination or substantial leaching of materials outside of the impoundment. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

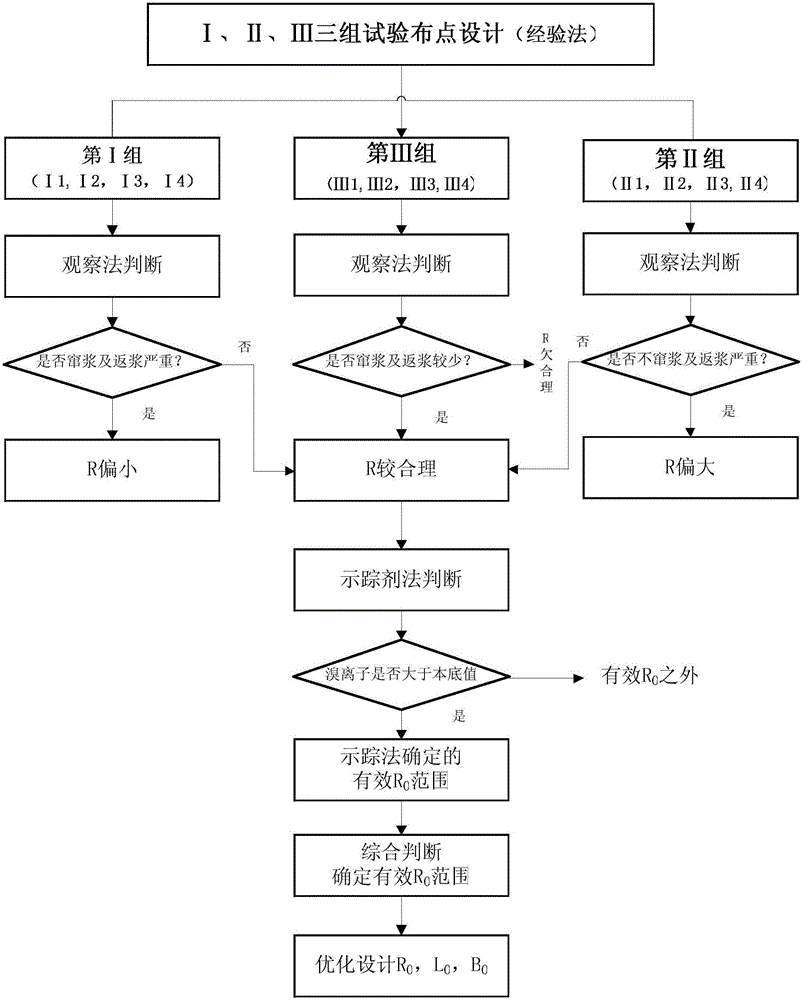

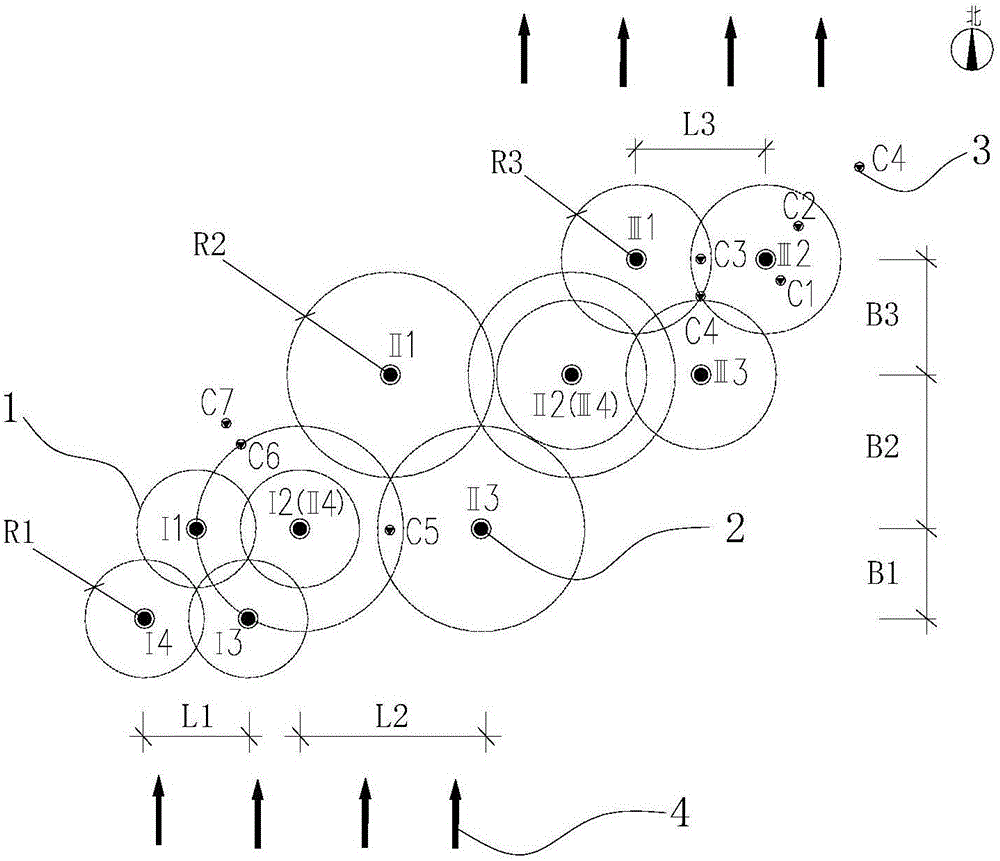

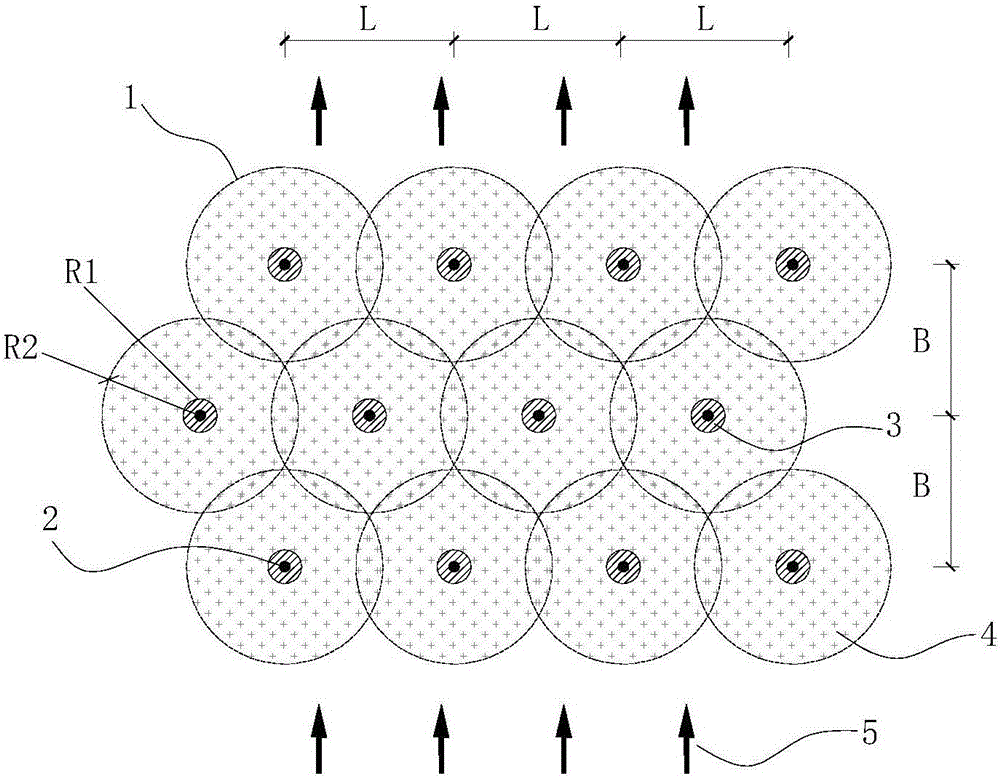

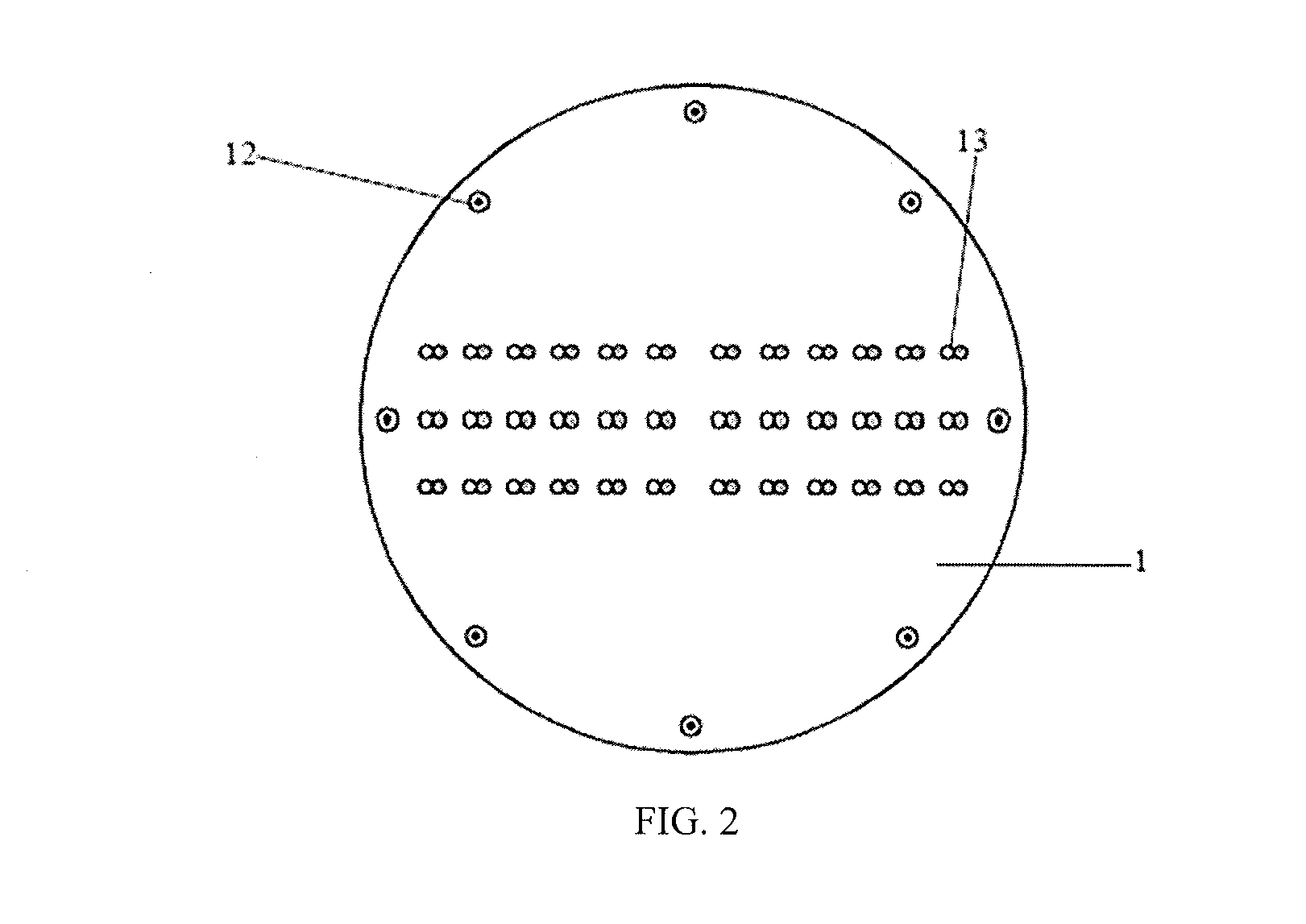

Method for determining in situ injection repair diffusion radiuses of contaminated soil and underground water

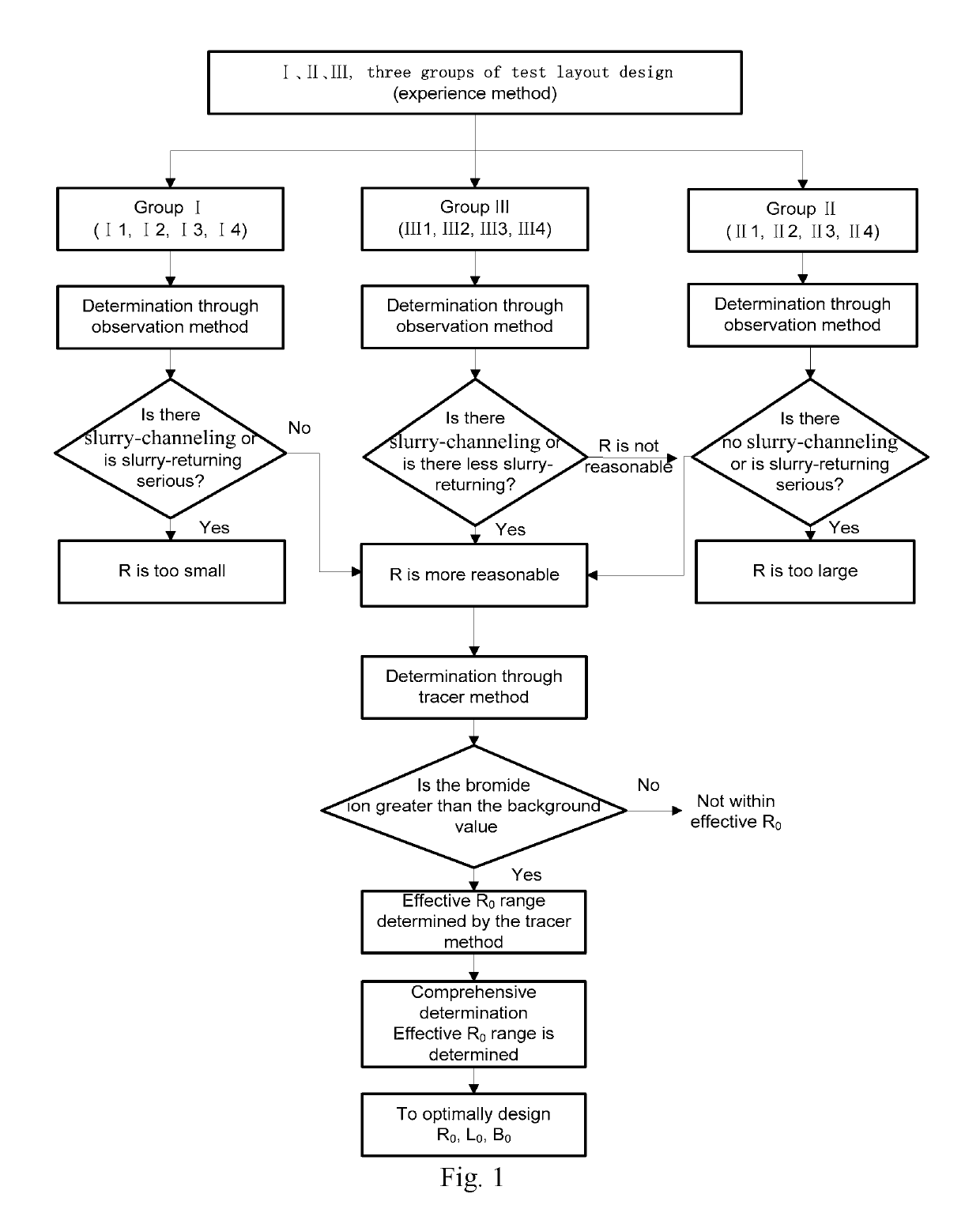

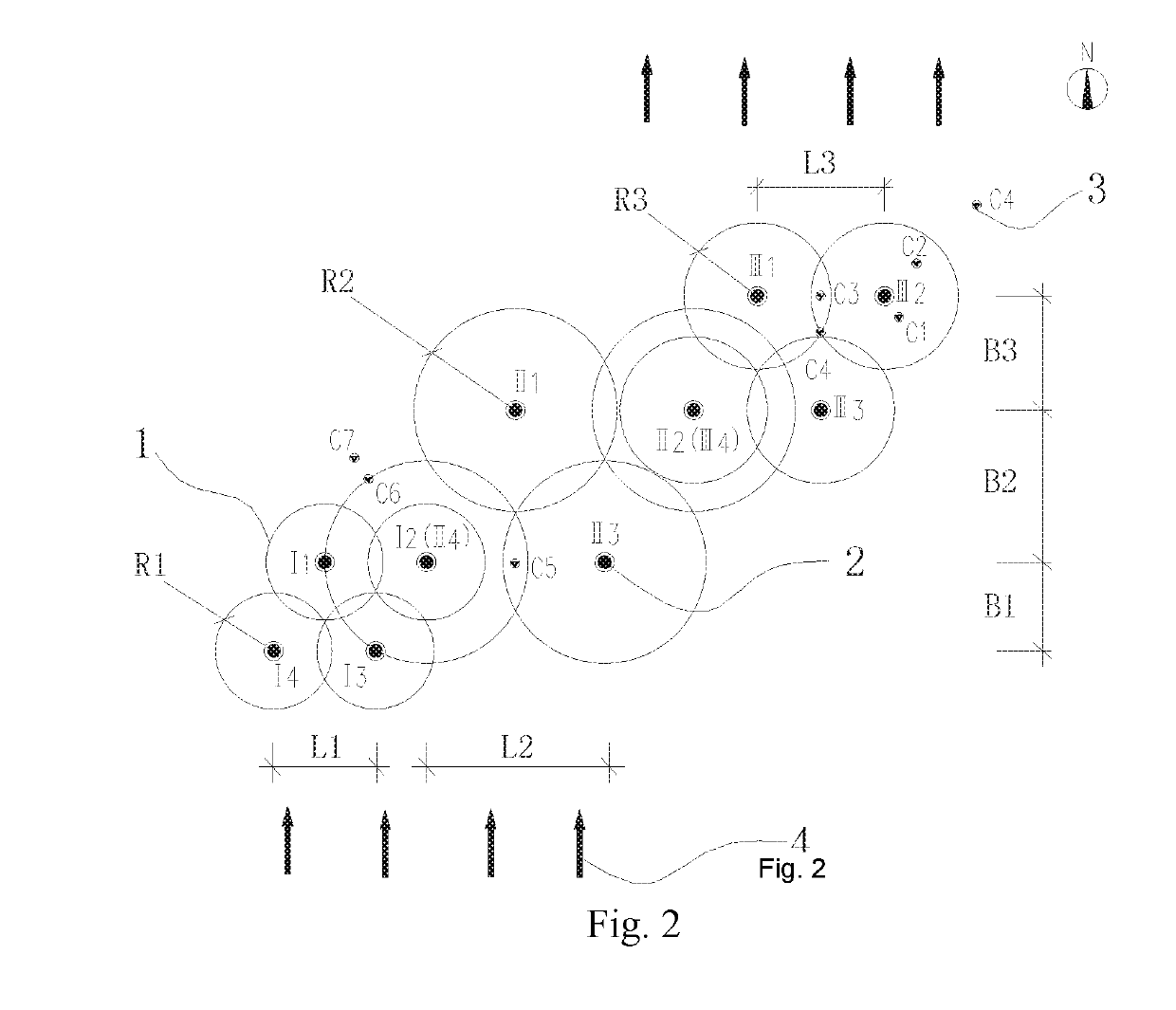

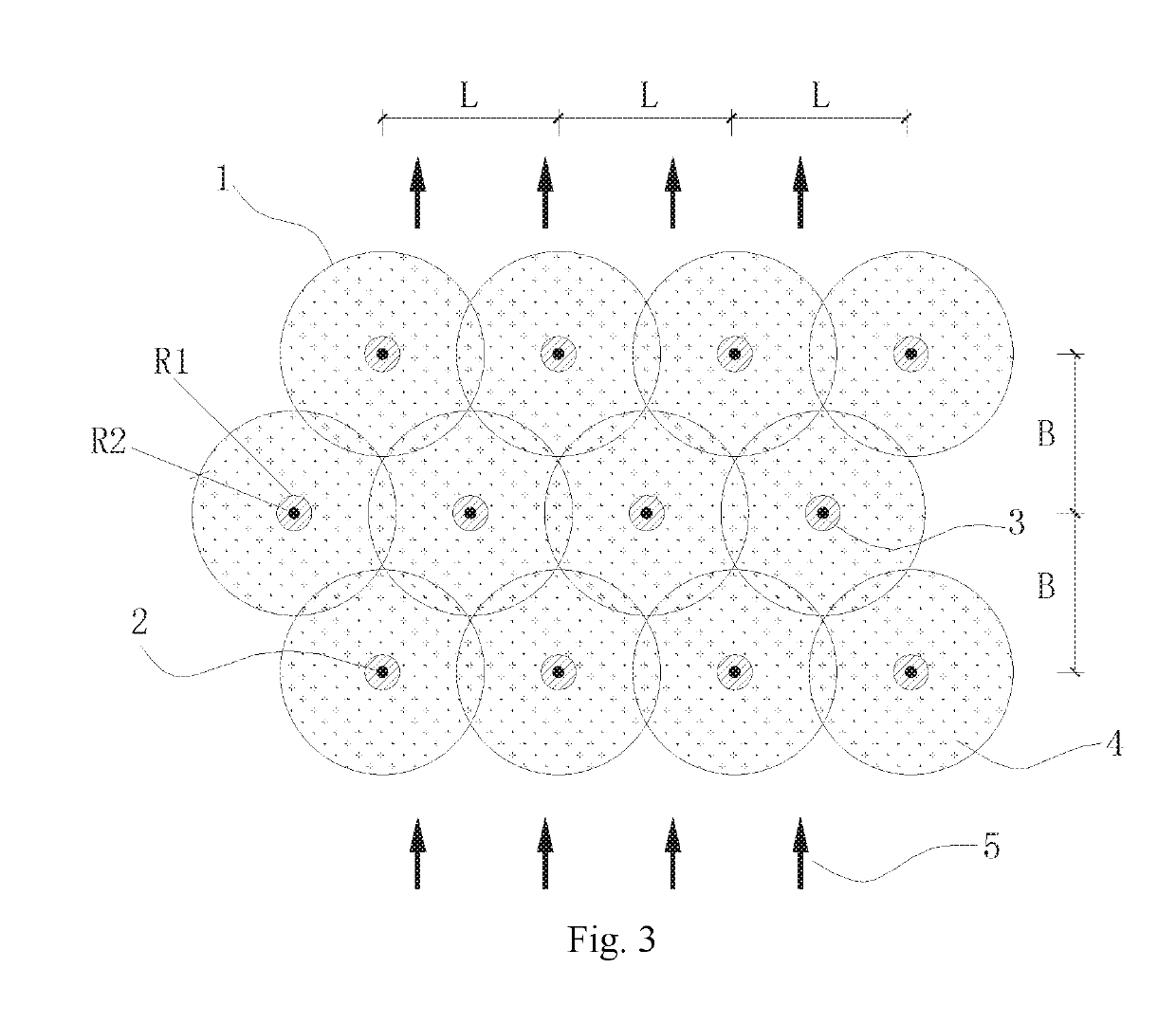

ActiveCN105973759ASolve the problem of back slurryEasy to operateConstructionsContaminated soil reclamationHigh pressureInjection test

