Sinking technology for expanding pilot well drilled by raise-boring machine, by using vertical well heading machine

A technology of raise drilling rig and roadheader, which is applied in the direction of sinking, shaft equipment, earthwork drilling and mining, etc., and can solve the problem that there is no shaft sinking technology that can drill to the designed diameter at one time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

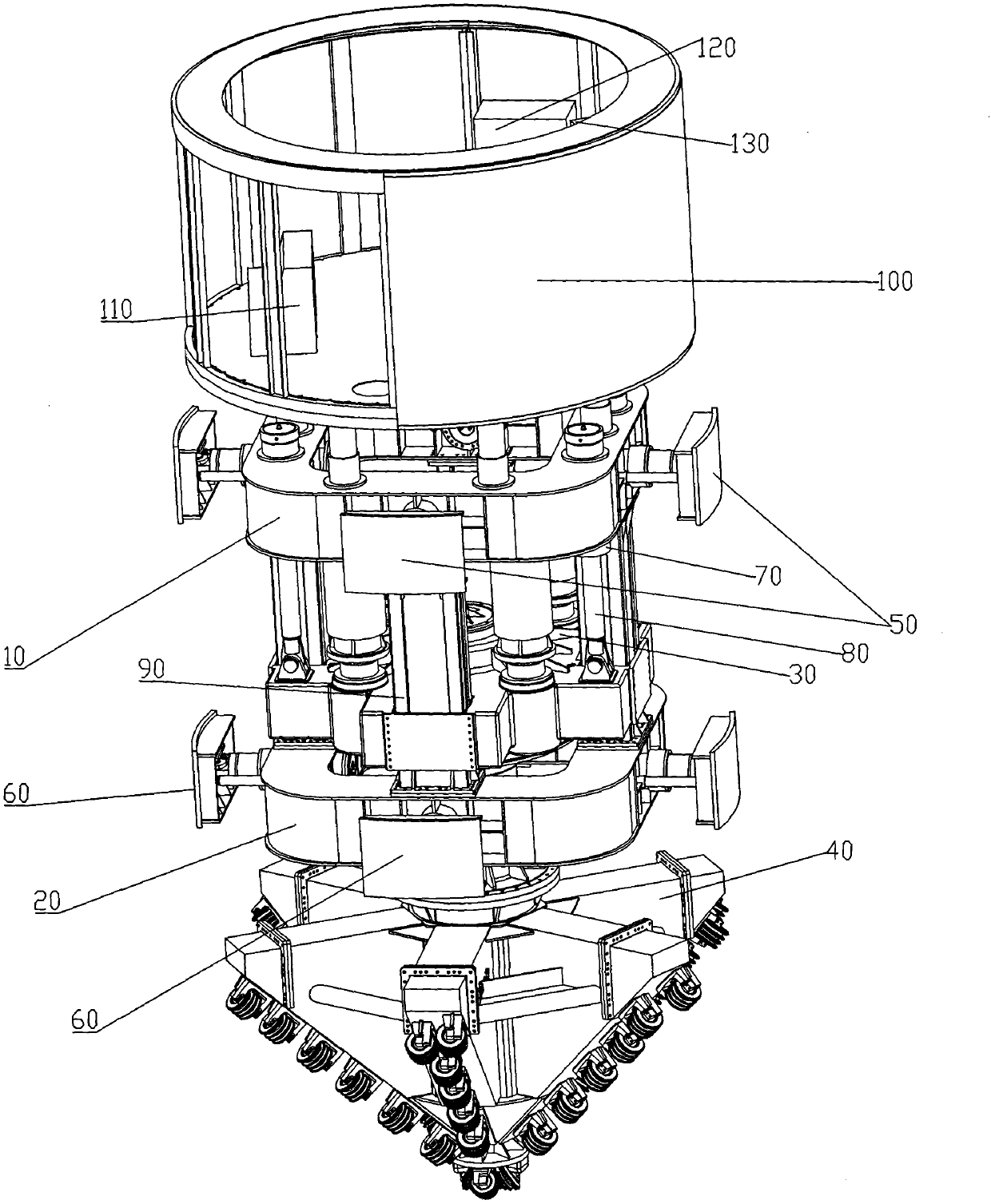

[0040] Such as Figure 6 As shown, the shaft boring machine of the present embodiment expands the sinking process of the guide well of the raise drilling machine, including the following steps:

