Vertical in-tunnel construction method of multilayer transverse channel of underground excavation station of metro, and construction method on east side and west side

A technology of lateral passage and construction method, applied in tunnels, earthwork drilling, shaft equipment, etc., can solve the problems of high safety risk, high material input, slow speed, etc., and achieve the effect of reducing risks, reducing settlement, and avoiding risky operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

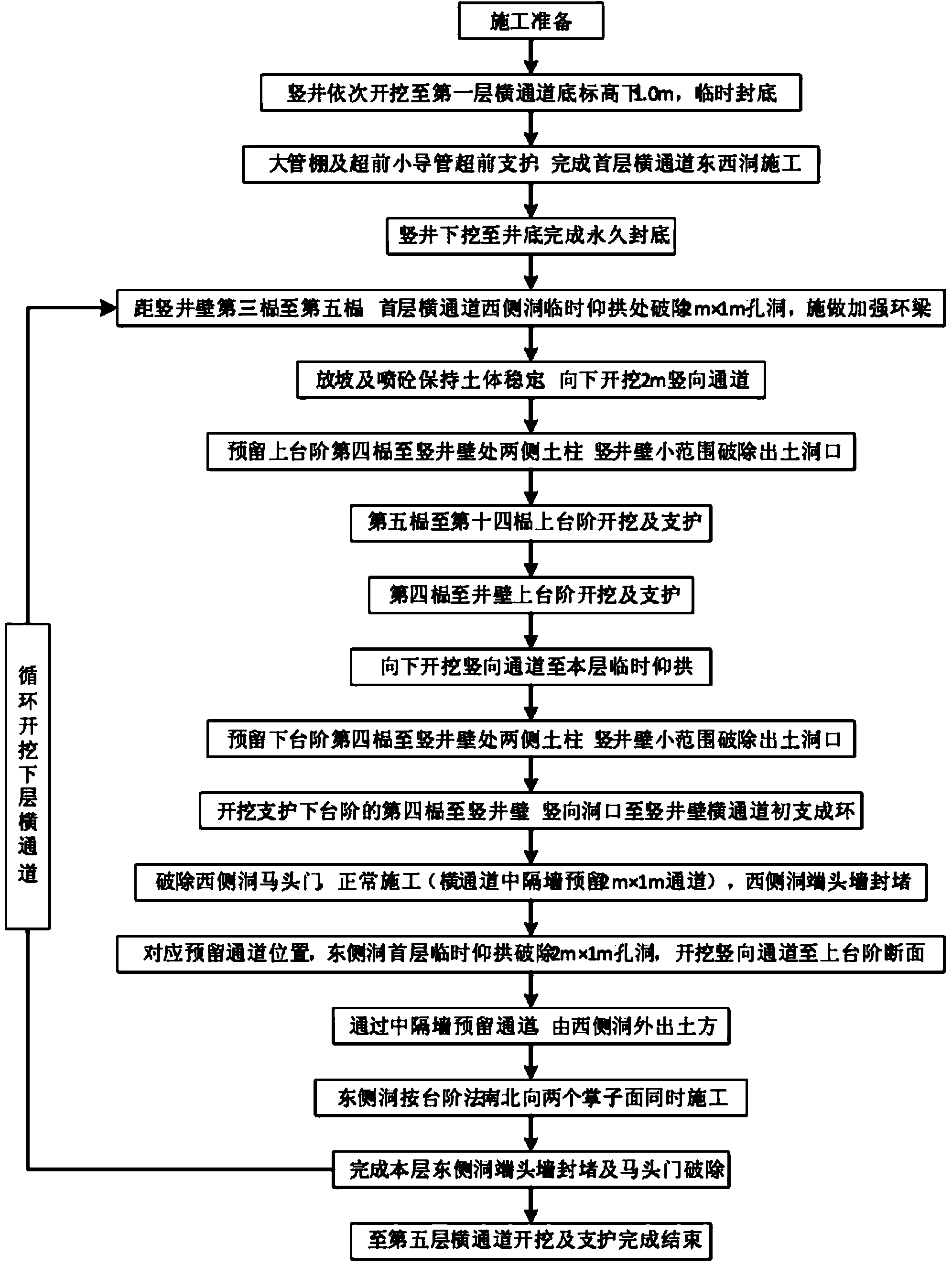

[0059] Such as Figure 1 to Figure 20 As shown, the present embodiment is a method for vertically entering a hole in a multi-layer horizontal channel of a subway underground excavation station, comprising the following steps:

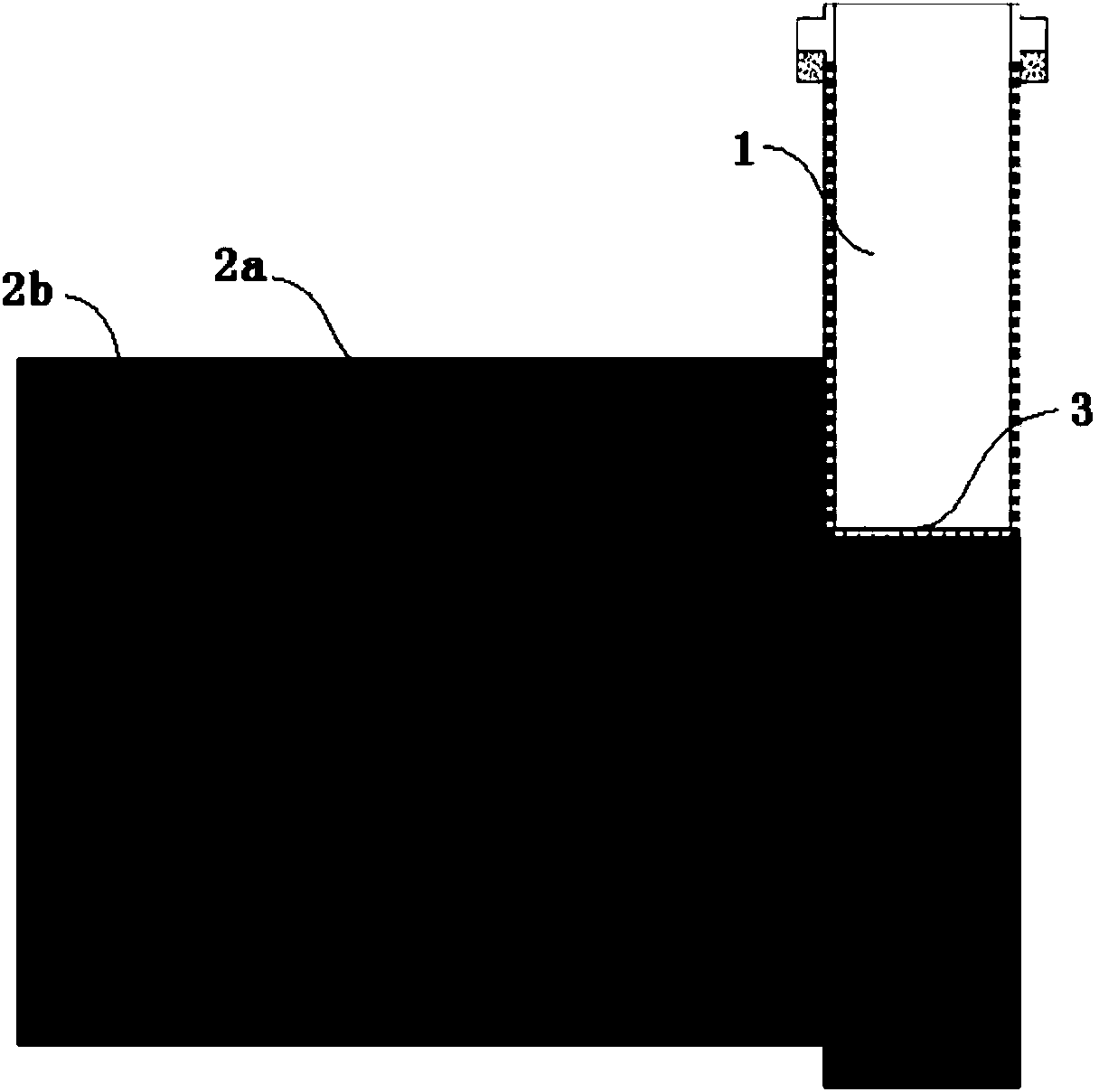

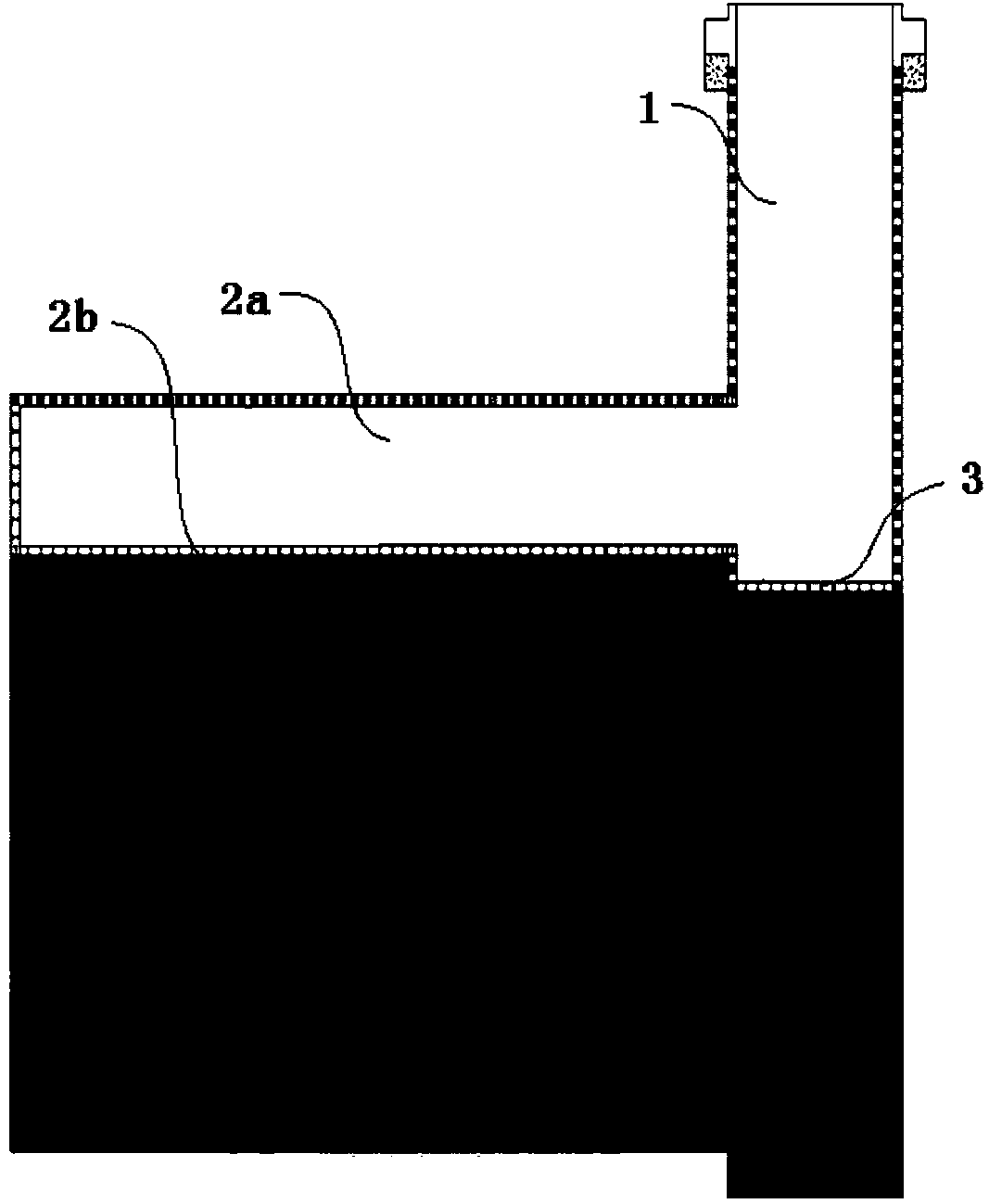

[0060] a. Excavate vertical shaft 1 to below the bottom level of horizontal channel 2a on the first floor, and temporarily seal the bottom of vertical shaft 1 by section steel and C20 sprayed concrete. For details, please refer to figure 2 ;

[0061] b. Set up the working platform, carry out measurement and setting out, release the horse head gate excavatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com