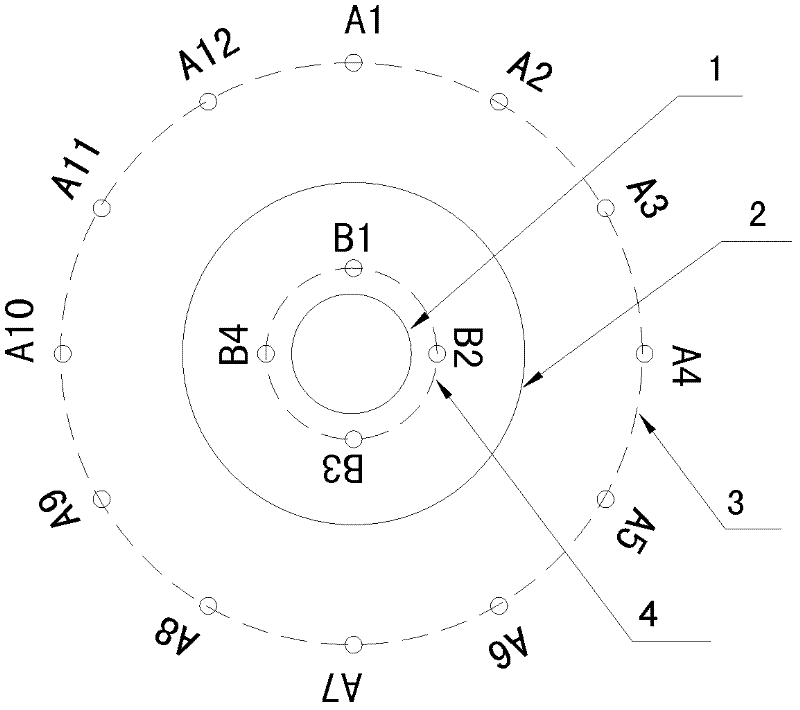

The invention discloses a method for determining in situ injection repair diffusion radiuses of contaminated soil and underground water. According to the method, points are distributed according to a triangle method, pitch-row is designed to be perpendicular to the flowing direction of the underground water, array pitch is in the flowing direction of the underground water, and the flow expansion of a repair reagent in the underground water within the reaction effective time is taken into account. The method comprises three steps: firstly, observation method: the repair reagent and a definite proportion of bromide ion serving as tracers are simultaneously injected into an aqueous stratum in the condition of high pressure whirl spraying injection. The diffusion of the reagent is judged by observing the phenomena of grout return and grout leaking between adjacent injection points; secondly, bromide ion tracer method: after the completion of injection, underground water depth setting rapid sampling is performed, the concentration of the tracers is rapidly detected in field, and the concentration of the bromide ion in the underground water is compared with a background value; thirdly, bromide ion tracer method and observation method: the optimum diffusion radiuses are determined through synthetic judgment. The method is applied to optimal design of diffusion radiuses and hole arrangement parameters and monitoring of injection effect in soil and underground water in situ injection tests and repair construction.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

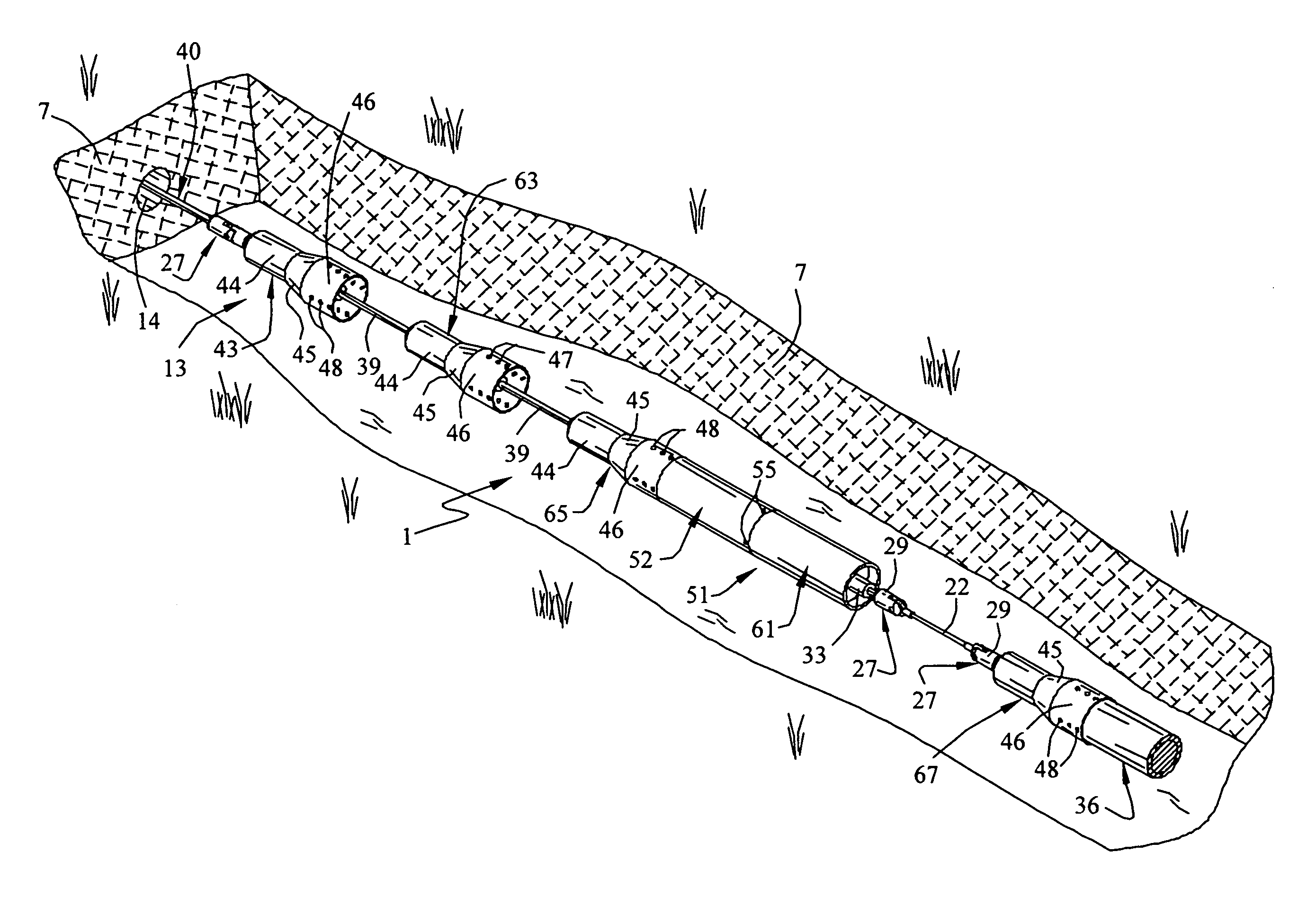

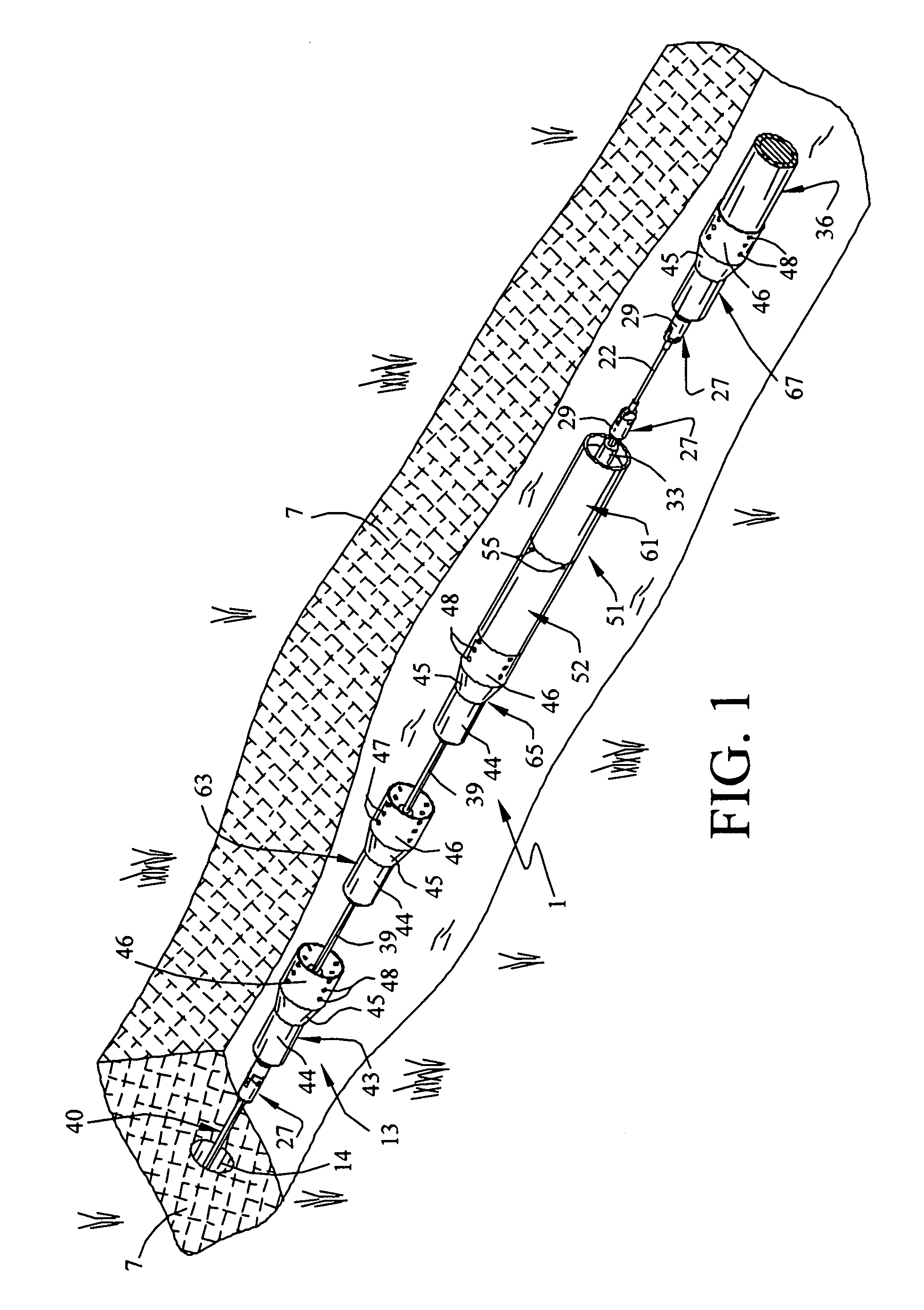

Sinking technology for expanding pilot well drilled by raise-boring machine, by using vertical well heading machine

The invention discloses a sinking technology for expanding a pilot well drilled by a raise-boring machine, by using a vertical well heading machine, which comprises the following steps of (a) drilling the pilot well by using the raise-boring machine; (b) drilling by using the vertical well heading machine to enable the pilot well to be enlarged into a vertical well at a desirable diameter in a brushing way; (c) hanging a net on and jetting concrete onto the wall of the vertical well to form a temporary supporting well wall; (d) after enlarging in the brushing way and heading to a lower tunnel by using the vertical well heading machine, gradually removing components of the vertical well heading machine from top to bottom. By the adoption of the technology provided by the invention, in the presence of the pilot well, a vertical well hole at a design diameter is formed through the one-time drilling of the vertical well heading machine; therefore the technology is applicable for the construction of underground mine vertical well holes for coal mining, metal, nonmetal and the like.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

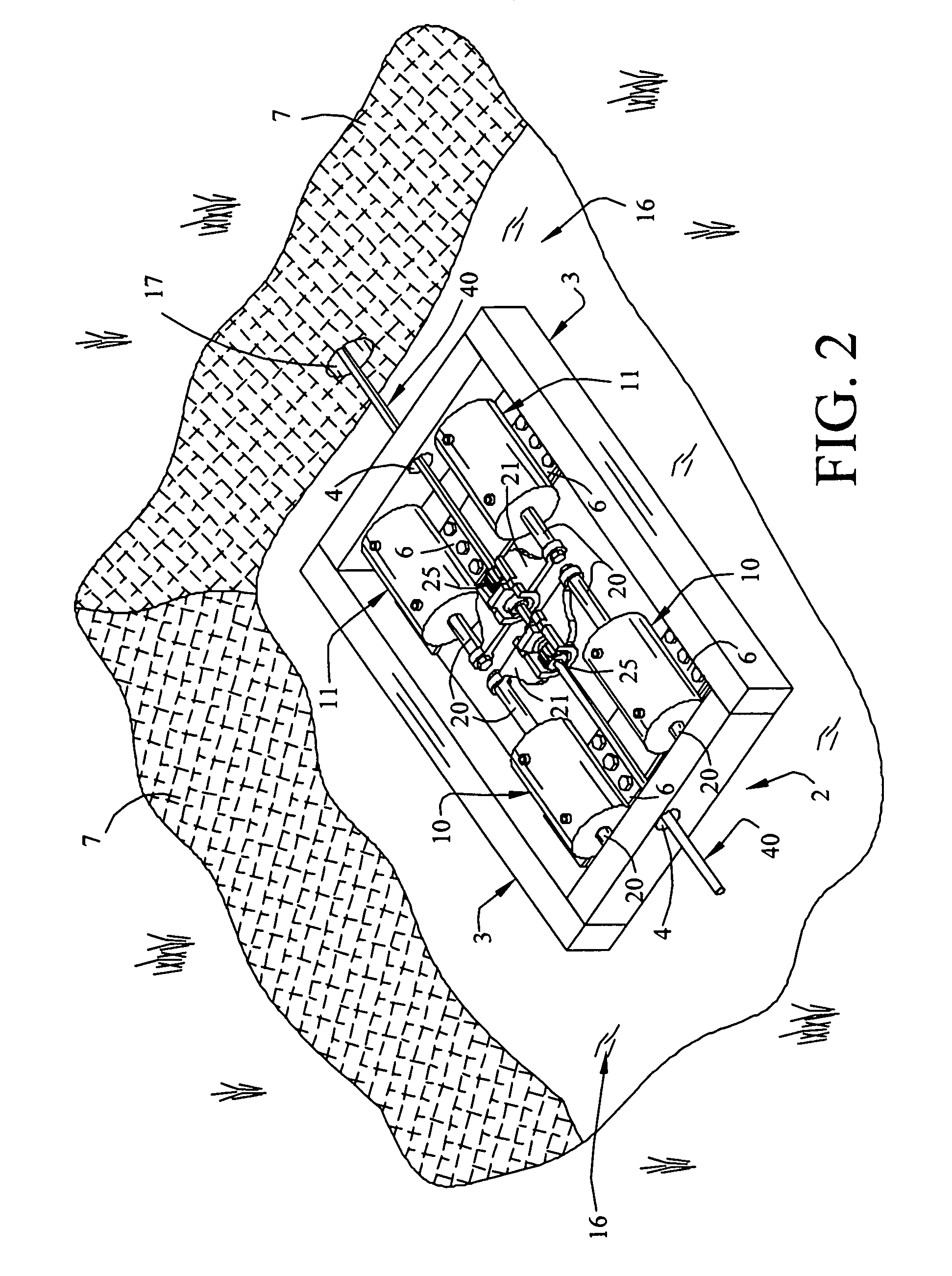

Apparatus and method for pilot-tube guided auger boring

An apparatus and method for trenchless, underground emplacement of man-sized product pipe between first and second shaft locations is disclosed. The apparatus comprises a pilot tube assembly having a pilot tube segment and a steering head mounted to the pilot tube segment. The steering head is configured to operatively guide the pilot tube assembly from the first shaft location to the second shaft location. The apparatus further comprises an intermediate sleeve assembly having an intermediate sleeve segment and an intermediate cutting head mountable to the pilot tube assembly and to the sleeve segment. The intermediate cutting head has a diameter substantially greater than the diameter of the pilot tube assembly and is configured to be operably guided by the pilot tube assembly. An enlarging assembly of the apparatus comprises a drive sleeve segment and an enlarging cutting head mounted to the intermediate sleeve assembly and to the drive sleeve segment. The enlarging cutting head has a diameter substantially larger than the diameter of the intermediate sleeve assembly and the drive sleeve segment. The enlarging cutting head and the drive sleeve segment are operably guidable by the intermediate sleeve assembly. A drive assembly successively advances the pilot tube assembly, the intermediate sleeve assembly, the trailing assembly, and product pipe from the first shaft location to the second shaft location.