[0041] (a) Drilling the pilot well with a raise drilling rig

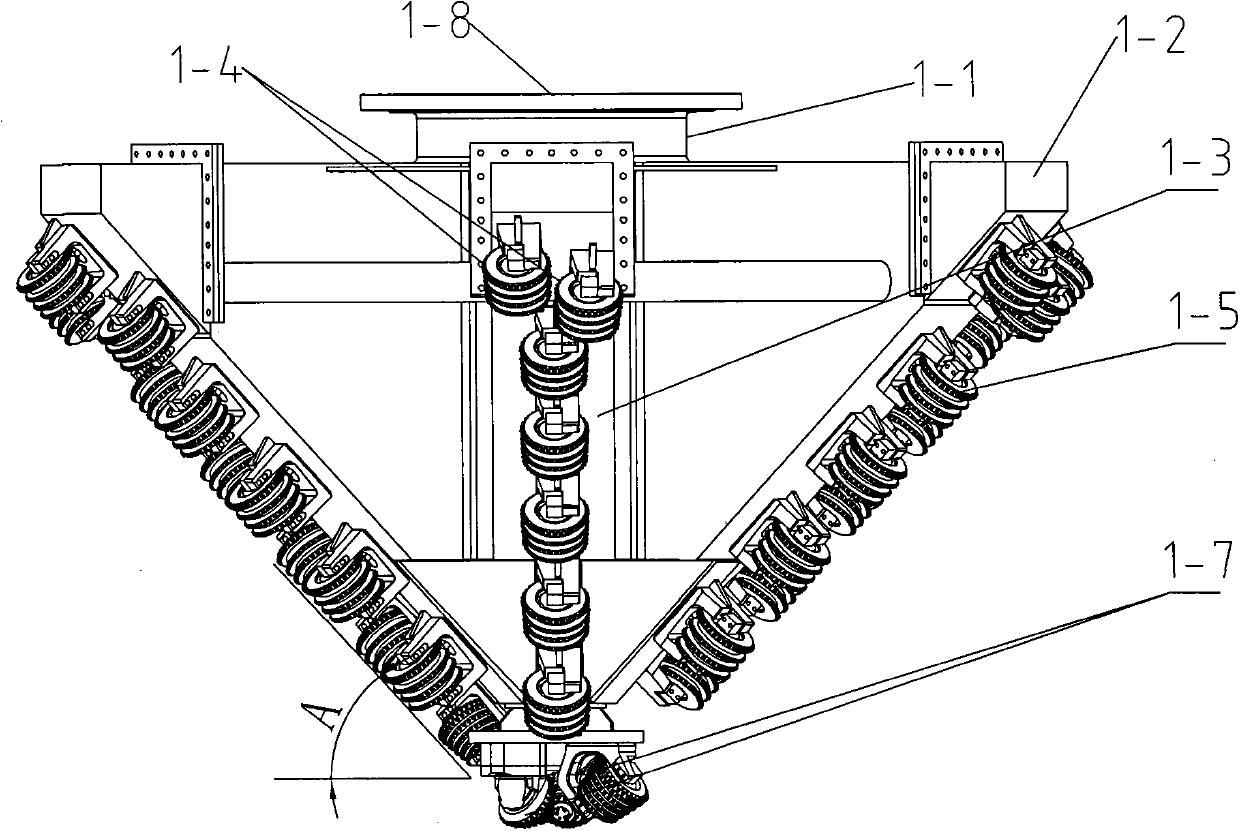

[0042] First, excavate the unstable stratum on the ground, pour concrete to form the foundation of the raising drilling machine and the lock of the shaft boring machine, and install the raising drilling machine on the basis of the raising drilling machine; secondly, use the raising drilling machine from top to bottom, and the drilling diameter is 1.6 -1.8m borehole, the lower opening of the borehole is connected with the lower roadway, the deviation of the borehole is controlled at less than or equal to 0.5%, and the borehole is used as a guide well for brushing. After the guide well drilling is completed, guide the well to the lock Excavate the concrete at the mouth;

[0043] (b) Drilling with a shaft boring machine to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com