Bore construction method by bore explosion

A construction method and deep well technology, which can be used in sinking, shaft equipment, earthwork drilling and mining, etc. It can solve the problems of high chemical consumption, difficulty in meeting project needs, poor blasting effect, etc., and achieve the effect of improving project progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

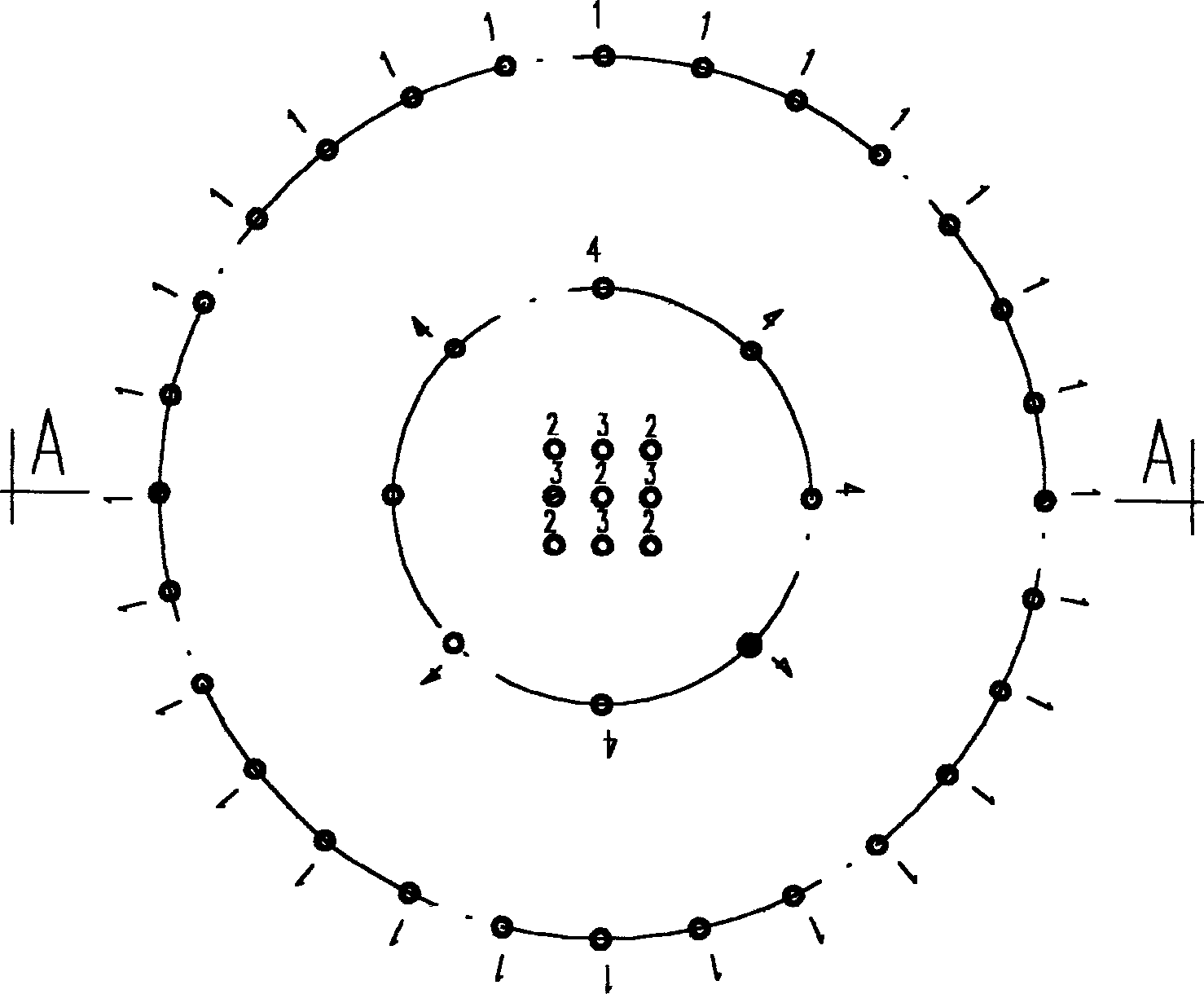

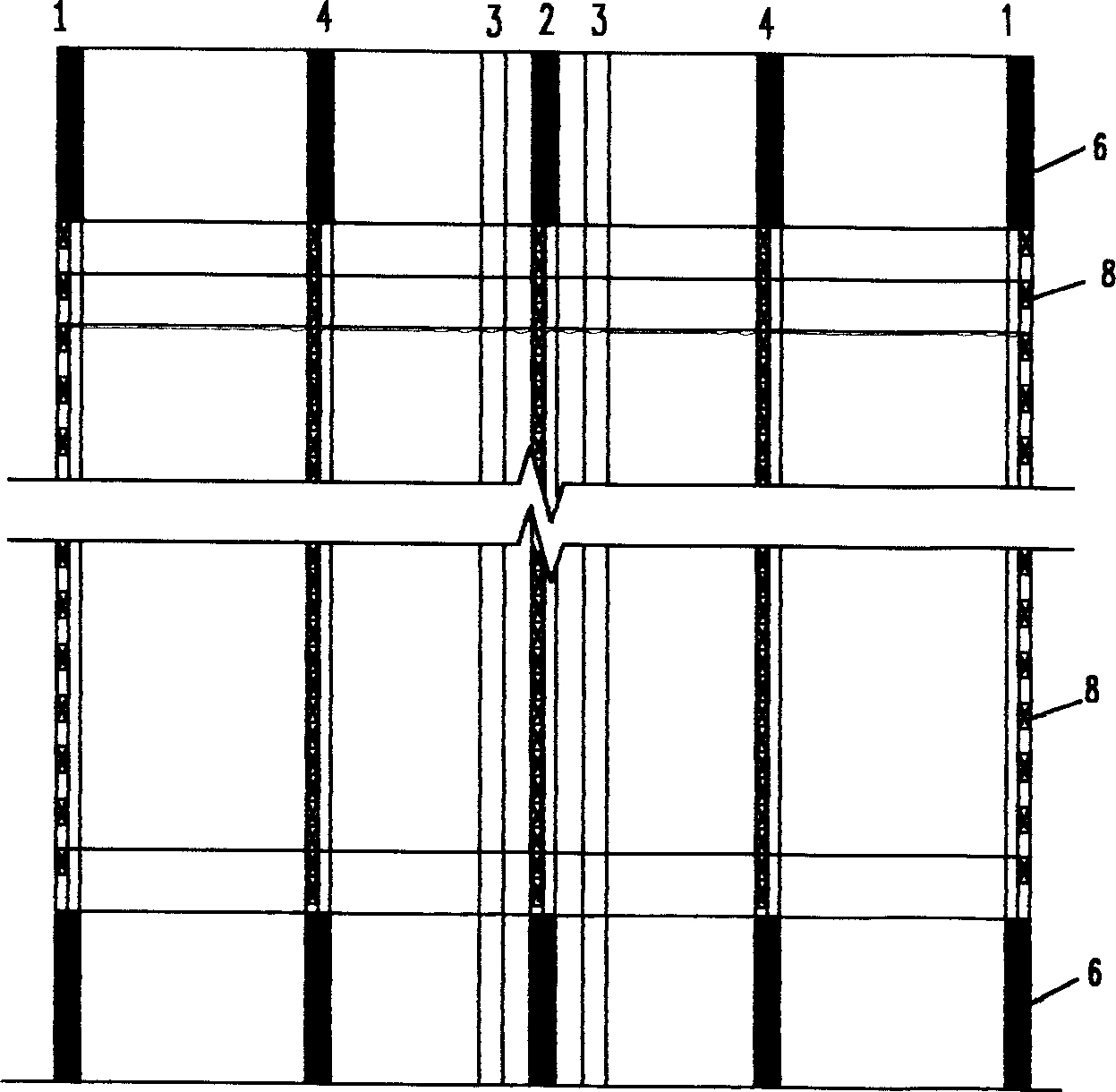

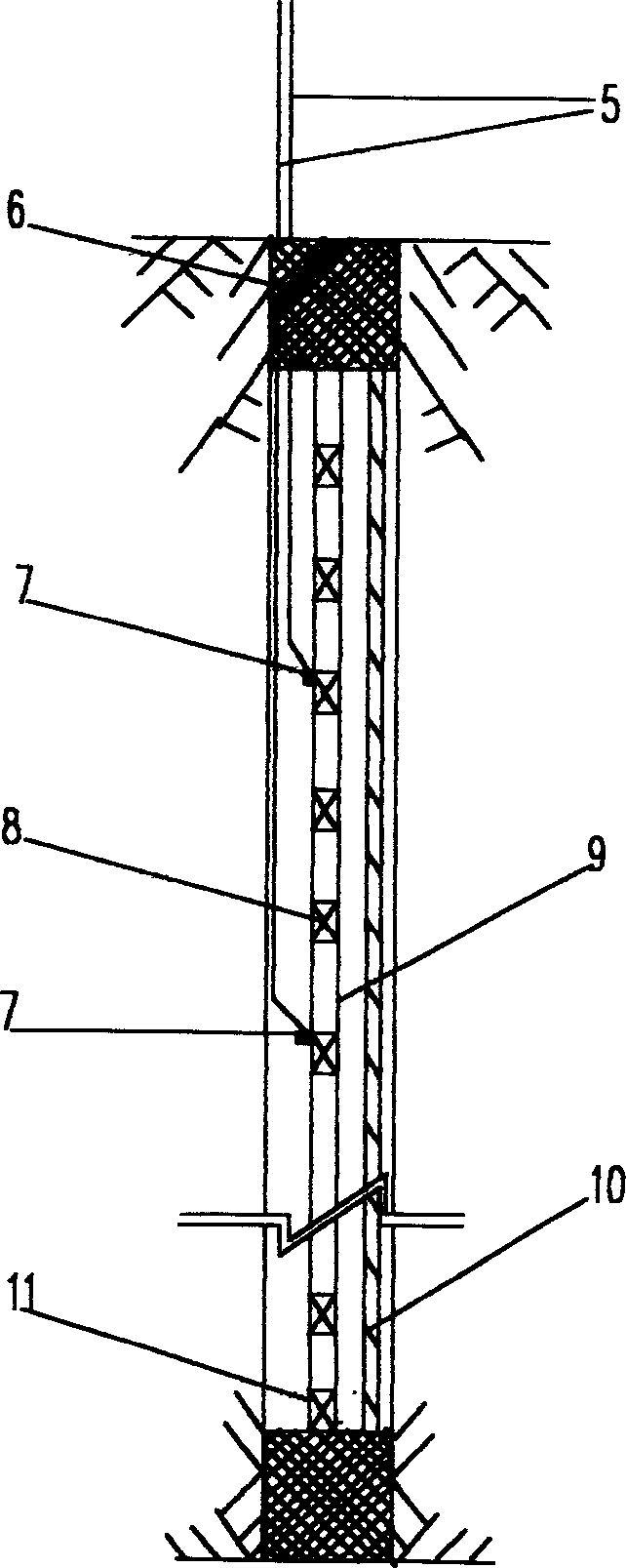

[0010] The construction method of deep well blasting into a well of the present invention is described in detail with reference to the drawings and embodiments as follows: the depth of the well to be dug is 26.5m, and two horizontal roadways with different elevations must be connected by a vertical shaft. The horizontal section of the shaft is circular, with a diameter of 5.50m and a depth of 26.50m. The total excavation volume is 629.30m 3 . The entire shaft is in sandstone, with well-developed rock masses and severe weathering, with Platts coefficient f=7-9. According to the construction conditions, the design adopts the full-face and full-depth one-time drilling charge, and uses two sections of detonators to perform millisecond blasting with a delay of 50ms. The surrounding area is pre-cracked, and then the rock mass in the well is crushed, broken and cracked at the same time. The ballast can slide down automatically, that is, the overall plan adopts a deep well construction me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com