Owner:EXACTGRADE UNDERGROUND INFRASTRUCTURE

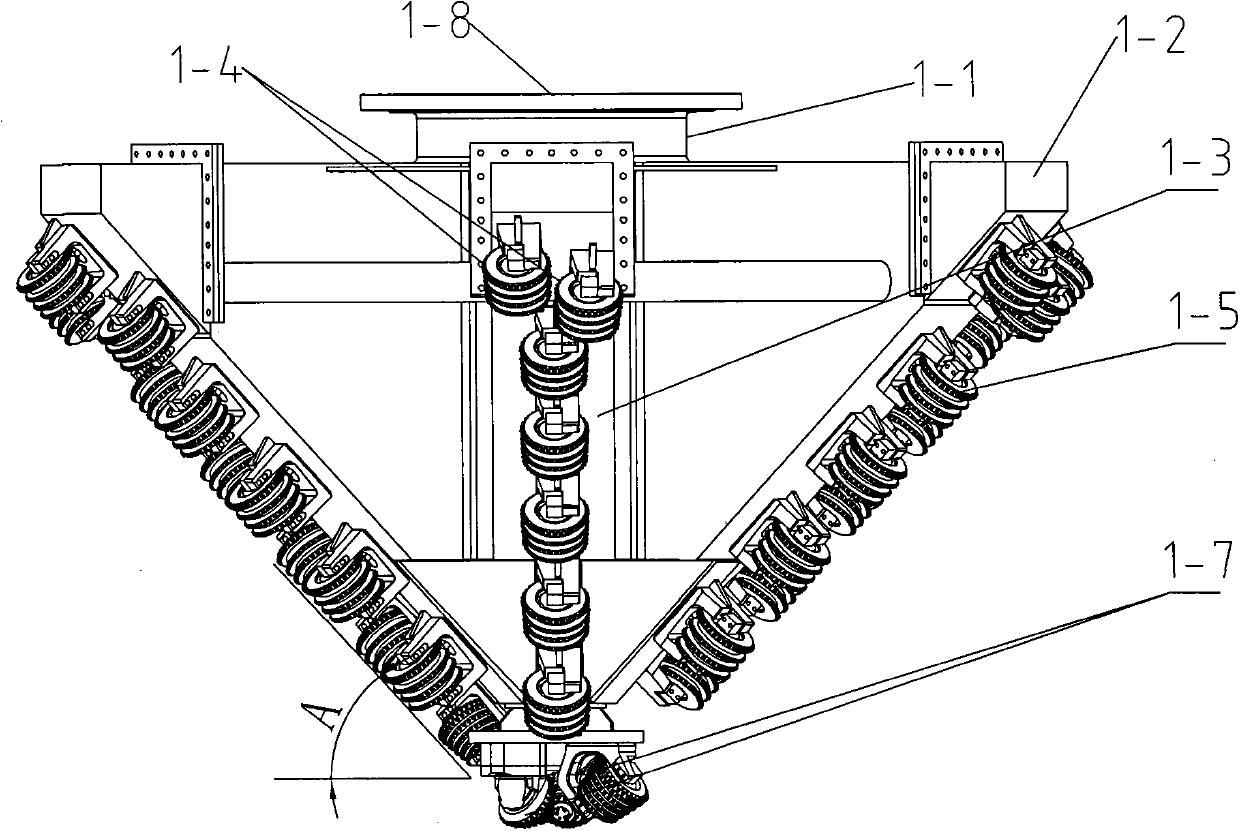

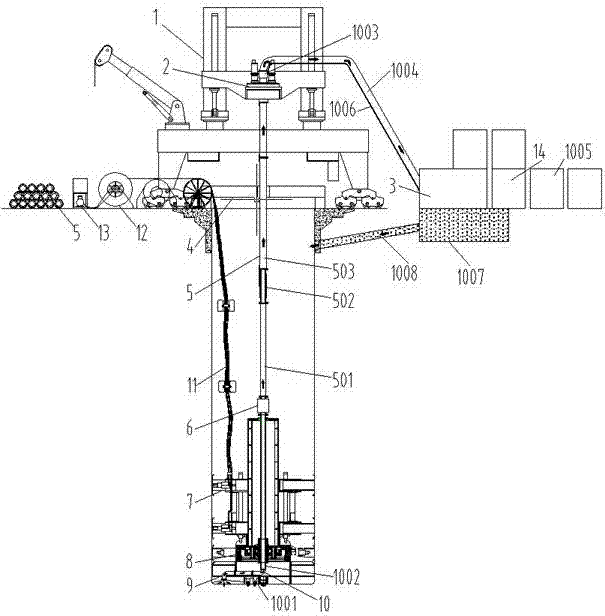

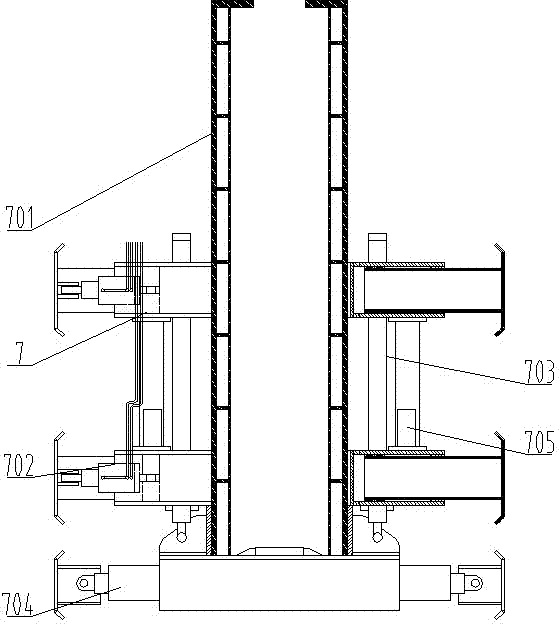

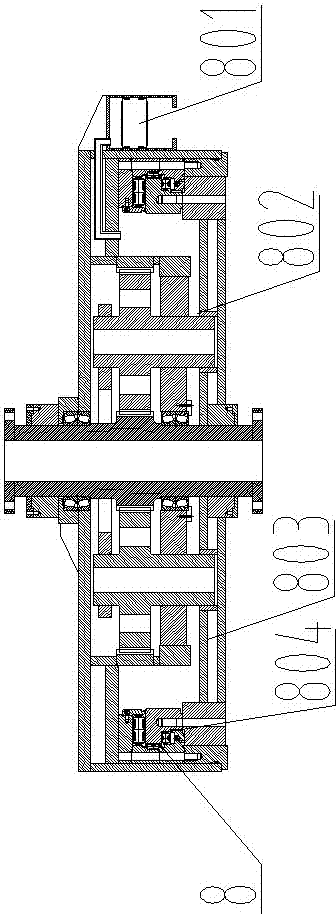

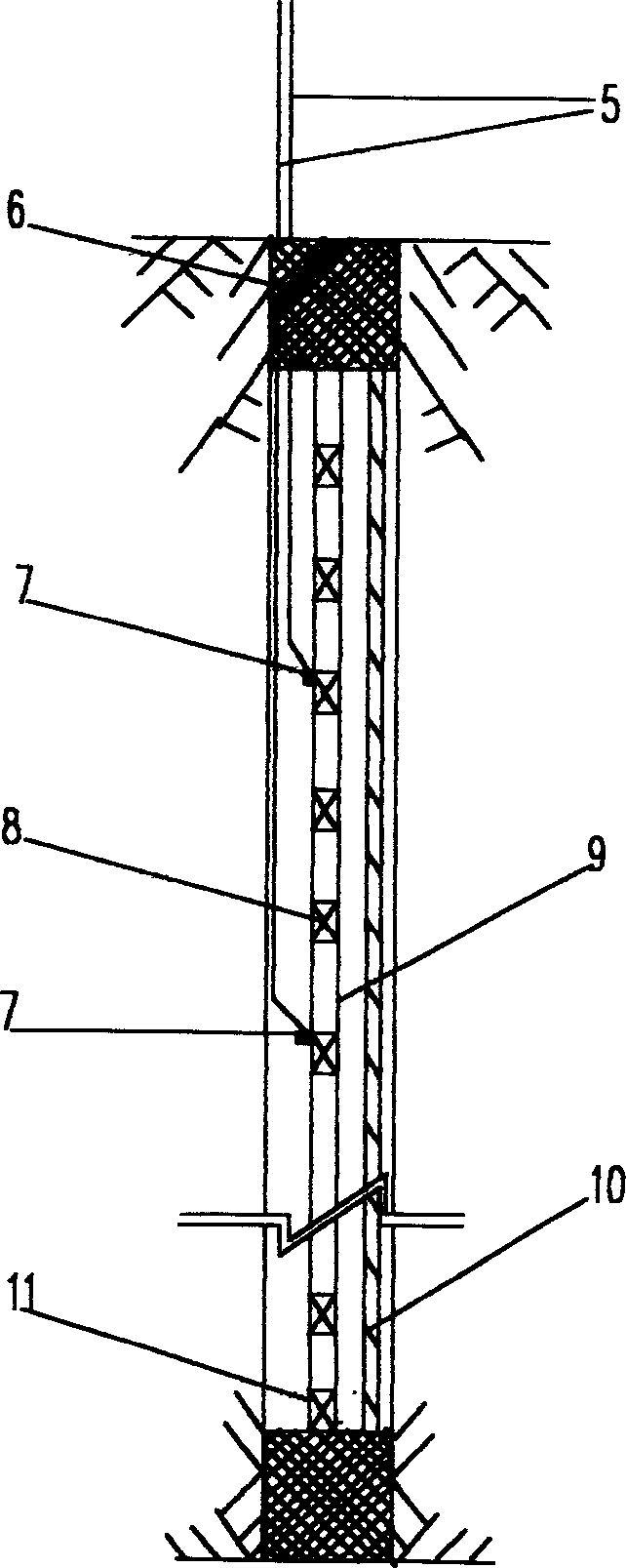

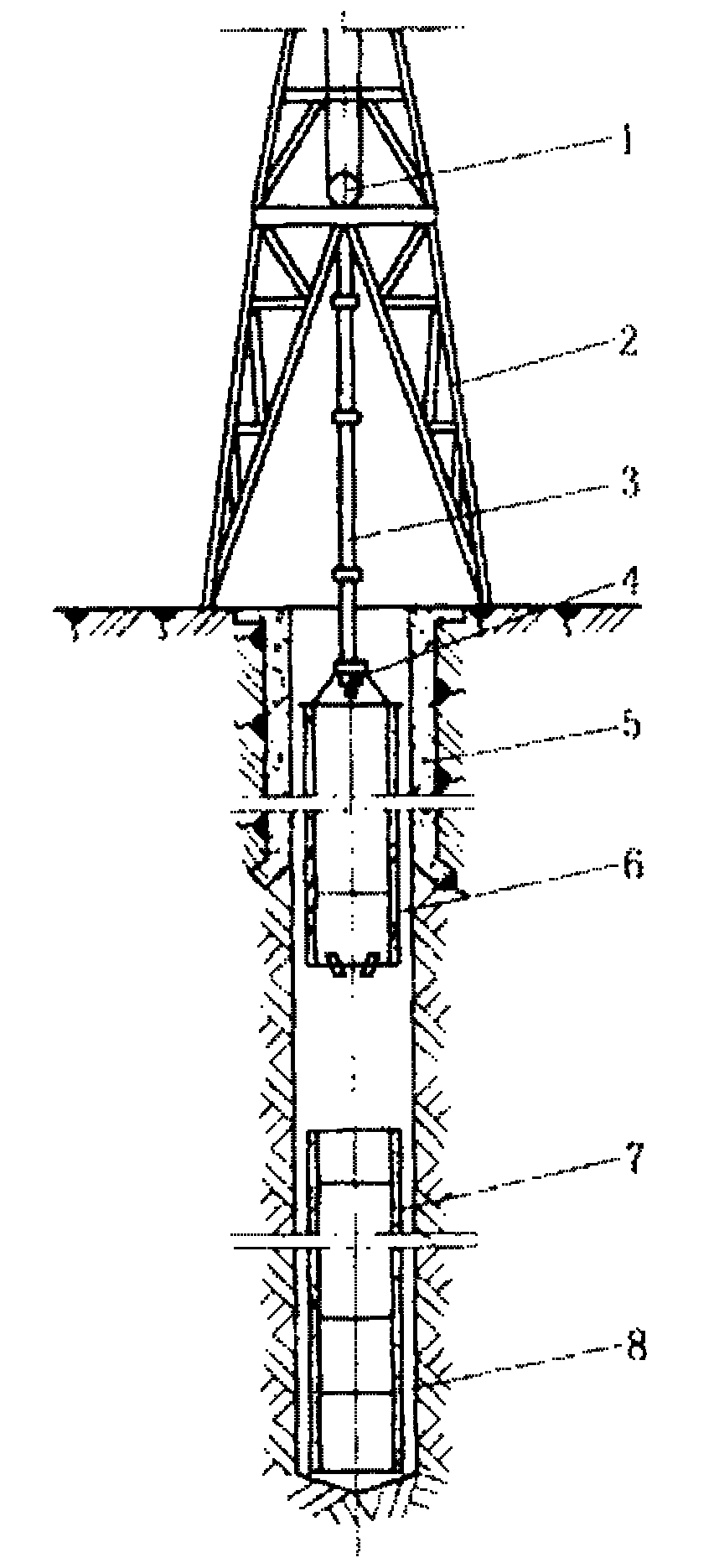

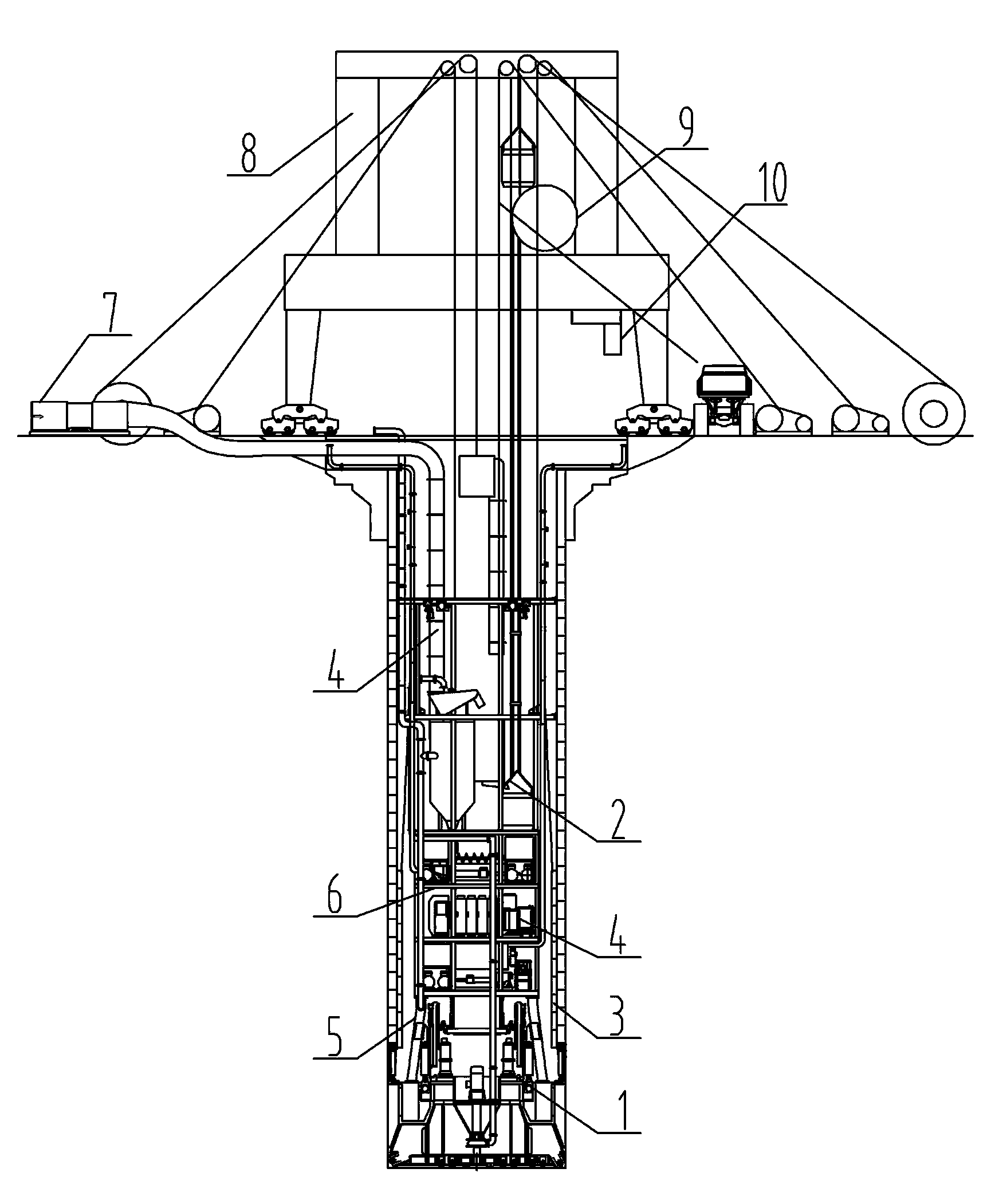

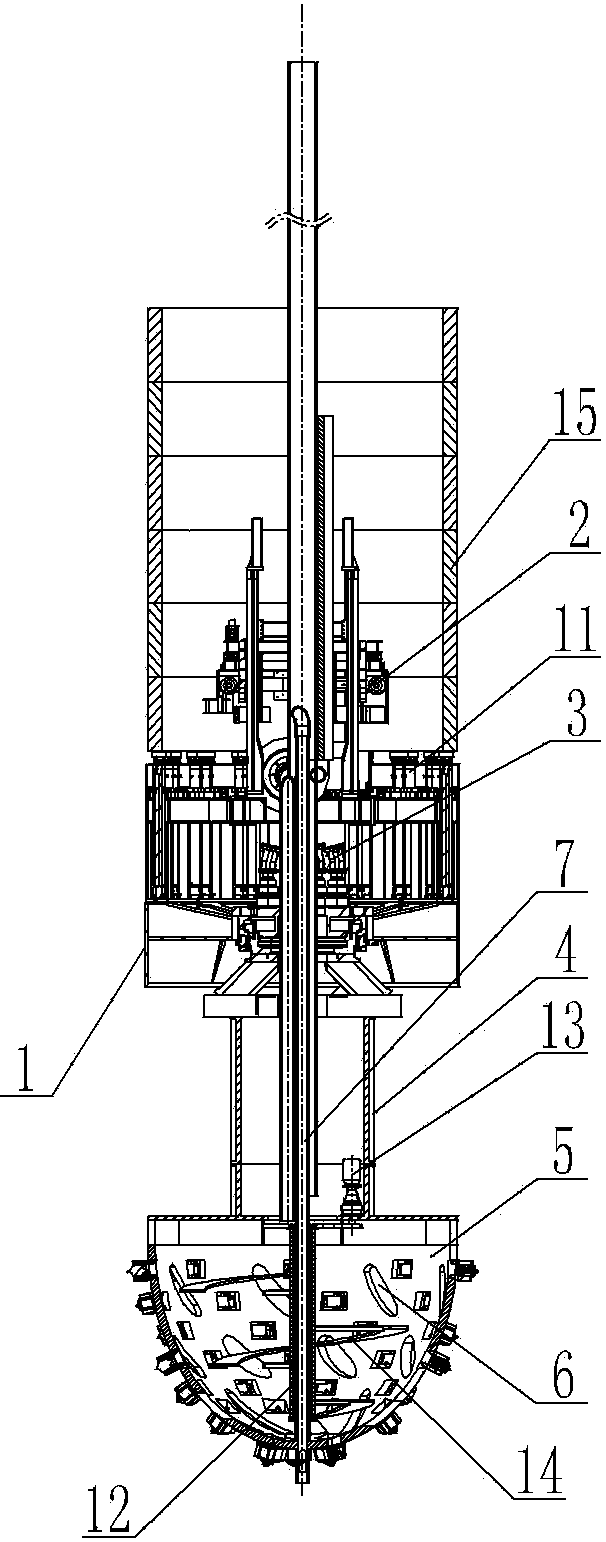

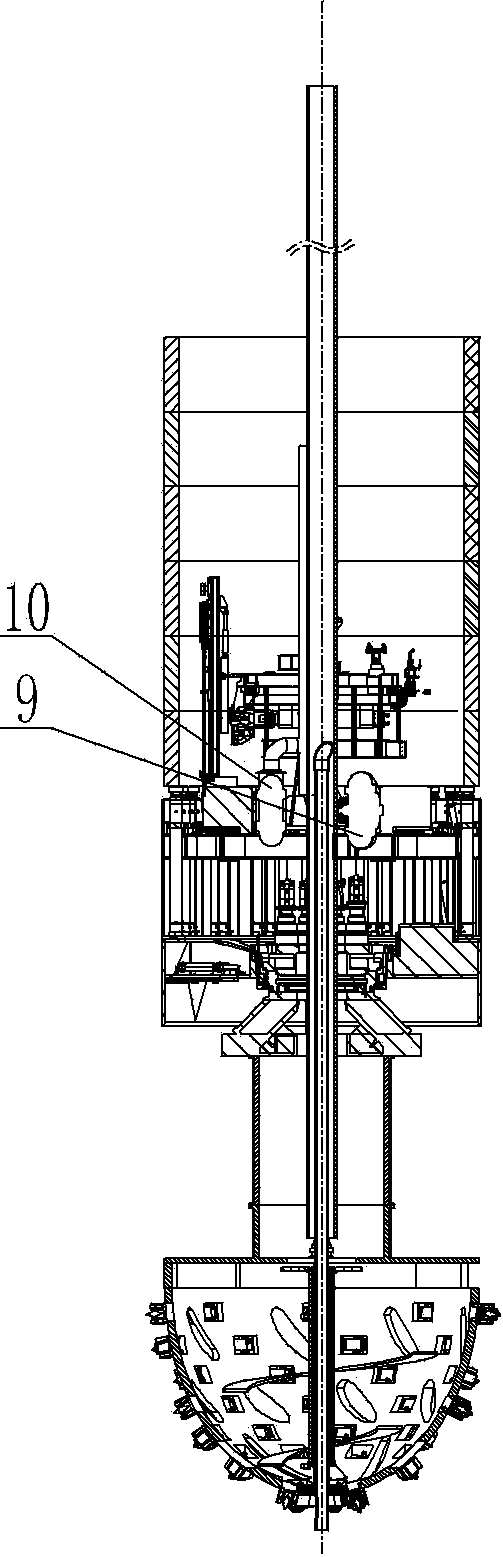

Novel drilling method for shaft drilling machine

ActiveCN103899316AImprove stabilityImprove construction efficiencyDerricks/mastsBorehole drivesSlagWell drilling

A novel drilling method for a shaft drilling machine mainly comprises a derrick and an opening-sealing flat wagon which are arranged at a well opening, and further comprises a drill rod, a flexible connector, a stable pressing device, a torque amplification driving device, a cutter head, a slag discharging system, a mud treatment station, an electric appliance cabinet, a hydraulic pressure station and a power pipeline. A main drive is arranged on the derrick, the lower portion of the main drive is connected with the drill rod, the flexible connector is arranged on the drill rod, the lower end of the drill rod is connected with the torque amplification driving device, the lower end of the torque amplification driving device is connected with the cutter head, the stable pressing device is arranged outside the torque amplification driving device; muck dug by the cutter head in a well is delivered to the mud treatment station on the ground through the slag discharging system. According to the novel drilling method for the shaft drilling machine, stability of the whole machine is increased, pressing force of equipment is improved, drilling torque is increased, construction in soft soil layers is available and construction in rock stratums of high hardness is also available, guide is more accurate, so that shaft construction efficiency can be improved, shaft construction cycle is shortened, and finished well quality is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

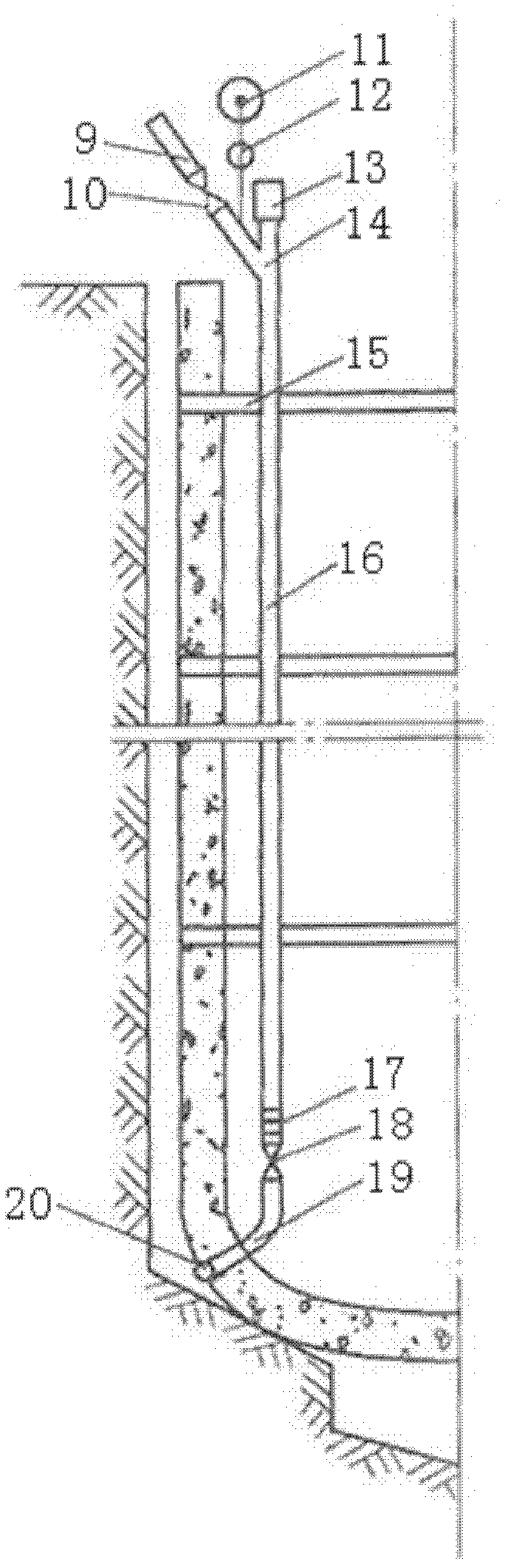

Vertical shaft working face ahead pre-grouting method

ActiveCN104453913AGuarantee the construction qualityConstruction safetyShaft sinkingShaft liningWater filterSlurry

The invention discloses a vertical shaft working face ahead pre-grouting method which comprises the steps that a thick liquid stopping pad construction is carried out, wherein after a vertical shaft driving working face reaches a thick liquid stopping pad position, a grouting hole opening pipe, a checking hole opening pipe and a water filtering pipe are arranged according to the position and the dipping angle, a water filtering layer is paved, and then concrete placing is carried out; wall-back grouting is carried out, wherein back-wall cement thick liquid injection is carried out on the shaft wall of a supported vertical shaft; and pre-grouting is carried out, wherein after the steps are carried out, hole drilling is carried out from the buried the grouting hole opening pipe until water inflow amount exceeds preset amount, at the time, drilling is stopped, thick liquid is injected, after thick liquid is subjected to final setting, hole cleaning is carried out until water inflow amount exceeds the preset amount, then drilling stopping is carried out, thick liquid in injected until water inflow amount is smaller than the preset amount, then hole drilling is carried out continuously, the steps are carried out repeatedly, subsection-down type hole drilling grouting is carried out, and hole cleaning is carried out to the full depth. A pre-burying grouting hole opening pipe and shaft wall back-wall grouting are combined, working face drilling hole grouting is carried out through the grouting hole opening pipe, full blocking of a water inflow working face developed from a vertical shaft rock joint fissure is achieved, and the advantages of a short working period and good water blocking effect are achieved.

Owner:YUXI DAHONGSHAN MINING

Bore construction method by bore explosion

The present invention provides a deep shaft one-step explosion well-forming construction method, and it is characterized by that three types of blast-holes can be drilled on the full face of the deepshaft, first type is of rock presplitting holes which are distributed along periphery of circular well to make peripheral smoothwall blasting, second type is of rock breaking holes which are distributed on the inner side of peripheral presplitting holes, and third type is of pulverizing holes with are distributed in the axis zone of shaft. The presplitting hole adopts non-coupled air column spaced charging powder, and the breaking hole and pulverizing hole adopt conventional non-coupled continuously-charging powder.

Owner:中国人民解放军工程兵第四十一旅

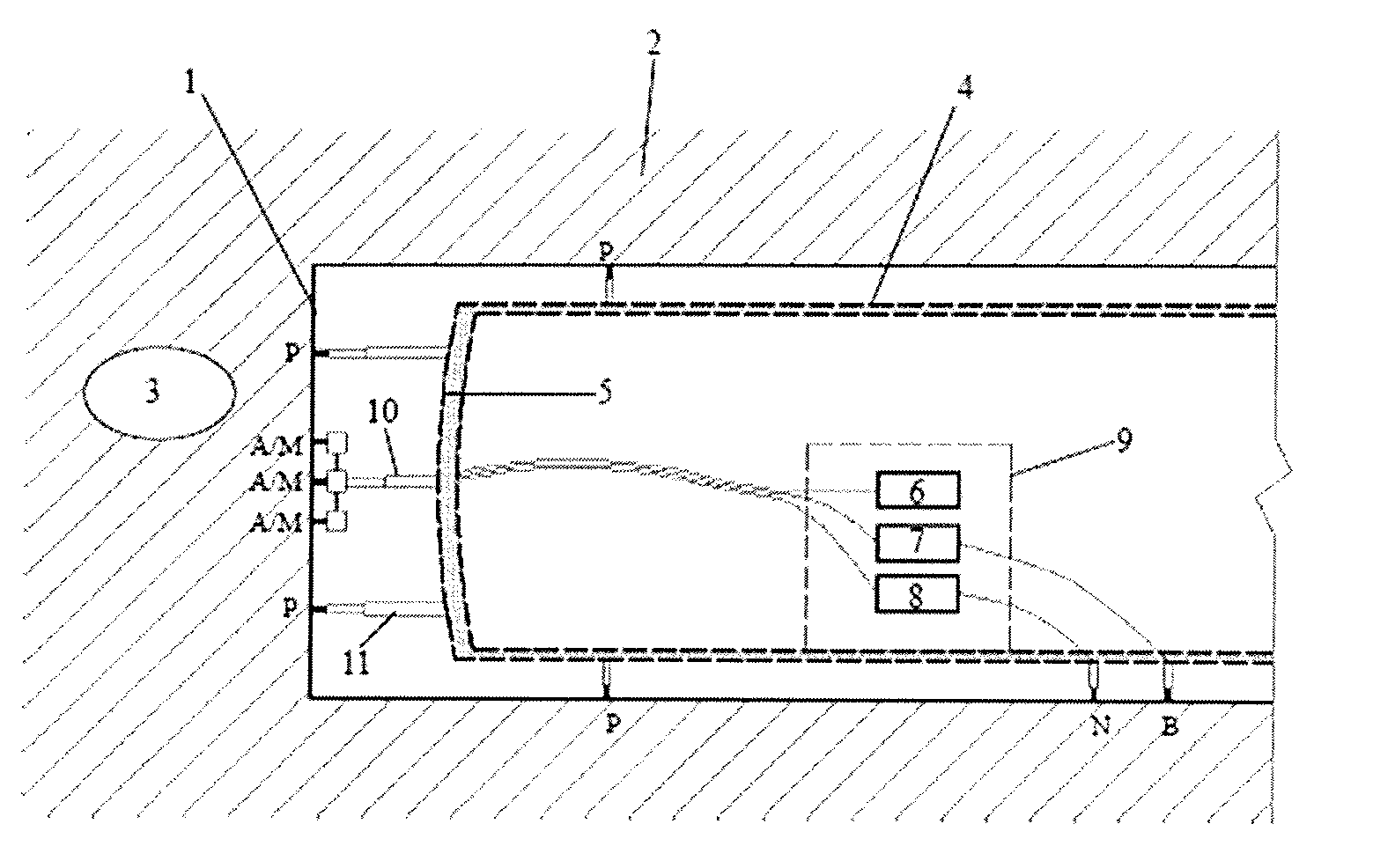

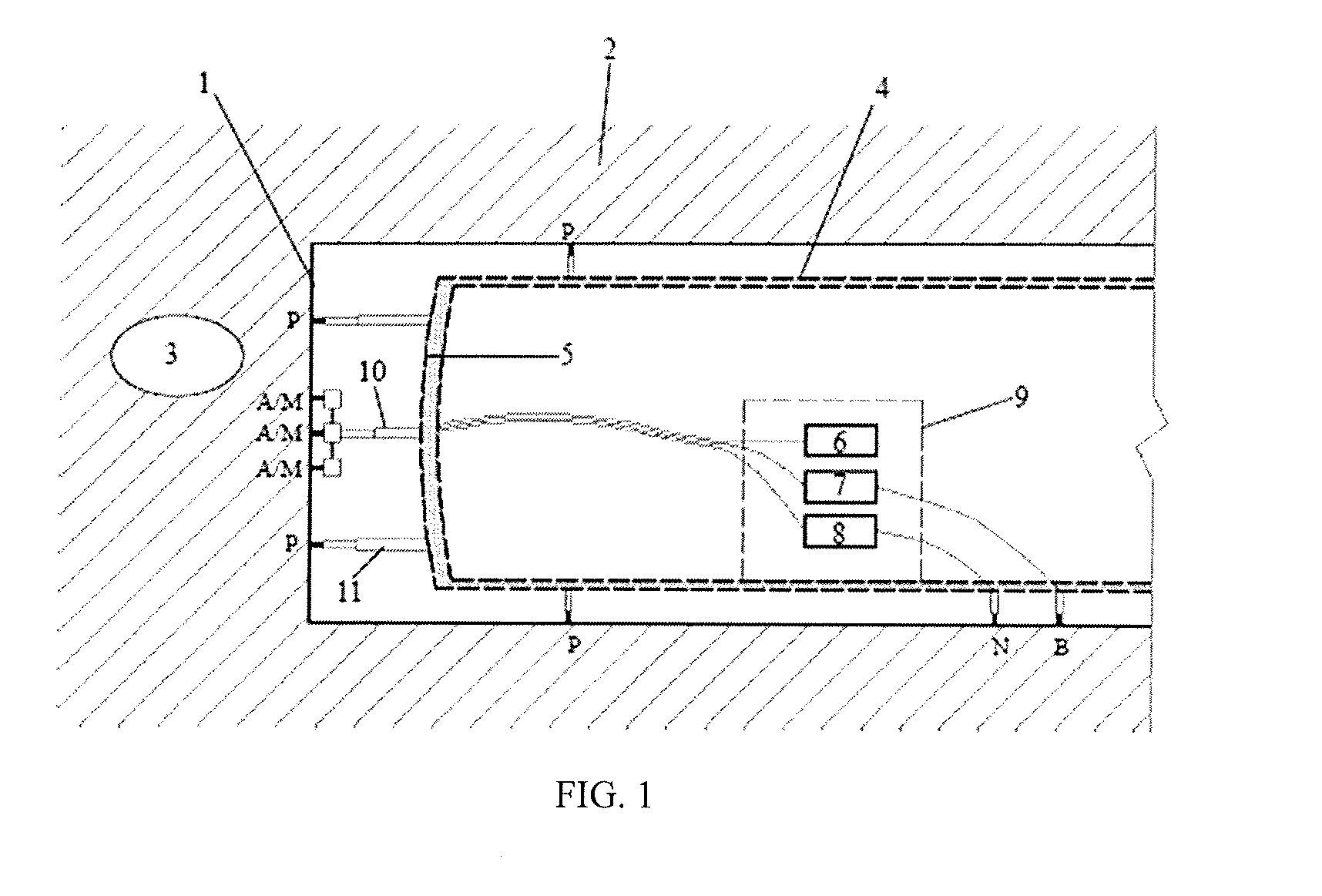

Advanced detector system and method using forward three-dimensional induced polarization method for tbm construction tunnel

ActiveUS20140333308A1Improve work efficiencyLow costElectric/magnetic detection for well-loggingSurveyBound waterEngineering

Disclosed is an advanced detector system and method using a forward three-dimensional induced polarization method for a TBM (Tunnel Boring Machine) construction tunnel. A narrow detection space of a full-face excavated tunnel is fully used, a controller controls doors of a source and measuring electrode compartment and a shielding electrode compartment to open and controls a corresponding hydraulic delivery device to automatically and quickly arrange a source electrode system, a measuring electrode system and a shielding electrode system. Under the action of a shielding current system, tomography detection supply current is directed ahead of the working face. Three-dimensional geologic information can be obtained, and the relationship between an induced polarization half-decay time difference and a water quantity can be used to quantitatively forecast the water quantity of a water-bearing body, and meanwhile, the half-decay time difference parameter has a high capacity of distinguishing free water from bound water.

Owner:SHANDONG UNIV

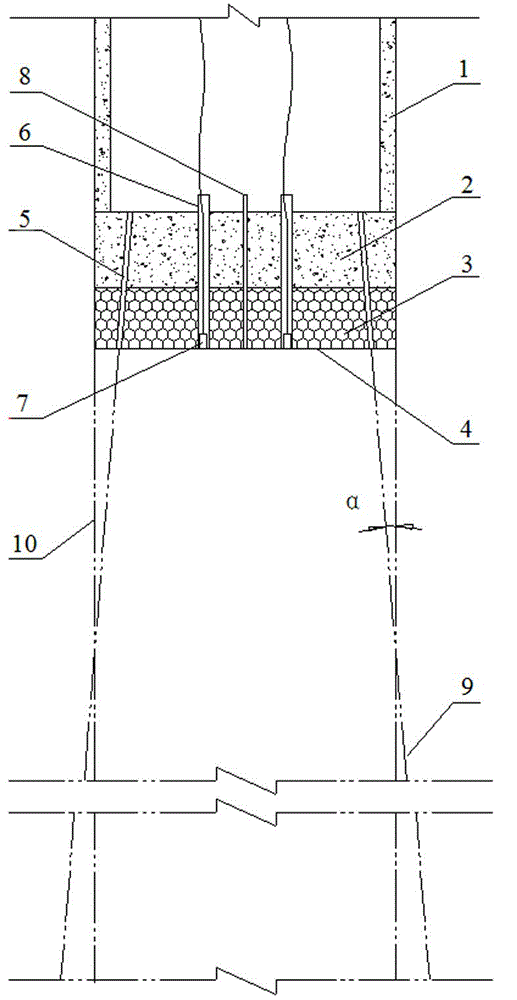

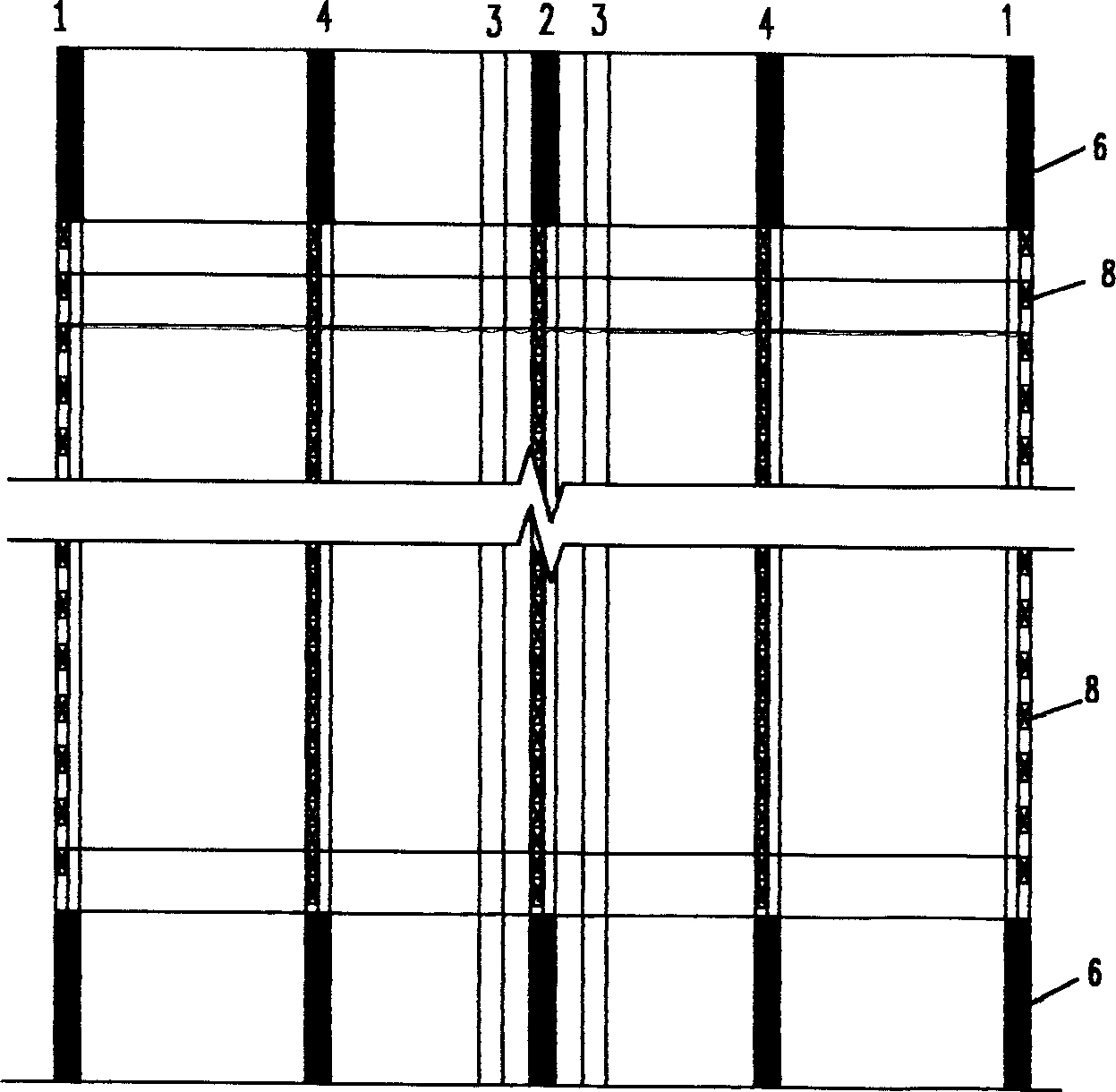

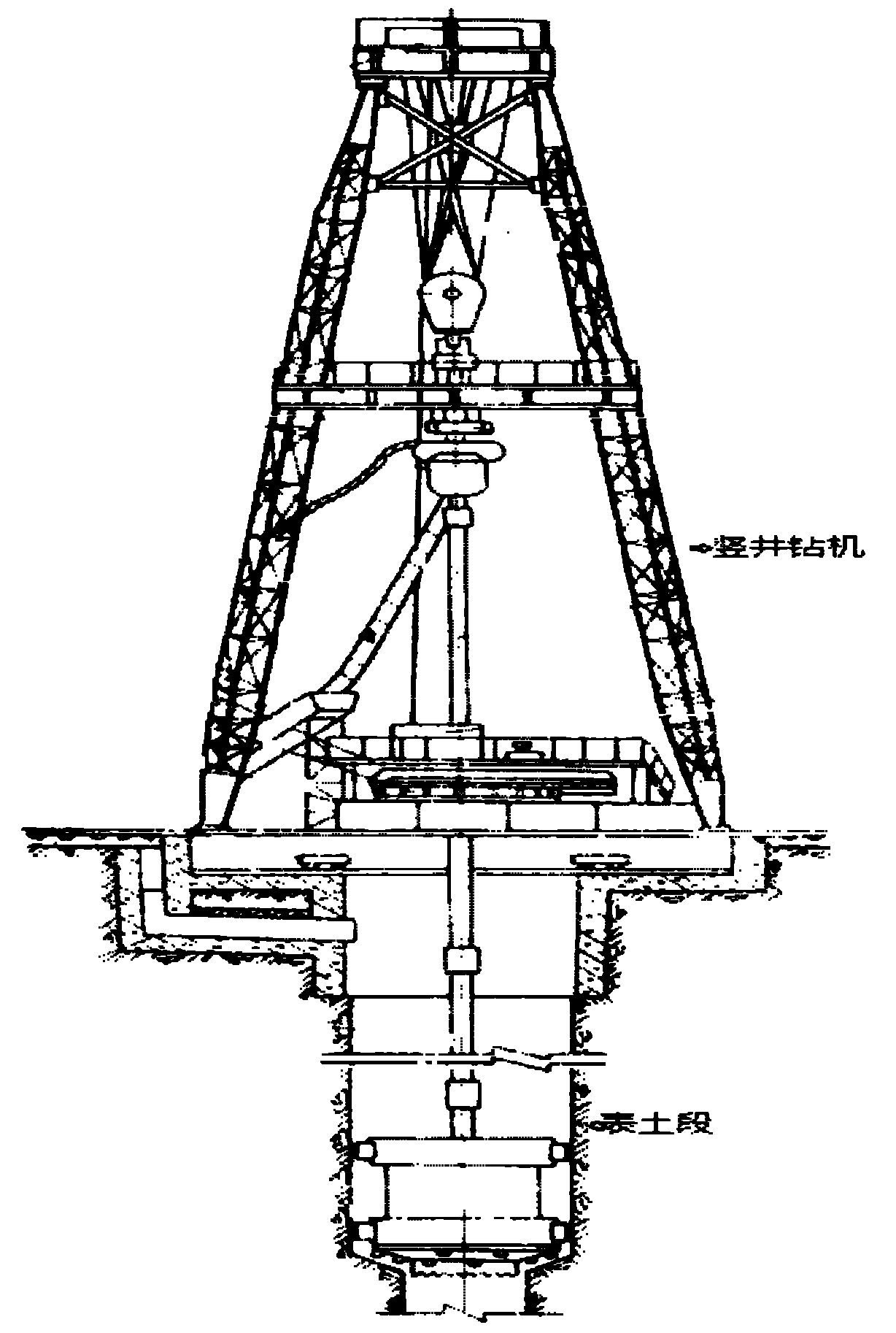

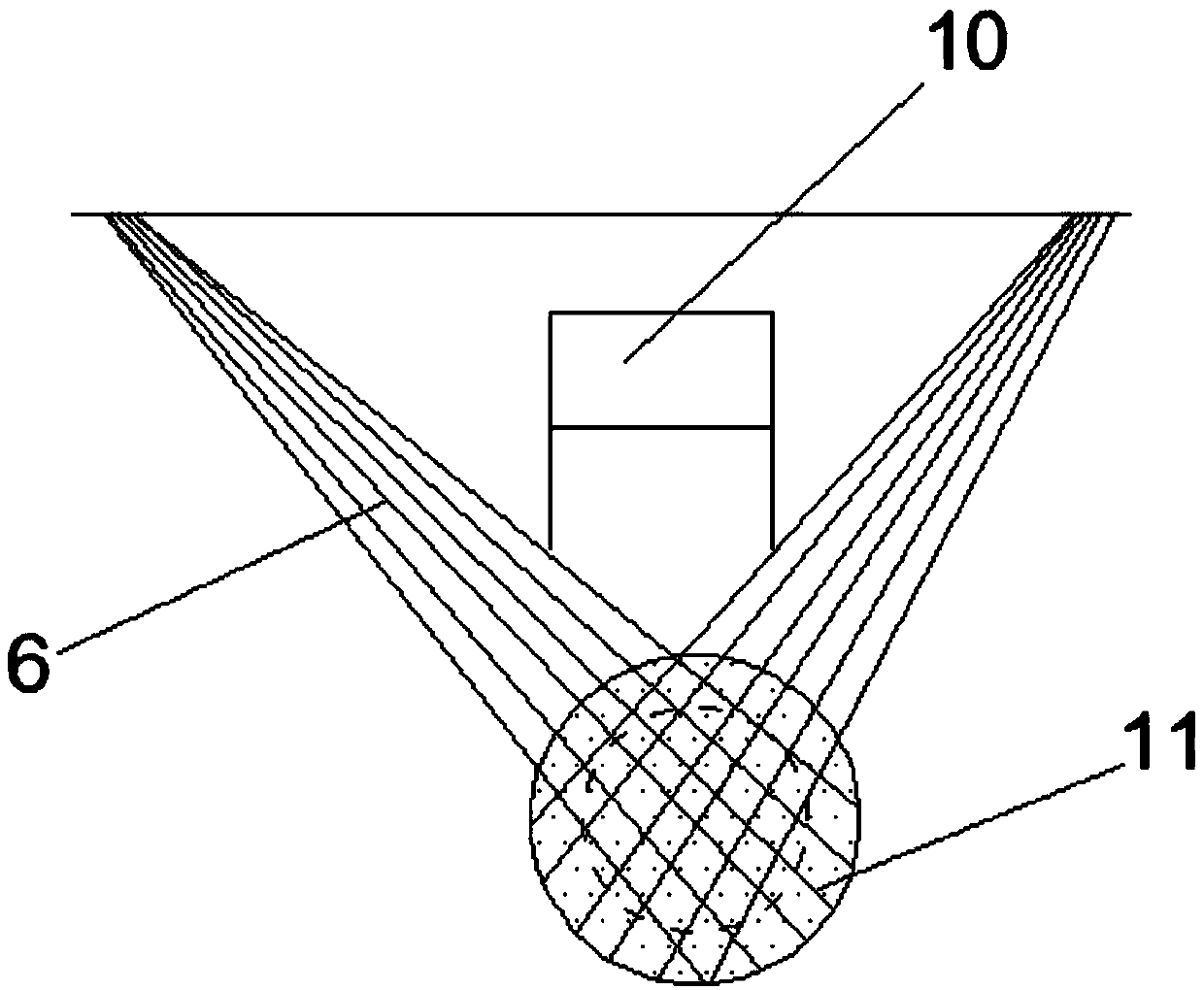

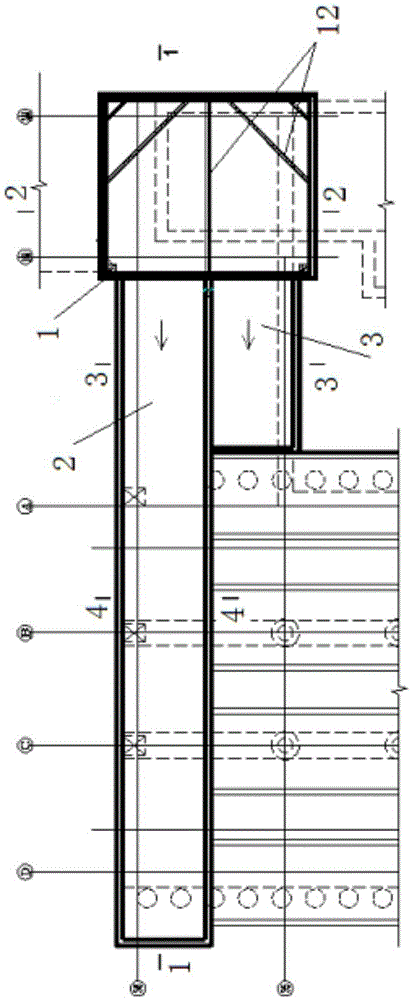

Comprehensive shaft sinking method of positive and raising boring for vertical shaft

InactiveCN102493809AReduce construction costsFast well formationShaft sinkingShaft raisingBedrockWell drilling

The invention discloses a comprehensive shaft sinking method of positive and raising boring for a vertical shaft, which comprises the following steps: drilling into a bedrock section by utilizing a vertical shaft drill machine, forming surface soil section well holes, discharging rock-debris-containing slurry produced during the well drilling process to the ground at high speed through air lifting; prefabricating sections of well walls on the ground; adding counter weight water in the drill well, slowly sinking the sections of well walls to the surface soil section well holes by utilizing buoyancy force of slurry to the well walls in the drill well, and sequentially welding the well walls to the surface soil section well holes; filling grout between the well walls and the rock sides on the outer sides of the well walls, filling cement paste in the lowest layer, then alternatively filling upwards the cement paste and rubbles layer by layer, and obtaining a surface soil section drill well; selecting a suitable raise-bore drilling machine according to practical requirements of the diameter and depth of a bed rock section shaft; lowering the raise-bore drilling machine and fixing the raise-bore drilling machine at the bottom of the surface soil section drill well; inversely expanding the holes by utilizing the raise-bore drilling machine to form bing-holes; and the diameter of the bing-holes is enlarged to preset shaft diameter. The comprehensive shaft sinking method of the positive and raising boring for the vertical shaft greatly improves well forming speed of shaft sinking and is safe, reliable and low in construction cost.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Method for determining diffusion radius of in-situ injection and remediation of contaminated soil and groundwater

ActiveUS20190120741A1Easy to operateConstructionsContaminated soil reclamationDiffusionPollution soil

A method for determining the diffusion radius of in-situ injection and remediation of contaminated soil and groundwater. According to the triangle method, the hole spacing is perpendicular to the groundwater flow direction, the row spacing is along the groundwater flow direction, and the flow diffusion in the groundwater during the effective time of the remediation agent reaction is considered. Under high pressure rotary injection, the remediation agent and a certain proportion of bromide ions are simultaneously injected into the aquifer as a tracer. The diffusion of the agent is determined by observing the phenomenon of slurry-returning and slurry-channeling of adjacent injection points. After the completion of the injection, the groundwater is quickly sampled in fixed depth, the tracer concentration is quickly detected on site, and the concentration of bromide ions in the groundwater is compared with the background value. Comprehensive determination determines the optimal diffusion radius.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

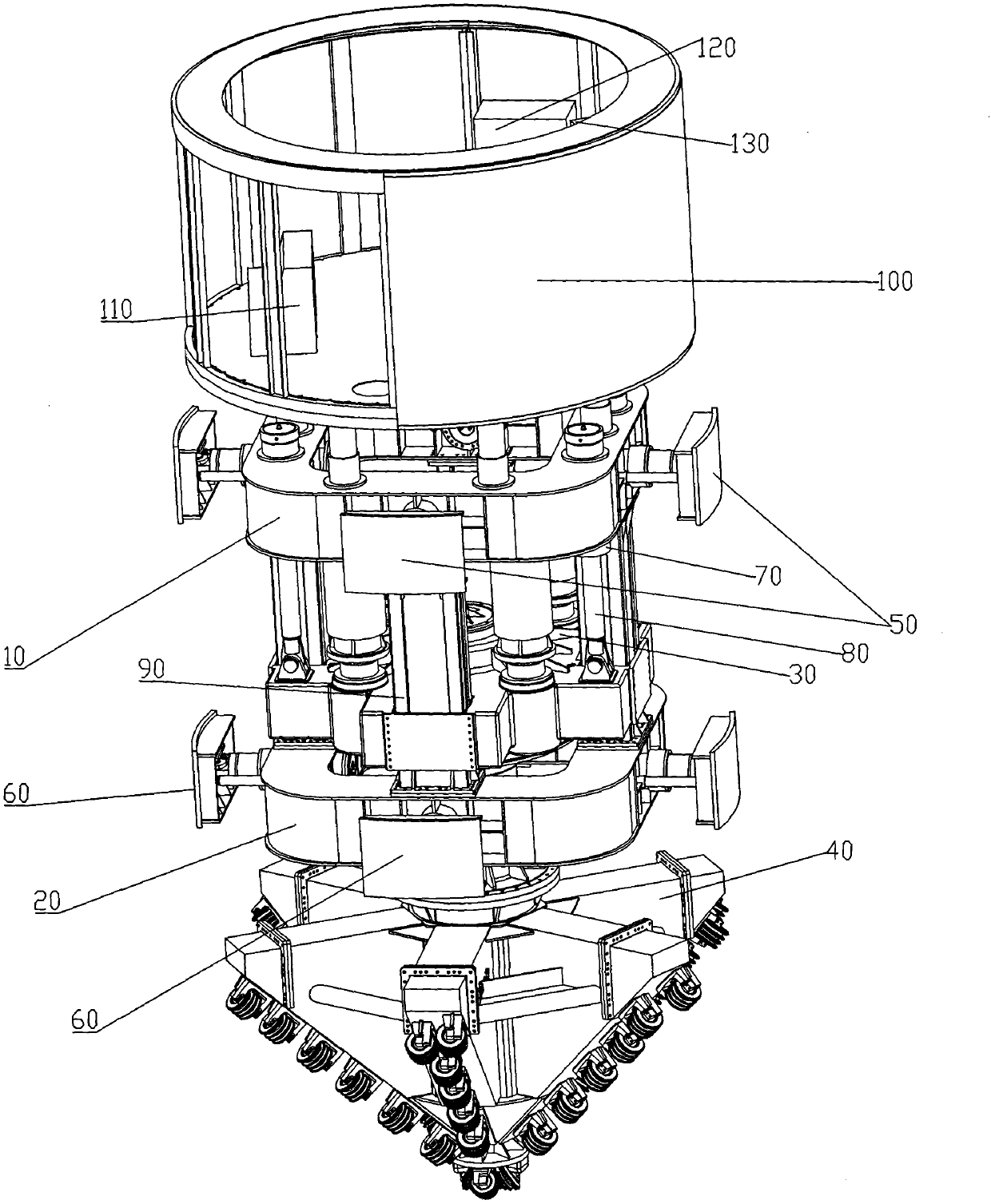

Full-fracture-surface vertical shaft drilling machine

ActiveCN103670420AEfficient constructionImprove construction efficiencyShaft sinkingShaft liningSlagControl engineering

The invention belongs to the technical field of mineral product machinery and discloses a full-fracture-surface vertical shaft drilling machine which comprises a device main girder, device platforms, a head frame, a tunneling system, a personnel and material conveying system, a shaft wall supporting and protecting system, a guaranteeing system and a manipulating chamber. The tunneling system is installed at the front end of the device main girder, the device platforms are installed at the rear end of the device main girder, the head frame is arranged on a shaft mouth, the manipulating chamber is arranged on the head frame, the personnel and material conveying system and the guaranteeing system are installed on the rear portion of the tunneling system, the shaft wall supporting and protecting system is arranged on the rear portion of the tunneling system and the periphery of the tunneling system, the personnel and material conveying system comprises a hoister, a first-level separation station, a slag storage cabin, a second-level separation station, a feeding mechanism and a conveying pump, the shaft wall supporting and protecting system comprises an auxiliary crane, a hoister, an underground concrete mixing tank, a concrete pump and an anchoring system, and the auxiliary crane, the hoister, the underground concrete mixing tank, the concrete pump and the anchoring system are installed on the device platforms respectively. The full-fracture-surface vertical shaft drilling machine solves the construction problems of large-scale vertical shafts such as coal mines, complete equipment of automation, mechanization and integration of the functions of shaft tunneling, slag tapping, supporting, protection, water discharging, ventilation and the like, the construction efficiency is improved, the construction cost is reduced, the construction safety is improved, and the application range is wide.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

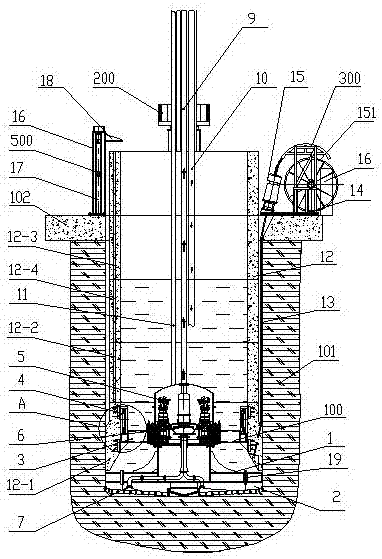

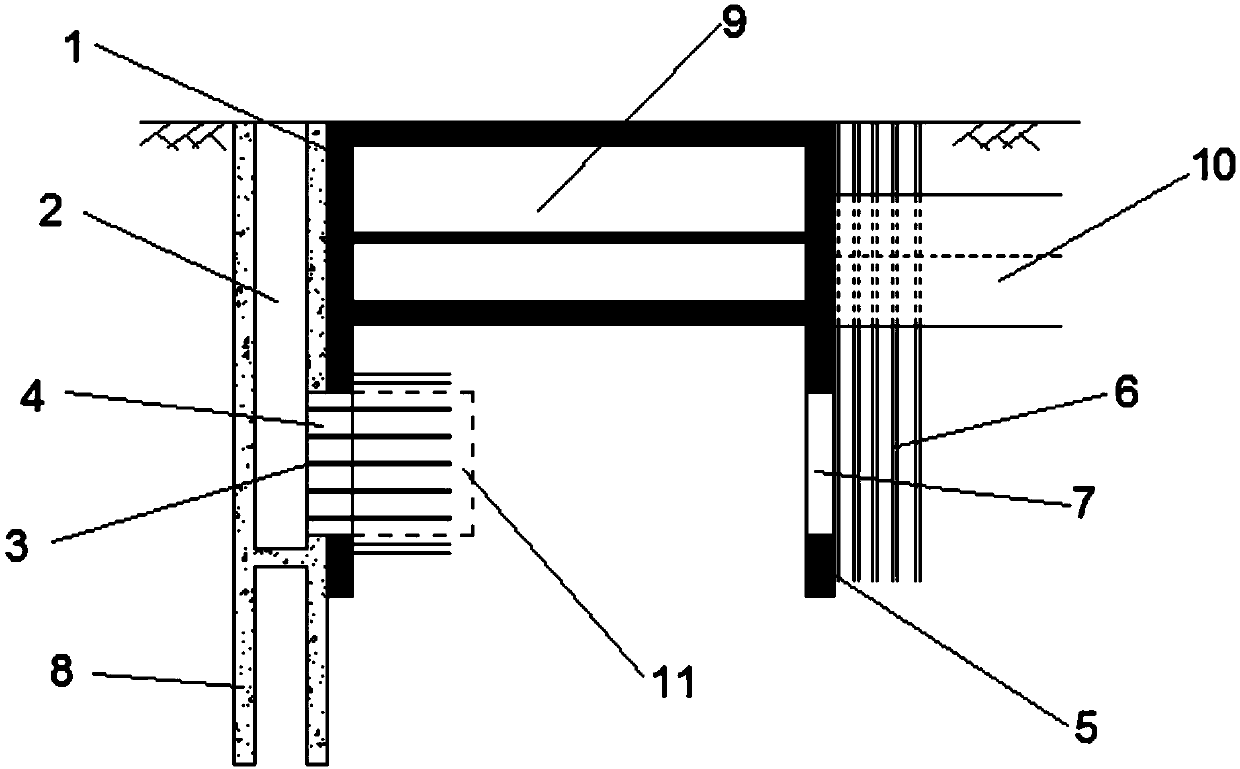

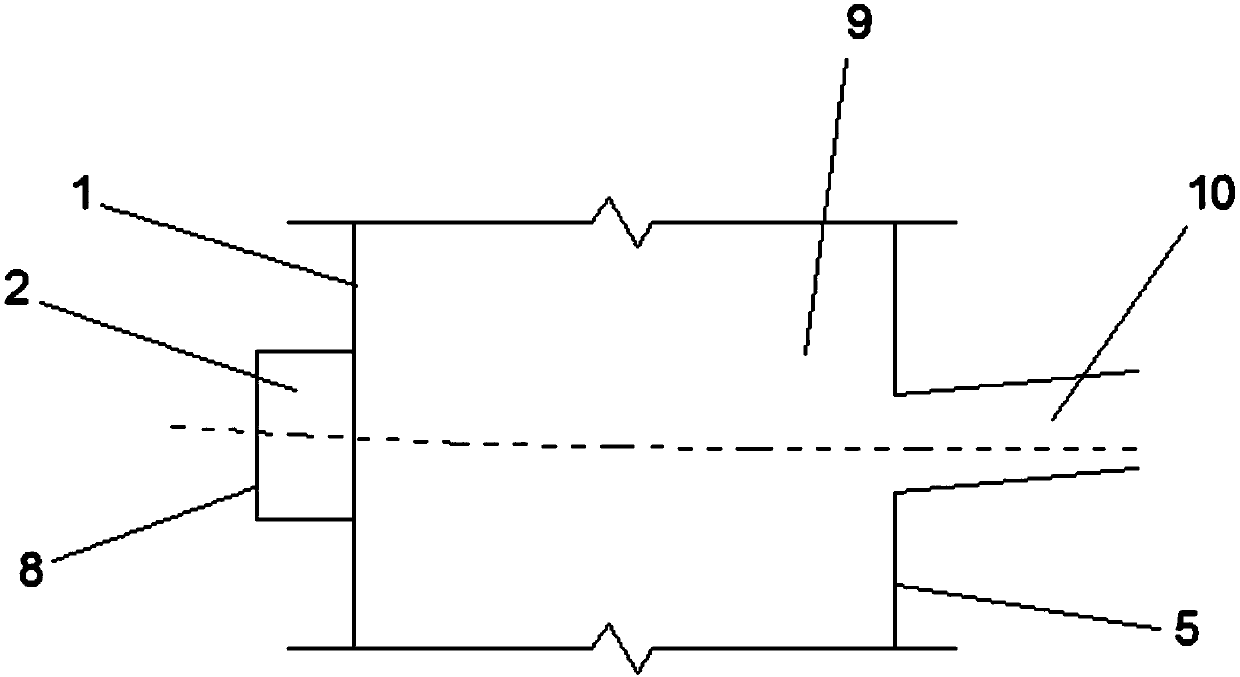

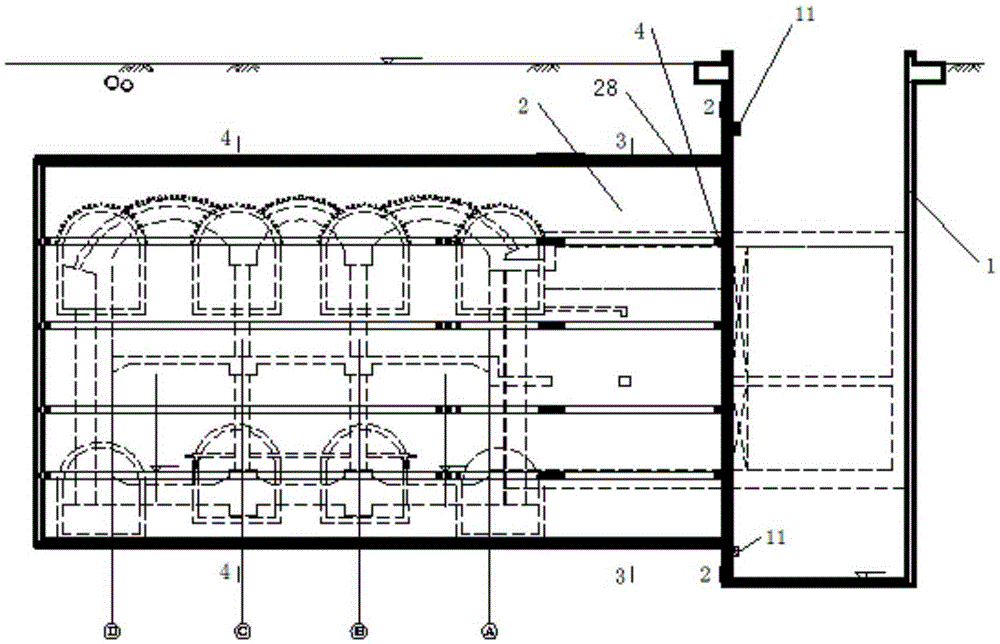

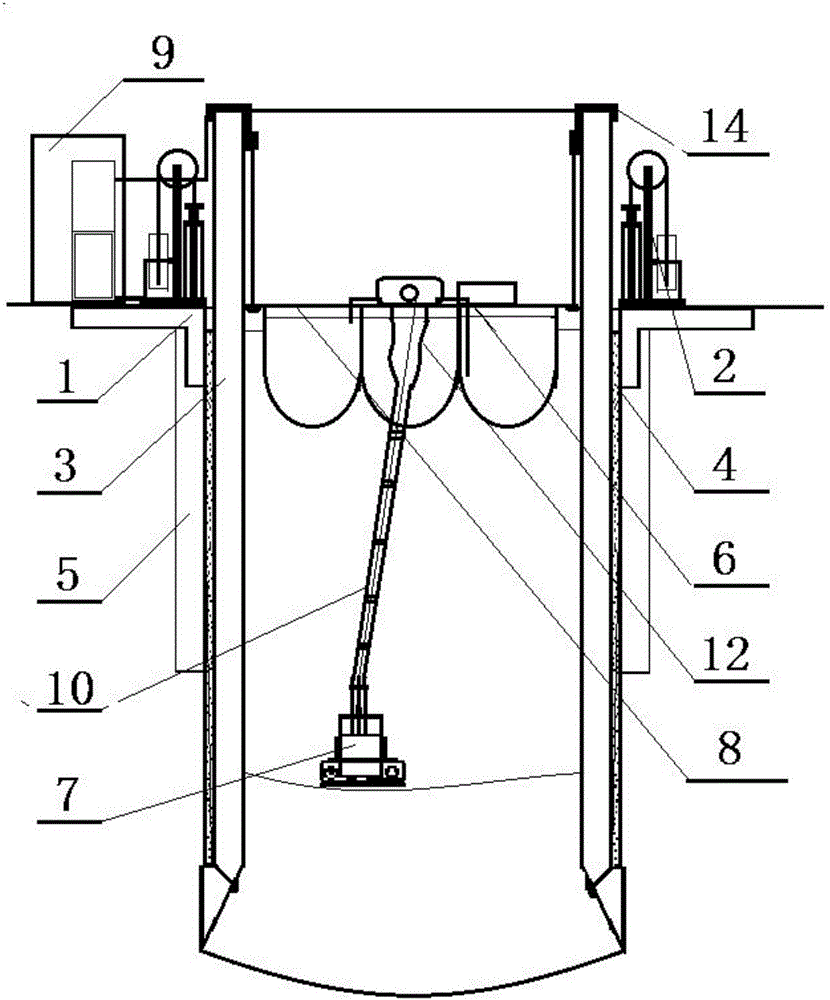

Vertical shaft tunnel boring machine by shaft sinking method and construction method of tunnel boring machine

ActiveCN107461197AChange the method of excavationReduce construction riskHydro energy generationShaft sinkingSludgeArchitectural engineering

The invention provides a vertical shaft tunnel boring machine by a shaft sinking method and a construction method of the tunnel boring machine, and solves the problems of low mechanization degree and efficiency, high risk and the like of devices and construction methods in the prior art. The tunnel boring machine comprises a tunneling mechanism, a pipe arrangement mechanism, a shaft lifting mechanism, a slurry separation system and an auxiliary pressure mechanism are mutually connected, the pipe arrangement mechanism, the shaft lifting mechanism, the slurry separation system and the auxiliary pressure mechanism are positioned on an over-ground wellhead ring beam, the tunneling mechanism comprises a tunneling shell, a cutter head is arranged at the front end of the tunneling shell, a driving fixing frame is arranged at the rear end of the tunneling shell, a feeding device and a driving device are arranged on the driving fixing frame, and the feeding device and the cutter head are connected with the driving device. The tunnel boring machine has mechanized excavation, sludge discharge and support functions and is operated on the ground, safe and reliable, underground operators are omitted in the working process of the vertical shaft tunnel boring machine, traditional shaft bottom excavation modes are changed, construction risks are greatly reduced, and operating efficiency is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Apparatus and methods of milling a restricted casing shoe

A method of removing a restriction in a tubular located in a well includes providing a drilling assembly with a drill bit and a reamer, the reamer having a cutting structure for removing the restriction; drilling through a lower portion of the tubular; expanding the reamer at a location below the restriction; and urging the reamer back toward the restriction to remove the restriction.

Owner:WEATHERFORD TECH HLDG LLC

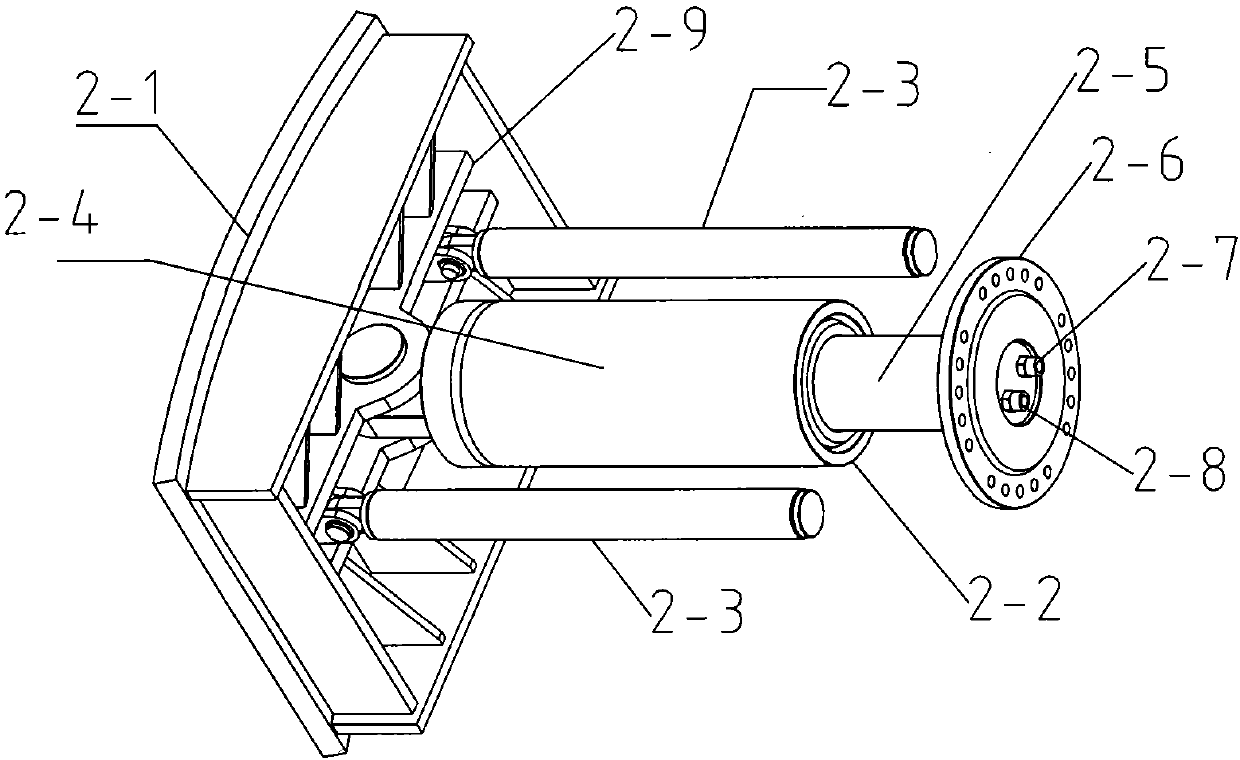

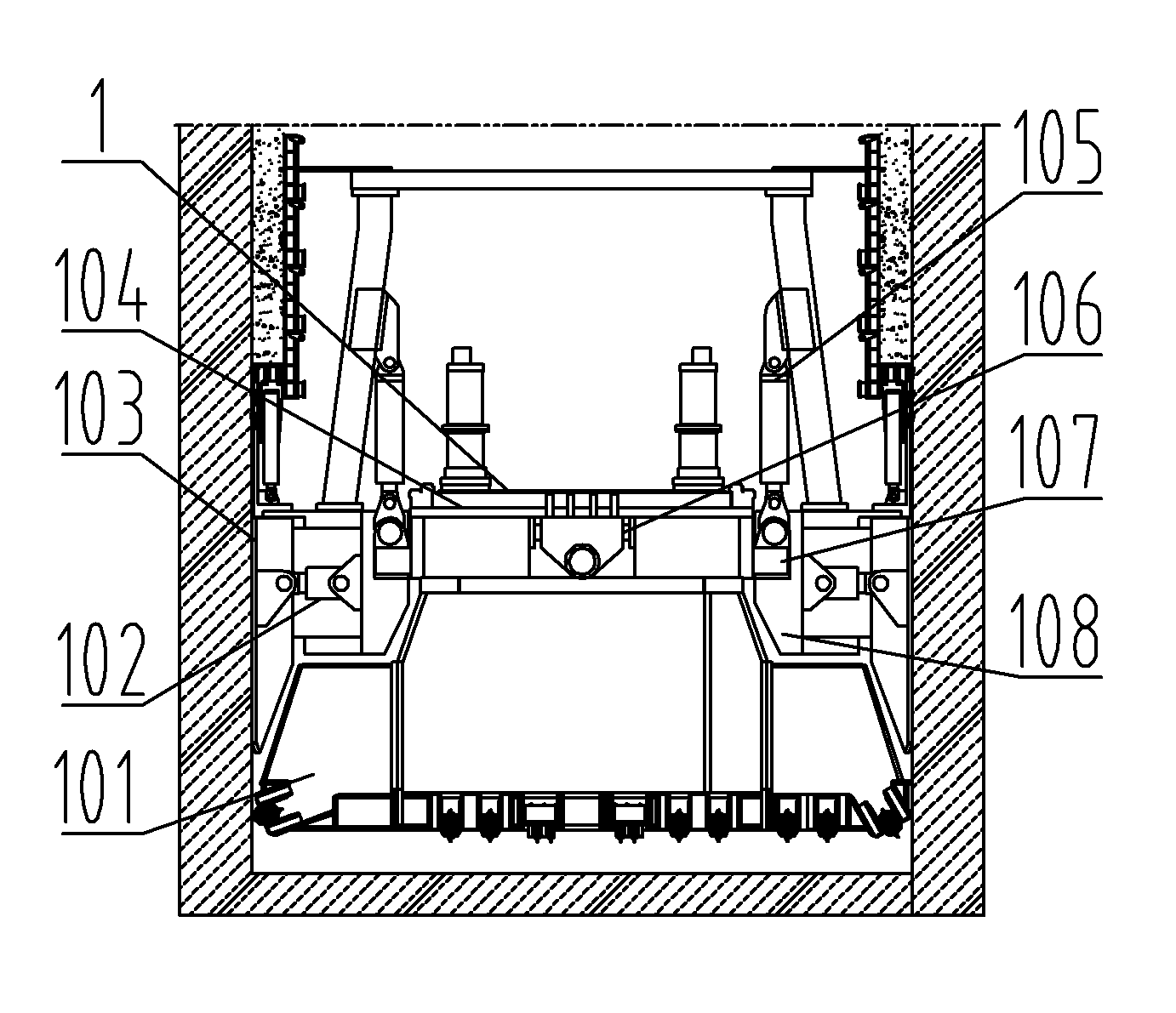

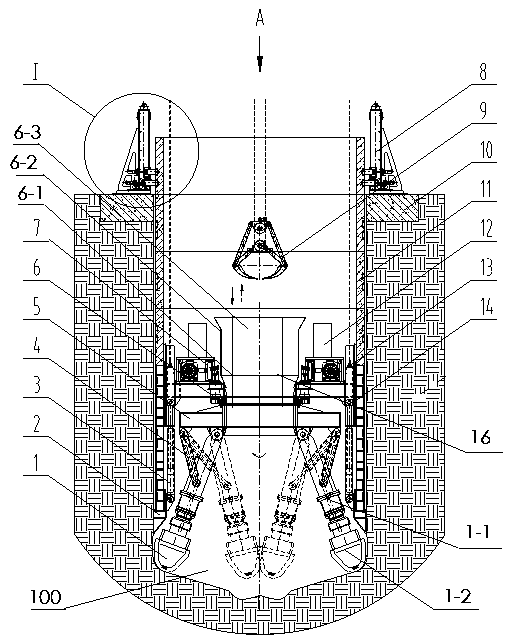

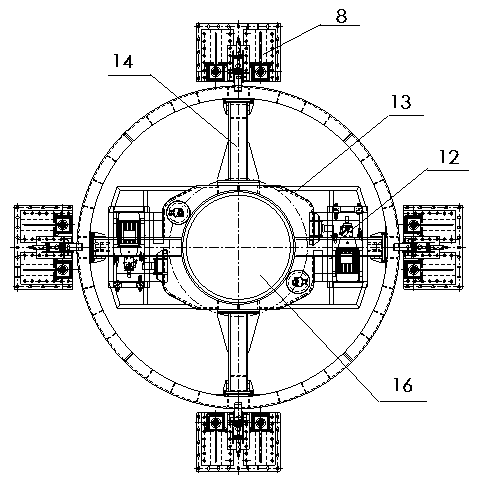

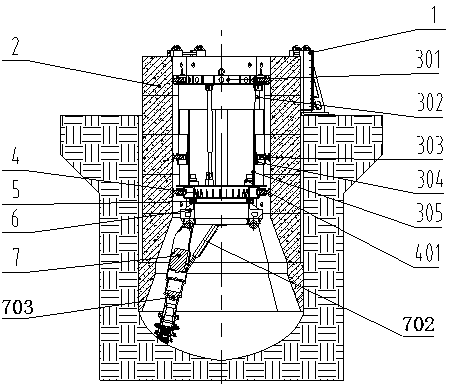

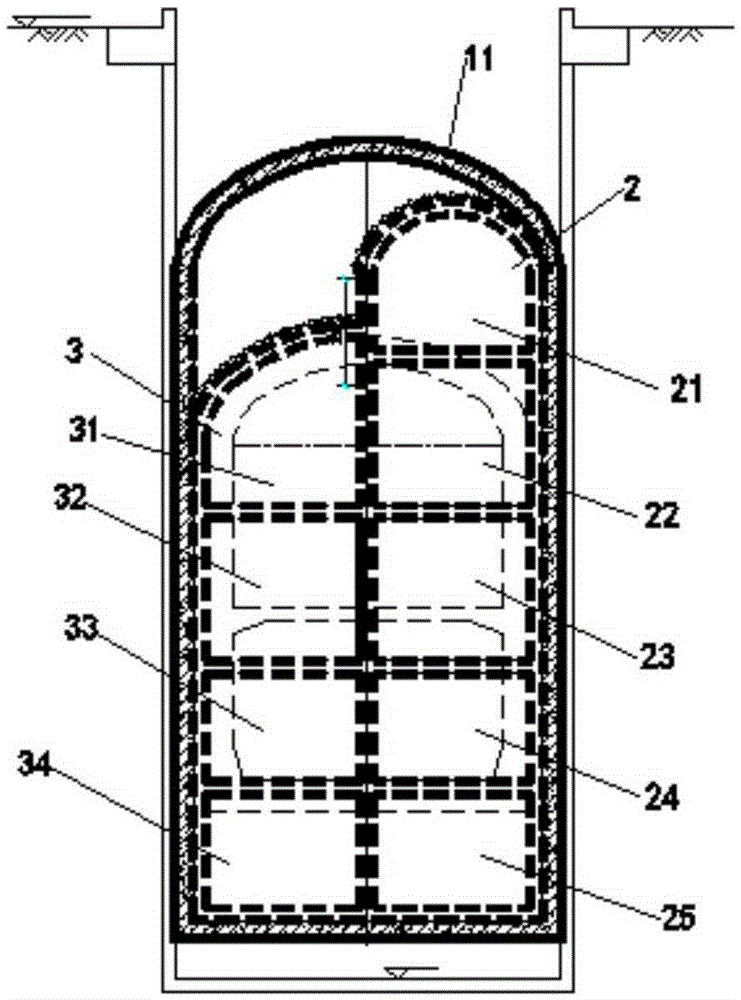

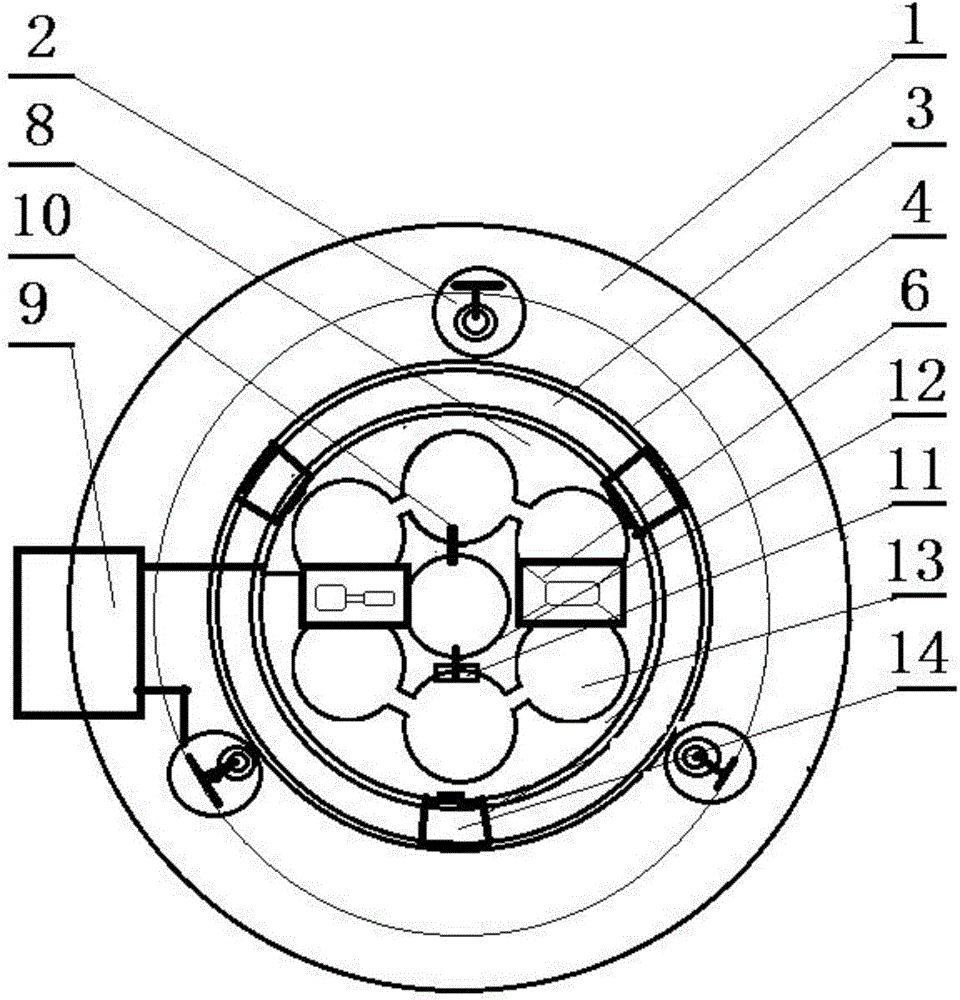

Drop-shaft-sinking-based shaft well tunneller and construction method thereof

PendingCN109139017AEasy maintenanceEasy to operateShaft sinkingHydro energy generationSlagControl system

The invention discloses a drop-shaft-sinking-based shaft well tunneller and a construction method thereof so that problems of shaft well excavation mechanization, low automation degree and high risk coefficient in the prior art can be solved. The drop-shaft-sinking-based shaft well tunneller comprises a tunneling system, a control system and a detection system. The tunneling system includes an excavation device and a well wall lifting and pressing device. A bottom pipe joint and a guiding base are arranged in a starting shaft well; the bottom pipe joint is arranged below the guiding base; anda driving fixation rack is arranged at the guiding base and the lower part of the driving fixation rack is connected with the bottom pipe joint by a propulsion cylinder. A rotating device is arrangedat the driving fixation rack; a rotation rack is arranged at the lower part of the rotating device; and an excavating device is connected with the rotation rack. A hydraulic pump station, a driving device and a slag discharging device are arranged at the rotating device; and the slag discharging device corresponds to a lifting grab bucket. The drop-shaft-sinking-based shaft well tunneller is a modular shaft well tunneling machine that is used for mechanical excavation and support of a shaft well; the excavation precision and excavation speed of the whole process are improved; the mechanical automatic construction is realized; and the work efficiency and construction safety factor are increased.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

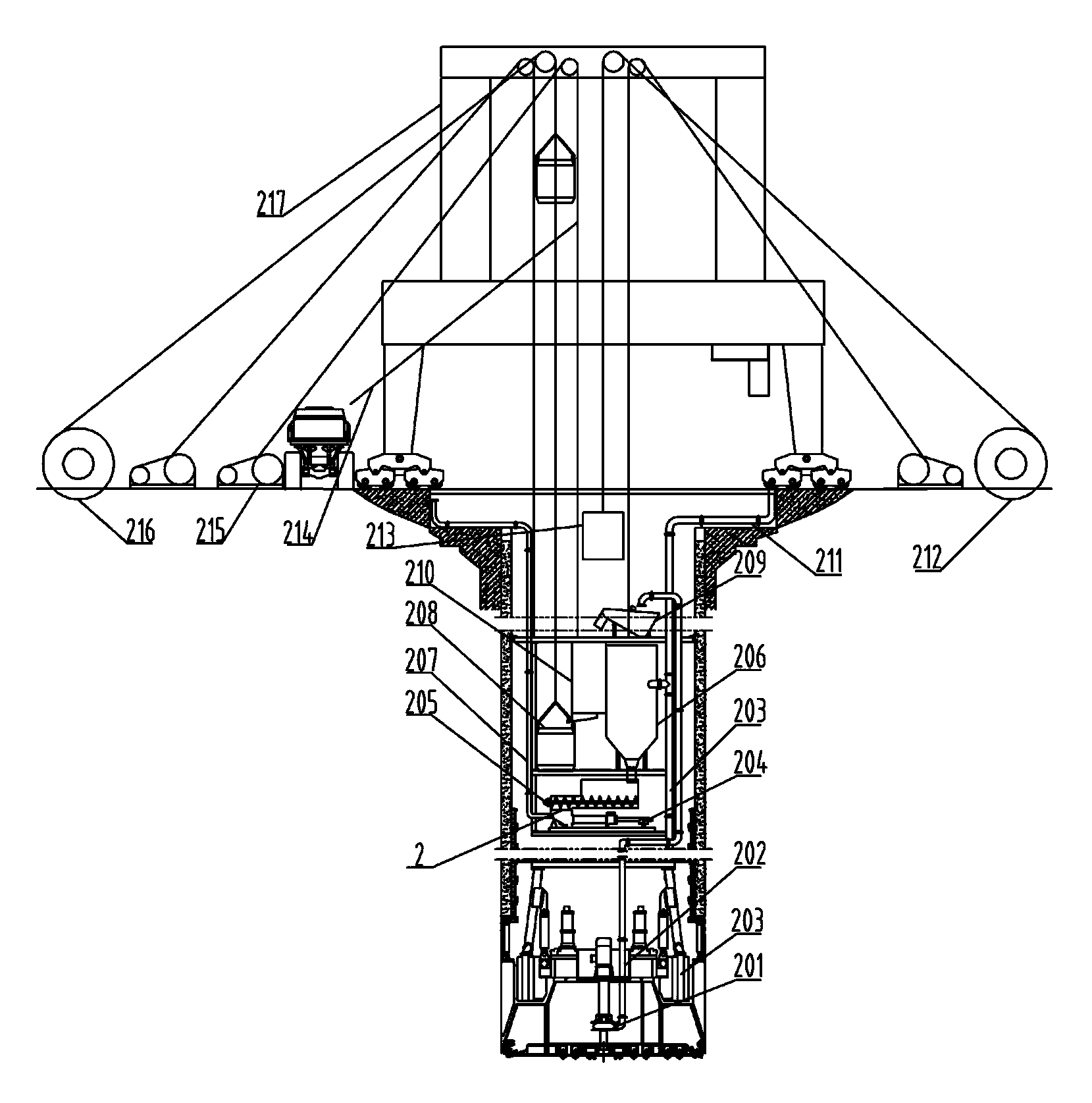

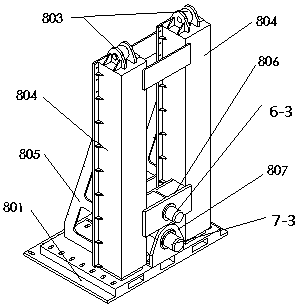

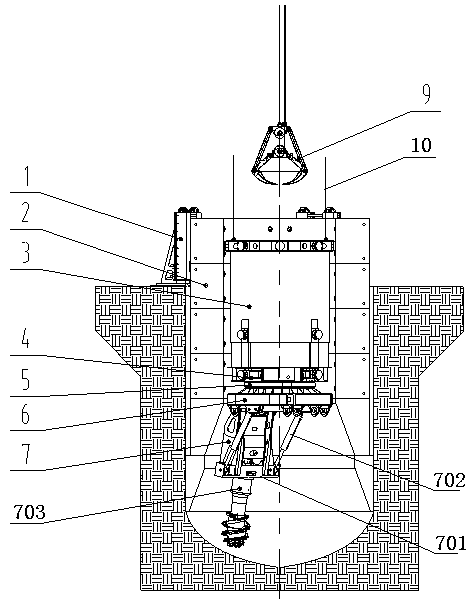

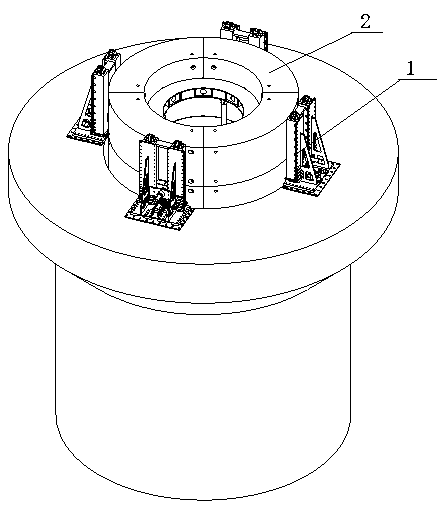

Shaft boring machine by open caisson method and construction method thereof

PendingCN109630124AImprove securityImprove construction safetyDrilling rodsShaft sinkingSlagMechanization

The invention discloses a shaft boring machine by an open caisson method and a construction method thereof, and solves the problems of low mechanization degree, difficult disassembly and assembly andlow working efficiency of a shaft excavation device in the prior art. The shaft boring machine by the open caisson method comprises a tunneling system, a control detection system and a slag dischargesystem. A pipe joint pressure lifting device is arranged on a wellhead ring beam on the ground. The tunneling system comprises a propulsion device, a rotary support, a rotary platform and an excavation device. The upper part of the propulsion device is connected with a hydraulic power system on the ground, and the lower part of the propulsion device is provided with an equipment platform. The equipment platform is connected with the rotary support, and the rotary support is connected with a driving device arranged on the equipment platform. The upper part of the rotary platform is connected with the rotary support, and the excavation device is arranged at the lower part of the rotary platform. According to the shaft boring machine by the open caisson method, the step-by-step excavation ofthe excavation device is realized through the propulsion device, and the efficient and safe excavation is realized through the tightening and stabilization of the excavation device. The shaft boring machine can be quickly disassembled and assembled in the process of entering and exiting the well, thereby saving the construction period and improving the well-forming efficiency.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Construction method of subway tunnel penetrating through underground continuous walls of subway station

The invention discloses a construction method of a subway tunnel penetrating through underground continuous walls of a subway station. The construction method comprises the following steps that a vertical shaft is excavated on the outer side of the first continuous wall, and a space enclosing structure is arranged; construction is conducted on a first freezing pipe to reinforce a first freezing pipe of soil mass in the rear of the first continuous wall in the vertical shaft in the direction of a newly-built subway tunnel, and the first freezing pipe is removed after reinforcing is completed; the first continuous wall is broken away in the direction of the newly-built subway tunnel, and thus a first tunnel portal is formed; slag and accumulated water in the vertical shaft are cleaned, and backfilling is conducted on the vertical shaft; a shield tunneling machine penetrates through the vertical shaft and the first continuous wall in the opening direction of the first tunnel portal; the shield tunneling machine is utilized to tunnel to the position of the second continuous wall, and tightly attached to the second continuous wall; a second freezing pipe for reinforcing soil mass is arranged on the outer side of the second continuous wall in a mode of obliquely drilling from the ground surface, and the second freezing pipe penetrates through the position below the newly-built subwaytunnel; shield position opening is conducted, the second continuous wall is broken away in the direction of the newly-built subway tunnel, and thus a second tunnel portal is formed; and the second freezing pipe is removed, and the shield tunneling machine penetrates through the second continuous wall in the opening direction of the second tunnel portal.

Owner:GUANGZHOU METRO DESIGN & RES INST

Bore hole reaming apparatus and method

Owner:PUTNAM SAMUEL W

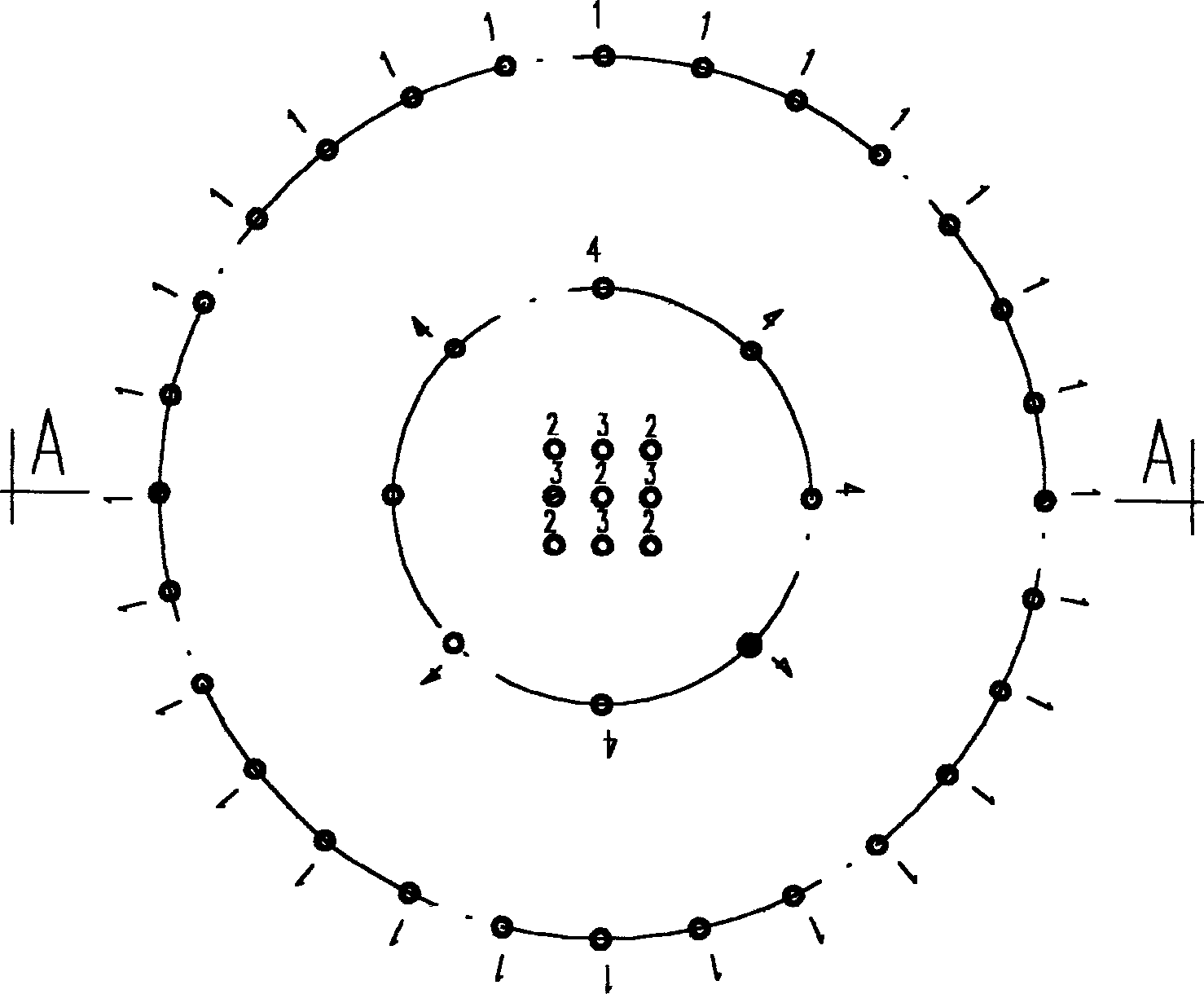

None-full-depth freezing method for penetrating through ultra-thick water-rich bed rock in shaft deepening

The invention discloses a none-full-depth freezing method for penetrating through ultra-thick water-rich bed rock in shaft deepening. According to the method, a shaft penetrates through surface soil, the water-rich bed rock, a water-resisting layer and low-permeability bed rock sequentially from top to bottom, and main freezing pipes penetrate through the surface soil and the water-rich bed rock sequentially from top to bottom, penetrate into the water-resisting layer by 10m-20m and stop in a low-permeability rock stratum; a none-full-depth freezing depth is 240m-260m and a wall-caving-preventing freezing depth is 40m-45m; the main freezing pipes are annularly arranged with the circle center of the shaft as a circle center and the distance between the main freezing pipes and the outer wall of the shaft is 2m; wall-caving-preventing freezing pipes penetrate into the surface soil only by 43m and are annularly arranged with the circle center of the shaft as a circle center, and the distance between the wall-caving-preventing freezing pipes and the outer wall of the shaft is 1m. The method is fast in construction, safe and efficient and capable of preventing water damage caused when underground water damages a horsehead and related chamber rock mass along annular water diversion channels during construction of the horsehead after a full-depth freezing shaft is frozen, wherein the annular water diversion channels are formed by the freezing pipes and temperature measuring pipes; therefore, cost for treating water burst is saved, and safety construction of the horsehead and a chamber is guaranteed.

Owner:陕西彬长矿业集团有限公司 +1

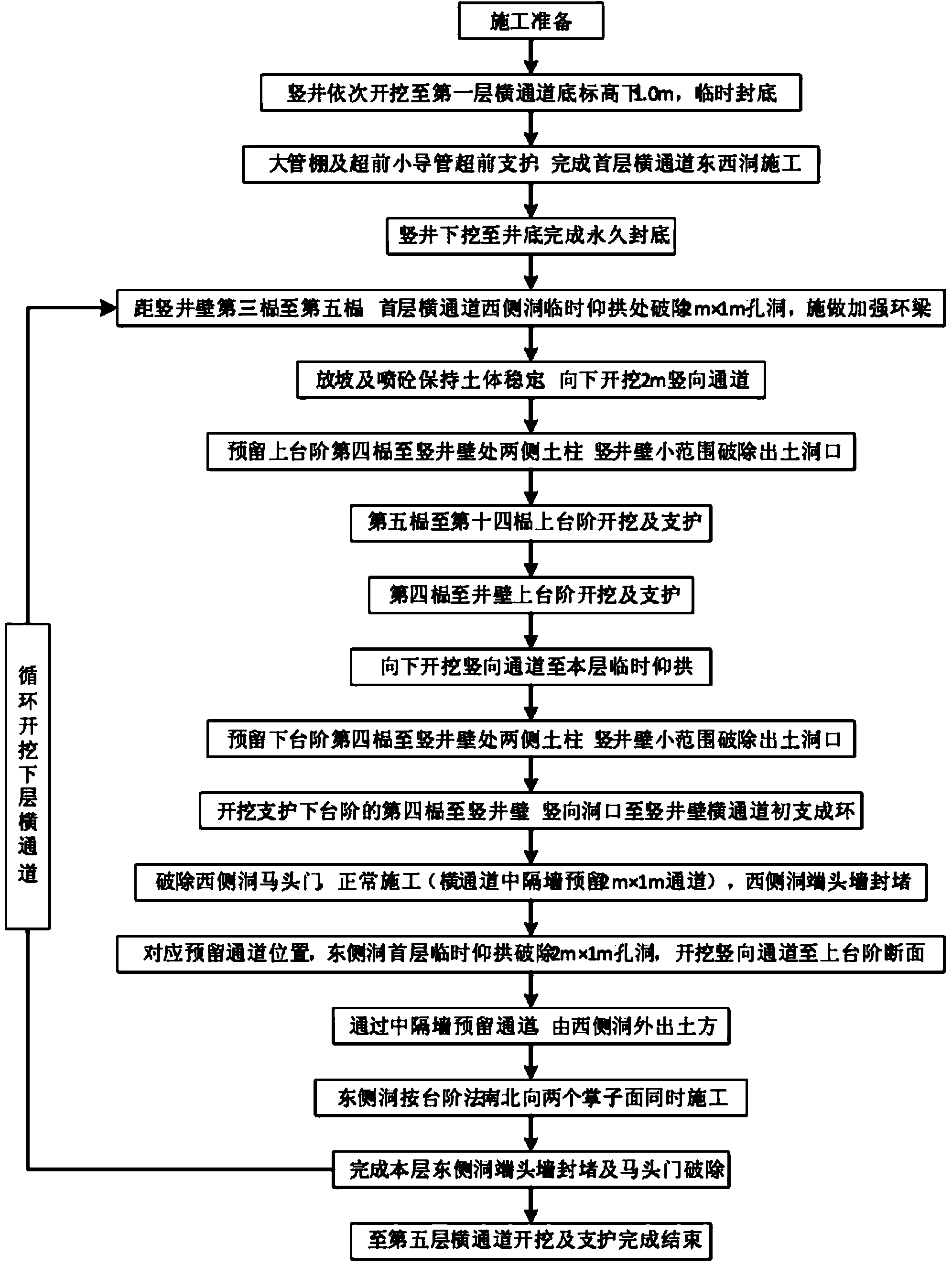

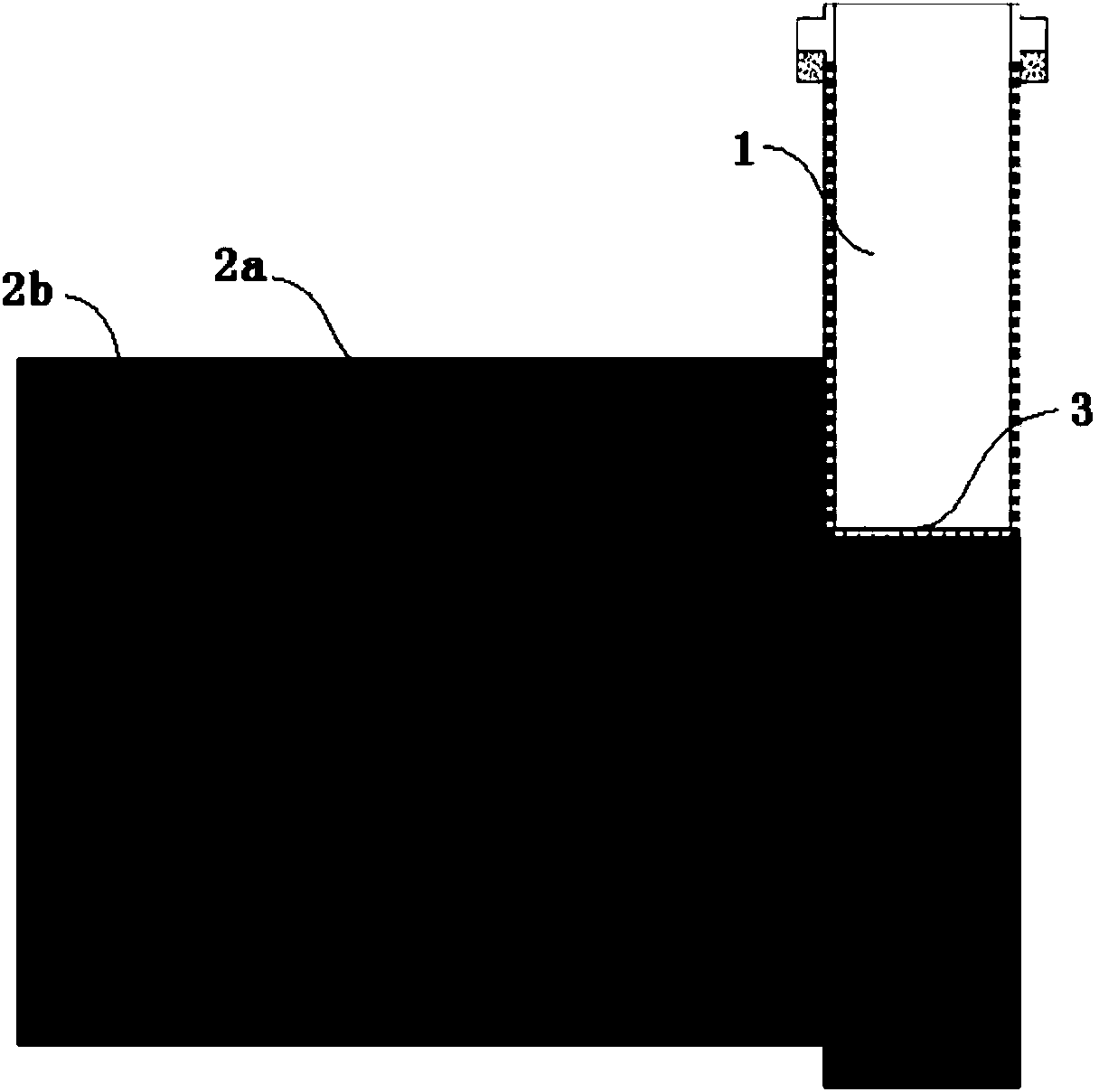

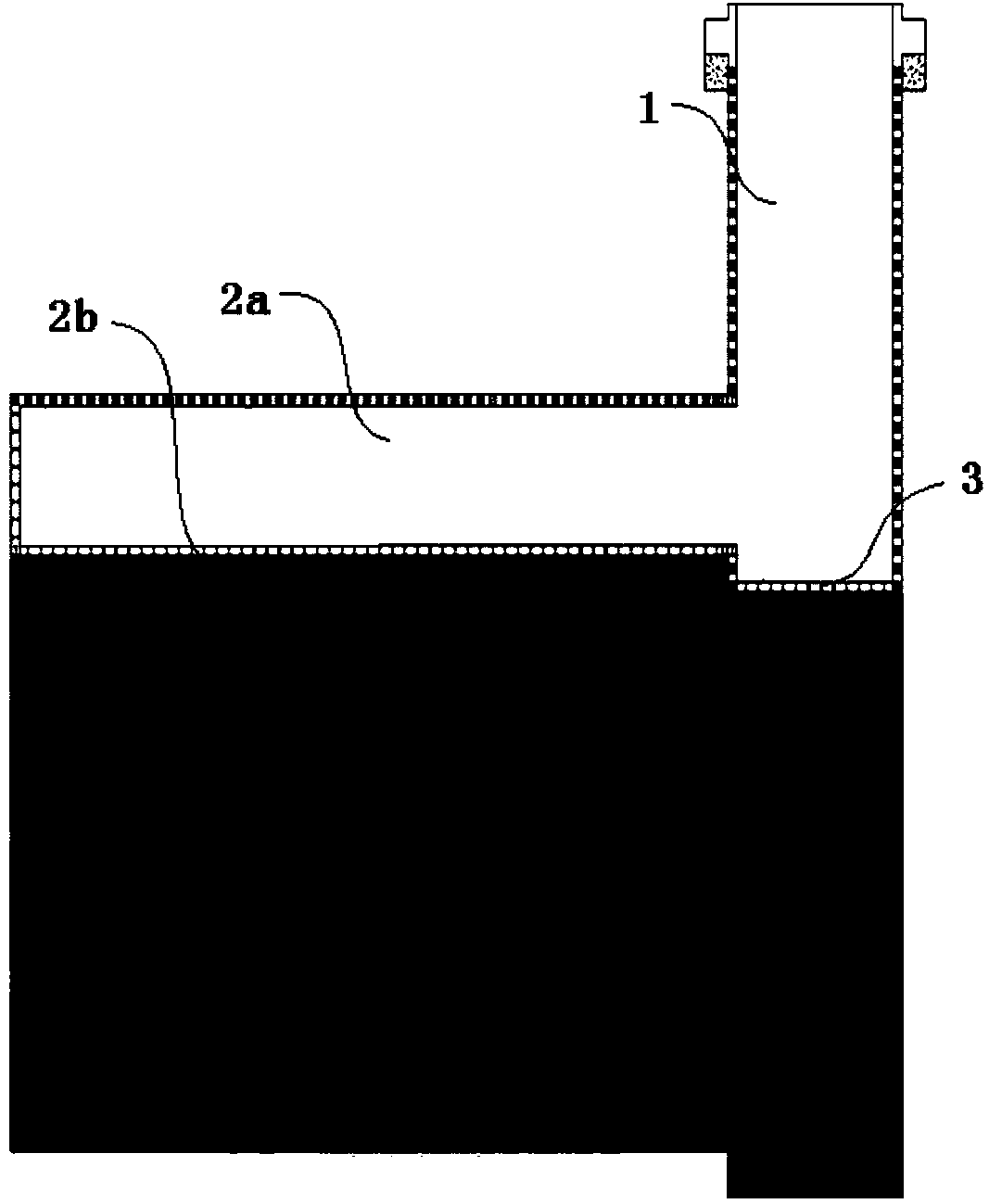

Vertical in-tunnel construction method of multilayer transverse channel of underground excavation station of metro, and construction method on east side and west side

The invention discloses a vertical in-tunnel construction method of a multilayer transverse channel of an underground excavation station of a metro. The vertical in-tunnel construction method comprises the following steps: a, excavating a silo till below a bottom elevation of the transverse channel at the first floor, and temporarily sealing the bottom of the silo through section steel and C20 net spraying concrete; and b, setting up a working platform to carry out surveying and lining, and releasing a horsehead of the transverse channel at the first floor to excavate a contour line so as to complete construction of the transverse channel at the first floor. When the horsehead at the lower-layer transverse channel is destroyed, a ring is formed in the horsehead, so that deposition caused by break of the horsehead is reduced, that is to say, risk of breaking the horsehead is greatly reduced through a manner of forming the ring in the transverse channel and then breaking the horsehead.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +2

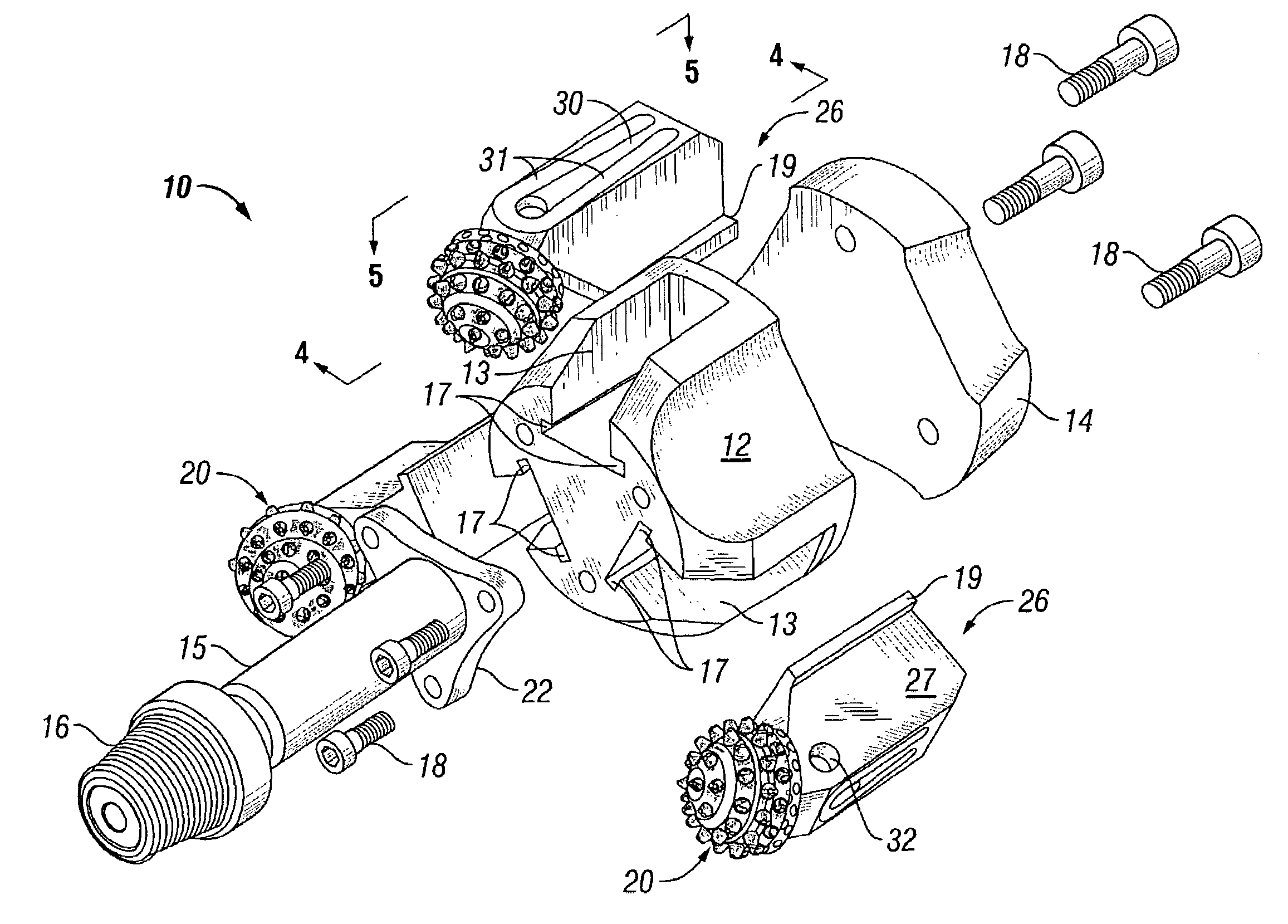

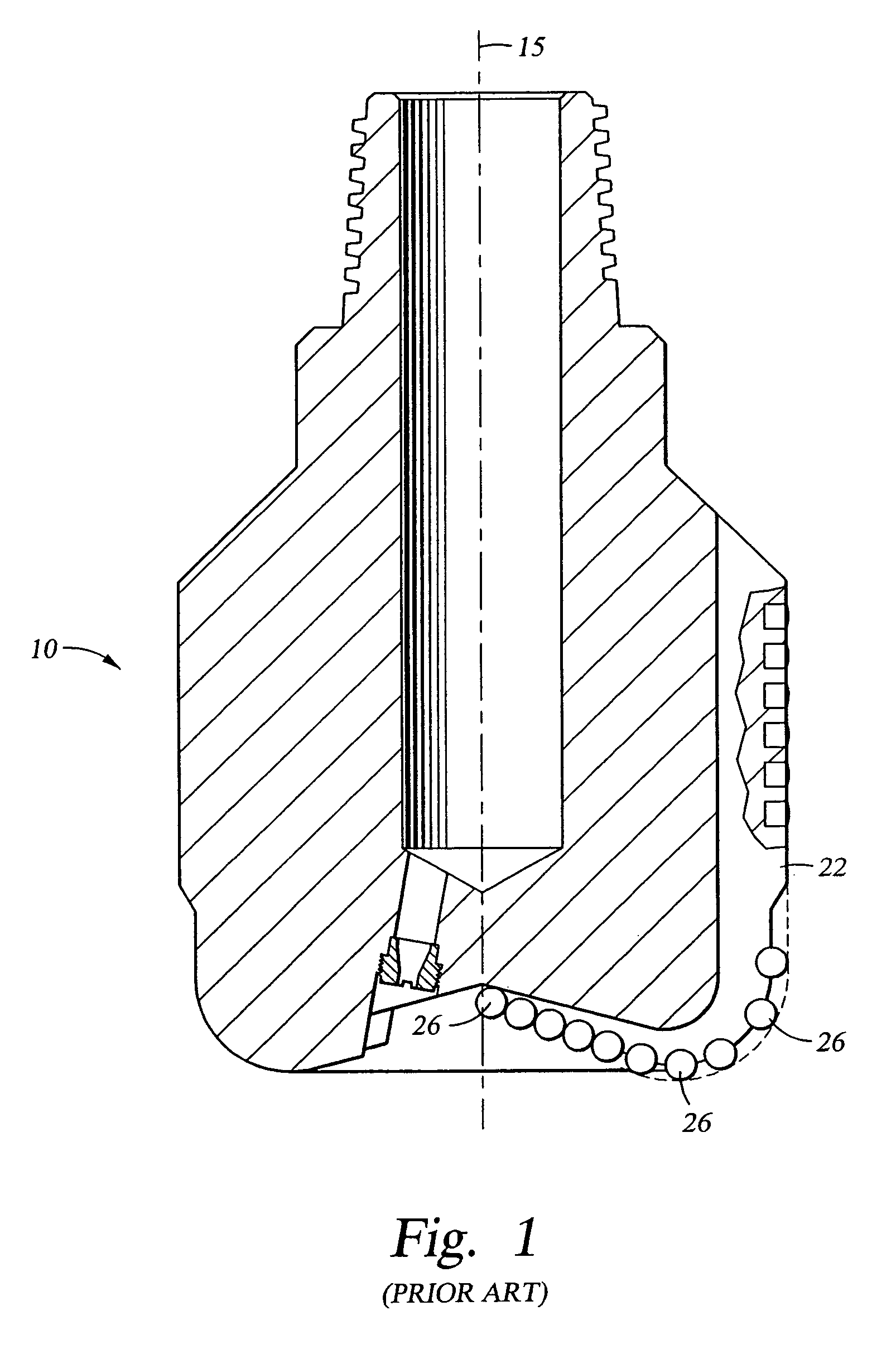

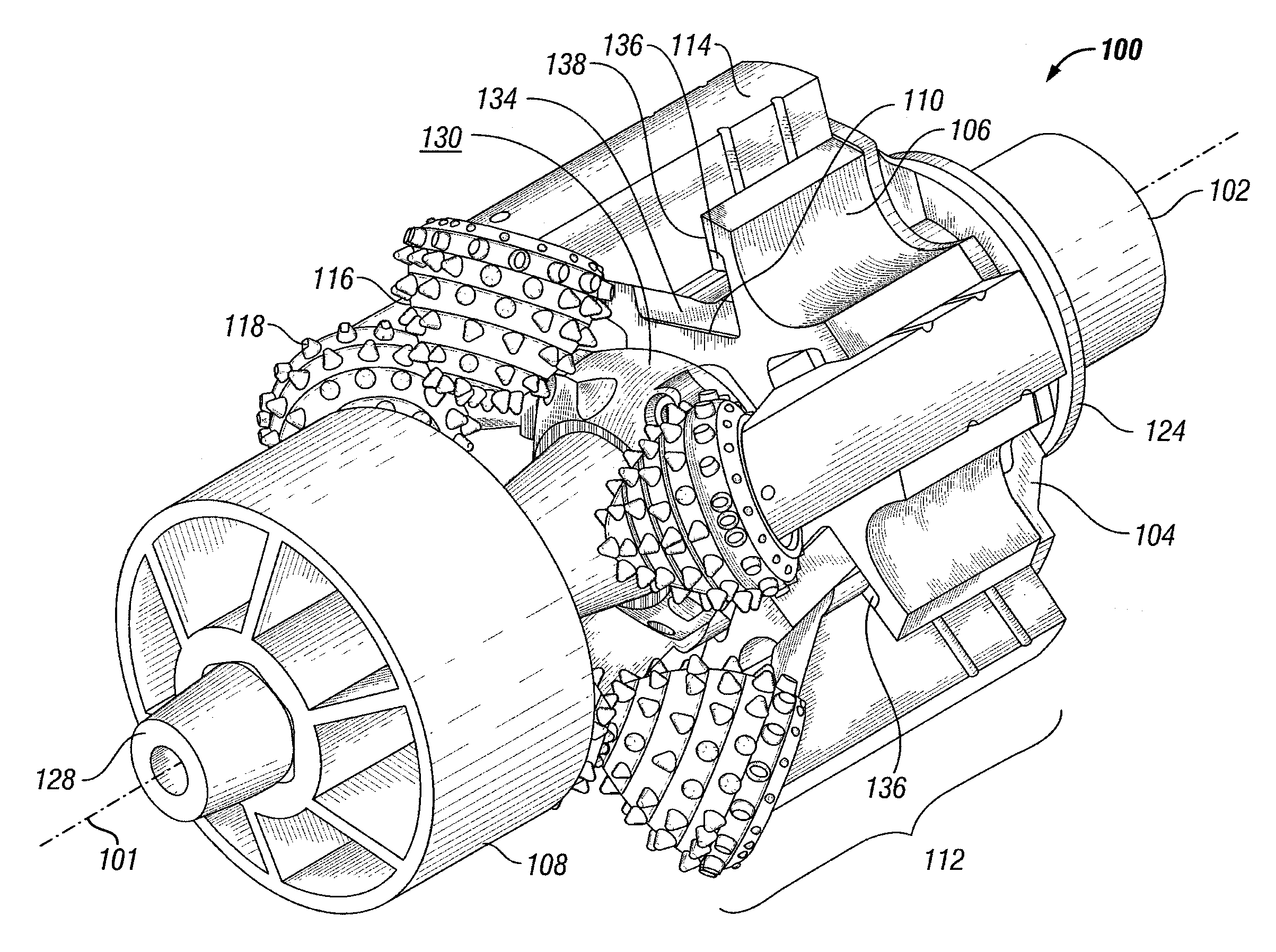

Downhole tool leg retention methods and apparatus

A back reamer includes a drive stem configured to support a main reamer body, the main reamer body including a plurality of receptacles, and a plurality of cutting leg assemblies in positive locking engagement with the plurality of receptacles to restrict radial movement of the cutting leg assemblies.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

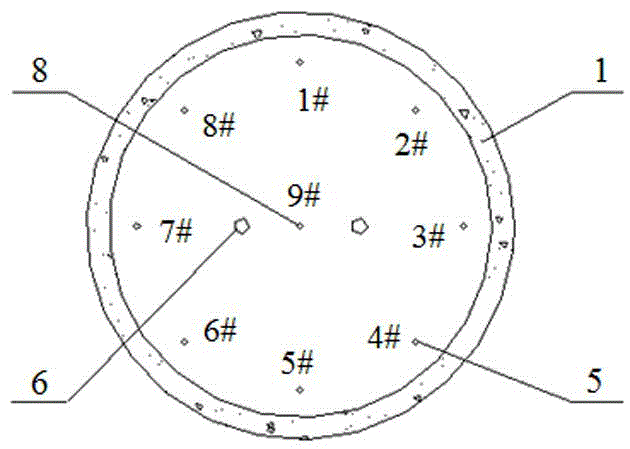

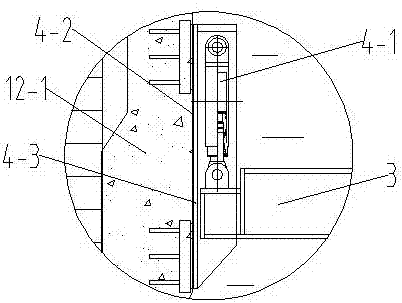

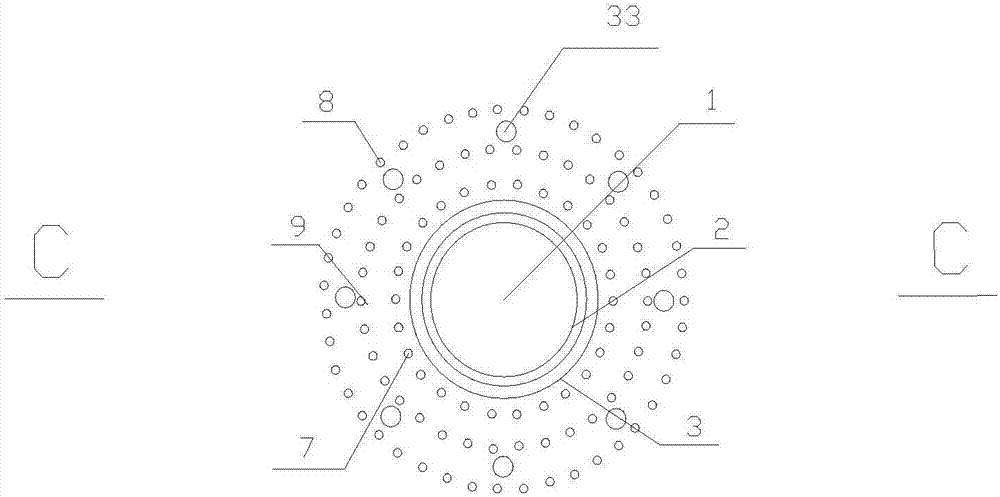

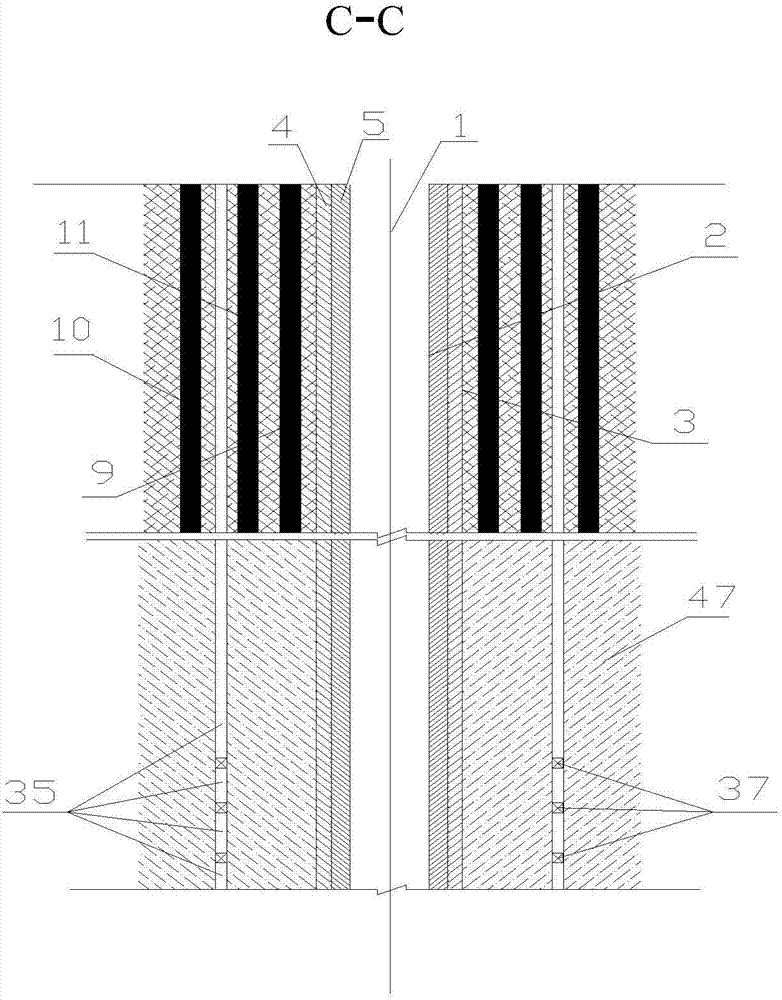

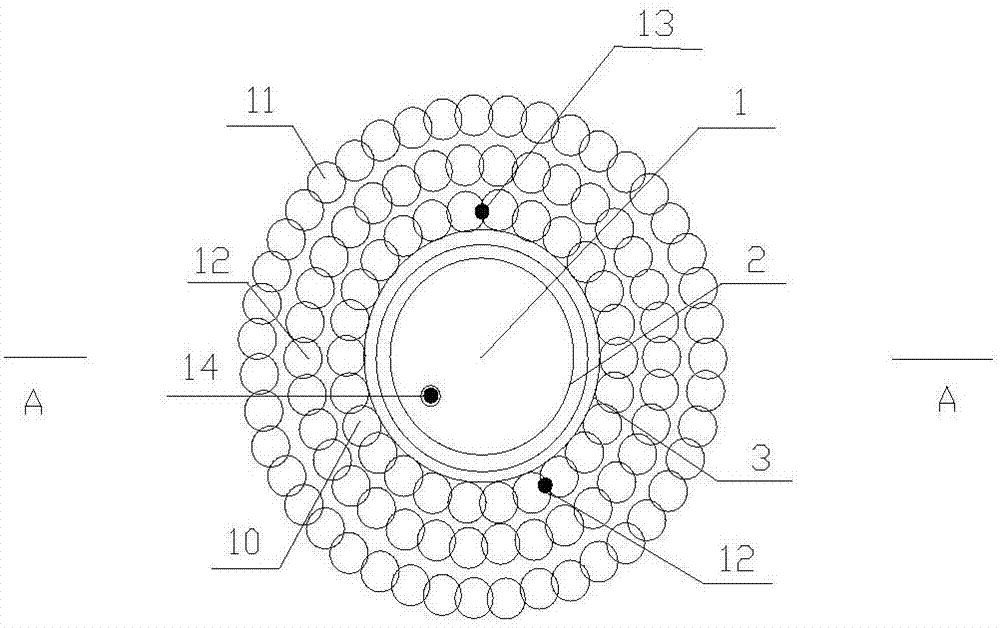

Vertical shaft wall structure in bad stratum and construction device and method

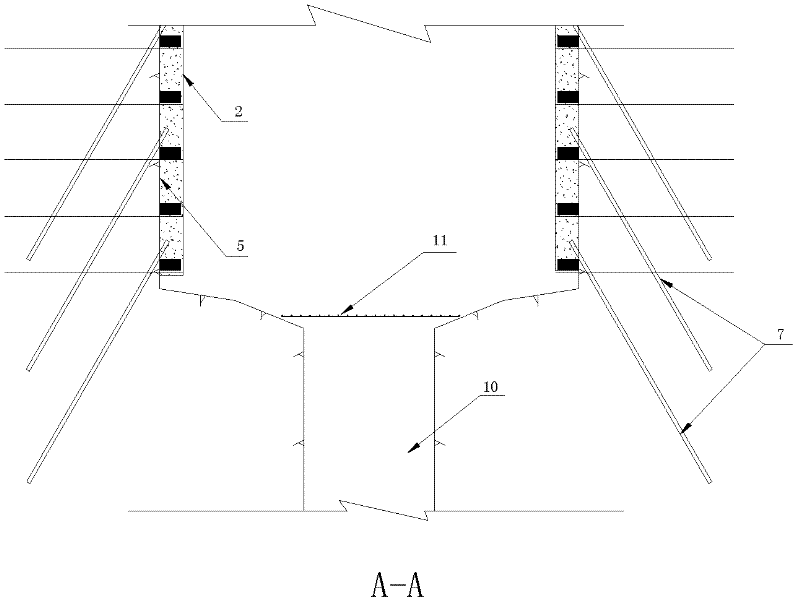

ActiveCN107246267AQuick diggingNovel ideaDirectional drillingHydro energy generationGrout curtainMechanical engineering

The invention relates to a vertical shaft wall structure in a bad stratum and belongs to mine vertical shaft construction. The vertical shaft wall structure comprises a shaft arranged in the bad stratum and is characterized in that the upper shaft collar section of a vertical shaft is provided with a high-pressure-jet-grouting curtain pile shaft wall structure, a bedrock section is provided with a positioning targeting grouting section shaft wall structure and a shaft wall, and the upper and lower shaft wall structures are concentric, identical in diameter and tightly integrally connected to protect the shaft wall; the high-pressure-jet-grouting curtain pile shaft wall structure is provided with at least three circles of annular high-pressure-jet-grouting curtain walls with sealed heads and tails on the periphery, 0.6m away from a shaft outer diameter line, of the shaft outer diameter line by using the center of the shaft as the circle center, the positioning targeting grouting section shaft wall structure is provided with at least 8 positioning targeting grouting sections, vertical to the ground, on the periphery, 2m away from the shaft outer diameter line, of the shaft outer diameter line, and the two wall structures protect the shaft wall. The vertical shaft wall structure has the advantages that the vertical shaft wall structure is novel in concept, simple, stable and reliable; the high-pressure-jet-grouting curtain walls and the positioning targeting grouting sections protect the shaft wall, bearing capacity and deformation resistance are enhanced, and a good water blocking effect is achieved; the vertical shaft wall structure is fast and convenient in construction, fast shaft construction can be achieved, cost can be saved, and mine production can be performed safely and smoothly.

Owner:MAGANG (GROUP) HOLDING CO LTD

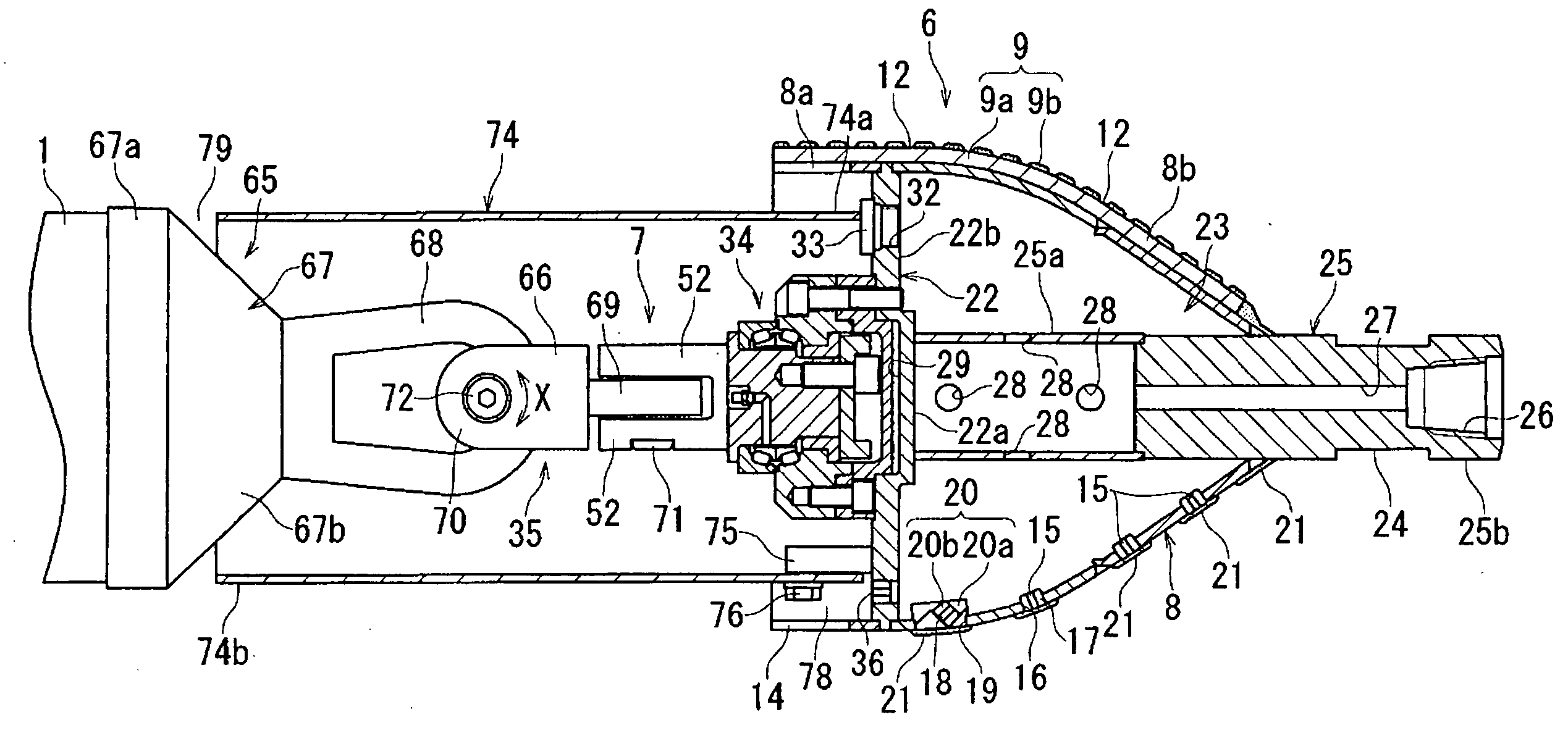

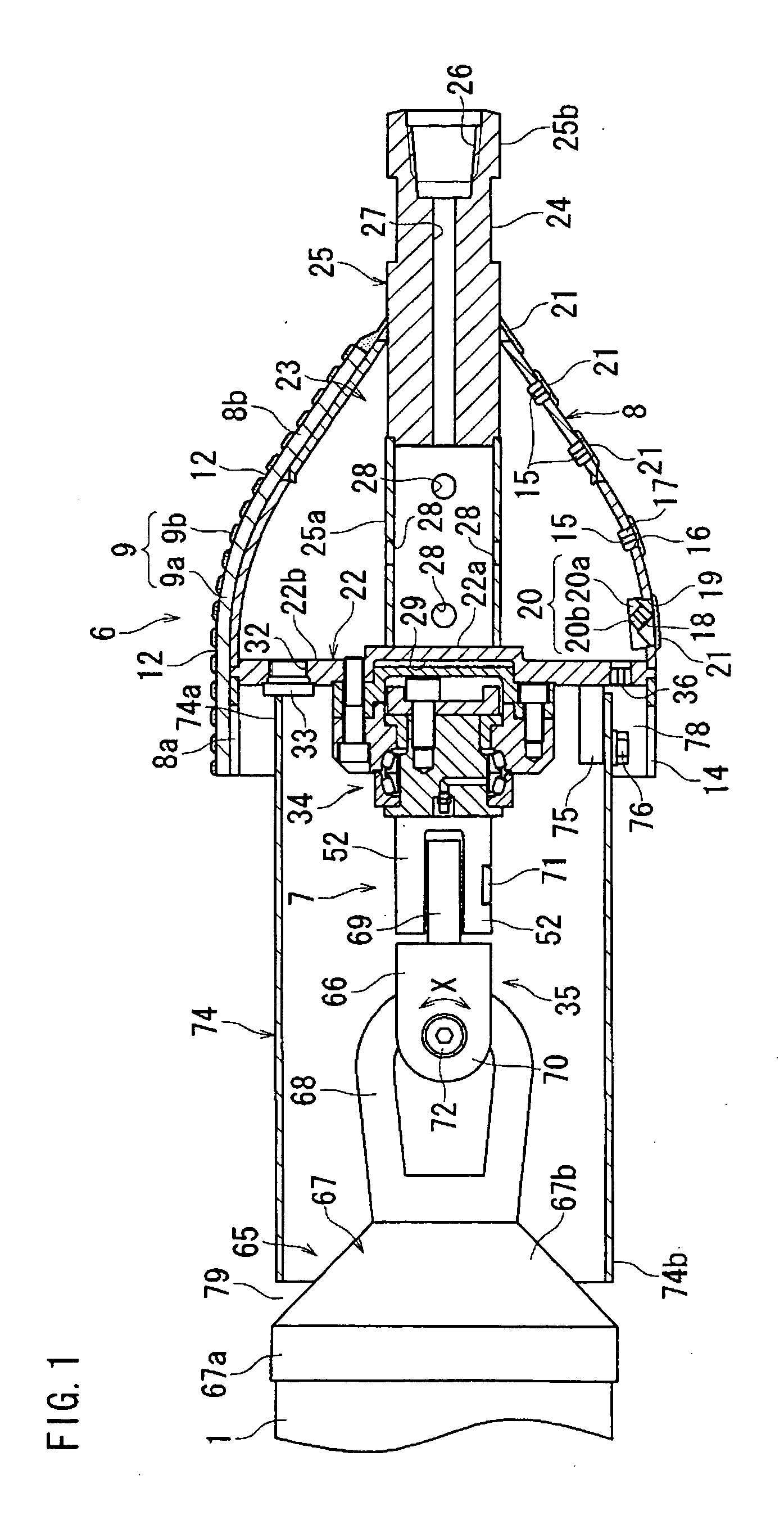

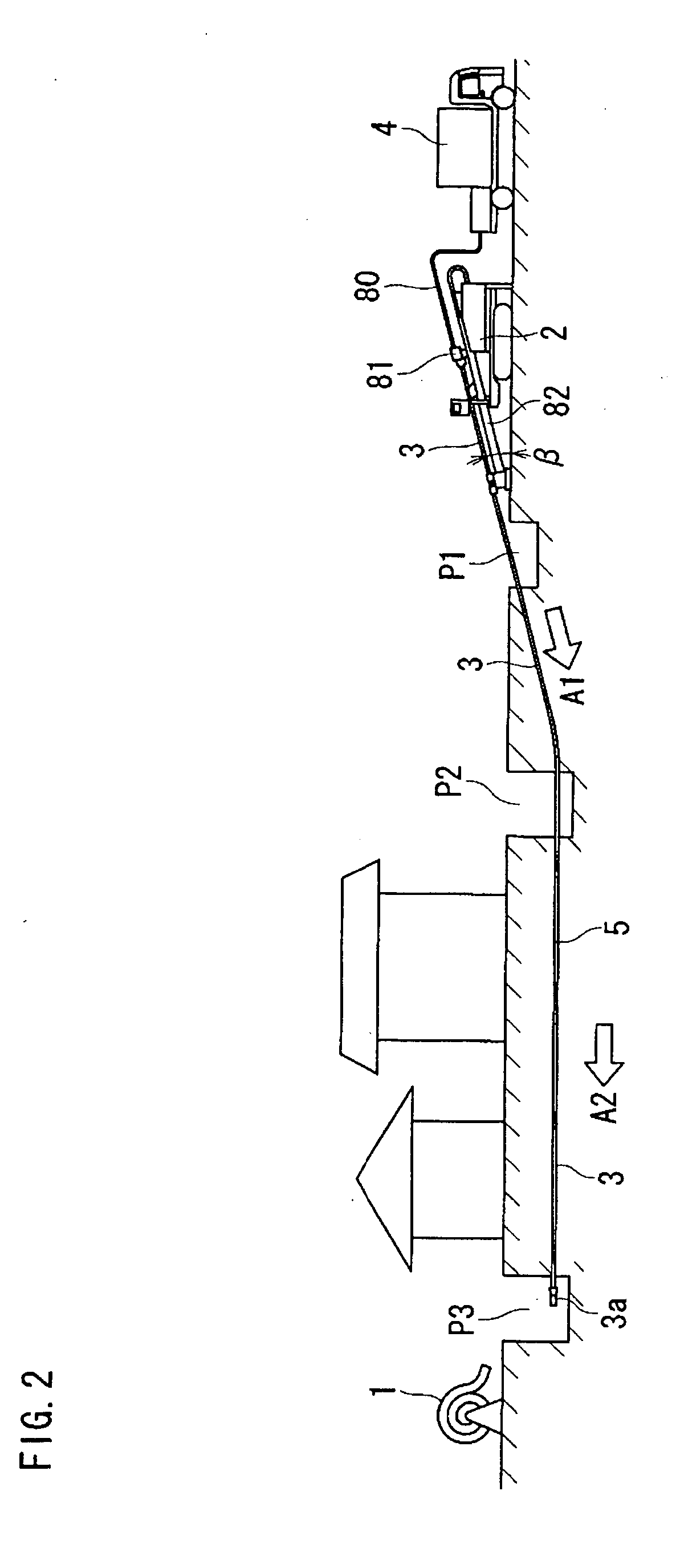

Reamer apparatus for ground boring machine

The invention provides a reamer apparatus for a ground boring machine that is capable of restricting increase in drawing resistance when performing drawing of a buried pipe by using a reamer and of efficiently performing drawing operations of the buried pipe without degrading properties such as flexibility and rotatability. The reamer apparatus includes a reamer main body of substantially hollow conical shape that reduces in diameter towards a drawing side, and a rod connecting portion that provided at a narrow diameter end portion of the reamer main body and connected with a rod. The reamer main body is connected to a buried pipe through a coupling structure disposed on an opposite side to the rod connecting portion. The coupling structure has a Swivel joint that allows rotation of the reamer main body with respect to the buried pipe, wherein a main portion of the Swivel joint is substantially accumulated in the reamer main body.

Owner:KOMATSU LTD

Construction method for auxiliary air duct structure of underground excavation station

ActiveCN105298501AReduce construction scaleReduce the impactUnderground chambersShaft sinkingStructural engineeringBuilding construction

The invention discloses a construction method for an auxiliary air duct structure of an underground excavation station. The method at least comprises station transverse passageway construction and air duct transverse passageway construction. The construction method includes the following construction steps that first, a vertical well out of the ground range of an air duct is constructed by the adoption of an inverted-hanging well wall method; second, temporary supports are arranged in the vertical well; third, a horsehead reinforced ring beam is constructed; fourth, a station transverse passageway advance support with the arch portion arranged in a 180-degree mode is driven; fifth, an air duct transverse passageway is excavated on the half side; sixth, a station transverse passageway and the air duct transverse passageway are back-filled to an air duct structure bottom plate, an air duct secondary lining structure is back-constructed, and the integral type structure is completed. Due to the facts that the auxiliary air duct structure is constructed through the underground excavation method and only the half-side air duct is subjected to underground excavation to be adopted as station transverse passageway pilot tunnels, the construction scale of the underground excavation station transverse passageway is reduced, the construction period is shortened, and the construction cost is lowered.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Vertical shaft shield tunneling machine

ActiveCN103452559AFast constructionSolve the problem of low efficiency of construction slag dischargeShaft sinkingEngineeringSlurry

The invention discloses a vertical shaft shield tunneling machine. A cutter head driving system is arranged in a shield body of the vertical shaft shield tunneling machine; the rotation output end of the cutter head driving system is fixedly provided with a connection barrel extending to the front end; the front end of the connection barrel is fixedly provided with a cutter head with a closed cavity inside; the connection barrel is rotationally supported on the shield body by a main bearing; a stirring device is arranged in the cavity of the cutter head; a cutter is arranged on the outer surface of the cutter head; a slag inlet for communicating the cavity of the cutter head and the outside is reserved on the cutter head; a girder is arranged in the shield body; a slurry input pipeline and a slagging pipeline are arranged in the girder; the front end of the slurry input pipeline extends to the front end face of the cutter head; the rear end part of the cutter head is provided with the slagging pipeline communicated with the cavity of the cutter head; the rear end of the slagging pipeline extends out of the girder; the rear end of the shield body is provided with a propelling system; a thrust oil cylinder of the propelling system is used for being pressed against a duct piece assembled by a duct piece splicing machine. According to the invention, full- face integral forming of a vertical shaft can be implemented and the tunneling speed of the vertical shaft is greatly improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

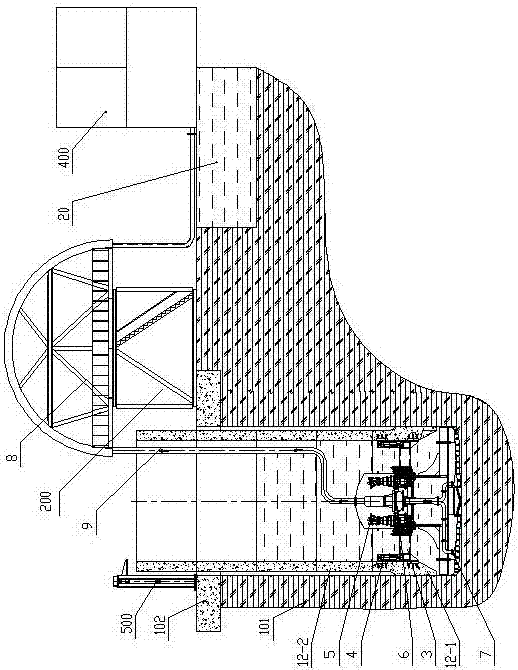

Multifunctional numerical control shaft sinking device and construction method

ActiveCN106121657AIncrease motivationEasy to operateShaft sinkingShaft liningNumerical controlEngineering

The invention belongs to the field of mechanized equipment and underground structure engineering, and particularly relates to a multifunctional numerical control shaft sinking device. The multifunctional numerical control shaft sinking device comprises a floating workbench, a heading unit, a shaft and a shaft overlapped well with the same shape as the shaft. The floating workbench is provided with a mud pit, a mud water separating device, a pond and a high-pressure pump station. The heading unit is controlled by an operation control system and is placed in the shaft for underwater tunneling. The heading unit is connected with a soil discharging pipe and a high-pressure water supply hose. The shaft overlapped well is provided with three or more sinking propulsion units capable of collecting data, guiding, locating and correction. The shaft overlapped well is arranged at the connecting position of the shaft and the ground. Thixotropic slurry is injected into the gap between the shaft overlapped well and the wall of the shaft to serve as a lubricating device. By the adoption of the multifunctional numerical control shaft sinking device, the sinking perpendicularity and balance degree of the shaft are guaranteed through numerical control so that the shaft can achieve steady propulsion and safety sinking. The invention further discloses a construction method of the multifunctional numerical control shaft sinking device.

Owner:杭州牛斯顿地下空间科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com